Liquid-phase hydration separation ash treatment process

A treatment process and hydration technology, which is applied in the direction of changing the crystal water content of alkali metal carbonate, can solve the problems of endangering the normal operation of the separation and drying system, deteriorating hydration operating conditions, and loss of raw materials, so as to achieve low cost of process transformation and prevent Environmental pollution and waste of soda ash, the effect of increasing the content of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, liquid-phase hydration separation ash treatment process, comprises the following steps:

[0032] (1) adopt light ash and mother liquor to carry out liquid phase hydration reaction and prepare monohydrate sodium carbonate wet material;

[0033] (2) The wet material of sodium carbonate monohydrate is dried in the heavy ash fluidized bed to obtain heavy ash, and the tail gas produced by the heavy ash fluidized bed is passed into the cyclone separator for separation to obtain separated ash and dusty air, wherein the separated ash is The content of sodium carbonate is;

[0034] (3) Dry the separated ash in a separated ash fluidized bed to obtain heavy ash, and the tail gas generated by the separated ash fluidized bed is passed into a cyclone separator for further cyclone separation.

[0035] The separated ash is dried in a separated ash fluidized bed to obtain heavy ash with high sodium carbonate content, which is added to the heavy ash product to improve the ...

Embodiment 2

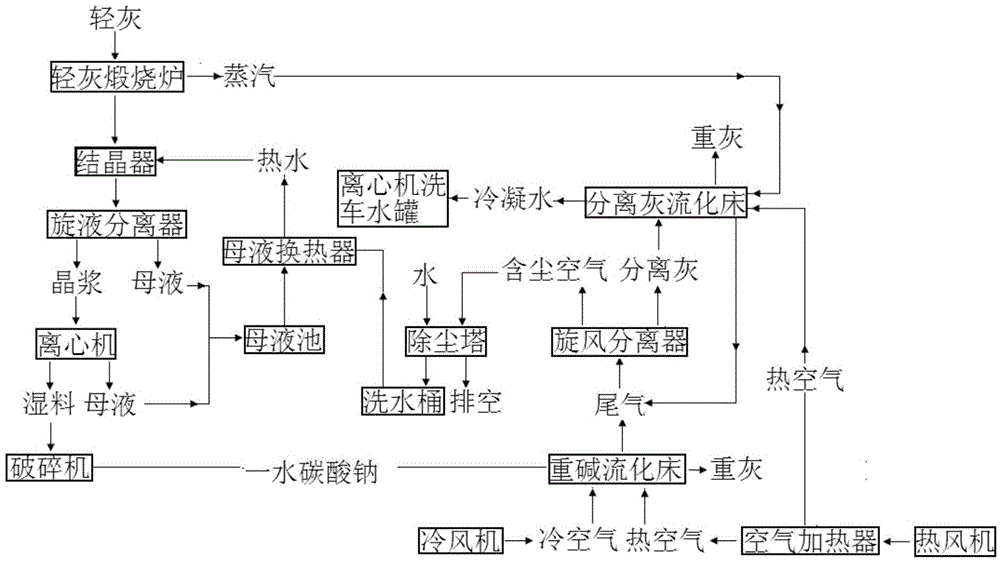

[0036] Example 2, such as figure 1 As shown, the liquid-phase hydration separation ash treatment process includes the following steps:

[0037] (1) After the light ash is calcined in a light ash calciner, high-temperature light soda ash and water vapor are obtained, and the high-temperature light soda ash and mother liquor are hydrated to obtain a monohydrate alkali containing a large amount of water, and the monohydrate alkali containing a large amount of water is obtained Separation of solid and liquid through liquid cyclone separator and centrifuge in turn to obtain monohydrate alkali wet material and mother liquor;

[0038] (2) the wet material of sodium carbonate monohydrate after the crushing is dried in the heavy ash fluidized bed to obtain heavy ash, and the tail gas produced by the heavy ash fluidized bed is passed into the cyclone separator to separate and obtain separated ash and dusty air;

[0039](3) The separated ash is exchanged with hot air at 140-160°C and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com