Automatic regulating system for combustion process of circulating fluid bed in boiler

A circulating fluidized bed and boiler combustion technology, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, combustion methods, etc., can solve the problem of starting point of analysis, deviation of key points, disorder of the adjustment system circuit, automatic adjustment can only Problems running in a localized, stable environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

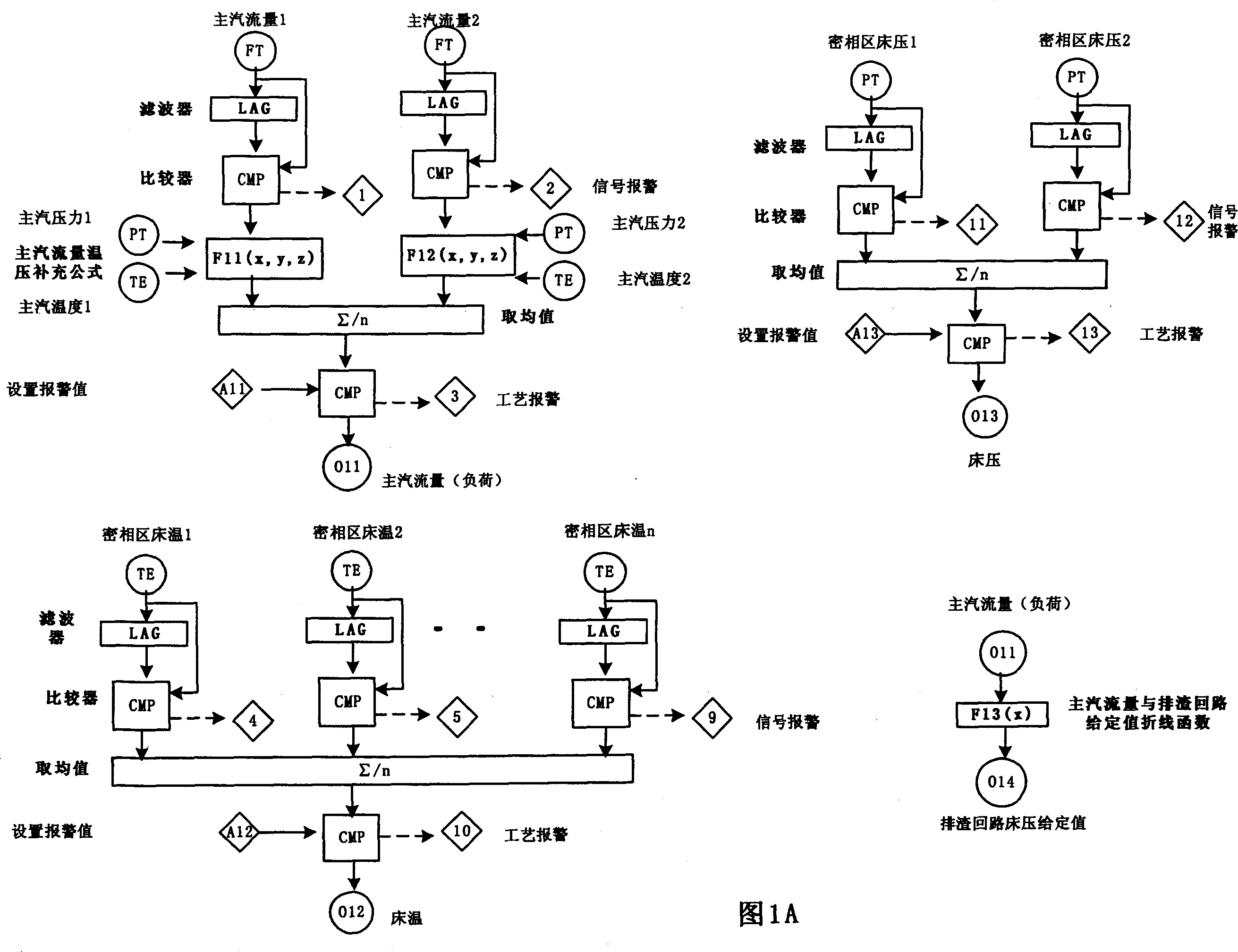

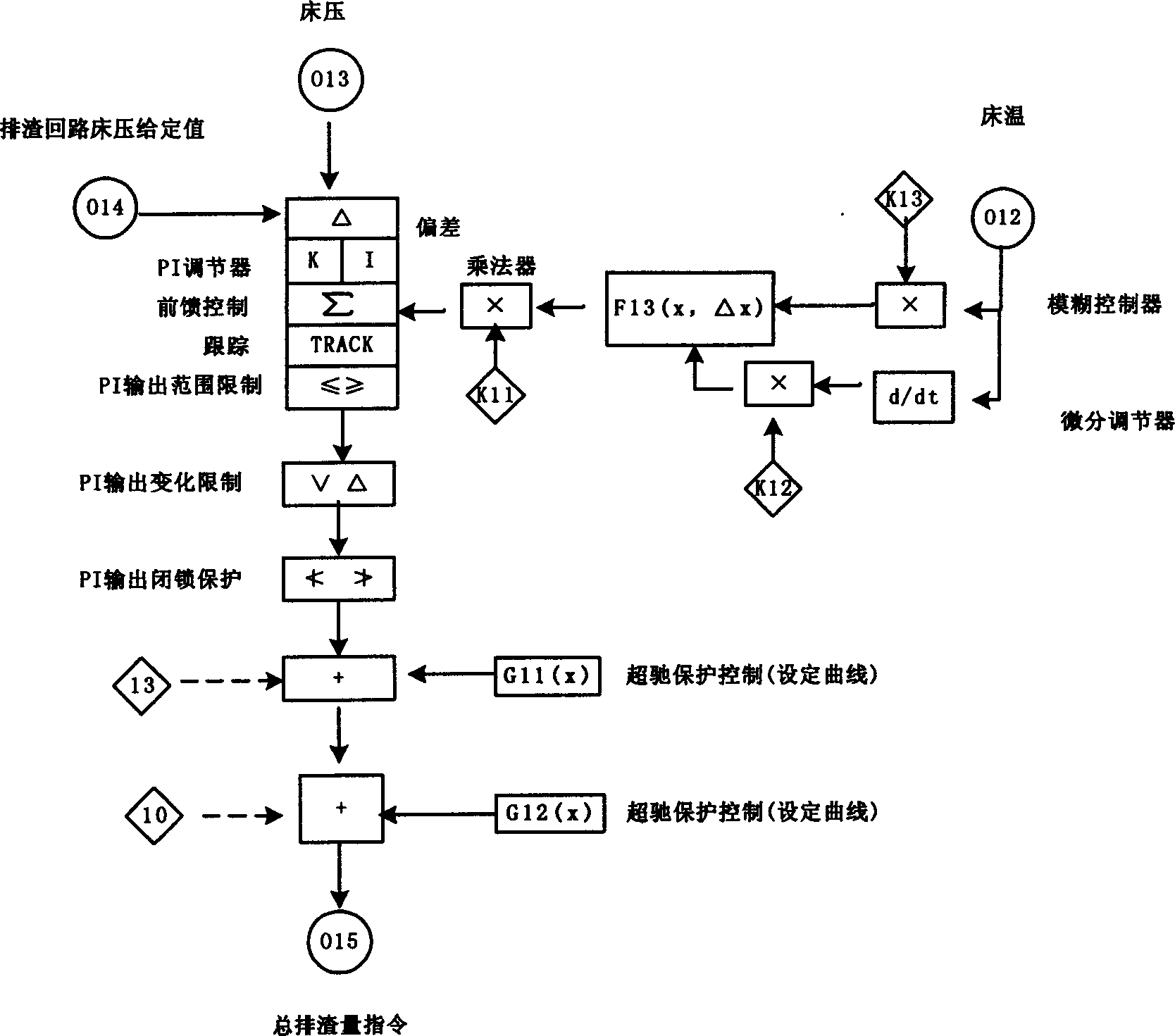

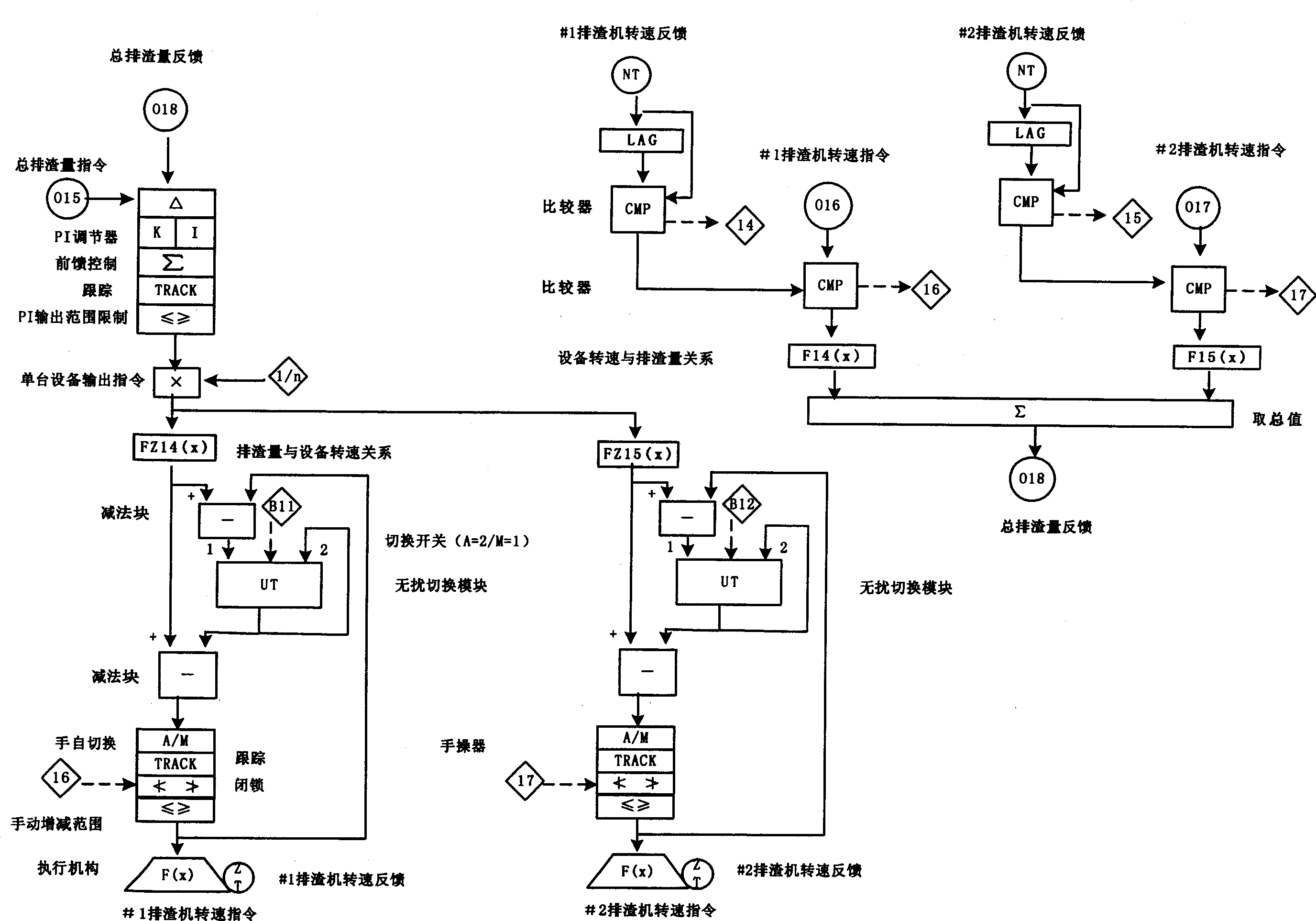

[0024] During on-site adjustment, when an adjusted variable changes, because the adjusted variable is coupled, one or several adjusted variables must be adjusted from the system point of view to realize the adjustment. It is difficult to judge which adjusted variable occupies the main location. Therefore, in the present invention, instead of using the adjusted quantity as the name and main focus of the control loop, the adjusted quantity is used as the name and main focus of the control loop to meet the on-site adjustment requirements and comply with operating habits. Accordingly, the combustion automatic adjustment system of the present invention includes: a slag discharge adjustment circuit, a primary air volume adjustment circuit, a coal feeding adjustment circuit, a secondary air volume adjustment circuit, and an induced air volume adjustment circuit. In order to adapt to the complexity and diversity of the process and solve the difficulty of adjusting control variables, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com