White carbon black production process for producing sodium fluoride and co-producing cryolite by using fluorosilicic acid

A production process, sodium fluoride technology, applied in the production process of sodium fluoride co-production cryolite white carbon black with fluorosilicic acid, can solve the problem of sodium fluoride yield, crystallinity, aluminum fluoride conversion rate is not high enough, waste water Can not be fully utilized, sodium fluoride raw material cost is high, etc., to achieve the effect of improving the efficiency of production enterprises, ensuring quality, increasing yield and enterprise efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

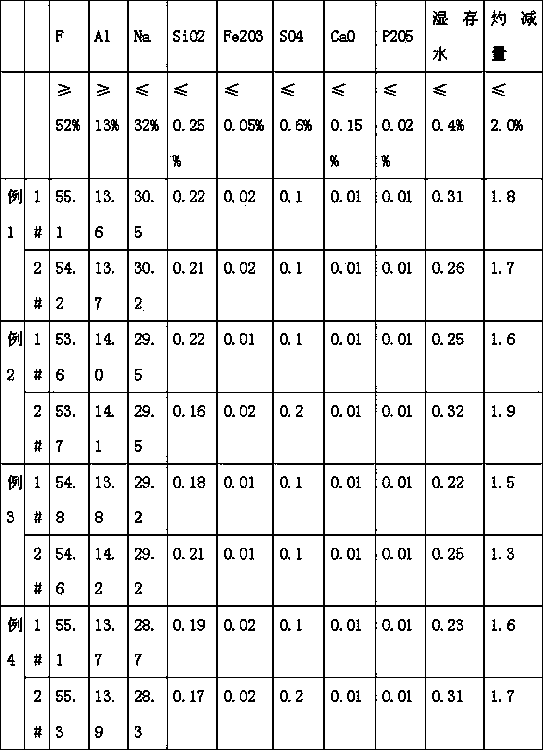

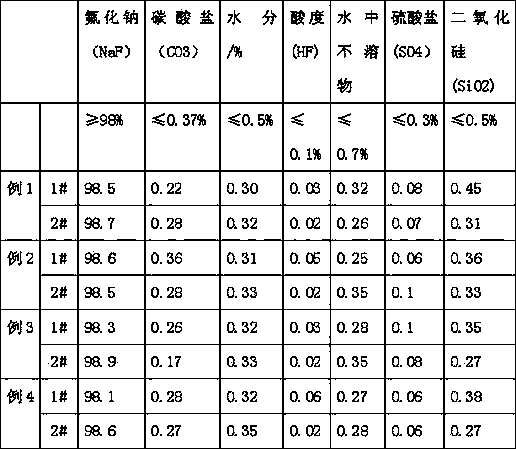

Embodiment 1

[0029] 1. After dissolving sodium carbonate decahydrate with water or sodium fluoride mother liquor, pour 20% fluorosilicic acid into the reaction kettle at a constant speed of 0.9 times the reaction ratio, start stirring, turn on the steam, fully react, and the pH value at the end of the reaction is 8 -9.

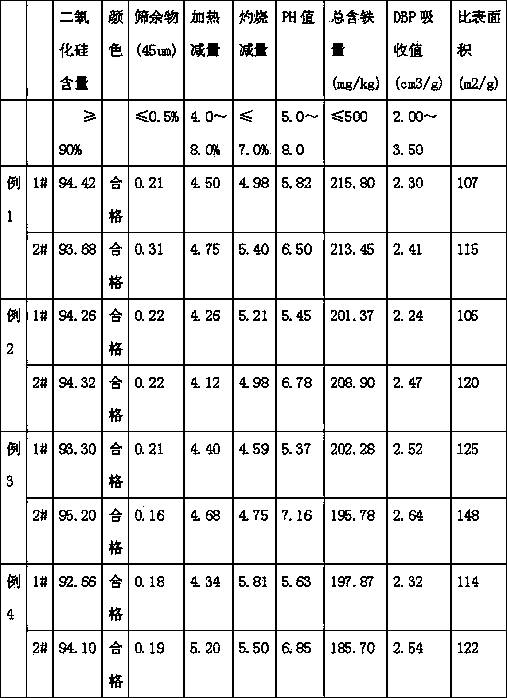

[0030] 2. After the reaction of the solution in the reactor is complete, use the specific gravity difference reaction solution to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtration and drying. After sodium fluoride is centrifuged and dried, it is the finished product of sodium fluoride. Part of the sodium fluoride mother liquor is dissolved in sodium carbonate decahydrate, and the excess sodium fluoride mother liquor is filtered and then enters the sodium fluoride mother liquor storage tank as a raw material for producing cryolite.

[0...

Embodiment 2

[0034] 1. After dissolving sodium carbonate decahydrate with water or sodium fluoride mother liquor, pour 30% fluosilicic acid into the reaction kettle at a constant speed of 0.9 times the reaction ratio, start stirring, turn on the steam, and fully react. The pH value at the end of the reaction is 8 -9.

[0035] 2. After the reaction of the solution in the reactor is complete, use the specific gravity difference reaction solution to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtration and drying. After sodium fluoride is centrifuged and dried, it is the finished product of sodium fluoride. Part of the sodium fluoride mother liquor is dissolved in sodium carbonate decahydrate, and the excess sodium fluoride mother liquor is filtered and then enters the sodium fluoride mother liquor storage tank as a raw material for producing cryolite.

[003...

Embodiment 3

[0039] 1. After dissolving sodium carbonate decahydrate with water or sodium fluoride mother liquor, pour 40% fluorosilicic acid into the reaction kettle at a constant speed of 0.9 times the reaction ratio, start stirring, turn on the steam, fully react, and the pH value at the end of the reaction is 8 -9.

[0040] 2. After the reaction of the solution in the reactor is complete, use the specific gravity difference reaction solution to carry out solid-solid separation after flotation, and the solid-solid separation is sodium fluoride and silicon dioxide. Silica can be sold as white carbon black after pressure filtration and drying. After sodium fluoride is centrifuged and dried, it is the finished product of sodium fluoride. Part of the sodium fluoride mother liquor is dissolved in sodium carbonate decahydrate, and the excess sodium fluoride mother liquor is filtered and then enters the sodium fluoride mother liquor storage tank as a raw material for producing cryolite.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com