A Communication Heterogeneous Feed System for CNC Machine Tool and Its Debugging Method

A technology of feed system and CNC machine tool, applied in the direction of digital transmission system, transmission system, data exchange network, etc., can solve the problem of lack of literature, and achieve the effect of increasing openness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

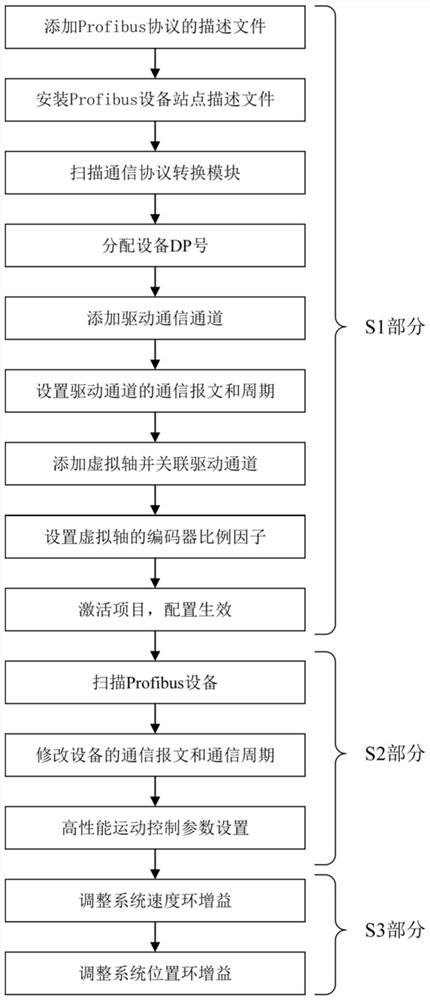

Method used

Image

Examples

Embodiment 1

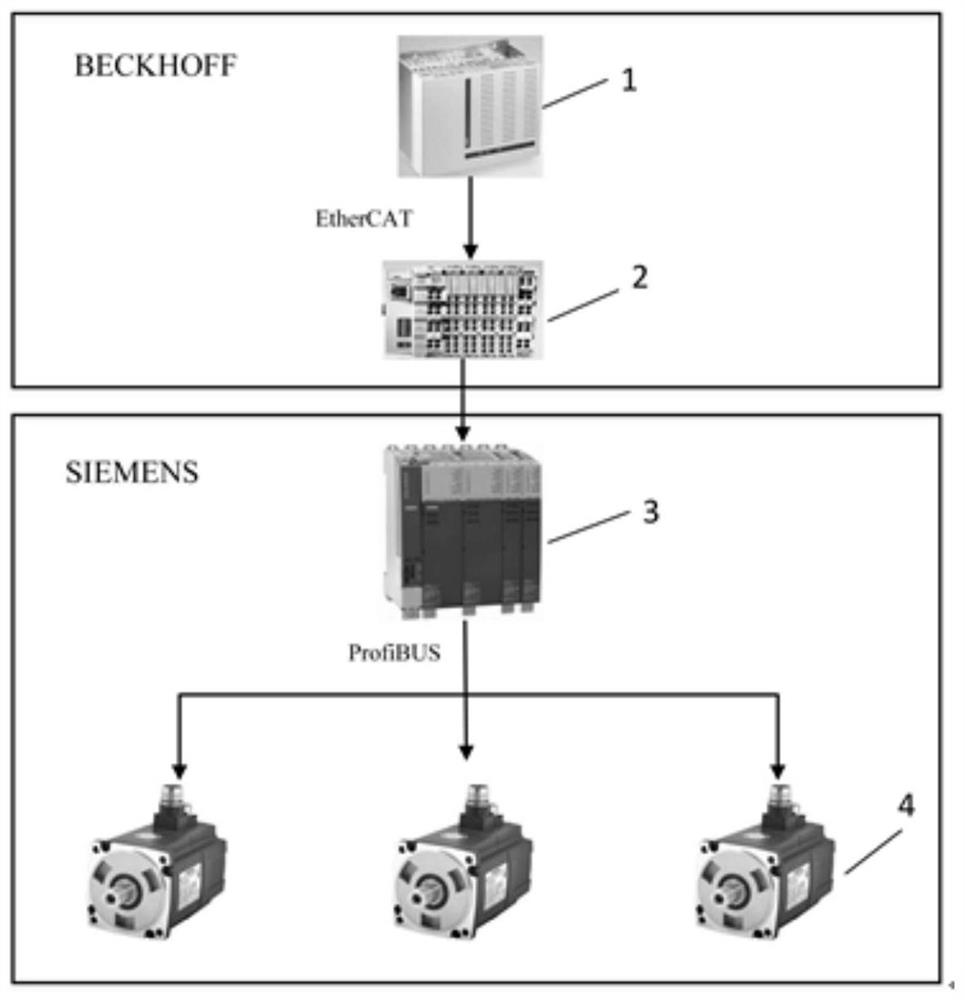

[0060] Embodiment 1: The present invention will be specifically described by taking a laser processing machine tool feed system as an example.

[0061] Such as Figure 4 Shown is a physical picture of the electrical cabinet of a laser processing machine tool, in which the industrial computer adopts Beckhoff C6640-0040 industrial computer, equipped with CoreTM i7 2.3GHz CPU, with 8G running memory, the system uses win7 professional version, and installs TwinCAT software, supports EtherCAT protocol.

[0062] The servo system adopts Siemens CU320 motor control unit, S120 DC / AC servo motor driver, and 1FK7 series servo motors, all of which support the ProfiBUS protocol.

[0063] The communication protocol conversion module adopts Beckhoff EL6731 module.

[0064] The power supply and communication wiring of the feeding system are as follows: the industrial computer adopts single-phase 220V power supply, the Siemens servo adopts three-phase 380V power supply, and the EL6731 module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com