Patents

Literature

565results about How to "Restore activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

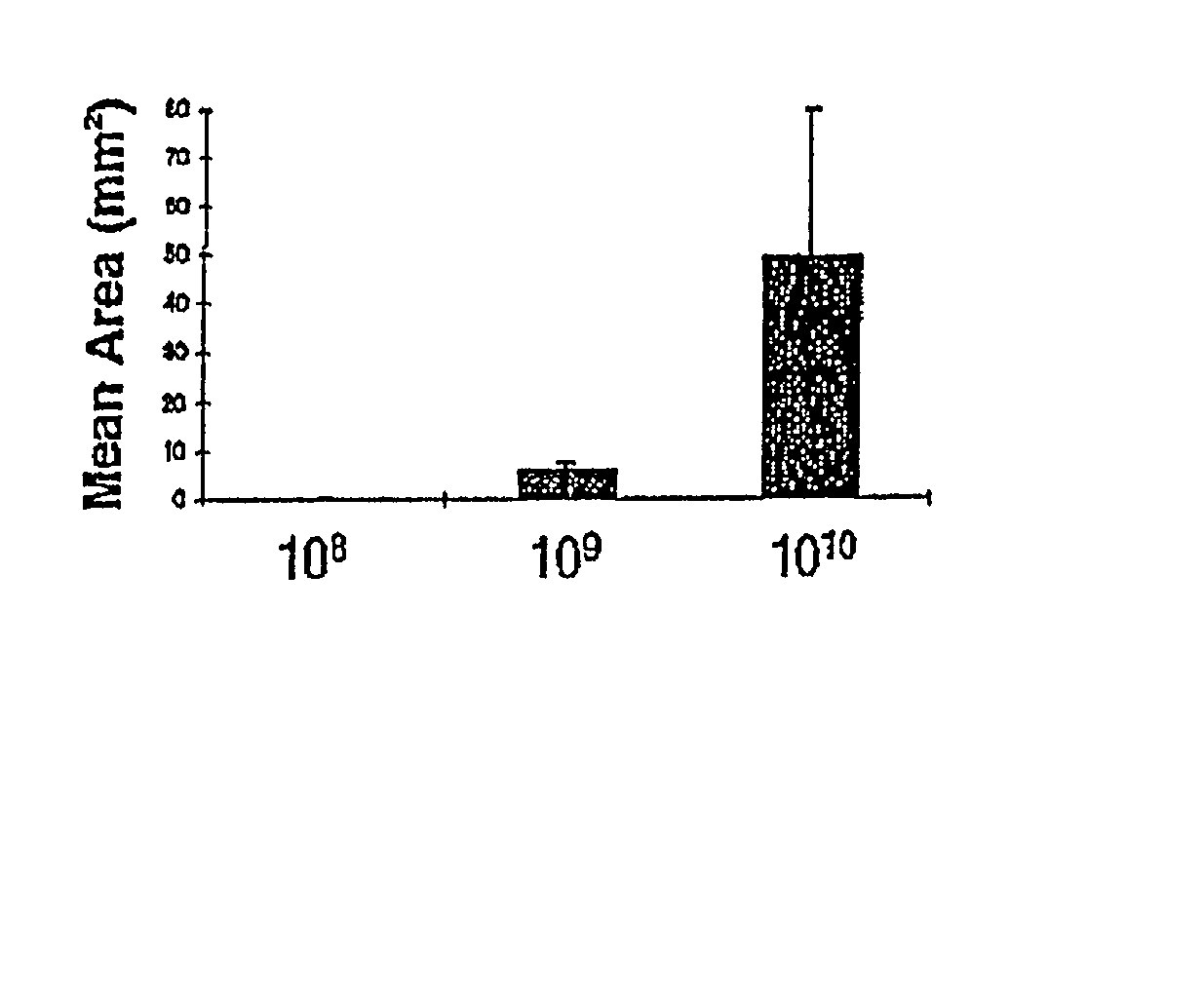

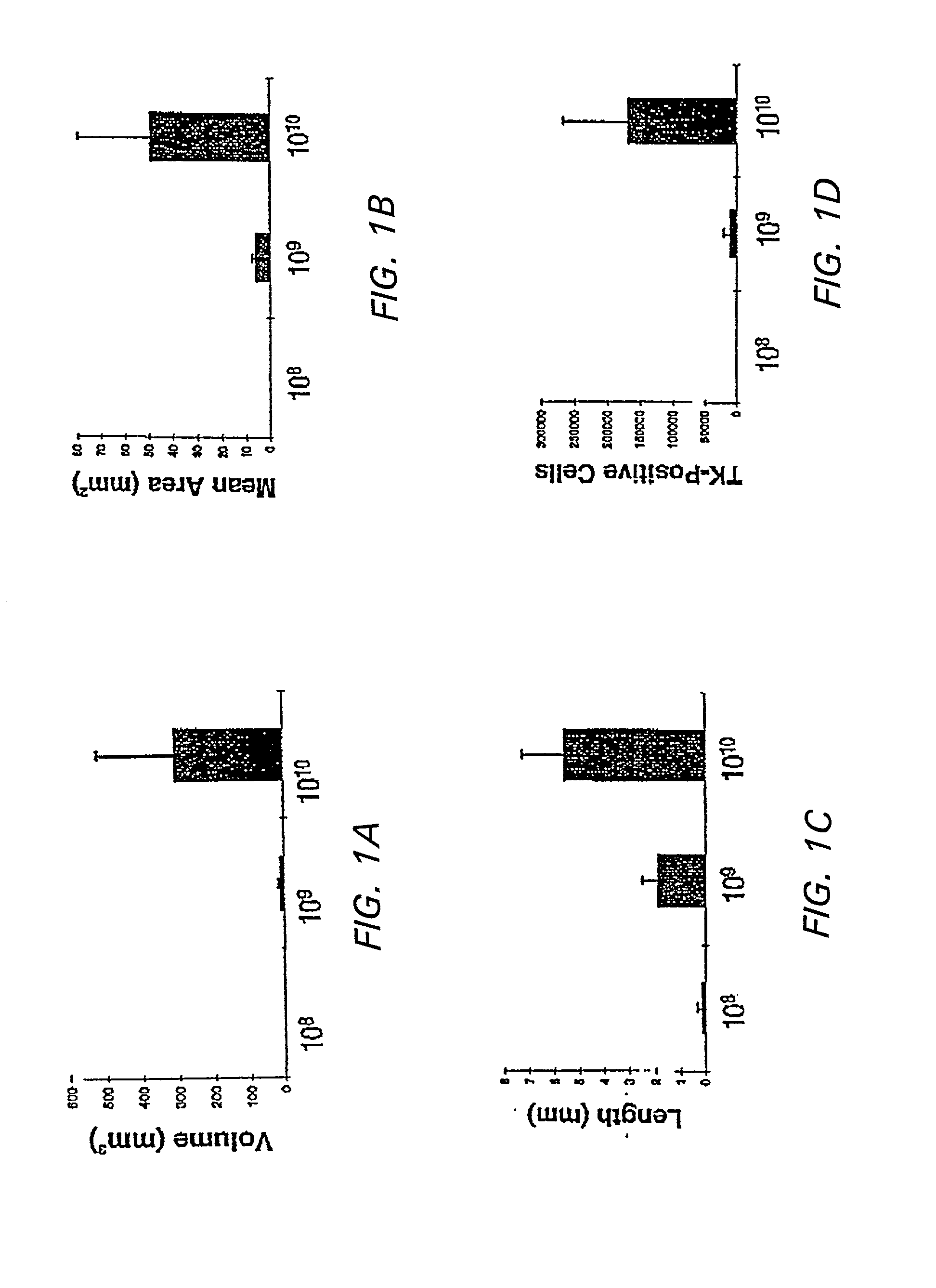

Convection-enhanced delivery of AAV vectors

InactiveUS20020141980A1Efficient deliveryEfficient expressionBiocideOrganic active ingredientsDiseaseConvection-Enhanced Delivery

Methods of delivering viral vectors, particularly recombinant AAV virions, to the CNS are provided. Also provided are methods of treating Parkinson's Disease.

Owner:GENZYME CORP

Adsorbing material for effectively adsorbing formaldehyde and other harmful substances in air

The invention relates to an adsorbing material for effectively adsorbing formaldehyde and other harmful substances in the air, belonging to the field of the adsorbing material for improving the air quality. The adsorbing material has the technical scheme that the material is characterized by comprising the raw materials based on the parts by weight: 10-20 parts of zeolite, 20-30 parts of sepiolite, 15-25 parts of diatomite, 10-15 parts of bentonite, 15-25% of active carbon and 6-12 parts of silicasol, wherein the silicasol is nanoscale silicon dioxide colloid water solution. The technical scheme also comprises the raw materials based on the parts by weight: 10-15 parts of higher molecular weight organic amine polymer with the molecular weight of 1800-50000, 5-10 parts of active carbon fiber and 10-20 parts of non-woven fabrics. The invention selects the substances with very strong adsorbing function and designs a set of formulation according to the different adsorption capacity and selectivity of the substances, so as to lead the substances to be matched with each other for adsorbing common indoor pollution gases such as formaldehyde, benzenes, hydrocarbons, other organic gas molecules larger than oxygen and nitrogen molecules in the air as well as virus bacterium and fine dust, thus purifying the indoor air, preventing decoration disease and improving the health level of residents.

Owner:傅桂云 +1

Metal oxide catalyst for synthesizing methyl carbonate by urea process and its prepn

InactiveCN1416949ASolve key problems such as difficult separation and recyclingHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateCoprecipitation

The metal oxide catalyst for urea alcoholysis process of synthesizing methyl carbonate consists of 1-3 kinds oxides of Li, Mg, Ni, Zn, Pb, Al, Fe, Mo, Zr and La, and has ZnO as main component accounting for 35-95 wt%. When it consists of three kinds of metal oxide, the other two except ZnO have the same weight percentage. It is prepared through thermal decomposition process, precipitation process, or coprecipitation process. The catalyst is easy to prepare, separate, recover and regenerate, and has high catalytic activity for urea alcoholysis process of synthesizing methyl carbonate, yield up to 49.7%, no corrosion of equipment and no environmental pollution.

Owner:HEBEI UNIV OF TECH

Face-painting product having function of dispelling stria gravidarum and method for preparing the same

ActiveCN101152138APromote absorptionPenetrate more fasterCosmetic preparationsToilet preparationsCentella asiatica extractCollagen i

The present invention relates to a cosmetic product with dispelling striae gravidarum effectiveness and a manufacturing method. Nutrient components synergy and can repair the elastic fiber effectively. Sweet almond oil and olive oil in the formula are rich in unsaturated fatty acid, which is totally identical with fats secretory of human; so essential fatty acid is added; the skin is repaired. Vitamin E has anti-aging and antioxidant effectiveness; small molecule faba bean peptide and nanometer parcel epidermal growth factor biomimetic peptide have strong physiological excitation signal which is easily absorbed by the skin; so the skin is stimulated to compose collagen which markedly amends the striae gravidarum. Centella asiatica extract can promote the composition of collagen I and III and can promote the composition of polysaccharide, which effective prevents and repairs the striae gravidarum.

Owner:天津盛世永业科技发展有限公司

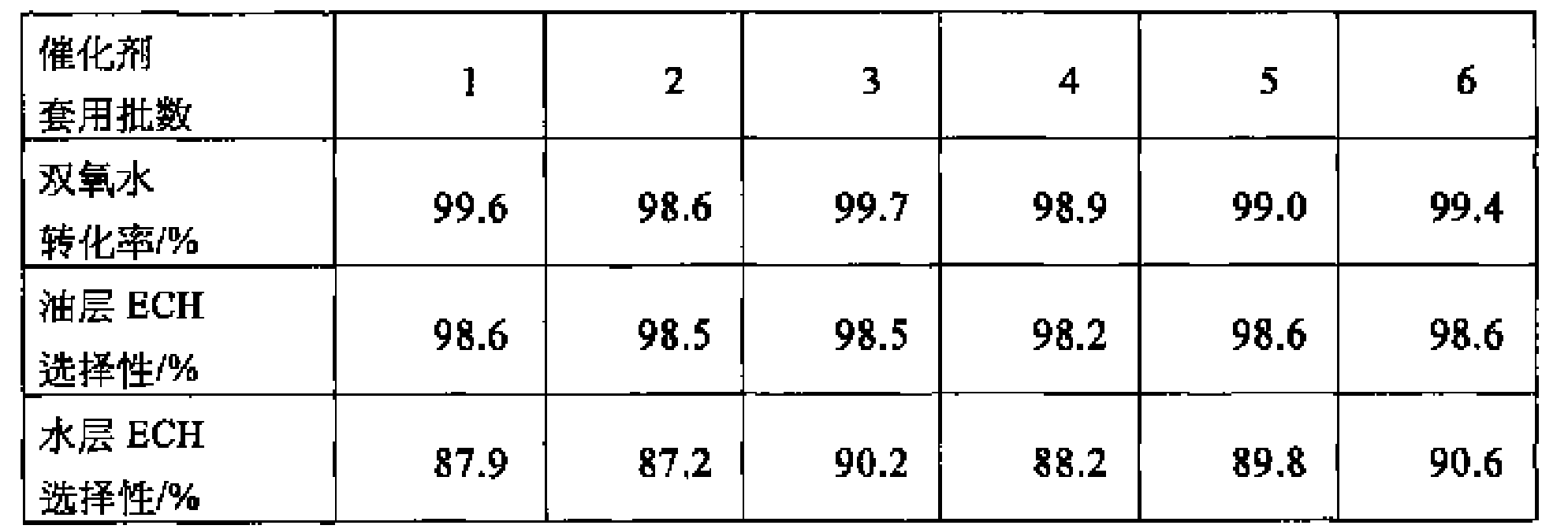

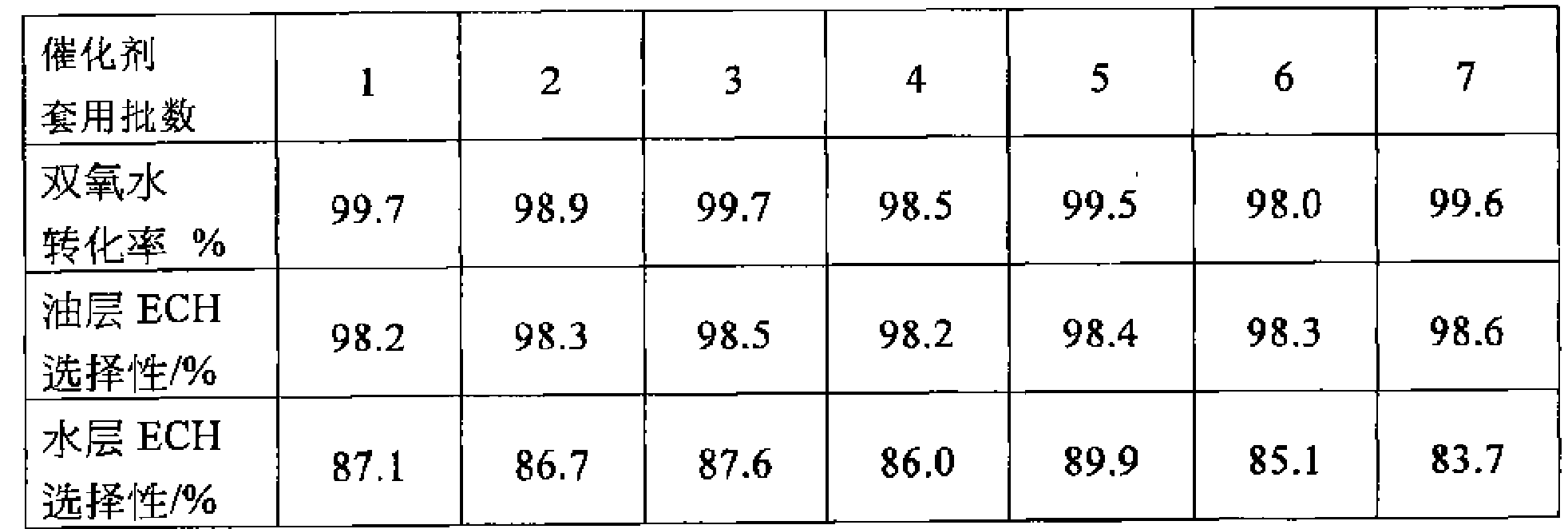

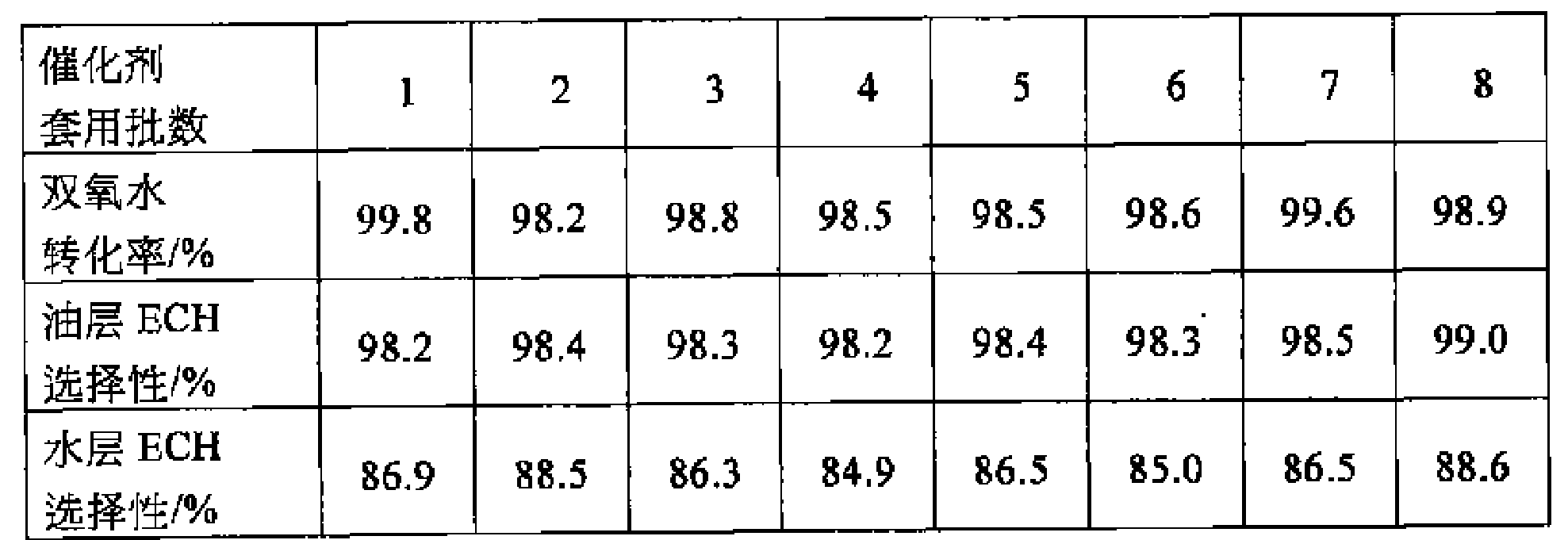

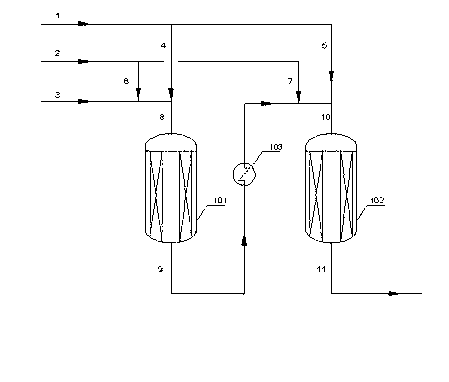

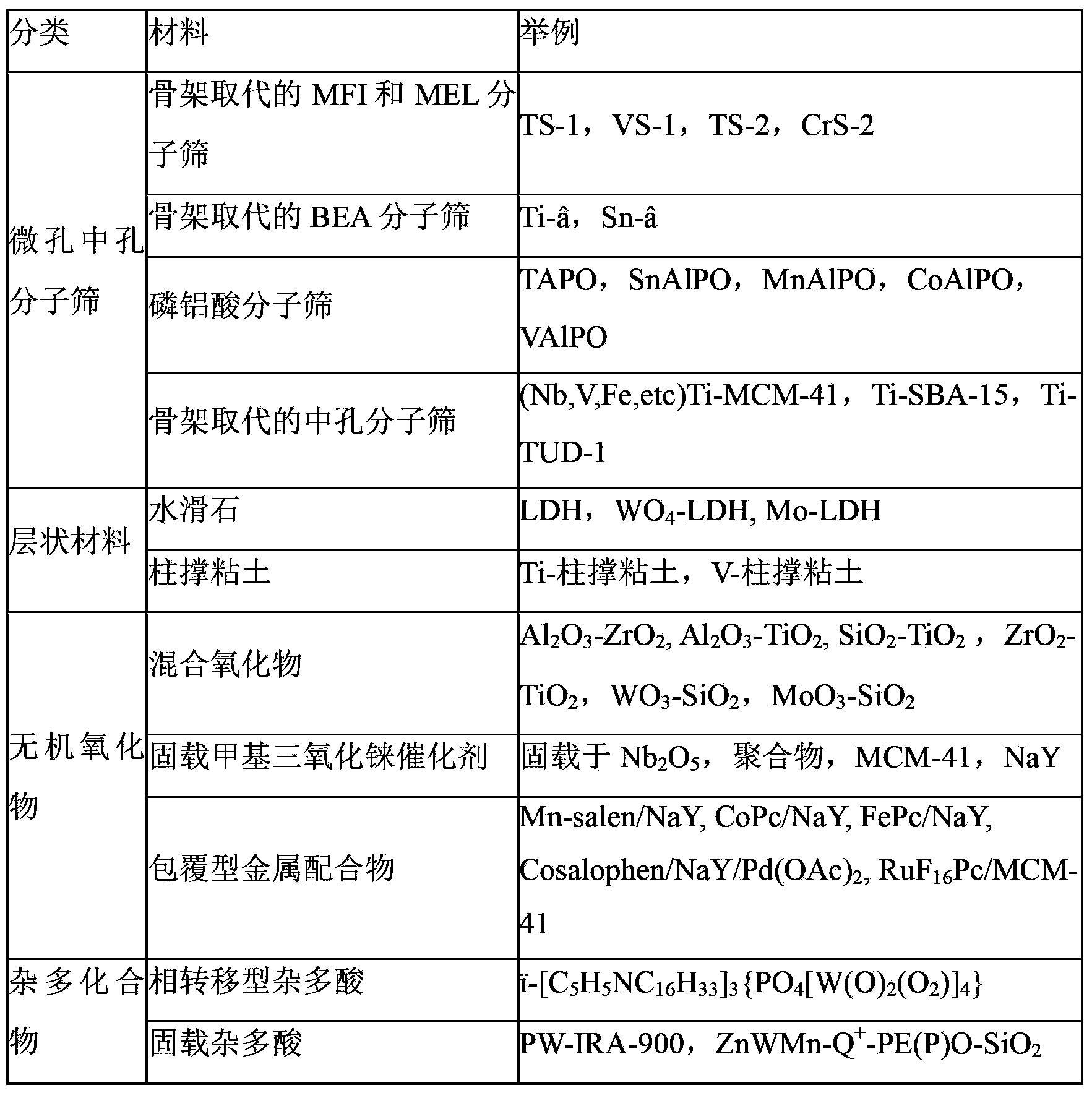

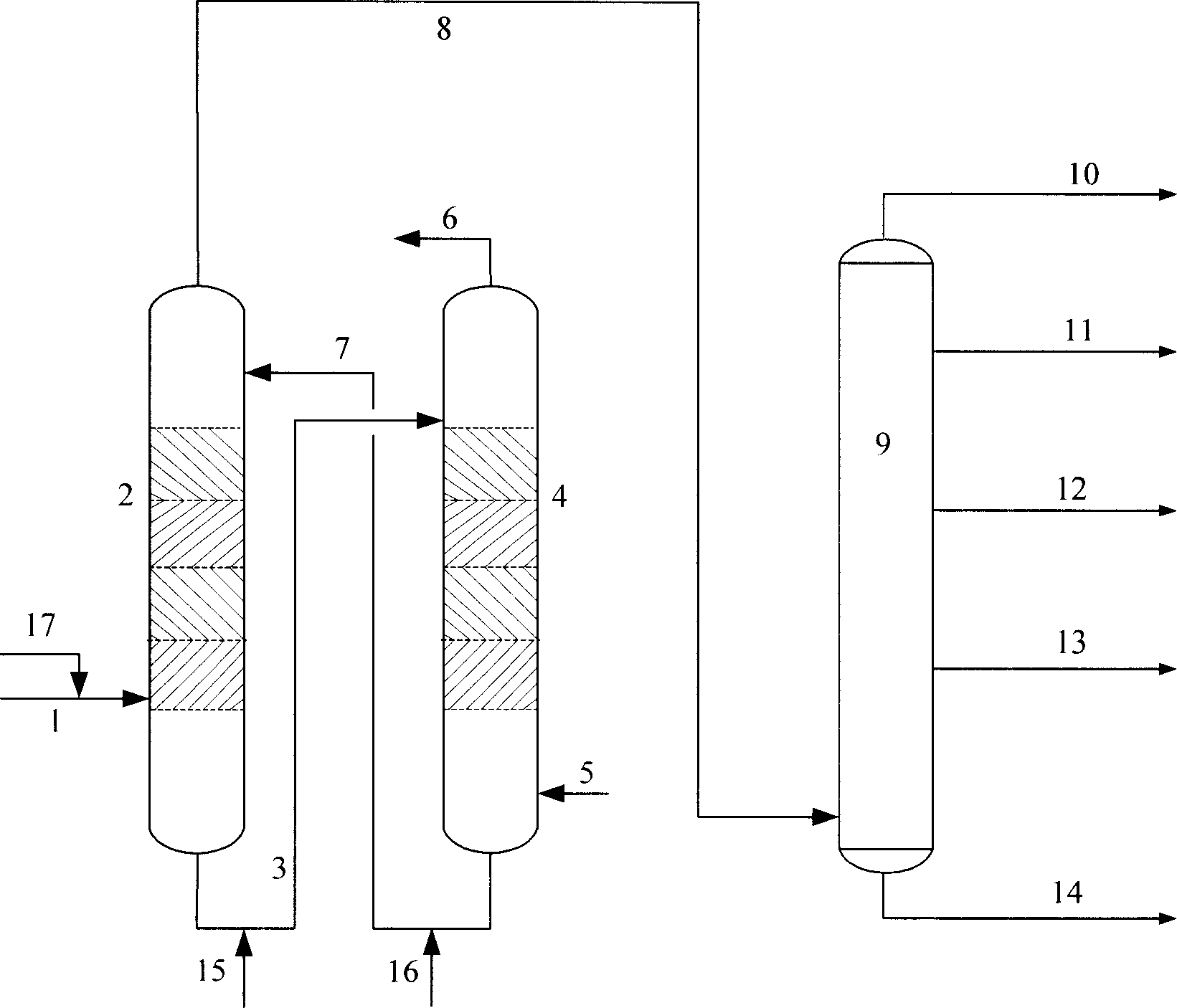

Method for regenerating titanium-silicon molecular sieve catalyst

ActiveCN101480623AGood regeneration performanceImprove securityOrganic chemistryMolecular sieve catalystsDecompositionSolvent

The invention provides a catalyst used as a titanium-silicate molecular sieve in the process of preparing epoxide from olefin and hydrogen peroxide. The invention is characterized by comprising the following steps: washing with or without a small amount of methanol solvent; purging the catalyst cake with steam directly after reaction; extracting few organic matters absorbed in the catalyst; then stirring in a regenerating kettle and dropwise adding H2O2 with a certain concentration simultaneously; removing the organic matters and low polymers absorbed on the catalyst and in a pore path through oxidative decomposition; and finally, washing with a small amount of methanol or deionized water to remove the organic acid generated by oxidation on the surface of the catalyst. The regenerated catalyst can be circularly used for the epoxidation reaction of olefin to stably maintain the activity of the epoxidation reaction.

Owner:JIANGSU YANGNONG CHEM GROUP +2

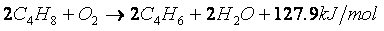

In-situ regeneration method of butylene oxy-dehydrogenation catalyst

InactiveCN103071544AReduce steamPromote crystal phase transitionCatalyst regeneration/reactivationHydrocarbonsPtru catalystButadiene Dioxide

The invention relates to an in-situ regeneration method of a butylene oxy-dehydrogenation catalyst, which mainly solves the problems that the in-situ regeneration effect of the butylene oxy-dehydrogenation catalyst is poor, so that the life of the catalyst is shortened, the conversion rate and yield of reaction are reduced, and the change of the catalyst results in long stopping time of a device and influences the output of the device in the prior art. The method comprises the following steps of: a) stopping feeding of oxygen-containing gas and then a butylene raw material, purging the catalyst with 300-500 DEG C superheated water vapor for 0.2-56h, b) gradually reducing the amount of the water vapor till the airspeed of the water vapor is 500-2000h<-1>, filling in air till the molar ratio of the air to the water vapor is 0.05-0.2, controlling the regeneration temperature at 360-450 DEG C, conducting regeneration of the oxy-dehydrogenation catalyst, and c) reducing the amount of the vapor, allowing the temperature rise of a bed to be reduced gradually till the temperature at an inlet and an outlet of the catalyst bed keeps constant, and accomplishing the technical scheme of catalyst regeneration. The method solves the problems better, and can be used for industrial production of preparing butadiene through butylene oxy-dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Functional nutritional good composition for improving sub-health and preparation method thereof

InactiveCN104799146AIncrease metabolic rateRestore activityFood preparationBiotechnologyLicorice roots

The invention discloses a functional nutritional good composition for improving sub-health and a preparation method thereof. Edible and medicinal raw materials such as aloe, licorice root, chrysanthemum flower, green tea, semen cassiae, lotus leaf, fructus crataegi, radix angelicae, white hyacinth bean, lilium brownii, mint, red bean, clove, sword bean and seville orange flower are combined with the modern nutrients such as L-carnitine, methionine, fructo-oligose, fructose, medium chain triglyceride grease powder, protein, vitamins and mineral substances to prepare four types of products. The four types of products are matched with one another in use and can be used for replenishing various nutritional ingredients required by the human body so as to realize the aims of repairing cells, activating the immunity and improving the sub-health.

Owner:SHANGHAI SHILINMEI BIOTECH CO LTD

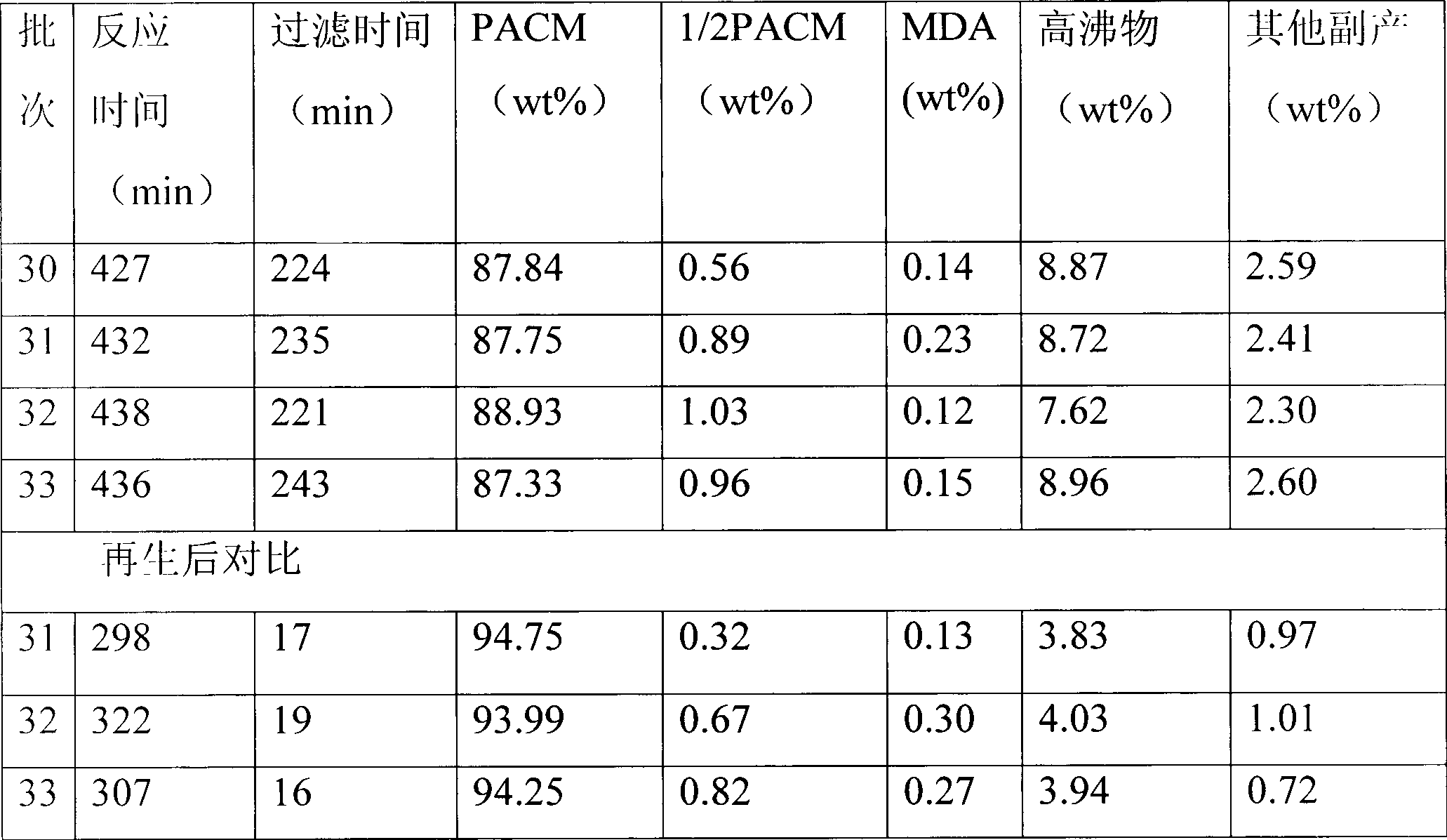

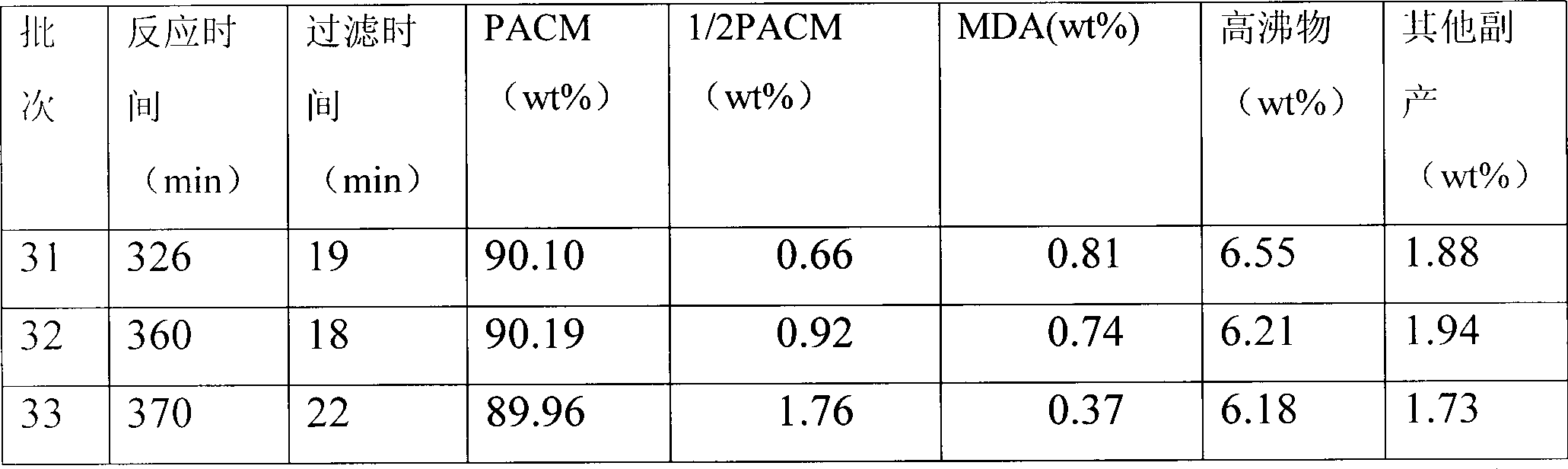

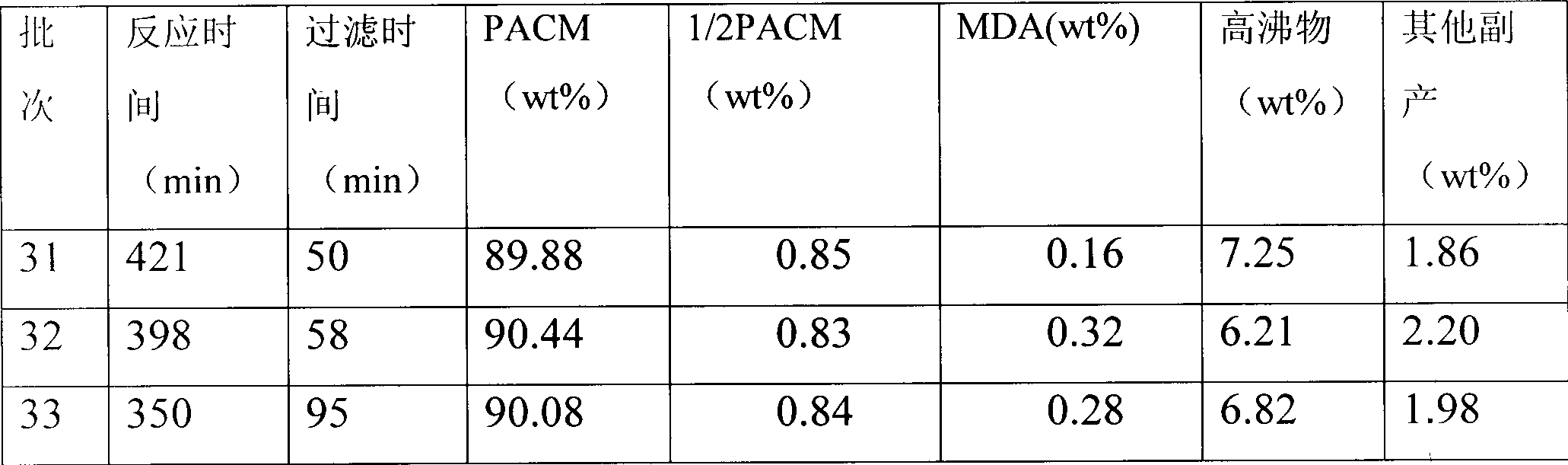

Method for regenerating ruthenium hydrogenation catalyst

ActiveCN103816923ARestore activityExtended service lifeMetal/metal-oxides/metal-hydroxide catalystsActive componentRuthenium

The invention discloses a method for regenerating a ruthenium hydrogenation catalyst. The method comprises the following steps: (a) inactivated load ruthenium hydrogenation catalyst is ultrasonically cleaned in ultrasonic equipment under the protection of inert gas in presence of a solvent; (b) the catalyst treated in the step (a) is oxidized and regenerated in liquid phase in presence of an oxidant; (c) the catalyst treated in the step (b) is dried and reduced. The method for regenerating the ruthenium hydrogenation catalyst can effectively remove high-boiling organic matters attached on the surface of the catalyst, can supplement load active components lost in the catalyst, can effectively recover the activity and selectivity of the catalyst, can prolong the service life of the catalyst, and can reduce the production cost.

Owner:WANHUA CHEM GRP CO LTD +1

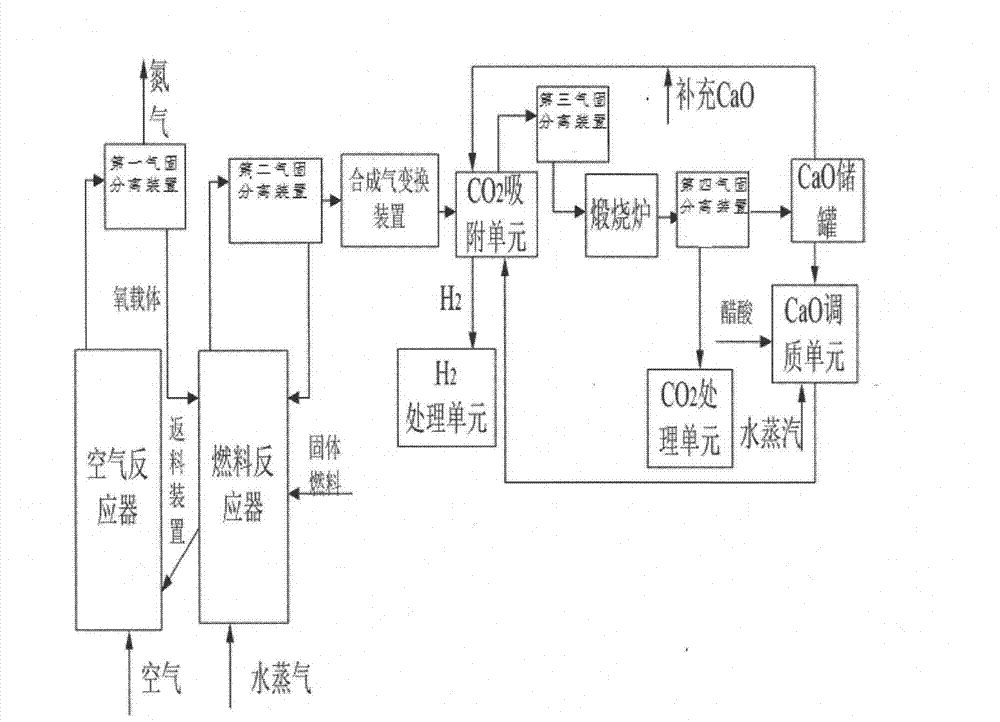

Solid fuel chemical-looping gasification hydrogen production system and method

ActiveCN103113917AEfficient separationAchieve near-zero emissionsHydrogen separation using solid contactCombustible gas productionSolid fuelProcess engineering

The invention provides a solid fuel chemical-looping gasification hydrogen production system and method. The solid fuel chemical-looping gasification hydrogen production system is characterized by comprising an air reactor, wherein the air reactor is connected with a first gas-solid separation device; the first gas-solid separation device is connected with a fuel reactor; the fuel reactor is connected with a second gas-solid separation device; a gas outlet of the second gas-solid separation device is connected with a synthetic gas converter; the synthetic gas converter is connected with a CO2 adsorption unit; a discharge port of the CO2 adsorption unit is connected with an H2 processing unit; an outlet of the CO2 adsorption unit is connected with a third gas-solid separation device; a CaCO3 solid outlet of the third gas-solid separation device is connected with a calcining furnace; the calcining furnace is connected with a fourth gas-solid separation device; a gas outlet of the fourth gas-solid separation device is connected with a CO2 processing unit; a solid outlet of the fourth gas-solid separation device is connected with a CaO storage tank; and the CaO storage tank is connected with the CO2 adsorption unit. The system can implement near zero discharge of CO2 in the hydrogen production process, and thus, reduces the influence of greenhouse gas on the environment.

Owner:SHANGHAI BOILER WORKS

Catalyst of composite oxides of molybdenum, cupper bimetal in use for synthesizing diphenyl carbonate through ester exchange

InactiveCN1915504AHigh catalytic activityEasy to separateMetal/metal-oxides/metal-hydroxide catalystsPreparation from organic carbonatesMethyl carbonateCopper

A catalyst with high activity and selectivity and able to be recovered easily for preparing diphenyl carbonate from dimethyl carbonate and phenol ester by ester exchange is basically and proportionally prepared from the oxide of Mo and the oxide of Cu through co-deposition or grinding, and calcining at 300-900 deg.C.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and preparation method thereof

InactiveCN101905155AHigh catalytic activityImprove catalytic performanceCatalyst activation/preparationPreparation from organic carbonatesCoprecipitationTitanium

The invention discloses a complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and a preparation method thereof. The catalyst basically consists of a molybdenum-titanium complex oxide, wherein the weight ratio of the molybdenum to the titanium is 100:10-100; the roasting temperature is between 300 and 600 DEG C; base raw materials for preparing the catalyst are a molybdenum compound and a titanium compound; and the preparation method adopts a coprecipitation method or mechanical grinding method. The catalyst has high catalytic activity and good selectivity for the reaction of synthesizing the diphenyl carbonate by ester exchange, and particularly has the advantages of simple preparation method, easy separation and recycling, no environmental pollution, no corrosion to equipment and the like, so the catalyst can be widely applied to production of the diphenyl carbonate.

Owner:CHANGZHOU INST OF CHEM

Method for regenerating precious metal hydrogenation catalyst

ActiveCN101376115AReduced activityRestore activityCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsHydrogenation processLight hydrocarbons

The invention relates to a hydrogenation catalyst regeneration method for a light hydrocarbon noble metal, which comprises the following steps: the hydrocarbon feeding is firstly stopped by using a reactor, heating or heat-exchange equipment, and hydrogen in the hydrogenation process of the light hydrocarbon noble metal; and then the hydrogen is heated by the heating or heat-exchange equipment, so as to enter the reactor to contact an inactivating noble metal catalyst. The catalyst regeneration method is organically combined with a hydrogenation process for the light hydrocarbon, conducts the catalyst regeneration by fully using the conditions in the hydrogenation technology process, and has the advantages of simple process, low cost, short time and good regeneration effect, and can be applied in the regeneration process of hydrogenation catalyst of various light hydrocarbon noble metals.

Owner:CHINA PETROLEUM & CHEM CORP +1

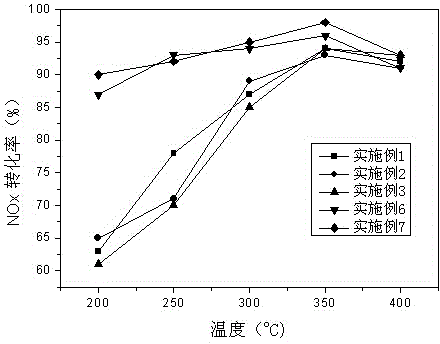

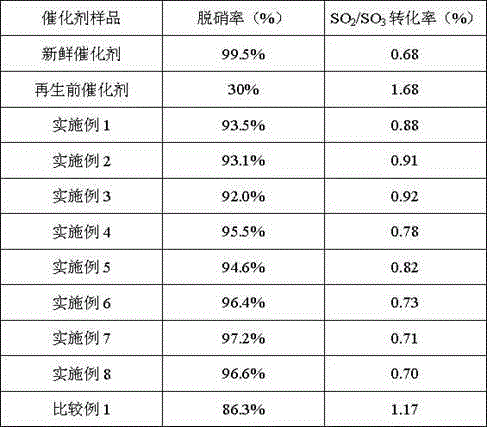

Denitration catalyst regeneration solution and preparation method thereof as well as catalyst regeneration method

ActiveCN103949291AGood water solubilityImprove catalytic performanceCatalyst regeneration/reactivationIonCopper nitrate

The invention discloses a denitration catalyst regeneration solution and a preparation method thereof as well as a catalyst regeneration method. The denitration catalyst regeneration solution comprises the following raw material ingredients in parts by weight: 4-6 parts of vanadyl oxalate, 0.08-0.10 part of cerium nitrate, 0.11-0.13 part of lanthanum nitrate, 0.05-0.07 part of copper nitrate, 0.4-0.6 part of silica sol ST-O and 95 parts of deionized water. The catalyst regeneration method comprises the following steps of firstly, evenly mixing vanadyl oxalate and the deionized water; then, feeding cerium nitrate, lanthanum nitrate and copper nitrate into mixed solution, and fully stirring until the mixture is completely dissolved; finally, feeding silica sol ST-O, and continuing to stir until homogeneous phase is obtained; and sequentially carrying out strong scavenging and ultrasonic cleaning on an inactivated denitration catalyst module, soaking the module in cleaning solution for 18-25 minutes, continuing soaking the module in the regeneration solution for 25-40 minutes, taking out the denitration catalyst module and drying. After the denitration catalyst regeneration solution and the catalyst regeneration method are adopted, the activity of the inactivated denitration catalyst can be efficiently recovered, and the temperature range of the catalyst activity is widened.

Owner:江苏万德环保科技有限公司

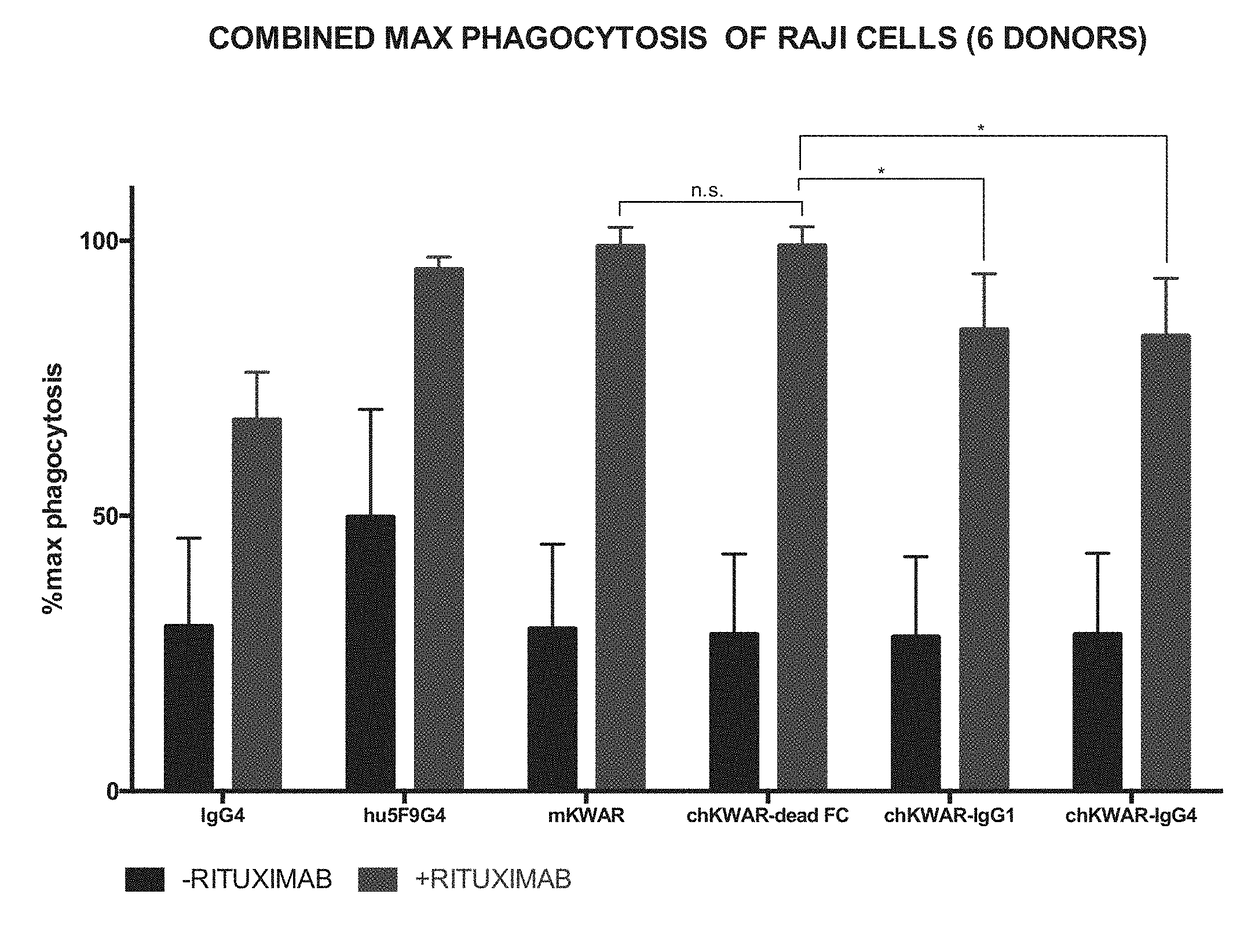

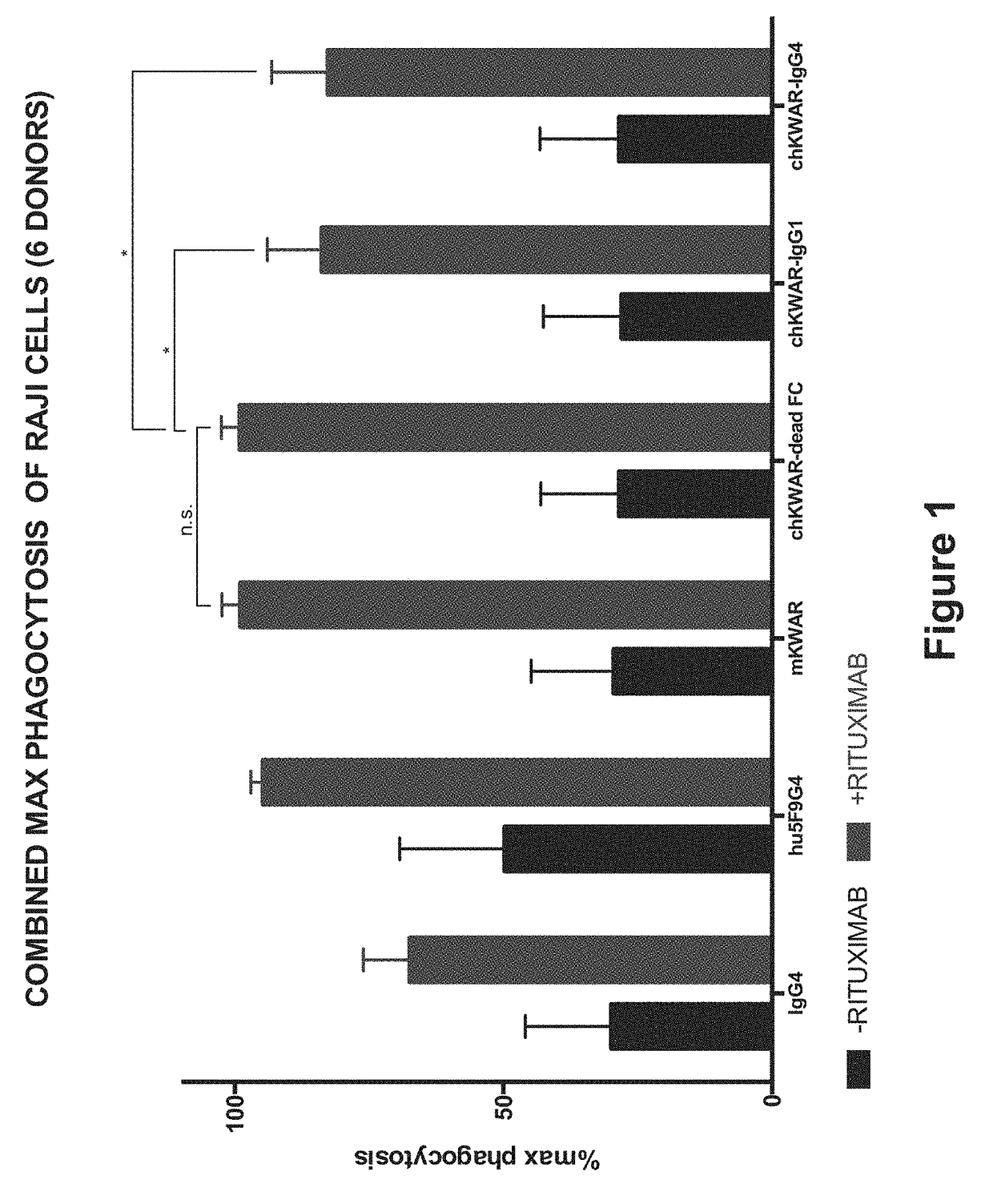

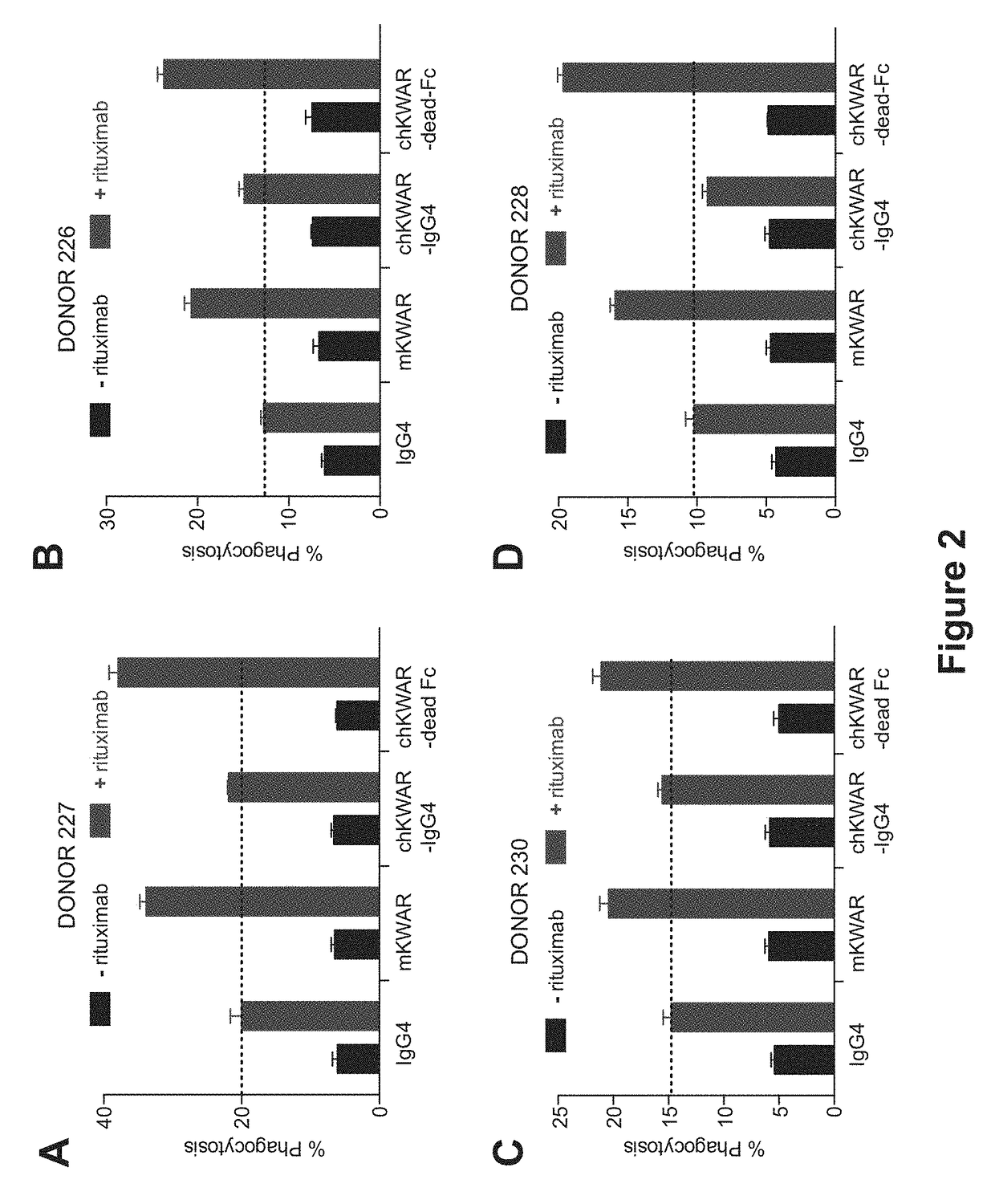

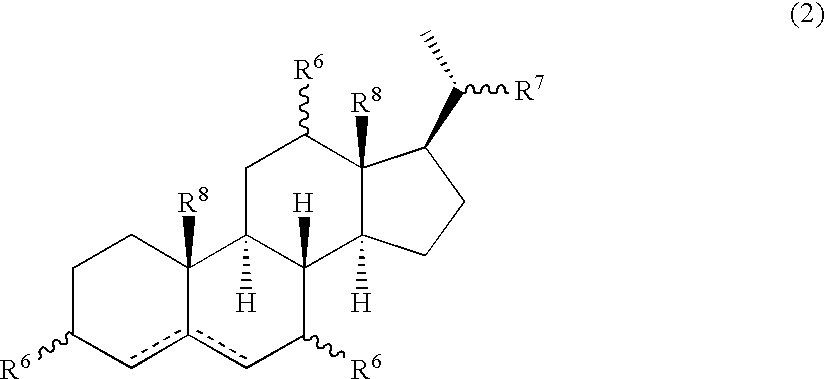

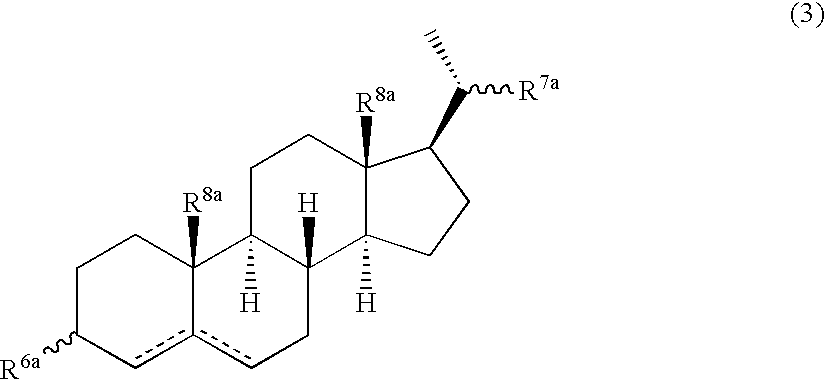

Disrupting FC Receptor Engagement on Macrophages Enhances Efficacy of Anti-SIRPalpha Antibody Therapy

ActiveUS20180037652A1Reduce it effectivenessRestore activityImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsDrugFc receptor

Anti-SIRPα antibodies, including multi-specific anti-SIRPα antibodies, are provided, as are related compositions and methods. The antibodies of the disclosure bind to SIRPα and can block the interaction of CD47 on one cell with SIRPα on a phagocytic cell. The subject anti-SIRPα antibodies find use in various therapeutic methods. Embodiments of the disclosure include isolated antibodies and derivatives and fragments thereof, pharmaceutical formulations comprising one or more of the anti-SIRPα antibodies; and cell lines that produce the antibodies. Also provided are amino acid sequences of exemplary anti-SIRPα antibodies.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Solid base catalyst for synthesis of glycerol carbonate and its preparation method and application

InactiveCN103007915AHigh catalytic activityHigh activityMetal/metal-oxides/metal-hydroxide catalystsPreparation from organic carbonatesAlkali metal oxideGlycerol

The invention relates to a solid base catalyst for synthesis of glycerol carbonate. The catalyst is composed of 0.66%-28.77% by mass of a base metal oxide and the balance Mg-Al hydrotalcite, with the base metal oxide loaded on the Mg-Al hydrotalcite. Specifically, in the Mg-Al hydrotalcite, Mg and Al are in a mole ratio of 1-5:1. The solid base catalyst provided in the invention has the advantages of good stability, no pollution, and high activity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Clear essence containing fullerene polypeptide

InactiveCN109464343ARestore activityImprove antioxidant capacityCosmetic preparationsToilet preparationsHydroxyphenyl propamidobenzoic acidDefoaming Agents

The invention provides clear essence containing fullerene polypeptide and relates to the technical field of cosmetics. Essence composition comprises fullerene, a humectant, a sweetening agent, a defoaming agent, a lubricant, a surfactant, polypeptide, a plant extract, a preservative, a bifida ferment lysate, hydroxyphenyl propamidobenzoic acid and ascorbyl palmitate. The essence is rich in fullerene, plant extract and polypeptide, and can strongly resist oxidation and scavenge free radicals. After fullerene is added to the composition and combined with vitamins and polypeptide, active oxygen generated under various conditions can be eliminated, antioxidant duration is long, strong antioxidant effect can still be ensured under the conditions of light and high temperature, and the essence can resist aging, reduce wrinkles and restore skin vitality after use.

Owner:广州灵润生物科技有限公司

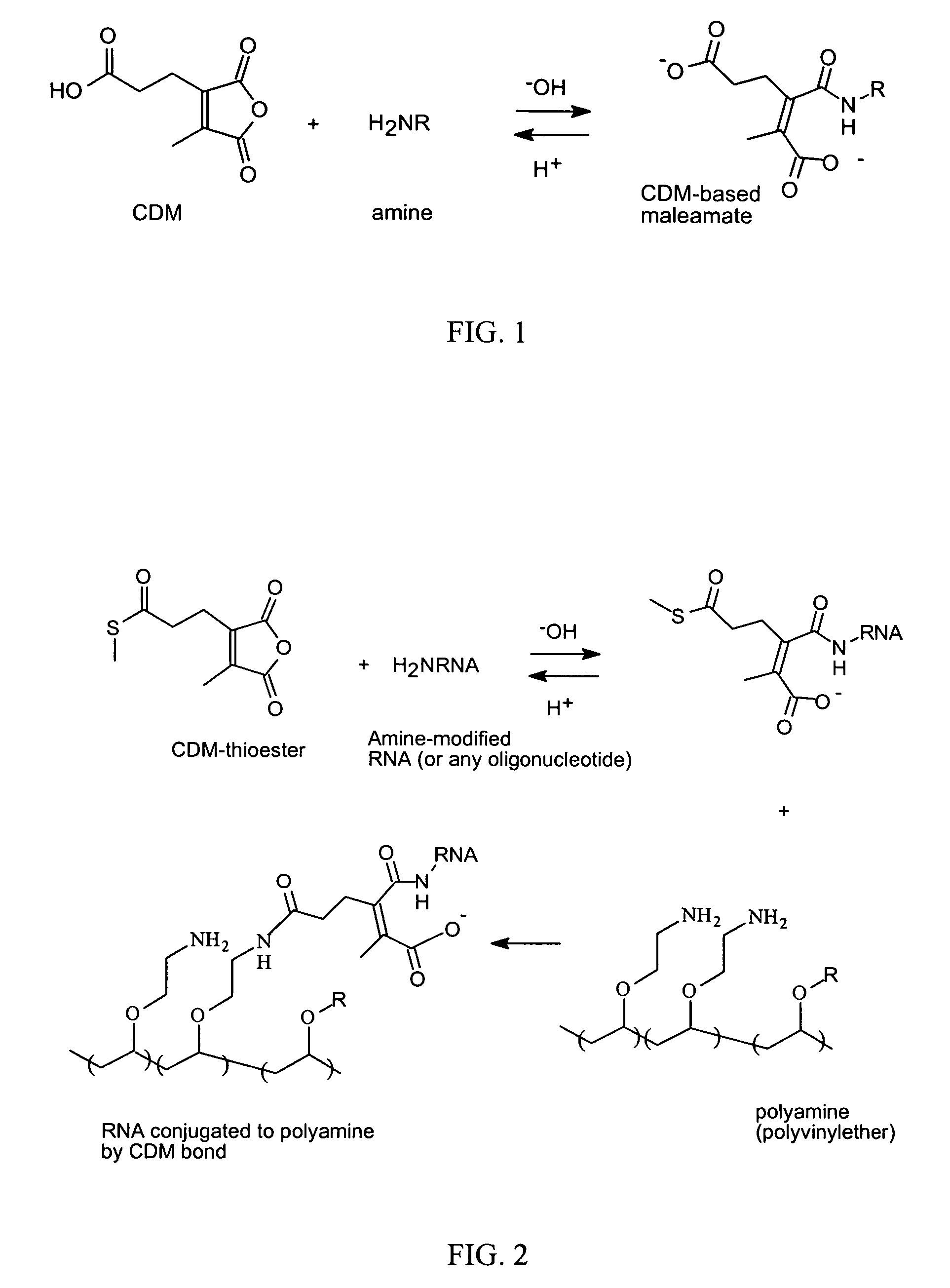

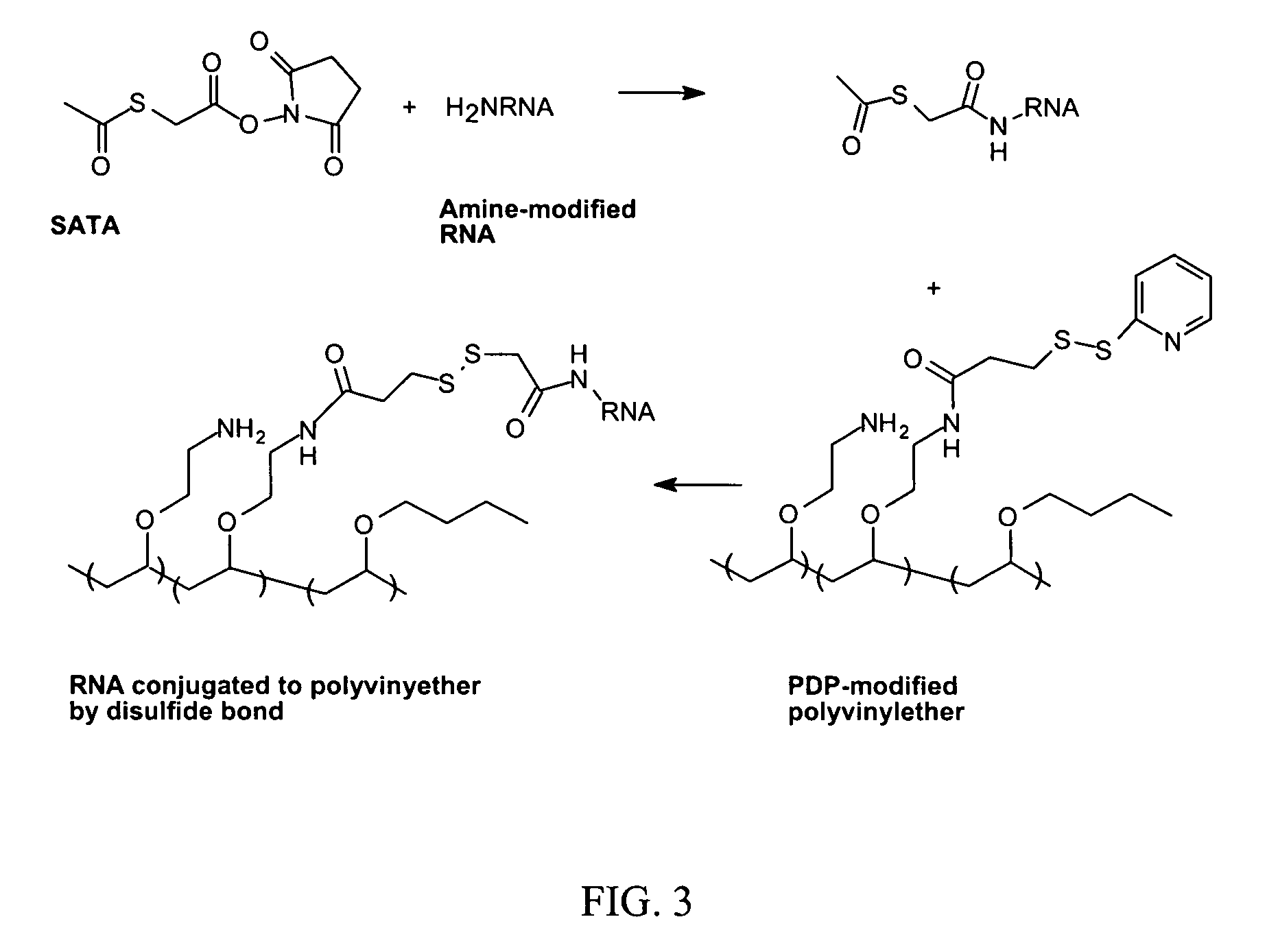

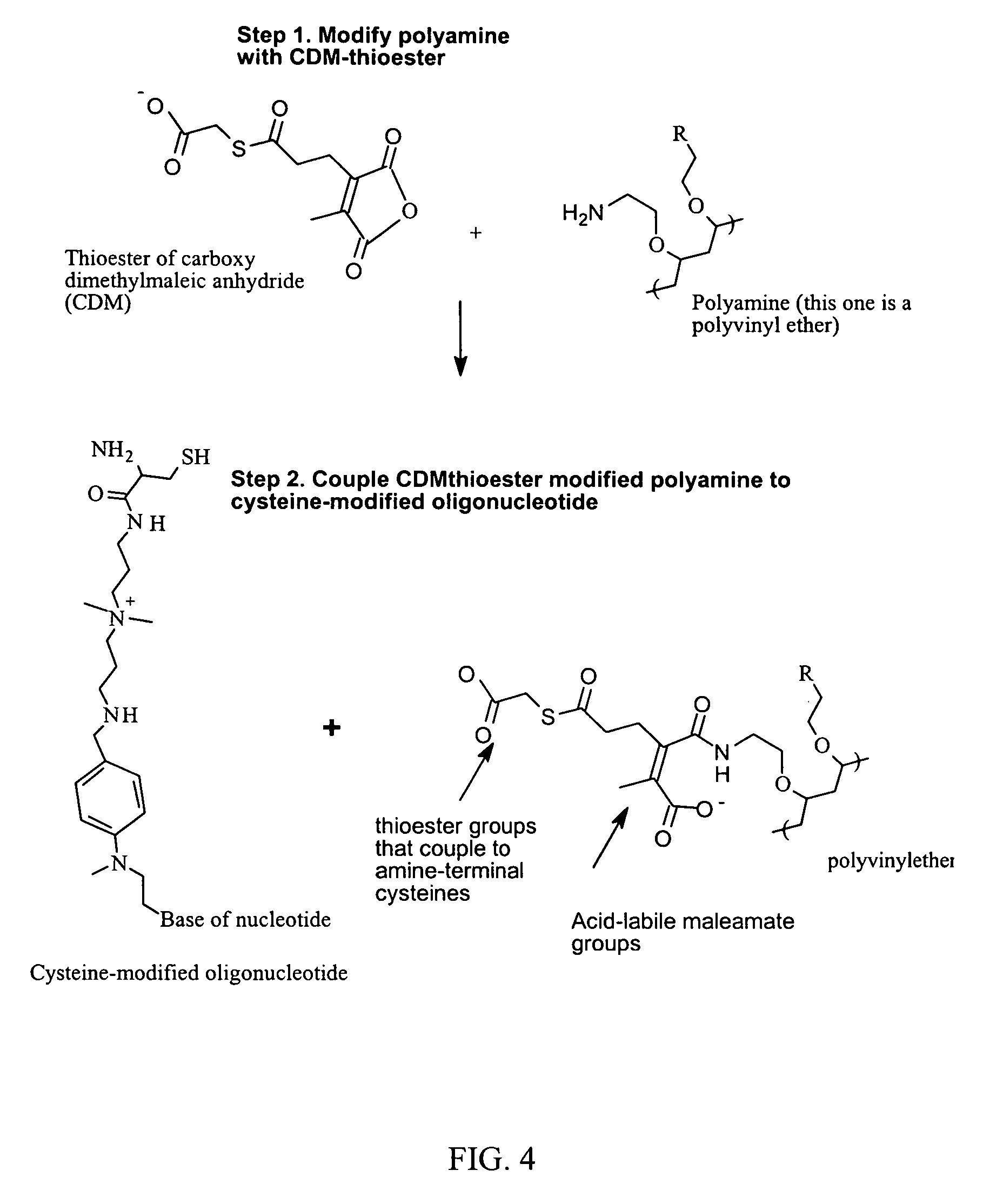

Reversible attachment of a membrane active polymer to a polynucleotide

ActiveUS7816337B2Reduce membrane activityReduces membrane activityBiocideSpecial deliveryToxicityNucleotide

Described is a process for delivering a biologically active compound to a cell by reversibly linking the compound to a membrane active polymer. In particular, polymer-polynucleotide conjugates are described. Methods for reversibly modifying the polymers to decrease cellular toxicity and improve efficacy are provided.

Owner:ARROWHEAD MADISON

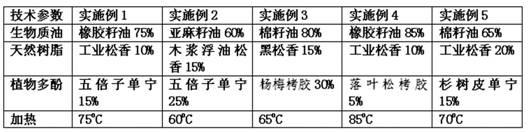

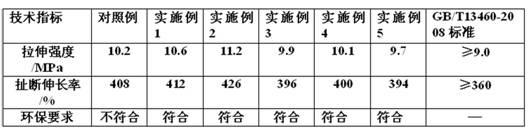

Environmentally-friendly biomass compound rubber regenerant and preparation method thereof

The invention provides an environmentally-friendly biomass compound rubber regenerant. The regenerant is prepared from the following raw materials in mass percentage: 60-85% of bio-oil, 10-20% of natural resin and 5-30% of plant polyphenol. The preparation method of the regenerant comprises the following steps: (1) heating the bio-oil to 60-85 DEG C; (2) respectively adding the natural resins andthe plant polyphenol to the bio-oil and evenly mixing; and (3) naturally cooling the evenly mixed product to room temperature to finally obtain the environmentally-friendly biomass compound rubber regenerant product. In the invention, the bio-oil, the natural resins and the plant polyphenol which are extracted from plants are taken as raw materials, and the raw materials are renewable materials, which realizes maximum resource utilization and reduces dependence on petrochemical resource so as to achieve the purpose of green production of reclaimed rubber. The regenerant has the advantages of good rubber regeneration effect, high product quality, low production cost and no pollution and nuisance during the production process. The environmentally-friendly reclaimed rubber produced by the regenerant can be widely applied to various rubber products and can replace rubber materials, thus saving rubber resources.

Owner:KUNMING PHOENIX RUBBERS

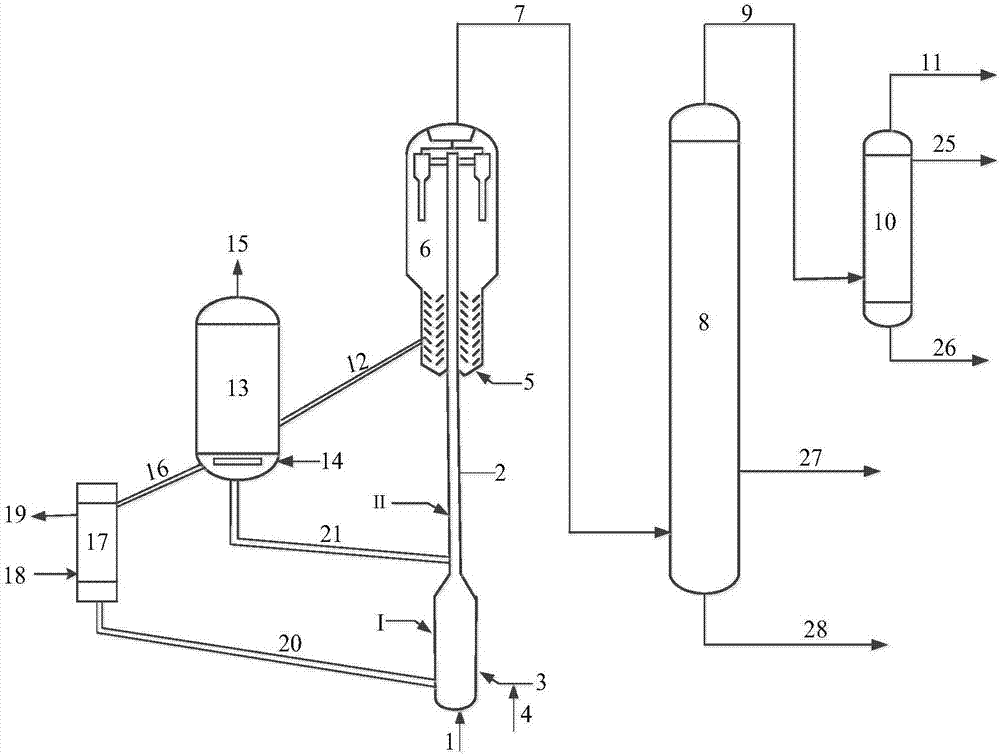

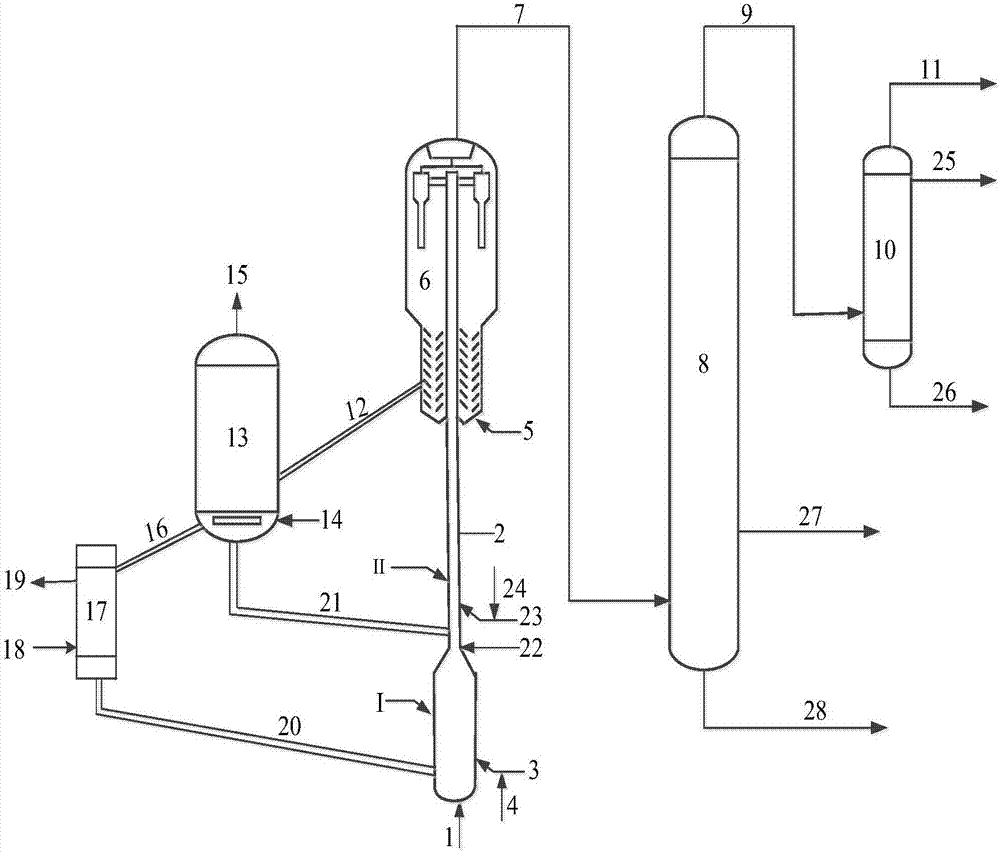

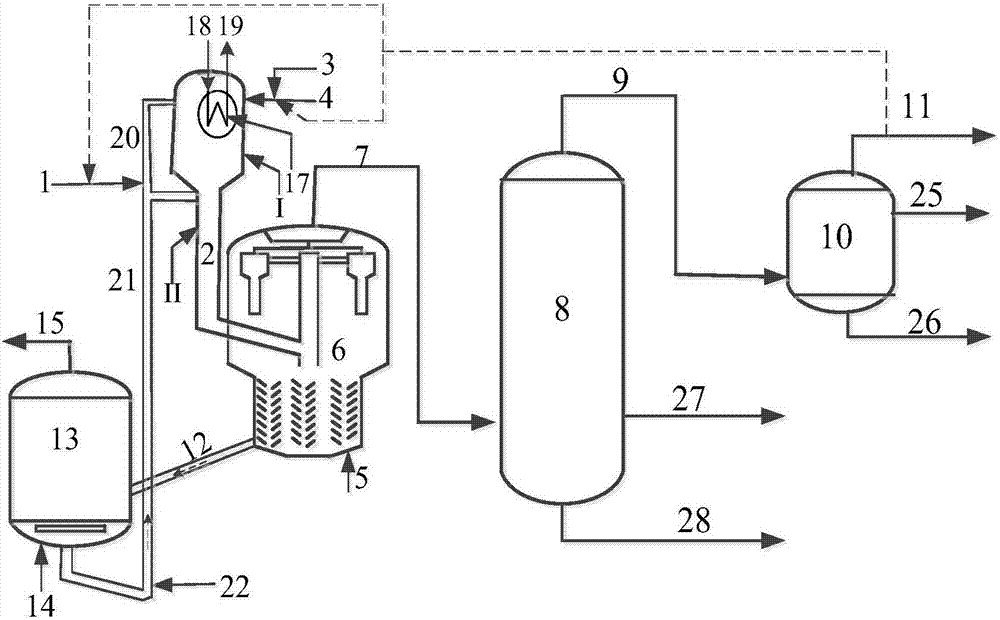

Processing method and system for inferior crude oil

ActiveCN107267211AEliminates rich gas compressorReduce device energy consumptionTreatment with hydrotreatment processesChemistryDry gas

The invention discloses a processing method and system for inferior crude oil. The method comprises the steps as follows: a, feeding hydrogen-containing gas and the inferior crude oil into a fluidized bed hydrogen absorption zone (I) of a fluidized bed riser reactor for contact with a first catalytic cracking catalyst and a hydrogen adsorption reaction to obtain a hydrogen absorption product; b, feeding the hydrogen absorption product obtained in the step a into a riser cracking zone (II) of the fluidized bed riser reactor for contact with a second catalytic cracking catalyst and a catalytic cracking reaction to obtain catalytic cracked oil-gas. The inferior crude oil processed by the system with the method has the advantages that the conversion rate of the inferior crude oil can be increased substantially, the yield of dry gas and coke is reduced, and accordingly, clean and efficient use of the inferior crude oil is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

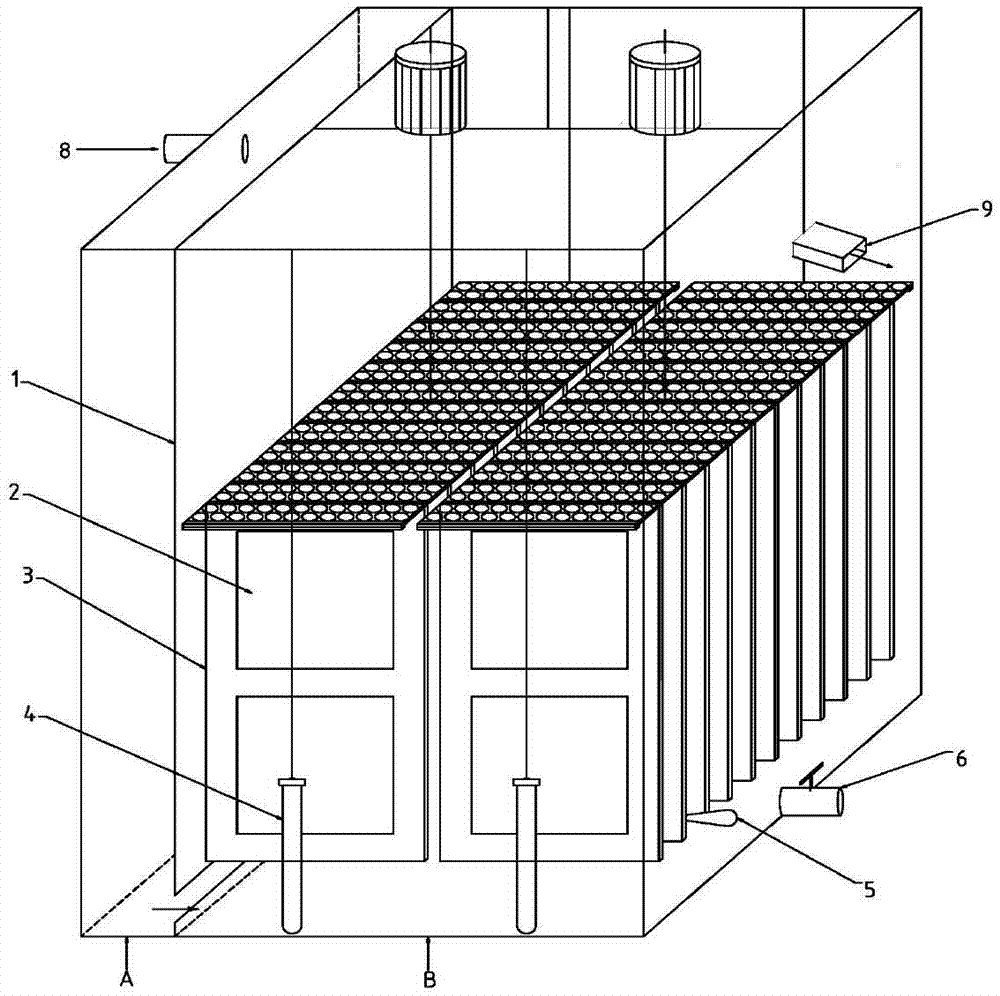

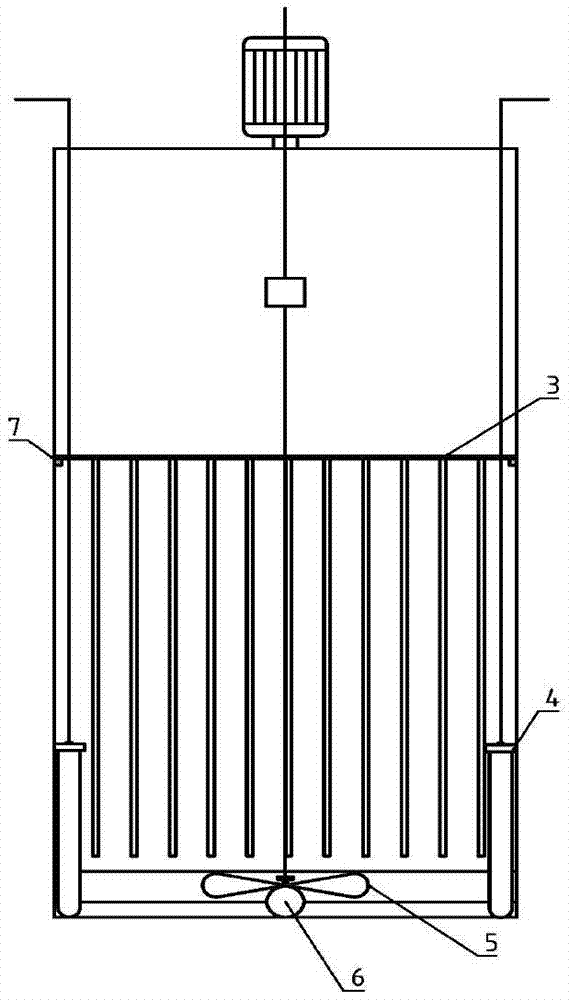

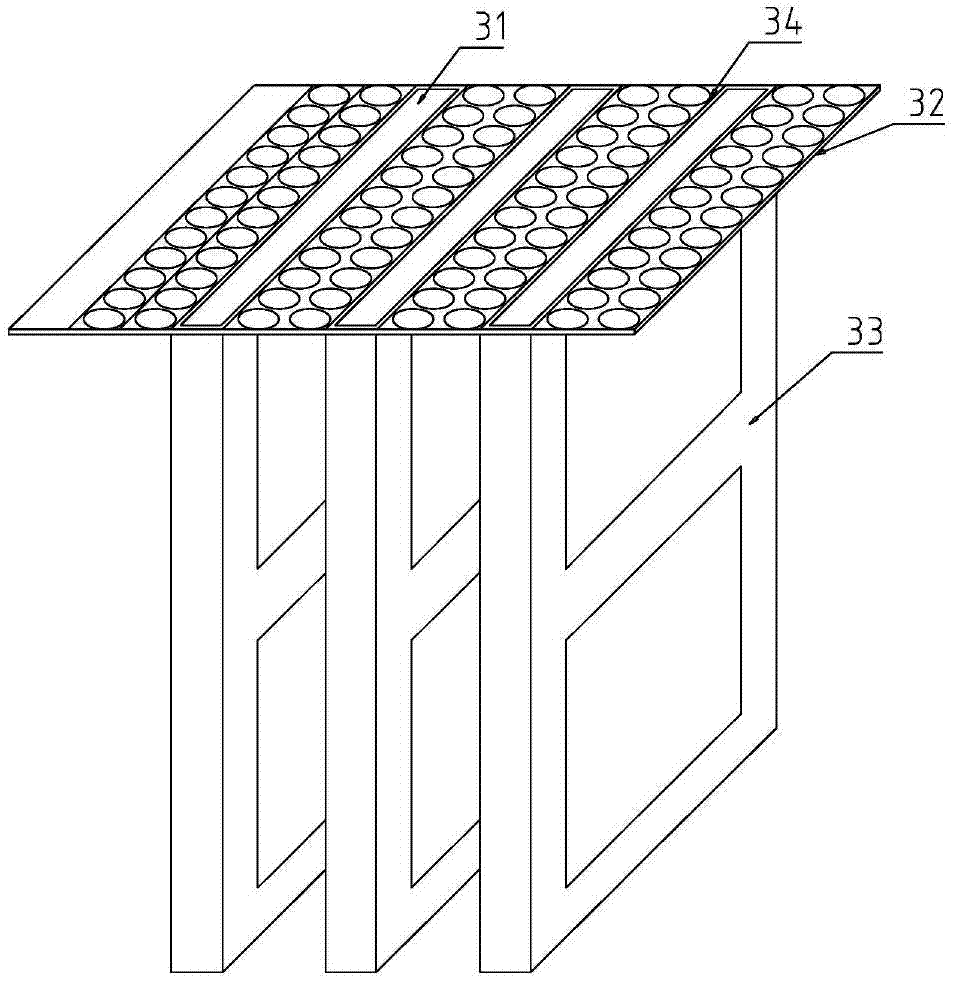

Up-flow solid carbon source biofilm carrier denitrification bioreactor

ActiveCN103172172AGood biodegradabilitySimple system structureTreatment with anaerobic digestion processesChemistryFixed frame

Owner:CHONGQING UNIV

Catalyst and method preparing dimethyl carbonate by using catalyst

InactiveCN105251496AFlexible processMild process conditionsChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsTrans esterificationPtru catalyst

The invention discloses a catalyst and a method preparing dimethyl carbonate by using the catalyst. The method comprises two steps: step 1, with urea and aliphatic dihydric alcohol as raw materials, reacting urea with aliphatic dihydric alcohol under the action of the catalyst to synthesize ethylene carbonate or propylene carbonate, wherein reaction conditions are that reaction temperature is 100 to 200 DEG C and 0.5 to 5 mL of nitrogen is introduced into a reaction system per minute; and step 2, subjecting ethylene carbonate or propylene carbonate and methanol to ester interchange so as to synthesize dimethyl carbonate, wherein a reaction condition is that reaction temperature is 60 to 170 DEG C, and the catalyst is a supported catalyst prepared by preparing a solution with a certain concentration from a metal salt or metal oxide and then impregnating a same-volume carrier with the solution. The technical characteristics of the invention are that reaction conditions are mild; reaction is carried out at normal pressure; and the catalyst is easy to separate and recycle, can be repeatedly used and poses no corrosion to equipment and no environmental pollution.

Owner:SICHUAN LUTIANHUA

Double component carried catalyst for synthesizing diphenyl carbonate and its preparing method

InactiveCN1391986AHigh catalytic activityGood repeatabilityMolecular sieve catalystsOrganic compound preparationPhenolOxidative carbonylation

The present invention relates to double-component carried catalyst PdCl2-Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions, PdCl2 in 0.1-10 weight portions and Cu(OAc)2 in 0.1-30 weight protions. It is prepared through equi-volume soaking and roasting at 250-750 deg.c. The catalyst system has also metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bride as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

Regeneration method of SCR denitration catalyst

ActiveCN105709861ARestore activityReduce adverse effectsCatalyst regeneration/reactivationRoom temperatureSodium tungstate dihydrate

The invention discloses a regeneration method of an SCR denitration catalyst. The regeneration method includes: (1), performing ash blowing, cleaning and drying on the SCR denitration catalyst which is waste and deactivated; (2), smashing the waste SCR denitration catalyst which is dried well, adding a strong base solution of 10 wt%-40 wt% in mass concentration, and reacting for 3-8 h at temperature of 150-200 DEG C; (3), adjusting pH value of reaction liquid in the step (2) to 9-10, filtering and separating to obtain recovery liquid containing sodium tungstate and sodium vanadate, and adjusting concentration of vanadium in regeneration liquid to 2-10 g / L; (4), soaking the deactivated SCR denitration catalyst dried well in the step (1) in the regeneration liquid with concentration fixed well in the step (3) at room temperature for regeneration, and taking out before placing for 60 min at room temperature; (5), drying, roasting and cooling a catalyst in the step (4) to obtain a regenerated SCR denitration catalyst. The regeneration method has the advantages of good regeneration effect, low SO2 / SO3 conversion rate and low regeneration cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional molecular complexes for gene transfer to cells

InactiveUS20050239204A1Restore activitySsRNA viruses negative-senseMicroencapsulation basedChemistryCompound s

A multifunctional molecular complex for the transfer of a nucleic acid composition to a target cell is provided. The complex is comprised of A) said nucleic acid composition and B) a transfer moiety comprising 1) one or more cationic polyamines bound to said nucleic acid compositions, 2) one or more endosome membrane disrupting components attached to at least one nitrogen of the polyamine and 3) one or more receptor specific binding components.

Owner:WYETH

Regeneration method of protein foam extinguishing agent

The invention discloses a regeneration method for a protein foam extinguishing agent which consists of the following steps: (1) the inactive protein foam extinguishing agent is placed into a reaction kettle with the temperature being controlled between 60 DEG C and 70 DEG C; (2) under the situation of mixing, surfactant, salt-mixture, inorganic ammonia salt and one or more of mixtures of organic ammonia salt are added to dissociate the protein for the sedimentation of the protein, the mixing time is 30min to 60min; (3) sedimentation is rested for 30min to 60min; (4) a clear liquid is taken; (5) the clear liquid is heated in the reaction kettle with the temperature being controlled between 35 DEG C and 50 DEG C; (6) stabilizer and preservative are added into the clear liquid under the situation of mixing, the mixing time is 30min to 60min; (7) resting; (8) the clear liquid is taken so as to acquire the regenerated protein foam extinguishing agent. The regeneration method of the protein foam extinguishing agent can carry out treatment on the inactive protein foam extinguishing agent and lead various indexes to suit for GA219-1999 requirements, thus realizing the regeneration and secondary utilization of the protein foam extinguishing agent.

Owner:江苏锁龙消防科技股份有限公司

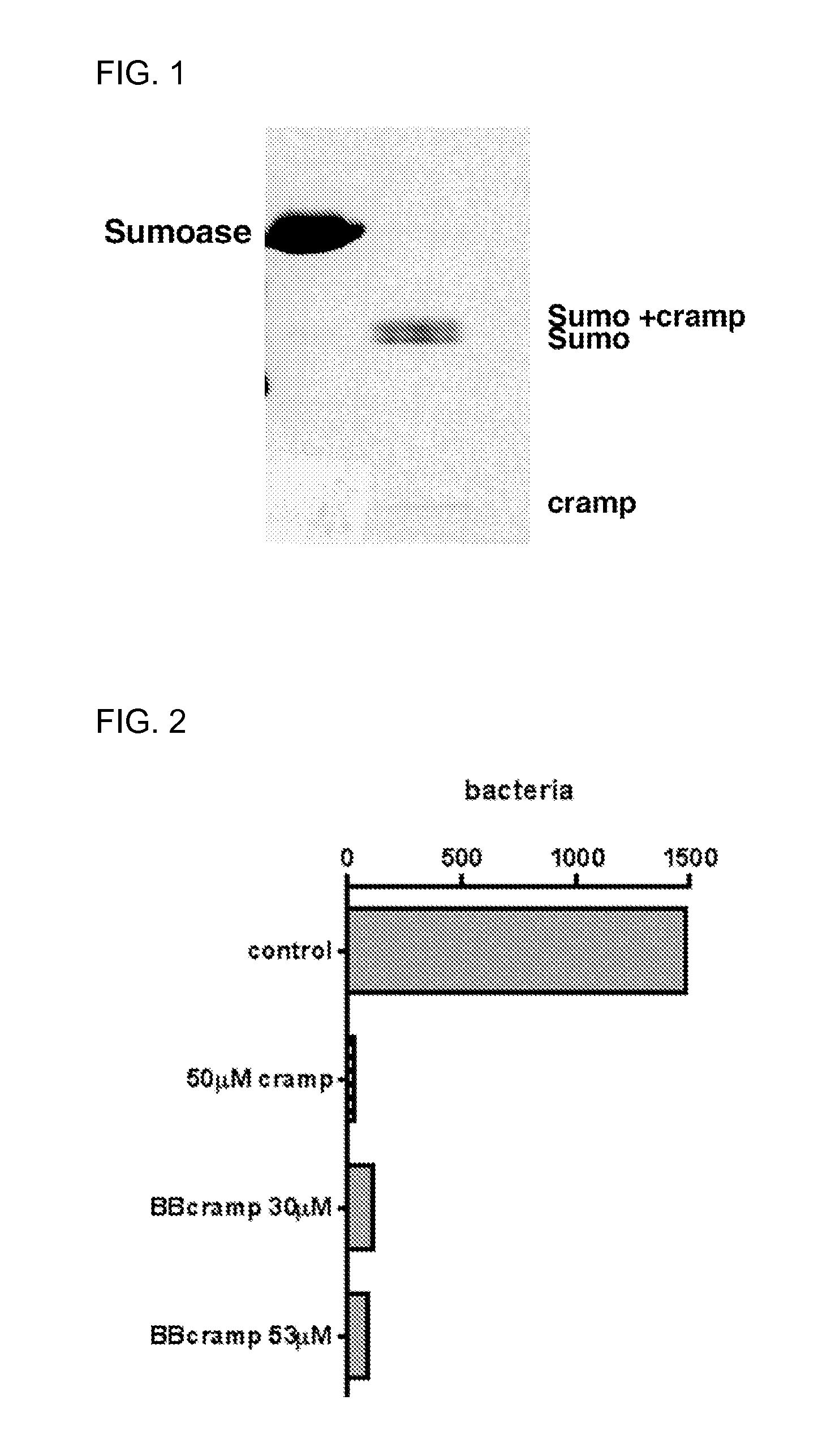

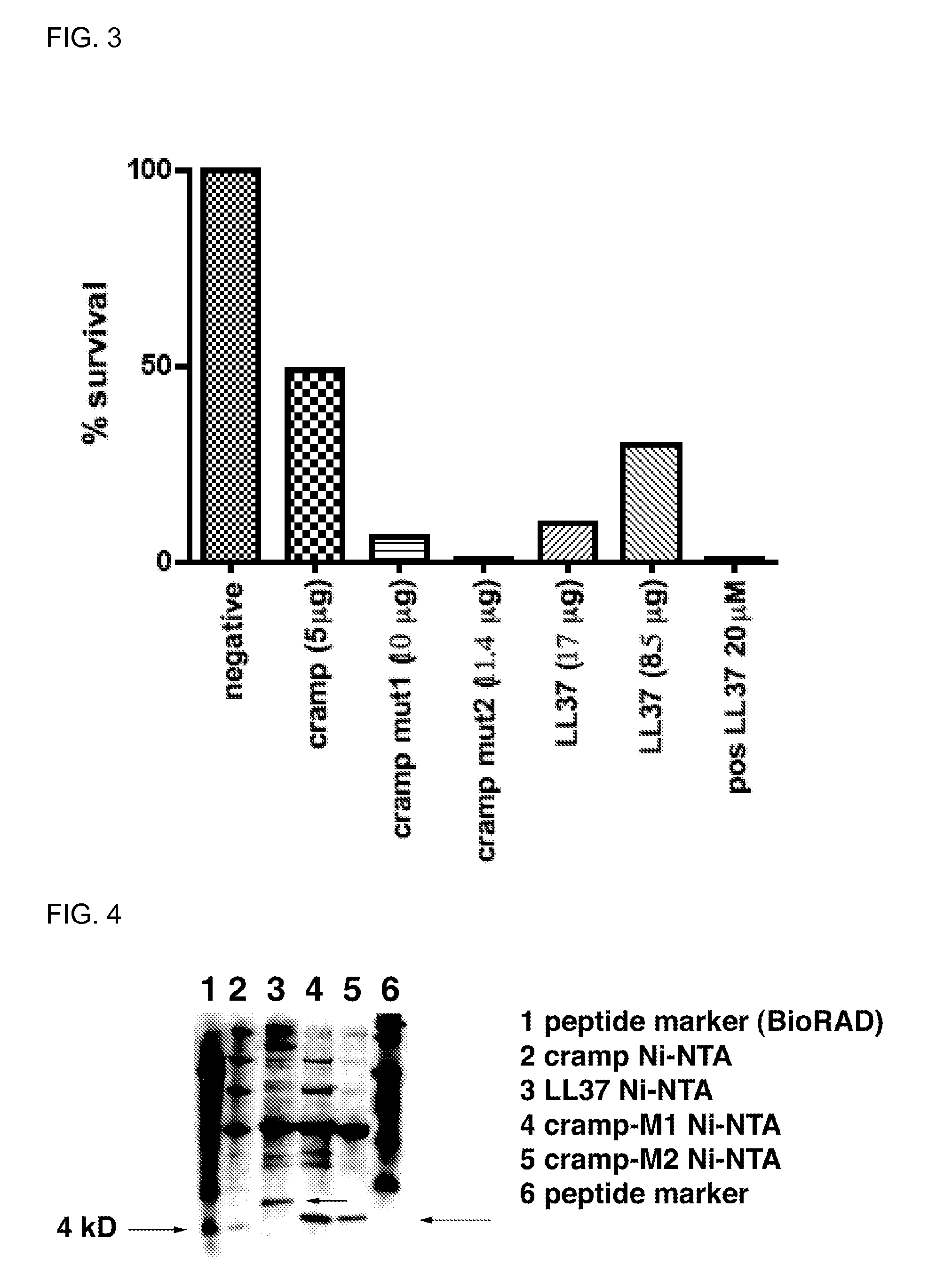

Production of Anti-microbial peptides

InactiveUS20100048480A1Decrease native antimicrobial activityImprove stabilityAntibacterial agentsBiocideMicroorganismAnti microbial peptide

The present application provides methods of producing antimicrobial peptides (AMPs) in a cell, for example by expression a fusion protein that includes small ubiquitin related modifier (SUMO) and an AMP in the cell. Also provided are nucleic acid and protein sequences of SUMO-AMP fusion proteins, and kits that include such molecules.

Owner:EMORY UNIVERSITY

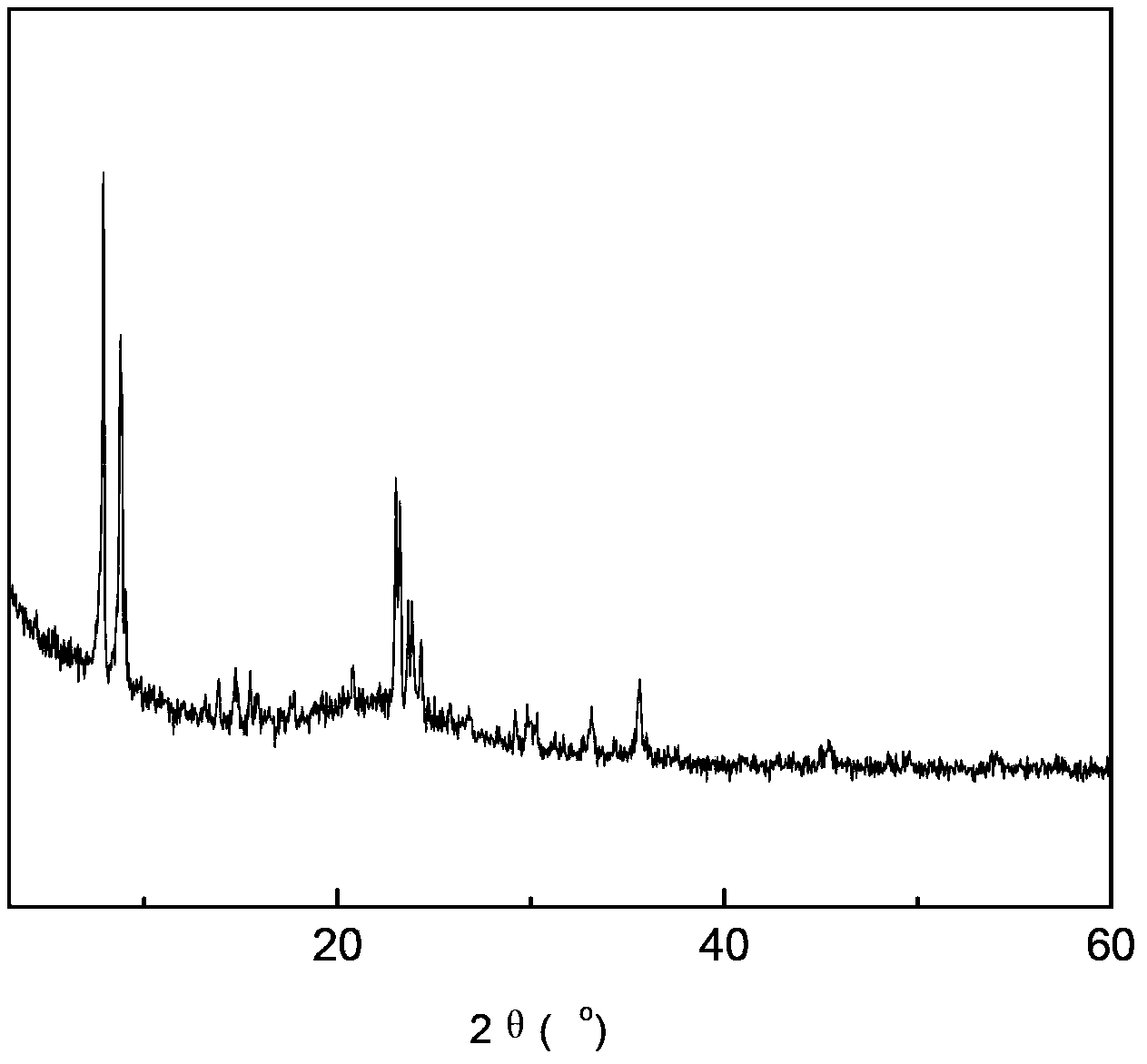

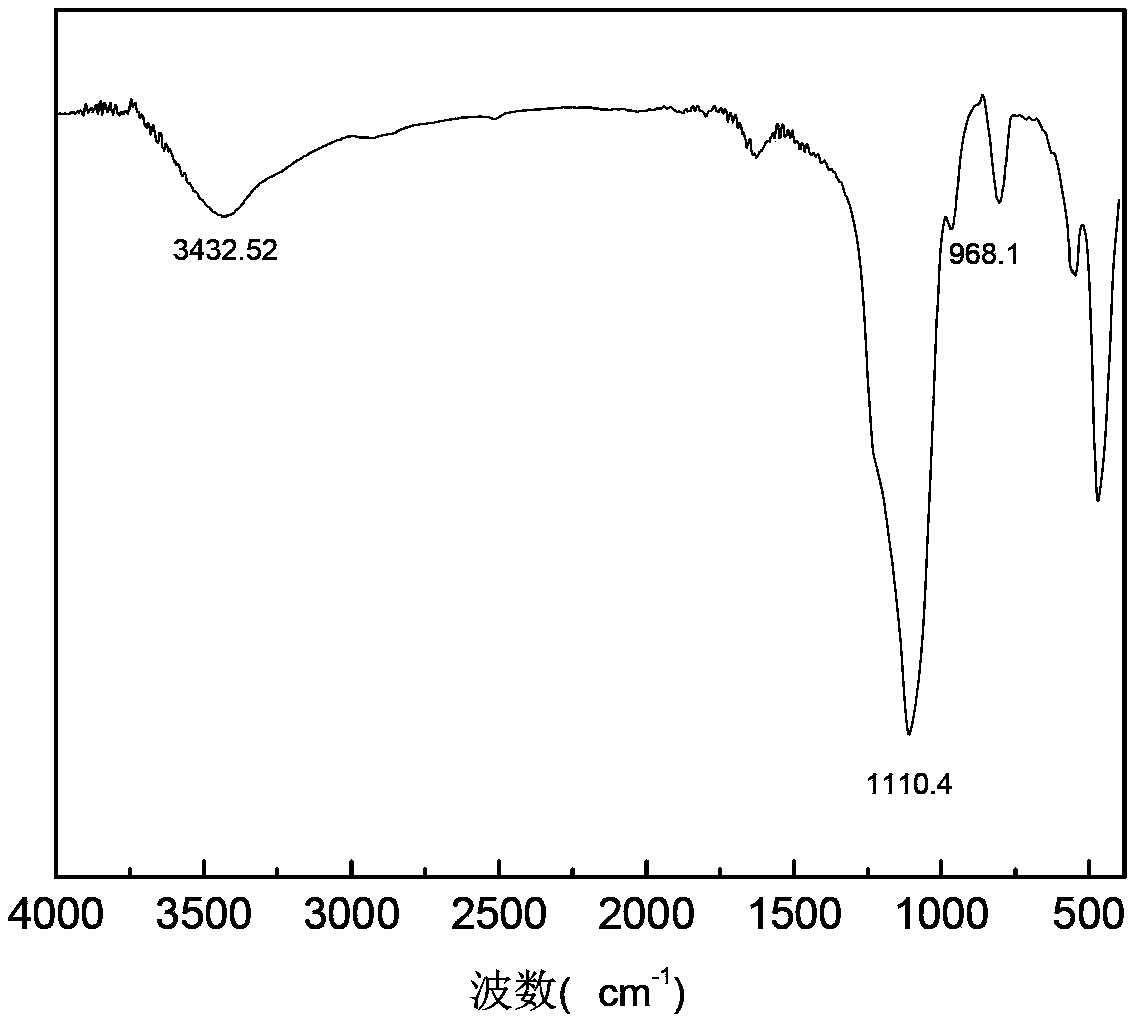

Magnetic titanium silicon molecular sieve with compact protective layer and its application

ActiveCN103406145AHigh catalytic activityEasy to separateOrganic chemistryMolecular sieve catalystsFerrous saltsSio2 nanoparticle

The invention discloses a magnetic titanium silicon molecular sieve with a compact protective layer and its application. The preparation method of the magnetic titanium silicon molecular sieve consists of the steps of: (1) preparing a ferric salt or ferrous salt water solution, performing a reflux reaction to obtain Fe nanoparticles; (2) adding the Fe nanoparticles prepared in step (1) into an isopropyl alcohol solution containing NH3.H2O and water, stirring them uniformly, then adding tetraethyl orthosilicate and leaving them to react completely, then carrying out separation to obtain solid particles, and conducting roasting to obtain Fe / SiO2 nanoparticles with a compact SiO2 layer; (3) mixing the Fe / SiO2 nanoparticles with the compact SiO2 layer with a glucose water solution, performing crystallization to obtain carbon-coated Fe / SiO2 / C nanoparticles; and (4) preparing a TS-1 molecular sieve mother liquor, mixing the carbon-coated Fe / SiO2 / C nanoparticles with the TS-1 molecular sieve mother liquor, and carrying out crystallization and roasting, thus obtaining the magnetic titanium silicon molecular sieve with a compact protective layer. The magnetic titanium silicon molecular sieve can be used as a catalyst in preparation of epichlorohydrin by epoxidation of allyl chloride and hydrogen peroxide, and has good catalytic properties.

Owner:ZHEJIANG UNIV OF TECH

Catalytic no-hydroprocessing adsorbing desulfurization for hydrocarbon oil in moving bed reactor

The non-hydrocatalyzing adsorption process for desulfurizing hydrocarbon oil in a moving bed reactor includes feeding sulfur containing hydrocarbon oil material and fluidizing medium into the moving bed reactor, contacting alternately with filled sulfur converting agent and sulfur adsorbent, separating the reacted matter flow to obtain product, steam stripping the deactivated sulfur converting agent and sulfur adsorbent and burning to regenerate, and returning the regenerated sulfur converting agent and sulfur adsorbent to the moving bed reactor for circular use. The process completes the catalytic conversion of organic sulfide into inorganic sulfide and the timely adsorption of inorganic sulfide cooperatively inside one reactor, and can realize deep desulfurization of gasoline in non-hydrogenation condition in the desulfurizing rate up to 96 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pollution-free laying hen breeding feed

The invention discloses belongs to pollution-free laying hen breeding feed, belongs to the field of laying hen feed, and aims to provide the non-harmful, non-residual, and nutrient balanced laying hen breeding feed. The technical scheme adopted is that the pollution-free laying hen breeding feed is matched by the following raw materials in part by weight: 300-350 parts of maize, 80-90 parts of soybean meal, 60-70 parts of bran, 4-6 parts of rock flour, 3-4 parts of hydrogen and calcium, 2-5 parts of methionine, 0.1-1 parts of lysine, 0.1-1 parts of phytase, 5-15 parts of salt, and 1-10 parts of premix. A laying hen fed by adopting the feed has higher qualified rate in tibia length and weight, good chicken uniformity, and high later period egg laying rate.

Owner:山西翼众农牧有限公司

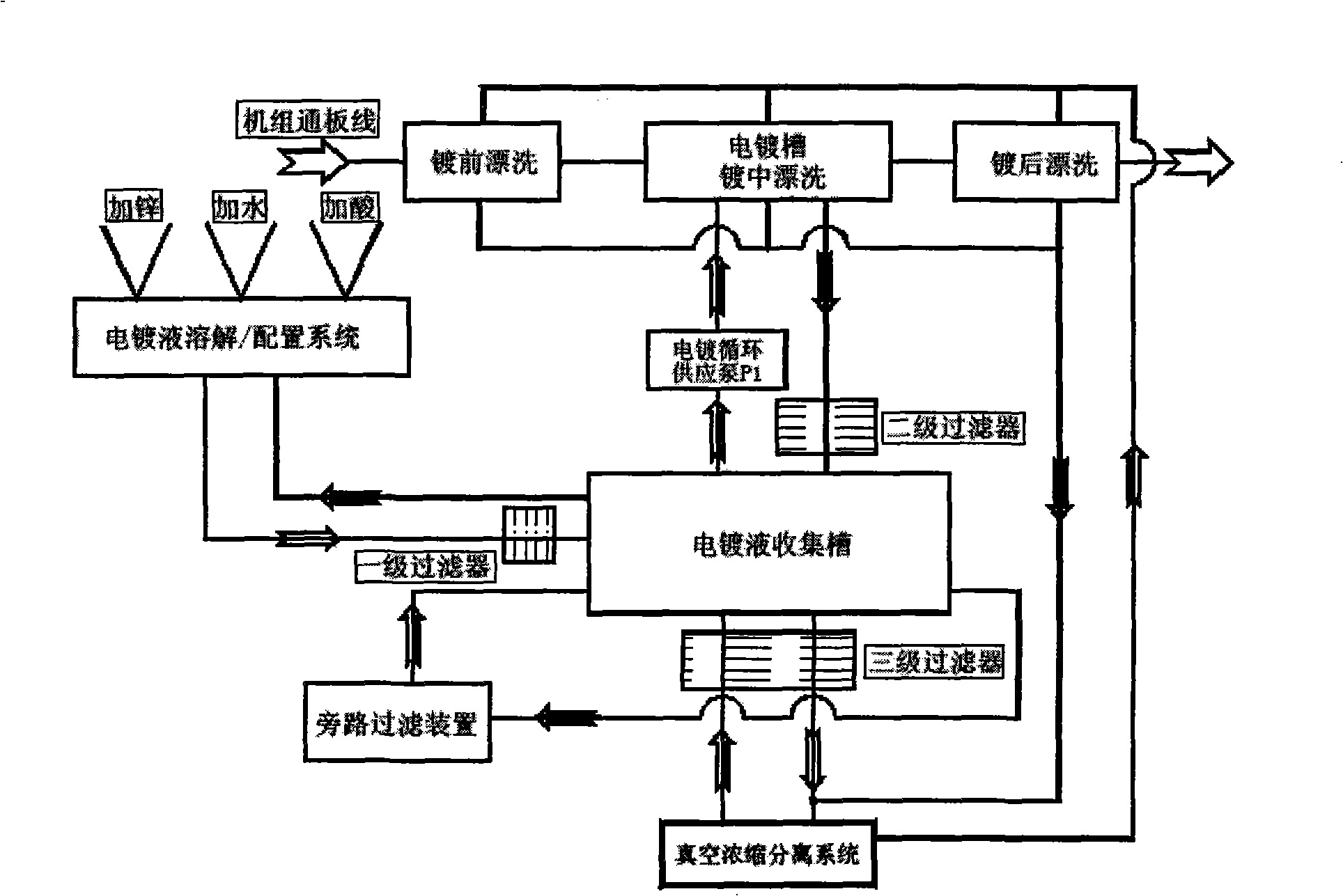

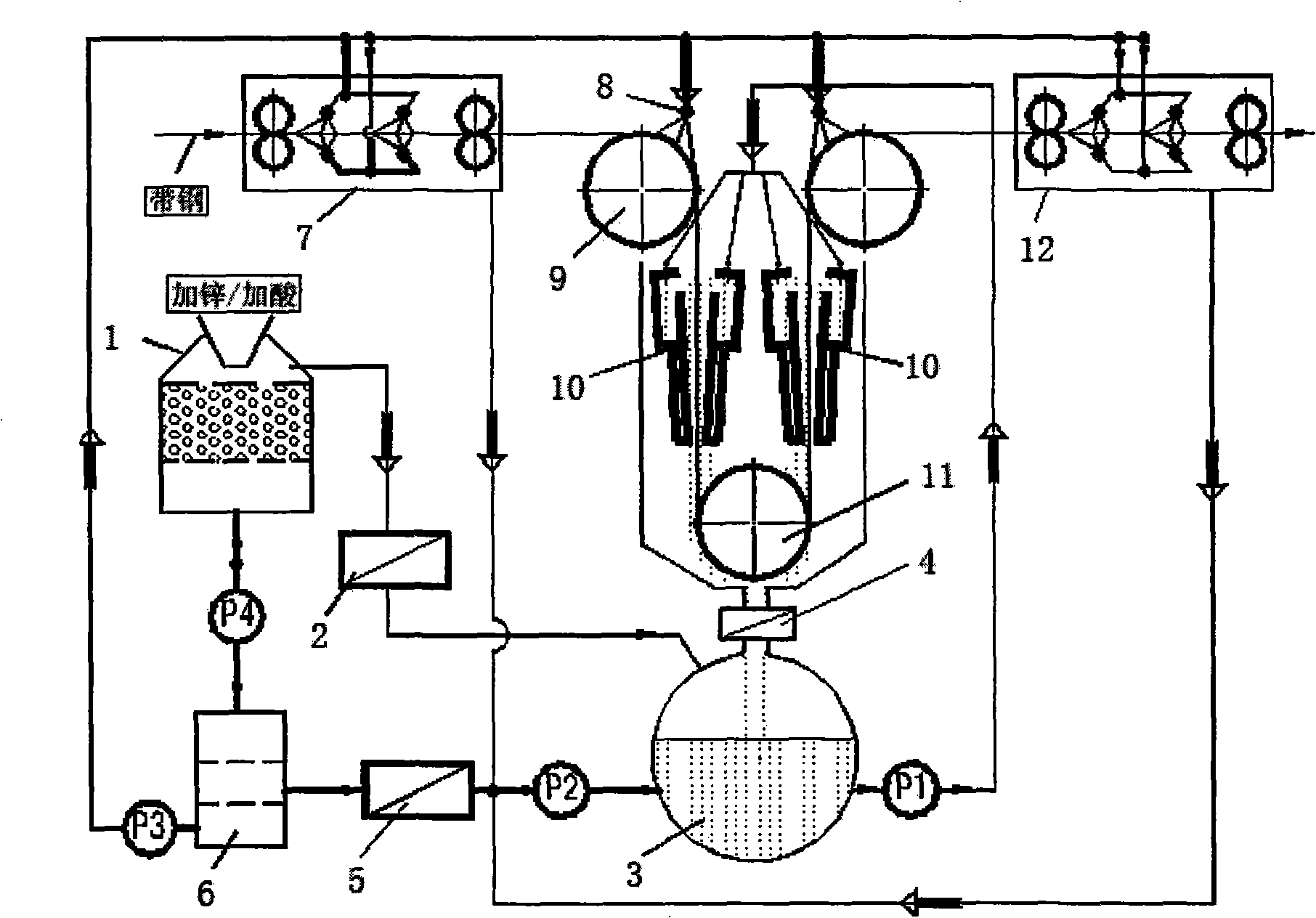

Electro-galvanizing liquid automatic allocating and updating system

The invention provides an automatic configuration-updating system of electrogalvanizing solution, comprising a dissolving / configuration system of the electrogalvanizing solution, a filtering system, a vacuum concentration separation system, a circulating system and an electroplating solution collecting tank. Impurities of a filter are taken out regularly by the reasonable and optimized configuration of all the systems; and the diluted electroplating solution is separated into water and the concentrated electroplating solution by the vacuum concentration separation system so as to realize clean production and recover the activity of the electroplating solution, therefore, the electroplating solution can be used circularly without regular updating and waste water discharging, and the environment is effectively protected. The system supplies the electrogalvanizing solution to an electroplating bath and a rinse-system, the electrogalvanizing solution works stably and continuously in the processes of electroplating, filtering, concentration, dissolving and the like, simultaneously, SO4<2-> is relatively stable, and the activity of the solution is easy to be recovered, thus being favorable to the repeated use of the solution and ensuring the stable quality of the electroplating solution.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com