Patents

Literature

193results about How to "Reduce steam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

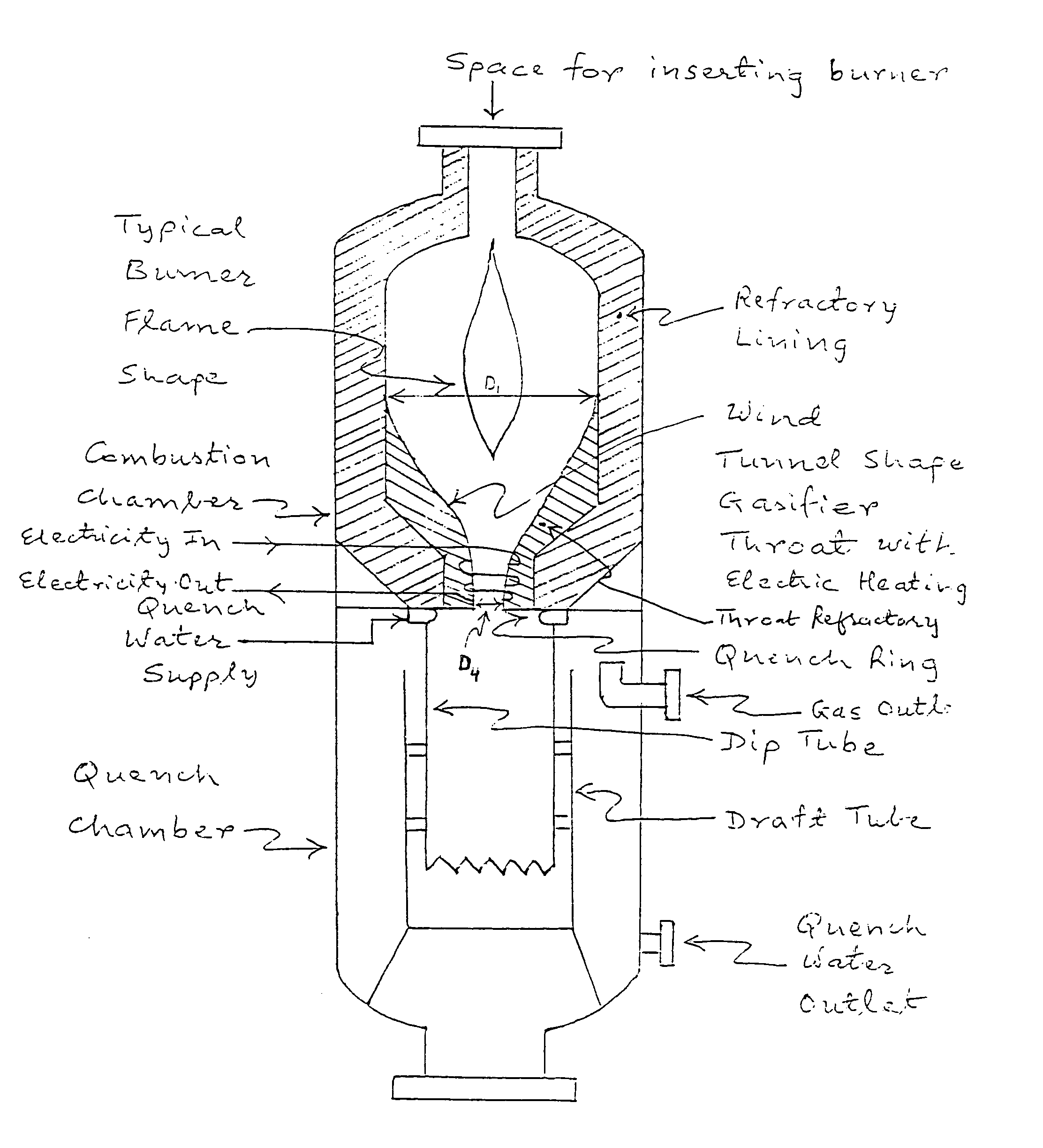

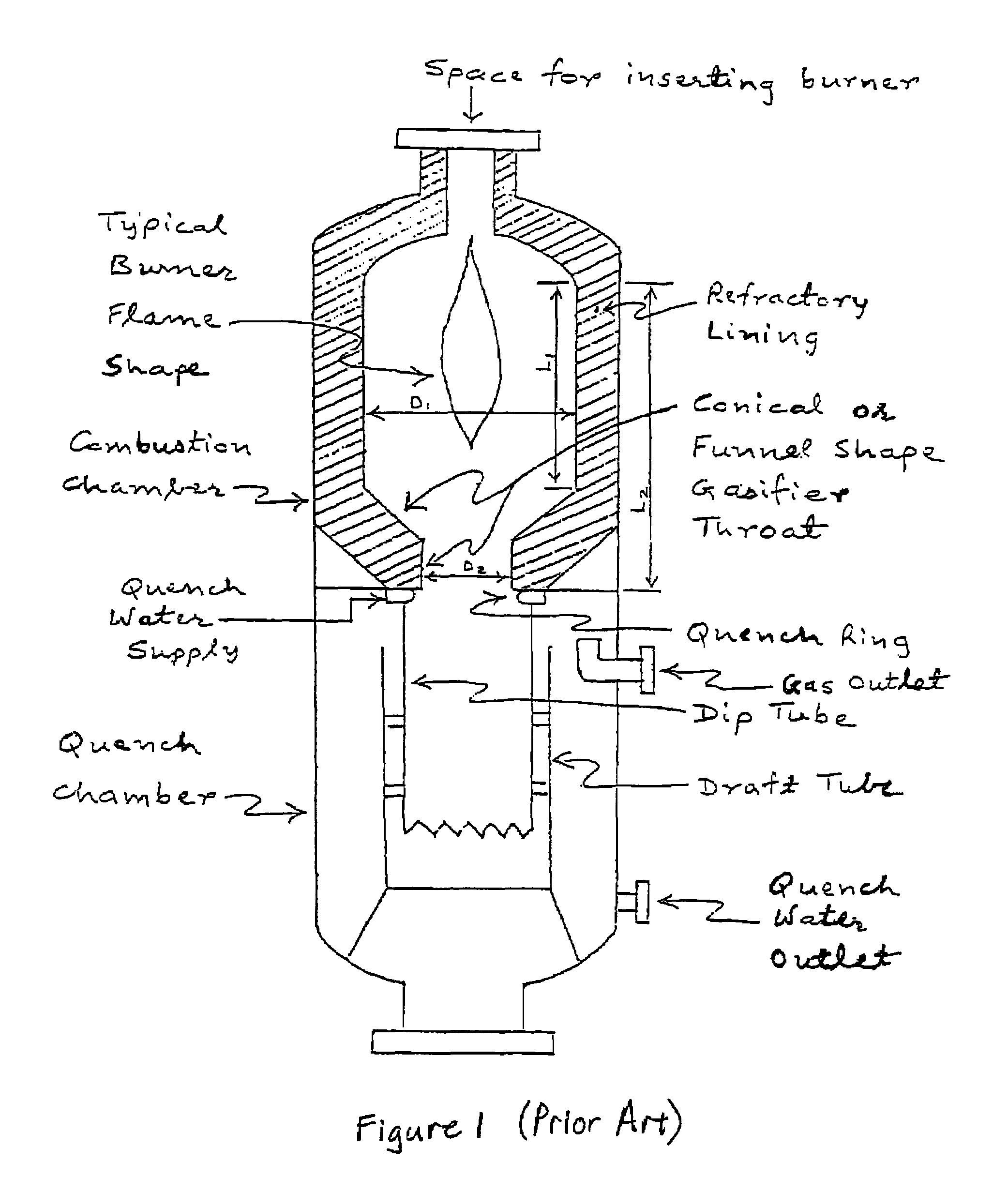

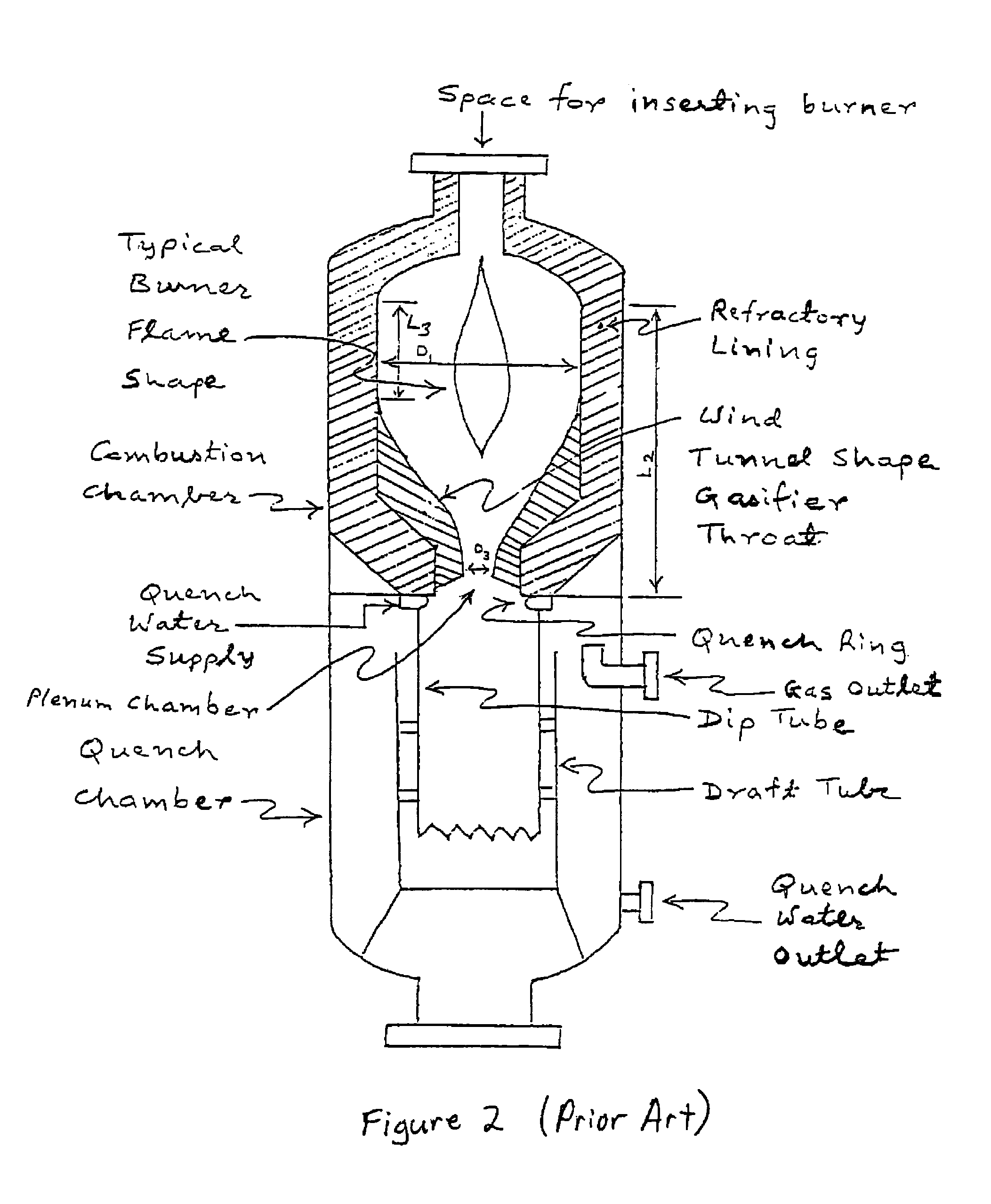

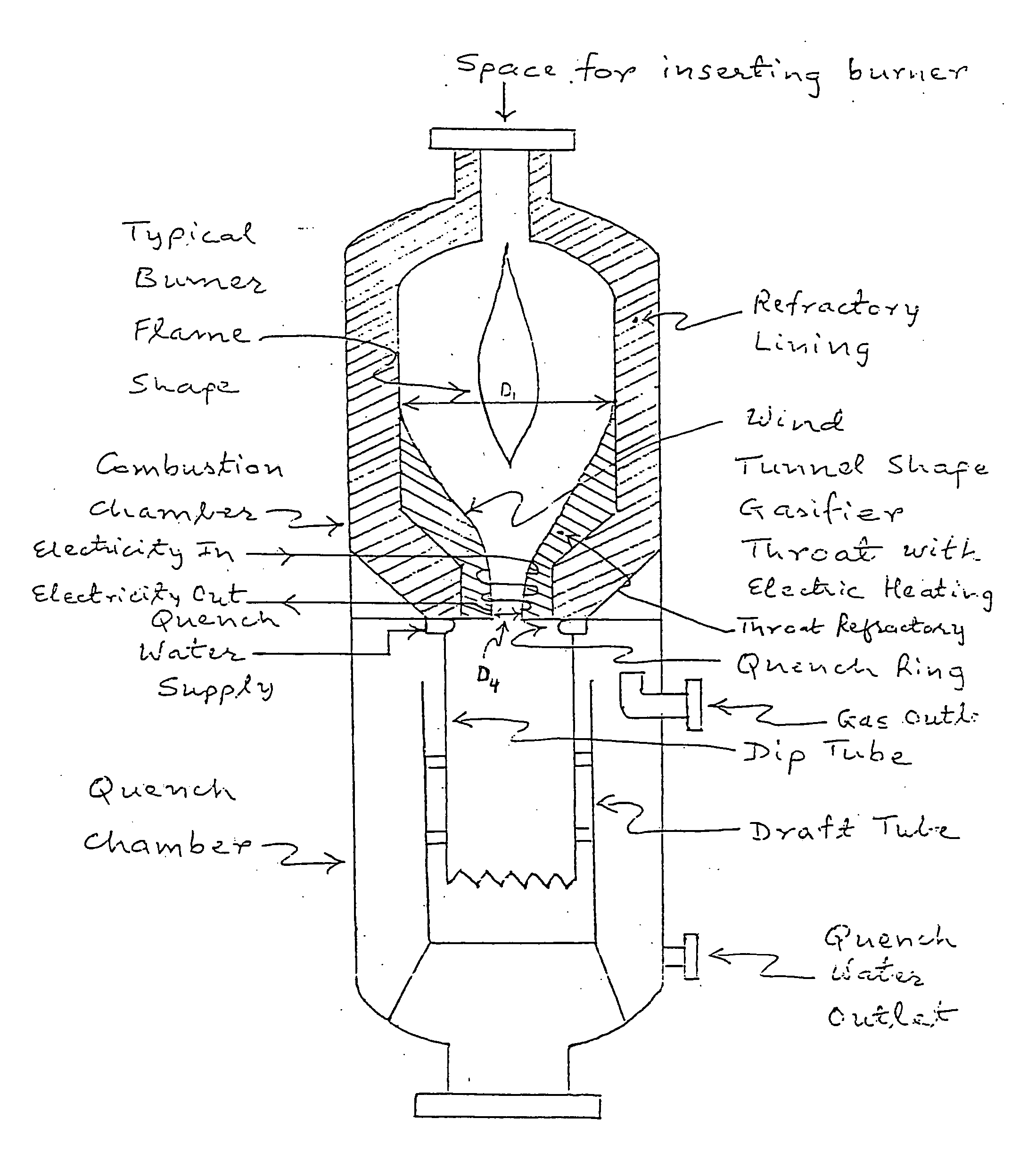

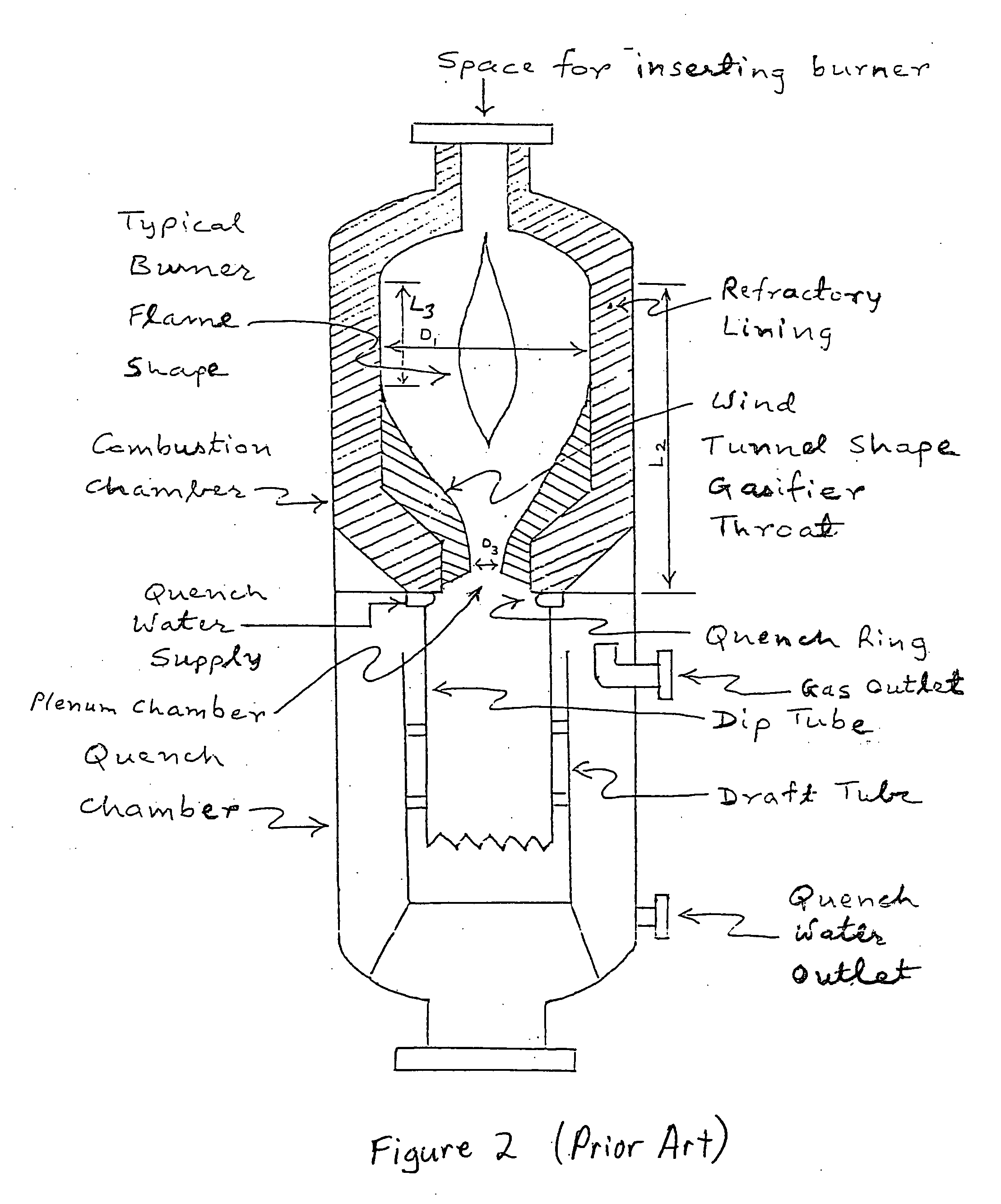

Combustion chamber design for a quench gasifier

InactiveUS7090707B1Increase consumptionIncrease working temperatureGasifier mechanical detailsGas modification by gas mixingThroatElectricity

A new combustion chamber design for a quench gasifier. Electrical heating is used in the throat area of the combustion chamber to achieve temperatures up to 3500° F. to melt ash deposits and to increase carbon conversion (reduce soot production). Silicon carbide and / or silicon nitride refractory materials are used in the hot face of the throat to withstand high temperatures and high temperature shocks. The proposed design reduces the capital cost of a gasification plant by eliminating the need for soot recovery and recycle system. This design also reduces the operating cost of the gasification plant by decreasing the frequent refractory damages that have been experienced in the throat area of the existing quench gasifiers.

Owner:BAROT DEVENDRA T

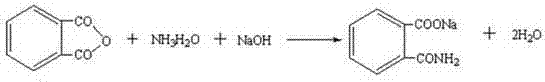

In-situ regeneration method of butylene oxy-dehydrogenation catalyst

InactiveCN103071544AReduce steamPromote crystal phase transitionCatalyst regeneration/reactivationHydrocarbonsPtru catalystButadiene Dioxide

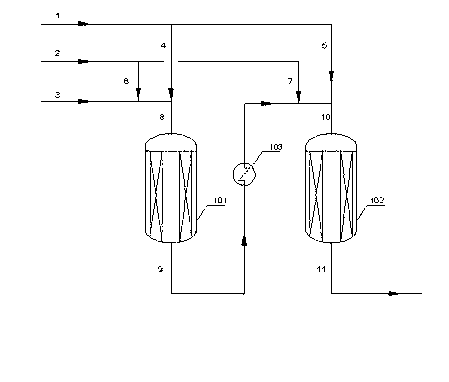

The invention relates to an in-situ regeneration method of a butylene oxy-dehydrogenation catalyst, which mainly solves the problems that the in-situ regeneration effect of the butylene oxy-dehydrogenation catalyst is poor, so that the life of the catalyst is shortened, the conversion rate and yield of reaction are reduced, and the change of the catalyst results in long stopping time of a device and influences the output of the device in the prior art. The method comprises the following steps of: a) stopping feeding of oxygen-containing gas and then a butylene raw material, purging the catalyst with 300-500 DEG C superheated water vapor for 0.2-56h, b) gradually reducing the amount of the water vapor till the airspeed of the water vapor is 500-2000h<-1>, filling in air till the molar ratio of the air to the water vapor is 0.05-0.2, controlling the regeneration temperature at 360-450 DEG C, conducting regeneration of the oxy-dehydrogenation catalyst, and c) reducing the amount of the vapor, allowing the temperature rise of a bed to be reduced gradually till the temperature at an inlet and an outlet of the catalyst bed keeps constant, and accomplishing the technical scheme of catalyst regeneration. The method solves the problems better, and can be used for industrial production of preparing butadiene through butylene oxy-dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

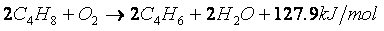

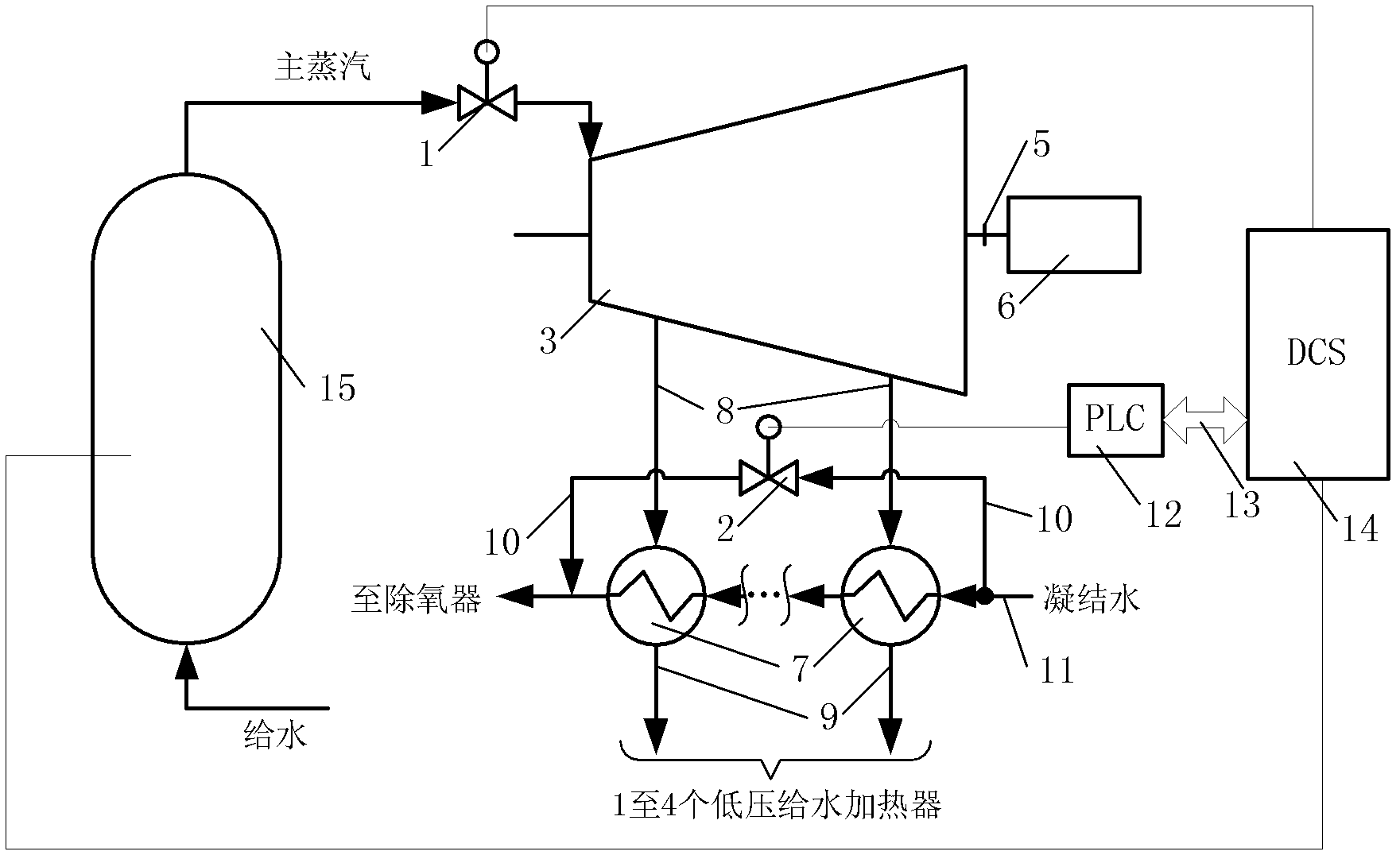

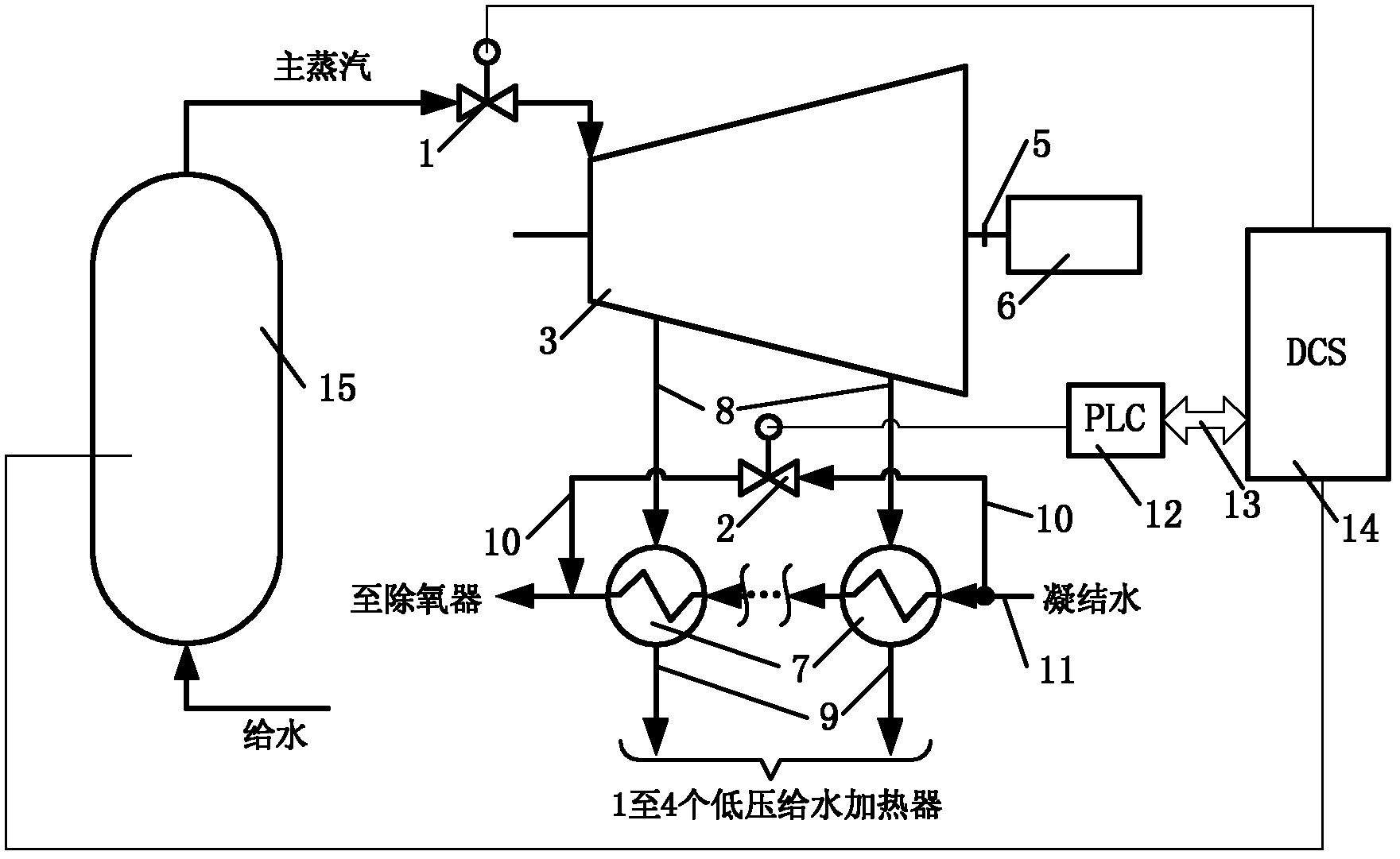

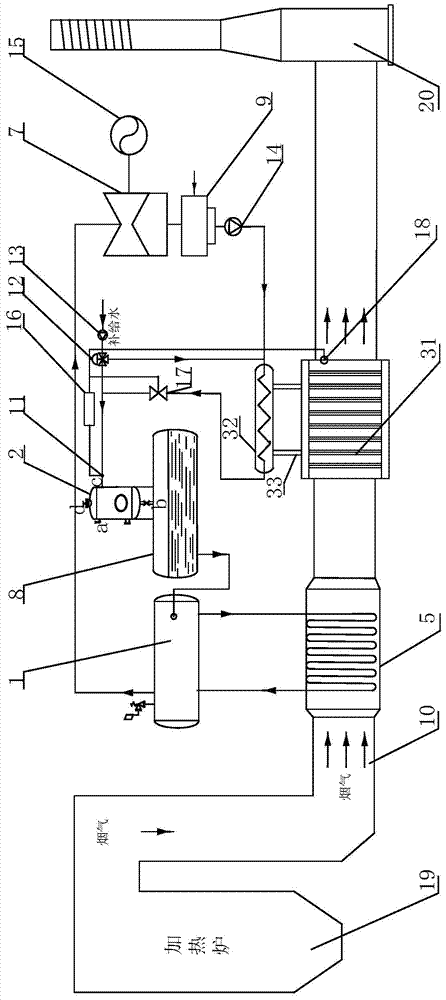

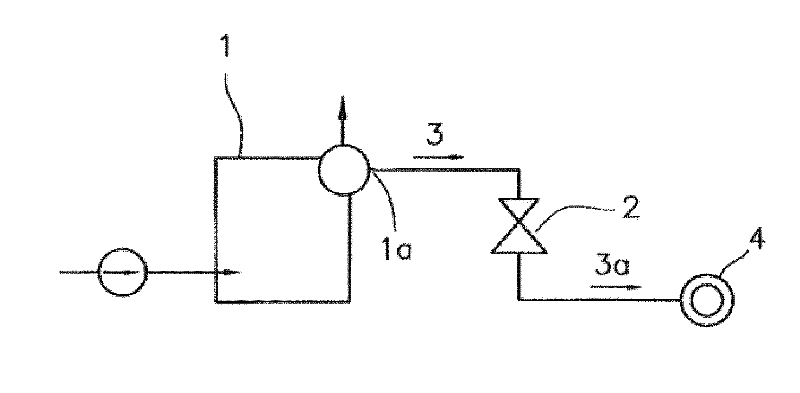

Energy-saving quick power regulating system of thermal generator set and method

ActiveCN102588938AQuick adjustment of powerDoes not affect the water levelFuel supply regulationLiquid degasificationDistribution controlControl system

Disclosed are an energy-saving quick power regulating system of a thermal generator set and a method. The system comprises a distribution type control system, a PLC (programmable logic control) unit and a low-pressure heater condensate bypass regulating system, the PLC unit is connected with the distribution type control system by a bidirectional interface, and the low-pressure heater condensate bypass regulating system is in communication connection with the PLC unit. The method includes that opening of a bypass regulating valve is reduced by the PLC unit when load needs to be quickly added, and the opening of a fully opened high-pressure regulating valve is reduced by the PLC unit via the distribution control system when the load needs to be reduced quickly. Unnecessary loss is avoided on the premise of guaranteeing safety and stability of the system, the requirement of a power grid on power regulating speed of the set is met, and quick power regulation and economical running of the thermal generator set are realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

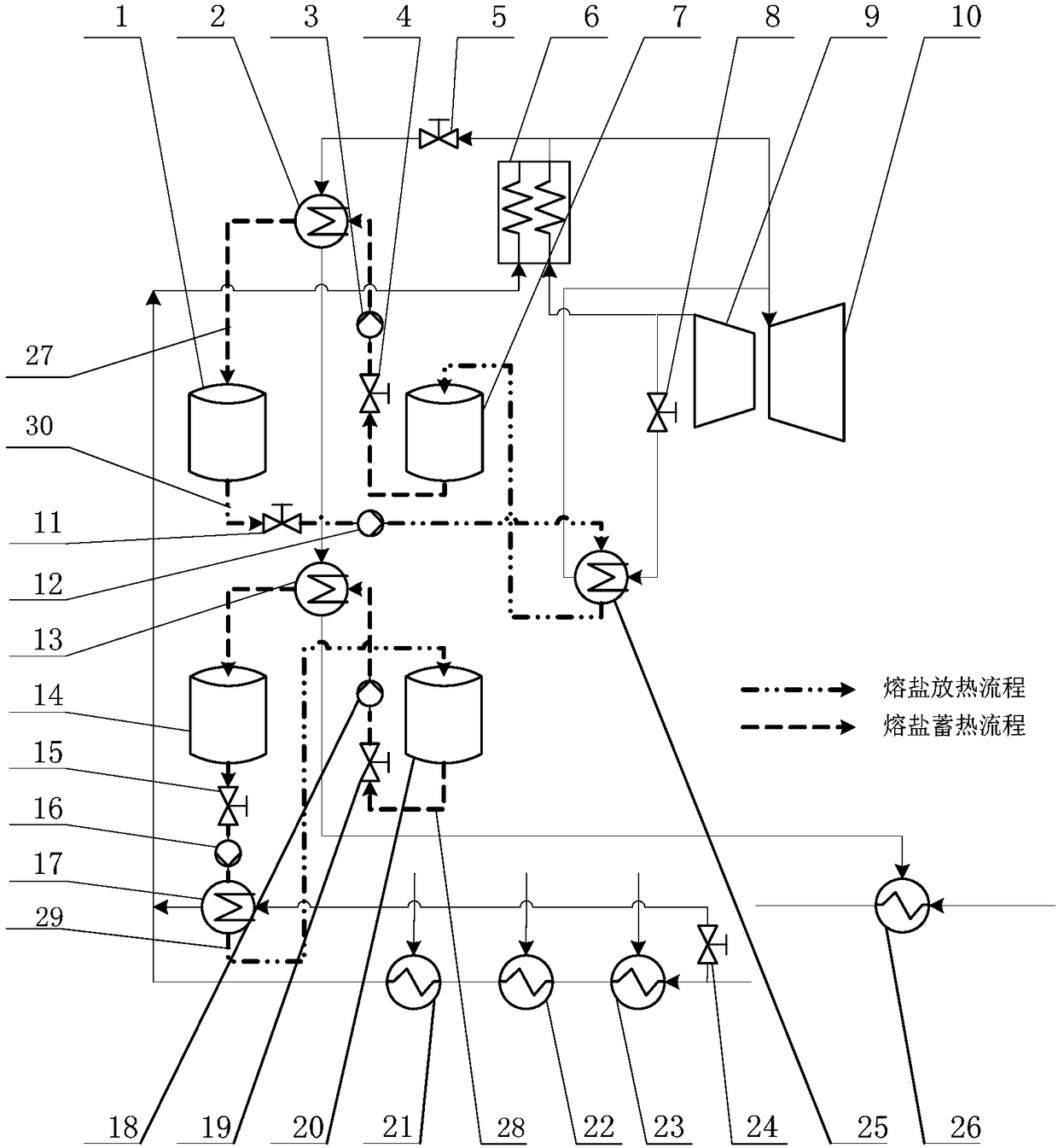

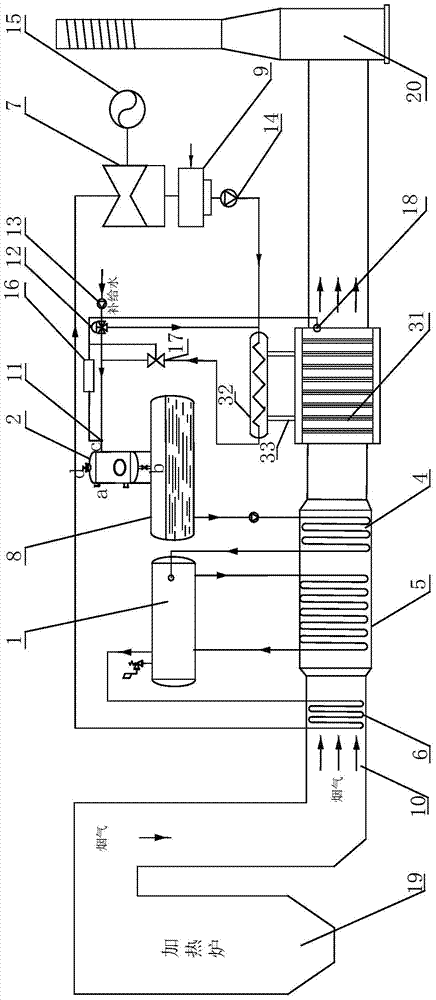

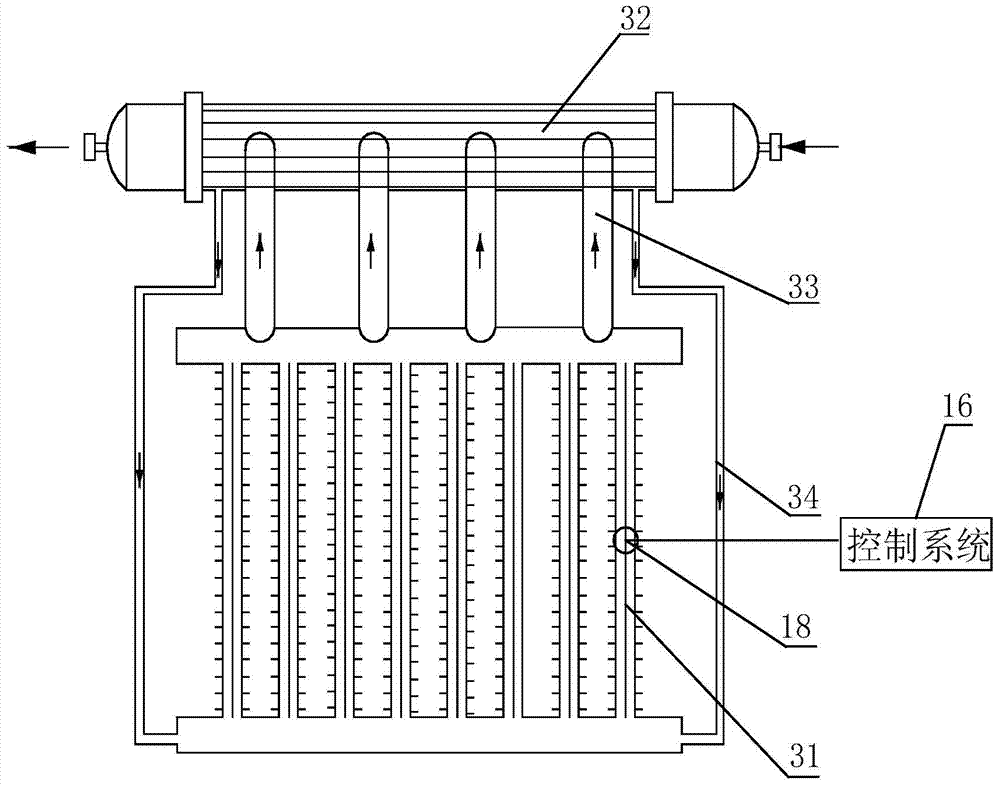

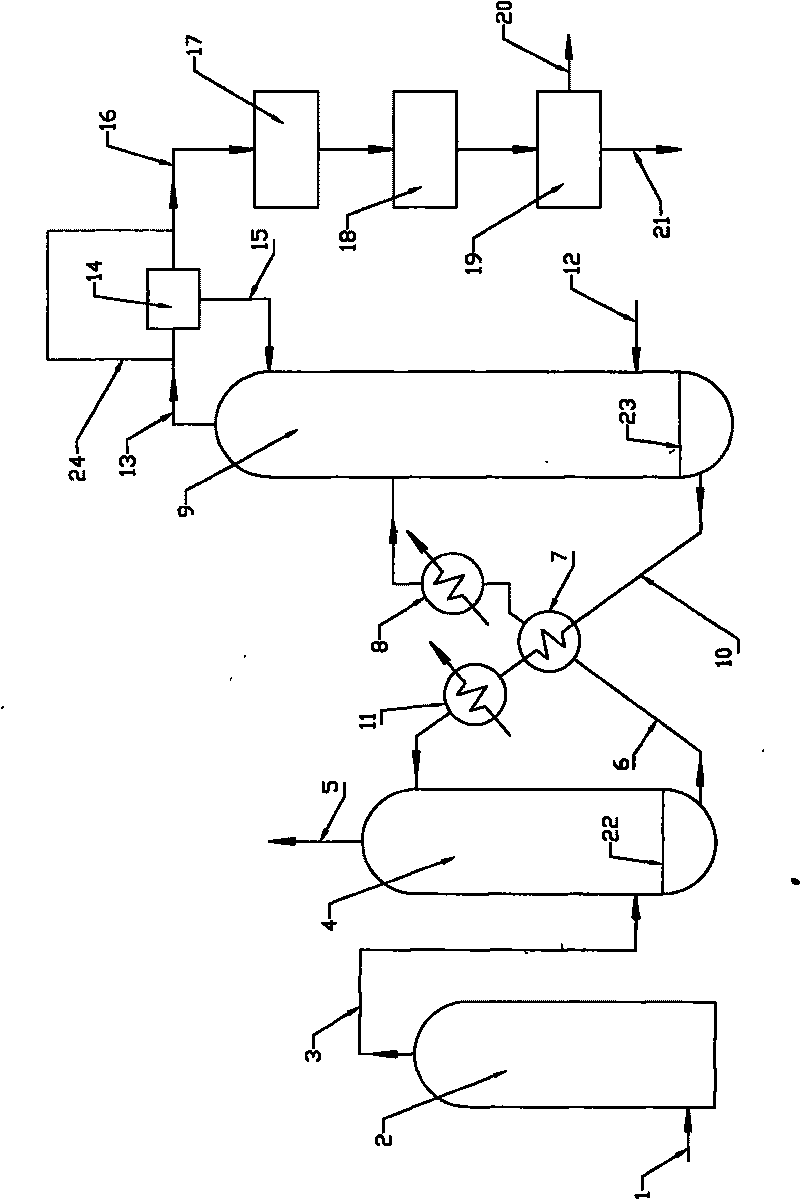

Fused salt heat storage and heat release peak load regulating system for thermal power generating unit

The invention discloses a fused salt heat storage and heat release peak load regulating system for a thermal power generating unit. According to the fused salt heat storage and heat release peak loadregulating system, a fused salt heat storage system, an I-stage fused salt low-temperature heat release system and a II-stage fused salt high-temperature heat release system are additionally arrangedon the basis of the original thermal power generating unit, and therefore peak load regulating of a power grid is realized through heat storage and heat release of fused salt; when the dispatching load of the power grid is decreased, part of high-temperature reheat steam is extracted from an outlet of a boiler reheater and exchanges heat with the fused salt in the fused salt heat storage system, and therefore consumption and utilization of the reheat steam in the electricity utilization off-peak season are completed; when the dispatching load of the power grid is increased, a part of high-pressure feedwater flowing to a high-pressure heater is divided into the I-stage fused salt low-temperature heat release system to exchange heat with the fused salt; and meanwhile, the steam discharge amount of a high-pressure cylinder is increased, part of increased exhaust steam of the high-pressure cylinder is fed into the II-stage fused salt high-temperature heat release system to exchange heat with the high-temperature fused salt, the heated steam enters an intermediate-pressure cylinder to apply work, the amount of the steam entering the intermediate-pressure cylinder and the output of a steam turbine can be increased, and the electric power of the thermal power generating unit can be rapidly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

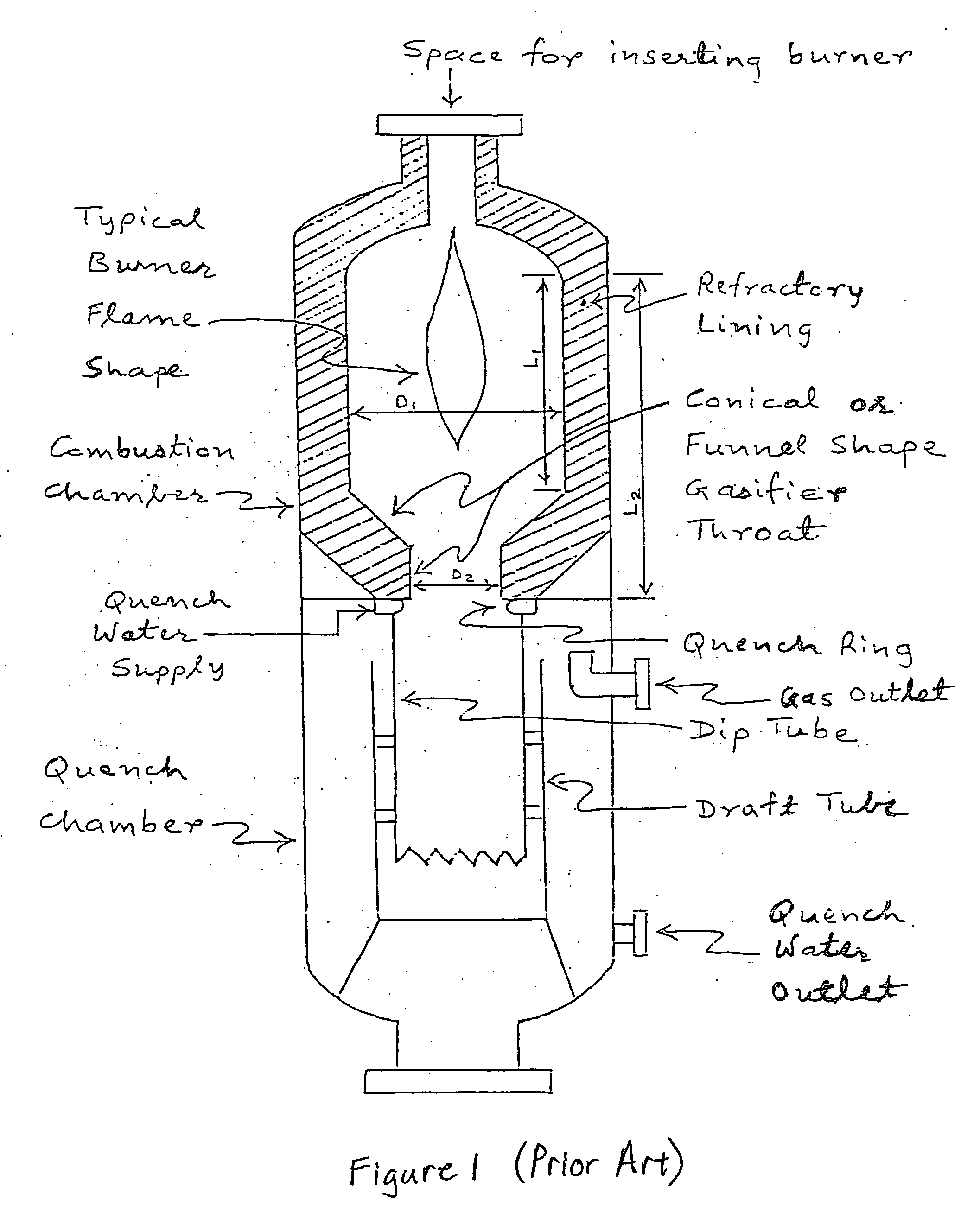

Combustion chamber design for a quench gasifier

InactiveUS20060260192A1Increase consumptionIncrease working temperatureHydrogenGasifier mechanical detailsThroatElectricity

A new combustion chamber design for a quench gasifier. Electrical heating is used in the throat area of the combustion chamber to achieve temperatures up to 3500° F. to melt ash deposits and to increase carbon conversion (reduce soot production). Silicon carbide and / or silicon nitride refractory materials are used in the hot face of the throat to withstand high temperatures and high temperature shocks. The proposed design reduces the capital cost of a gasification plant by eliminating the need for soot recovery and recycle system. This design also reduces the operating cost of the gasification plant by decreasing the frequent refractory damages that have been experienced in the throat area of the existing quench gasifiers.

Owner:BAROT DEVENDRA T

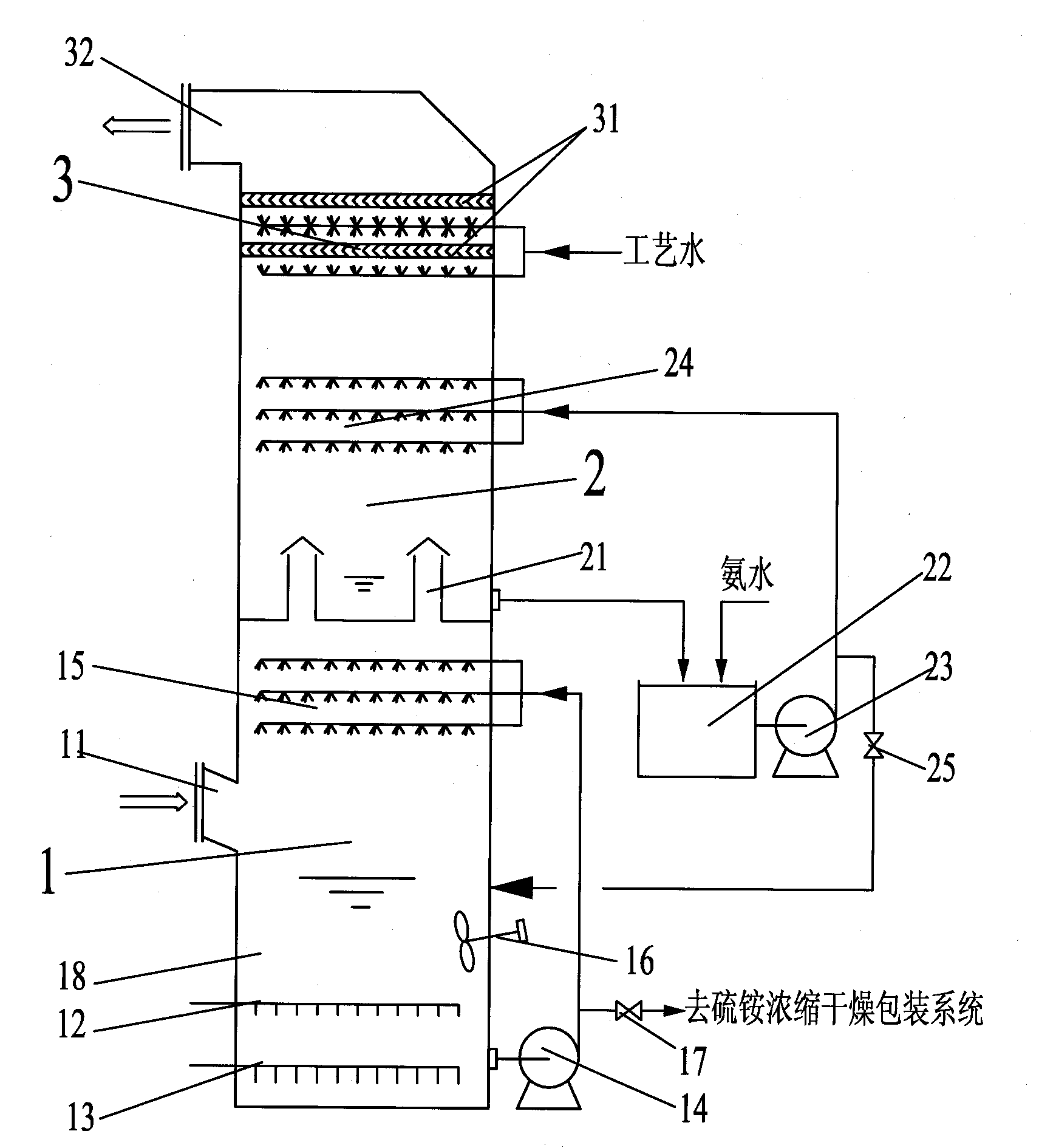

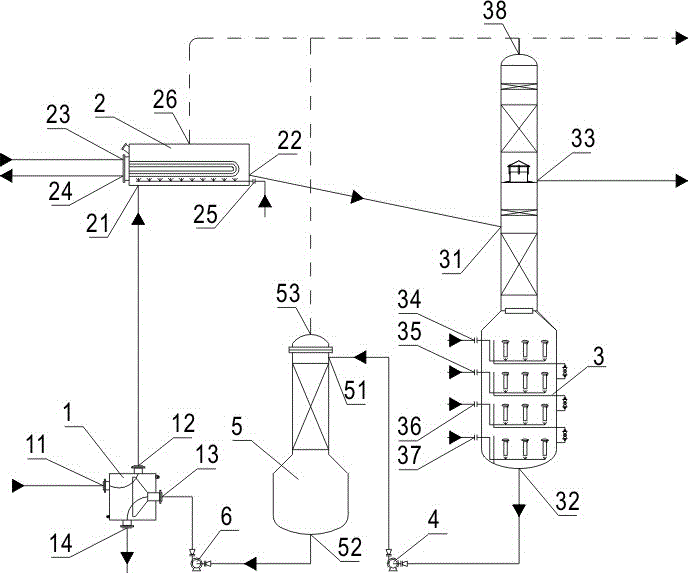

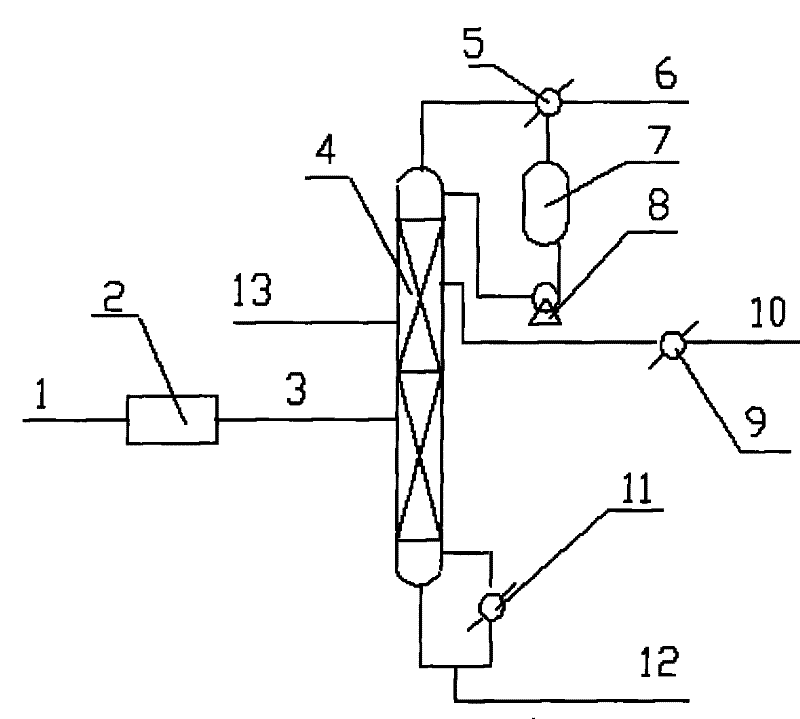

Method and system for improving quality of desulfuration byproduct ammonium sulfate

InactiveCN101844030AIncrease concentrationAvoid secondary pollutionDispersed particle separationAmmonium sulfatesFlue gasSulfate

The invention discloses a method and a system for improving the quality of a desulfuration byproduct ammonium sulfate. After flue gas enters a desulfurizer, the method comprises the processes of ammonium sulfate crystallization, SO2 absorption and demisting and ammonia removal. The system comprises an ammonium sulfate crystallization section, a SO2 absorption section and a demisting and ammonia removal section from bottom to top in turn, wherein the ammonium sulfate crystallization section is provided with a flue gas inlet; an ammonia water adding device, an oxidant adding device and a stirrer are arranged in a slurry tank below the flue gas inlet; and a primary circulating spraying device is arranged above the flue gas inlet and connected with the slurry tank through a circulating pump. Through reasonable addition of strong oxidizers such as ozone and ammonia water, the oxidation of (NH4)2SO3 is strengthened, the concentration of the ammonia sulfate in the slurry is improved, and secondary pollution in the concentrating and drying processes of the ammonia sulfate is avoided; and through reasonable utilization of the heat energy of the flue gas per se, the using amount of steam for drying the ammonia sulfate is reduced, and the quality of the desulfuration byproduct ammonium sulfate is integrally improved.

Owner:浙江菲达环保科技股份有限公司

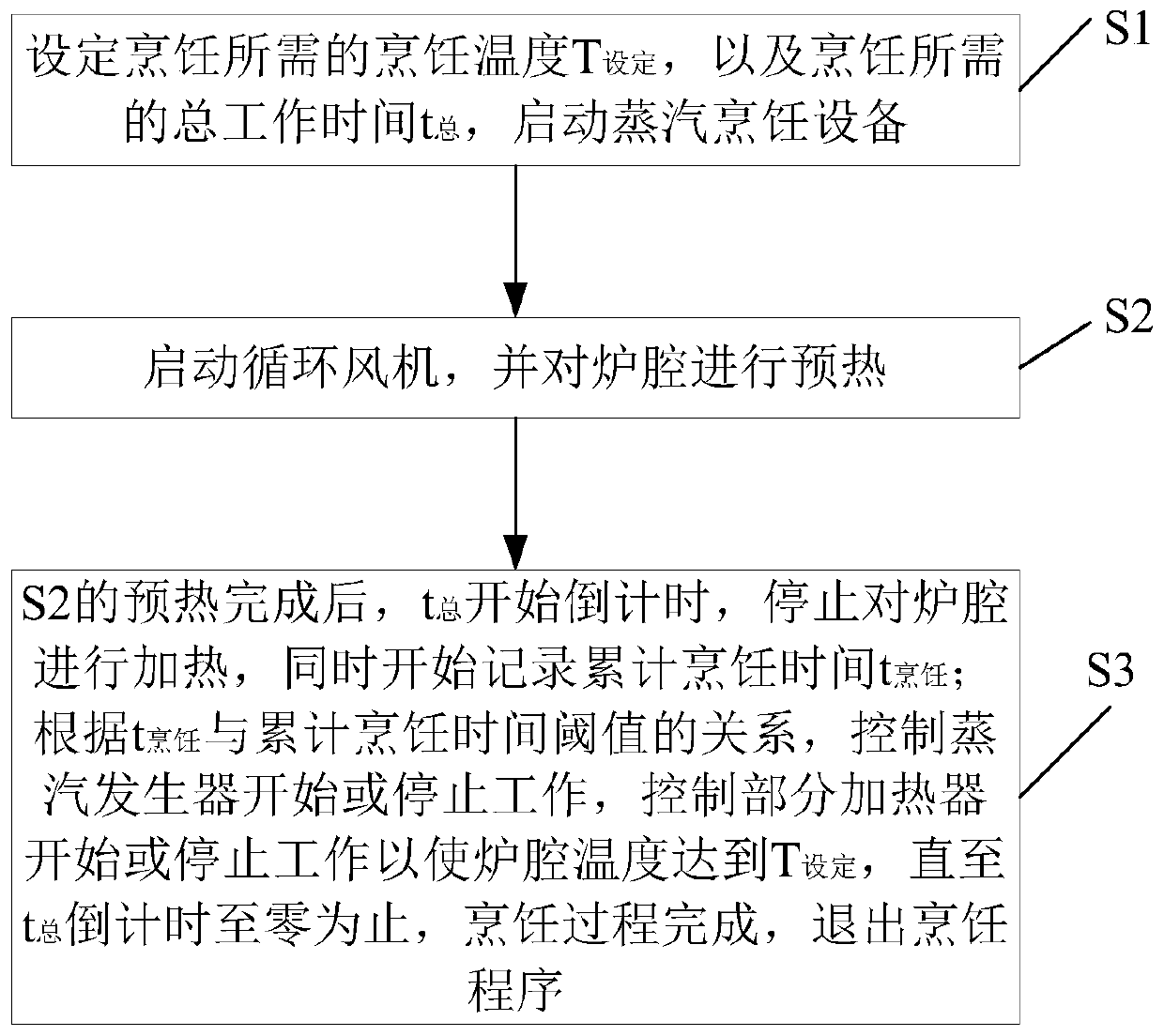

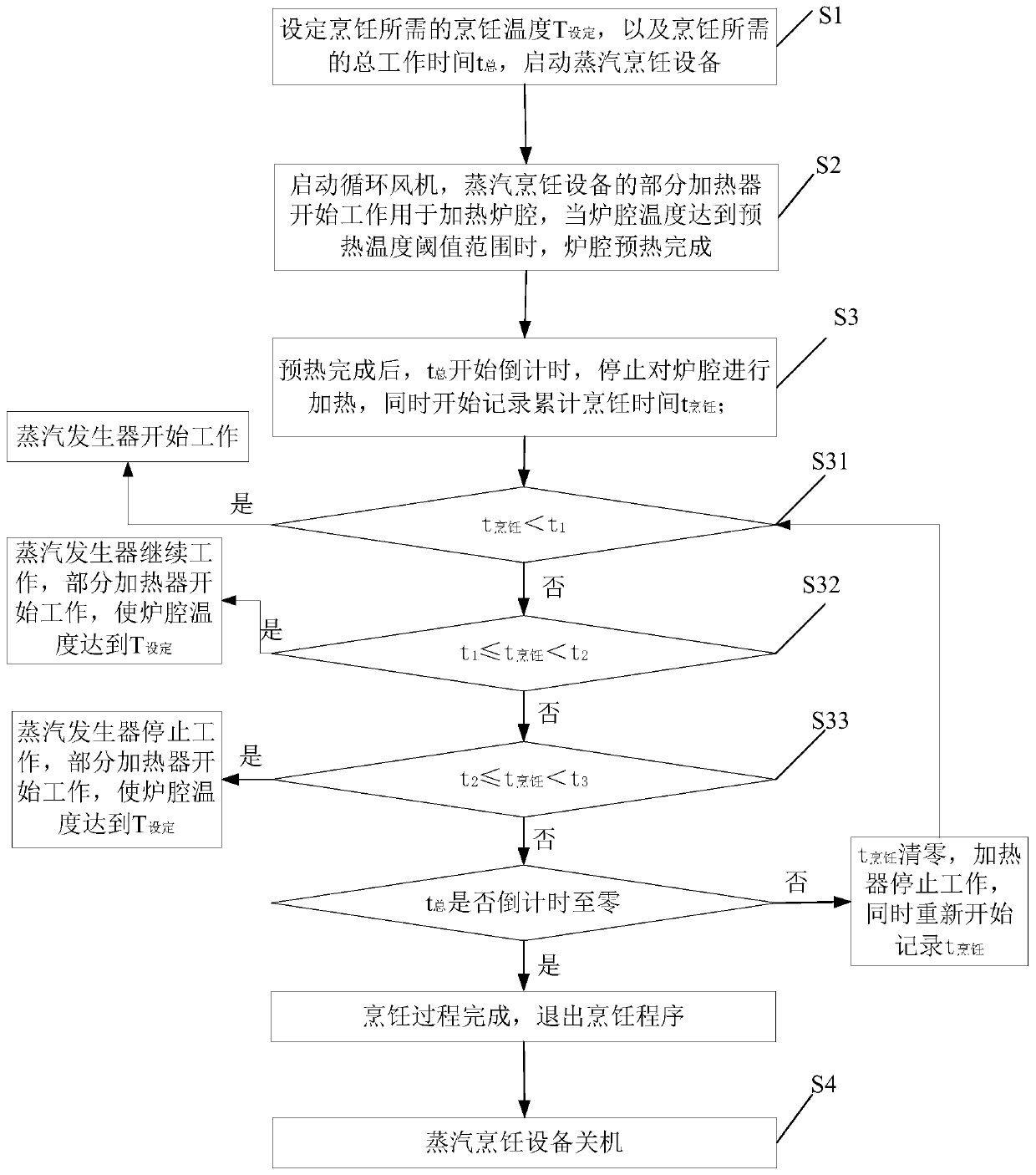

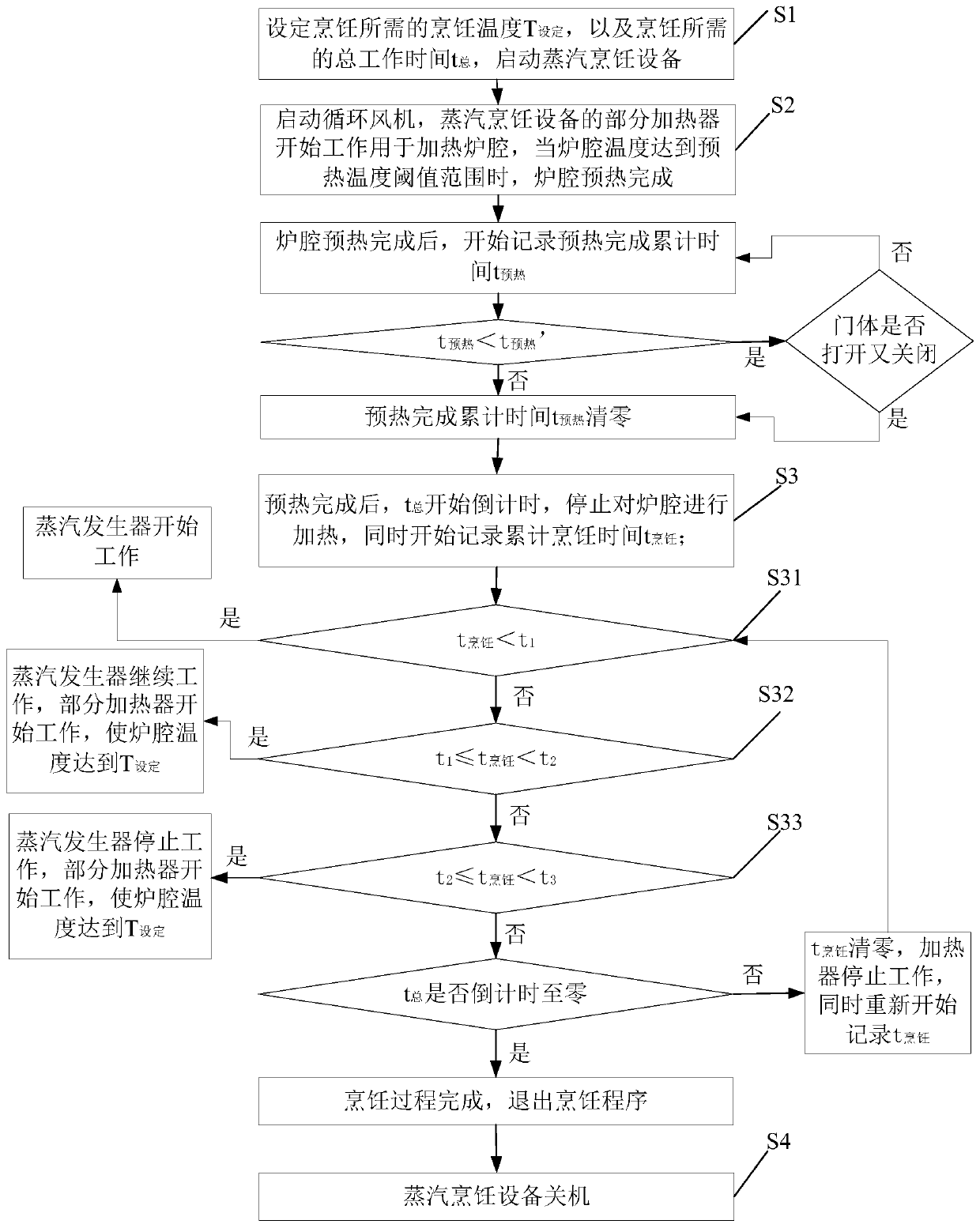

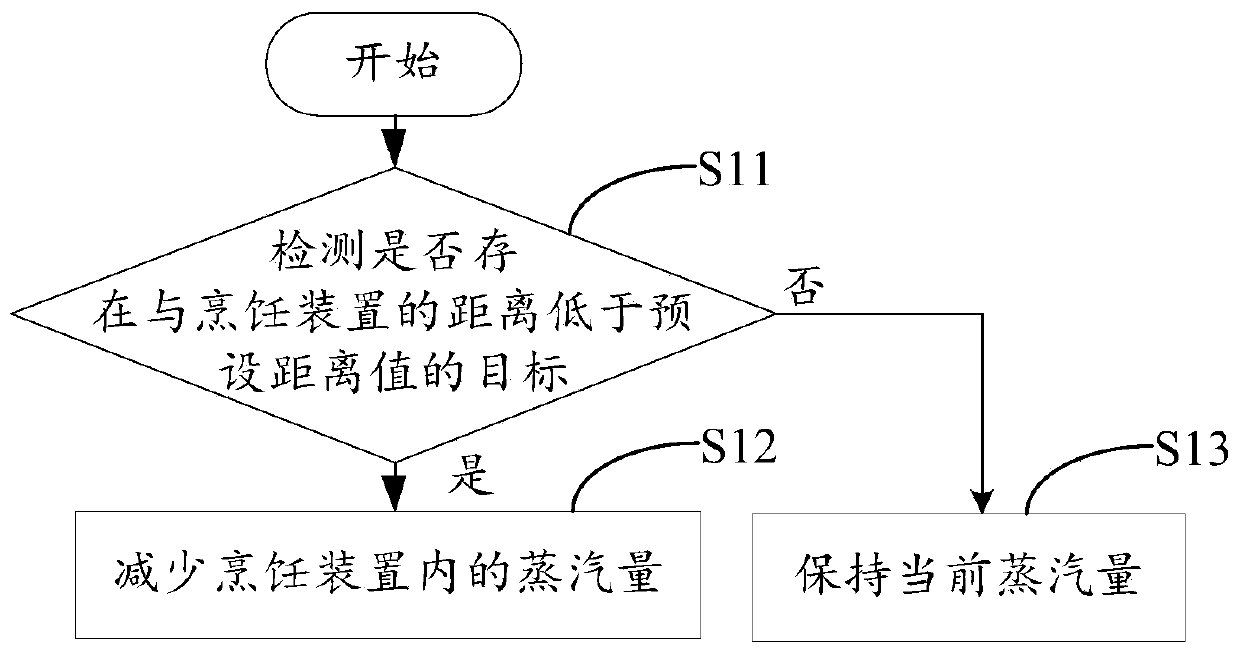

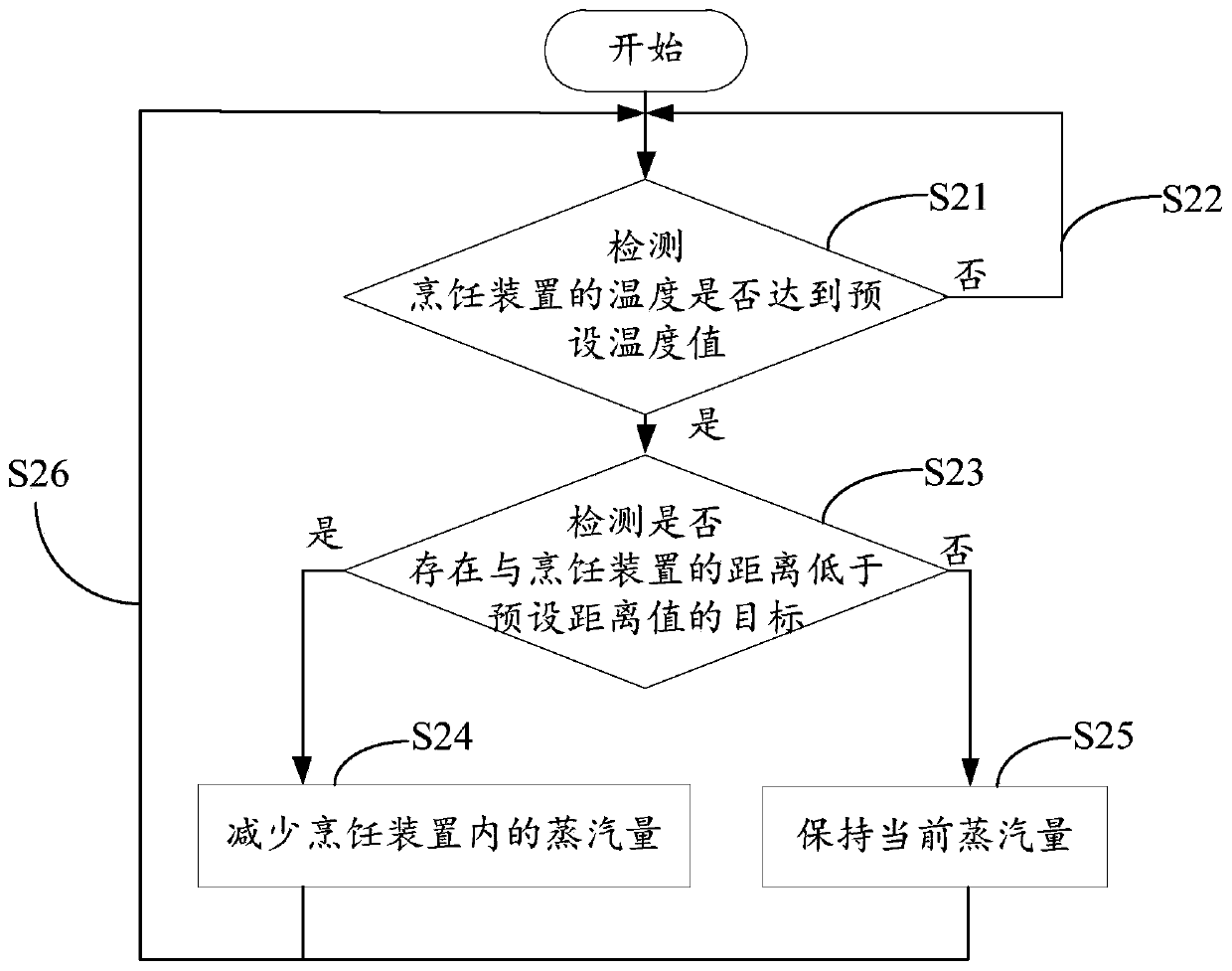

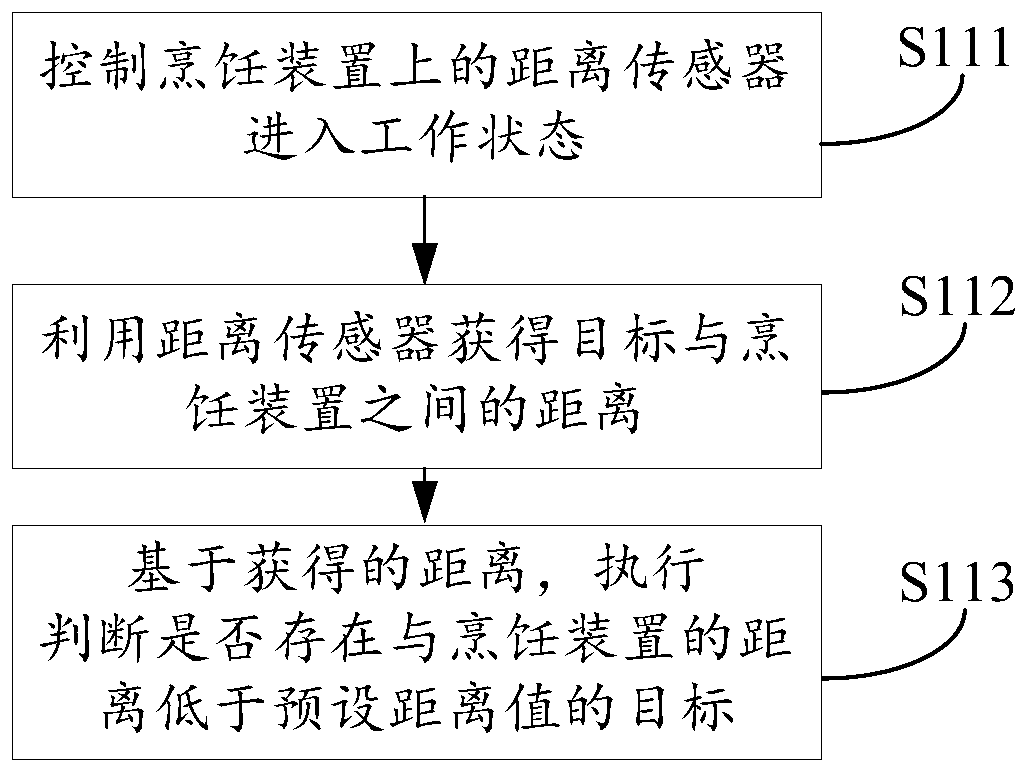

Control method for furnace chamber temperature and steam quantity of steam cooking equipment

InactiveCN111329328AIncrease speedGuaranteed steam volume and temperatureSteam cooking vesselsRoasters/grillsProcess engineeringCooking process

The invention belongs to the technical field of steam cooking equipment, and discloses a control method for furnace chamber temperature and steam quantity of steam cooking equipment, which comprises the following steps of: S1, setting cooking temperature T required by cooking and total working time t<total> required by cooking, and starting the steam cooking equipment; S2, starting a circulating fan, and preheating the furnace chamber; S3, after S2 is completed, enabling t<total> to start countdown, stopping heating of the oven cavity, meanwhile starting to record the accumulated cooking timecooking<cooking>, controlling the steam generator to start or stop working according to the relationship between t<cooking> and the accumulated cooking time threshold, controlling a part of heaters tostart or stop working so as to enable the temperature of the oven cavity to reach T<setting> until t<total> countdown is zero, finishing the cooking process, and exiting the cooking program. According to the method, the problem that the actual working power of existing steam cooking equipment is too large is solved.

Owner:VATTI CORP LTD

Methyl chloride recovery and refining method

ActiveCN101417923AReduce dosageMitigate the impact of stable operationGroup 4/14 element organic compoundsHalogenated hydrocarbon separation/purificationFluidized bedGas phase

The invention relates to a recycling and refining method of chloromethane. After being condensed by a chloromethane compressor, the coarse chloromethane gas from a washing tower end cooler enters into a chloromethane tower for refining in gas phrase state from an inlet under a return flow inlet of a coarse monomeric tower; the recycled chloromethane gas obtained from the upper lateral line of the chloromethane tower is directly led into a chloromethane superheater, is heated and then flows into a fluidized bed to carry out fluidized reaction. The invention improves the charging and discharging technical process of the present chloromethane refining tower and simplifies the unnecessary processes, which greatly reduces the investment to disposable equipment and the energy consumption in the production process, thereby reaching the purpose of saving equipment and energy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL +1

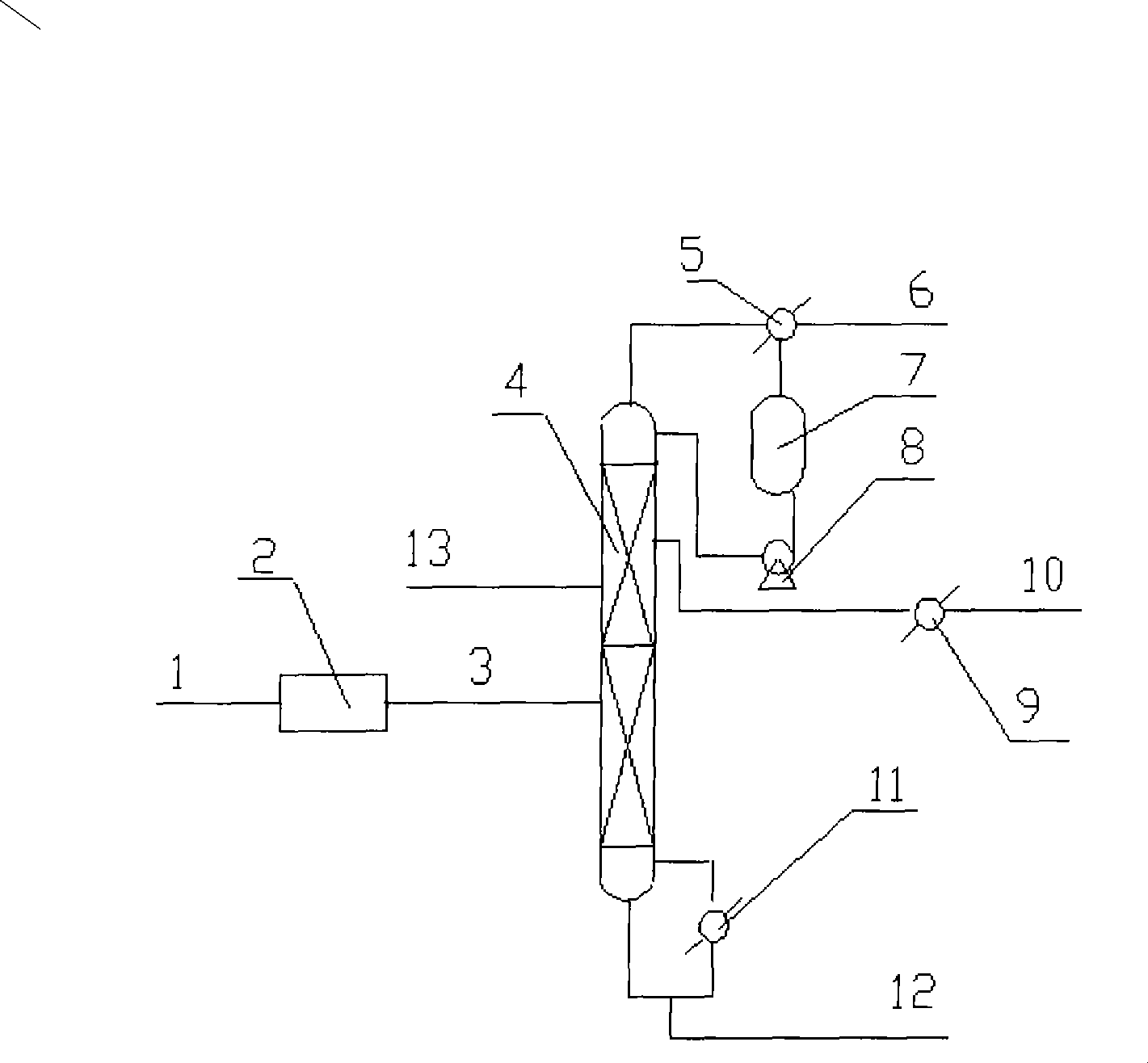

Self-deoxidization waste heat boiler suitable for sulfur-containing fuel

ActiveCN104713058ALower exhaust gas temperatureReduce steamLiquid degasificationSteam generation using hot heat carriersEngineeringOxygen

The invention provides a self-deoxidization waste heat boiler suitable for sulfur-containing fuel. The self-deoxidization waste heat boiler comprises a waste heat recovery device, a flash evaporator internally provided with a steam and water separator, a deoxidization water tank communicated with the flash evaporator, a steam pocket and an evaporator arranged in a flue. A heat absorption section and a heat release section of the waste heat recovery device are connected through an ascent pipe and a descent pipe, the heat absorption section is arranged in the flue, the steam pocket is connected with the evaporator through a circulation pipeline, a boiler water supply pipe is connected with a water inlet of the flash evaporator after passing through the heat release section, and a water outlet of the deoxidization water tank is connected with the steam pocket. The flash evaporator is adopted for deoxidization, heat energy used for deoxidization is smoke waste heat of the boiler, the temperature of exhausted smoke of the waste heat boiler can be effectively reduced, waste heat of the boiler is fully used, steam does not need to be extracted in the deoxidization process after the flash evaporator is additionally arranged, the steam amount of the boiler is saved, and the efficiency of the boiler is improved.

Owner:SHANGHAI FUBO ENVIRONMENTAL PROTECTION EQUIP

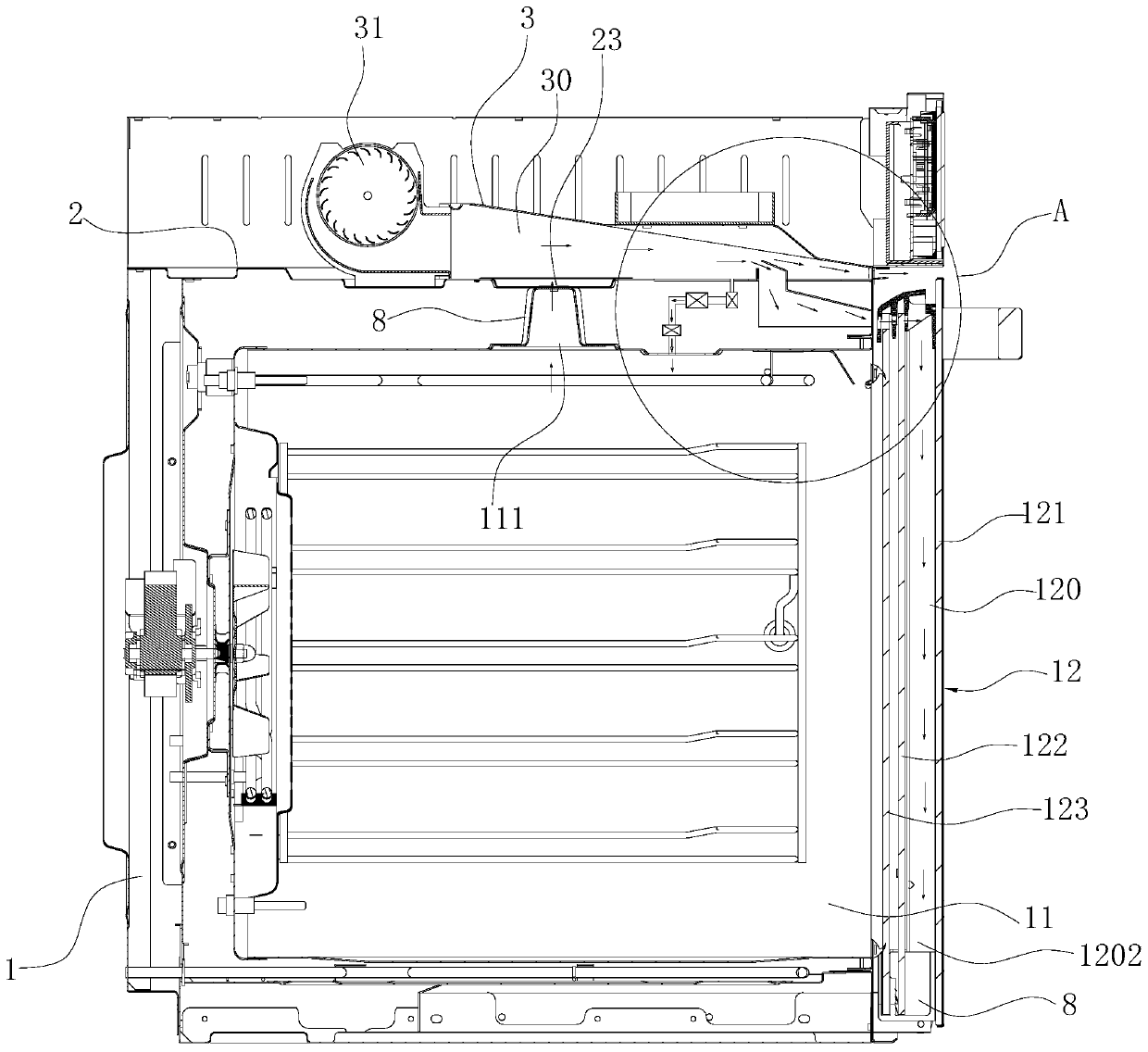

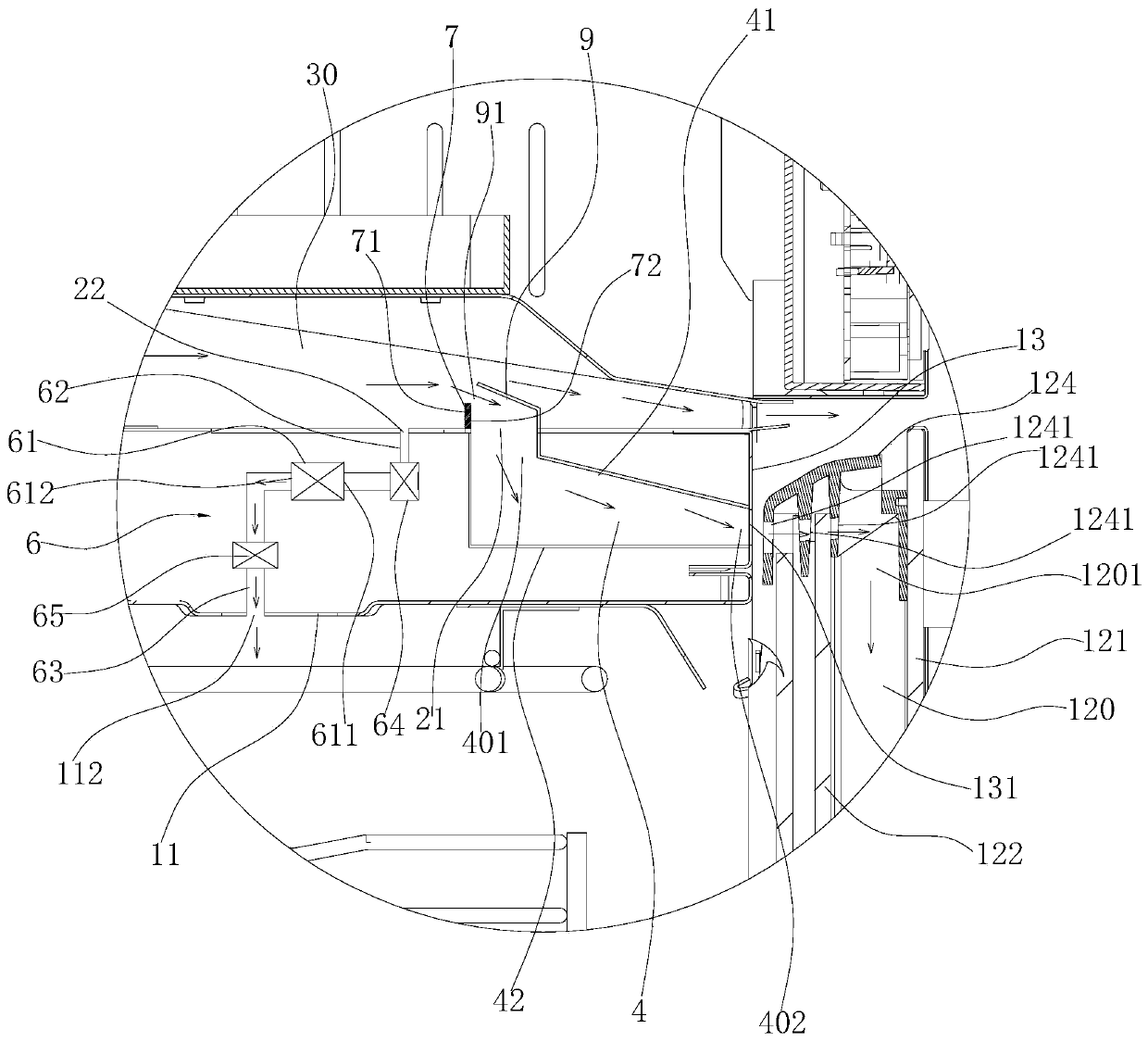

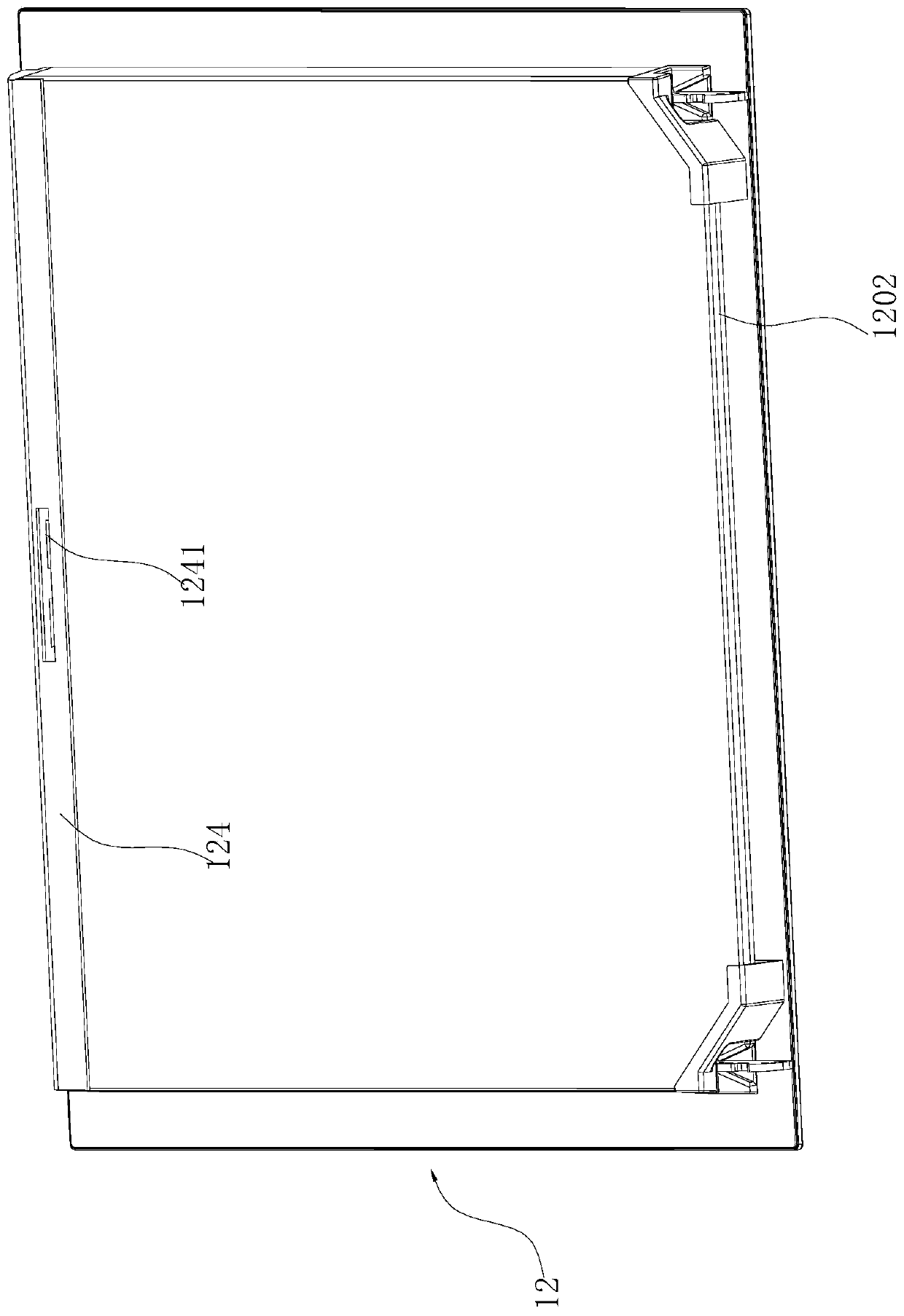

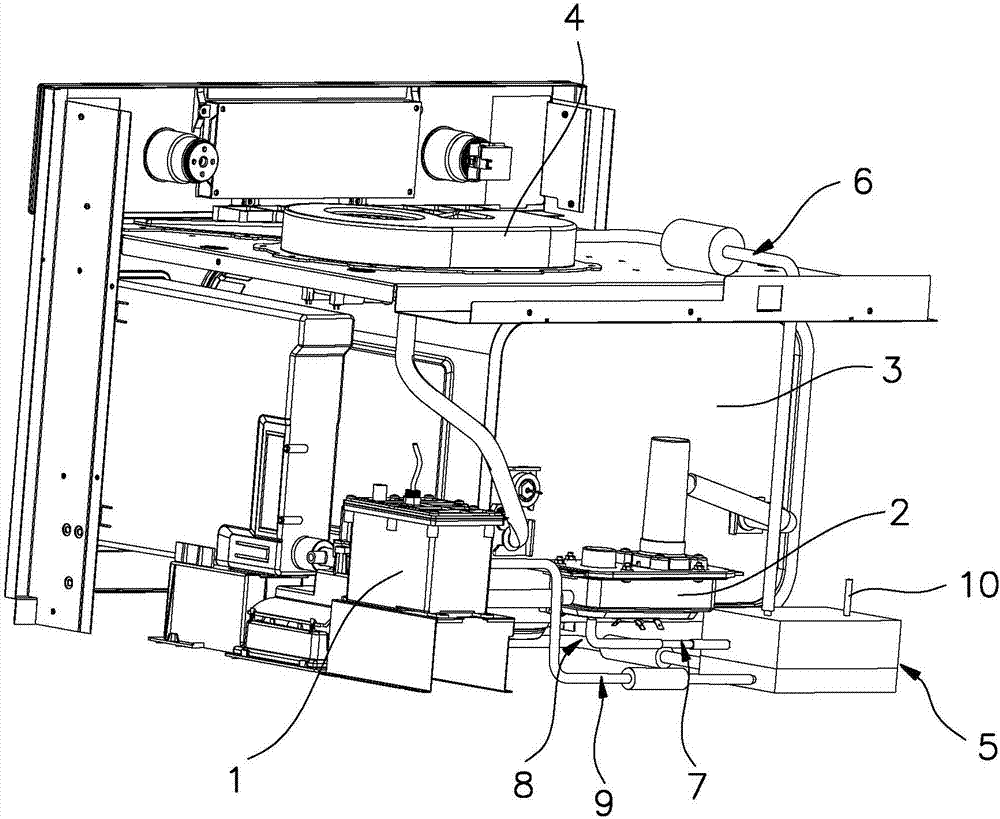

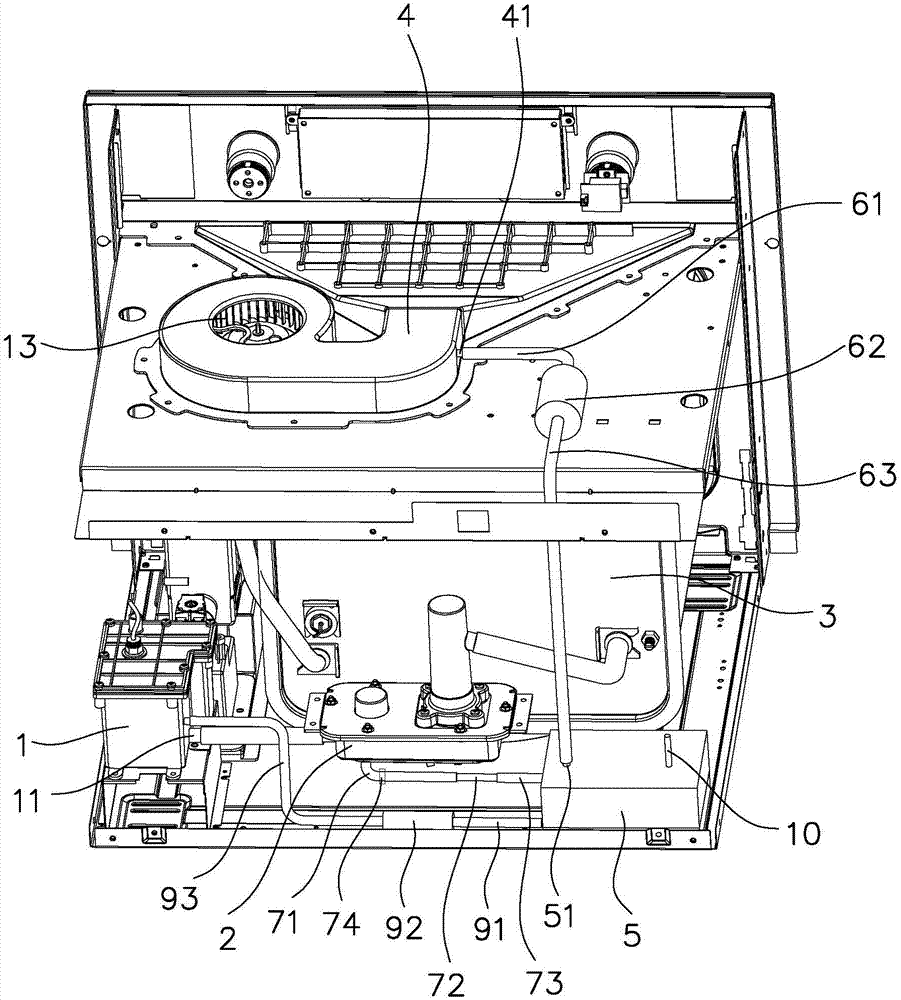

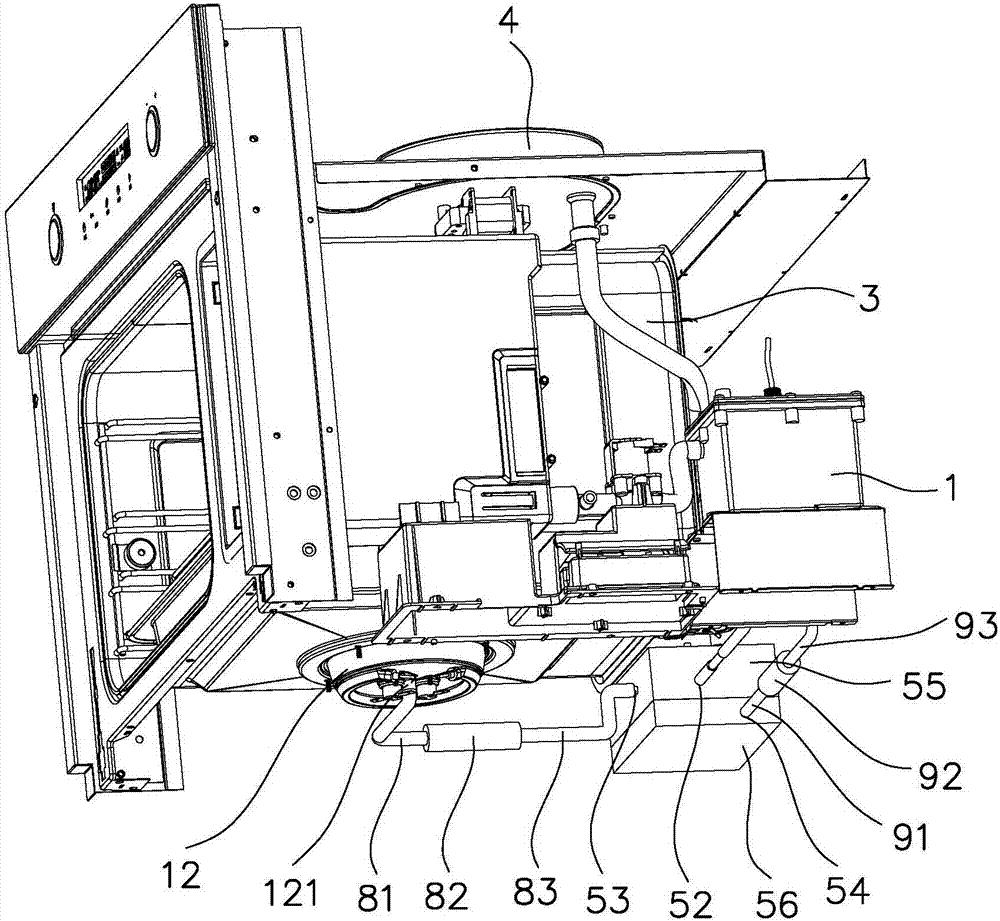

Steaming and baking integrated machine

PendingCN110960074AReduce exhaustReduce the temperatureSteam cooking vesselsRoasters/grillsActive coolingEngineering

The invention relates to a steaming and baking integrated machine that comprises a box body and a door body, wherein an inner container, an upper mounting plate and an air guide cover are arranged inthe box body; the air guide cover covers the upper surface of the upper mounting plate to form a first exhaust air duct; the machine further comprises a second exhaust air duct, the door body is provided with a ventilation interlayer, an air guide opening is formed in the side wall of the air outlet end of the first exhaust air duct, an air inlet end opening of the second exhaust air duct is communicated with the air guide opening, an air outlet end opening of the second exhaust air duct is in fluid communication with an upper air inlet of the ventilation interlayer, and a semiconductor chilling plate is arranged in the first exhaust air duct. According to the invention, part of gas exhausted from the first exhaust air duct is shunted through the second exhaust air duct, so the exhaust amount in the first exhaust air duct is reduced; the air outlet end opening of the second exhaust air duct is communicated with the ventilation interlayer on the door body, the semiconductor chilling plate can cool air flow entering the second exhaust air duct, the cooled air flow can actively cool the door body after entering the ventilation interlayer, and therefore the temperature of the door bodyis reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

De-sulfur method with reproducible desulfurizer for preparing sulfuric acid as final product

InactiveCN101721894AReduce contentReduce steamDispersed particle separationSulfur compoundsChemistryFlue gas

The invention provides a de-sulfur method with reproducible desulfurizer for preparing sulfuric acid as a final product, comprising the steps of the pretreatment of desulfurized flue gas, the absorption of SO2, the desorption of desulfurizer, the recycling of SO2, the preparation of sulfuric acid and the like. The method is characterized in that the endogenetic steam of a desorption tower is replaced by thermal process gas with the oxygen content being greater than 10%; the desorption energy is mainly provided by the absorption solution entering the desorption tower; the volume percentage concentration of the SO2 in the mixed gas exhausted from the desorption tower is controlled to be greater than or equal to 3%. The method provided by the invention solves the problems of dual waste of energy, function surplus, and big primary investment existing in the prior art to meet the needs of desulfurization projects of different types, meanwhile, the method is especially adaptable for the desulfurization system of a sintering machine.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

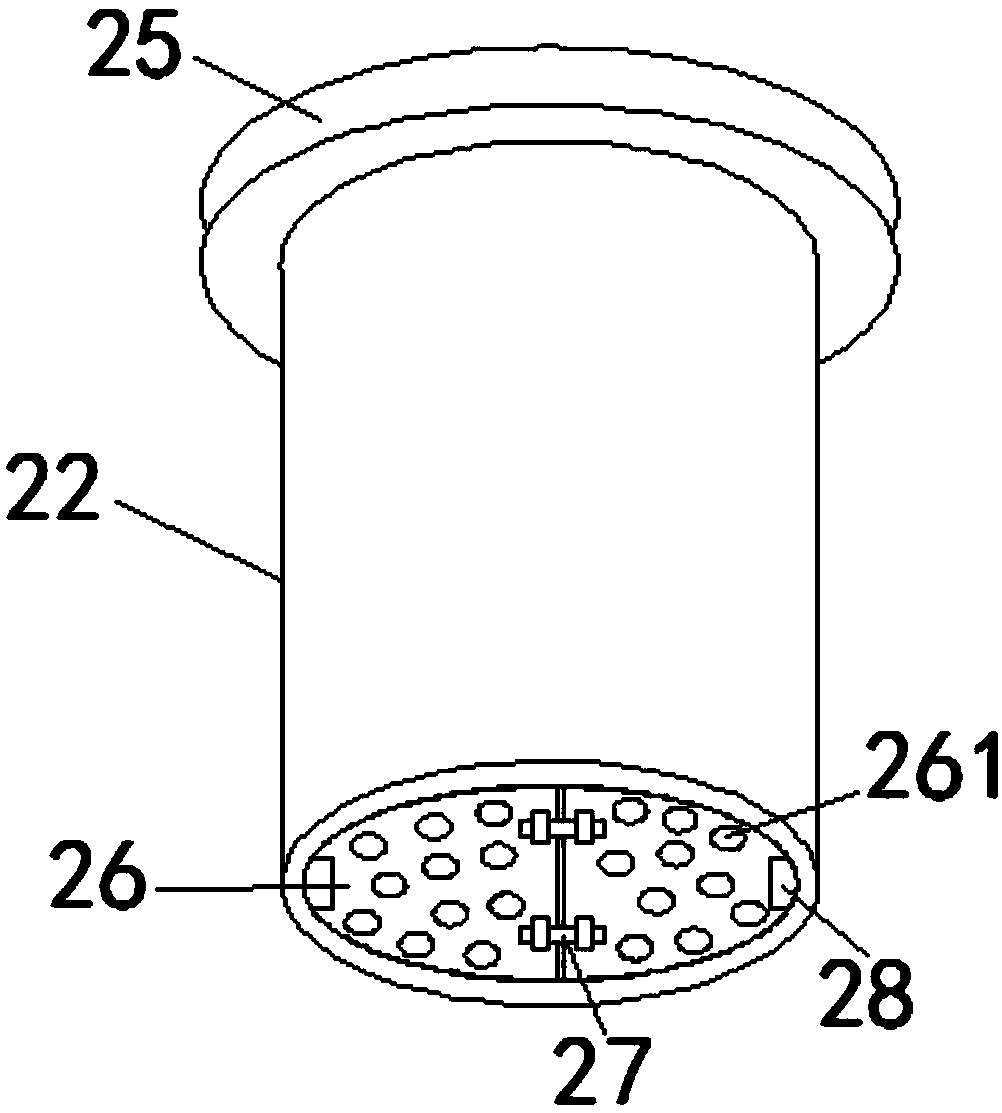

Water recycling device for steam box

The invention provides a water recycling device for a steam box. The water recycling device comprises a water storage box, a steam generator, a liner, an air guide cover and a water storage tank, wherein the water storage tank is provided with a first water inlet, a second water inlet, a third water inlet and a water outlet, a first circulating water channel is arranged between a first outlet of the air guide cover and the first water inlet, a second circulating water channel is arranged between a second outlet in the bottom of the steam generator and the second water inlet, a third circulating water channel is arranged between a third outlet of an evaporating plate on the bottom of the linear and the third water inlet, and a pumpback water channel is arranged between the water outlet of the water storage tank and a water return hole of the water storage box. For the water recycling device for the steam box, through the first circulating water channel, the second circulating water channel and the third circulating water channel, part of steam exhausted by the air guide cover, residual condensate water on the bottom of the liner, and residual high-temperature steam and hot water inthe steam generator are recycled to the water storage tank, through the pumpback water channel, water recycled to the water storage tank is pumped back to the water storage box for recycling use, therefore, the utilization ratio of water is improved, and the quantity of steam of an air exhaust hole is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

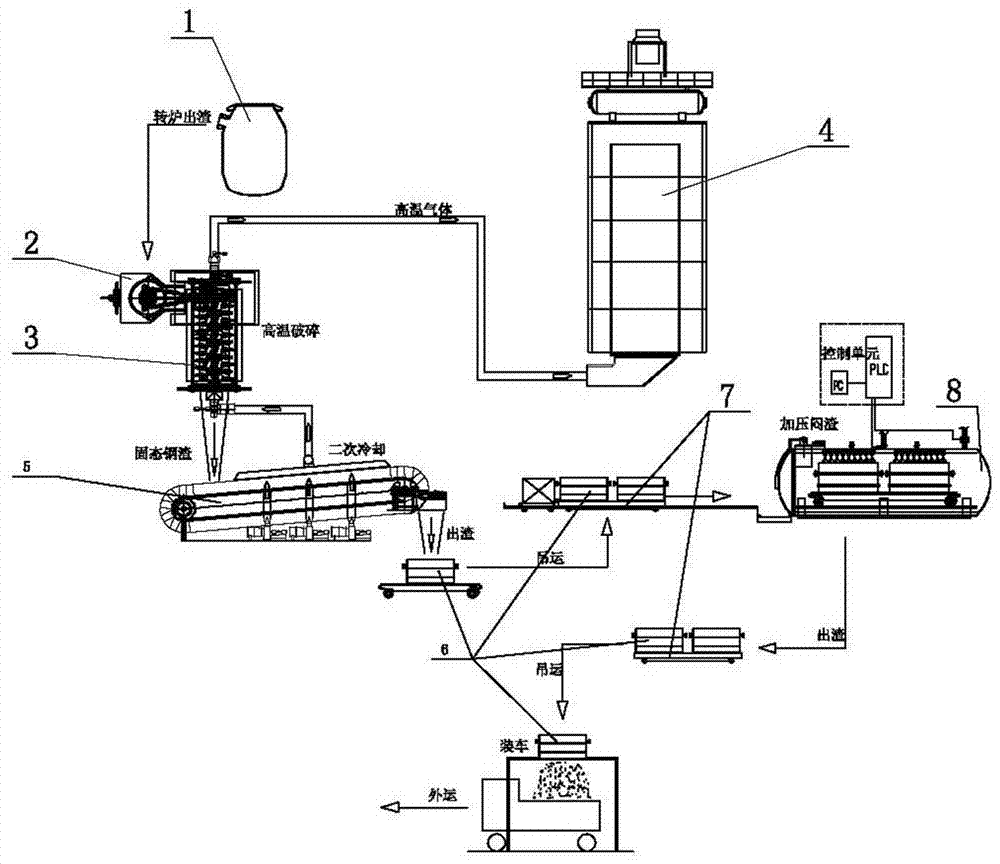

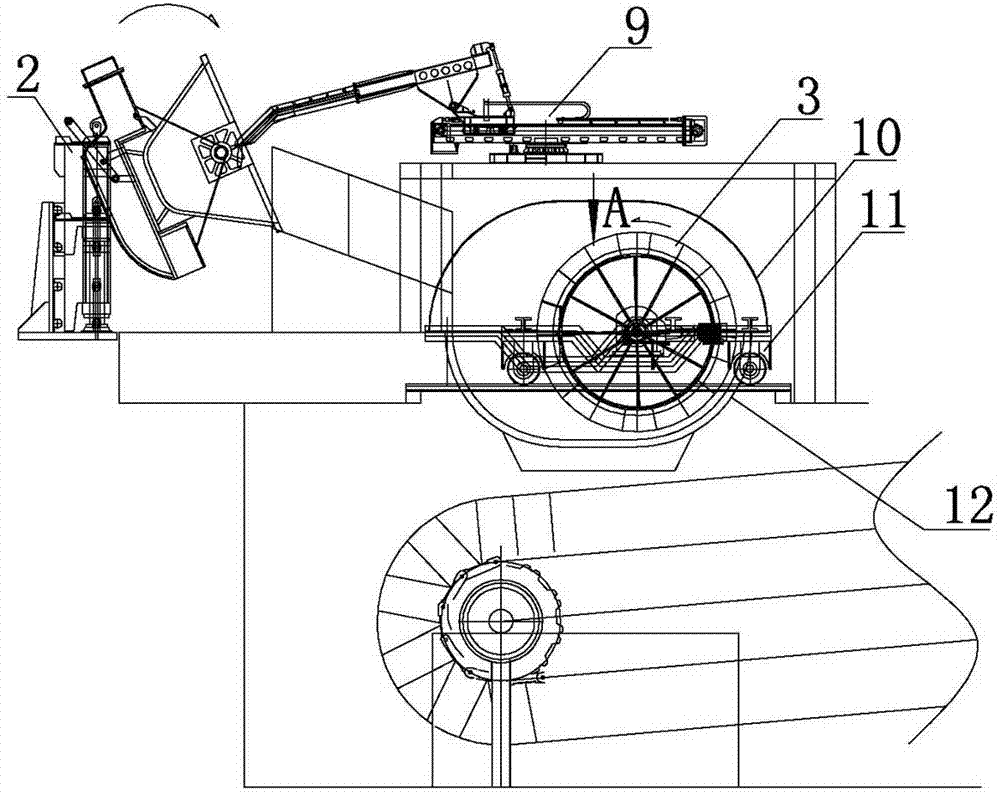

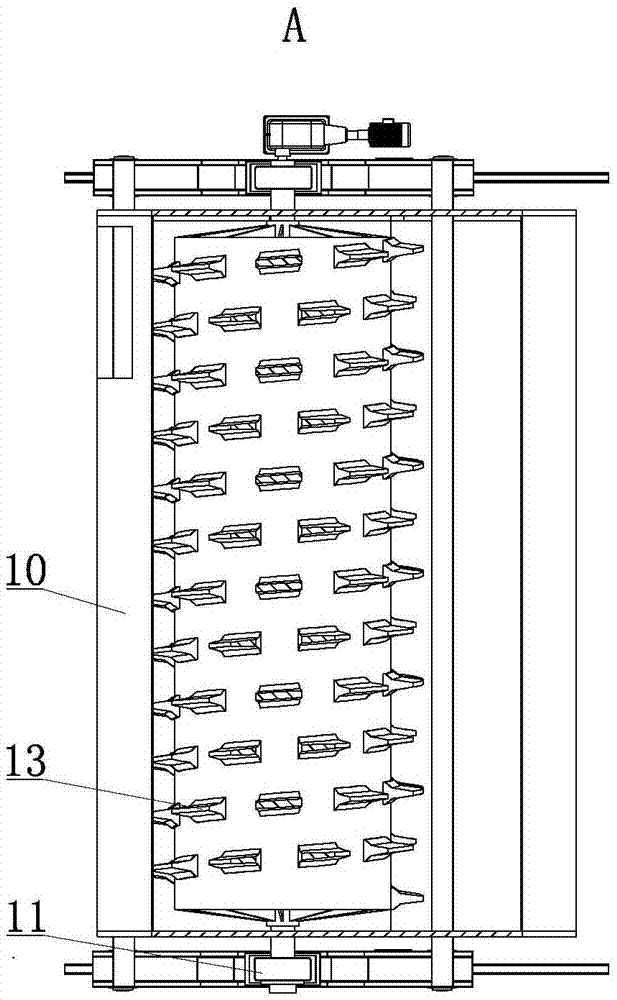

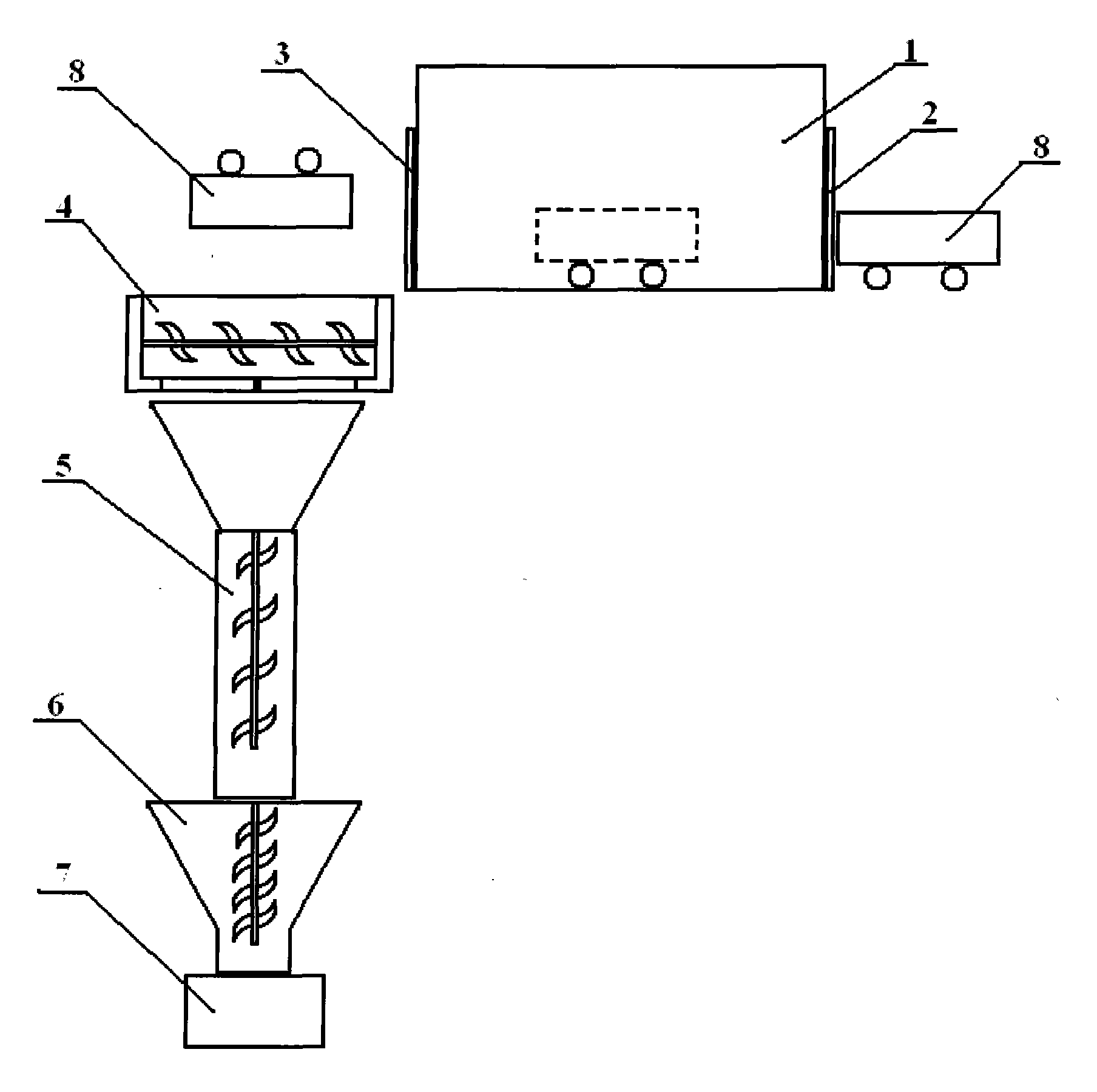

Steel slag waste heat recovery and pressurized slag disintegrating system and technology

PendingCN107164588AImprove stabilityIncrease resource valueExhaust gas handlingIncreasing energy efficiencySlagWaste heat

The invention discloses a steel slag waste heat recovery and pressurized slag disintegrating system and technology. The system comprises a slag ladle tilting mechanism, a roller, a waste heat boiler, a straight-line cooler, a slag disintegrating tank, a slag ladle trolley, slag disintegrating pressurization kettles and a slag removal machine. The slag ladle tilting mechanism can tilt a slag ladle containing steel slag. The surface of the roller is provided with spirally-arranged roller teeth. The lower portion of the roller is provided with a steel slag groove. The steel slag groove is provided with a sealing cover. The steel slag in the tilted slag ladle can be conveyed into the steel slag groove through the slag removal machine, and a discharge outlet of the steel slag ladle is located above the straight-line cooler. Air is adopted as a heat exchange medium, a first fan blows air into a high-temperature material layer of the straight-line cooler, indoor-temperature air penetrates through the high-temperature steel slag from bottom to top, air is heated, and first-step heat exchange is completed. Air subjected to heat exchange through the straight-line cooler enters the roller, gas penetrates through the stirred steel slag to be further heated, and secondary heat exchange is completed. High-temperature gas is sucked to the waste heat boiler through a second fan, and therefore waste heat recovery is achieved.

Owner:JIGANG INT ENG & TECH CO LTD

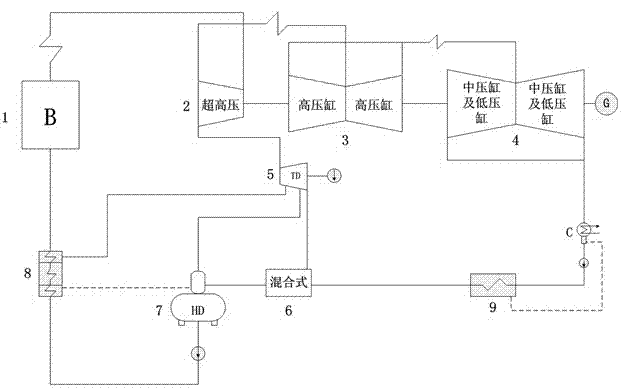

Matching method of supercritical secondary reheating unit reheater and thermal system

The invention belongs to the field of large supercritical secondary reheating thermal power generating units, and relates to a method capable making a heat exchange area needed by secondary reheating and a thermal system matched, in particular to a matching method of a supercritical secondary reheating unit reheater and the thermal system. According to the scheme, the heated face needed by the reheater is reduced, reasonable match between the reheater and the thermal system is achieved, exhausted steam of a water pump turbine is absorbed through a hybrid heater, the heat exchange area is reduced, and initial investment of a power plant is reduced. Heat for pumping steam of the water pump turbine can be finally recycled to the thermal system, and economical performance of the power plant is improved. Therefore, according to the scheme, the method is favorable for reducing the initial investment of the power plant and improving operating benefits of the power plant.

Owner:GUODIAN SCI & TECH RES INST +1

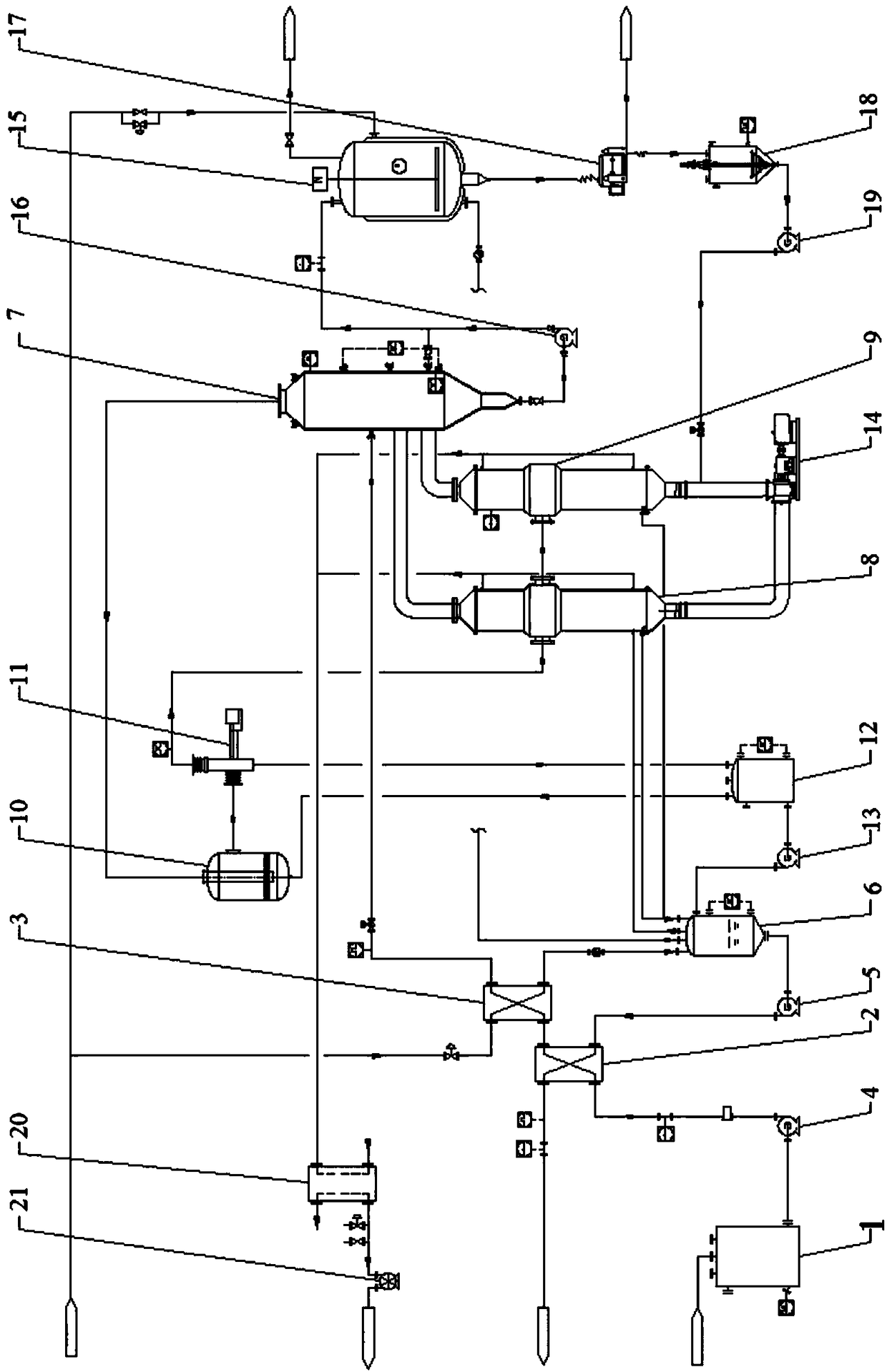

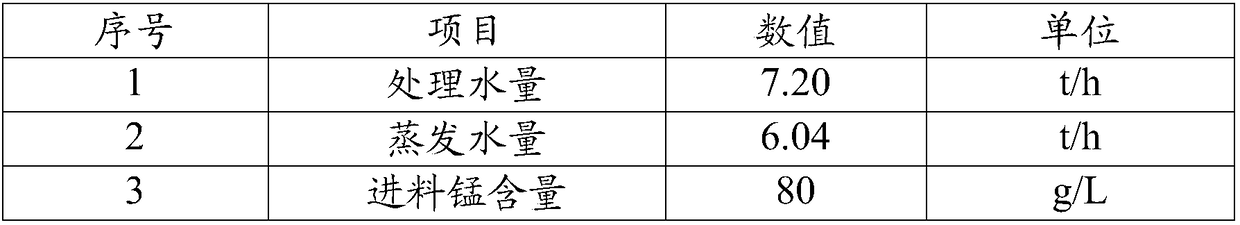

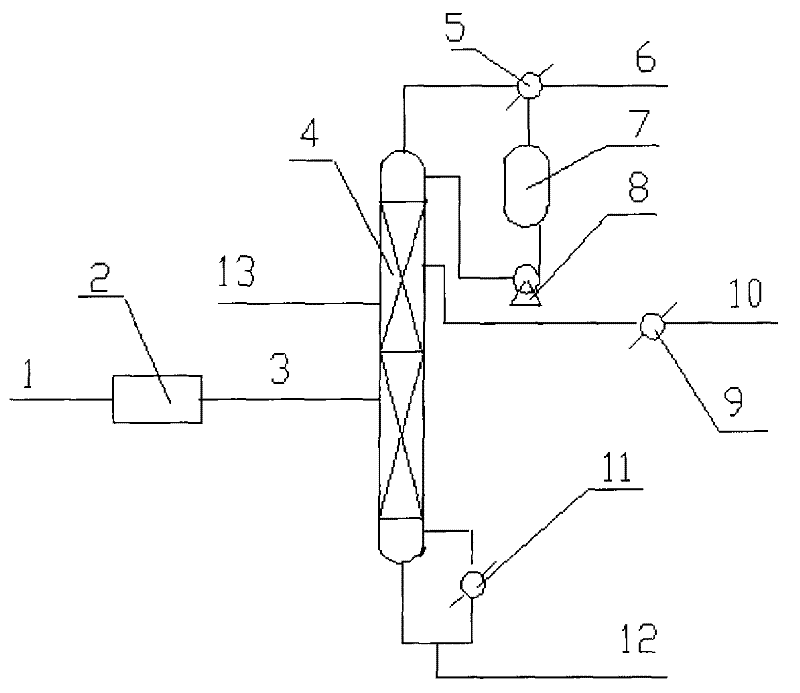

Manganese sulfate evaporative crystallization equipment and process

ActiveCN108568135AFree from destructionIncrease productivitySolution crystallizationCrystallization plant arrangementsSulfateSmall footprint

The invention discloses manganese sulfate evaporative crystallization equipment. The manganese sulfate evaporative crystallization equipment comprises a stock solution preheating system, an evaporative concentration system, a high-temperature crystallization system and a filtering-separating system which are sequentially connected, and further comprises a control mechanism, wherein the high-temperature crystallization system comprises an enamel high-temperature kettle; and the control mechanism is in signal connection with the stock solution preheating system, the evaporative concentration system, the high-temperature crystallization system and the filtering-separating system. The equipment can be used for directly evaporating and crystallizing lean manganese ore with relatively low manganese sulfate content to obtain manganese sulfate monohydrate, is simple in structure, is small in floor space, is low in investment, realizes an automatic production process of manganese sulfate monohydrate from manganese sulfate stock solution treatment to product package, is high in production efficiency, is free of damage to environment, and is the equipment with low energy consumption and highdegree of automation. The invention further discloses a process for preparing manganese sulfate by utilizing the equipment, and the process is simple in step, is low in energy consumption, is low in production cost, increases the yield of manganese sulfate produced by lean manganese ores, and is low in consumed steam amount.

Owner:SHENZHEN SUNEVAP TECH

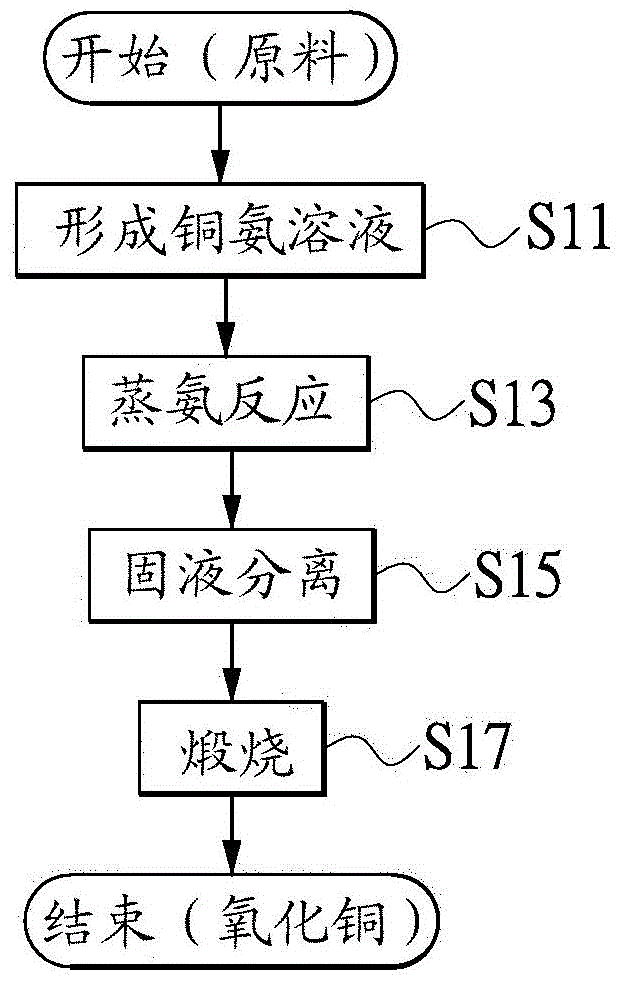

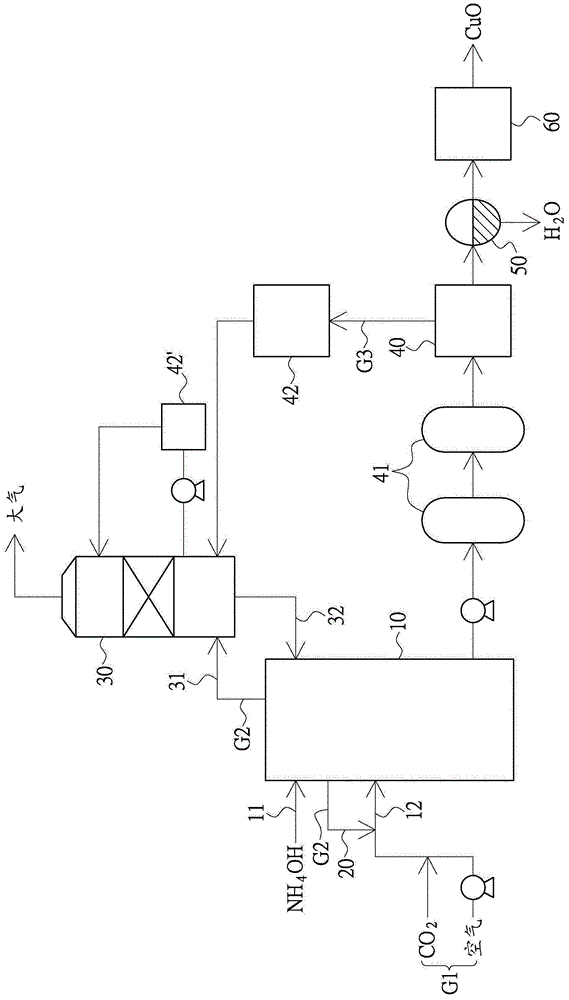

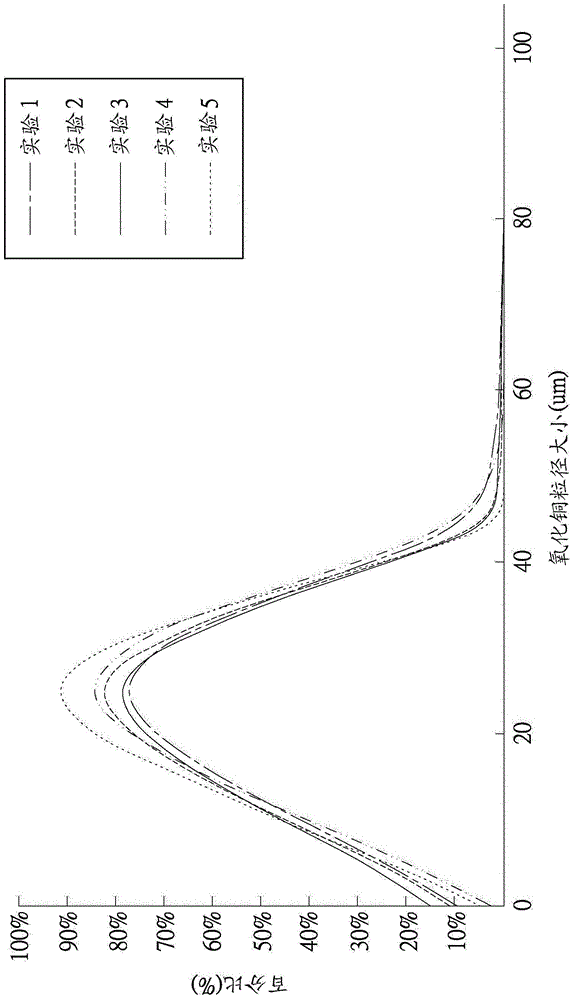

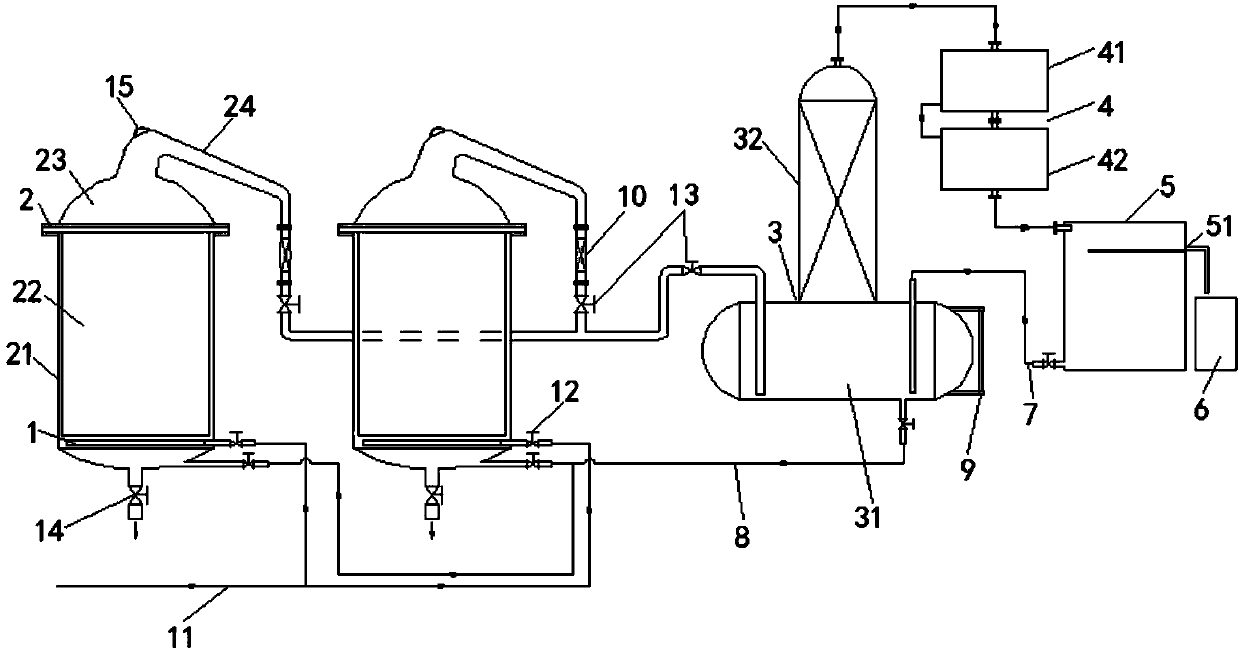

Copper oxide making method and copper oxide making equipment

InactiveCN104891551AIncrease productionReduce usageCopper oxides/halidesBasic copper carbonateAmmonium hydroxide

Owner:CO TECH DEV CORP

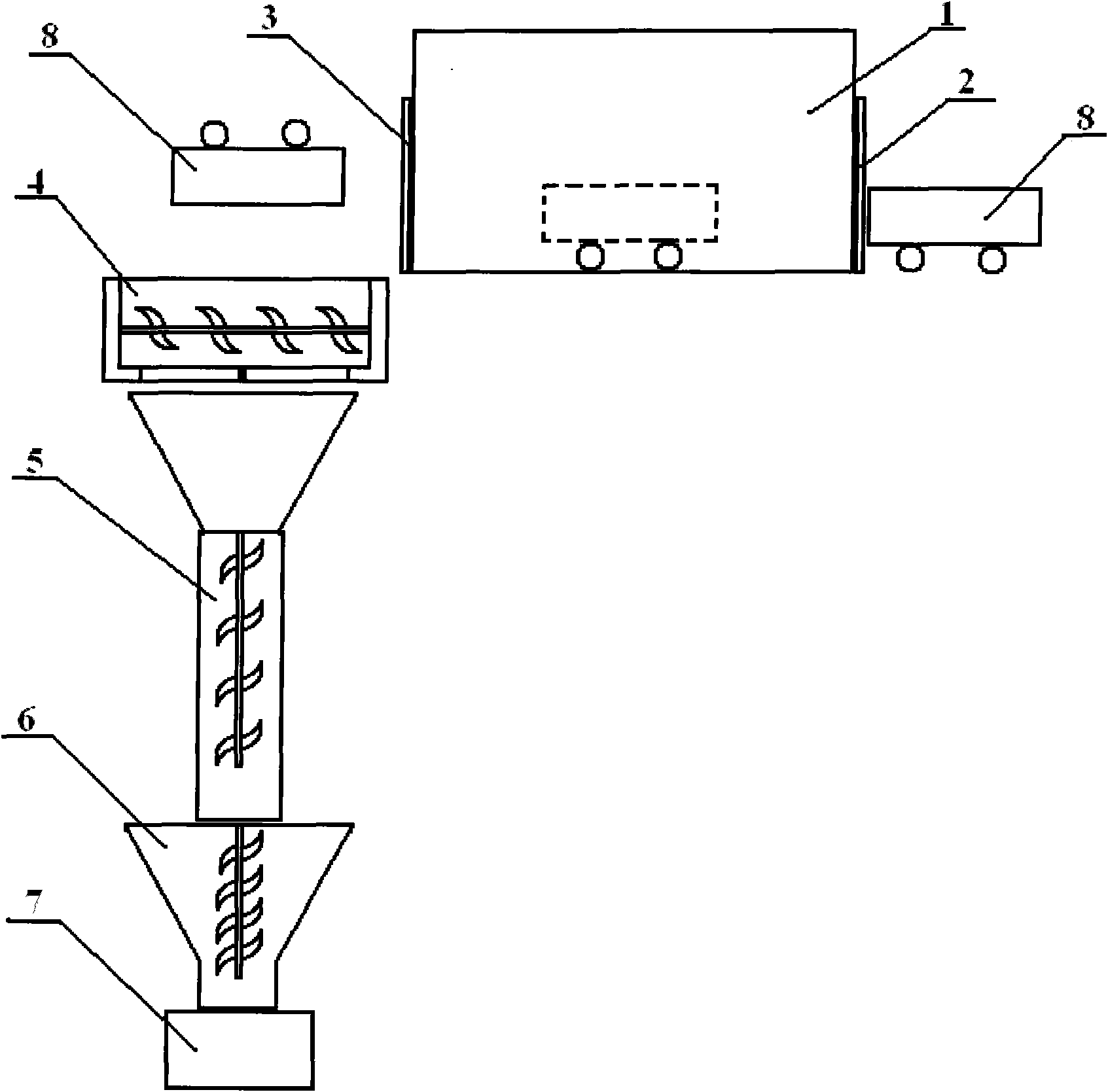

Device and process method for extracting plant aromatic oil

PendingCN110387289AImprove oil yieldReduce the temperatureEssential-oils/perfumesReboilerPulp and paper industry

The invention relates to the technical field of separation and extraction of plant aromatic oil, in particular to a device for extracting the plant aromatic oil. The device comprises a steamer, a reboiler, a cooling device, an oil-water separator, a heating coil and a collector; a tower kettle is located at the bottom of a fractionating tower, the top of the steamer conveys oil-water vapor into the reboiler through a distillation air duct, and the heating coil for heating raw materials is arranged at the bottom of the steamer; the top of the cooling device is connected to the top of the reboiler through a guide pipe, the bottom of the cooling device is connected to the top of the oil-water separator through a guide pipe, the oil-water separator is provided with an oil outlet, and the oil outlet is connected with the collector; and the bottom of the oil-water separator is connected to the reboiler through a primary water return pipe, and the bottom of the tower kettle of the reboiler isconnected to the bottom of the steamer through a secondary water return pipe. The invention further discloses a process method for extracting the plant aromatic oil. By adopting the device and the process method, the oil yield is high, and energy consumption is low.

Owner:GUANGXI FORESTRY RES INST

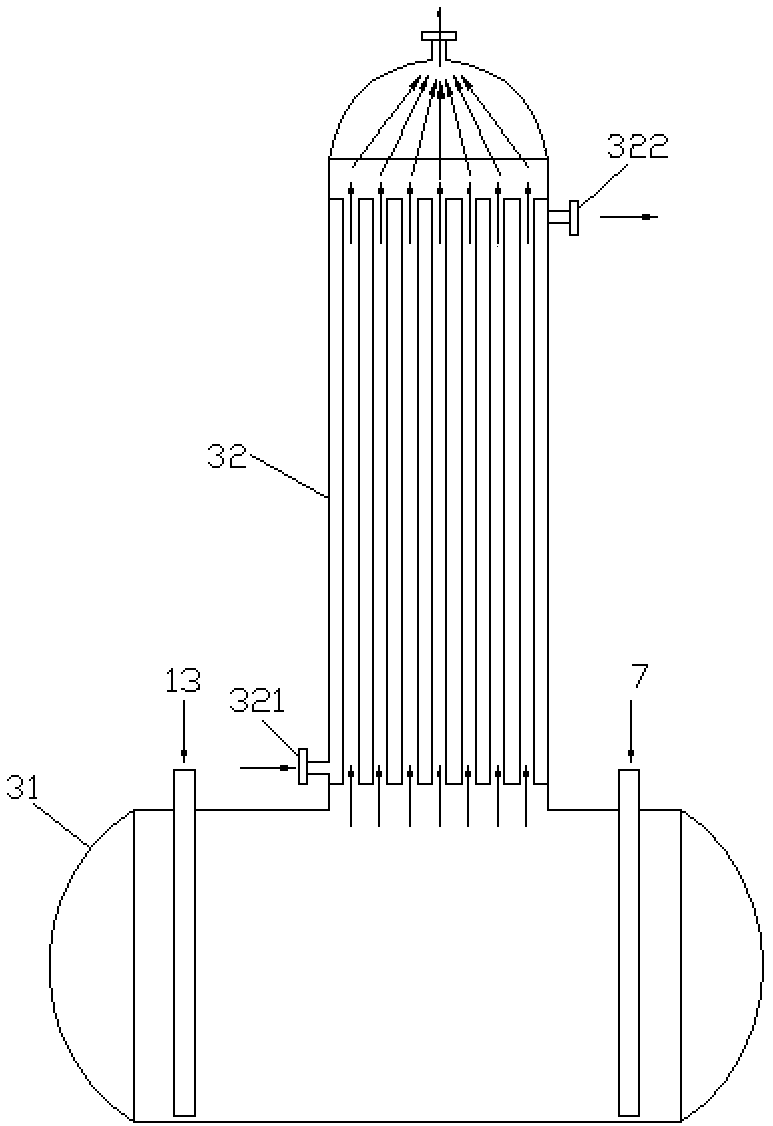

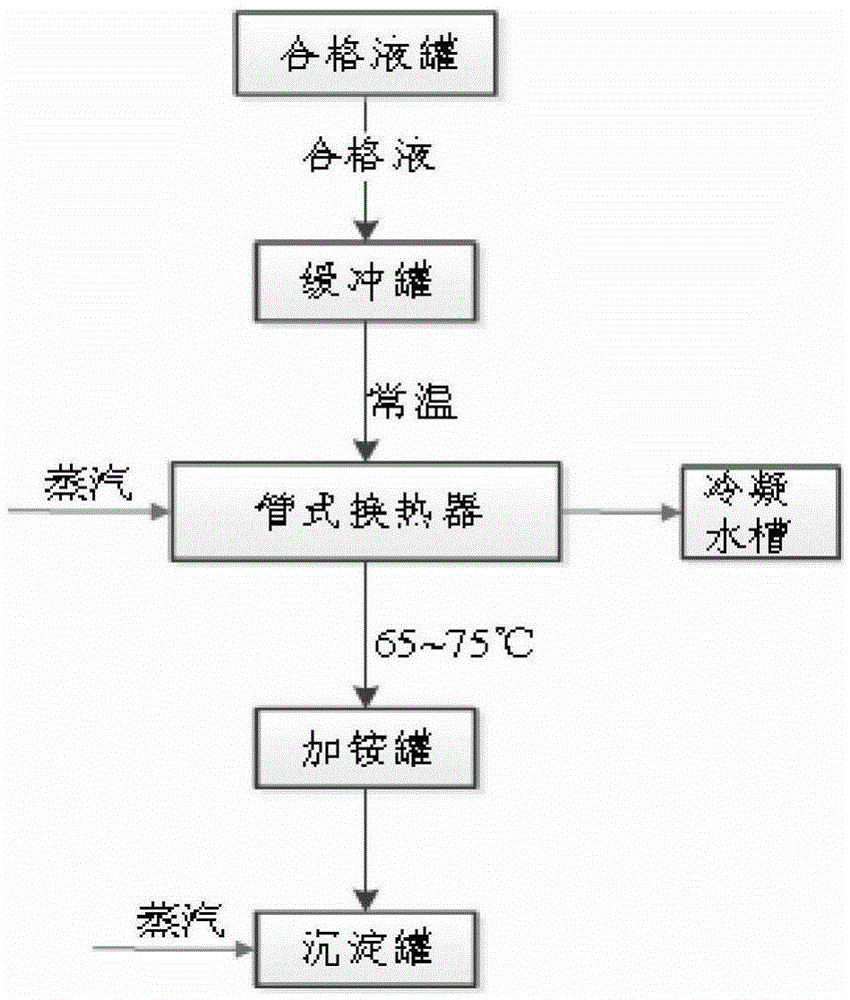

Vanadium pentoxide preparation method

The invention belongs to the field of hydrometallurgy and particularly relates to a vanadium pentoxide preparation method. The preparation method comprises the following steps that (a) the temperature of acidic vanadium liquid rises from normal temperature to 65-75 DEG C in the preheating process of a vanadium precipitation process by using a static mixer pipe and utilizing steam heat exchange; (b) the acidic vanadium liquid subjected to heat exchange is added into an ammonium tank, ammonium sulfate is added, and stirring is performed to obtain mixed liquid; (c) the mixed liquid is added into a sedimentation tank, stirring is performed, a pH value is regulated to be 1.5-2, and steam heating is performed to reach 90 DEG C to boiling so as to obtain an ammonium poly-vanadate solution; (d) precipitate obtained after the ammonium poly-vanadate solution precipitates is washed, dried and calcinated to obtain vanadium pentoxide. The flowing state of the acidic vanadium liquid in the pipe is changed by utilizing a mixing unit body fixed in the static mixer pipe, the formation of a laminar flow bottom layer is inhibited to enable the acidic vanadium liquid to rapidly disperse in the pipe, the temperature distribution of all parts of the solution tends to be uniform, the formation of a scale layer is retarded, and the production efficiency of the vanadium pentoxide is improved.

Owner:攀钢集团西昌钒制品科技有限公司

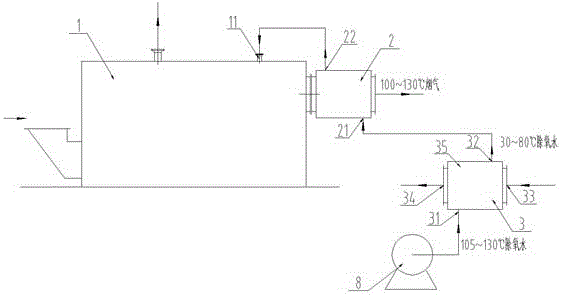

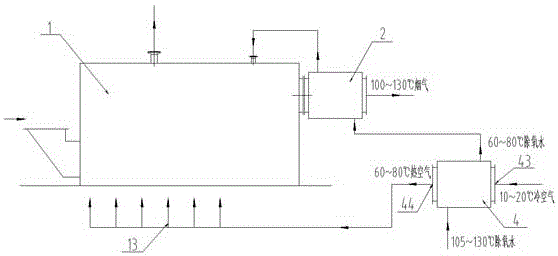

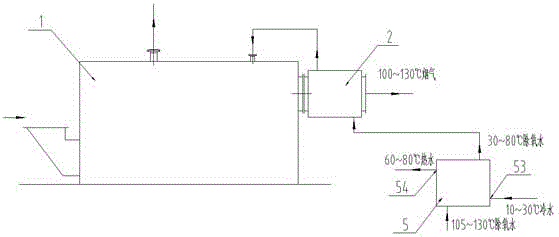

Energy-saving method and energy-saving device for boiler

InactiveCN104990062ALower exhaust gas temperatureMuch layoutLiquid degasificationFeed-water heatersBoiler feedwater pumpEngineering

The invention discloses an energy-saving method and an energy-saving device for a boiler. Heat exchange on high-temperature boiler feedwater at the temperature ranging from 105 DEG C to 130 DEG C is carried out through a boiler feedwater temperature reduction device, so that the temperature falls to range from 30 DEG C to 80 DEG C; then heat exchange between the boiler feedwater ranging from 30 DEG C to 80 DEG C and boiler smoke is carried out through a boiler economizer, so that the boiler exhausted smoke temperature falls to range from 100 DEG C to 130 DEG C; and the high-temperature boiler feedwater obtained after heat exchange enters a boiler system. The energy-saving device comprises the boiler and the boiler economizer, and further comprises the boiler feedwater temperature reduction device; a first boiler feedwater inlet of the boiler feedwater temperature reduction device is connected with a boiler feedwater pump, and a first boiler feedwater outlet of the boiler feedwater temperature reduction device is connected with a second boiler feedwater inlet of the boiler economizer; and a second boiler feedwater outlet of the boiler economizer is connected with a water inlet of the boiler, and the boiler feedwater temperature reduction device is further provided with a cold medium inlet and a hot medium outlet. As the energy-saving method and the energy-saving device are used for conducting energy-saving transformation on the boiler, the boiler exhausted smoke temperature can be reduced by more than 10 DEG C to 60 DEG C, and the boiler heat efficiency can be improved by more than 2%.

Owner:HENAN FORCE HEAT ENERGY EQUIP MFG

Dry oil deodorizing process and equipment

The invention discloses dry oil deodorizing process and equipment. Oil to be deodorized is heated by a heat exchanger and a vacuum heater to a deodorizing temperature; the oil then enters a deodorizing column for stripping deodorizing; the deodorized oil is pumped into a dry steaming column for dry steaming and is pumped into the heat exchanger to engage in heat exchange with oil to be deodorized, for cooling, thus deodorized oil is obtained; fatty acid distillate from the deodorizing column is stored in a fatty acid tank; low carbon chain molecules from the dry steaming column are removed under the vacuum action and captured and stored in the fatty acid tank. The dry oil deodorizing process has the advantages that steam quantity can be effectively reduced by 20-30%, finished oil yield is increased by 20-30%, formation rate of free fatty acid and trans-fatty acids is reduced, and the flavor of the deodorized finished oil is improved and guaranteed. The dry oil deodorizing equipment is simple and handy, small in size, lower in cost and lower in energy consumption.

Owner:郑州远洋油脂工程技术有限公司

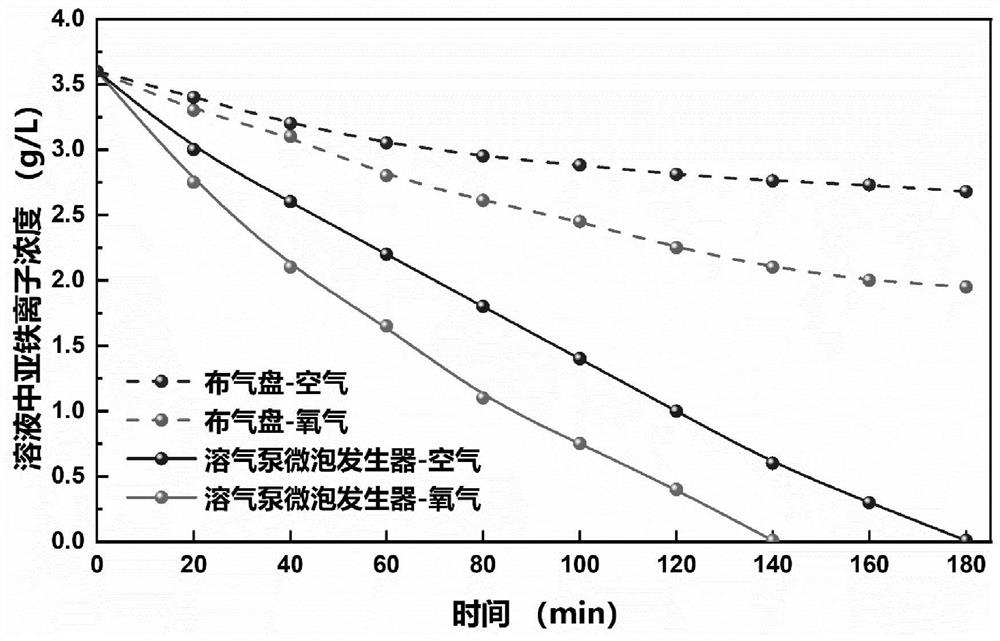

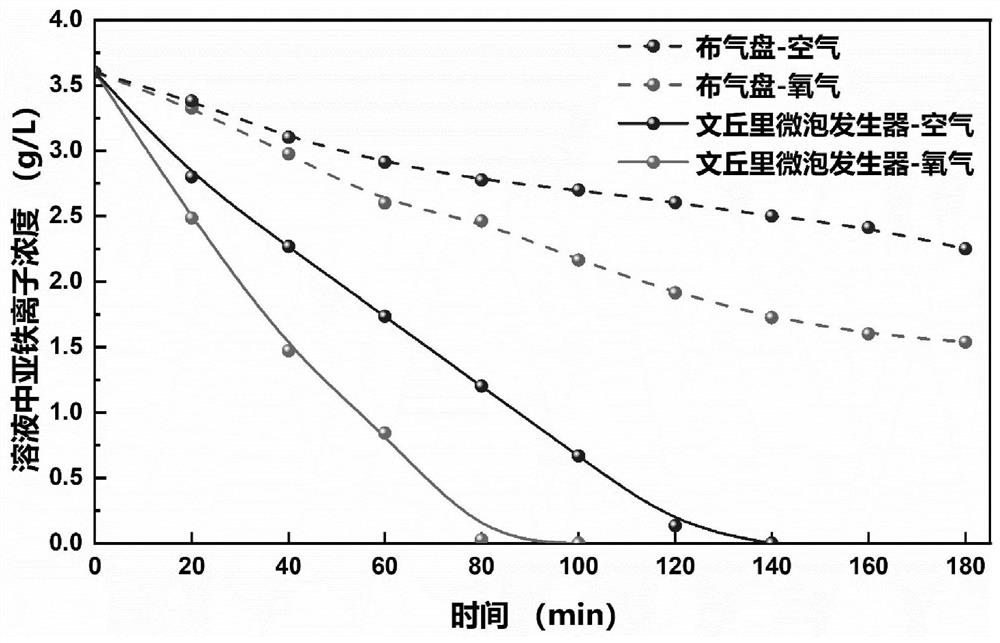

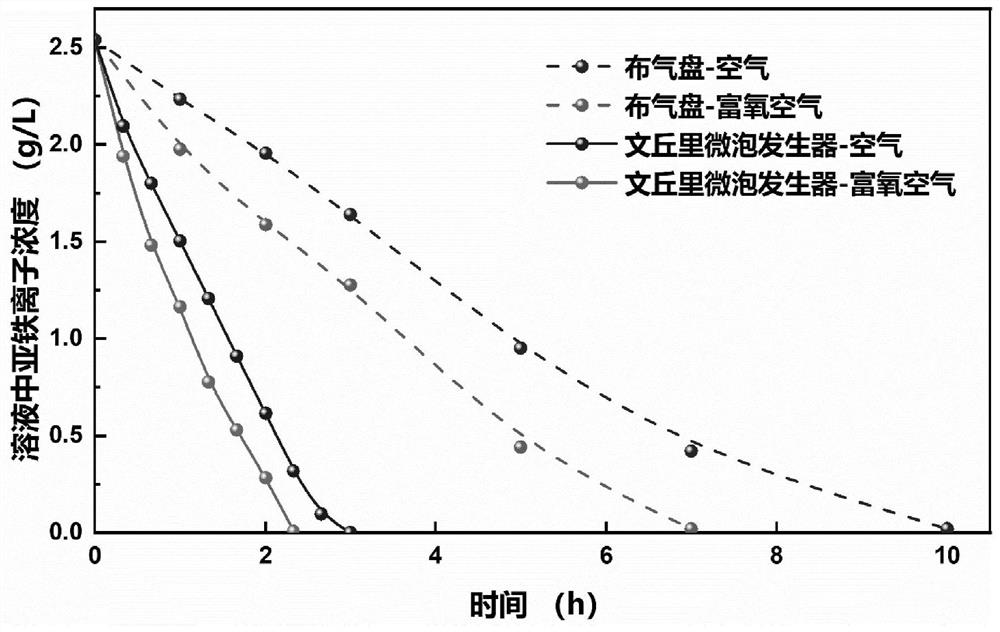

Method for strengthening iron removal by oxygen oxidation in solution by using microbubble generating device

InactiveCN111663040AIncrease dissolved oxygenReduce running timeProcess efficiency improvementPregnant leach solutionOxygen utilization rate

The invention discloses a method for strengthening iron removal by oxygen oxidation in a solution by using a microbubble generating device. The method uses the microbubble generating device to form oxygen-containing micro-nano bubbles in a wet smelting leaching liquid or a wet smelting leaching suspension liquid to strengthen Fe2+ oxidation, and realizes the rapid oxidation iron removal of the wetsmelting leaching liquid. Compared with an existing aeration disk or an aeration tube type oxygenation, oxygen utilization rate is significantly improved, and the method has the significant advantages such as shortening the oxidation iron removal time, increasing the iron ion purification depth, expanding the production capacity and saving energy consumption.

Owner:CENT SOUTH UNIV

Acid reducing process of rice oil

The invention discloses an acid reducing process of rice oil. The process comprises the following steps of: with rice bran containing rice germs as raw material, preparing crude oil by a leaching method; adding phosphoric acid into the crude oil to remove non-hydratable phospholipid, adding hot water for hydrating and deguming, and then drying, de-waxing, de-coloring, separating oxygen by a de-aerator, separating acid for the first time in a film evaporator, performing physical secondary acid removing in a combined plate type tower through a heater, adding alkali liquor, carrying out soap removing separation in a centrifugal machine, washing in a water washing centrifugal machine, de-coloring again, removing odor, and finally de-greasing by a winterization filter, so as to obtain low-acid-value rice oil. The acid reducing effect of the acid reducing process is significant, the acid value of the crude oil is reduced from 28+ / -1mg / g to 0.2-0.5mg / g; so low-avid-value and high-quality rice oil is possibly prepared from high-acid-value crude oil.

Owner:BENGBU QIONGHUAI GRAIN & OIL

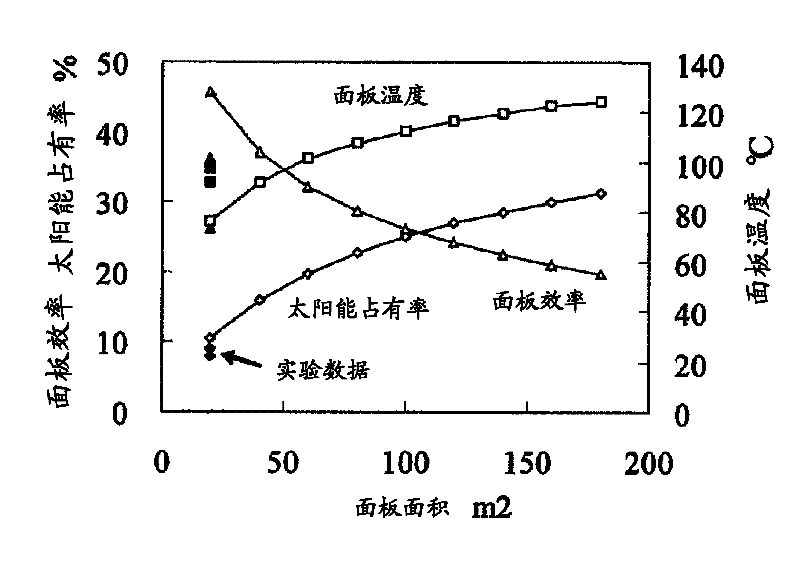

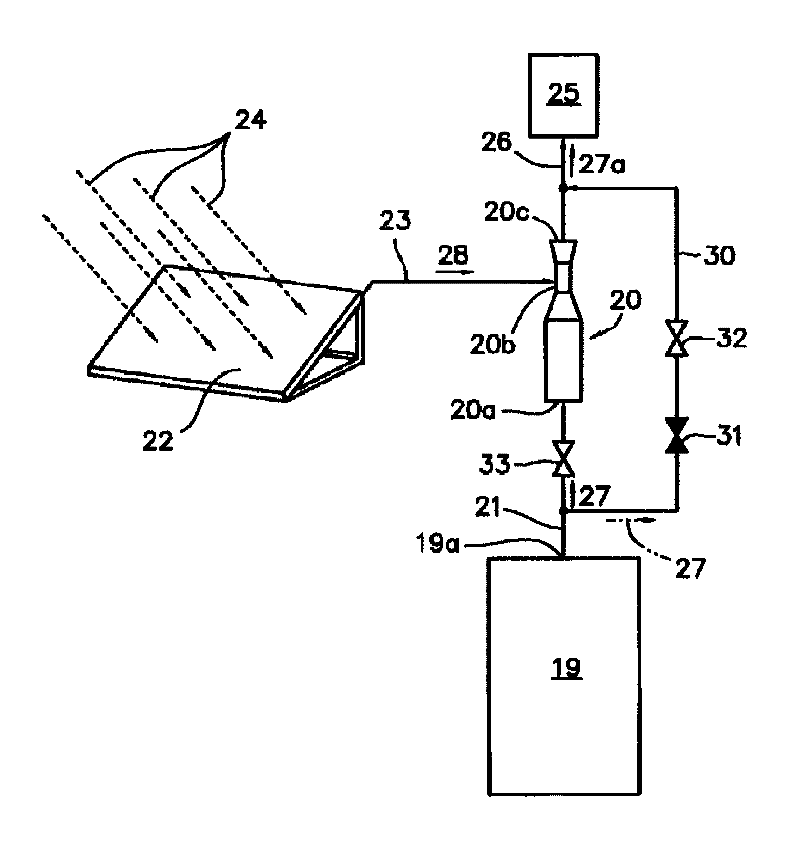

Vapor supply device

InactiveCN102472483AGood effectLess quantitySolar heating energySolar heat devicesEngineeringHigh pressure

A vapor supply device is formed by connecting the vapor inlet (20a) of a vapor injector (20) to the vapor outlet (19a) of a high-pressure-vapor generating boiler (19). A solar heat collector (22) is connected to the suction inlet (20b) of the vapor injector (20), and a vapor-using device (25) is connected to the discharge outlet (20c) of the vapor injector. The vapor injector (20) is driven by high-pressure, high-temperature vapor (27) generated by the high-pressure-vapor generating boiler (19), and the pressure at the suction inlet (20b) decreases. Water having a temperature which has been increased by irradiation of the sunlight (24) to the water boils and evaporates within the solar heat collector (22) at a temperature lower than 100 DEG C to generate low-temperature, low-pressure vapor (28), the pressure within the solar heat collector (22) decreasing as the pressure at the suction inlet (20b) is decreased. The vapor (28) is led to the vapor injector (20) and mixed with the high-pressure, high-temperature vapor (27) generated by the high-pressure-vapor generating boiler (19), and as a result, medium-pressure, medium-temperature vapor (27a) is generated. Supplying the vapor (27a) to the vapor-using device (25) reduces the amount of vapor generation by the high-pressure-vapor generating boiler (19).

Owner:IHI CORP

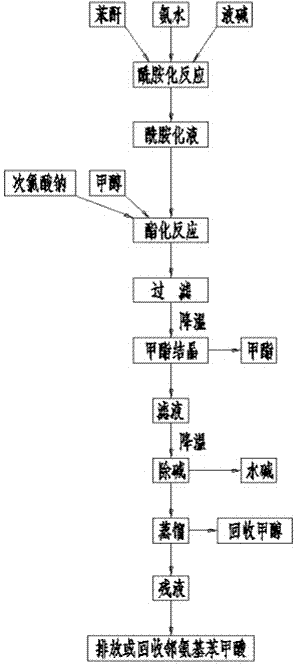

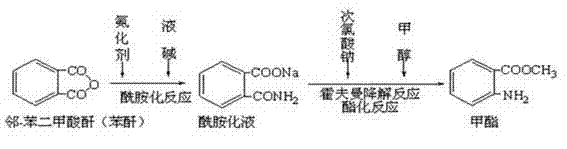

Clean production technology of methyl anthranilate

InactiveCN104844469AReduce saltEmission reductionOrganic compound preparationCarboxylic acid amides preparationSolubilitySolvent

A clean production technology of methyl anthranilate is characterized in that the solubilities of methyl ester, sodium carbonate and sodium chloride in water are different, no other solvents or reagents are introduced, and a solution obtained after esterification and hydrolysis is successively cooled to obtain methyl ester and sodium carbonate decahydrate (called scale for short). The technology shortens the technologic route and reduces impurities in a recovered material, so the quality of the obtained recovered product is high; the technology effectively reduces a large amount of technologic water and recovers reaction byproducts to realize conversion of industrial wastes as a secondary raw material and reinforce recycling of the wastes; the technology realizes comprehensive utilization of energy and reduces total consumption of energy, so the product production cost is greatly reduced; and the technology uses change of physical properties to obtain the methyl ester, and does not use a chemical solvent to extract the methyl ester residual in a mother liquor, so the generation of new pollutants is effectively avoided, and the whole production process is clean and environmentally friendly.

Owner:尹罡煜 +1

Methyl chloride recovery and refining method

ActiveCN101417923BReduce dosageMitigate the impact of stable operationGroup 4/14 element organic compoundsHalogenated hydrocarbon separation/purificationFluidized bedGas phase

The invention relates to a recycling and refining method of chloromethane. After being condensed by a chloromethane compressor, the coarse chloromethane gas from a washing tower end cooler enters into a chloromethane tower for refining in gas phrase state from an inlet under a return flow inlet of a coarse monomeric tower; the recycled chloromethane gas obtained from the upper lateral line of thechloromethane tower is directly led into a chloromethane superheater, is heated and then flows into a fluidized bed to carry out fluidized reaction. The invention improves the charging and discharging technical process of the present chloromethane refining tower and simplifies the unnecessary processes, which greatly reduces the investment to disposable equipment and the energy consumption in theproduction process, thereby reaching the purpose of saving equipment and energy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL +1

Method for preparing edible mushroom culture bar

The invention discloses a method for preparing an edible mushroom culture bar, which comprises the following steps: (1) crushing and uniformly stirring substrate raw materials; (2) heating, pressurizing and sterilizing the raw materials and reducing the pressure of the raw materials to a normal pressure with stirring; (3) performing surface heat exchange and reducing a temperature; (4) adding sterilized substrate components which cannot withstand high temperature and high pressure, adjusting water content and uniformly stirring the mixture; (5) inoculating liquid strains with stirring; and (6) bagging the strains to obtain the edible mushroom culture bar. As the surface heat exchange method is adopted to reduce the temperature, the method, compared with the prior art, has the advantages that: cooling water does not need sterilizing and can be recycled; heat generated by the surface heat exchange can be recycled, which saves the heat and shortens cooling time; labor required for bag-by-bag injection addition with an injector is saved; and sterilizing time is short, and labor intensity and cost are low.

Owner:天津紫荆能源技术有限责任公司

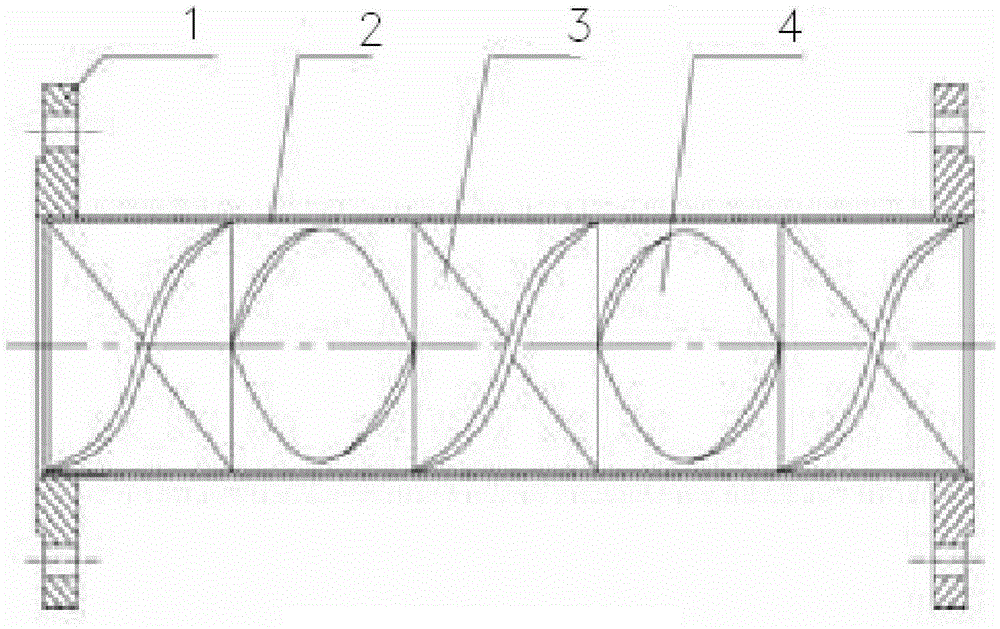

Water beam with thermal insulating sleeve for heating furnace

The invention relates to the field of thermal insulation accessories for universal furnaces, kilns, baking furnaces or distillation furnaces, in particular to a water beam with a thermal insulating sleeve for a heating furnace. The water beam with the thermal insulating sleeve for the heating furnace comprises an anchoring nail (1), a water beam (2) and a castable (3), wherein one end of the anchoring nail (1) is fixedly welded on the outer side face of the water beam (2); and the castable (3) is cast on the outer surface of the water beam (2) and is used for wrapping the anchoring nail (1). The water beam is characterized by also comprising an insulating sleeve (4) and a fiber blanket (5), wherein the insulating sleeve (4) is formed by weaving fibers and is sleeved on the outer surface of the anchoring nail (1); and the fiber blanket (5) is wrapped on the outer side face of the water beam (2). The water beam makes construction convenient, has long service life due to the adoption of refractory materials, and has a good energy-saving effect.

Owner:BAOSTEEL IND FURNACE ENG TECH

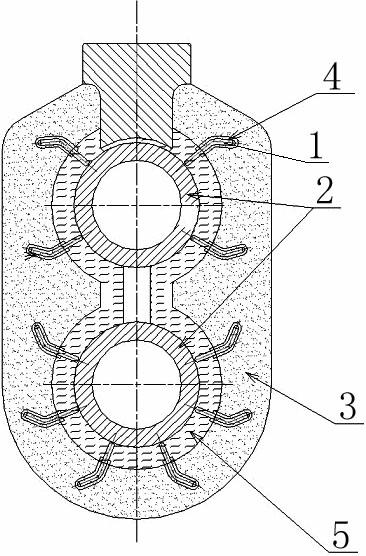

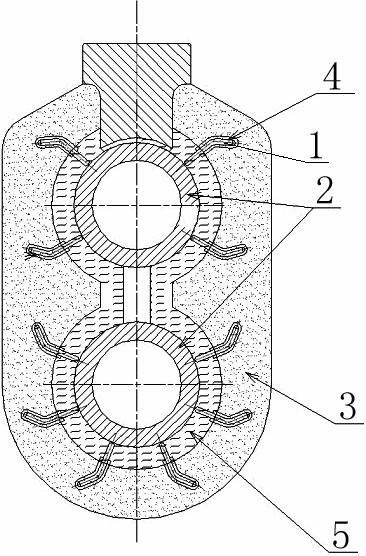

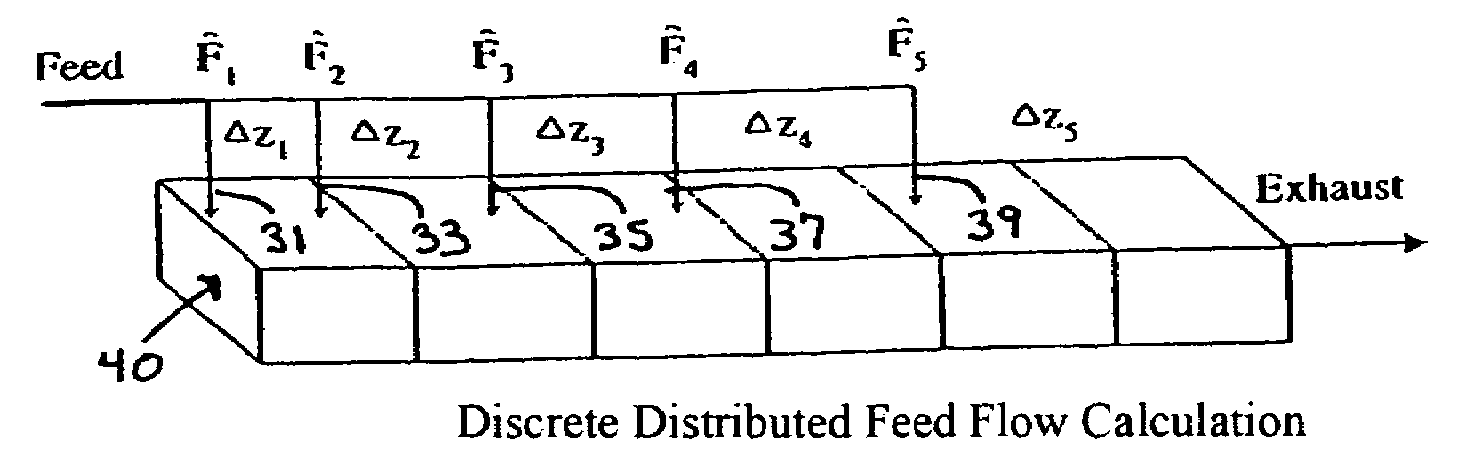

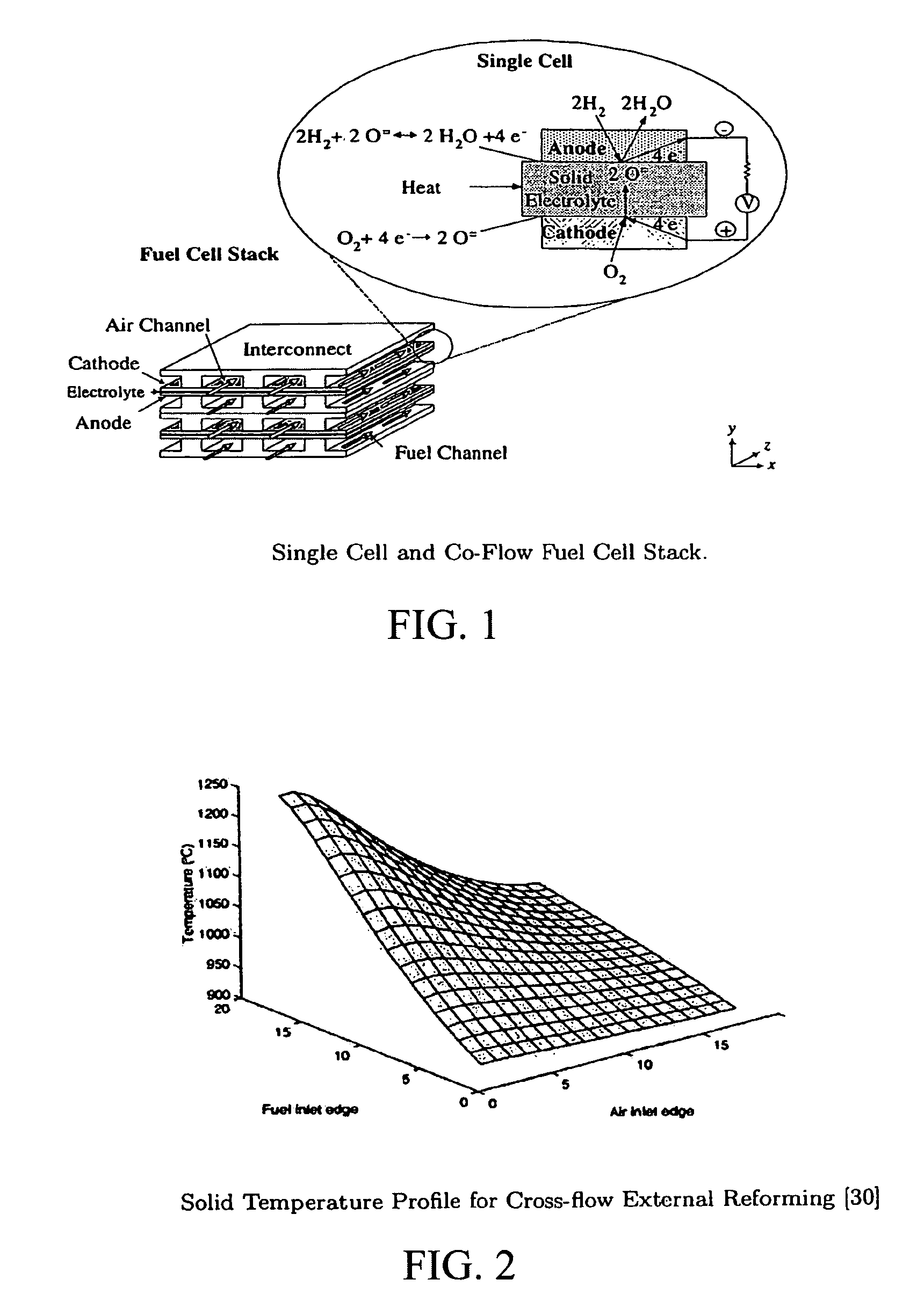

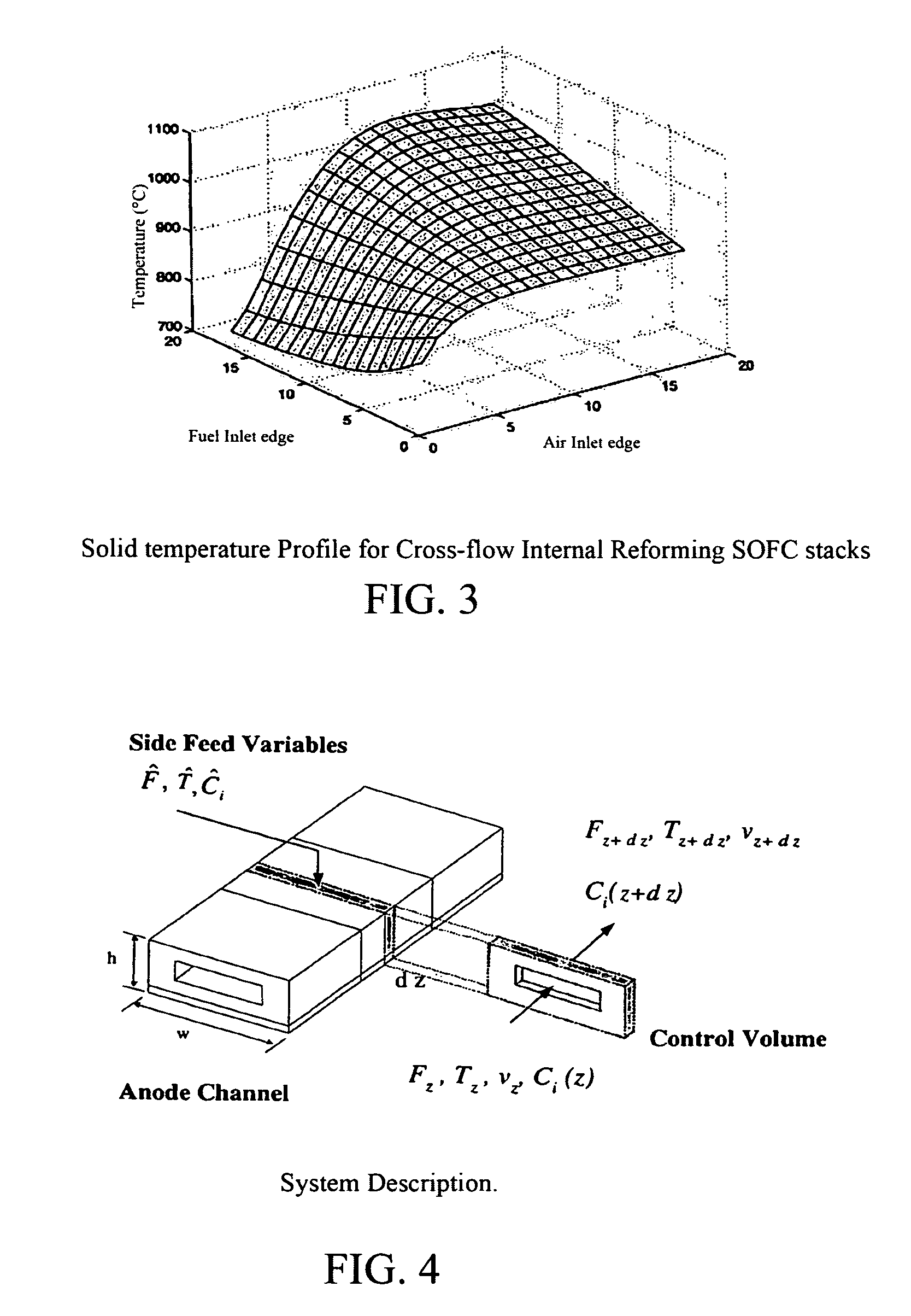

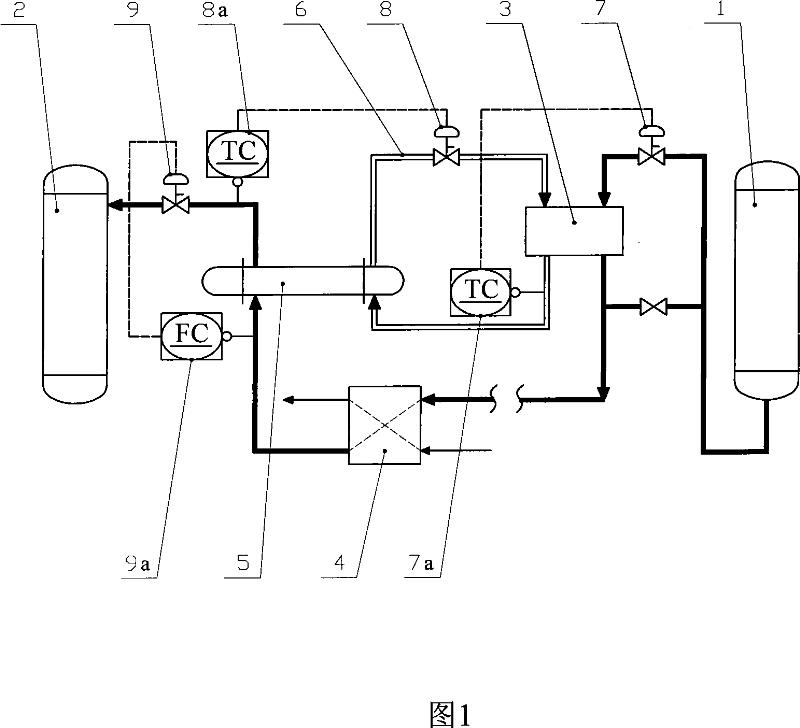

Distributed feed fuel cell stack

InactiveUS7632596B2Improved thermal distribution and mass and thermal integrationImproved thermal managementFuel cells groupingFuel cell auxillariesFuel cellsNuclear engineering

A fuel cell having a distributed fuel feed in which the heat generation profile can be better controlled. Fuel channel stack and system efficiency improvements are achieved.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Device and method for reducing temperature of poor-absorption liquid feed material of Ethylene Oxide absorption tower

ActiveCN101037424AUse economical and reasonableReduce steamOrganic chemistryEpoxyTemperature control

The invention discloses a device for reducing the feed temperature of the rare absorption liquid in the epoxy ethane absorption tower including epoxy ethane desorption tower, epoxy ethane absorption tower, refrigerating engine and rare absorption liquid cooler, wherein the refrigerating engine and rare absorption liquid cooler are orderly arranged between epoxy ethane desorption tower and the epoxy ethane absorption tower, additionally, including rare absorption liquid back cooler and low temperature water circuit, wherein the rare absorption liquid back cooler is located downstream of the rare absorption liquid cooler and upstream of the epoxy ethane absorption tower and located together with the refrigerating engine in the low temperature water circuit. The inventive operation solves the problem of higher EO content in the top tower gas phase output which is generated by EO inadequate absorption produced by the higher temperature. Rare absorption liquid feed temperature is controlled at 25-33 DEG C and the EO content in the EO top absorption tower gas is controlled <= 100ppm molar rate. The invention is mainly suitable for the Shell company technology or the epoxy ethane / glycol device similar to.

Owner:CHINA PETROLEUM & CHEM CORP

Steam treatment method, related device and storage device

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com