Method for generating electricity by burning wet coal ash from Ender furnace

A technology of burning power generation and wet coal ash, which is applied in the direction of combustion method, fuel burned in molten state, combustion type, etc., to achieve the effect of reducing pollution and occupying land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

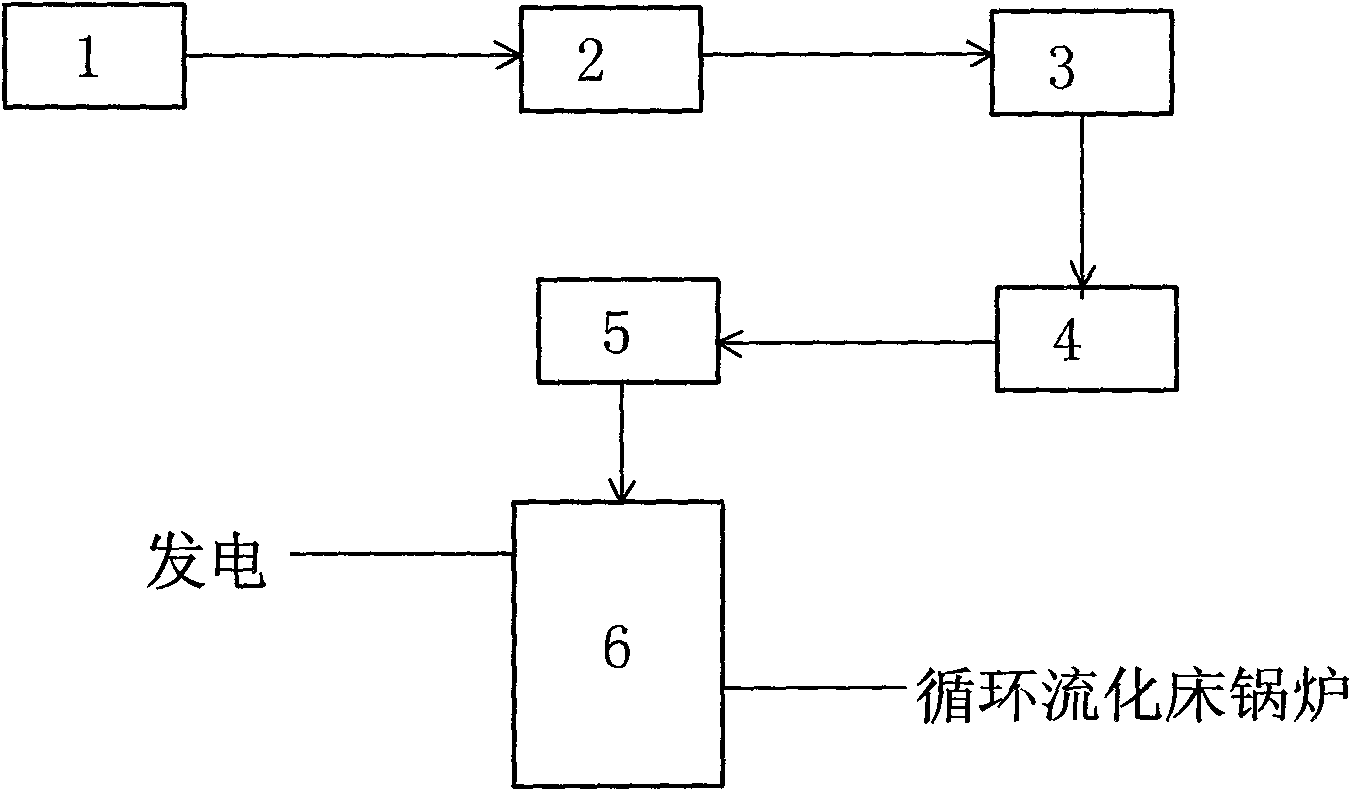

[0015] 1. Wet coal ash preparation process

[0016] The wet coal ash generated from the Ender gas furnace is collected and stored in the silo as raw material for wet coal ash.

[0017] 2. Wet coal ash strong mixing process

[0018] The wet coal ash raw material in the silo is added to a strong mixer for stirring, so that the wet coal ash is homogenized to form homogenized wet coal ash.

[0019] 3. Wet coal ash screening process

[0020] Put the homogenized wet coal ash into the vibrating sieve for vibratory screening, separate the large particles, and pass through the 100×100mm sieve to become wet coal ash powder.

[0021] 4. Water-adding pulping process

[0022] Add 30-50% of water to the wet coal ash powder according to the mass percentage, and stir to form the wet coal ash slurry.

[0023] 5. Pipeline transportation process

[0024] The wet coal ash slurry is delivered to the wet coal ash inlet at the upper end of the circulating fluidized bed boiler through the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com