Patents

Literature

38 results about "Ash preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microcrystal glass prepared through microwave heating and method thereof

The invention provides microcrystal glass prepared through microwave heating and a method thereof, which relate to microcrystal glass and a preparation method thereof and aim at solving the problems that the existing microcrystal glass preparation method has high raw material cost, the finished product rate is low, the energy source waste is serious, and in addition, the environment protection is unfavorably realized. The microcrystal glass prepared through microwave heating is prepared from 50 to 90 weight parts of sludge pyrolysis ash, 10 to 30 weight parts of calcium oxide, 1 to 20 weight parts of silicon dioxide and organic solvents through microwave heating or is prepared from 50 to 90 weight parts of sludge pyrolysis ash, 10 to 25 weight parts of cullet, 15 to 25 weight parts of calcium dioxide and organic solvents through microwave heating. The preparation method comprises the following steps of: 1, sludge pyrolysis ash preparation; 2, forming; 3, microwave sintering; and 4, microwave nucleation crystallization. The method is mainly used for preparing the microcrystal glass.

Owner:HARBIN INST OF TECH

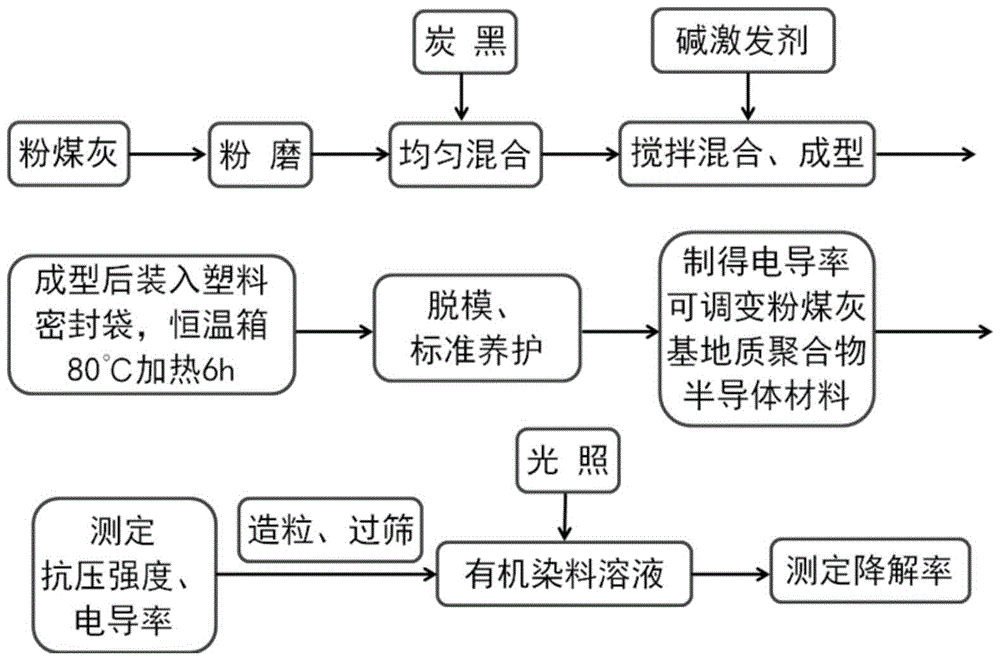

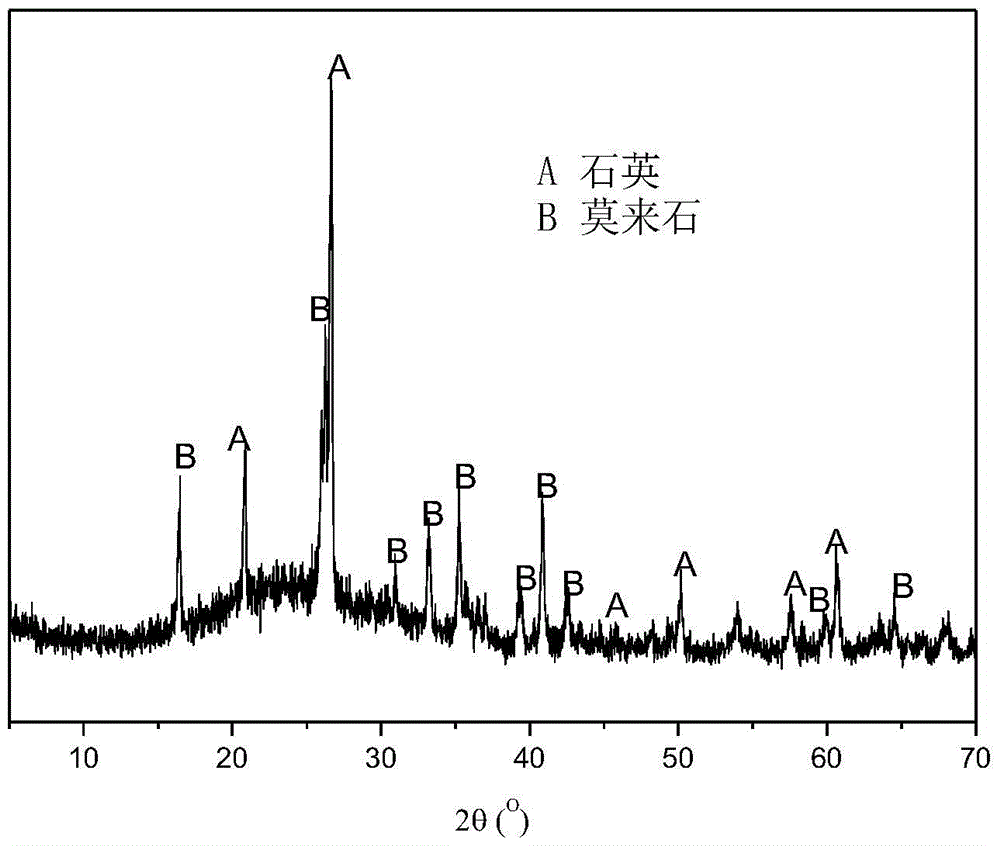

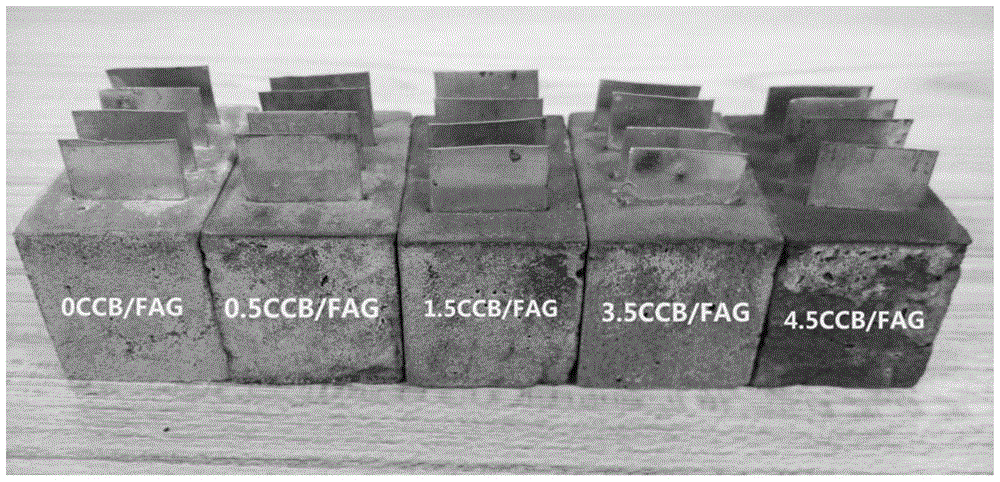

Preparation and application of conductivity-controllable fly ash-based geopolymer material

The invention discloses a preparation method of a conductivity-controllable fly ash-based geopolymer semiconductor material. The preparation method comprises the following steps: putting fly ash, carbon black, sodium silicate nonahydrate and an aqueous solution of potassium hydroxide into a stirring device and mixing; and forming with a mould and curing to obtain the conductivity-controllable fly ash-based geopolymer semiconductor material, wherein the dosage of the sodium silicate nonahydrate, potassium hydroxide, carbon black and water accounts for 15%, 7%, 0.5-4.5% and 30-40% of the fly ash mass respectively; the stable conductivity of the prepared fly ash-based geopolymer semiconductor material can be controlled in a range from 0.00025 to 0.65 (S / m) in a curing age of 28 days; and when the prepared conductivity-controllable fly ash-based geopolymer semiconductor material is used as a novel photocatalyst for degrading malachite green organic dye, a change law that the conductivity of the material is directly proportional to the degradation rate of the dye is discovered. The preparation technology is simple, the cost is low, the discharge of three wastes is avoided in the preparation process, and the conductivity-controllable fly ash-based geopolymer semiconductor material can be used as a dye degrading high-activity catalyst.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Interplanting method for potato and garlic in organic sorghum land

InactiveCN105940898AEnergy balanceHigh organic contentPlant cultivationCultivating equipmentsShootSoil organic matter

The application discloses an interplanting method for potato and garlic in organic sorghum land comprising following steps: potato variety selection and potato seed preparation; garlic variety selection and garlic seed preparation; organic sorghum straw harvest and plant ash preparation; soil preparation, reapplying base fertilizer and excavating drainage ditch; the row ratio of potato to garlic; planting potato; ridging for potato; interplanting garlic; harvesting potato and weeding, fertilizing and earthing for garlic; later-period management; harvesting young garlic shoot; harvesting garlic. By means of the method, the target of maintaining land with land is achieved; the Hongyingzi organic sorghum land system energy balance is kept; the soil organic matter content is greatly increased; soil is effectively fertilized; the yield of organic sorghum is increased without increasing other production cost.

Owner:贵州茅台酒厂(集团)红缨子农业科技发展有限公司 +1

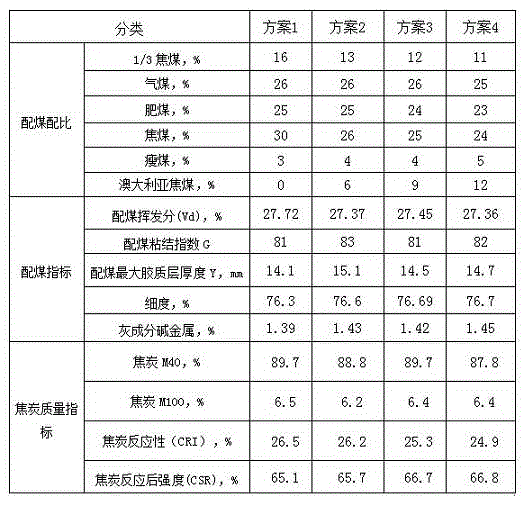

Coke matched with Australian coking coal for use and coking method

InactiveCN105219412AIncrease resourcesEfficient use ofSpecial form destructive distillationAsh preparationPulverized fuel ash

The invention discloses coke matched with Australian coking coal for use and a coking method, and mainly aims to solve the technical problems that coke refined by the Australian coking coal is high in reactivity (CRI), low in post-reaction strength and cannot reach quality requirements of high-quality metallurgical coke due to the fact that coking properties of the Australian coking coal in the prior art are lower than those of high-quality coking coal. According to the technical scheme adopted by the invention, the coke matched with Australian coking coal for use is prepared by mixing and coking the following blending coal in percentage by mass: 12%-17% of 1 / 3 coking coal, 18%-25% of gas coal, 20%-26% of fat coal, 28%-35% of coking coal, 6%-10% of lean coal, and 6%-12% of Australian coking coal. According to the characteristics of the Australian coking coal, corresponding control indexes, namely coal ash preparation components and alternative coal types, are disclosed, so that the quality stability of the coking coal is guaranteed when the Australian coking coal resources are used.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

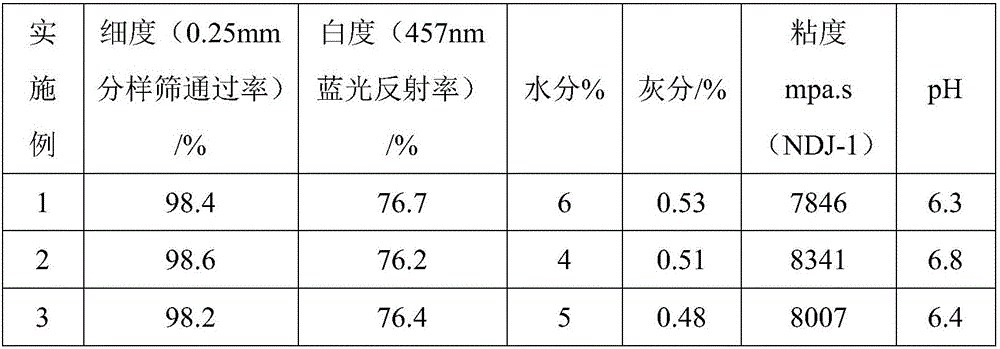

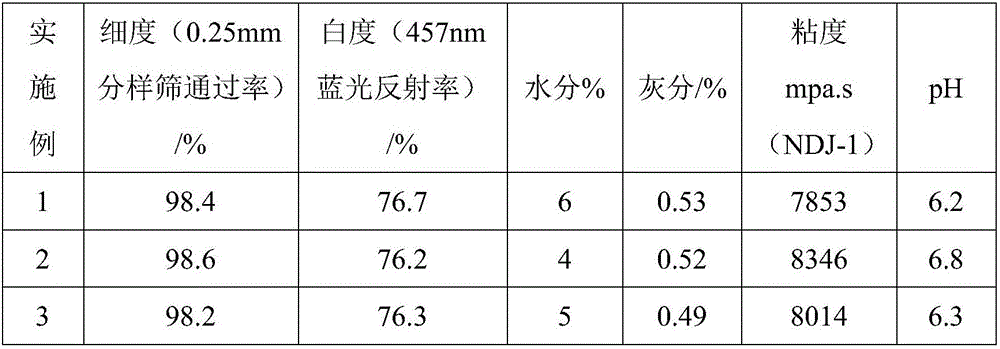

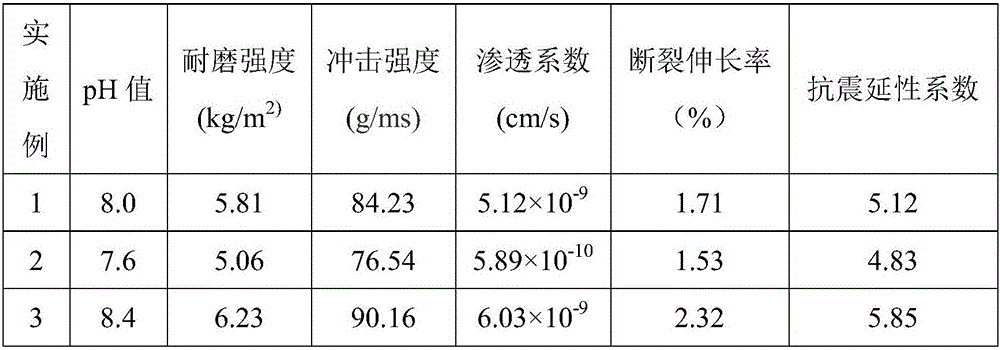

Preparation method of novel 3D printing clay material

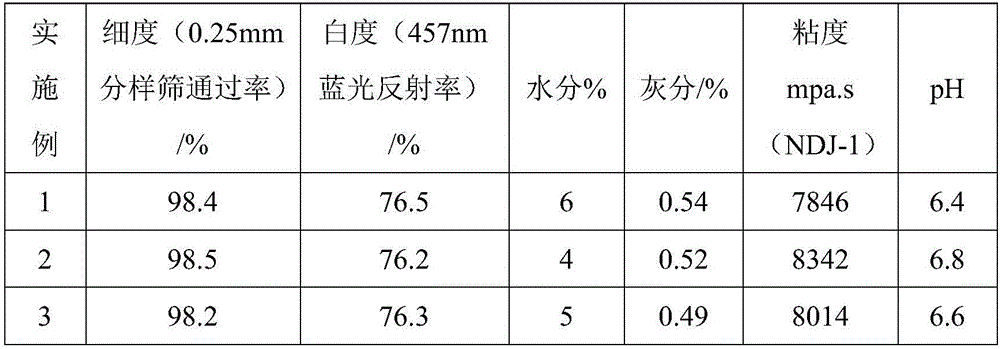

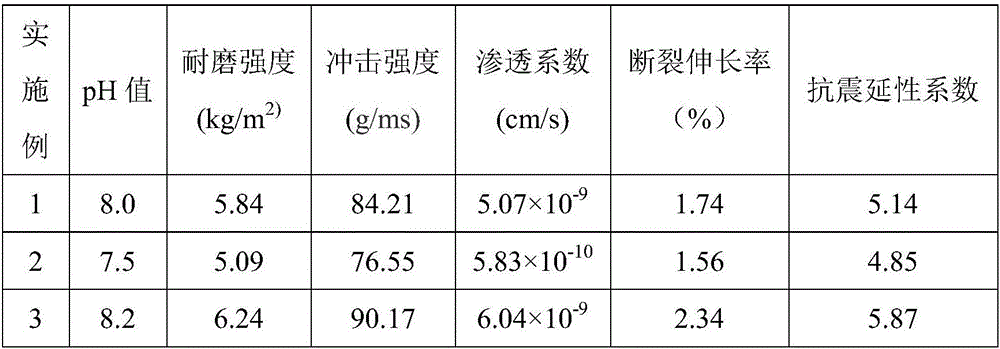

InactiveCN106316346AImprove wear resistanceHigh impact strengthAdditive manufacturing apparatusCeramic materials productionMaterials preparationAsh preparation

The invention discloses a preparation method of a novel 3D printing clay material and belongs to the technical field of 3D printing material preparation. The novel 3D printing clay material is prepared from clay, calcium carbonate powder, plant ash, a specific synthesis agent, a starch synthesis agent and water according to a mass ratio of 20-30: 8-16: 6-10: 5-8: 4-6: 10-25. The preparation method comprises clay preparation, calcium carbonate powder preparation, plant ash preparation, normal temperature crushing, modification with a specific synthesis agent and a starch synthesis agent, and extruding granulation. The clay material has the advantages of high wear resistance, impact strength, shock strength, good plasticity, molding easiness and high precision, is suitable for a 3D printing molding technology, promotes 3D printing molding technology promotion and has a wide market prospect.

Owner:NANNING MENGHUAN 3D ENVIRONMENTAL PROTECTION TECH CO LTD

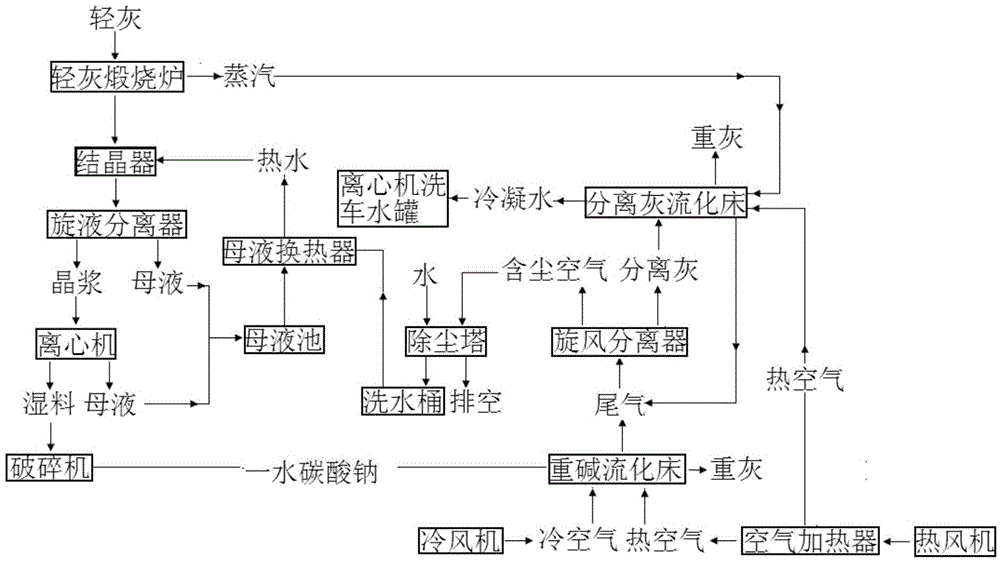

Novel environment-friendly circulation technological system and novel environment-friendly circulation technological method on basis of combined soda ash preparation processes

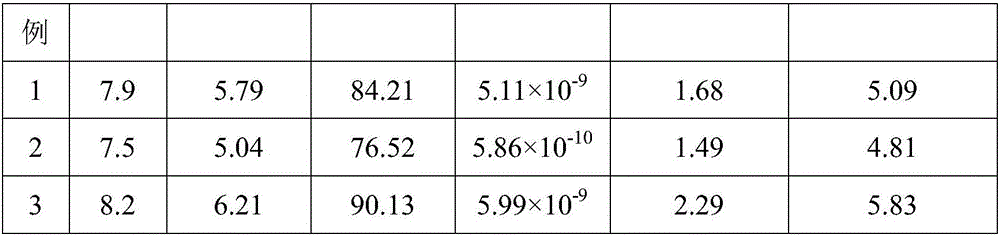

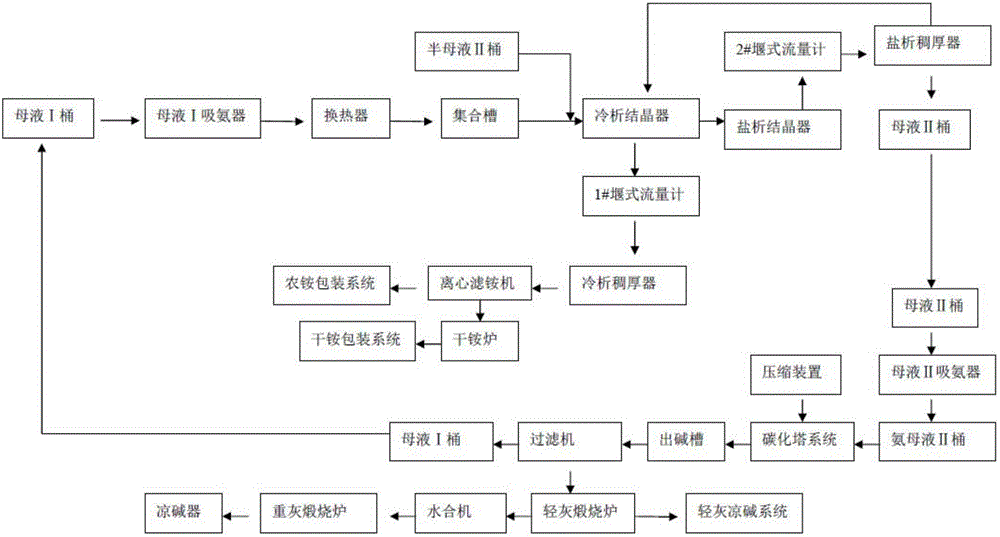

InactiveCN106276982AIncrease productivityAlkali metal carbonatesAmmonium chlorideSalting outTechnological system

The invention relates to a novel environment-friendly circulation technological system and a novel environment-friendly circulation technological method on the basis of combined soda ash preparation processes. The novel environment-friendly circulation technological system comprises a mother liquor II barrel, an ammonia absorber II, an ammonia mother liquor II barrel, a carbonization tower system, a compression device, a soda outlet tank, a filter, a light ash calcining furnace, a light ash soda cooling system, a hydration machine, a heavy ash calcining furnace, an soda cooler, a mother liquor I barrel, an ammonia absorber I, a heat exchanger, a semi-mother liquor II barrel, a gathering tank, a cold separation crystallizer, a salting-out crystallizer, a No.2 weir type flow meter, a salting-out thickener, a No.1 weir type flow meter, a cold separation thickener, a centrifugal ammonium filter, a dense ammonium packaging system, an ammonium drying furnace and a dry ammonium packaging system. The novel environment-friendly circulation technological system and the novel environment-friendly circulation technological method have the advantages that generated 'waste mixed water' can be completely digested in a self-circulation manner; waste gas can be discharged after being treated and reaching standards; AII mud and residues can be reused as desulfurizing agents for boilers after being treated; the novel environment-friendly circulation technological system is high in production efficiency, the yield of ammonium chloride can reach 650 thousand tons / year, and the yield of soda can reach 600 thousand tons / year (the yield of dense soda is 400 thousand tons / year).

Owner:中盐昆山有限公司

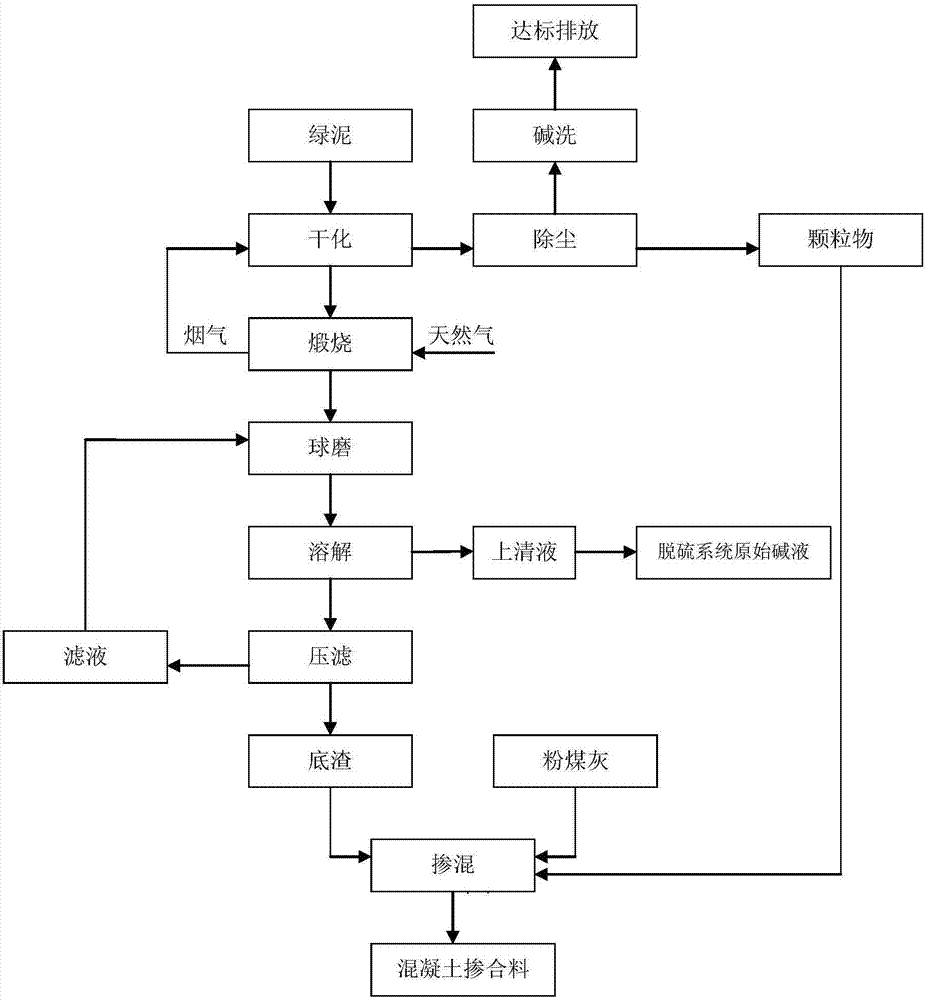

Method for preparation of concrete admixture from papermaking green mud alkali recovery bottom slag

The invention discloses a method for preparation of a concrete admixture from papermaking green mud alkali recovery bottom slag, green mud ash powder is obtained by drying, calcining and ball milling of papermaking green mud, supernatant and bottom slag can be obtained by mixing, dissolving and standing of the green mud ash powder, and the bottom slag is filtered by pressing and mixed with fly ash to obtain the concrete admixture. On the one hand, papermaking green mud burying is avoided, on the other hand, a large amount of waste residue generated after green mud alkali recovery is effectively utilized; meanwhile, the supernatant of the green mud ash solution can be used in a coal fired boiler desulfurization system of a paper making plant.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

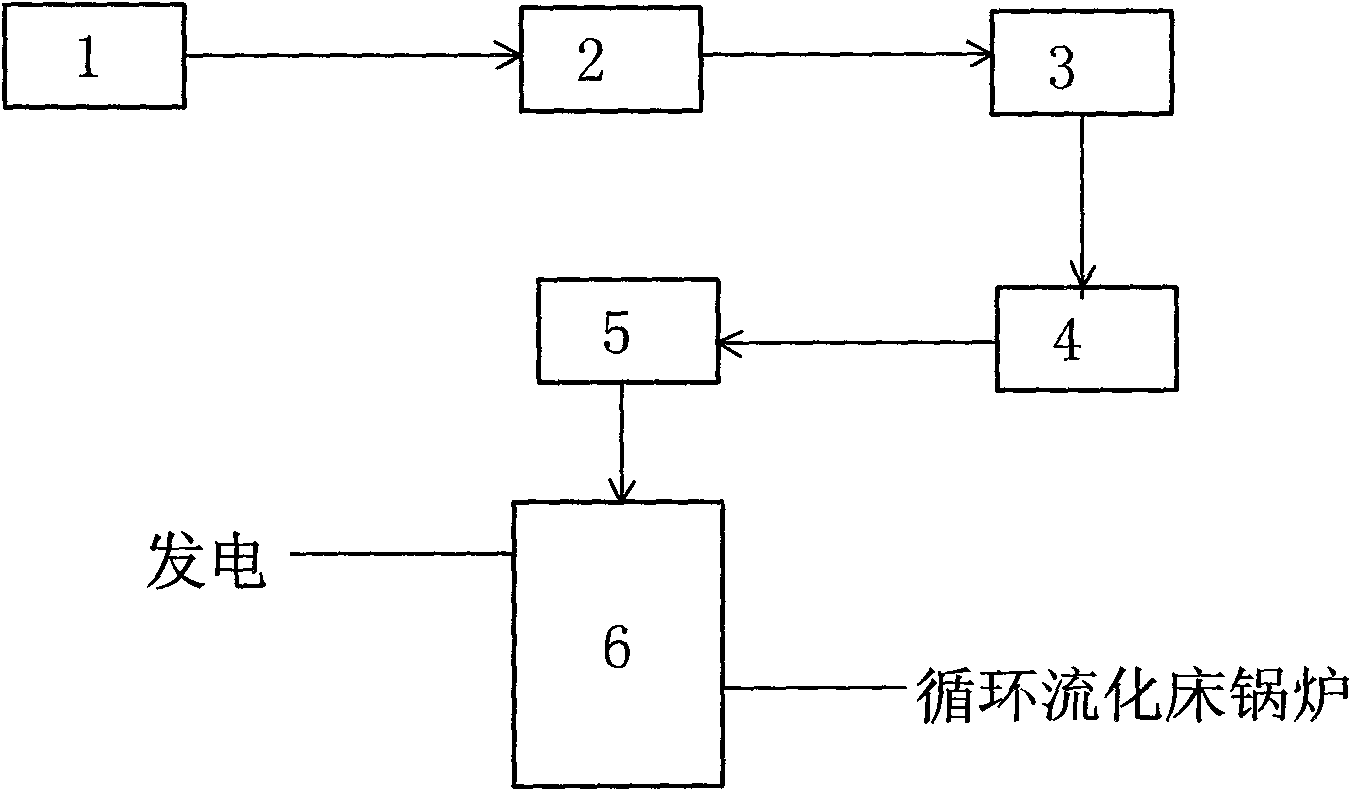

Method for generating electricity by burning wet coal ash from Ender furnace

InactiveCN101566350ATake advantage ofReduce pollutionFluidized bed combustionApparatus for fluidised bed combustionLand resourcesSludge

The invention relates to a method for generating electricity by burning wet coal ash from an Ender furnace. Through a wet coal ash preparation process 1, an intense wet coal ash stirring process 2, a wet coal ash screening process 3, a water-adding slurrying process 4, a pipe conveying process 5 and a process 6 for adding the wet coal ash into a cyclic fluidized bed boiler to participate in combustion, the wet coal ash slurry is added into the boiler and burned with boiler fuels together so as to obtain heat for generating the electricity. The method can use the wet coal ash generated by the Ender furnace as a fuel to burn in the cyclic fluidized bed boiler so as to generate the electricity, realizes the full utilization of the wet coal ash, reduces discharge, environment pollution and occupied land resources, and achieves dual effects on energy conservation and environmental protection. The method also can utilize carbon-containing wastes such as coal with low thermal value, coal slurry, organic sludge and the like, and is applicable to generating the electricity by the fuels with low thermal value.

Owner:中冶葫芦岛有色金属集团有限公司

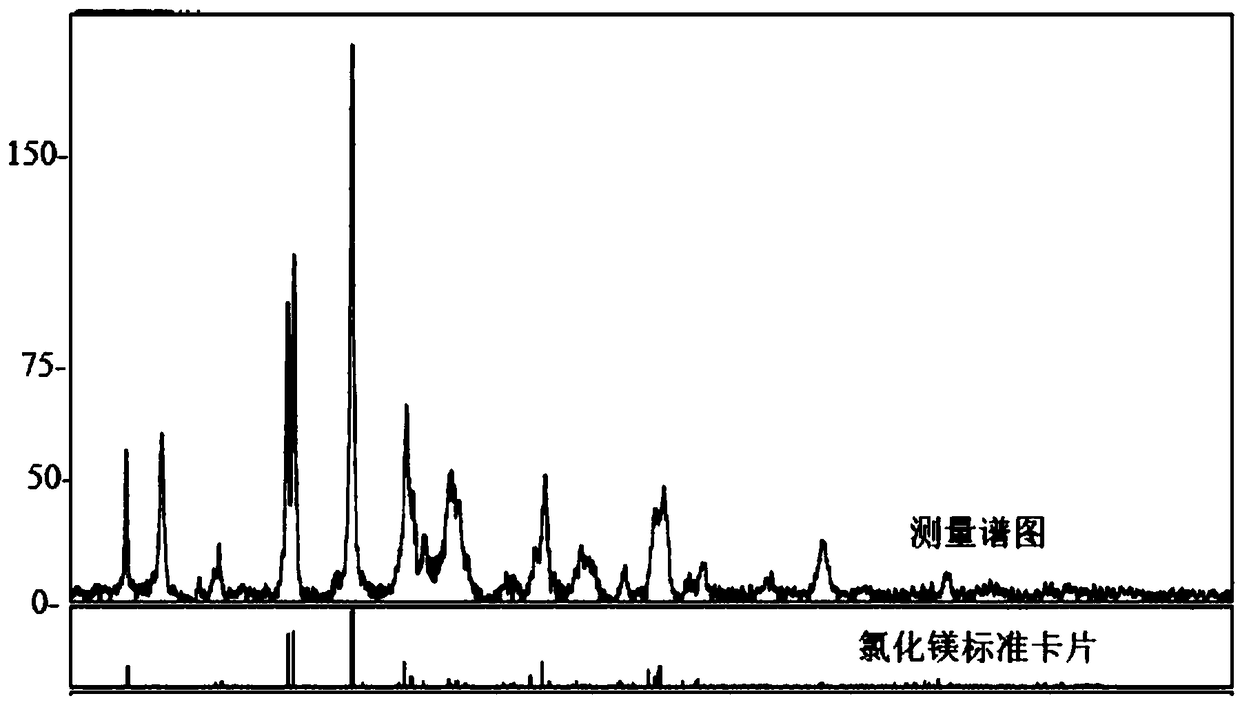

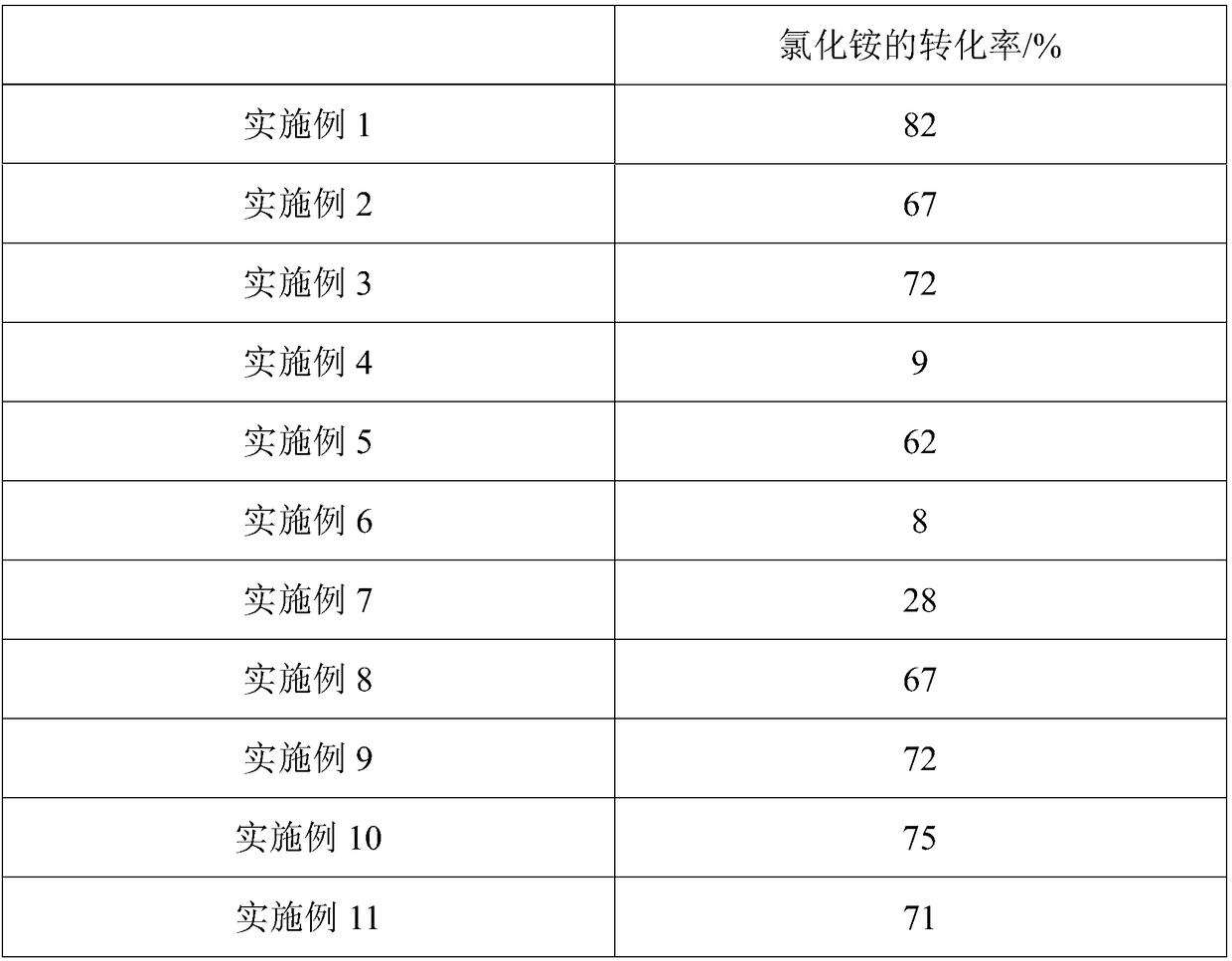

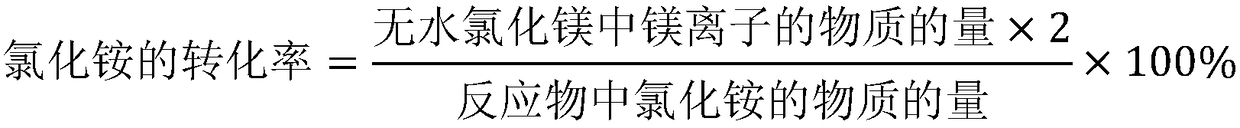

Method for preparing magnesium chloride and application of magnesium chloride prepared through method

ActiveCN109279631AOvercoming pollutionOvercome resourcesProductsMagnesium fertilisersElectrolysisPotassium

The invention relates to a method for preparing magnesium chloride. The preparation method comprising the steps of: (1) mixing ammonium chloride with magnesium carbonate so as to obtain a mixture; and(2) heating the mixture obtained in the step (1) so as to obtain anhydrous magnesium chloride, wherein both the ammonium chloride and the magnesium carbonate are solid. The preparation method has a simple and easy process, ammonium chloride which is a by-product of a soda ash preparation method is adopted as a reactant, and the product is magnesium chloride which can be applied to antifreeze liquid, snow melting agents, magnesium fertilizer, magnesium potassium fertilizer or a raw material for magnesium preparation through a molten electrolysis method; and by-products ammonia and carbon dioxide can be applied to preparation of soda ash. Through combination of the method for preparing magnesium chloride with a process for producing soda ash, zero discharge can be achieved, the requirementsof energy conservation and environmental protection can be met, and the economic benefits of enterprises are improved.

Owner:HEBEI UNIV OF TECH

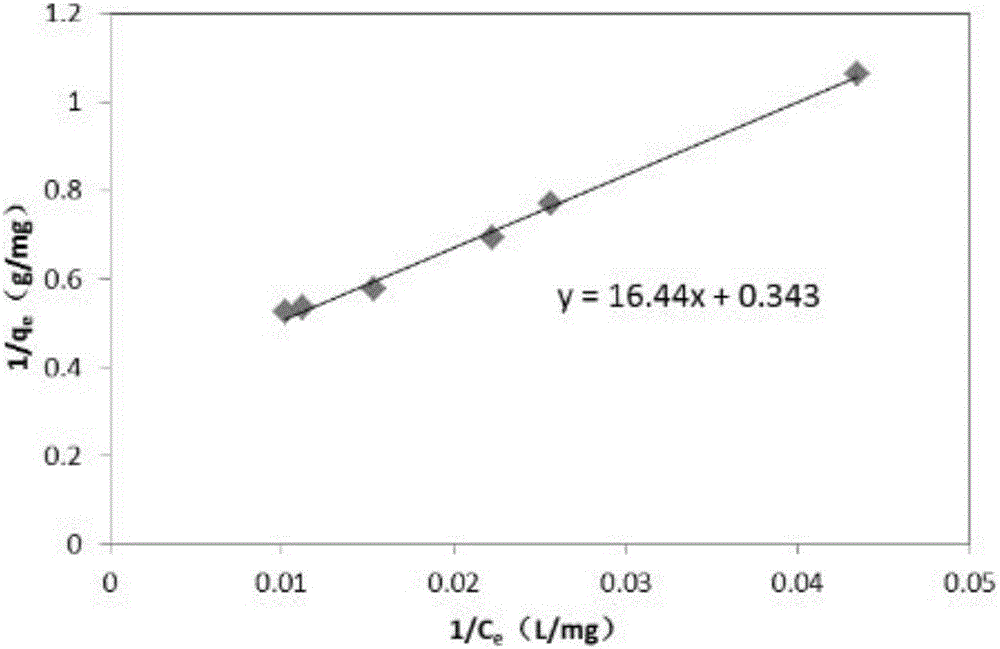

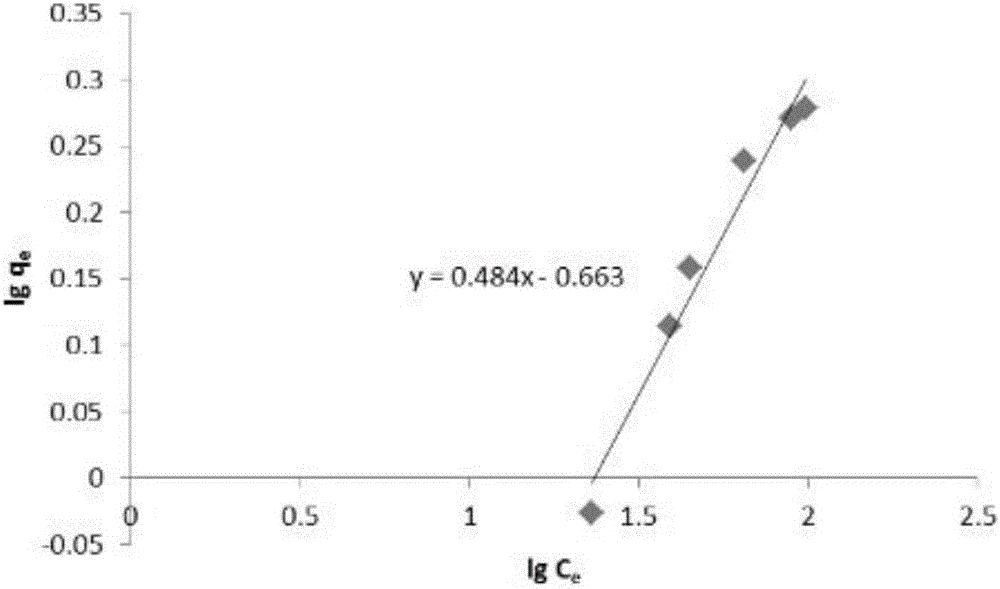

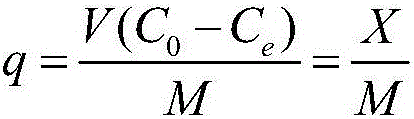

Preparation and application of modified fly ash for deeply treating refinery waste water

InactiveCN106237977AImprove adsorption capacityTo achieve the purpose of treating waste with wasteOther chemical processesSilicon compoundsRoom temperatureAsh preparation

The invention relates to preparation of modified fly ash for deeply treating refinery waste water. The preparation comprises the steps of (1) forming a modifying agent: adopting 1g of fly ash as the basis, and adding 0.05g of sodium chloride, 0.5ml of sulfuric acid with the concentration of 2mol / L, and 0.5ml of hydrochloric acid with the concentration of 4mol / L into the modifying agent; (2) modifying the fly ash, mixing and stirring the fly ash and the modifying agent at room temperature, filtering, washing, drying and grinding to prepare acid modified fly ash. An application method of the modified fly ash is characterized by adding the prepared modified fly ash into waste water to be treated according to the proportion of the waste water to the modified fly ash as 100ml to 10g, and stirring and adsorbing for 45 to 60 minutes. According to the preparation and application of the modified fly ash for deeply treating the refinery waste water provided by the invention, the adsorption capacity of the fly ash is greatly improved, the aim of dealing with waste by waste is achieved, the cost is low, the land use is less, the environment protection and the economy are realized.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

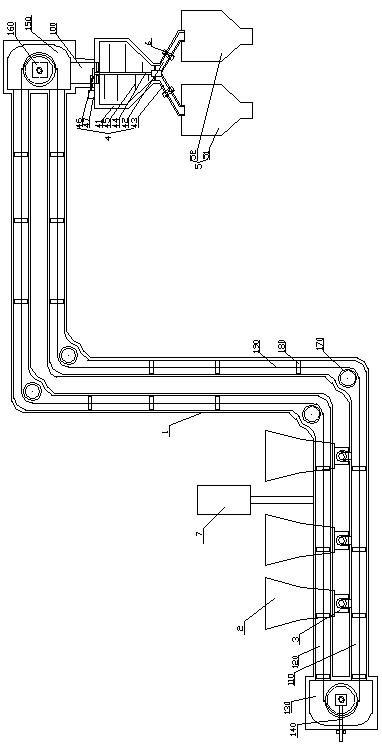

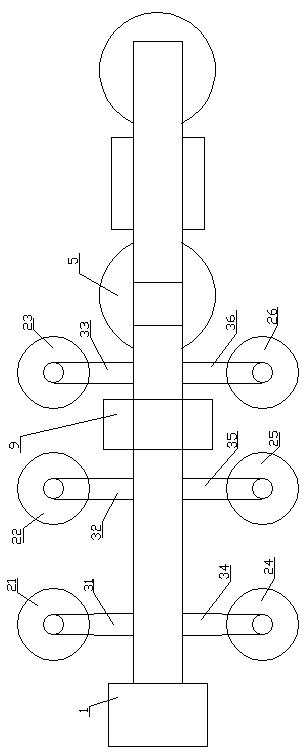

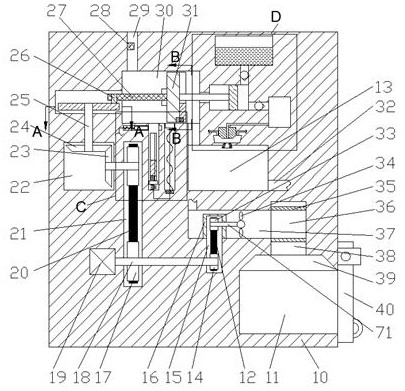

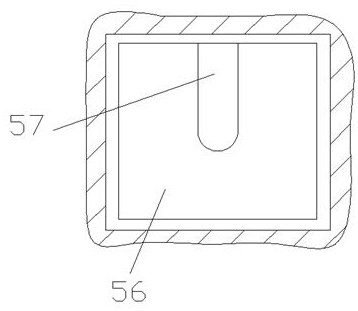

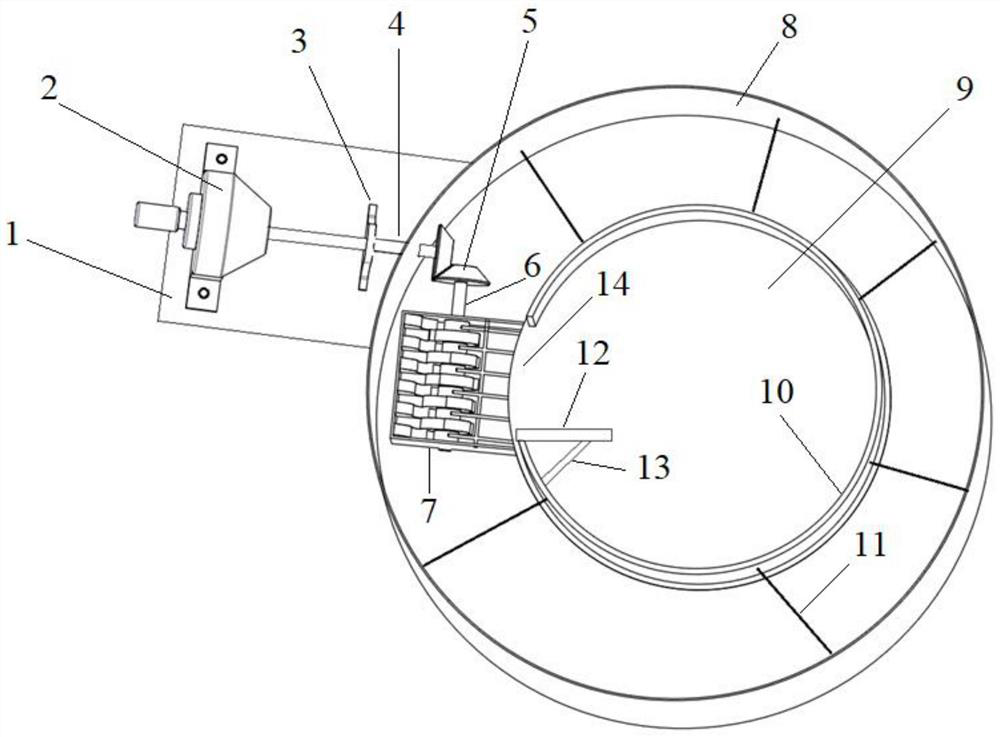

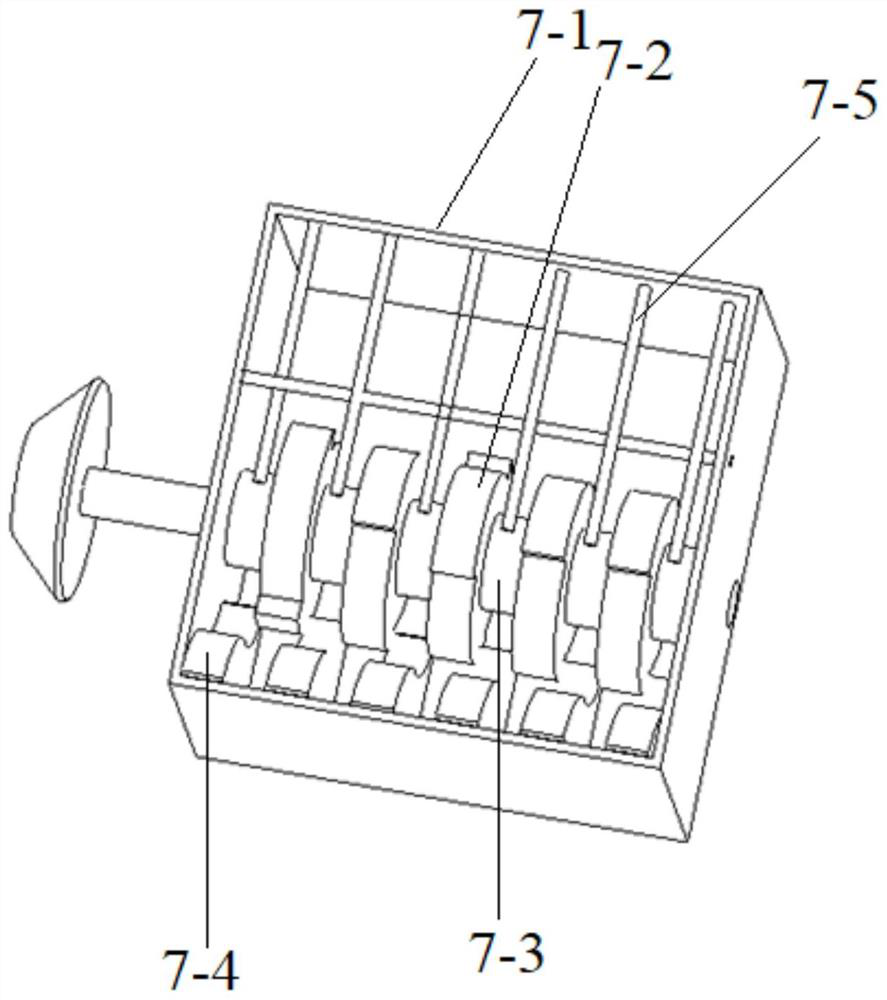

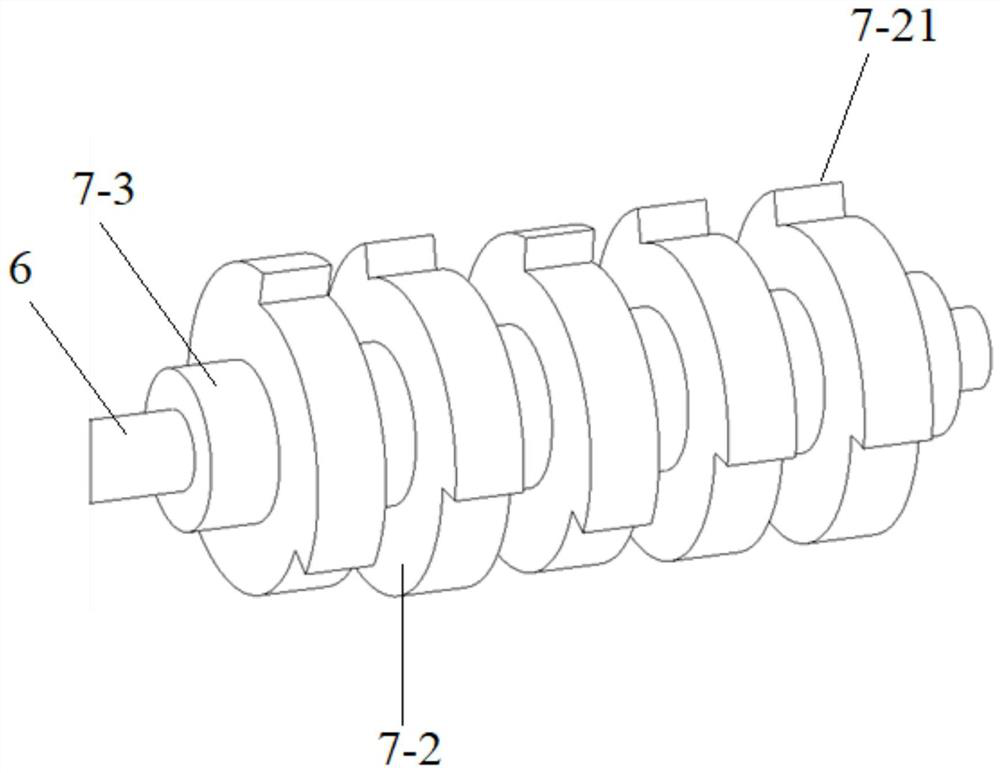

Mortar ash mixing station adopting pipe chain conveying, and preparation method and application thereof

PendingCN111037751ARealize continuous feedingImprove production efficiencyConveyorsDischarging apparatusProcess engineeringChain conveyor

The invention discloses a mortar ash mixing station adopting pipe chain conveying, and a preparation method and an application thereof. The mortar ash mixing station comprises a pipe chain type conveyor (1), wherein the pipe chain type conveyor (1) has a section of head part used for injecting combined component materials of mortar ash, another section of head part used for discharging the mortarash, and a middle section part arranged between the section of head part and the other section of head part. By means of the pipe chain type conveyor (1), continuous feeding of combined component materials of the mortar ash and continuous discharging of the mortar ash are achieved, and therefore the mortar ash preparation efficiency is improved.

Owner:山东新大地环保建材股份有限公司

Alkali manufacturing technology for combined production of sulfuric acid and cement

InactiveCN102351155AReduce manufacturing costSolve environmental problemsSulfur compoundsChemical industryManufacturing technology

An alkali manufacturing technology for the combined production of sulfuric acid and cement. According to the invention, anhydrous sodium sulfate, calcium oxide and fine coal are used as basic raw materials. By the basic technological principle of the soda ash preparation technology, a calcium chloride waste liquid formed during the soda ash preparation and ammonia regeneration process is recovered so as to obtain dihydrate calcium sulphate. By the adoption of the gypsum acid making technological principle, the dihydrate calcium sulphate is used as a raw material for the combined production of soda ash, sulfuric acid and cement clinker, thus greatly reducing the comprehensive production cost of the products and solving problems caused by ammonia-nitrogen emission and a lot of by-products during the soda ash production process. The invention is of great importance for the energy saving and emission reduction, comprehensive utilization of resources and development of circular economy in the chemical industry.

Owner:HUNAN HENGGUANG TECH

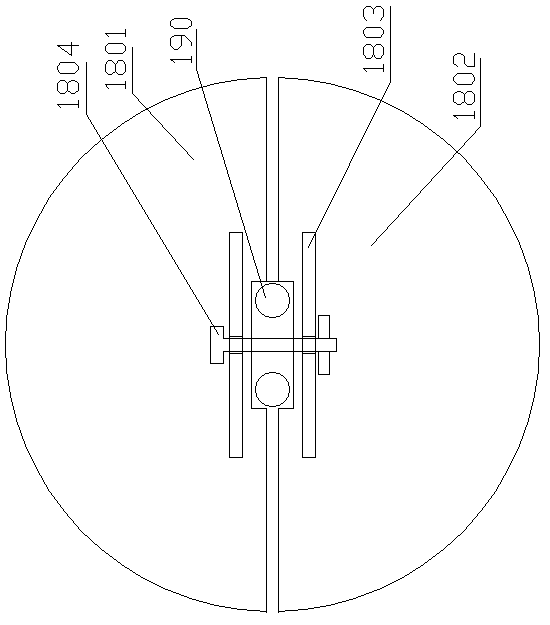

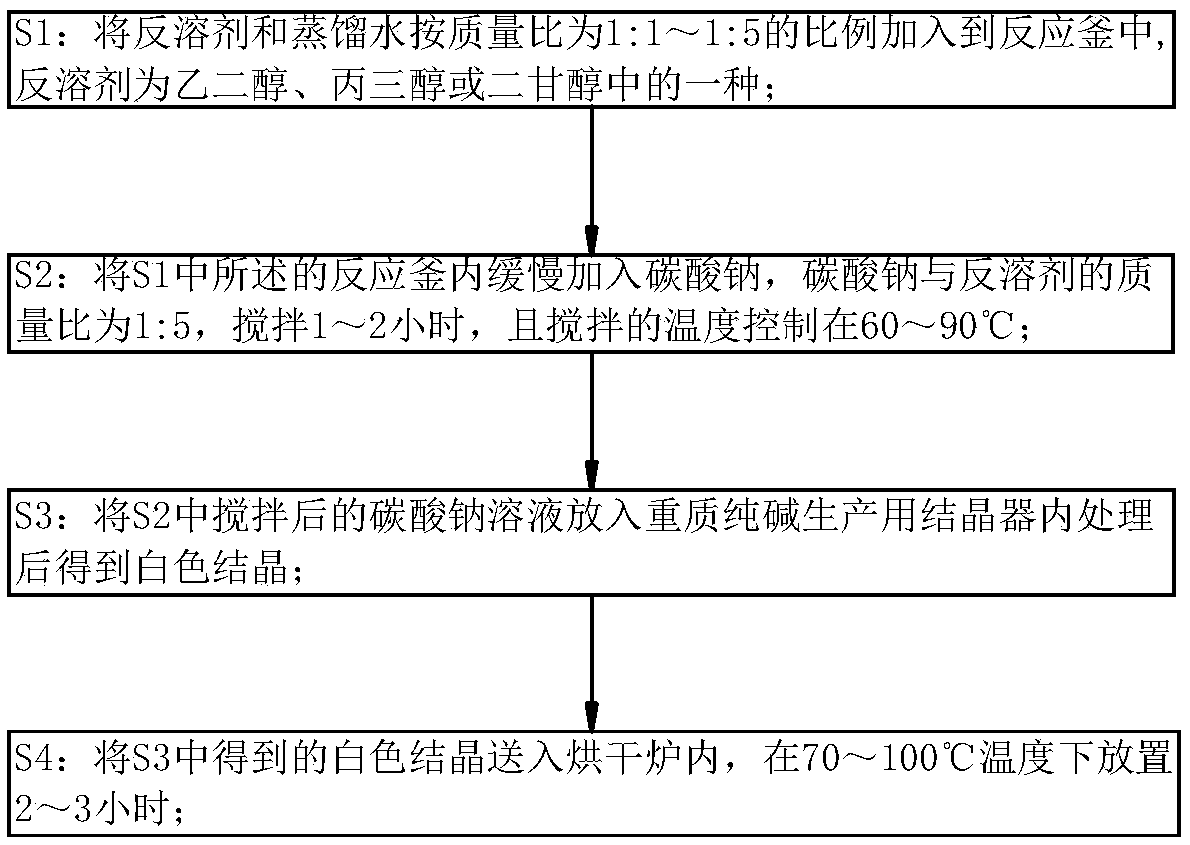

Preparation process of dense soda ash

ActiveCN109455743AReduce investmentThe process steps are simpleVarying alkali metal carbonate water contentDistilled waterDiethylene glycol

The invention belongs to the technical field of soda ash preparation, in particular to a preparation process of dense soda ash. The process comprises the steps that an antisolvent and distilled waterare added into a reaction kettle according to a mass ratio from 1:1 to 1:5, wherein the antisolvent is one of ethanediol, glycerol or diethylene glycol; sodium carbonate is slowly added into the reaction kettle, wherein a mass ratio of the sodium carbonate to the antisolvent is 1:5, stirring is carried out for 1-2 h, and the temperature of stirring is controlled at 60-90 DEG C; the stirred sodiumcarbonate solution is placed into a crystallizer for dense soda ash production to be treated to obtain white crystals; and the obtained white crystals are fed into a drying oven, and placed for 2-3 hat the temperature of 70-100 DEG C, so that the white granule dense soda ash is obtained. The steps are simple, the dense soda ash can be obtained without calcination through the antisolvent crystallization technology, staff input is reduced, and the working efficiency is improved.

Owner:BEIJING JINJING WISDOM CO LTD

Method for recycling return sand in soda ash production

The invention relates to the technical field of soda ash production, in particular to a method for recycling return sand in soda ash production, which comprises the following steps of: mixing the return sand and gravels, feeding the mixture into a kiln, and calcining the mixture to obtain quick lime. Return sand can be recycled to obtain raw materials for the soda ash preparation process, so thatresource waste is eliminated, profits are increased, environmental pollution is reduced, and huge economic benefits are increased for enterprises.

Owner:山东海天生物化工有限公司

Method for preparing new clay material for 3D printing

InactiveCN106336195AImprove plasticityEasy to shapeAdditive manufacturing apparatusCeramic materials productionMaterials preparationAsh preparation

The invention discloses a method for preparing a new clay material for 3D printing, and belongs to the technical field of preparation of materials for 3D printing, and the new clay material for 3D printing is prepared by the following steps: clay material preparation, calcium carbonate powder preparation, plant ash preparation, low temperature crushing, addition of a specific synthetic agent and a starch synthesis agent for modification, extruding, granulating and the like. The new clay material has the advantages of good plasticity, easy molding, good mechanical performance and high accuracy, is suitable for 3D printing technologies, promotes the popularization and application of the 3D printing technologies, and has a broad market prospect.

Owner:庞用

Passion fruit overwintering method

InactiveCN110367029AVitality preservationGet throughCultivating equipmentsHorticulture methodsAsh preparationPassion fruit

The invention relates to passion fruit planting techniques, in particular to a passion fruit overwintering method. The method includes: step one, branch pruning; step two, plant ash preparation; stepthree, ash mud preparation, to be specific, taking plant ash prepared in the step two, adding soil, and adding water to obtain ash mud, wherein a weight ratio of the plant ash to the soil is 1:0.1-5;step four, spraying to branches. According to the method, after pruning of passion fruit seedlings, the ash mud consisting of the plant ash and the soil is sprayed to main veins, the passion fruit seedlings do not freeze internally in cold winter due to the alkaline effect of the plant ash and the heat preservation effect of the soil, internal structures of the passion fruit seedlings are protected from being damaged by ice crystals, vitality is kept, and accordingly the passion fruit seedlings live through the cold winter smoothly, and conditions are provided for high yield in the next year.

Owner:河源市九里红酒业有限公司

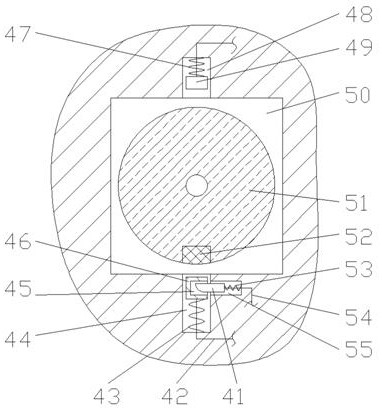

Plant ash preparation device with waste gas purification function

InactiveCN112619369AIncrease contact areaGuaranteed absorptionGas treatmentDispersed particle filtrationCombustion chamberWood ash

The invention relates to the related field of waste gas purification, and discloses a plant ash preparation device with a waste gas purification function, which comprises a main box body; a combustion chamber with a rightward opening is arranged in the main box body, the right end surface of the main box body is hinged with a baffle plate positioned on the right side of the combustion chamber, and the upper end wall of the combustion chamber is communicated with a collection cavity; filter bags are fixedly connected between the left end wall and the right end wall of the smoke removal cavity, the contact area of lime slurry and waste gas is increased by spraying atomized lime slurry, so that the desulfurization efficiency is improved, nitric oxide in the waste gas is adsorbed by moving an activated carbon plate in a reciprocating mode to achieve denitration, and the denitration efficiency is improved. The plant ash waste gas is subjected to desulfurization and denitrification treatment, so that the environment is protected; in addition, nitric oxide in the waste gas is subjected to automatic induction treatment, then activated carbon is automatically replaced, it is guaranteed that nitric oxide in the waste gas is absorbed, and the effectiveness of the device is improved.

Owner:南京盛御泽商贸有限公司

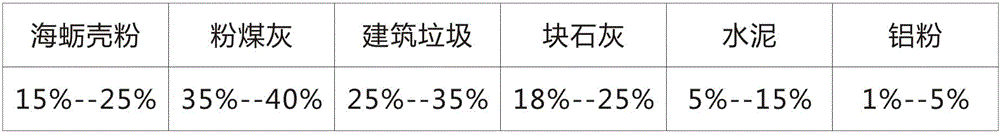

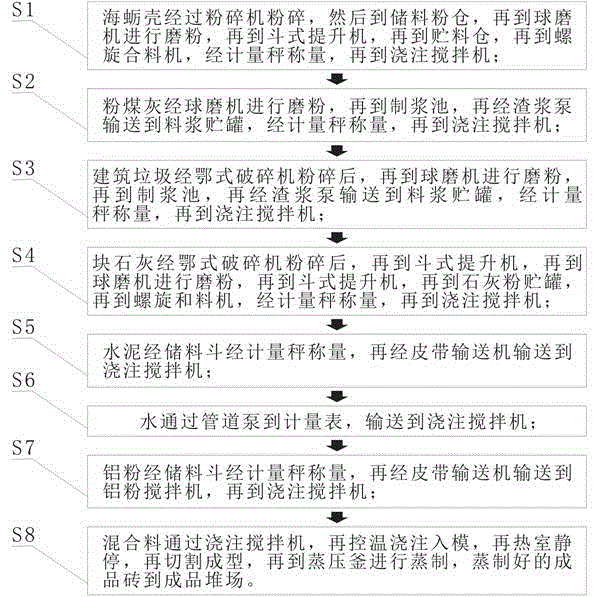

Aerated concrete block and production process thereof

InactiveCN105985072AGood freezing resistanceImprove lightnessSolid waste managementCeramicwareBrickOyster shells

The invention discloses an aerated concrete block. The aerated concrete block is prepared from 15 to 25% of oyster shell powder, 35 to 40% of fly ash, 25 to 35% of constructional waste, 18 to 25% of lump lime, 5 to 15% of cement and 1 to 5% of aluminum powder. According to the invention, oyster shells (mussel shells) are crushed and ground and rationally proportioned as main aggregate for production of the aerated concrete block; due to characteristics of the oyster shells (mussel shells), the physical properties (including lightweight, heat insulating ability, anti-compression performance, fire resistance, sound absorption performance, durability, water seepage resistance, workability and the like) of the aerated concrete block can be improved by 20% or above to a greatest extent; pollution is not produced in the process of processing and grinding; cementing materials (such as cement and gypsum) are saved; ash preparation through burning of the oyster shells produces pollution due to usage of coal, and pollution caused by the oyster shells (mussel shells) in coastal regions greatly perplexed local governments due to nondegradablility of the oyster shells (mussel shells) and exerts great influence on construction of livable cities; and with the help of the production process for the aerated concrete block, the life of people and the environment can be improved, the waste is turned into the valuable, the policy of cyclic utilization advocated by the government is abided by, and energy conservation and emission reduction are realized.

Owner:林强

Testing and metering method for content of sodium in coal

InactiveCN105510303ASolving the Problems Existing in Testing Sodium Content in CoalTest accuratePreparing sample for investigationAnalysis by thermal excitationWater bathsAsh preparation

The invention relates to an analysis method for chemical components of coal and discloses a more accurate testing and metering method for the content of sodium in coal. The method comprises the following steps: extraction of a coal sample; leaching of the coal sample; ash preparation at low temperature; respective measurement of the contents of Na2O in coal in the steps of leaching and ash preparation; and calculation of the content of and / or the content of sodium in the coal. In the step of leaching, the coal sample and ultrapure water or a hydrochloric acid solution with a concentration of 0.1 to 0.5 mol / L are maintained in a constant-temperature water-bath shaking table at a constant temperature of 40 to 80 DEG C for 2 to 24 h; then leaching liquid and a filter residue are separated in vacuum; an inductively coupled plasma atomic emission spectrometer (ICP) is employed to measure the content of sodium in filtrate; calculation is carried out so as to obtain the content of Na2O; and the obtained filter residue is dried and metered, and ash preparation is carried out at 550 to 700 DEG C. The method provided by the invention realizes more accurate testing and metering of sodium in coal and is favorable for better research on the proportions of sodium of different occurrence forms and the migration rule of sodium at different temperatures.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

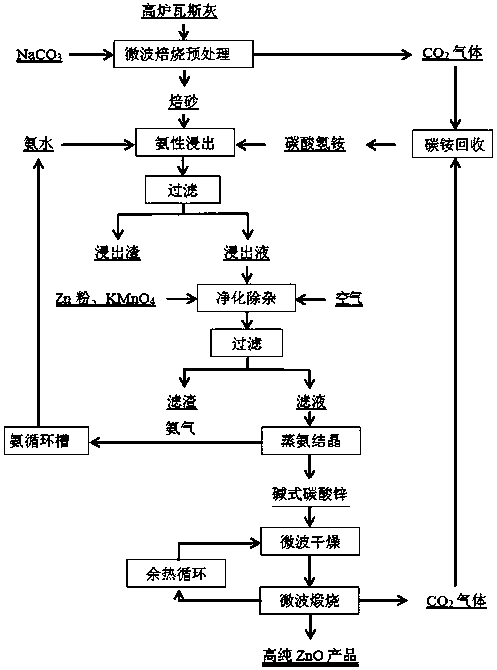

A method for preparing ZNO from microwave roasting pretreatment-ammonia leaching blast furnace gas ash

ActiveCN105543490BImprove leaching rateShorten the leaching timeProcess efficiency improvementSlagDistillation

Owner:KUNMING UNIV OF SCI & TECH

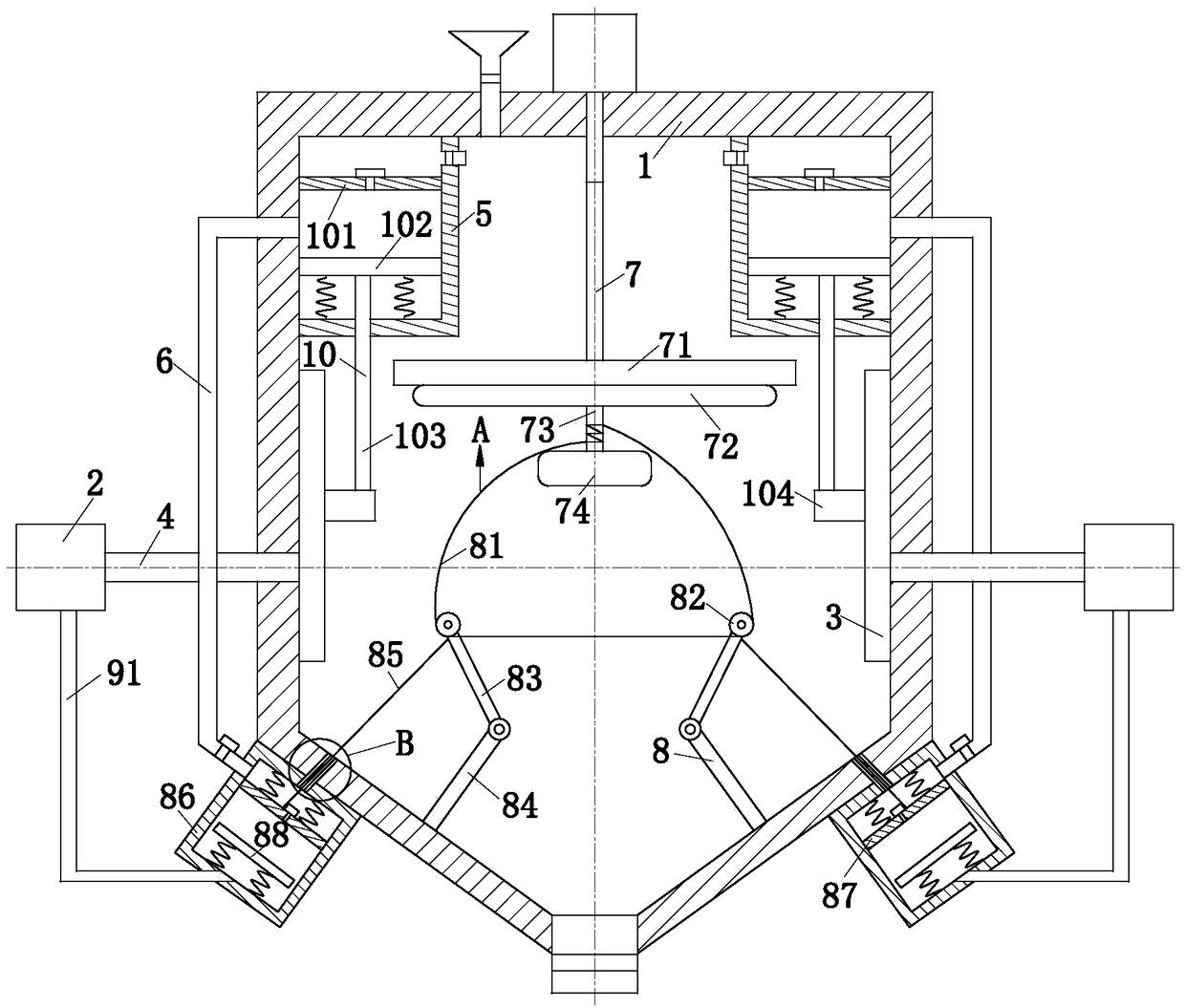

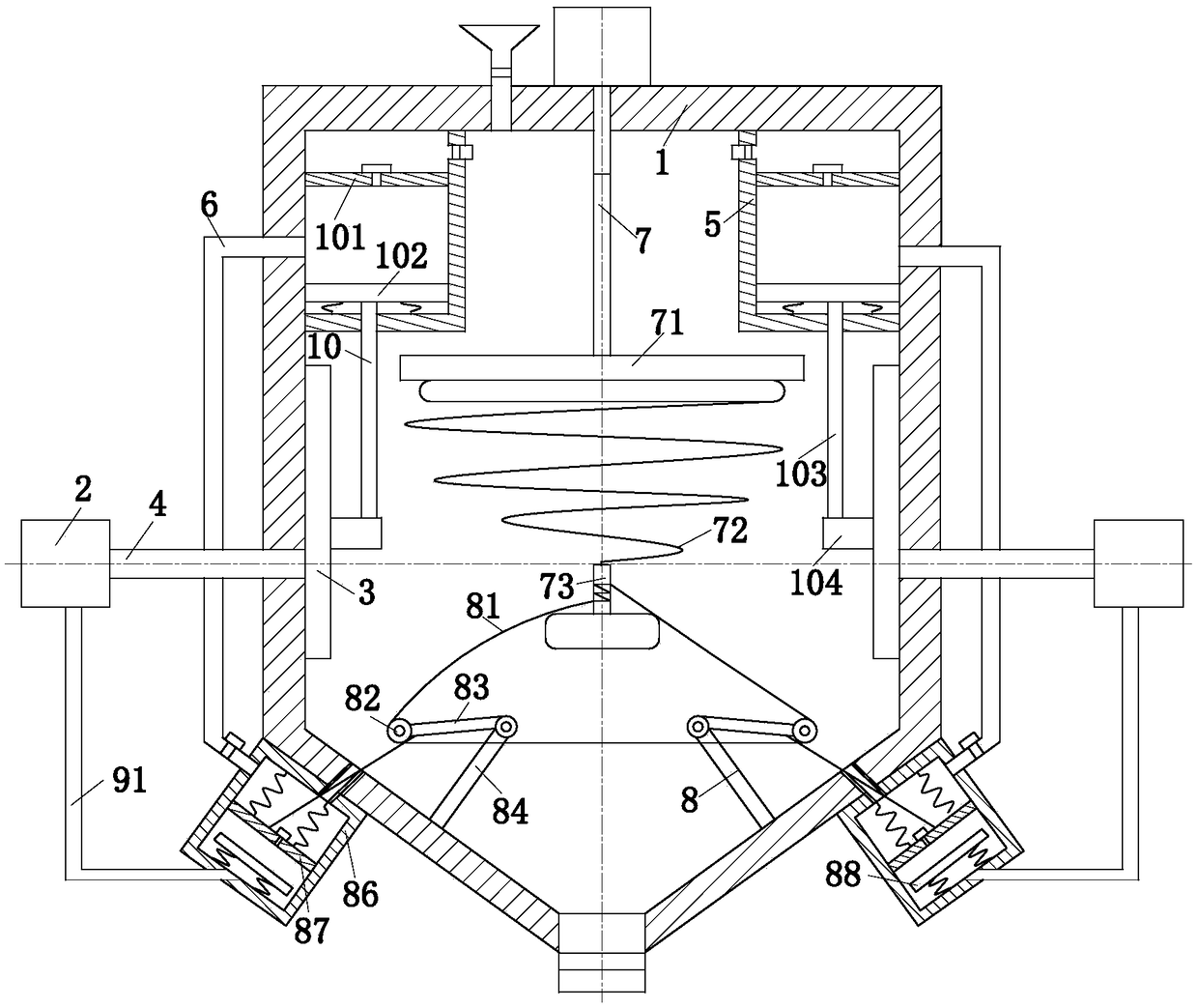

Lime kiln tumor breaking machine device in underground circulating soda ash preparation

PendingCN113091475ALabor intensiveAvoid damageIncrustation removal devicesLime productionLime kilnMechanical equipment

Owner:江苏苏盐井神股份有限公司 +1

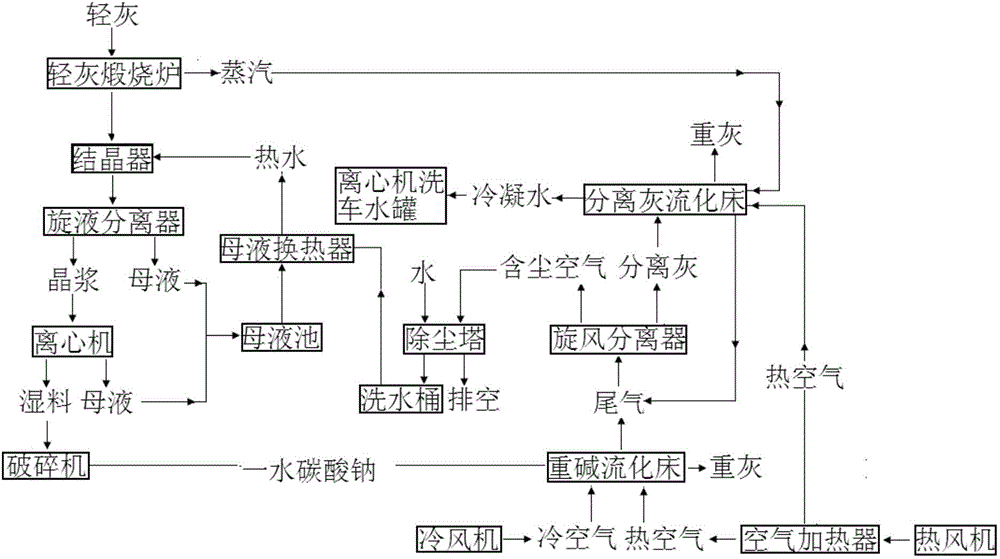

Liquid-phase hydration method separation ash treatment process

InactiveCN104528774AAvoid pollutionReduce wasteVarying alkali metal carbonate water contentCyclonic separationFluidized bed

The invention provides a liquid-phase hydration method separation ash treatment process comprising the following steps: (1) a sodium carbonate monohydrate wet material is prepared with a liquid-phase hydration method; (2) the sodium carbonate monohydrate wet material is added into a heavy ash fluidized bed, and drying is carried out, such that heavy ash is obtained; tail gas produced in the heavy ash fluidized bed is separated in a cyclone separator, such that separation ash and dust-containing air are obtained; (3) the separation ash is added into a separation ash fluidized bed, and drying is carried out, such that heavy ash and separation ash tail gas are obtained; and the separation ash tail gas is subjected to cyclone separation again in the cyclone separator. The process provided by the invention has the following advantages: separation ash is subjected to the drying treatment on the basis of an original liquid-phase hydration method heavy ash preparation process, such that separation ash alkali content is improved, and heavy ash product quality is improved; a situation of low separation ash total alkali content and the restriction on variety alkali production of prior arts are solved.

Owner:青岛海湾集团有限公司

Method for preparing clay material for 3D printing

InactiveCN106336193AImprove plasticityImprove mechanical propertiesAdditive manufacturing apparatusClaywaresMaterials preparationAsh preparation

The invention discloses a method for preparing a clay material for 3D printing, and belongs to the technical field of preparation of materials for 3D printing, and the clay material for 3D printing is prepared by the following steps: clay material preparation, calcium carbonate powder preparation, plant ash preparation, low temperature crushing, addition of a specific synthetic agent and a starch synthesis agent for modification, extruding, granulating and the like. The clay material has the advantages of good plasticity, easy molding, good mechanical performance and high accuracy, is suitable for 3D printing technologies, promotes the popularization and application of the 3D printing technologies, and has a broad market prospect.

Owner:庞用

Novel clay material for 3D printing

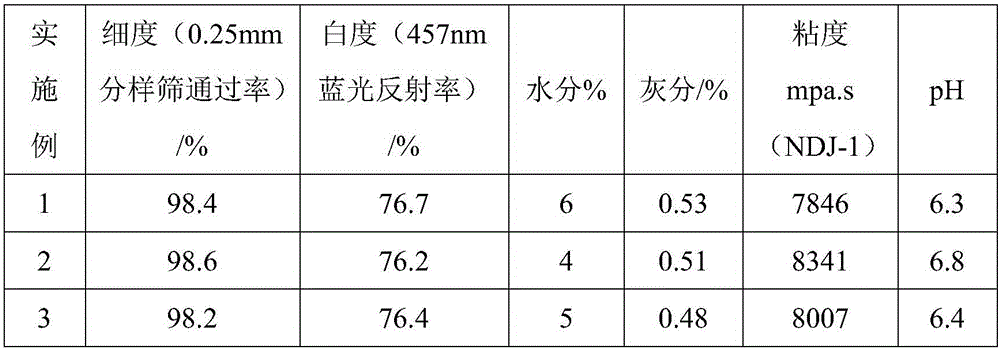

InactiveCN106278146AImprove wear resistanceHigh impact strengthAdditive manufacturing apparatusCeramic materials productionMaterials preparationAsh preparation

The invention discloses a novel clay material for 3D printing and belongs to the technical field of preparation of materials for 3D printing. The novel clay material for 3D printing is prepared from the following raw materials: clay material, calcium carbonate powder, plant ash, a particular composition, a starch composition, and water, in a mass ratio of (20-30): (8-16): (6-10): (5-8): (4-6): (10-25). The novel clay material for 3D printing is prepared through the steps of clay material preparation, calcium carbonate powder preparation, plant ash preparation, crushing at a normal temperature, adding of the particular composition and the starch composition for modification, extruding granulation, etc. The clay material of the invention has high abrasive strength, impact strength and shock strength, good plasticity, favorable formability, high precision, and the like, and is applicable to the 3D printing forming technique; the popularization and application of the 3D printing forming technique are promoted; and the clay material has favorable market prospect.

Owner:NANNING MENGHUAN 3D ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of efficient and harmless treatment method of mine copper cyanide wastewater

ActiveCN110885108BStrong specific adsorption capacityAchieve recyclabilityWaste water treatment from quariesOther chemical processesAluminium chlorideEmulsion

The invention discloses a method for efficient and harmless treatment of copper cyanide wastewater in mines, comprising the following steps: step 1, preparation of modified straw ash: adding straw ash to deionized water and ultrasonically dispersing for 30-40 minutes, and the ultrasonic power is 300-40 minutes 400W, then add ferric chloride and aluminum chloride in turn and continue to stir for 20-30min. The modified straw ash used in the present invention is treated with raw materials such as ferric chloride and aluminum chloride, then compounded with modified bentonite, and finally through the establishment of a blending system. The use of straw ash has the potential of resource reuse. The effect is in line with the concept of environmental protection. The modification of bentonite is poured with a modified liquid. The modified liquid can form a pore structure in the bentonite, so that the straw ash enters the bentonite, and finally seals the pores with the microsphere emulsion to prepare the material. Has a strong specific adsorption capacity.

Owner:安徽焦冲矿业有限公司

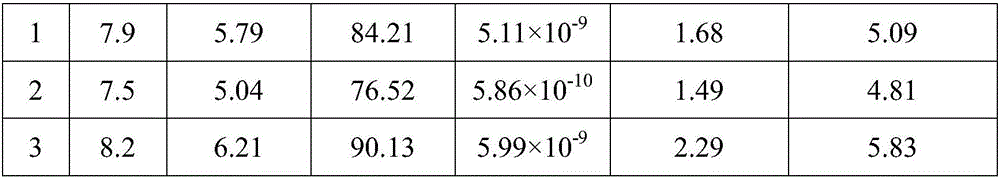

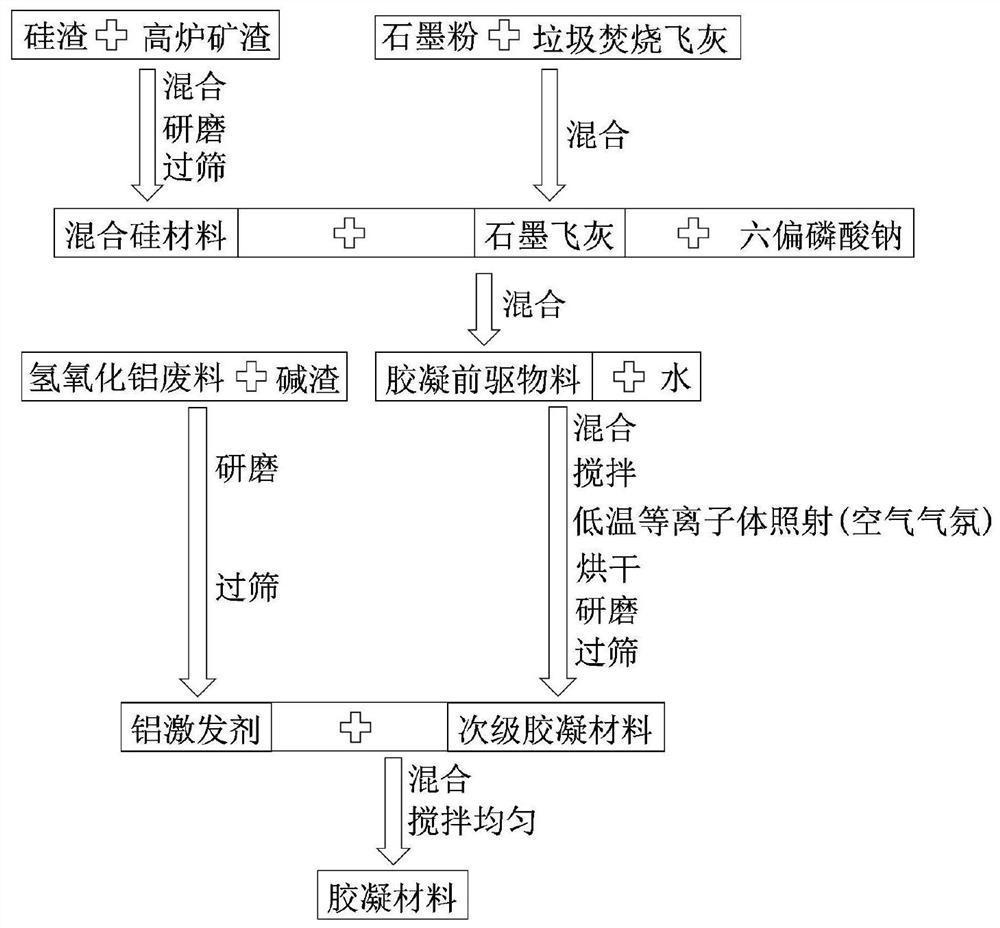

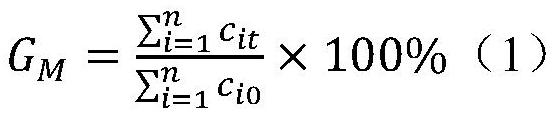

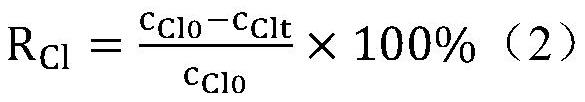

A method for preparing non-sintering cementitious material by using waste incineration fly ash

ActiveCN111592246BImplement resourcesAvoid secondary pollutionCement productionAluminium hydroxideSlag

Owner:浙江慧科环保科技有限公司

Preparation of a descaling and antiscaling agent for ash removal water system

ActiveCN101851028BEliminate the disadvantage of easy hydrolysisGood dispersionScale removal and water softeningPhosphateAsh preparation

The preparation of a kind of descaling and antiscaling agent used in the deashing water system provided by the present invention is prepared raw materials in parts by weight, consisting of 28-35 parts of itaconic acid-styrenesulfonic acid-acrylic acid copolymer, 27 parts of polyol phosphate -36 parts, 16-23 parts of glycolic acid, 19-25 parts of pure water; its best preparation: 30 parts of itaconic acid-styrenesulfonic acid-acrylic acid copolymer, 30 parts of polyol phosphate, 20 parts of glycolic acid, It is composed of 20 parts of pure water; when preparing, add pure water first, then put its components into the reaction kettle in turn, stir for 40-50 minutes, and control the temperature at 20-35°C to obtain the product; among them, itaconic acid-styrenesulfonic acid- For the synthesis of acrylic acid copolymer, take 10-14 parts of itaconic acid, 5-7 parts of styrenesulfonic acid, 3-5 parts of isopropanol, and 30-38 parts of pure water, put them into the reaction kettle in turn, stir, and heat to 95°C , dropwise add 22-25 parts of acrylic acid and 2 parts of ammonium persulfate solution (dilute with 18 parts of water first), control the dropwise addition within 30 minutes, keep warm for 110-122 minutes, drop to room temperature and discharge, pH value 1.5-2.5 , It can be obtained when it is light yellow transparent liquid. This product is used for descaling and antiscaling of ash removal water in power plants and reinjection water in oil fields, and the dosage is 5-10mg / L.

Owner:XINJIANG DELAND

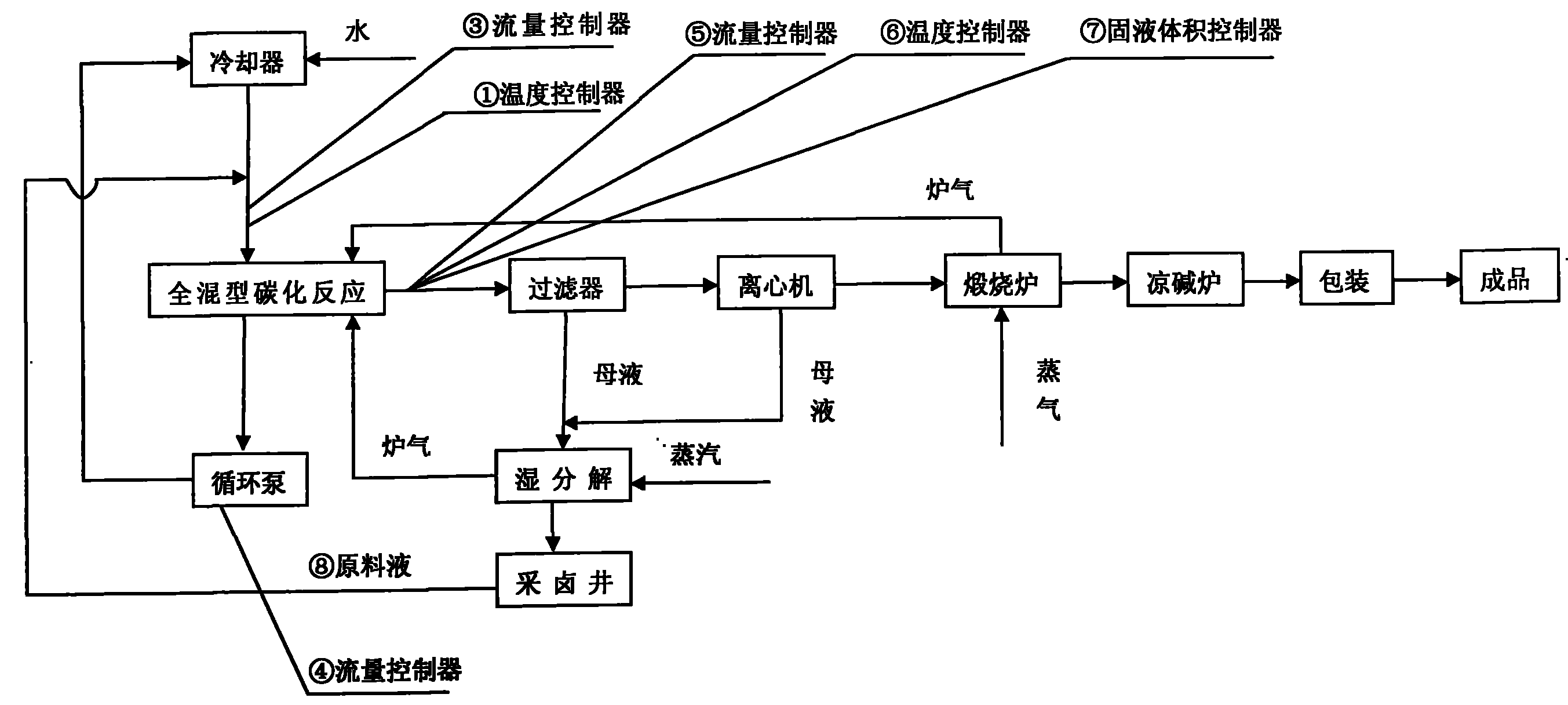

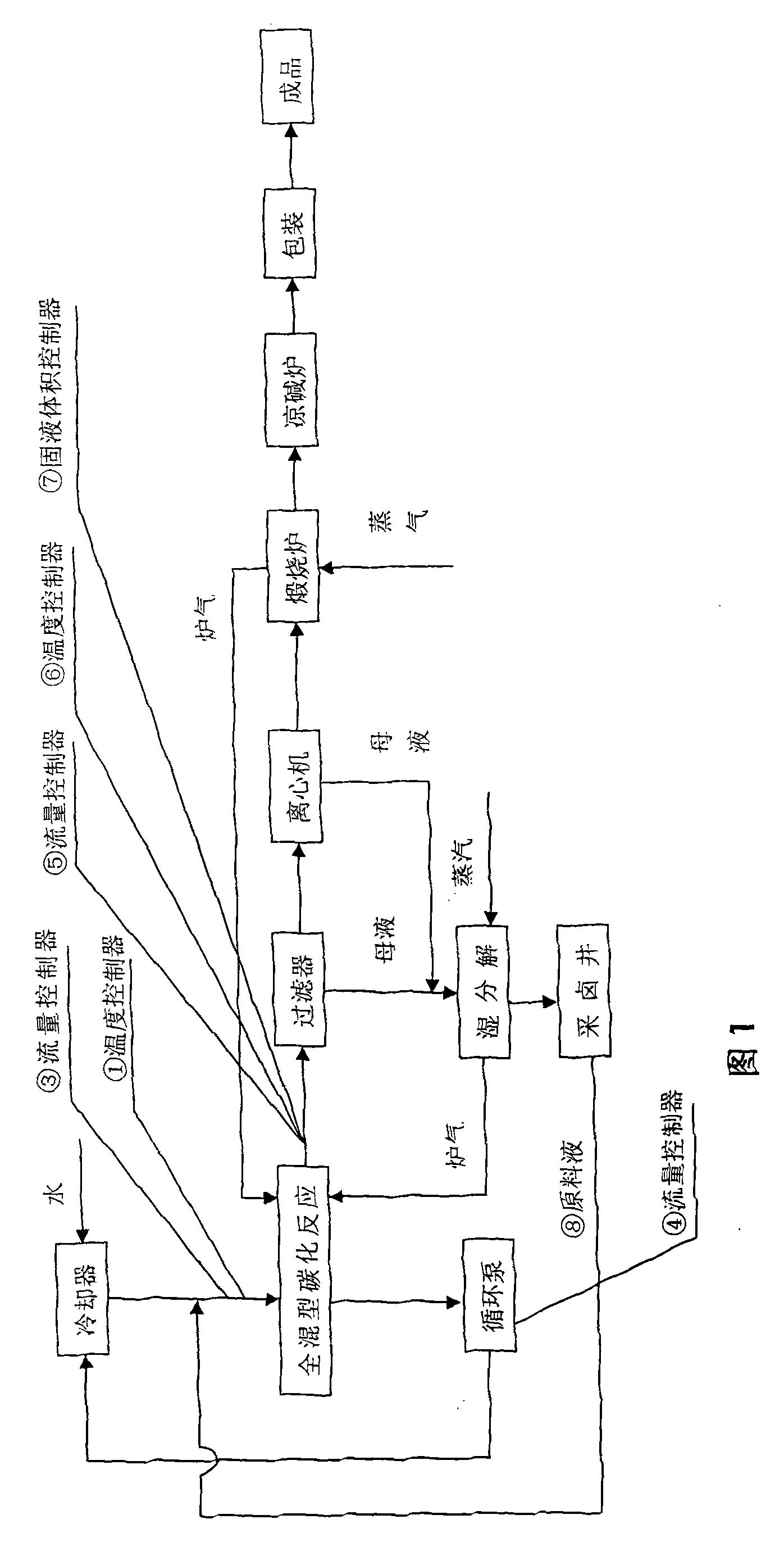

Process for preparing calcined soda by high salt low alkali forced-circulation carbonization

ActiveCN101475195BIncrease profitRealize fully enclosed operationCarbonate preparationCarbonizationProcess engineering

The invention discloses soda ash preparation technology by a high-salt low-alkali forced circulation carbonization method, which comprises the following steps that: a soda solution is pumped into a forced circulation full mixing type carbonization tank, and a device is orderly provided with a carbonization system, a separation system and a calcination system; a raw material liquid with the composition of Na2CO3, NaHCO3 and NaCl, and a temperature of between 50 and 52 DEG C and furnace air CO2 are injected into a circulation pump of the carbonization system respectively; and the raw material liquid passes through the carbonization system, the separation system and the calcination system, and finally reaches a packaging system to obtain a finished product of granular light soda ash. The technology mainly takes sesquibasic low-alkali high-salt as a raw material to pass through a full mixing type carbonization reactor through the steps of controlling process indexes, improves production efficiency, also improves the utilization rate of the raw material, realizes the fully-closed operation of the flow, and ensures that the production process is continuous, steady and safe.

Owner:HENAN ZHONGYUAN CHEM

Ammoniated treatment method by taking radix rubiae as feed

InactiveCN109221657AHelps regulate enzymatic hydrolysisAvoid destructionAnimal feeding stuffAccessory food factorsFiberMedicine

The invention belongs to the technical field of radix rubiae ammoniated treatment and in particular relates to an ammoniated treatment method by taking radix rubiae as feed. The method comprises the following steps: collecting radix rubiae, separating leaves from stems and vines, preparing a plant ash preparation, and performing ammoniated treatment. Compared with the prior art, the method disclosed by the invention has the advantages that the leave, stems and vines of the radix rubiae are respectively treated, the stems and vines are fixed and disinfected with a warm salt solution, the plantash preparation is prepared by taking the leaves as raw materials, the prepared plant ash preparation comprises active materials and organic components capable of regulating enzymolysis of crude fibers, xylogen and lignin compounds in radix rubiae stems and vines, the ammoniation conditions are strictly controlled, the active ingredients in the stems and vines are avoided from being damaged, and the ammoniation time is shortened, so that the ammoniation material of radix rubiae is complete in ammoniation and is difficult to rot or stink and easy to store, the nutritive materials are well maintained, and the immunity of the animals is enhanced while maintaining comprehensive nutrition.

Owner:蚌埠市金牛湾农业科技发展有限公司

Liquid-phase hydration separation ash treatment process

InactiveCN104528774BAvoid pollutionReduce wasteVarying alkali metal carbonate water contentFluidized bedCyclonic separation

The invention provides a liquid-phase hydration method separation ash treatment process comprising the following steps: (1) a sodium carbonate monohydrate wet material is prepared with a liquid-phase hydration method; (2) the sodium carbonate monohydrate wet material is added into a heavy ash fluidized bed, and drying is carried out, such that heavy ash is obtained; tail gas produced in the heavy ash fluidized bed is separated in a cyclone separator, such that separation ash and dust-containing air are obtained; (3) the separation ash is added into a separation ash fluidized bed, and drying is carried out, such that heavy ash and separation ash tail gas are obtained; and the separation ash tail gas is subjected to cyclone separation again in the cyclone separator. The process provided by the invention has the following advantages: separation ash is subjected to the drying treatment on the basis of an original liquid-phase hydration method heavy ash preparation process, such that separation ash alkali content is improved, and heavy ash product quality is improved; a situation of low separation ash total alkali content and the restriction on variety alkali production of prior arts are solved.

Owner:青岛海湾集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com