Patents

Literature

342 results about "Coal gasifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gasification refers to the conversion of coal to a mixture of gases, including carbon monoxide, hydrogen, methane, and other hydrocarbons, depending on the conditions involved.

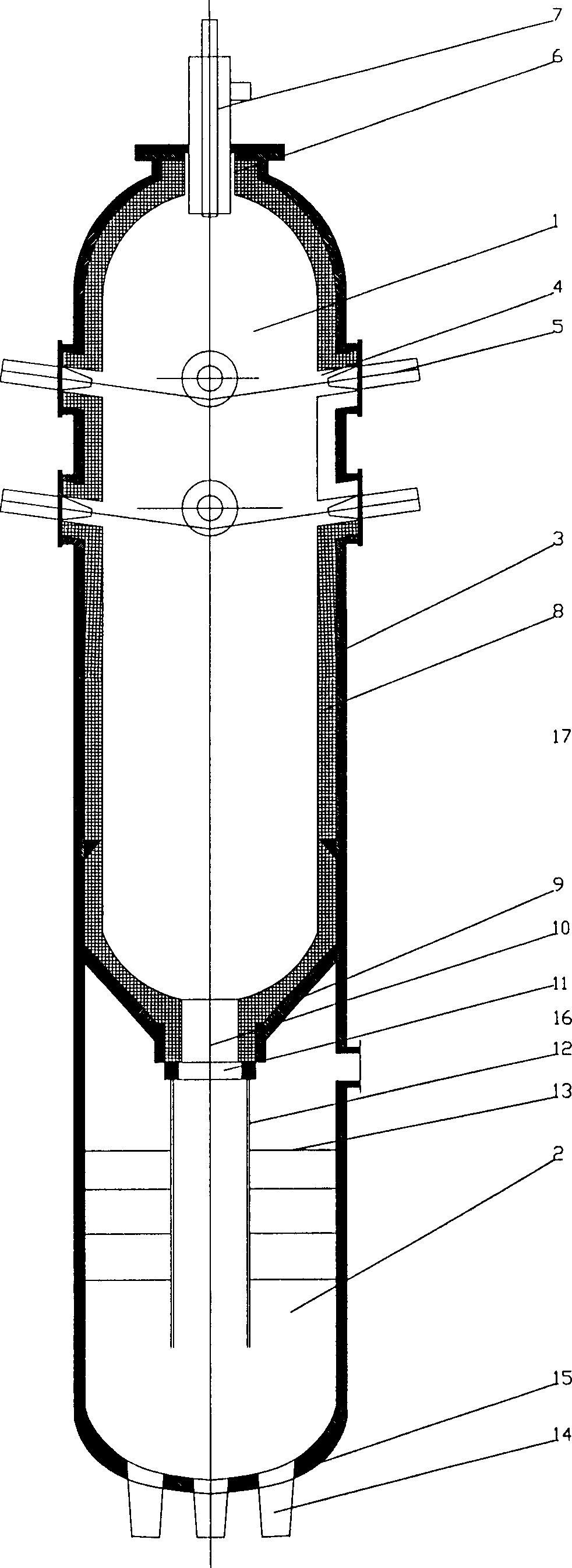

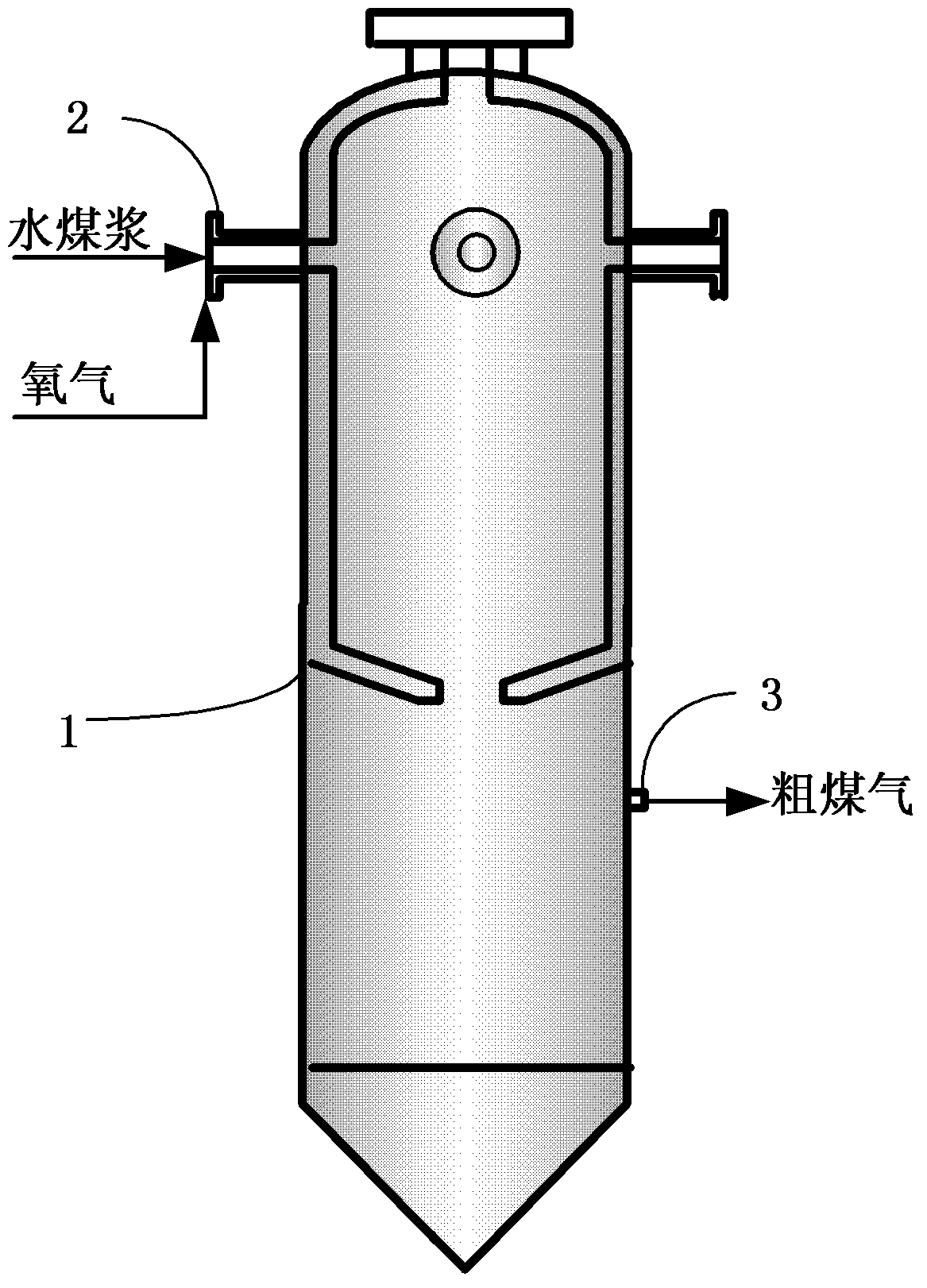

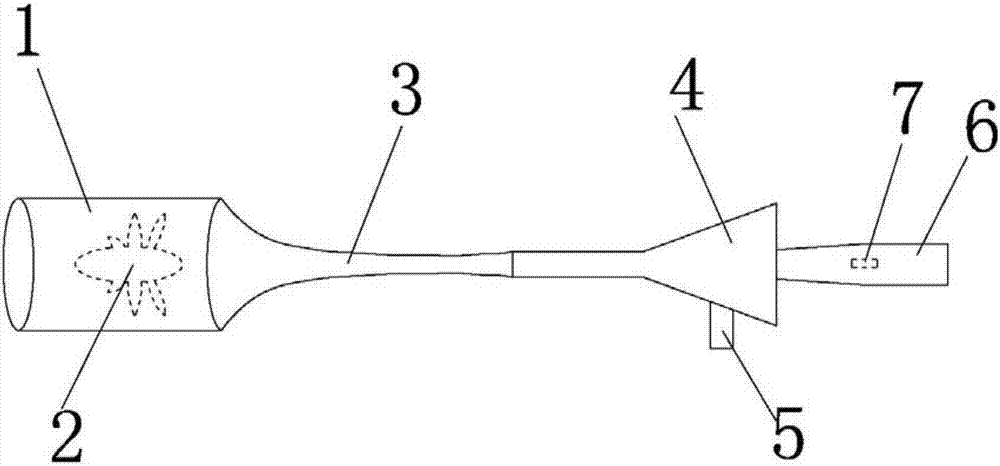

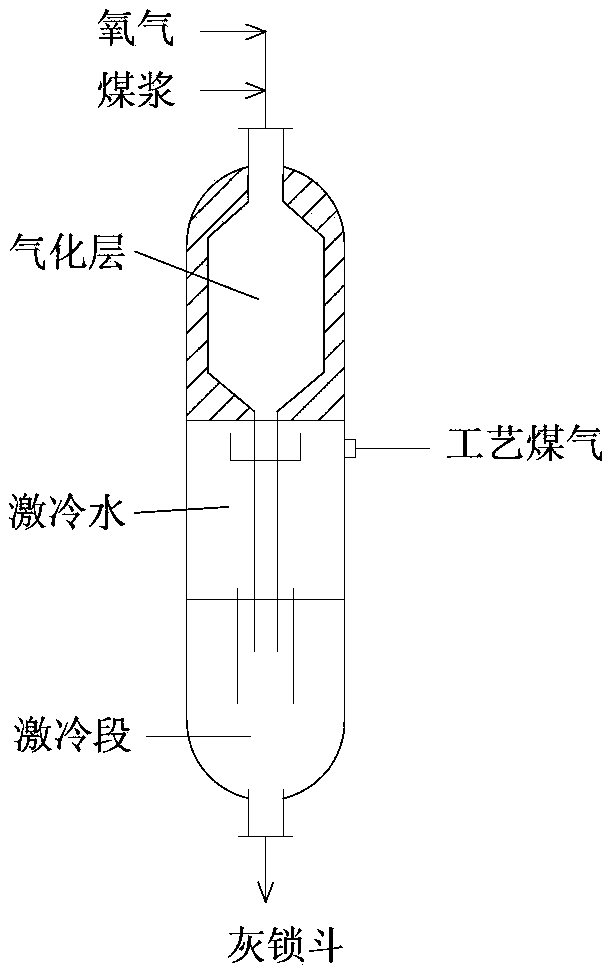

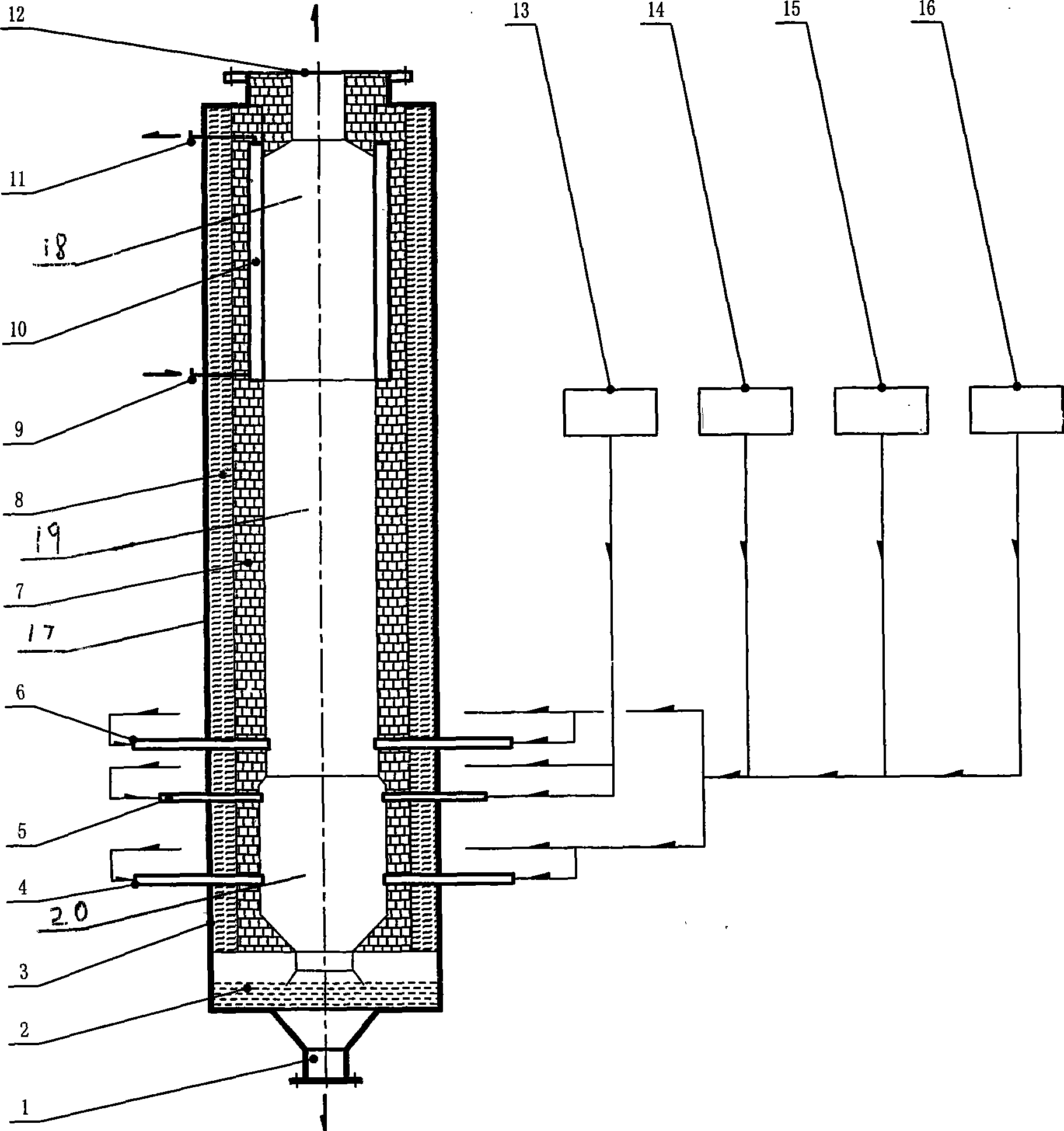

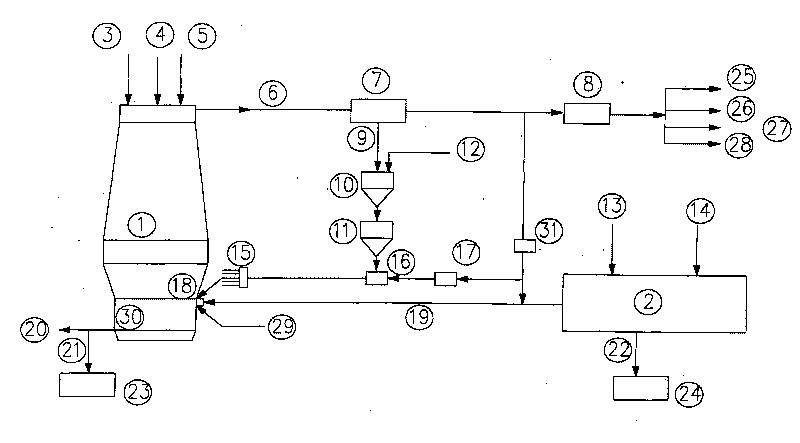

Multi-nozzle coal water mixture or fine coal gasifying furnace and its industrial application

ActiveCN1775920AUniform temperature distributionLess investmentCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

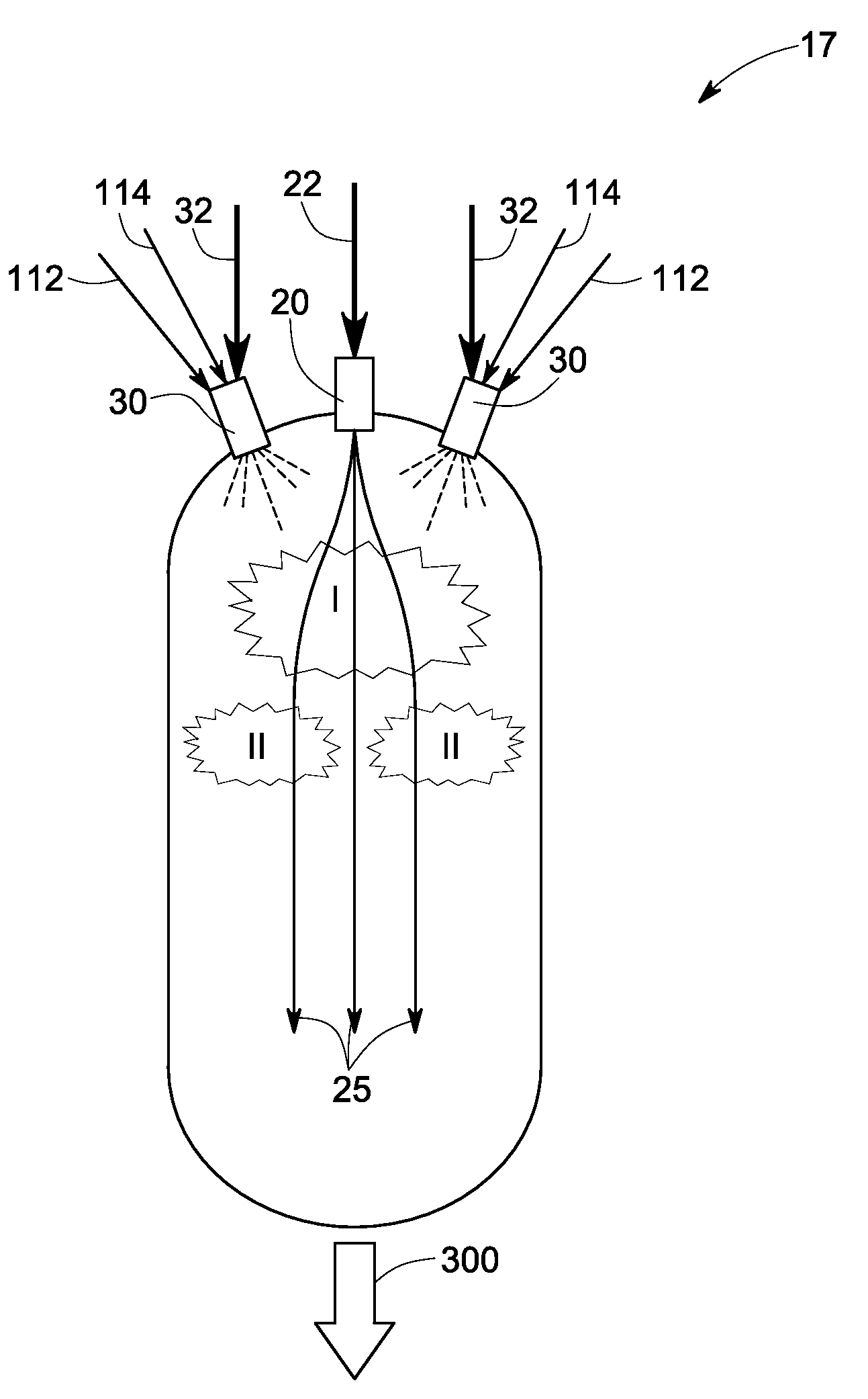

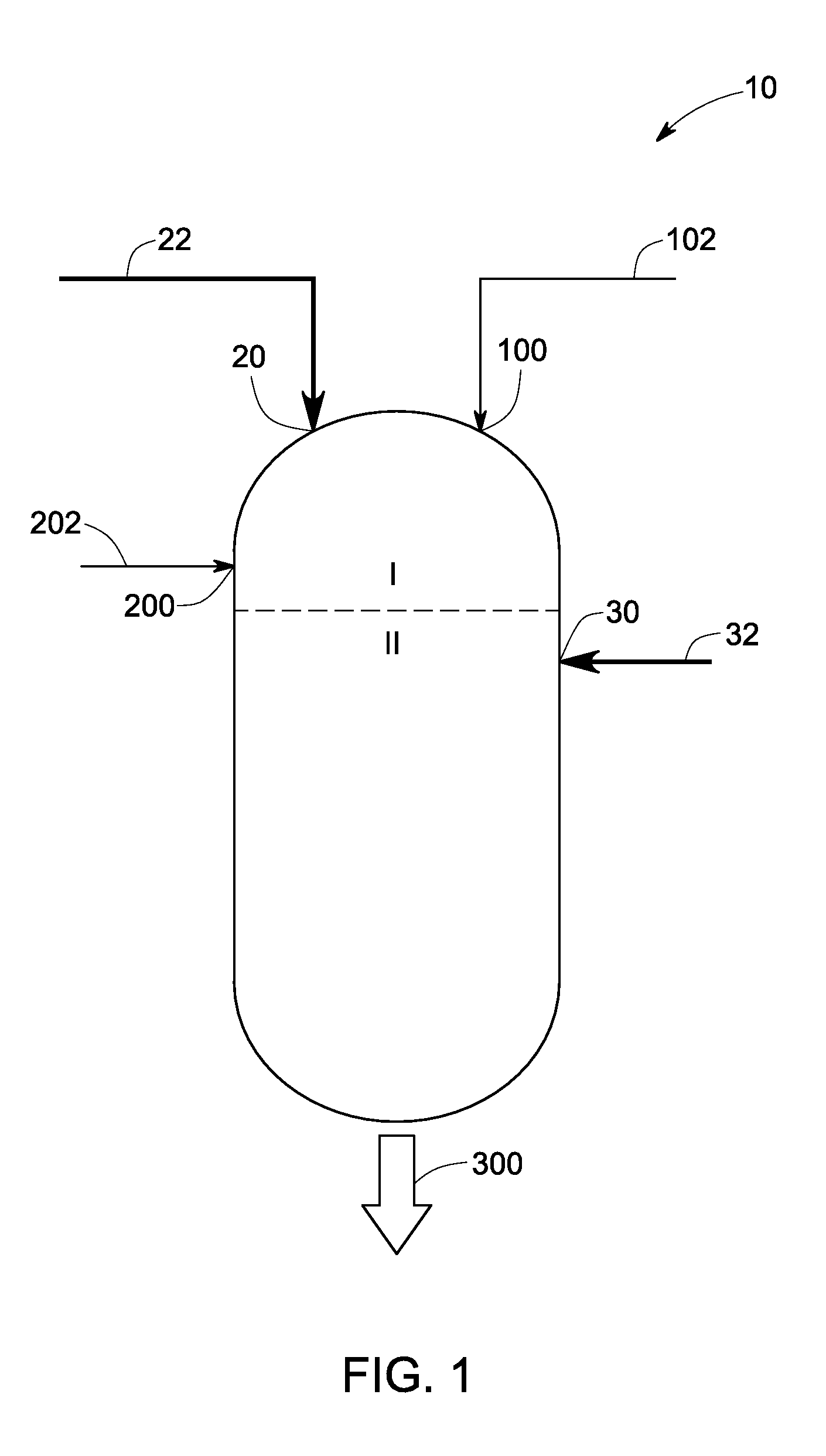

The invention discloses a plural muzzles coal water slurry or fine coal gasification furnace used for gasifying coal water slurry or fine coal. The gasification room is made up of case, process muzzle room, process muzzle, preheating muzzle room, and preheating muzzle. The case has firebricks in it and washing cooling room is made up of chilling circle, down take, vesicle breaking stick and roughing slag outlet. The transforming ratio of the furnace is over 98%, and is especially suited for large scale gasification produce technology that produces 3000-5000T / day.

Owner:EAST CHINA UNIV OF SCI & TECH

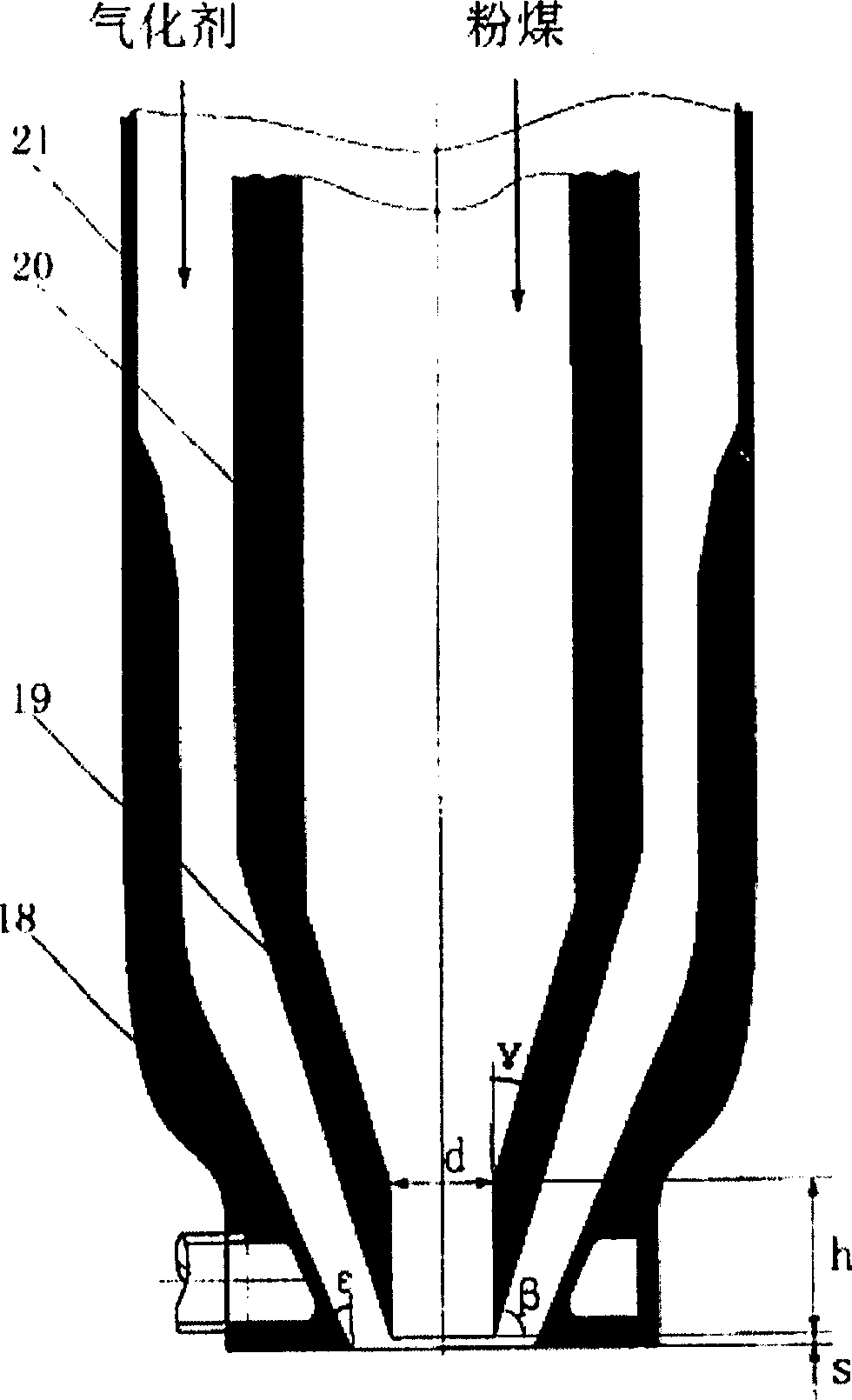

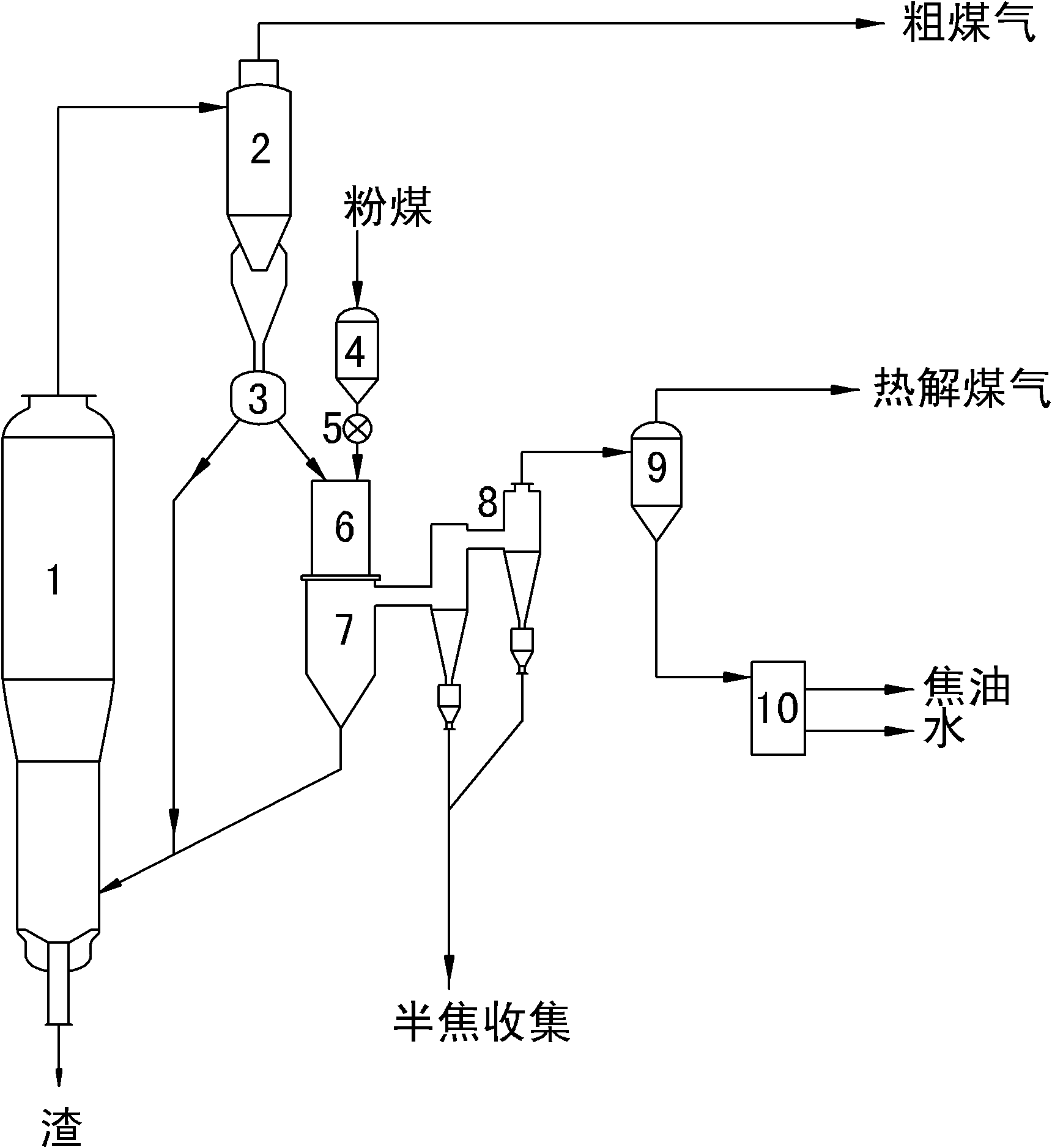

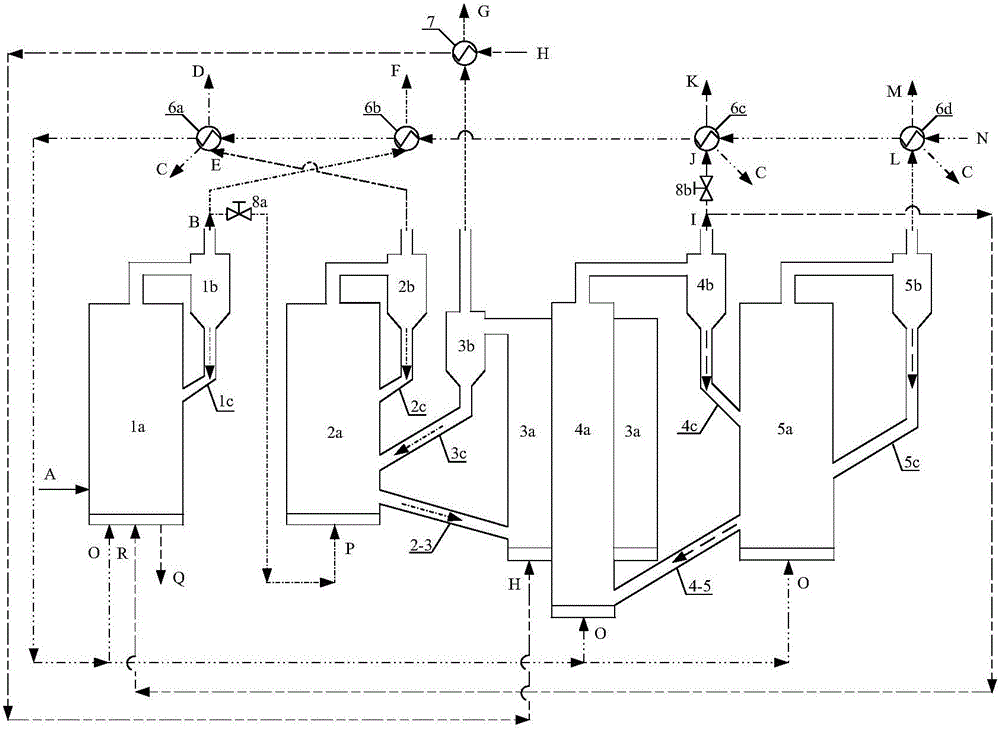

Air-oil co-production device and method adopting fluidized bed pulverized coal gasification and solid heat carrier pyrolysis coupling

ActiveCN101921627ASolve problems such as low thermal efficiency of the processDirect heating destructive distillationChemical industryHeat carrierLoop control

The invention relates to an air-oil co-production device and method adopting fluidized bed pulverized coal gasification and solid heat carrier pyrolysis coupling. The high-temperature circulating semicoke of a fluidized bed pulverized coal gasifier adopts two-loop control, one loop enters a pyrolysis reactor to be used as heat carrier for performing pyrolysis with coal and forming semicoke, the formed semicoke enters the fluidized bed pulverized coal gasifier; and the other loop directly returns to the return fluidized bed pulverized coal gasifier. The invention is based on the fluidized bed pulverized coal gasification technology, uses the high-temperature circulating semicoke as heat carrier to pyrolyze raw material and generate pyrolysis coal gas and tar before sending raw material to the coal furnace; and the semicoke generated through pyrolysis returns the fluidized bed pulverized coal gasifier for further burning and gasifying, thus raw gas can be produced and air-oil co-production can be realized. The problems such as low process heat efficiency of the traditional solid heat carrier can be overcome, thus the method of the invention is better than the traditional solid heat carrier technology.

Owner:陕西华祥能源科技集团有限公司

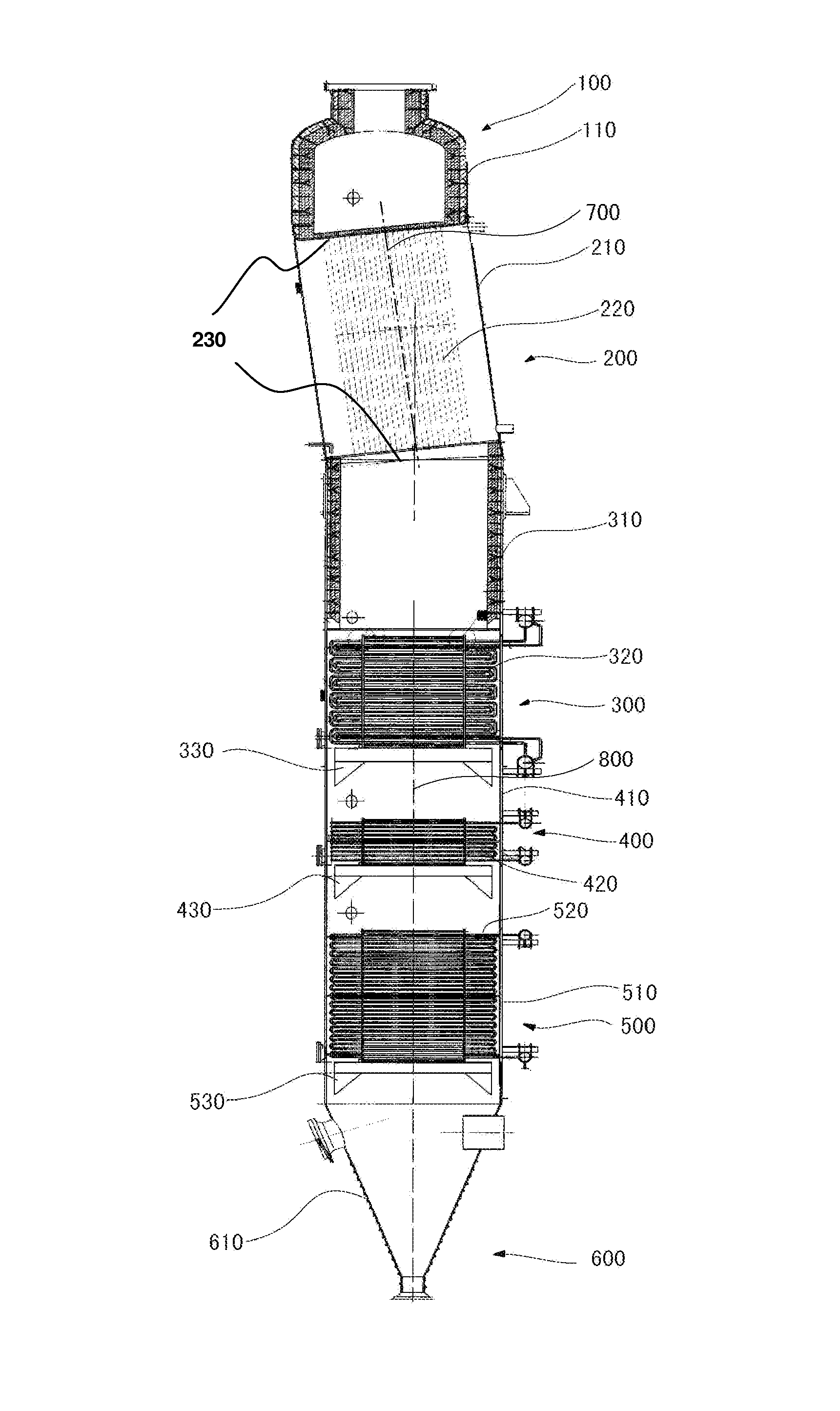

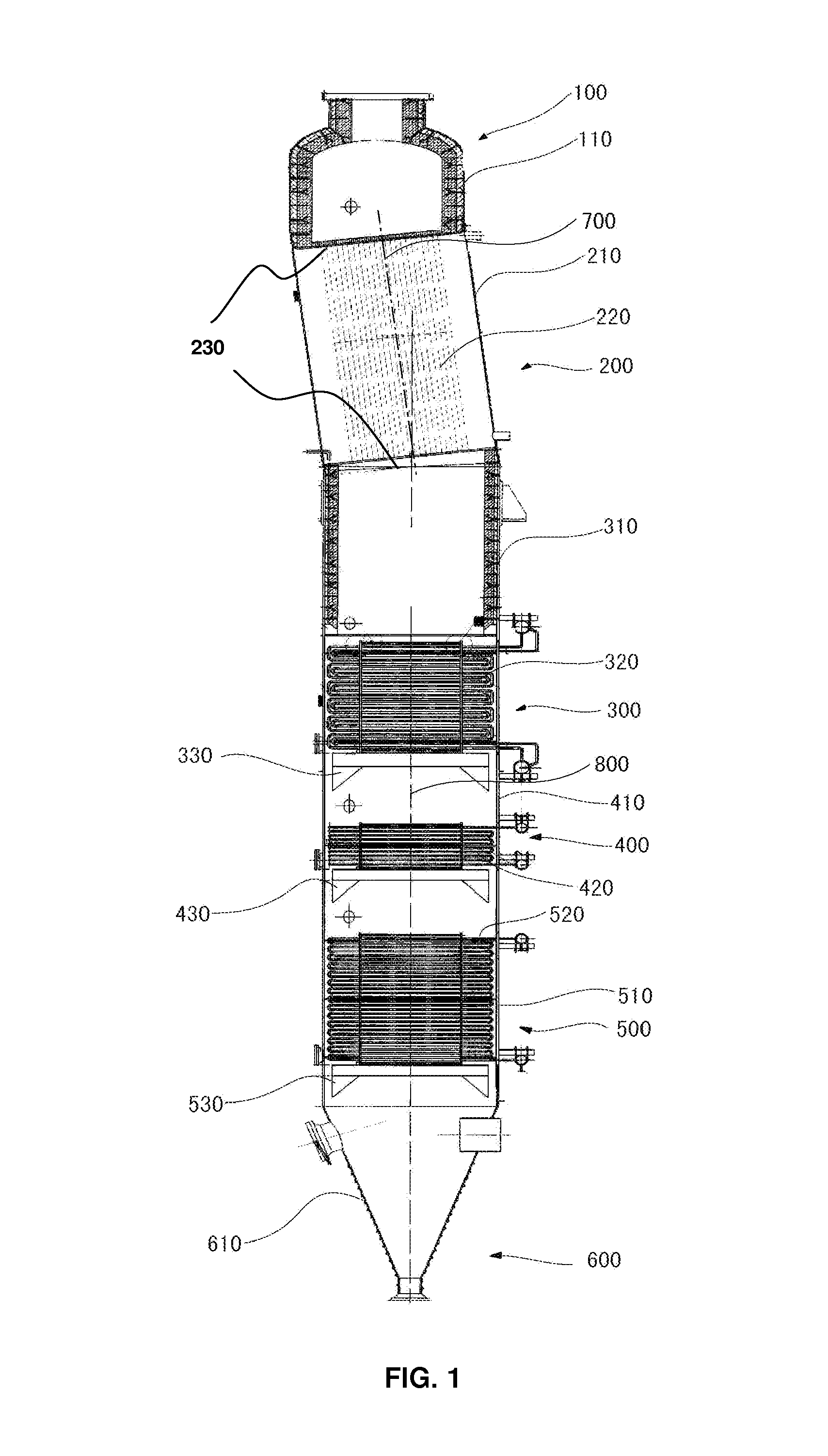

HRSG for fluidized gasification

ActiveUS9103234B2Reduce wearSaving space occupiedInternal combustion piston enginesEnergy inputSyngasFluidized bed

Owner:GAS TECH INST

Material formula for preparing gasification furnace slag ceramisite and production method of ceramisite

InactiveCN102372496AHigh hardnessHigh strengthCeramic materials productionCeramicwareSlagRaw material

The invention discloses a material formula for preparing a gasification furnace slag ceramisite and a production method of the ceramisite. The formula comprises the following components by weight percent: 80-95% of coal gasification furnace slag, 0-15% of clay and 5-15% of fluxing agent, wherein the fluxing agent is CaO, MgO, NaO, CaSO4 or glass powder. The coal gasification furnace slag is used as the raw material so that the prepared ceramisite product has more excellent adsorption property and wider application range.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

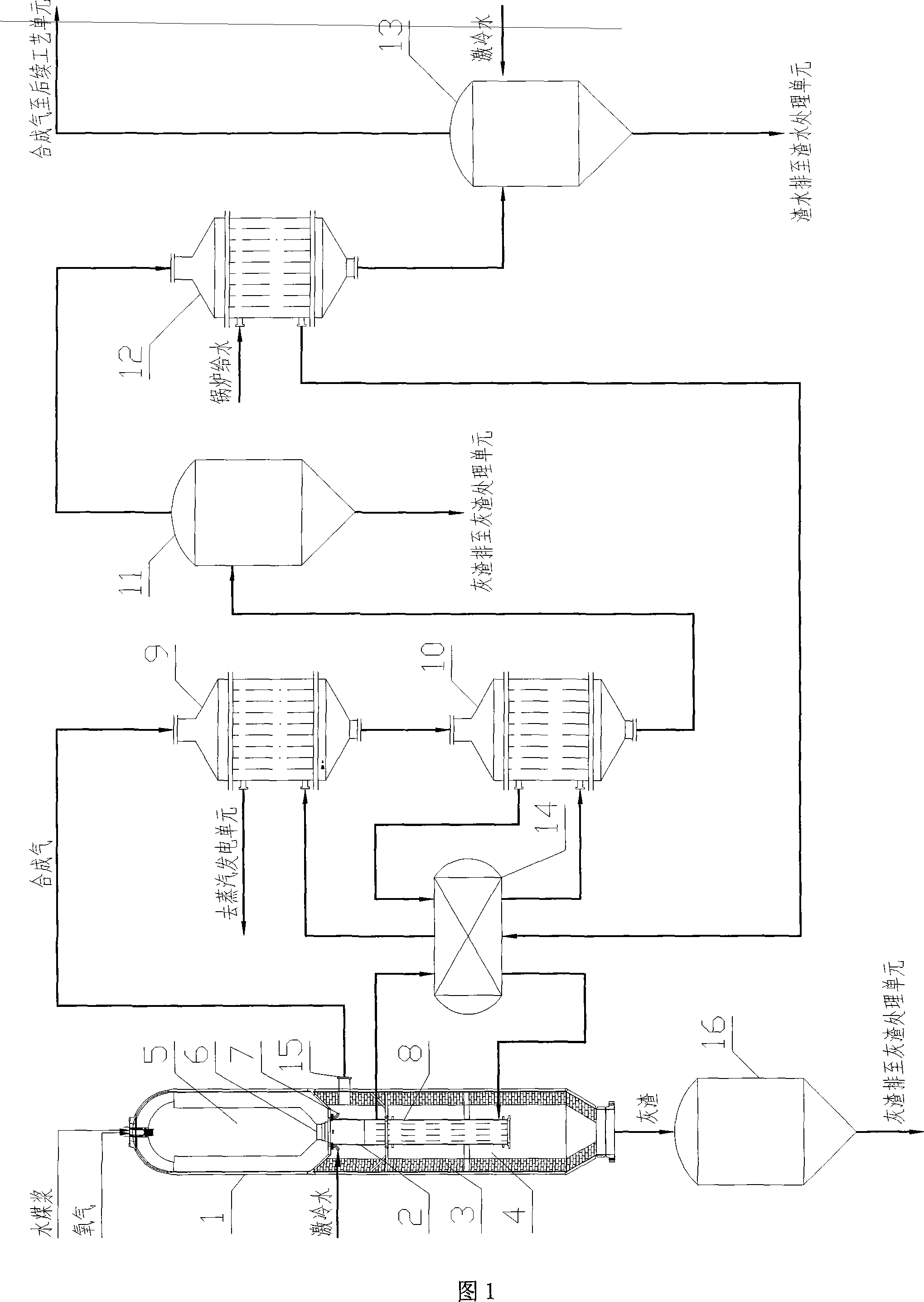

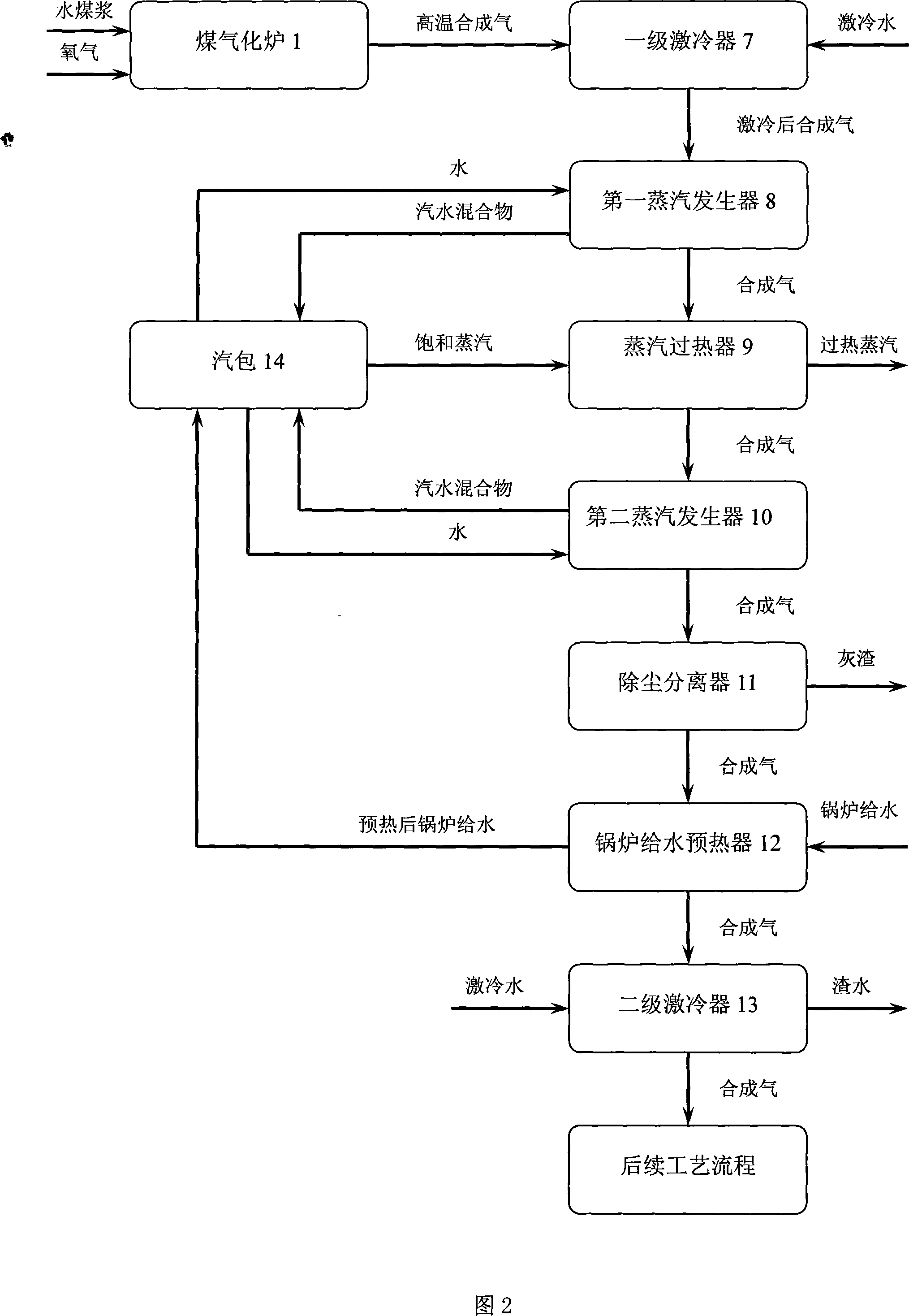

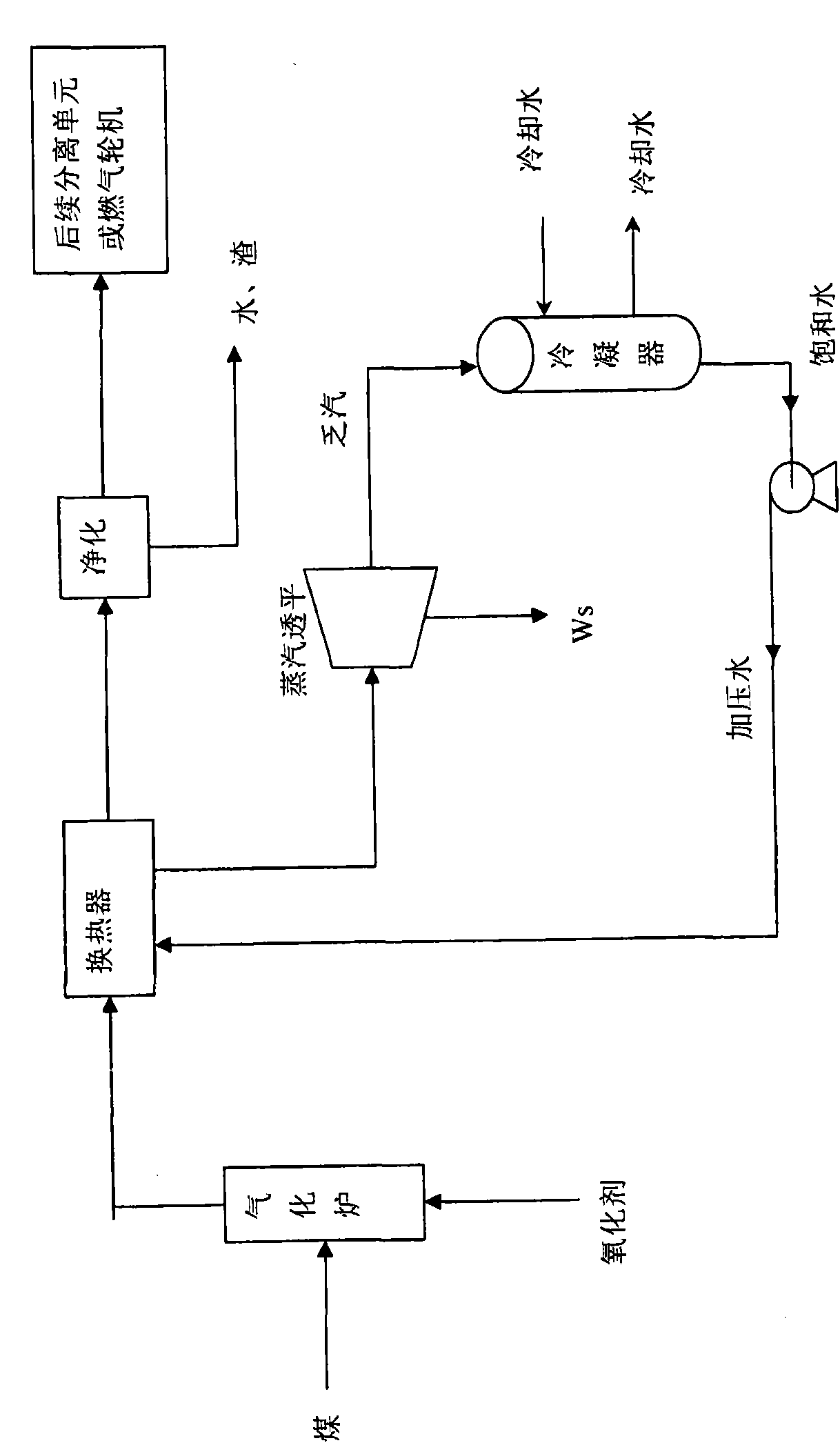

Heat recovering technique for synthetic gas production process by coal gasification

ActiveCN101161792AImprove use valueAvoid stickingChemical industryCombined combustion mitigationThermal energySyngas

The invention discloses a heat recovery technological method for making synthetic gas during coal gasification, including the following steps: the high-temperature synthetic gas and the scoria are generated inside the vaporizer of a coal gasification furnace; chill water is sprayed into the outlet of the furnace through a primary chiller to chill the synthetic gas and the scoria below ash fusion point T1; the chilled synthetic gas and scoria are fed into a first steam generator, a steam superheater and a second steam generator for reclaiming the afterheat of the synthetic gas; moreover, part fine clinker is removed through a dust separator and residual fine clinker is removed inside a secondary chiller after further heat recovery through a boiler feeding preheater; meanwhile, the synthetic gas is humidified and then is fed into a next process unit. The invention increases the unitization value of recycled heat energy and prevents scoria from solidifies on the tube wall of the first steam generator, thereby further reducing energy consumption of equipment.

Owner:WISON ENG

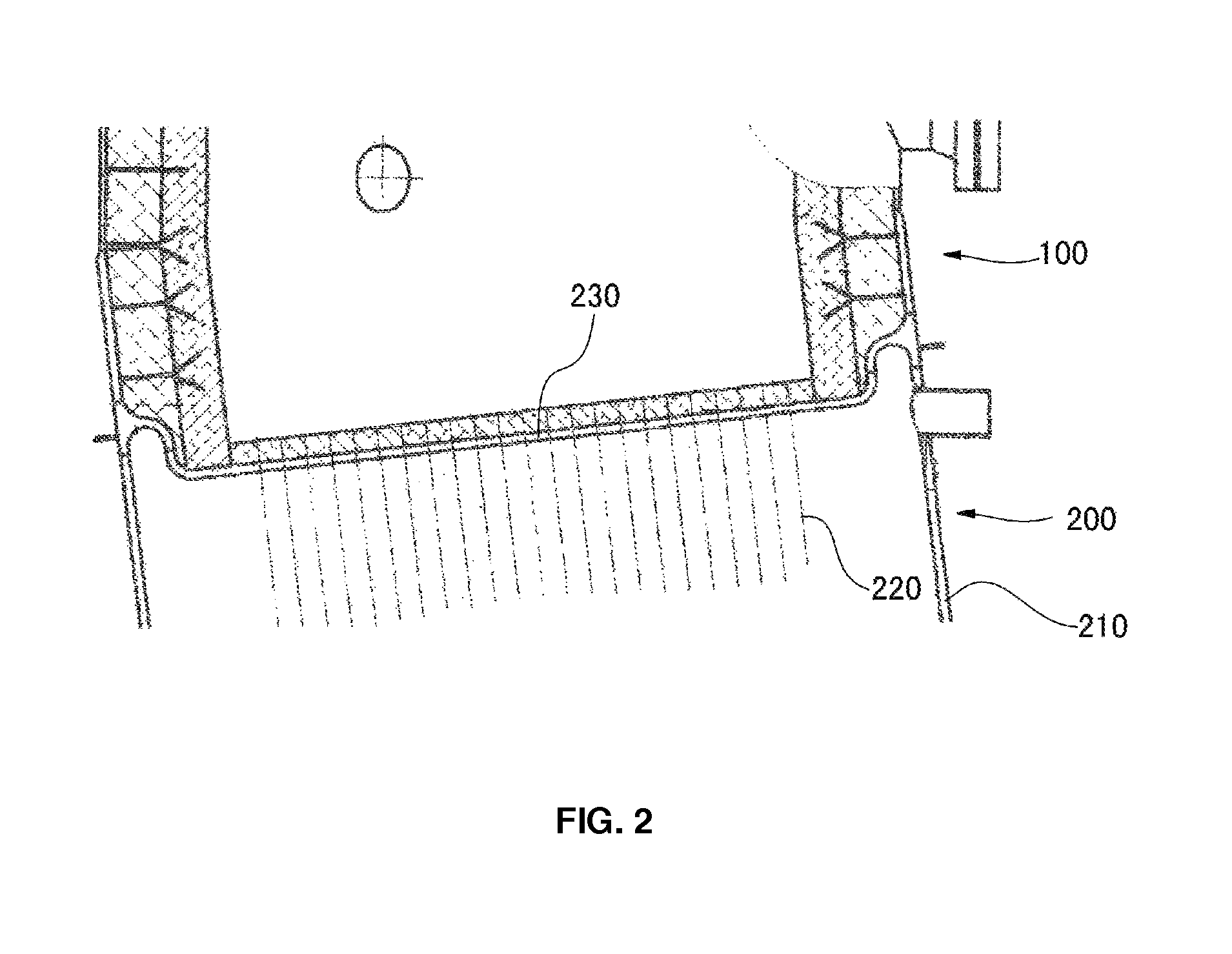

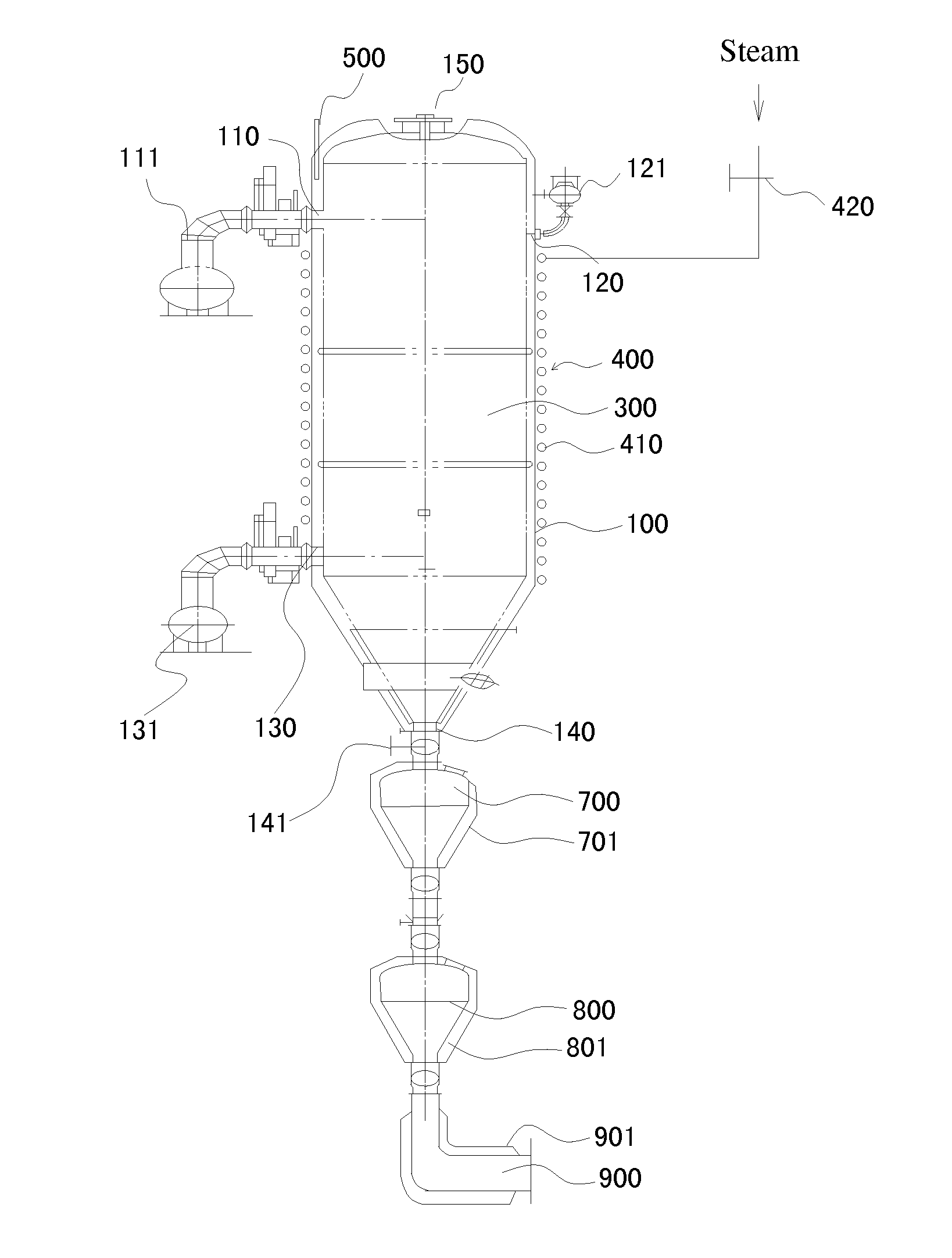

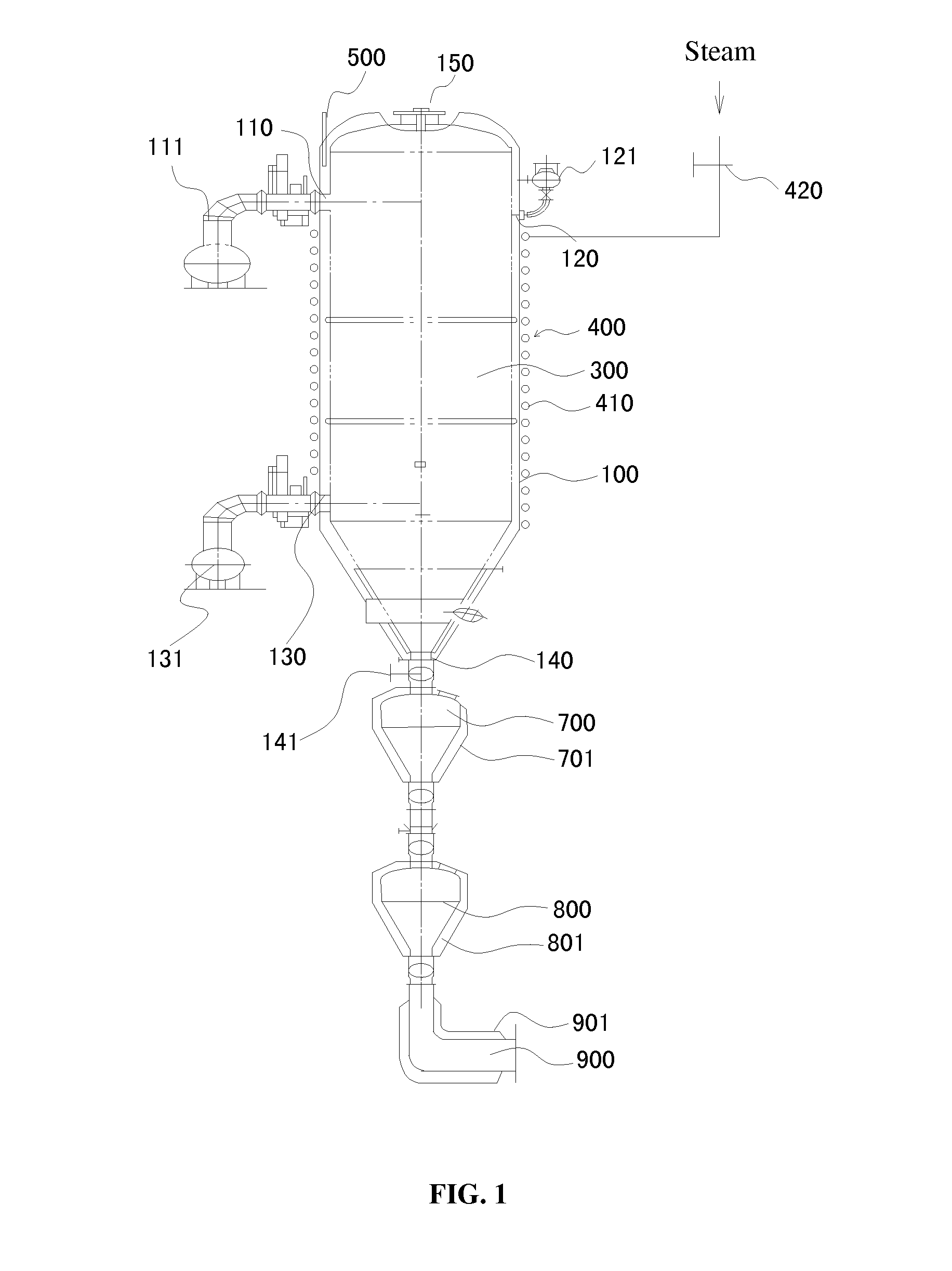

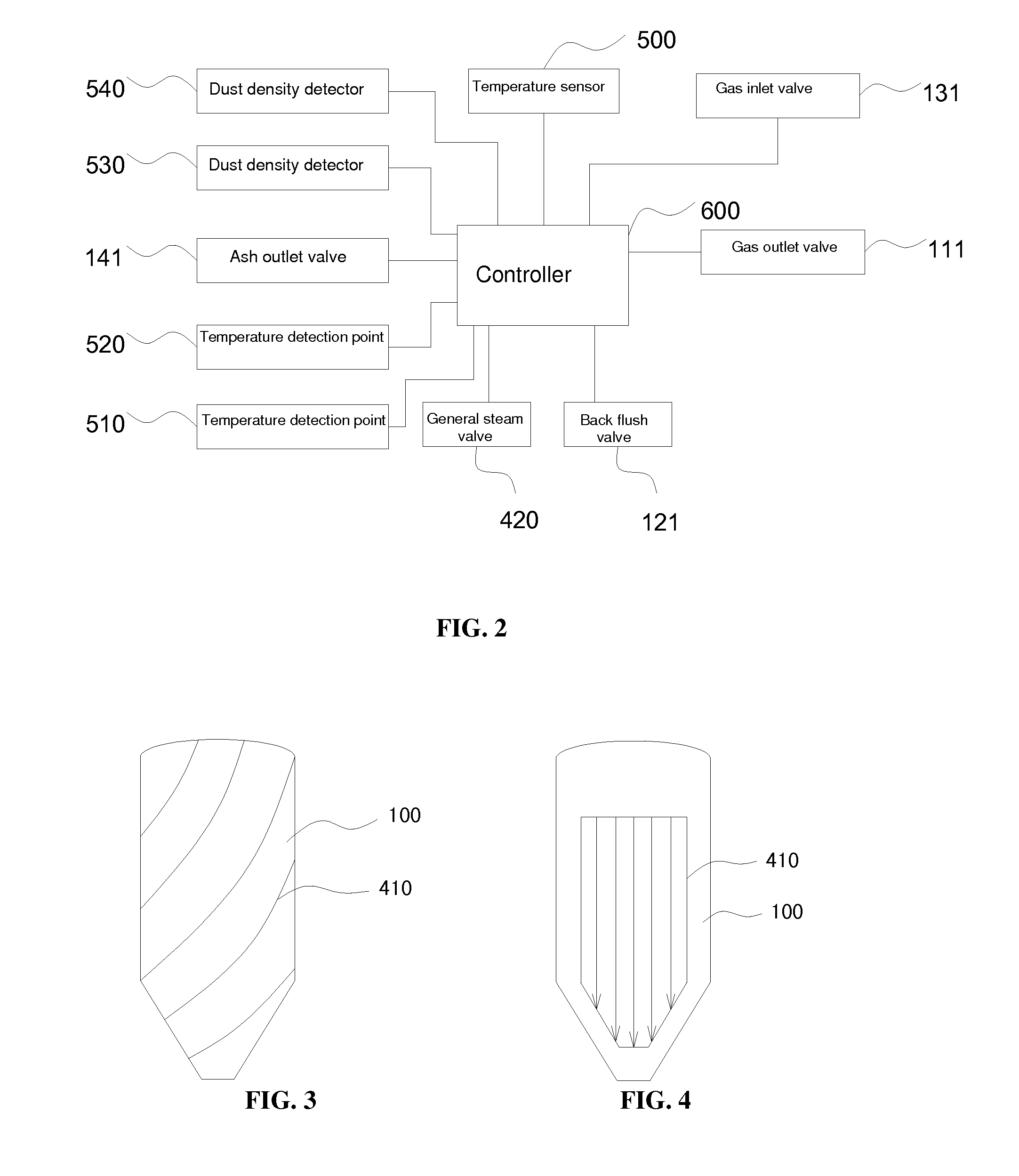

Dust Removal Method Using Baghouse Filters And Dust Removal Apparatus Therefor

ActiveUS20110265652A1Reduce in quantityImprove air tightnessCombination devicesAuxillary pretreatmentPresent methodFluidized bed

A dust removal method using baghouse filter to process raw syngas from fluidized bed coal gasifier, wherein temperature in the baghouse (300) is maintained at 180° C.-250° C., pressure difference between the gas inlet (130) of the baghouse (300) and the gas outlet (110) of the baghouse (300) is controlled at 1000-5000 Pa, the raw syngas from the fluidized bed coal gasifier enters the gas inlet under the pressure of 0.2-3.0 Mpa. The present method effectively solves the technical problems of condensation and baghouse block due to high steam and ash content in the raw syngas from the fluidized bed coal gasifier and the present method is also applicable to remove dusts from the raw syngas produced by the fluidized bed coal gasifier under the conditions of high water-gas ratio (the water-gas ratio is up to 37%), high dust content (15-100 g / Nm3 dusts) and 0.2-3.0 Mpa pressure. The present invention also discloses a baghouse dust collector and a dense phase pneumatic conveying apparatus for the method.

Owner:GAS TECH INST

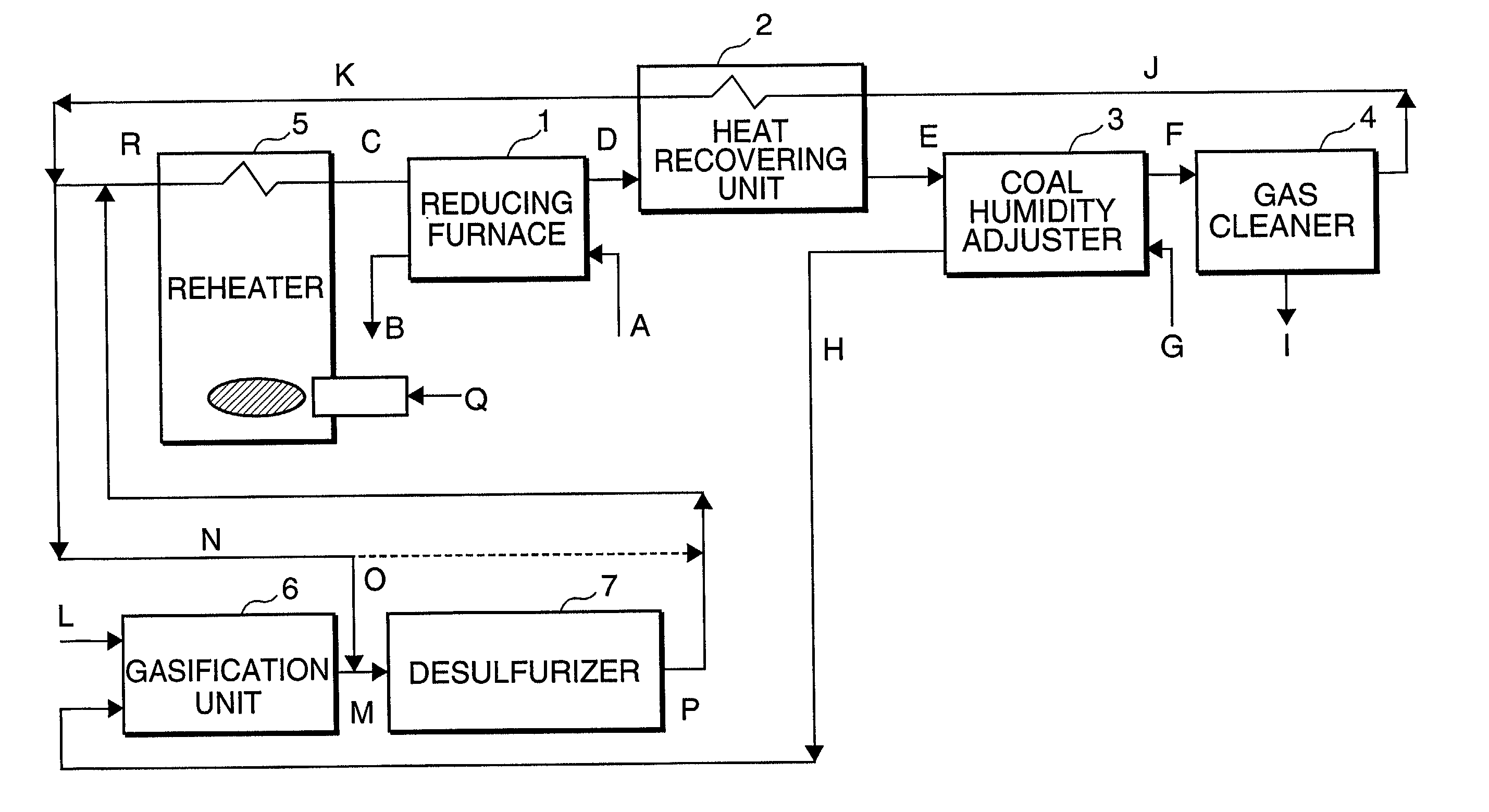

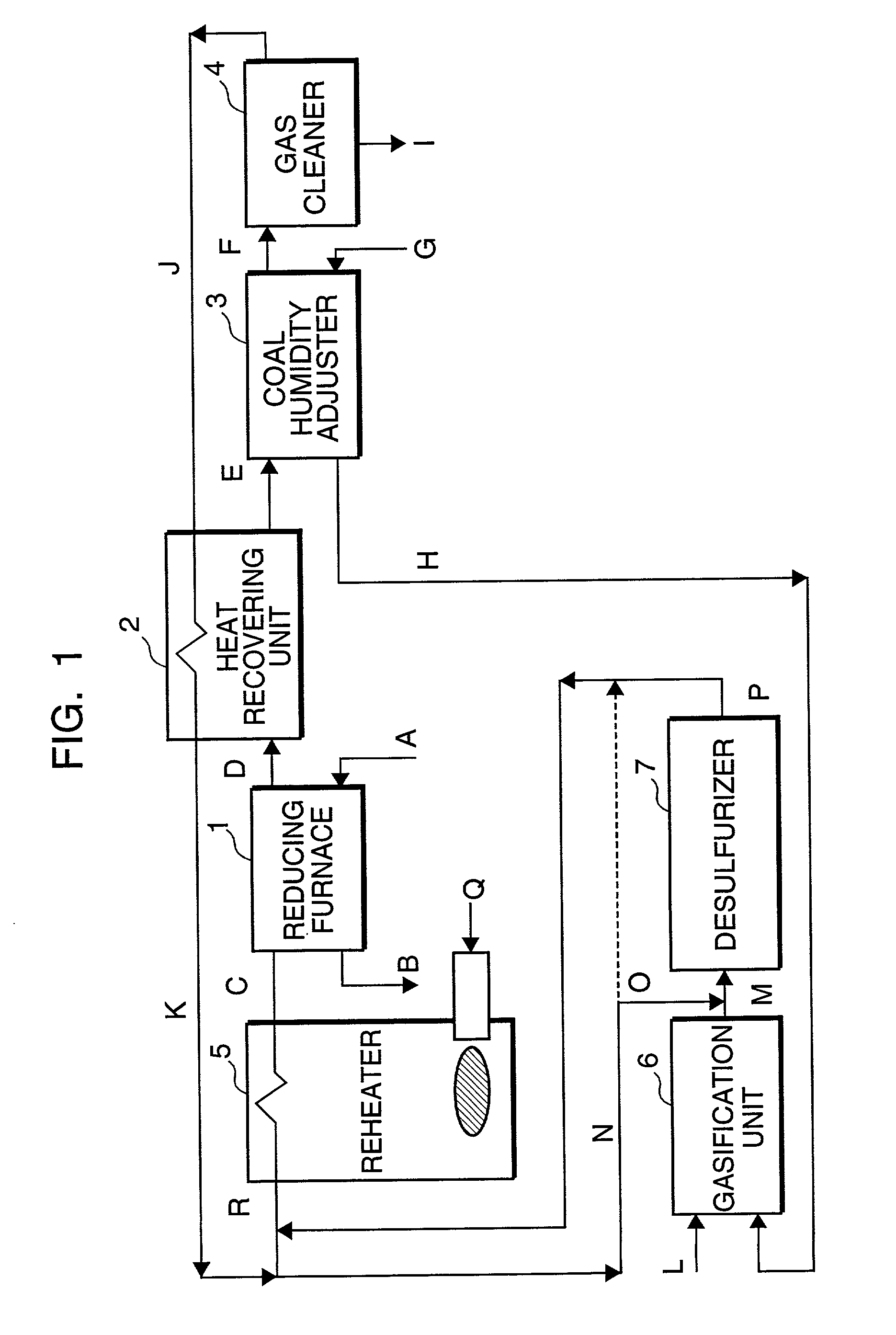

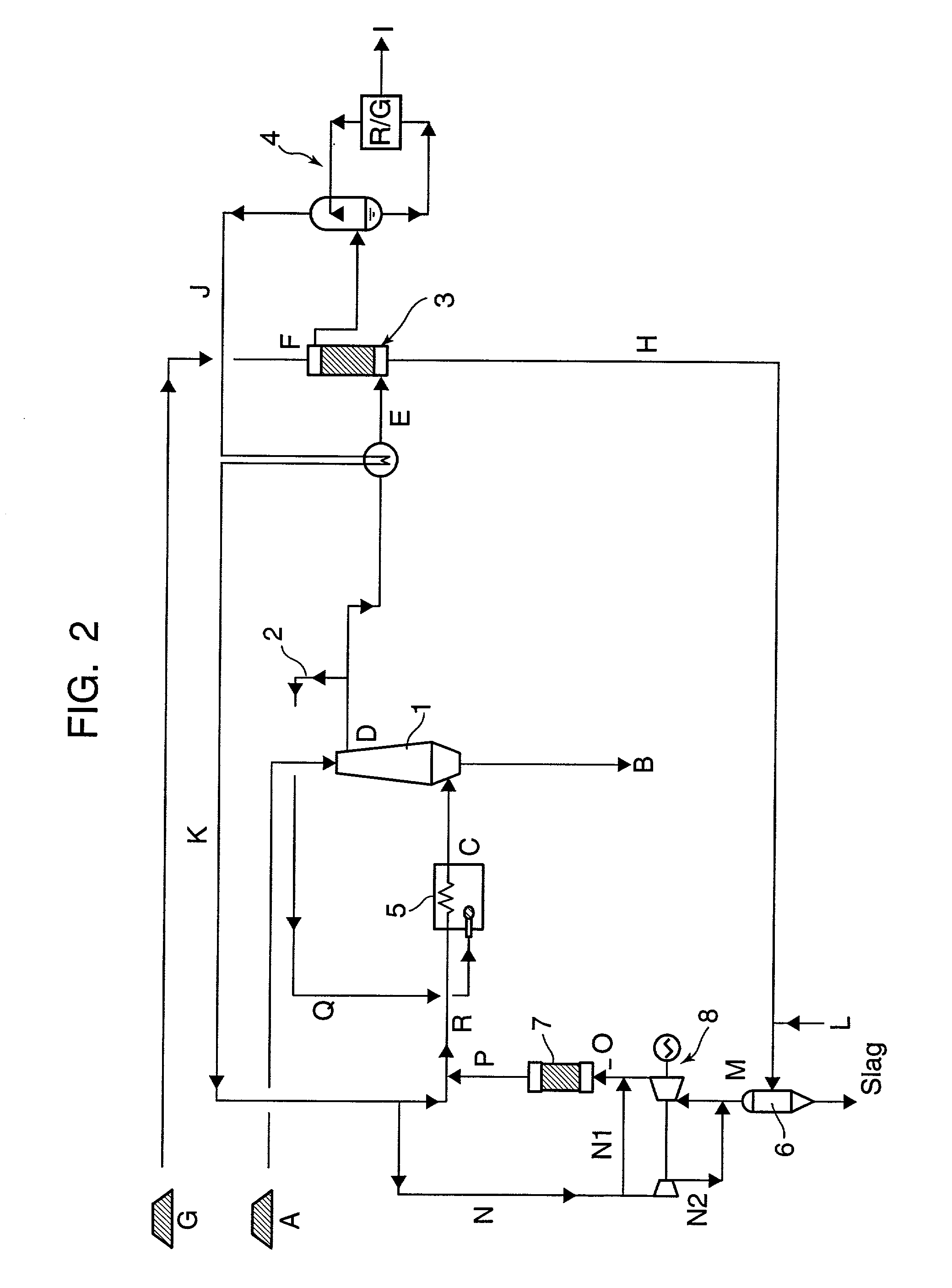

Method of producing direct reduced iron with use of coal-derived gas

InactiveUS20020078795A1Efficient use ofLow degreeTuyeresBell-and-hopper arrangementProduct gasCoal gasifier

In a method of producing direct reduced iron with use of a coal-derived gas, coal is heated to lower the moisture thereof, and the moisture-lowered coal is gasified in a coal gasification furnace to produce a coal-derived gas containing a reducing gas. The reducing gas is then utilized to reduce iron ore in an iron ore reducing furnace. With use of an exhaust gas from the iron ore reducing furnace, the coal is heated in the step of heating coal.

Owner:KOBE STEEL LTD +1

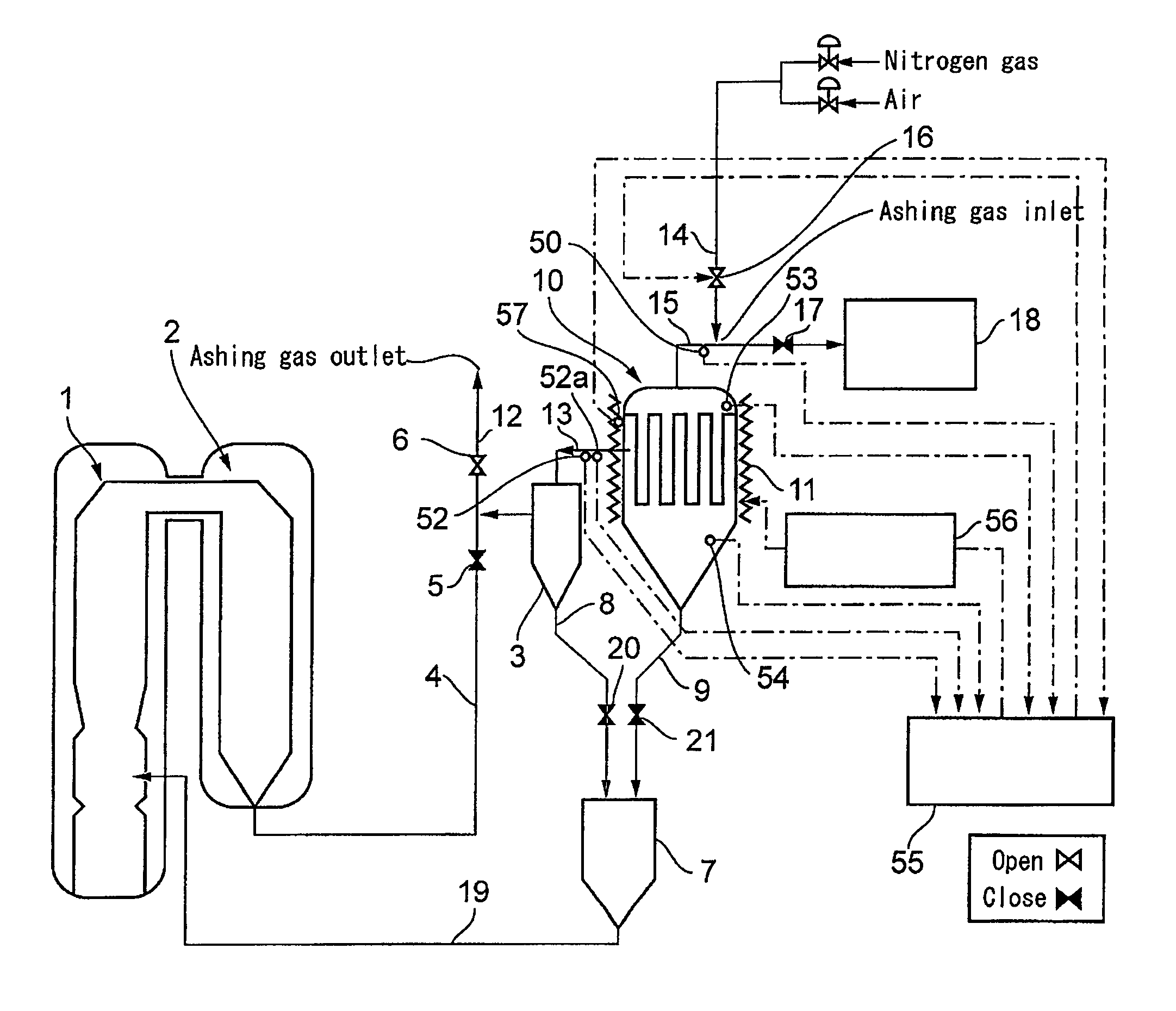

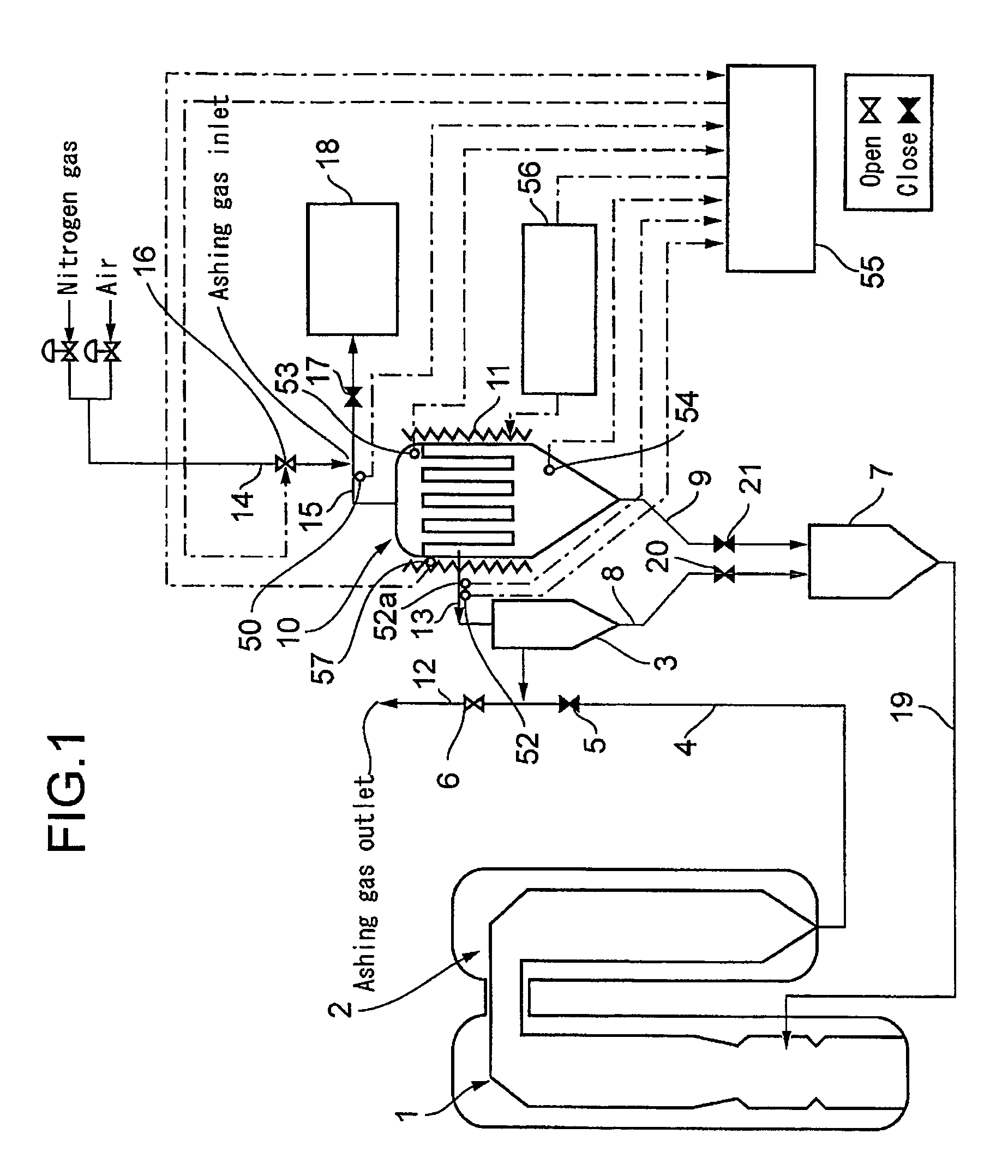

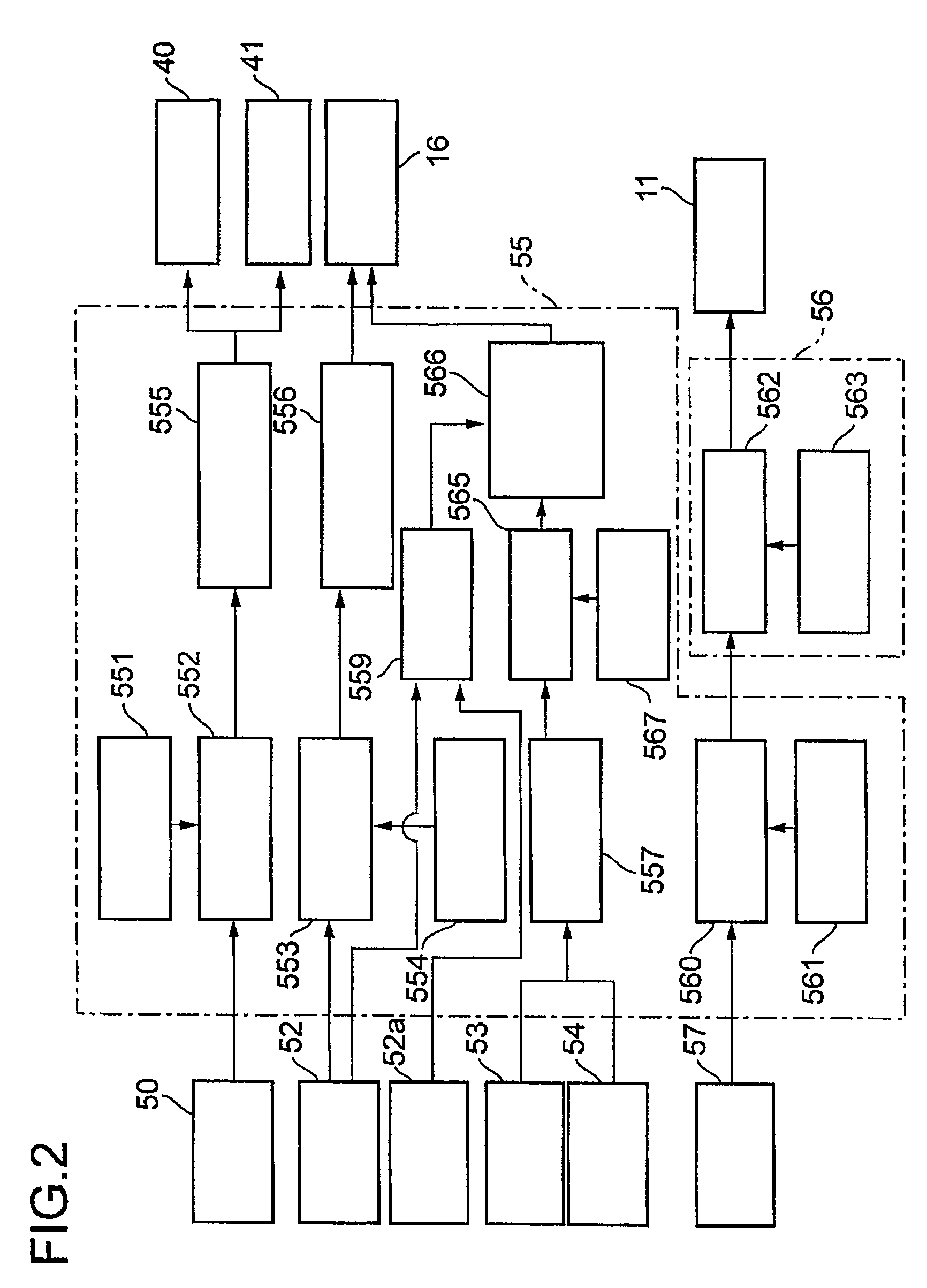

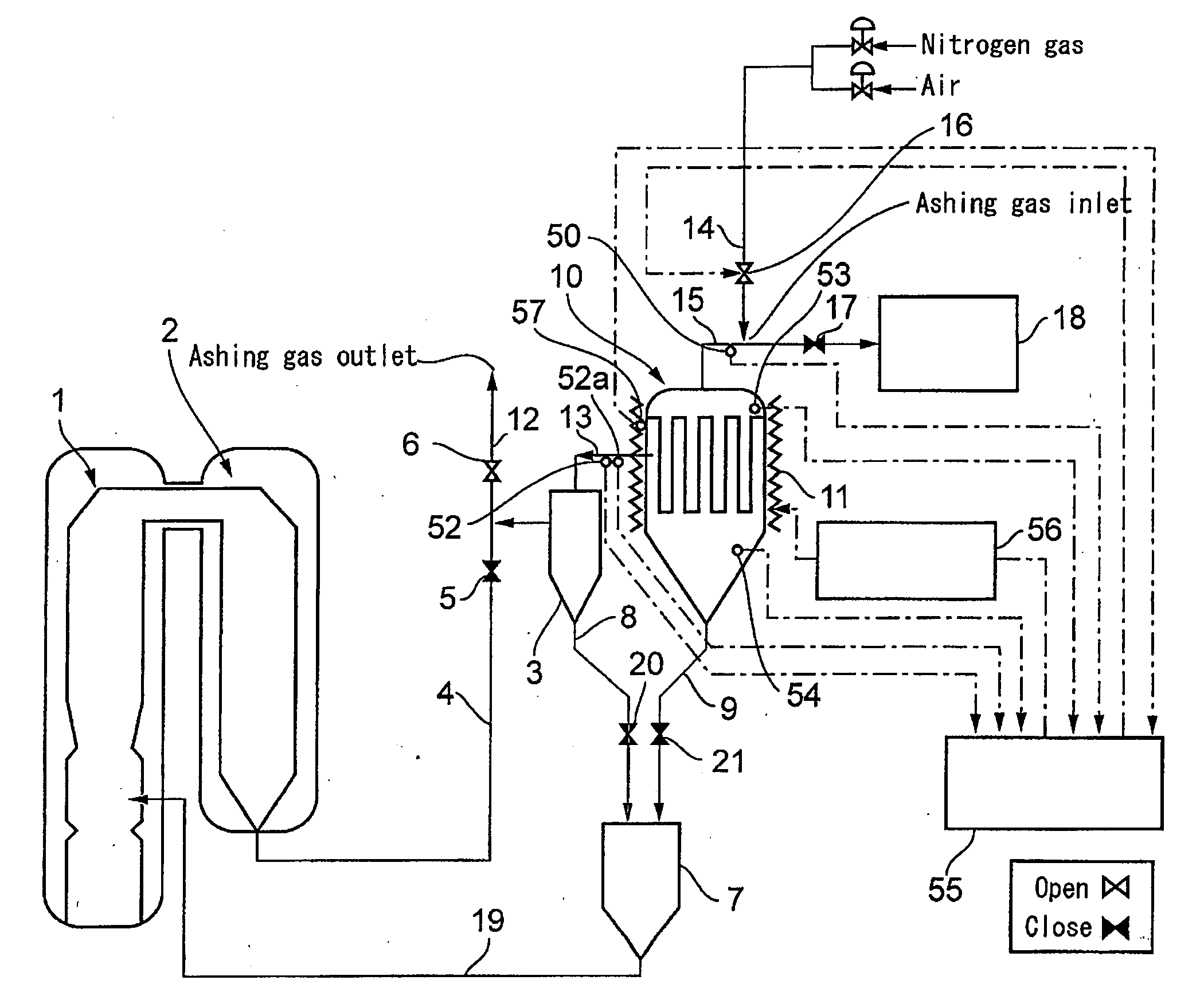

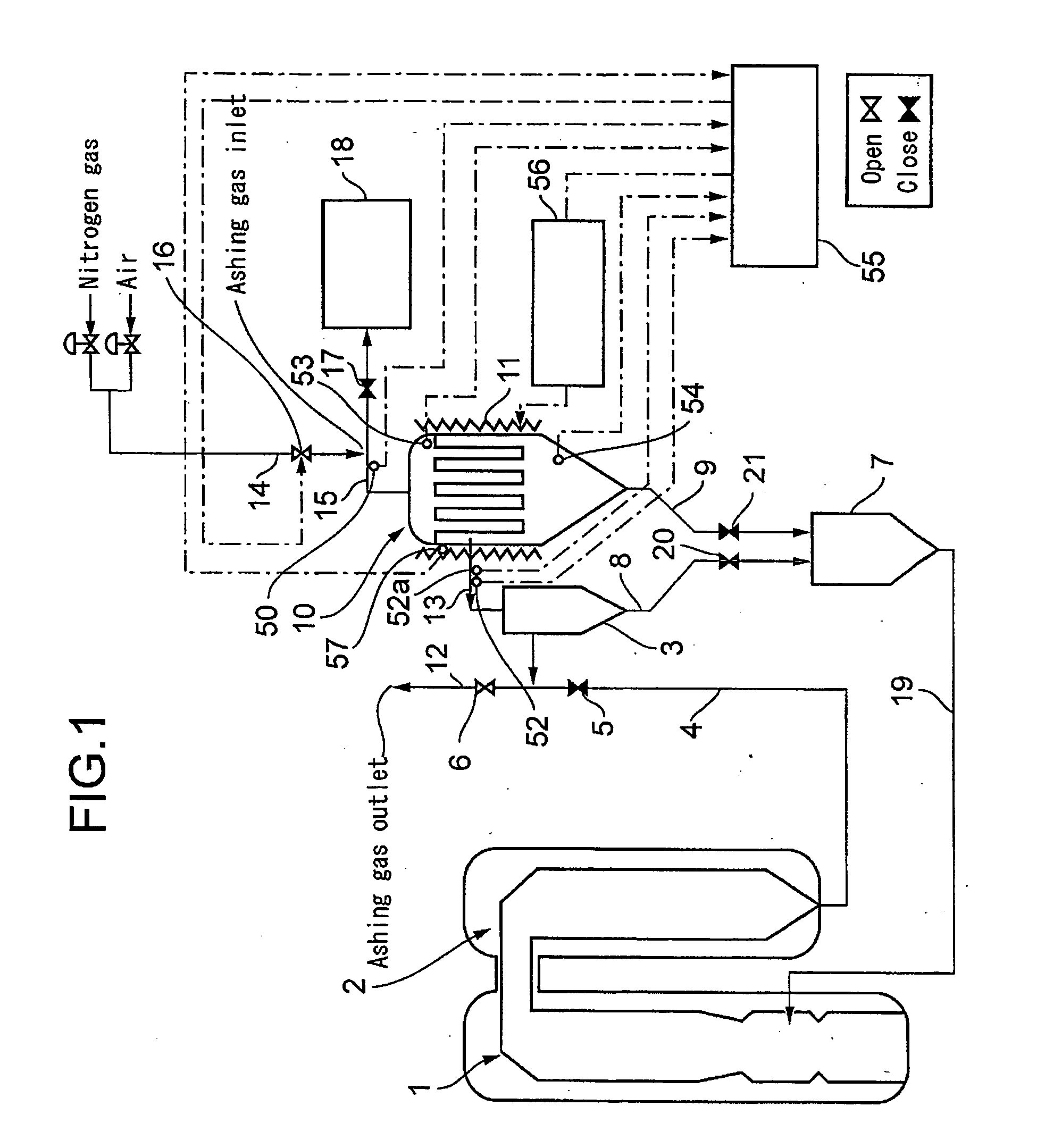

Method for regenerating filter and apparatus thereof

ActiveUS7896956B2Shorten regeneration timeShorten the timeCombination devicesAuxillary pretreatmentProcess engineeringCoal gasifier

A filter regeneration apparatus of a coal gasification system having a filter for capturing char (unburned matter) present in exhaust gas at an exhaust gas passage communicating with exhaust gas source including a coal gasification furnace, fills the filter container with inactive gas having oxygen concentration of less than 5 vol. % and heat the filter to a target temperature of 400 to 450° C. and feed ashing gas having oxygen concentration of 5 to 15 vol. %, thereby ashing char in the filter. This method and apparatus achieve ashing of char in a safe manner and shortens the time of regenerating the filter by controlling the oxygen concentration in the ashing gas and the filter temperature constantly to reach preset target values.

Owner:MITSUBISHI POWER LTD

Method for regenerating filter and apparatus thereof

ActiveUS20080127824A1Improve responseShorten regeneration timeCombination devicesAuxillary pretreatmentExhaust fumesProcess engineering

A filter regeneration apparatus of a coal gasification system having a filter for capturing char (unburned matter) present in exhaust gas at an exhaust gas passage communicating with exhaust gas source including a coal gasification furnace, fills the filter container with inactive gas having oxygen concentration of less than 5 vol. % and heat the filter to a target temperature of 400 to 450° C. and feed ashing gas having oxygen concentration of 5 to 15 vol. %, thereby ashing char in the filter. This method and apparatus achieve ashing of char in a safe manner and shortens the time of regenerating the filter by controlling the oxygen concentration in the ashing gas and the filter temperature constantly to reach preset target values.

Owner:MITSUBISHI POWER LTD

Coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle apparatus and coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle method

ActiveCN106244241AHigh purityPurity does not affectGasification processes detailsHydrogen productionSyngasCombustion

The invention discloses a coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle apparatus and a coal gasification-to-synthesis gas and chemical chain-to-oxygen-hydrogen combined cycle method. With the apparatus and the method of the present invention, the high investment and the high energy consumption deep-cooling air separation oxygen production unit are eliminated, and the system efficiency is beneficially improved. Compared to the traditional coal gasification-to-hydrogen apparatus, the apparatus of the present invention has the following advantages that only three processes such as gasification, combustion and water decomposition hydrogen production are required to be performed, such that the process is simple; the H2 purity is substantially increased and is up to more than 99%; the high purity CO2 capture is achieved so as to substantially reduce the CO2 emission; the high purity O2 is produced, the purity is much higher than the oxygen produced through the deep cooling air separation, and the purity of the prepared synthesis gas is higher than the purity of the synthesis gas prepared by the traditional coal gasification apparatus; the apparatus of the present invention is adapted to the variable load operation of the coal gasification furnace; when the apparatus works in the pressurization state, the pressure can be determined according to the requirement of the gasification furnace, such that the purities of the produced CO2, the produced O2 and the produced H2 cannot be affected; and the ratio of the synthesis gas to the H2 can be flexibly adjusted.

Owner:SOUTHEAST UNIV

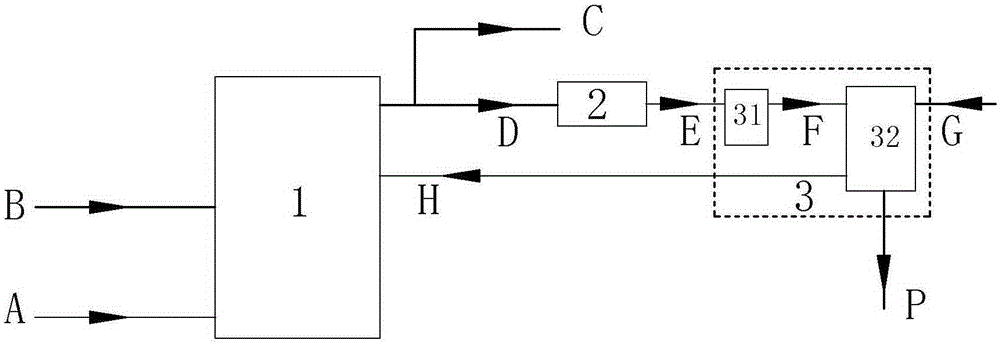

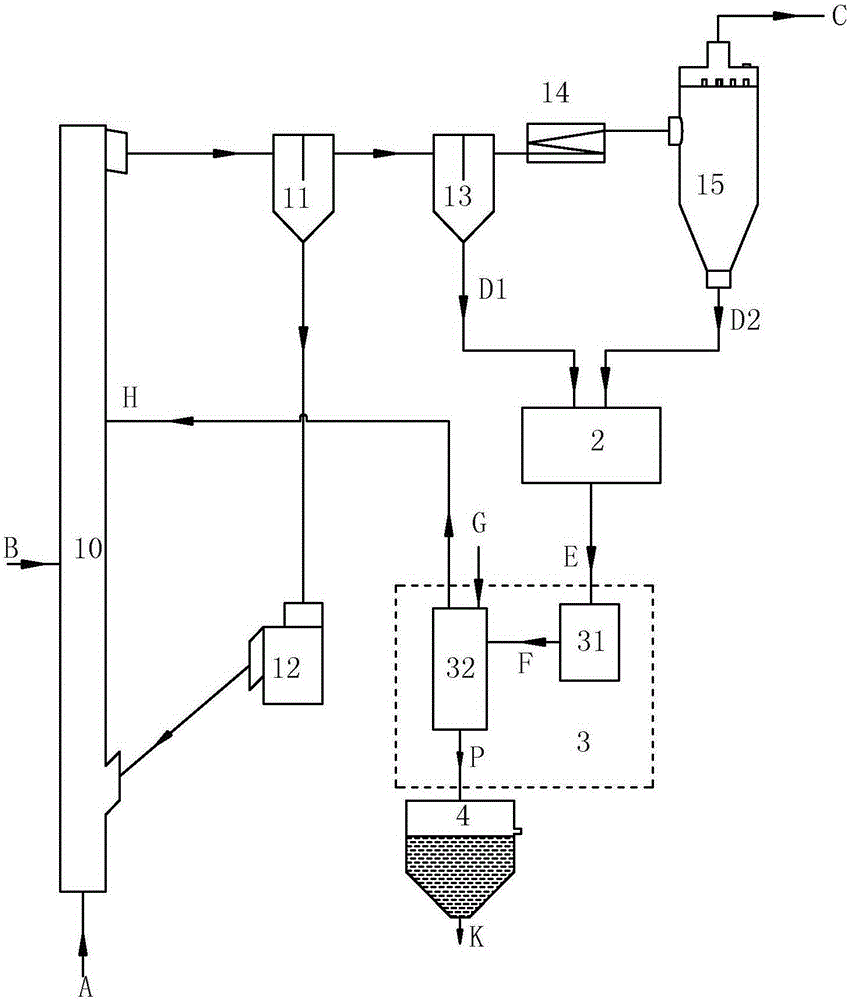

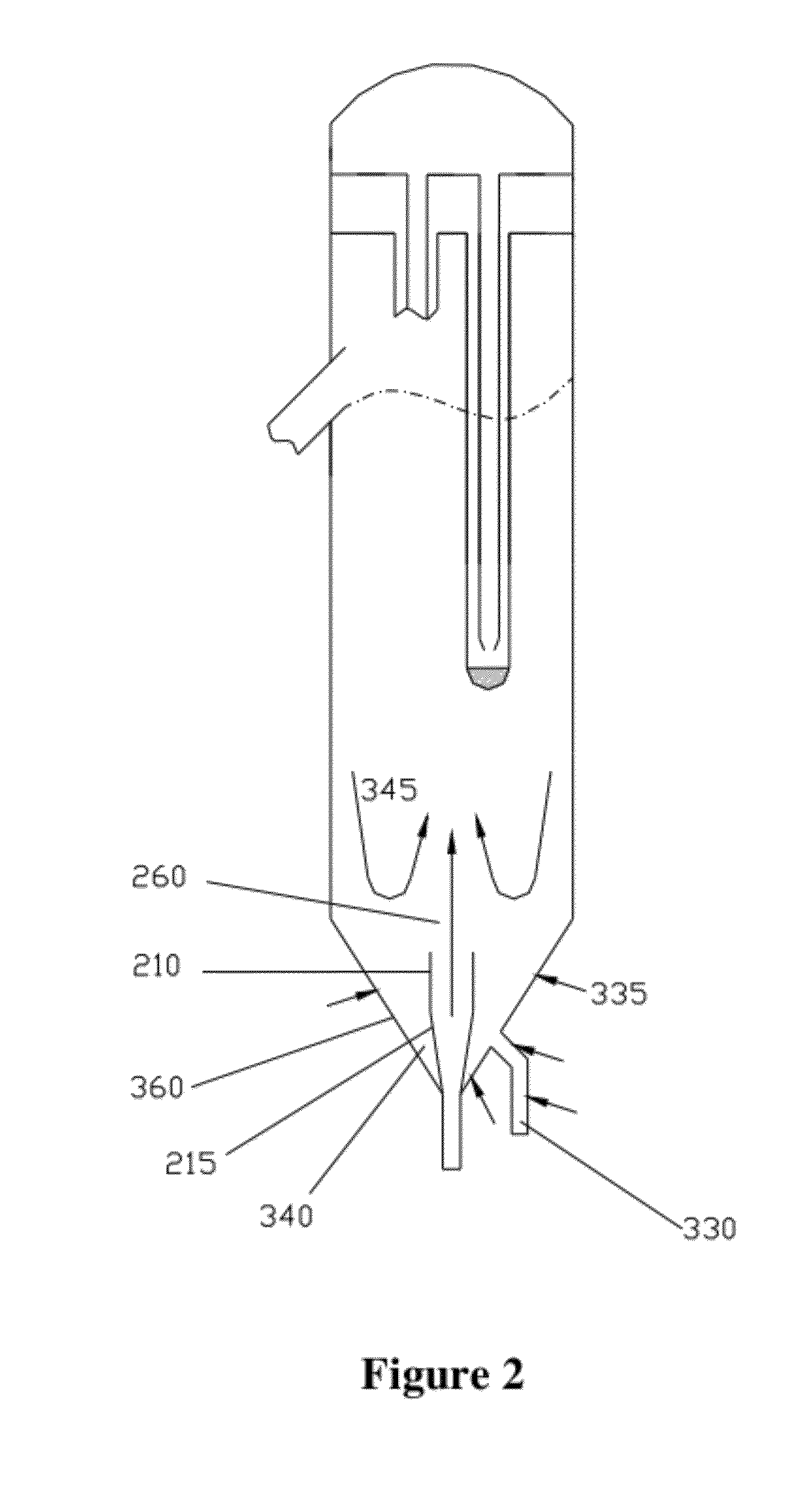

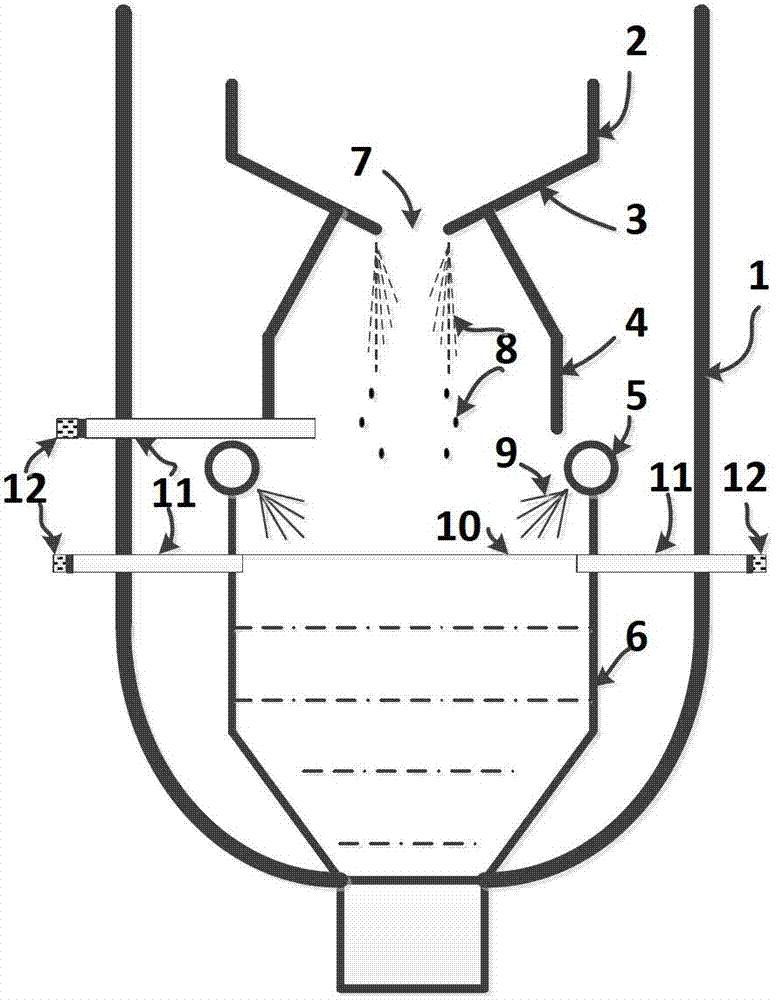

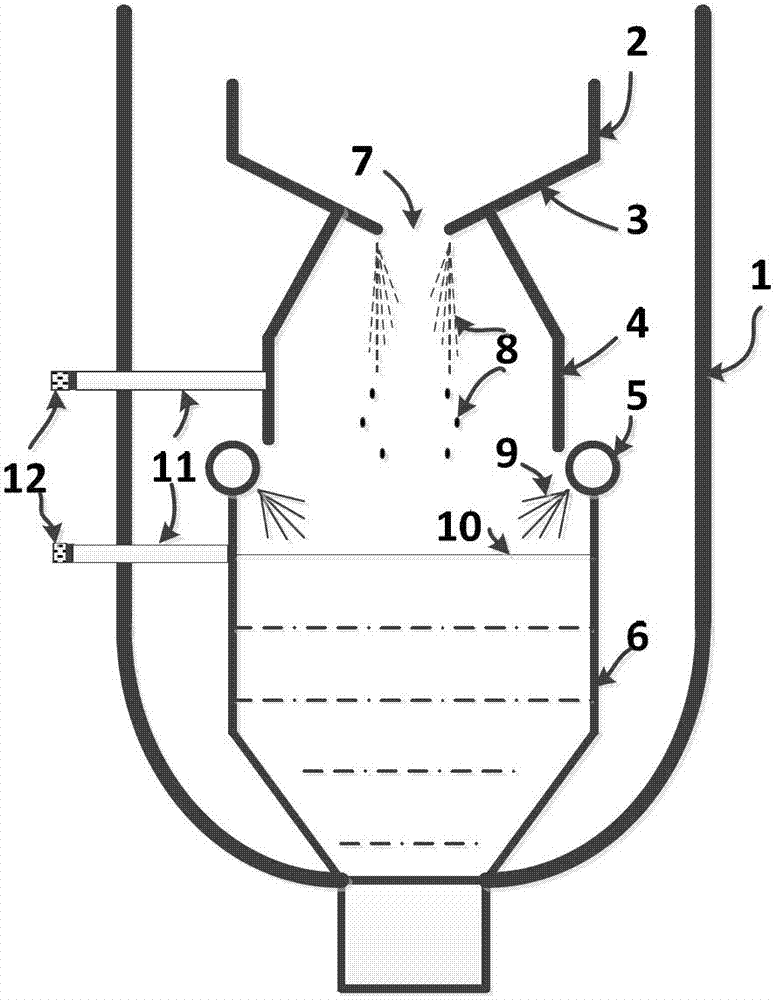

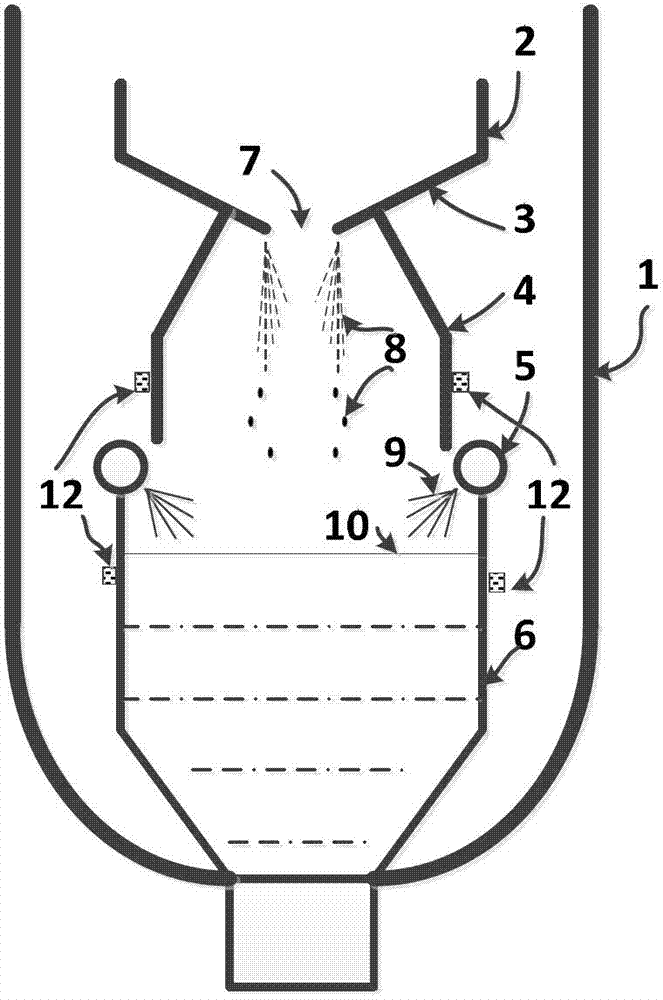

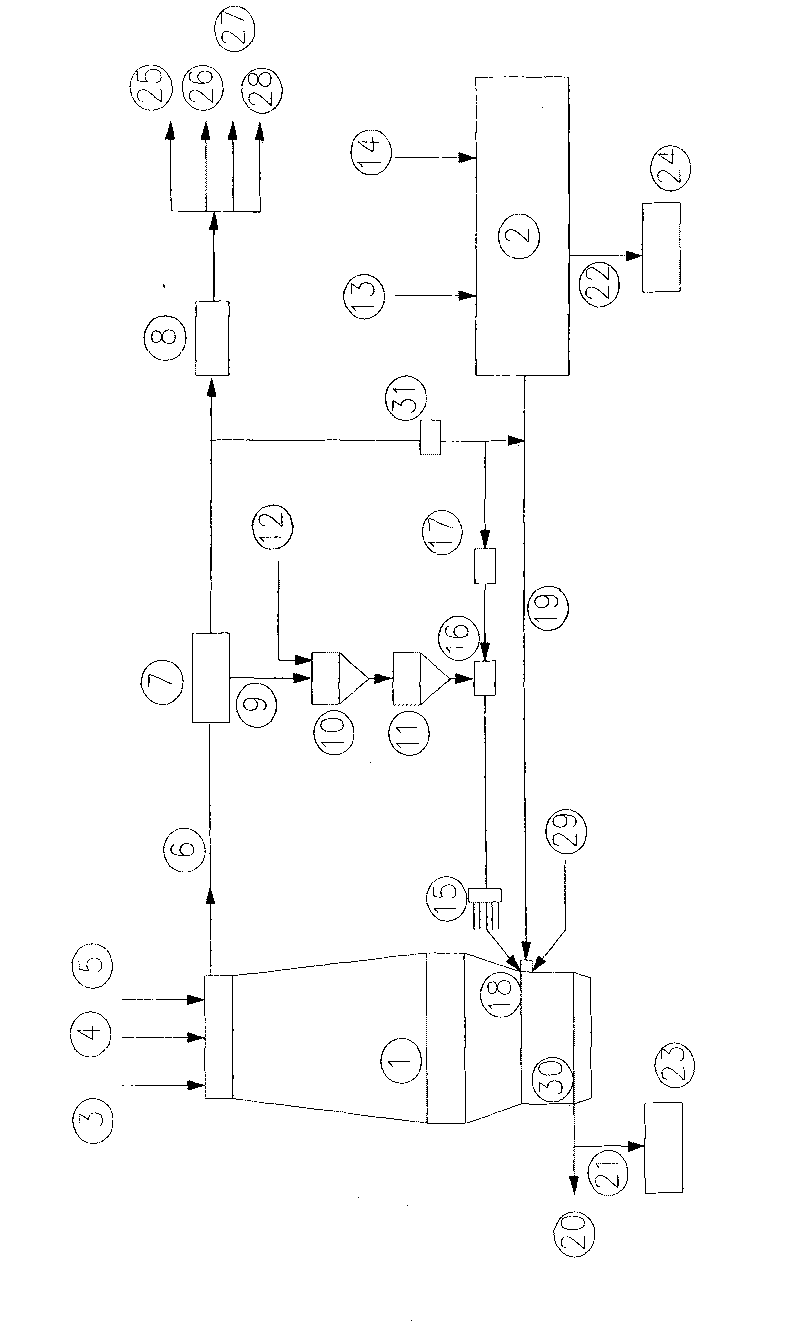

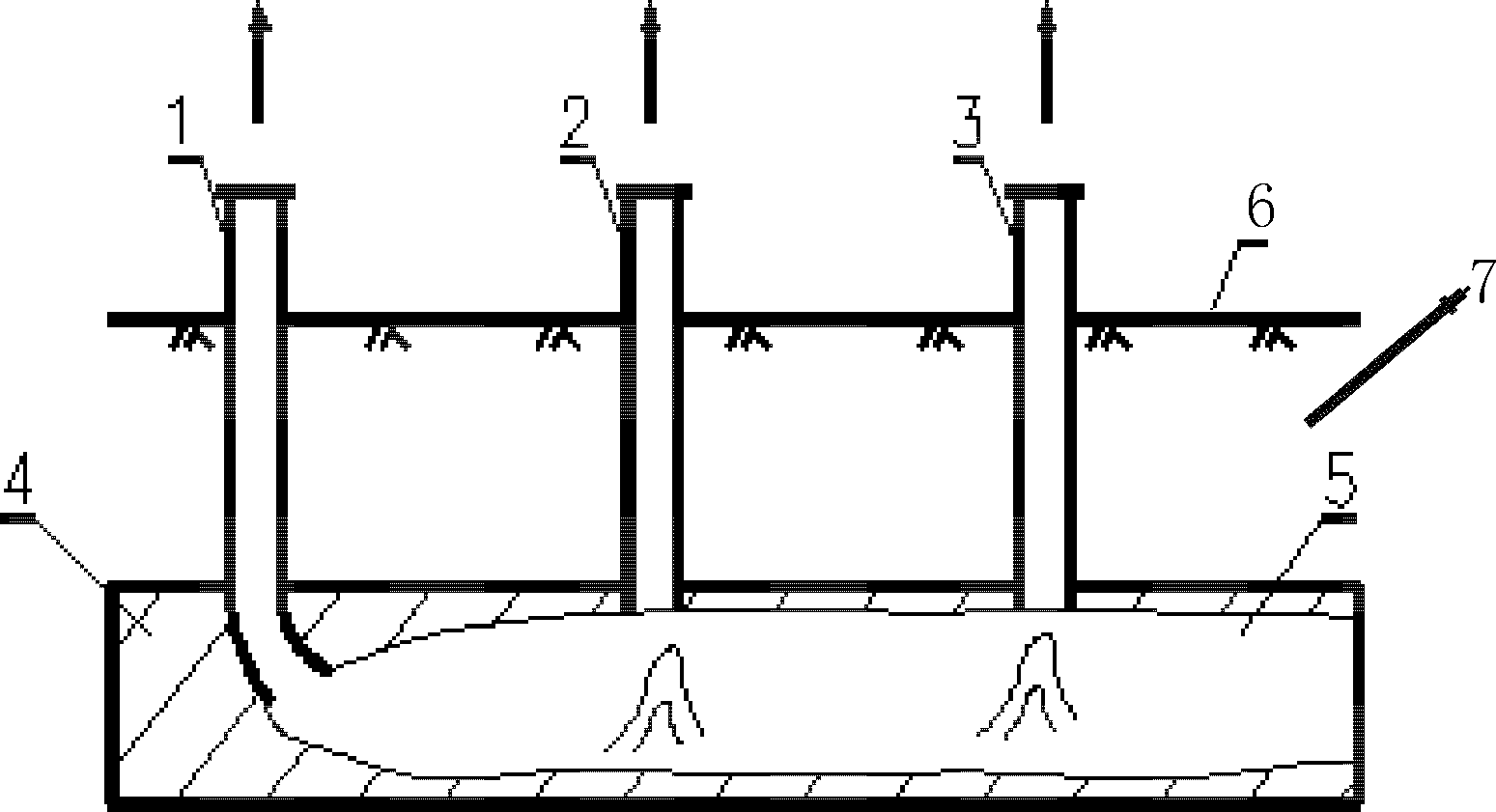

Circulating fluidized bed coal gasification method and device with fine powder ash fusion

ActiveCN106554826AImprove carbon conversionImprove qualityGranular/pulverulent flues gasificationFluidized bedCoal gasifier

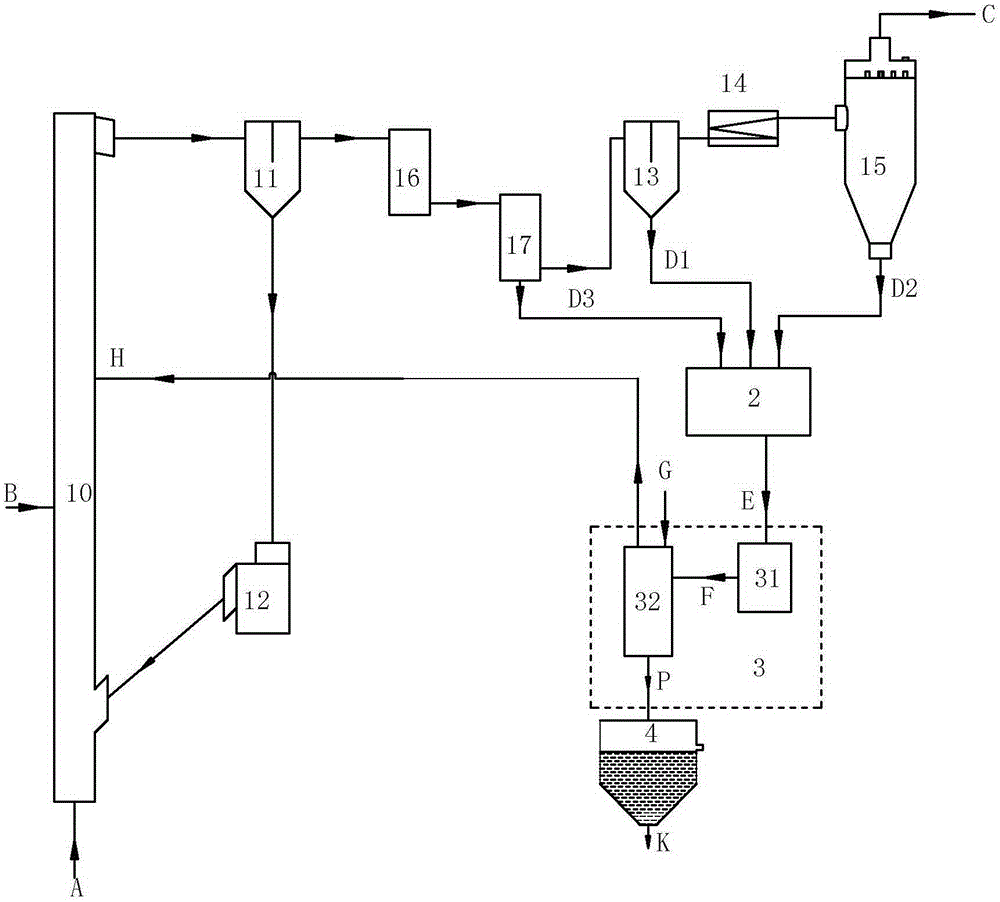

A circulating fluidized bed coal gasification method with fine powder ash fusion comprises the following steps that (a), coal (B) and a gasifying agent (A) are delivered into a circulating fluidized bed coal gasification furnace (1) to be subjected to a gasification reaction, and coal gas (C) and gasified fine powder ash (D) are generated; (b), the coal gas (C) and the gasified fine powder ash (D) are separated; (c), the separated gasified fine powder ash (D) is collected; (d), the gasified fine powder ash (D) obtained in the step (c) is delivered into a smelting furnace (3); (e), carbon-contained high temperature gas (H) rich in CO and CO2 and high temperature liquid slag (P) are generated; and (f), the carbon-contained high temperature gas (H) is delivered back into a gasification furnace hearth of the circulating fluidized bed coal gasification furnace (1) or a refeed valve, and the high temperature liquid slag (P) is discharged out of the smelting furnace (3). The invention further provides a circulating fluidized bed coal gasification device with the fine powder ash fusion. The circulating fluidized bed coal gasification device and method with the fine powder ash fusion are high in gasification efficiency and carbon conversion efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Feed gas separation method and apparatus of coal gasification apparatus

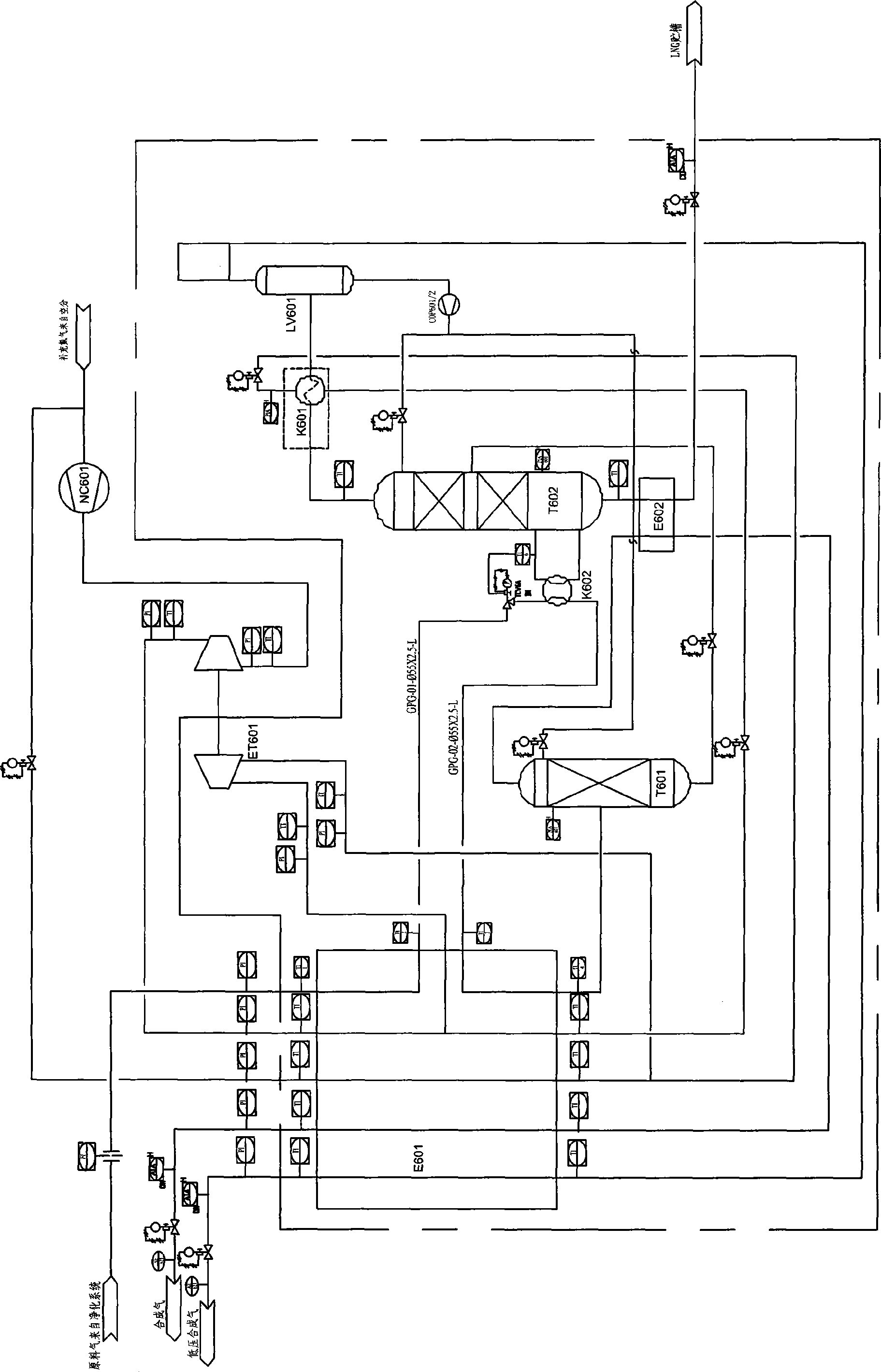

InactiveCN101476813ASmall resistance lossEmission reductionSolidificationLiquefactionExhaust gas emissionsStreamflow

The invention relates to a separation system for separating carbon monoxide / hydrogen into a fluid for a downstream to serve as synthesis gas and separating liquefied methane (LNG) into another fluid for commercial sale in raw material gas which comes from a coal gasifier and comprises basic constituents of the carbon monoxide, the hydrogen and methane. The separation system adopts a double tower flow of a scrubbing tower and a CH4-CO rectifying tower, and most of raw material synthesis gas is scrubbed and then forms the synthesis gas with the content of the methane lower than 1 percent at the tower top in reasonably controlling the reflux ratio; and a liquid phase after the scrubbing is sent into the CH4-CO rectifying tower, and separated CH4 is liquefied into the LNG. The CH4-CO rectifying tower has small flow, reduces 10 percent of separation power consumption compared with a single tower flow, and can also reduce the number of tower plates, so the double tower flow reduces the height of the tower, saves cost, and also ensures that the raw material synthesis gas has smallest resistance consumption to the synthesis gas. The separation system has the advantages of a small discharge amount of waste gas, environmental protection, and energy conservation, and has good economic benefit and social benefit.

Owner:成都蜀远煤基能源科技有限公司

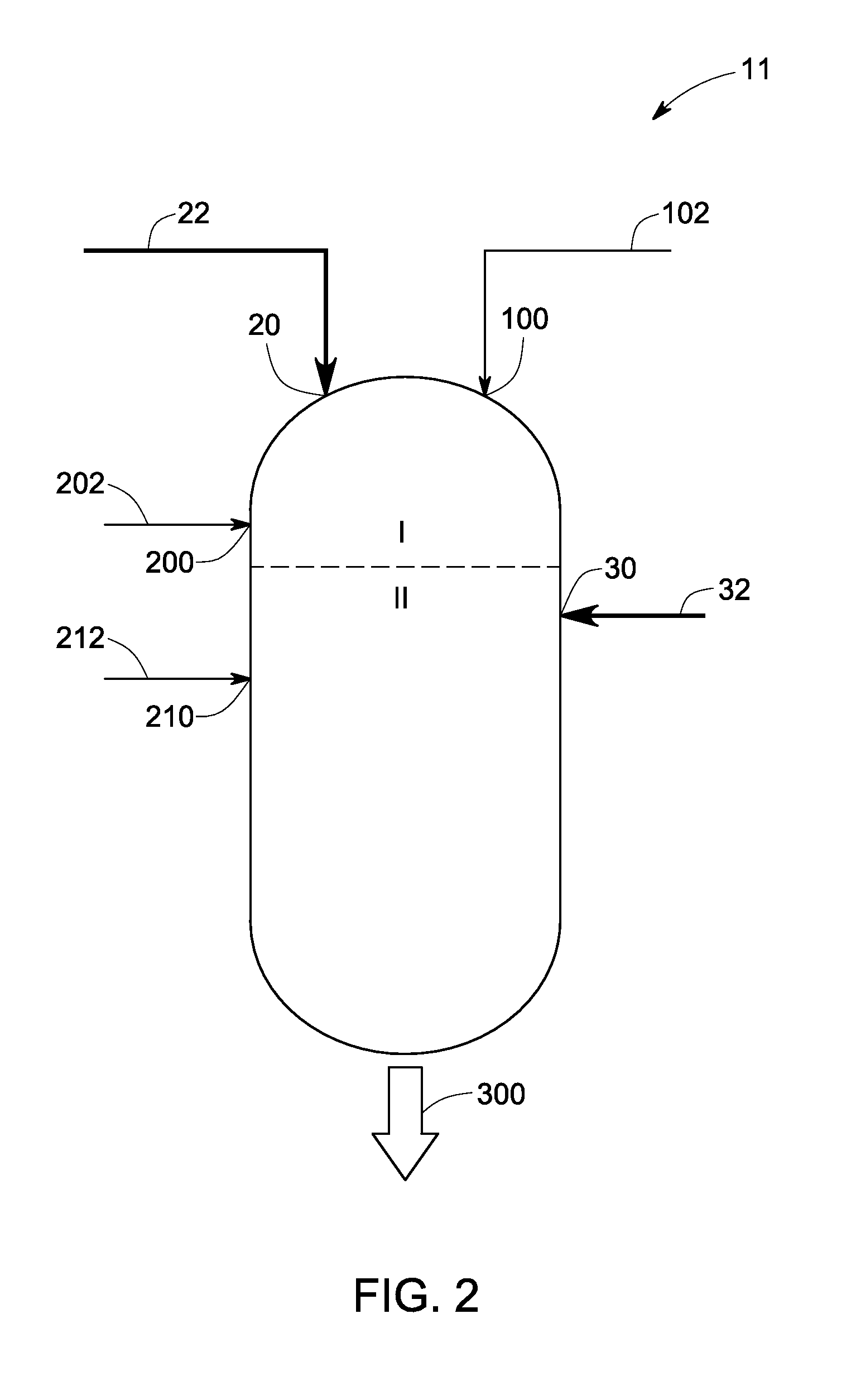

Method of retrofitting a coal gasifier

A coal gasifier is retrofitted to achieve multiple advantages such as reduced oxygen consumption, reduced CO2 and NOx emissions, better H:C ratio, better carbon conversion etc. This is achieved by dividing the coal into at least two zones and modifying the gasifier and operating it as described. The coal is injected into a first zone, configured to devolatilize a substantial portion of the injected coal to produce coal char and volatiles. The operation is tuned to substantially consume the oxidant injected in the first zone. A low-calorific-value, high oxidant feedstock is injected in second zone of the gasifier. The devolatilization of the low-calorific-value, high oxidant content feedstock provides the oxygen containing compounds which gasify at least a portion of the coal char generated in the first zone.

Owner:AIR PROD & CHEM INC

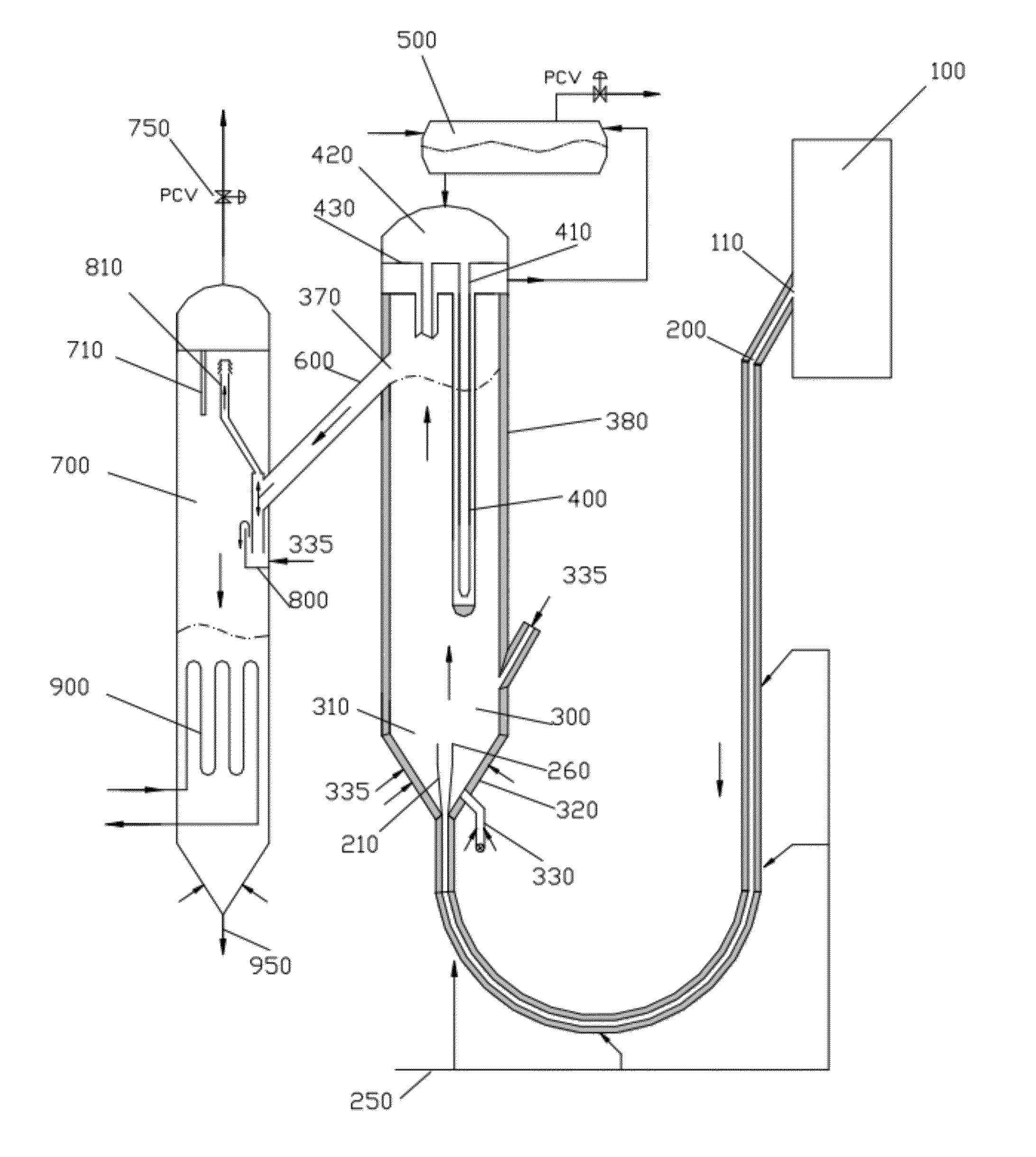

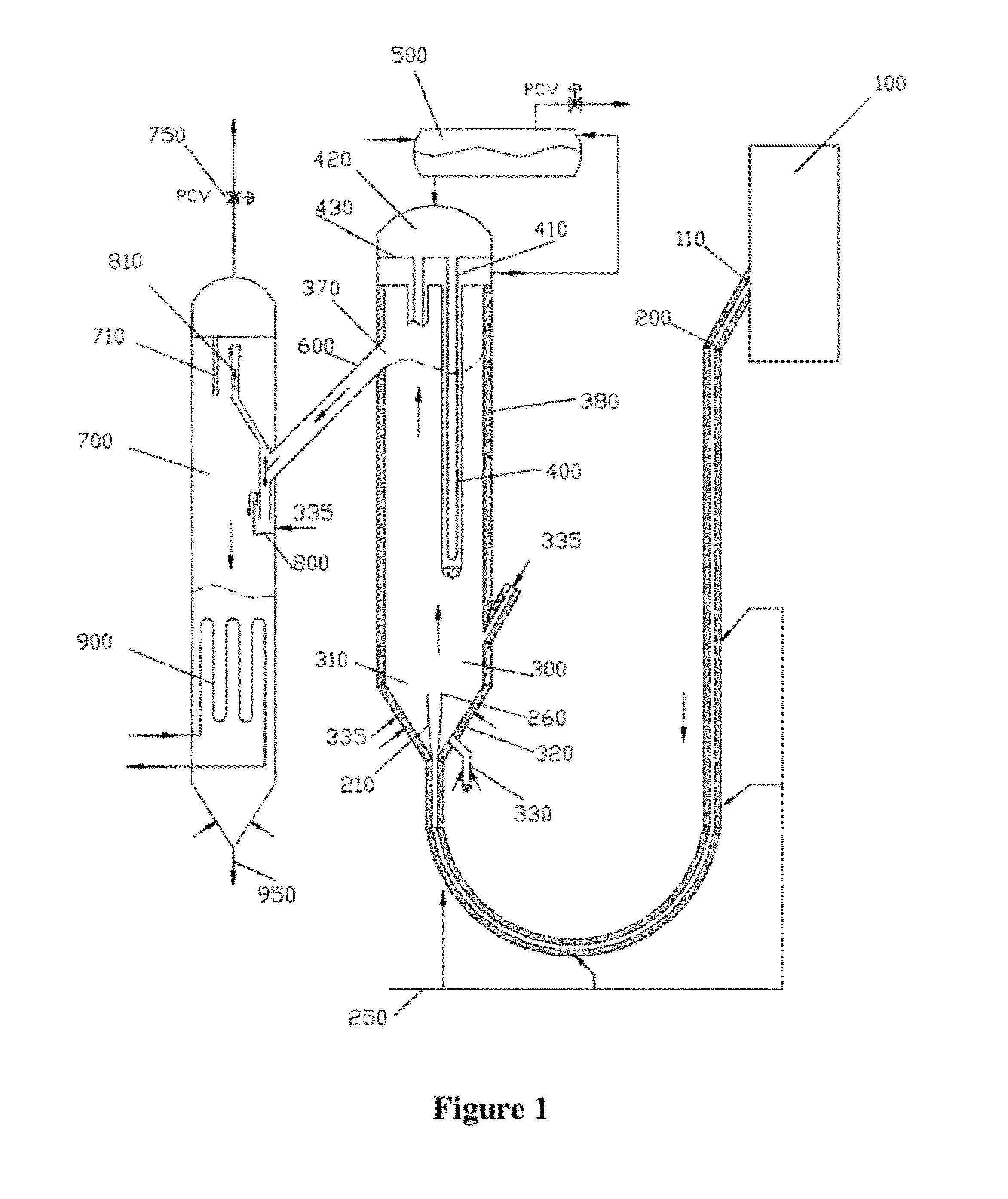

Ash And Solids Cooling In High Temperature And High Pressure Environment

ActiveUS20120031584A1Avoid interferenceEnsure sufficient separationFluidized bed combustionCorrosion preventionSolid particleHigh pressure

Disclosed are cooling and depressurization system equipment, arrangement and methods to cool solid particles from a coal gasifier operating at high temperature and pressure. Ash from the coal needs to be continuously withdrawn from a circulating fluidized bed gasifier to maintain the solids inventory in the gasifier. The system disclosed enables use of conventional materials of construction for heat transfer surfaces. The supports for the cooling surfaces are located on the lower temperature upper section of the primary cooler. The cooled solids along with the fluidizing gas exits the primary cooler to a secondary receiving vessel where the solids can be further cooled by conventional means. The fluidizing and entrained gas entering the secondary vessel is filtered and vented through a vent pressure control valve. The column of cooled solids in the secondary vessel is depressurized by a continuous depressurization system to low pressures which are sufficient for conveying the solids to silos for disposal. The system and methods proposed are equally applicable to many high temperature, high pressure processes that require cooling and depressurization of process solids.

Owner:THE SOUTHERN CO

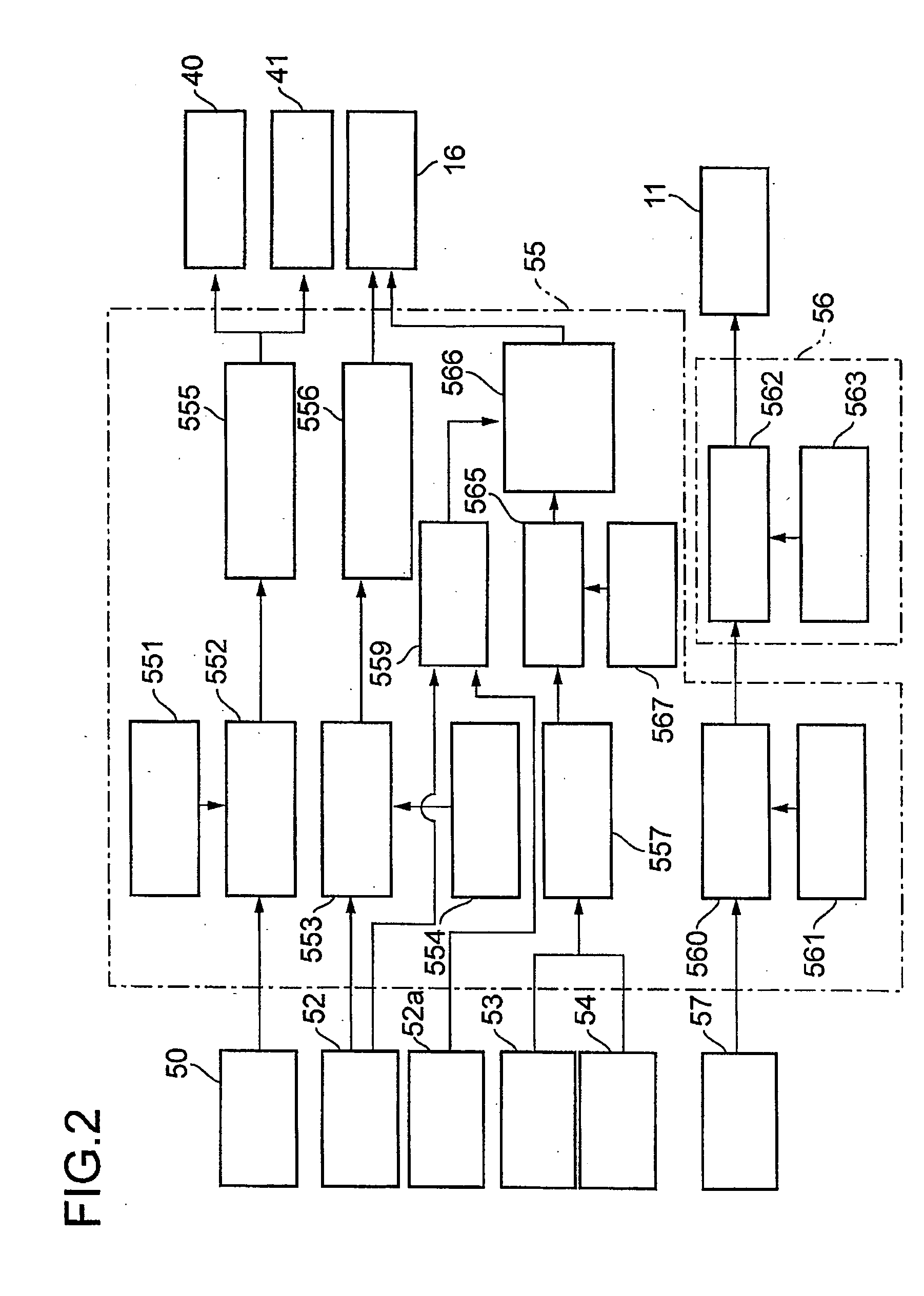

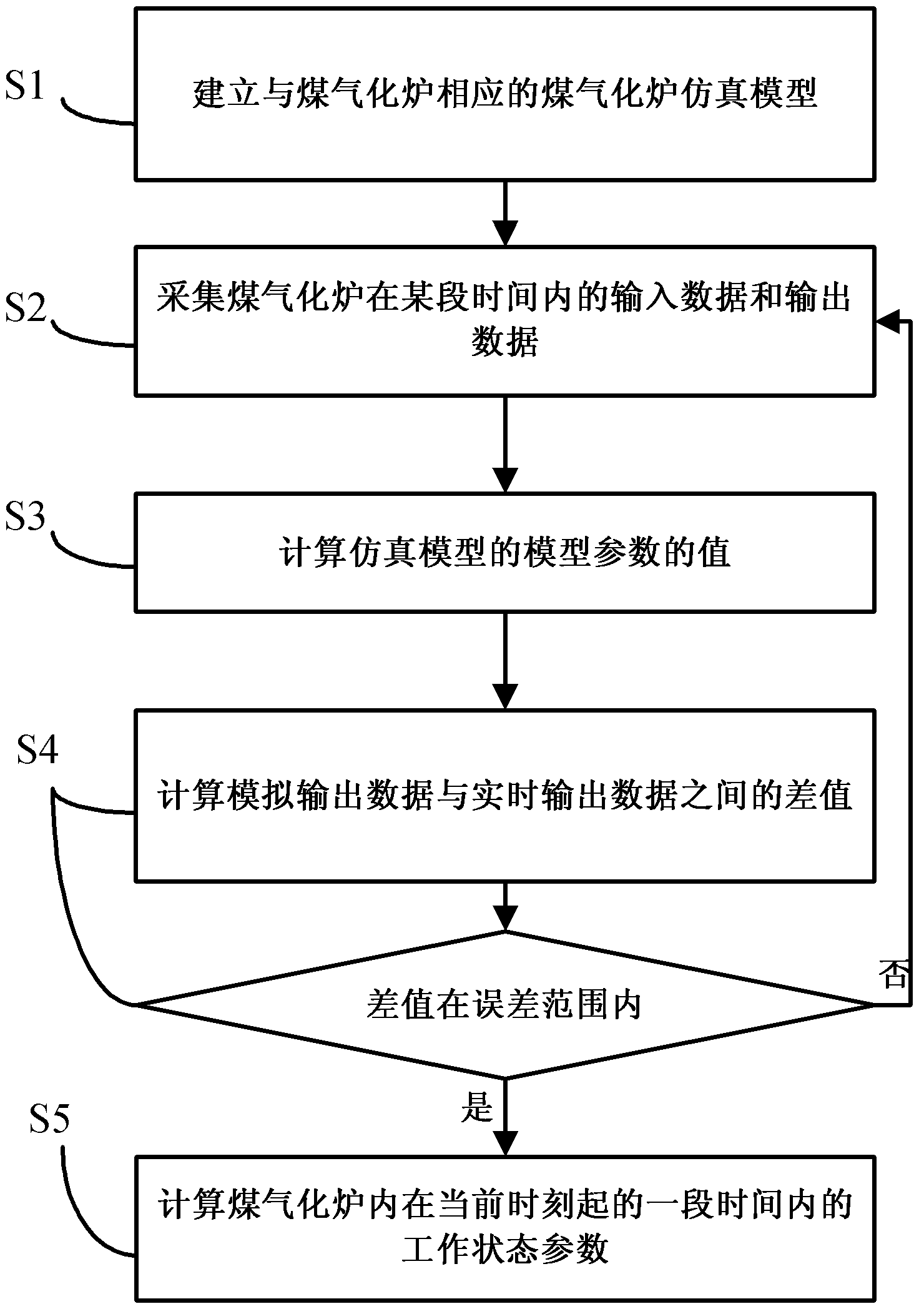

Control method for coal gasifier

ActiveCN102799748AAccurate adjustment effectAccurate monitoringCombined combustion mitigationSpecial data processing applicationsState parameterSimulation

The invention discloses a control method for a coal gasifier, which comprises the following steps implemented sequentially: S1, establishing a coal gasifier simulation model corresponding to the coal gasifier, wherein the coal gasifier simulation model comprises a plurality of model parameters; S2, collecting input data and output data of the coal gasifier during a certain time period, wherein the input data and the output data refer to constituents and contents as well as all the work parameters of input and output substances of the coal gasifier; S3, calculating values of the model parameters of the simulation model according to the input data and the output data collected; S4, collecting the real-time input data and the real-time output data of the coal gasifier, calculating the difference between the simulated output data and the real-time output data through the simulation model, returning to S2 if the difference is outside the error range, or continuing the next step if else; and S5, calculating work state parameters of the coal gasifier within a time period from the current time, and thus monitoring and adjusting the work state of the coal gasifier. The control method can adjust and monitor the coal gasifier efficiently and precisely in real time.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

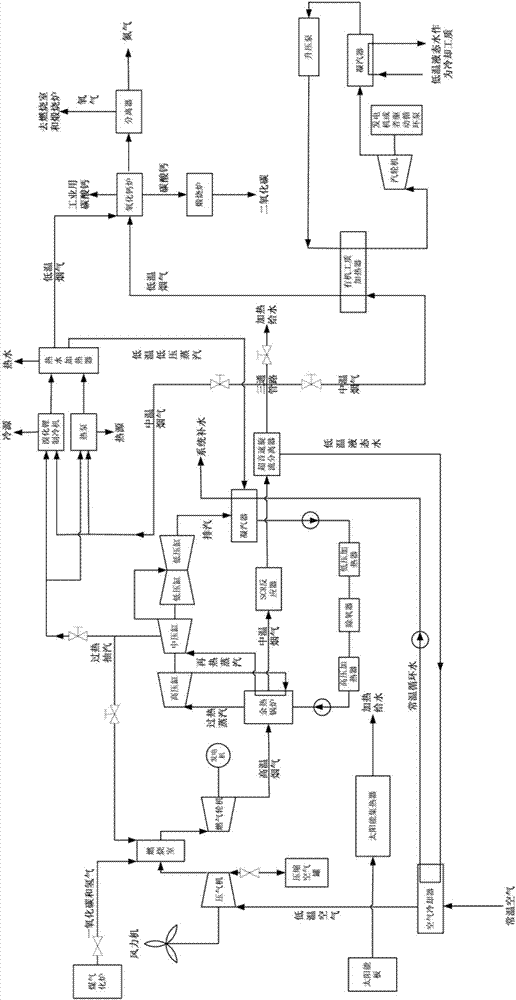

Efficient water-saving controllable gas turbine quadruple-cogeneration system

ActiveCN107165723AImprove absolute internal efficiencyIncrease incomeGas turbine plantsEnergy storageSeparation technologyCogeneration

The invention relates to an efficient water-saving controllable gas turbine quadruple-cogeneration system. The gas turbine quadruple-cogeneration system is efficient and controllable, saves water and achieves in-plant circulation and zero emission. According to the technical scheme, the efficient water-saving controllable gas turbine quadruple-cogeneration system comprises a gas turbine, an air cooler, a coal gasifier, a cyclone separator, a refrigerating machine, a heat pump, a Rankine cycle system and a low-temperature smoke processing system. The efficient water-saving controllable gas turbine quadruple-cogeneration system fully utilizes available resources, wind energy and solar energy, in a factory, achieves an efficient and controllable gas turbine combustion and acting system and achieves an more economical and adjustable heat-electricity-coldness-hot water quadruple-cogeneration system, a supersonic separation technology is applied to a gas turbine power plant for the first time, the quadruple-cogeneration has the advantages of being high in dewatering efficiency, safe and stable and effectively preventing low-temperature corrosion, low-temperature smoke is efficiently utilized, zero emission is achieved at the same time, waste heat is reasonably utilized, the thermal efficiency reaches 42% or above, and the combined cycle thermal efficiency reaches 63% or above.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

Method for detecting fluidity of slag in coal gasifier

The invention discloses a method for detecting fluidity of slag in a coal gasifier. The method comprises the following steps of: acquiring a sound wave signal; preprocessing the sound wave signal; extracting feature parameters of the sound wave signal; building a prediction model; and detecting the fluidity of the slag. The method for detecting the fluidity of the slag in the coal gasifier by combining an acoustic emission sensor or an acceleration sensor and a wave guiding rod has the characteristics of stability, safety, environmental friendliness and the like, and is applicable to on-line detection of an industrial production process; a sound wave receiving device array is adopted, and measurement accuracy is improved by multi-sensor data fusion; and on-line detection of the fluidity of the slag is realized by a slag fluidity index number detecting technology based on sound wave detection. Compared with the prior art, the method is sensitive and is high in detection accuracy; and early warning of slag blockage is realized by a slag blockage early warning and control technology based on slag fluidity index number detection, the viscosity of the slag can be controlled within a range above or below an objective value by 5%, and the slag blockage is effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

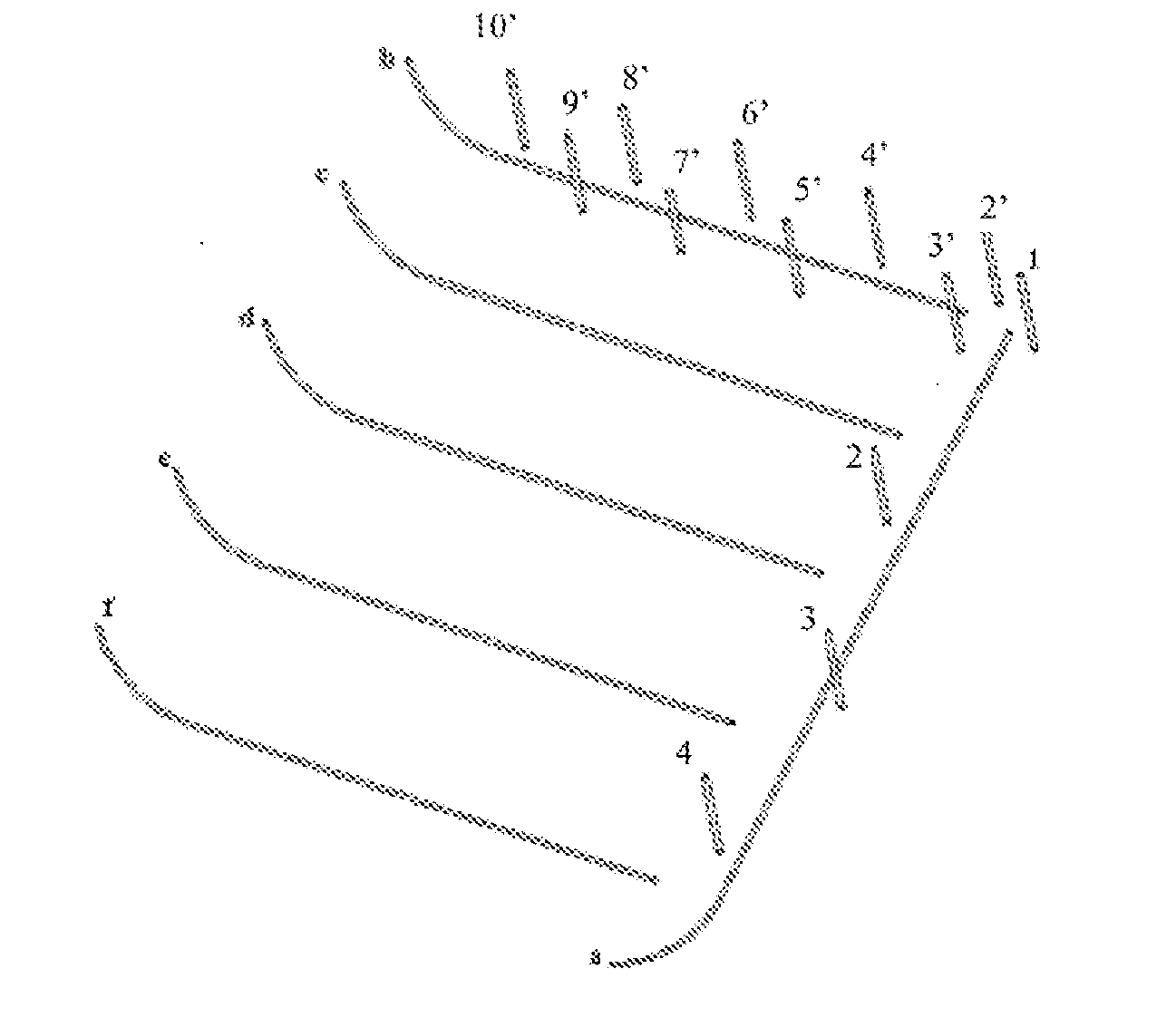

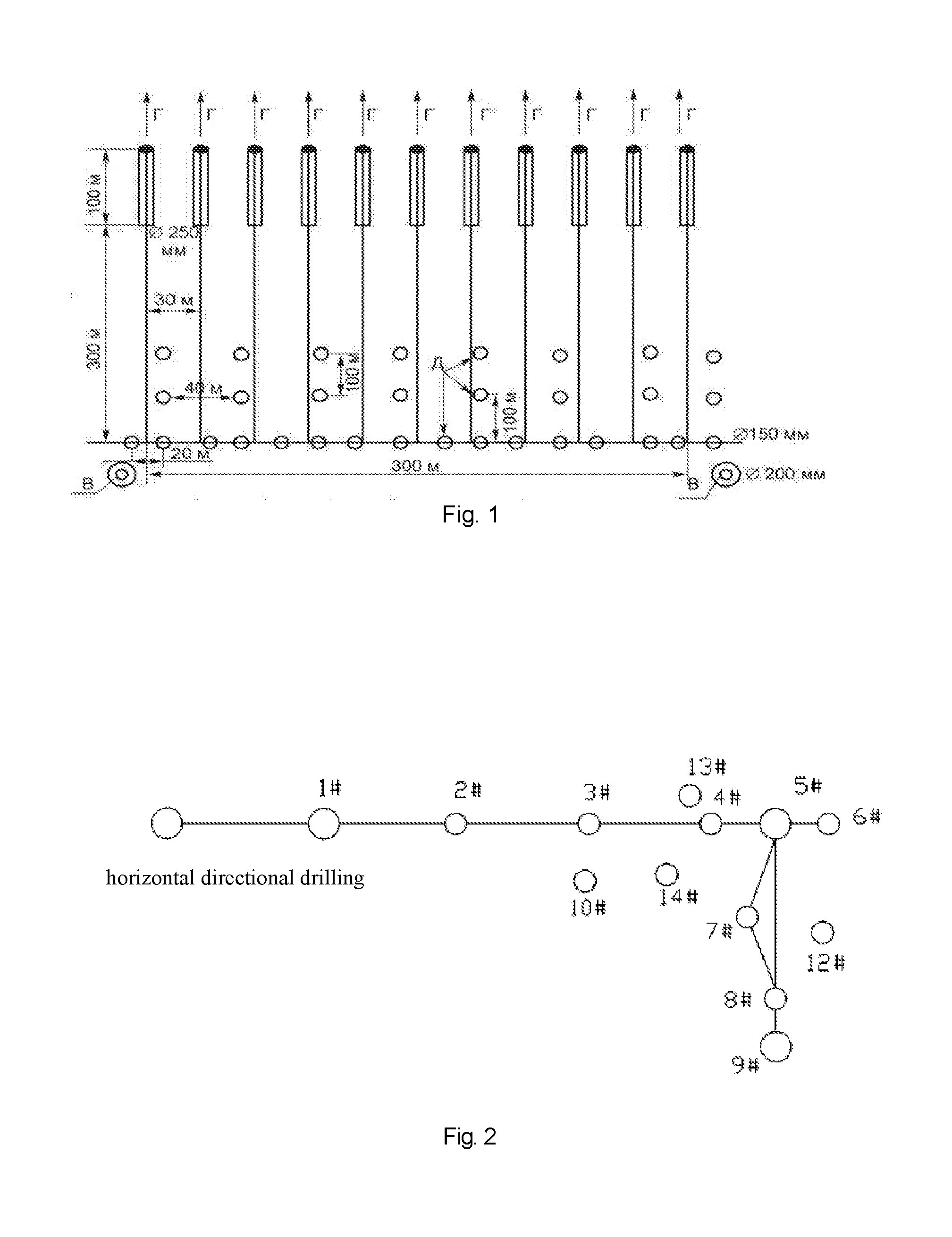

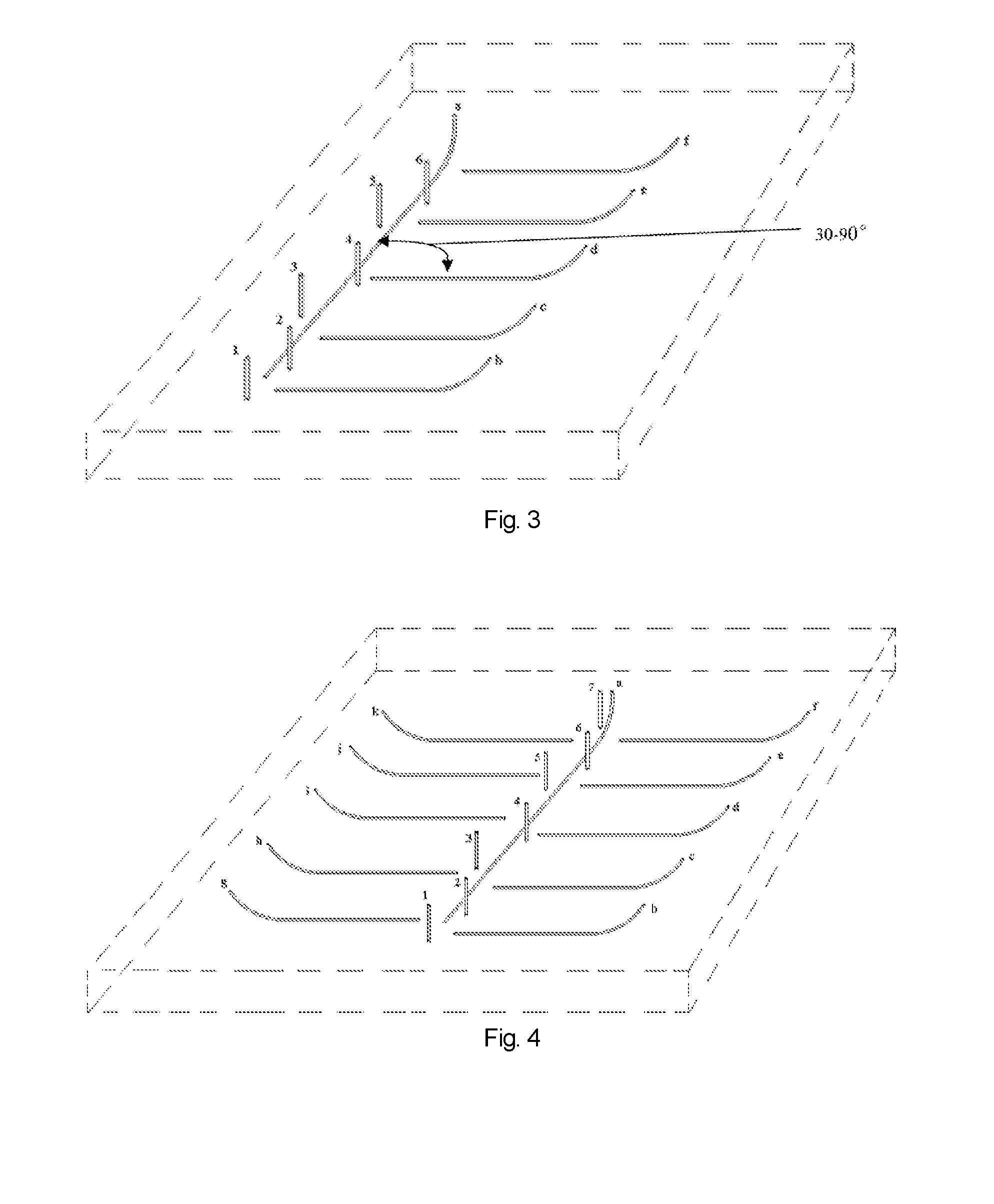

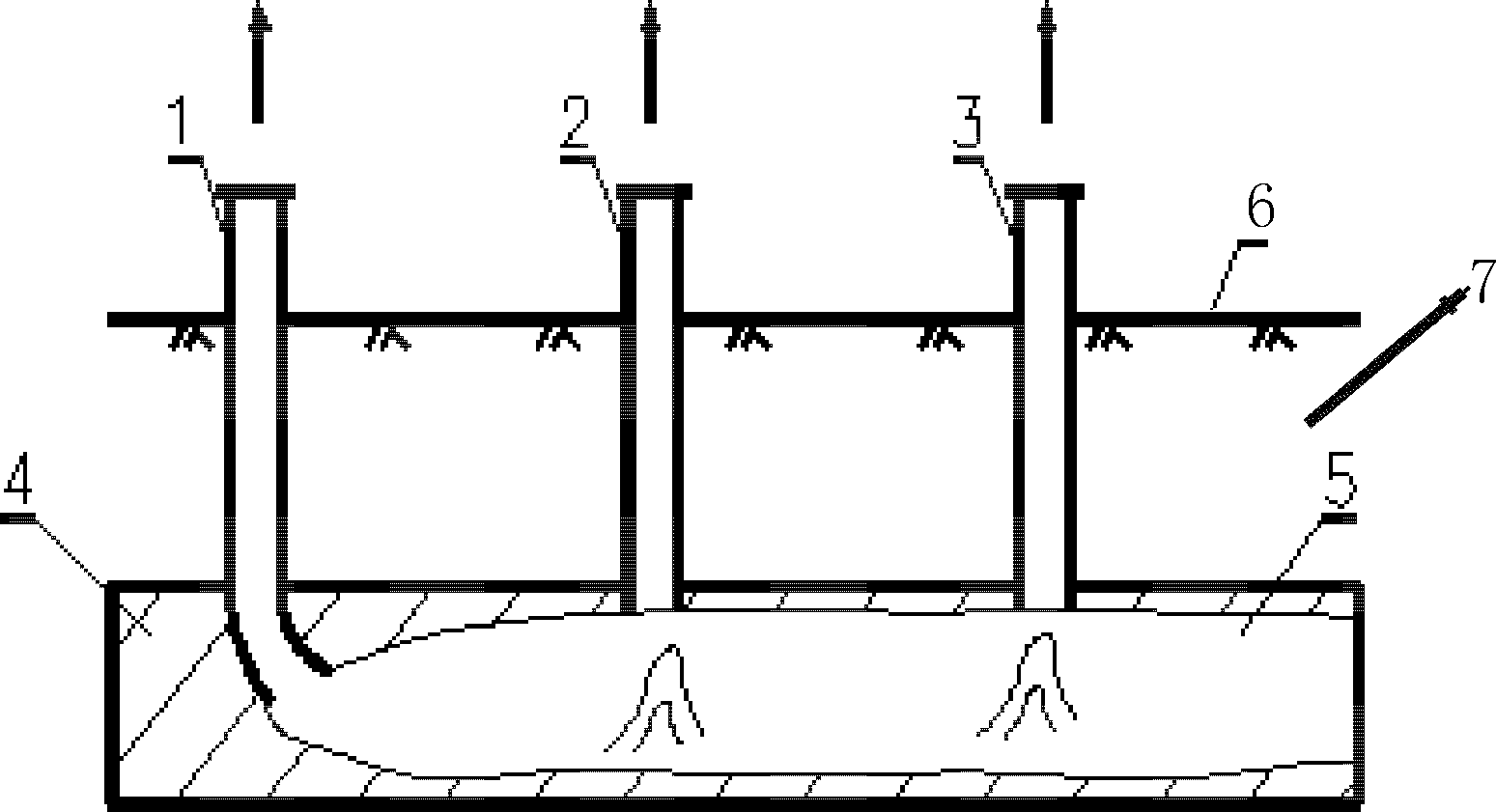

Underground coal gasification furnace and underground coal gasification method

InactiveUS20160194945A1Shorten speedUnstable structureConstructionsFluid removalWell drillingDirectional drilling

An underground coal gasification furnace comprises an ignition system and a gas injection system. The ignition system is provided with a first vertical drilling well and a first horizontal directional drilling well in communication with the first vertical drilling well. The gas injection system is provided with a second drilling well introduced into a coal seam. At least one second horizontal directional drilling wells of a horizontal section in the coal seam serves as the second drilling well. Also provided is an underground coal gasification method. The method comprises: enabling a flaming fire region of a first horizontal directional drilling well to withdraw in a second horizontal directional drilling well until withdraw to near a coal feeding point. The underground coal gasification furnace eliminates the defects of low cut-through speed and unstable structure in a gasification production stage in the prior art.

Owner:ENN COAL GASIFICATION MINING

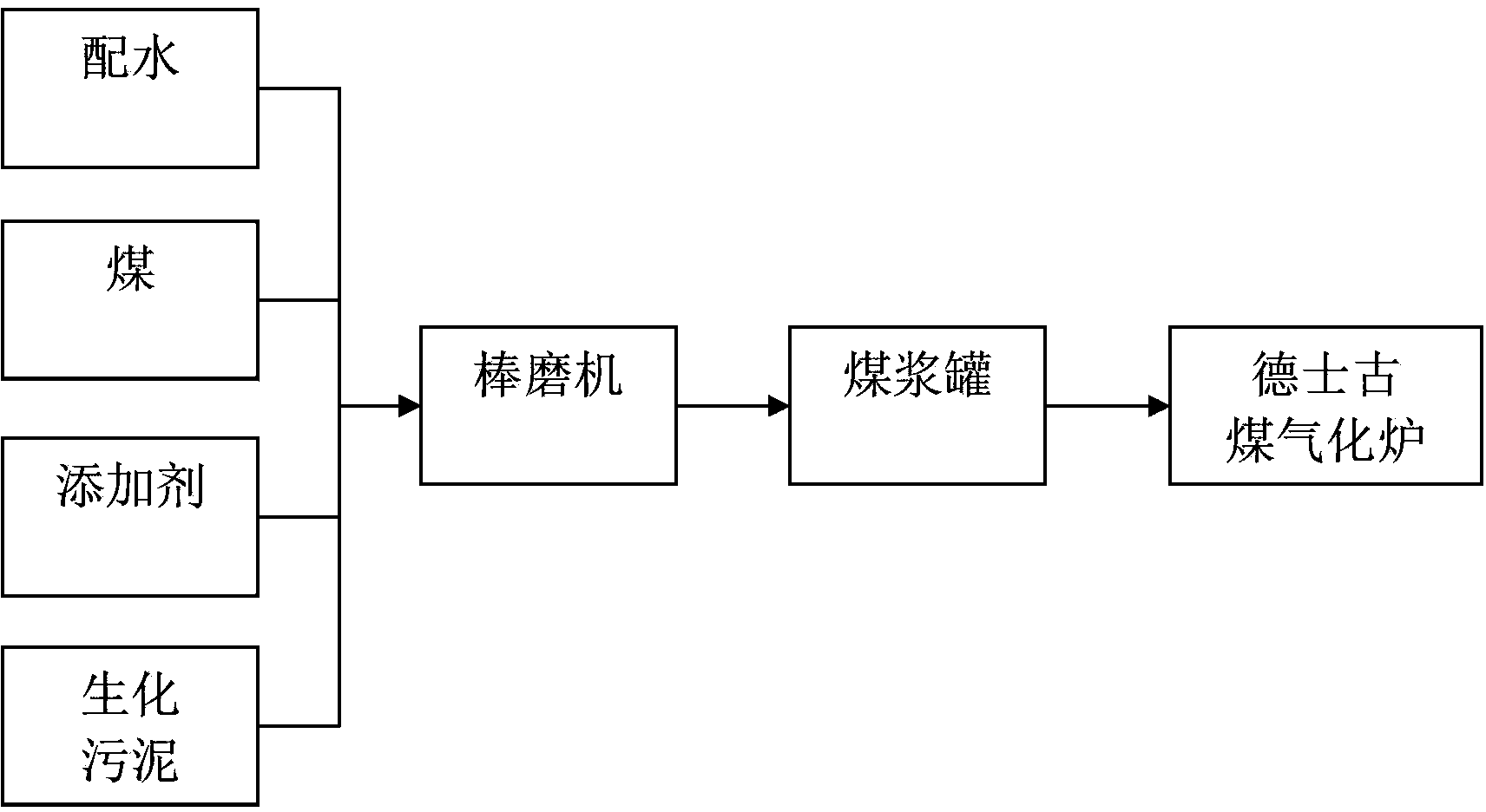

Biochemical sludge processing method

The invention relates to a biochemical sludge processing method; biochemical sludge is mixed in the preparation of water coal slurry, and the water coal slurry is gasified at high temperature by use of a texaco coal gasification furnace, so that the biochemical sludge is completely gasified for n implementation of harmless biochemical sludge, in the gasification process, the water coal slurry is decomposed into process gas, and the end product is hydrogen. According to the biochemical sludge processing method, the biochemical sludge can be directly used for the preparation of the coal water slurry without drying, so that the cost of drying the biochemical sludge is saved; by use of the texaco coal gasification furnace in the prior art for processing the coal water slurry with the biochemical sludge, biochemical sludge treatment equipment investment is reduced, no new processing equipment is needed, and the method has good economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

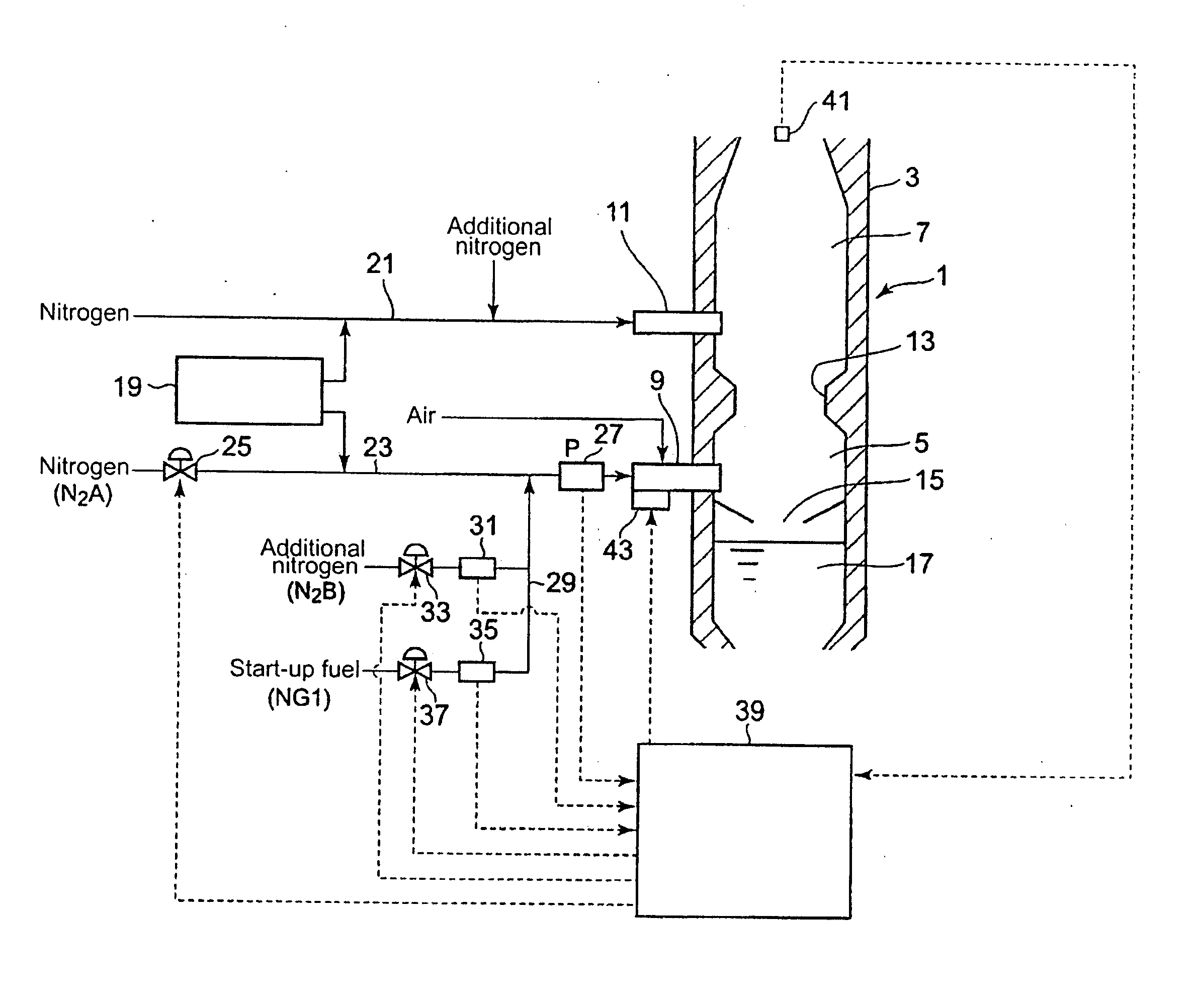

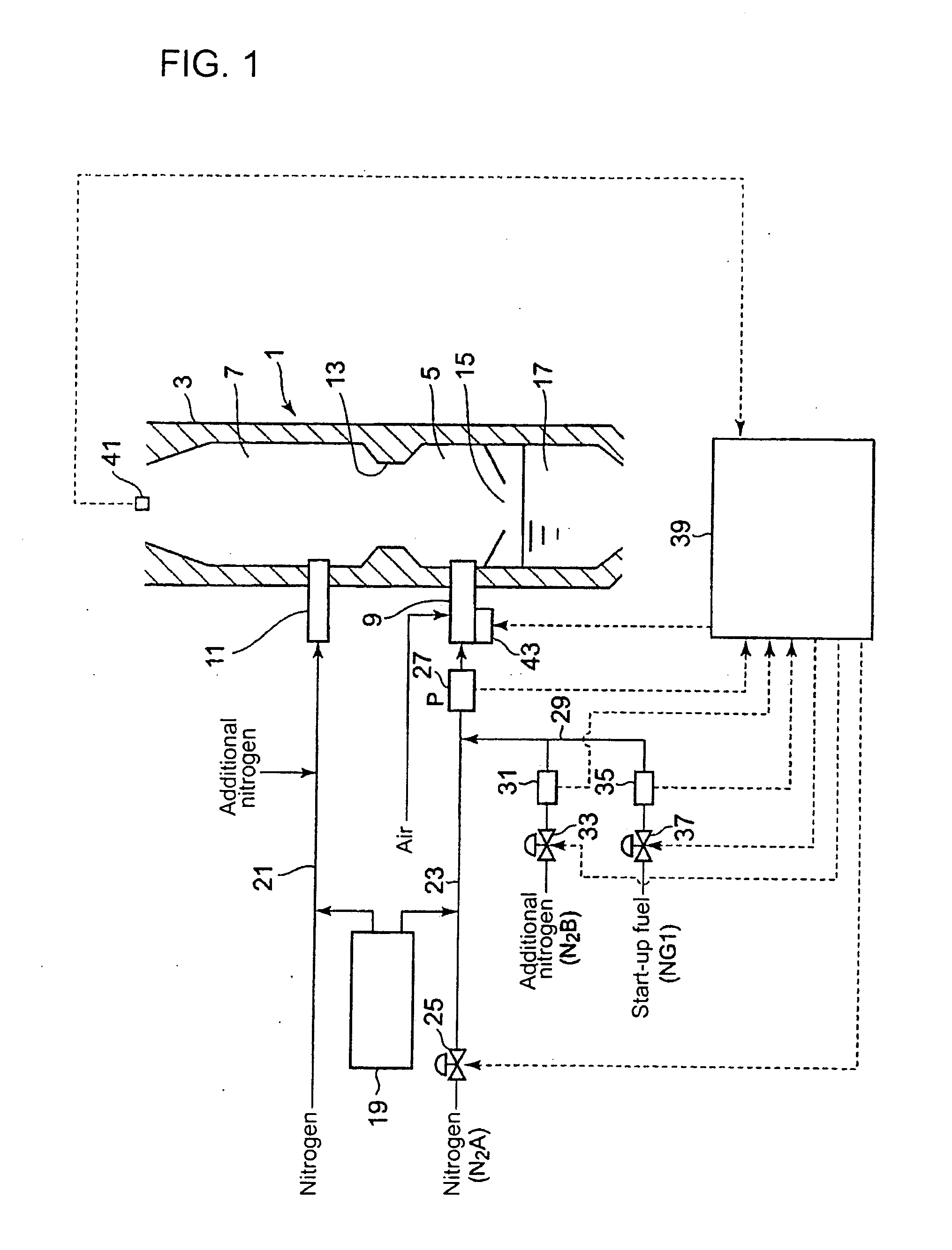

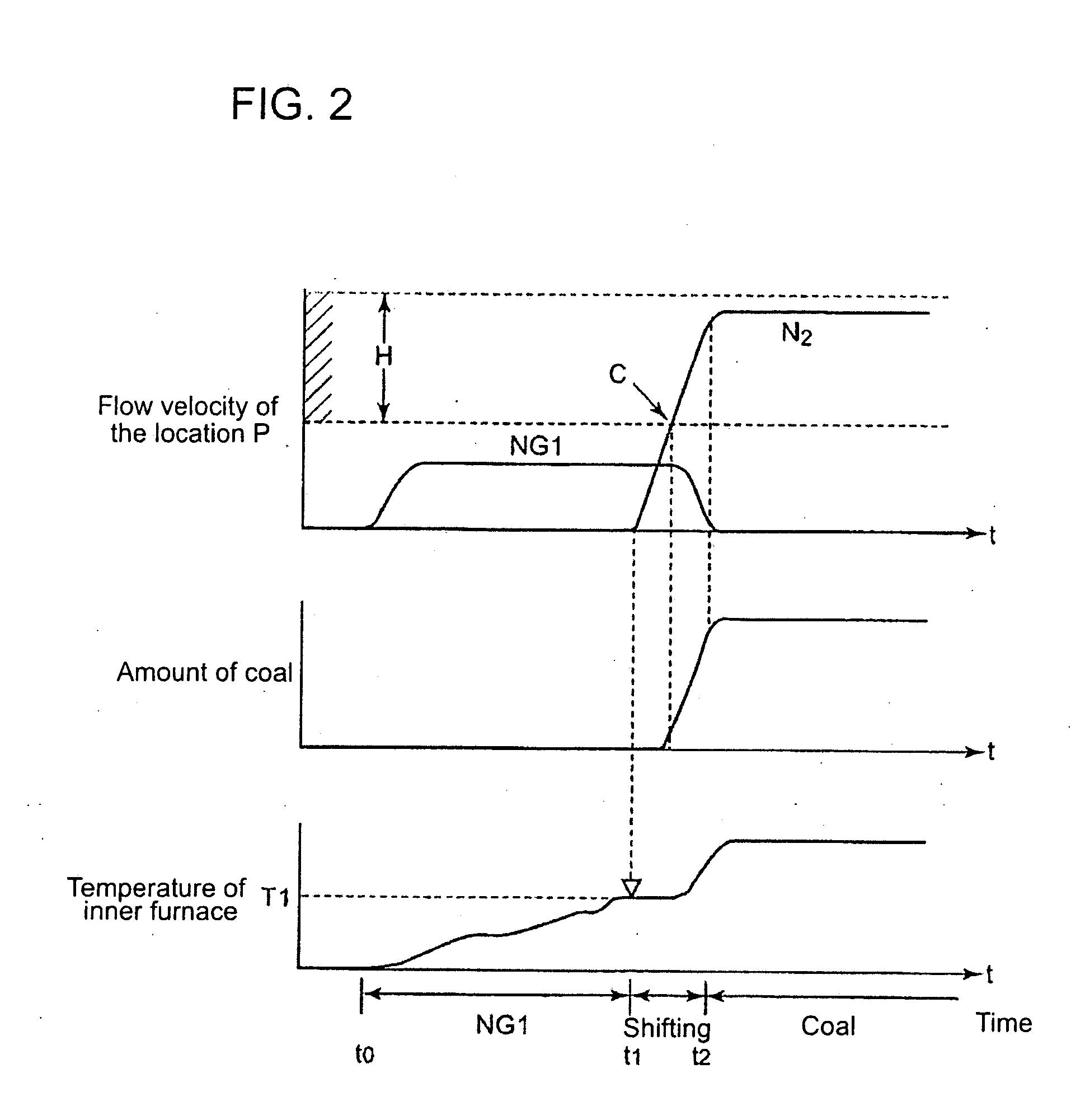

Starting method of coal gasifier and starting device therefor

ActiveUS20100180503A1Inhibition heightMultiple metal hydridesCarburetting by solid carbonaceous material pyrolysisCombustion chamberCombustor

In a coal gasification furnace adapted to feed pulverized coal thereinto by the use of inert carrier gas and gasify the same, any startup burner can be unnecessitated thereby eliminating any startup combustion chamber. Further, even in the use of a startup burner, it is smaller and lighter in weight than conventional startup burners, allowing the startup combustion chamber to be compact and limiting the height of the entirety of the gasification furnace. As a characteristic feature, a pulverized coal fuel supply passageway (23) to a combustor burner (9) is provided at its midstream portion with a startup gas supply passageway (29) for supply of a startup combustible gas (NG1). After reaching of the temperature of the furnace interior to a first temperature (T1) allowing ignition of pulverized coal with reference to a detected value from furnace interior temperature detecting means (41), transition to combustion by the pulverized coal and carrier gas is effected by increasing the input rate of pulverized coal and carrier gas while decreasing the supply rate of combustible gas (NG1) from the startup gas supply passageway (29).

Owner:MITSUBISHI POWER LTD

Dry coal dust gasification furnace for carbon dioxide emission reduction

The invention belongs to a fine coal gasification generator, in particular to a fine coal gasification furnace which can reduce the emission of carbon dioxide and improve the yield of coal gas. A gasification furnace and a feeding device are used as main production devices, and fine coal, water and oxygen are used as main raw materials. The technical key points are as follows: the gasification furnace is provided with a carbon dioxide feeding port which is communicated with a carbon dioxide storage tank and by which carbon dioxide is supplied to the gasified coal, and the carbon dioxide takes part in the reaction in the gasification furnace, thereby improving the yield of the coal gas and reducing the emission of the carbon dioxide.

Owner:彭思尧

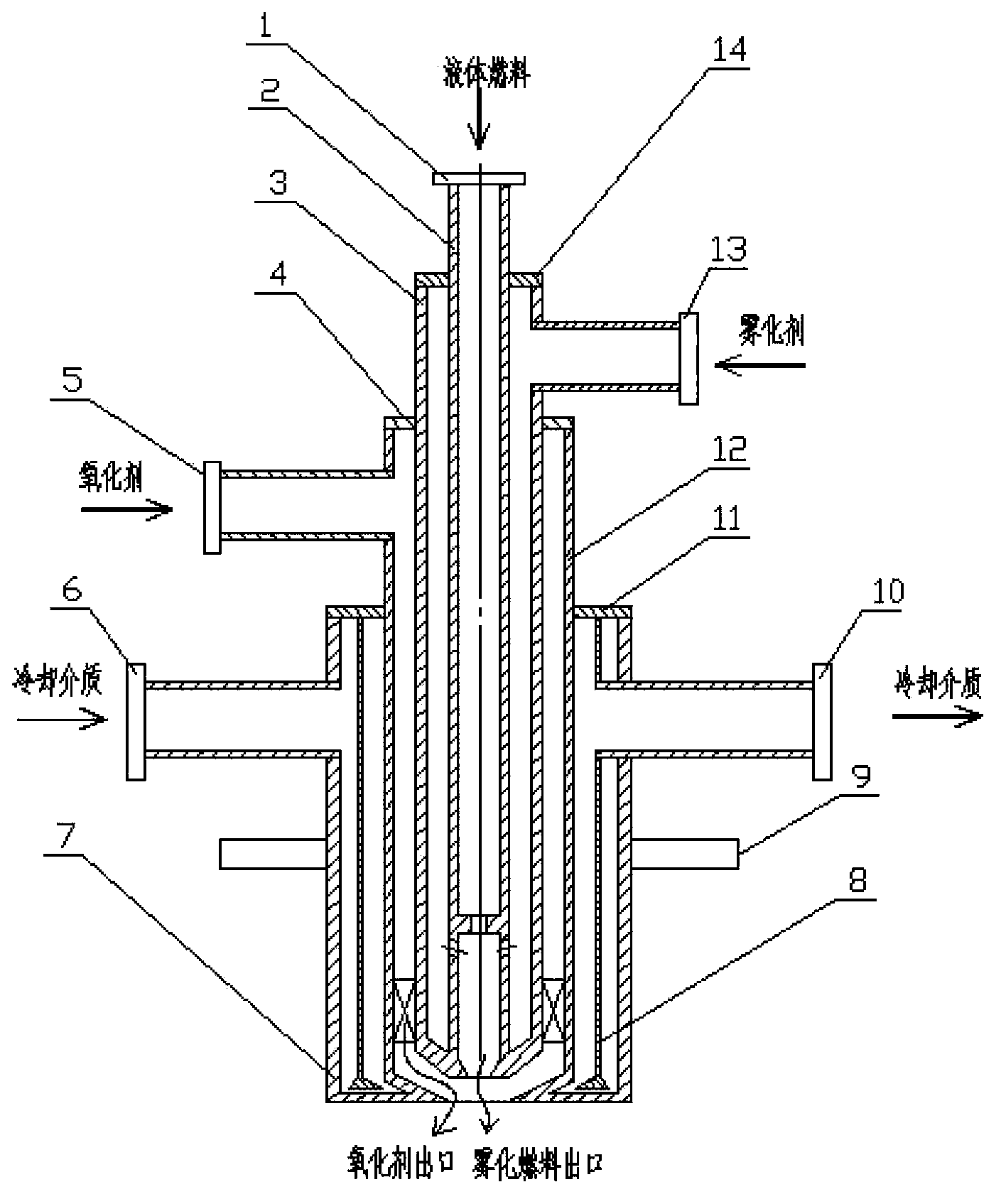

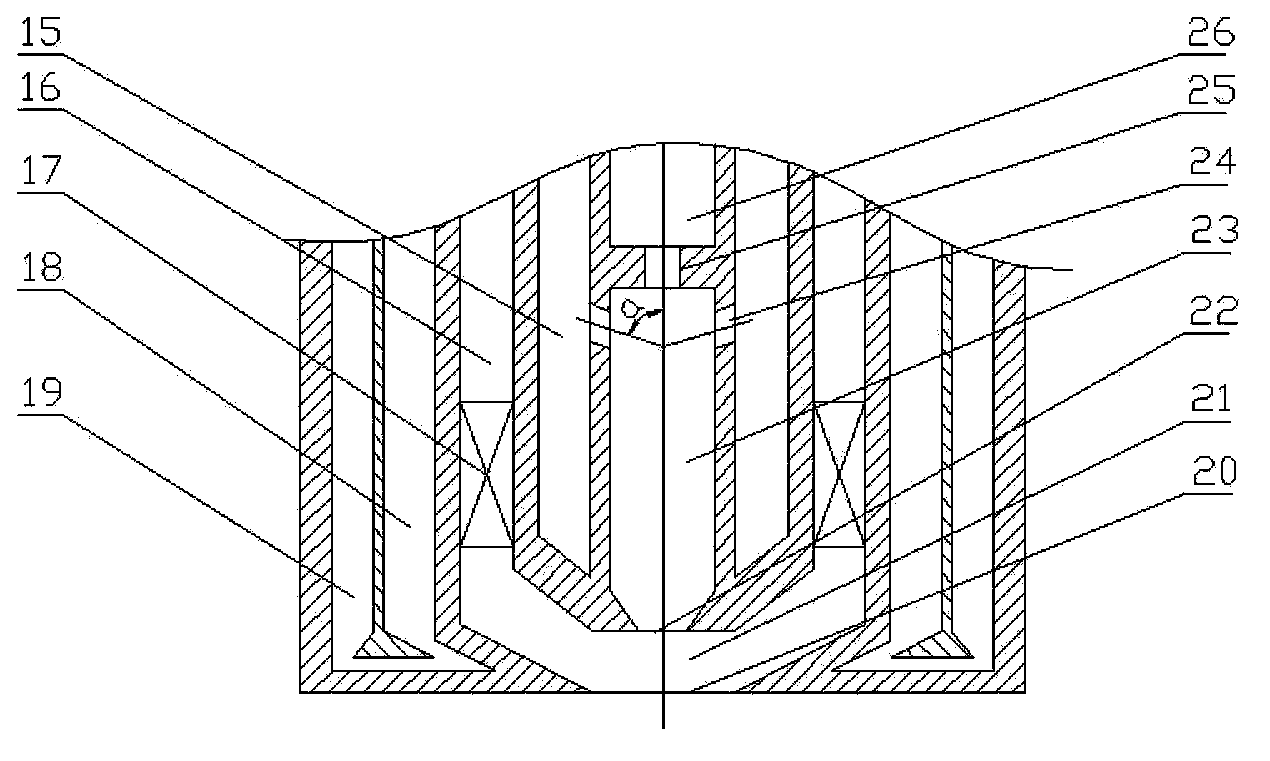

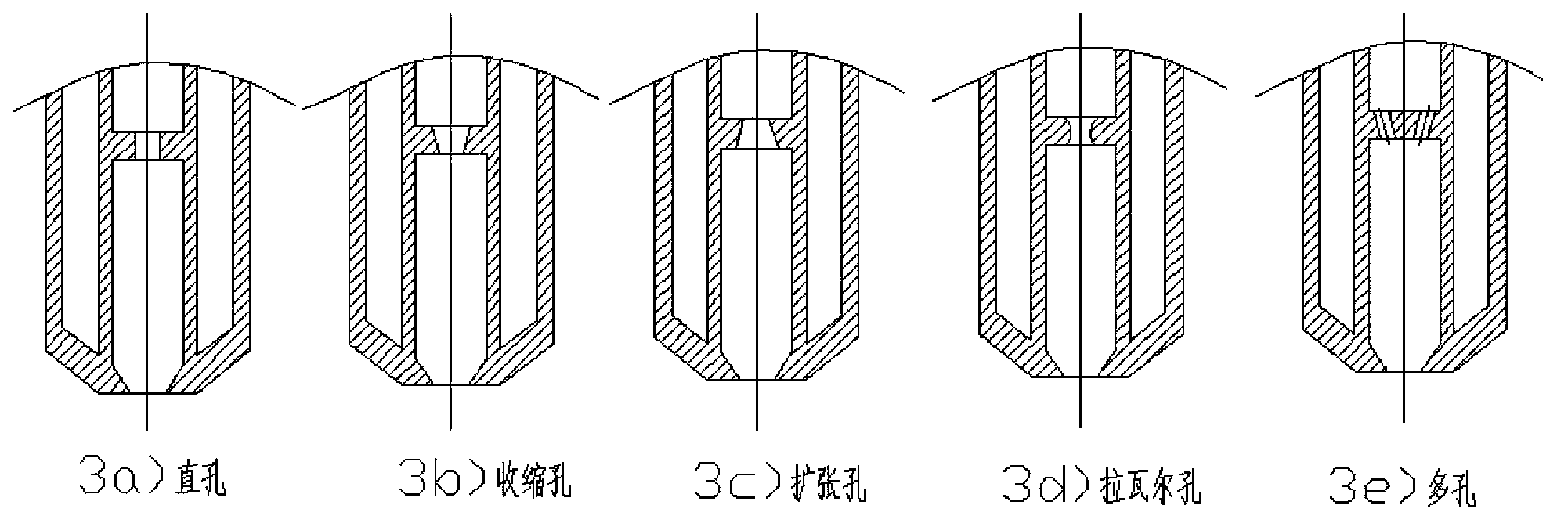

Variable-pressure and variable-working-condition oil burning nozzle

ActiveCN103822207AExtended service lifeImprove anti-ablation performanceBurnersFurnace temperatureEngineering

The invention provides a variable-pressure and variable-working-condition oil burning nozzle. The variable-pressure and variable-working-condition oil burning nozzle is a technical burning nozzle which is adapt to high-pressure environments, applicable to coal gasifiers, provided with igniting and burning capabilities in an operation process with random fixed pressure, variable pressure and continuous variable working conditions in a pressure range of 0-2.0MPaG, and used for igniting the coal gasifiers. The burning nozzle comprises body sleeves and a premix jet flow head. The body sleeves are in coaxial arrangement and include a liquid fuel outer sleeve, an atomizing agent outer sleeve and an oxidizing agent outer sleeve sequentially from inside to outside, and an annular space between each two sleeves form a medium passage. The premix jet flow head comprises inner and outer contraction type sonic or subsonic nozzles and two-level atomizing and mixing chambers and capable of realizing efficient atomizing and mixing of fuels and oxidizing agents and stable ignition and combustion. A double-layer closed annular passage cooling structure is arranged on the outermost layers of the head and the body of the burning nozzle, the burning nozzle is hermetically connected with a coal gasifier body through a mounting flange, and tightness and ablation avoidance of the burning nozzle under the furnace pressure of 0-8MPaG and at the furnace temperature of 1200-1700DEG C can be guaranteed.

Owner:CHANGZHENG ENG

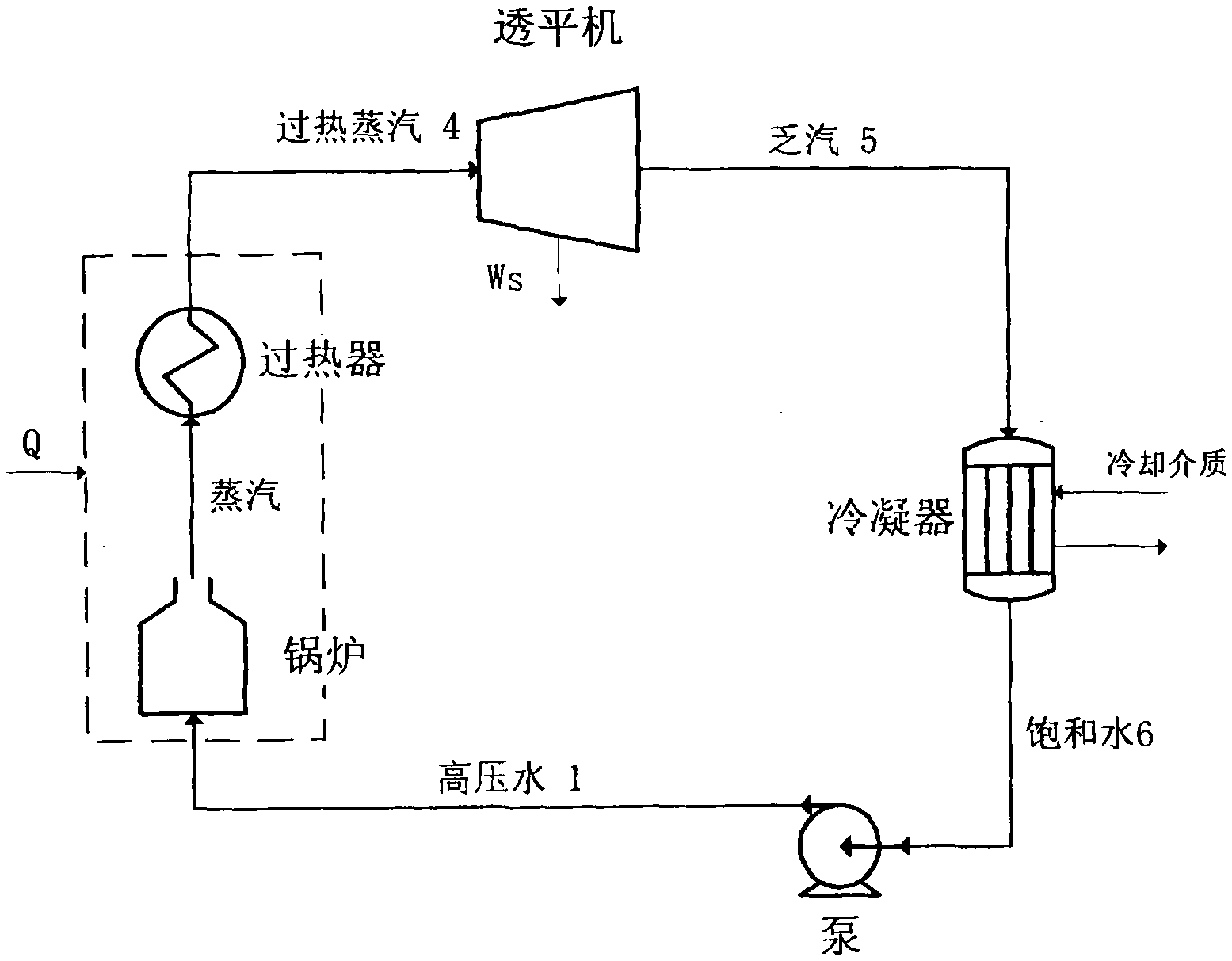

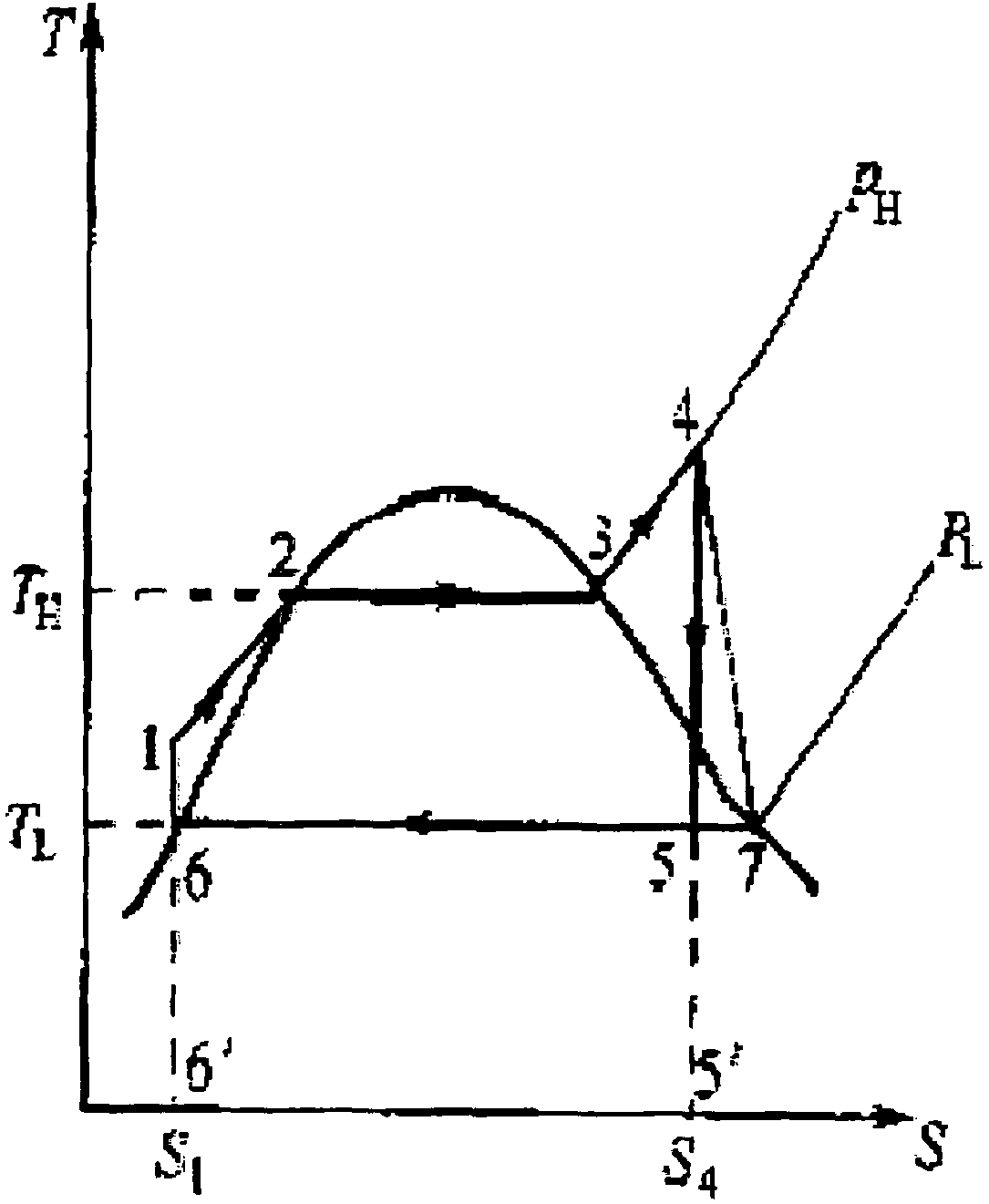

Coupling method of coal gasification process, residual carbon oxidation process and steam turbine power generation process

The invention discloses a coupling method of a coal gasification process, a residual carbon oxidation process and a steam turbine power generation process. The technology comprises the steps of: cooling a high temperature reacted mixture departing from a coal gasifier so as to obtain high temperature and high pressure steam, which is then subjected to power generation in a Rankine cycle, separating the reacted mixture so as to obtain slurry-like residual carbon and syngas, leaving the slurry-like residual carbon to complete oxidation in subcritical or supercritical water with the presence of excess oxygen, thus obtaining a mixture of carbon dioxide and water, introducing the low temperature water obtained from decompressional expansion and gas-liquid separation of the mixture of carbon dioxide and water, as well as the low temperature syngas obtained from decompressional expansion of the syngas into a condenser of the Rankine cycle, or first using the low temperature water and the low temperature syngas to cool cooling water, then leading the cooling water the condenser of the Rankine cycle so as to serve as a cooling medium for exhaust steam cooling, thus improving the power generation efficiency of the Rankine cycle.

Owner:ENN SCI & TECH DEV

Process for producing molten hot molten iron

InactiveCN101724721ANo emissionsReduce the use effectBlast furnace detailsProcess efficiency improvementSlagExhaust gas emissions

The invention belongs to the technical field of metallurgy, and in particular relates to a process for producing hot molten iron. The process comprises the following steps: directly blowing high-temperature reducing gas generated by a coal gasifier from a tuyere of a hearth of a blast furnace, feeding lump ore / pellet, limestone / dolomite and coke of a stock yard from a roof of the blast furnace, performing purification treatment on blast-furnace gas conducted out from the blast furnace roof through a roof coal dry-method dust catcher, and discharging molten iron and slag through an iron port. A product output by the process is high-quality hot molten iron, water slag and high-quality blast-furnace gas. The blast furnace has no a pulverized coal blowing system and no hot blast furnace system, has a violent reducing atmosphere turning region caused by the tuyere part of the blast furnace, and has no emission of dust, waste liquid and exhaust gas. The process can be widely applied to the production of the hot molten iron.

Owner:CISDI ENG CO LTD

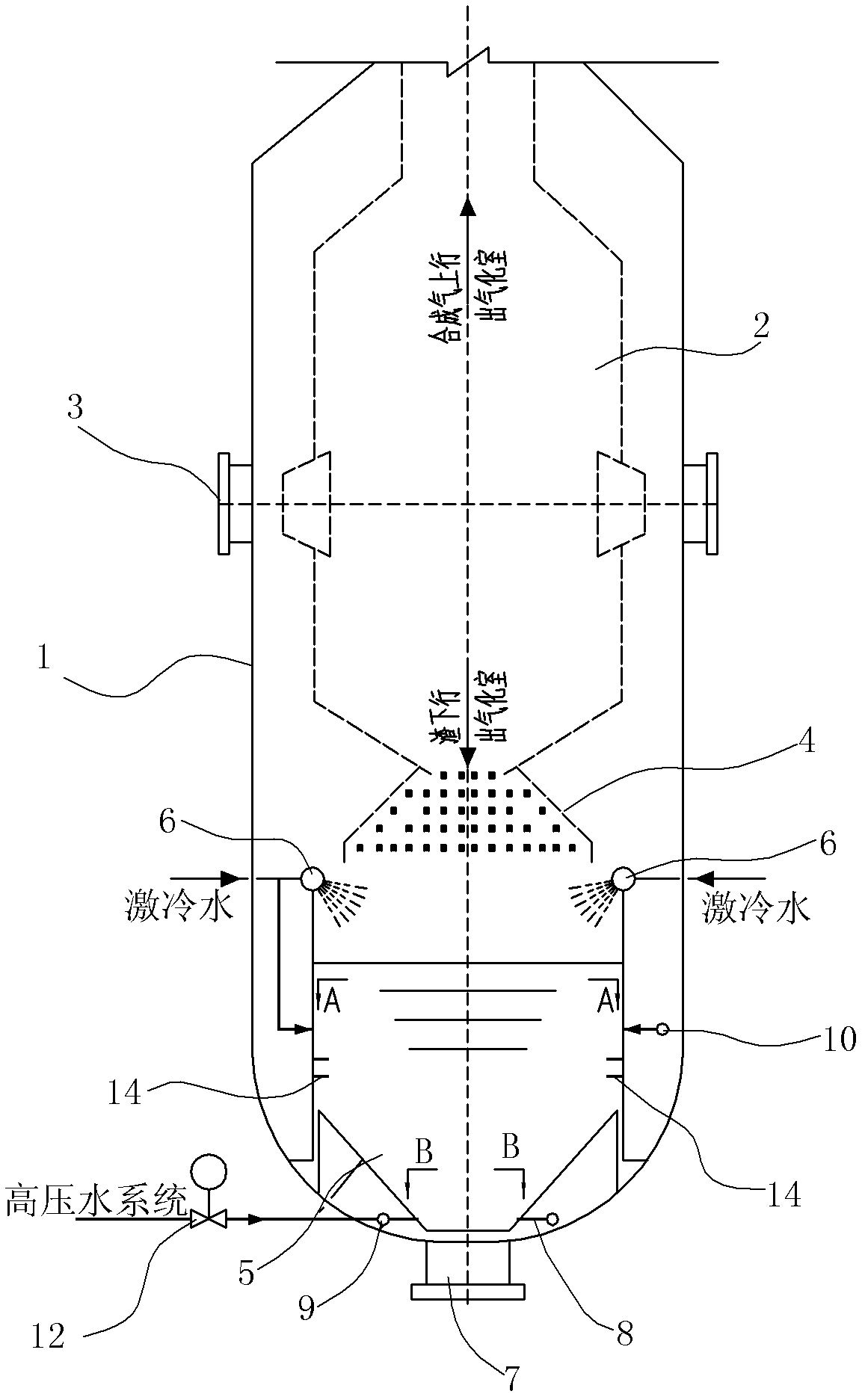

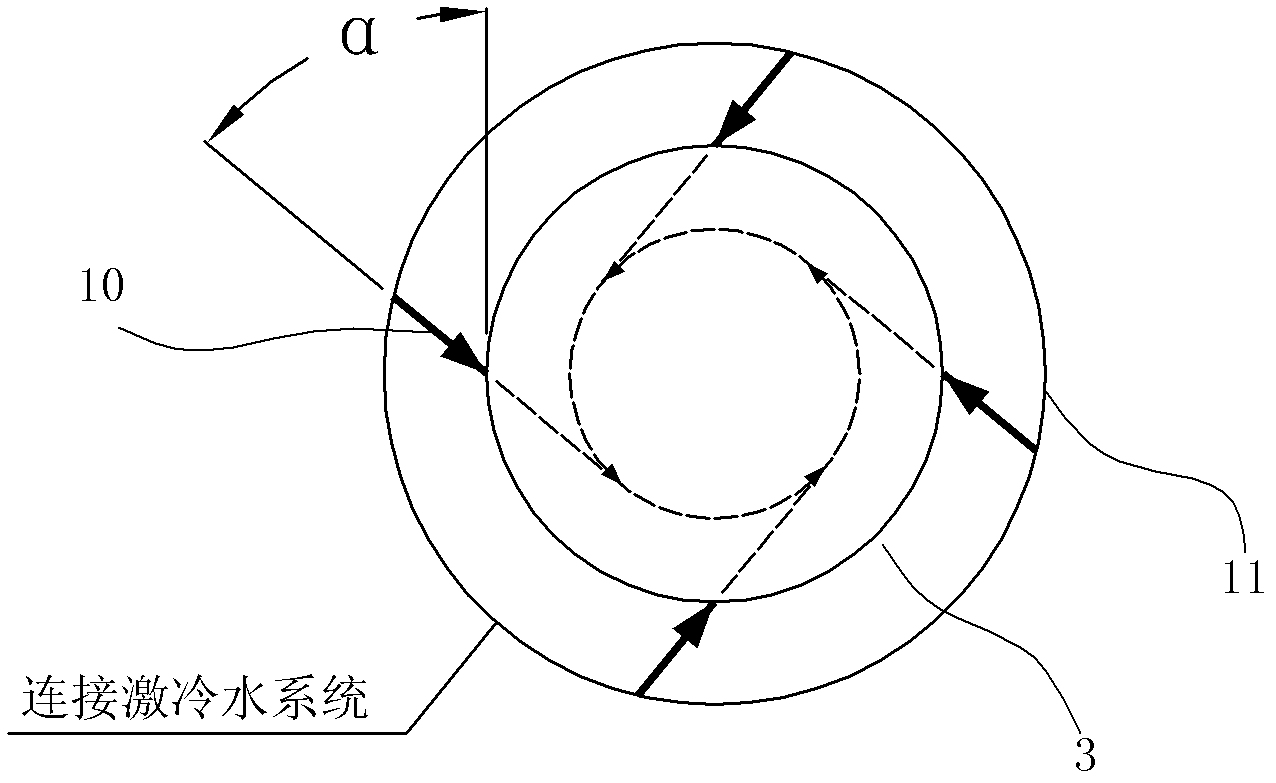

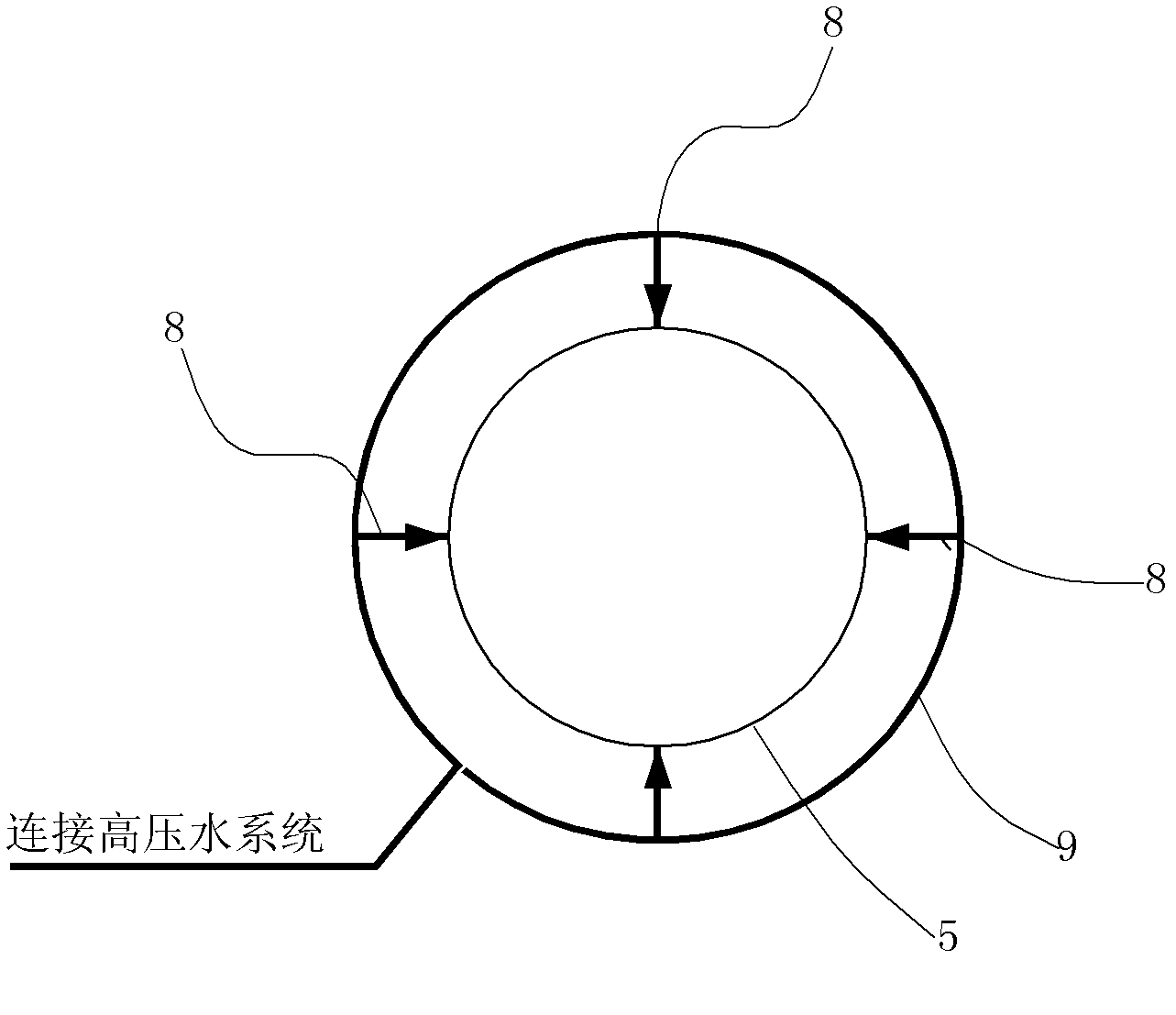

Slag-discharge system of pulverized coal gasification furnace

ActiveCN102634379ABroken GuaranteeImprove crushing effectGranular/pulverulent flues gasificationSlagChilled water

The invention relates to a slag-discharging system of a pulverized coal gasification furnace. A gasification chamber communicated with a feed port is arranged in the shell of the pulverized coal gasification furnace. A slag chamber is positioned below the gasification chamber and is communicated with the gasification chamber through a slag screen. The upper end of the slag chamber is provided with a chilling circular pipe for spraying chilling water towards coal slag entering the slag chamber, and the lower end of the slag chamber is communicated with a slag hole arranged at the bottom of the shell through a tapered slag hopper. The slagging system of the pulverized coal gasification furnace is characterized in that the peripheral wall of the slag chamber is provided with a plurality of water injection nozzles connected with a chilling water system. Compared with the prior art, the slagging system of the pulverized coal gasification furnace can effectively avoid slag blockage in the slag chamber, therefore, the gasification furnace can stably operate for a long term, the maintenance cost is saved, and the production efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

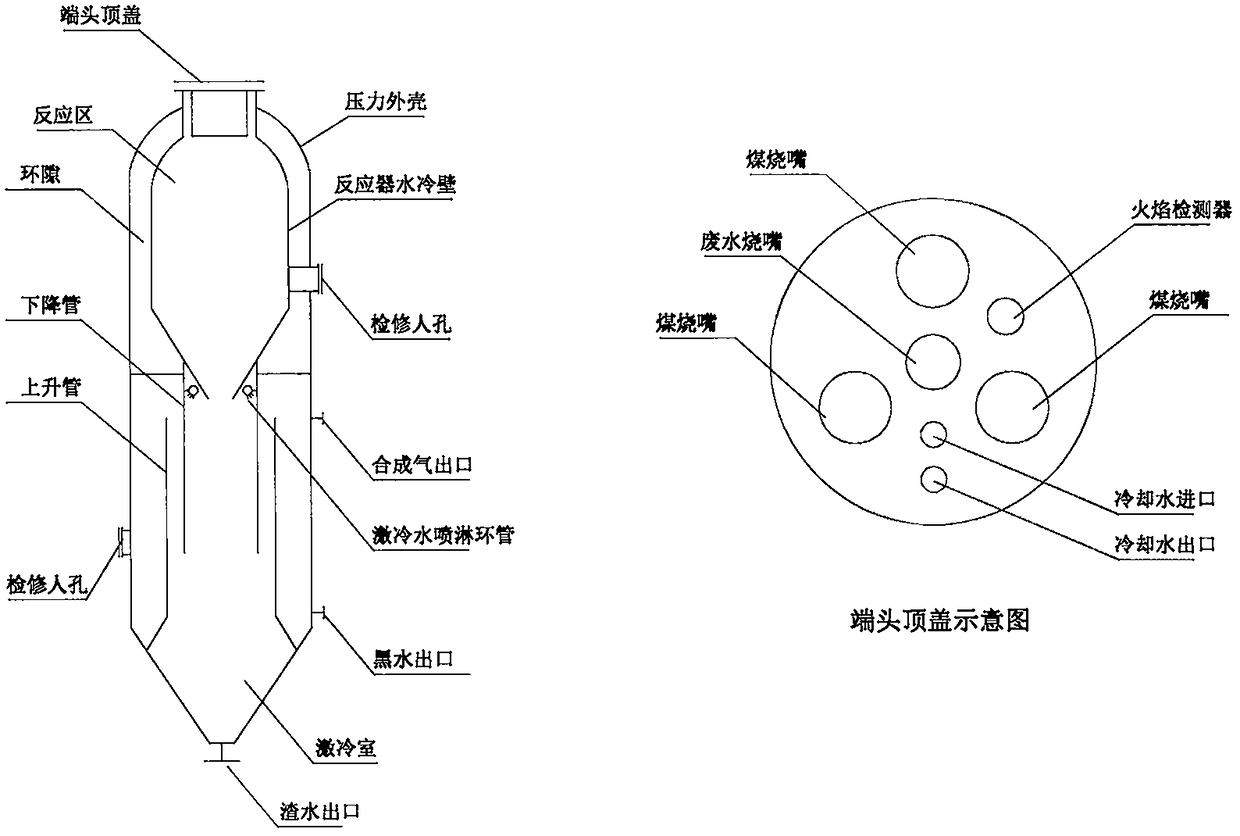

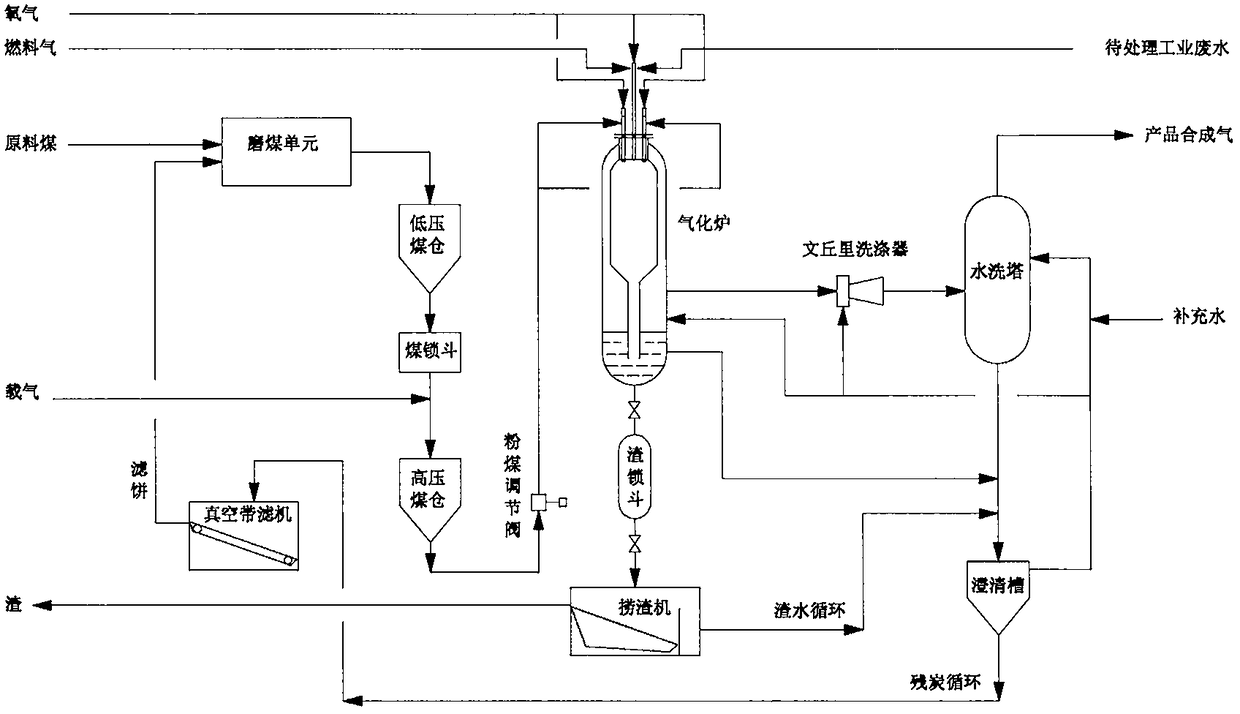

Coal gasification furnace for recycling industrial wastewater and gasification process

InactiveCN108329952ALower oxygen consumptionSolve the pollution of the environmentGasification processes detailsGranular/pulverulent flues gasificationIndustrial effluentSlag

The invention discloses a coal gasification furnace for recycling industrial wastewater. The coal gasification furnace comprises a pressure-bearing furnace body, the top of the furnace body is provided with a top cover which is connected by a flange, a waste water burning nozzle and mounting openings of three coal burning nozzles surrounding the waste water burning nozzle are arranged in the center of the top cover, a reactor is isolated in the inner part of the furnace body by a water cooling wall, and a chilling water spraying ring is arranged below the slag opening in the bottom of the reactor, and a chilling chamber is provided with a descending pipe and an ascending sleeve pipe. The invention further relates to a gasification process using the gasification furnace.

Owner:北京瑞达科博技术有限公司

Furnace lining of coal gasifier and preparation method thereof

The invention relates to a furnace lining of a coal gasifier and a preparation method thereof. The technical scheme adopted by the invention is that the furnace lining consists of a working layer refractory castable and a permanent layer refractory castable. The working layer refractory castable comprises the following preparation steps: uniformly mixing calcium hexaluminate fine powder, alpha-Al2O3 micro powder, silicon micro powder, calcium aluminate cement and polycarboxylic acid, then mixing with calcium hexaluminate particles and calcium hexaluminate-alloy composite particles, adding water, stirring and curing. The permanent layer refractory castable comprises the following preparation steps: uniformly mixing corundum fine powder, alpha-Al2O3 micro powder, silicon micro powder, calcium aluminate cement and polycarboxylic acid, then mixing with corundum particles and corundum-alloy composite particles, adding water, stirring and curing. The furnace lining of the coal gasifier, prepared by the preparation method provided by the invention, can automatically adjust the temperature, is long in service life and can effectively solve the problems that a furnace shell of the coal gasifier is ultrahigh in temperature and high in energy consumption and is corroded by the enrichment of low-temperature mediums for the furnace shell.

Owner:WUHAN UNIV OF SCI & TECH

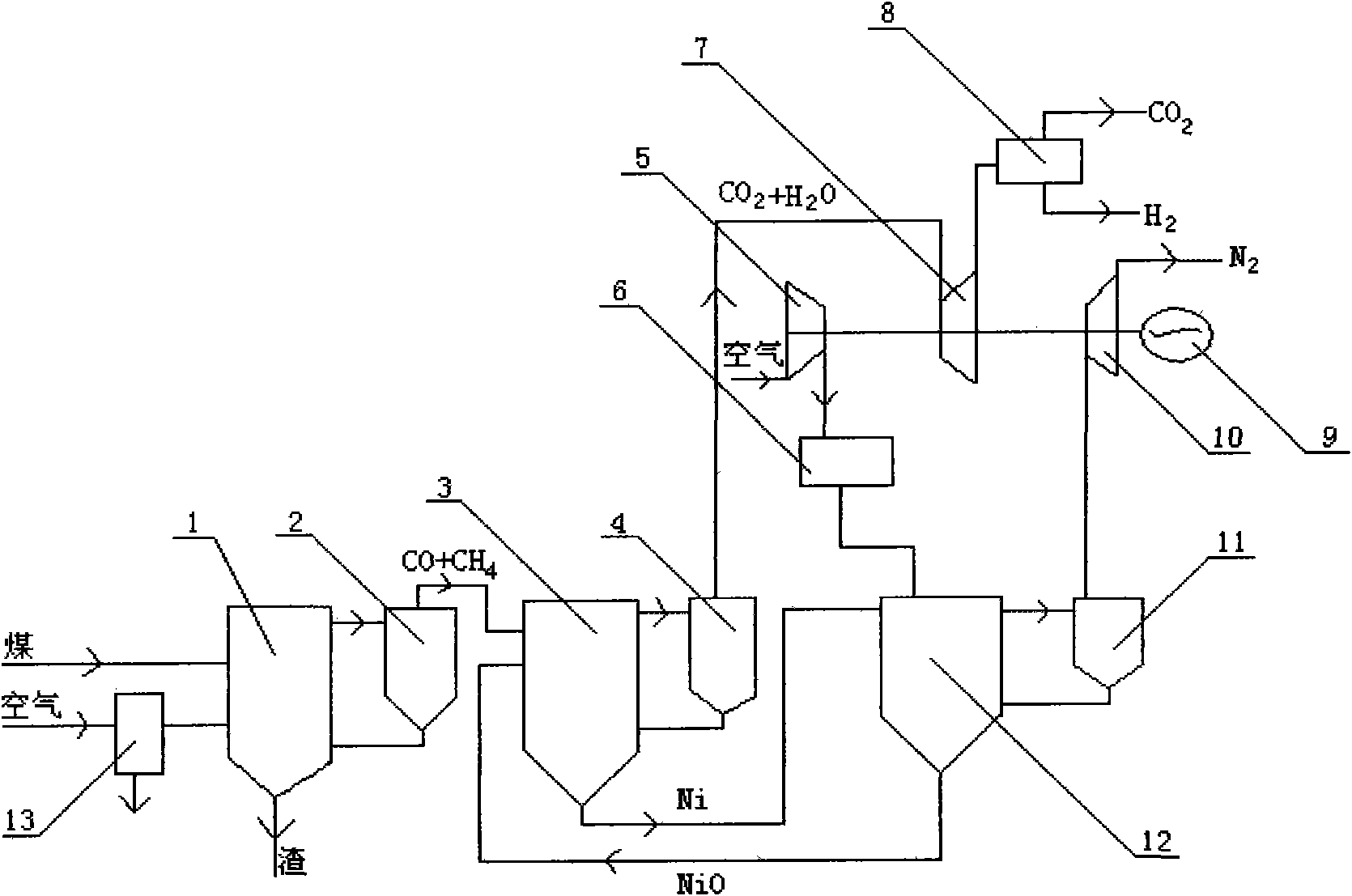

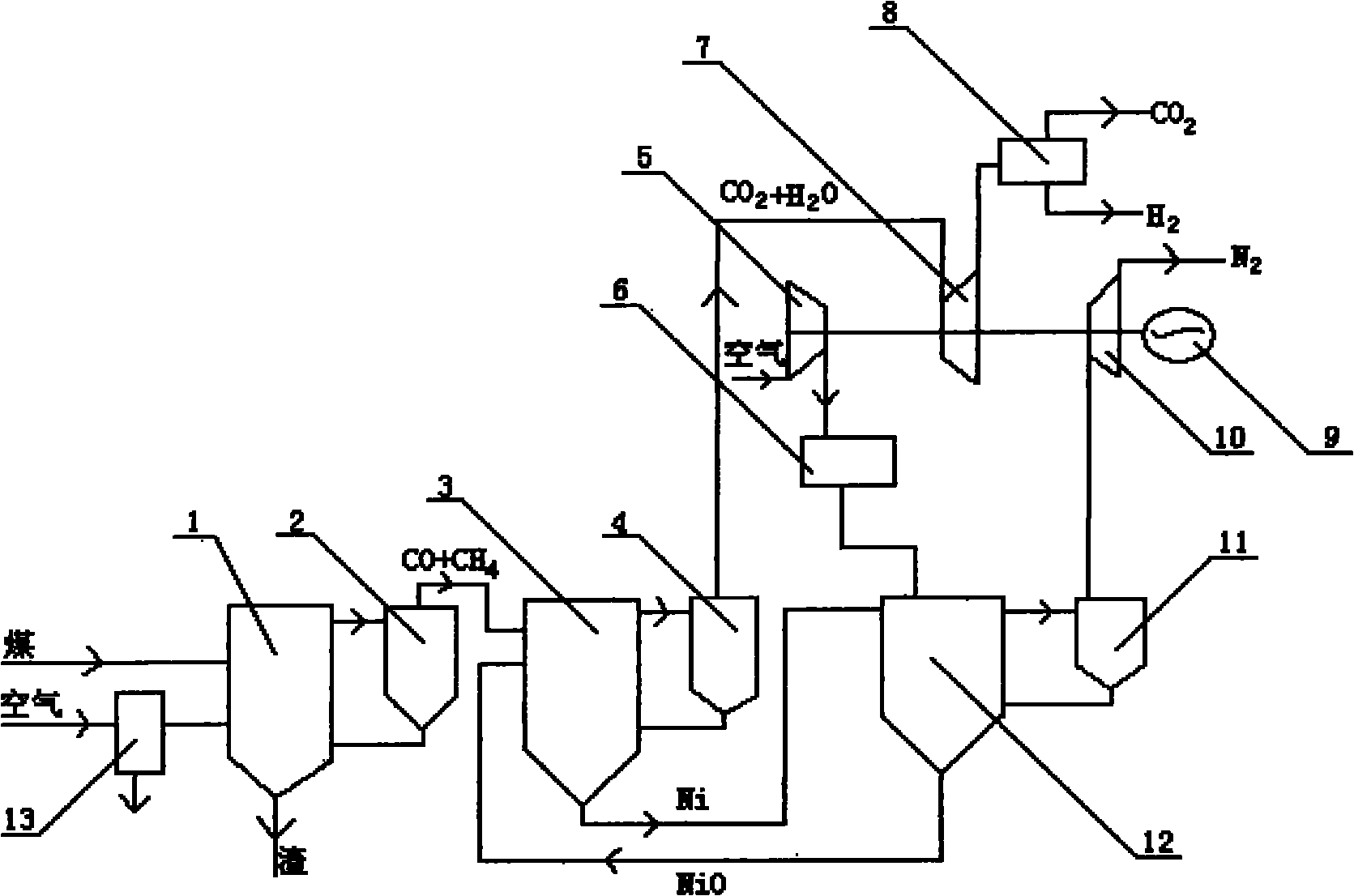

Coal chemical chain combustion generating process and device

InactiveCN102052102AEmission controlSteam engine plantsGranular/pulverulent flues gasificationCycloneCombustion

The invention discloses a coal chemical chain combustion generating process and a coal chemical chain combustion generating device, which are applied to occasions on which carbon dioxide needs to be absorbed for coal power generation. The device mainly comprises a coal gasification furnace, a coal cyclone separator, a reducer, a reducer cyclone separator, an oxidizer, an oxidizer cyclone separator, an air compressor, a first-stage turbine, a saturator, a second-stage turbine, a condenser and a generator. The process comprises the following steps of: gasifying coal into CO and CH4 in the gasification furnace; feeding the CO and the CH4 into the reducer; reacting the CO and the CH4 with NiO in the reducer so as to generate high-temperature and high-pressure pure CO2 gas; doing work in the first-stage turbine to drive the generator to generate power; condensing gas exhausted from the first-stage turbine by using the condenser to obtain pure CO2 gas and water; and recovering the pure CO2 gas. The process is flameless combustion technology, in which pure CO2 is separated in a chemical chain combustion mode, so that CO2 emission is controlled effectively.

Owner:SHAOXING UNIVERSITY

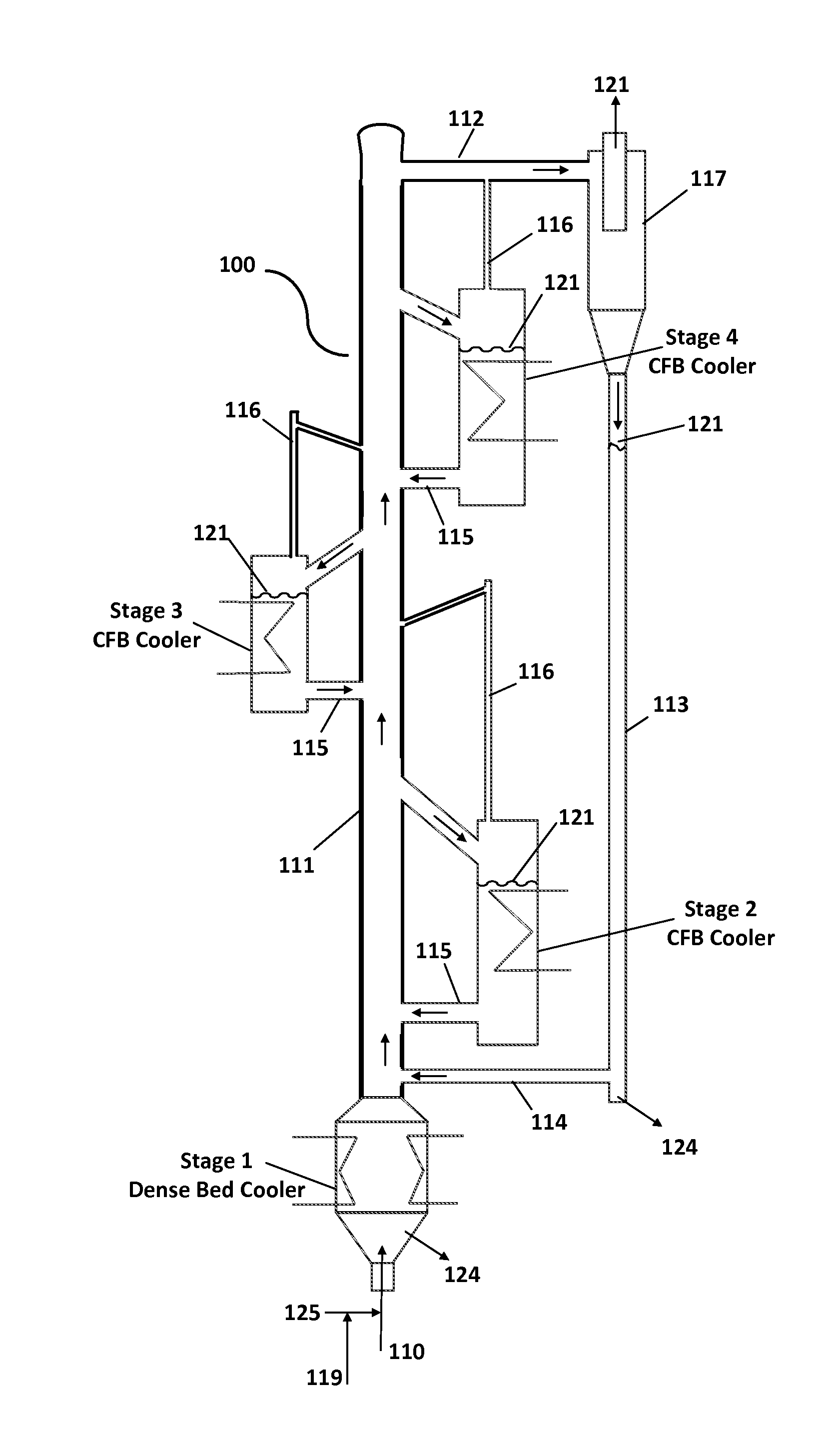

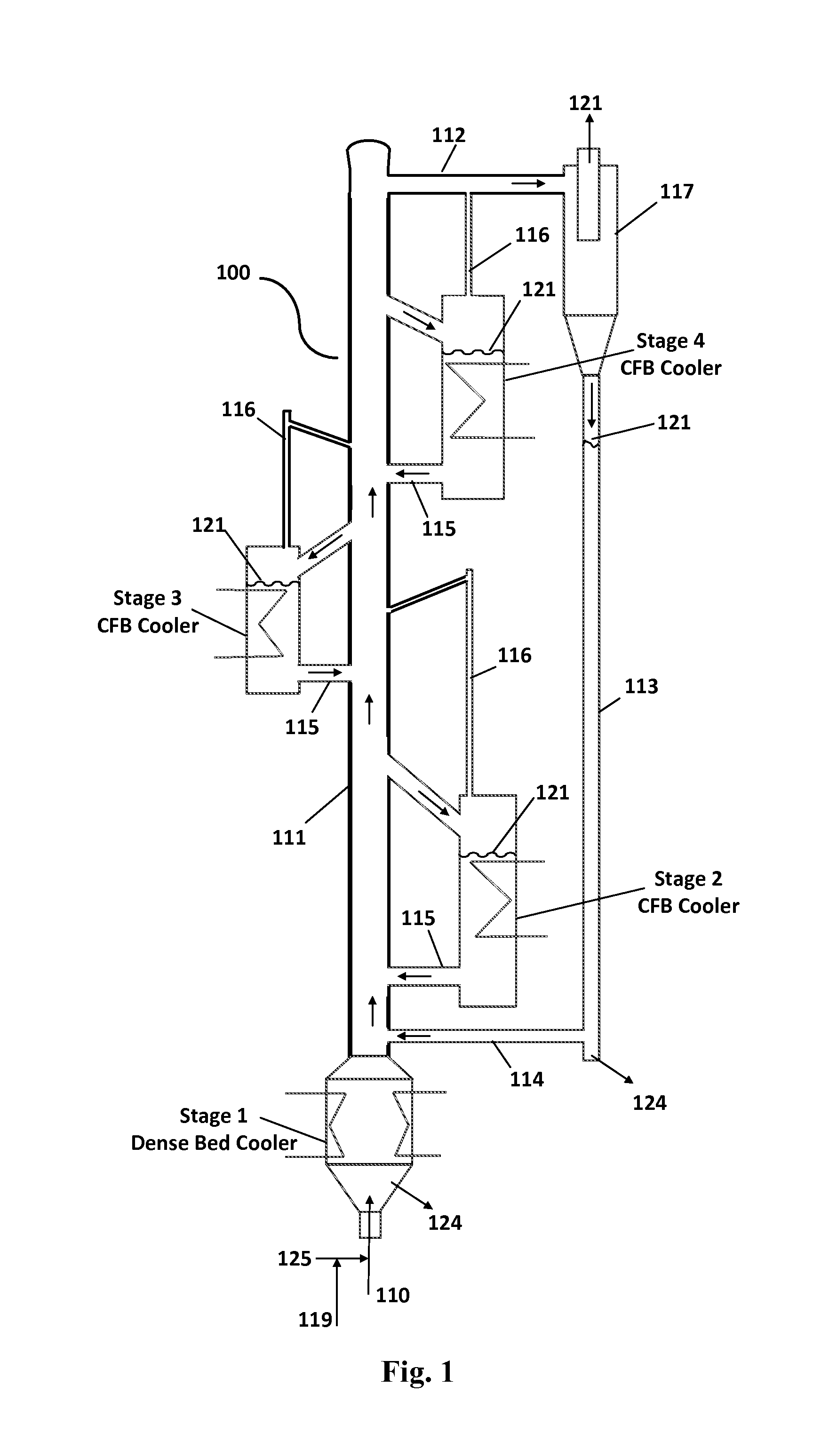

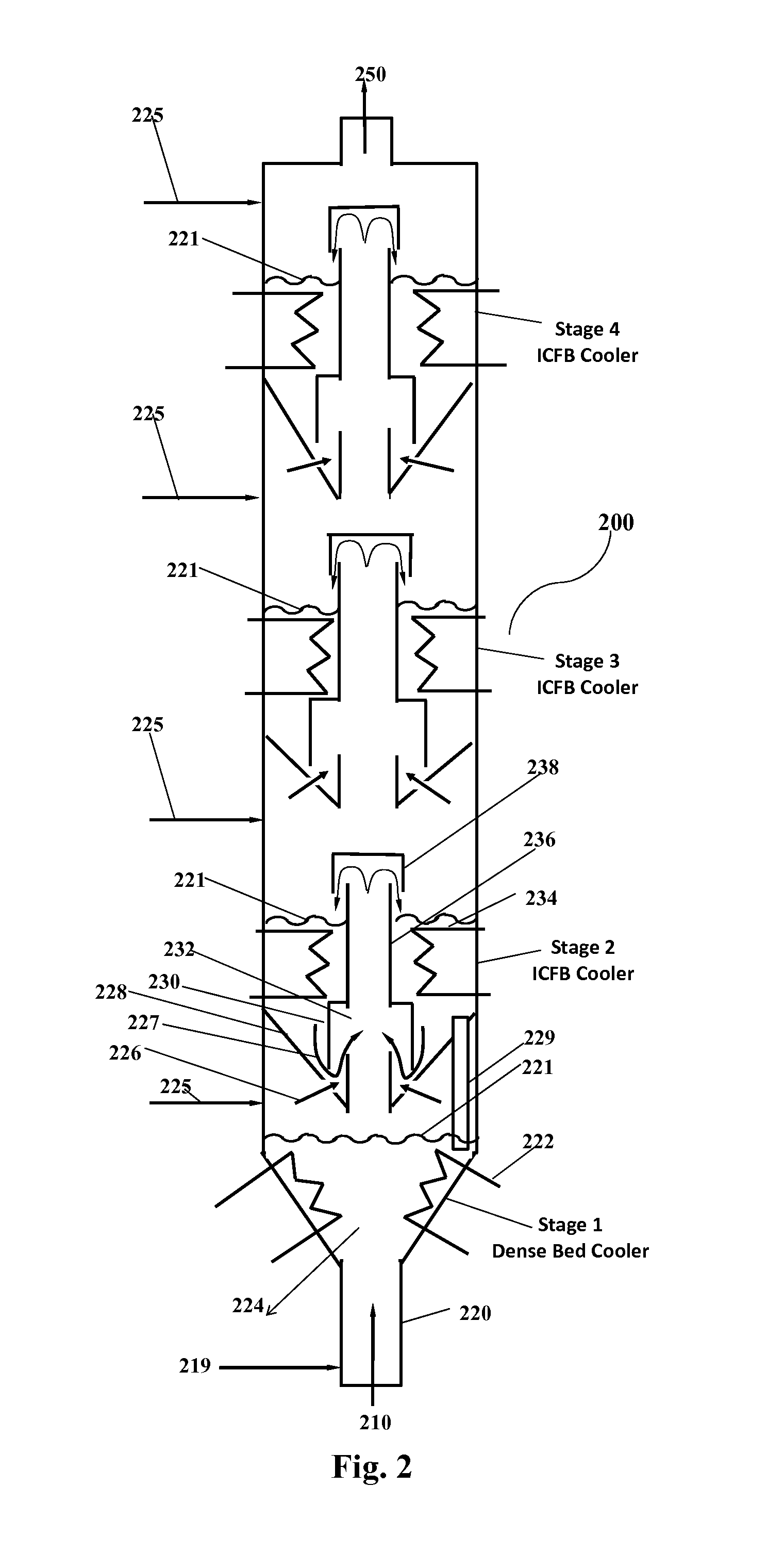

Multi-Stage Circulating Fluidized Bed Syngas Cooling

ActiveUS20140054011A1Eliminate the problemEasy to disassembleRecuperative heat exchangersGasification processes detailsSyngasFluidized bed

A method and apparatus for cooling hot gas streams in the temperature range 800° C. to 1600° C. using multi-stage circulating fluid bed (CFB) coolers is disclosed. The invention relates to cooling the hot syngas from coal gasifiers in which the hot syngas entrains substances that foul, erode and corrode heat transfer surfaces upon contact in conventional coolers. The hot syngas is cooled by extracting and indirectly transferring heat to heat transfer surfaces with circulating inert solid particles in CFB syngas coolers. The CFB syngas coolers are staged to facilitate generation of steam at multiple conditions and hot boiler feed water that are necessary for power generation in an IGCC process. The multi-stage syngas cooler can include internally circulating fluid bed coolers, externally circulating fluid bed coolers and hybrid coolers that incorporate features of both internally and externally circulating fluid bed coolers. Higher process efficiencies can be realized as the invention can handle hot syngas from various types of gasifiers without the need for a less efficient precooling step.

Owner:THE SOUTHERN CO

Method for quenching underground coal gasifier

ActiveCN102587883ASimple and fast operationEasy to controlConstructionsCoal gasificationEngineeringCoal gasifier

Disclosed is a method for quenching an underground coal gasifier. The underground coal gasifier comprises a burned-out area and at least one pipe extending from the burned-out area to the ground. The method includes: connecting an exhaust fan to an outlet of each pipe; and operating the exhaust fans to pump out gas in the burned-out area to vacuum the burned-out area, and accordingly guiding water in a surrounding of the burned-out area into the burned-out area to quench the gasifier, wherein when at least one pipe is used for vacuuming, other pipes are sealed. The method is simple in operation, easy in control and easy in implementation, and the cost is low as no extra equipment is needed.

Owner:ENN SCI & TECH DEV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com