Double fluidized bed low-carbon combustion and gasification heat and electricity polygeneration device and method

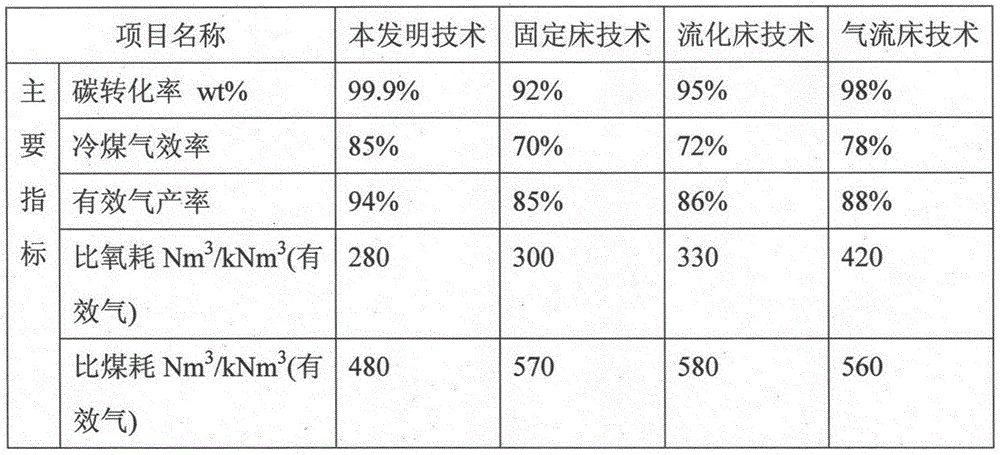

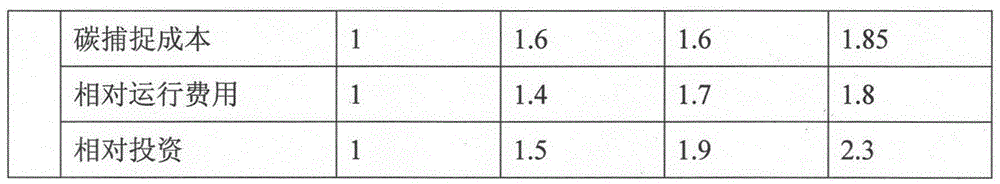

A double fluidized bed, polygeneration technology, applied in the field of polygeneration, can solve the problems of system reliability and stability, reduce carbon capture economy, difficult separation of tar, etc., to improve the composition ratio and cold gas efficiency , Easy to scale up and reduce oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

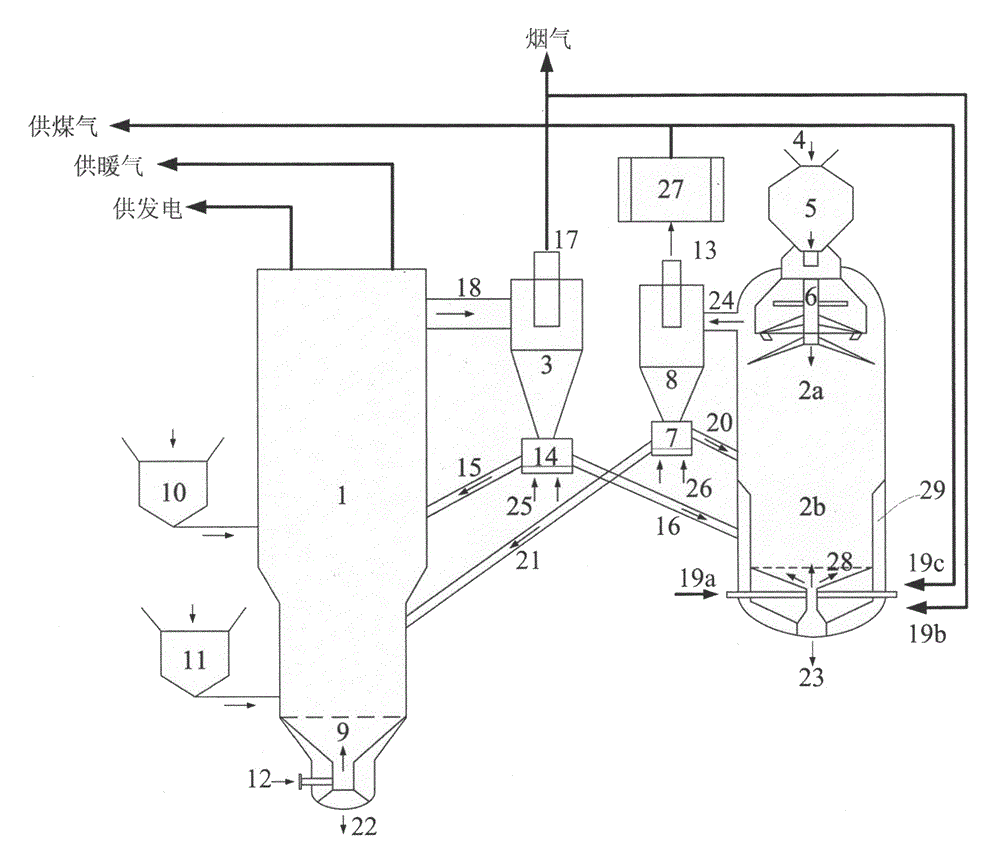

Embodiment 1

[0058] In order to achieve polygeneration of heat, electricity, and synthesis gas, etc., the polygeneration design is carried out for a circulating fluidized bed boiler system with a power generation capacity of 300 MW and a fixed bed gasification system with a coal processing capacity of 1000 t / d. The present invention provides a A dual-fluidized bed low-carbon combustion and gasification heat and electricity cogeneration device consists of two subsystems, namely a combustion system and a gasification system, and the combustion system is connected to the gasification system through a recycling system. The gasification system includes a gasifier body 2, and the gasifier body 2 includes a low-temperature section 2a of the gasifier and a high-temperature section 2b of the gasifier. The operating temperature of the low temperature section 2a of the gasifier is 600°C, and the operating temperature of the high temperature section 2b of the gasifier is 800°C.

[0059] A double-fluid...

Embodiment 2

[0067] In order to achieve polygeneration of heat, electricity, and synthesis gas, etc., the polygeneration design is carried out for a circulating fluidized bed boiler system with a power generation capacity of 300 MW and a fixed bed gasification system with a coal processing capacity of 1000 t / d. The present invention provides a A dual-fluidized bed low-carbon combustion and gasification heat and electricity cogeneration device consists of two subsystems, namely a combustion system and a gasification system, and the combustion system is connected to the gasification system through a recycling system. The gasification system includes a gasifier body 2, and the gasifier body 2 includes a low-temperature section 2a of the gasifier and a high-temperature section 2b of the gasifier. The operating temperature of the low-temperature section 2a of the gasifier is 700°C, and the operating temperature of the high-temperature section 2b of the gasifier is 850°C.

[0068] A double-fluid...

Embodiment 3

[0076] In order to achieve polygeneration of heat, electricity, and synthesis gas, etc., the polygeneration design is carried out for a circulating fluidized bed boiler system with a power generation capacity of 300 MW and a fixed bed gasification system with a coal processing capacity of 1000 t / d. The present invention provides a A dual-fluidized bed low-carbon combustion and gasification heat and electricity cogeneration device consists of two subsystems, namely a combustion system and a gasification system, and the combustion system is connected to the gasification system through a recycling system. The gasification system includes a gasifier body 2, and the gasifier body 2 includes a low-temperature section 2a of the gasifier and a high-temperature section 2b of the gasifier. The operating temperature of the low-temperature section 2a of the gasifier is 800°C, and the operating temperature of the high-temperature section 2b of the gasifier is 1100°C.

[0077] A double-flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com