Air-oil co-production device and method adopting fluidized bed pulverized coal gasification and solid heat carrier pyrolysis coupling

A solid heat carrier and fluidized bed technology, which can be used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the chemical industry, and can solve problems such as low thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

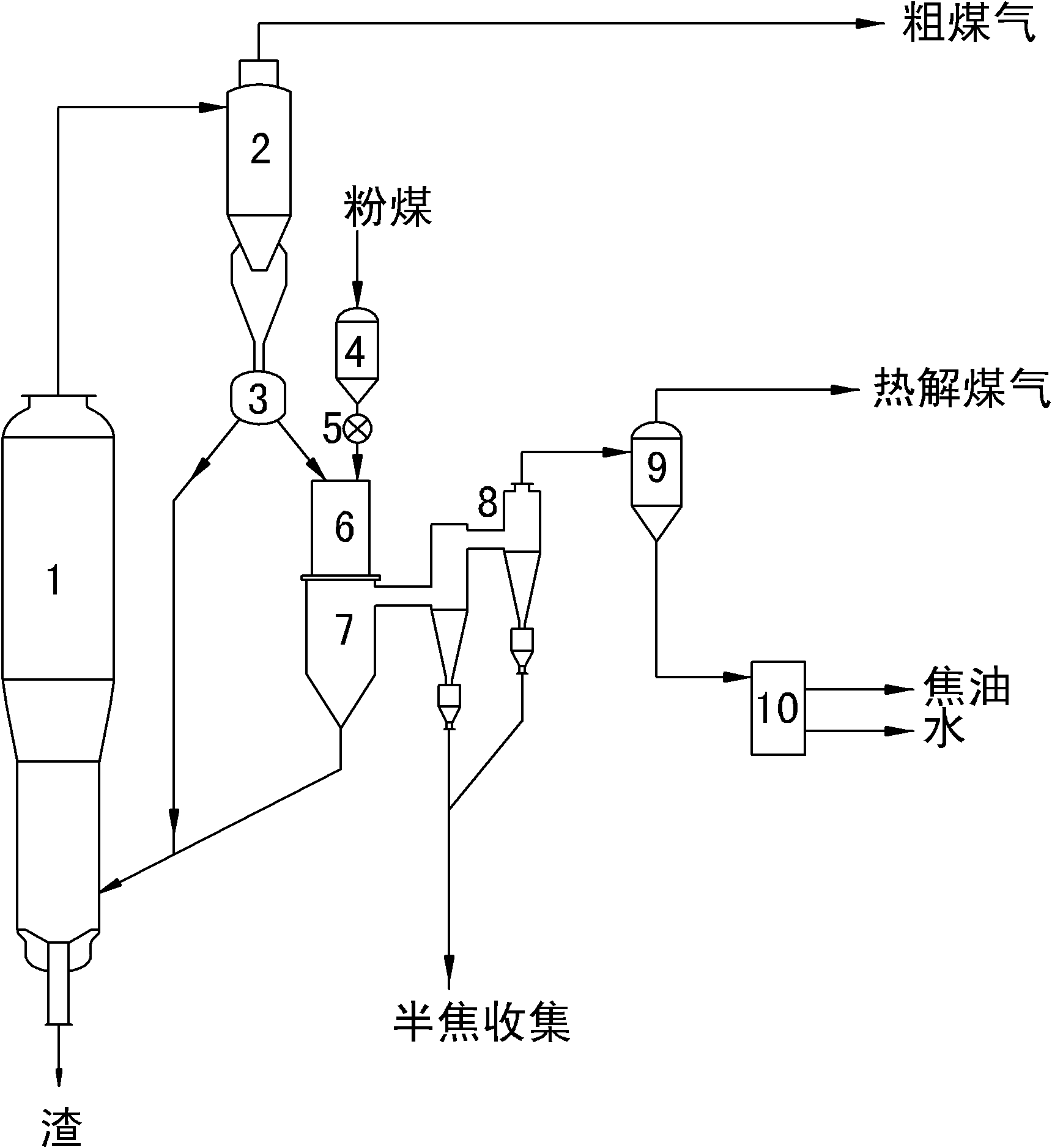

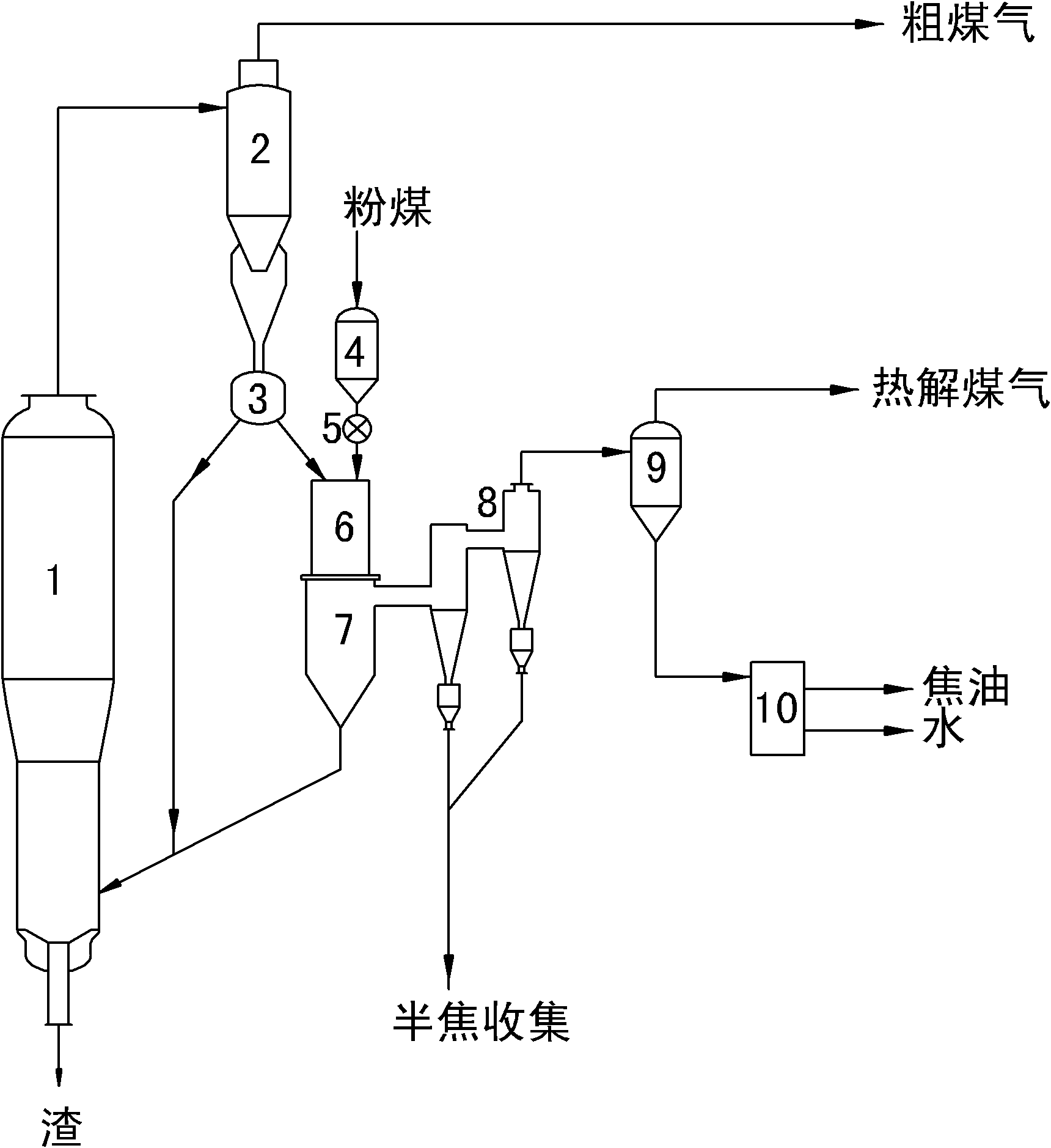

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , the present invention comprises a fluidized bed pulverized coal gasifier 1 and a cyclone dust collector 2 connected with the crude gas outlet of the fluidized bed pulverized coal gasifier 1, and the crude gas passed through the cyclone dust collector 2 is discharged from the upper end of the cyclone dust collector 2 , the discharge port of the cyclone dust collector 2 is connected with the splitter 3, and the high-temperature circulating semi-coke is split through the splitter 3, and all the way enters the pyrolysis reactor 7 through the mixer 6 as a heat carrier and coal for pyrolysis to form semi-coke and enters the fluidized bed Pulverized coal gasifier 1, the other way directly returns to fluidized bed pulverized coal gasifier 1, and the mixer 6 is also connected with a star feeder 5 and a coal bunker 4, and the temperature from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com