Method and device for jet/preoxidation/pyrolysis/fluidized bed gasification of carbon-containing solid fuel

A technology of fluidized bed gasification and fluidized bed gasification furnace, which is applied in the direction of manufacturing combustible gas, granular/powdered fuel gasification, petroleum industry, etc., and can solve the difficulty of dealing with caking coal and the technical difficulty of ash fusion problems such as large size and low carbon conversion rate, and achieve the effects of reducing the possibility of coking and coking, enhancing adaptability, and expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

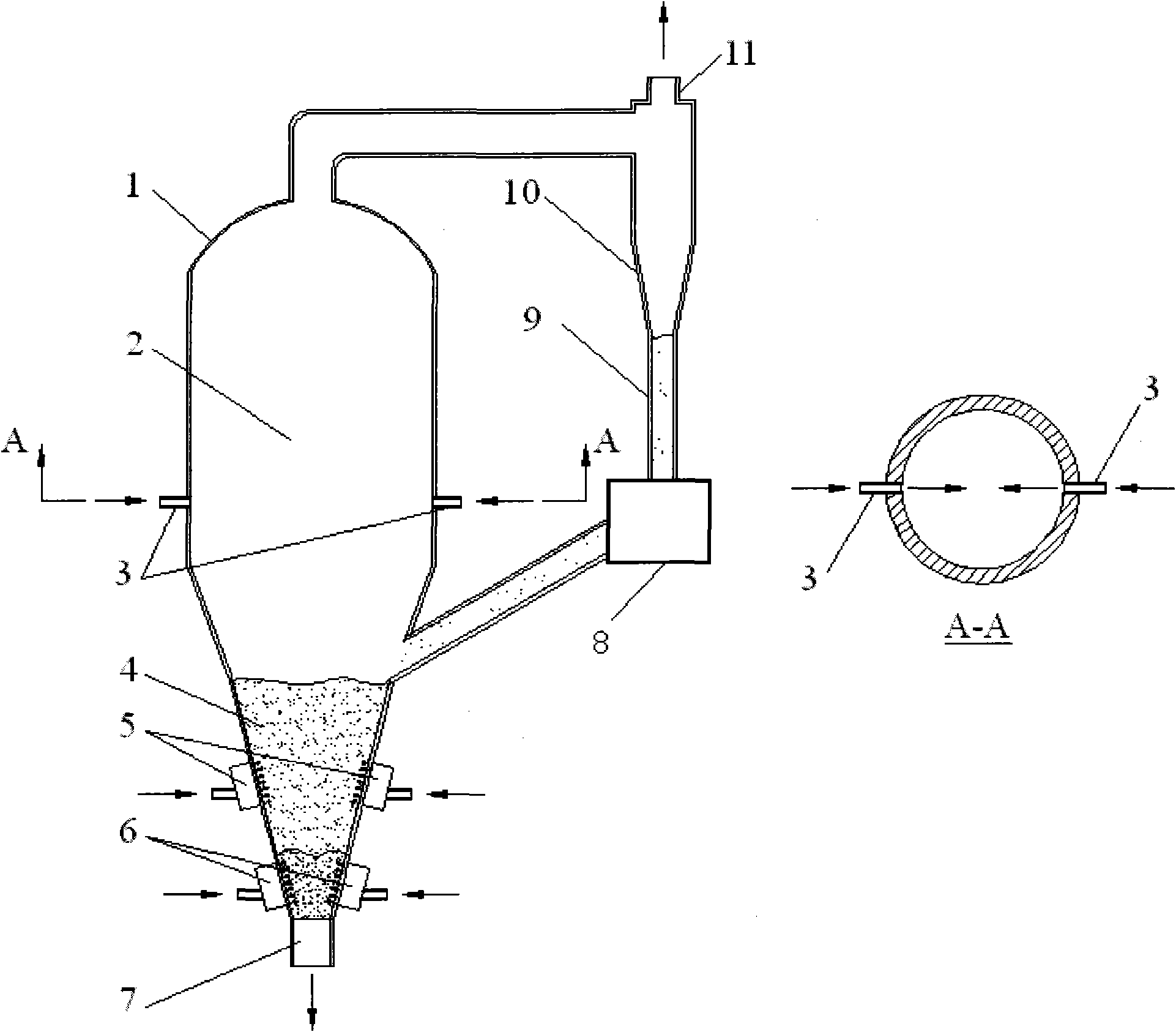

[0056] The jet flow pre-oxidation pyrolysis fluidized bed gasification device with two opposed fuel nozzles in this embodiment is as follows: figure 1 As shown, it mainly includes: fluidized bed gasifier 1, fluidized bed dilute phase zone 2, fuel nozzle 3, fluidized bed dense phase bed 4, oxygen-containing oxidizing agent first feeding system 5, oxygen-containing gasification Agent second feeding system 6, ash outlet 7, feeder 8, return pipe 9, cyclone separator 10 and crude gas or synthesis gas outlet 11.

[0057] There is an outlet on the top of the fluidized bed gasifier 1, which is connected to the material inlet of the cyclone separator 10 through a pipeline, and the material outlet of the cyclone separator 10 is connected to the inlet of the return pipe 9 The outlet of the return pipe 9 is connected with the inlet of the return device 8, and the outlet of the return device 8 is connected to the inlet provided on the lower furnace wall of the fluidized bed gasifier 1 thro...

Embodiment 2

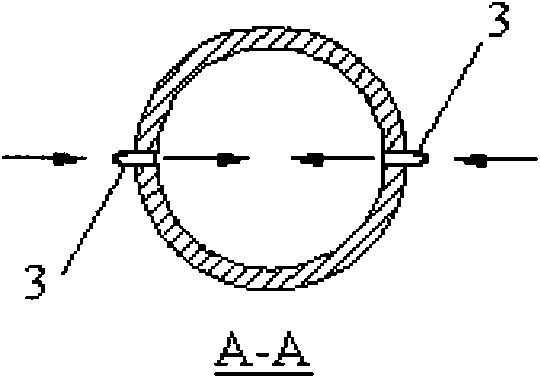

[0064] The jet flow pre-oxidation pyrolysis fluidized bed gasification device used in this embodiment is basically the same as that in Embodiment 1, except that two obliquely facing fuel nozzles are arranged upwards, and the hood is arranged obliquely downward. Its structure is as follows figure 2 shown. The oblique upward angle of the two obliquely facing fuel nozzles is 5-70 degrees (angle with the horizontal plane), and the installation direction of the wind cap is obliquely downward 30° with the horizontal plane

[0065] The method of jet pre-oxidation pyrolysis fluidized bed gasification of coal particles using the above-mentioned jet pre-oxidation pyrolysis fluidized bed gasification device with two obliquely facing upward fuel nozzles is roughly the same as that of embodiment 1, except that the fuel nozzle 3 The speed of the mixture of coal particles with a particle size below 3mm and the oxygen-containing oxidant should be within the range of 10-20m / s, and the gasific...

Embodiment 3

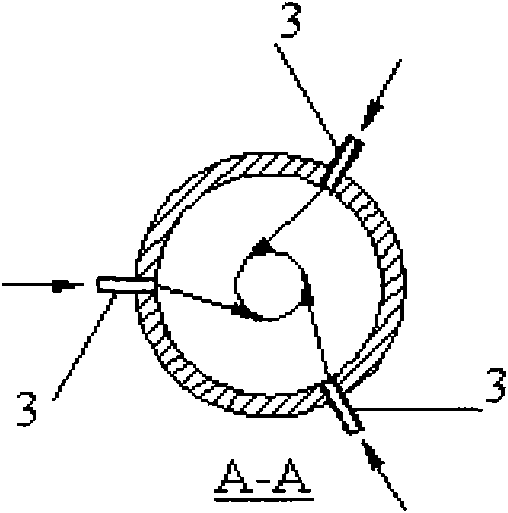

[0068] The jet flow pre-oxidation pyrolysis fluidized bed gasification device used in this embodiment is basically the same as that in Embodiment 1, except that three nozzles are evenly arranged in the furnace along the cross section of the above-mentioned gasification furnace at the lower part of the above-mentioned fluidized bed dilute phase zone 2. The direction of the fuel nozzle is deflected at the same angle and arranged in a tangential circle. Its structure is as follows image 3 shown. The method of jet pre-oxidation pyrolysis fluidized bed gasification of petroleum coke particles using the above-mentioned device is roughly the same as in Example 1.

[0069] The difference from Example 1 is that in the gasification process, petroleum coke particles are used as the gasification raw material, and the mixture of petroleum coke particles (below 6 mm in particle size) and gasification agent (oxygen) is injected from the three fuel nozzles 3 respectively. According to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com