In-situ regeneration method of butylene oxy-dehydrogenation catalyst

A technology of oxidative dehydrogenation and in-situ regeneration, which is applied in the direction of catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., and can solve the problems affecting the extension of catalyst life and reaction conversion efficiency, reaction yield, poor in-situ regeneration effect of butene oxidative dehydrogenation catalyst, and long shutdown time of the device, so as to achieve the effects of preventing carbon formation, recovery of activity, and shortened shutdown time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

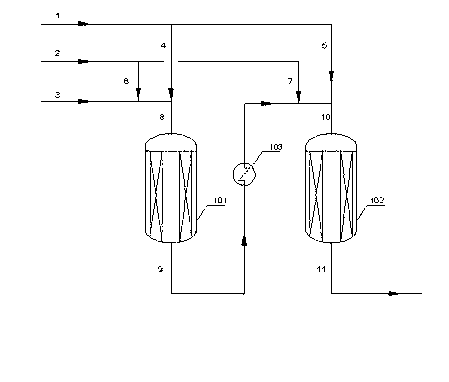

[0042] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology adopts an iron-based catalyst, its main composition includes iron, zinc, and magnesium components, and the molar ratio of each component is: Fe:Zn:Mg=10:2:5, prepared by coprecipitation method, the main crystal Phase is ZnFe 2 o 4 Spinel, the reactor is two-stage, and the two-stage reactor is an adiabatic radial fixed-bed reactor. The total amount of raw material butene is 19670kg / h, the total amount of air is 36000 kg / h, and the total amount of water vapor is 66000 kg / h. The butene raw material is divided into two parts. The flow rate of butene in the first stage is 9400 kg / h. After mixing with air and water vapor according to the ratio of butene: oxygen: water (mol) of 1:0.52:15, the temperature is 320°C and the pressure is Under the condition of 0.12MPaG, it enters the first-stage oxidative dehydrogenation reactor. The outlet gas temperature of the first-s...

Embodiment 2

[0046] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology adopts an iron-based catalyst, its main composition includes iron, zinc, and magnesium components, and the molar ratio of each component is: Fe: Zn: Mg=10:2:6, prepared by coprecipitation method, the main crystal Phase is ZnFe 2 o 4 Spinel, the reactor is three-stage, all three-stage reactors are adiabatic radial fixed-bed reactors, the total amount of raw material butene is 18920kg / h, the total amount of air is 36000 kg / h, the total amount of water vapor is 47500 kg / h, The butene raw material is divided into three parts. The flow rate of butene in the first stage is 9200 kg / h. After mixing with air and water vapor according to the ratio of butene: oxygen: water (mol) of 1:0.5:15, the temperature is 320 °C and the pressure is Under the condition of 0.13MPaG, it enters the first-stage oxidative dehydrogenation reactor. The outlet gas temperature of the first-s...

Embodiment 3

[0050] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant adopts figure 1 The process technology uses an iron-based catalyst whose main composition is Fe 2 o 3 · MgO · ZnO · P 2 o 5 ·ZnxOy, the reactor is two-stage, and the two-stage reactors are adiabatic radial fixed-bed reactors. The total amount of raw material butene is 19,670 kg / h, the total amount of air is 36,000 kg / h, and the total amount of water vapor is 30,200 kg / h. The olefin raw material is divided into two parts. The flow rate of butene in the first stage is 9400 kg / h. After mixing with air and water vapor according to the ratio of butene: oxygen: water (mol) of 1:0.52:10, the temperature is 330 °C and the pressure is 0.12. Under the condition of MPaG, it enters the first-stage oxidative dehydrogenation reactor. The outlet gas temperature of the first-stage reactor is 495°C. The flow rate of butene is 10270 kg / h, the ratio of butene:oxygen:water (mol) at the inlet of the secondary reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com