Patents

Literature

283results about How to "Guaranteed conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymerization ferric sulfate water treatment agent and preparation method thereof

ActiveCN103224256AGuaranteed utilizationFast productionIron sulfatesWater/sewage treatment by flocculation/precipitationSulfateReaction temperature

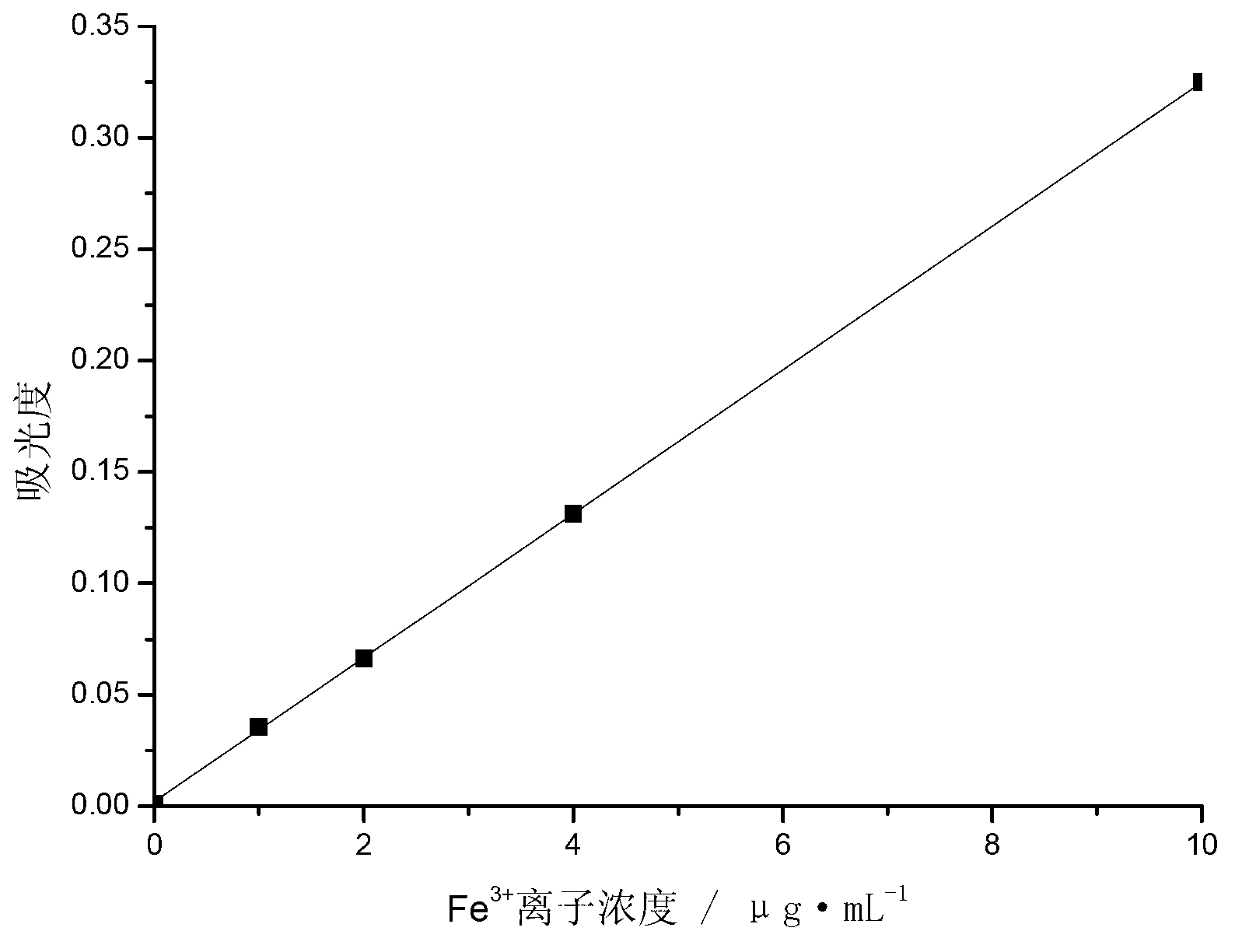

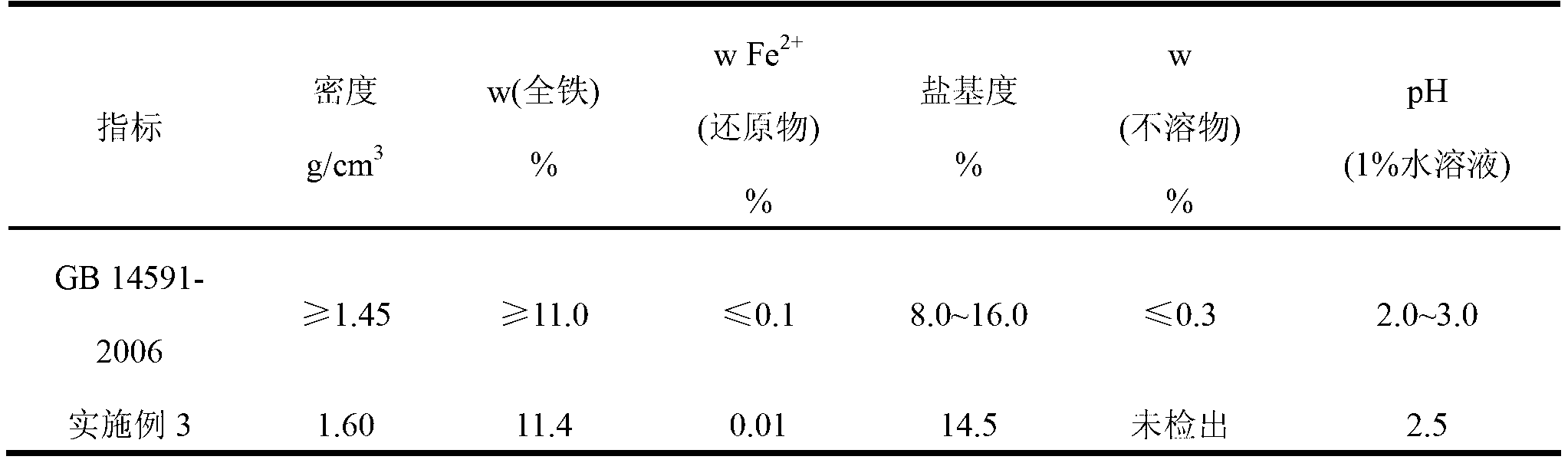

The present invention discloses a polymerization ferric sulfate water treatment agent and a preparation method thereof. According to the present invention, H2O2 and FeSO4.7H2O are adopted, a molar ratio of the H2O2 to the FeSO4.7H2O is 1.1-2.0:2, and the H2O2 and Fe<2+> are subjected to an oxidation reaction to prepare the polymerization ferric sulfate water treatment agent so as to rapidly produce products meeting user requirements, wherein production is rapid, a reaction temperature is controlled no higher than 40 DEG C so as to ensure a H2O2 utilization rate and a Fe<2+> conversion rate, and raw material utilization rate can be more than 95%; and the method has characteristics of simple production process, simple reaction apparatus, easy operation, low raw material consumption, and low cost, and can be used for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

System and method for simultaneously producing methacrylic acid and methacrolein

ActiveCN106631759AGuaranteed conversion rateGuaranteed pressureOrganic compound preparationChemical industryFixed bedAcid washing

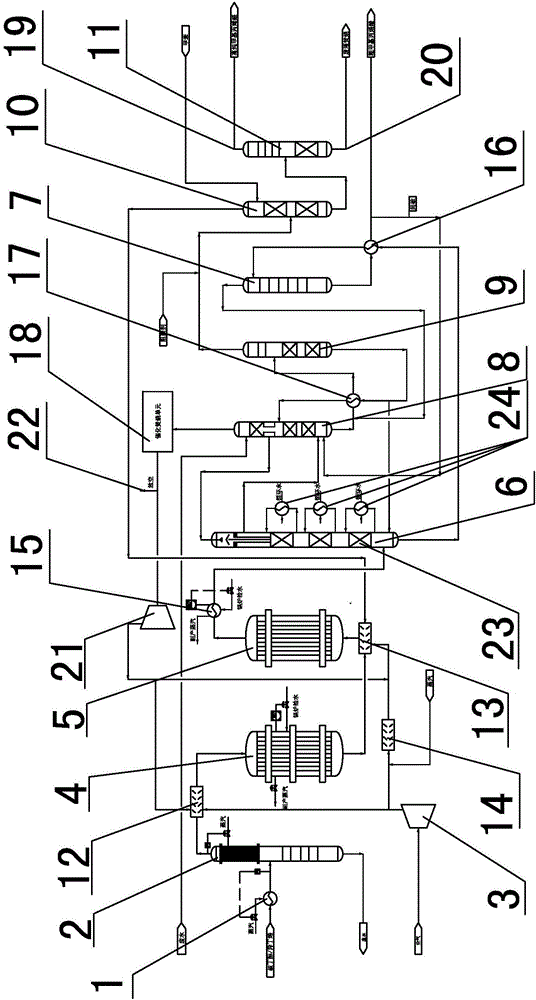

The invention discloses a method and system for simultaneously producing methacrylic acid and methacrolein. The system comprises a raw material feed preheater, a raw material vaporizing tower, a first oxidation reactor, a second oxidation reactor, a rapid cooling / acid washing coupled tower, a methacrolein stripping tower, a methacrolein absorption tower, a methacrolein recovery tower, a methacrolein light component removal tower and a methacrolein heavy component removal tower. The method comprises the following steps: preheating and vaporizing a raw material tert-butyl alcohol or isobutylene; then mixing with air and water; feeding to a catalyst-filled fixed-bed reactor; performing oxidation reaction to generate methacrylic acid and methacrolein; and performing effective rapid cooling, absorption and rectification to finally obtain 99%wt methacrolein and 30%wt crude methacrylic acid. The method and system have the advantages that the reaction conversion rate is high, the unreacted raw material can be effectively recovered, impurities and solid particles are removed, and high-purity methacrylic acid and methacrolein are produced.

Owner:齐翔华利新材料有限公司

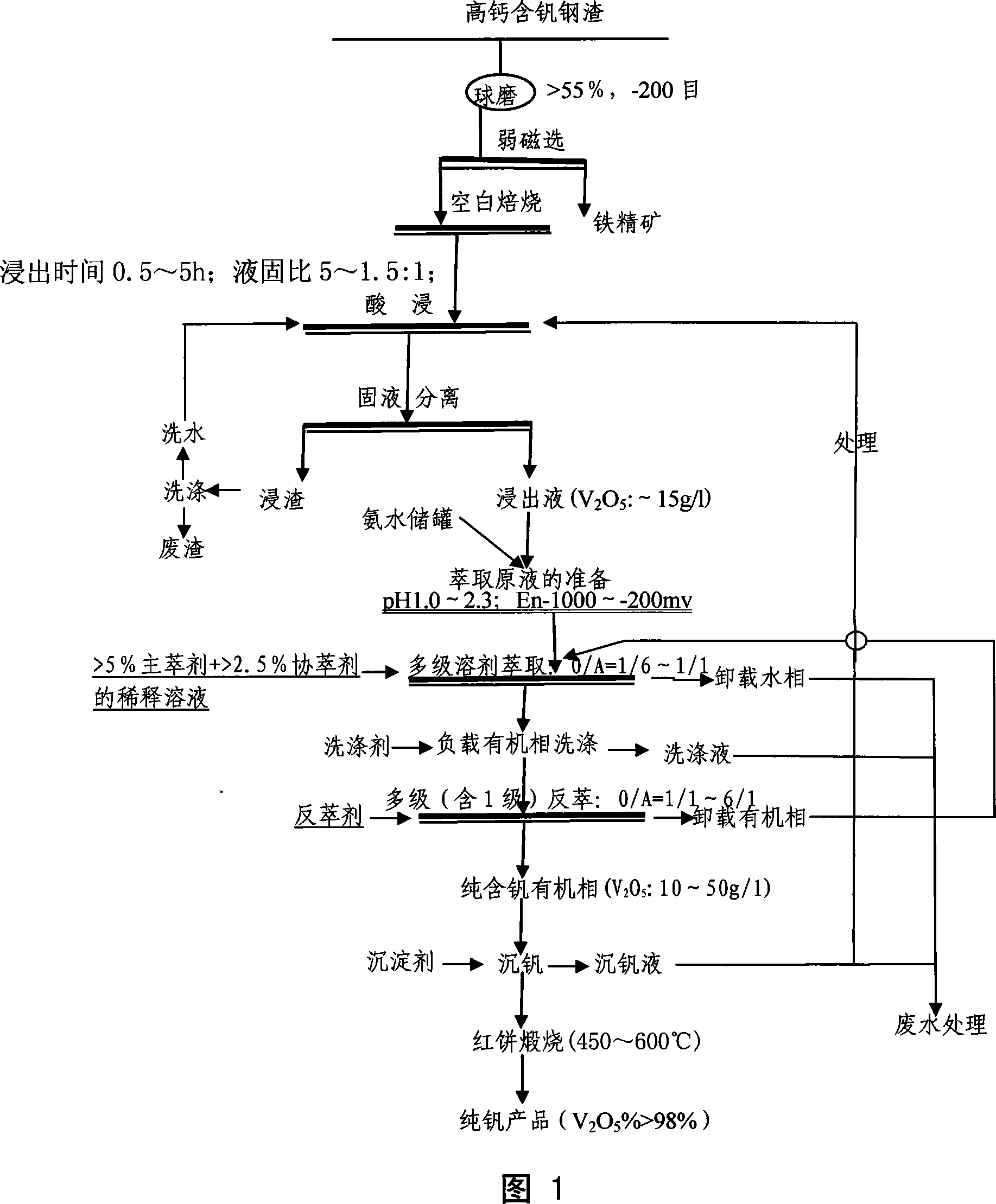

Technique for reclaiming vanadium and iron from high-vanadium high-iron steel slag

InactiveCN101121966AReduce accumulationReduce difficultySolid separationProcess efficiency improvementSlagOxidation reduction

A novel technology is used for recycling iron and vanadium from calcium-rich or iron-rich steel slag. The invention relates to a metallurgical method of extracting vanadium, in particular to a method that extracts vanadium or iron from abandoned steel slag with multidisciplinary technologies. The technology has the following procedures: (1) The calcium-rich or iron-rich steel slag is crushed, the iron contained in the steel slag is recycled by magnetic separation, and the material that will correspondingly change low-valent vanadium is roasted into high-valent vanadium contained in the material, or the material is first roasted and then magnetic separated; (2) the material is soaked with 95-98 percentage concentrated sulfuric acid, and then solid-liquid separation is conducted; (3) the acidity of lixivium is adjusted, to make sure the pH of the lixivium is in 1.0 to 2.3, and the oxidation-reduction potential is -1000 to 200mv; (4) Extraction above grade two is adopted, the extraction phase ratio O / A is 1 / 6 to 1 / 1, and then the aqueous phase unloaded; (5) the organic washing is applied in the load to remove iron, and the washing agent used is sulphate; (6) 0.25M to 1.5M alkaline solution is adopted as a stripping agent for back-extraction, with a phase ratio of O / A 1 / 1 to 6 / 1, so as to deposit vanadium contained in solution. The invention is characterized by simple technology, low cost, small environmental pollution and high recovery ratio in the process of extracting vanadium and iron from calcium-rich or iron-rich steel slag.

Owner:KUNMING UNIV OF SCI & TECH

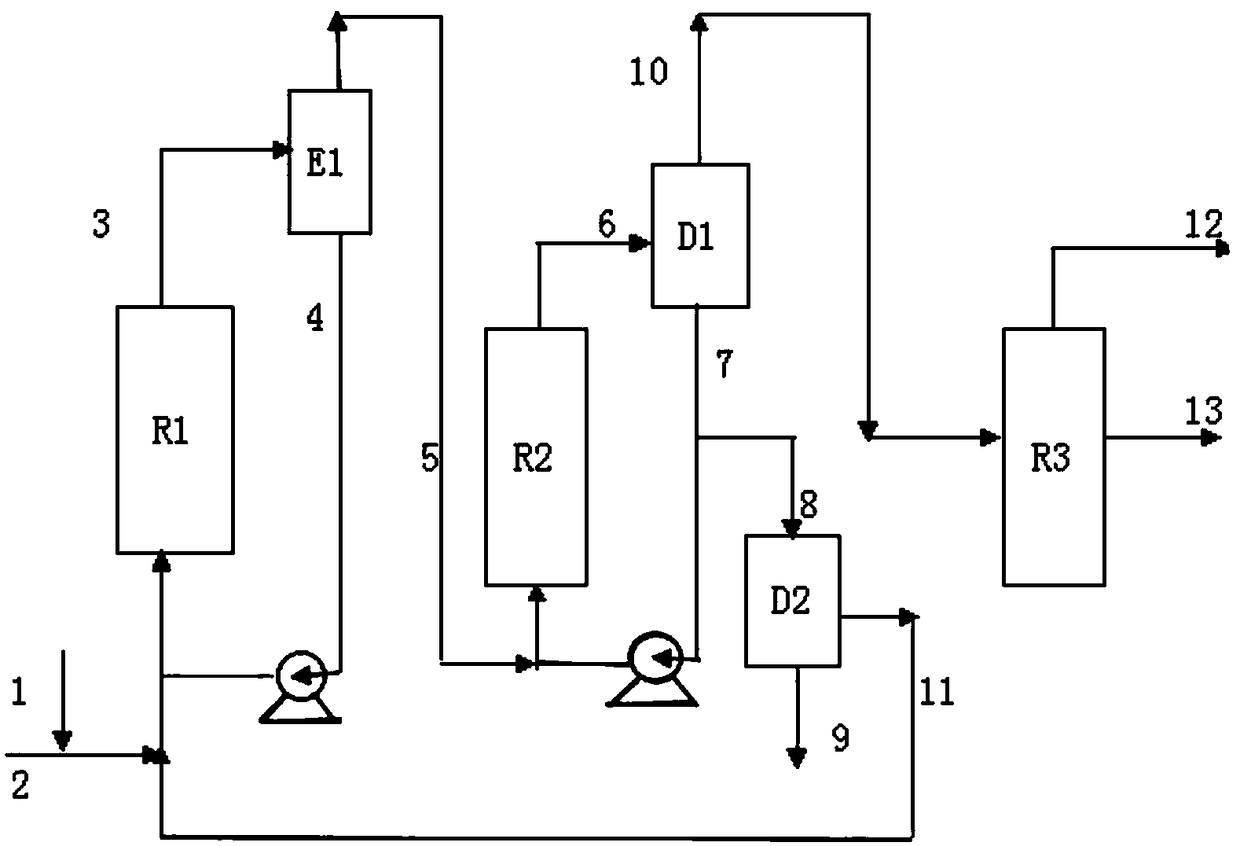

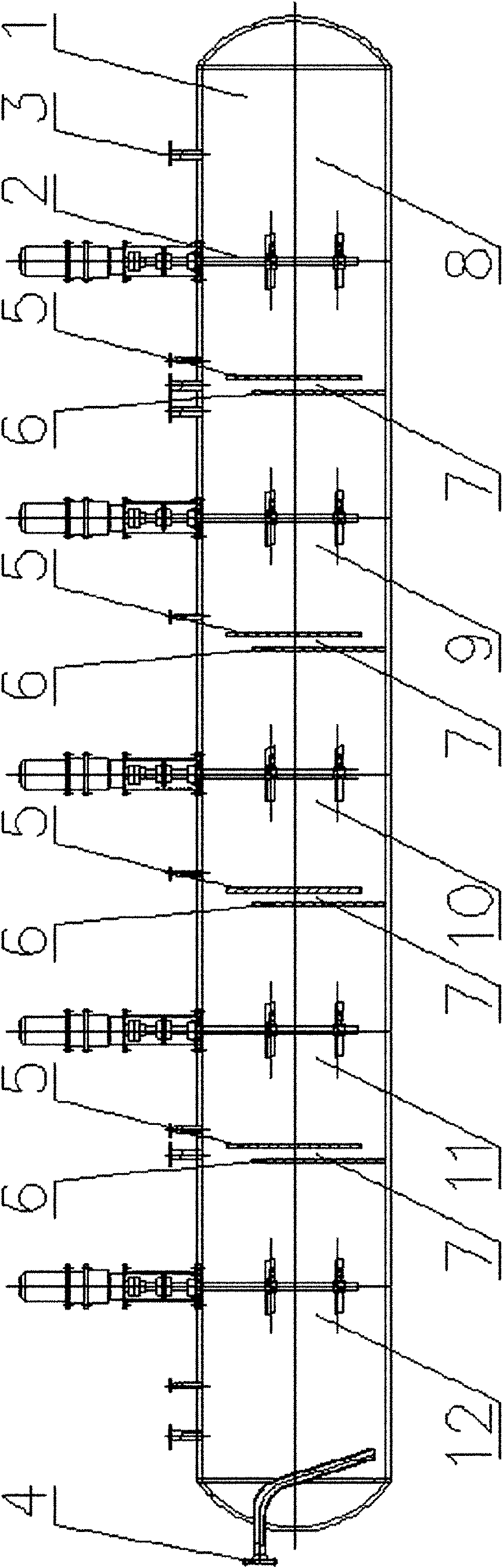

Heavy oil hydrogenation method and hydrogenation system

ActiveCN108659882AEnough time to stayGuaranteed conversion rateTreatment with hydrotreatment processesHydrogenRetention time

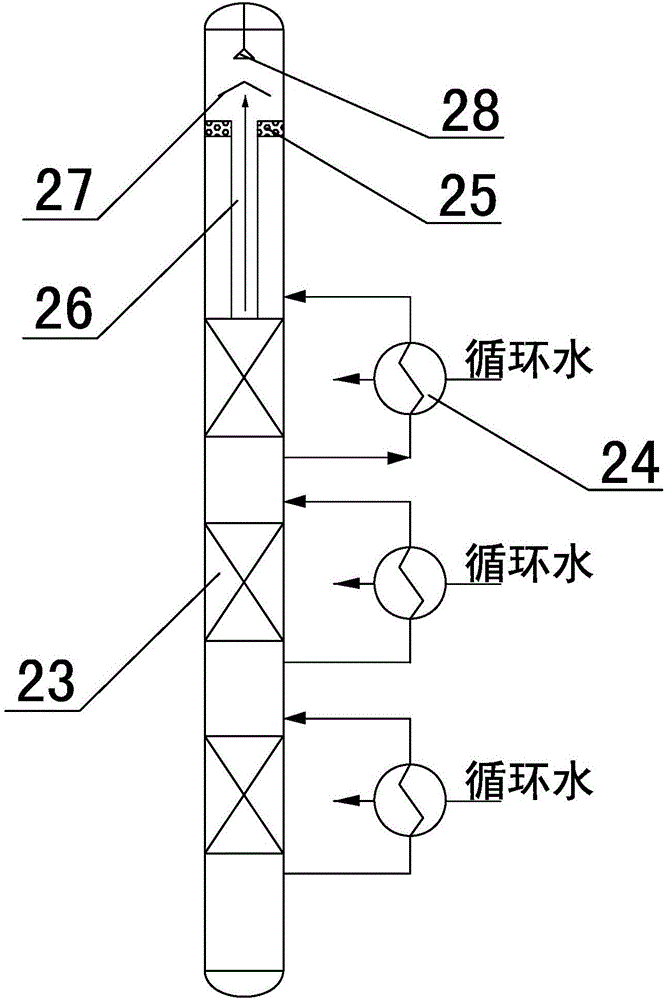

The invention relates to a heavy oil hydrogenation method and a hydrogenation system. The heavy oil hydrogenation method comprises the steps of mixing heavy oil, circulation oil, a valcanizer and a catalyst, performing hydrocracking on the heavy oil, the circulation oil, the valcanizer, the catalyst and hydrogen in a first reactor to form a first reaction product, allowing part of first reaction product to return to the first reactor, performing hydrocracking on the rest of the first reaction product in a second reactor to form a second reaction product, dividing the second reaction product into a light component and a heavy component, returning part of the heavy component to the second reactor, separating the rest of the heavy component to form distillate oil as the circulation oil, and hydrofining the light component in a third reactor to form a light oil product. The method improves heat transfer and mass transfer efficiency, ensures retention time of the material in the reactors, and increases a heavy oil conversion rate and a light oil yield. According to the hydrogenation system for the method, internal members of the reactors are simplified, and equipment investment and operation energy consumption are reduced.

Owner:CCTEG CHINA COAL RES INST

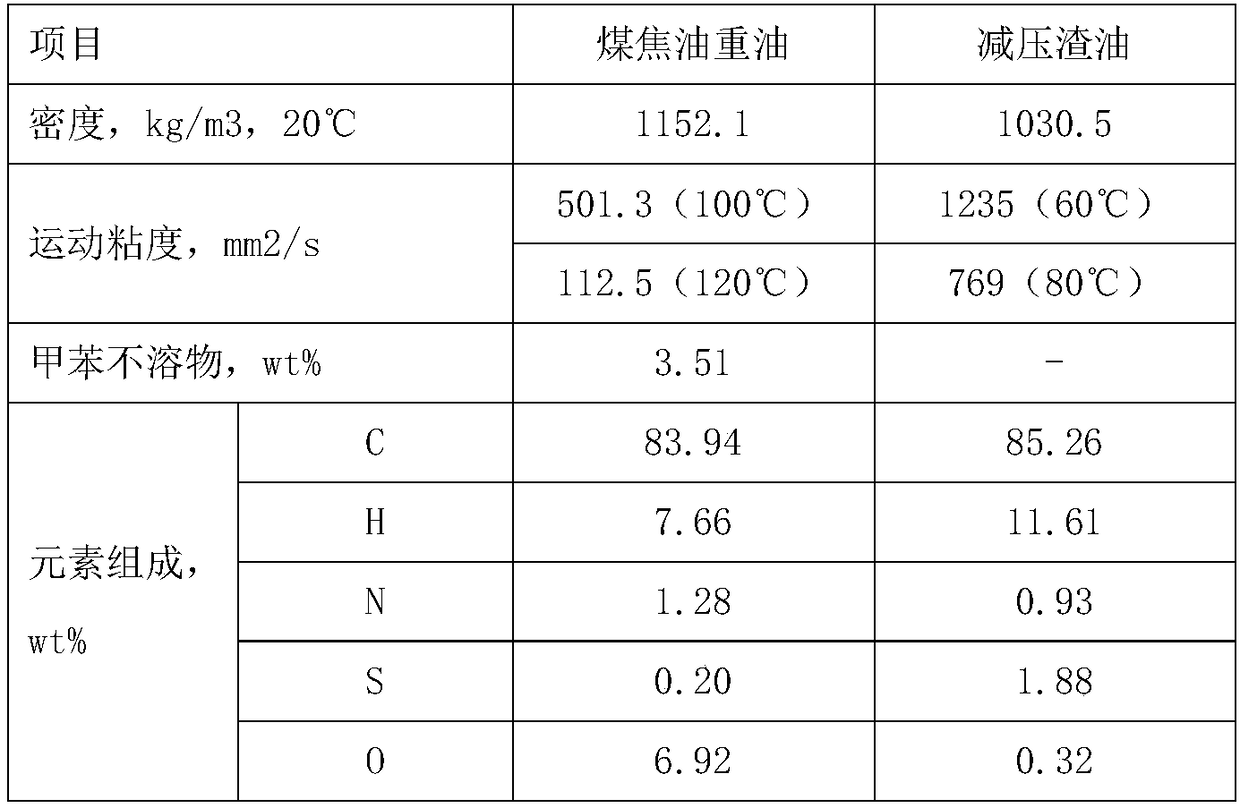

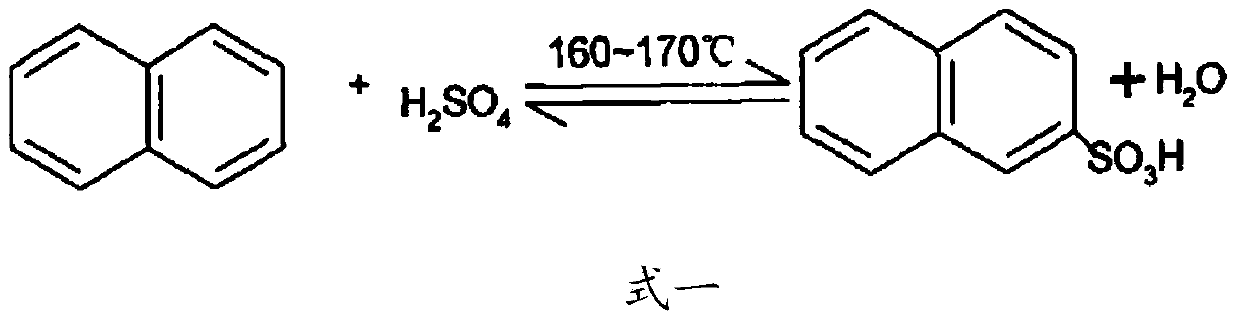

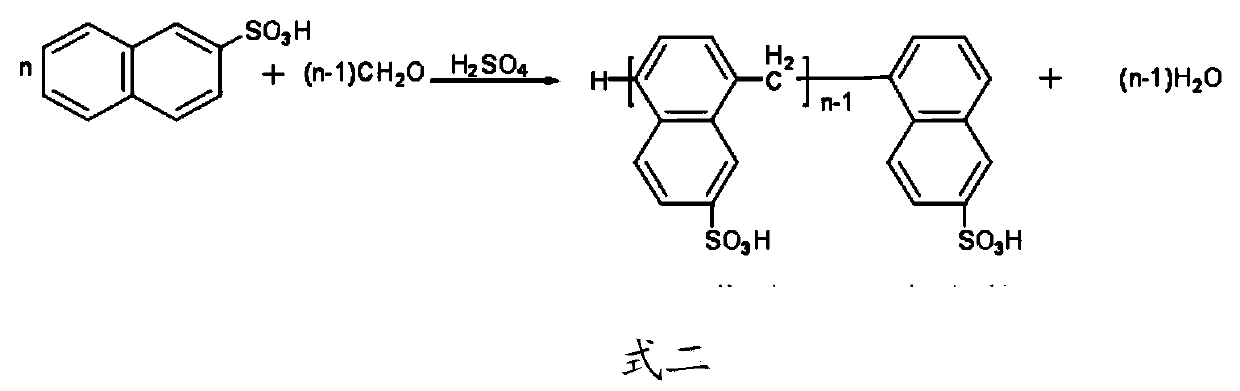

Production method for naphthalene high-concentration water reducer

The invention discloses a production method for a naphthalene high-concentration water reducer. The production method comprises the following steps: (1), preparing industrial naphthalene, 98% concentrated sulfuric acid and 37% formaldehyde in a weight ratio being 1:0.889:0.598; (2), adding the industrial naphthalene; (3), sulfonating, namely adding the concentrated sulfuric acid within 25-30 minutes while rising a temperature of the naphthalene to 150 DEG C; after adding the acid, carrying out sulfonation reaction at 160-165 DEGC; increasing steps of circulating a solvent and removing residual solvent in the sulfonating process, and controlling acidity to 26-27%; (4), hydrolyzing, namely adding water into reaction liquor and hydrolyzing for 15 minutes at 110-125 DEG C; (5), condensing, namely adding the formaldehyde within 2 hours when the temperature is 102 + / -2 DEG C, condensing and preserving the heat to react for 3 hours, and controlling the temperature to 115-125 DEG C and controlling the pressure to 0.10-0.15MPa; and (6), neutralizing. According to the production method, a conversation ratio of a beta-naphthalenesulfonic acid-formaldehyde condensation compound is greatly increased, the time is shortened, the energy consumption is lowered, and the discharge of waste gas is reduced.

Owner:广东瑞安科技实业有限公司

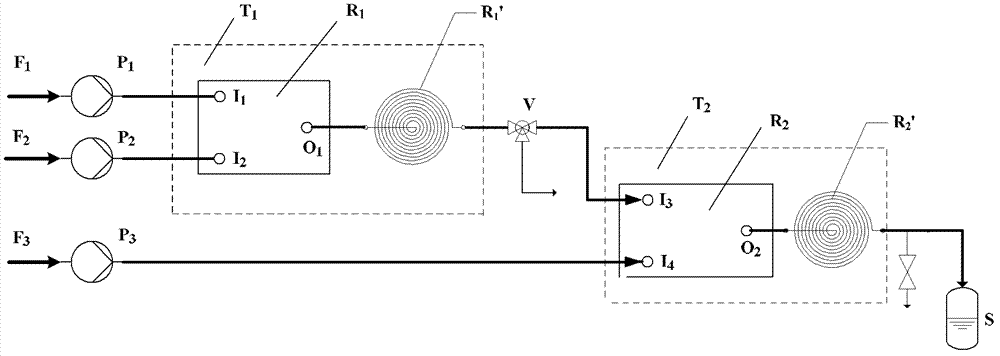

Synthesizing method of epoxy fatty acid ester

The invention relates to a synthesizing method of an epoxy fatty acid ester. According to the method, formic acid (acetic acid) contacts and is mixed with hydrogen peroxide in a first micro-reactor, such that a peroxidation reaction is initiated; when a material of the initiated peroxidation reaction flows out of the micro-reactor, the reaction of the material is continued for several minutes in an extension pipe (capillary or micro-channel) connected to the outlet of the first micro-reactor, such that peroxyformic acid (peroxyacetic acid) is produced; the in-situ produced peroxyformic acid (peroxyacetic acid) contacts and is mixed with non-reacted hydrogen peroxide and fatty acid ester in a second micro-reactor, such that an epoxidation reaction is initiated; the reaction of the material of the initiated epoxidation reaction is continued for several minutes in an extension pipe connected to the outlet of the second micro-reactor, or other kettle-type material storage devices, such that epoxy fatty acid ester is produced. According to the method, organic acid peroxidation and double-bond epoxidation reactions are integrated in series, such that epoxy fatty acid ester is obtained by continuous synthesis. The process is safe and controllable. Under the optimized condition, double bond conversion rate in fatty acid ester is higher than 90%, and epoxy fatty acid ester selectivity is higher than 80%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

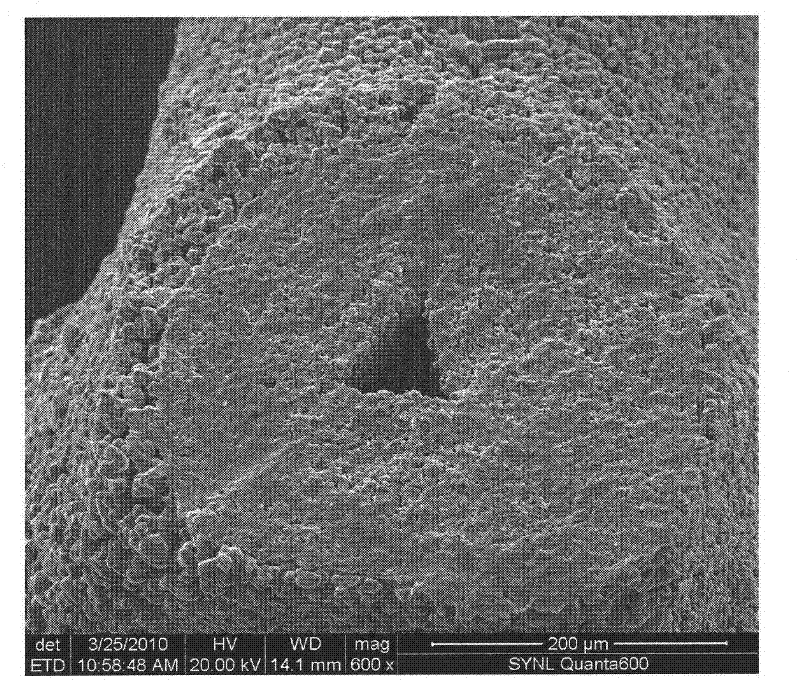

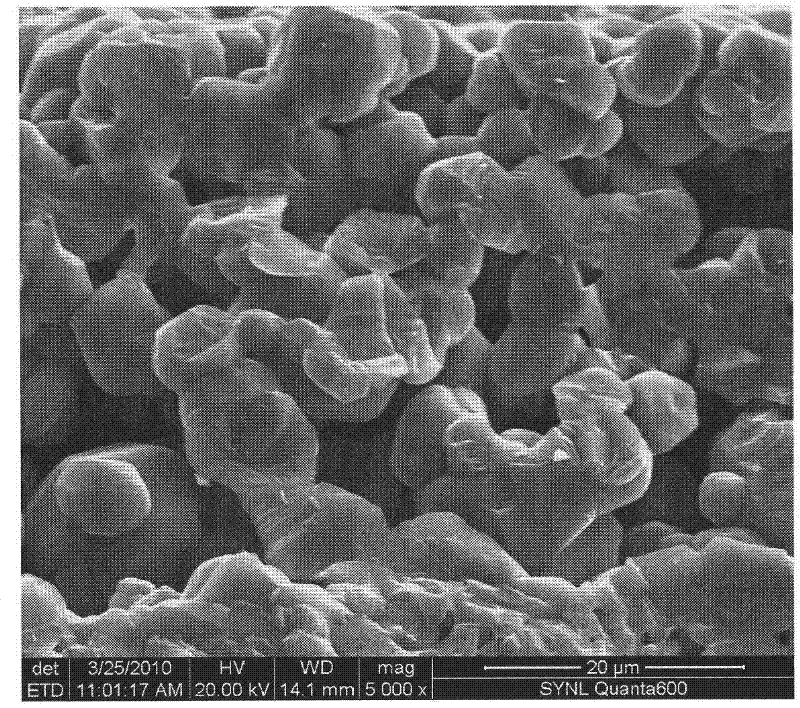

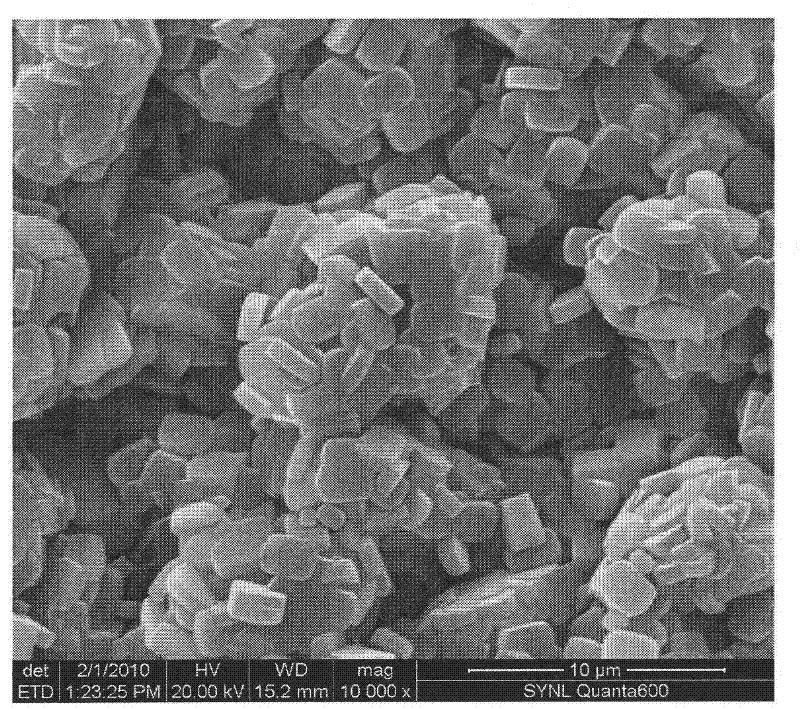

Monolayer, b-axis oriented zsm-5 zeolite coating material on porous silicon carbide surface and its preparation

ActiveCN102274744AHigh selectivityExtend your lifePolycrystalline material growthFrom normal temperature solutionsHoneycomb structureNutrients substances

The invention belongs to the technical field of a structured catalyst and an application thereof, in particular to a porous carborundum surface single-layered and b-axis oriented ZSM-5 zeolite coating material and a preparation method thereof. Foamy carborundum or honeycomb structured carborundum is taken as a carrier, wherein a porous layer which is composed of overlapped carborundum grains is formed on the outer surface of the carrier; a zeolite coating layer is uniformly formed in the zeolite coating; the zeolite coating layer has a single-layer structure; and a b axis of a zeolite crystalis vertical to the surface of the carborundum carrier. The preparation method comprises the following steps: growing a layer of seed crystal colloid in situ on a carborundum ceramic surface in advance; controlling the basicity of a secondary growing solution, the concentration of nutrient substances and an added quantity of alkali metallic ions; and realizing the controllable growth of zeolite crystal on the surface of the carborundum carrier. The channel of the structured catalyst is opened; the molecular diffusion property is excellent; a specific surface area and a load are bigger; a contact area between the zeolite crystal and the carborundum carrier is big; the strengthened mass transfer and heat transfer are boosted; and the contact time among the reactant, the reaction product and the catalyst is shortened.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

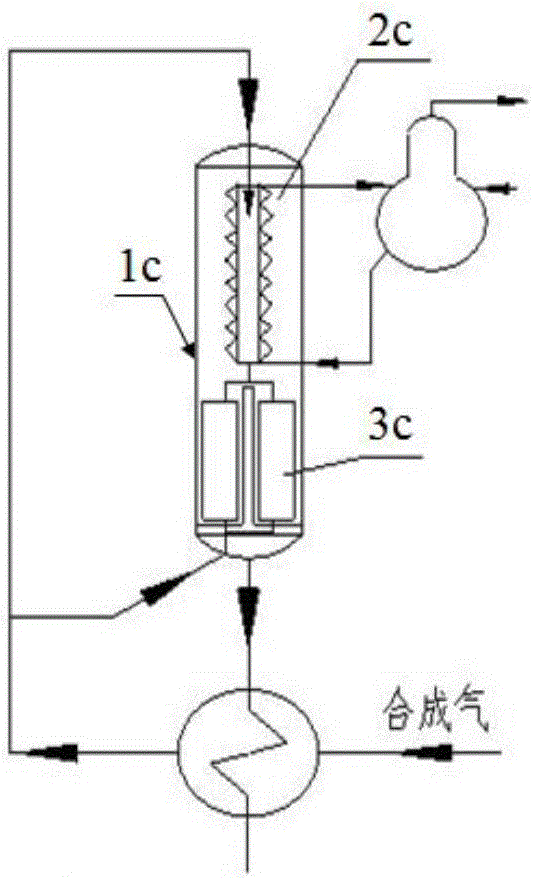

Methyl nitrite preparation method by reaction of NO and nitric acid and methanol

ActiveCN106565494AGood technical effectGuaranteed conversion rateNitrous acid preparation ester preparationNitric oxideChemistry

The invention relates to a method for preparing methyl nitrite by a reaction of NO and nitric acid and methanol. By the method, the problems such as high supply cost of nitrogen oxide and severe equipment corrosion existing in present glycol preparation technology by synthesis gas are mainly solved. According to the technical scheme, a gas-phase raw material containing nitric oxide and a liquid-phase raw material containing nitric acid and methanol react in a trickle bed reactor to obtain methyl nitrite. By the technical scheme, the above problems are greatly solved. The method of the invention can be used for industrial production of methyl nitrite in the glycol preparation technology by synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cultivation method of organic selenium-enriched mulberry

ActiveCN103404402APromote growthImprove conversion rateFertilising methodsCultivating equipmentsFruit treeGram

The invention belongs to the fruit tree cultivation field and particularly relates to a cultivation method of organic selenium-enriched mulberry. The cultivation method of the selenium-enriched mulberry comprises applying nano selenium fertilizer in different growing periods of mulberry trees, wherein the fertilizer applying periods can be divided into three phases of phase one, applying the nano selenium fertilizer to the mulberry trees at 30-50 grams per tree in the growing period of the mulberry trees in March; phase two, applying the nano selenium fertilizer to the mulberry trees at 50-60 grams per tree in late April; phase tree, after mulberry harvest, applying the nano selenium fertilizer to the mulberry trees at 50-60 grams per tree in the periods from early June to late August and from late August to early October. According to the cultivation method of the organic selenium-enriched mulberry, by applying the nano selenium fertilizer in different growing periods of the mulberry trees, most of harvested mulberry products have a selenium content of between 28.85 micrograms per hundred grams and 48.74 micrograms per hundred grams and the ratio of organic selenium is more than 80%.

Owner:SERICULTURAL RES INST ANHUI ACADEMY OF AGRI SCI

Carbon nanotube supported palladium catalyst used for methane catalysis combustion, and preparation method and application thereof

InactiveCN103962129AGuaranteed conversion ratePromote resultsGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsDeposition precipitationActive component

The invention relates to a carbon nanotube supported palladium catalyst (Pd / MWNTs) used for methane catalysis combustion, and a preparation method and an application thereof. The catalyst uses carbon nanotubes as a carrier and palladium as an active component, and palladium particles are uniformly dispersed on the surface of the carbon nanotubes; and the content of palladium accounts for 0.1-5% of the total weight of the catalyst, and the particle size of the palladium particles is 2-5nm. The method comprises the following steps: pre-treating the carbon nanotubes, and preparing a Pd / MWNTs catalyst precursor by using an isopyknic immersion process or a deposition-precipitation process. The catalyst prepared by adopting the method has the advantages of high activity, good hydrothermal stability, toxin immunity and the like, can be used in the methane catalysis combustion process, and can also be used in the efficient removal utilization process of other VOC gases.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

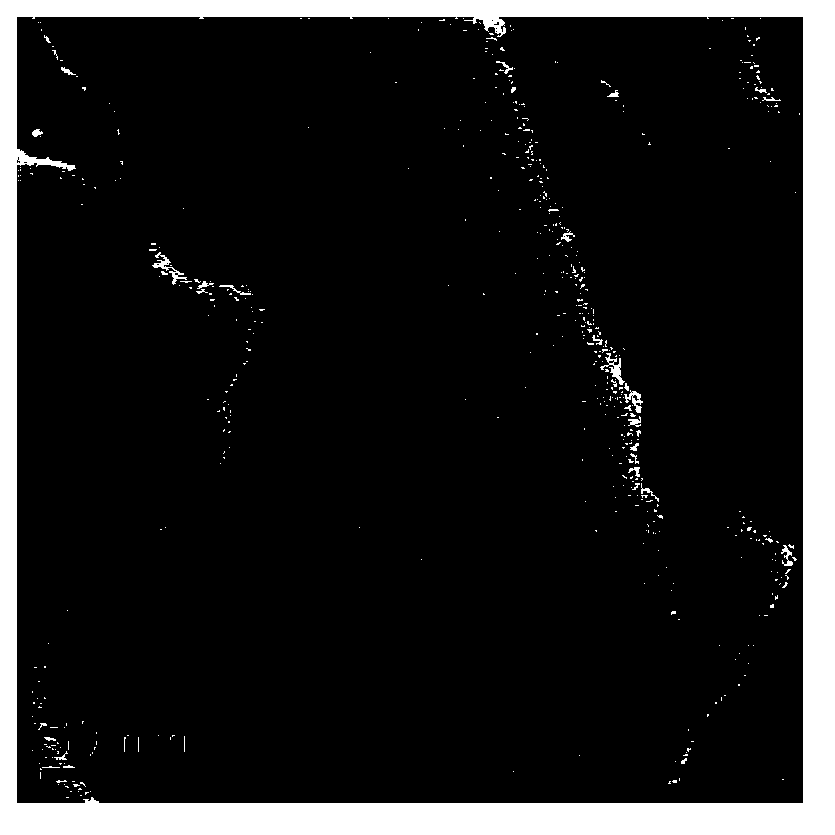

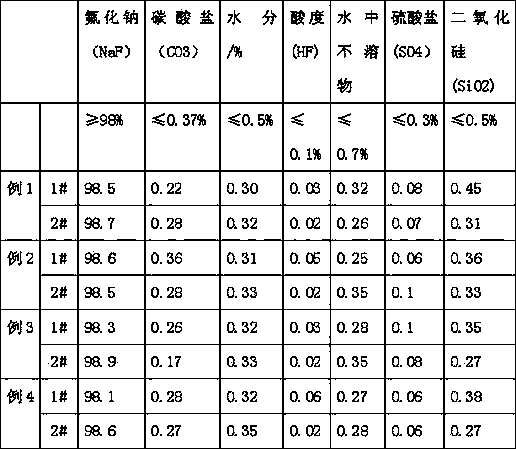

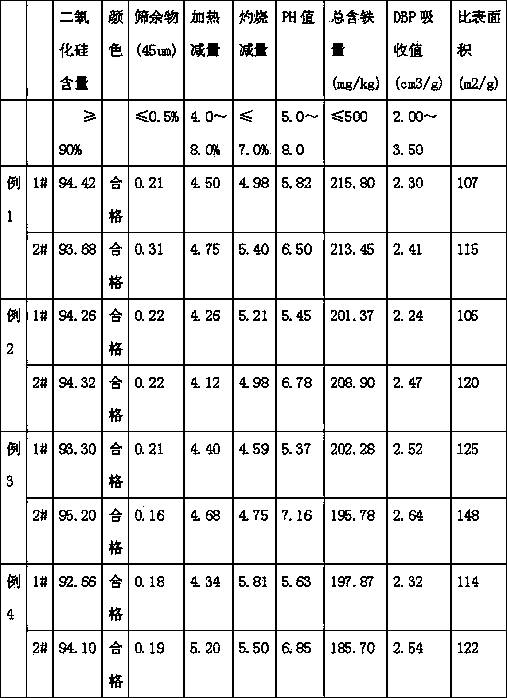

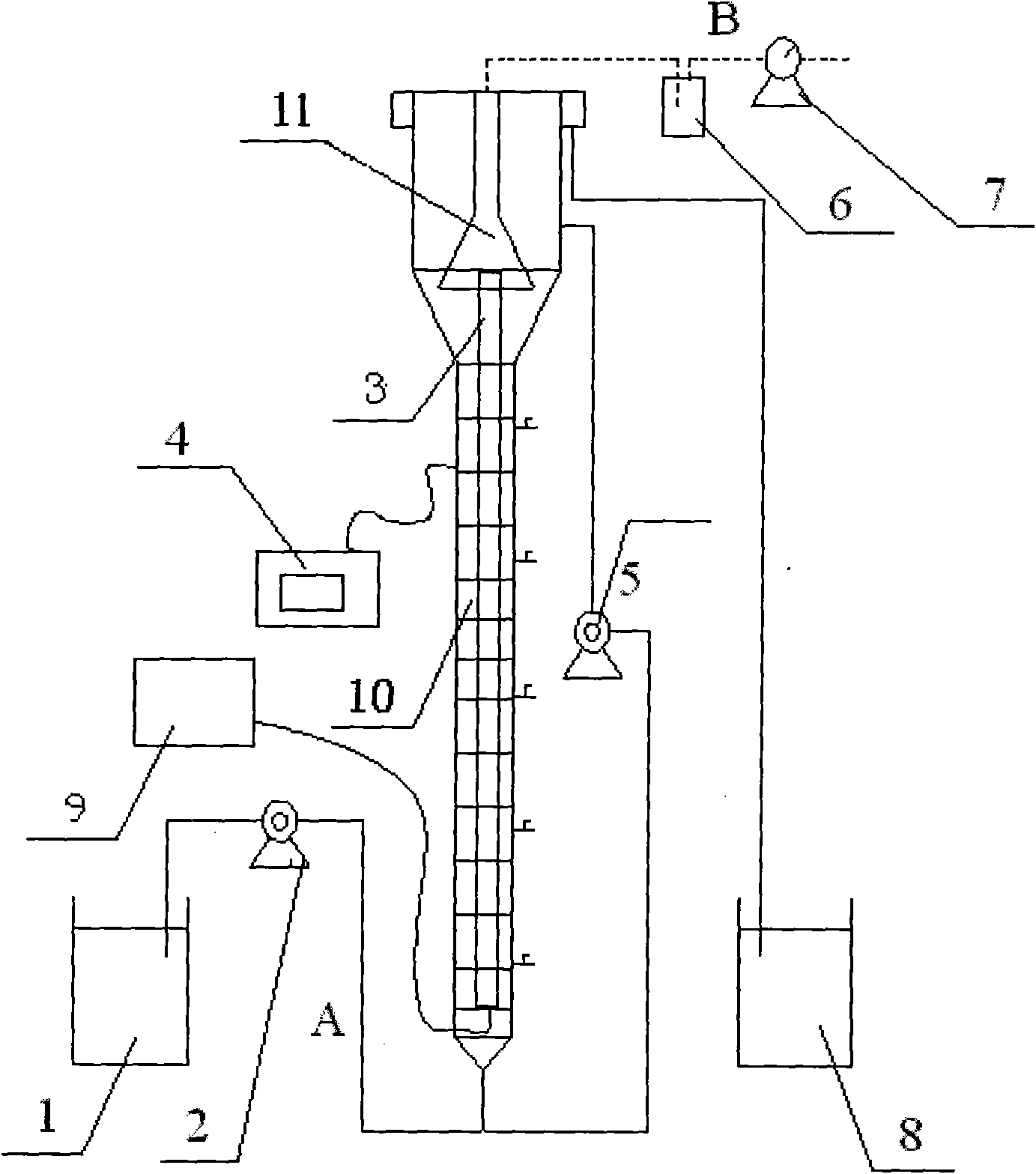

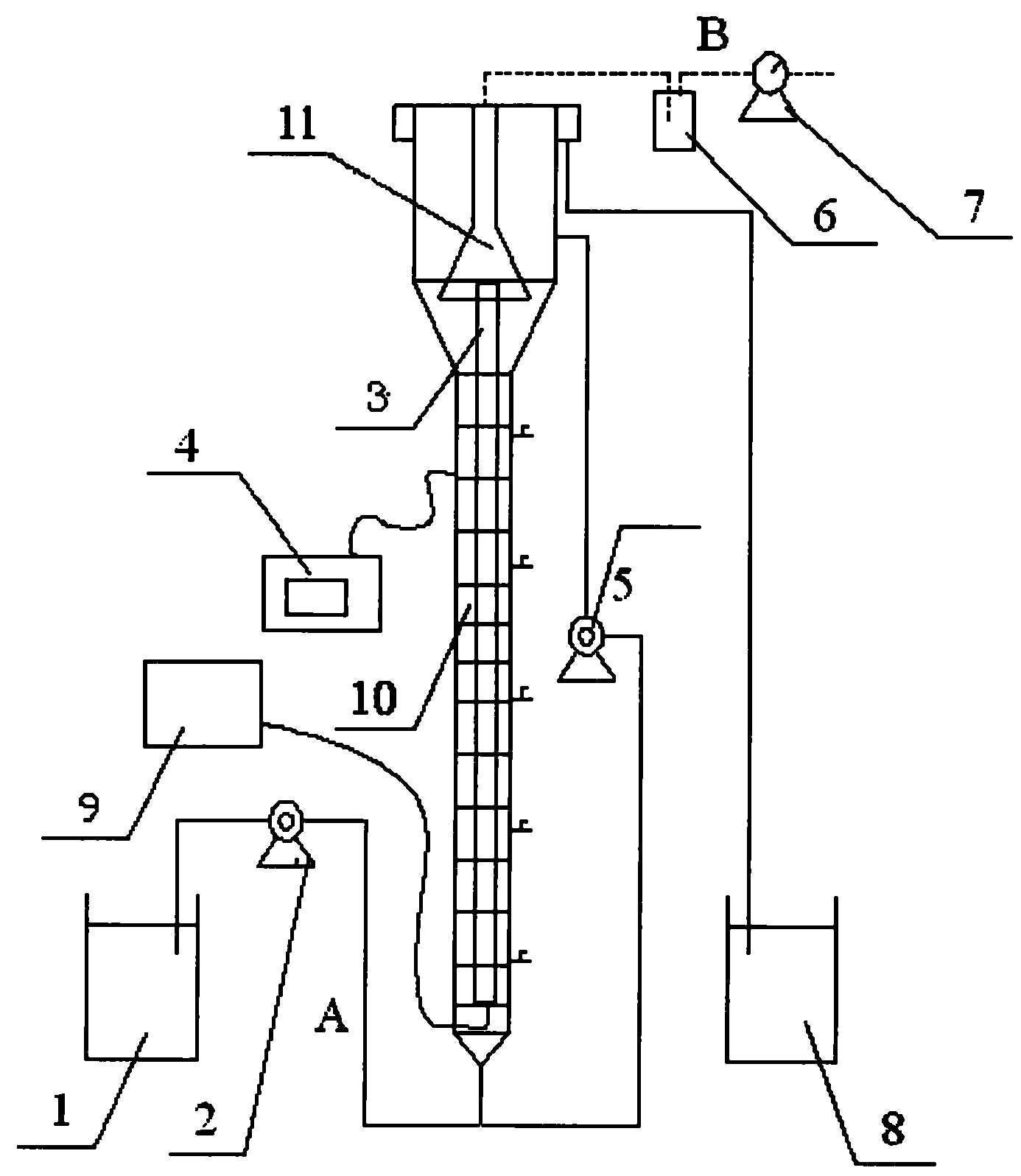

White carbon black production process for producing sodium fluoride and co-producing cryolite by using fluorosilicic acid

ActiveCN104030317AHigh yieldImprove business efficiencySilicaAlkali metal fluoridesAluminium hydroxideEngineering

The invention provides a white carbon black production process for producing sodium fluoride and co-producing cryolite by using fluorosilicic acid. The production process is used for producing sodium fluoride and co-producing high-purity silicon dioxide and cryolite by using fluorosilicic acid, sodium carbonate decahydrate and aluminum hydroxide as main raw materials. The white carbon black production process provided by the invention can be used for reducing the cost of sodium fluoride and cryolite raw materials and further improving the benefits of sodium fluoride production enterprises.

Owner:JIANGXI QUCHENG CHEM

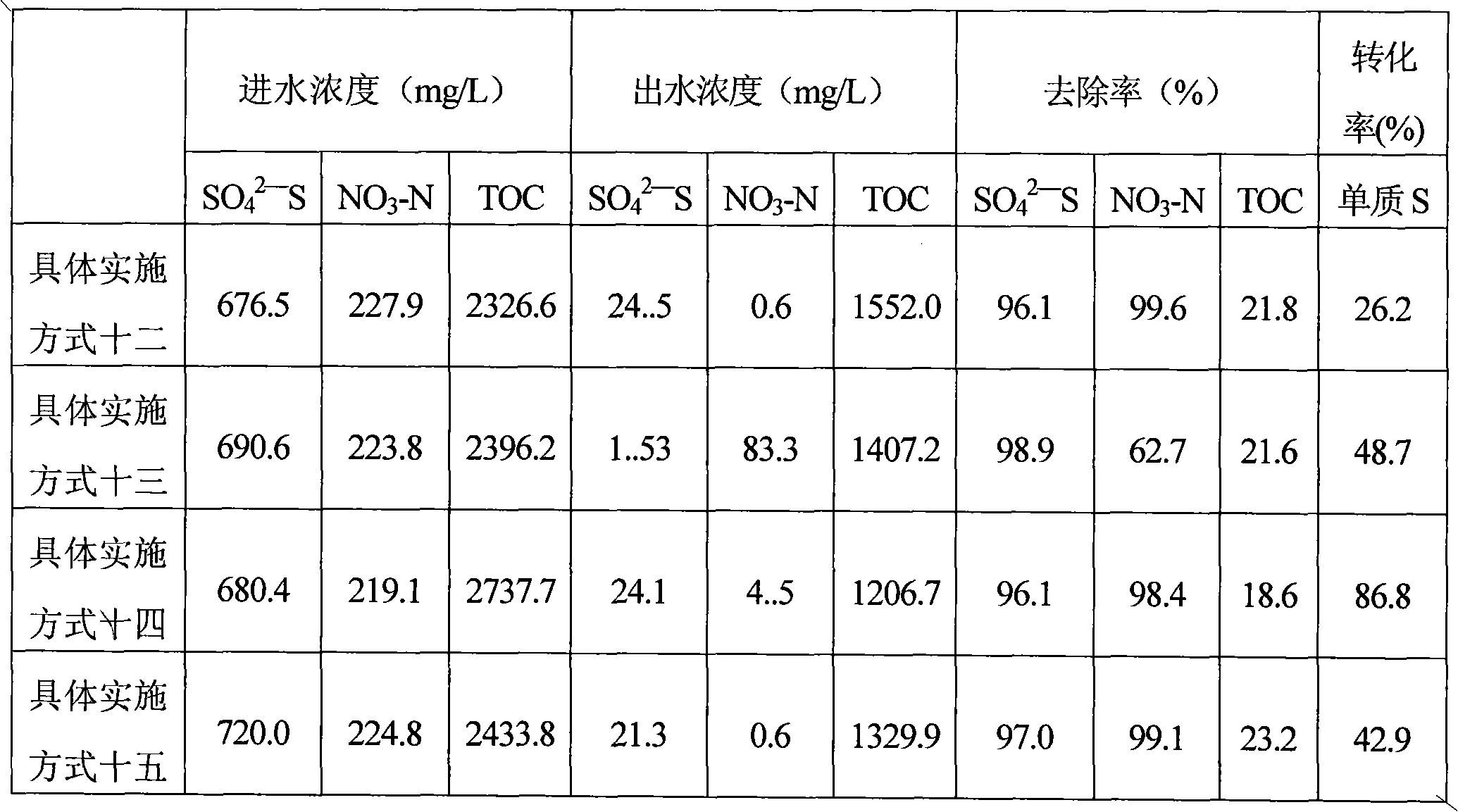

Method and equipment for synchronous removal of carbon, nitrogen and sulfur

InactiveCN101774692AImprove processing efficiencyHigh yieldWater/sewage treatmentTreatment with aerobic and anaerobic processesAeration rateChemistry

The invention discloses a method and equipment for synchronous removal of carbon, nitrogen and sulfur, relating to a water treatment method and equipment thereof. The invention solves the problem of complex process, low processing efficiency, poor operability and low elemental sulfur conversion rate which easily leads to secondary pollution in the existing method for synchronous removal of carbon, nitrogen and sulfur. The method is as follows: adding active sludge into the equipment used for synchronous removal of carbon, nitrogen and sulfur, and controlling the temperature of the equipment, pH, and concentration of dissolved oxygen, the volume load of elemental sulfur, the volume load of NO3-N, the aeration rate and the hydraulic retention time. In this way, the carbon, nitrogen and sulfur can be removed synchronously. The equipment comprises a fluidized bed reactor, a gas flowmeter, a tapered gas collecting hood, an aeration pump and a microporous aeration strip. With the method, the efficiency is high, the conversion rate of the elemental sulfur is high, the problem of secondary pollution easily caused by low elemental sulfur conversion rate is solved, the process is simple and easy to control and the operating cost is low.

Owner:HARBIN INST OF TECH

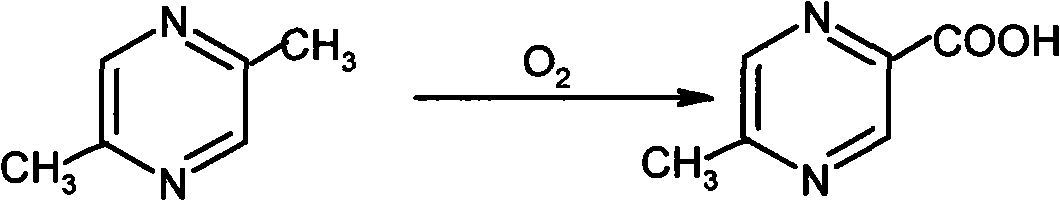

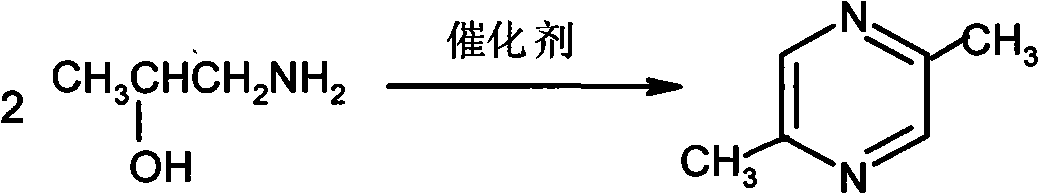

Preparation method of 5-methylpyrazine-2-carboxylic acid

The invention relates to an improved preparation method of 5-methylpyrazine-2-carboxylic acid. The method comprises the following steps of: carrying out an oxidation reaction in an acetic acid solvent by using 2,5-dimethylpyrazine as raw materials, cobalt acetate and manganese acetate as catalysts and potassium bromide as a cocatalyst, wherein the temperature of the oxidation reaction is 90-110 DEG C; when a small quantity of unreacted 2,5-dimethylpyrazine is detected to be still in the reaction system, ending the oxidation reaction; and cooling reaction liquid obtained after the oxidation reaction is ended, crystallizing, filtering and drying to obtain the 5-methylpyrazine-2-carboxylic acid, wherein the 2,5-dimethylpyrazine is prepared by using isopropanolamine as raw materials, introducing H2 and N2 in the presence of an activated Al-Cu-Ag-Zn catalyst at 200-280 DEG C for a continuous feeding reaction and simply distilling the reaction liquid. The method has easy obtaining of raw materials, simple and convenient operation, short step, good product quality and low product cost and is more suitable for industrial production.

Owner:常州市康瑞化工有限公司

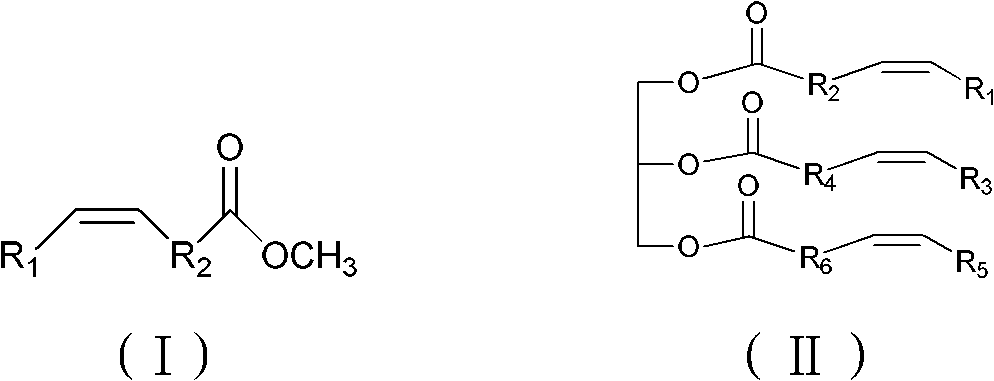

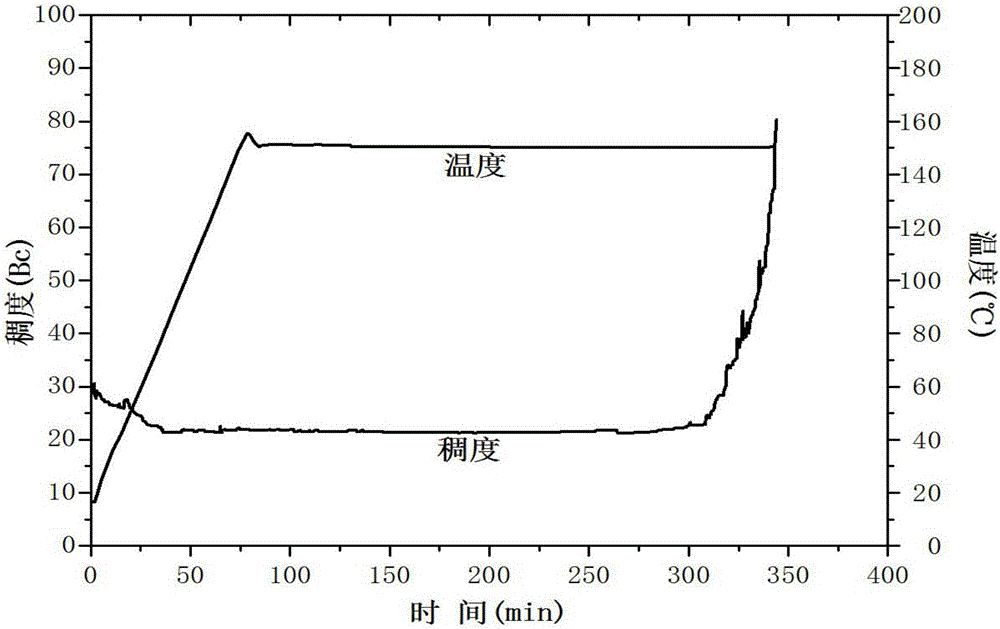

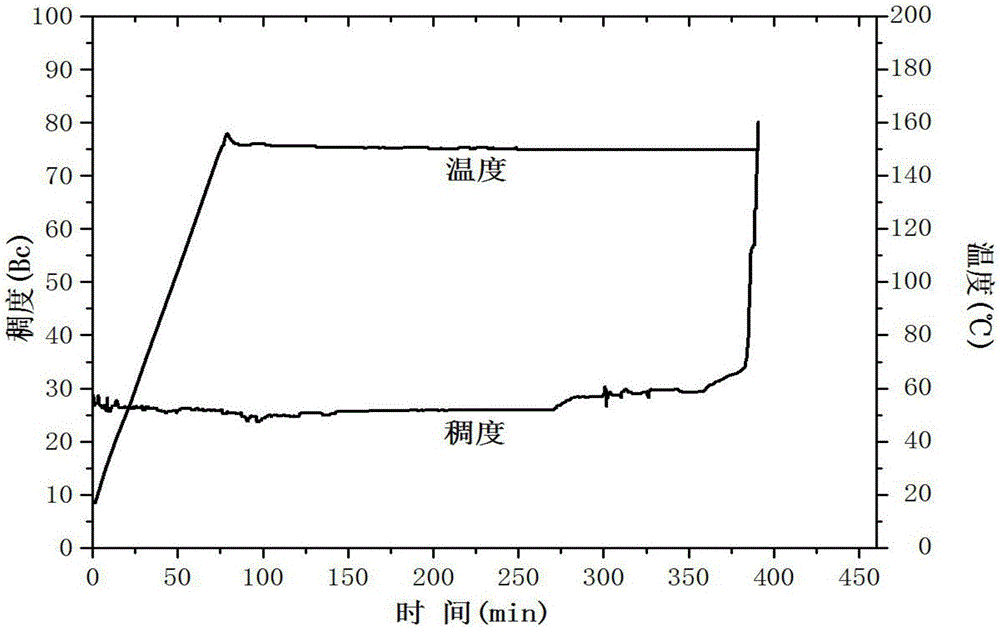

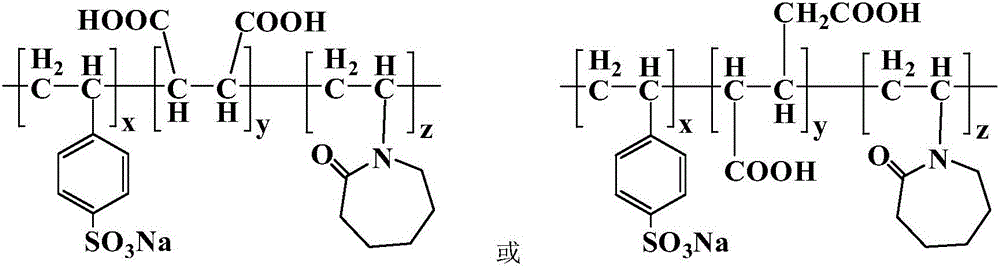

High-temperature-resistant oil-well cement retarder and preparation method thereof

InactiveCN106085389AIncrease success rateEasy to operateDrilling compositionViscous liquidPotassium persulfate

The invention discloses a high-temperature-resistant oil-well cement retarder and a preparation method thereof. The cement retarder comprises three structural units of sodium p-styrenesulfonate, maleic acid or itaconic acid, and N-vinylcaprolactam. The preparation method for the cement retarder comprises the following steps: (1) mixing odium p-styrenesulfonate, maleic acid or itaconic acid, and N-vinylcaprolactam according to the mass ratio of 10-17:2-7:1-3, dissolving in deionized water, controlling the total mass concentration of the monomers in the solution to be 10-20%, and adjusting the pH value of the solution to be 4-9; (2) introducing nitrogen into a reactor for removing oxygen, and adding an initiator potassium persulfate into the reaction system after the temperature of the reaction system raises to 55-70 DEG C; and (3) reacting 3-7 h, cooling the yellow slightly-viscous liquid product to room temperature, and performing purification, drying and crushing. The cement retarder possesses high-temperature resistance as well as high-temperature settlement stability, and the preparation method of the cement retarder has reliable principle, is convenient to operate, and possesses wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

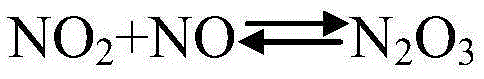

Method for reducing NOX concentration in tail gas of waste acid cracking device

InactiveCN106731826AEfficient denitrification rateLeading environmental protection conceptGas treatmentDispersed particle separationAmmonium hydroxideReducing agent

The invention relates to a method for reducing NOX concentration in a tail gas of a waste acid cracking device. After the exhaust gas at an outlet of a fifth section of an acid-making converter is adjusted by a heat exchanger or a waste heat recovery device, a SCR selective catalytic reduction reactor is introduced, a reducing agent (such as NH3 and ammonium hydroxide) and a catalyst are utilized to selectively react with NOx in the tail gas and generate non-toxic and pollution-free N2 and H2O, and then the reducing agent NH3 is oxidized into N2 and H2O through an oxidation catalyst layer at the tail end of the SCR reactor and the N2 and H2O are discharged together with the tail gas of a tail absorbing tower. A selective catalytic reduction system is composed of a catalyst reactor, an ammonia supplying device, an ammonia jetting device and related detection equipment and instrument control instruments. The selective catalytic reduction system has the advantages of compact structure, less occupied space, convenience in maintenance and low investment cost.

Owner:JIANGSU KERUI ENG DESIGN CO LTD

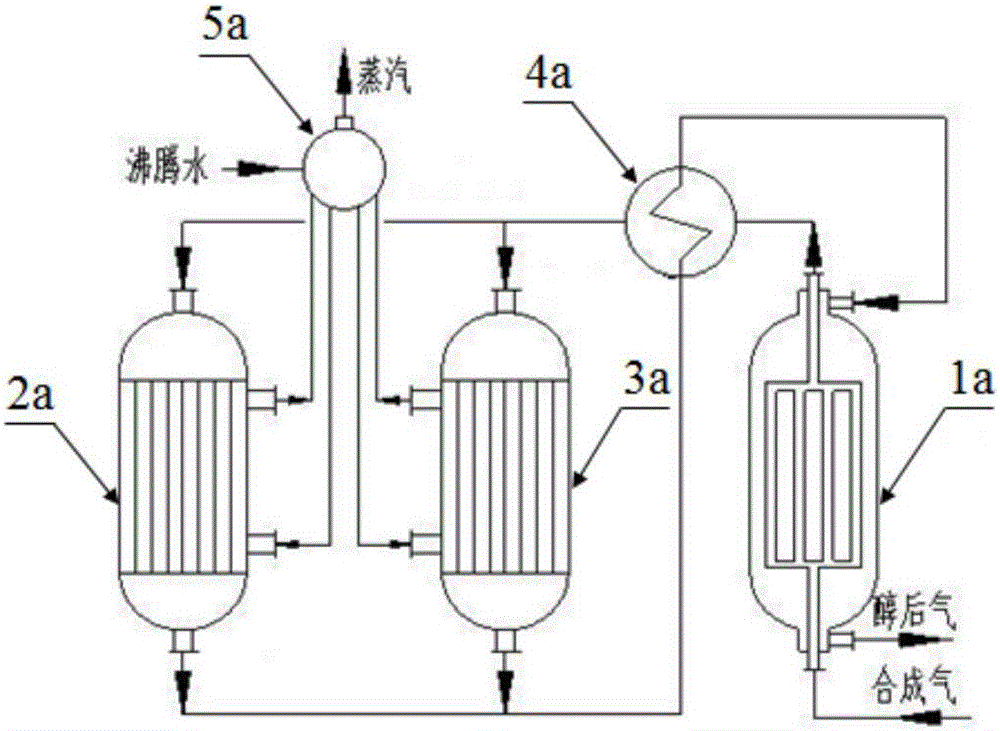

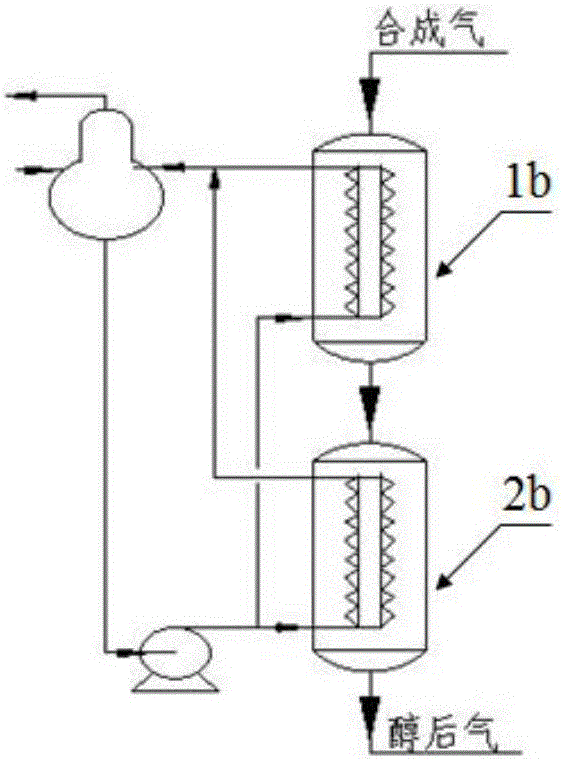

Energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation method and energy-saving inter-section high low temperature gradient alcohol-division two-stage alcohol generation device

ActiveCN105753646AReduce CO concentrationGuaranteed conversion rateOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation method which comprises the following steps: respectively reheating fresh synthesis gas and recycle gas, mixing the fresh synthesis gas with the recycle gas, introducing the mixed gas into a first reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the first reactor, guiding the mixture to flow to a first methyl alcohol separator, separating out methyl alcohol, pressurizing the separated gas, preheating, then introducing into a second reactor, and enabling part of carbon oxides to react to obtain methyl alcohol; cooling a mixture containing synthesis gas and methyl alcohol steam output from the second reactor, guiding the mixture to flow to a second methyl alcohol separator, separating out methyl alcohol, preheating the separated gas which separately serves as the recycle gas and fresh synthesis gas, mixing the recycle gas and the fresh synthesis gas, and feeding the mixture into the first reactor so as to perform next round of circulating preparation of methyl alcohol. The invention further discloses an inter-section high low temperature gradient alcohol-division two-stage alcohol generation device. The method is relatively high in single-pass alcohol net value and relatively small in circulation ratio, achieves a ton-alcohol steam yield as high as 1.2-1.3 ton, and is high in energy heat recovery amount.

Owner:NANJING GOODCHINA CHEM TECH

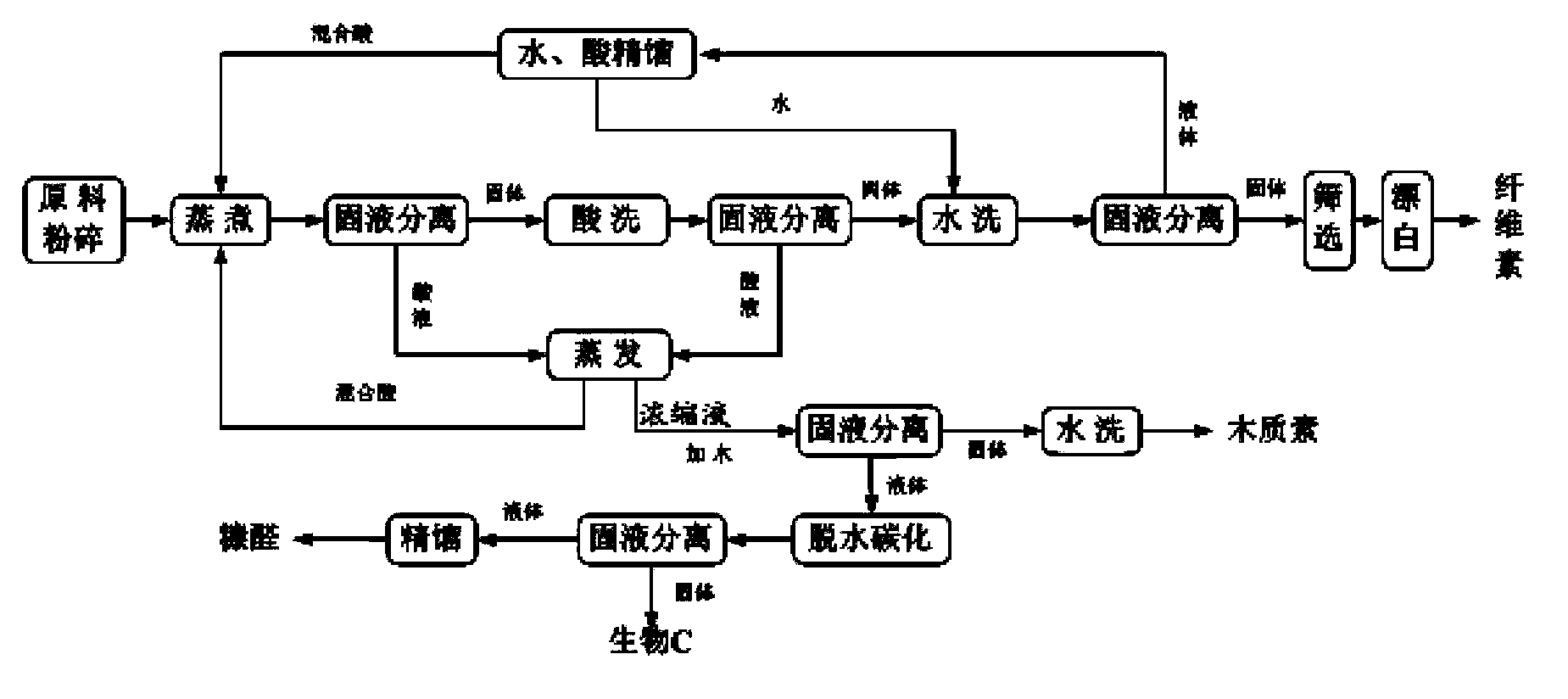

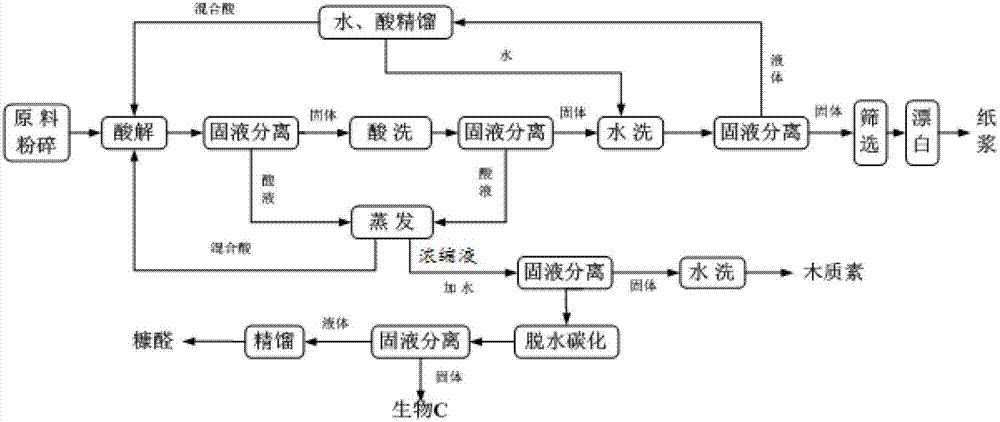

Comprehensive utilization method of biomass raw material

ActiveCN103898787AImprove extraction efficiencyShorten cooking timePulp bleachingCarbon preparation/purificationOrganic acidFormic acid

The invention relates to a comprehensive utilization method of a biomass raw material, and concretely relates to a method for comprehensively utilizing celluloses, hemicelluloses and lignin in the biomass raw material. The method is characterized in that the celluloses, lignin and the hemicelluloses can be respectively extracted by boiling the biomass raw material through a formic acid and acetic acid mixed organic acid under the catalysis action of hydrogen peroxide in order to obtain highly pure celluloses and lignin, the combined production of furfural and biochar is realized by utilizing a residual sugar solution, and the highly pure celluloses can be used in the textile industry.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Method for preparing cationic polyacrylamide through photo-initiating system

ActiveCN107151289AChain growth proceeds uniformly and orderlyGood linearityWater/sewage treatment by flocculation/precipitationSolventIon

The invention relates to a method for preparing cationic polyacrylamide through a photo-initiating system. The method comprises the following steps of sequentially adding deionized water, acrylamide monomer, cationic monomer and cosolvent into a quartz reaction device until the materials are completely dissolved; adjusting a pH value of a solution; sequentially adding an azo initiator and a redox initiator into the reaction device while introducing high-purity nitrogen; sealing the reaction device and then putting the reaction device on an ultrasonicscope to be evenly oscillated; putting the reaction device on a rotary disk which rotates at a constant speed; utilizing a control method of low light intensity at first and then high light intensity to react; curing, washing, refining, drying and grinding generated polyacrylamide colloid to obtain a final product. The method can keep a certain concentration of free radicals in a reaction system and guarantees that chain growth proceeds evenly and orderly; the prepared polyacrylamide has good solubility and good flocculating performance; furthermore, an ultraviolet photo-initiating method has the advantages of low production energy consumption, high production efficiency, simpleness to operate, easiness to control and the like; the method disclosed by the invention has a good market application prospect.

Owner:SHENGLI OIL FIELD FANGYUAN CHEM IND

Method for preparing macromolecular adsorbents with large specific surface area

ActiveCN107955093AGuaranteed conversion rateGuaranteed hardnessOther chemical processesAlkali metal oxides/hydroxidesSol-gelSorbent

The invention discloses a method for preparing macromolecular adsorbents with large specific surface area by means of step-by-step suspension copolymerization pelletization by the aid of sol-gel procedure of vinylsilane coupling agents. The method mainly includes steps of (1), carrying out step-by-step suspension copolymerization on the vinylsilane coupling agents, polyethylene aromatic monomers and ethylene aromatic monomers to obtain copolymer beads; (2), extracting pore-forming agents from the copolymer beads and then hydrolyzing and cross-linking the copolymer beads in acid environments toobtain the macromolecular adsorbents cross-linked after sol-gel treatment. The method has the advantages that the method includes simple procedures and is environmentally friendly, secondary cross-linking steps are carried out, and accordingly, reagents such as chloromethyl methyl ether and dichloroethane with high toxicity can be omitted; the compressive properties and the heat stability of themacromolecular adsorbents prepared by the aid of the method can be obviously improved.

Owner:WANHUA CHEM GRP CO LTD +1

Method for planting mulberries

The invention discloses a method for planting mulberries. The method comprises steps of roots treatment of mulberry seedlings comprising washing roots of the mulberry seedlings in the middle ten days of February, drying in the air, soaking the roots of the mulberry seedlings in a rooting powder solution special for mulberries for 3 to 5 hours, taking out and drying in the shade for 2 to 4 days; mulberry seedling grafting; seedling culture using grafting bodies comprising fully stirring a composite fertilizer, silkworm excrement, clayey soil and an anticorrosion aqueous solution to form nutrient soil, wrapping the nutrient soil surrounding the middle-lower portion of stocks of the grafting bodies, planting in a nursery, pinching and bifurcating when mulberry buds on ears for cutting of the grafting bodies survive and as high as 10 to 15 cm, and cultivating the grafting bodies until the grafting bodies grow to mulberry seedlings and each having 2 to 3 branches; and filed plantation of the mulberry seedlings. The method for planting mulberries is short in period, high in survival rate, high in yield and low in cost, and mulberry seedlings obtained by the method can quickly grow up.

Owner:安徽韵沣农业发展股份有限公司

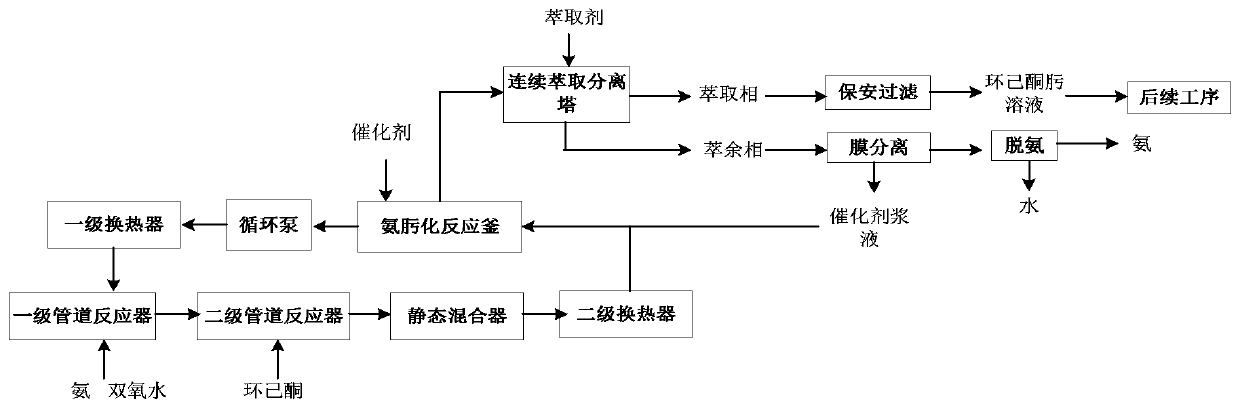

Preparation method of heterogeneous cyclohexanone oxime

The invention discloses a preparation method of heterogeneous cyclohexanone oxime. The method includes the following steps that ammonia and hydrogen peroxide react to generate hydroxylamine under theeffect of a catalyst, then the hydroxylamine reacts with cyclohexanone to generate cyclohexanone oxime, cyclohexanone oxime is extracted in an extraction phase to complete the separation of an organicphase and an inorganic phase, the extraction phase enters subsequent processes after filtering, and after being subjected to membrane separation, and extraction-phase catalyst slurry is returned to an ammoximation reaction kettle to participate in a catalytic reaction again. The ammoximation reaction is performed in a solvent-free state, the use of organic solvents is avoided, the energy consumption is low, there are fewer side reactions and fewer by products, and the subsequent refining process has small pressure. As there is no solvent, the reaction space is saved, and compared with the solvent-containing ammoximation reaction using the same device for production, the yield is improved. A hydroxylamine mechanism serves as a reaction mechanism, the conversion frequency of the hydroxylamine mechanism is about 2.5 times of that of an imine mechanism at 80 DEG C, and the conversion rate of cyclohexanone is high.

Owner:河北美邦工程科技股份有限公司

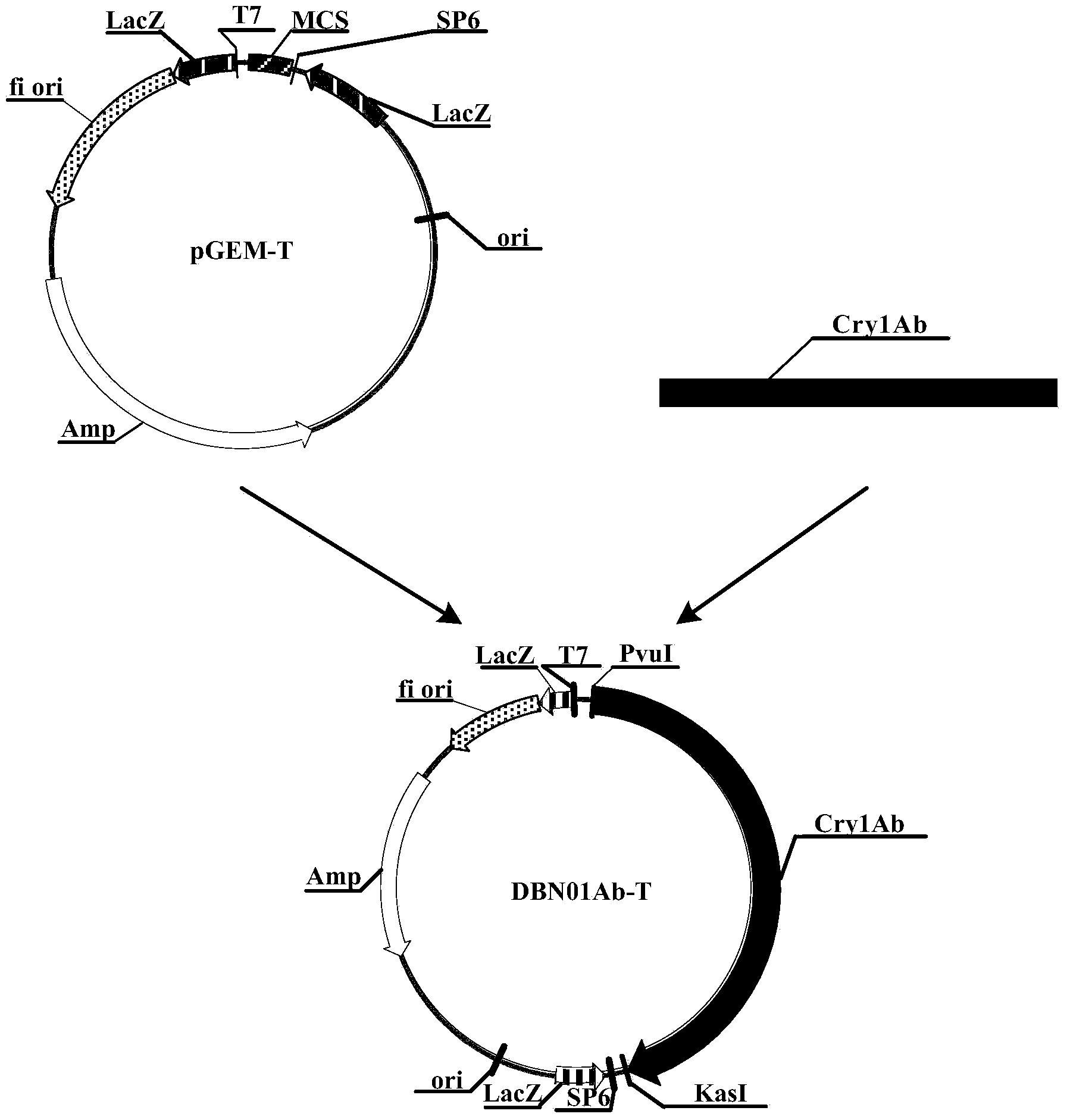

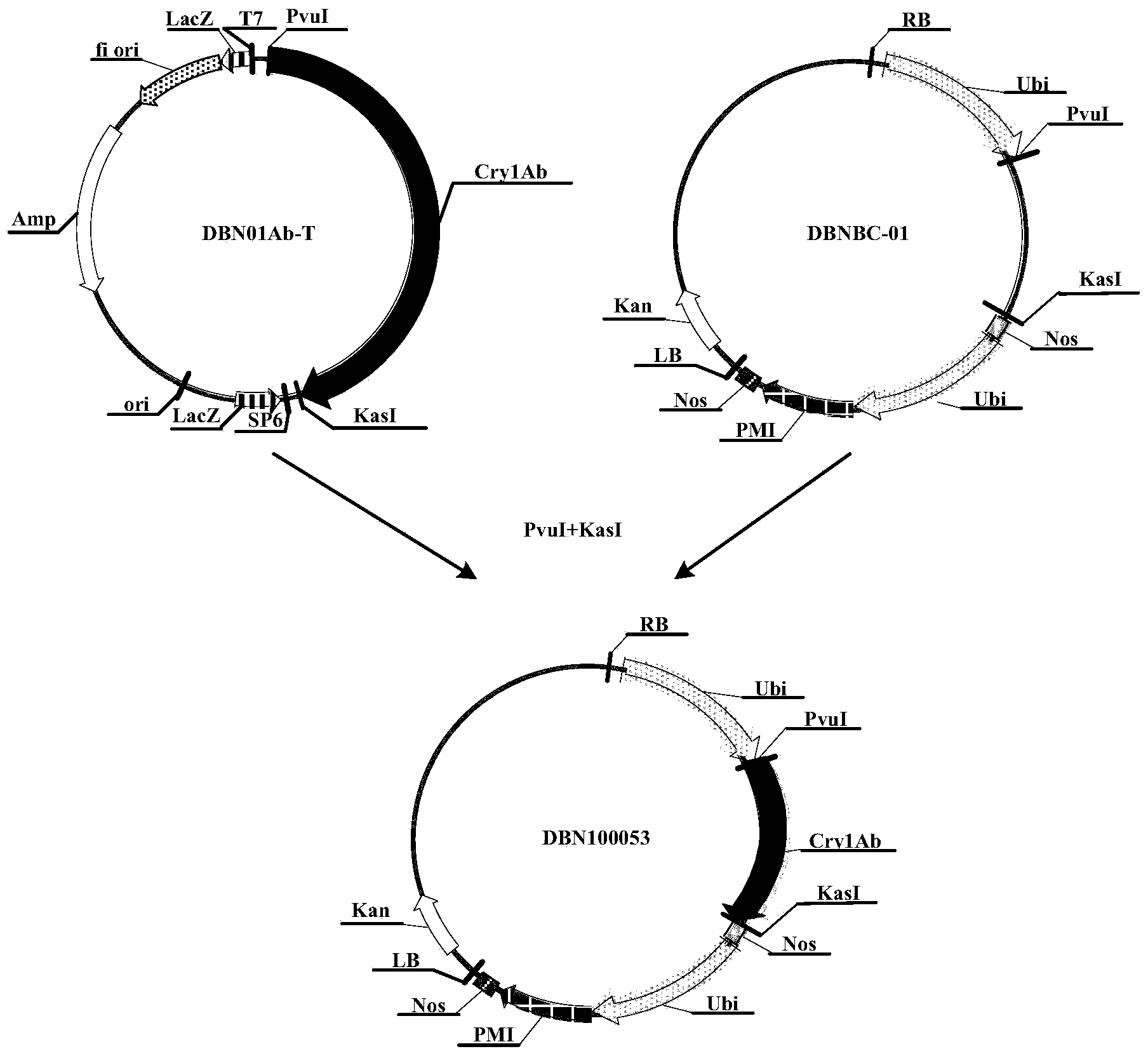

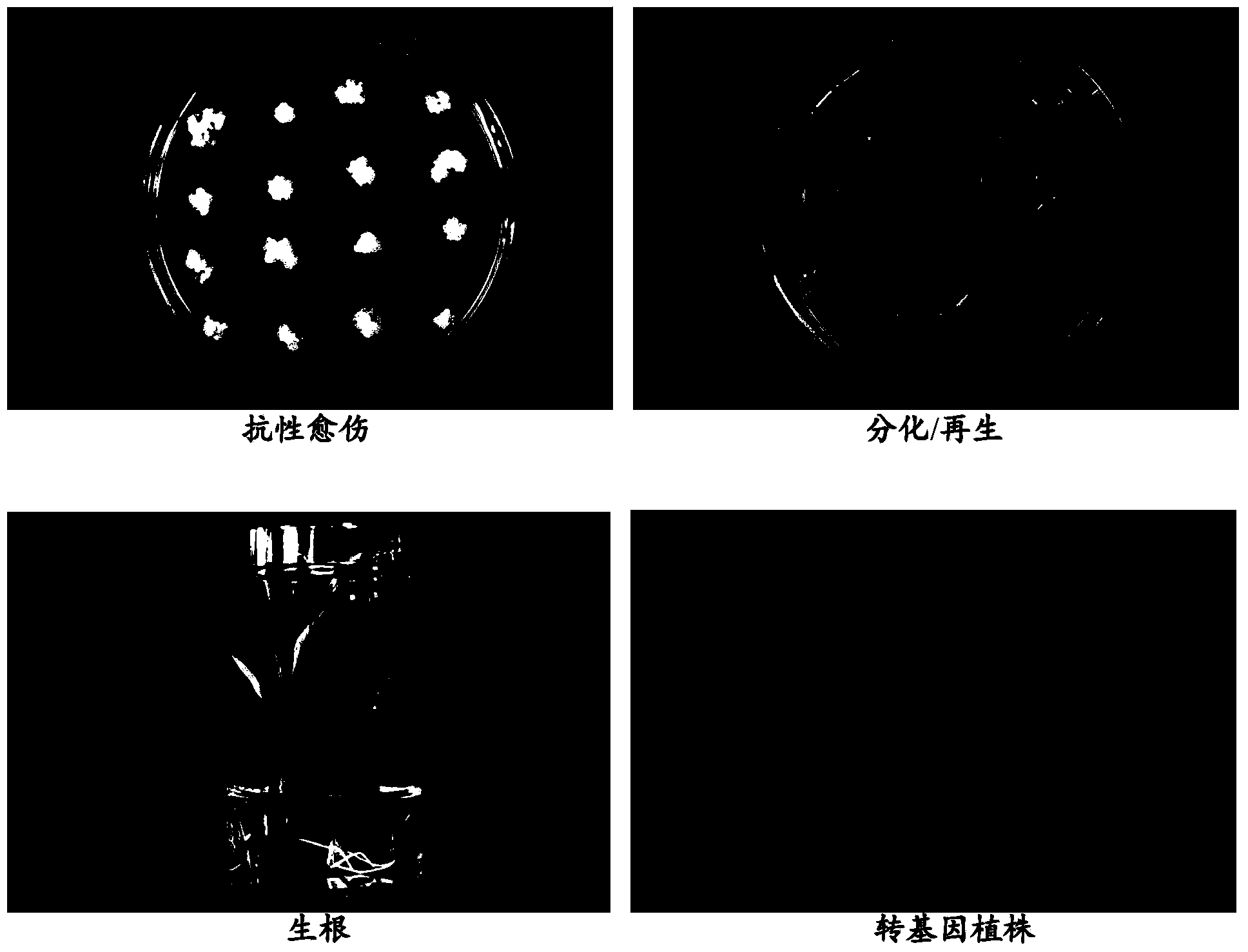

Maize transformation method

The invention relates to a maize transformation method which comprises the following steps: stripping young maize embryos for inducing callus; and infecting the callus by agrobacterium. The maize transformation method fulfills the purpose that the callus induced by the young maize embryos serves as an acceptor material for transformation for the first time, and ensures that the transformation rate can reach up to 5%; meanwhile, the maize callus with high quality and large amount can be obtained for subculture propagation, and can be easily available and also be supplied on a large scale, so that the requirement of maize transformation on the acceptor material can be fully met; the defect that the harvest condition of explants cannot be accurately predicted due to the limitation of weather conditions on field materials can be overcome, so that maize genetic transformation is not influenced by seasons, and the requirement on annual stable transformation can be met; in addition, the dependence on the young maize embryo in the prior art is cut, and maize does not need to be planted in a greenhouse and the like in non-maize-planting seasons, so that the cost for obtaining the acceptor material is greatly reduced.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

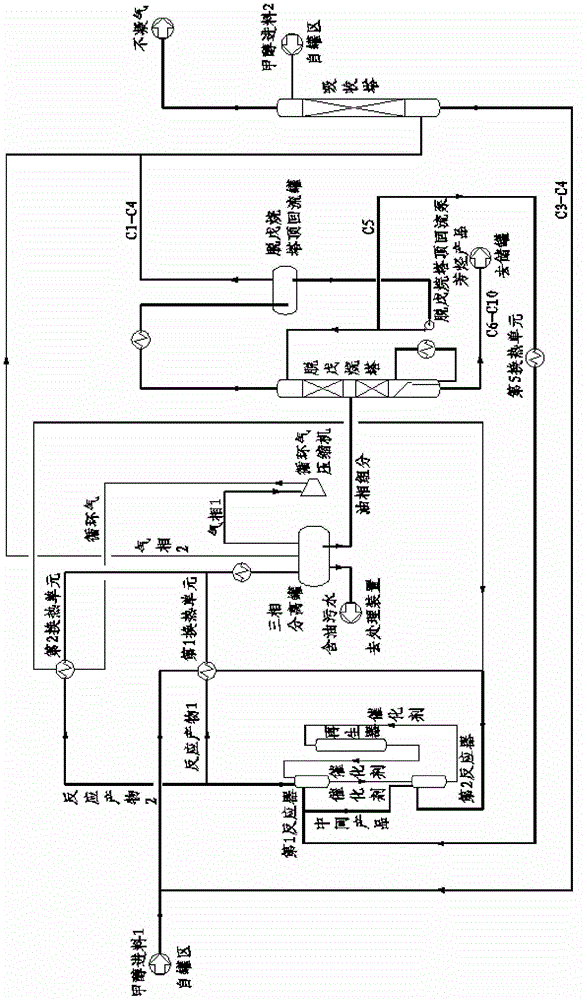

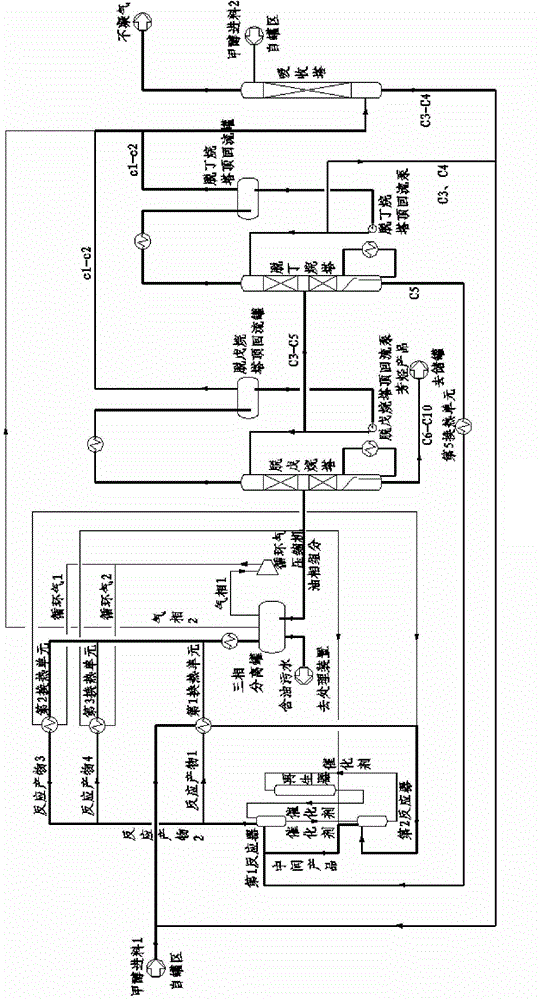

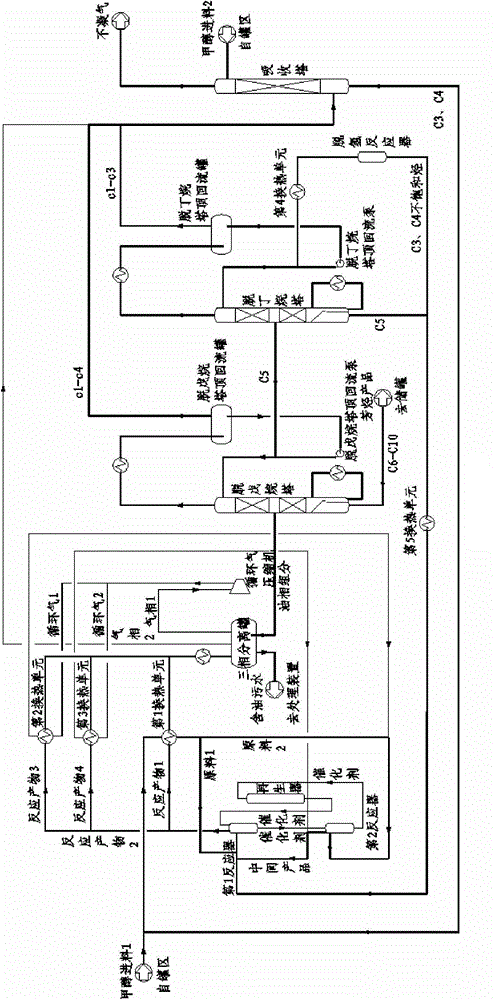

Moving bed methanol-to-hydrocarbon method

ActiveCN104818042AGuaranteed conversion rateImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAromatic hydrocarbonMoving bed

The invention relates to a moving bed methanol-to-hydrocarbon method. The method comprises the steps of hydrocarbon synthesis, separation and post-treatment, at least two serially connected reactors are adopted in the hydrocarbon synthesis step, a reaction raw material and a catalyst sequentially flow through the reactors in a countercurrent direction, low carbon olefin-containing circulation gas generated in the separation step returns to different feeding positions in the hydrogen synthesis step as quenching gas or raw material supplement gas in the hydrocarbon synthesis step, and a raw material methanol is used to wash and absorb C1-C4 light components generated in the separation step, returns, is fed and is converted in order to convert methanol into mixed aromatic hydrocarbon-containing stable light hydrocarbon with high added values. The method allows step complete utilization of the activity of the catalyst to be carried out, so the method improves the fine control of the reaction process, realizes effective material utilization and heat integration between processing processes, improves the product yield, reduces energy consumption and reduces environmental pollution.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Comprehensive utilization technology of biomass raw materials

ActiveCN103031763AGood filterabilitySimple process routeOrganic chemistryPulp bleachingOrganic acidAcetic acid

The invention relates to a comprehensive utilization method of biomass raw materials, in particular to a method of utilizing the biomass raw materials to make paper pulp, to recover lignin and to co-produce furfural and biological carbon. The method comprises the steps that mixed organic acid of formic acid and acetic acid is utilized to boil the biomass raw materials by the catalytic action of hydrogen peroxide; in a process of making the paper pulp, the lignin in black liquor is recovered; and a residual sugar solution is utilized to co-produce the furfural and the biological carbon. According to the utilization method, reasonable technological parameters are designed to ensure that a whole technological route is simple; the whole technology is applicable to wood raw materials and grass raw materials; a follow-up bleaching technology of the technological route is simple; and the obtained paper pulp has good drainability.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Acrylic emulsion of novel transfer adhesive and preparation method of acrylic emulsion

ActiveCN104193888AGood adhesionGood transferabilityEster polymer adhesivesPolyethylene terephthalate glycolSodium sulfate

The invention discloses an acrylic emulsion of a novel transfer adhesive. The acrylic emulsion comprises the following raw materials: alkyl alcohol polyether, lauryl sodium sulfate, a pH regulator, ammonium persulfate, tert-butyl hydroperoxide, sodium hydrogen sulfite, ammonia water and isothiazolinone; inner-core monomers comprise styrene, methyl methacrylate, butyl acrylate, acrylic acid and N-hydroxymethyl acrylamide; and outer-shell monomers comprise styrene, methyl methacrylate, butyl acrylate, acrylic acid and N-hydroxymethyl acrylamide. The acrylic emulsion has the beneficial effect that the solid content is not less than 50%, and the characteristics such as adhesion, transfer and folding resistance are excellent; the acrylic emulsion can be widely applied to transferring to paper products from aluminum-coated layers on polymer base materials such as BOPP (biaxially-oriented Polypropylene) and PET (polyethylene terephthalate), is safe and environmentally friendly, low in VOC (volatile organic compounds) and capable of satisfying the industries with safety and sanitation requirements such as cigarette packaging.

Owner:ETABONG QINGDAO INDAL

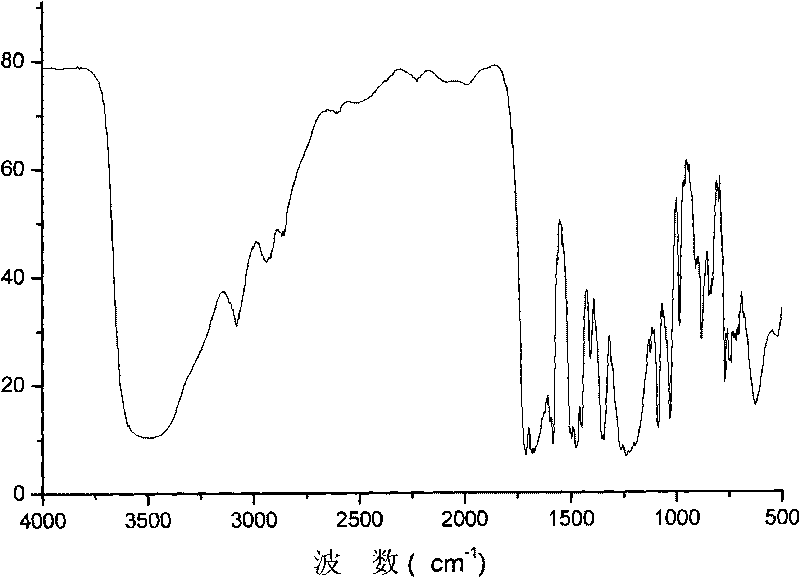

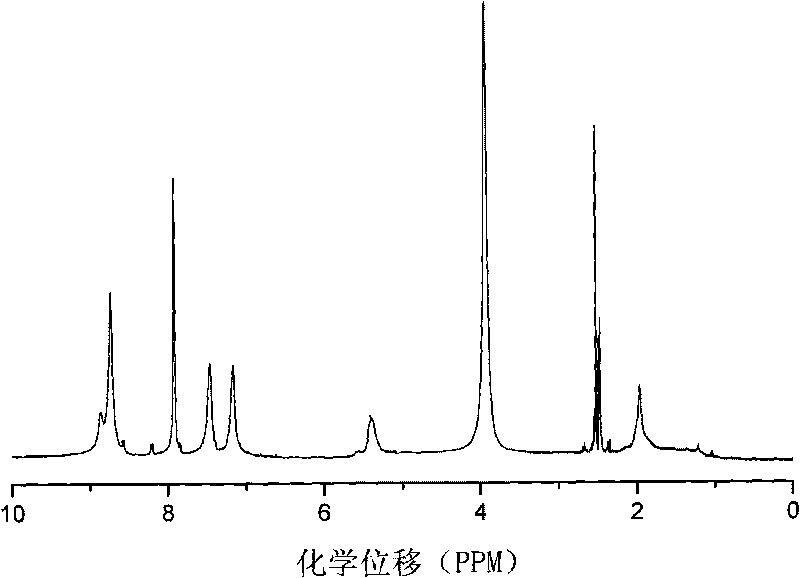

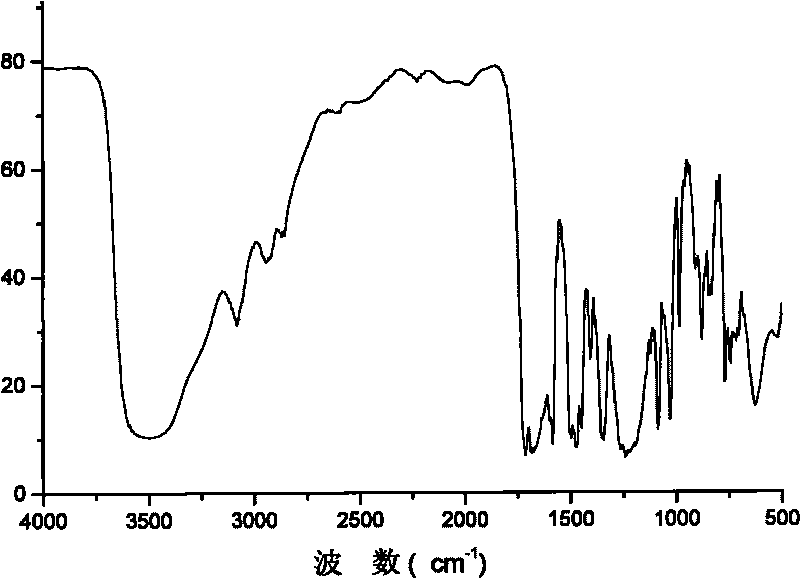

Segmented copolymer of fully sulfonated polymide and partly sulfonated polybutadiene and preparation method thereof

InactiveCN101701072AHigh mechanical strengthImprove machinabilityCell component detailsFuel cell detailsNaphthalenetetracarboxylic dianhydrideAcetic anhydride

The invention discloses a segmented copolymer of fully sulfonated polymide and partly sulfonated polybutadiene and a preparation method thereof. Sulfonated diamino monomer and naphthalene tetracarboxylic acid dianhydride monomer in a specific proportion are used as the raw materials to be subjected to polycondensation to obtain amino-terminated fully sulfonated polymide, and thionyl chloride is used for modifying carboxyl terminated polybutadiene to prepare chloroacyl terminated polybutadiene; the above two prepolymers react under the anhydrous condition, thus the segmented copolymer of fully sulfonated polymide and polybutadiene can be obtained; and finally acetyl sulfonic ester prepared by concentrated sulphuric acid and acetic anhydride is used for carrying out post sulfonation on the polybutadiene segment, thus preparing the segmented copolymer of the fully sulfonated polymide and partly sulfonated polybutadiene. The segmented copolymer of the invention is dissolved in an organic solvent and is coated with membranes, thus preparing proton exchange membranes applied to fuel cells. The membranes have good proton-conducting properties and mechanical properties. The segmented copolymer has extensive application prospect in the field of the proton exchange membranes applied to fuel cells.

Owner:SHANGHAI JIAO TONG UNIV

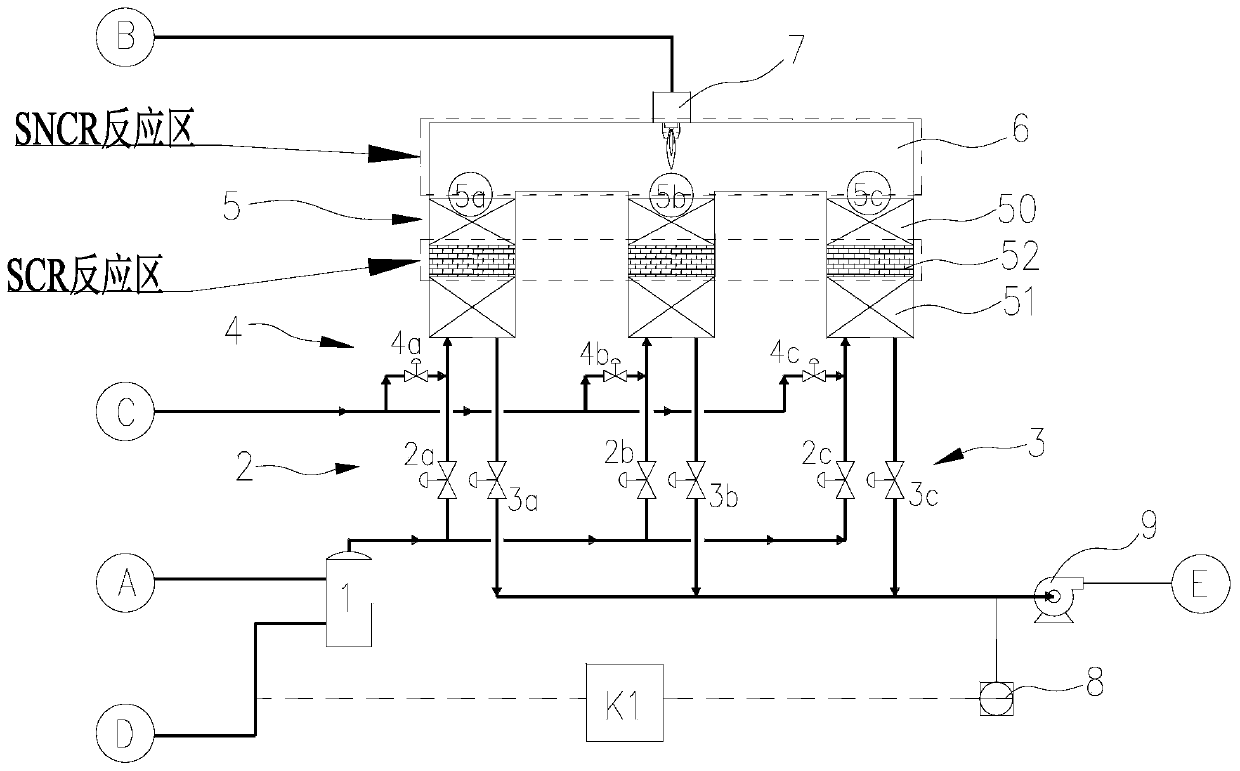

Treatment device and process integrating VOCs purification and denitration

PendingCN110605019AEfficient removalReduce energy consumptionDispersed particle separationIncinerator apparatusCombustorCombustion chamber

The invention discloses a treatment device and process integrating VOCs purification and denitration. The treatment device includes an RTO reactor; the RTO reactor comprises a combustion chamber and aplurality of regenerative chambers, the combustion chamber and the regenerative chambers are communicated, and the combustion chamber is located on the upper portions of the regenerative chambers; each regenerative chamber comprises an upper-section heat accumulator, a lower-section heat accumulator and a middle SCR catalyst bed layer; an air inlet valve, an air outlet valve and a purging valve are arranged at the bottom of any regenerative chamber; the input end of the gas inlet valve is connected with a buffer tank, and the buffer tank is connected with a VOCs waste gas pipeline and an ammonia gas pipeline; the input end of the purge valve is connected with a purge gas supply pipeline; a combustor is further arranged at the top of the combustion chamber, wherein the input end of the combustor is connected with a fuel gas pipeline. According to the device, the high-temperature environment in the RTO reactor is fully utilized in the SNCR-SCR reaction, ultra-clean emission of VOCs andNOx is achieved, and the purpose of reducing energy consumption is achieved. Meanwhile, a corresponding treatment process is provided, so that VOCs can be effectively purified and NOx can be effectively removed at the same time, and the operation is reliable.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

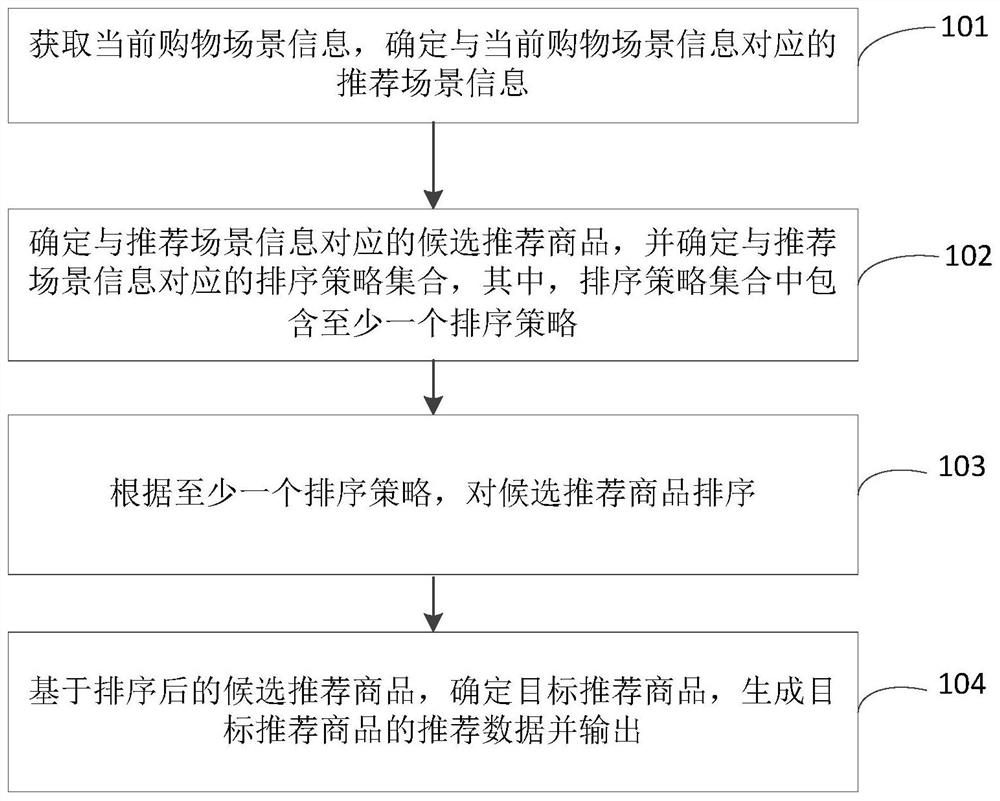

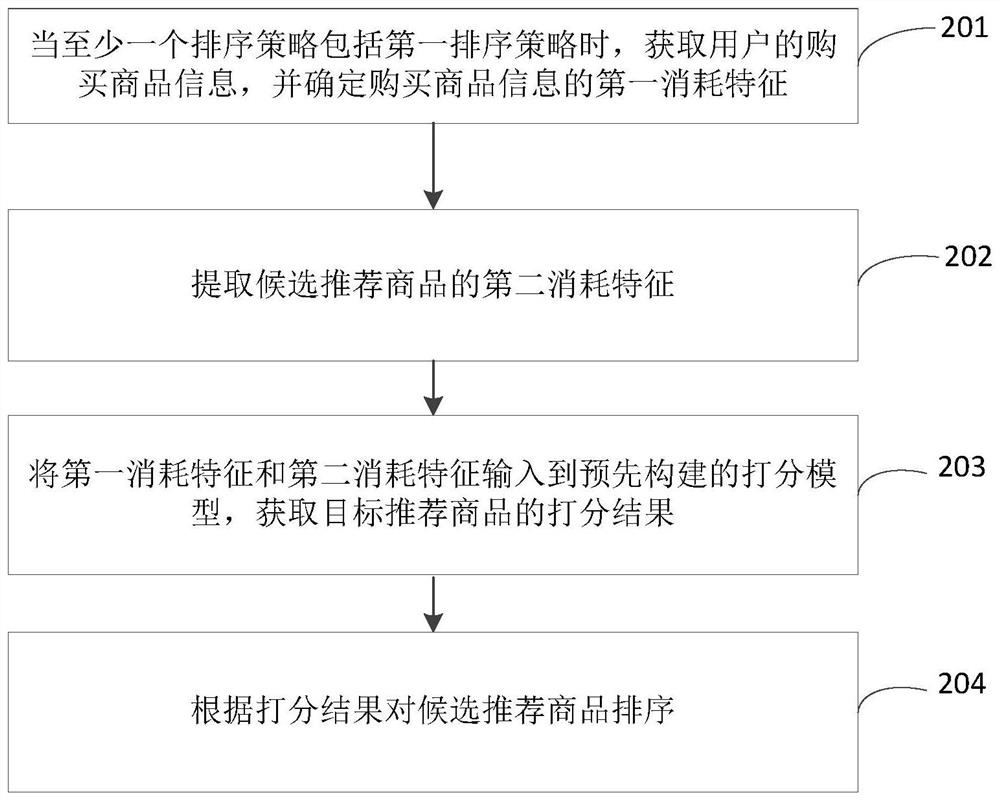

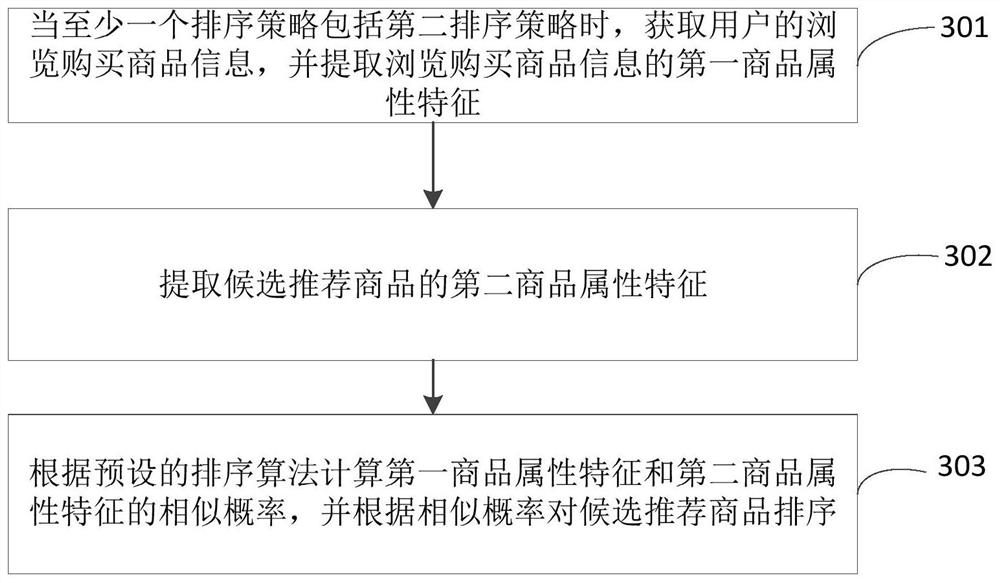

Commodity recommendation method and device combining RPA and AI

PendingCN112288517AGuaranteed conversion rateBuying/selling/leasing transactionsData miningData science

Owner:BEIJING LAIYE NETWORK TECH CO LTD +1

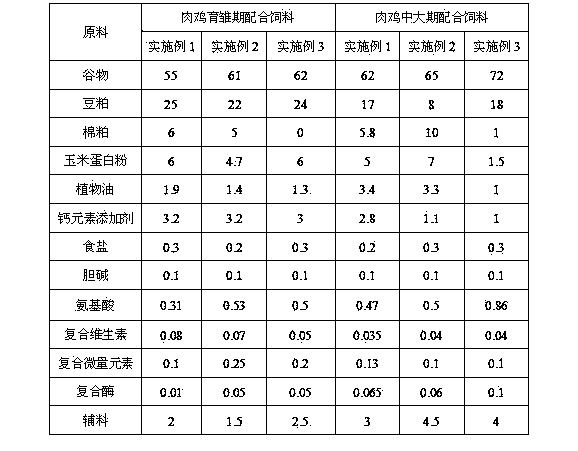

Antibiotic-free compound feed for fryers

InactiveCN103385375AImprove balanceImprove conversion rateAnimal feeding stuffVegetable oilAntibiotic Y

An antibiotic-free compound feed for fryers comprises following raw materials in parts by weight: 50 to 75 parts of cereal, 5 to 25 parts of soybean meal, 0 to 10 parts of cotton seed meal, 0 to 8 parts of corn protein flour, 1.0 to 3.5 parts of vegetable oil, 0.3 to 4.0 part of calcium addictive, 0.1 to 0.3 part of salt, 0.1 to 1.5 parts of amino acid, 0.05 to 0.25 part of choline, 0.05 to 0.30 part of compound trace elements, 0.03 to 0.10 part of compound vitamins, 0.01 to 0.10 part of compound enzymes, and 1 to 5 parts of auxiliary materials, which comprise following components: oligosaccharides, acidifying agent, bacillus subtilis, garlic, capsicum, pine needle powder, spine date seed and flue-cured tobacco seed. The antibiotic-free compound feed is capable of effectively increasing the growth speed of the fryers and reducing the death rate of the fryers. The yield of the fryers fed by the antibiotic-free compound feed is higher than that of the fryers fed by the antibiotic feed or the antibiotic-free feed. The problem that the fryer product contains drug residuals because of anti-biotic addictive in the feed can be solved, the problem that bacteria are resistant to drugs because of long term use of antibiotic can be avoided, and the antibiotic-free compound feed has a important meaning for production of no-harm fryer product.

Owner:SHENYANG DONGSHUN FEEDING

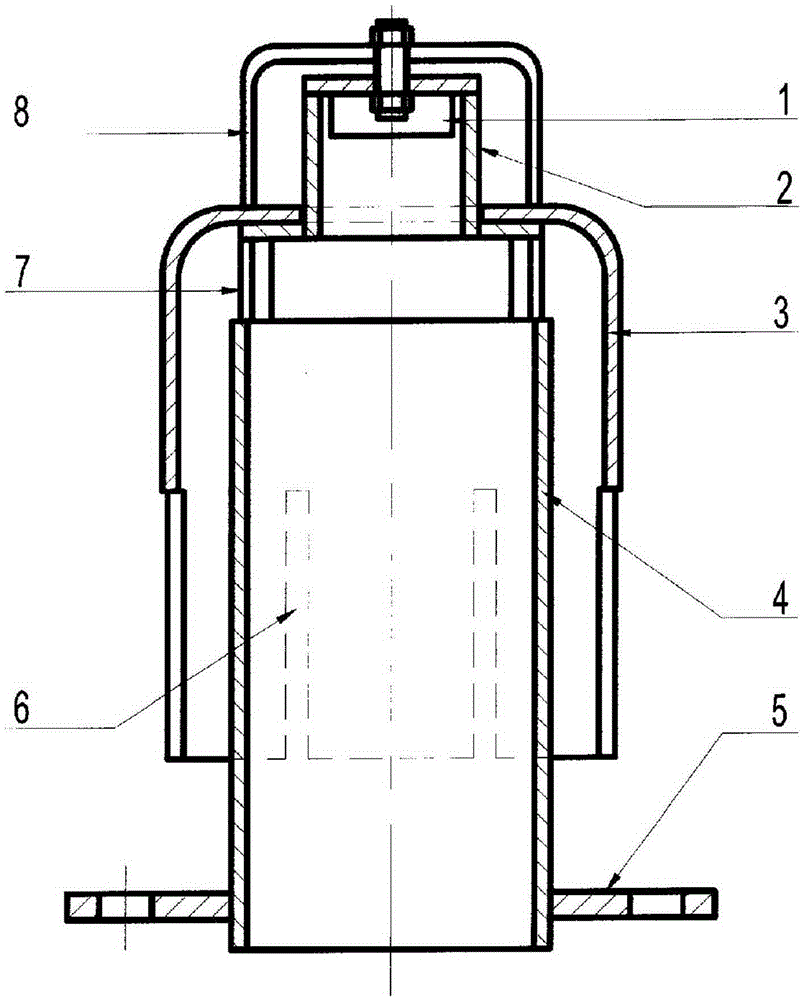

Material conveying method for horizontal reactor of potassium manganate

InactiveCN102161512ARealize continuous operationLess investmentChemical/physical/physico-chemical stationary reactorsManganates/permanganatesRetention timePotassium manganate

The invention provides a material conveying method for a horizontal reactor of potassium manganate. The method is characterized in that: a multi-stage stirring reaction chamber is arranged inside the horizontal reactor; the reaction chamber is divided into relatively-independent reaction spaces by a deflection plate; and the materials are pushed to flow from the lower part of a previous chamber to the upper part of a next chamber, that is, the materials flow from the lower part of a first chamber to the upper part of a second chamber, and then flow from the lower part of the second chamber to the upper part of a third chamber and by analogy to an outlet of the reactor. The material conveying method provided by the invention effectively solves the problem that the potassium manganate product deposits at the bottom of the reaction materials and can not overflow to the next reaction chamber because the specific weight of the potassium manganate product is higher than that of the materials, increases the retention time of the materials in the reactor, and avoids the 'short-cut' of the materials, therefore, the reaction efficiency and the conversion rate are increased, the continuous operation and continuous reaction is realized, the volume of the reactor is reduced, the heat loss is reduced, the equipment investment and the running cost are reduced, and the floor area occupied by the equipment is reduced. The method can be applied to the reactions of high-grade and low-grade materials, and has a board material applicable range.

Owner:YUNNAN JIANSHUI MANGANESE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com