Vertical net laying system for honeycomb porous structure cotton and using method thereof

A porous structure, vertical technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of weak functionality and unable to change the internal structure of the textile body, and achieve strong functionality, strong cross effect, and long running distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

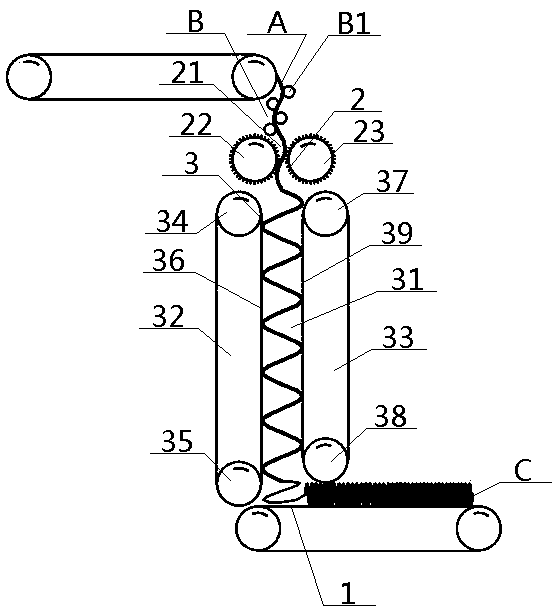

[0050] see Figure 1 to Figure 6 , a vertical web laying system for honeycomb porous structure cotton, comprising a reciprocating cotton feeding device 2, a vertical cotton discharge device 3 and a horizontal conveyor belt 1, and the reciprocating cotton feeding device 2 includes a left reciprocating roller 22, a right reciprocating roller The roller 23 and the cotton feeding channel 21 sandwiched therebetween, the vertical cotton discharge device 3 includes a left cotton discharging part 32, a right cotton discharging part 33 and a cotton discharging channel 31 sandwiched therebetween, the bottom of the cotton feeding channel 21 The outlet communicates with the top inlet of the cotton discharge channel 31, and the bottom outlet of the cotton discharge channel 31 communicates with the top surface of the horizontal conveyor belt 1 directly below it; the top inlet of the cotton feeding channel 21 communicates with the filament introduction area B, The front and rear filaments B1...

Embodiment 2

[0053] Basic content is the same as embodiment 1, the difference is:

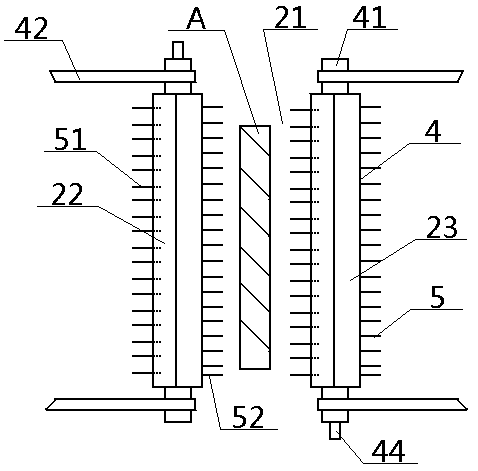

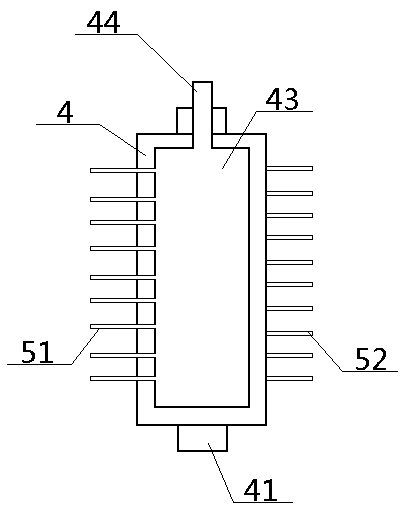

[0054]The inside of the reciprocating roller body 4 is provided with a roller cavity 43, the end of the roller cavity 43 is connected with the inner end of the air inlet pipe 44, and the outer end of the air inlet pipe 44 passes through the end of the reciprocating roller body 4 successively, drives The shaft 41 communicates with the external air source behind; the reciprocating needle 5 includes a ventilation needle 51 and a closing needle 52, the ventilation needle 51 is arranged on the left side of the reciprocating roller body 4, and the closing needle 52 is arranged on the right side of the reciprocating roller body 4 On the outside, the breathable needle 51 is a hollow structure, the inner end of the breathable needle 51 is connected with the inner cavity 43 of the roller, and the outer end of the breathable needle 51 passes through the inner cavity 43 of the roller and extends to the left side of the ...

Embodiment 3

[0057] Basic content is the same as embodiment 1, the difference is:

[0058] The left cotton discharge section 32 includes a plurality of left licker-in rollers 6 arranged sequentially from top to bottom, and the right cotton discharge section 33 includes a plurality of right licker-in rollers 60 arranged sequentially from top to bottom. The structure of the roller 6 and the right licker-in roller 60 is consistent, and both include a licker-in roller body 61 and a plurality of row burrs 62 uniformly arranged along its side circumference, the row burrs 62 on the left licker-in roller 6, and the row burrs on the right licker-in roller 60. A cotton discharge channel 31 is sandwiched between the cotton burrs 62 .

[0059] In the process of passing through the cotton discharge channel 31, the cotton discharge needles 62 on the left licker-in roller 6 and the cotton discharge needles 62 on the right licker-in roller 60 continuously punch the textile body A after reciprocating foldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com