Patents

Literature

97 results about "Sodium carbonate decahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

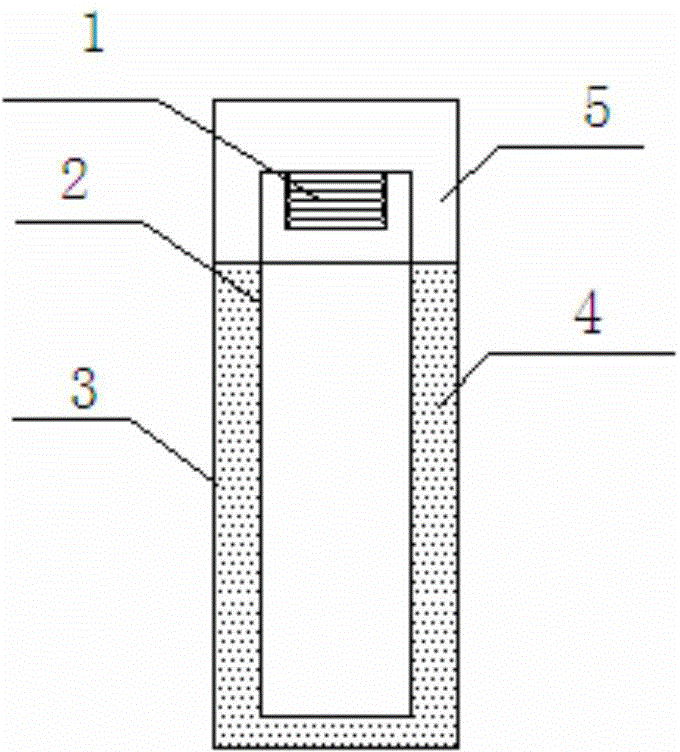

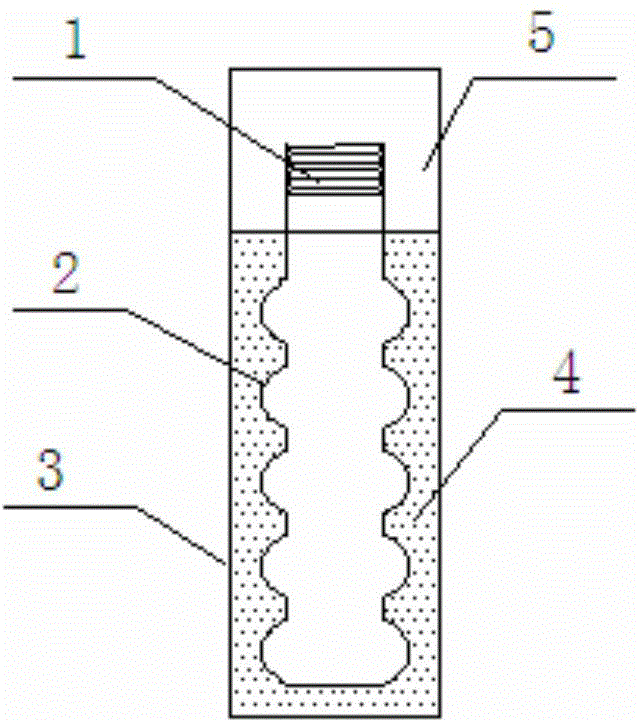

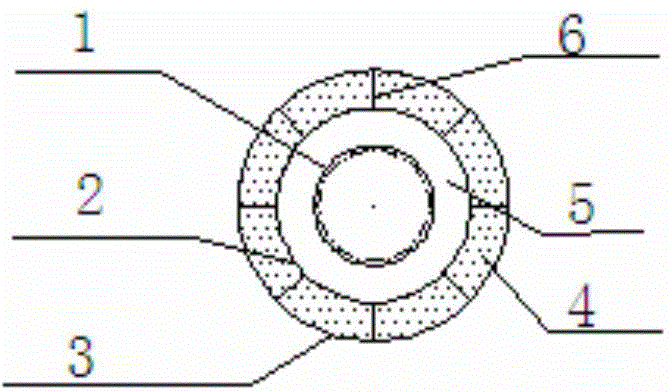

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

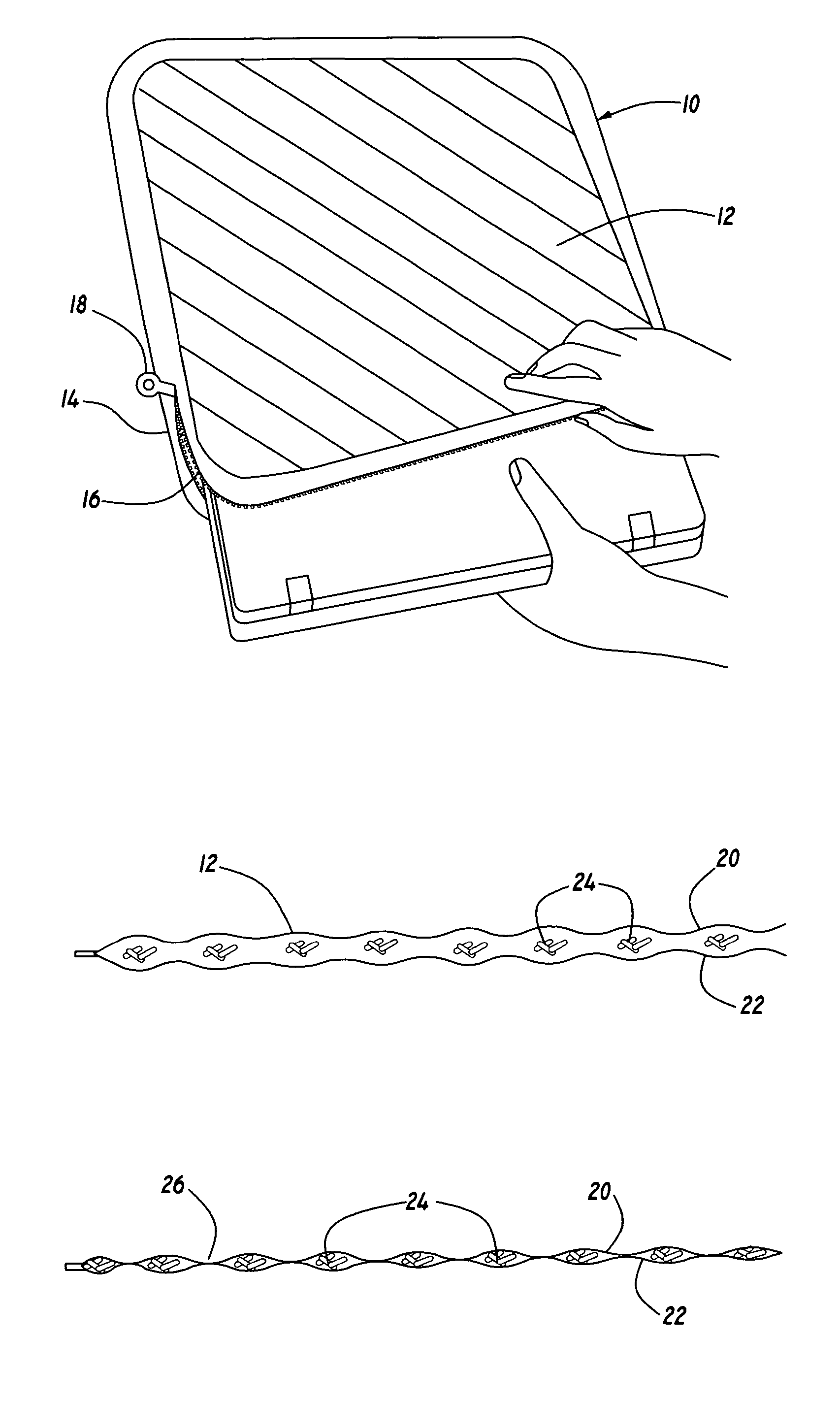

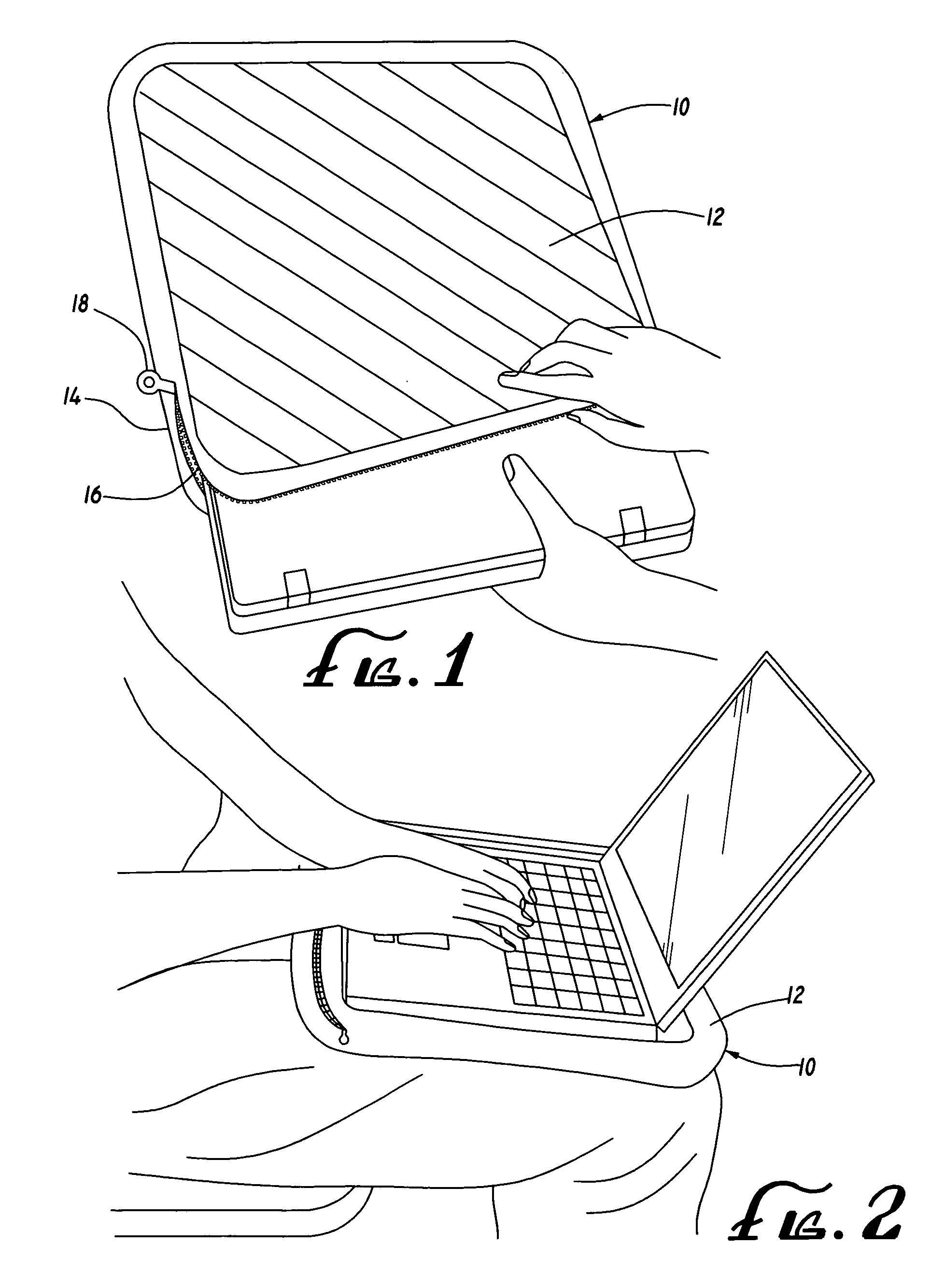

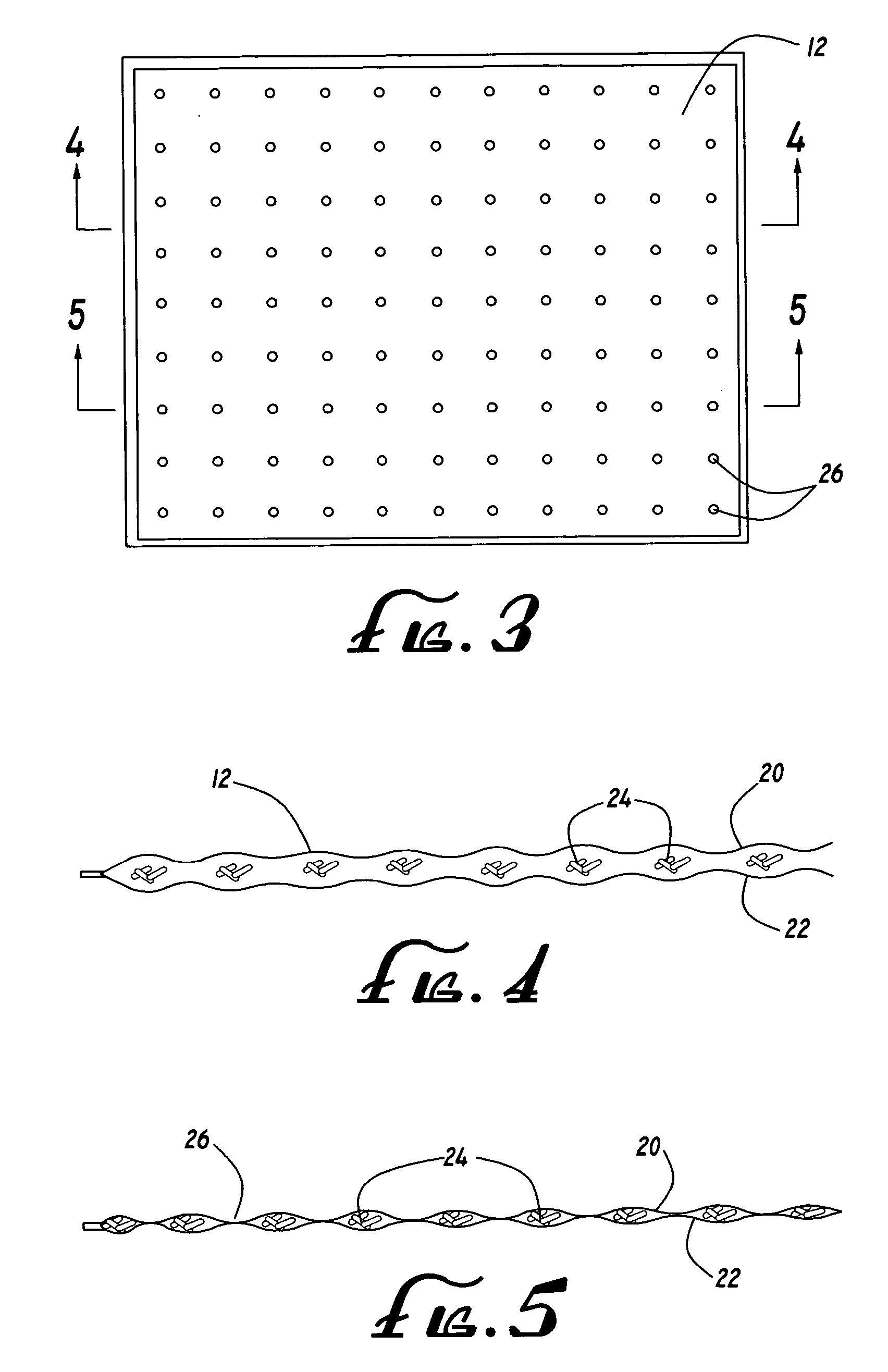

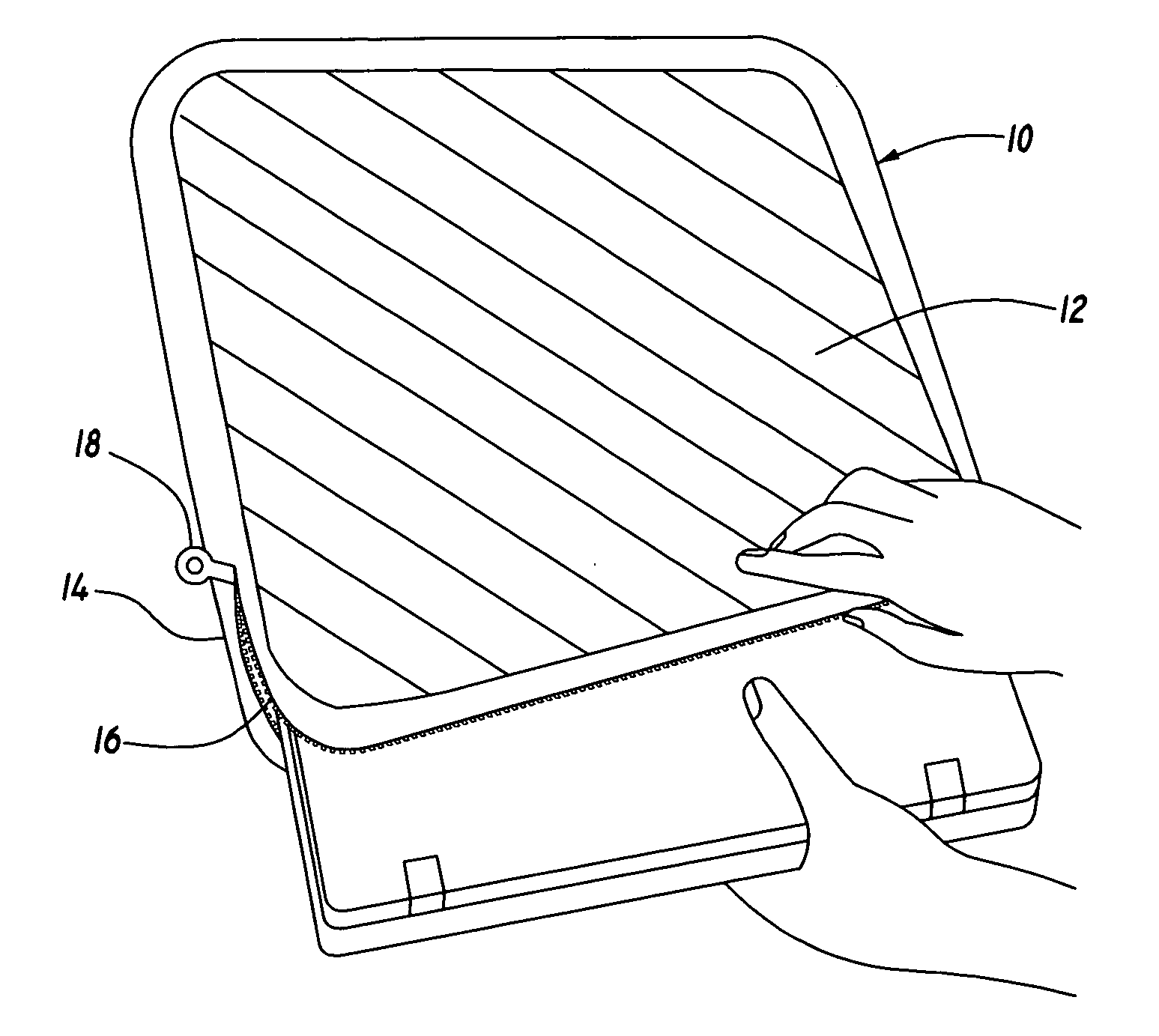

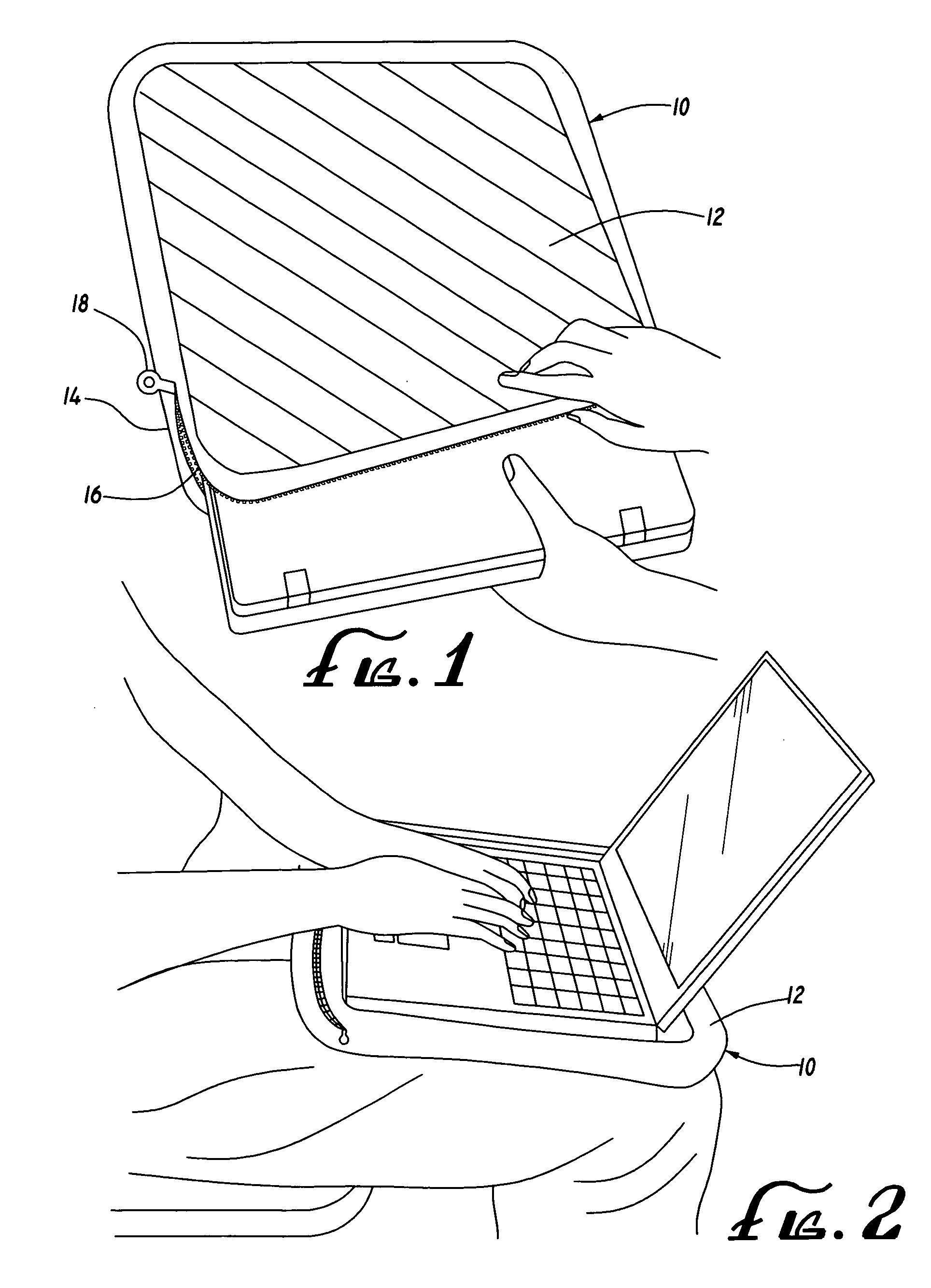

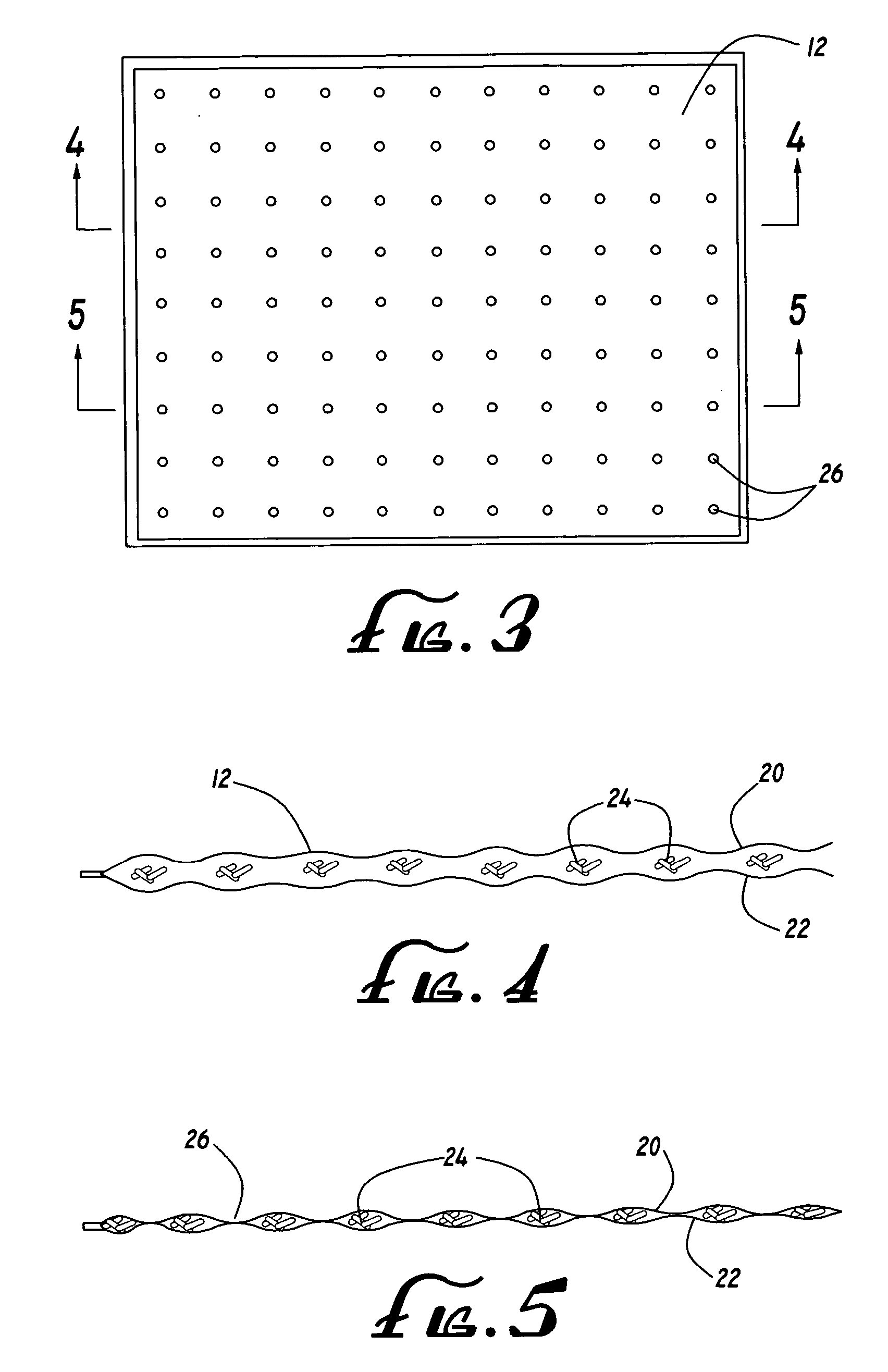

Conductive cooling pad for use with a laptop computer

InactiveUS7324340B2Details for portable computersCooling/ventilation/heating modificationsDisodium phosphateSodium Thiosulfate Pentahydrate

A self contained laptop computer cooling pad that does not require any electrical power to operate and will effectively and efficiently reduce the operating temperature of the computer and reduce the heat being transferred into the user's lap. The cooling pad contains a phase-changing compound such as sodium sulfate decahydrate, sodium carbonate decahydrate, disodium phosphate dodecahydrate or sodium thiosulfate pentahydrate, and may be made of a soft, flexible material that will contain the phase-changing compound and prevent excess shifting within the cooling pad. The cooling pad is placed under the laptop computer when operating the computer to effectively transfer heat away from the computer by conduction and prevent passage onto the user. The cooling pad may be in the form of a sleeve to additionally provide padded storage for the computer when not in use.

Owner:XIONG WEI

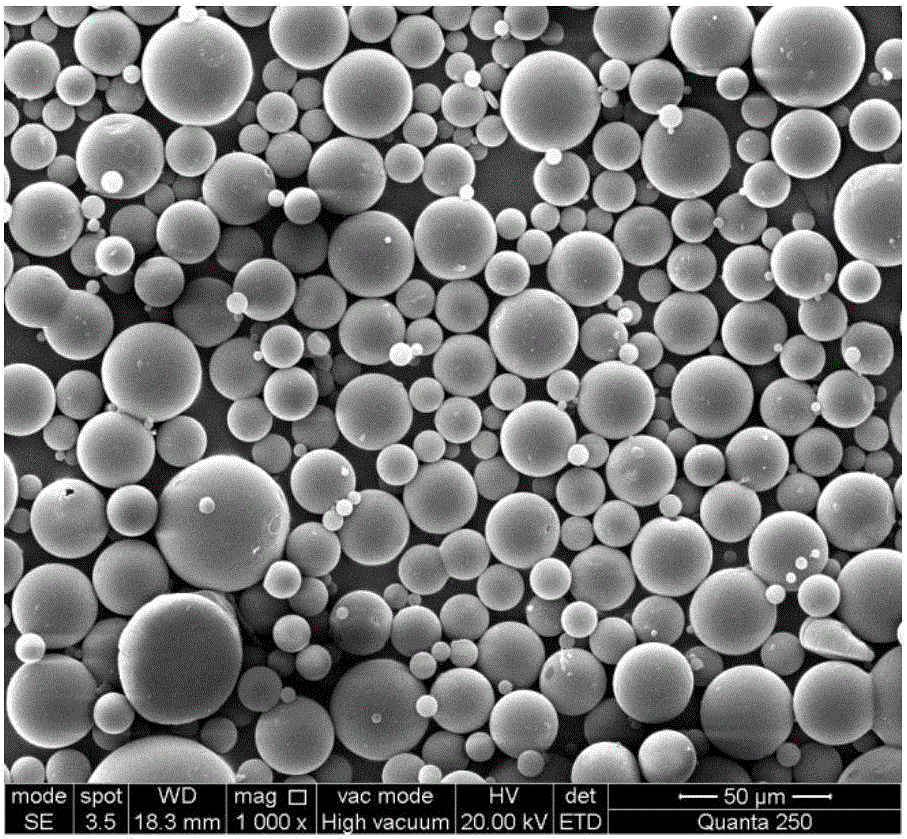

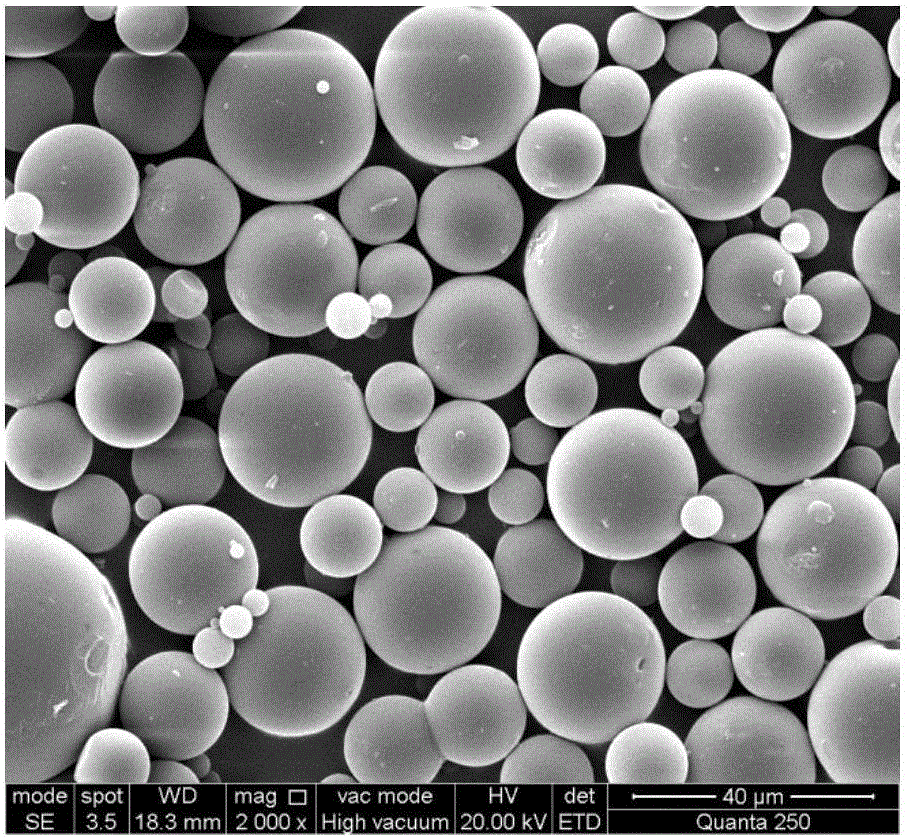

Inorganic hydrous salt phase change microcapsule energy-storage material and preparing method

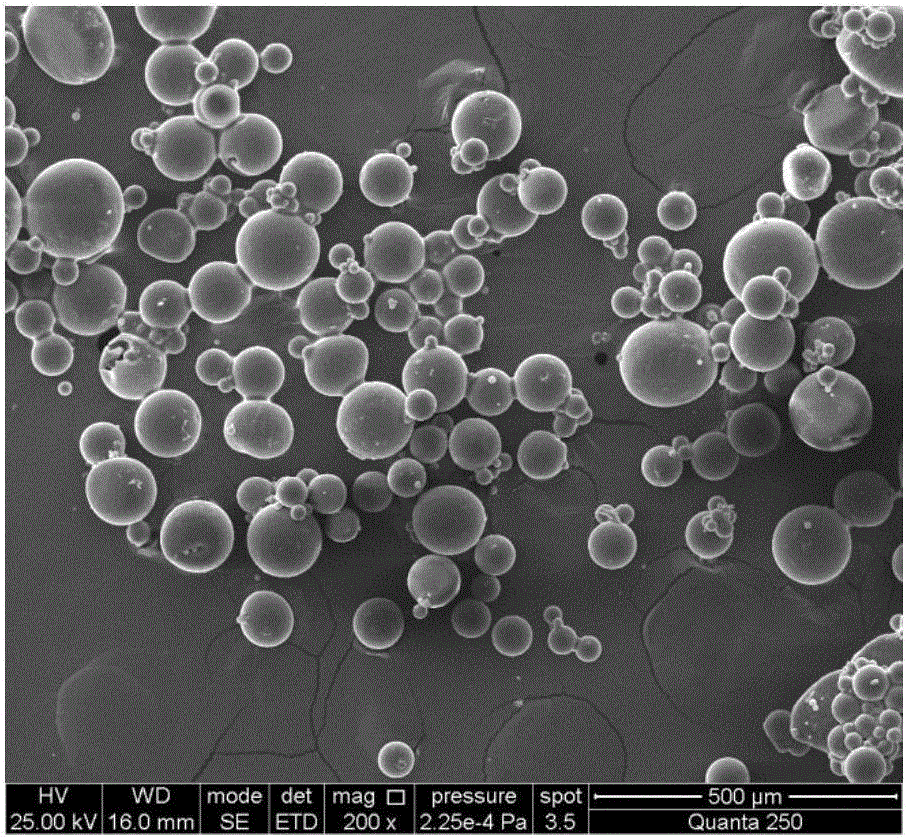

InactiveCN106221674AAchieve solidificationImprove heat transfer efficiencyHeat-exchange elementsCalcium Chloride HexahydrateSodium Thiosulfate Pentahydrate

The invention relates to a preparing method of an inorganic hydrous salt phase change microcapsule energy-storage material and belongs to preparing methods of energy-storage materials. The energy-storage material comprises a core material and a wall material, wherein the core material is prepared from one or more of calcium chloride hexahydrate, sodium sulfate decahydrate, sodium thiosulfate pentahydrate, disodium hydrogen phosphate dodecahydrate, sodium acetate trihydrate and sodium carbonate decahydrate inorganic hydrous salt, and the wall material is prepared from one or more of polystyrene, polymethyl methacrylate, poly(ethyl acrylate), polyurethane, cellulose acetate butyrate (CAB) and a diphenylmethane diisocyanate polymer, the core material accounts for 30-80% of the microcapsule energy-storage material by mass, and the wall material is prepared from the polymer and accounts for 20-70% of the microcapsule energy-storage material by mass. The phase change point of the obtained phase change microcapsule energy-storage material ranges from 20 DEG C to 90 DEG C, and the particle size ranges from 1 micrometer to 100 micrometers. The phase change microcapsule energy-storage material prepared with the method is high in encapsulation rate, good in sealing performance, large in phase change latent heat value, simple in preparing method and large in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

Selective Salt Recovery from

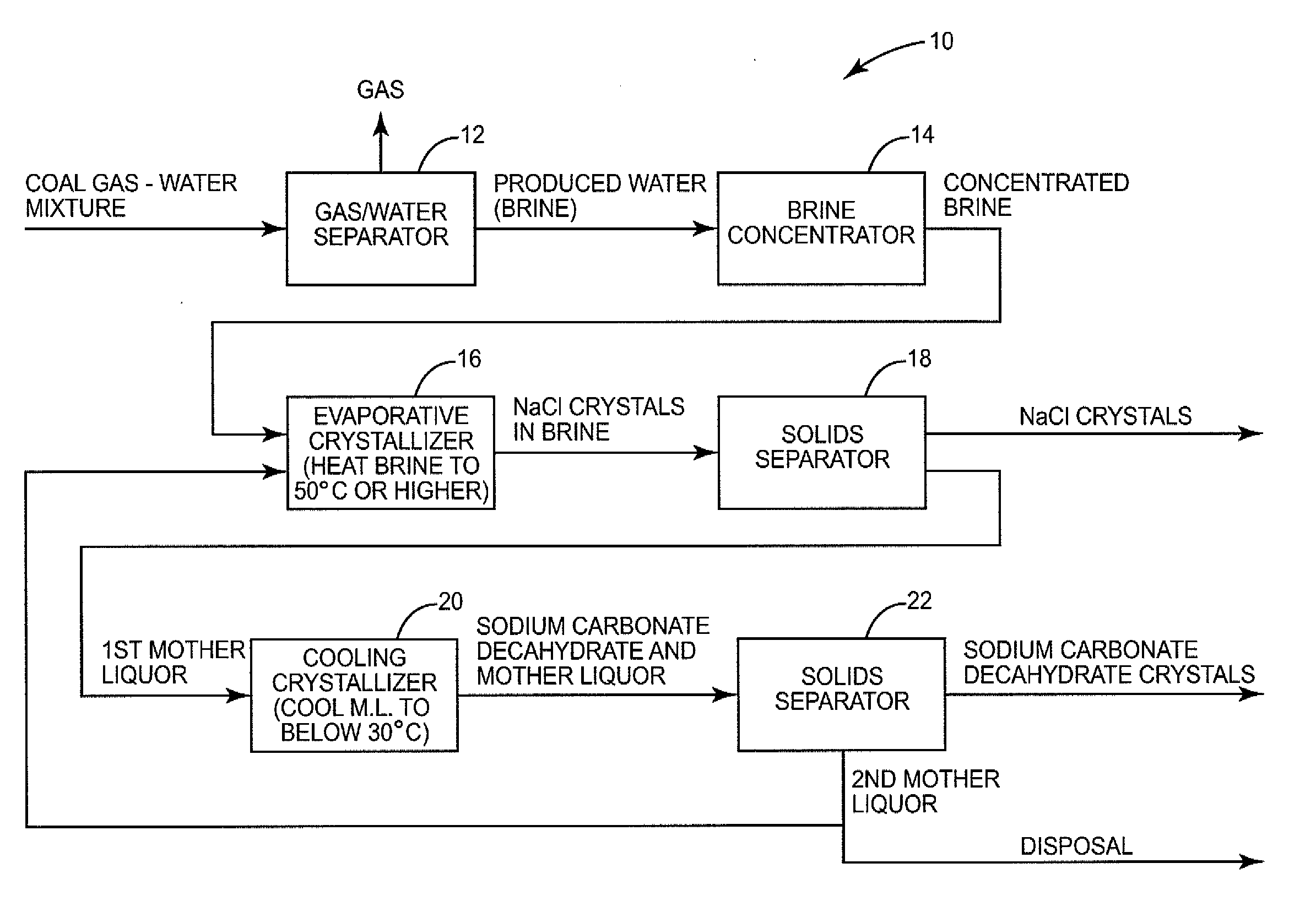

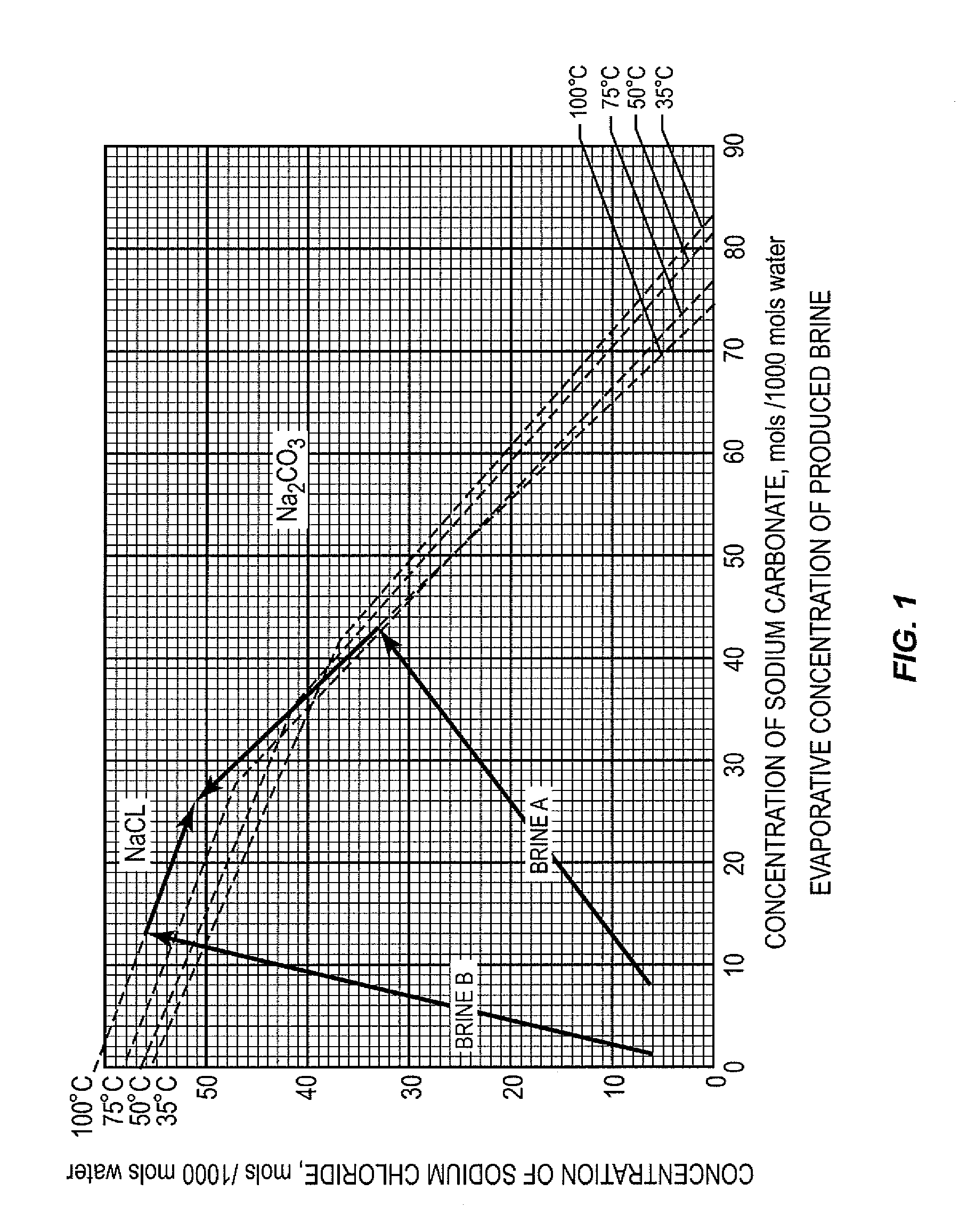

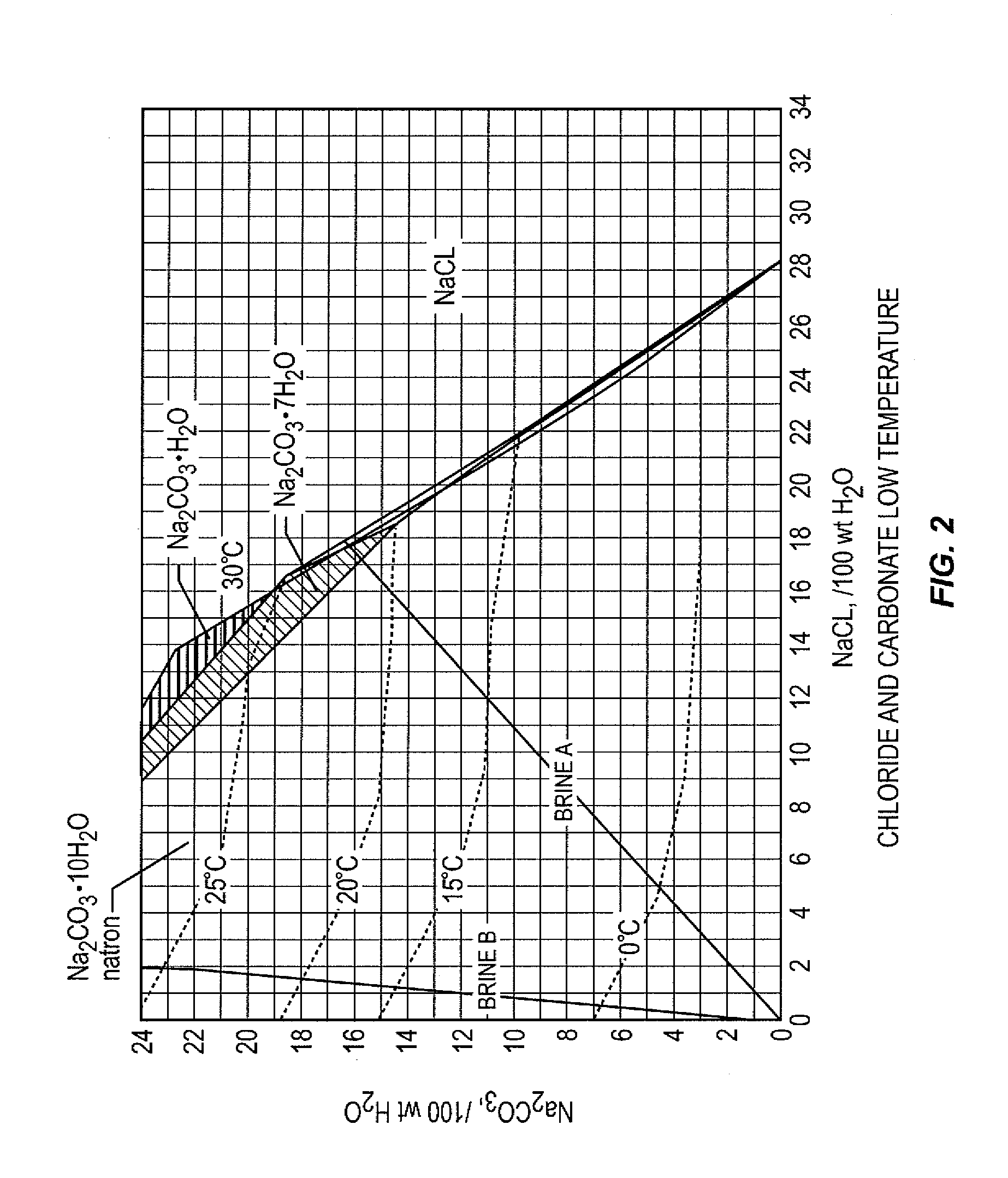

InactiveUS20120213689A1Rubidium/caesium/francium compoundsAlkali metal chloridesSodium bicarbonateSalt water

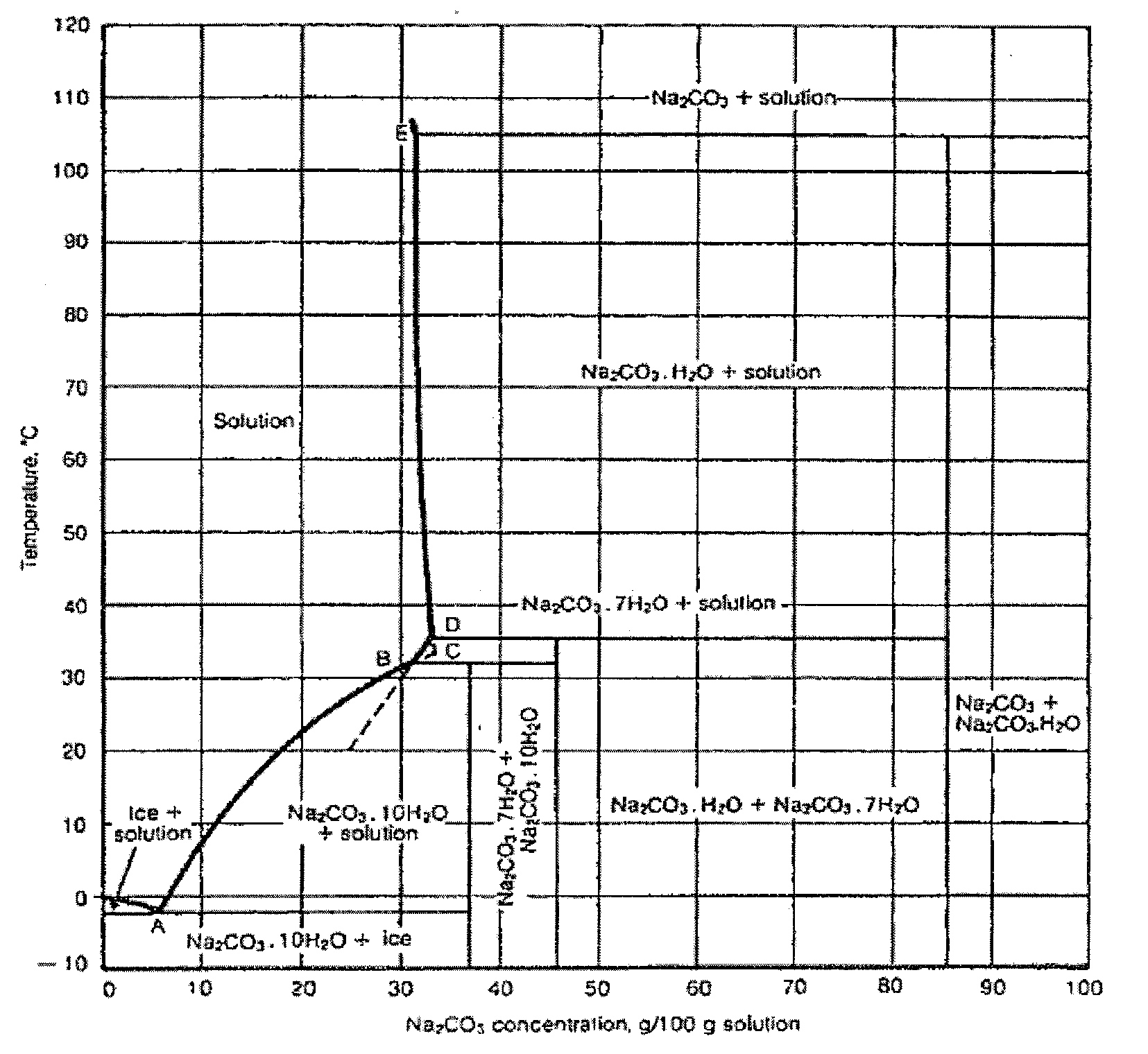

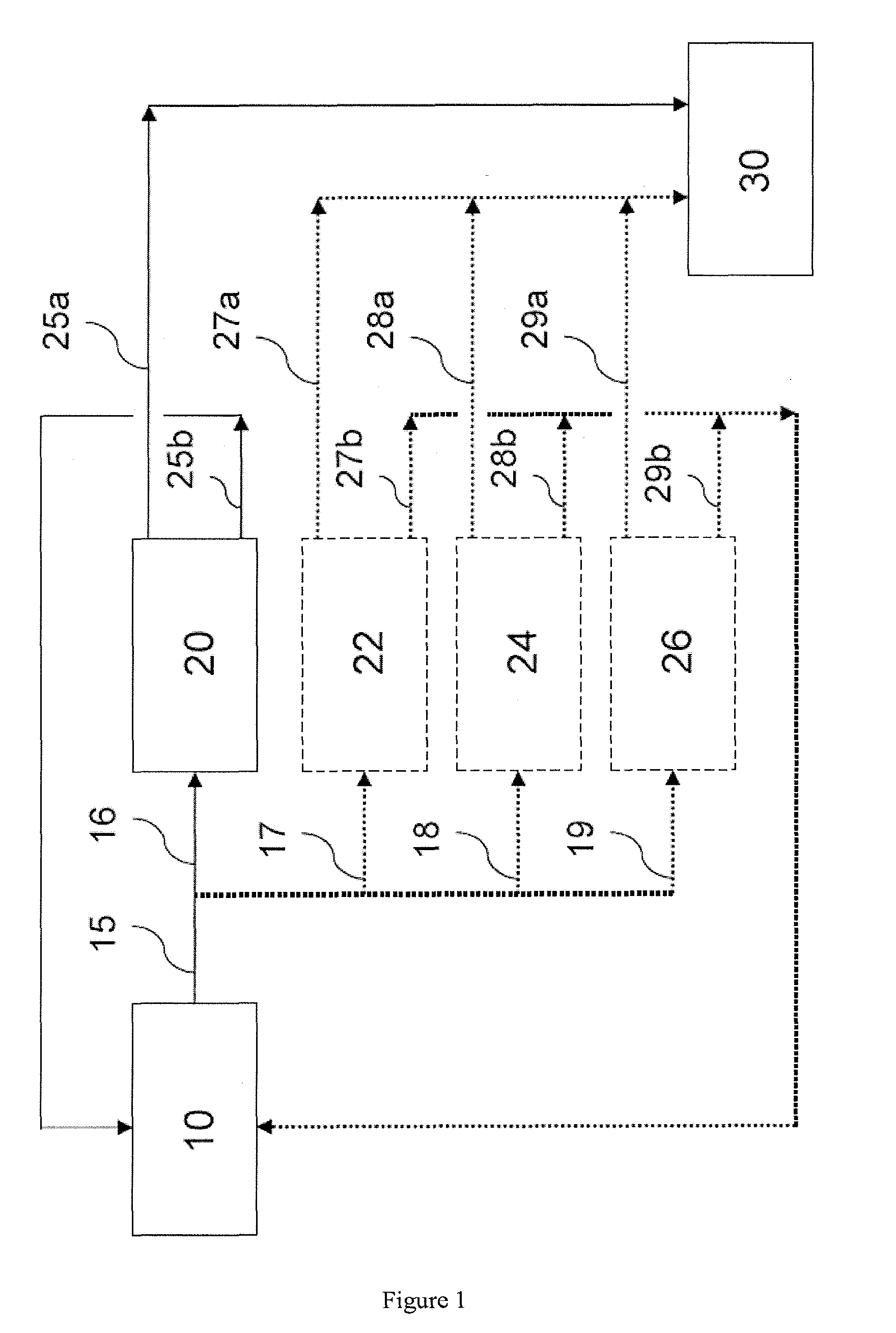

A process is provided for recovering sodium chloride crystals and sodium carbonate decahydrate crystals from a concentrated brine that results from a gas mining operation where gas and produced water is recovered and the produced water constitutes a brine. An initial pre-concentration process is carried out where the brine is concentrated and in the process carbon dioxide is removed from the brine and at least some sodium bicarbonate is converted to sodium carbonate. In one process, the concentrated brine is directed to a sodium chloride crystallizer where the brine is heated and further concentrated to form sodium chloride crystals which are separated from the brine to yield a product and wherein the resulting brine is termed a first mother liquor. The first mother liquor is then directed to a sodium carbonate decahydrate crystallizer where the first mother liquor is cooled and concentrated resulting in the formation of sodium carbonate decahydrate crystals and a second mother liquor. The second mother liquor is split into two streams where one stream is directed back to the sodium chloride crystallizer while the other stream is wasted or further treated.

Owner:VEOLIA WATER TECH INC

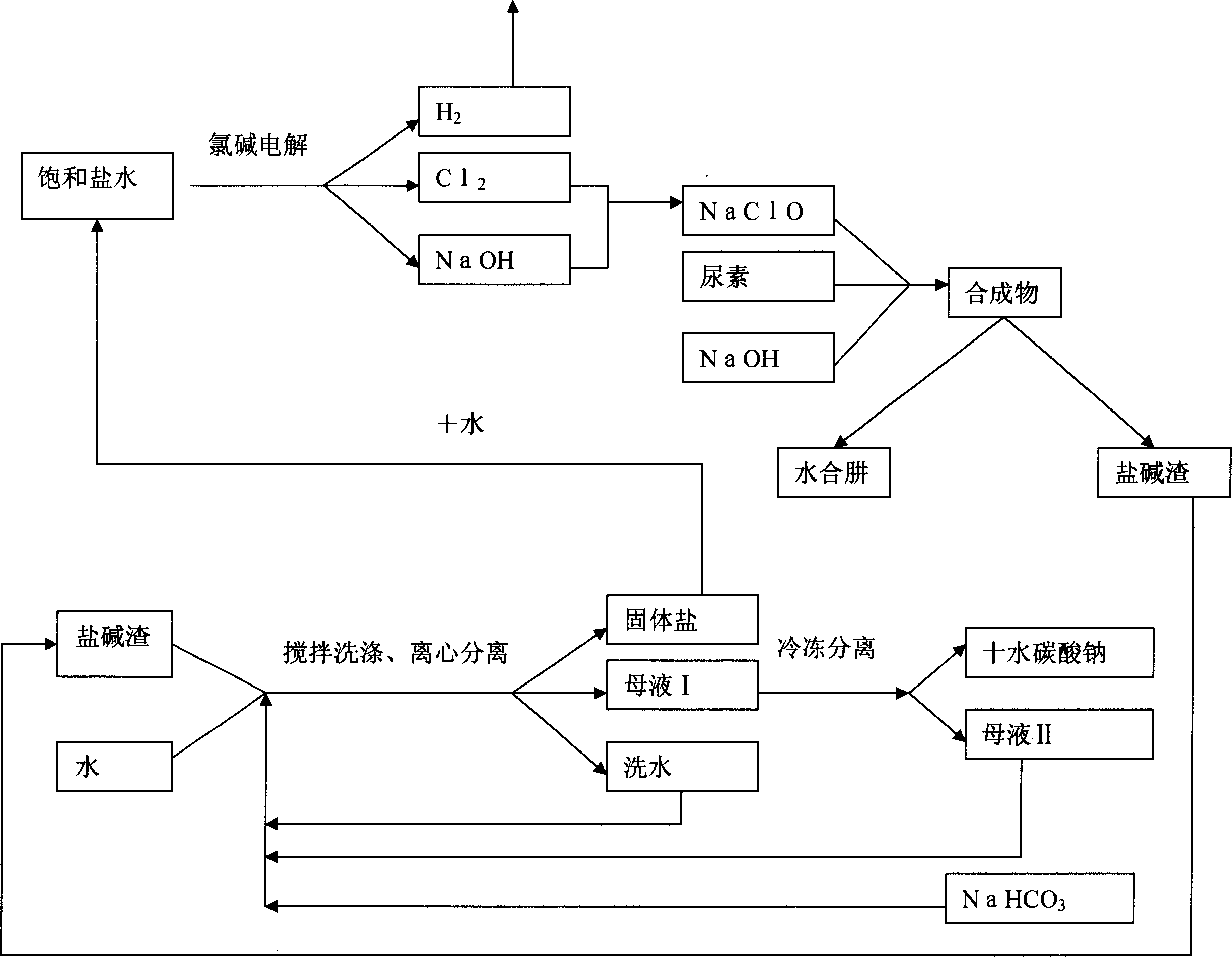

Separation of salt and alkali from waste salt and alkali residue in production of hydrazine hydrate and technique of cyclic utilization

InactiveCN1796280ANo pollutionNo need for external dischargeHydrazineAlkali metal chloridesSodium bicarbonateHydrazine compound

This invention describes a process for the recovery and recycle of industrial waste solids, especially the salt-alkali separation and recycle of the waste salt-alkali solids from the manufacturing of hydrated nitriles. This invention uses water, mother liquid and sodium bicarbonate to wash the waste salt-alkali solids from the manufacturing of hydrated nitriles, so that Na2CO3 and NaOH in the waste salt-alkali solids are washed into the solution. The washing solution is then cooled to 0-5deg.C, and filtrated and separated to obtain solid sodium carbonate decahydrate, which can be commercialized after washing. The mother liquid, after separating the solid alkali, is directed to the next process for washing the waste salt-alkali solids without discharge. During the circulatory washing of the waste salt-alkali solids, the table salt keeps in the solid state. After centrifugal separation, the table salt containing 3% of alkali can be obtained and used for sodium carbonate industry. The said table salt NaCl, after washing and separation to remove a small amount of hydrazine and amine, can be used for chlorine-alkali industry. Chlorine Cl2 and sodium hydroxide NaOH are raw materials for sodium hypochlorite NaClO, which is a raw material for producing hydrazine hydrate. In addition, sodium hydroxide is directly involved in the reaction for producing hydrazine hydrate N2H4íñH2O, thus constituting an internal recycling system of a manufacturing plant without discharging, which not only is environmentally friendly but also reduces transportation load and production cost. This invention describes a rational process for large-scale hydrazine hydrate manufacturing plants.

Owner:陈大元

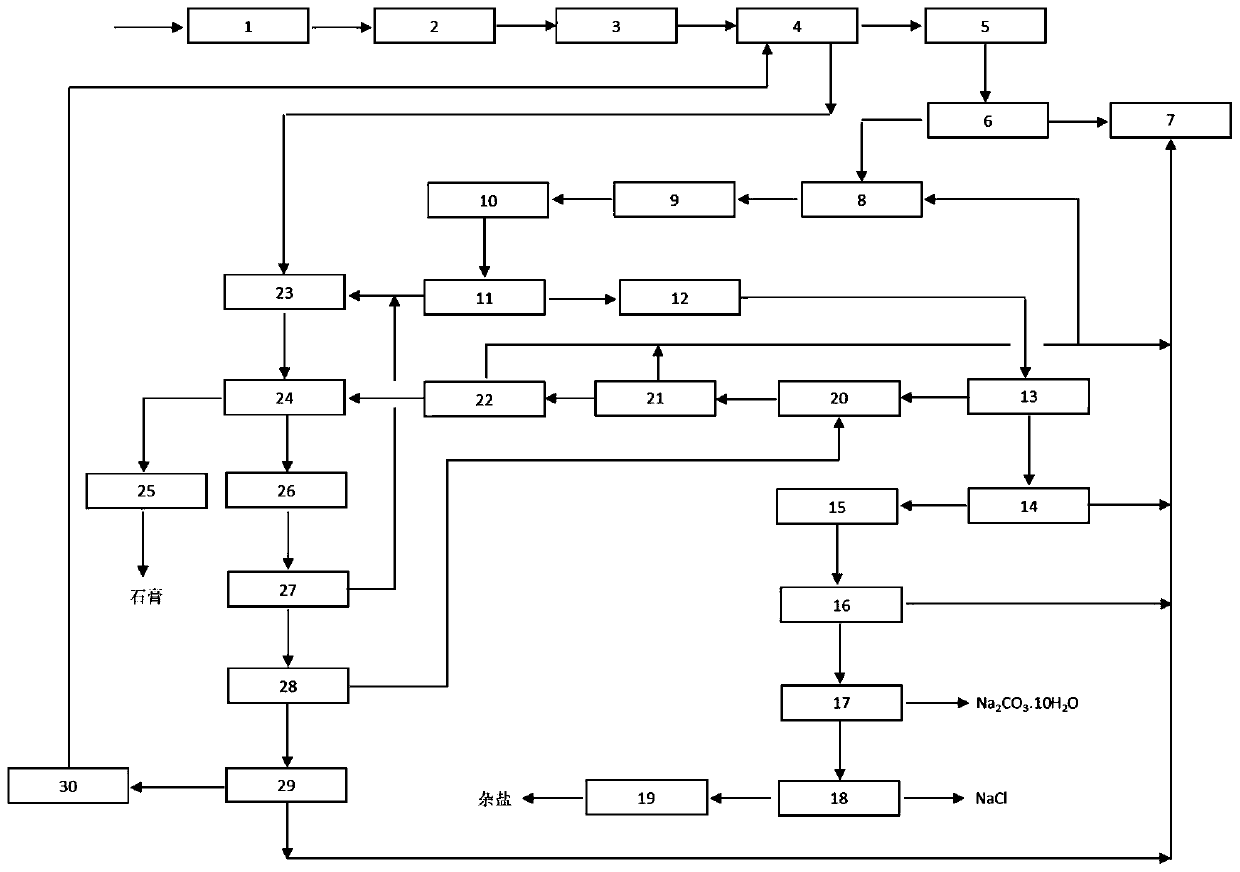

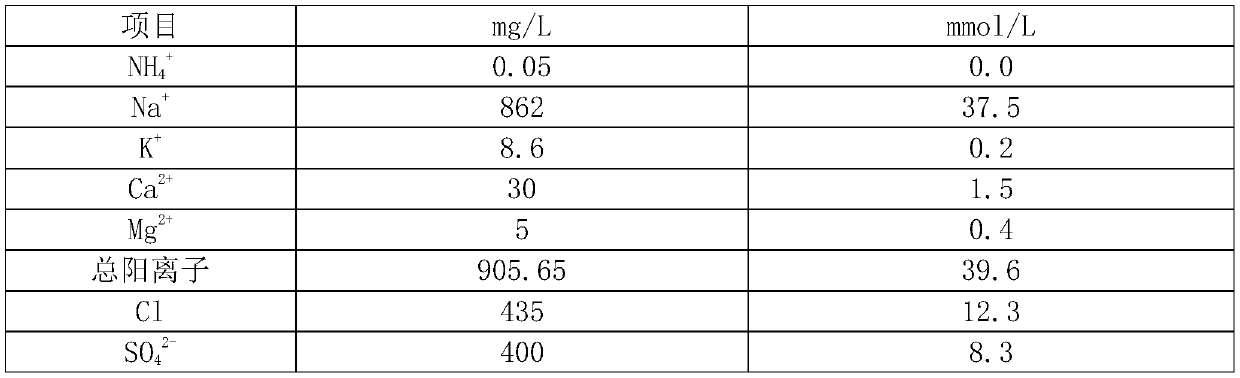

High-salinity coal mine water standard treatment and resource utilization device and use method thereof

ActiveCN111362453AReduce softening and hardening costsStable calcium sourceWaste water treatment from quariesGeneral water supply conservationWater desalinationLiquid storage tank

The invention relates to a high-salinity coal mine water standard treatment and resource utilization device and a use method thereof. The device comprises a homogenizing adjusting tank, a high-densityclarification tank, a gravity type filter tank, a sodium bed device, an ultrafiltration device, a reverse osmosis device, a recycled water tank, an ozone reaction tank, a concentrated water high-density clarification tank, a multi-media filter, a concentrated water weak acid resin bed, a concentrated water ultrafiltration device, a nanofiltration device, a nanofiltration produced water reverse osmosis device, a strong brine tank, a nanofiltration produced water evaporation concentration device, a sodium carbonate decahydrate freezing crystallization device, a sodium chloride evaporation crystallization device, an impure salt crystallization device, a nanofiltration concentrated water tank, a nanofiltration concentrated water evaporation concentration device, a sodium sulfate decahydrate freezing crystallization device, a resin regeneration waste liquid storage tank, a calcium sulfate settling tank, a calcium sulfate dehydrator and the like. The device has the advantages that the structural design is reasonable, consumption of softening agents for mine water desalination treatment is reduced, the system reliability is improved, the additional value of salt products is increased, and maximum utilization of resources is achieved.

Owner:BEIJING BAILINGTIANDI ENVIRONMENTAL PROTECTION TECH

White carbon black production process for producing sodium fluoride and co-producing cryolite by using fluorosilicic acid

ActiveCN104030317AHigh yieldImprove business efficiencySilicaAlkali metal fluoridesAluminium hydroxideEngineering

The invention provides a white carbon black production process for producing sodium fluoride and co-producing cryolite by using fluorosilicic acid. The production process is used for producing sodium fluoride and co-producing high-purity silicon dioxide and cryolite by using fluorosilicic acid, sodium carbonate decahydrate and aluminum hydroxide as main raw materials. The white carbon black production process provided by the invention can be used for reducing the cost of sodium fluoride and cryolite raw materials and further improving the benefits of sodium fluoride production enterprises.

Owner:JIANGXI QUCHENG CHEM

Process for producing biurea through optimized urea method

InactiveCN104892463AIncrease concentrationReduce yieldOrganic chemistryChemical industryBiureaHydrazine compound

The present invention discloses a process for producing biurea through an optimized urea method. The process comprises that: during the biurea preparing, the crude solution of hydrazine hydrate produced through the urea method is adopted as a raw material and is subjected to repeated evaporation concentration and freezing crystallization for a plurality of times to respectively separate out sodium chloride and sodium carbonate so as to obtain a fine hydrazine solution of the hydrazine hydrate; the sodium chloride is separated at the evaporation section and the sodium carbonate decahydrate is separated at the freezing crystallization section during each evaporation, a salt extracting pump is used to extract, and the solid sodium chloride is separated out by a salt separation centrifuge; and the liquid is subjected to freezing crystallization, is separated, and then returns to the cold hydrazine solution at the evaporation section, pre-cooling is performed, and then the obtained material is conveyed to the crystallization kettle. The process of the present invention has the following beneficial effects that: the hydrazine hydrate-containing crude solution produced through the urea method is adopted as the raw material, alkali removing through freezing is performed while the cold energy and the heat energy are recovered, the repeated circulating method is used, the hydrazine hydrate concentration is improved in the low cost manner, and the process has characteristics of less raw material consumption, less energy source consumption, low cost, and high single-kettle yield during condensation.

Owner:HANGZHOU HI TECH FINE CHEM

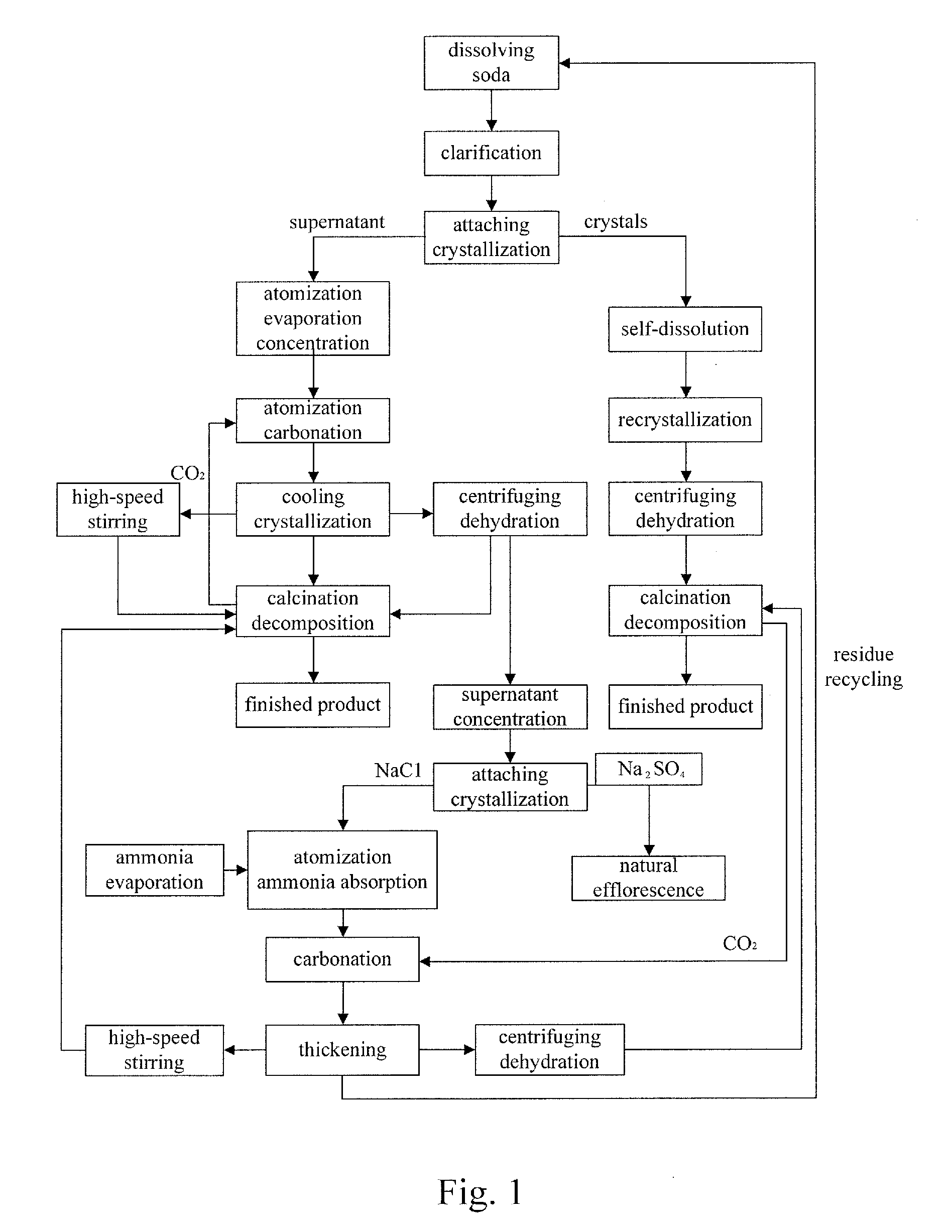

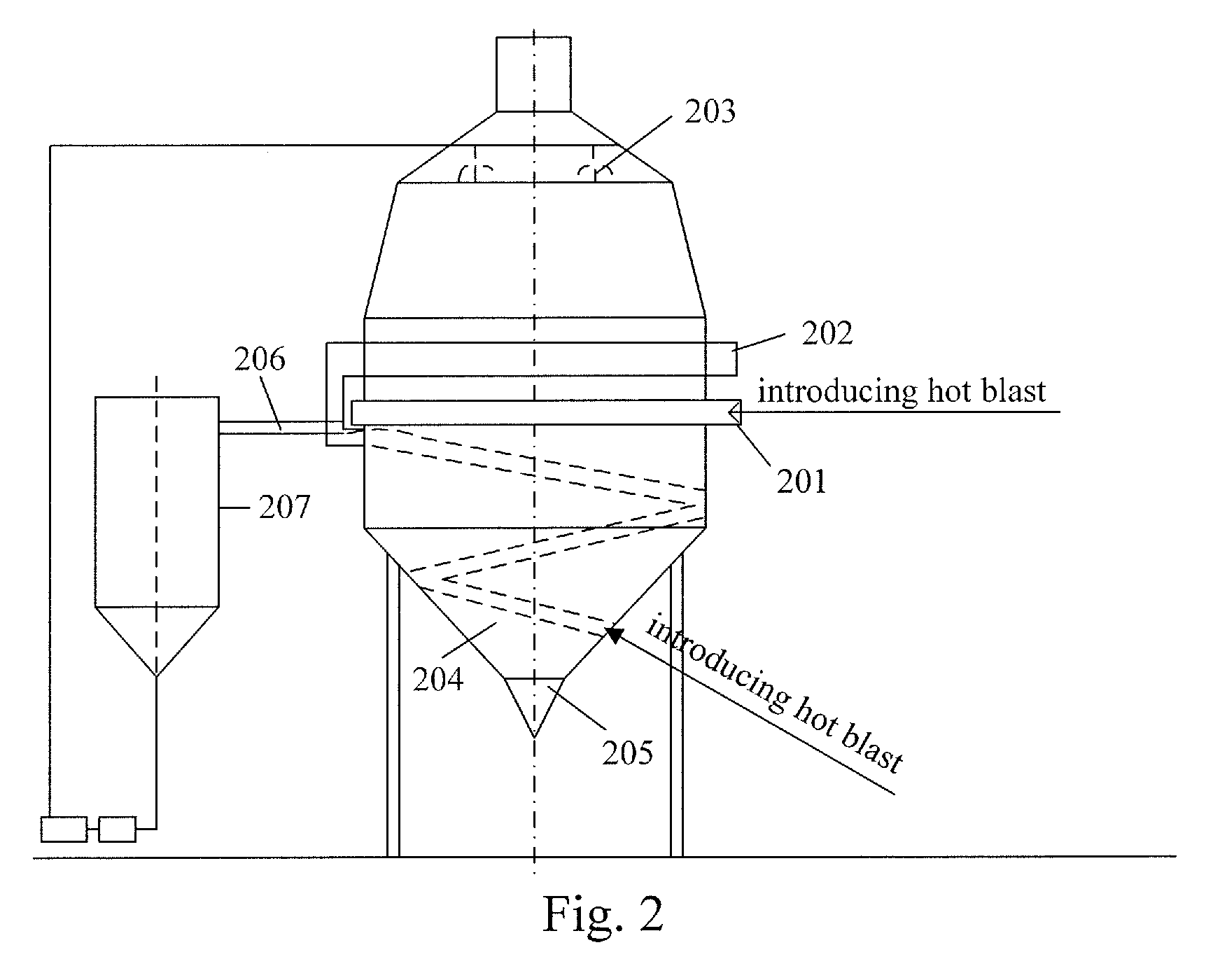

Combined process for preparing calcined soda by applying surface engineering technology to natural soda preparation

InactiveUS20110027152A1Improve conventional manufacturing technologyIncrease choiceAlkali metal oxides/hydroxidesAlkali metal chloridesSurface engineeringCombined method

The invention relates to a combined process for preparing a calcined soda from a natural soda containing sodium chloride, soda and sodium sulphate, which comprises steps: (a) dissolving the natural soda to prepare an aqueous solution; (b) obtaining sodium carbonate decahydrate crystals from the natural soda solution by using a separation method of attaching crystallization; and (c) treating the obtained sodium carbonate decahydrate crystals to obtain the calcined soda. The selection to raw materials in the combined process is widened, and the associated minerals, such as sodium chloride, soda and sodium sulphate, can be separated as simple substances. The species of the obtained calcined soda and anhydrous sodium sulphate are abundant, and their purities are high. Moreover, the entire processes can be recycled, and there is no discharge of smoke, dust, waste liquid and so on.

Owner:CUI HUAIQI

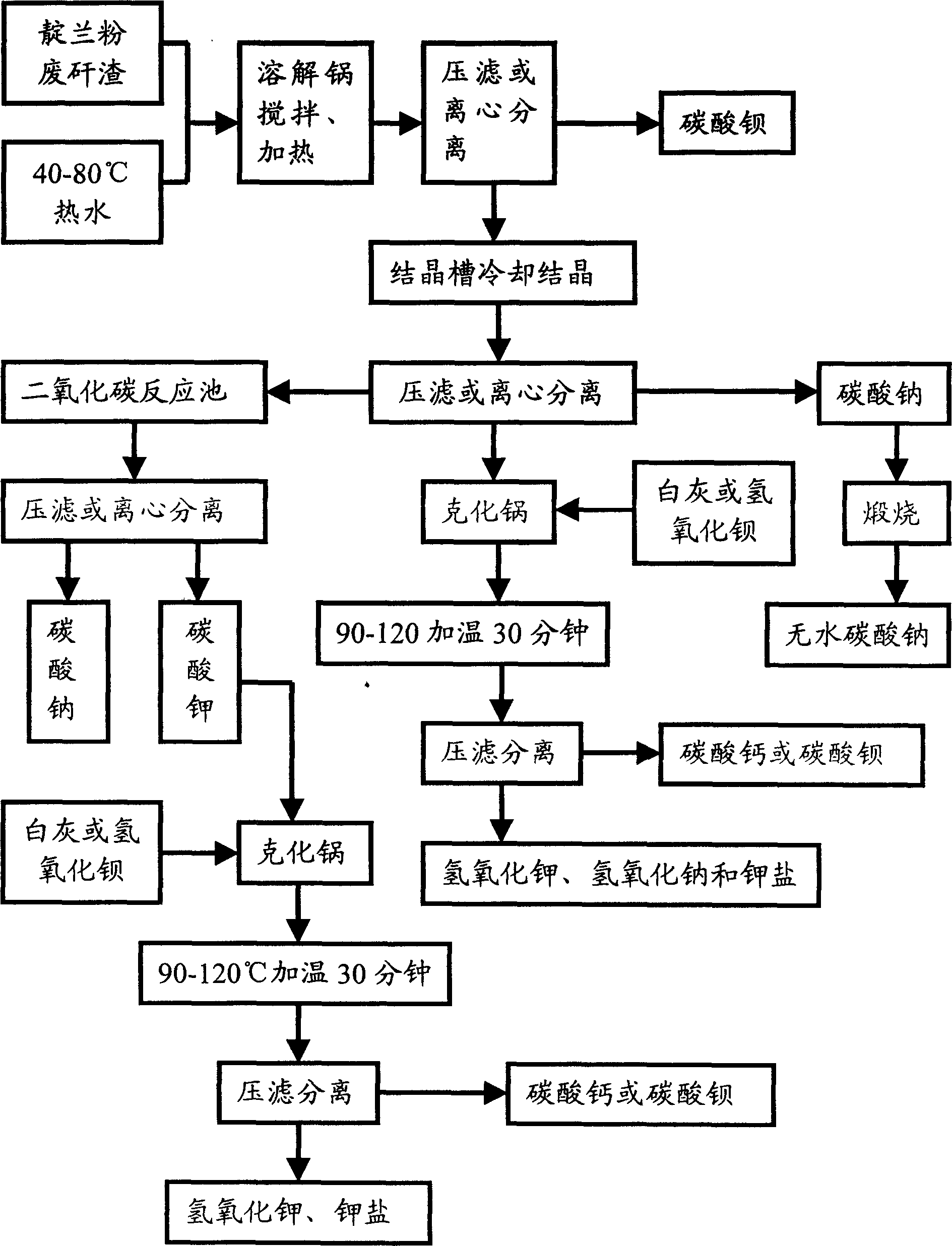

Comprehensive process for recovering and treating indigo blue powder waste slag

InactiveCN1557708AReasonable process designThe preparation method is simple and feasibleSolid waste disposalAlkali metal hydroxidesSlagPotassium hydroxide

The comprehensive indigo powder waste gangue slag recovering treatment process includes heating the mixture of waste gangue slag and water in a reactor to 4-80 deg.c for the waste gangue slag to dissolve fully; centrifugally separating to eliminate dreg and create mother liquid A; cooling mother liquid an in a crystallizing tank for 12-30 hr; press filtering or centrifuging to separate crystal as mixture of crystal carbonate and natron from crystallized liquid A; and calcining the crystal mixture to obtain anhydrous sodium carbonate. The said process can recover sodium hydroxide, potassium hydroxide, potassium carbonate, potassium salt and sodium carbonate in low cost and high yield.

Owner:贾升

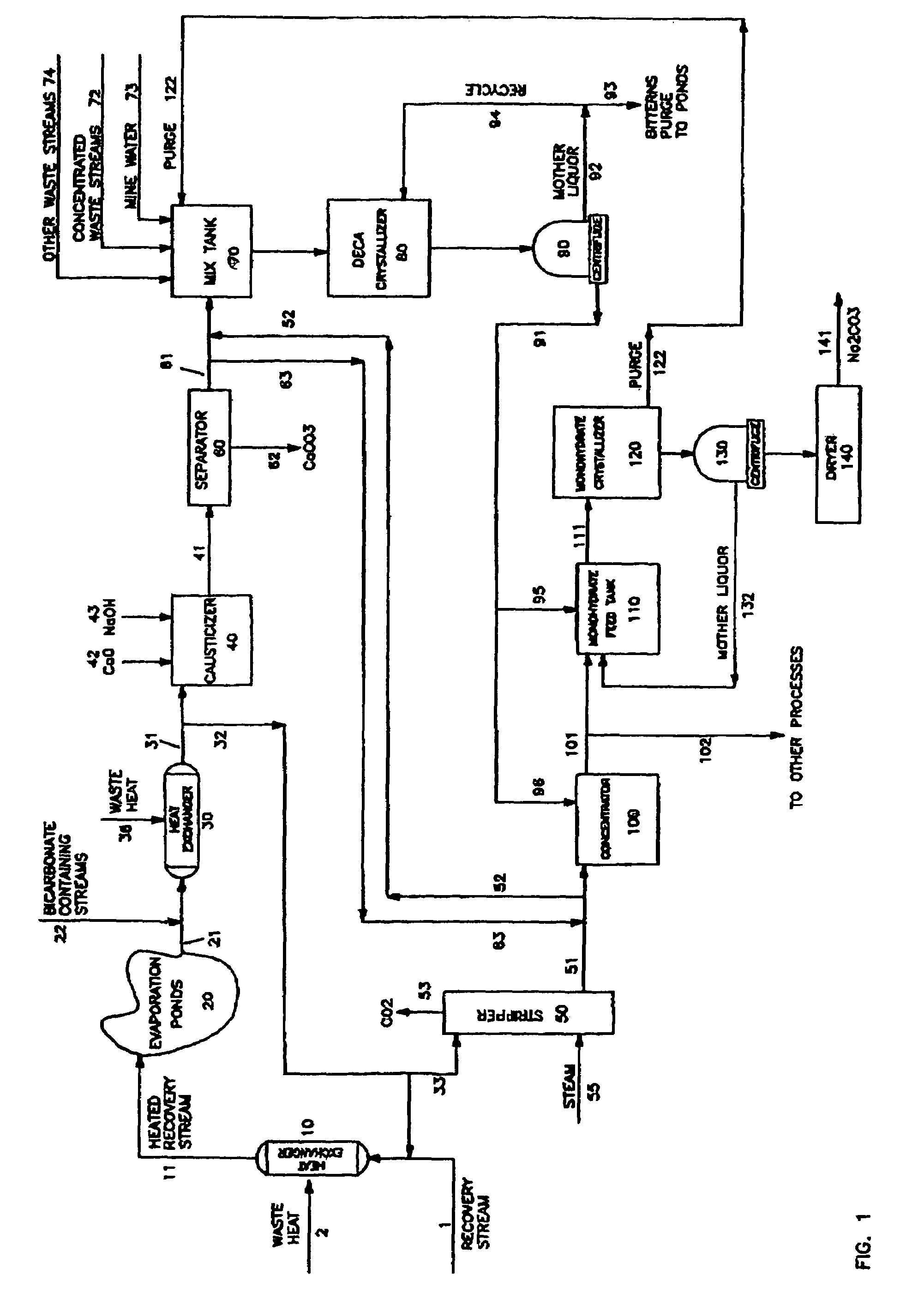

Sodium carbonate recovery from waste streams and impounded sodium carbonate decahydrate deposits

InactiveUS7645435B2Promote recoveryExtend the life cycleVarying alkali metal carbonate water contentCarbonate purificationSodium bicarbonateWaste stream

A process is described for recovering sodium carbonate or other sodium-based chemicals from sodium-bearing streams, including in particular mine water, evaporative pond water and sodium carbonate decahydrate deposits, recycle and purge streams, and other waste streams. In the process sodium bicarbonate-bearing streams are decarbonized to reduce the sodium bicarbonate concentration in a combination with other sodium-bearing streams, resulting in a liquor suitable as feed to a sodium carbonate decahydrate or sodium carbonate monohydrate process. The sodium bicarbonate stream is combined in a mix tank with other sodium carbonate bearing streams where the concentration is adjusted to form a liquor suitable to feed a sodium decahydrate or sodium carbonate monohydrate evaporation / crystallization step. In the process the combination of the various sodium-bearing streams is decarbonized to below 3.5% sodium bicarbonate when fed to a sodium decahydrate process and to below 1% sodium bicarbonate when fed to a sodium carbonate monohydrate process. The feed streams are adjusted in sodium carbonate concentration by higher concentrated sodium carbonate-bearing streams or by addition of sodium carbonate decahydrate produced from said streams or recovered form evaporation pond deposits, are then processed to produce sodium carbonate decahydrate or sodium carbonate monohydrate or further processed to form other sodium carbonate salts.

Owner:TATA CHEM NORTH AMERICA INC

Phase-change gel heat-preservation material and preparation method thereof

InactiveCN107488020AWith insulationWith energy storageCalcium Chloride HexahydratePolyethylene glycol

The invention discloses a phase-change gel heat-preservation material and a preparation method thereof. The heat-preservation material comprises the following components in parts by weight: 23-48 parts of magnesium oxide, 12-35 parts of magnesium sulfate heptahydrate, 3-11 parts of paraffin, 2-10 parts of polyethylene glycol, 4-12 parts of sodium sulfafe decahydrate, 5-9 parts of calcium chloride hexahydrate, 3-9 parts of sodium carbonate decahydrate, 2-12 parts of aluminum hydroxide, 1-8 parts of hydrogen peroxide, 3-15 parts of a polypropylene fiber and 4-13 parts of a glass fiber. The phase-change gel heat-preservation material disclosed by the invention has excellent properties of heat preservation, energy storage and light weight and is high in strength and good in anti-cracking property.

Owner:苏州仲勉装饰有限公司

Cooling pad for laptop computer

InactiveUS20060232935A1Details for portable computersCooling/ventilation/heating modificationsDisodium phosphateThermal relief

A self contained laptop computer cooling pad that does not require any electrical power to operate and will effectively and efficiently reduce the operating temperature of the computer and reduce the heat being transferred into the user's lap. The cooling pad contains a phase-changing compound such as sodium sulfate decahydrate, sodium carbonate decahydrate, disodium phosphate dodecahydrate or sodium thiosulfate pentahydrate, and may be made of a soft, flexible material that will contain the phase-changing compound and prevent excess shifting within the cooling pad. The cooling pad is placed under the laptop computer when operating the computer to effectively transfer heat away from the computer by conduction and prevent passage onto the user. The cooling pad may be in the form of a sleeve to additionally provide padded storage for the computer when not in use.

Owner:XIONG WEI

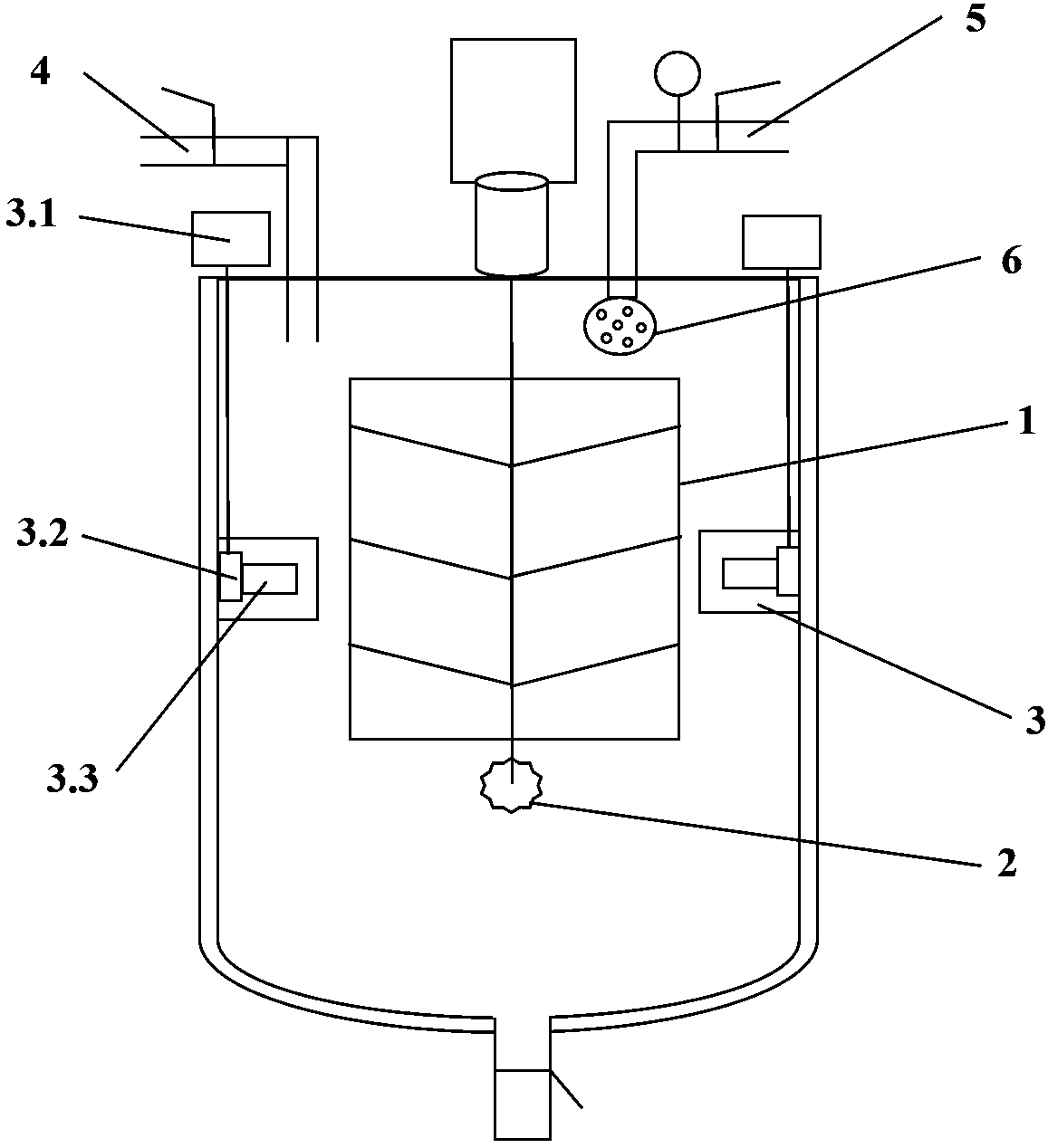

Production technology for producing sodium fluoride from sodium fluosilicate and co-producing white carbon black

InactiveCN108751227AGood effectReduce thermal resistanceSilicaAlkali metal fluoridesDissolutionUltrasonic generator

The invention relates to a production technology for producing sodium fluoride from sodium fluosilicate and co-producing white carbon black. Sodium fluorosilicate and byproduct white carbon black areobtained with sodium fluorosilicate and sodium carbonate or sodium carbonate decahydrate as raw materials through steps of pulping, alkali dissolution, reaction, settling separation, drying and the like. The reaction is conducted in an ultrasonic reactor and at least one ultrasonic generator is arranged in the reactor. The technology has the advantages as follows: reactants or products cannot scaron the wall of the reactor easily, the thermal resistance of the reactor is low, the heat transfer efficiency is high, and continuous production can be realized. The separation effect on sodium fluorosilicate and white carbon black is good, and the product purity is high; the refresh cycle of mother liquor is prolonged, the replacement amount of the mother liquor is reduced, waste liquor emissionis reduced, and the production is more environmentally friendly and more convenient.

Owner:HUNAN UNIV OF TECH

Method for comprehensively utilizing hydrazine hydrate by-product sodium carbonate decahydrate through urea method

ActiveCN103274432AIncrease concentrationHigh economic valueCarbonate preparationCooking & bakingSodium bicarbonate

The invention provides a method for comprehensively utilizing hydrazine hydrate by-product sodium carbonate decahydrate through a urea method. The method comprises the following steps: pulping sodium carbonate decahydrate subjected to freezing crystallization, heating up, forming a sodium carbonate solution with a certain concentration, filtering, removing the impurities, introducing CO2 and carbonizing in a carbonizing tower so as to generate sodium bicarbonate, centrifuging and separating the sodium bicarbonate generated in the reaction, and drying to obtain baking soda; taking a small amount of finished baking soda, adding the baking soda into a hydrazine hydrate solution prepared by the urea method, controlling the PH value, and neutralizing the excessive caustic soda solution in the crude hydrazine solution. The method has the beneficial effects that the sodium carbonate decahydrate which serves as the waste for performing low-price treatment is comprehensively utilized, and the economic value of the by-product is greatly improved; and moreover, more sodium carbonate decahydrate can be obtained in the subsequent freezing sodium carbonate removal link, the concentration of the hydrazine hydrate in the crude hydrazine is improved, and the consumption of acid in the biurea condensation reaction process is reduced.

Owner:HANGZHOU HI TECH FINE CHEM

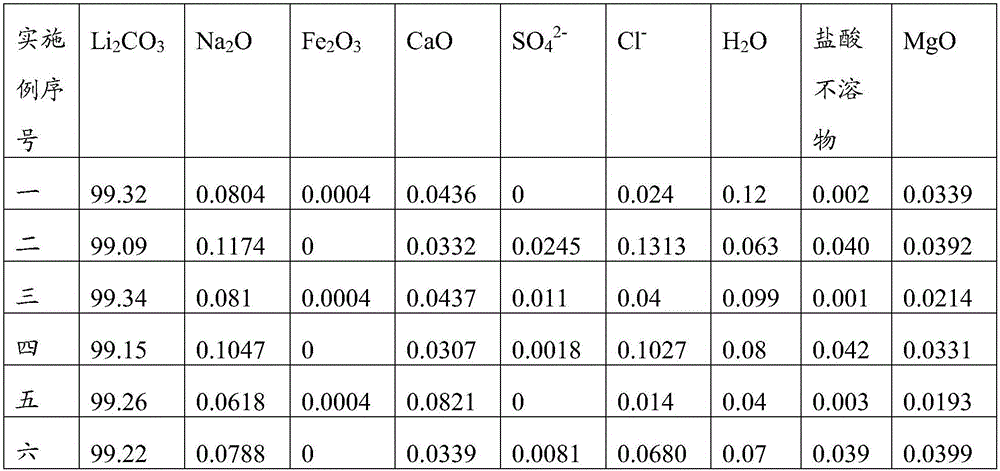

Preparation technology of lithium carbonate

ActiveCN106745102AReduce manufacturing costQuality improvementLithium carbonates/bicarbonatesLithium carbonateCarbonization

The invention discloses a preparation technology of lithium carbonate. The preparation technology comprises the following steps: S1, a process of impurity removal and concentration: carrying out impurity removal and concentration on salt lake brine to obtain lithium-containing concentrated liquor; S2, a process of carbonization lithium-settling: adding sodium carbonate decahydrate crystals which is a by-product produced in a process of preparing biurea by means of urea treatment into the lithium-containing concentrated liquor obtained in the S1 so as to form reaction liquid, wherein the molar ratio of sodium carbonate to lithium in the reaction liquid is equal to (1.2-1.6): 2 in an initial state, and carrying out a reaction to generate lithium carbonate precipitate; S3, a process of aftertreatment: separating out the lithium carbonate precipitate generated in the step S2, washing, and drying to obtain the lithium carbonate product. The preparation method utilizes the sodium carbonate decahydrate crystals which is the by-product produced in a process of preparing the biurea by means of urea treatment, thus realizing the effects of recycling the material and reducing the long-distance transport cost of the material; furthermore, the preparation method also lowers the preparation cost of the lithium carbonate, thus having higher economic benefit. After the preparation technology is adopted, the high-quality lithium carbonate product also can be obtained and is beneficial to later use.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Synthesizing method for confecting inner-outer wall coating water-proof stain-resistant latex

InactiveCN101096400AEnvironmentally friendlyWaterproofAntifouling/underwater paintsPaints with biocidesBottleEthyl acrylate

The invention discloses a method for synthesizing the water resistance antibiotic emulsion of inner or exterior wall paint, which comprises the following steps: dissolving sodium carbonate decahydrate in the water; dissolving the ammonium peroxodisulfate with the water; dispersing the nanometer powder with the water; dissolving the tert-butyl hydroperoxide with the water; dissolving sodium formaldehyde sulfoxylate in the water; adding various emulsifier in the deionized water; getting preemulsion by adding butyl acrylate, ethyl acrylate, methyl methacrylate and N-methylol acrylamide and mixing; adding the nanometer material after adding the rest water, emulsifier and sodium carbonate decahydrate solution in the bottle and mixing; heating; adding the preemulsion and initiating agent solution; dropping the rest preemulsion and initiating agent solution after reacting; keeping the temperature; reducing the temperature; adding tert-butyl hydroperoxide solution; adding formaldehyde sodium sulphoxylate solution; proceeding with the reaction; reducing the temperature; adjusting pH value with smmonia water; stopping mixing; getting the material by filtering. The invention has the water resistance, the environmental protection, the age resistance and the antibiosis.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

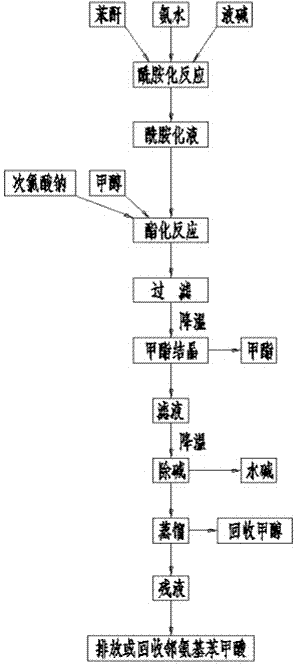

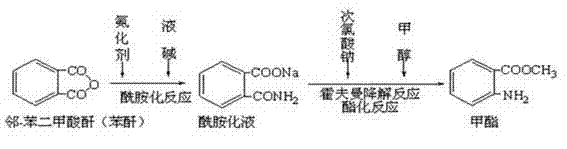

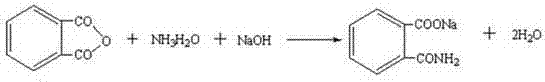

Clean production technology of methyl anthranilate

InactiveCN104844469AReduce saltEmission reductionOrganic compound preparationCarboxylic acid amides preparationSolubilitySolvent

A clean production technology of methyl anthranilate is characterized in that the solubilities of methyl ester, sodium carbonate and sodium chloride in water are different, no other solvents or reagents are introduced, and a solution obtained after esterification and hydrolysis is successively cooled to obtain methyl ester and sodium carbonate decahydrate (called scale for short). The technology shortens the technologic route and reduces impurities in a recovered material, so the quality of the obtained recovered product is high; the technology effectively reduces a large amount of technologic water and recovers reaction byproducts to realize conversion of industrial wastes as a secondary raw material and reinforce recycling of the wastes; the technology realizes comprehensive utilization of energy and reduces total consumption of energy, so the product production cost is greatly reduced; and the technology uses change of physical properties to obtain the methyl ester, and does not use a chemical solvent to extract the methyl ester residual in a mother liquor, so the generation of new pollutants is effectively avoided, and the whole production process is clean and environmentally friendly.

Owner:尹罡煜 +1

Method of producing sodium carbonate decahydrate

InactiveUS20100290976A1Rubidium/caesium/francium compoundsAlkali metal carbonatesInorganic saltsSalt deposit

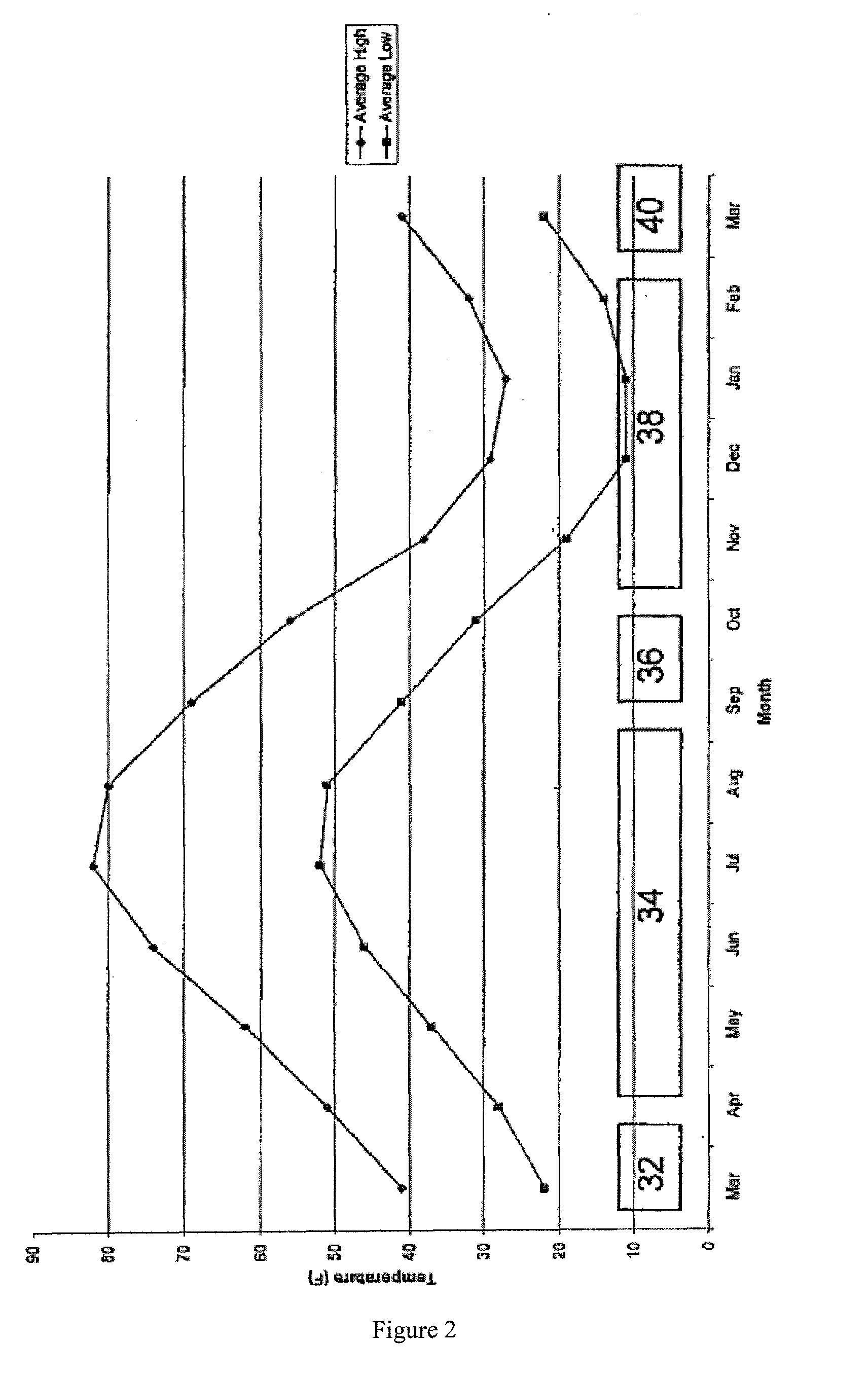

A method of producing crystals of crystallizable mineral salt comprises introducing an effluent comprising a dissolved crystallizable mineral salt at a temperature higher than the mineral salt crystallization temperature to a crystallization pond area to provide a pond solution; cooling the pond solution to provide cooling crystallization promoting conditions effective to form a crystalline mineral salt deposit; stopping the flow of the effluent; draining remaining spent liquor to a liquor pond area; and recovering the deposit. Cooling the pond solution may comprise exposure to cool ambient temperatures which are lower than the crystallization temperature. Preferably, the mineral salt includes or is sodium carbonate decahydrate; the pond solution comprises less than 10% NaCl; and / or the decahydrate deposit is sent or recycled to a soda ash plant. The deposit thus formed by cooling crystallization has a higher purity, lower hardness, and / or lower density than a deposit formed by evaporative crystallization.

Owner:SOLVAY CHEM INC

Method for recycling fluorosilicone in high-salt ammonia-nitrogen wastewater and producing sodium fluoride with coproduction of white carbon black

InactiveCN108862323AGood effectReduce processing costsSilicaWater contaminantsDecompositionHexafluorosilicic acid

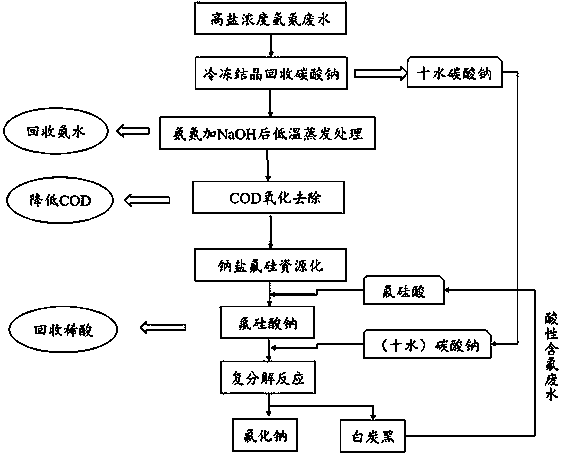

The invention relates to a method for recycling fluorosilicone in high-salt ammonia-nitrogen wastewater and producing sodium fluoride with coproduction of white carbon black. The method is characterized in that sodium fluoride is produced by taking sodium fluorosilicate and sodium carbonate decahydrate or sodium carbonate as raw materials; sodium carbonate decahydrate is produced by crystallizingsodium carbonate component in high-salt ammonia-nitrogen wastewater; a reaction by-product which is white carbon black is used as a raw material for preparing sodium fluorosilicate; sodium fluorosilicate is generated by taking fluosilicic acid and sodium chloride or sodium sulfate as raw materials through double decomposition reaction; sodium chloride or sodium sulfate is produced by the high-saltammonia-nitrogen wastewater; fluosilicic acid is prepared by reacting acidic fluorine-containing wastewater with the white carbon black; or fluosilicic acid which is a by-product in the phosphate fertilizer industry is directly used. The method has the advantages that fluorosilicone in the high-salt ammonia-nitrogen wastewater is recycled and is used for producing sodium fluoride with coproduction of white carbon black, the contents of ammonia-nitrogen and salt in the wastewater can be greatly reduced, the treatment cost of the wastewater is reduced, the wastewater is reused, the waste is changed into wealth, and the economic benefit is increased.

Owner:HUNAN UNIV OF TECH

Method of preparing azodiisobutyronitrile

InactiveCN103896808AEasy to produceReduce manufacturing costCarboxylic acid nitrile preparationOrganic compound preparationEthyl ChlorideAcetone cyanohydrin

The invention relates to a method of preparing azodiisobutyronitrile. The method comprises the following steps: a, carrying out a reaction on acetone cyanohydrin and hydrazine hydrate to generate diisobutyronitrile hydrazine; and b, introducing chlorine to diisobutyronitrile hydrazine to react to generate azodiisobutyronitrile, wherein hydrazine hydrate used in the step a is prepared by a urea method. The hydrazine hydrate is specifically prepared by the following steps: (1) introducing chlorine to a caustic soda solution to generate sodium hypochlorite; (2) adding solid urea to prepare a urea saturated solution and carrying out a reaction with sodium hypochlorite to obtain a coarse solution containing hydrazine hydrate; and (3) freezing and crystallizing the coarse solution containing hydrazine hydrate to separate sodium carbonate decahydrate so as to obtain a refined solution of hydrazine hydrate, adding a neutralizer to neutralize the pH to 2-3, removing sodium hydroxide and sodium carbonate in the solution, and then adding the refined solution of hydrazine hydrate to reversely neutralize to PH to 10-10.5. According to the method provided by the invention, the purification process of the hydrazine hydrate solution is canceled and the production procedure is simplified, so that the production cost is greatly lowered.

Owner:唐山晨虹实业有限公司

Chemical ice bag

InactiveCN101929775AReasonable formulaEasy to useDomestic cooling apparatusLighting and heating apparatusAmmonium nitrateSodium nitrate

Owner:林海英

Cheek cold compressing face mask

InactiveCN106377352ATo achieve the effect of cold compressShorten the timeTherapeutic coolingTherapeutic heatingRespiratorEngineering

The invention relates to a cheek cold compressing face mask. The size of the cheek cold compressing face mask is a little greater than that of an ordinary mask; the cheek cold compressing face mask can better wrap parts easily generating edema on the face, but the mouth and nose parts are exposed. In the use process, substances in a disposable ice bag are poured into the face mask; the ice bag is broken through pinching when being used; ammonium salt is dissolved in water for absorbing heat, and ammonium nitrate takes a reaction with sodium carbonate decahydrate for absorbing heat, so that the temperature of the face mask is lowered; the cold compressing effect is achieved. The face mask is used in an ear hanging mode, and does not need to be fixed on the face by hand; some other things can be made during cold compressing, so that the time is saved.

Owner:GONGCHENG YAO AUTONOMOUS COUNTY GONGCHENG HIGH SCHOOL

Whitened red phosphorus with high flame-retardant efficiency and preparation method of whitened red phosphorus

ActiveCN107974257AHigh flame retardant efficiencyHigh whitenessChemical inhibitorsMoisture absorptionMelamine formaldehyde resin

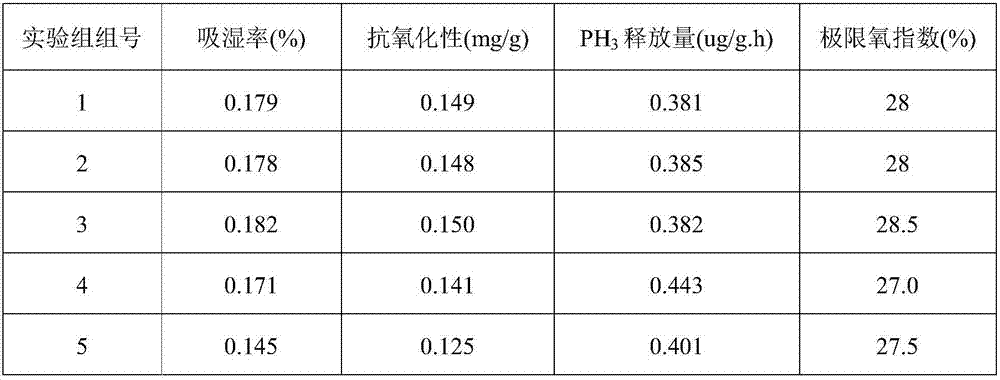

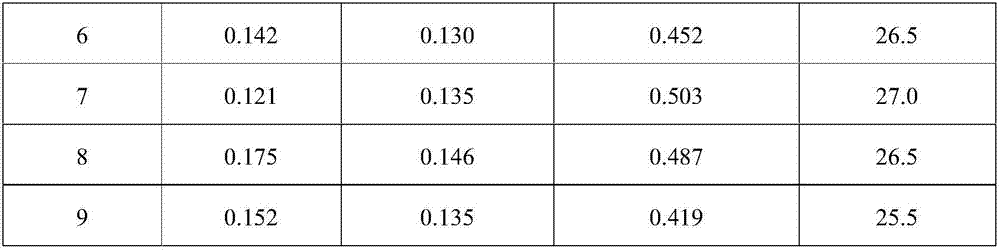

The invention relates to the technical field of modification of flame retardant, and provides whitened red phosphorus with high flame-retardant efficiency and a preparation method of the whitened redphosphorus. The preparation method comprises the steps of: adding penetrant and emulsifier into water to form a first solution, adding red phosphorus and an aluminum salt into the first solution to form a second solution, heating the second solution to prepare an emulsifying dispersion system, dissolving sodium hypophosphite in water to obtain a sodium hypophosphite solution, and adding the sodiumhypophosphite solution into the emulsifying dispersion system so as to obtain a third solution and prepare a first coating layer at the moment; adding aluminum sulfate octadecahydrate into water to obtain an aluminum sulfate solution, adding sodium carbonate decahydrate into water to form a sodium carbonate solution, adding the aluminum sulfate solution and sodium carbonate solution into the third solution to form a fourth solution, and conducting aging to obtain a second coating layer; adding a formaldehyde solution into melamine to obtain a melamine-formaldehyde resin prepolymer; and addingrutile titanium dioxide and the melamine-formaldehyde resin prepolymer into the fourth solution to form a fifth solution to obtain the whitened coated red phosphorus. The whitened red phosphorus hasa low addition amount, high flame-retardant efficiency, high whiteness, good moisture absorption and good oxidation resistance.

Owner:CHENGDU TEXTILE COLLEGE +1

Preparation ingredients and preparation method of preserved duck eggs

The invention discloses preparation ingredients of preserved duck eggs. The ingredients include duck eggs, plant ash, salt, tea residues, sodium carbonate decahydrate, loess, rice husks, quicklime, ethylenediamine tetraacetic acid and flavoring powder. The mass ratio of the ingredients is as follows: 50.0-100.0 parts of the duck eggs, 500.0-1000.0 parts of the plant ash, 150.0-300.0 parts of the salt, 40.0-80.0 parts of the tea residues, 7000.0-9000.0 parts of the rice husks, 250.0-500.0 parts of the sodium carbonate decahydrate, 550.0-1100.0 parts of the quicklime, 10.0-30.0 parts of the ethylenediamine tetraacetic acid and 100.0-200.0 parts of the flavoring powder. Compared to the prior art, the beneficial effects of the invention are as follows: lead powder is a necessary ingredient when producing traditional preserved duck eggs, but the use of the lead powder greatly increases the lead content of the traditional preserved duck eggs. However, through adopting the ethylenediamine tetraacetic acid to replace the lead powder, not only is preserved duck egg production not be influenced, but also the lead content of the preserved duck eggs can be effectively reduced; and meanwhile, through adding the flavoring powder, the produced preserved duck eggs have a five-spice flavor so as to be convenient for preserved duck egg selling.

Owner:安徽省卓创信息科技服务有限公司

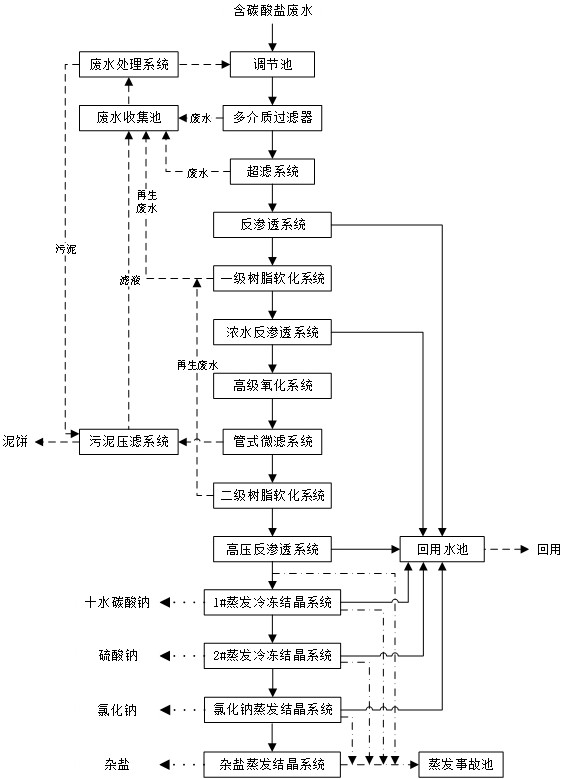

Treatment method of carbonate-containing wastewater

InactiveCN112811701ASolve the impact of scalingSolve the problem of pollutionWater treatment parameter controlScale removal and water softeningSludgeSodium sulfate

The invention discloses a treatment method of carbonate-containing wastewater. The carbonate-containing wastewater passes through a regulating reservoir, a multi-medium filter, an ultrafiltration system, a reverse osmosis system, a primary resin softening system, a concentrated water reverse osmosis system, an advanced oxidation system, a tubular microfiltration system, a secondary resin softening system, a high-pressure reverse osmosis system, a sludge filter pressing system, an evaporation freezing crystallization system, an evaporation crystallization system, a wastewater treatment system, a recycling water tank and the like for process treatment to obtain sodium carbonate decahydrate product salt and by-products sodium sulfate and sodium chloride product salt. The treatment method has the advantages of strong anti-pollution capability, high concentration multiple, high recovery rate, high crystallized salt quality, high automation degree, low investment and low operation cost.

Owner:BEIJING NEWBIOLINK TECH DEV

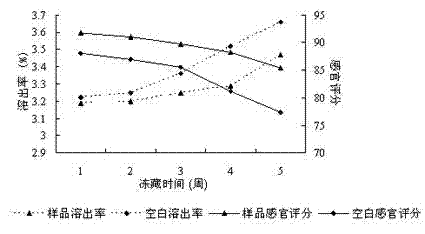

Preparation method of frozen noodles added with food microemulsion

The invention relates to a preparation method of frozen noodles added with food microemulsion. The preparation method is characterized by comprising the following steps of: weighing 100g of flour, 30g of distilled water, 1g of iodized salt, 0.1g of sodium carbonate decahydrate and 0.3g of microemulsion, and stirring for 12min; pouring made dough into a clean self-sealing bag, and standing and curing for 20min; pressing cured dough into flour tapes by a noodle press, and continuously rolling three time to finally obtain flour tapes with the thickness of 1.1mm; afterwards cutting the flour tapes into wide noodles with the width of 3.4mm through a noodle cutting machine, and picking out incomplete noodles; steaming the prepared uncooked noodles for later use in a steamer for 6min, then boiling the noodles in boiling water until white lines in the centers of the noodles just disappear, quickly fishing out the noodles by using a colander, cooling the noodles with distilled water for 30s, draining and putting the cooled noodles into the self-sealing bag, putting the self-sealing bag into a square box and quickly freezing at -40 DEG C for 15min, taking out the square box, and refrigerate the square box in an environment at -18 DEG C for later use.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Pure mung bean noodles and preparation method thereof

InactiveCN101675767AMaintain nutritional contentKeep the tasteFood preparationRoom temperatureToxic material

Pure mung bean noodles are prepared by taking mung bean powder obtained by grinding mung beans as the raw material and eggs, salt, sodium carbonate decahydrate and water as the auxiliary materials. 5-10 parts of eggs, 0.1-1.5 parts of salt, 0.1-1.5 parts of sodium carbonate decahydrate and 2-10 parts water by weight are added to every 100 parts of mung beans by weight. The mung bean noodles are prepared by the following steps: first adding water accounting for 5-10% of the material amount into the mung bean residues, turning and stirring the mixture at room temperature and sealing the mixturefor 8-12h, carrying out peeing after purification and then using a stone mill to mill the mixture into 80-120-mesh fine powder for standby use; and mixing the eggs, salt and sodium carbonate decahydrate with mung bean powder according to the above proportion, adding water to knead dough and rolling the dough to noodles by a plodder with revolution of 20-50r / min. The noodles feature reasonable proportion of primary and auxiliary materials, are easy to shape up, maintain the nutritions and taste of the mung beans, have good edible ductility, unique, smooth and refreshing taste and have the effects of clearing away heat and toxic materials, moistening skins, invigorating primordial energy, coordinating five internal organs and tranquilizing the mind and caring skins.

Owner:顾井芹

Deoxidization preservative

InactiveCN102068020ANo increase in fixed investment costsLow cost of occupancyFood preservationFlavorAdditive ingredient

The invention relates to a deoxidization preservative, which is mainly used for pastry foods and various fried foods or fat-rich foods, and is prepared from active iron powder, sodium carbonate decahydrate, activated carbon, salt, glycerol monostearate, glutinous rice and nanometer silicon dioxide. The deoxidization preservative is nontoxic and odorless, thoroughly deoxidizes the foods quickly, ensures that various foods are difficult to mildew, and keeps the original flavor, freshness and nutritional ingredients of the foods unchanged simultaneously.

Owner:张军辉

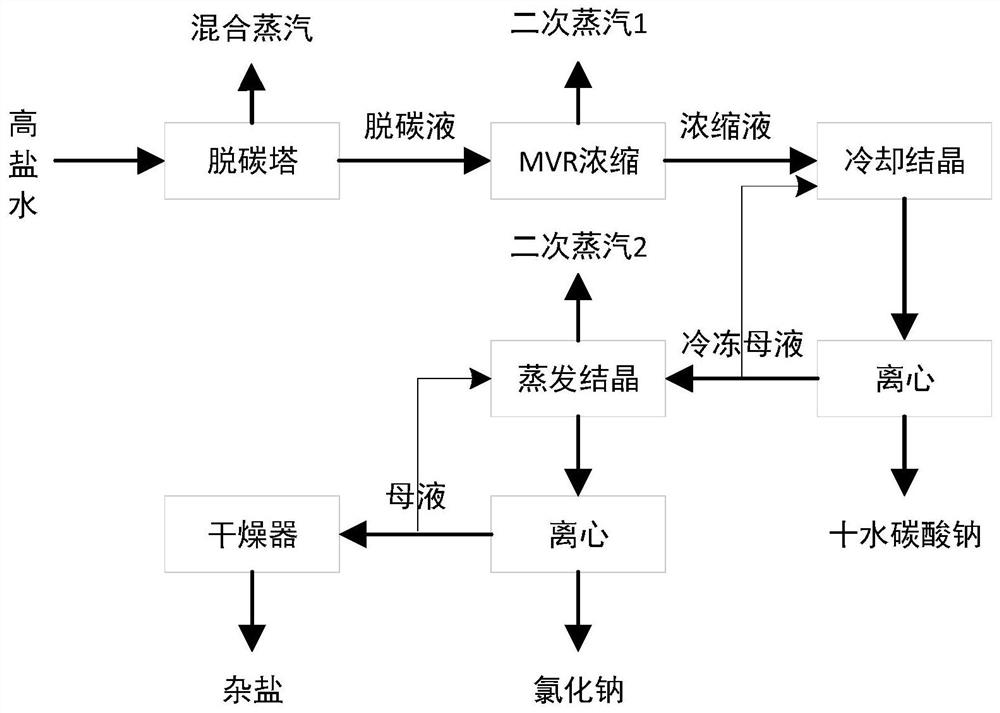

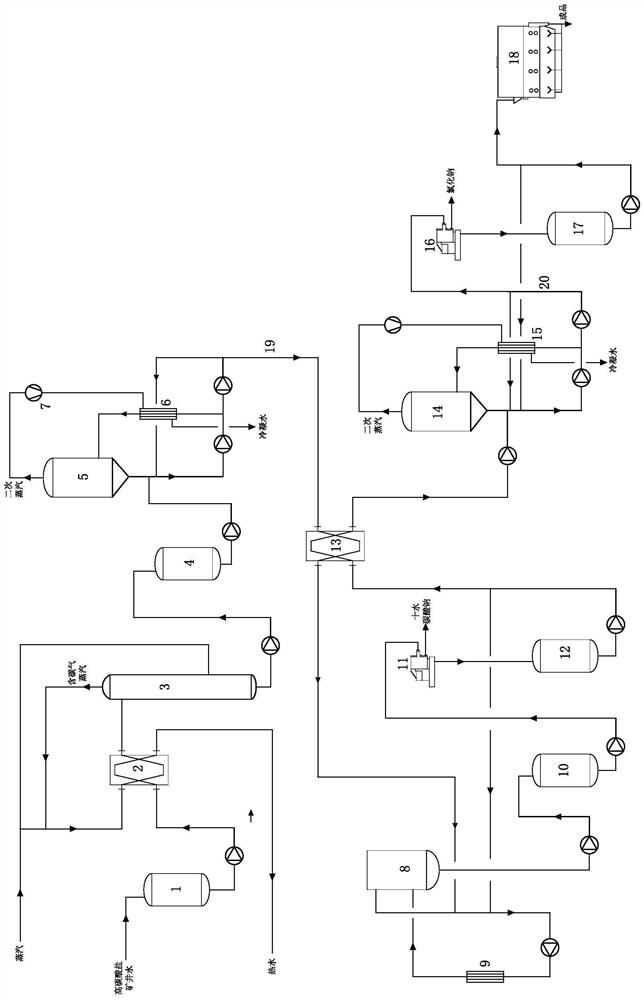

Zero-discharge treatment method and system for high-carbonate mine water

PendingCN112110591AHigh purityGuaranteed cycleWater/sewage treatment by centrifugal separationWater treatment parameter controlWastewaterWater resources

The invention relates to a high-carbonate mine water zero-emission treatment method and system. The system comprises: a decarburization unit for converting bicarbonate radicals in high-carbonate minewater into carbonate radicals and removing CO2 dissolved in the mine water; an evaporation and concentration unit for evaporating and concentrating the decarburized mine water to obtain an evaporationand concentration solution containing sodium chloride with the mass concentration of 9-11.8% and sodium carbonate with the mass concentration of 18-20.5%; a cooling crystallization unit for cooling,crystallizing and centrifugally separating the evaporation and concentration solution to obtain sodium carbonate decahydrate and a frozen mother liquor; an evaporative crystallization unit for evaporating, concentrating and centrifugally separating the frozen mother liquor to obtain sodium chloride and an evaporated mother liquor; and a drying unit for drying the evaporated mother liquor discharged by the evaporative crystallization unit to obtain miscellaneous salt. According to the method, sodium carbonate and sodium chloride in high-carbonate mine water can be recycled with low cost and high efficiency, the environmental protection pressure of enterprises is reduced, the treatment cost of the high-salt mine water is reduced, and comprehensive utilization of wastewater resources is realized.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com