Vanadium pentoxide preparation method

A technology of vanadium pentoxide and vanadium liquid, which is applied in vanadium oxide and other directions, can solve the problems of unseen heat exchanger scaling, low vanadium pentoxide production efficiency, and high pipeline cleaning cost, so as to reduce the amount of condensed water and save energy. resources, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

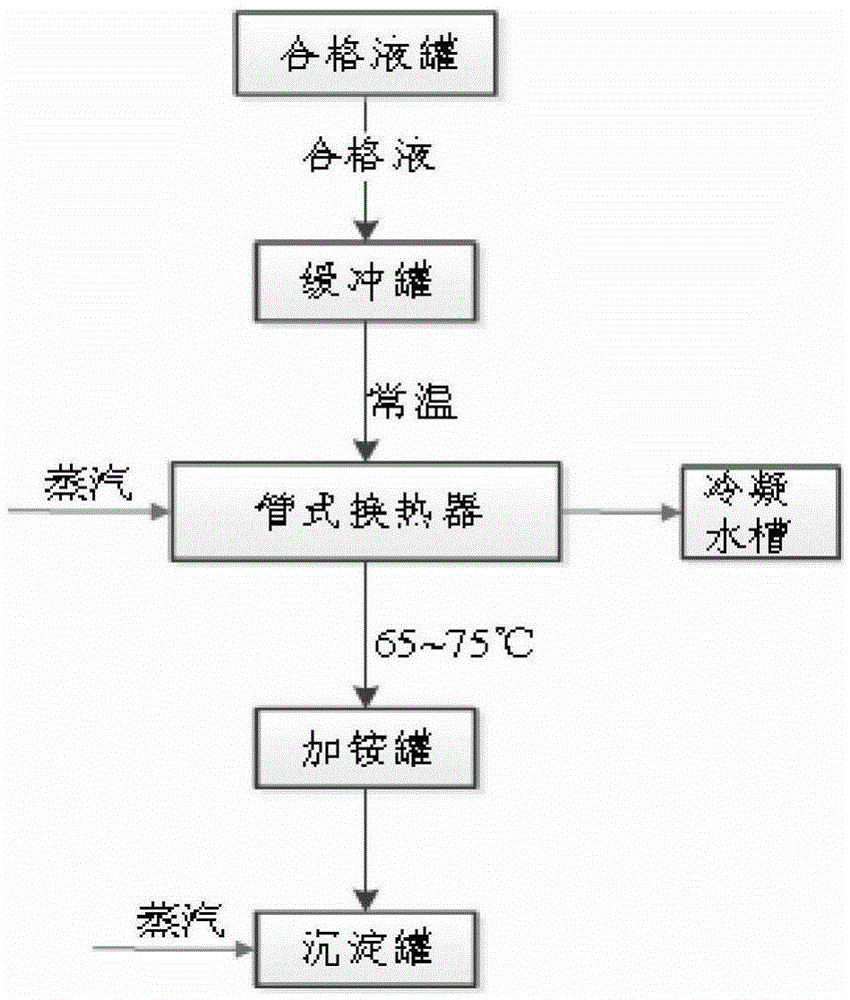

[0025] A kind of preparation method of vanadium pentoxide of the present invention, comprises the following steps:

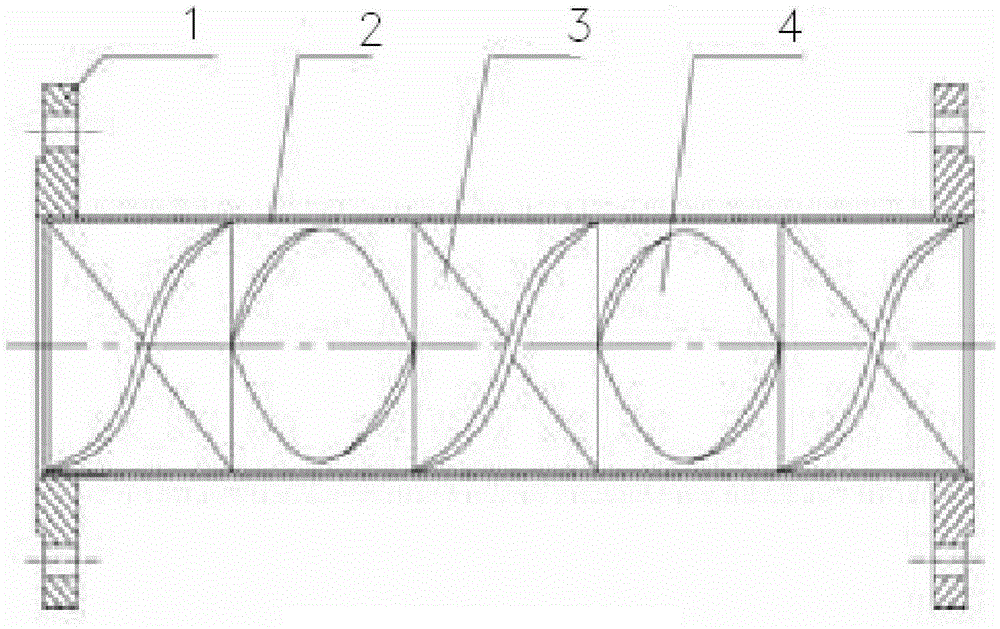

[0026] a. Replace the inner pipe of the tubular heat exchanger in the preheating process of the vanadium precipitation process with a static mixer pipe, and use steam heat exchange to raise the temperature of the acidic vanadium liquid from normal temperature to 65-75°C;

[0027] b. Add the acidic vanadium solution after heat exchange in step a into the ammonium addition tank. According to the molar ratio, NH 4 + : TV=0.6~0.9:1, add ammonium sulfate, stir to obtain the mixed solution;

[0028] c. Add the mixed solution obtained in step b into a precipitation tank, stir, adjust the pH value to 1.5 to 2, and heat to 90° C. to boiling with steam to obtain ammonium polyvanadate solution;

[0029] d. Settling the ammonium polyvanadate solution obtained in step c, taking ammonium polyvanadate for precipitation, washing, drying, and calcining to obtain vanadium pento...

Embodiment 1

[0038] A kind of preparation method of vanadium pentoxide of the present invention, comprises the following steps:

[0039] a. The preheating process of the vanadium precipitation process uses a SK-type static mixer to use steam heat exchange at about 180°C to raise the temperature of the acidic vanadium liquid from normal temperature to 65°C; the initial flow rate of the acidic vanadium liquid through the heat exchanger pipe is >50m 3 / h, the frequency of the pump remains unchanged at 50Hz, and the composition of the acidic vanadium liquid passing through the heat exchanger for a period of time is calculated as TV: 20g / L, pH value is 3, the heat exchanger is used intermittently, and the operation time is 3h each time. The interval time is 3h;

[0040] b. Add the acidic vanadium solution after heat exchange in step a into the ammonium addition tank. According to the molar ratio, NH 4 + : TV=0.6:1, add ammonium sulfate, stir, obtain mixed liquor;

[0041] c. Add the mixed so...

Embodiment 2

[0046] A kind of preparation method of vanadium pentoxide of the present invention, comprises the following steps:

[0047] a. The SL static mixer is used in the preheating process of the vanadium precipitation process, and the temperature of the acidic vanadium liquid is raised from normal temperature to 75°C by using steam heat exchange at about 180°C; the initial flow rate of the acidic vanadium liquid through the heat exchanger pipe is >50m 3 / h, the frequency of the pump remains unchanged at 50Hz, and the composition of the acidic vanadium liquid passing through the heat exchanger for a period of time is calculated as TV: 25g / L, pH value is 3.5, the heat exchanger is used intermittently, and the operation time is 3h each time. The interval time is 3h;

[0048] b. Add the acidic vanadium solution after heat exchange in step a into the ammonium addition tank. According to the molar ratio, NH 4 + : TV=0.9:1, add ammonium sulfate, stir, obtain mixed liquor;

[0049] c. Add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com