Patents

Literature

38 results about "Sodium Carbonate Monohydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium carbonate, monohydrate - Green circle - The chemical has been verified to be of low concern based on experimental and modeled data. from EPA Safer Choice Literature

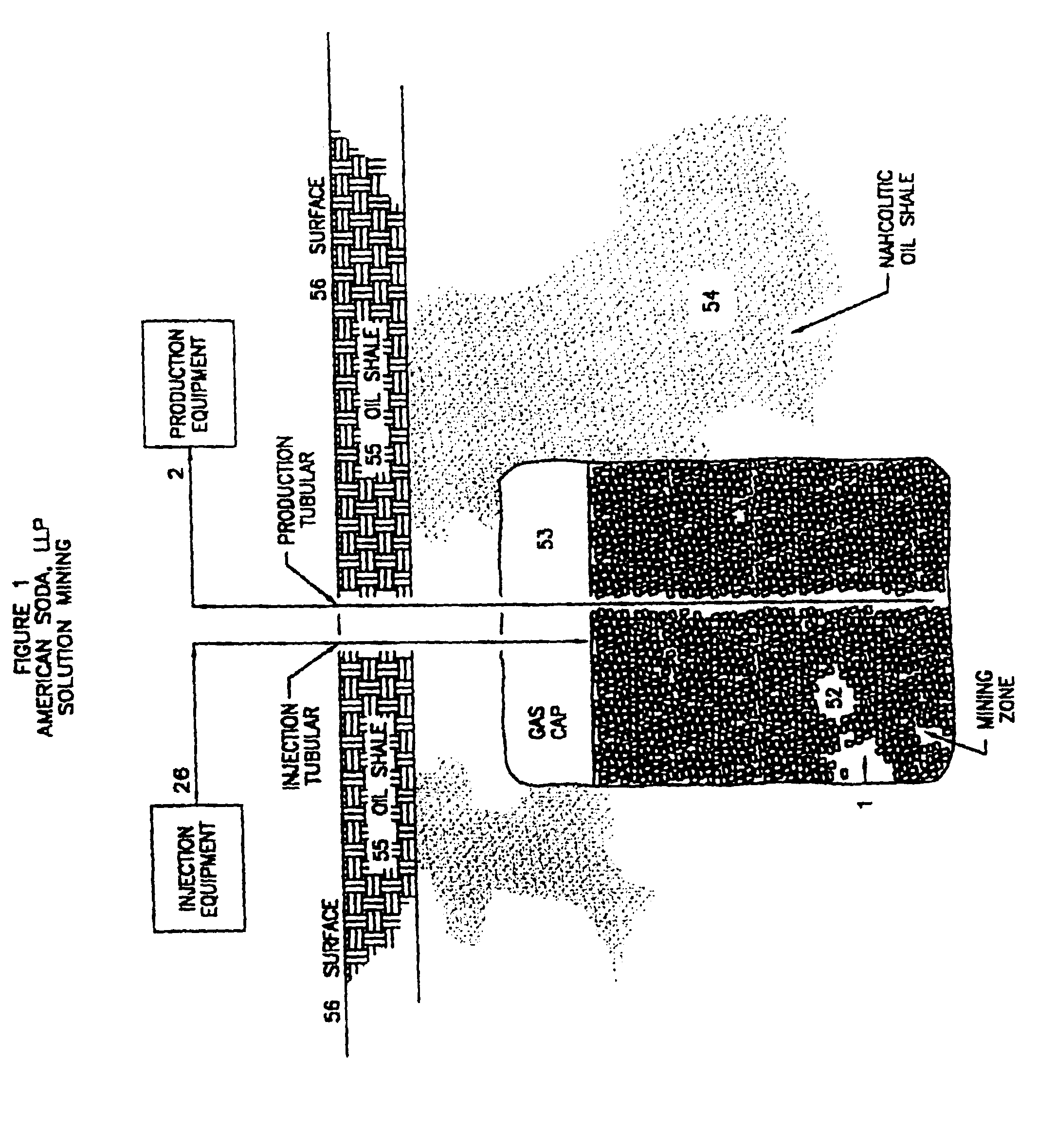

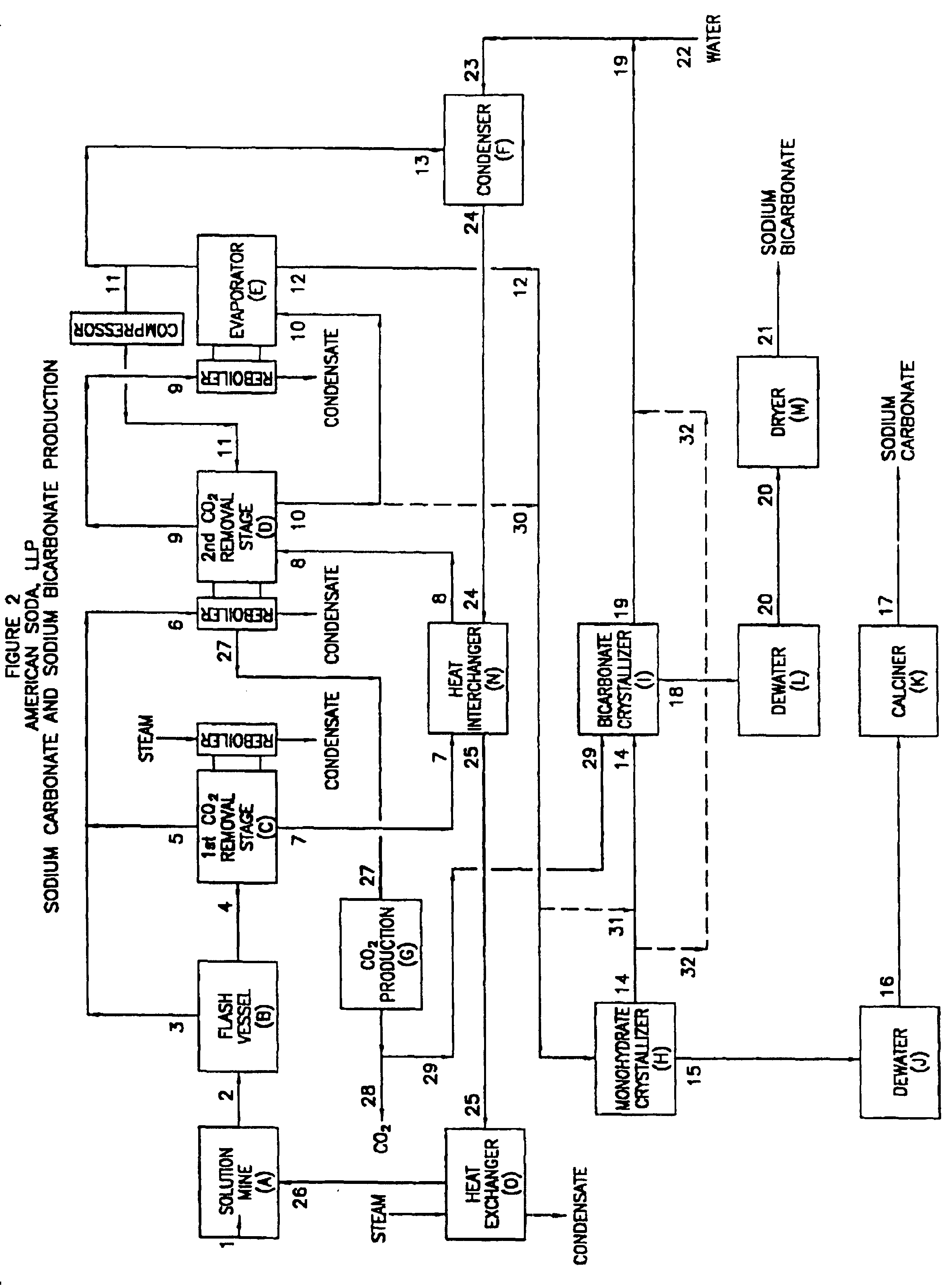

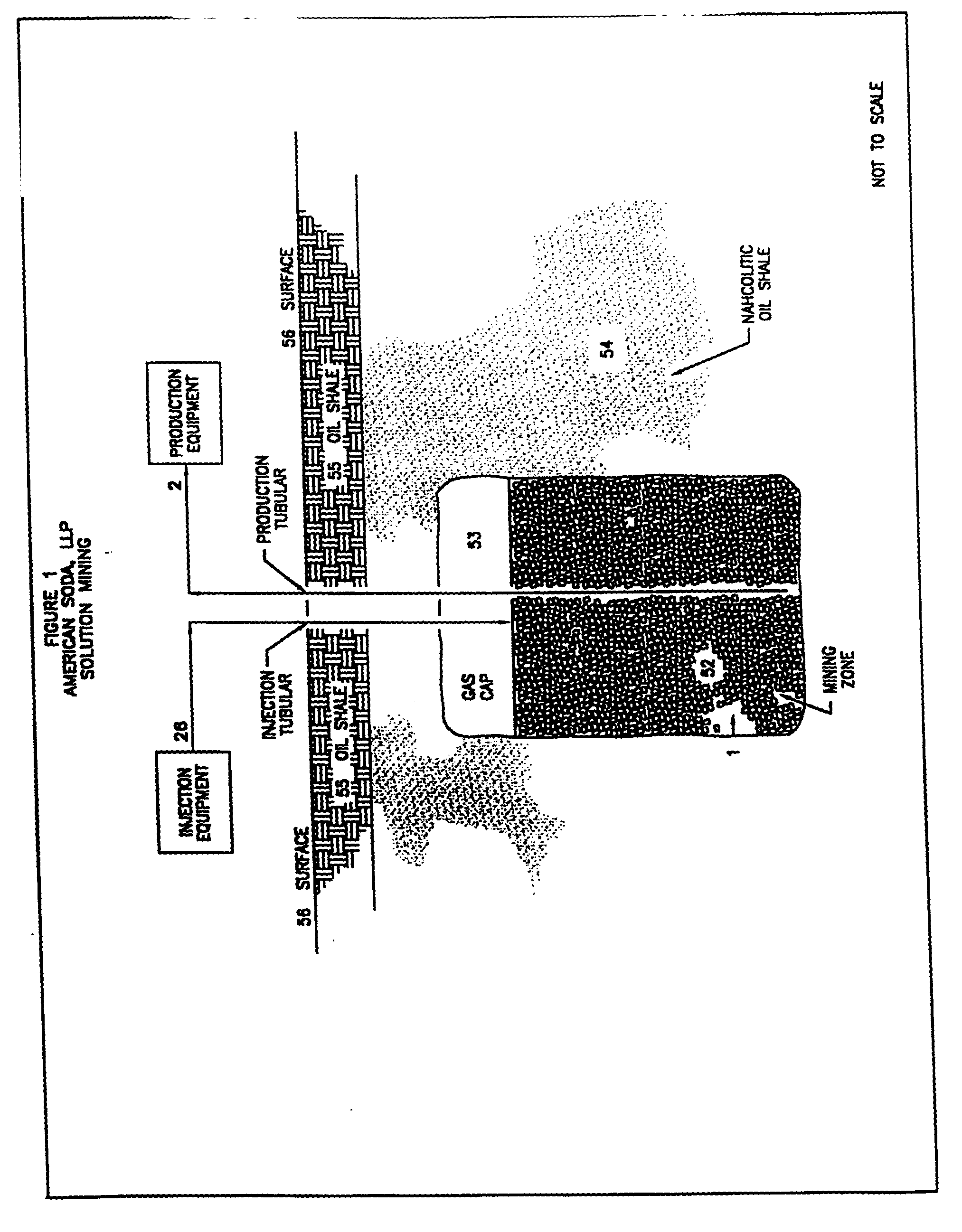

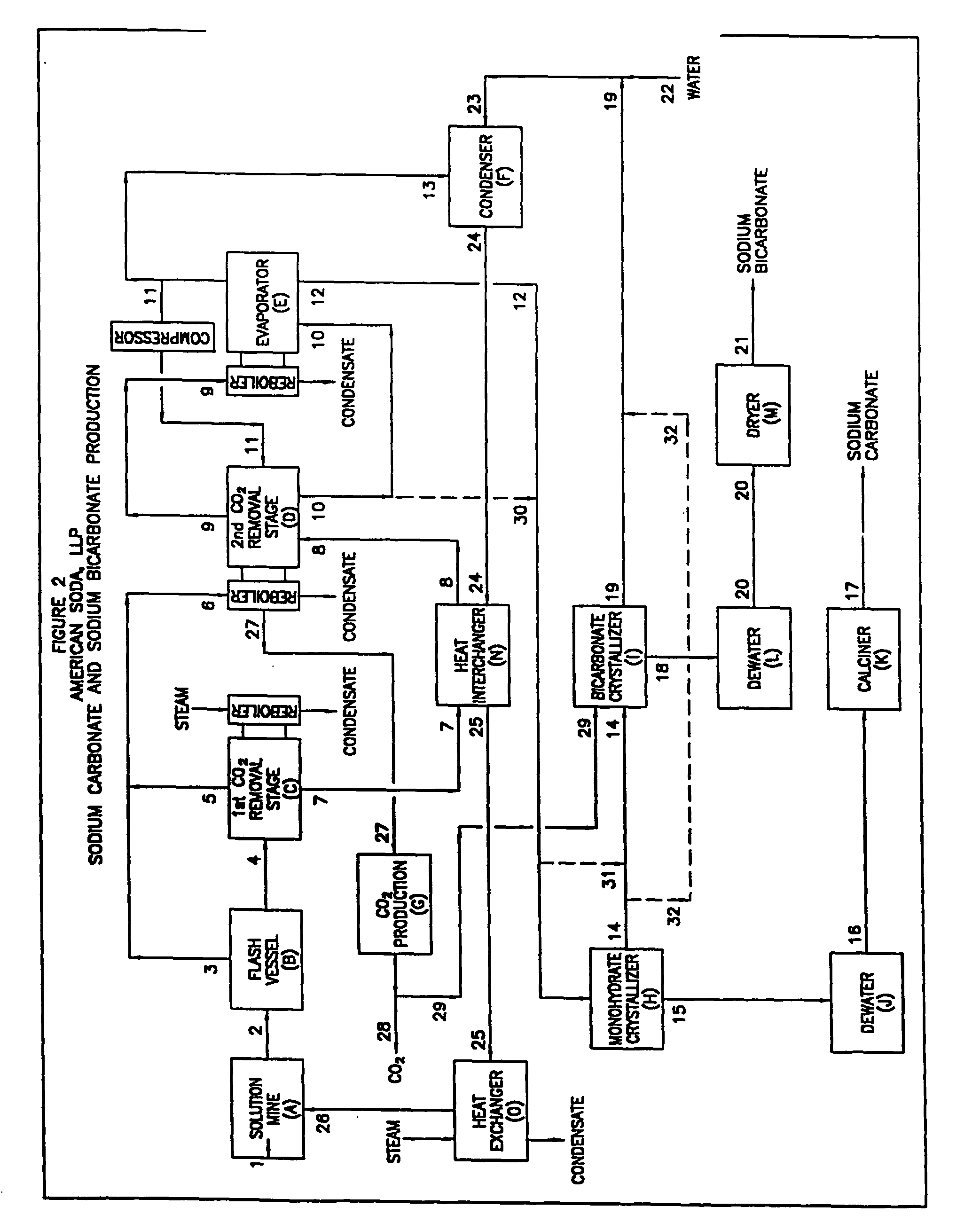

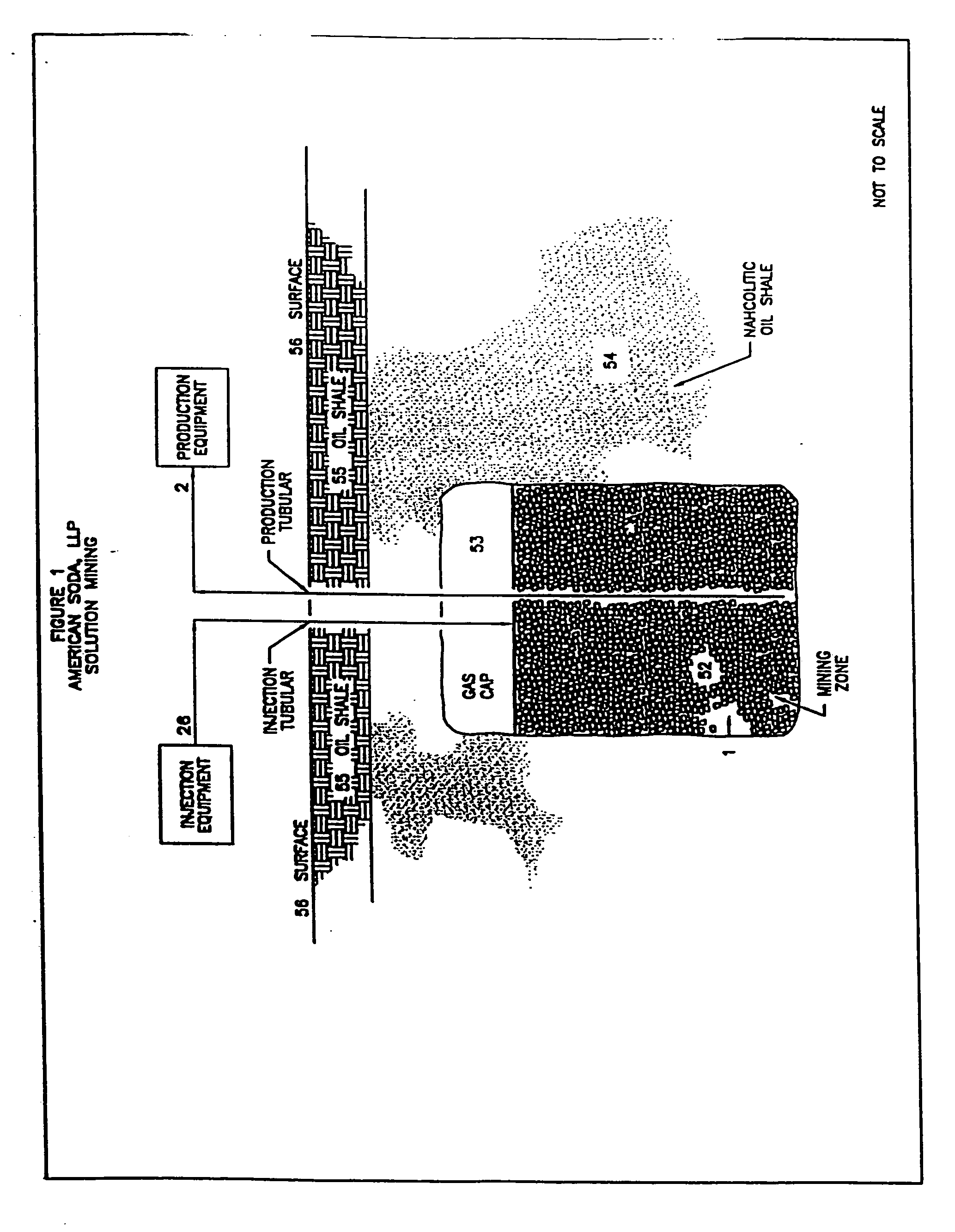

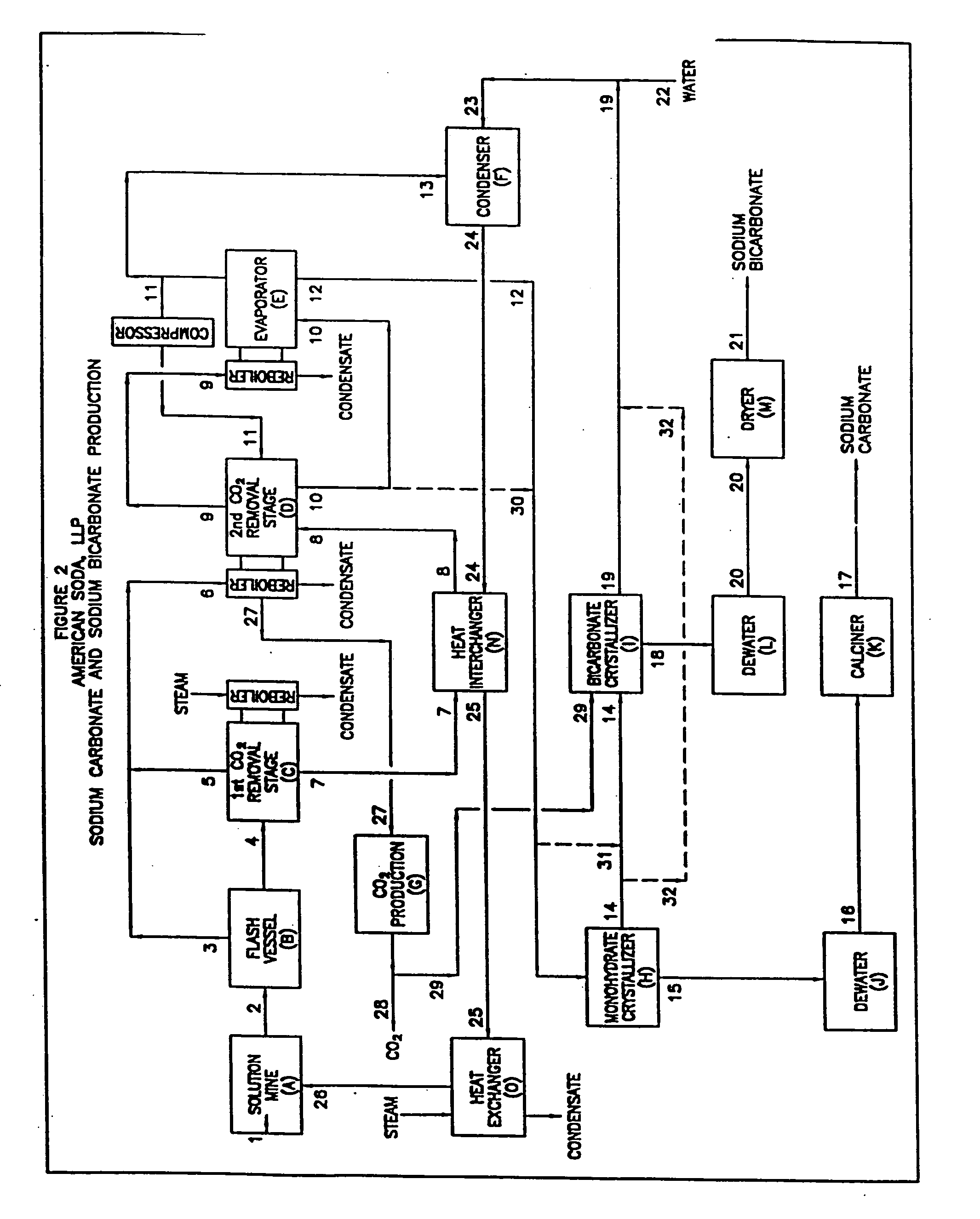

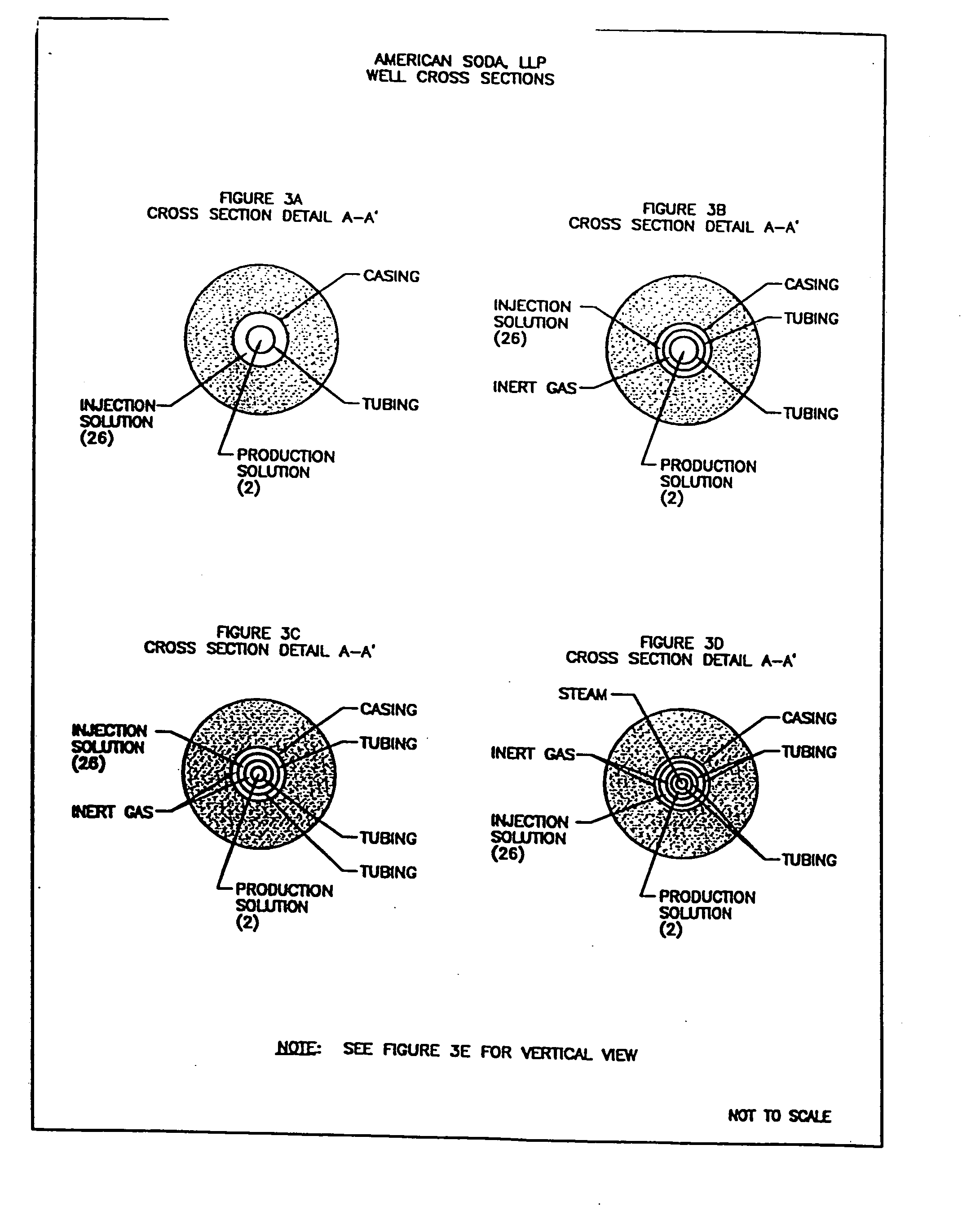

Sodium carbonate and sodium bicarbonate production from nahcolitic oil shale

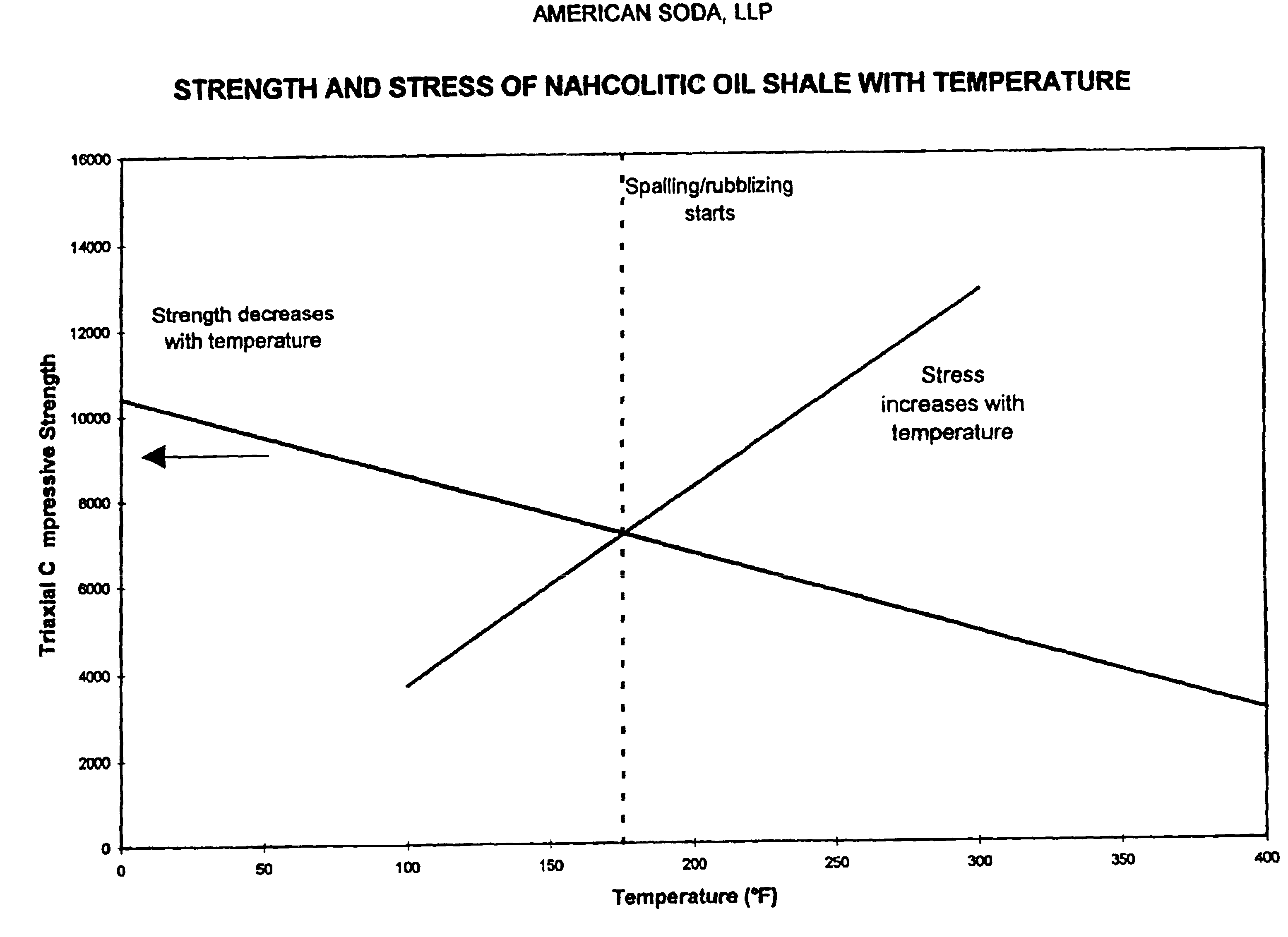

InactiveUS6854809B1Solve the blockageEfficient executionVarying alkali metal carbonate water contentUnderground miningSodium bicarbonateNahcolite

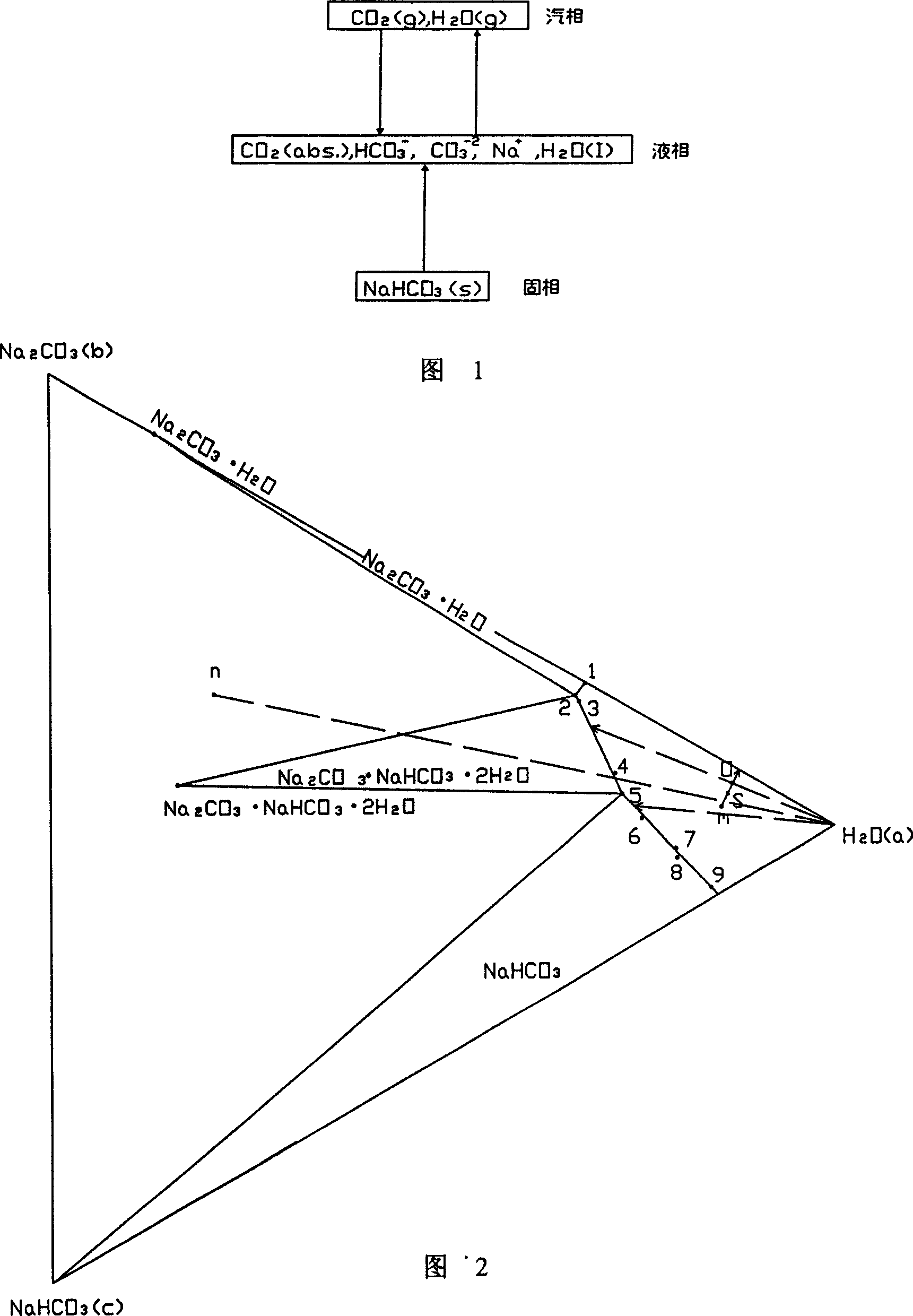

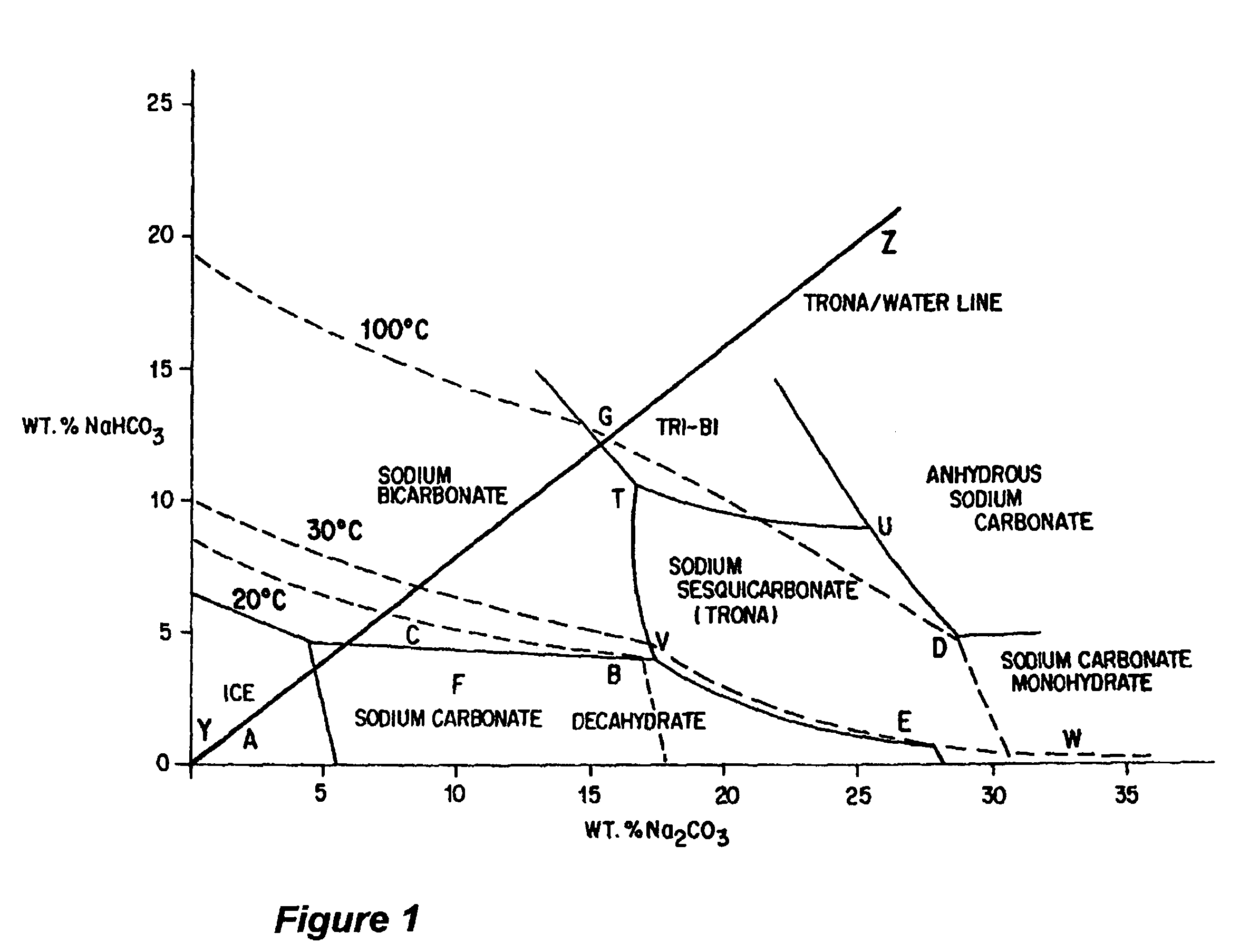

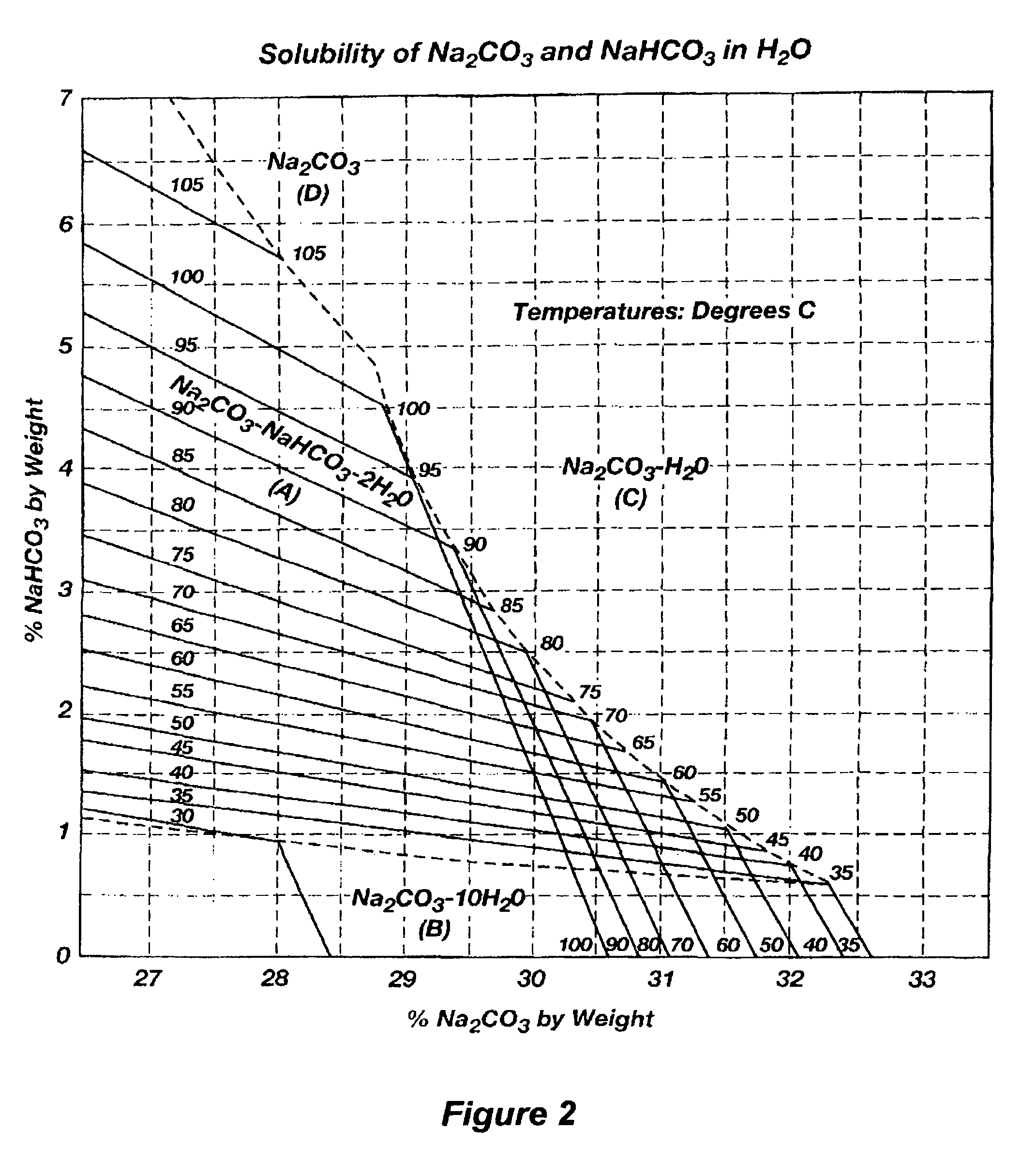

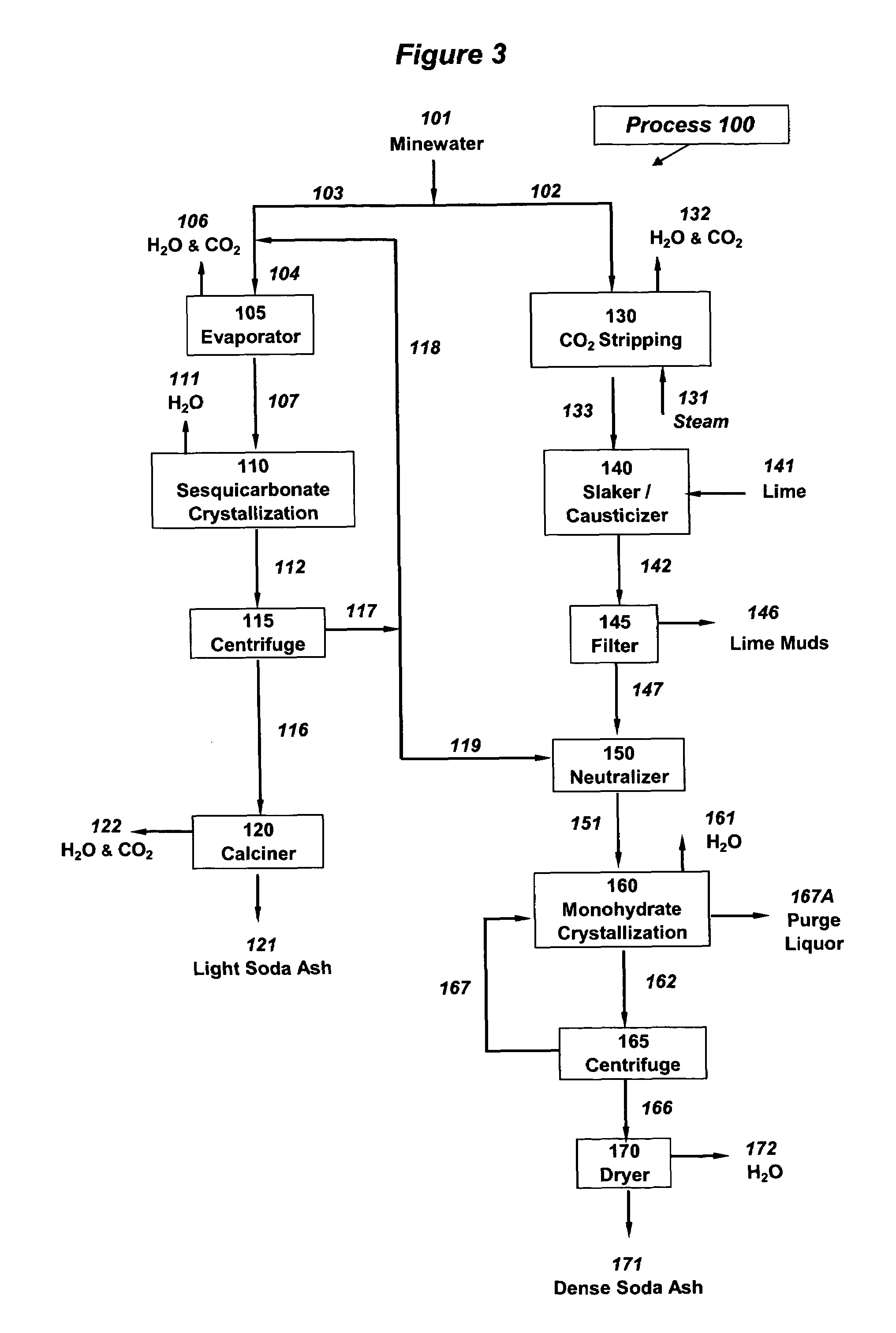

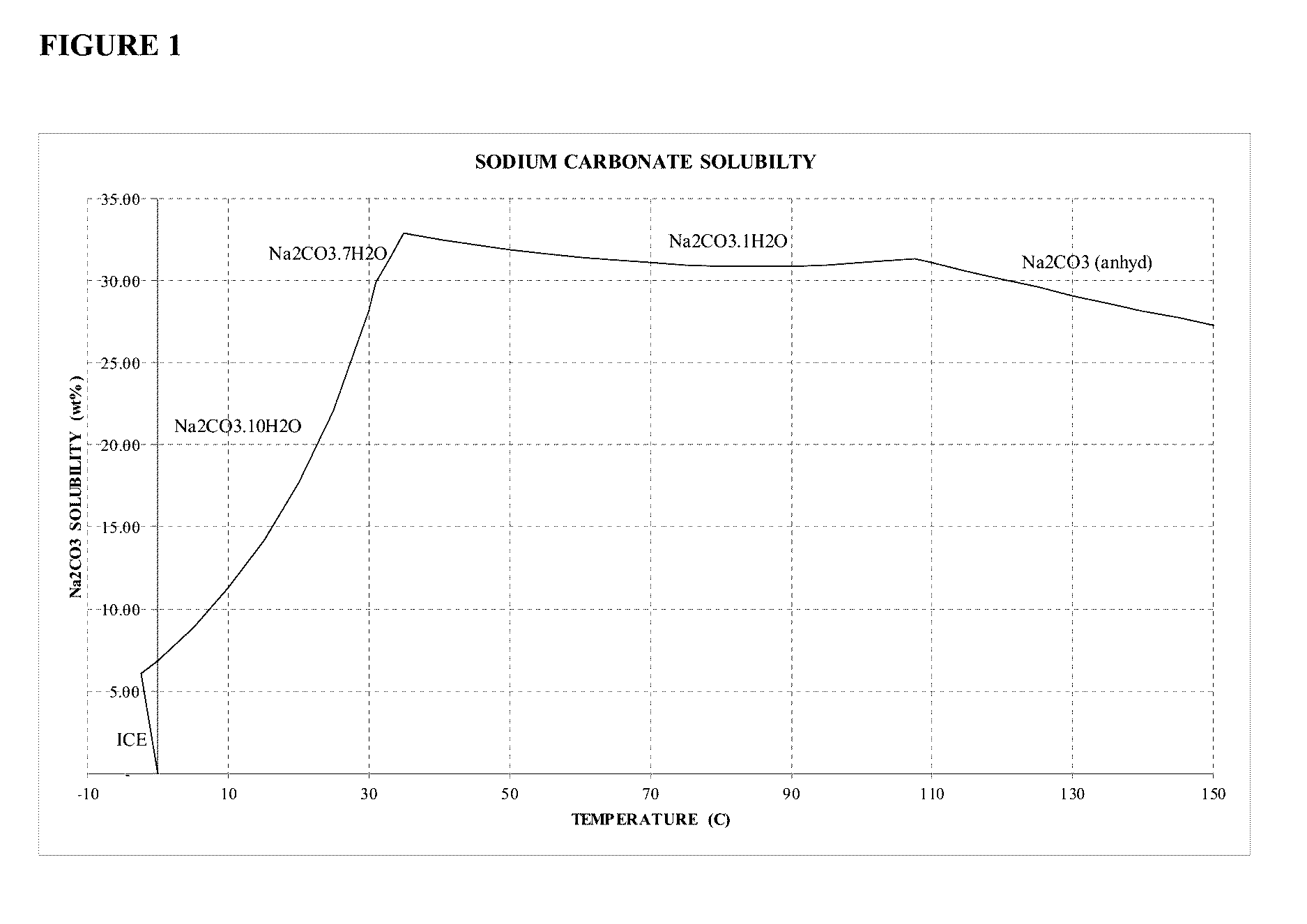

A method for solution mining nahcolite, capable of extracting nahcolite from geological formations lean in nahcolite comprising injecting high pressure water (which may include recycled aqueous solution of bicarb and sodium carbonate) at a temperature of at least 250° F. into the formation, dissolving nahcolite in the hot water to form a production solution and recovering the production solution. The invention also includes the processing of the production solution to provide sodium carbonate and, optionally, sodium bicarbonate, comprising: decomposing the sodium bicarbonate portion of the hot aqueous production solution to form a hot aqueous solution of sodium carbonate; evaporating water from the hot aqueous solution comprising sodium carbonate to form a concentrated solution of sodium carbonate; producing sodium carbonate monohydrate from the concentrated solution of sodium carbonate by crystallization; and dewatering and calcining the sodium carbonate monohydrate to produce anhydrous sodium carbonate.

Owner:AMERICAN SODA

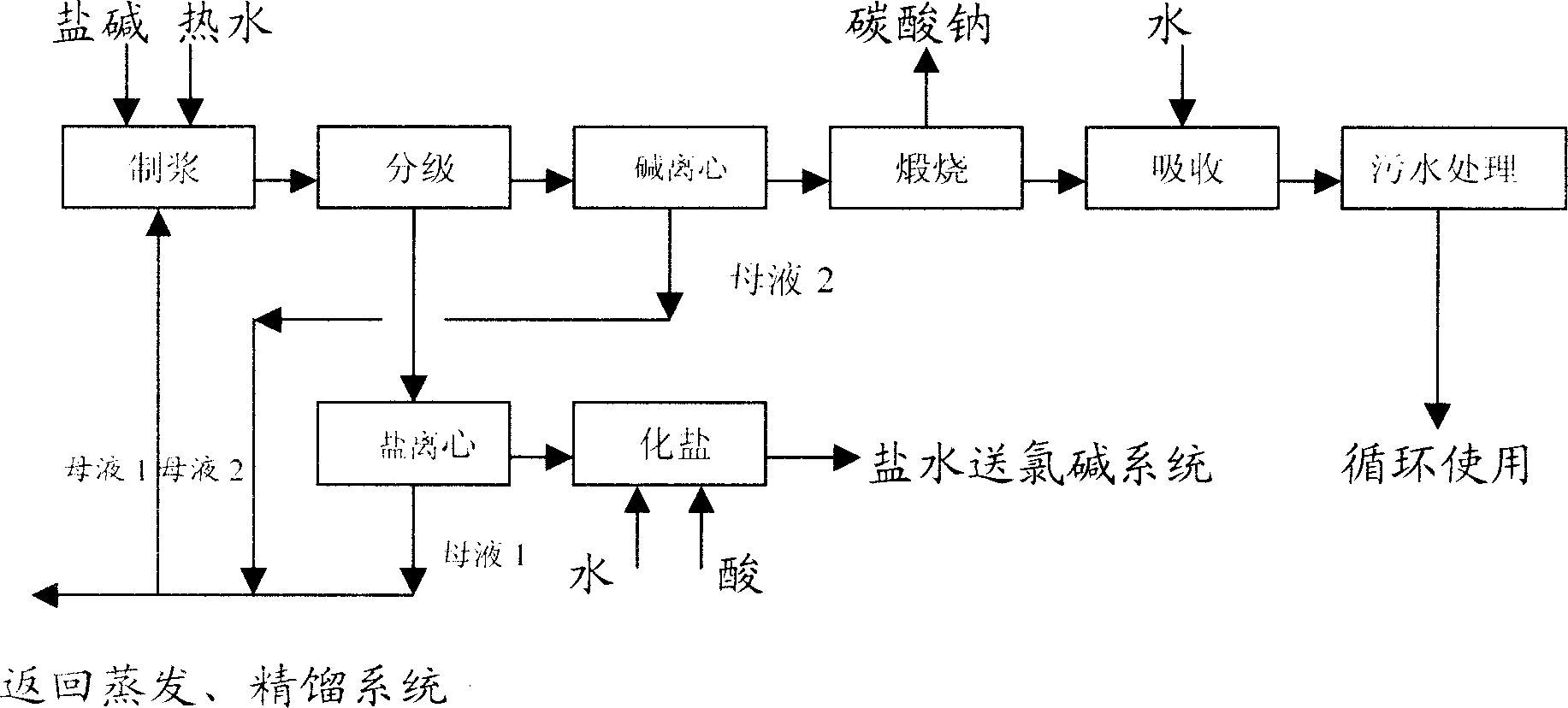

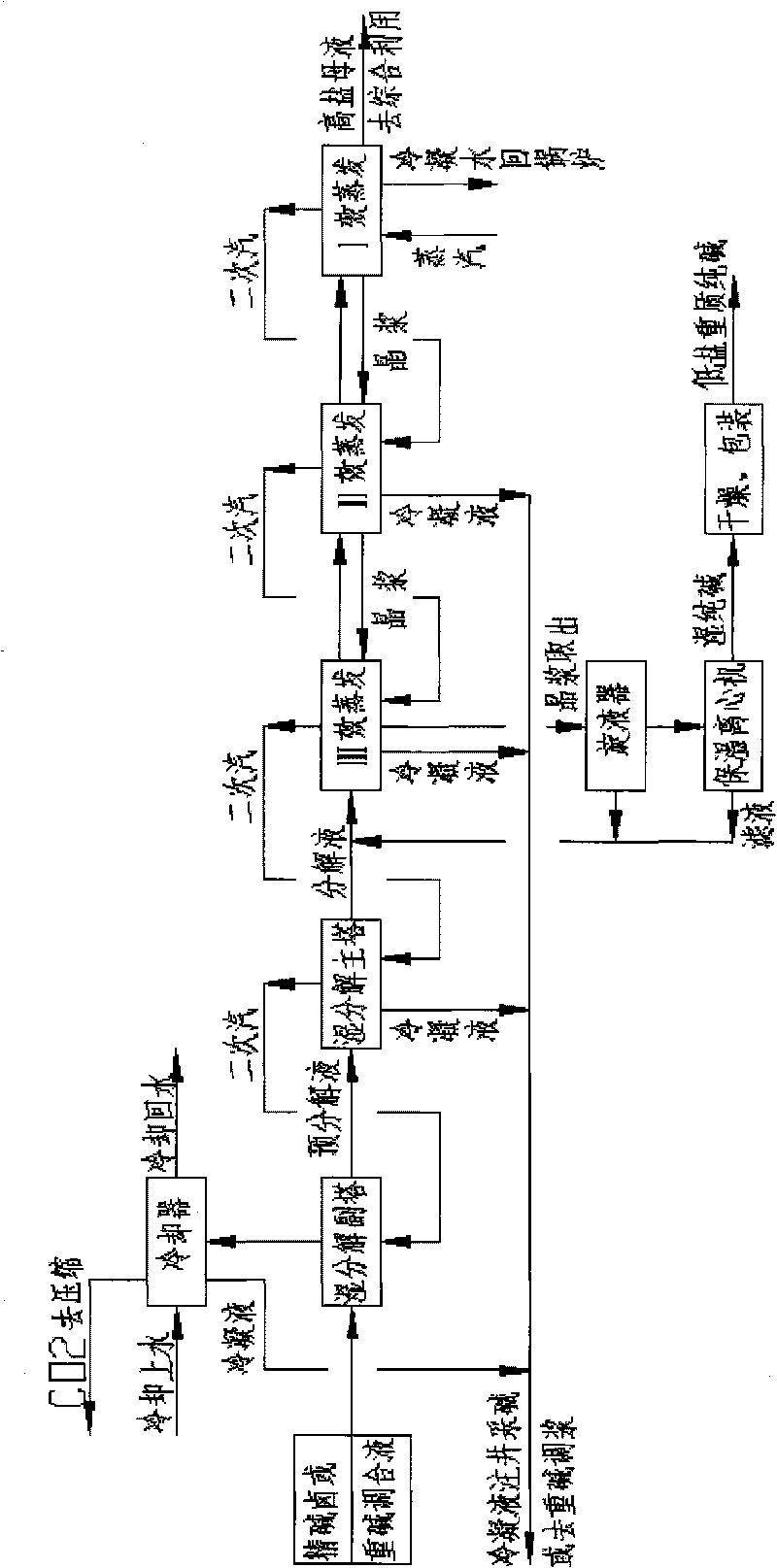

Recovering treatment of hydrated hydrazine by-product saline-alkali by urea method

A process for reclaiming the salt and alkali as the by-product generated in preparing hydrazine hydrate from urea, sodium hypochlorite and sodium hydroxide by oxidizing method includes such steps as preparing slurry by use of rejected hot water, separating salt slurry from alkali slurry, treating the salt slurry through recovering solid salt, dissolving to become saline, refining and reusing it, treating the alkali slurry through calcining low-grade monohydrated sodium carbonate and absorbing tail gas by water, and reusing the mother liquid to prepare slurry.

Owner:YIBIN TIANYUAN GRP CO LTD

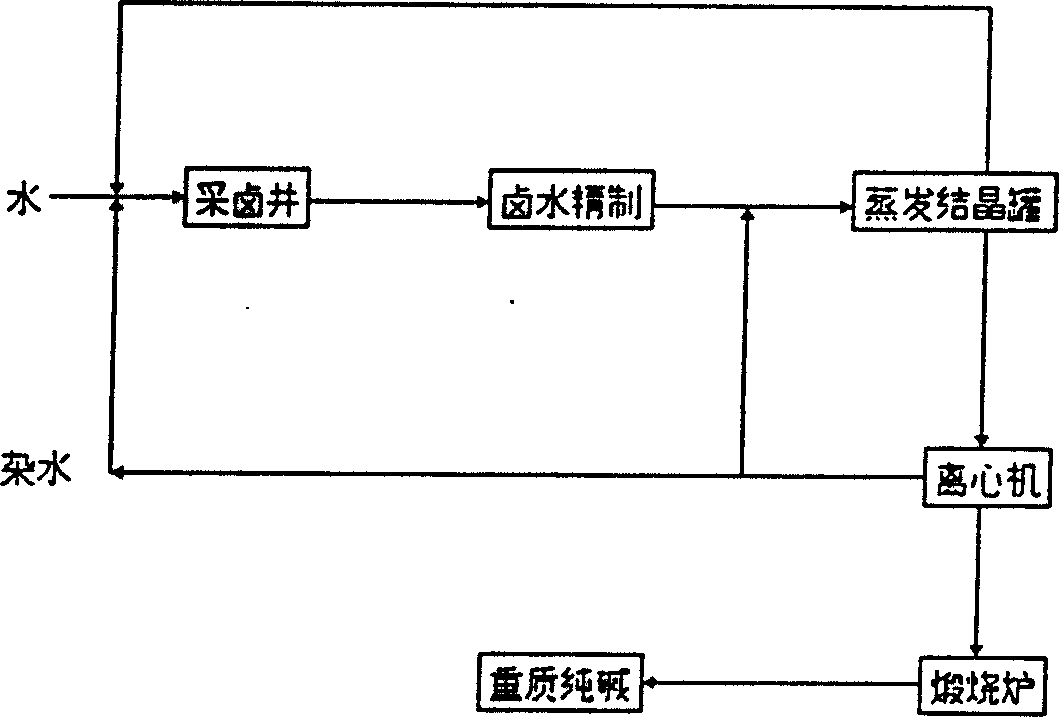

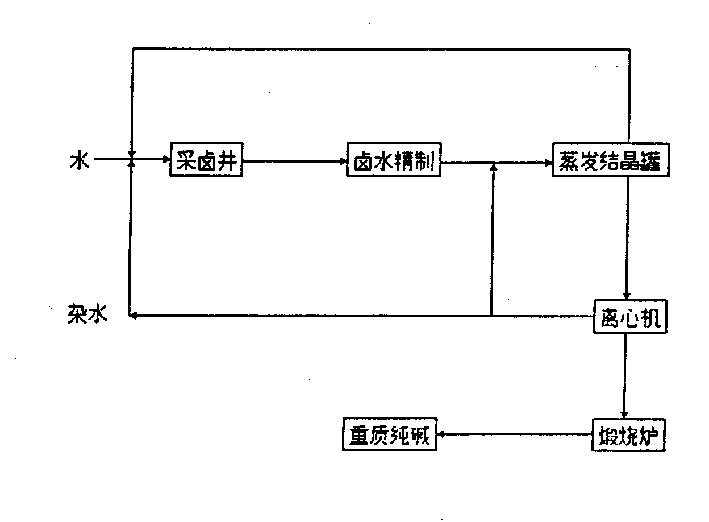

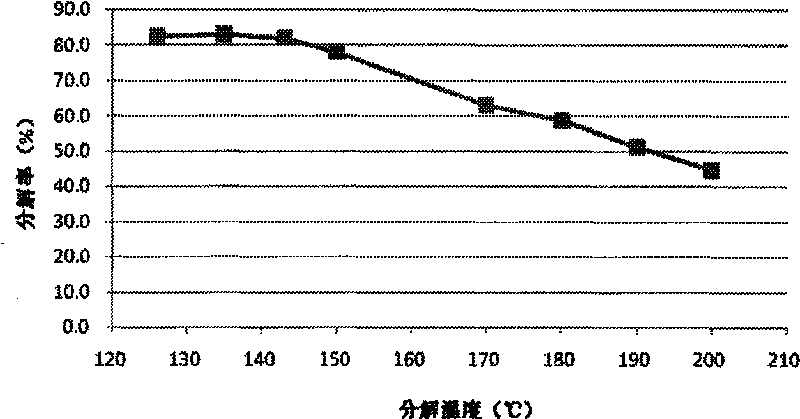

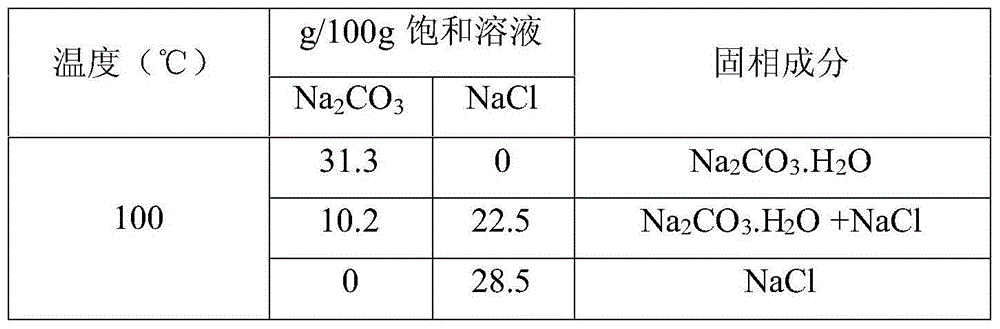

Process for preparing calcined soda by trona containing abundant sodium bicarbonate

The process for producing anhydrous sodium carbonate by utilizing natural alkali richly containing sodium hydrogen carbonate includes the following steps: purifying alkali bittern, feeding it into evaporation crystallization tank, introducing steam to make evaporation, concentration, wet decomposition (stripping) and crystallization so as to make most of sodium hydrogen carbonate in the alkali bittern be decomposed and converted into sodium carbonate, finally, in the crystallizer separating the sodium carbonate in the form of crystal carbonate and concentrated crystal soda mixed crystal from mother liquor, and calcining the mixed crystal to obtain invented product heavy anhydrous sodium carbonate whose stacking density is greater than 0.9.

Owner:INNER MONGOLIA YIKE SCI & TECH

Process for preparing low-salt heavy soda ash

The invention relates to a method for preparing low-salt heavy soda ash by applying a multi-temperature phase diagram of a Na2CO3-NaHCO3-H2O ternary system, utilizing the feature that the system can precipitate anhydrous sodium carbonate crystals at the appropriate temperature and the composition and adopting the anhydrous sodium carbonate flow process. The method comprises the following steps: carrying out pressure wet decomposition on mixed solution of the heavy soda ash which is rich in sodium bicarbonate or refined natural alkali halide, leading the content of the sodium bicarbonate and the content of sodium carbonate in the solution to achieve the corresponding proportion, further leading the solution to enter into a multi-effect evaporator for evaporation and concentration, controlling the crystallization temperature to be above the phase transition point from anhydrous sodium carbonate to sodium carbonate monohydrate, and ensuring that the precipitated solid phase is the anhydrous sodium carbonate; and taking out a magma by self-pressure, carrying out thermal insulation and separation, obtaining a filter cake which mainly contains the anhydrous sodium carbonate, and drying the filter cake for preparing the low-salt heavy soda ash. The process can change the traditional two-step dry calcination to one-step wet calcination, simplify and shorten the process flow, reduce the area occupied by devices, improve the operation environment, simultaneously improve the quality of a product and reduce the energy consumption.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

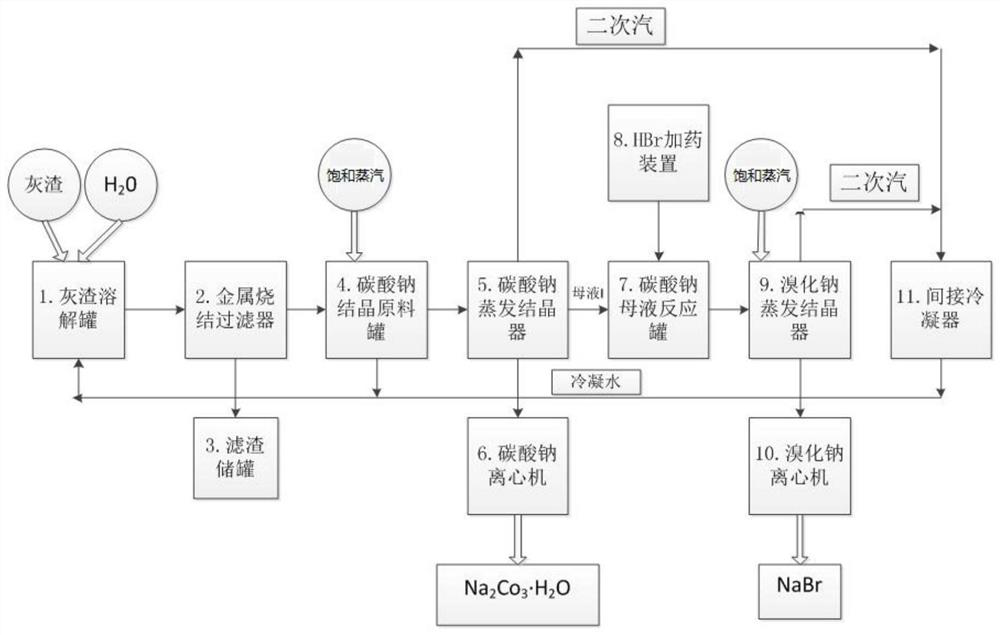

PTA incineration boiler ash residue solution salt separation crystallization process

ActiveCN112811444AFulfill quality requirementsRealize resourcesAlkali metal carbonates shape formationEnergy inputPhysical chemistryWastewater

The invention relates to a PTA incineration boiler ash residue solution salt separation crystallization process, and belongs to the technical field of evaporative crystallization. The process comprises the following steps of: dissolving ash of the PTA incineration boiler with waste heat into a nearly saturated solution of sodium carbonate and sodium bromide, and removing metals and other insoluble substances from the solution by adopting a metal sintering filter, separating the obtained filtrate by adopting an evaporative crystallization method to obtain sodium carbonate monohydrate crystals, removing sodium carbonate from the mother liquor by adopting a replacement method, and then separating by adopting an evaporative crystallization method to obtain sodium bromide crystals. Sodium carbonate and sodium bromide in the PTA boiler ash are separated and recovered by adopting an evaporative crystallization method, the process flow is simple, the operation conditions are simple, convenient and stable, and industrialization is facilitated; the high-purity sodium carbonate and sodium bromide recovered by the method can meet the quality requirements of industrial-grade products and can be directly recovered and reused or sold as by-products, so that the purpose of treating waste residues and wastewater is achieved, the requirements of the current environmental protection situation are met, waste can be turned into wealth, recycling of salt is realized, and the benefits of factories are improved.

Owner:河北工大晟珂工程科技有限公司

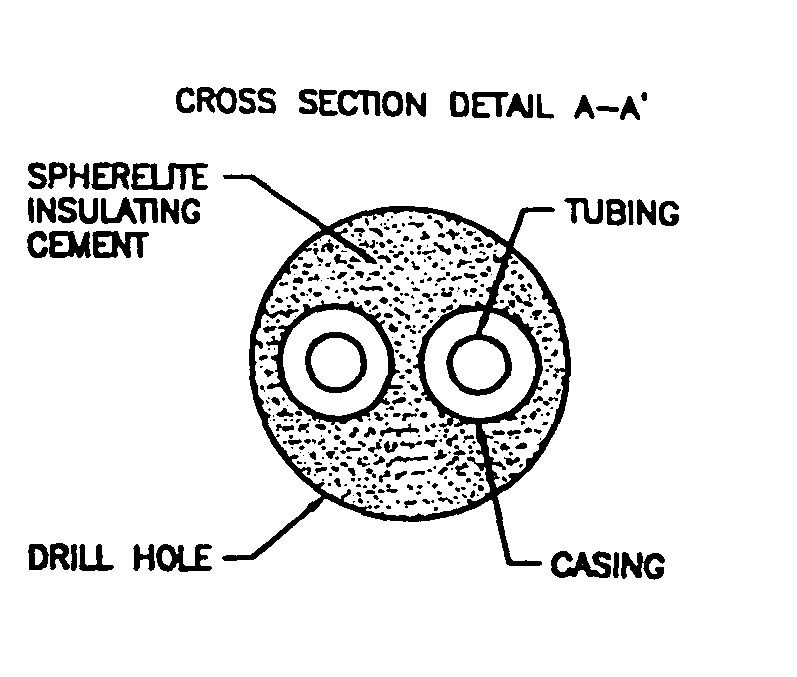

Sodium carbonate and sodium bicarbonate production from nahcolitic oil shale

InactiveUS20040026982A1Reduced compressive strengthIncrease pressureVarying alkali metal carbonate water contentConstructionsSodium bicarbonateNahcolite

A method for solution mining nahcolite, capable of extracting nahcolite from geological formations lean in nahcolite comprising injecting high pressure water (which may include recycled aqueous solution of bicarb and sodium carbonate) at a temperature of at least 250° F. into the formation, dissolving nahcolite in the hot water to form a production solution and recovering the production solution. The invention also includes the processing of the production solution to provide sodium carbonate and, optionally, sodium bicarbonate, comprising: decomposing the sodium bicarbonate portion of the hot aqueous production solution to form a hot aqueous solution of sodium carbonate; evaporating water from the hot aqueous solution comprising sodium carbonate to form a concentrated solution of sodium carbonate; producing sodium carbonate monohydrate from the concentrated solution of sodium carbonate by crystallization; and dewatering and calcining the sodium carbonate monohydrate to produce anhydrous sodium carbonate.

Owner:SOLVAY CHEM INC

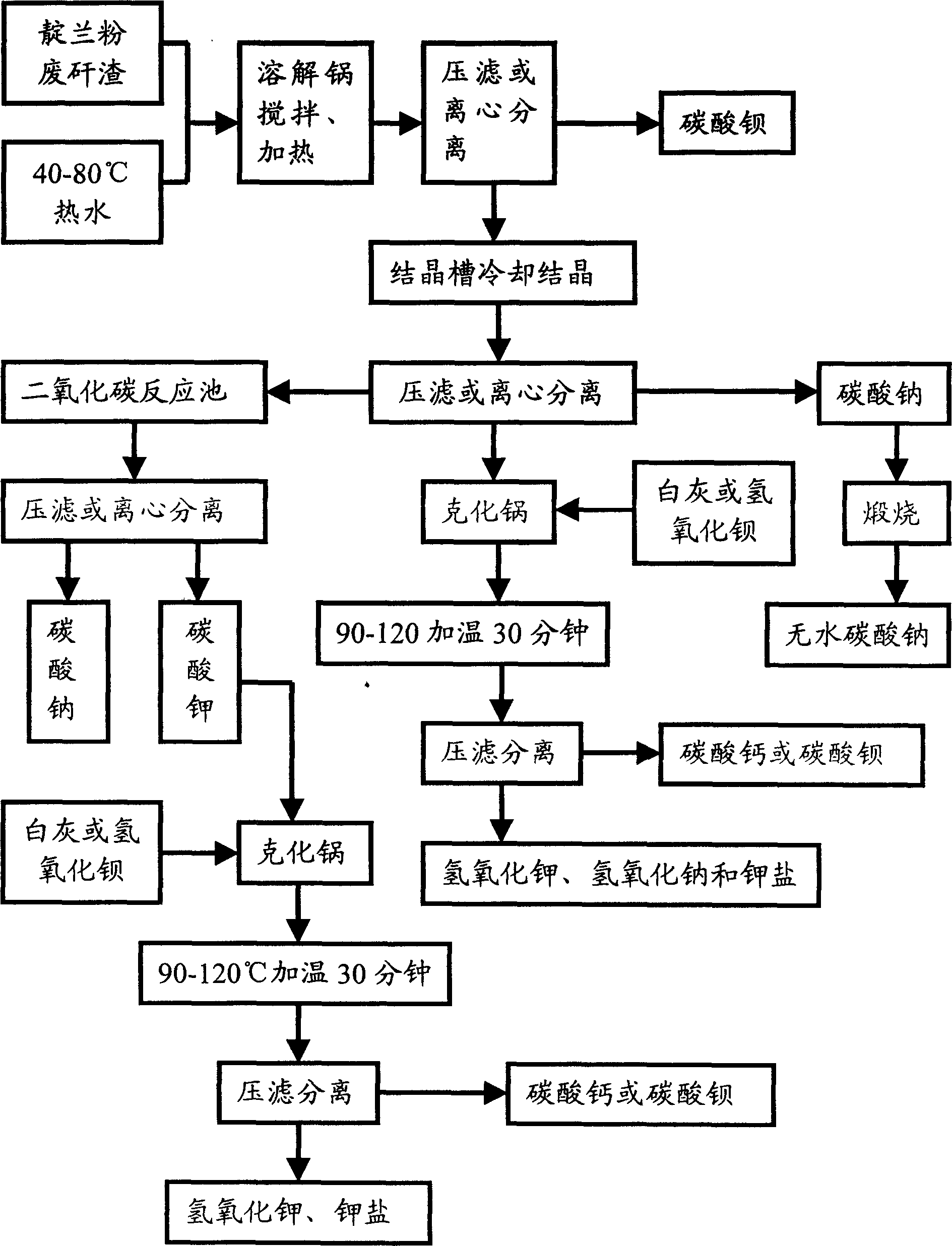

Comprehensive process for recovering and treating indigo blue powder waste slag

InactiveCN1557708AReasonable process designThe preparation method is simple and feasibleSolid waste disposalAlkali metal hydroxidesSlagPotassium hydroxide

The comprehensive indigo powder waste gangue slag recovering treatment process includes heating the mixture of waste gangue slag and water in a reactor to 4-80 deg.c for the waste gangue slag to dissolve fully; centrifugally separating to eliminate dreg and create mother liquid A; cooling mother liquid an in a crystallizing tank for 12-30 hr; press filtering or centrifuging to separate crystal as mixture of crystal carbonate and natron from crystallized liquid A; and calcining the crystal mixture to obtain anhydrous sodium carbonate. The said process can recover sodium hydroxide, potassium hydroxide, potassium carbonate, potassium salt and sodium carbonate in low cost and high yield.

Owner:贾升

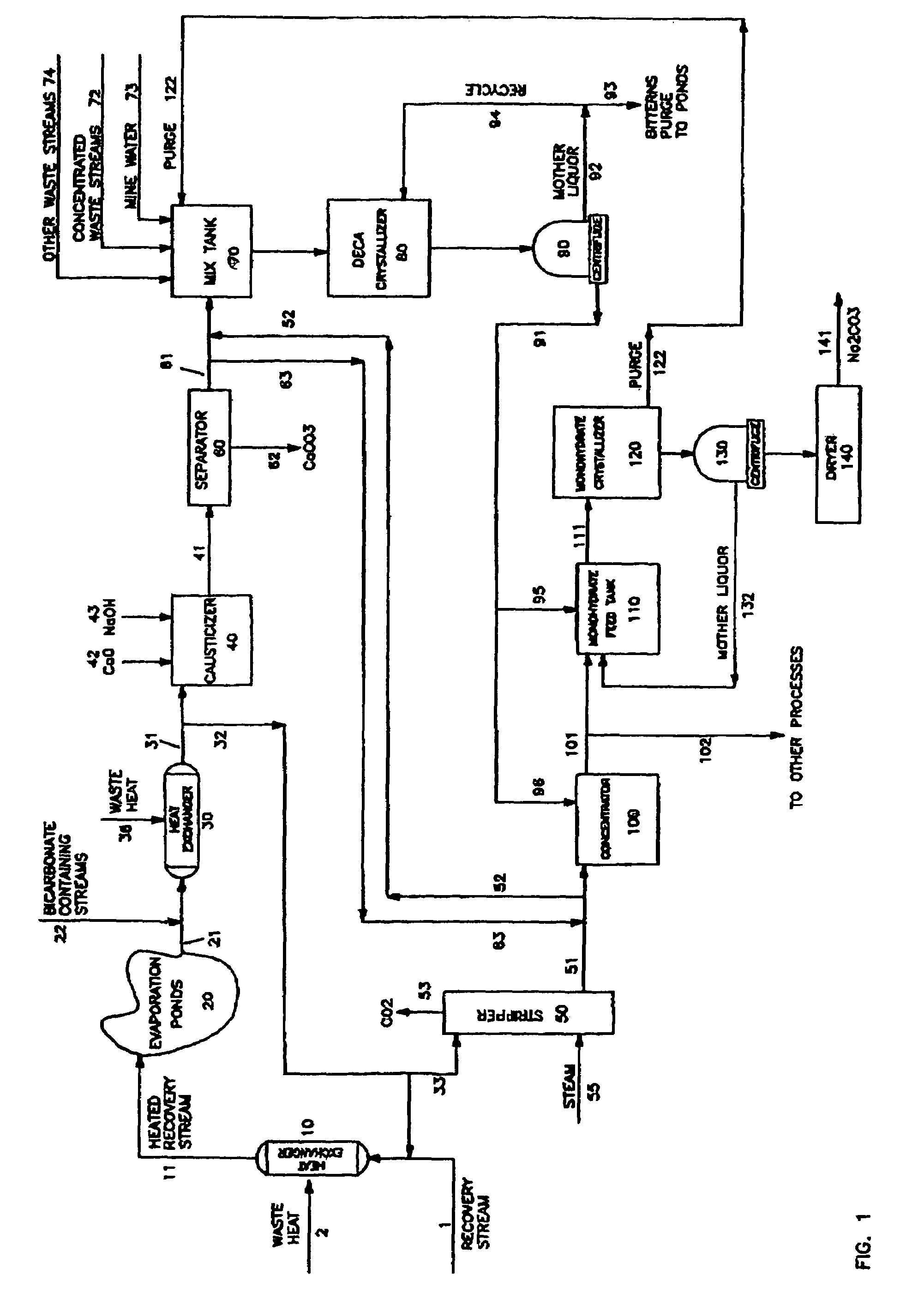

Sodium carbonate recovery from waste streams and impounded sodium carbonate decahydrate deposits

InactiveUS7645435B2Promote recoveryExtend the life cycleVarying alkali metal carbonate water contentCarbonate purificationSodium bicarbonateWaste stream

A process is described for recovering sodium carbonate or other sodium-based chemicals from sodium-bearing streams, including in particular mine water, evaporative pond water and sodium carbonate decahydrate deposits, recycle and purge streams, and other waste streams. In the process sodium bicarbonate-bearing streams are decarbonized to reduce the sodium bicarbonate concentration in a combination with other sodium-bearing streams, resulting in a liquor suitable as feed to a sodium carbonate decahydrate or sodium carbonate monohydrate process. The sodium bicarbonate stream is combined in a mix tank with other sodium carbonate bearing streams where the concentration is adjusted to form a liquor suitable to feed a sodium decahydrate or sodium carbonate monohydrate evaporation / crystallization step. In the process the combination of the various sodium-bearing streams is decarbonized to below 3.5% sodium bicarbonate when fed to a sodium decahydrate process and to below 1% sodium bicarbonate when fed to a sodium carbonate monohydrate process. The feed streams are adjusted in sodium carbonate concentration by higher concentrated sodium carbonate-bearing streams or by addition of sodium carbonate decahydrate produced from said streams or recovered form evaporation pond deposits, are then processed to produce sodium carbonate decahydrate or sodium carbonate monohydrate or further processed to form other sodium carbonate salts.

Owner:TATA CHEM NORTH AMERICA INC

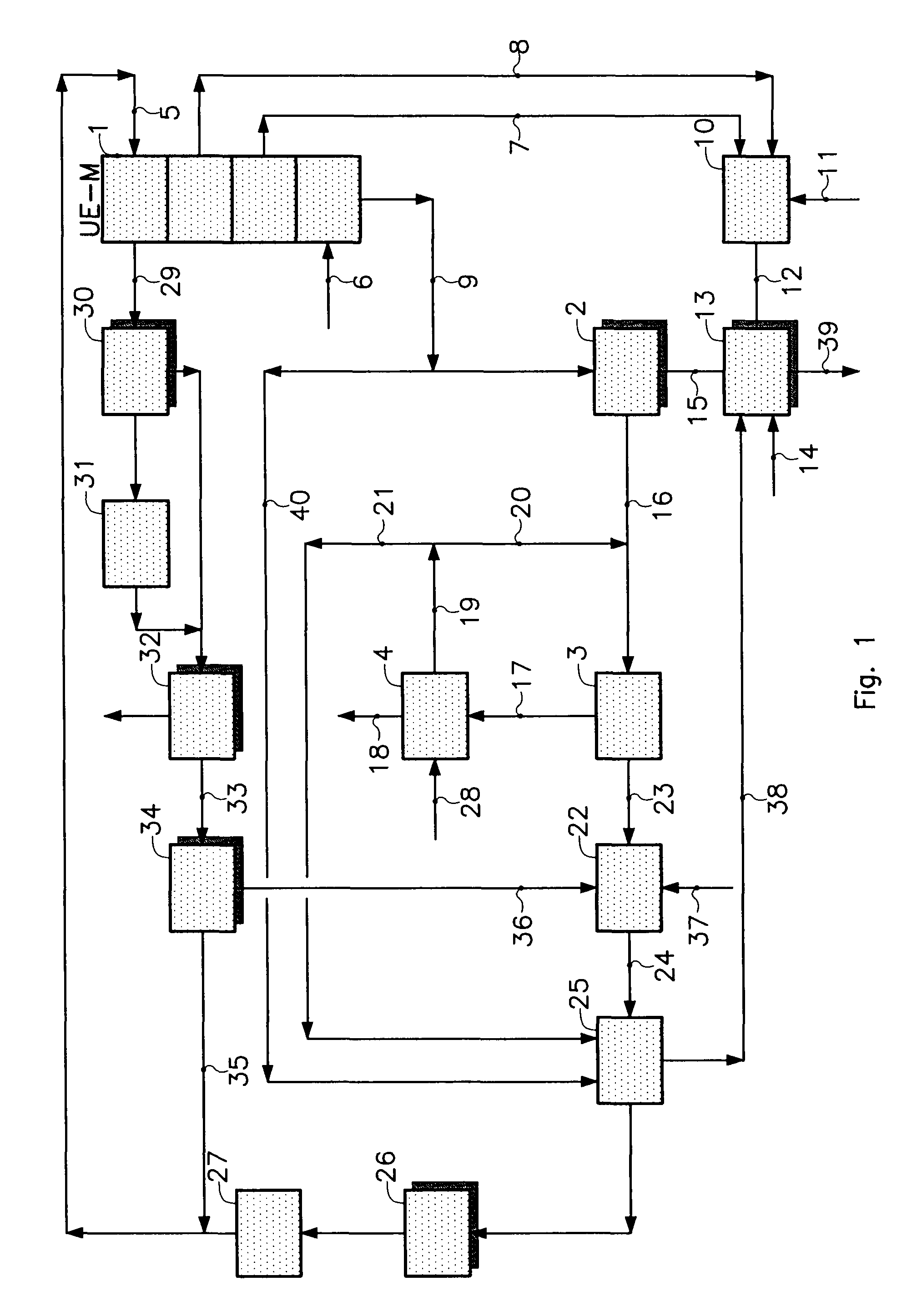

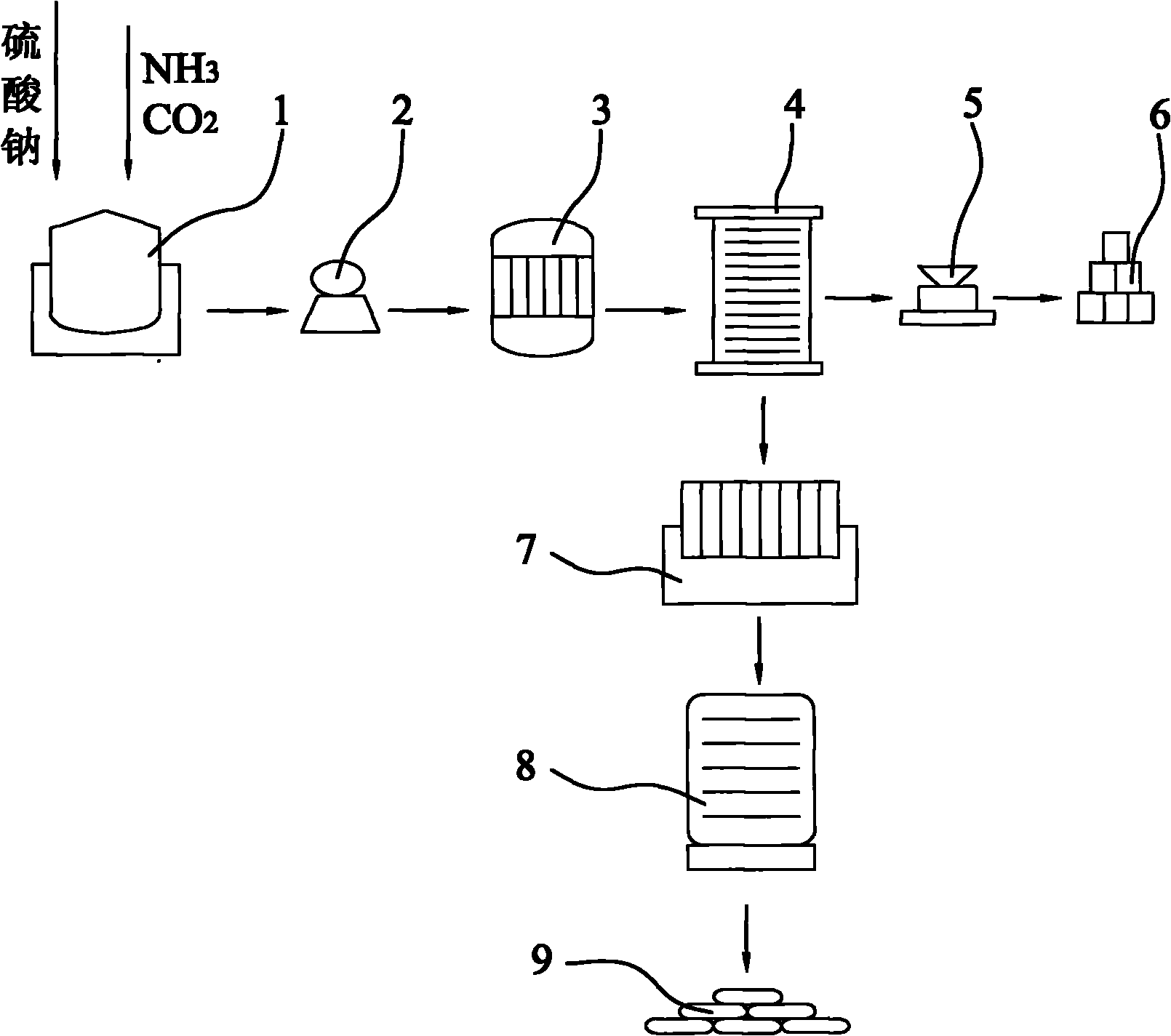

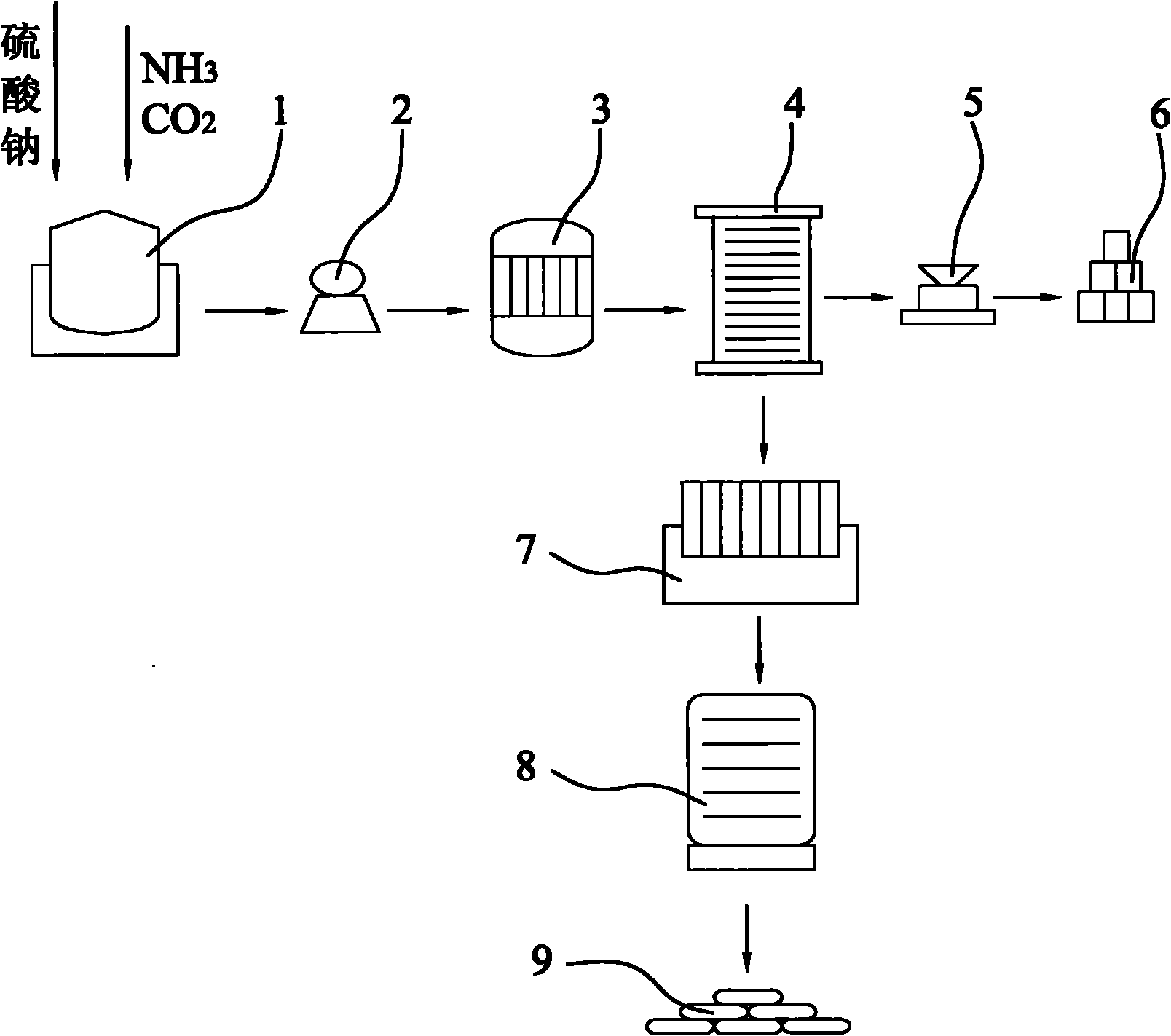

Method for obtaining sodium carbonate monohydrate crystals

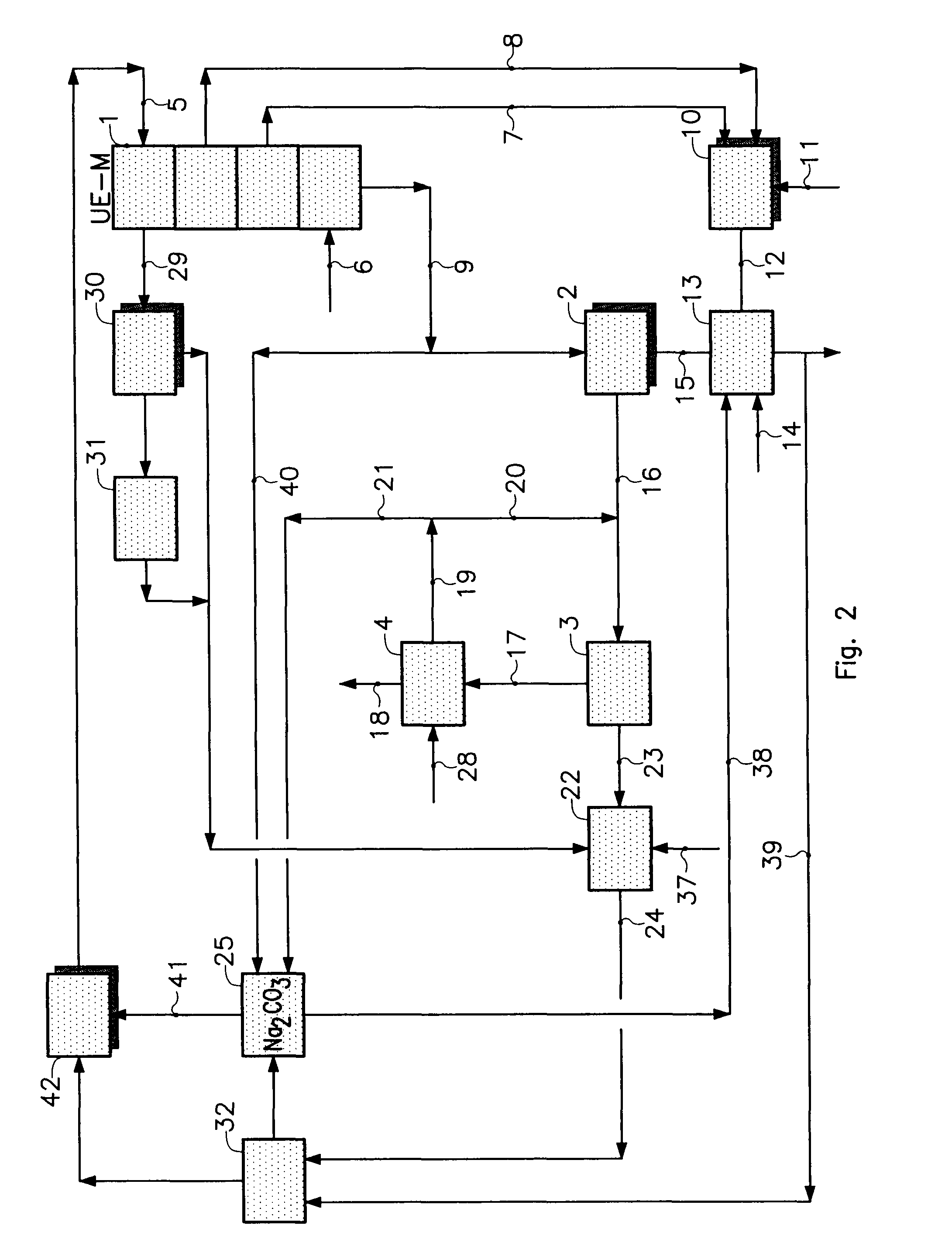

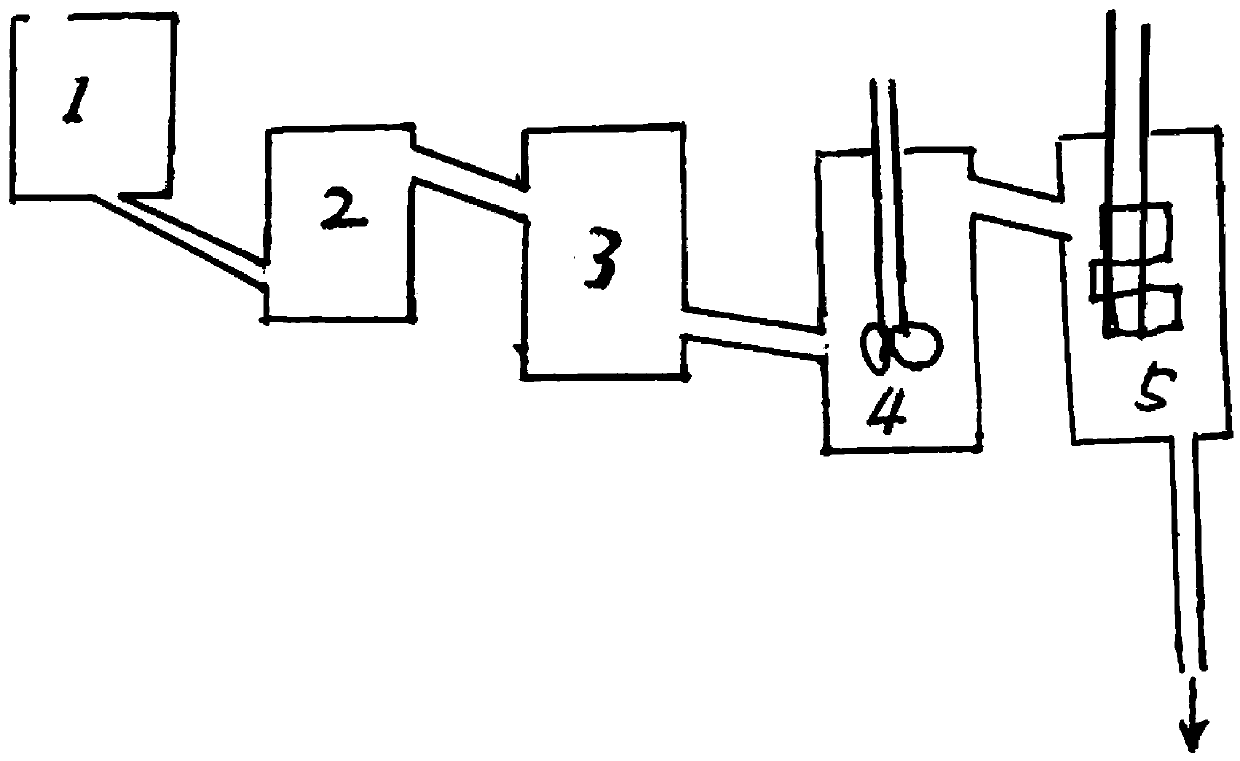

InactiveUS8202659B2Easy to implementCheap productionSesquicarbonate preparationElectrolysis componentsAqueous sodium hydroxideSlurry

A method for producing sodium carbonate monohydrate, according to which an aqueous sodium chloride solution (5) is electrolyzed in a membrane-type cell (1) from which an aqueous sodium hydroxide solution (9) is collected, and carbonated by direct contact with carbon dioxide (15) to form a slurry of crystals of a sodium carbonate monohydrate (16), and the slurry or its mother liquor is evaporated (3) to collect sodium carbonate monohydrate (18).

Owner:SOLVAY SA

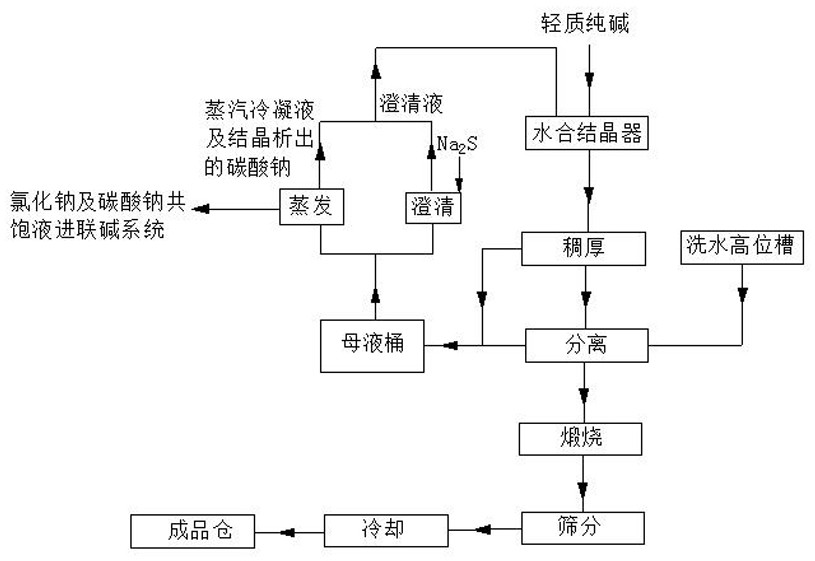

Production method of heavy soda ash

InactiveCN112551558AImprove product qualityReduce accumulationAlkali metal carbonatesSodium bicarbonateHydration reaction

The invention discloses a production method of heavy soda ash. The production method comprises the following steps: adding light soda ash and a sodium carbonate saturated solution into a hydration crystallizer; introducing crystal mush into a thickener to adjust the solid-to-liquid ratio after the reaction, separating the crystal mush in the thickener in a centrifugal machine, and introducing thesupernatant of the thickener into a mother liquor barrel; separating, washing with washing water, removing salt and impurities on the surface of crystal mush, and feeding centrifugate into the motherliquor barrel; treating the centrifuged solid to obtain a heavy soda ash product; evaporating the 20-50% mother liquor until the common saturation point of sodium carbonate and sodium chloride is reached to separate out sodium carbonate monohydrate crystals, mixing the sodium carbonate monohydrate crystals and steam condensate, recycling the mixture into a hydration crystallizer, and feeding the residual sodium chloride and sodium carbonate co-saturated solution into a combined-soda system vacuum salt making device; enabling 50-80% mother liquor to enter a clarification device, adding sodium sulfide, removing iron impurities, and enabling clarified liquor to enter a hydration crystallizer to continue to prepare heavy soda ash. According to the method, sodium chloride and iron impurities inthe sodium bicarbonate mother liquor in the current sodium bicarbonate production process can be removed, discharge of the sodium bicarbonate mother liquor is reduced, and the quality of the sodium bicarbonate product is improved.

Owner:TIANJIN BOHUA YONGLI CHEM IND

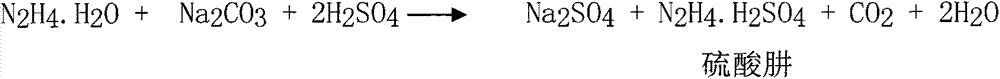

Green cycle production novel method of hydrazine hydrate, hydrazonium salts, and ADC foaming agent

InactiveCN103935971AAchieve mutual separationReduce energy consumptionOrganic chemistryHydrazineHydrazine compoundEvaporation

The invention relates to a green cycle production novel method of hydrazine hydrate, hydrazonium salts, and ADC foaming agent. The green cycle production novel method is characterized in that: sodium sulfate or sodium carbonate, or a mixture of sodium sulfate and sodium carbonate, is reacted with chlorine and lime emulsion so as to obtain causticized sodium hypochlorite, and the obtained causticized sodium hypochlorite is used for synthesizing hydrazine hydrate; multi-effect continuous evaporation is adopted for separating sodium chloride, sodium carbonate, sodium hydroxide, hydrazine hydrate, and water in an obtained low-concentration hydrazine hydrate solution, hydrazine-containing water vapour obtained via evaporation is subjected to acid neutralization absorption so as to obtain the hydrazonium salts, and left water vapour which is not absorbed is taken as a heat source of a next time of evaporation for reutilization, the hydrazonium salts are continuously collected from different levels of packing absorbing column kettles, sodium chloride and sodium carbonate crystals precipitated after multi-effect evaporator evaporative concentration are subjected to salt and alkali gravity fractionation so as to obtain sodium chloride and monohydrate sodium carbonate respectively; a hydrazine hydrate synthesis reaction liquid is refrigerated, evaporation by-products sodium carbonate decahydrate and monohydrate sodium carbonate are reacted with chlorine and lime emulsion so as to obtain causticized sodium hypochlorite, and then the obtained causticized sodium hypochlorite is recycled for synthesizing hydrazine hydrate.

Owner:赖中胜

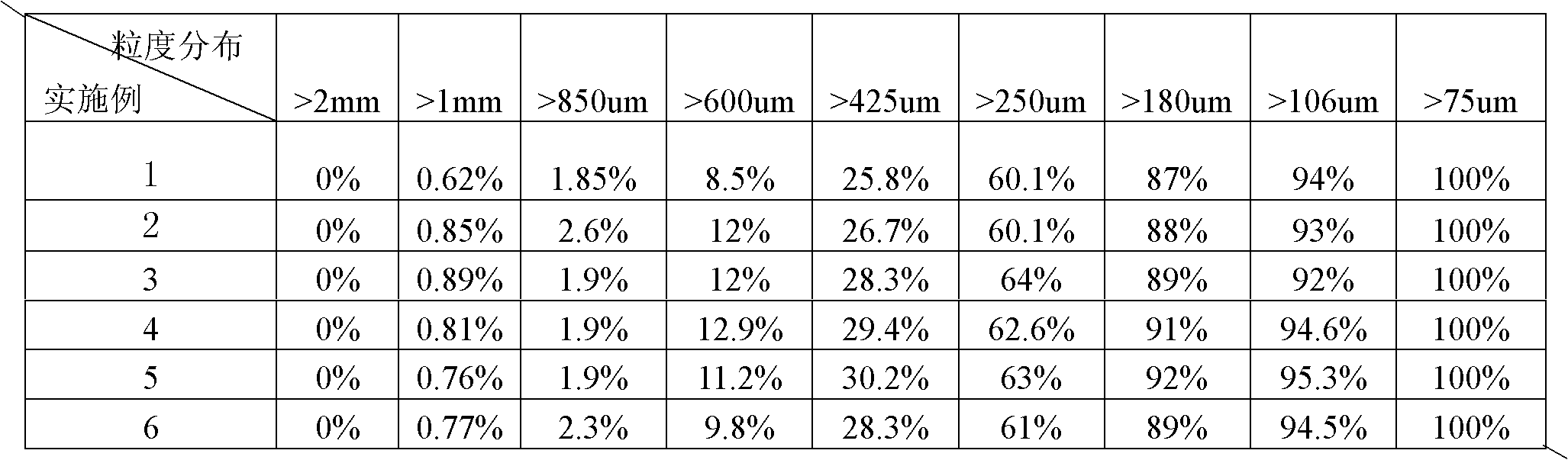

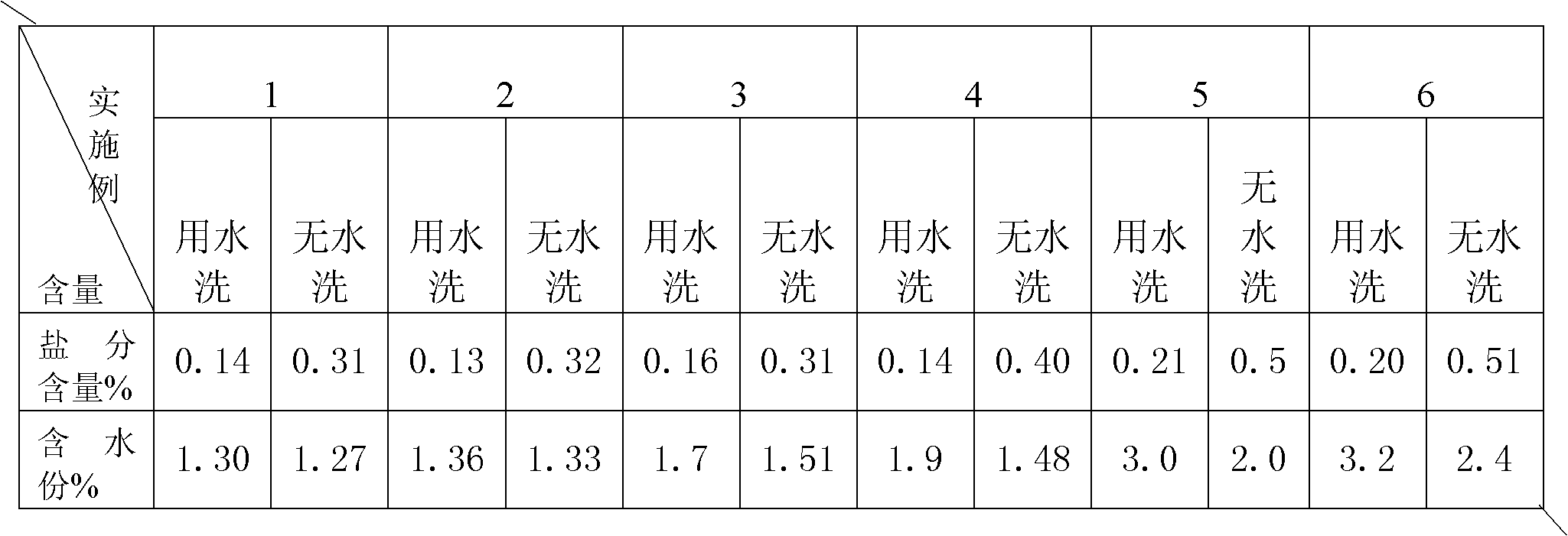

Method for improving mother solution salinity and reducing pure alkali loss

InactiveCN101891230AQuality assuranceReduce the loss of soda ashCalcium/strontium/barium carbonatesSlurrySalinity

The invention discloses a method for improving mother solution salinity and reducing pure alkali loss, which comprises the following steps of: controlling the salinity of heavy pure alkali mother solution to be 60 to 110 grams per liter, and adding washing water into crystallized monohydrate sodium carbonate slurry to remove a part of salt and impurities from monohydrate sodium carbonate filter cakes when the slurry enters a centrifugal machine to perform solid-liquid separation, wherein the adding amount of the washing water for washing the monohydrate sodium carbonate filter cakes is 45 to 150 kilograms per ton of heavy pure alkali. Compared with the prior art, the method has the advantage that: the heavy pure alkali product quality can be ensured and the pure alkali loss can be reduced by reasonably controlling the adding amount of the washing water and the salinity of the heavy pure alkali mother solution. The salt mass content index of the product produced by adopting the method is below 0.25 percent, the moisture mass content index is below 5 percent, the alkali consumption is reduced by over half, and the energy consumption is slightly increased.

Owner:TIANJIN BOHUA YONGLI CHEM IND

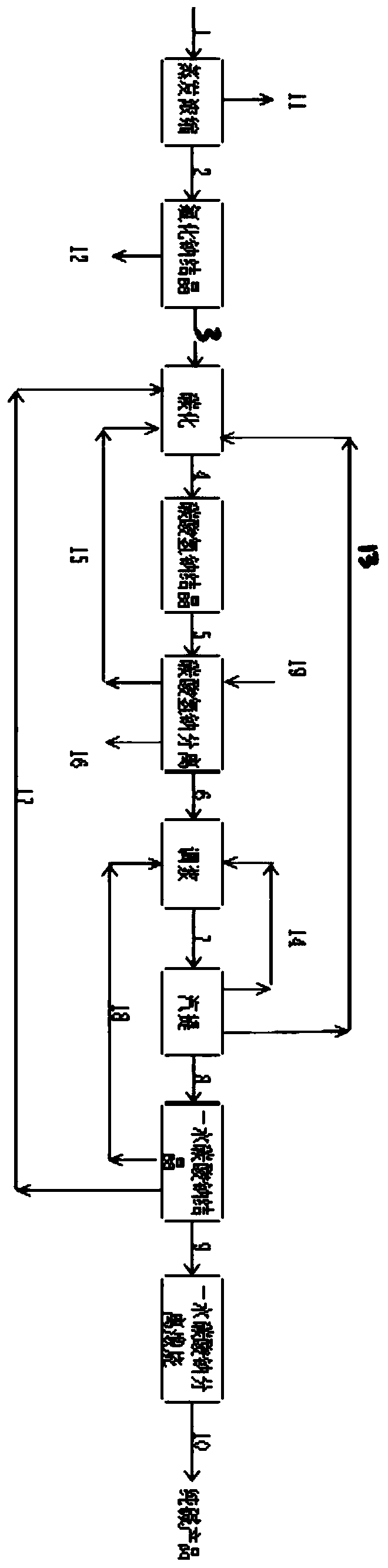

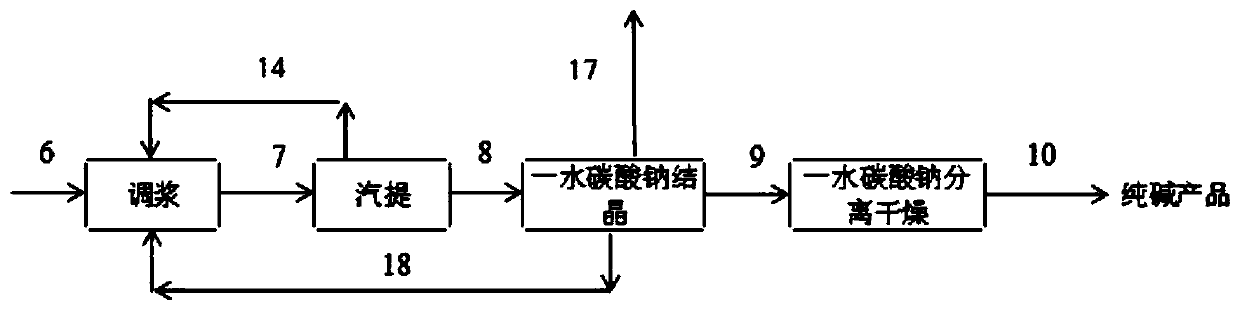

Process for preparing high-quality heavy soda ash by using crude sodium bicarbonate

ActiveCN110937612AImprove product qualityReduce manufacturing costCarbonate preparationSodium Carbonate MonohydrateProcess engineering

The invention provides a process for preparing high-quality heavy soda ash by using crude sodium bicarbonate, wherein the high-quality heavy soda ash with low impurity content is obtained by using crude sodium bicarbonate through slurry regulating and steam stripping, sodium carbonate monohydrate crystallization, sodium carbonate monohydrate separation and drying and other steps. According to theprocess for preparing high-quality heavy soda ash by using crude sodium bicarbonate, the production cost can be effectively reduced, and the product quality can be improved.

Owner:CHINA TIANCHEN ENG

Sodium carbonate and sodium bicarbonate production

InactiveUS20060120942A1Solve the blockageEfficient executionVarying alkali metal carbonate water contentFluid removalNahcoliteProcess engineering

A method for solution mining nahcolite, capable of extracting nahcolite from geological formations lean in nahcolite comprising injecting high pressure water (which may include recycled aqueous solution of bicarb and sodium carbonate) at a temperature of at least 250° F. into the formation, dissolving nahcolite in the hot water to form a production solution and recovering the production solution. The invention also includes the processing of the production solution to provide sodium carbonate and, optionally, sodium bicarbonate, comprising: decomposing the sodium bicarbonate portion of the hot aqueous production solution to form a hot aqueous solution of sodium carbonate; evaporating water from the hot aqueous solution comprising sodium carbonate to form a concentrated solution of sodium carbonate; producing sodium carbonate monohydrate from the concentrated solution of sodium carbonate by crystallization; and dewatering and calcining the sodium carbonate monohydrate to produce anhydrous sodium carbonate.

Owner:AMERICAN SODA

Production of sodium sesquicarbonate and sodium carbonate monohydrate

InactiveUS7638109B2Lower Level RequirementsSuitable for useCalcium/strontium/barium carbonatesSesquicarbonate preparationSodium bicarbonateWater flow

A process for the production and recovery of crystalline sodium sesquicarbonate and of crystalline sodium carbonate monohydrate from aqueous liquors containing sodium carbonate and sodium bicarbonate. The crystalline products may optionally be heated or calcined to produce soda ash. The process is particularly suited for the recovery of soda ash from aqueous minewater streams obtained from solution mining of subterranean trona ore deposits.

Owner:GENESIS ALKALI WYOMING LP

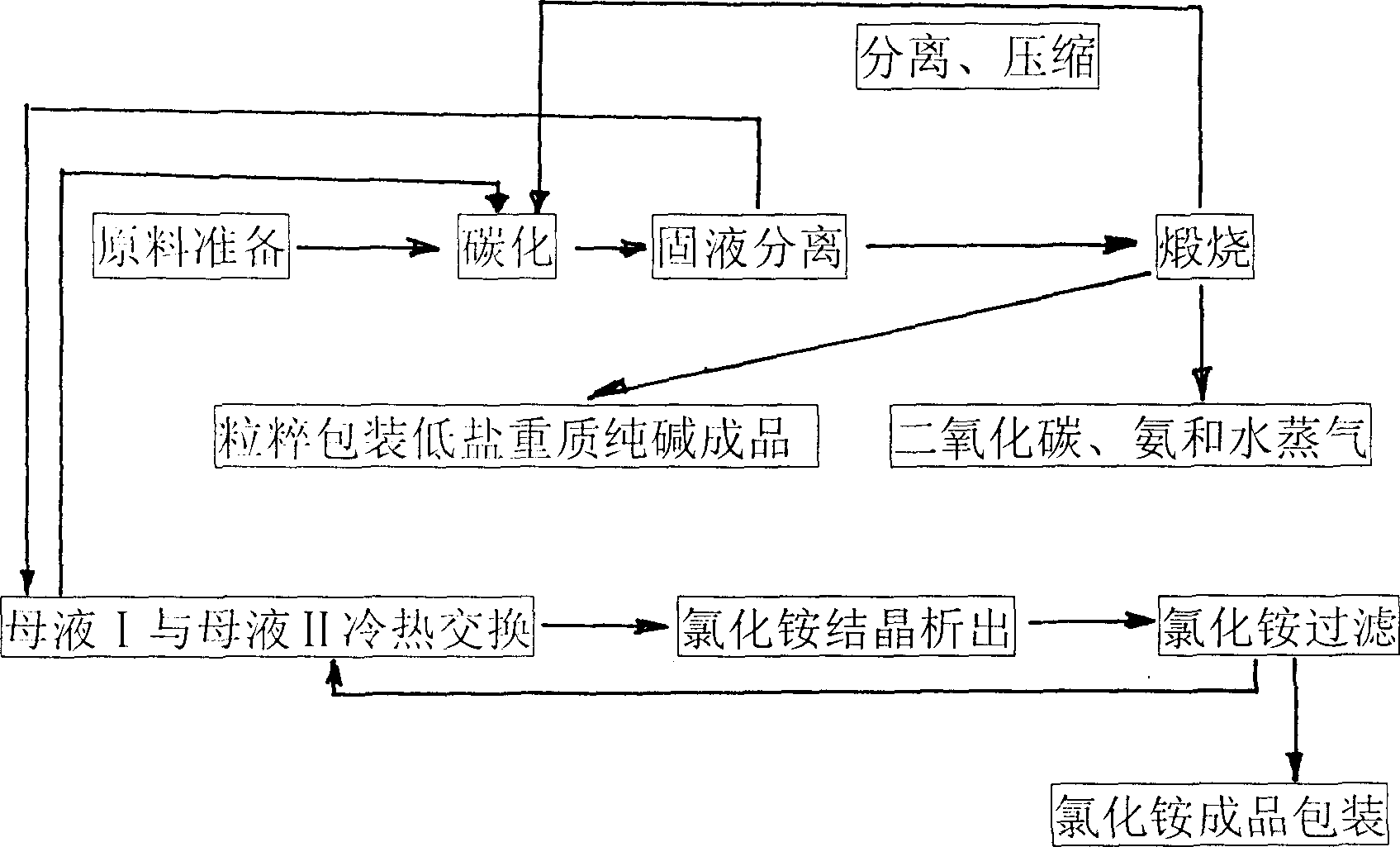

Process for preparing high-quality low-salt low-potassium heavy sodium carbonate and ammonium chloride

InactiveCN1096418CReduce energy consumptionLow costAmmonium halidesCarbonate preparationPotassium sulfateImpurity

A process for preparing high-quality low-salt low-potassium heavy sodium carbonate and ammonium chloride through direct vapour calcine, washing impurities (sodium chloride and potassium sulfate) withcondensed water in high-temp condition, reaction to generate water, hydrating with sodium carbonate and hot-air drying includes preparing raw materials, carbonifying, solid-liquid separation, calcine, packing finished sodium carbonate, heat exchange of liquid crystallizing, filtering and packing finished ammonium chloride. Its advantages include short technologica route, simple equipment and low energy consumption.

Owner:王修立 +1

Desalting and reusing method of high-salinity heavy ash mother liquor in combined-soda system

The invention discloses a desalting and reusing method of high-salinity heavy ash mother liquor in a combined-soda system, which comprises the following steps that (1) when the sodium chloride content of heavy ash mother liquor is higher than 60 g / L, a part of high-salinity heavy ash solution is required to be discharged, and the discharged solution is conveyed to an evaporator to evaporate; (2) the discharged high-salinity heavy ash solution is evaporated to the co-saturated point of sodium carbonate and sodium chloride, so that monohydrate sodium carbonate crystals are precipitated out, and the monohydrate sodium carbonate crystals are separated from residual mother liquor after evaporating; and (3) the separated crystals are dissolved, so that a solution with a sodium chloride content of less than 20 g / L is obtained, and the solution is returned to a heavy ash system to reuse; and the residual mother liquor is applied to a salt-leaching process of a vacuum salt manufacturing device. In a solution which can be reused in the system and obtained by using the method disclosed by the invention, the sodium chloride content of is less than 20 g / L, and the sodium carbonate content is about 310 g / L, so that the solution can meet the index requirements of the heavy ash system.

Owner:TIANJIN BOHUA YONGLI CHEM IND

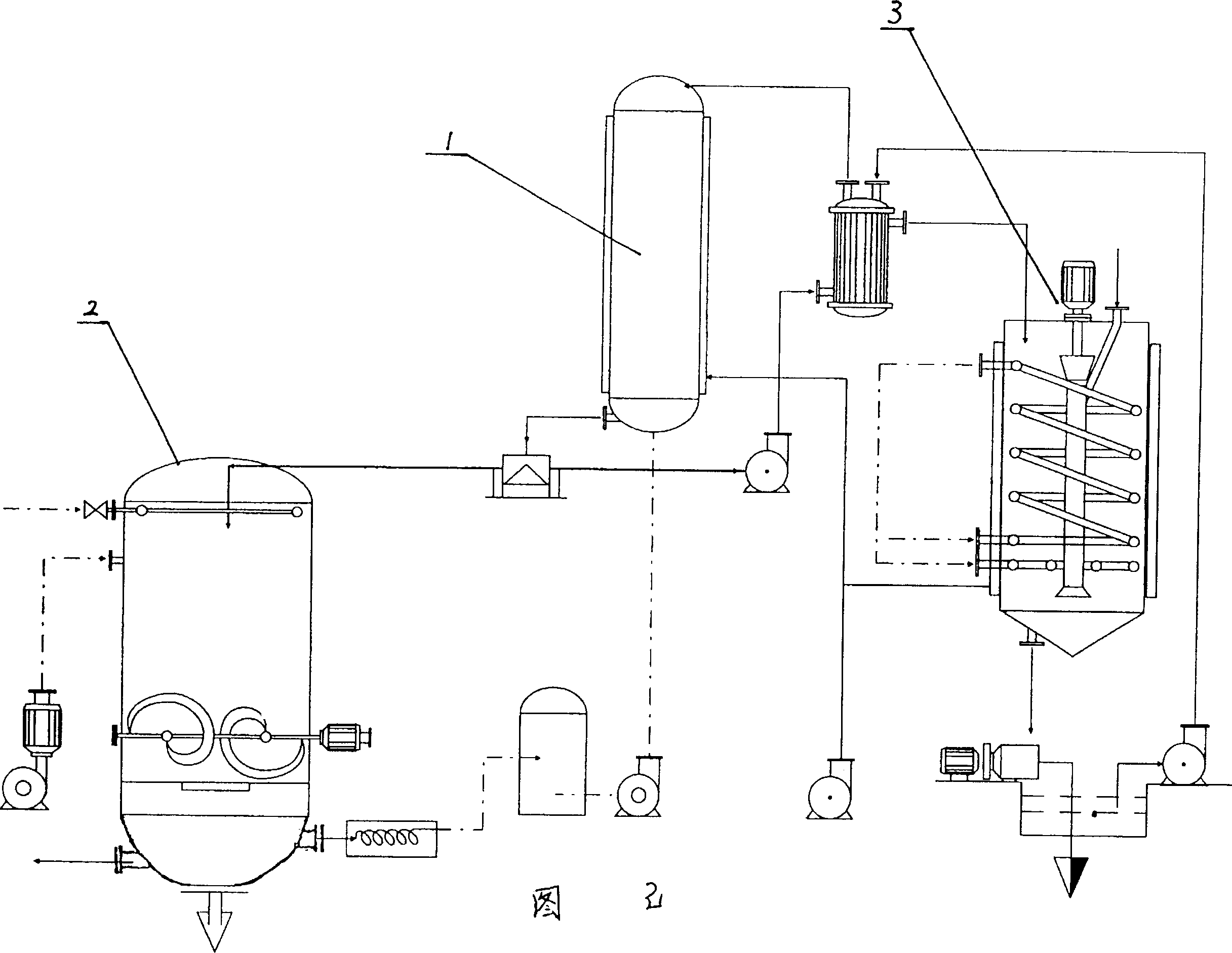

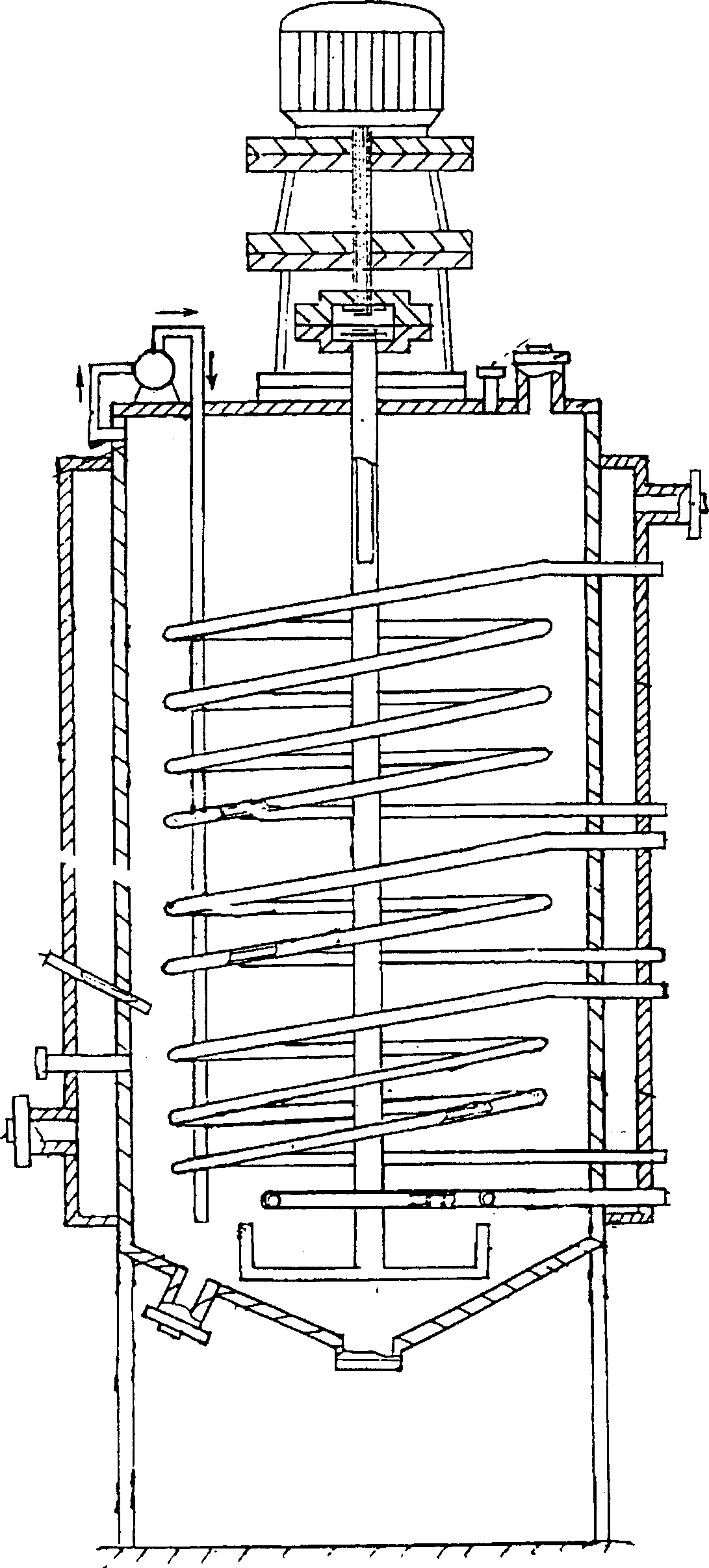

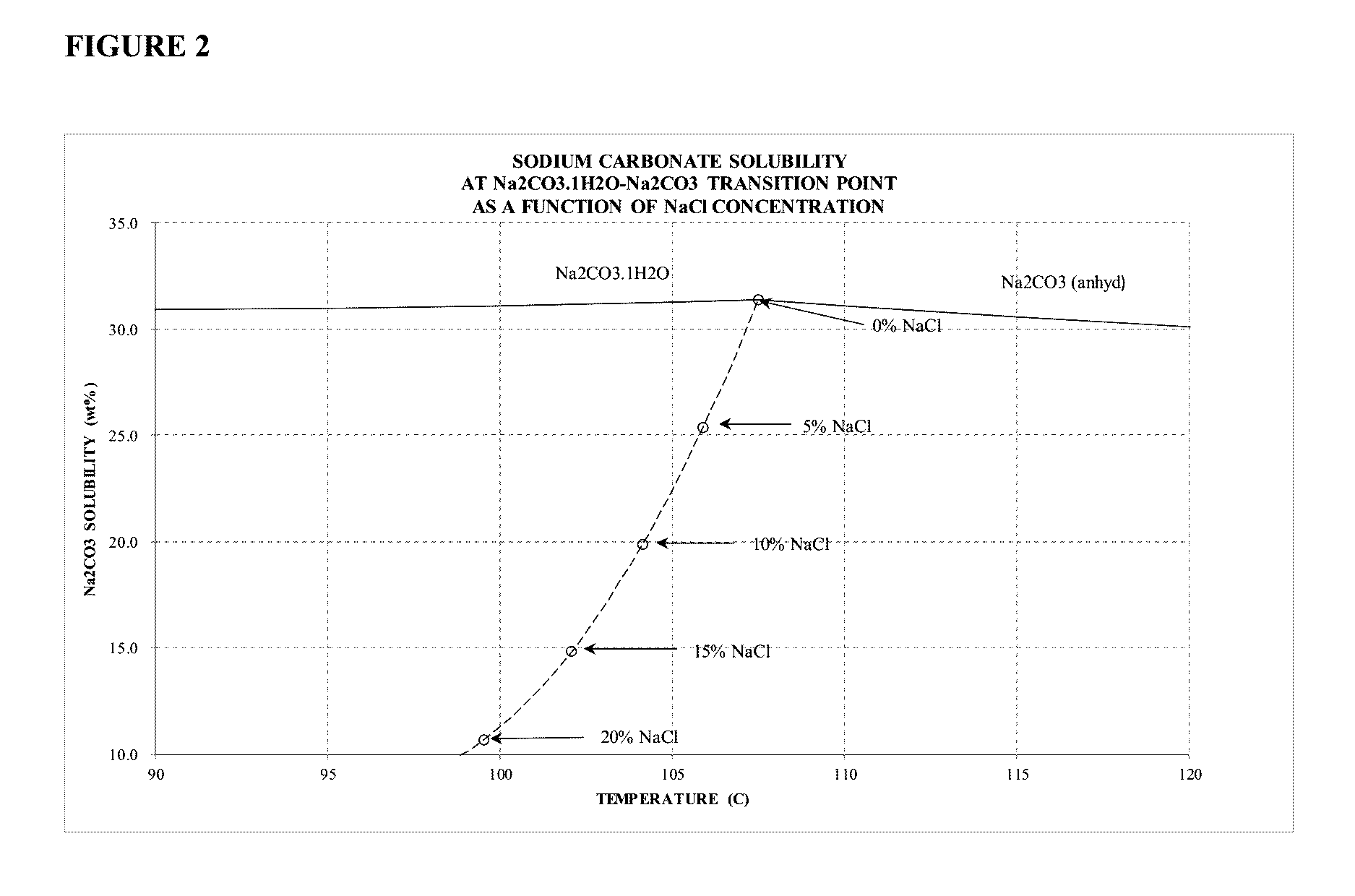

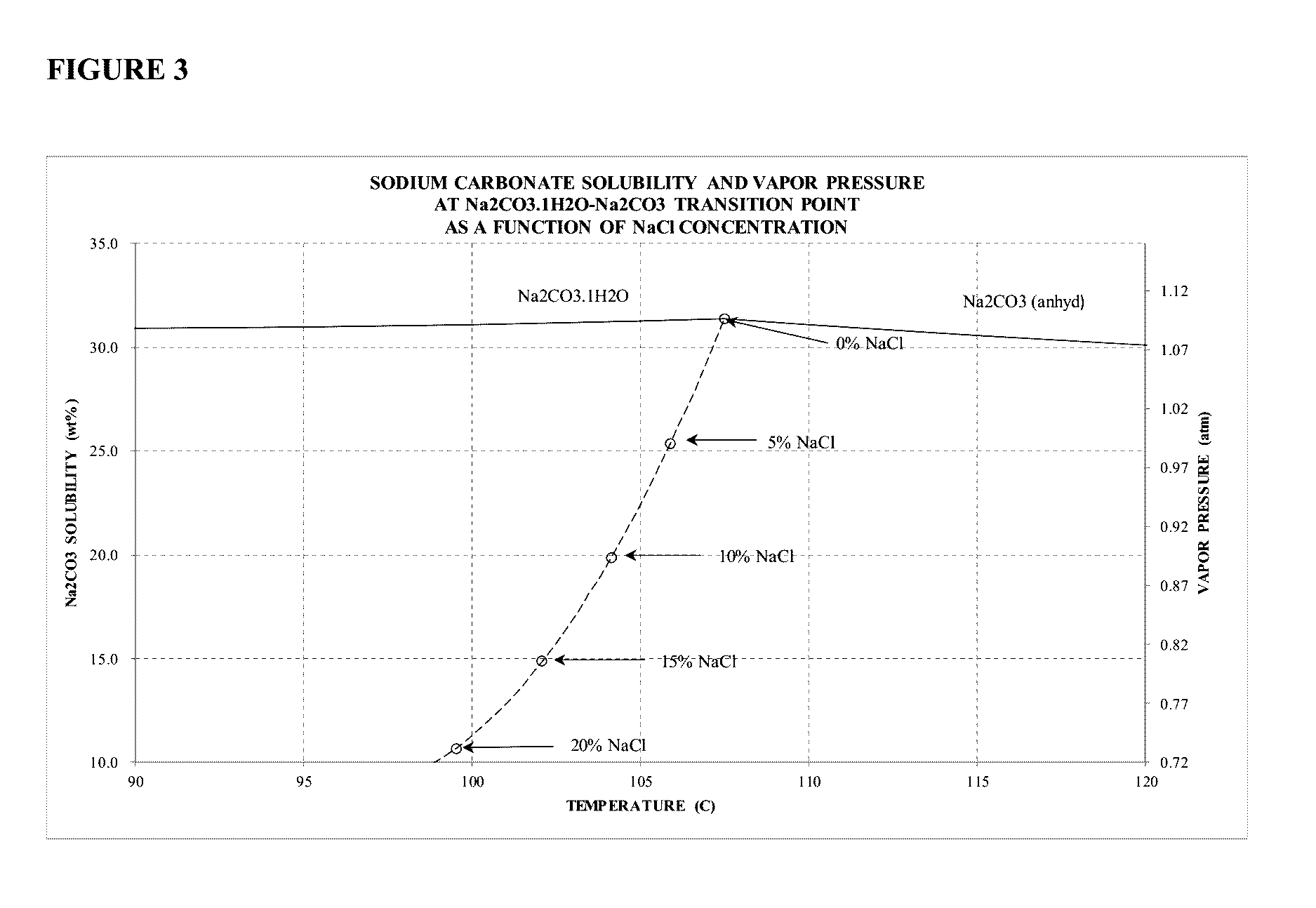

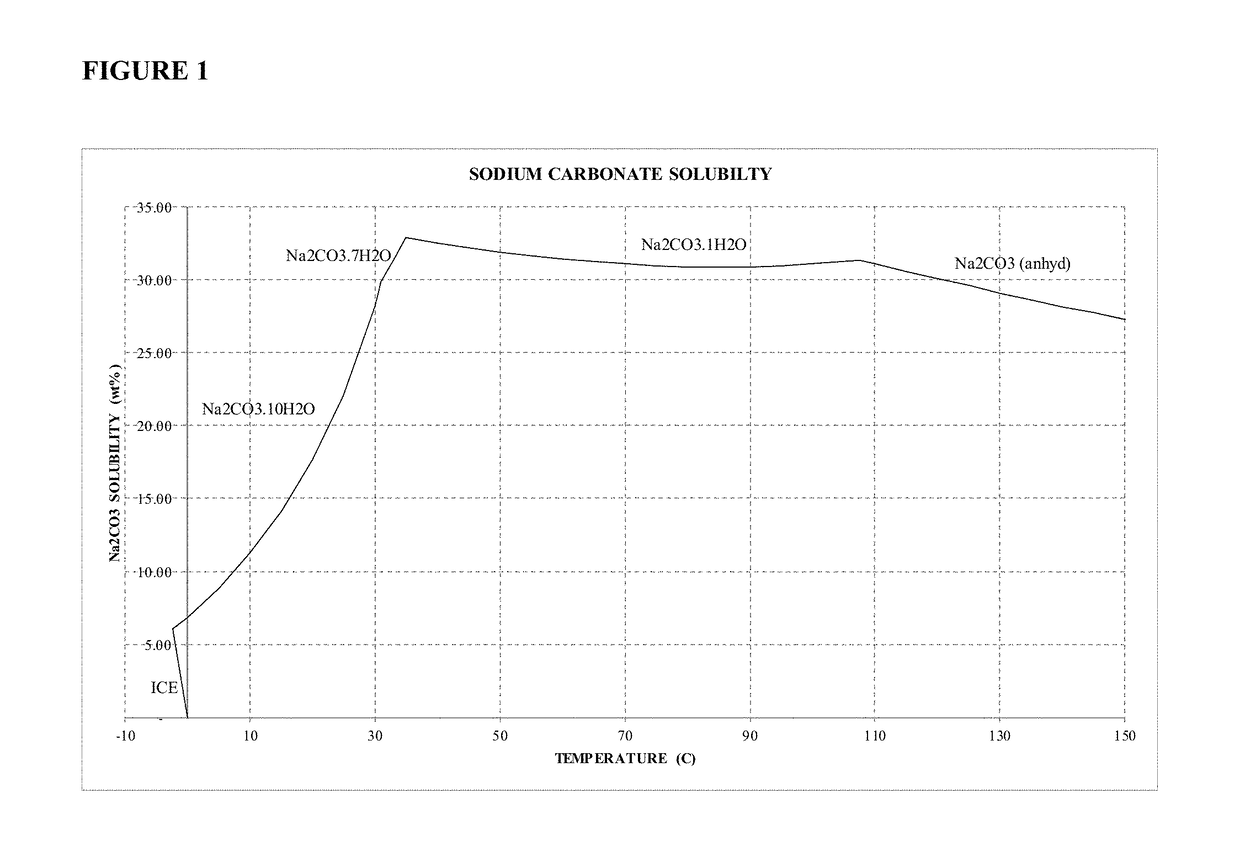

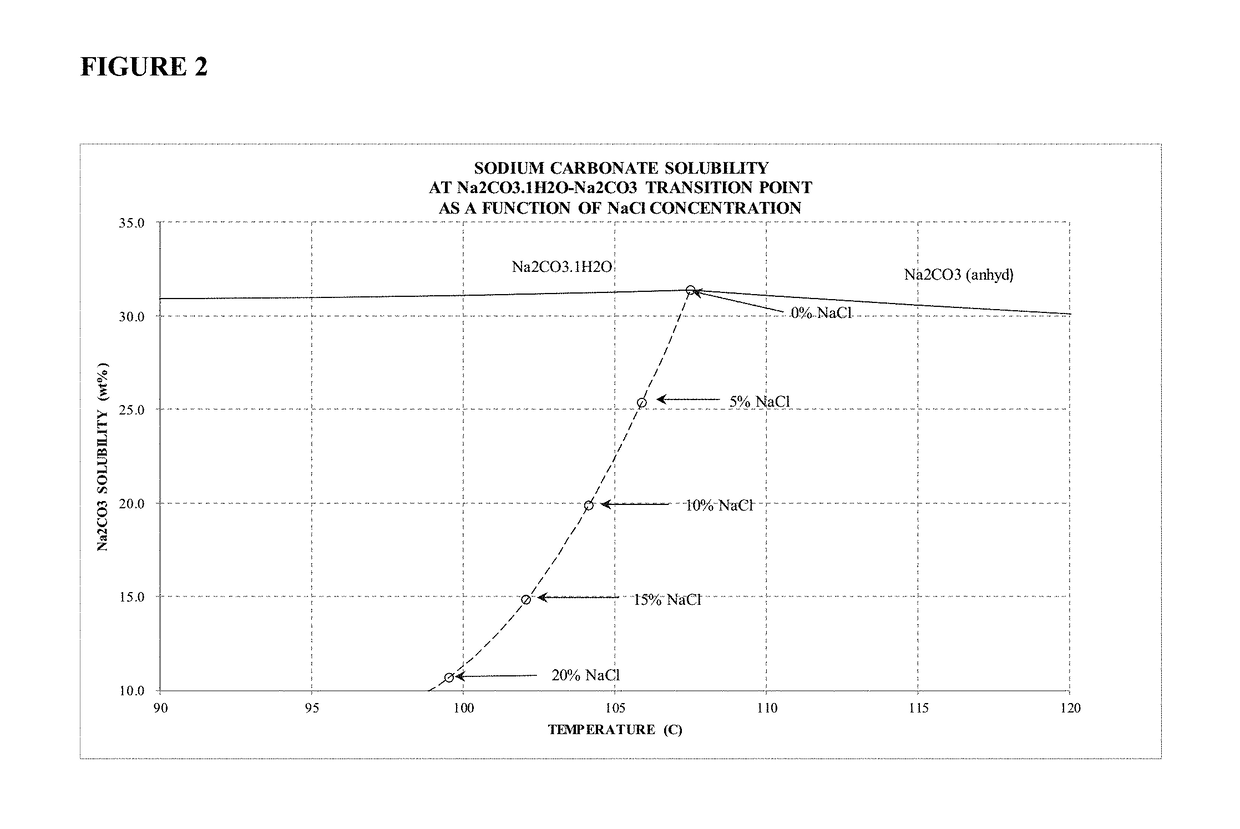

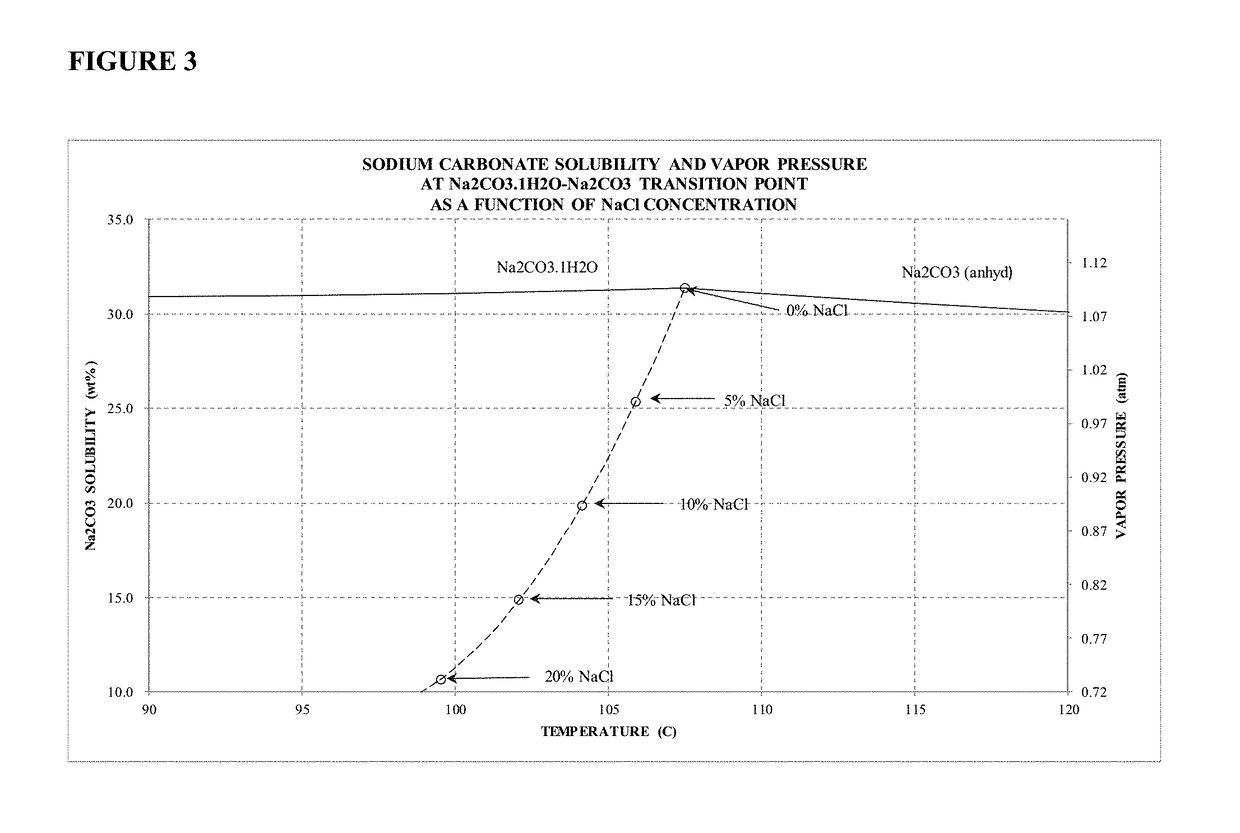

Sodium Carbonate Monohydrate Crystallization

InactiveUS20170029283A1Increase productionHigh impurity concentrationCrystallization by component evaporationAlkali metal carbonatesCrystallizationSodium Carbonate Monohydrate

Owner:SWENSON TECH INC

Aluminum alloy surface treatment agent

The invention discloses an aluminum alloy surface treatment agent. The treatment agent is composed of the following components in parts by mass: 10-20 parts of sodium hydroxide, 5-10 parts of deionized water, dodecylbenzenesulfonic acid 10-20 parts of sodium, 2-5 parts of sodium carbonate water, 2-5 parts of silicone oil, 5-10 parts of cocamidopropyl betaine, 5-10 parts of glycerol boric acid fatty acid ester, tetrabasic zinc chromate 5‑10 parts, 5‑10 parts of diatomaceous earth, 1‑3 parts of dispersant, 5‑10 parts of reduced glutathione, 2‑5 parts of organic acid, 1‑3 parts of sodium laureth sulfate , 1‑3 parts of stabilizer, and the balance of water. The invention is beneficial in that it can remove rust and increase luster of aluminum alloy, has strong cleaning power, simple production process, low cost, stable and reliable quality, wide application range, good adsorption, lubricity, and corrosion resistance. And no damage to the surface of aluminum products.

Owner:徐州轩辕铝业有限公司

Sodium hydrogencarbonate crystal particles having low caking property and process for producing them

InactiveUS20070104635A1Longer treatment timeReduce cakingPhosphatesInorganic active ingredientsSodium bicarbonateAnticaking agent

Sodium hydrogencarbonate crystal particles, which comprise sodium hydrogencarbonate crystal particles having an average particle size of from 50 to 500 μm based on the mass, and anhydrous sodium carbonate, and sodium carbonate monohydrate and / or Wegscheider's salt, present on the surface of the sodium hydrogencarbonate crystal particles in such amounts that the total content of anhydrous sodium carbonate, sodium carbonate monohydrate, Wegscheider's salt and sodium sesquicarbonate in the sodium hydrogencarbonate crystal particles is from 0.04 to 1 mass % as calculated as anhydrous sodium carbonate, anhydrous sodium carbonate accounts for at least 40 mass % of the total content, and sodium carbonate monohydrate and / or Wegscheider's salt accounts for from 5 to 60 mass % of the total content. Sodium hydrogencarbonate crystal particles having a low caking property, which are useful in the field of food products, pharmaceuticals, bath additives, etc., which require no necessity to contain an anticaking agent, a process for producing them and a method for packaging them, can be provided.

Owner:ASAHI GLASS CO LTD

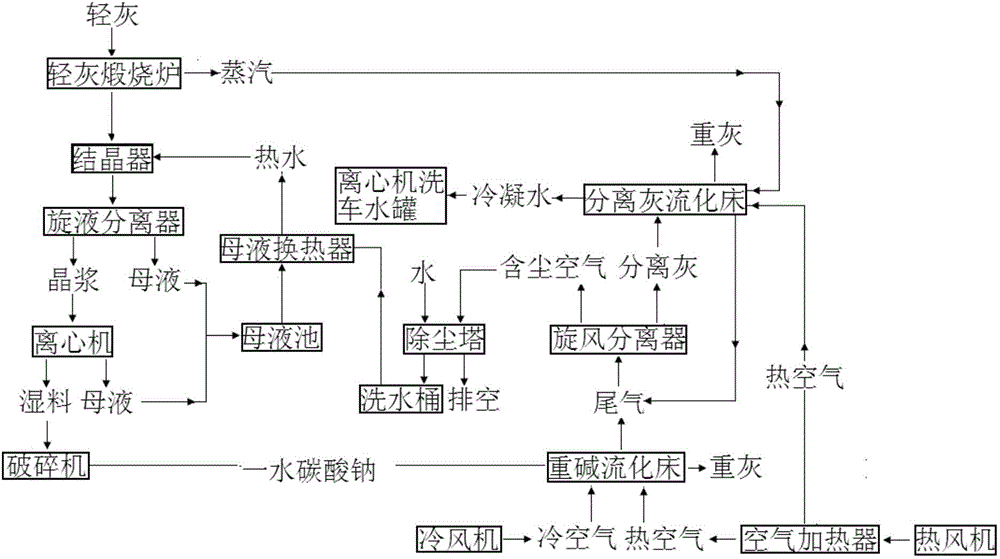

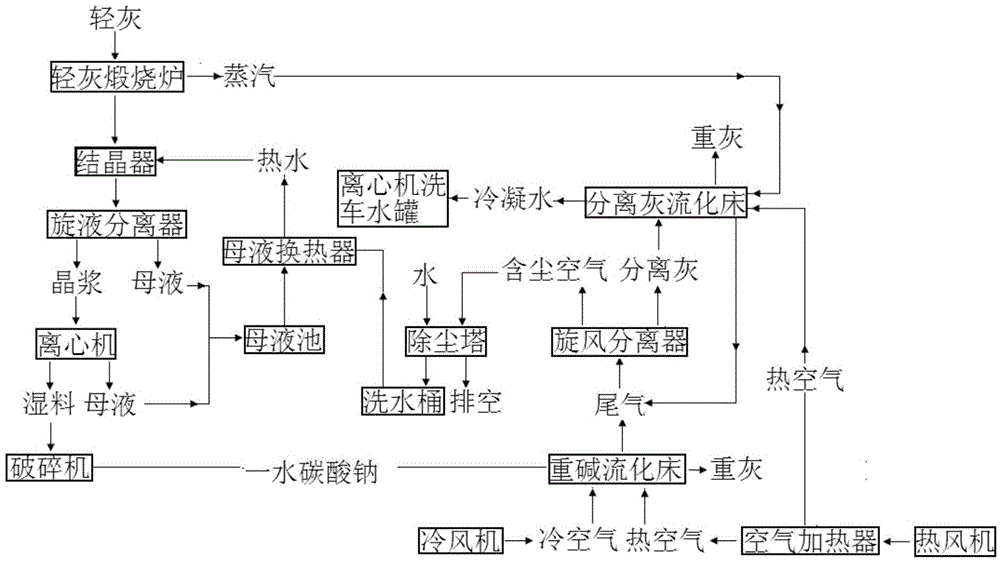

Liquid-phase hydration method separation ash treatment process

InactiveCN104528774AAvoid pollutionReduce wasteVarying alkali metal carbonate water contentCyclonic separationFluidized bed

The invention provides a liquid-phase hydration method separation ash treatment process comprising the following steps: (1) a sodium carbonate monohydrate wet material is prepared with a liquid-phase hydration method; (2) the sodium carbonate monohydrate wet material is added into a heavy ash fluidized bed, and drying is carried out, such that heavy ash is obtained; tail gas produced in the heavy ash fluidized bed is separated in a cyclone separator, such that separation ash and dust-containing air are obtained; (3) the separation ash is added into a separation ash fluidized bed, and drying is carried out, such that heavy ash and separation ash tail gas are obtained; and the separation ash tail gas is subjected to cyclone separation again in the cyclone separator. The process provided by the invention has the following advantages: separation ash is subjected to the drying treatment on the basis of an original liquid-phase hydration method heavy ash preparation process, such that separation ash alkali content is improved, and heavy ash product quality is improved; a situation of low separation ash total alkali content and the restriction on variety alkali production of prior arts are solved.

Owner:青岛海湾集团有限公司

Sodium carbonate monohydrate crystallization

InactiveUS10059600B2Increase concentrationIncrease productionCrystallization by component evaporationAlkali metal carbonatesCrystallizationSodium Carbonate Monohydrate

Owner:SWENSON TECH INC

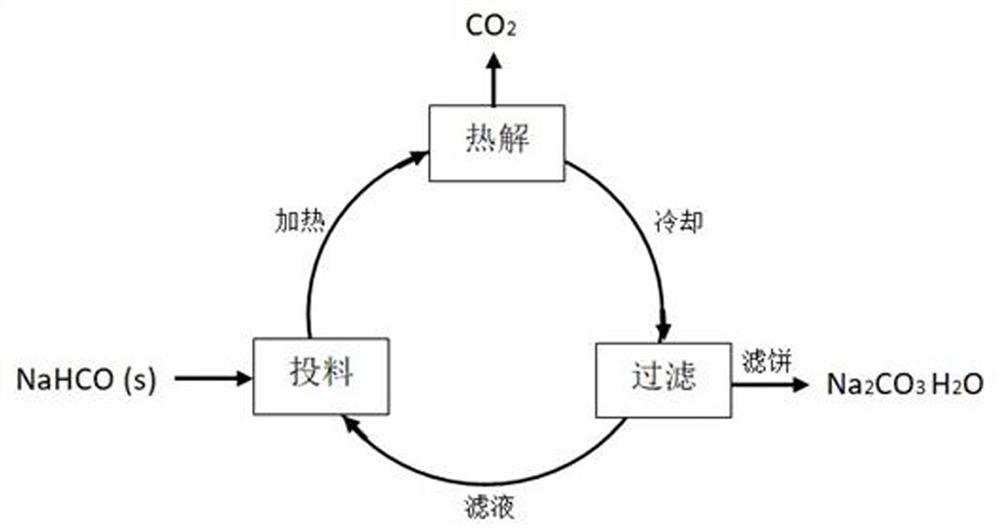

Process for preparing sodium carbonate crystal by wet pyrolysis of sodium bicarbonate solid

PendingCN113620319AWon't dissolveReduce solubilityCarbonate preparationProductsSodium Carbonate MonohydratePyrolysis

The invention discloses a process for preparing sodium carbonate crystals by wet pyrolysis of sodium bicarbonate solids, and belongs to the technical field of preparation of sodium carbonate crystals. The process comprises the following steps: S1, slowly adding a sodium bicarbonate solid into a sodium chloride-sodium carbonate double-saturated solution while stirring and heating; S2, after the materials are added, continuously stirring and heating to increase the temperature to 90-118 DEG C, and stopping heating when no carbon dioxide gas is generated; and S3, cooling and filtering to obtain sodium carbonate monohydrate crystals. The process is high in sodium bicarbonate decomposition rate and low in energy consumption, and the product is sodium carbonate solid.

Owner:杨仁春

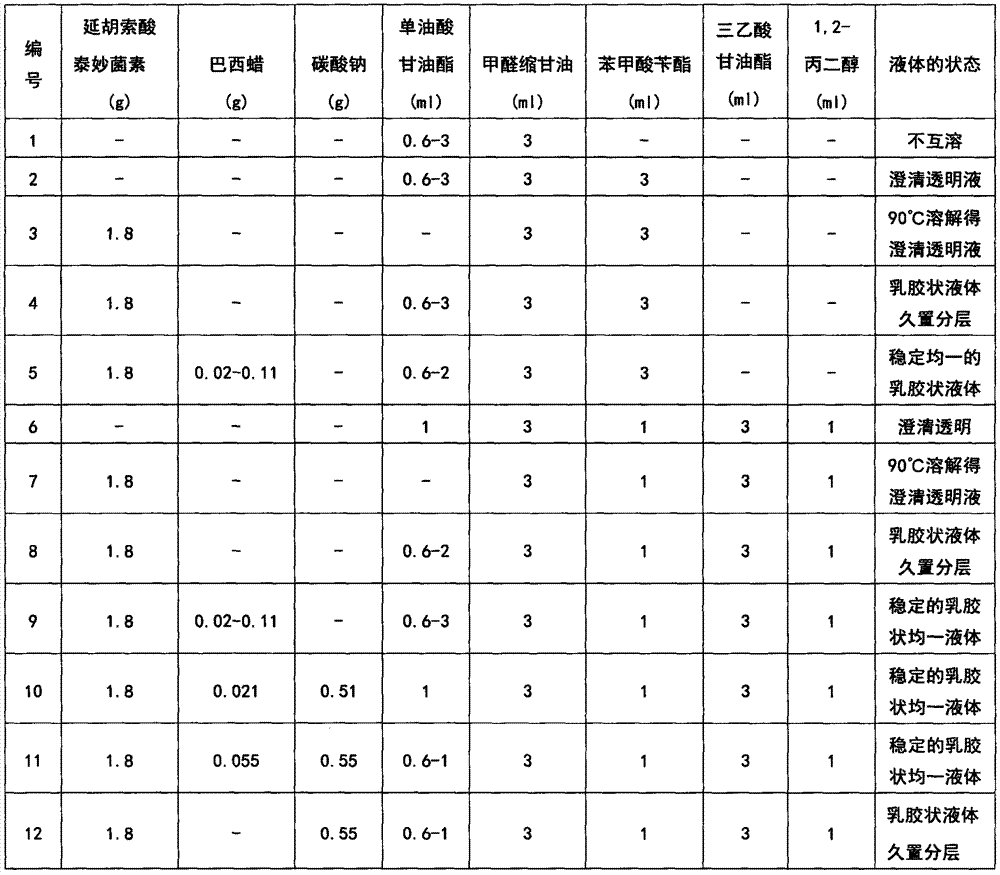

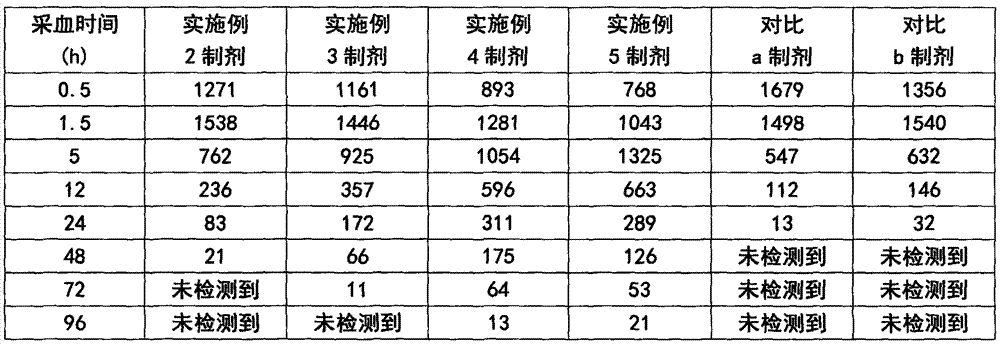

A kind of tiamulin colloid injection and preparation method thereof

ActiveCN104906591BGood sustained release effectGood value for commercial developmentAntibacterial agentsEmulsion deliveryGlycerolPropanediol

The invention relates to a colloid injection containing tiamulin, which contains 150-220 g of tiamulin fumarate and 1.5-11 g of Brazilian wax in every liter of the injection, and the dispersion medium is added to 1 liter. Described dispersing medium is: glycerol / benzyl benzoate with a volume ratio of 1:1 or glycerol triacetate / glycerol / 1,2-propylene glycol / benzene with a volume ratio of 3:3:1:1 Benzyl formate. Each liter of injection also contains 60-300ml monoolein. In the process of preparing the above injections, sodium carbonate decahydrate (Na2CO3 10H2O) can be added, and in every 1 liter of injection prepared, the addition of sodium carbonate decarbahydrate is 38.0-63.3g, and these Na2CO3 added will combine with fumarate The reaction of myocin causes tiamulin fumarate to be converted into tiamulin base, and the preparation thus prepared contains two active components of tiamulin base and unreacted tiamulin fumarate. The preparation has both quick-acting and long-acting effects.

Owner:中农华威制药股份有限公司

Liquid-phase hydration separation ash treatment process

InactiveCN104528774BAvoid pollutionReduce wasteVarying alkali metal carbonate water contentFluidized bedCyclonic separation

The invention provides a liquid-phase hydration method separation ash treatment process comprising the following steps: (1) a sodium carbonate monohydrate wet material is prepared with a liquid-phase hydration method; (2) the sodium carbonate monohydrate wet material is added into a heavy ash fluidized bed, and drying is carried out, such that heavy ash is obtained; tail gas produced in the heavy ash fluidized bed is separated in a cyclone separator, such that separation ash and dust-containing air are obtained; (3) the separation ash is added into a separation ash fluidized bed, and drying is carried out, such that heavy ash and separation ash tail gas are obtained; and the separation ash tail gas is subjected to cyclone separation again in the cyclone separator. The process provided by the invention has the following advantages: separation ash is subjected to the drying treatment on the basis of an original liquid-phase hydration method heavy ash preparation process, such that separation ash alkali content is improved, and heavy ash product quality is improved; a situation of low separation ash total alkali content and the restriction on variety alkali production of prior arts are solved.

Owner:青岛海湾集团有限公司

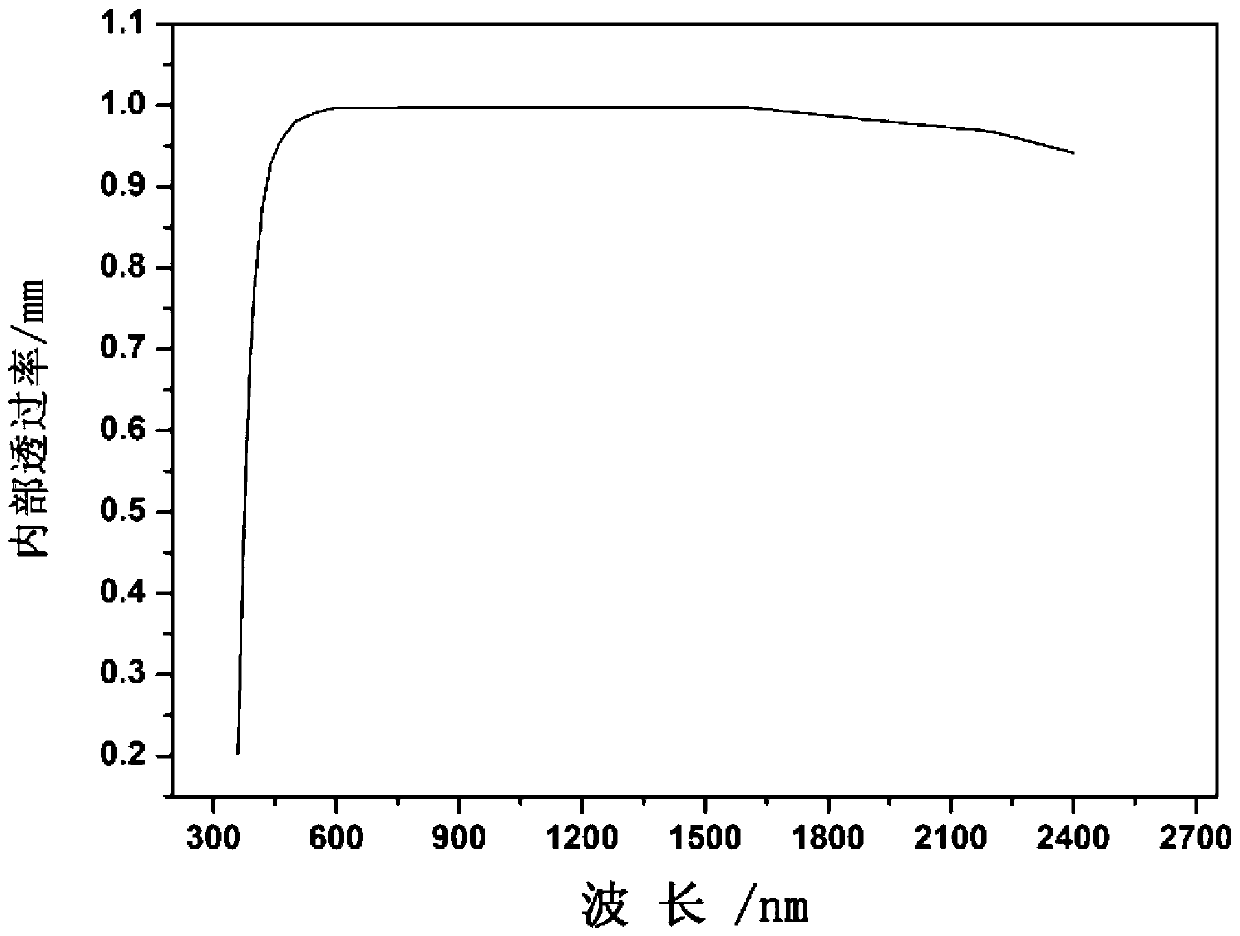

A kind of preparation method of high niobium low lanthanum optical glass containing titanium

The invention discloses a preparation method of titanium-containing high-niobium and low-lanthanum optical glass. First, quartz sand, anhydrous boric anhydride, barium carbonate, barium nitrate, titanium dioxide, lanthanum trioxide, calcium carbonate, zirconium Sodium carbonate water, niobium pentoxide, aluminum hydroxide, and antimony trioxide are uniformly mixed to obtain batch materials; then melted at high temperature in an air atmosphere to form molten glass, and then the molten glass is cast into shape, and cooled rapidly to room temperature, after crushing Add a small amount of raw material and put it into a multi-stage melting furnace for re-melting. After being stirred, clarified and homogenized, it is formed. After inspection and secondary annealing, the titanium-containing high-niobium and low-lanthanum optical glass is obtained. The optical glass has high refractive index, small dispersion, high light transmittance, low glass crystallization tendency, excellent chemical stability, does not contain heavy metal oxides Gd2O3, Ta2O5, PbO, WO3, etc., and can achieve large size, zero defect, continuous The preparation process is simple, the cost is low, and it is suitable for industrial production.

Owner:湖北戈碧迦光电科技股份有限公司

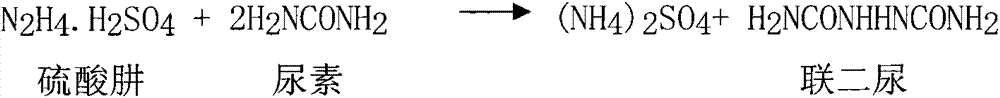

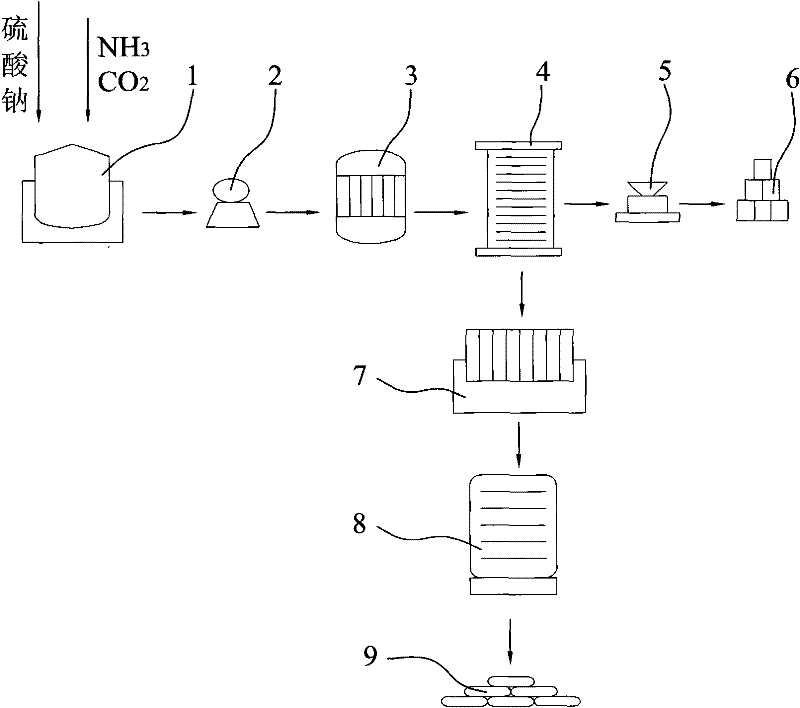

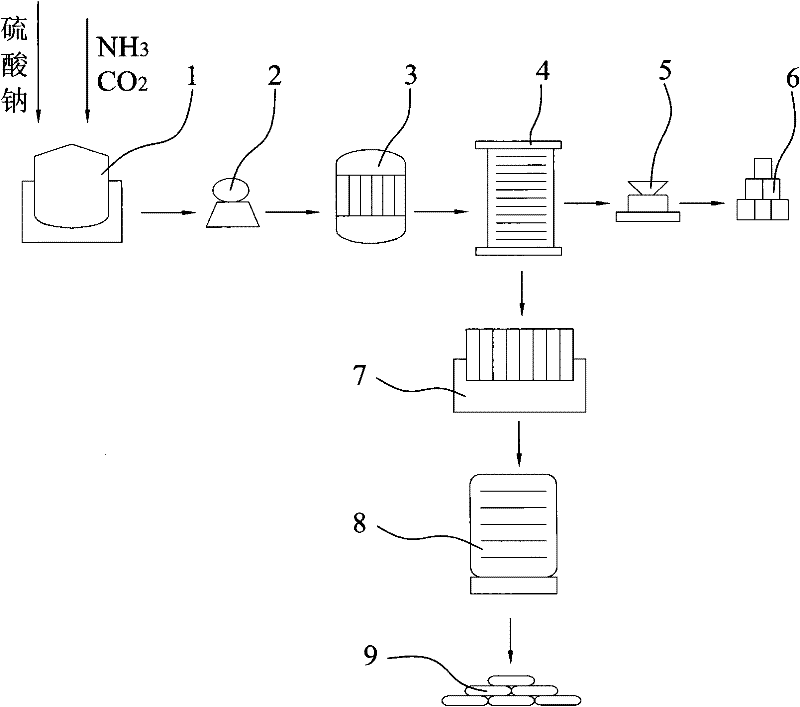

Method for preparing monohydrate sodium carbonate and ammonium sulfate from wastes produced in process for producing sodium cyanate by urea method

ActiveCN101955205AFully realize the potential valueReduce pollutionAmmonium sulfatesAlkali metal carbonatesEconomic benefitsAmmonia

The invention provides a method for preparing monohydrate sodium carbonate and ammonium sulfate from wastes produced in a process for producing sodium cyanate by a urea method. In the method, a process for preparing the sodium cyanate by the urea method is combined with a process for preparing calcined soda by an ammonia-soda method, the wastes produced in the process for preparing the sodium cyanate by the urea method are used as raw materials used in the process for preparing the calcined soda by the ammonia-soda method, and simultaneously, sodium sulfate serving as low-cost industrial raw materials are utilized so as to produce the monohydrate sodium carbonate and coproduce ammonium sulfate, so the potential value of the wastes produced in the process for preparing the sodium cyanate by the urea method is given full play, environmental pollution is reduced, and the economic benefits of enterprises are increased.

Owner:南通华山实业有限公司

Method for preparing monohydrate sodium carbonate and ammonium sulfate from wastes produced in process for producing sodium cyanate by urea method

ActiveCN101955205BFully realize the potential valueReduce pollutionAmmonium sulfatesAlkali metal carbonatesEconomic benefitsAmmonia

Owner:南通华山实业有限公司

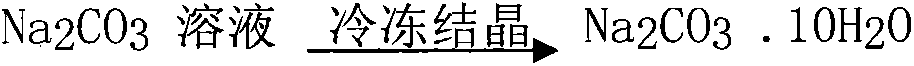

Method for preparing industrial sodium carbonate through hydrazine hydrate byproduct sodium carbonate decahydrate by means of multi-effect evaporation technology

InactiveCN105271314AUnique methodSimple processAlkali metal carbonatesMultiple-effect evaporationHydrazine compoundEvaporation

The invention relates to ADC foaming agent production technology improvement and wastewater recycling, in particular to a method for preparing industrial sodium carbonate through hydrazine hydrate byproduct sodium carbonate decahydrate by means of the multi-effect evaporation technology. The method comprises the steps that firstly, sodium carbonate decahydrate is dissolved into an alkali dissolution tank, after being preheated by a preheater, the sodium carbonate decahydrate enters all effect evaporators in parallel to be heated, evaporated and concentrated, the sodium carbonate decahydrate is evaporated and crystalized to form monohydrate sodium carbonate, the crystalized monohydrate sodium carbonate is deposited at the bottom of the evaporator, enters a centrifugal machine head tank after being thickened through a salt pump and a suspension separator, and is dehydrated through a centrifugal machine to obtain monohydrate sodium carbonate, and the centrifugal mother liquid is returned back to a sodium carbonate decahydrate storage tank; when the salt and hydrazine hydrate contents are high, the centrifugal mother liquid is fed to other processes to be recycled, then, water is separated out when the monohydrate sodium carbonate is heated, and the monohydrate sodium carbonate is converted into sodium carbonate at the temperature of 109 DEG C, and the finished industrial product sodium carbonate is obtained. The method is unique, no carbonization is needed, comprehensive waste residue government is achieved in the hydrazine hydrate production process, and the purpose of environmental protection is achieved.

Owner:NINGXIA RISHNEG HIGH NEW IND CO LTD

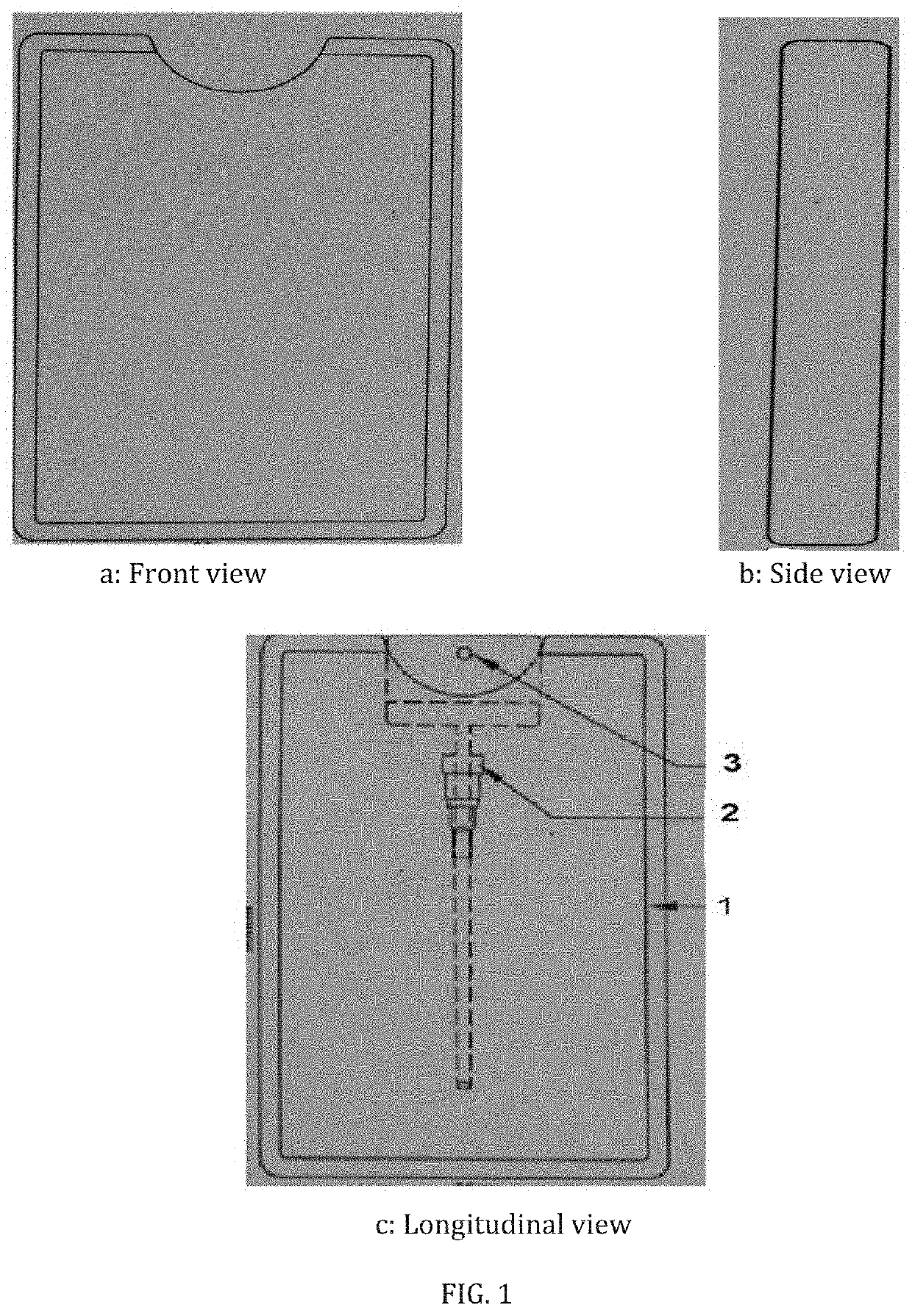

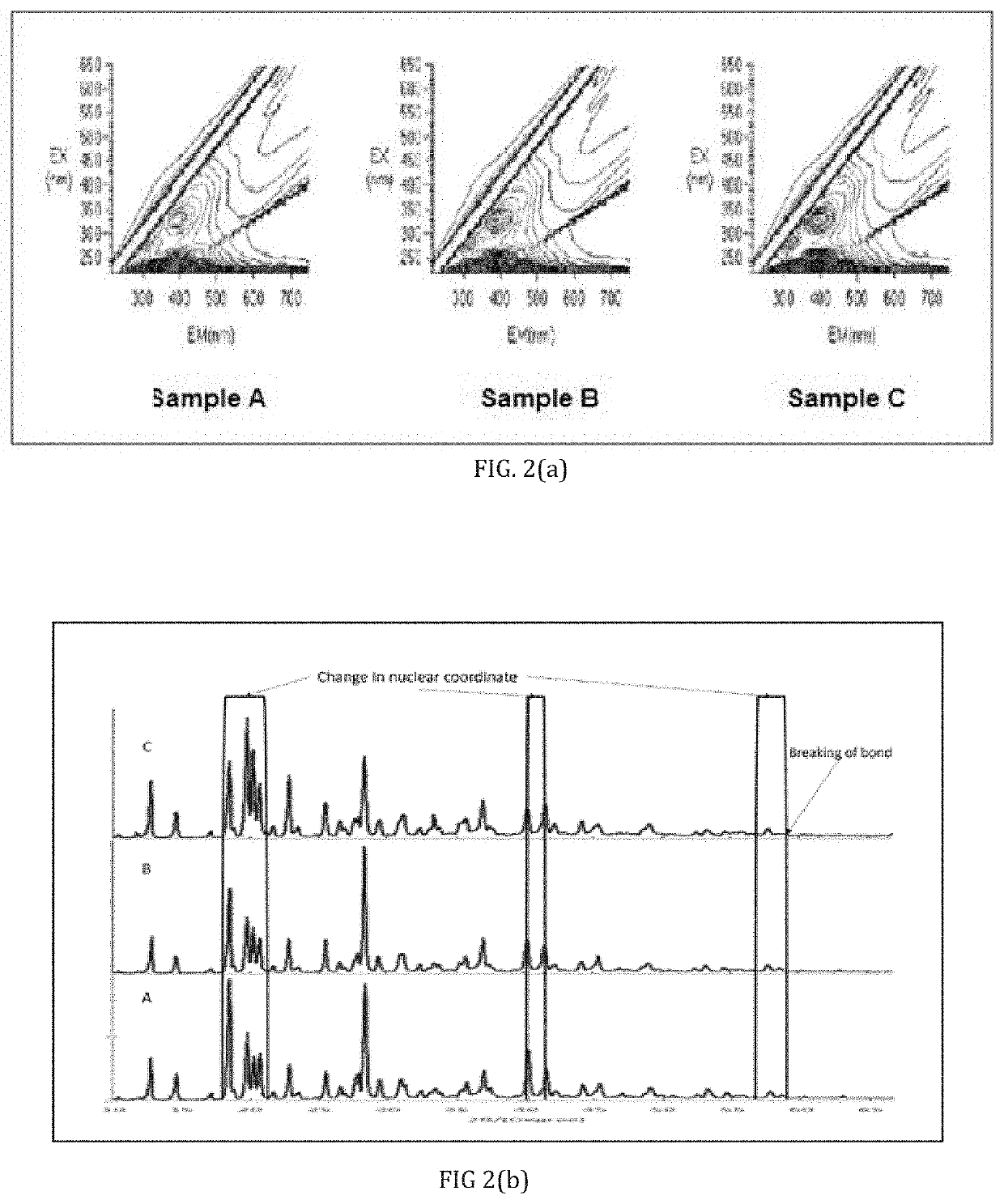

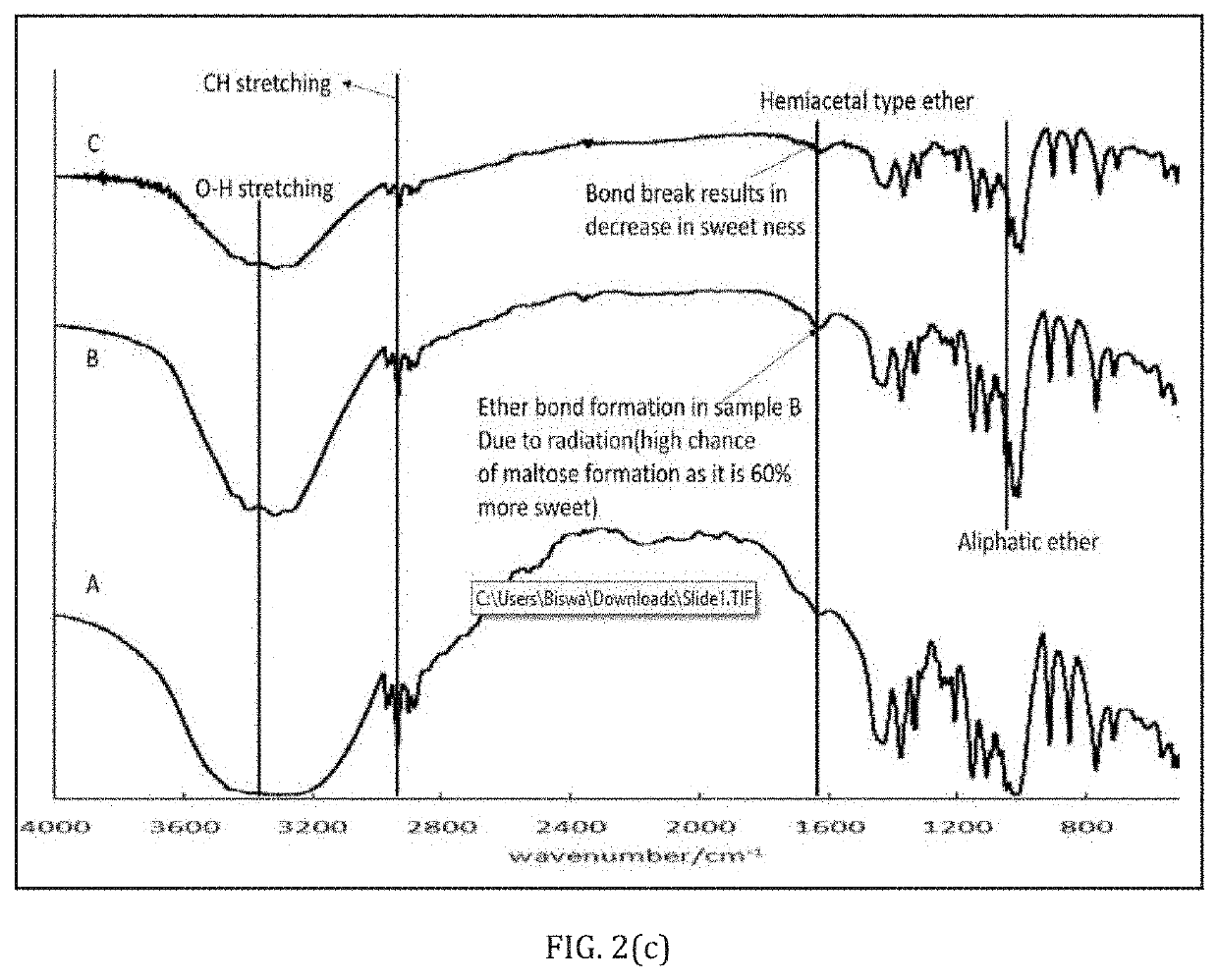

A multipurpose potentiator composition and the methods thereof

InactiveUS20210068388A1Extended shelf lifeProlong lifeBiocideLiquid surface applicatorsPotassium nitrateSodium carbonate anhydrous

Disclosed is a multipurpose potentiator composition comprising: sodium carbonate monohydrate, sodium carbonate anhydrous, potassium nitrate, sodium chloride and water such that the potentiating composition is applied to alter physical or chemical properties or both of a substance on which the potentiating composition is applied. Also provided is a container for holding the composition.

Owner:UMAKANTHAN T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com