Patents

Literature

2021 results about "Circulating fluidized bed boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

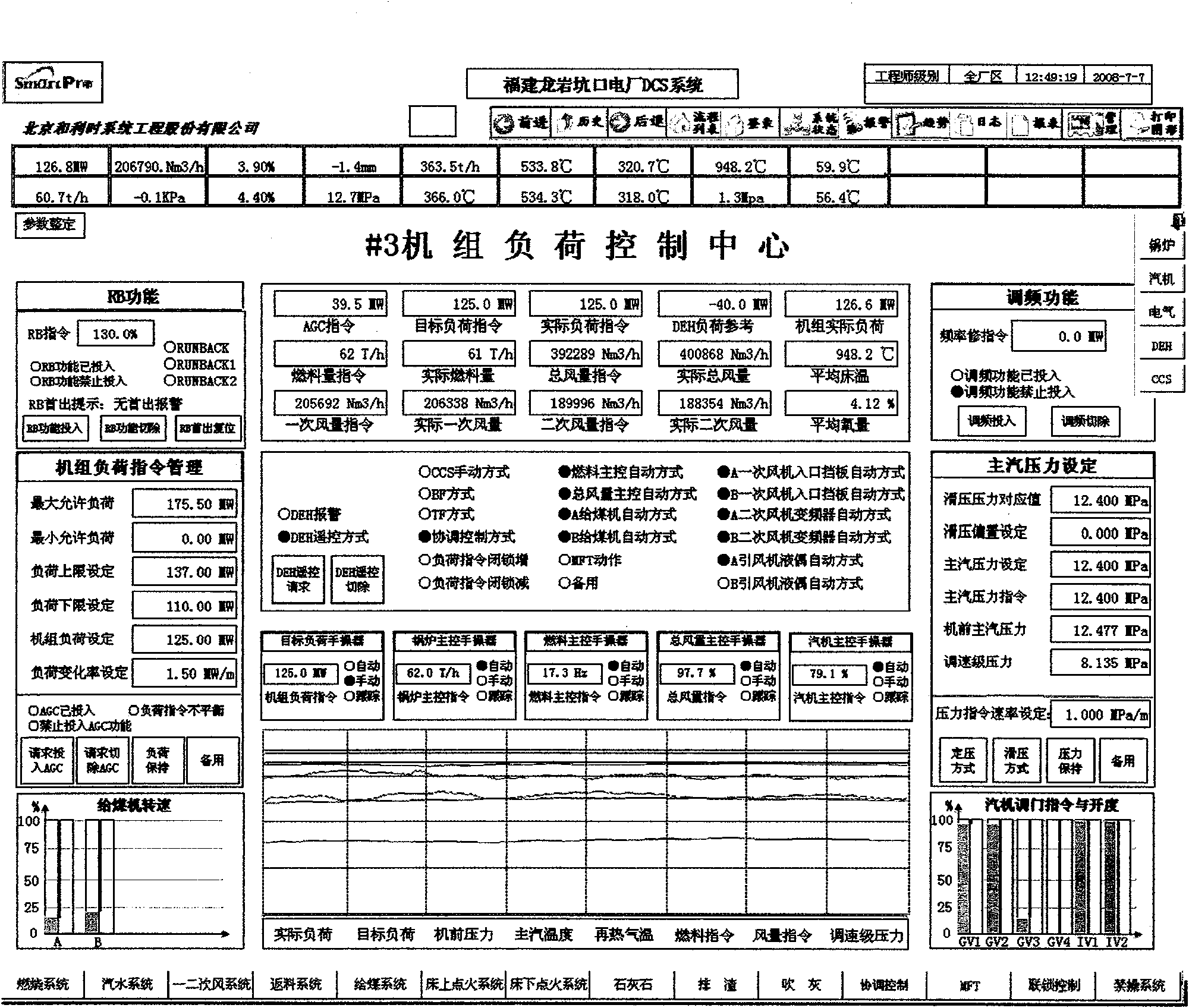

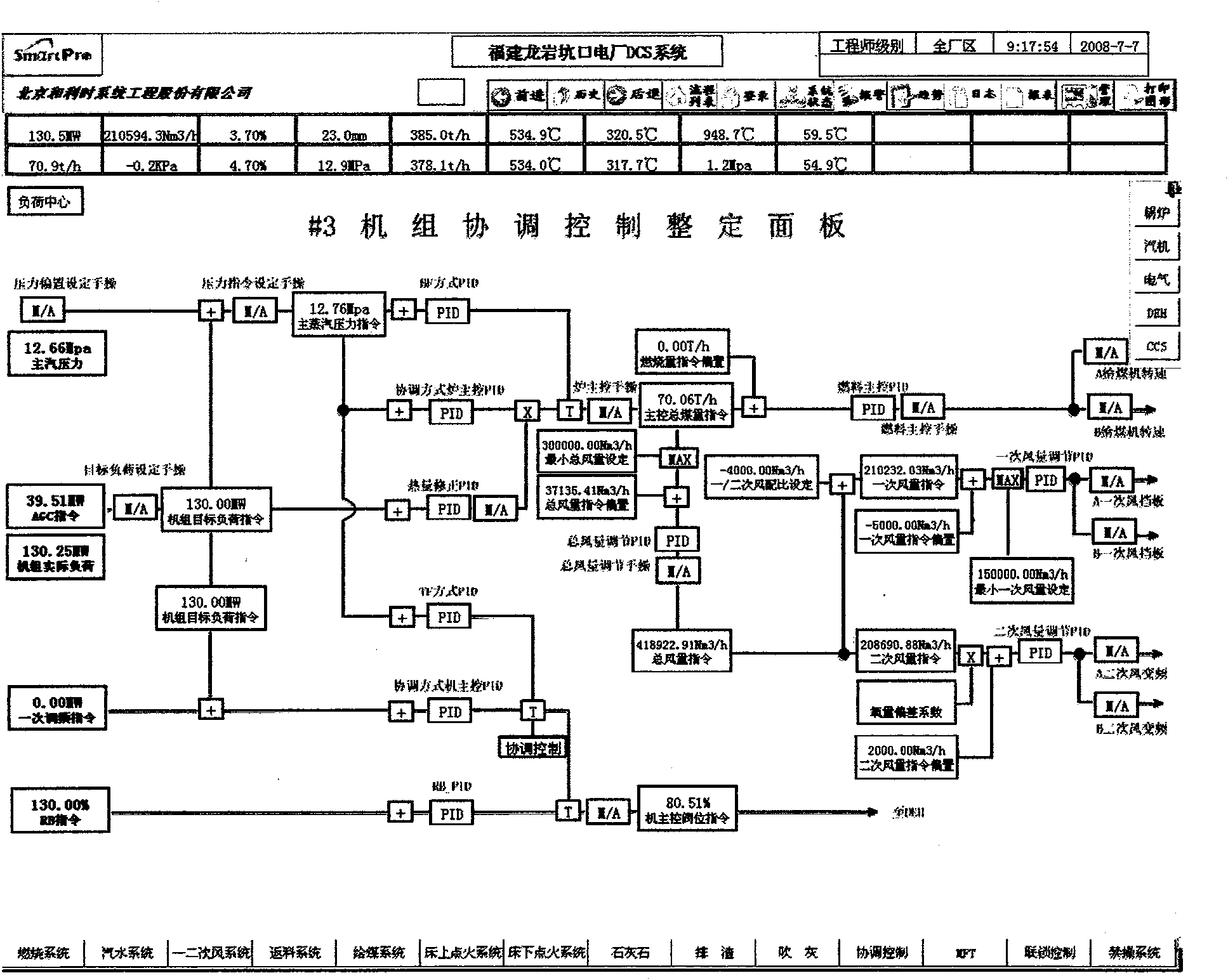

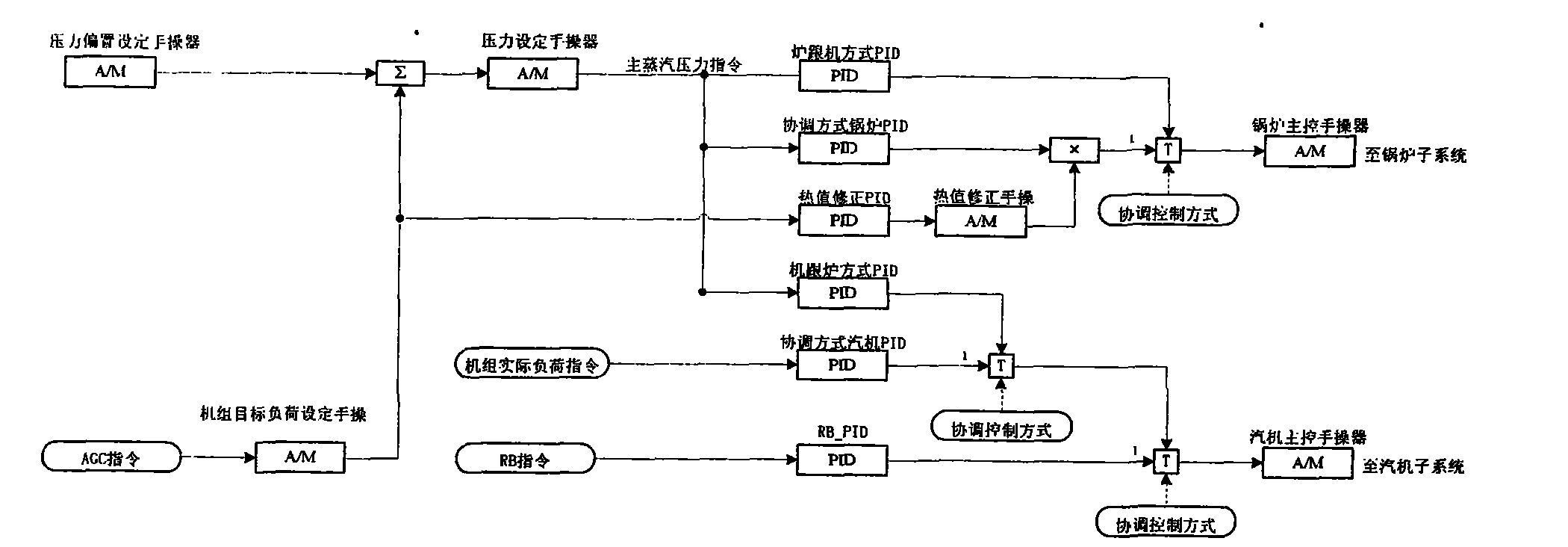

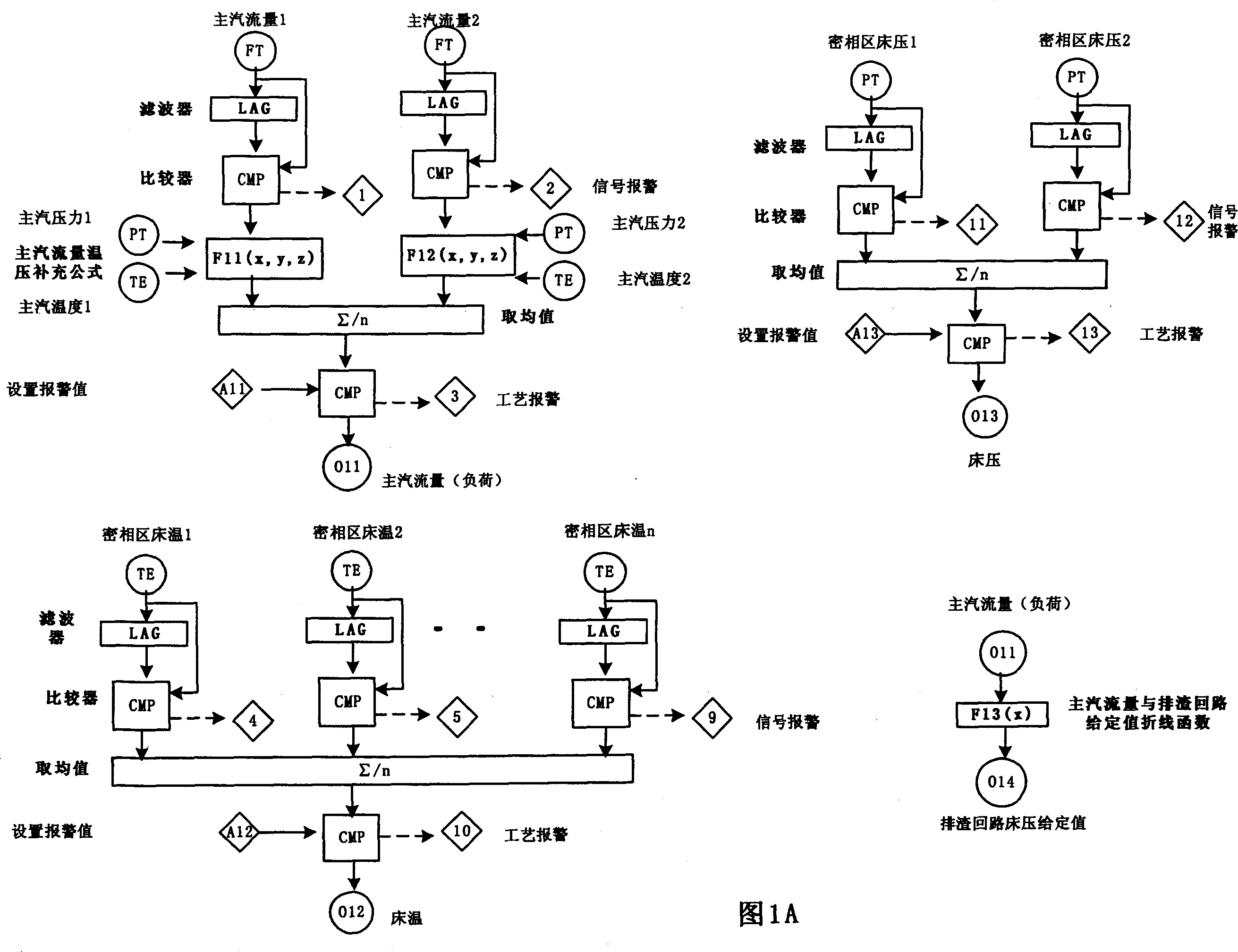

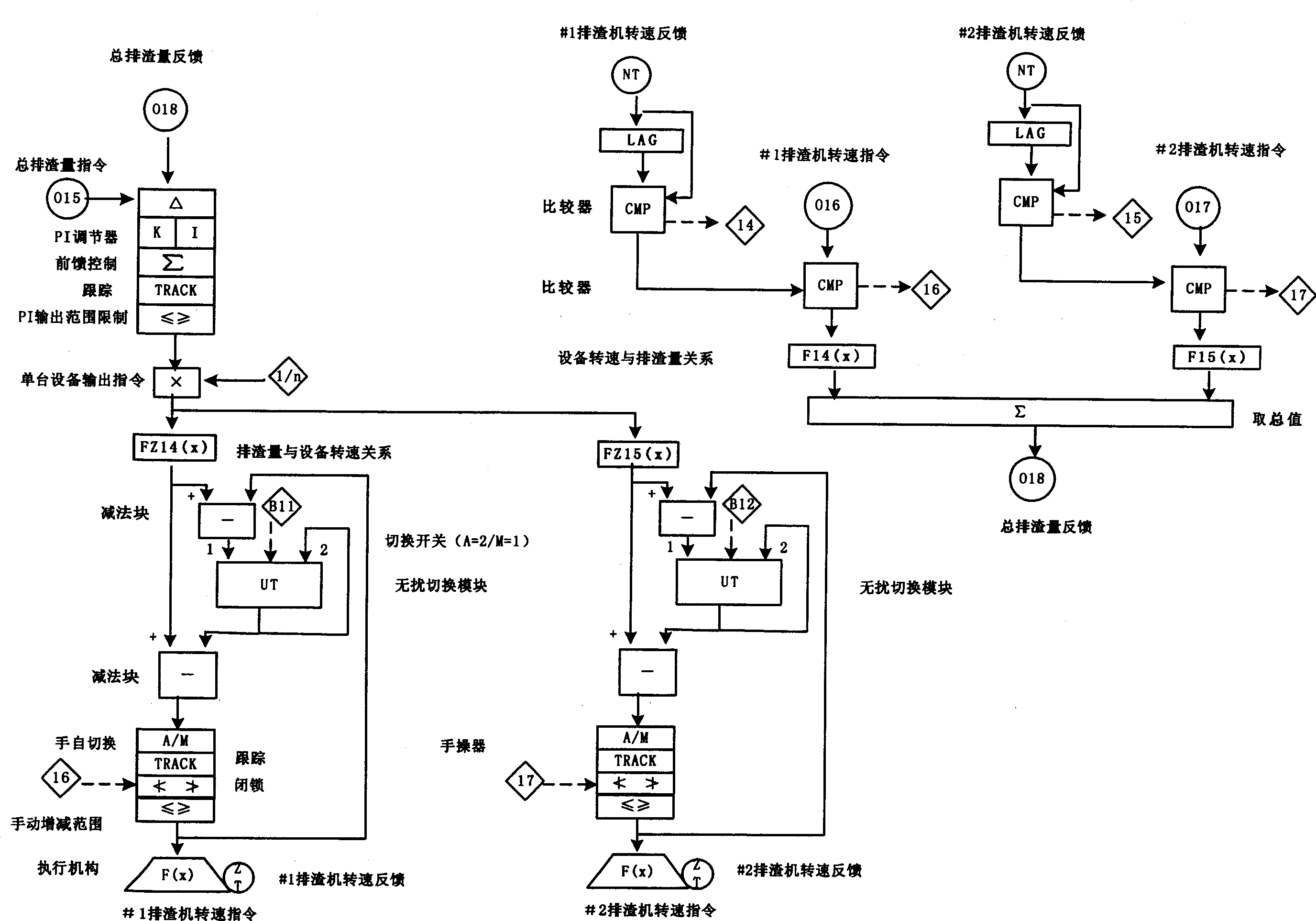

Coordinated control system (CCS) of large-size circulating fluidized bed boiler (CFBB) unit

ActiveCN101788809ARealize the coordinated control function of machines and furnacesImprove response speedFluidized bed combustionTotal factory controlControl functionCirculating fluidized bed boiler

The invention discloses a coordinated control system (CCS) of a large-size circulating fluidized bed boiler (CFBB) unit, consisting of a computer algorithm realization program and a human-machine interface program (HMI). The computer algorithm realization program mainly processes data and executes corresponding logical operation according to input parameters and outputs a turbine and boiler coordinated control instruction to various closed loop control systems of a dispersion control system (DCS). The HMI provides a human-machine interface which carries out instruction interaction with low-layer control equipment for a running operator and consists of a CCS operation interface and a parameter resetting panel. The system mainly achieves the coordinated control function of the CFBB unit andthe aims of completely and automatically controlling the generation process of the CFBB unit and reducing the labor intensity and economic running of the running operators.

Owner:HANGZHOU HOLLYSYS AUTOMATION

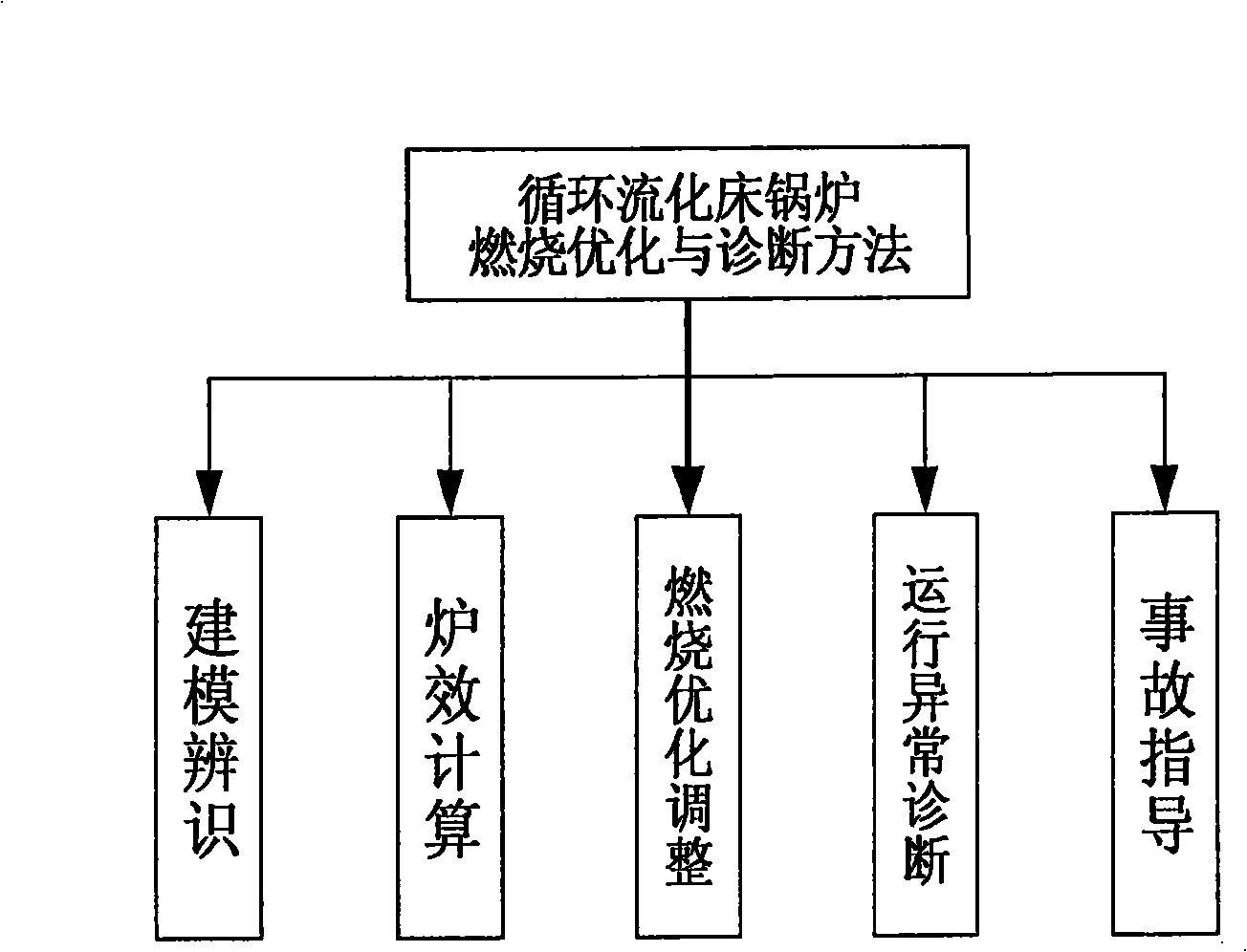

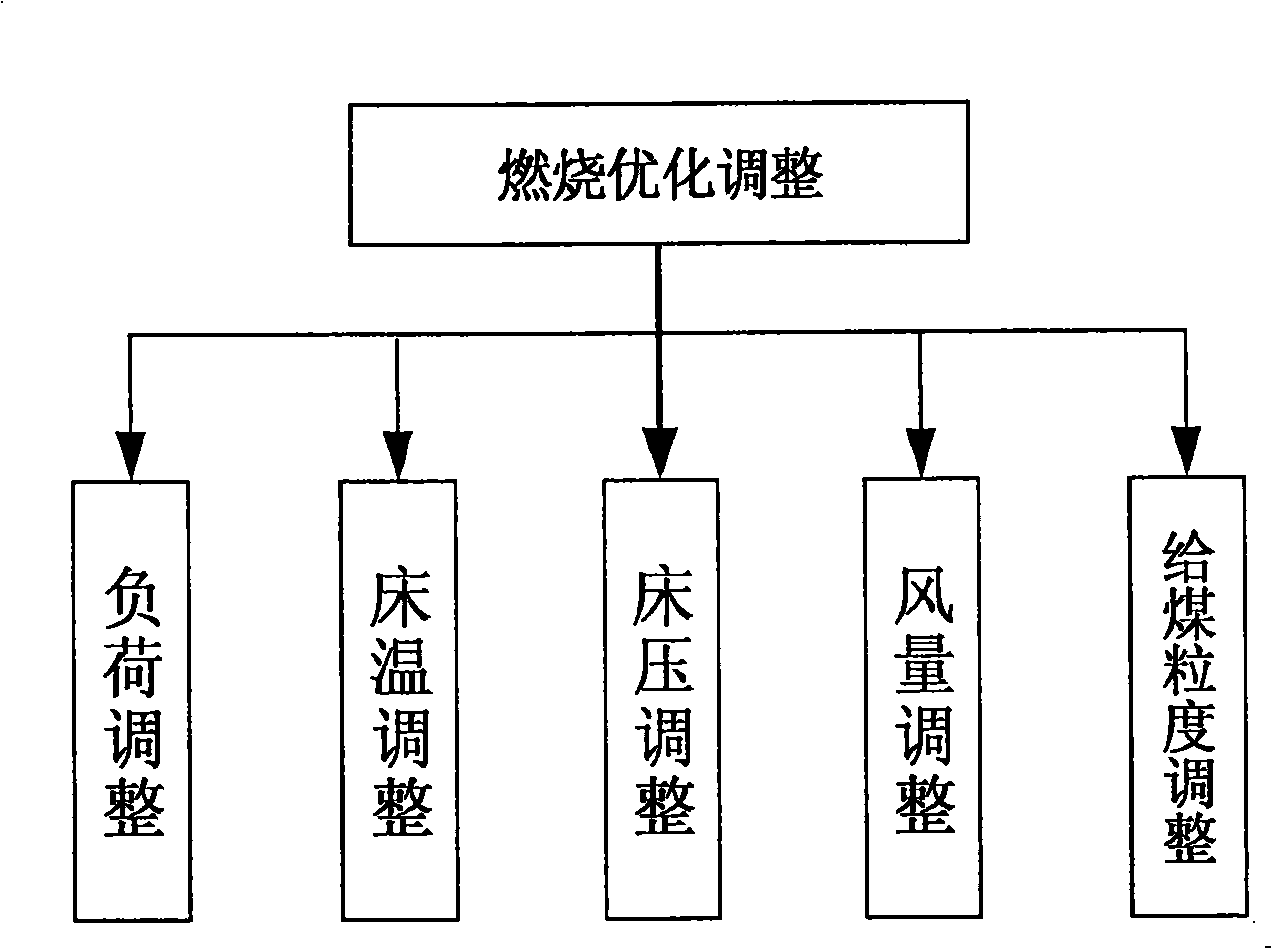

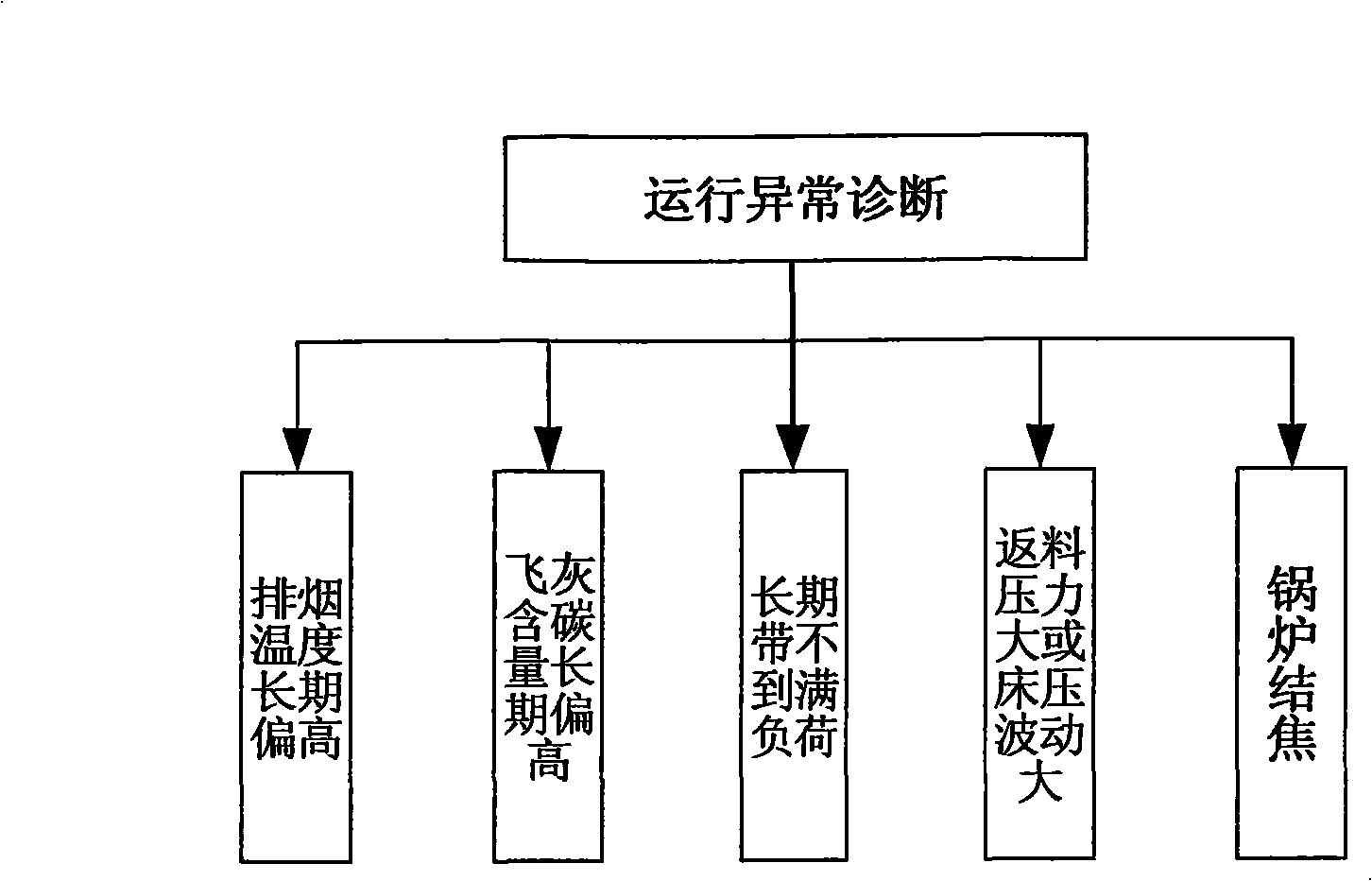

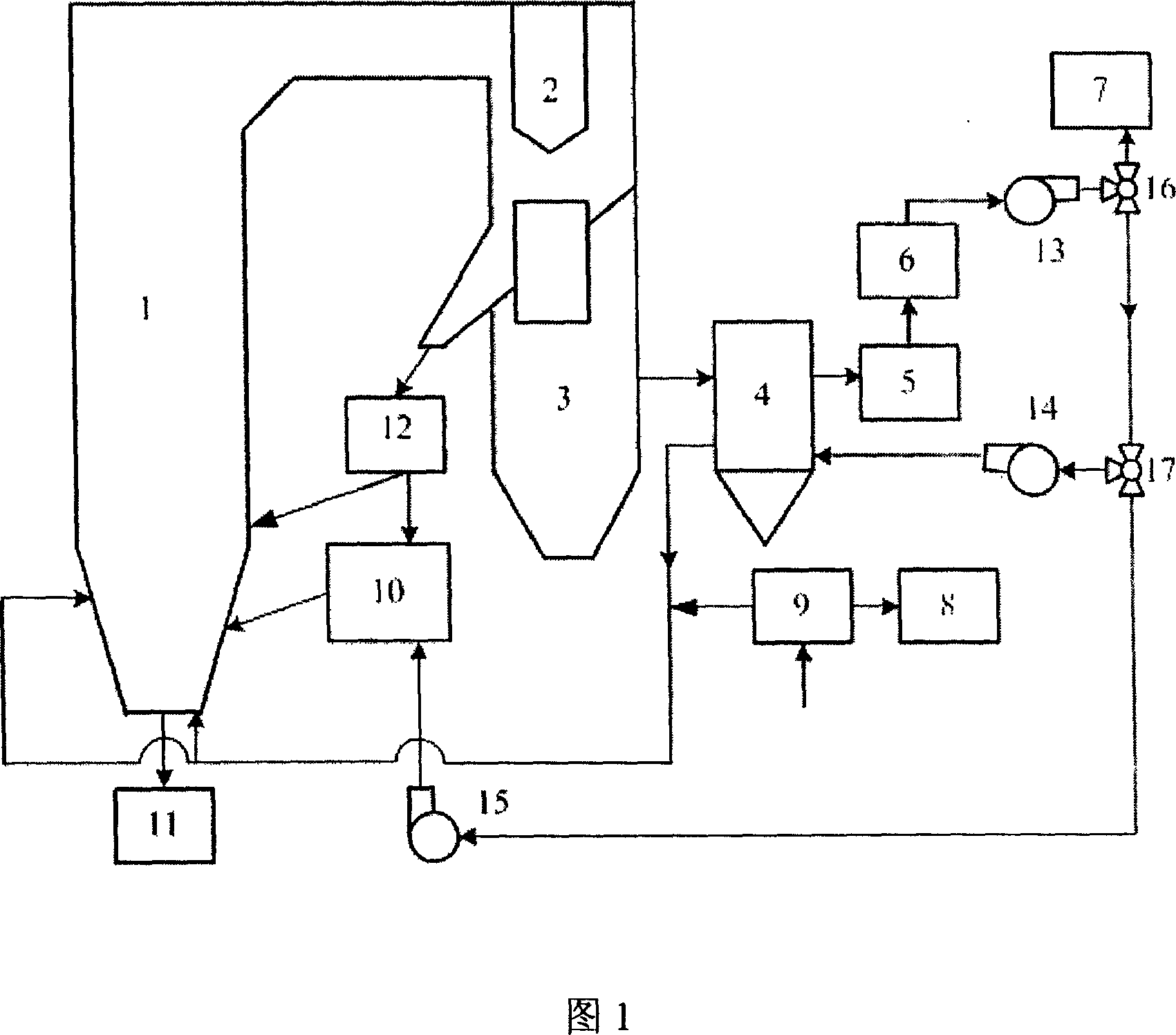

Method for optimizing and diagnosing circulating fluid bed boiler combustion

InactiveCN101329582AImprove economyFix security issuesElectric testing/monitoringAdaptive controlAir volumeEngineering

The invention relates to a circulating fluidized bed boiler combustion optimization and diagnosis method for acquiring and sorting out operation data such as bed temperature, bed pressure, load, efficiency, coal supply amount, limestone supply amount, primary air volume, primary wind pressure, upper secondary air volume and wind pressure, lower secondary air volume and wind pressure, oxygen content, induced air volume, slagging amount, NOx, Sox, etc., to build a neural network model as the basis for optimization adjustment and diagnosis. Field data of design value, measured value during operation, fuel chemistry assay value and etc. of the circulating fluidized bed boiler are utilized as the basis for optimization adjustment and diagnosis to calculate boiler efficiency as the basis for optimization adjustment and diagnosis; a judgment criterion for the optimization adjustment of combustion work condition is established and a corresponding solution is proposed, and therefore, optimization adjustment can be carried out when the circulating fluidized bed boiler deviates from the optimum combustion work condition; a judgment criterion for abnormal operation is established and a solution thereof is proposed; and therefore, problems which can not be solved after optimization adjustment can be diagnosed and analyzed. Common accident phenomena are summarized and processing strategies can be proposed, and therefore, guidance can be provided to accident handling.

Owner:SOUTHEAST UNIV

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

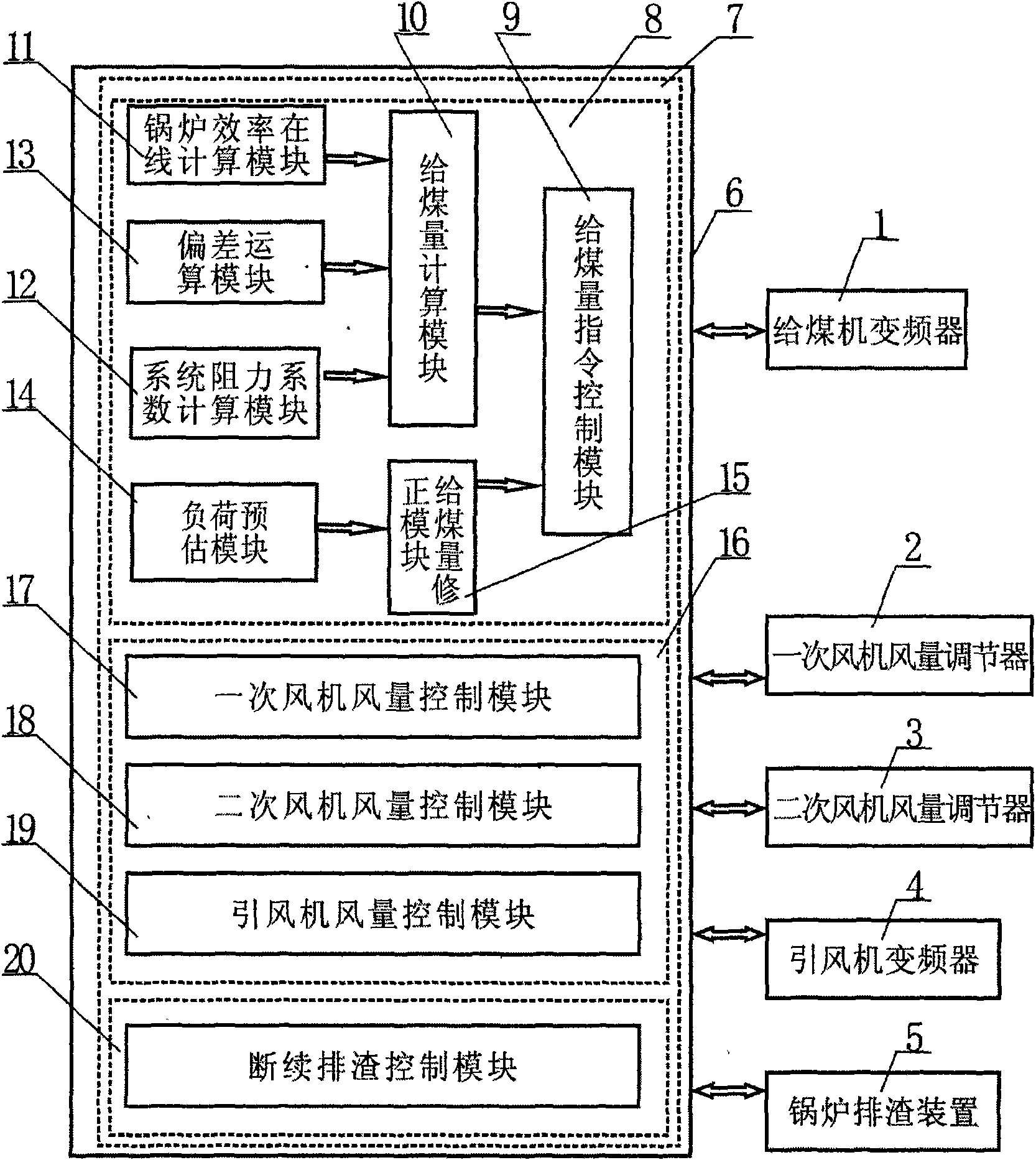

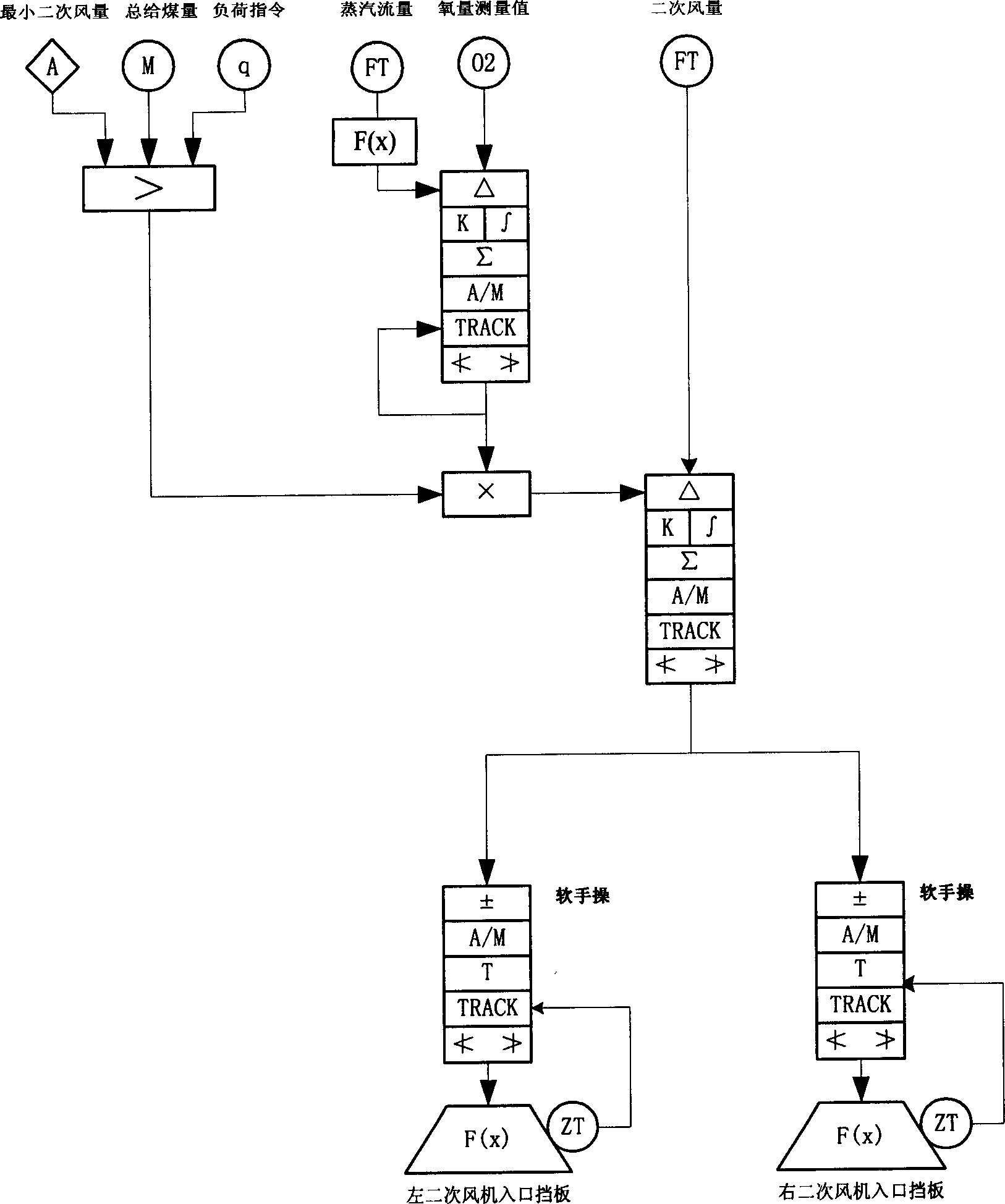

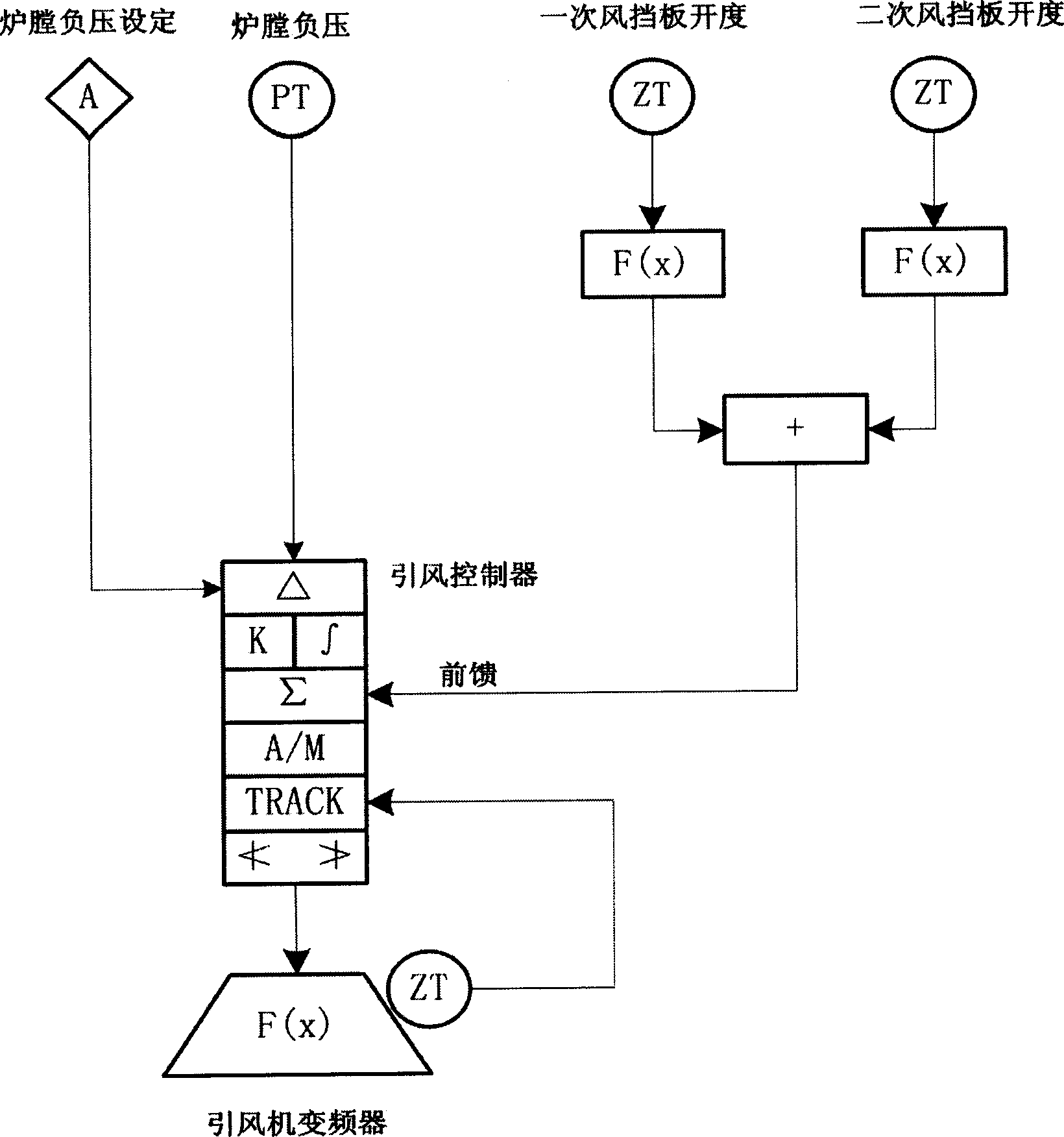

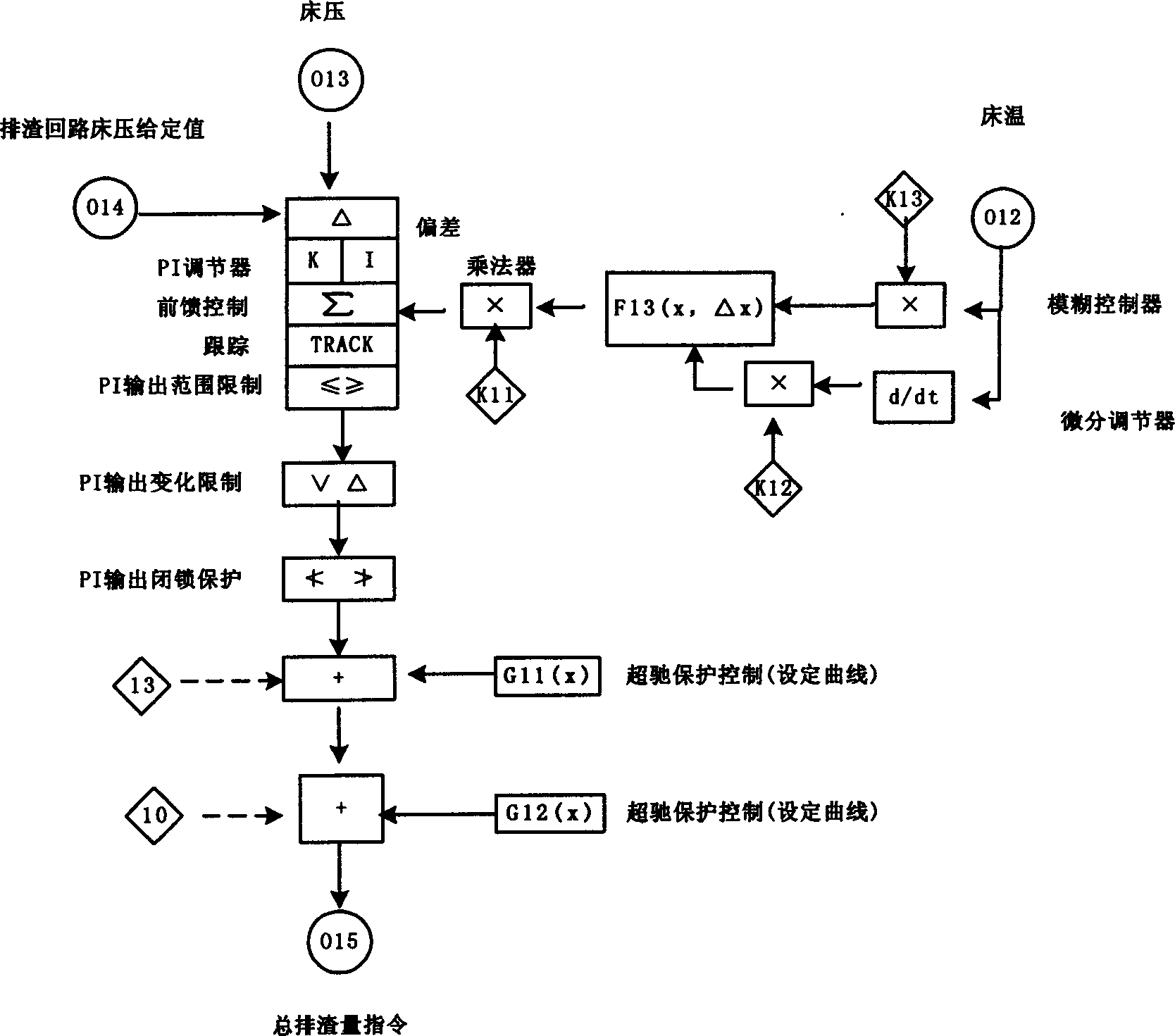

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

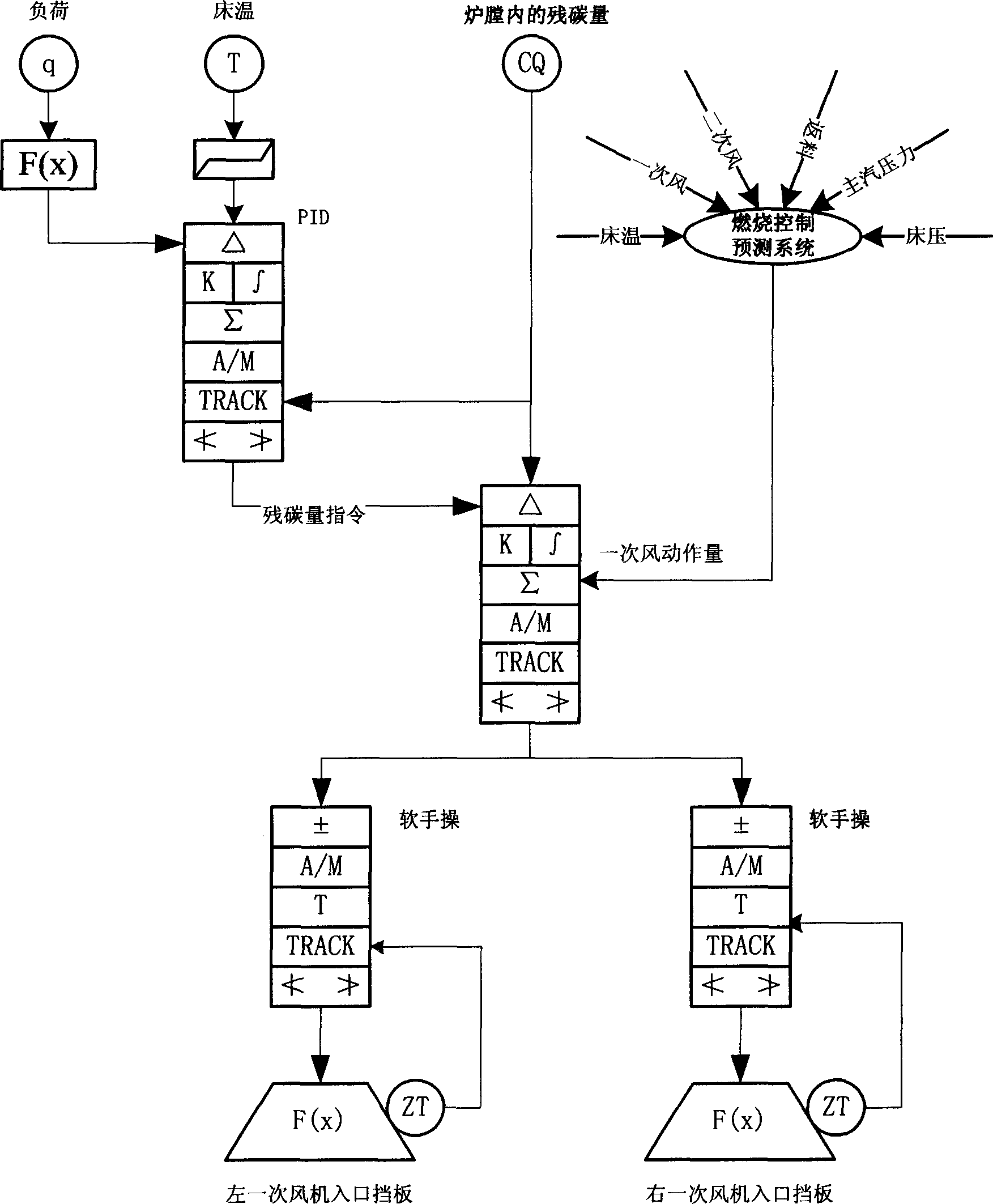

Method for controlling optimized burning in circulating fluid bed boiler

ActiveCN1916492AMeet instantaneous needsBalance and stabilityFluidized bed combustionApparatus for fluidised bed combustionCirculating fluidized bed boilerPower grid

A method for controlling combustion of circulation fluidized bed boiler includes using turbine to regulate load and using boiler to regulate pressure as well as using control system to receive load command when machine set is under coordination control system; carrying out uncoupling operation on load, main steam pressure, bed temperature and bed pressure of fluidized bed boiler when turbine load is changed greatly; and controlling carbon residual content in firepot for realizing energy balance control of machine set.

Owner:南京科远智慧能源投资有限公司

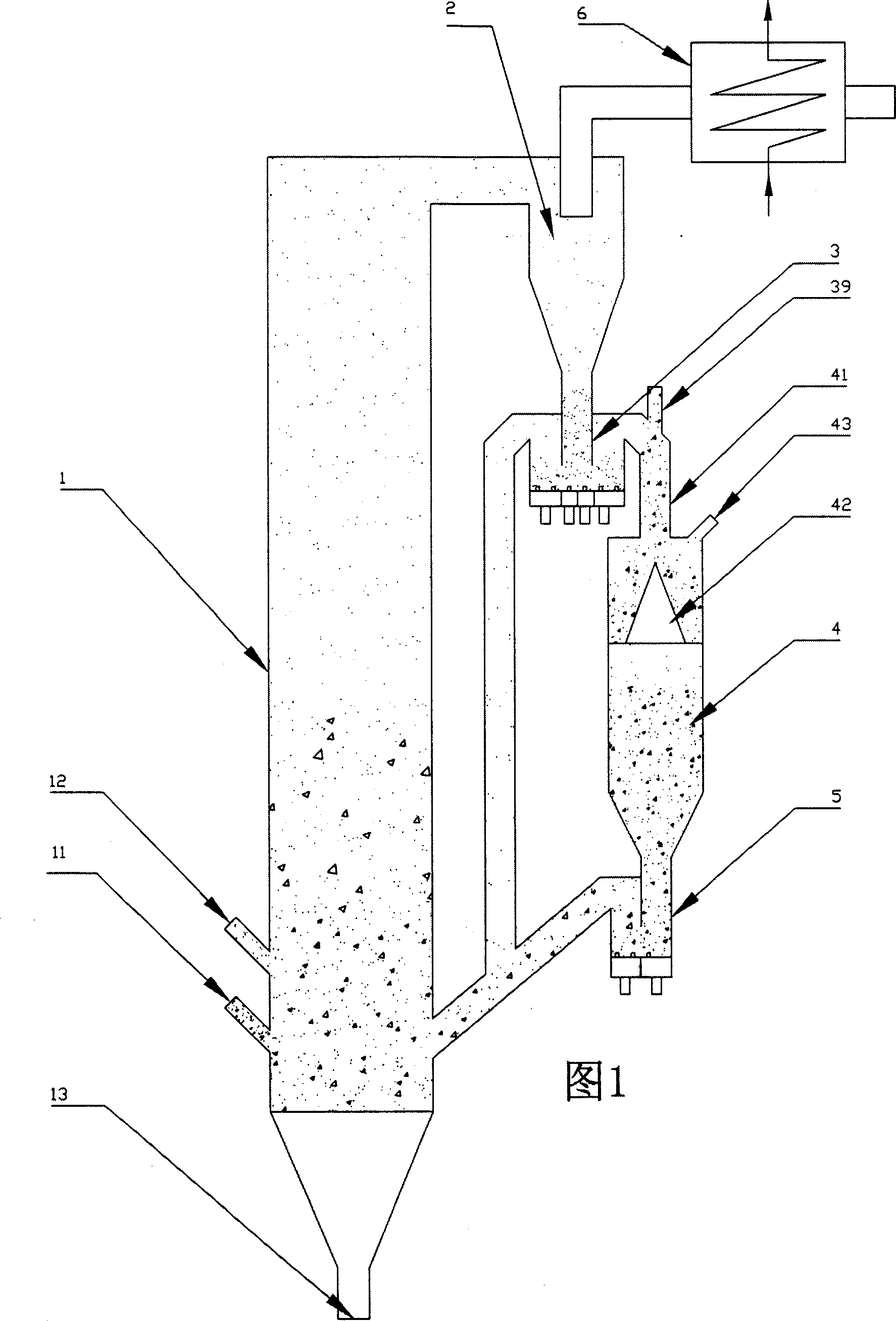

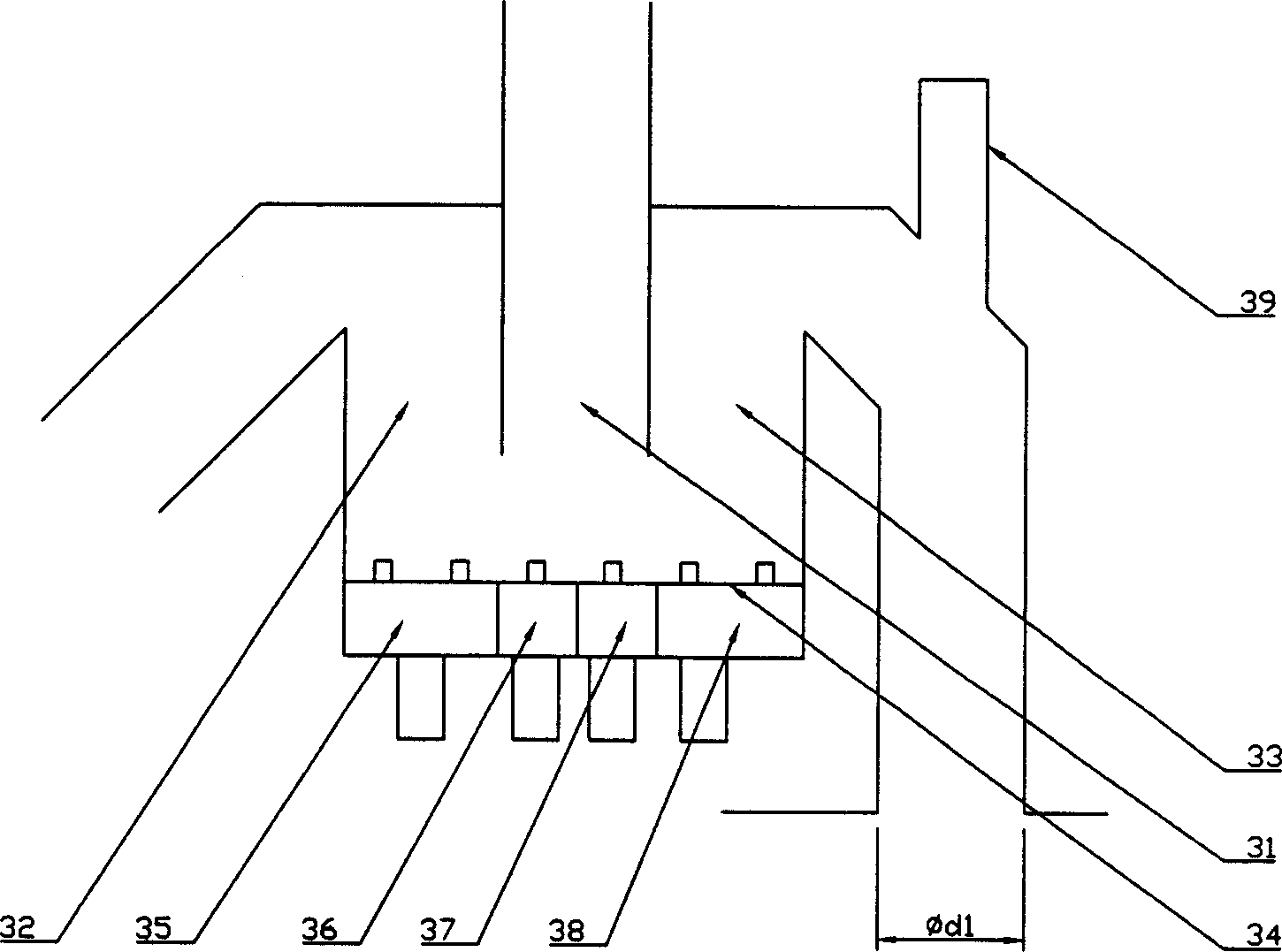

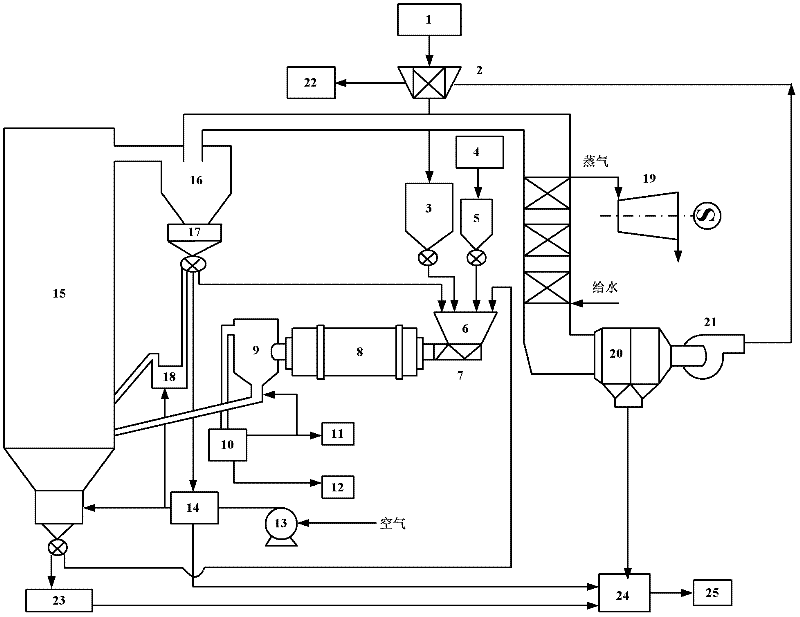

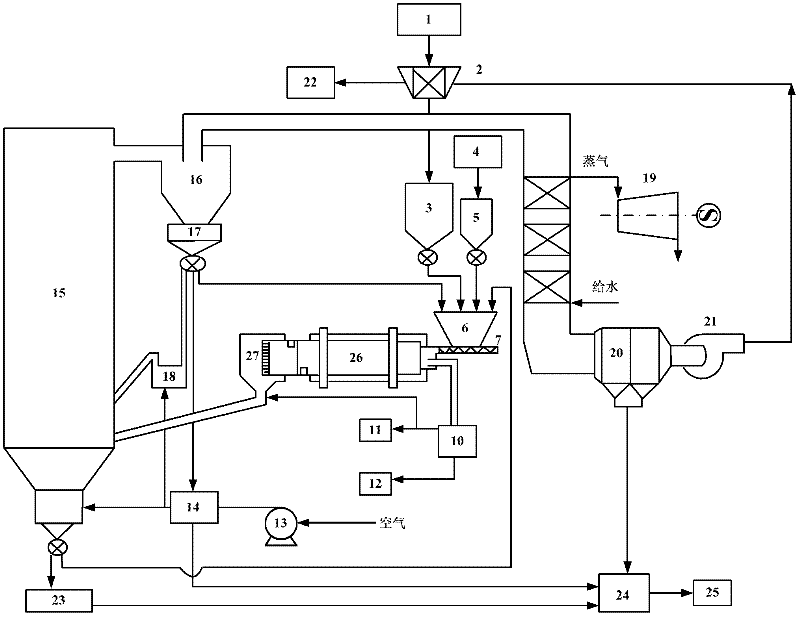

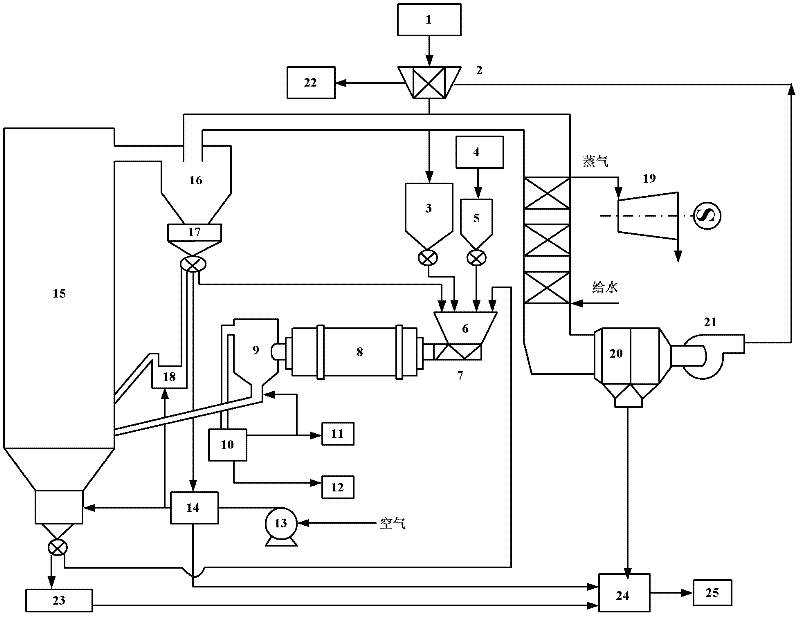

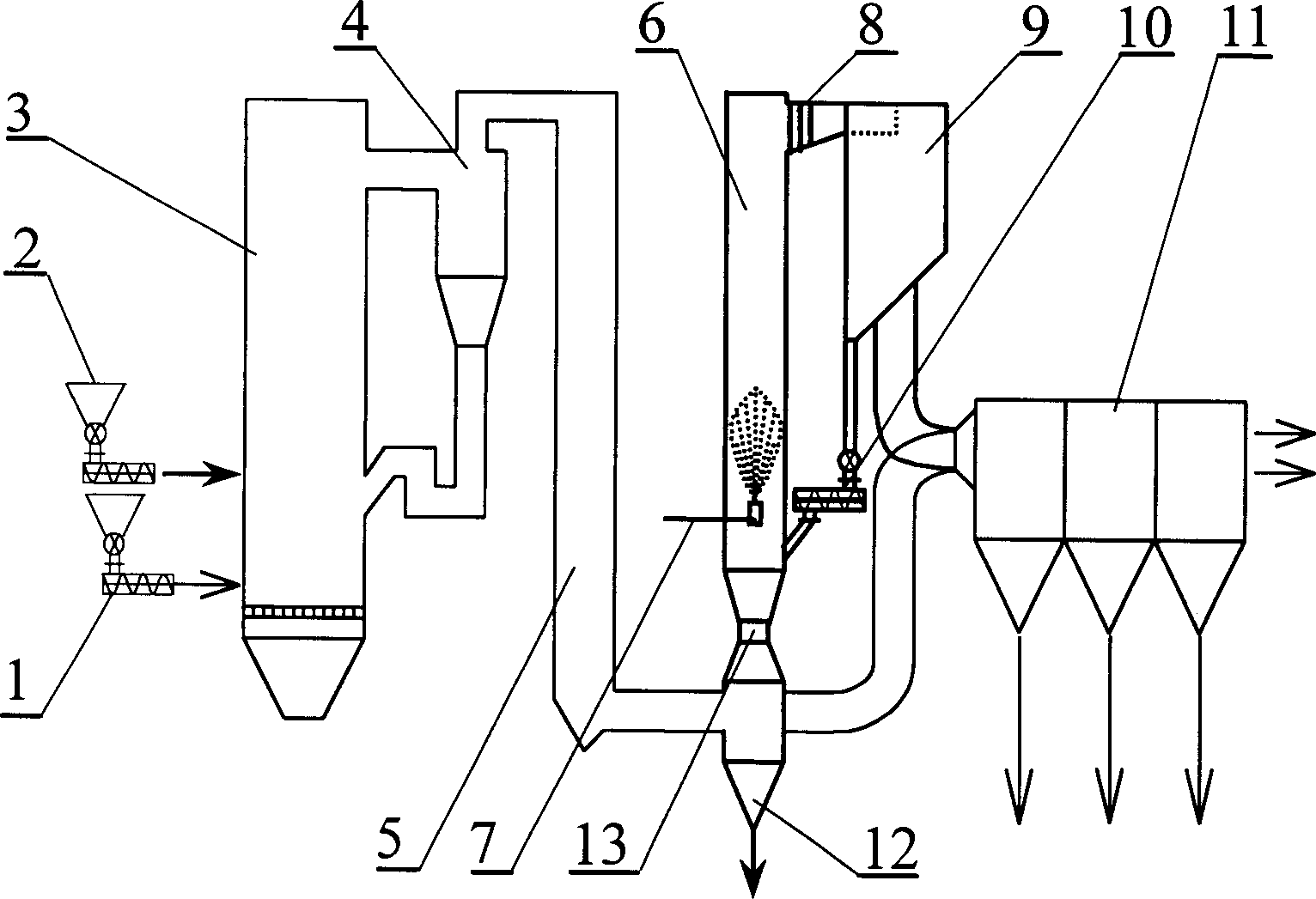

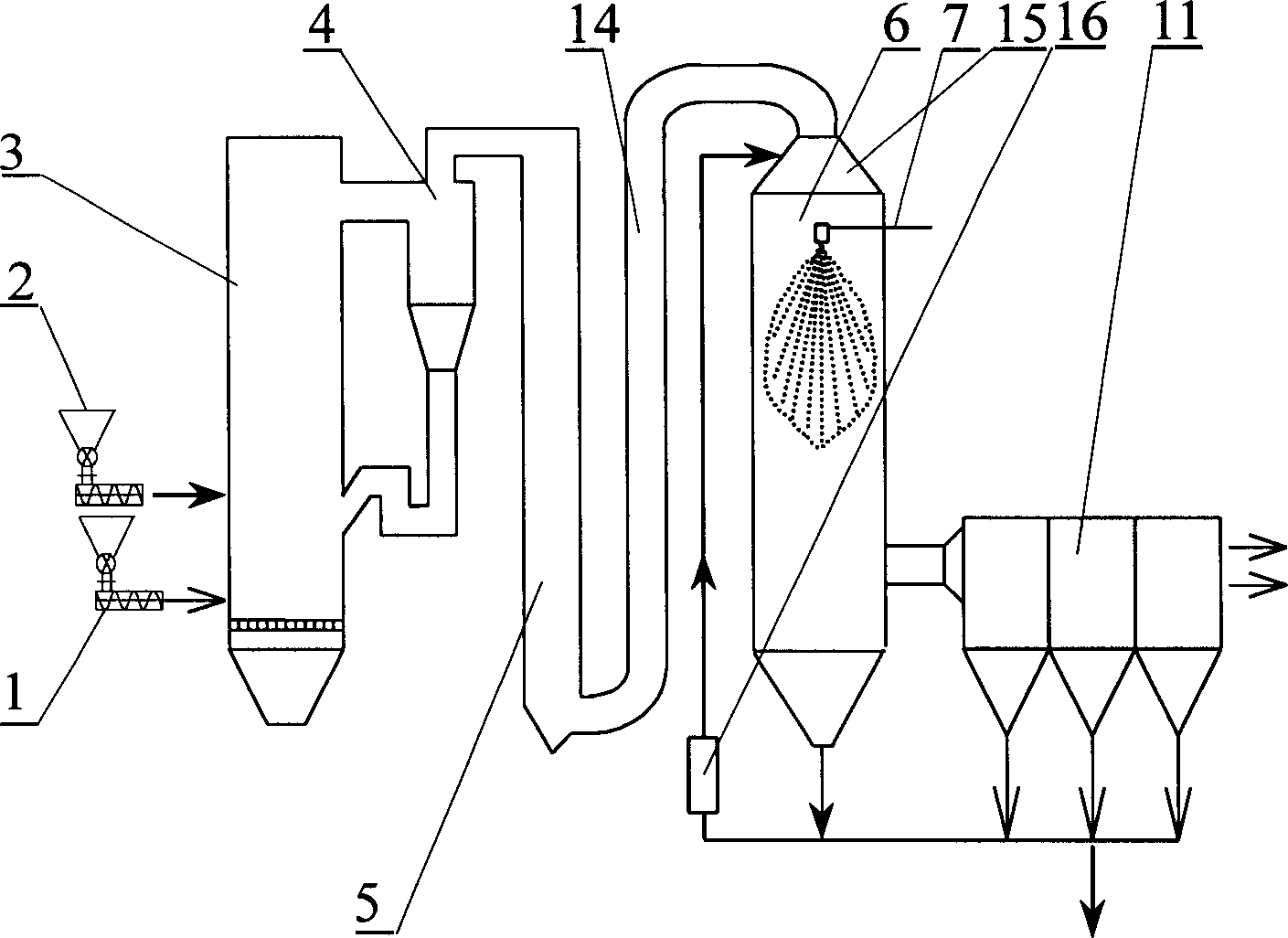

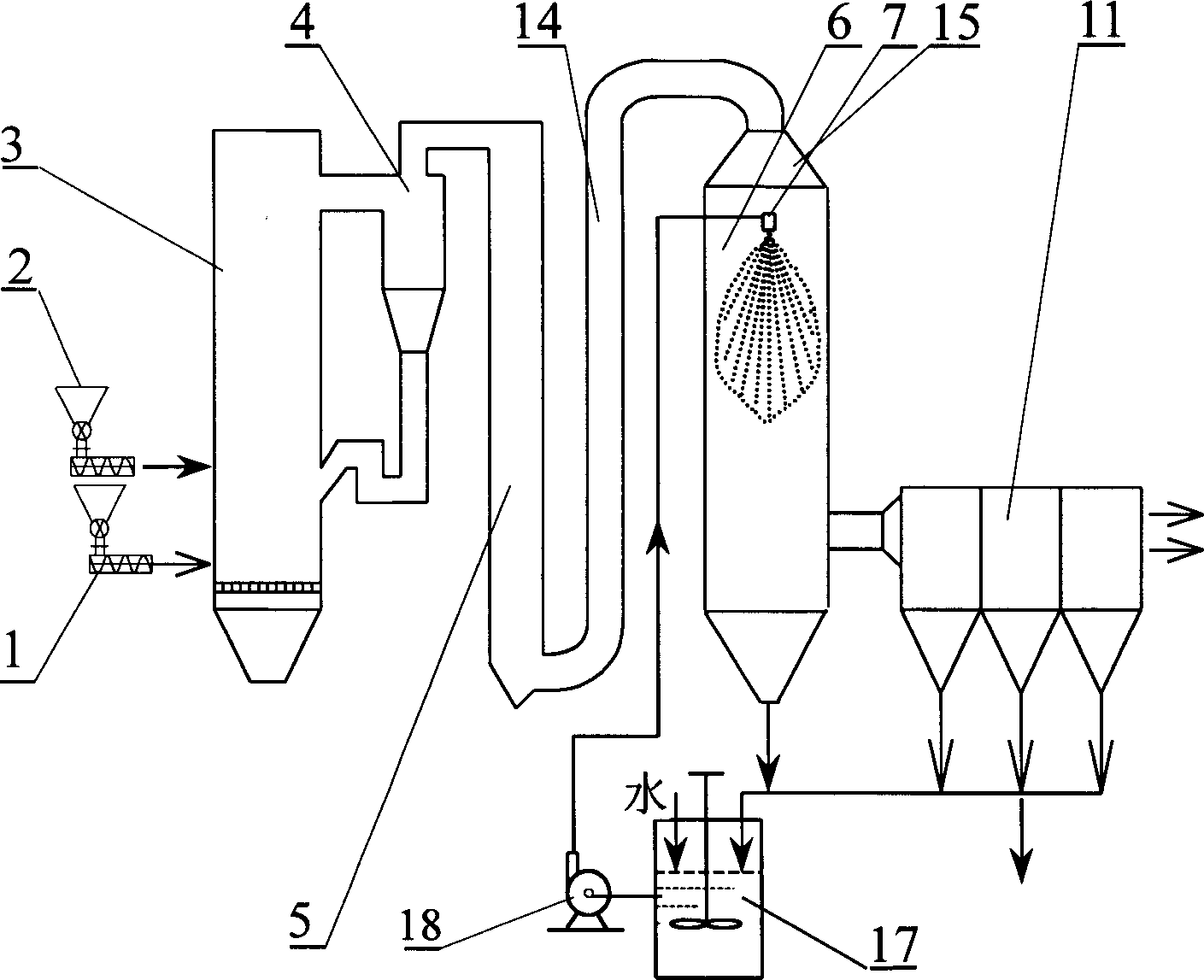

Method for producing both gas and steam, and boiler of circulating fluid bed with pyrolysis vaporizer

InactiveCN1727750AReduce solid impuritiesReduce tar contentFluidized bed combustionCombined combustion mitigationCombustion chamberEngineering

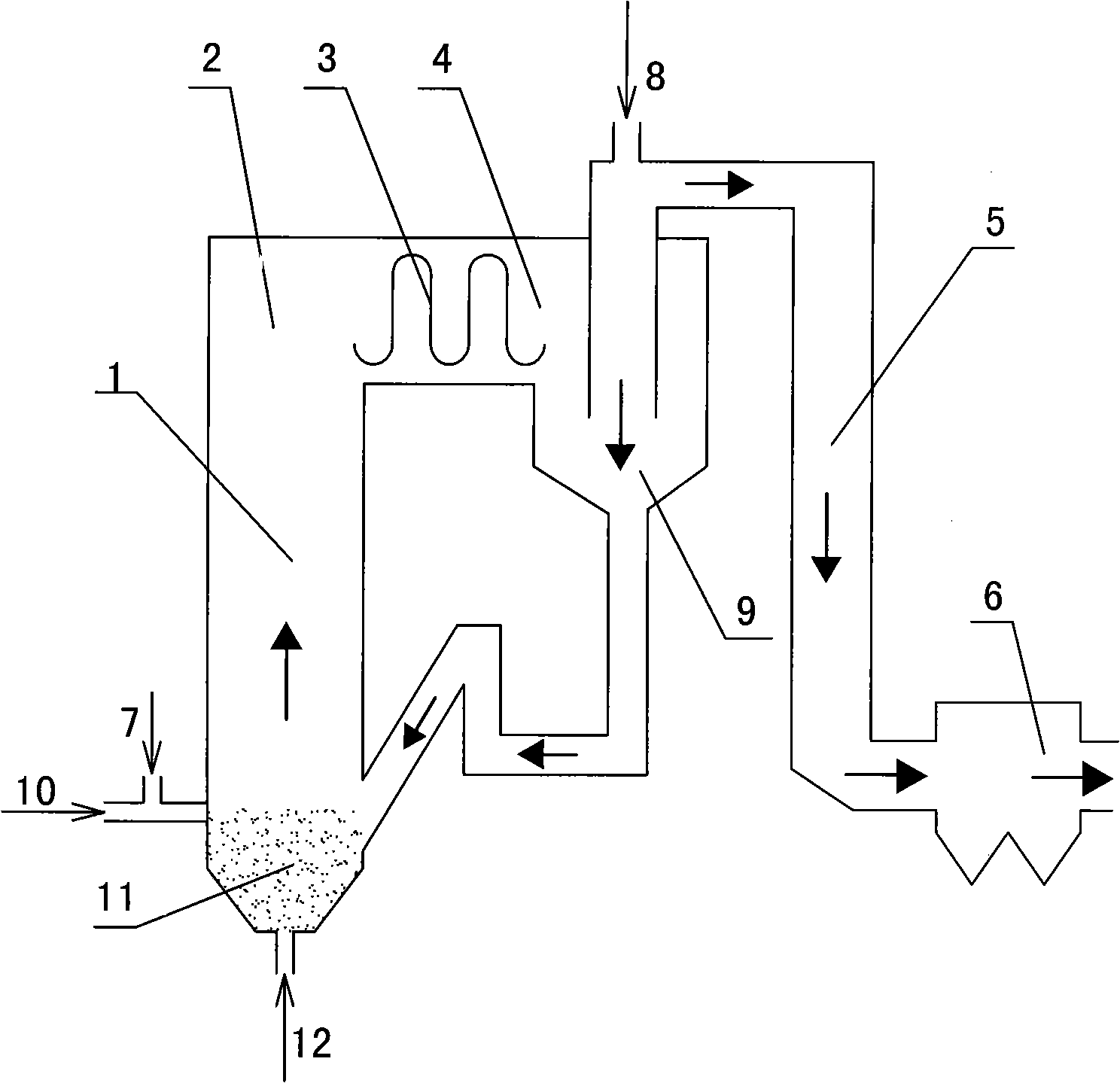

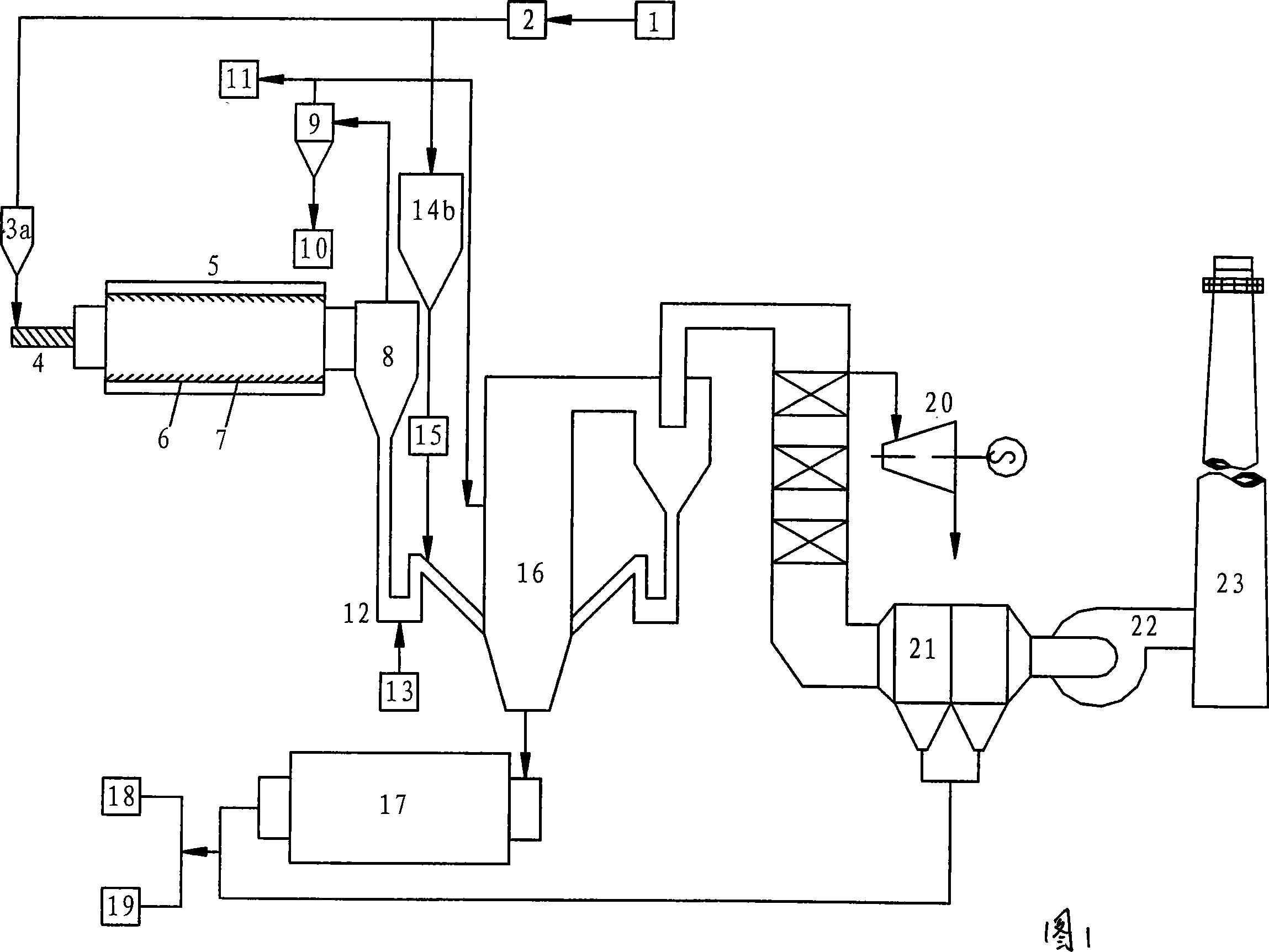

The present invention relates to a gas-steam joint production method and circulating fluidized-bed boiler. It includes the following portions: fluidized-bed combustion chamber, cyclone separator, hot ash distributor, pyrolysis gasification chamber, heat exchanger and differential bed material-retuning device. Said invention also provides its concrete technological process, it can be used as steam boiler, and can implement gas-steam joint production.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

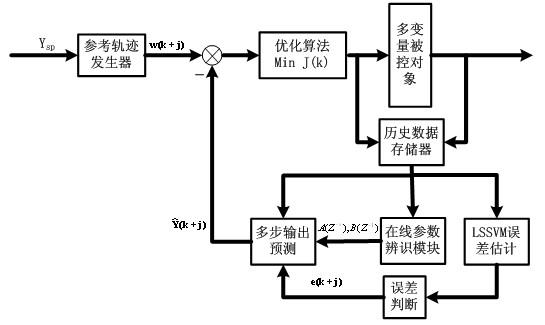

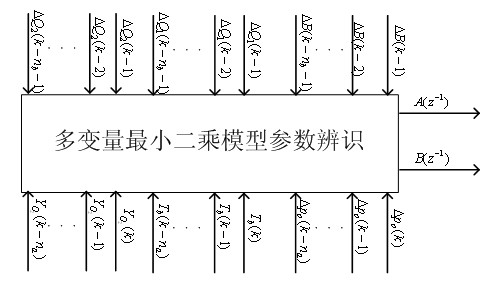

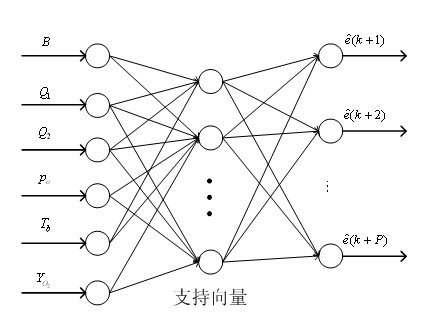

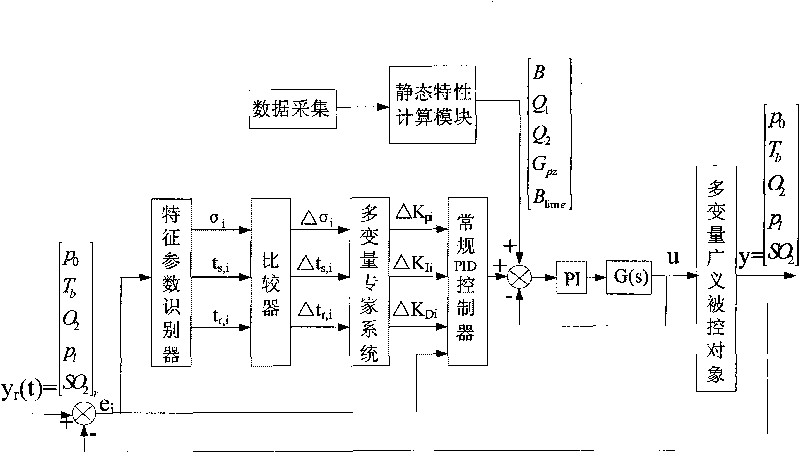

Combustion process multivariable control method for CFBB (circulating fluidized bed boiler)

InactiveCN102494336AImprove robustnessSolving time-varying problemsFluidized bed combustionApparatus for fluidised bed combustionSteam pressureData acquisition

The invention discloses a combustion process multivariable control method for a CFBB (circulating fluidized bed boiler), which is realized in the following procedures: in each control period, collecting operational parameters of the boiler through data collecting equipment and storing the operational parameters in a data storage module; utilizing the history data in a memorizer to on-line identify the CARIMA model and present P step future moment predominant values such as process output variable main steam pressure, material bed temperature and flue gas oxygen content through a model on-lineparameter identification module of GPC (generalized prediction control); performing error compensation to the process future moment prediction output through an error estimation module of an LSSVM (least square support vector machine); and referring the reference trace obtained by a trace generator, performing rolling optimization in GPC for the process future moment prediction output, and calculating through the optimized algorithm to enable the process actual output to reach the set value. The method provided by the invention solves the time varying problem of the model parameter, and enables the control system to have stronger robustness.

Owner:ZHEJIANG UNIV

Automatic regulating system for combustion process of circulating fluid bed in boiler

InactiveCN1480682ATake full advantage of precisionContinuous and stable investmentFluidized bed combustionApparatus for fluidised bed combustionAuto regulationCombustion system

An automatic regulation system for the combustion of circulating fluidized-bed boiler (CFBB) features that it has several regulation loops for the discharged cinder quantity, primary blowing rate, supplied coal quantity, secondary blowing rate and draught air volume, which are based on the coordination between fluidizing, combustion and heat exchange, the expert system, fuzzy control and composite cascaded PI regulation are combined, and the protecting tactics such as override protection, output restriction and lock distribution choosing and tracking are used.

Owner:BEIJING HOLLYSYS

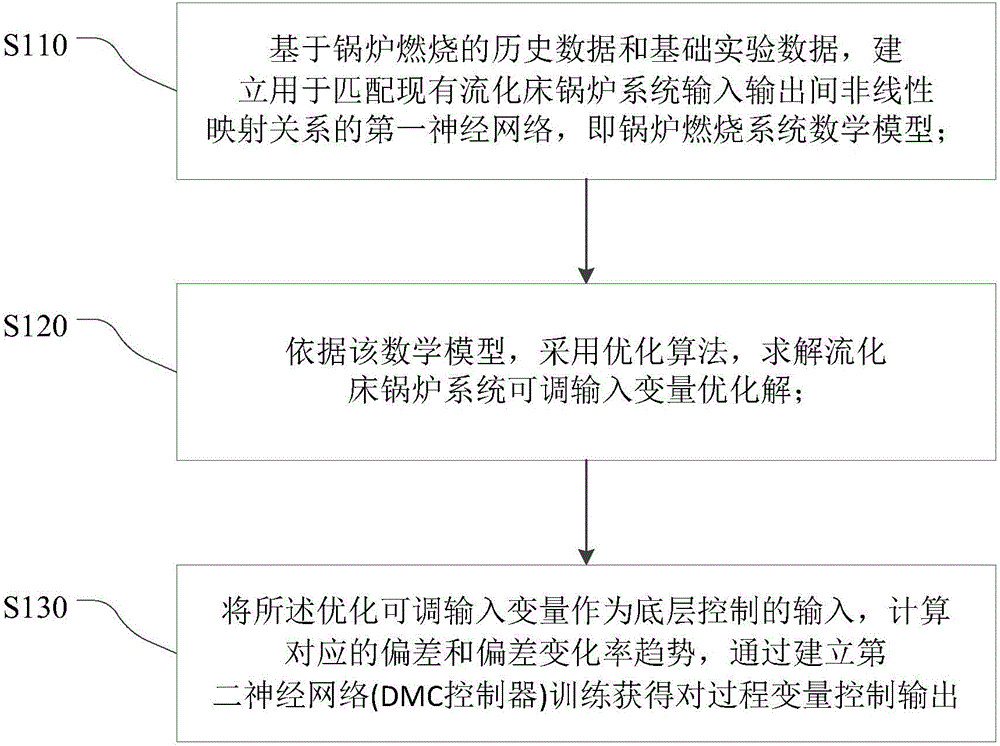

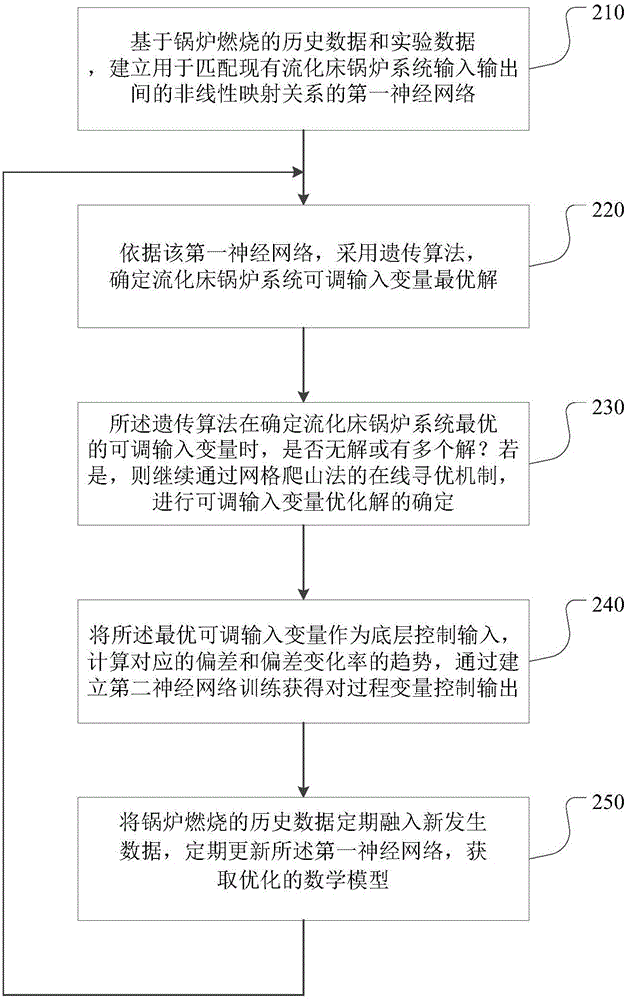

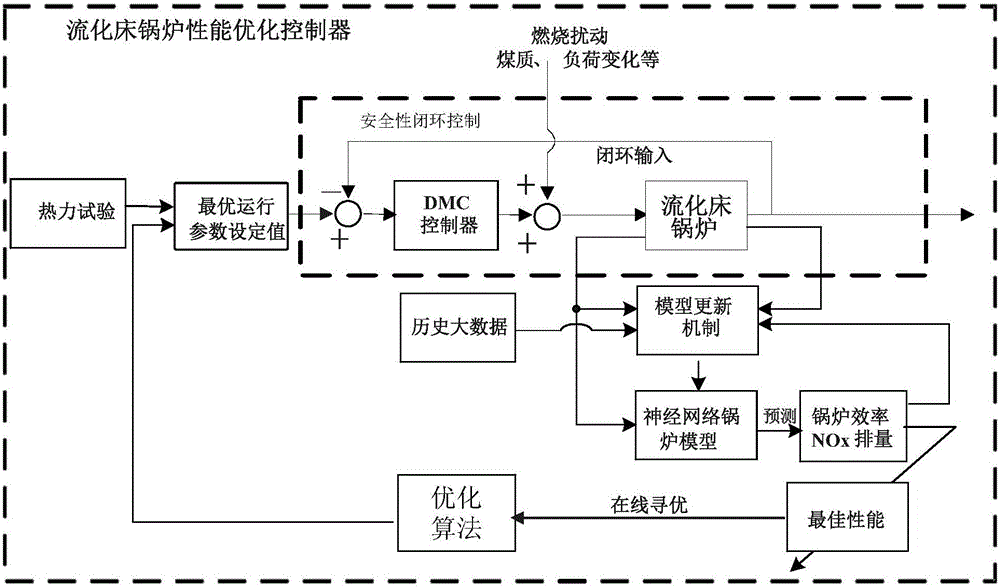

Method and system for optimizing and controlling combustion performance of circulating fluidized bed boiler in real time

ActiveCN105020705AGuaranteed uptimeImprove performanceFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention provides a method and system for optimizing and controlling combustion performance of a circulating fluidized bed boiler in real time. The method for optimizing and controlling combustion performance of the circulating fluidized bed boiler in real time includes the steps that based on historical data of combustion of the boiler, a first neural network used for being matched with a nonlinear mapping relation between the input and the output of an existing fluidized bed boiler system is established; according to the first neural network, the adjustable input variable of the input of the fluidized bed boiler system is determined; and the adjustable input variable serves as the bottom layer control input, the trends of corresponding deviation and the deviation change rate are calculated, and a second neural network is established for training and acquiring the process variable control output. By the adoption of the method and system, the boiler efficiency is improved, the power supply coal consumption is lowered, coking and slag bonding are prevented or treated, NOx emission is reduced, and the safety, the reliability and the economical efficiency of operation of the boiler are further improved.

Owner:INNER MONGOLIA RUITE TECH

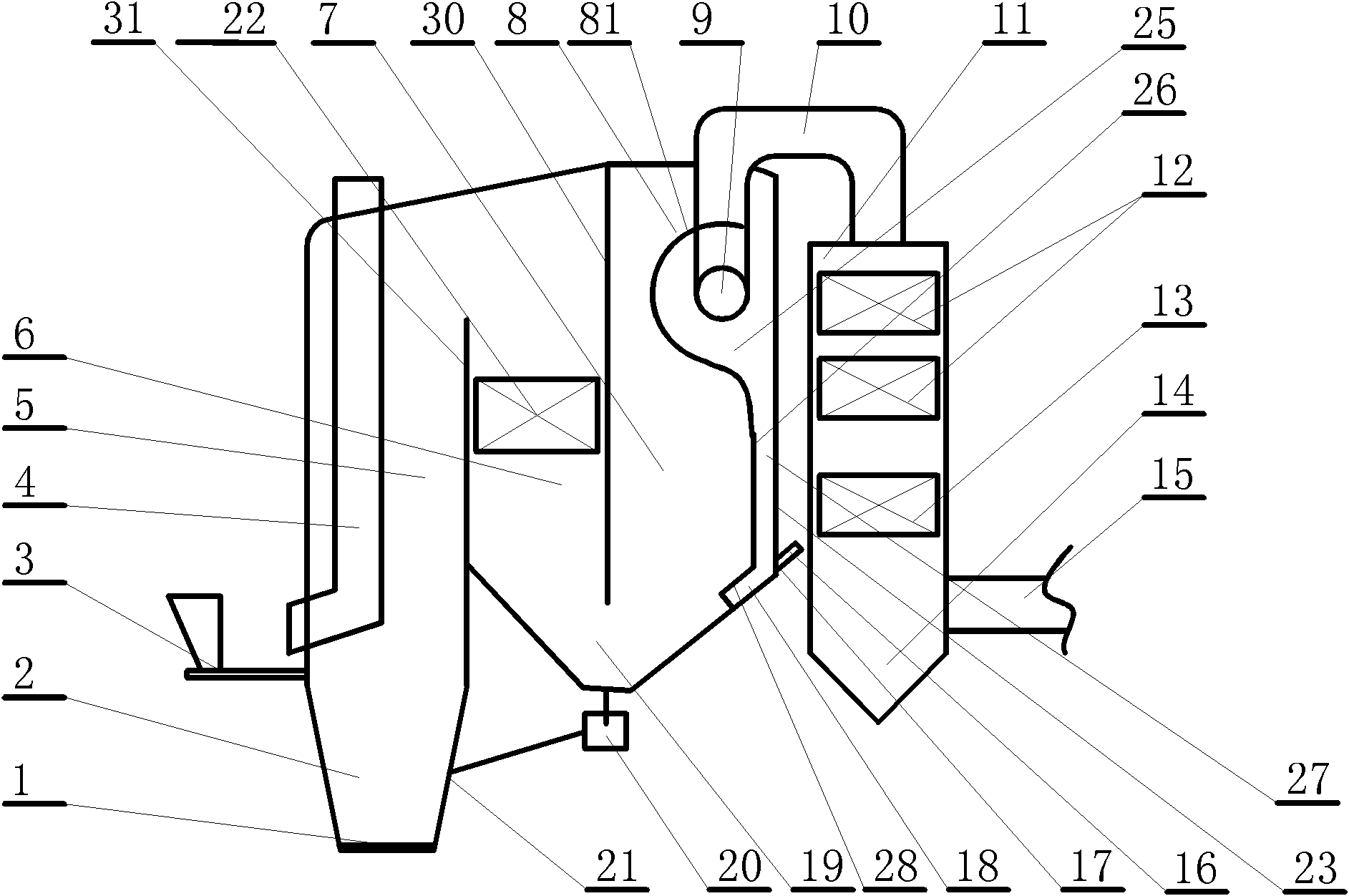

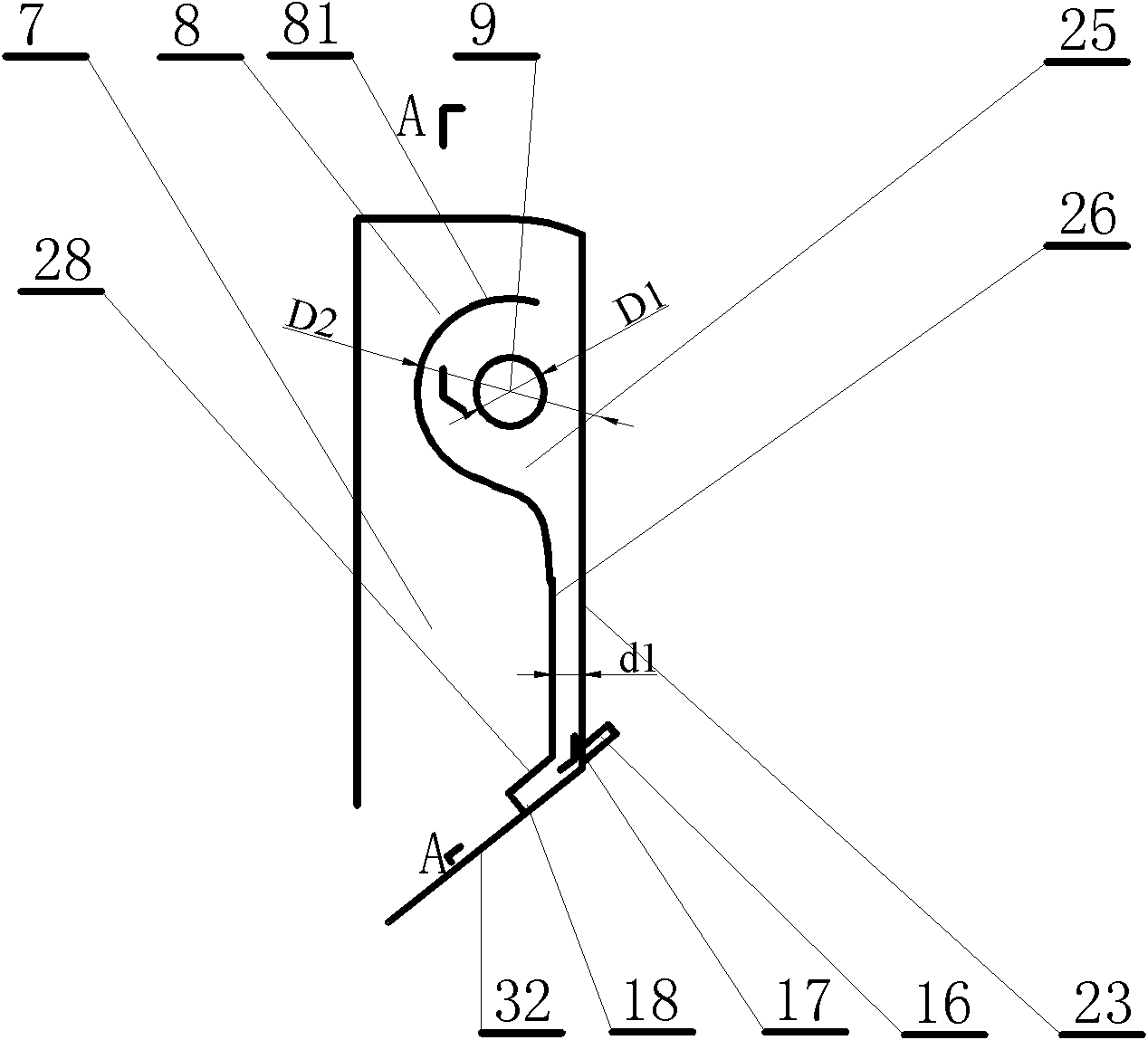

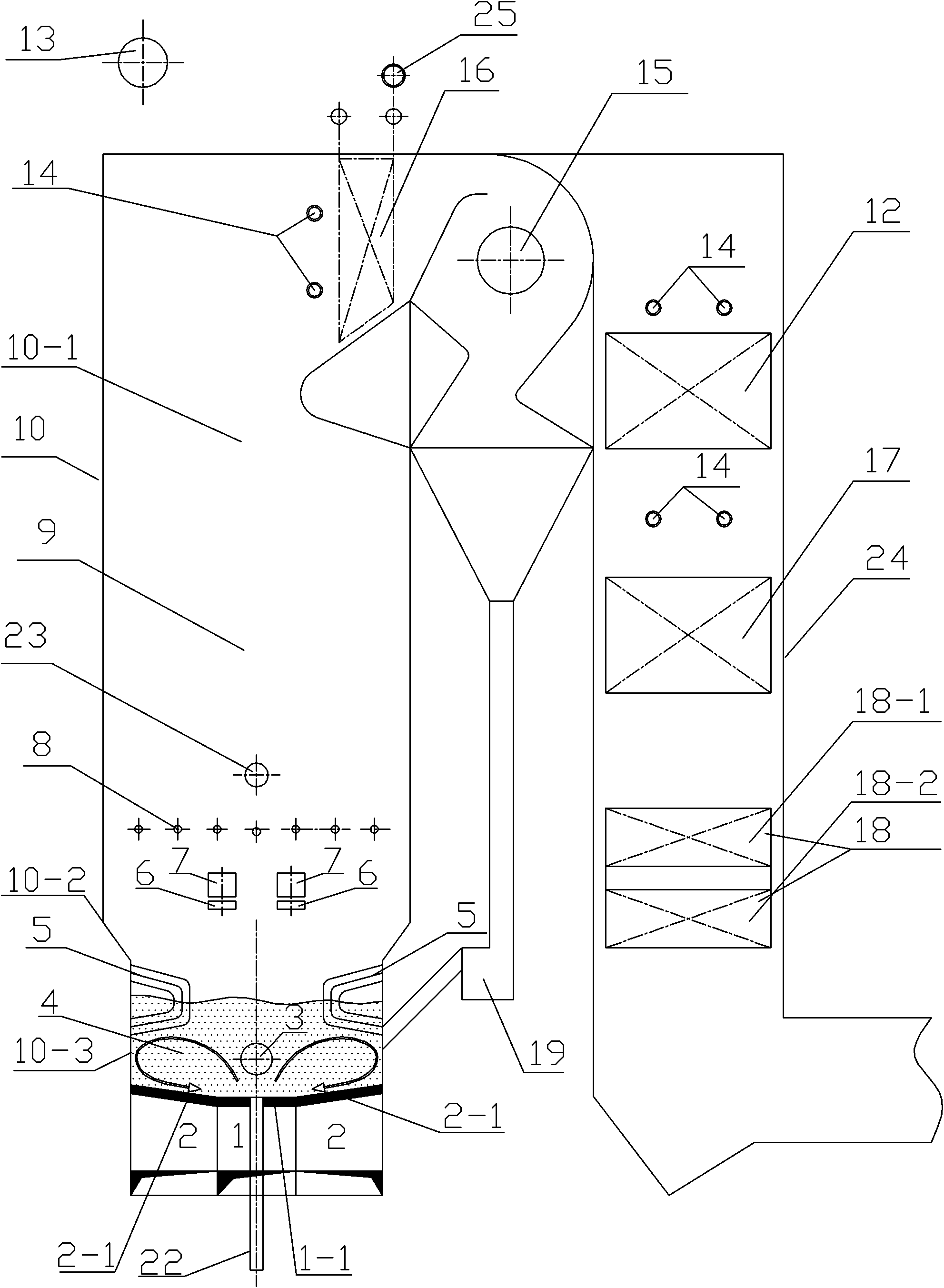

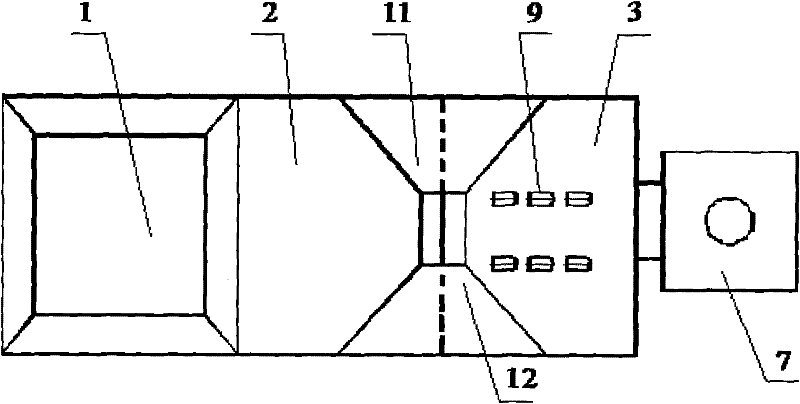

Horizontal type circulating fluidized bed boiler with horizontal cyclone separator

ActiveCN102537943ALow costReduce construction costsFluidized bed combustionReversed direction vortexCycloneCombustion chamber

The invention relates to a horizontal type circulating fluidized bed boiler with a horizontal cyclone separator, belonging to combustion equipment of inferior fuels such as inferior coal, solid waste, sludge or biomass and the like, and the horizontal type circulating fluidized bed boiler is particularly suitable for fluidized combustion of a biomass boiler with less ash content. The horizontal type circulating fluidized bed boiler consists of a main combustion chamber, a secondary combustion chamber, a burnout chamber and a tail gas flue, and a horizontal cyclone separator is arranged in the burnout chamber. The horizontal type circulating fluidized bed boiler in the invention changes a single-stage vertical circulating structure of a vertical circulating fluidized bed, can effectively reduce the height of a boiler and reduce the requirement for building height of a factory, meanwhile, the horizontal cyclone separator is integrated in the burnout chamber, the structure is more compact, thereby being beneficial to miniaturization of a circulating bed boiler and reducing the cost effectively. The horizontal type circulating fluidized bed boiler has all the advantages of a circulating fluidized bed and can combust fuels such as inferior coal, solid waste, municipal and industrial sludge, biomass and the like, has wide fuel adaptability and is high-efficiency combustion equipment with clean combustion, a compact structure and long service life.

Owner:TSINGHUA UNIV +1

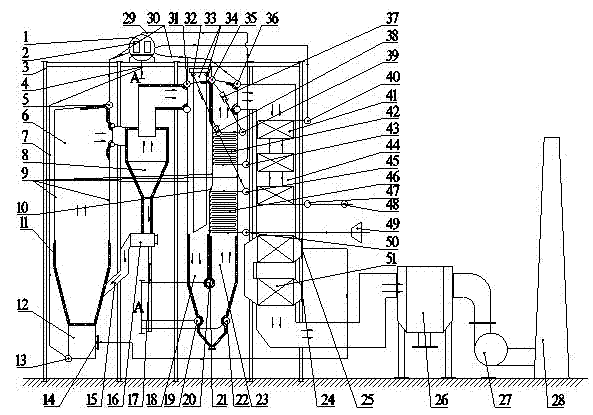

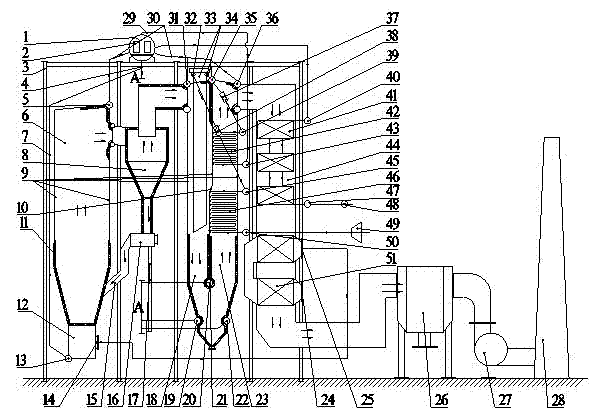

A membrane-type water-cooled wall four-flue biomass circulating fluidized bed boiler

InactiveCN102297423AIncrease profitGuaranteed uptimeFluidized bed combustionCombustion technology mitigationSuperheaterHeat energy

A membrane water-cooled wall four-flue biomass circulating fluidized bed boiler, including a drum, a furnace, a cyclone separator, a return device, a second flue, a third flue, a fourth flue, an economizer, and a dust collector appliance, induced draft fan, chimney. The furnace, the second flue and the third flue are surrounded by membrane water-cooled walls; in the lower part of the furnace and the inner surface of the flue gas outlet, the cyclone separator and the inner surface of the flue gas outlet, the second flue and the third flue Refractory castables are laid around the connecting parts of the flue; a medium-temperature screen superheater is arranged at the upper end of the second flue; high-temperature and low-temperature convection superheaters are spaced in the third flue; the middle wall adopts a tapered wall structure; low-temperature convection superheater The first water spray desuperheater and the second water spray desuperheater are respectively arranged between the high temperature convection superheater and the medium temperature screen convection superheater. The invention improves the combustion heat energy utilization rate of the biomass fluidized bed boiler, reduces the wear and alkali metal corrosion of the inner wall of the flue by high-speed and high-temperature flue gas, and enhances the wear resistance of the wall surface.

Owner:JIANGSU SIFANG BOILER +1

Boiler system of circulating fluid bed burning in oxygen enrichment

InactiveCN1959208AOvercome the problem of difficult temperature controlIncrease concentrationFluidized bed combustionIndirect carbon-dioxide mitigationHigh concentrationFluidized bed

A circulation fluidized-bed boiler of rich-oxygen combustion type is prepared as utilizing circulation fluidized-bed boiler with external fluidized bed heat exchanger to carry out combustion in mode of mixing mixture gas of high concentration oxygen from air separate and recirculation smoke from boiler tail with fuel, controlling load and firepot temperature of said boiler by regulating flow rate of fly ash particles entering into external fluidized bed heat exchanger.

Owner:HUAZHONG UNIV OF SCI & TECH

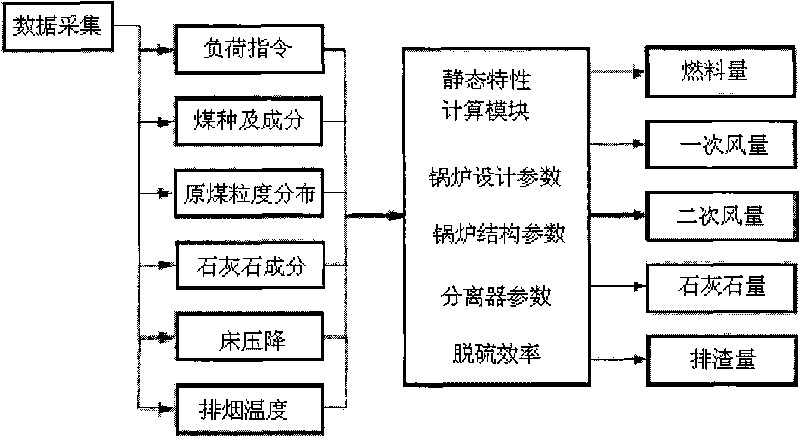

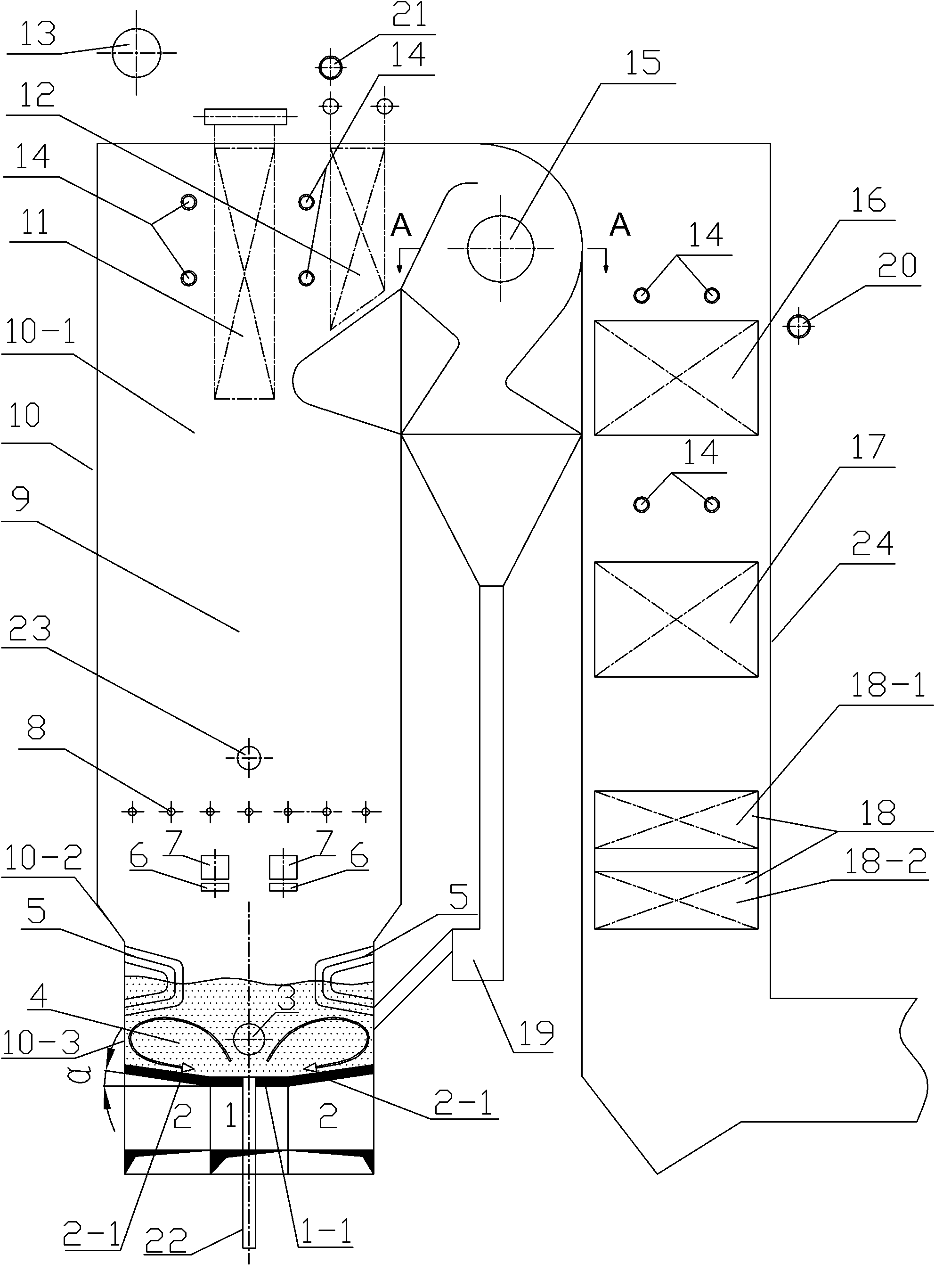

Control method of combustion system of circulating fluidized bed boiler

InactiveCN101713536AReal-time and accurate adjustment commandRealize combustion automatic controlFluidized bed combustionApparatus for fluidised bed combustionAir volumeAutomatic control

The invention relates to a control method of a combustion system of a circulating fluidized bed boiler, which adopts multivariable expert intelligent self-calibration PID control and is provided with an on-line calculation module for the static characteristics of the circulating fluidized bed boiler. The on-line calculation module for the static characteristics of the circulating fluidized bed boiler calculates the coal supply quantity, the limestone quantity and the deslagging quantity for realizing the optimizing combustion of the boiler under different loads, the primary air quantity and the secondary air quantity are optimized and proportioned and are used as load feedforward signals which are applied to a main steam pressure control loop, a limestone quantity control loop, a bed pressure drop control loop, a bed temperature control loop and an oxygen quantity control loop, and each control loop adopts an expert intelligent self-calibration PID controller to form a multivariable combustion control system of a CFB boiler. The invention is provided with the calculation module for the static characteristics of the circulating fluidized bed boiler, which can accurately send out each regulation quantity instruction at real time and realize automatic control; the multivariable expert system is in consideration of the nonlinearity and the strong-coupling property of the combustion system of the boiler and ensures the performance robustness of the control system; and meanwhile, the PID parameters are automatically regulated according to the change of the characteristics of a controlled object, so the automatic combustion control system of the circulating fluidized bed boiler has stable robustness.

Owner:TAIYUAN UNIV OF TECH

Low-ratio biomass circulating fluidized bed boiler and combustion method thereof

InactiveCN101949535AProlonged combustion residence timeSolve cokingFluidized bed combustionApparatus for fluidised bed combustionCombustionLow speed

The invention relates to a low-ratio biomass circulating fluidized bed boiler and a combustion method thereof, relating to a circulating fluidized bed boiler and a combustion method thereof and solving the problems of difficult feeding, grate slagging, bed material coking, tempering and output reduction, and the like existing in the operation of traditional grate furnaces and circulating fluidized bed boilers. A middle air chamber corresponds to the middle of a dense-phase area at the lower part, lateral grid plates are arranged between a lateral air chamber and the dense-phase area at the lower part, and a medium-temperature steam-cooled cyclone separator is arranged at the joint between a flue shaft at the tail part and a health outlet of a boiler body, respectively communicated with the flue shaft and the health outlet and communicated with the dense-phase area at the lower part through a material returner. The method adopts a negative-pressure feeding manner so that the fluidization air velocity of a high-speed area of the dense-phase area at the lower part is 4-5 m / s, the fluidization air velocity of a low-speed area is 1.5-2.0 m / s, the temperature of the dense-phase area at the lower part is 650-780 DEG C, and the material circulation ratio is below 10. The invention is suitable for the biomass circulating fluidized bed boiler for an electric power plant.

Owner:湖南博茂节能环保科技有限公司

Oil shale fluidized bed dry distillation system

InactiveCN101440293ARealize scientific utilizationImprove heat transfer efficiencySpecial form destructive distillationWater vaporOil shale gas

The invention relates to a carbonization system of an oil shale fluidized bed. Oil shale with high oil content and low pyrolysis temperature is used as a carbonization material; high-temperature steam-gas and circulating hot ash are utilized to fluidize and heat the oil shale in a carbonization chamber of the fluidized bed; after ash removal, mixed airflow of generated shale oil and noncondensable gas and vapour in the carbonization chamber of the fluidized bed enters a cooler; the condensed oil-water mixture is divided into shale oil and water through the oil-water separator; the shale oil is transported to a shale oil storage tank; the water is purified and is conducted to the cooler; and noncondensable gas which is not condensed through the cooler is transported to a fuel gas storage tank. Oil shale carbocoal produced through the carbonization chamber of the fluidized bed is directly transported to a boiler of an oil shale carbocoal circulating fluidized bed, is burned and discharges heat; one part of the produced steam-gas is used as fluidized wind of the carbonization chamber of the fluidized bed; the residual steam-gas is conducted to a steam turbine-dynamo system, applies work and generates electricity; and part of circulating ash in the boiler is used as a heat source of the carbonization chamber of the fluidized bed. The carbonization system can realize high-efficient, clean and economic comprehensive utilization of the oil shale.

Owner:SHANGHAI JIAO TONG UNIV

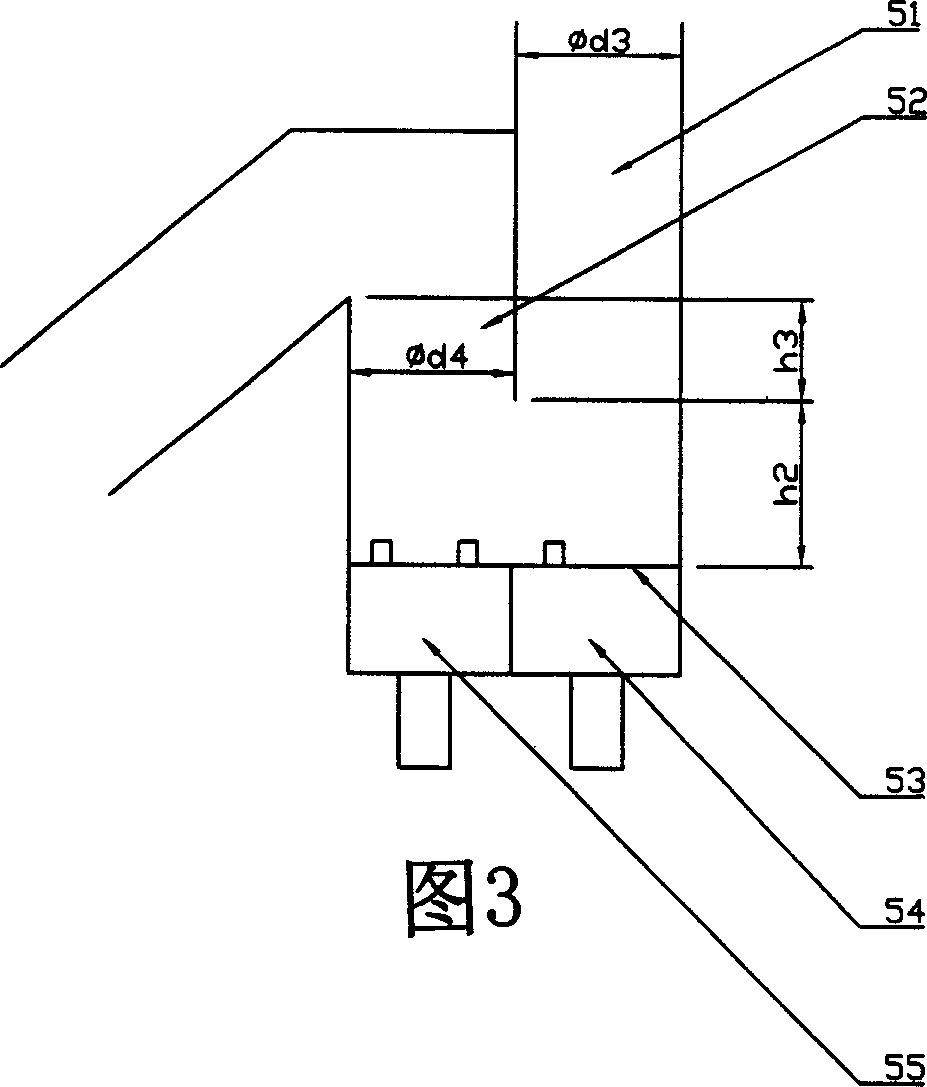

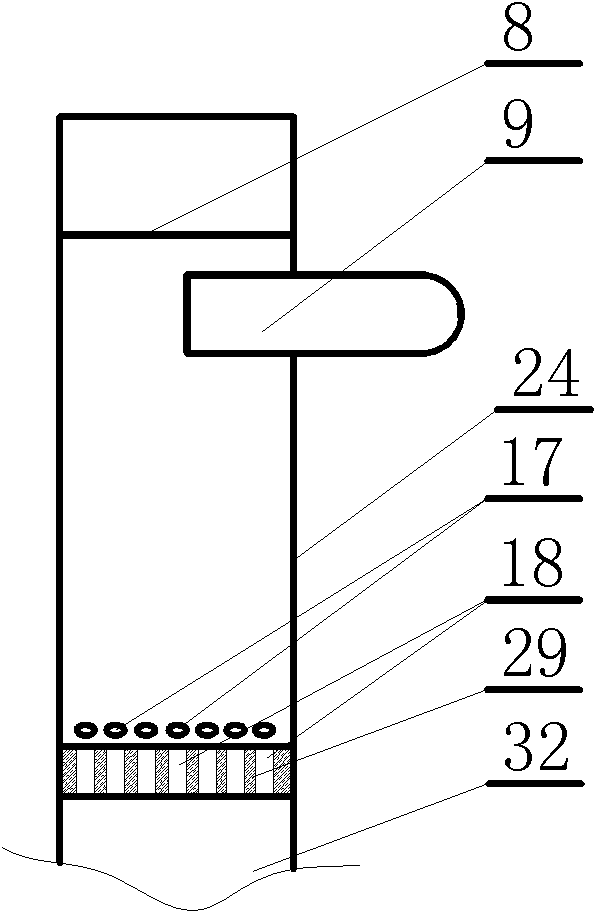

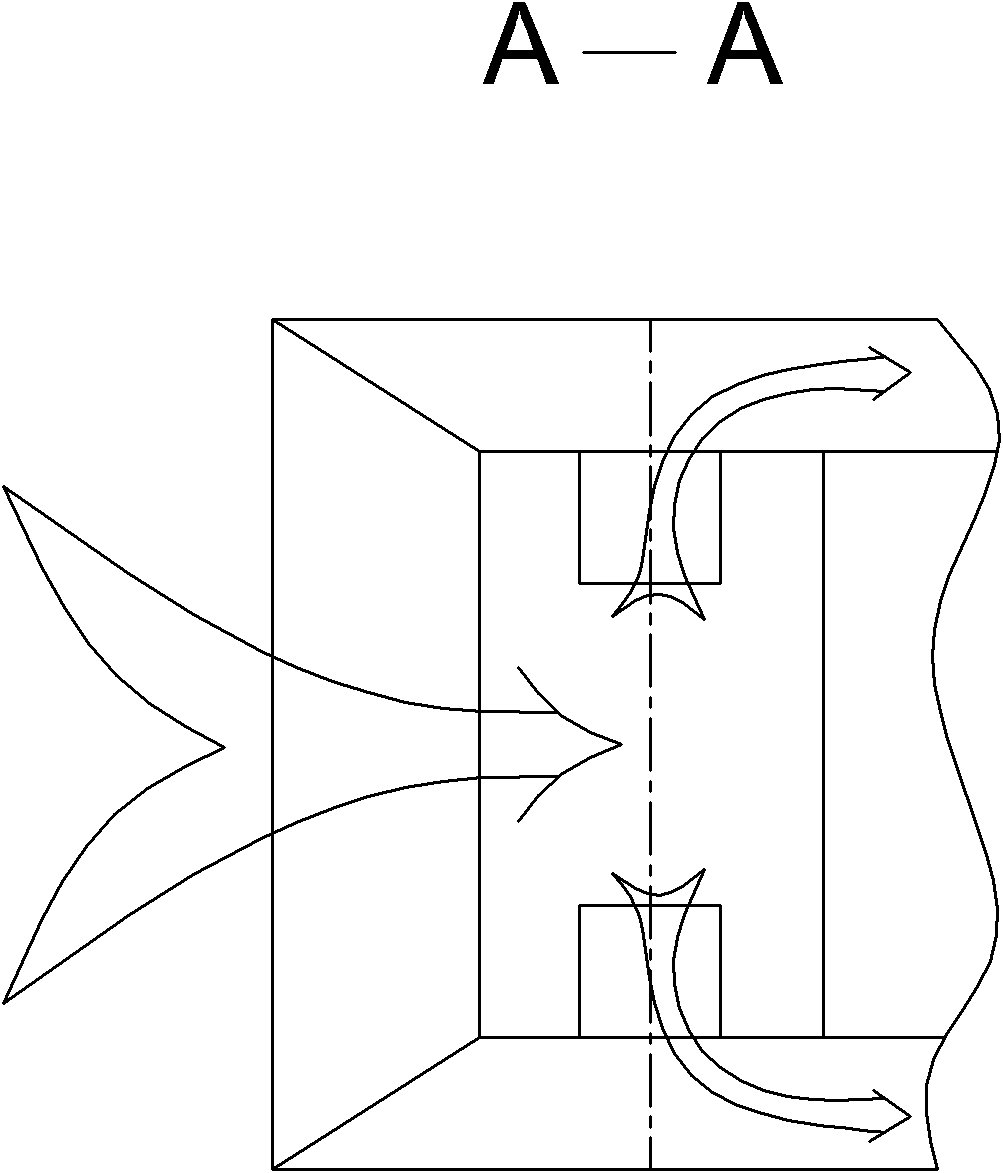

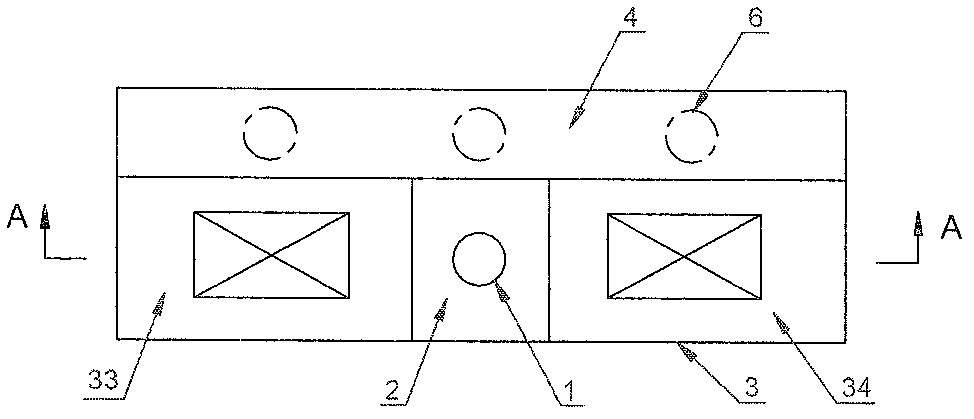

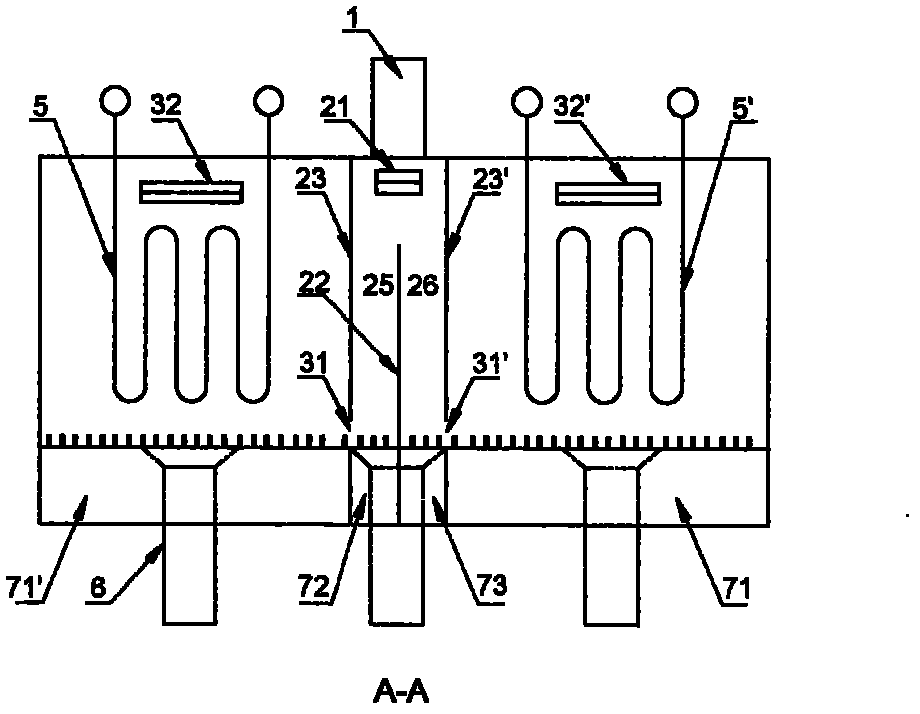

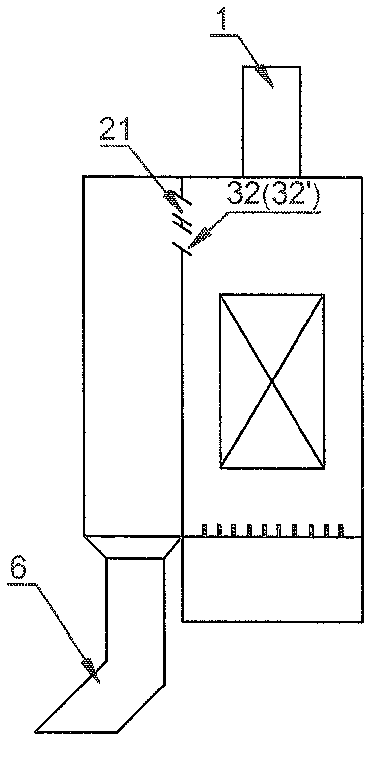

Compact parallel connection type external fluidized bed heat exchanger

ActiveCN102840578AImprove heat exchange capacityImprove heat transfer efficiencyFluidized bed combustionApparatus for fluidised bed combustionConnection typeFluidized bed

The present invention discloses a compact parallel connection type external fluidized bed heat exchanger, and relates to a fluidized bed heat exchange technology. The compact parallel connection type external fluidized bed heat exchanger comprises a material inlet, a material dispenser, two heat exchange chambers arranged in a parallel connection manner, and a material returning chamber. According to the compact parallel connection type external fluidized bed heat exchanger of the present invention, a pneumatic way is adopted to precisely control the amounts of circulating ash entering the two parallel heat exchange chambers, such that independent adjustments and controls of heat exchange powers of the two heat exchange chambers according to requirements can be achieved; with arrangement of the two heat exchange chambers in the parallel connection manner, heat exchange of the two heat exchange chambers has high heat transfer temperatures and high heat transfer pressures, such that a heat exchange efficiency between high temperature circulating particles and the heat exchange pipe bundles is improved while uniformity of the returned material of the large-size hearth and stability of the bed temperature are improved; and with the compact integration design, structure arrangement and operation adjustment of the large circulating fluidized bed boiler are flexible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

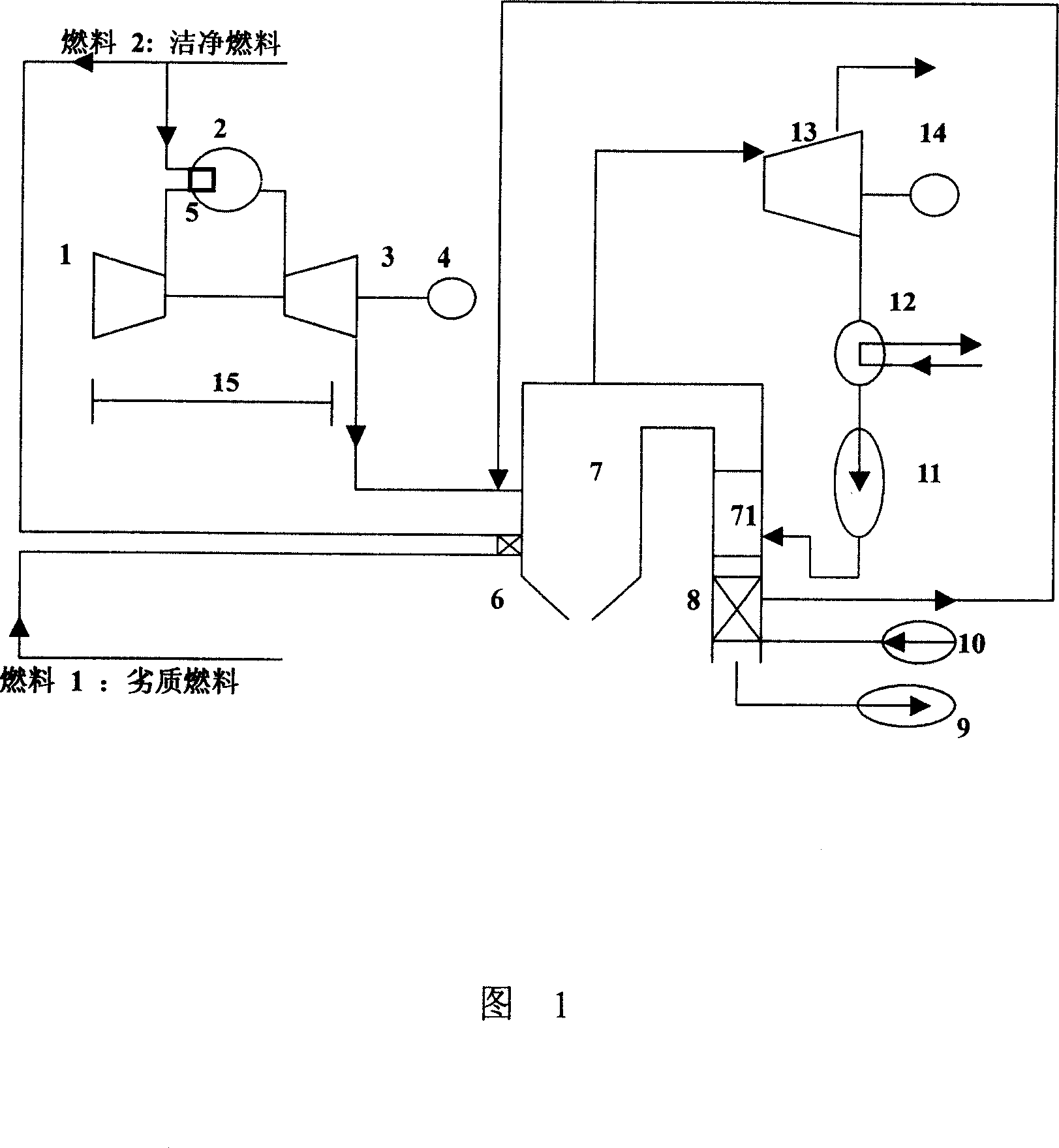

Double-fuel combustion-supporting type gas-steam combined cycle system

InactiveCN101144396AEliminate wasteNo wasteFluidized bed combustionSteam engine plantsCoalFuel supply

The invention relates to a dual fuel combustion-supporting type gas-steam combined cycle system, and belongs to the energy comprehensive utilization technical field. The invention is characterized in that the invention comprises a gas turbine power generating system, a steam turbine power generating system and a circulating fluidized bed boiler; the exhaust tube of the gas turbine of the gas turbine power generating system is communicated with the secondary air inlet tube of the circulating fluidized bed boiler through an exhaust pipeline, the circulating fluidized bed boiler is connected with the steam turbine of the steam turbine power generating system through a steam pipeline, and the steam turbine of the steam turbine power generating system is connected into the economizer of the circulating fluidized bed boiler through a condenser and a feed water pump; a lean fuel supply pipeline is divided into two branch lines, one branch line is led to the combustion engine fuel spraying nozzle of the gas turbine power generating system, and the other branch line is led to the burner of the circulating fluidized bed boiler; an inferior coal-related supply pipeline is accessed to the burner of the circulating fluidized bed boiler. The invention uses the wastes as raw materials to generate electric energy and steam, and thereby primary resource waste and environmental pollution are eliminated, the invention has no secondary pollution, as well as the environment is protected.

Owner:马龙根

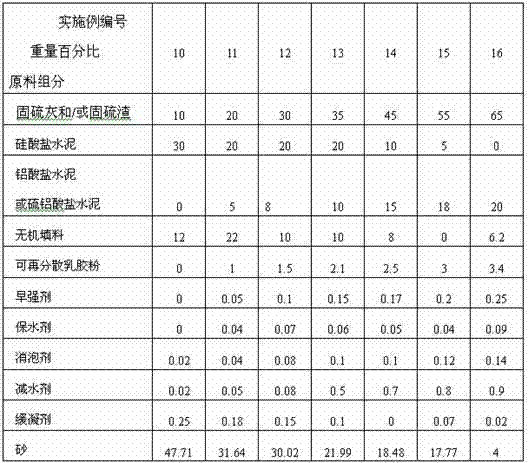

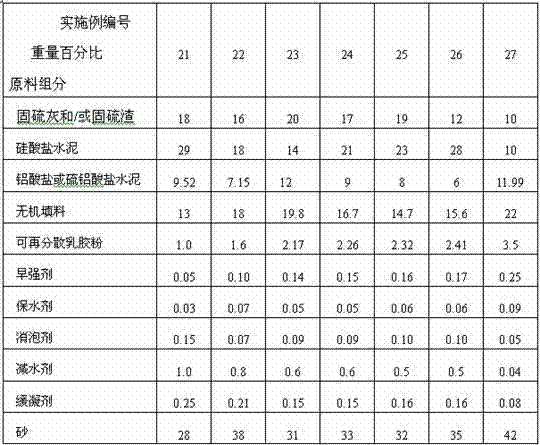

Circulating fluidized bed boiler ash cement-based self-leveling material

The invention discloses a circulating fluidized bed boiler ash cement-based self-leveling material, which is characterized by comprising the following components in percentage by weight: 10-70 percent of circulating fluidized bed boiler ash or / and cycled fluidized bed ash, 0-30 percent of silicate cement, 0-20 percent of aluminate cement or sulphoaluminate cement, 0-22 percent of inorganic filler, 0-3.5 percent of redispersible emulsion powder, 0-0.25 percent of early strength agent, 0-0.09 percent of water retention agent, 0-0.15 percent of defoaming agent, 0-1.0 percent of water reducing agent, 0-0.25 percent of inhibiting agent and 0-50 percent of sand. The cement-based self-leveling material is prepared by taking circulating fluidized bed boiler ash or / and cycled fluidized bed ash and the like as raw materials, so that circulating fluidized bed boiler ash or residues discharged by a circulating fluidized bed can be fully utilized, the waste of land resources and the pollution to the natural environment caused by open-air piling of fluidized bed boiler ash or residues are reduced, and the cost of the self-leveling material is reduced; and the prepared cement-based self-leveling material has the characteristics of high strength, high flowability, low contraction distortion and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

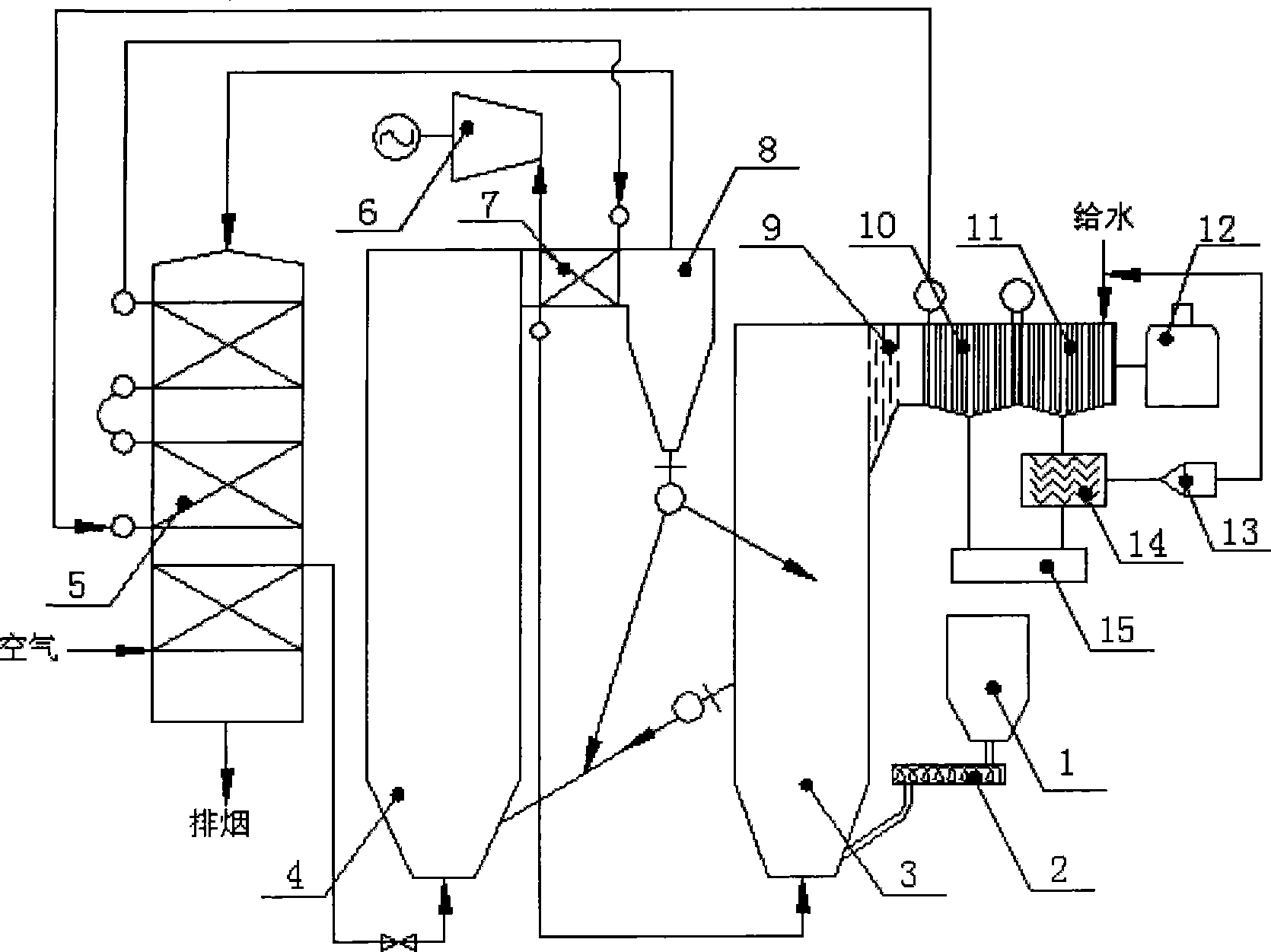

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

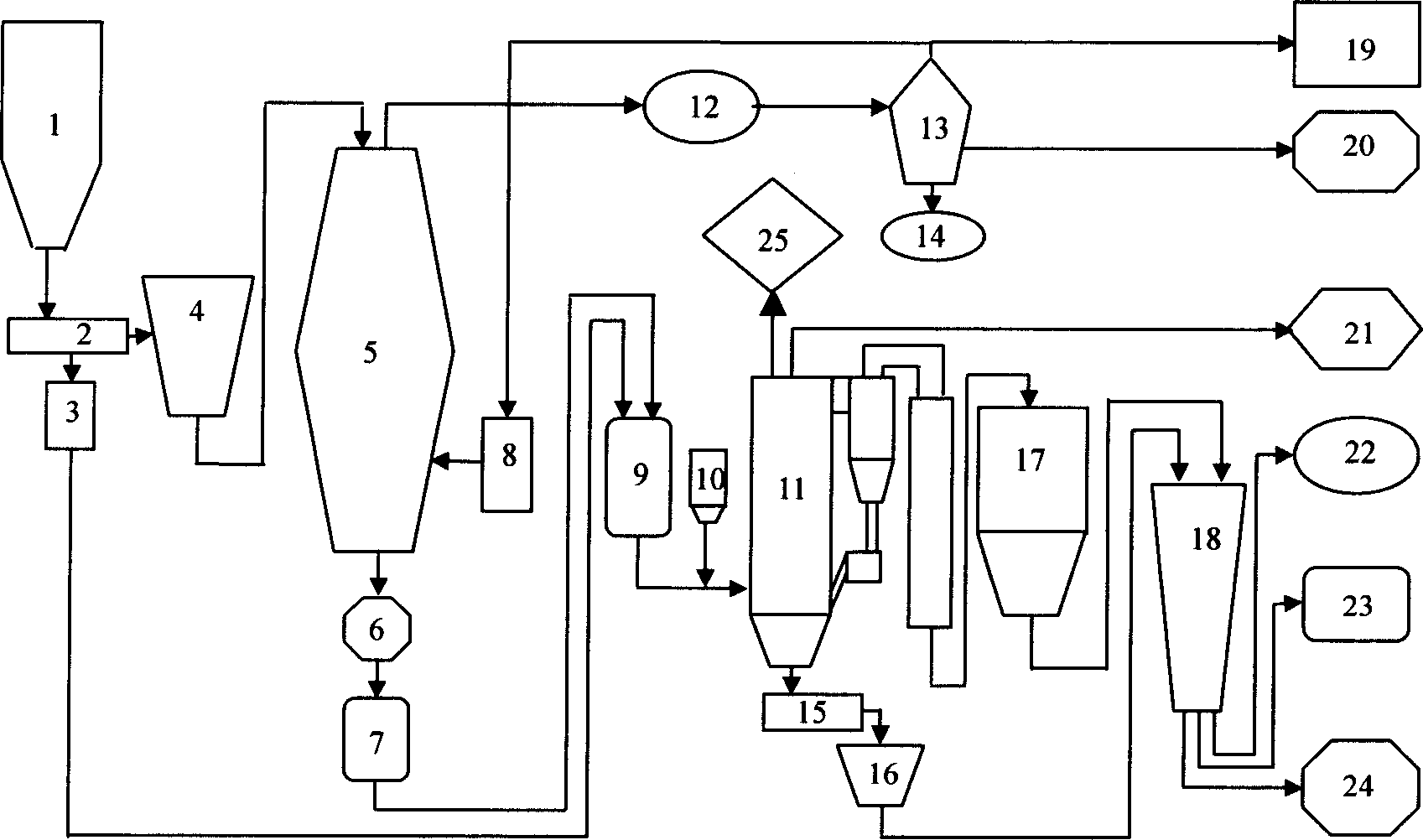

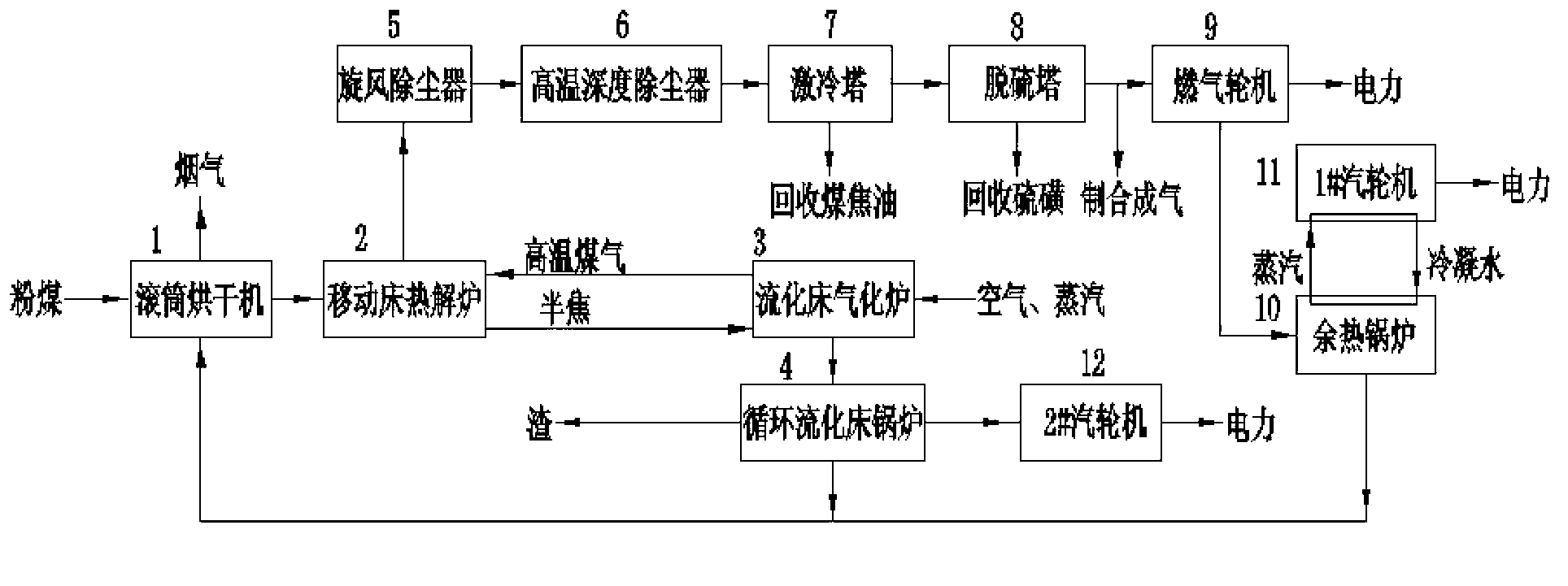

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

Compound desulfurizing process of circulating fluidized bed boiler

InactiveCN1401411AReduce loadOvercome high loadFluidized bed combustionDispersed particle separationCombustionFlue gas

A combined desulfurizing process for removing the SO2 gas from the flue gas generated by circualting fluidized-bed boiler is characterized by that the raw lime stone reacts with the SO2 in the bed layer of boiler to remove part of SO2 by combustion and the unreacted and escaped calcium oxide further reacts with SO2 in the moistening tower for external removal of SO2. Its advantages are low cost and optimal desulfurizing effect.

Owner:SHANDONG SHENHUA SHANDA ENERGY ENVIRONMENTAL

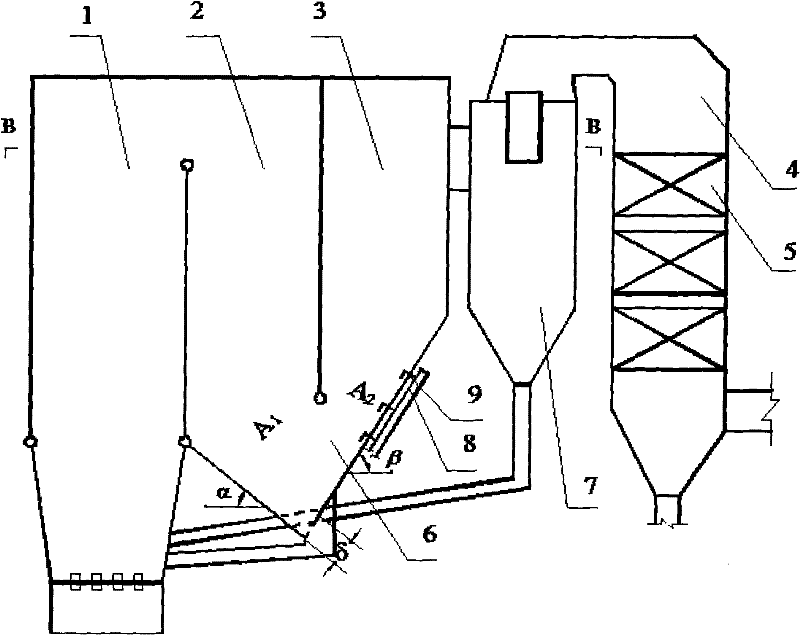

Multipath circulating fluidized bed boiler

ActiveCN101749696AGuaranteed separationGuaranteed long-term operationFluidized bed combustionIncinerator apparatusCombustion chamberPulp and paper industry

The invention discloses a multipath circulating fluidized bed boiler, which comprises a main combustion chamber, an auxiliary combustion chamber and an ash chamber which are parallel to the main combustion chamber, a tail flue, and a coal economizer and a centrifugal separator arranged in the tail flue; the bottom of the auxiliary combustion chamber is inclined to the ash chamber and the inclination angle alpha is between 30 and 60 degrees; the bottom of the ash chamber is inclined to the auxiliary combustion chamber and the inclination angle beta is between 45 and 75 degrees; a material falling passage is reserved between the bottom surface of the ash chamber and the bottom surface of the auxiliary combustion chamber; an asymmetrical inertia separation circulating device is formed by the bottom surfaces of the mutually inclined auxiliary combustion chamber, an inclined plate I and an inclined plate II fixed on the two sides, and the material falling passage; a flow area of the bottom of the ash chamber A2 is no more than half of a flow area A1 of the bottom of the auxiliary combustion chamber; and the bottom surface of the ash chamber is provided with a loose blast cap. The multipath circulating fluidized bed boiler can ensure the smooth conveying of materials and the required material separating amount, prevent the materials from accumulating on the bottom of the combustion chambers for a long time, and ensure smooth circulating, so that a combustion device normally operates for a long term.

Owner:TSINGHUA UNIV +1

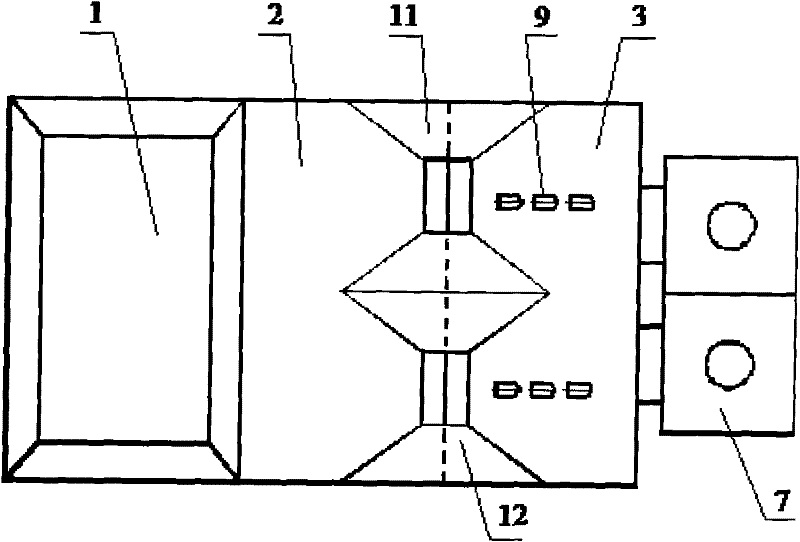

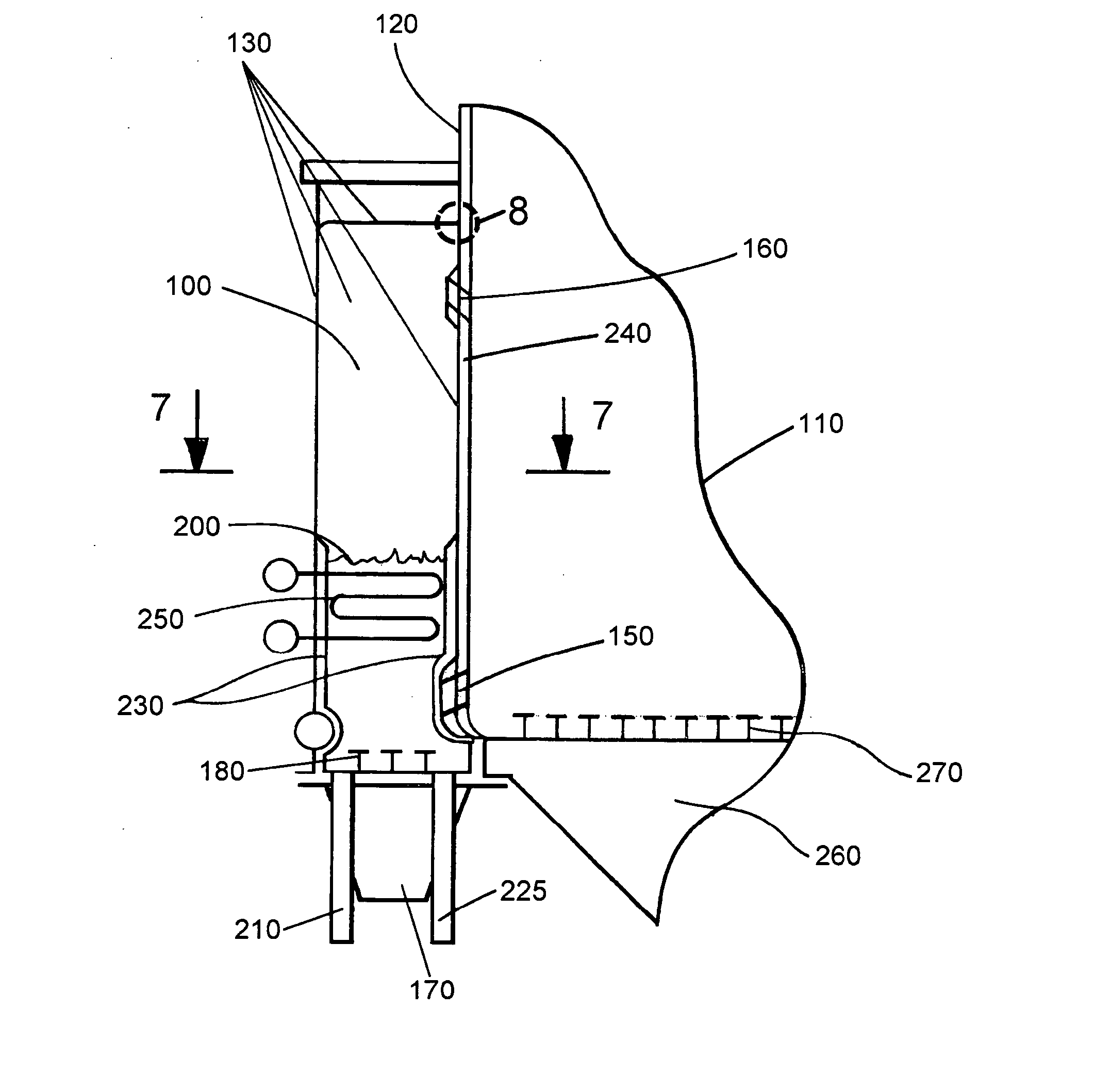

Integrated fluidized bed ash cooler

ActiveUS20070283902A1Reduction in size and weight and costSimple designFluidized bed combustionFluidised-bed furnacesHigh elevationFluidized bed

An integrated fluidized bed ash cooler for a fluidized bed boiler, particularly a circulating fluidized bed (CFB) boiler, employs at least two fluidized bed sections positioned in series along a solids flow path. Each section contains fluidizing means, the first section along the solids path being separated from a following section with a threshold. The first section contains means for measuring a bed temperature in the vicinity of the fluidizing means and at a higher elevation within the fluidized bed. Means are provided for removing oversized bed material from the first section to facilitate the removal of ash while minimizing the possibility of ash plugging during operation.

Owner:THE BABCOCK & WILCOX CO

Circulating fluid bed boiler flue calcium injection and desulfurization process

InactiveCN101311628AChange internal structureDoes not affect performance indicatorsLighting and heating apparatusSocial benefitsFlue gas

The flue gas injection calcium desulphurization process in a circulating fluidized bed boiler of the invention is characterized by sending CaO power to a horizontal flue of a cyclone separator with the temperature being equal or lesser than 850 DEG C or a first-level steam superheater or / and tail flue to carry out the desulphurization reaction for desulphurization. The concrete method is as following: spraying the desulfurizer power with the particle size being 100 to 800 items and the preference being 200 to 800 items to a furnace cavity through an overgrate air inlet, the middle part or the upper part of the furnace cavity of the boiler; wherein, the desulfurizer is limestone powder, raw lime powder or hydrated lime in powder. The device of the invention has the advantages of having a simple structure, not changing the inner structure of the boiler basically, not affecting the normal-index operation of the boiler, having high desulphurization efficiency, needing little investment and having low running cost, thereby realizing the ideal goal of low-cost desulphurization, achieving the perfect combination of economic benefit and social benefit of environmental-protection and discharging-reduction and having great popularization value.

Owner:YANKUANG GUOHONG CHEM

Method of combusting sulfur-containing fuel

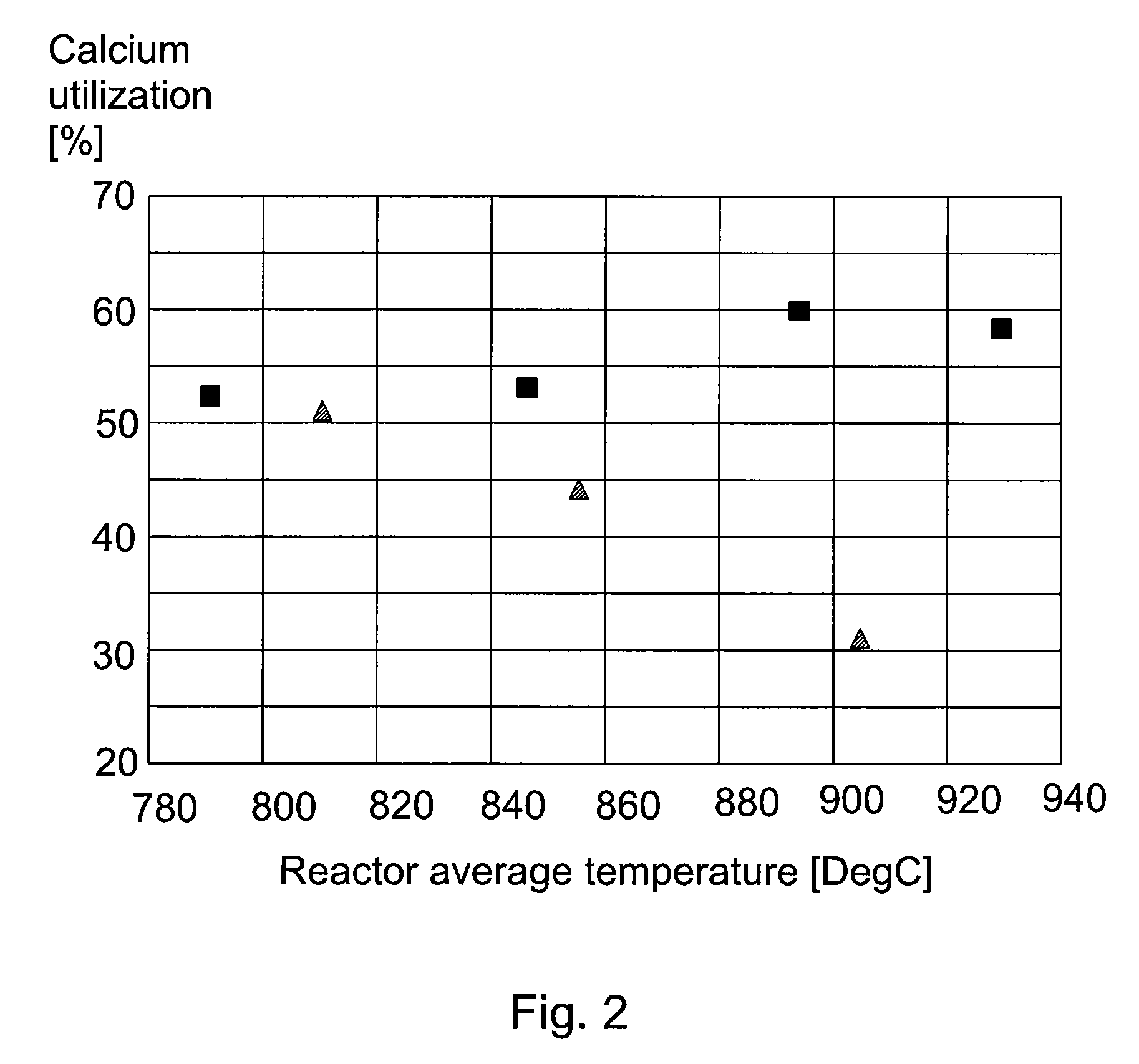

InactiveUS20100077947A1Easy to controlMaintain temperatureFluidized bed combustionAir supply regulationEngineeringComponents of crude oil

A method of combusting sulfur-containing fuel in a circulating fluidized bed boiler includes the steps of (a) feeding sulfur-containing fuel into a furnace of the circulating fluidized bed boiler, (b) combusting the fuel with oxidant gas consisting essentially of pure oxygen and circulated exhaust gas, so as to form exhaust gas having carbon dioxide and water as its main components, and (c) feeding calcium carbonate containing material into the furnace so as to capture sulfur dioxide into calcium sulfate in the furnace. The temperature in the furnace is maintained above 870° C.

Owner:FOSTER WHEELER ENERGY CORP

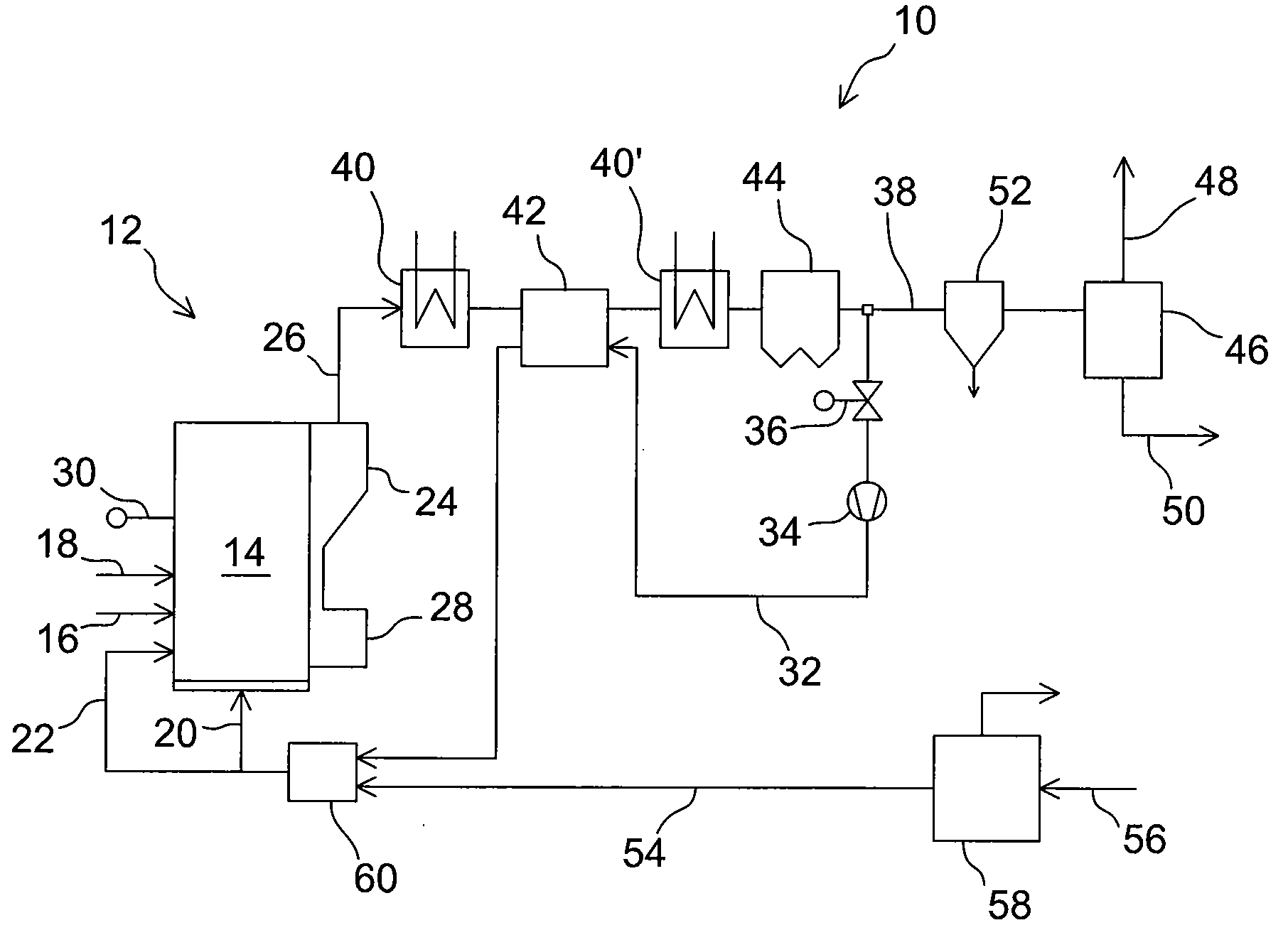

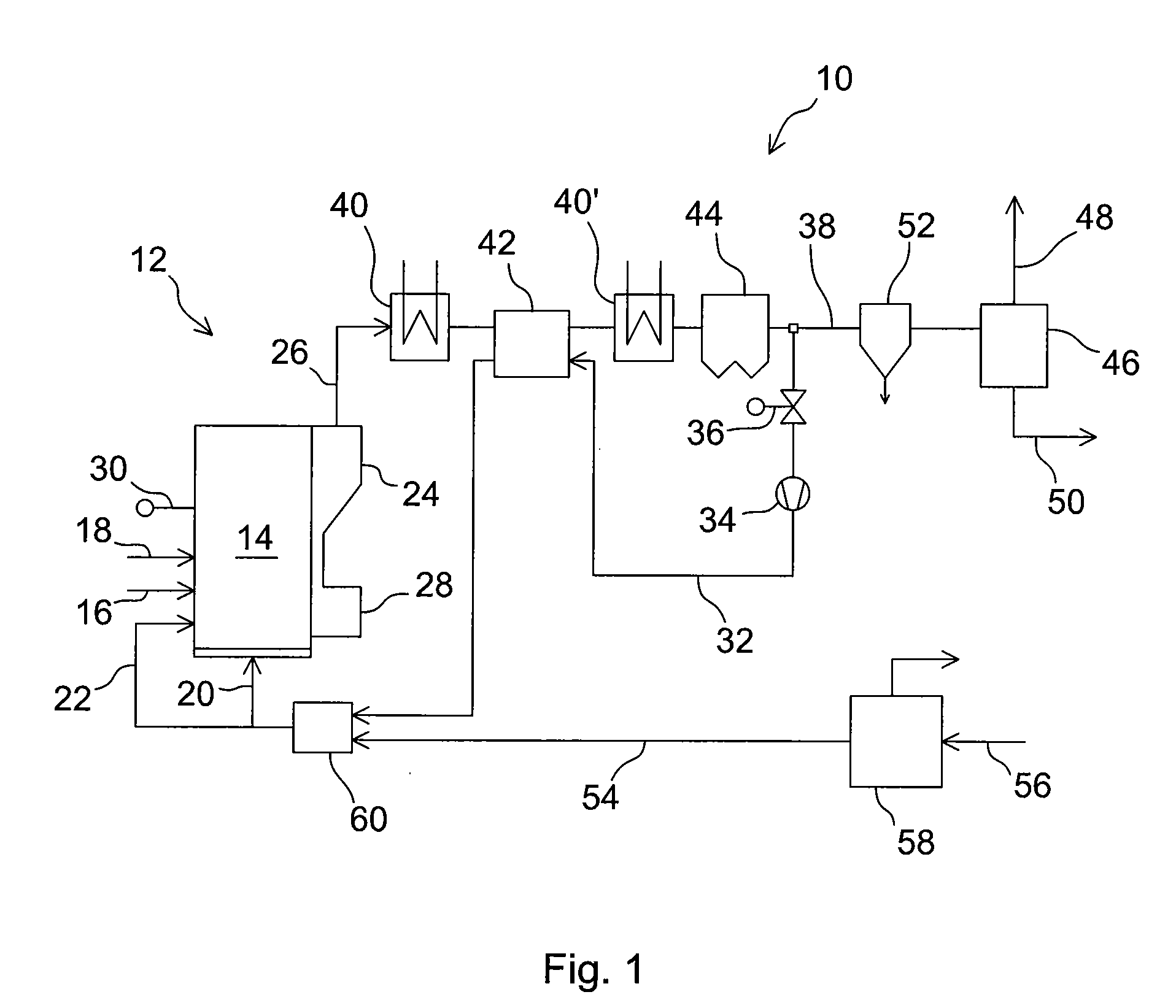

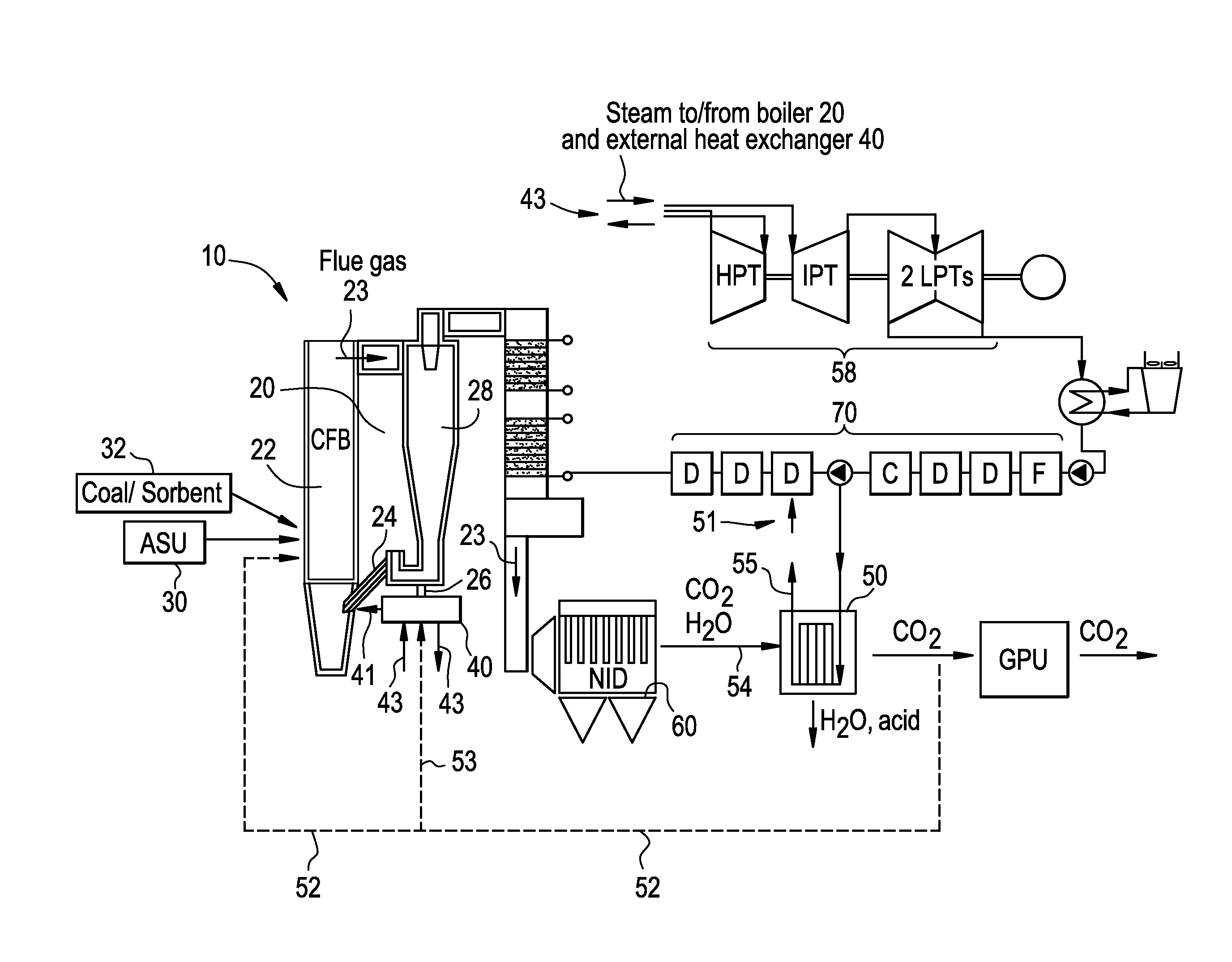

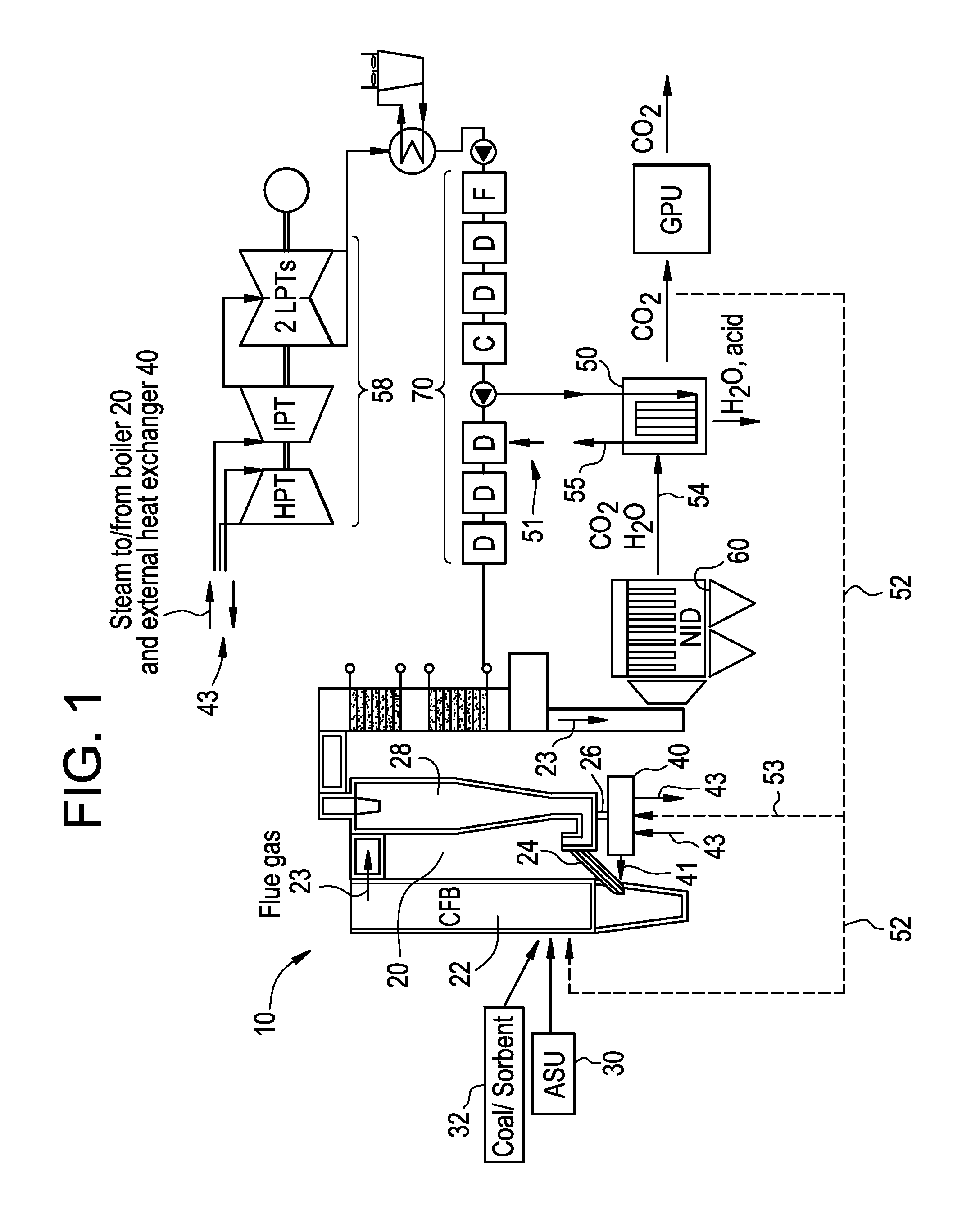

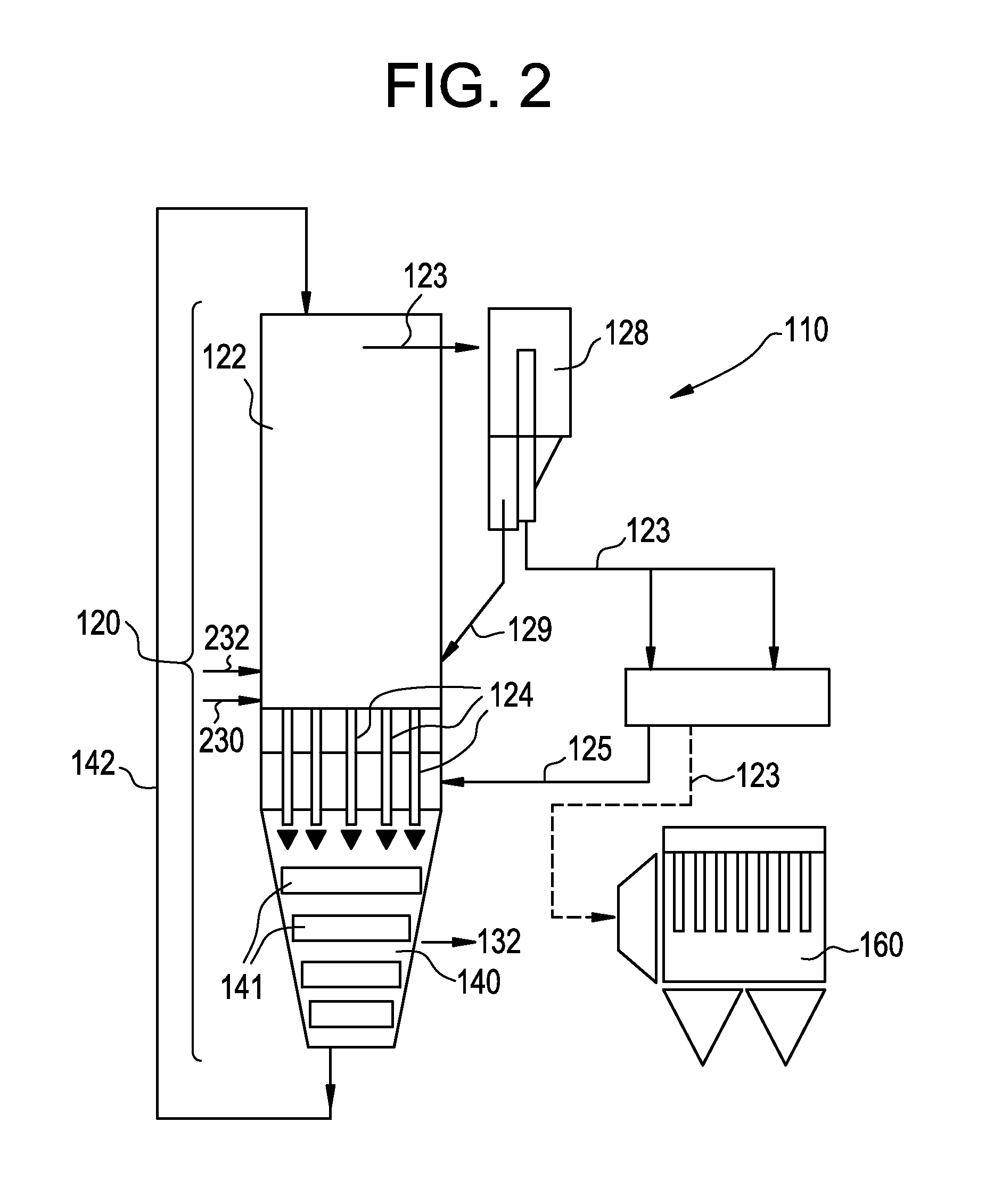

Pressurized oxy-combustion power boiler and power plant and method of operating the same

A pressurized oxy-combustion circulating fluidized bed power plant having a circulating fluidized bed boiler is provided. A combustion chamber of the boiler is in fluid communication with a separator and configured so that solids produced during combustion enter the separator. The power plant further includes an air separation unit that is in fluid communication with the combustion chamber. The air separation unit is configured to supply substantially pure oxygen to the combustion chamber at a pressure greater than 1 bar. An external heat exchanger is in fluid communication with the separator and in fluid communication with the combustion chamber. The external heat exchanger is configured so that a portion of the solids received in the separator pass through the external heat exchanger and transfer heat to a working fluid, after which the solids are returned to the combustion chamber to moderate or control the temperature in the combustion chamber.

Owner:GENERAL ELECTRIC TECH GMBH

Corundum mullite rock wear-resistant refractory castable

InactiveCN101570442AMeet the use requirementsExcellent medium temperature strengthAluminium hydroxideWear resistant

The invention discloses a corundum mullite rock wear-resistant refractory castable which belongs to refractory materials, aiming at providing an unshaped refractory material with high medium temperature strength and good thermal shock resistance and erosion and wear resistance. According to weight percentages, the invention is formed by evenly mixing 89-96% of wet pug, 2-6% of calcium aluminate cement and 2-5% of bonding agent; the bonding agent is prepared by 20-30% of industrial aluminum hydroxide fine powder, 67-79% of phosphoric acid with concentration being 45% and 1-3% of chromium oxide green fine powder; the wet pug is prepared by taking corundum with certain particle grading or mixture of corundum and mullite as aggregate and adding the bonding agent and additive, the additive is prepared by 60-76% of white alundum powder, 15-25% of activated alumina fine powder, 5-15% of silicon fine powder, 3-8% of sodiumtripolypolyphosphate and 1-8% of sodium borate. The invention is mainly used as an ideal refractory castable for circulating fluid bed boiler lining and cement kiln lining.

Owner:贵阳明通炉料有限公司

Kerosene shale comprehensive utilization process

InactiveCN101113344ALarge amount of processingHigh utilization rate of dry distillationInternal combustion piston enginesGaseous engine fuelsWorking fluidSlag

The invention relates to a comprehensive utilization process of oil shale. Oil shale raw ore is crushed by a crushing and screening device until the particle size is less than 15mm; one part of crushed oil shale particles are transported to a screw feeder and then to a microwave drum dry distillation device, the oil shale particles absorb microwave and generate high temperature methane gas, distilled char and methane gas are entered into a closed solid and gas separating device, separated high temperature methane gas is entered into a condensing and recycling device and cooled to separate the oil shale; low temperature methane gas after oil extraction is entered into an internal combustion engine to be combusted for power generation and / or entered into a circulating fluidized bed boiler to be combusted, heat quantity released from the combustion is transmitted to water by the heating surface of a boiler, the superheated steam is supplied as working fluid or sent into a steam turbine to generate electricity; carbon-content of the slag and ashes is less than 2 percent and the finished product can be directly as building raw materials without roasting. The invention has the advantages of short process, comparatively small occupying space, high comprehensive utilization, low cost, being scientific and rational, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com