IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

A low-deterioration pulverized coal, pyrolysis gasification technology, applied in the direction of gas turbine equipment, granular/powdered fuel gasification, combustible gas purification, etc., can solve the problems of high investment costs, economic competition, and inflexible operation, and achieve consumption The effect of small water volume, high thermal energy efficiency and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

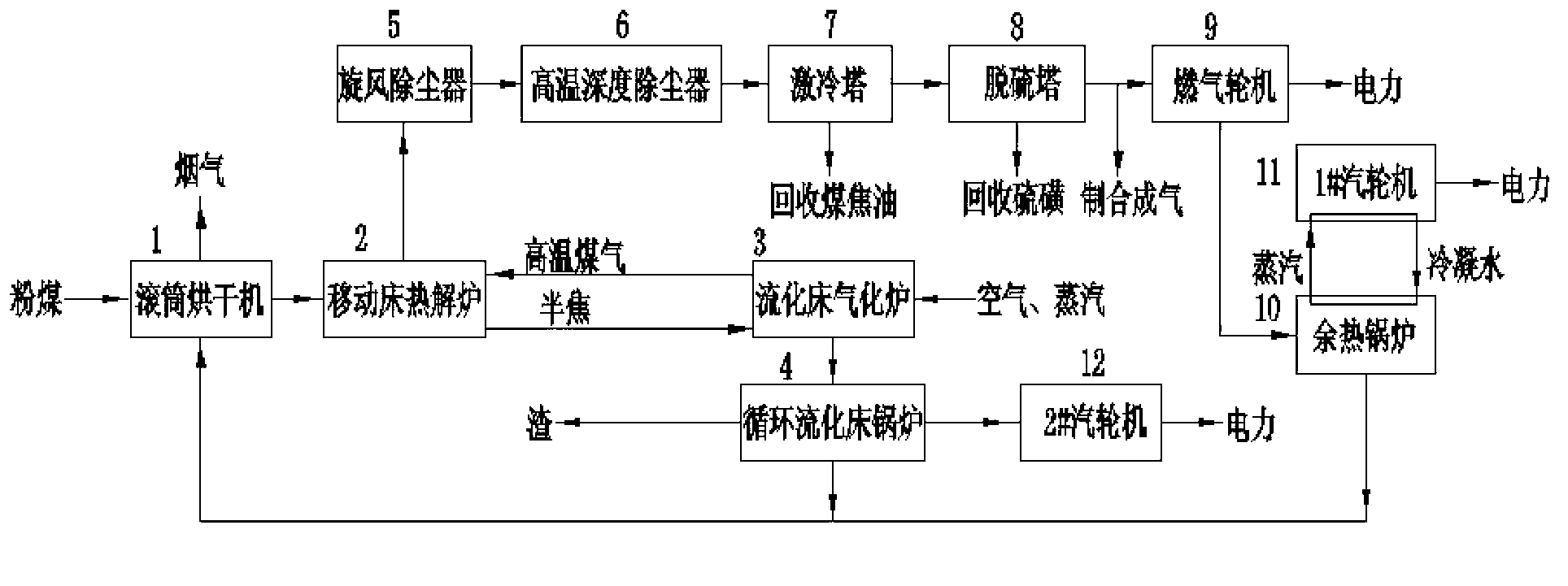

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see figure 1 , the device of the present invention includes a pyrolysis / gasification system, a gas purification system, a circulating fluidized bed boiler, a gas turbine / steam turbine system;

[0025] The pyrolysis / gasification system includes a tumble dryer 1, a moving bed pyrolysis furnace 2, and a fluidized bed gasification furnace 3 connected in sequence;

[0026] The gas purification system comprises a cyclone dust collector 5, a high-temperature depth dust collector 6, a quenching tower 7 and a desulfurization tower 8 connected in sequence, wherein the cyclone dust collector 5 communicates with the moving bed pyrolysis furnace 2;

[0027] The inlet of the circulating fluidized bed boiler 4 is connected with the fluidized bed gasifier 3, and the flue gas outlet of the circulating fluidized bed boiler is connected with the tumble dryer 1 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com