Efficient water-saving controllable gas turbine quadruple-cogeneration system

A gas turbine, high-efficiency technology, applied in gas turbine devices, liquid variable capacity machinery, engines, etc., can solve the problems of uncontrollable and unadjustable thermoelectric-cooling trigeneration, heat waste, low-temperature corrosion, etc., to improve absolute internal efficiency, increase Benefit, effect of reducing nitrogen oxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation of the present invention will be described in further detail below in conjunction with the examples.

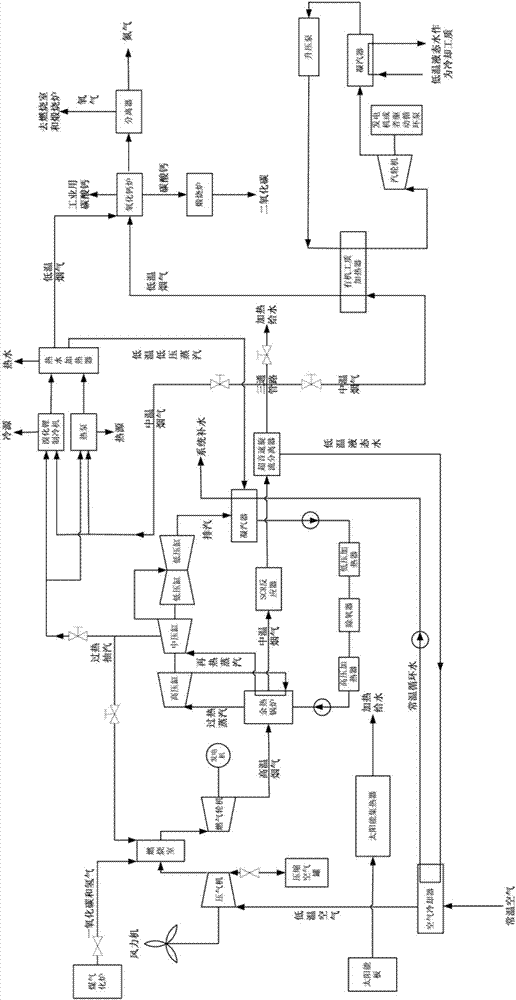

[0056] The invention is a gas turbine four-cogeneration system integrating high efficiency, water saving and controllability, the system includes a gas turbine, an air cooler, a coal gasifier, a cyclone separator, a refrigerator, a heat pump, a Rankine cycle system and a low temperature Flue gas treatment system;

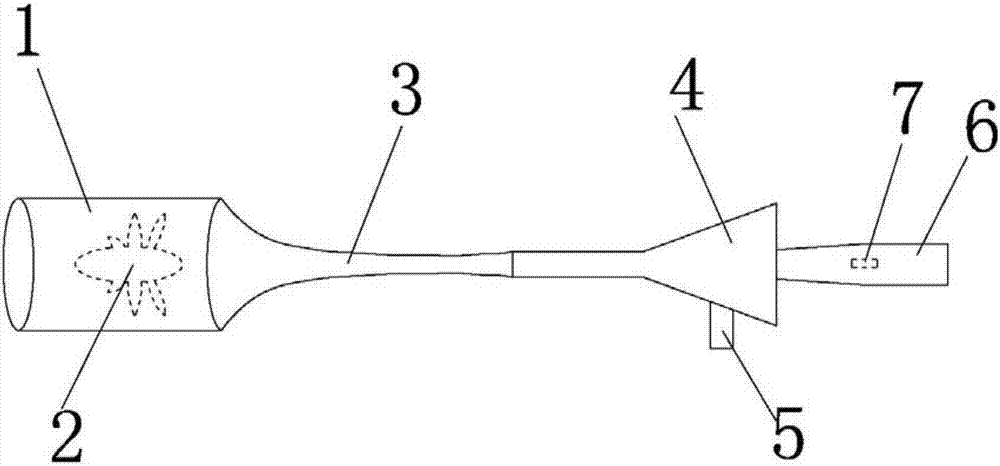

[0057] The low-temperature air outlet of the air cooler is connected with the air inlet of the compressor, and the air outlet of the compressor is respectively connected with the air inlet of the combustion chamber and the air inlet of the compressed air tank, and the power input end of the compressor is provided with a The carbon monoxide and hydrogen outlets of the coal gasifier are connected to the fuel inlet of the combustion chamber; the high-temperature flue gas outlet of the combustion chamber is connected to the gas turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com