Method and equipment for synchronous removal of carbon, nitrogen and sulfur

A technology for removing carbon and nitrogen, applied in the field of water treatment, can solve the problems of low conversion rate of elemental sulfur, low treatment efficiency, poor operability, etc., and achieve the effect of low operating cost, high treatment efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

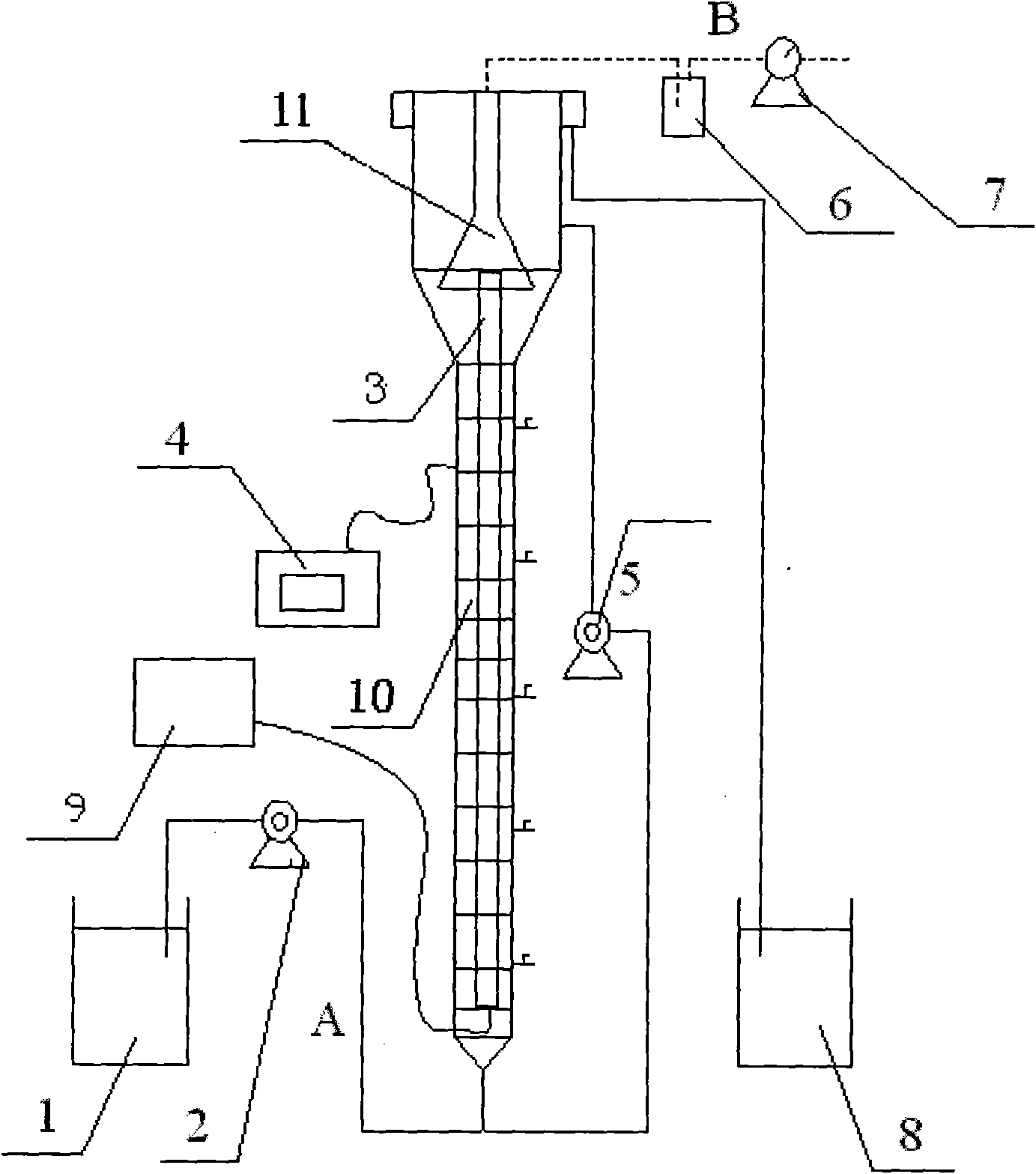

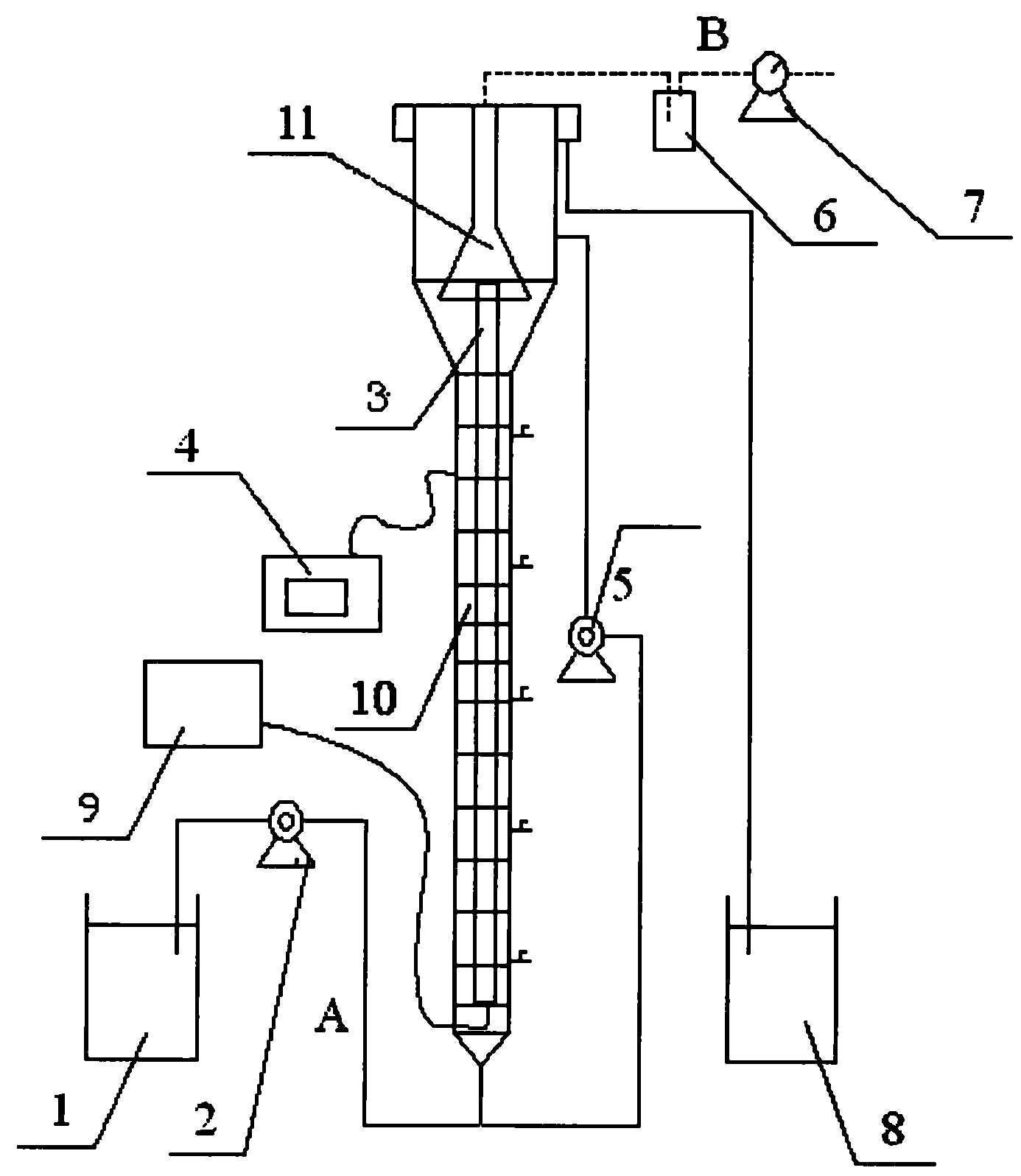

Method used

Image

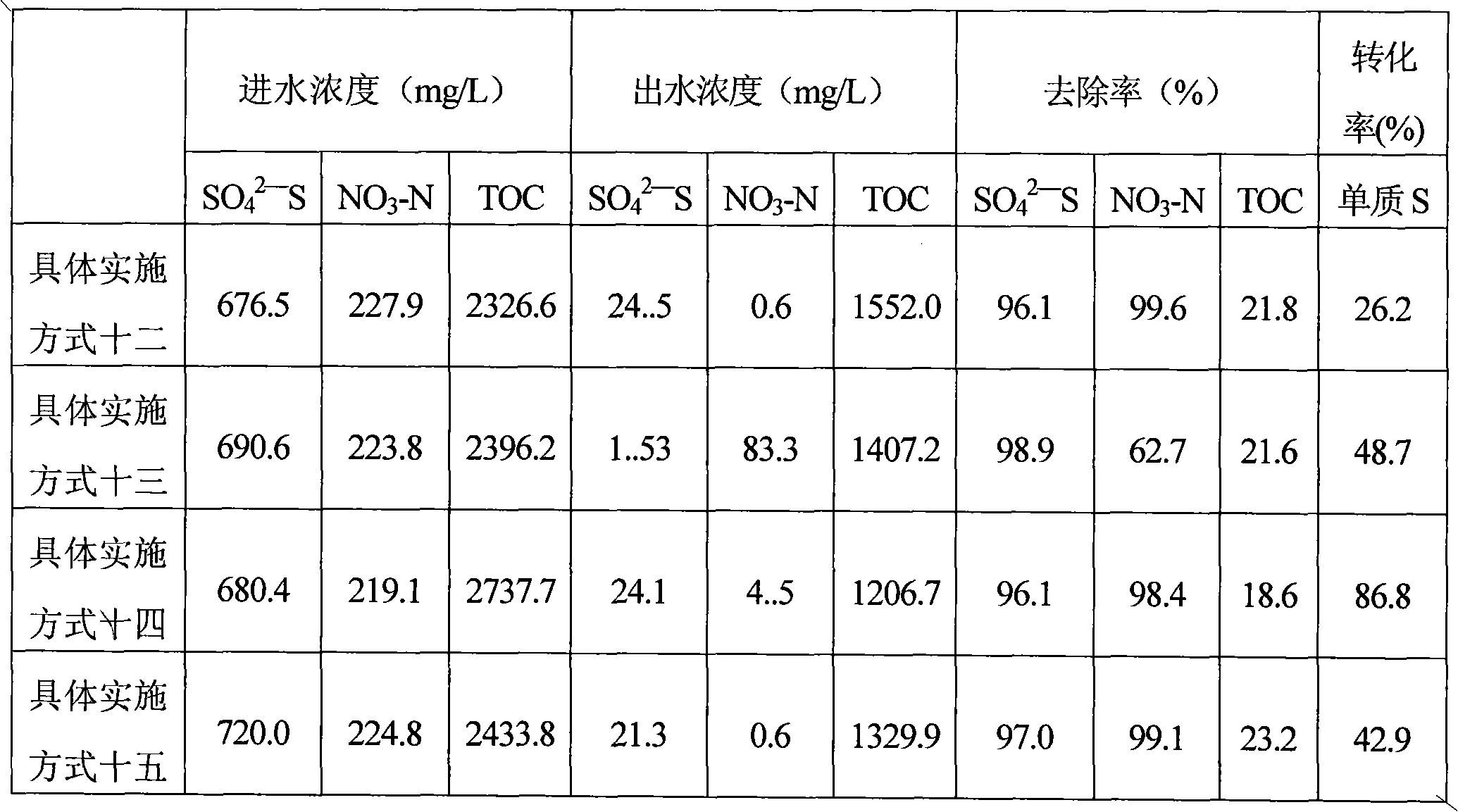

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the method for synchronous removal of carbon, nitrogen and sulfur in this embodiment is carried out according to the following steps: the activated sludge is added to the equipment for synchronous removal of carbon, nitrogen and sulfur, and then the waste water to be treated is passed into, and the ratio of sulfur to nitrogen is controlled to be 2-5:1, the carbon-sulfur ratio is 1.2-3:1, add 0.5-2mL trace element solution to each liter of wastewater, control the temperature of the carbon, nitrogen and sulfur synchronous removal equipment to 27-29°C, and the pH to 7.5 ~8.3, the concentration of dissolved oxygen is 0~0.4mg / L, SO 4 2- -S volume load is 1.80~1.90kg / m 3 d, NO 3 - The volume load of N is 0.60~0.70kg / m 3 d, the aeration rate is 5-35mL / min, and the hydraulic retention time is 34-38 hours, which realizes the simultaneous removal of carbon, nitrogen and sulfur.

[0019] In the method for simultaneous removal of carbon, nitrogen and s...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that every liter of trace element solution is composed of 500 mg of H 3 BO 3 , 500mg of ZnCl 2 , 500mg of (NH 4 ) 6 Mo 7 o 24 4H 2 O, 500mg of NiCl·6H 2 O, 500mg of AlCl 3 ·6H 2 O, 500mg of CoCl 2 ·6H 2 O, 500mg of CuSO 4 ·5H 2 O, 1000mg of NaSeO 3 ·5H 2 O, 1500mg of FeCl 3 ·6H 2 O, 5000mg of MnCl 2 4H 2 O and 5 ml of a 37% HCl solution. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the ratio of sulfur to nitrogen is 5:1, and the ratio of carbon to sulfur is 1.26:1. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com