Circulating fluid bed boiler flue calcium injection and desulfurization process

A technology of circulating fluidized bed and desulfurization process, which is applied in the field of flue gas calcium spraying desulfurization process in circulating fluidized bed boiler furnace, which can solve the problems of boiler output decline, affecting economic benefits, normal calcium spraying and desulfurization, etc., and achieves low investment , low operating cost and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

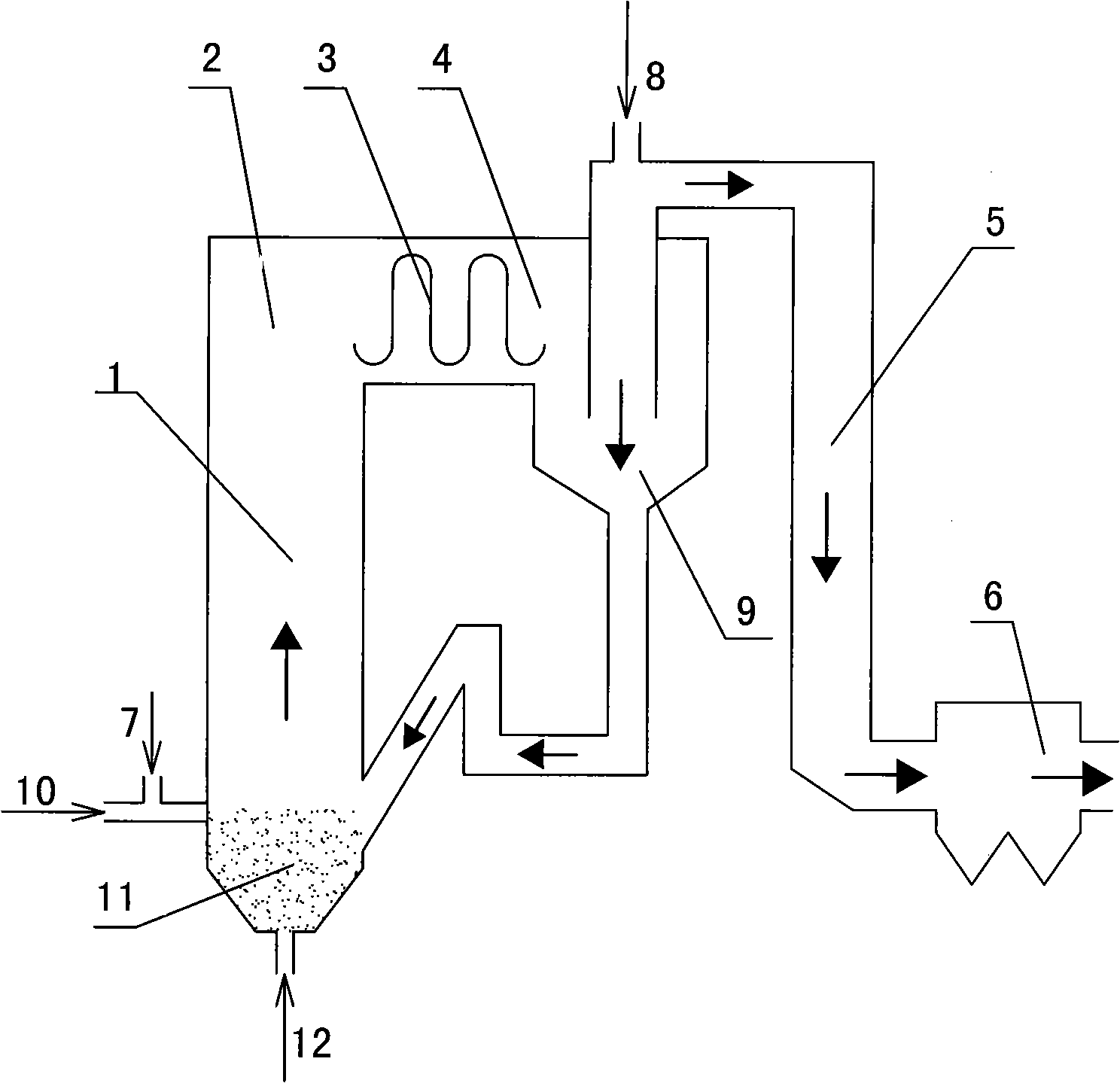

[0034] Below in conjunction with embodiment accompanying drawing description.

[0035] figure 1 Except for the desulfurizing agent inlet 7 and the desulfurizing agent inlet 8, it is a schematic structural diagram of an existing circulating fluidized bed boiler. Simultaneously showing the desulfurizer inlet 7 and the desulfurizer inlet 8 (on the horizontal flue, it can also be set on the tail flue, preferably the position of the horizontal flue) is for the convenience of description. In fact, for circulating fluidized bed boilers, the desulfurizer inlet 7 or other inlets close to it are generally selected (the desulfurizer inlet 8 is not provided), regardless of whether the desulfurizer is limestone powder, quicklime powder or slaked lime powder. And the desulfurizing agent inlet 8 only has the possibility to inject from this position when the desulfurizing agent is unslaked lime powder.

[0036] In the furnace 1 of the circulating fluidized bed boiler, the desulfurizer is sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com