Coal gasification furnace for recycling industrial wastewater and gasification process

A technology for industrial wastewater and gasifier, which is applied in gasification process, petroleum industry, granular/powder fuel gasification, etc., can solve the problems of high cost, difficulty in wastewater treatment, and difficulty in achieving complete and complete treatment effect. Improved economy, reduced oxygen consumption, improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

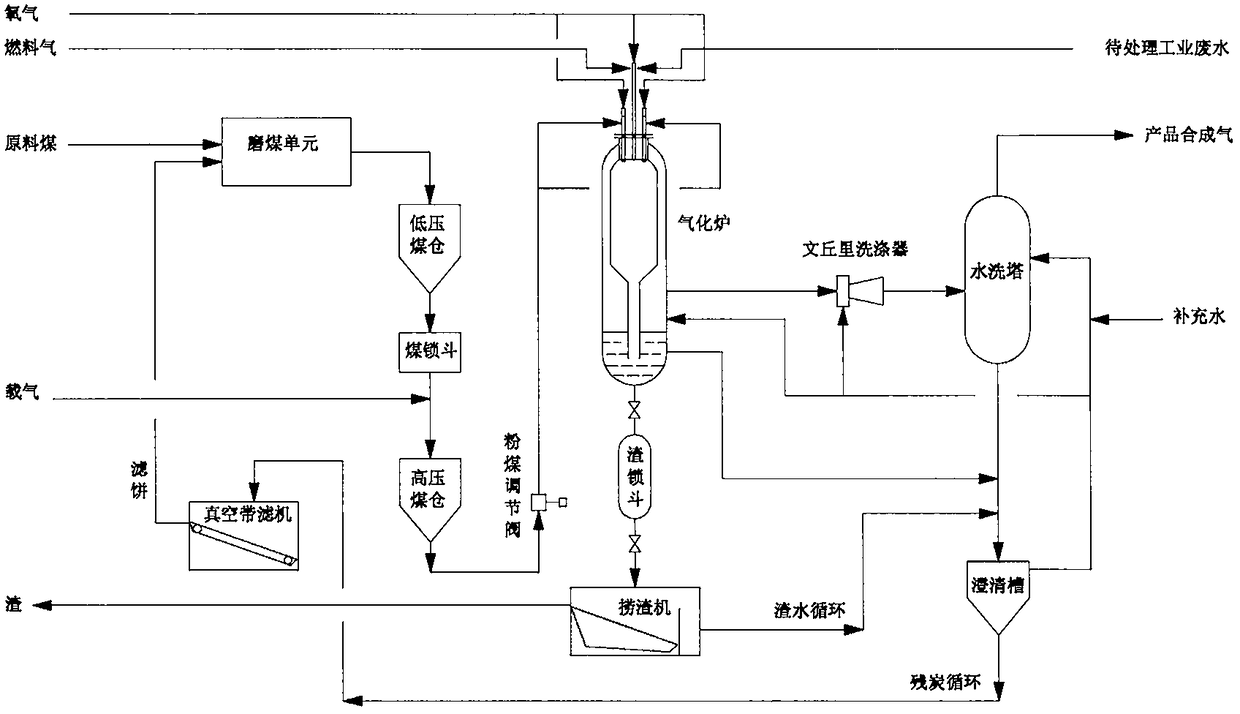

[0029] Example: A coal gasification synthetic ammonia urea project

[0030] A project with a daily output of 1,000 tons of synthetic ammonia intermediate products and 1,740 tons of urea requires coal gasification to produce 88,000 standard cubic meters of effective syngas (CO+H2) per hour.

[0031] The raw coal is a domestic commodity coal, with a moisture content of 14% on a received basis and an ash content of 7% on a dry basis. According to elemental analysis on an anhydrous and ash-free basis, it contains 80.72% carbon, 4.83% hydrogen, 1.03% nitrogen, and 0.45% sulfur. The base low calorific value is 25MJ / kg.

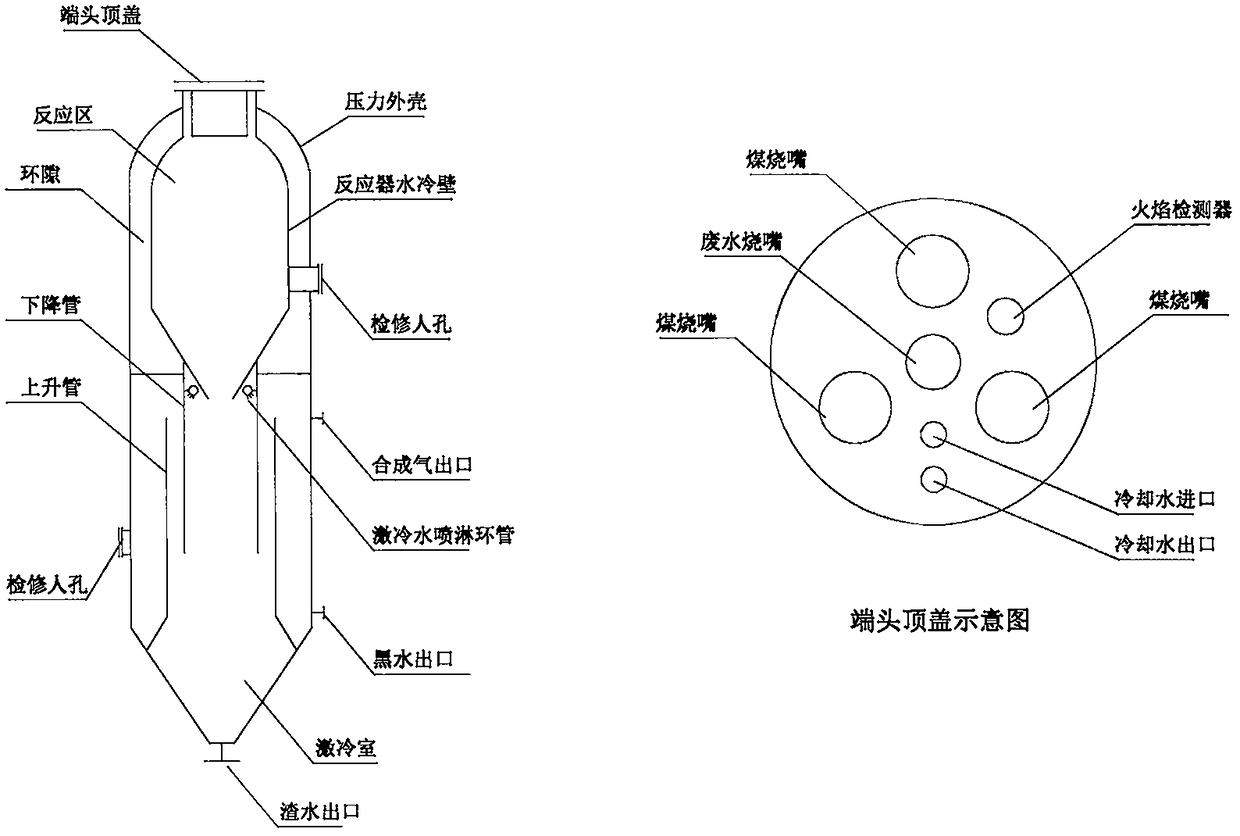

[0032] Set up a multi-burner cold-wall pulverized coal gasifier with a daily coal input capacity of 1,350 tons.

[0033] An average of 56 tons of raw coal is consumed per hour. The medium-pressure roller mill is used in the coal grinding unit to grind into pulverized coal, which is stored in a low-pressure coal bunker.

[0034] The pulverized coal enters the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com