Method of combusting sulfur-containing fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

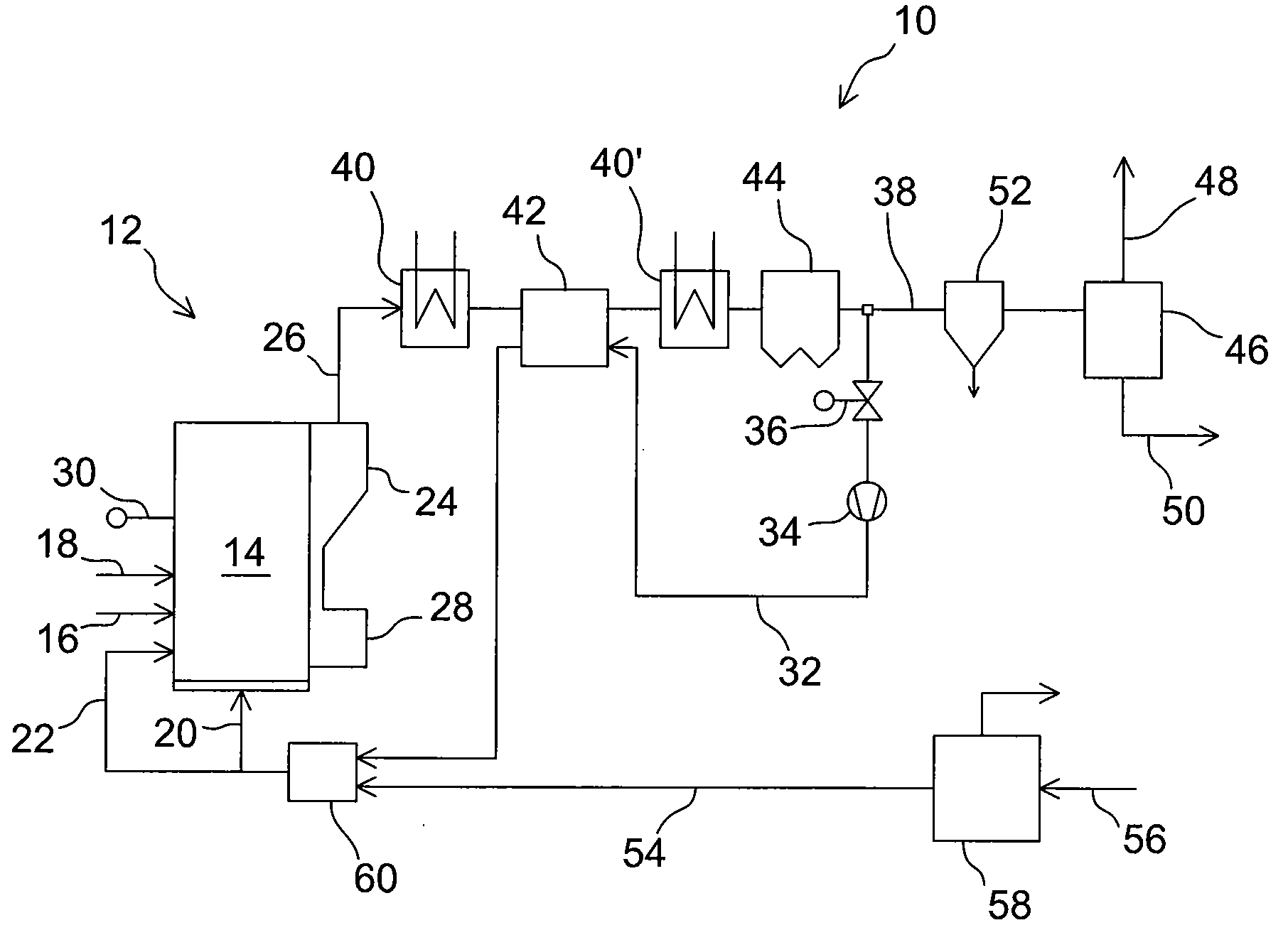

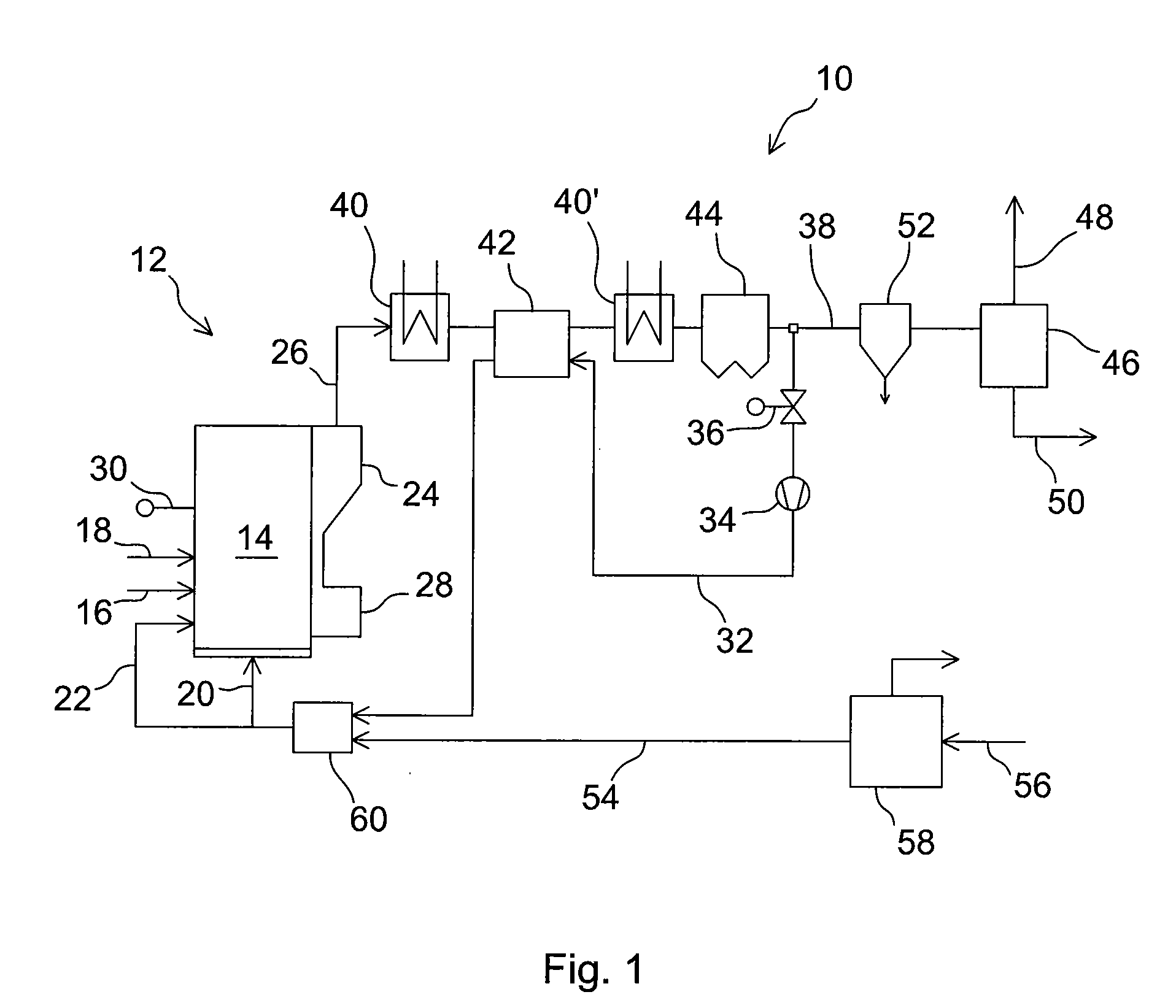

Method used

Image

Examples

Embodiment Construction

.

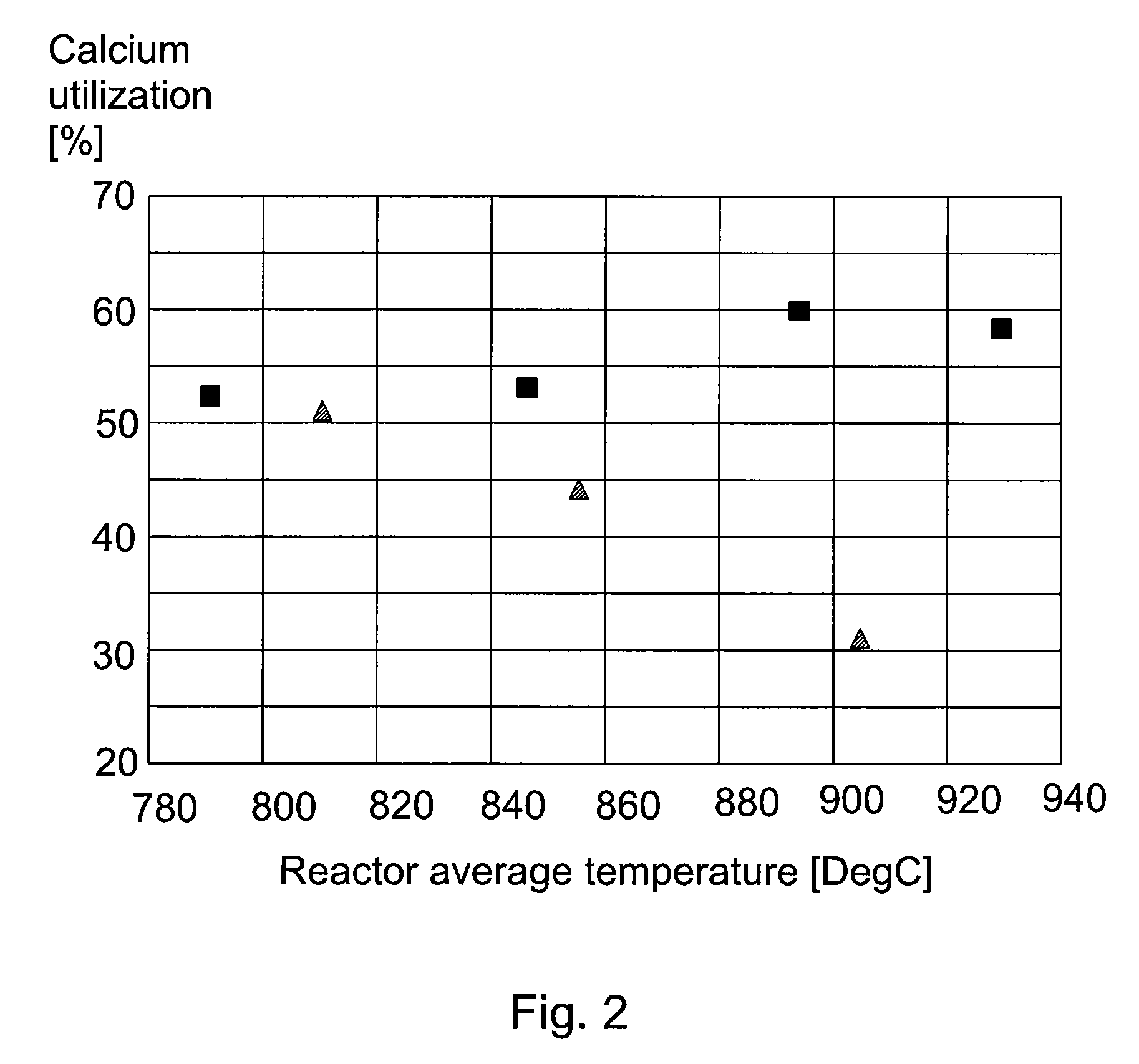

[0015]It appears that the conditions giving rise to a decreasing sulfur capture at high temperatures in air-firing fluidized bed boilers are changed in oxyfuel combustion. As a result of the change, the temperature range of decreasing efficiency appears to be removed, or at least shifted to a higher temperature. An improved sulfur capture in the furnace in oxyfuel combustion can be expected, at any temperature, on the basis of the extended time of SO2 presence in the furnace, due to the recirculation of the exhaust gas. In addition to that, the contents of the gas in the furnace are, in oxyfuel combustion, clearly different than those in air combustion. Thus, the enhanced sulfur capture at high temperatures may be related to the higher content of CO2 or O2 in the furnace.

[0016]Similar enhanced sulfur capture at high temperatures has been observed earlier in air-firing fluidized bed boilers when used at elevated pressures of 10 to 20 atm. In that case, the improved sulfur capture at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com