Magnetic titanium silicon molecular sieve with compact protective layer and its application

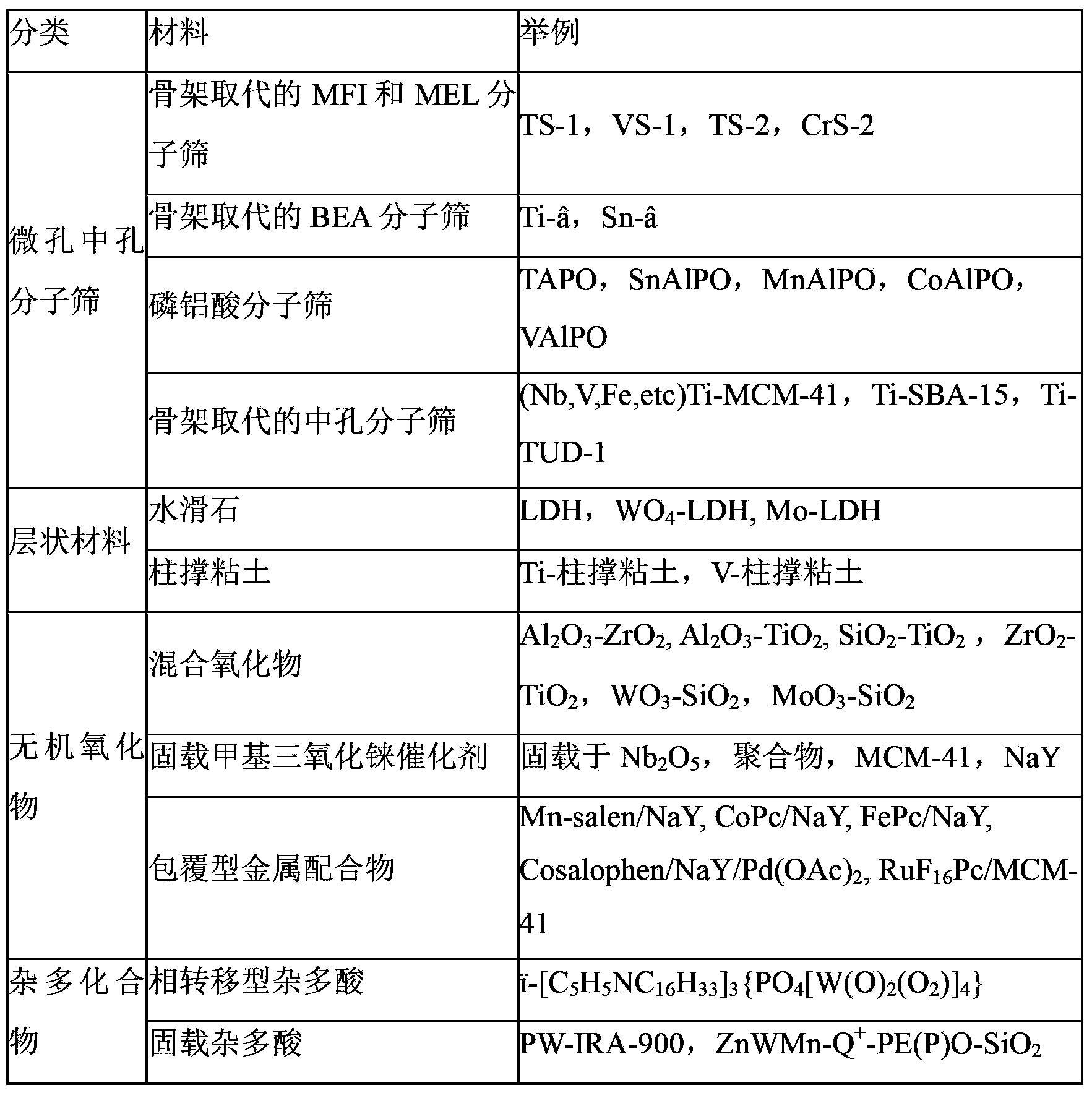

A titanium-silicon molecular sieve and protective layer technology is applied in the application field of the epoxidation of chloropropene to epichlorohydrin, which can solve the problems of equipment corrosion, many by-products, large energy consumption, etc. Non-polluting equipment, good catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 200ml, 2.0×10 -2 M FeCl 3 Add it into a 250ml three-neck flask, and reflux at 100°C for 2 days. The reaction product is centrifuged, washed with deionized water, and dried at room temperature to obtain Fe nanoparticles.

[0039] Take 0.5g Fe nanoparticles and add to 50ml containing 0.45M NH 3 ·H 2 O, 3.05M H 2 O in isopropanol solution, stirred at 40°C for 30min, then quickly added 100ml, 4.0×10 -3 Tetraethyl silicate (TEOS) of M was treated at room temperature for 15 h, the particles were collected by centrifugation, washed with ethanol, dried at 60 °C, and calcined at 800 °C for 5 h under Ar atmosphere to obtain dense SiO 2 layer of Fe / SiO 2 magnetic core.

[0040] Take 1g Fe / SiO 2 powder, and 40mL of 2mol / L glucose solution were added to a 50mL stainless steel reaction kettle, and crystallized at 180°C for 24h to obtain Fe / SiO with a C layer on the surface 2 nanomaterials.

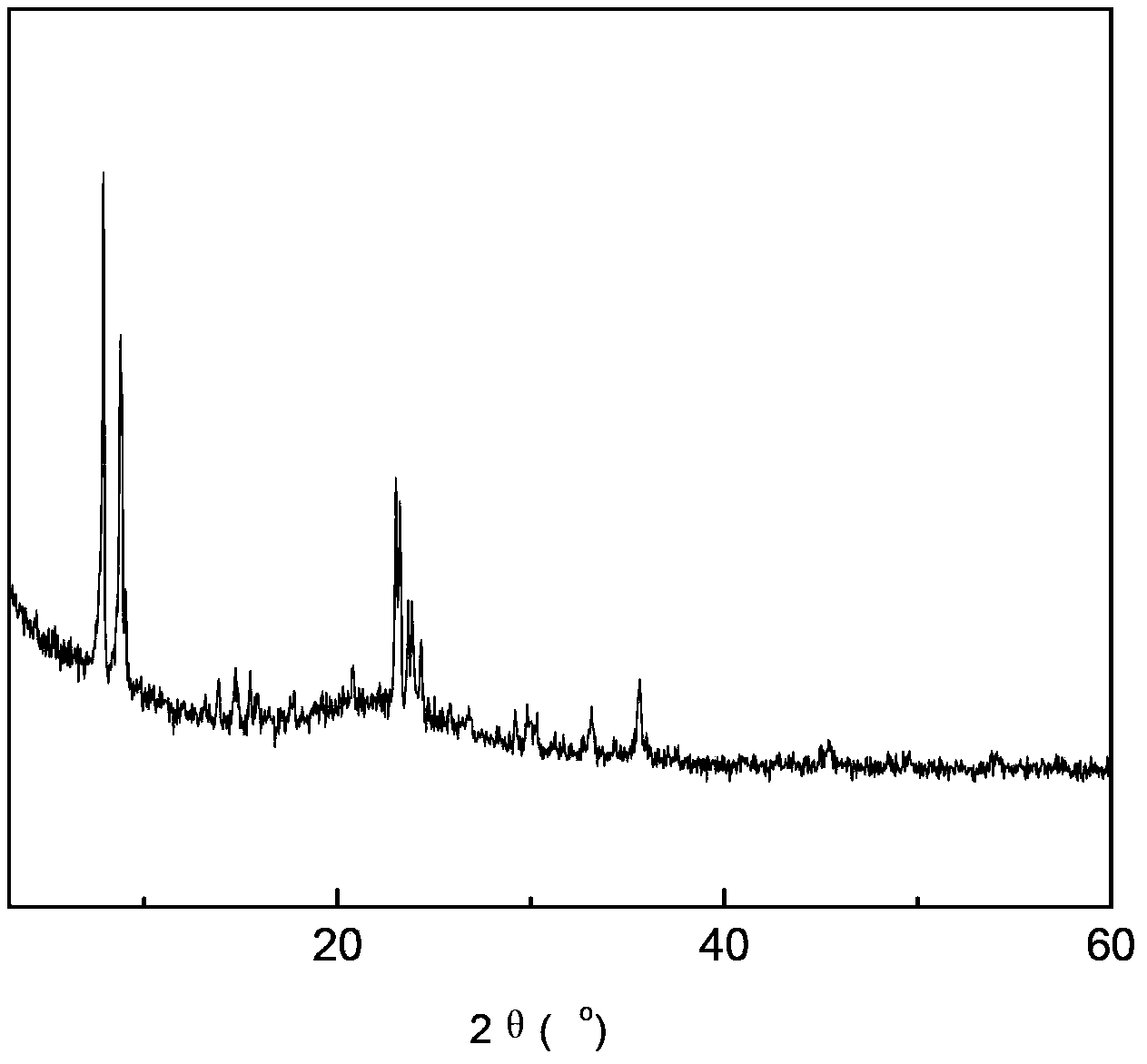

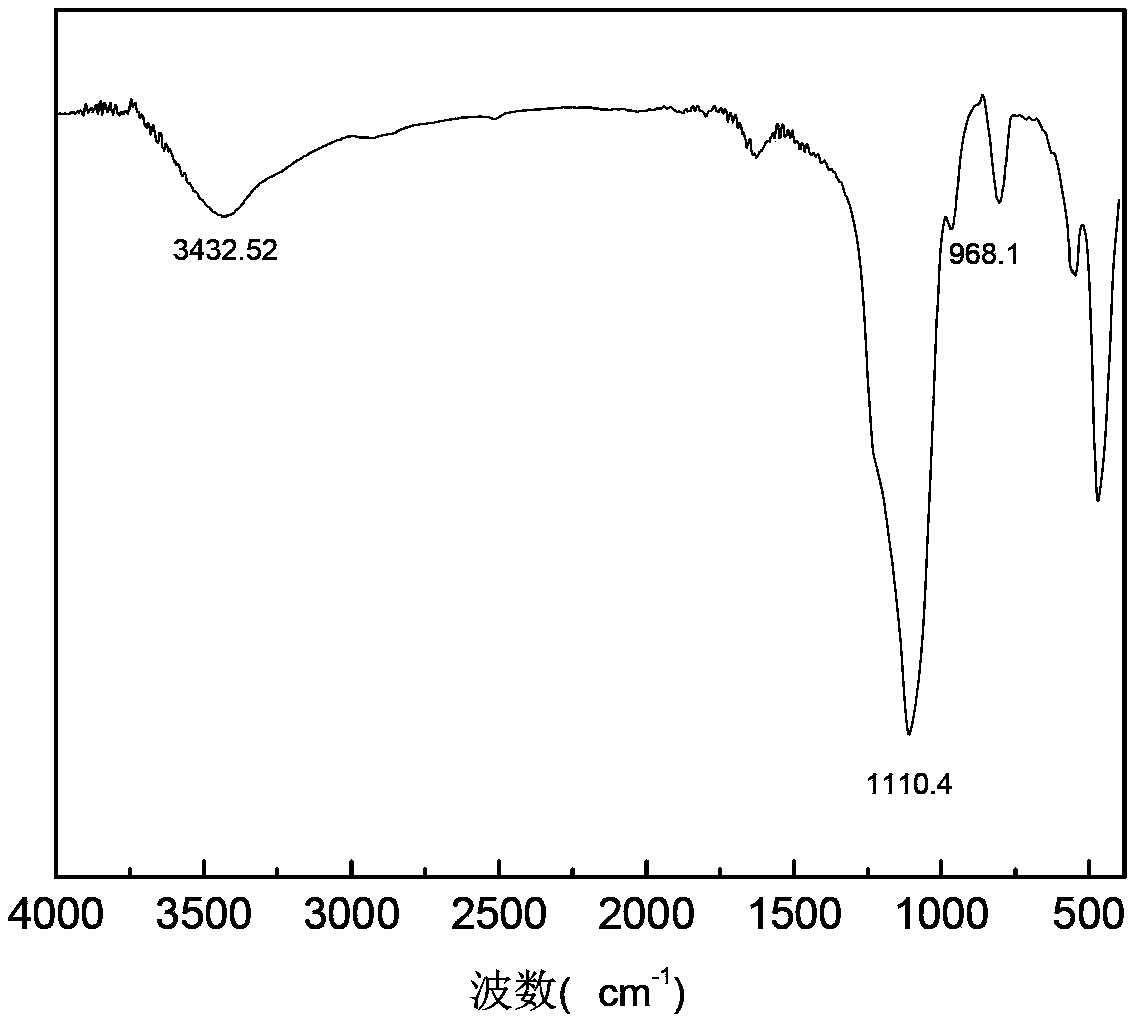

[0041] Take a certain amount of butyl titanate (TBOT) and add it to tetraethyl orth...

Embodiment 2

[0044] The preparation method of catalyst is the same as embodiment 1. SiO of titanium silicon mother liquor 2 :TiO 2 =1:0.01, the analytical method of reaction conditions and product is the same as embodiment 1. The results of catalyst activity are as follows: the conversion rate of allyl chloride is 68.6%, and the selectivity to epichlorohydrin is 88.1%.

Embodiment 3

[0046] The preparation method of catalyst is the same as embodiment 1. SiO of titanium silicon mother liquor 2 :TiO 2 =1:0.04, the analytical method of reaction conditions and product is the same as embodiment 1. The results of catalyst activity are as follows: the conversion rate of allyl chloride is 77.3%, and the selectivity to epichlorohydrin is 93.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com