Patents

Literature

139results about How to "Change internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

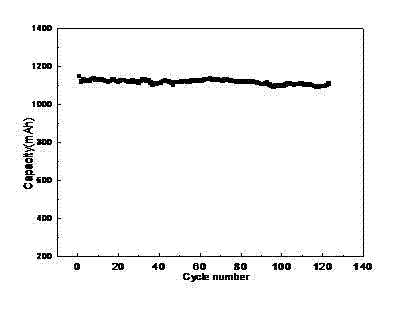

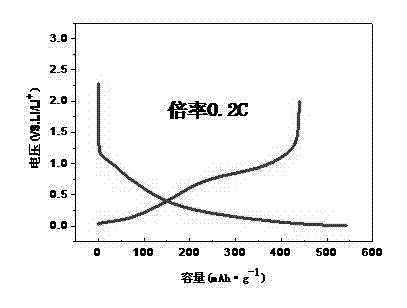

Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

InactiveCN102820455AIncrease capacityImprove the first Coulombic efficiencyCell electrodesDischarge efficiencyPhysical chemistry

The invention relates to a hard carbon negative electrode material of a lithium ion battery, and a preparation method and application of the hard carbon negative electrode material. The hard carbon negative electrode material is doped with silicon and phosphorus, wherein the mass ratio of silicon precursor, phosphorus precursor and hard carbon precursor is 1:(0.1 to 5):(5 to 30). Due to the addition of silicon / phosphorus, the hard carbon negative electrode material provided by the invention is remarkably improved in the first discharge capacity (up to 550.8mAh / g), the first charge / discharge efficiency (up to 80.9%) and the first coulombic efficiency by doping, is remarkably reduced in the irreversible capacity, and has the advantages of excellent cycle performance and rate capability, good PC (poly carbonate) consistency and high PC resistance, wherein the capacity retention ratio is above 95% after discharge cycle for 100 weeks at a high discharge rate of 10C.

Owner:天津市贝特瑞新能源科技有限公司

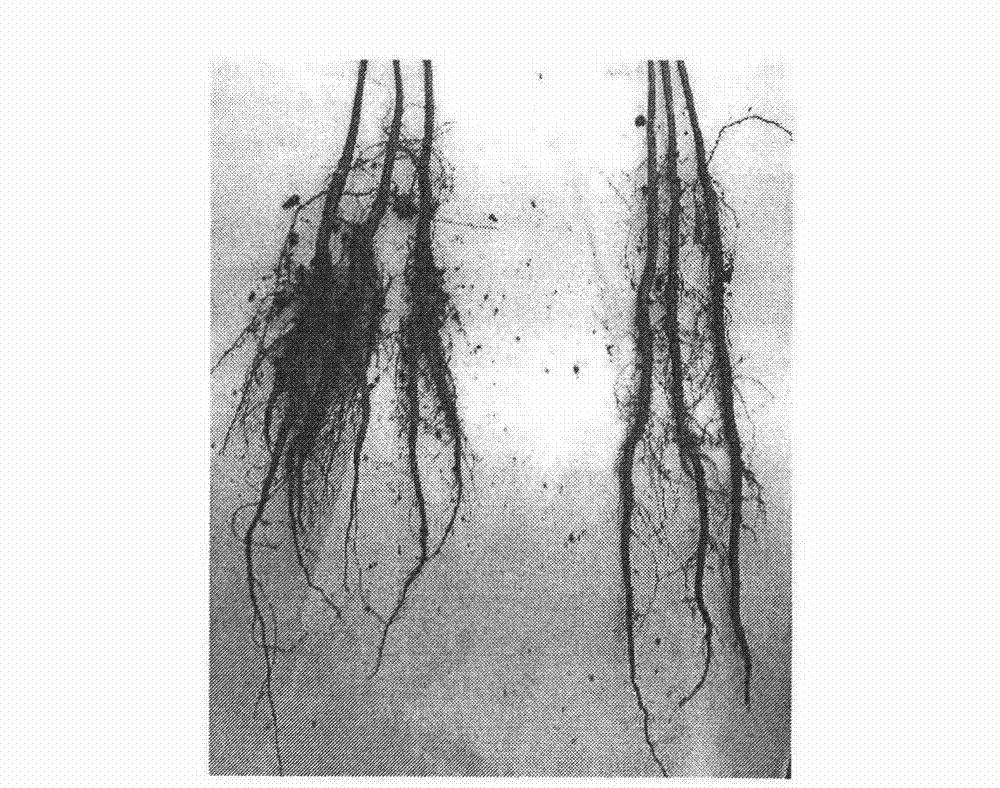

Method for promoting lateral rooting of annual carya illinoensis seed seedling

ActiveCN102823358AImprove germination rateShorten germination timeSeed and root treatmentHorticultureFruit treeCarya illinoensis

The invention belongs to the technical field of fruit trees and forestry cultivation, and discloses a method for promoting the lateral rooting of a annual carya illinoensis seed seedling, the root of a sprouting carya illinoensis seed seedling is mechanically cut, and a pair of scissors is utilized to cut the part below the fibrous root; and the seedling which is subjected to mechanical root cutting is transplanted into a nutrition pot, melon seed-shaped pebbles are laid on the bottom of the nutrition pot for 5 centimeters, and a nylon net is cushioned on the melon seed-shaped pebbles. A matrix is put in a container, the seedling is transplanted in a facility which is cold-proof and sun-proof for one month, a furrow which has the width of 13 centimeters and the depth of 20 centimeters is defined in a seedbed of a land, and the row spacing of the furrow is 30 centimeters. A layer of non-woven fabric is laid at the bottom of the furrow, a chemical rooting-resistant agent is coated on the non-woven fabric, and the nutrition pots which are planted with the seedlings are put on the non-woven fabric according to the planting distance of 20 centimeters, and are fixed finally. The water and fertilizer management period is normally carried out. The method can be used for effectively promoting the lateral rooting of the carya illinoensis seed seedling.

Owner:南京绿宙薄壳山核桃科技有限公司 +1

Dyeing technology of nylon-imitating high-elastic polyester yarn

InactiveCN103498350AImprove featuresEnsure stabilityFibre typesHeating/cooling textile fabricsTextile printerPolyester

The invention relates to the technical field of textile printing and dyeing, and provides a dyeing technology of a nylon-imitating high-elastic polyester yarn. According to the dyeing technology, by combining of low-elastic polyester and twisting into high-elastic polyester, the nylon yarn dyeing problem can be solved and an elastic hand feeling effect of the nylon yarn can be achieved, and the dyeing technology comprises a polyester yarn dyeing preprocessing process, a yarn reeling process, high temperature preforming, a dyeing process, a reduction cleaning process, a finishing process and a dehydration drying process.

Owner:福建锦丰印染有限公司

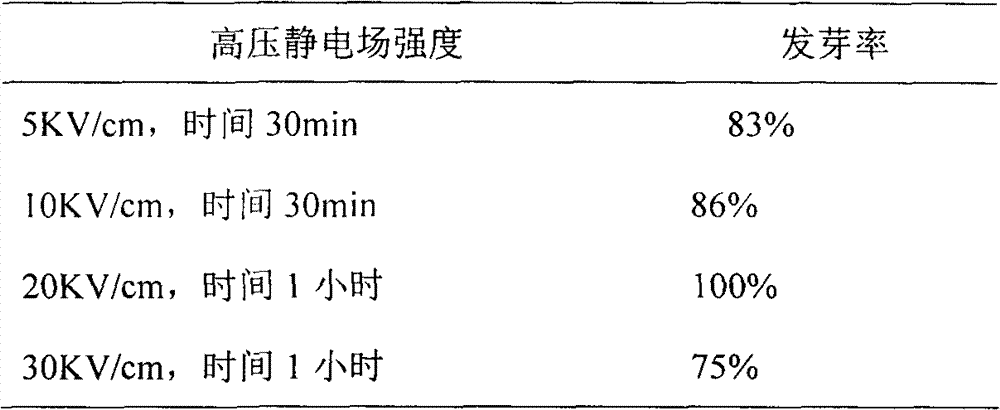

Method for accelerating germination of carya illinoensis seeds in late winter and early spring

ActiveCN102823357AImprove germination rateShorten germination timeSeed and root treatmentFruit treeLate winter

The invention relates to a method for accelerating germination of carya illinoensis seeds in late winter and early spring, belonging to the technical field of fruit tree and forest cultivation. The method comprises the steps of: 1) collecting seeds and removing impurities; 2) soaking the seeds in 3% of potassium permanganate solution for 30min for sterilization; 3) soaking the seeds in cold water for 5 days; 4) laminating and storing in sand at low temperature; 5) soaking the seeds by hormone: soaking the seeds in 500mg / L of GA3 (gibberellic acid), 50mg / L of IBA (indolebutyric acid) and 50mg / L of 6-BA (6-benzyl aminopurine) for 24 hours; 6) treating in a high-voltage electrostatic field (HVEF) with intensity of 30KV / cm for 1 hour; and 7) accelerating germination and sowing, and counting the germination rate after a month, wherein the germination rate is above 96%. By using the method, the sowing of the seeds is brought forward by more than 2 months and significance is brought to the seedling culture of the carya illinoensis.

Owner:南京绿宙薄壳山核桃科技有限公司 +1

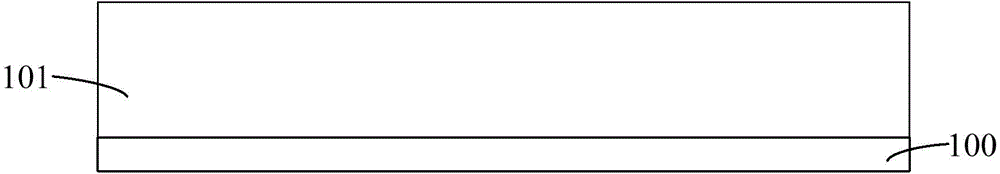

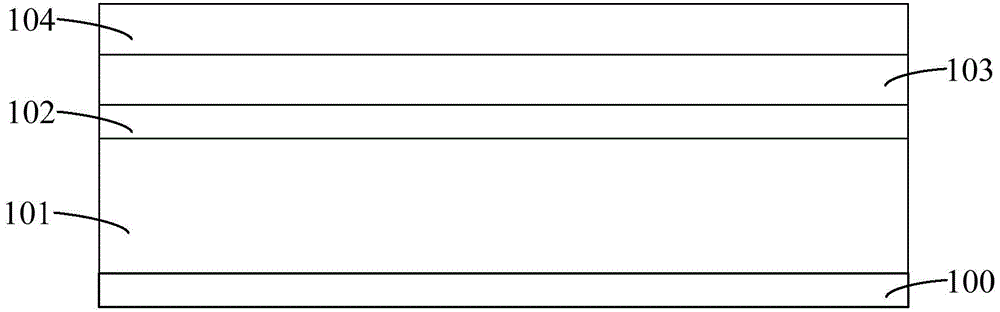

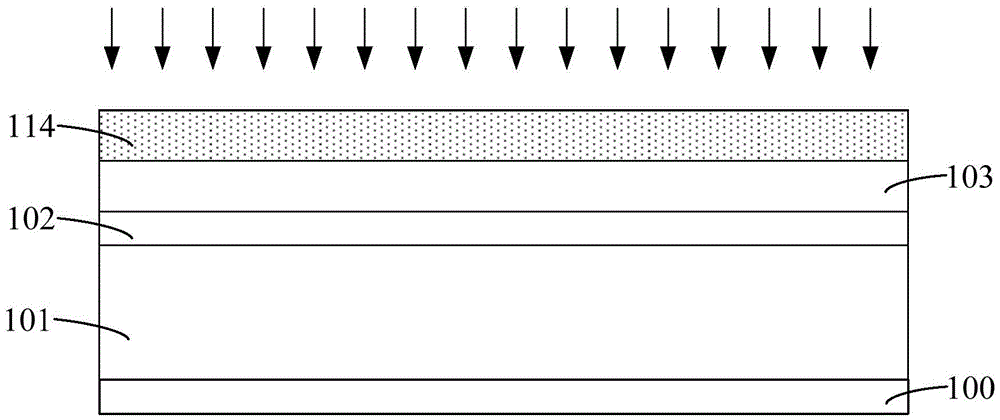

Formation method of semiconductor structure

ActiveCN105719956AHigh positioning accuracyEasy to shapeSemiconductor/solid-state device manufacturingSemiconductor structureDry etching

A method for forming a semiconductor structure, comprising: providing a base; forming an initial mask layer on the base; performing doping treatment on the initial mask layer to convert the initial mask layer into a doped mask layer; A first pattern layer having a first opening is formed on the surface of the doping mask layer; using the first pattern layer as a mask, a dry etching process is used to etch the doping mask layer along the first opening, forming a second opening through the doping mask layer, and the etching rate of the doping mask layer in the dry etching process is higher than the etching rate of the initial mask layer; removing the first pattern layer. The etching rate of the doped mask layer in the dry etching process of the present invention is greater than the etching rate of the initial mask layer, so there is no need to form an organic distribution layer, avoiding the problem of residual organic distribution layer materials, and improving the initial mask layer and the second mask layer. Second, the cleanliness of the opening improves the yield rate of the formed semiconductor structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

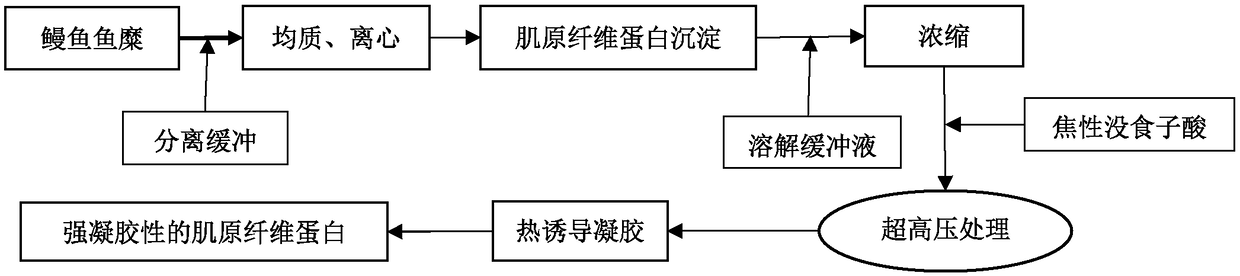

Preparation method of strong gelatin fibrillin

InactiveCN108617848AChange internal structureAdjust qualityProtein composition from fishProteins working-up by texturisingProtein solutionMyofibril

The invention discloses a preparation method of strong gelatin fibrillin. The method comprises the following steps of (1) preparing fibrillin; (2) dissolving the fibrillin; performing concentration toobtain concentration liquid; (3) adding the concentration liquid into pyrogallic acid; performing uniform mixing; thus obtaining a mixed protein solution after the placement at the normal temperature; (4) performing vacuum packaging on the mixed protein solution; performing treatment at ultrahigh pressure; (5) performing program temperature rise on materials obtained in the step (4); performing sharp cooling to obtain the strong gelatin fibrillin. The system oxidization degree of the fibrillin is weakened by using the oxidization resistance of pyrogallic acid; ultrahigh pressure treatment iscombined, so that the inside structure of the fibrillin is changed; the uniform three-dimensional network gel structure is formed. The method is applicable to the field of food processing auxiliary materials; the quality of fish meat products is regulated.

Owner:XIAMEN UNIV

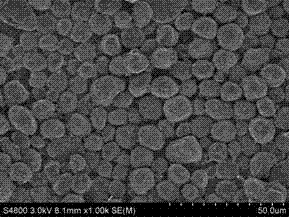

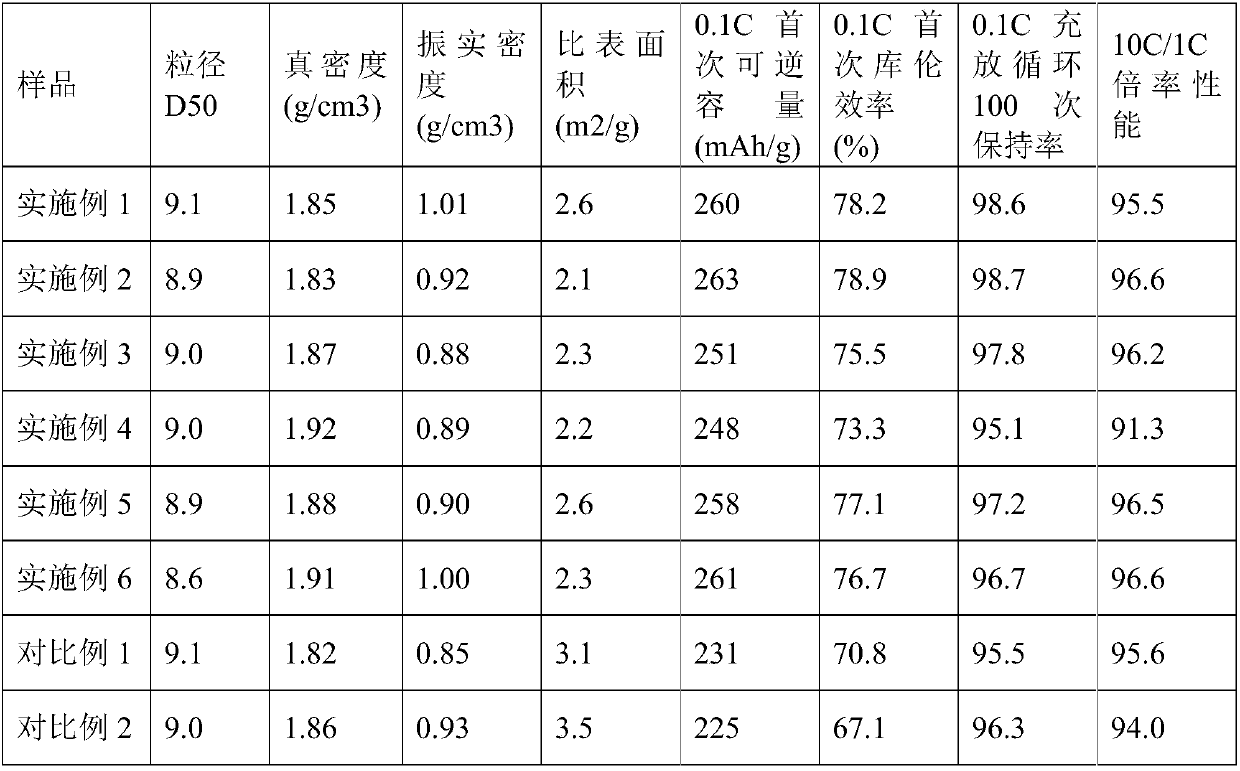

Preparation methods for high capacity biomass hard carbon anode material of sodium ion battery

InactiveCN109921018AAvoid the problem of high temperature melting and gelatinizationChange the environmentCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention relates to the technical field of a secondary battery, specifically preparation methods for a high capacity biomass hard carbon anode material of a sodium ion battery. A method comprisesthe following processing steps of crushing and screening a biomass raw material to obtain precursor powder; adding a dehydrating agent, carrying out uniform mixing to obtain a mixture, and carrying out dehydration curing reaction; mixing a curved biomass precursor with a modifier, carrying out mixing by taking water as a dispersant, and carrying out drying processing to obtain a modified biomassprecursor; and carrying out pre-carbonization processing and carbonization processing in sequence. Compared with the prior art, the method has the advantages that starch is taken as the raw material,through curving processing, the problem that the starch is melted and gelatinized due to a high temperature is effectively avoided, and doping and modification processing is carried out on cured starch granules, so a surface chemical environment and an internal structure of hard carbon are changed, and electrochemical performance of the biomass hard carbon anode material is effectively improved. Through curing reaction processing, hard carbon yield is also remarkably improved.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

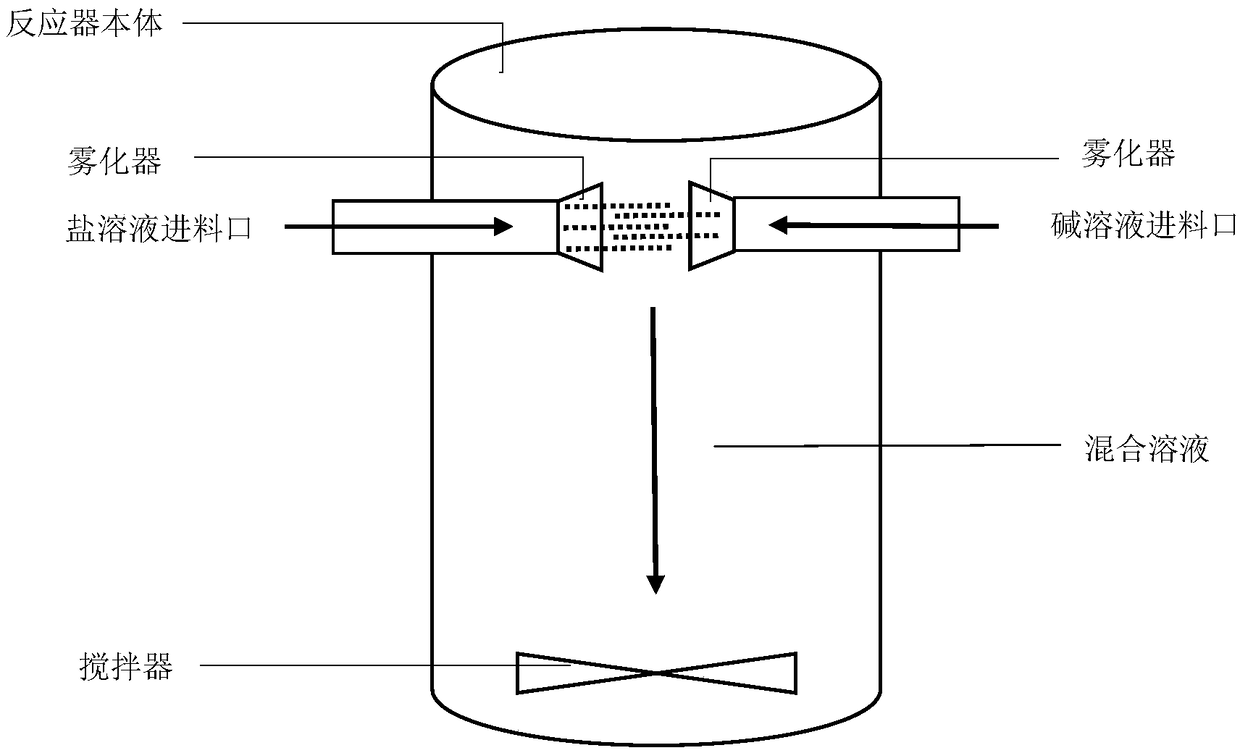

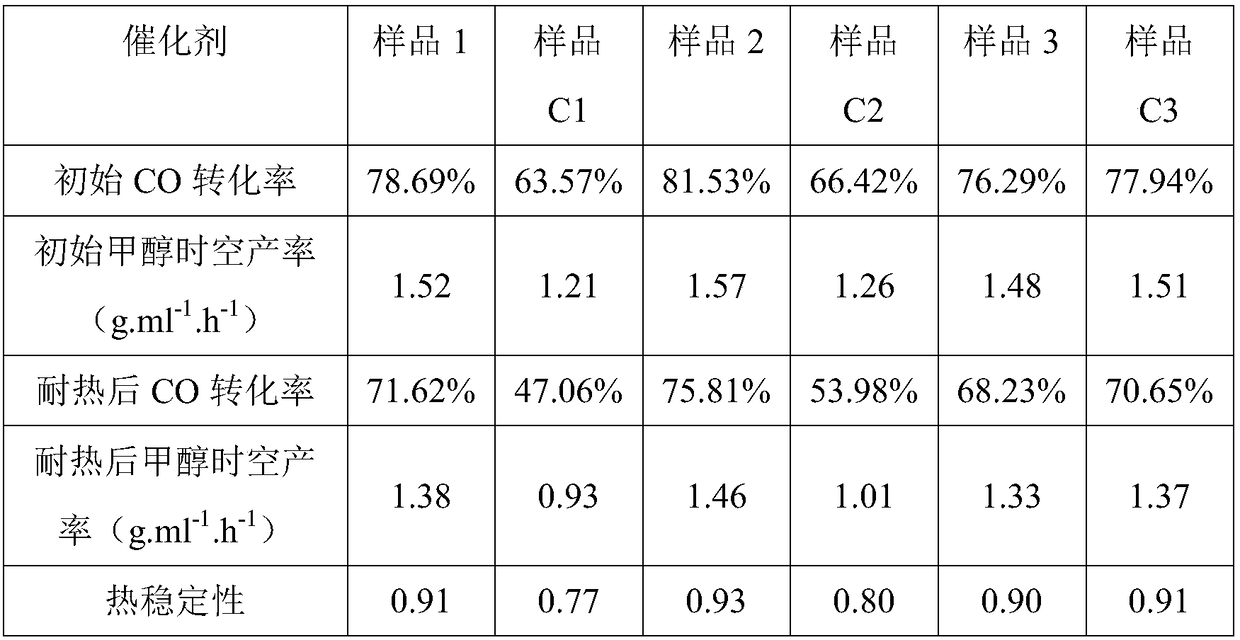

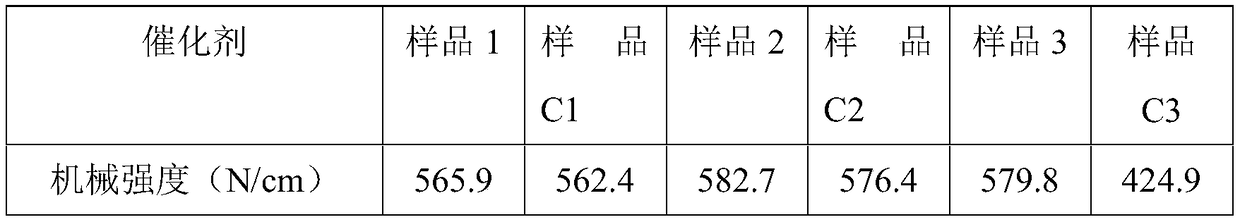

High stability and high strength catalyst for synthesis of methanol and preparation method thereof

ActiveCN109289854AGood activity at low temperatureImprove thermal stabilityOrganic compound preparationHeterogenous catalyst chemical elementsCoprecipitationGraphite

The invention discloses a high stability and high strength catalyst for synthesis of methanol and a preparation method thereof. The catalyst has excellent low temperature activity, good thermal stability and higher mechanical strength. The catalyst provided by the invention includes: 45-75% of CuO, 10-25% of ZnO, 5-30% of Al2O3, and 1-5% of MgO. The preparation method provided by the invention adopts a spray process to carry out two-step coprecipitation, and specifically the method includes: atomizing a mixed salt solution of zinc and aluminum and an alkali solution respectively, and then spraying the atomized solutions into a reactor for reaction to obtain a carrier structure precursor, then further spraying an atomized salt solution of copper, zinc, aluminum and magnesium and the alkalisolution into the reactor, and carry out the second step reaction, then conducting aging, filtering, washing, adding of graphite, repulping, roasting and moulding, thus obtaining the catalyst for synthesis of methanol. The preparation method provided by the invention has the advantages of scientific design, simple process and easy operation.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

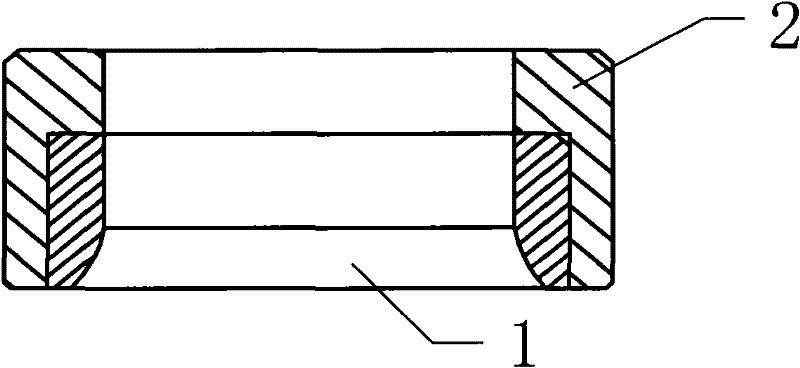

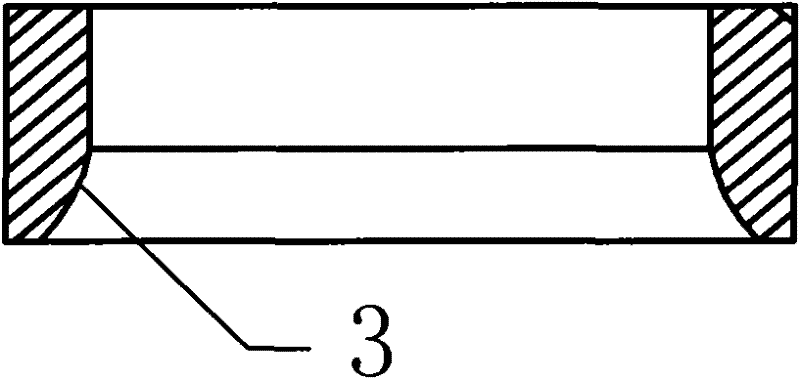

Ceramic gland mold and manufacturing method thereof

InactiveCN102233384AGood wear resistanceHigh coefficient of thermal expansionShaping toolsClosure capsCeramicOxide

The invention relates to a ceramic gland mold and a manufacturing method thereof. The ceramic gland mold comprises a gland mold body, wherein an inner mouth arc is arranged in the gland mold body. The ceramic gland mold is characterized in that: ceramics are used as main materials of the gland mold body; a rare earth oxide serving as a stabilizing agent is added into the ceramics to form solid solution and a complex body; and square and cubic phase ceramics with twin-crystal structures are formed by the ceramics in the inner mouth arc. By the steps of powder preparation, gland mold formation and sintering finish machining, the square and cubic phase ceramics with the double-crystal structures can be quickly and stably formed. Therefore, the ceramic gland mold has high-temperature resistance, chemical corrosion resistance and oxidation resistance. Simultaneously, the inner mouth arc has a reasonable design and high smooth finish and meets the requirement that a coating is not damaged during the pressing of a bottle cap.

Owner:陈中红

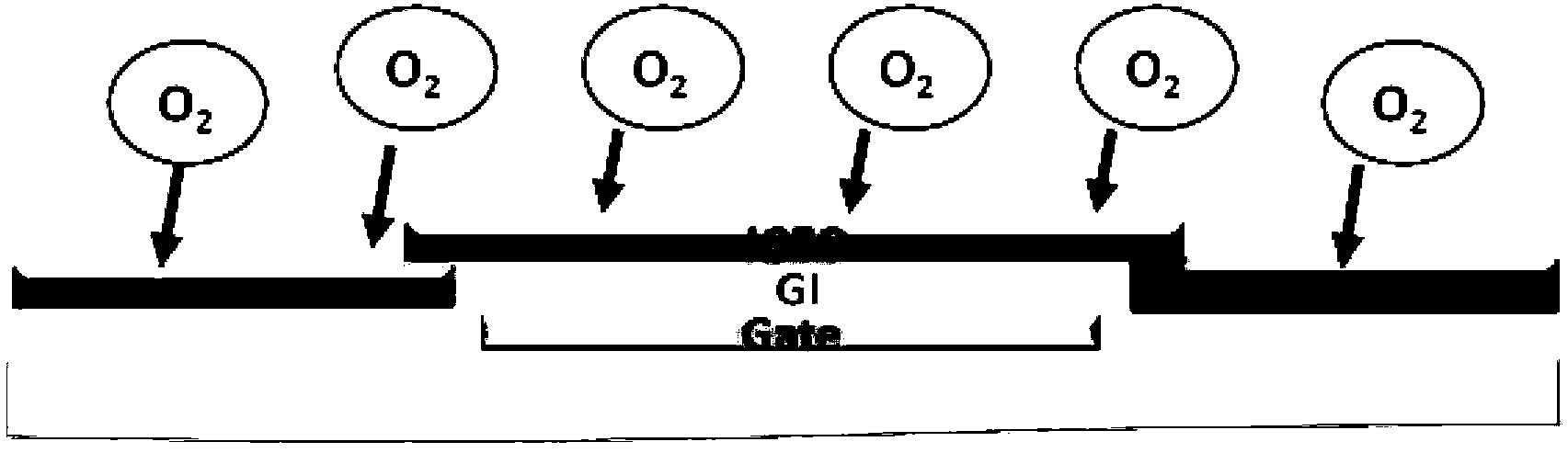

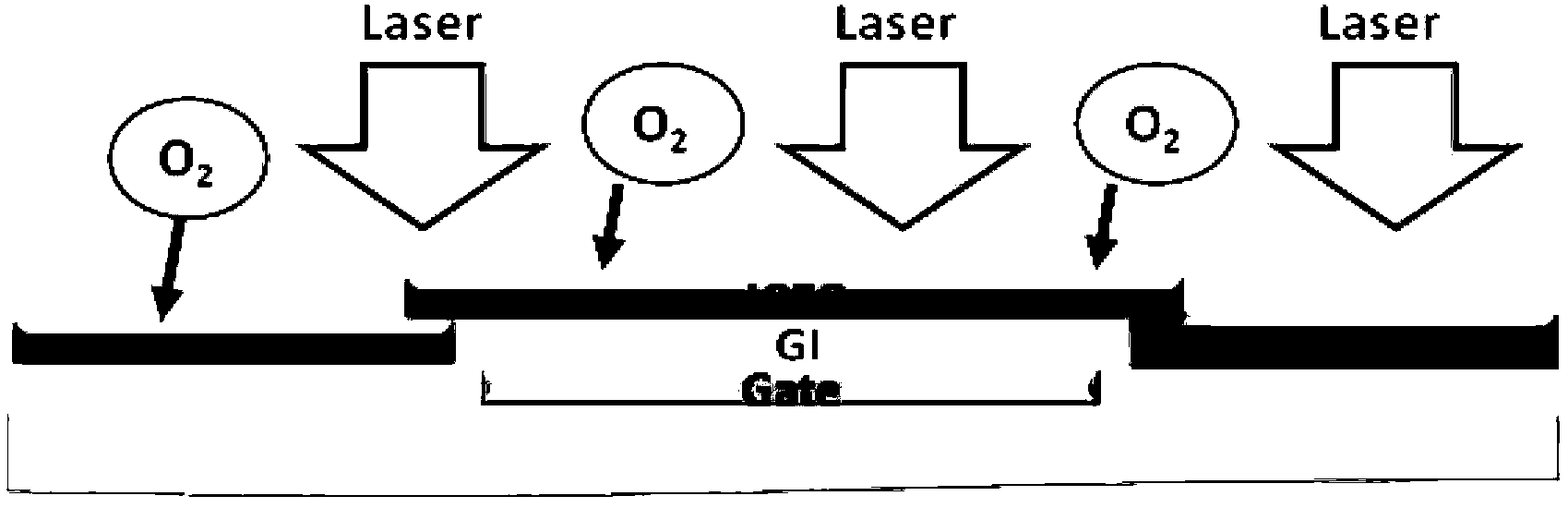

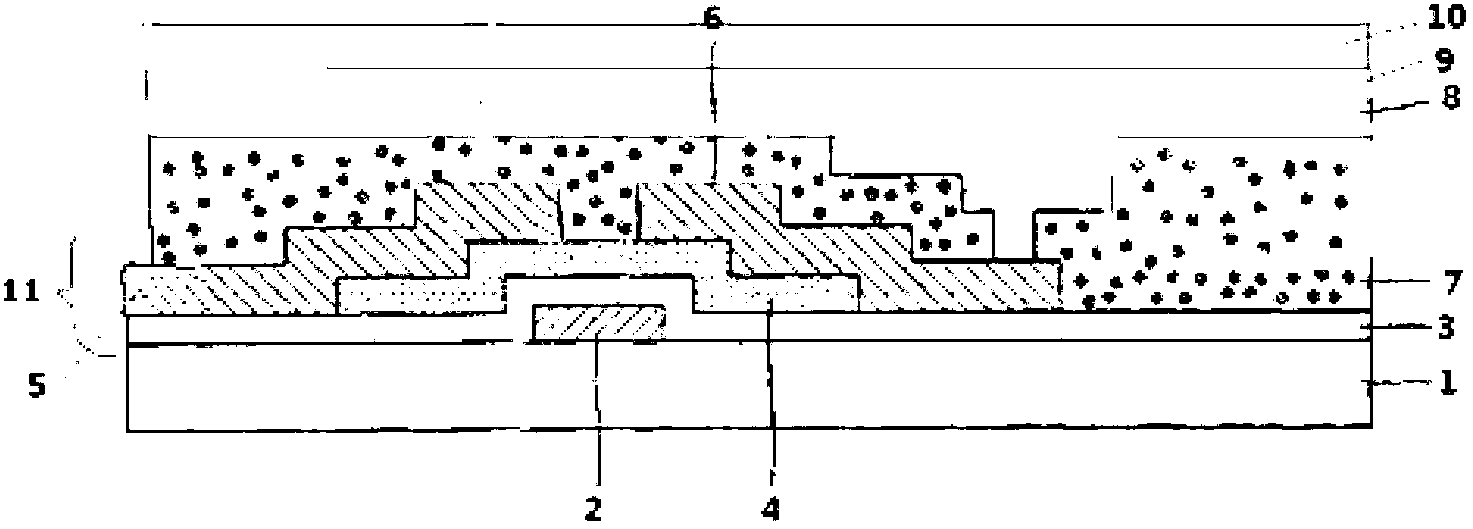

Metallic oxide semiconductor film and preparation method and application thereof

ActiveCN103065972AImprove stabilityImprove efficiencyTransistorSolid-state devicesOxide semiconductorVoltage

The invention belongs to the field of electron devices and particularly relates to a metallic oxide semiconductor film which is obtained by adopting of laser annealing craft, and application of the metallic oxide semiconductor film in a thin film transistor (TFT) device and an organic light emitting diode (OLED) device. The method of preparing of the metallic oxide semiconductor film includes of (1) preparing the metallic oxide semiconductor film which is based on zinc oxide and formed by adding of other metallic elements; (2), under oxygen atmosphere, the metallic oxide semiconductor film which is obtained in the step (1) conducting laser annealing for 3-6min, and the needed metallic oxide semiconductor film forming. Performance of the metallic oxide semiconductor film, such as migration rate and stability of threshold voltage, is greatly improved, compared with a traditional manner which uses a high-temperature annealing furnace for annealing, efficiency is higher, and stability is better.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

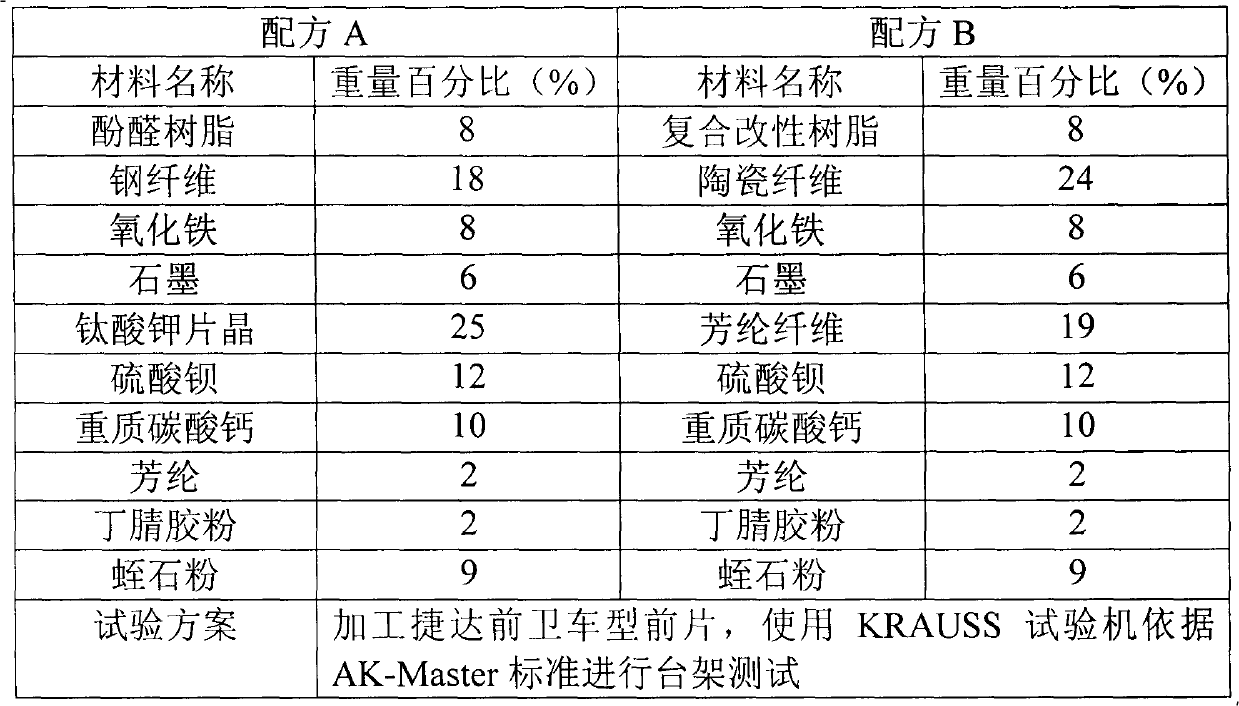

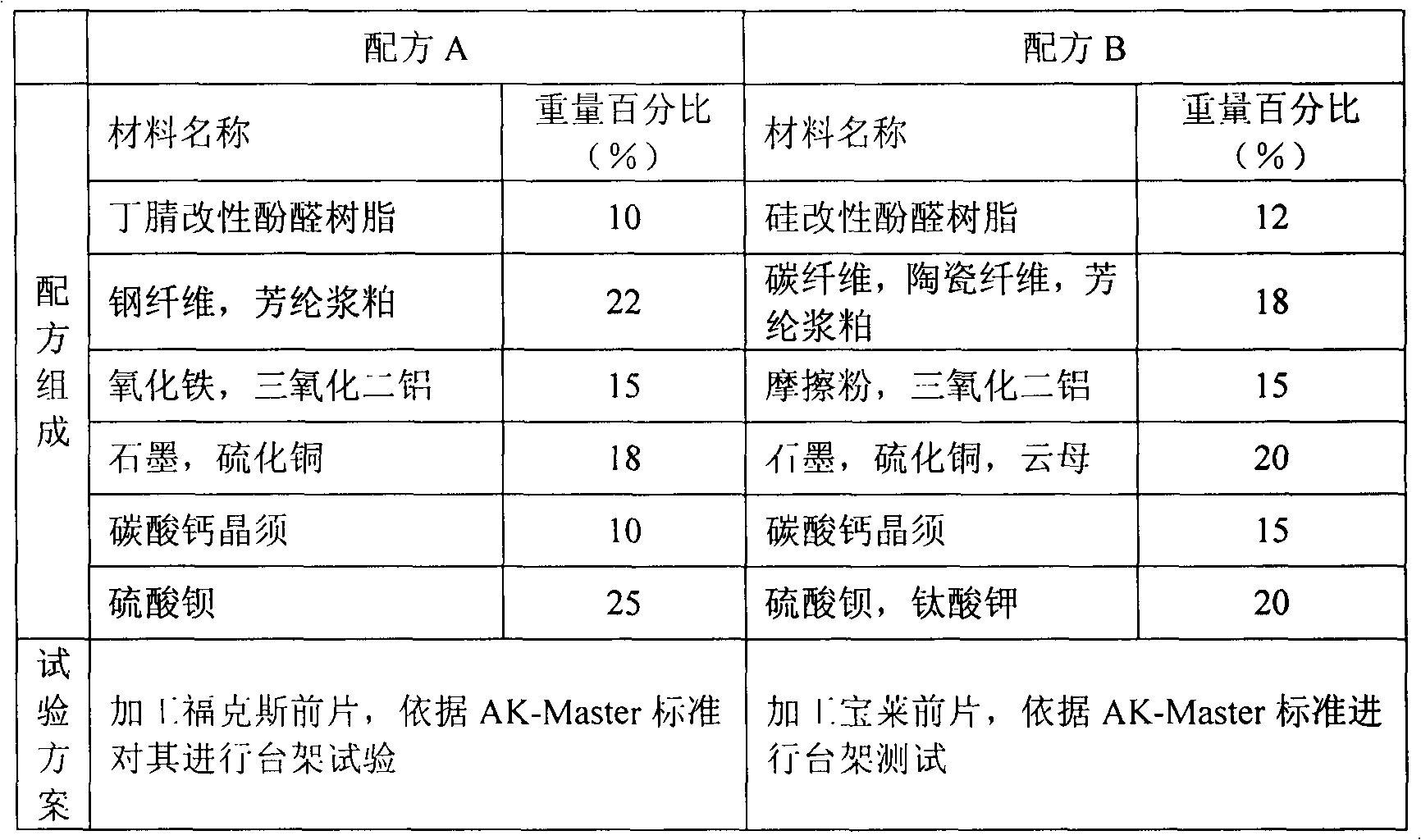

Method for preparing brake pad by utilizing ceramic fiber

The invention relates to a preparation method of a friction material in the field of automobile industry and provides a formula for preparing a brake pad, which can improve heat resistance and fading resistance of the friction material. The formula comprises an adhesive, a reinforcing material, a friction performance regulating agent and a filling material, wherein the adhesive is of compound modified phenolic resin, and the percentage by weight of the adhesive is 5-18%; the reinforcing material is of the ceramic fiber and aramid fiber, and the percentage by weight of the reinforcing material is 20-30%; the friction performance regulating agent comprises a grinding agent, graphite, molybdenum disulfide and mica, the grinding agent comprises aluminum oxide, ferric oxide and magnesium oxide, the percentage by weight of the grinding agent is 1-15%, and the graphite, the molybdenum disulfide and the mica account for 5-15% by weight in total; and the filling material comprises barium sulfate, potassium titanate and vermiculite powder. The brake pad produced by adopting the formula disclosed by the invention, heat fading phenomenon can be avoided at high temperature, the friction coefficient is stable, the abrasion of a product is small, the brake is comfortable during the using process, the noise can be avoided, and the service life can be up to above 70000km.

Owner:东营宝丰汽车配件有限公司

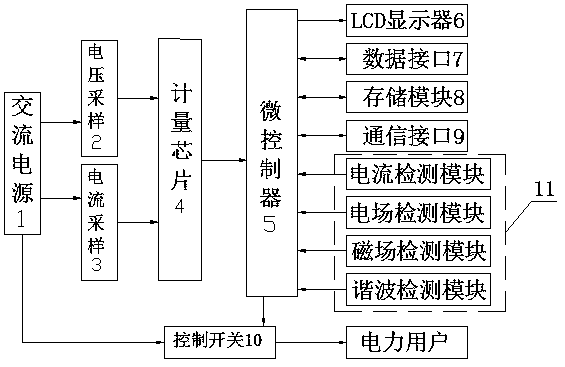

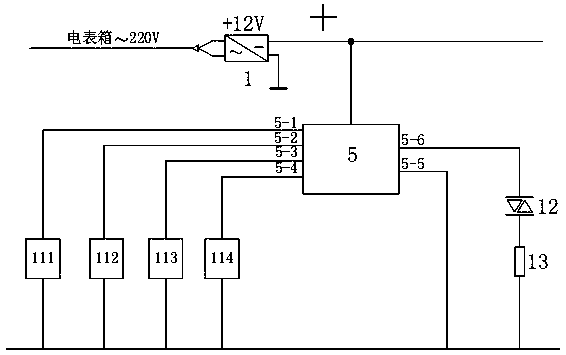

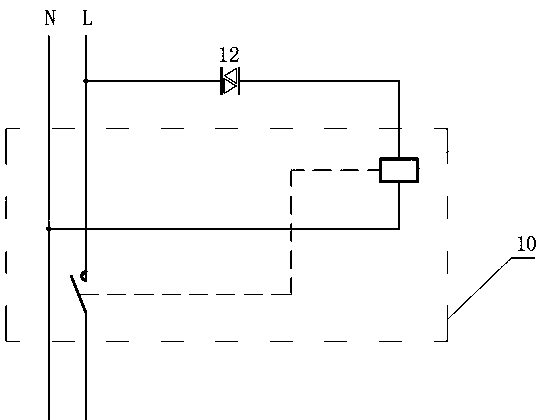

Intelligent watt-hour meter for electricity larceny prevention based on internet of things and monitoring system

PendingCN109813960AChange internal structurePrevent Electricity StealingElectrical measurementsInformation technology support systemMicrocontrollerElectric power system

The invention provides an intelligent watt-hour meter for electricity larceny prevention based on internet of things and a monitoring system. The intelligent watt-hour meter for electricity larceny prevention based on internet of things comprises a power supply module, a metering module, an electricity larceny prevention module, a monitoring system and the Internet of things, wherein the meteringmodule comprises a current sampling module, a voltage sampling module and a metering chip; the electricity larceny prevention module comprises a microcontroller, a thyristor relay, an environmental monitoring module and a control switch. The monitoring system comprises an acquisition terminal, a communication module and a background server, and the internet of things includes a monitoring system and a watt-hour meter on a site. Detection components are arranged in the watt-hour meter, a watt-hour meter environment is monitored and analyzed, whether electricity larceny occurs or not is judged,power supply is cut off in time when the electricity larceny occurs, the electricity larceny behavior is prevented from further occurring, and the property of a power system is protected from being lost. Moreover, switching-off power failure or switching-on power supply of a user can be achieved remotely or on site through the internet of things, and the intelligent watt-hour meter is more flexible and convenient.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Preparation method of mesoporous potamogeton pectinatus adsorption material for heavy metal ions

InactiveCN106179248AImprove adsorption performanceIncrease profitOther chemical processesWater contaminantsPectinatusIon

The invention relates to a preparation method of a mesoporous potamogeton pectinatus adsorption material for heavy metal ions, and belongs to the field of adsorption material preparation. According to the invention, Potamogeton pectinatus stems are taken as raw materials, and soaked in water to enable deionized water enter into inner pores of the stems, and quickly frozen by liquid nitrogen to enable water in the pores of the stems frozen, inner apertures of the stems are widened to increase porosities by using an ice splitting effect, namely the principle that water freezes to increase volume, then adsorption sites of the stems are treated by methanol to be fully exposed, the number of active groups on the surfaces of the stems and in the inner pores is further increased through composite fermentation modification of hydroxycitric acid in a garcinia cambogia extracting solution and microorganisms in biogas liquid to increase the adsorption rate of the stems, finally freeze drying is carried out to obtain the adsorption material. The method disclosed by the invention not only changes surface properties of the potamogeton pectinatus stems, but also changes the internal structures of the stems to improve adsorption properties of the stems so as to facilitate more thorough adsorption, thus the adsorption material can be thoroughly utilized, and the utilization rate of the adsorption material is increased.

Owner:吴迪

Beef fodder with bagasse and moso bamboo leaves as main raw materials and preparing method thereof

InactiveCN105685499AChange internal structureLow lignin contentFood processingAnimal feeding stuffPre treatmentFodder

The invention discloses beef fodder and a preparing method thereof. The beef fodder comprises bagasse, moso bamboo leaves, molasses, probiotics and traditional Chinese medicine additives. A continuous steam explosion technology is adopted to process bagasse in a puffing mode, then biological fermentation is conducted, and beef fodder is prepared. The preparing technology is simple, moso bamboo leaves, abandoned molasses and bagasse are recycled, preprocessed and subjected to biological fermentation, the palatability of the animal fodder is greatly improved, the nutrient-rich fodder is provided for cud chewers, the fodder is safe and free of toxin and can be stored for a long time, it is ensured that the fodder can be supplied all year around, and the problem that green grass fodder is in shortage in winter is solved.

Owner:GUANGXI STATE FARMS JINGUANG DAIRY IND CO LTD +1

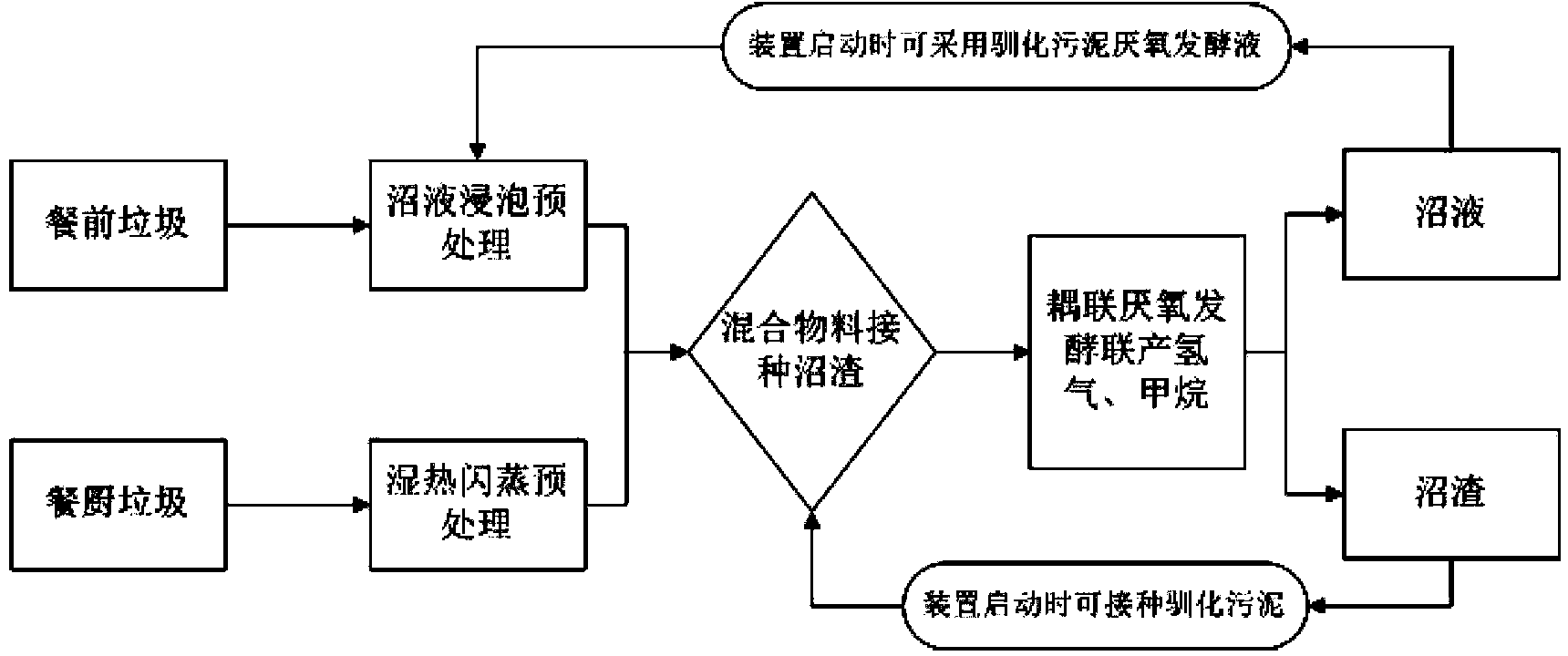

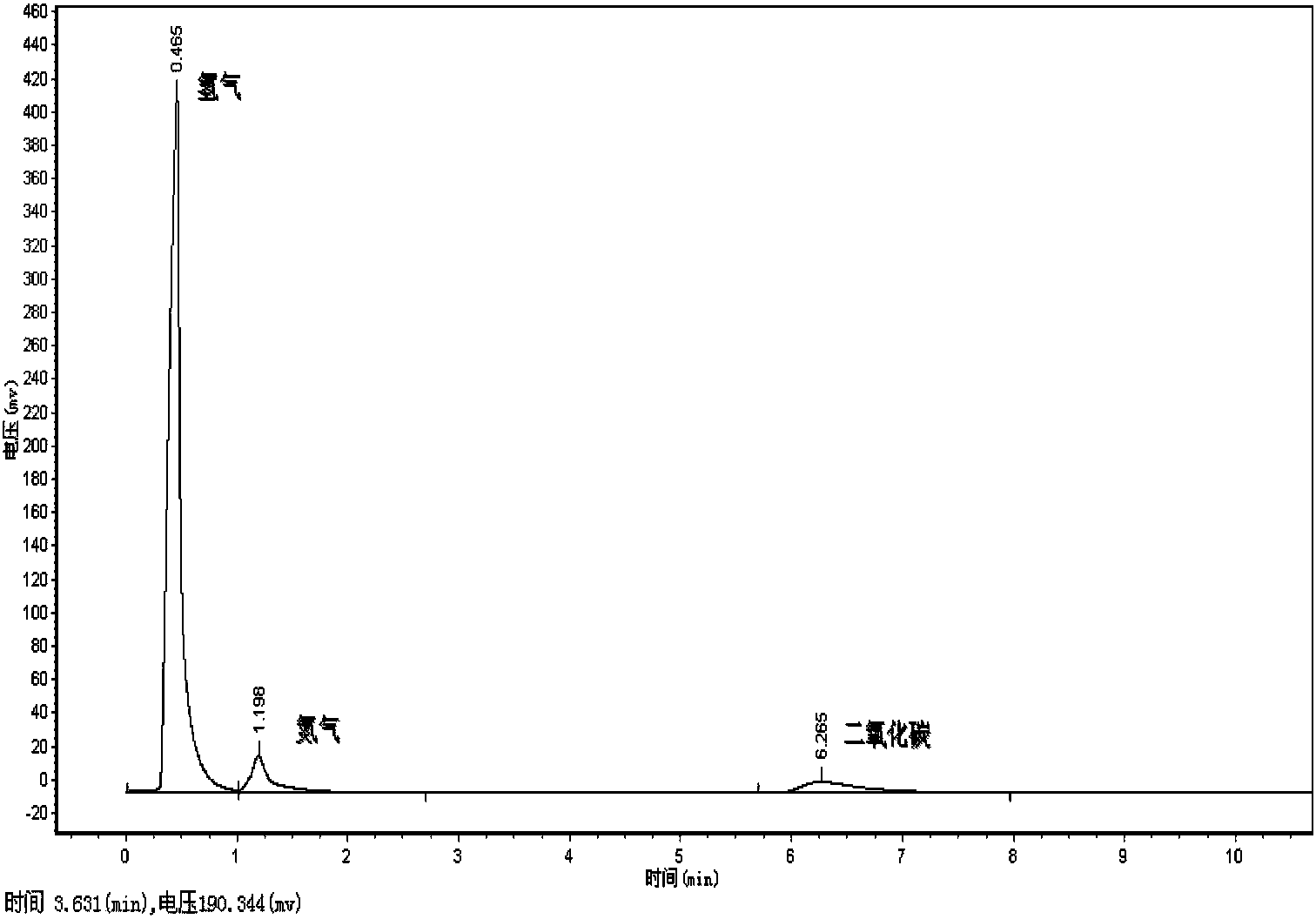

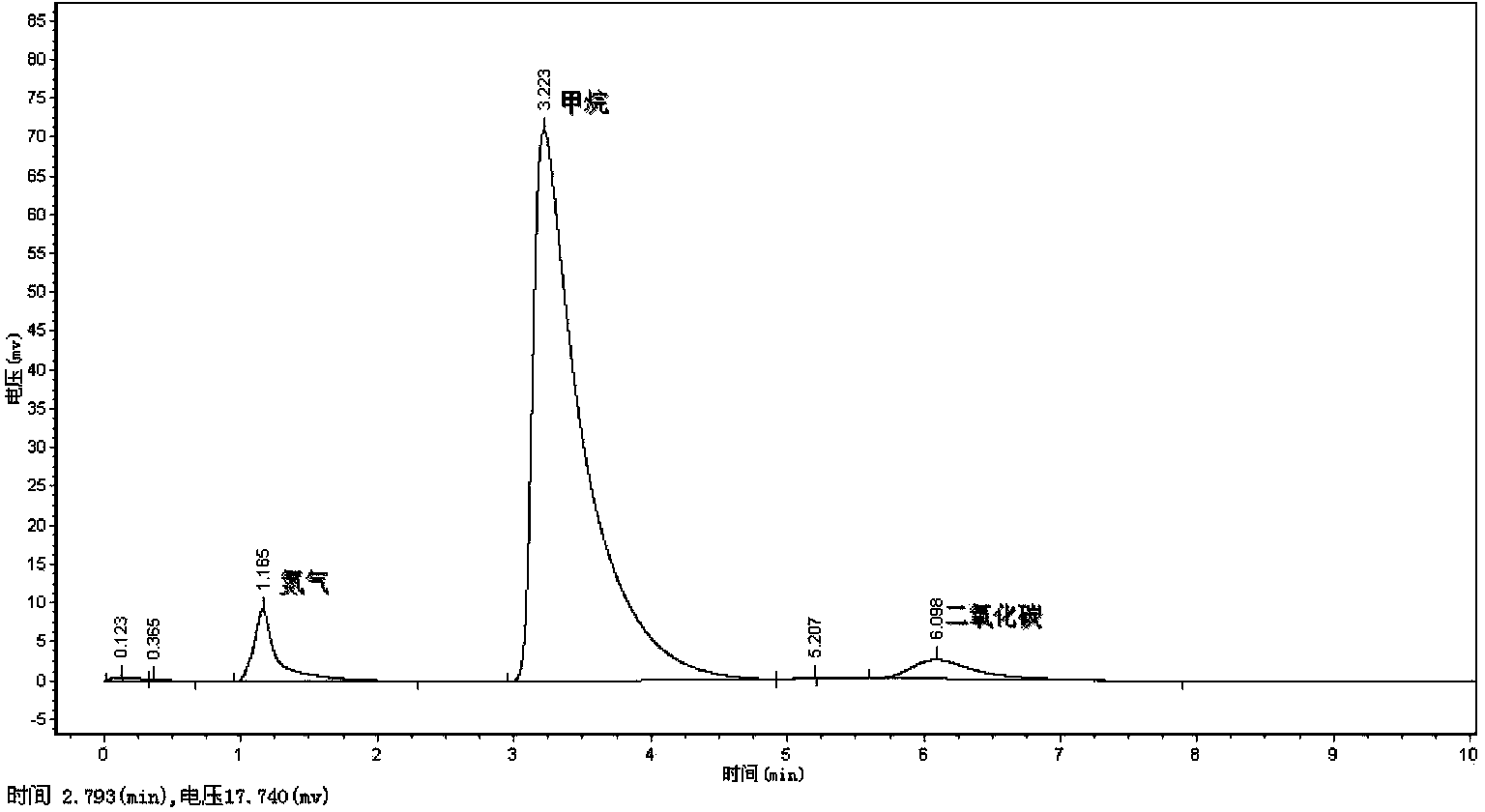

Method for jointly producing hydrogen and methane by carrying out coupling anaerobic fermentation on preprandial garbage and kitchen garbage

ActiveCN103451236ASolve secondary processing problemsReduce startup timeWaste based fuelFermentationCelluloseSlurry

The invention discloses an environment-friendly method for jointly producing hydrogen and methane by carrying out coupling anaerobic fermentation on preprandial garbage and kitchen garbage, and belongs to the technical field of solid waste treatment and biological energy. The method comprises the following steps: firstly carrying out soaking pretreatment on the preprandial garbage by utilizing biogas slurry generated through the anaerobic fermentation, and carrying out damp heat flash evaporation pretreatment on the kitchen garbage; then mixing the pretreated preprandial garbage and kitchen garbage to prepare the hydrogen and the methane through an anaerobic fermentation process by taking biogas residues discharged by a system after a methane production stage as inocula. The method disclosed by the invention is suitable for recovering the biomass energy contained in solid organic matters with multiple high-organic matters, high-water ratio and high-cellulose organic solid wastes in hydrogen and methane forms, integrates energy conservation, emission reduction, renewable resource utilization and pollution control into a whole, is a pollution-free, low-energy consumption and high-productive capacity kitchen garbage anaerobic fermentation treatment process and has the advantages of important environmental benefit and wide application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

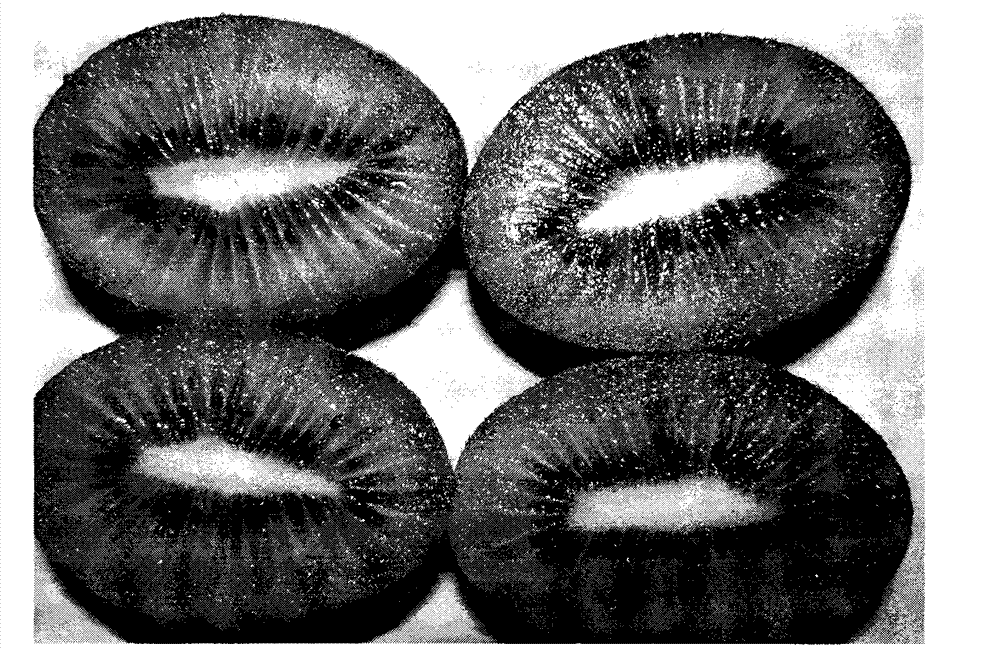

Collecting method of kiwi fruit seeds

InactiveCN102771260ASmooth germinationAchieve softnessSeed and root treatmentHarvestersFruit treeActinidia

The invention discloses a collecting method of kiwi fruit seeds, relates to a method for collecting plant seeds, and belongs to the field of fruit thremmatology and cultivation. The method includes the following steps: A, when kiwi fruit is mature, large fruit is selected and placed till the fruit is mature, after-ripened and softened; B, the softened kiwi fruit is cut into two halves along the traverse direction, pulp on the periphery of the fruit is cut off along the vertical direction, and then rectangular pulp thin slices containing seeds with the thickness as approximately 2mm are cut along the transverse direction; C, the pulp thin slices containing the seeds are paved and adhered to newspaper; D, the newspaper with the adhered pulp thin slices containing the seeds obtained in the step C is dry-processed; E, the seeds are collected from the paper surface with the pulp containing the seeds processed through drying in the step D; and F, afterprocessing procedures are conducted. By means of the method, the kiwi fruit seeds can be collected fast, an operation process is simple and practicable, and the method is suitable for large-scale seed collection of seedling breeding and collection of seeds required by large-scale seedlings cultured through grafting.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Carbon-ceramic based brake pad

InactiveCN102562890AHigh melting pointExcellent high temperature mechanical propertiesFriction liningCarbon fibersAdhesive

The invention relates to preparation of brake pads in the field of the automobile industry, in particular to a carbon-ceramic based brake pad, which is higher in strength and more stable in performance. In weight percent, the brake pad comprises 5-15% of adhesives, 20-30% of reinforcing materials, 20-30% of frictional property conditioning agents and 30-50% of packing in formula, wherein the adhesives include phenolic resin, silicone modified phenolic resin and butyronitrile modified phenolic resin, the reinforcing materials include carbon fibers, ceramic fibers and aramid pulp, the frictional property conditioning agents include grinding agents and lubricating agents, the grinding agents include aluminum oxide, ferric oxide, magnesium oxide and frictional powder, the lubricating agents include graphite, sulfide and mica, and the packing comprises barium sulfate, potassium titanate and magnesium oxide. The carbon-ceramic based brake pad has negative temperature coefficient, stable chemical performance and resistance to strong acid and strong alkali, and is nonhazardous and extremely high in mechanical performance.

Owner:东营宝丰汽车配件有限公司

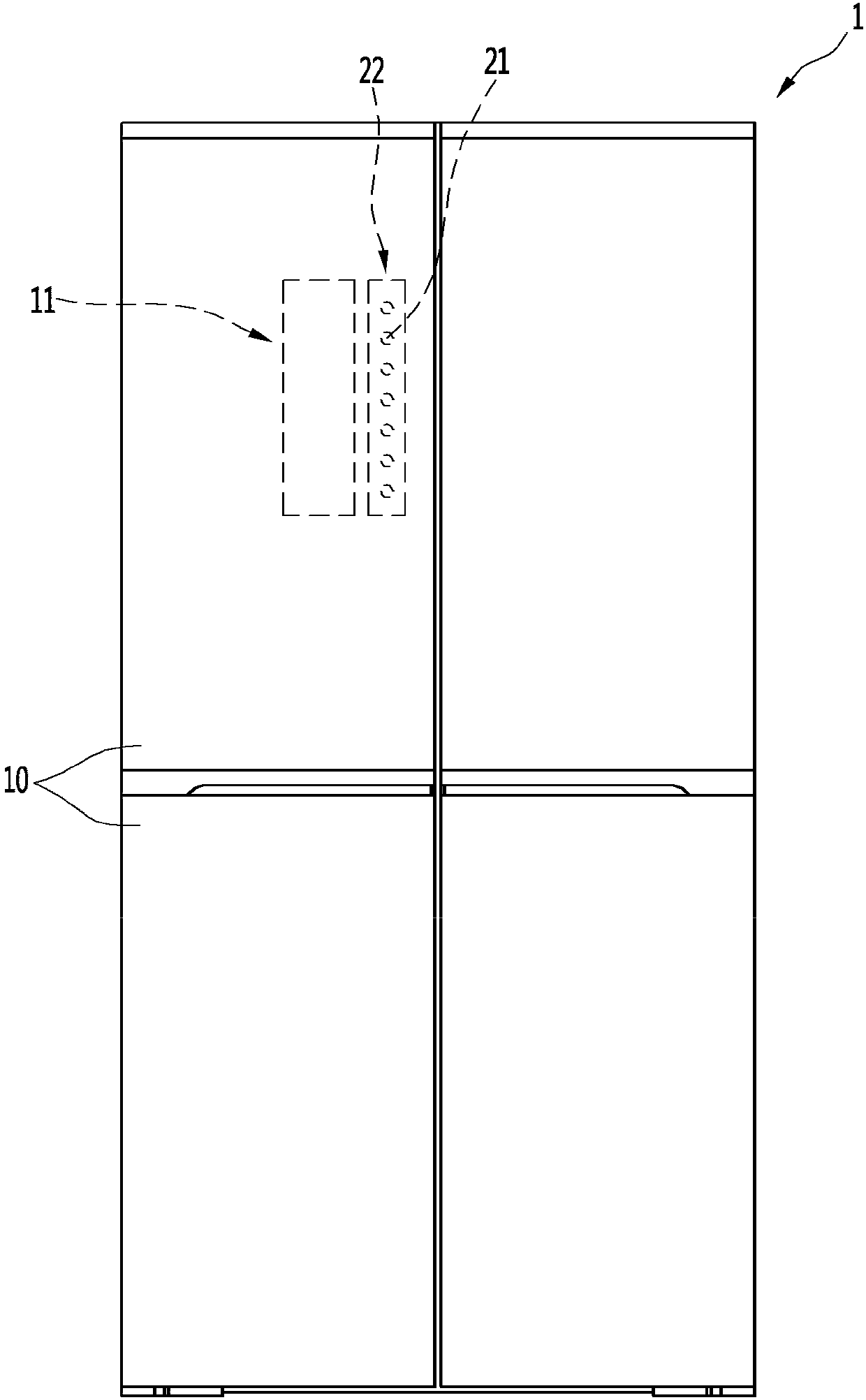

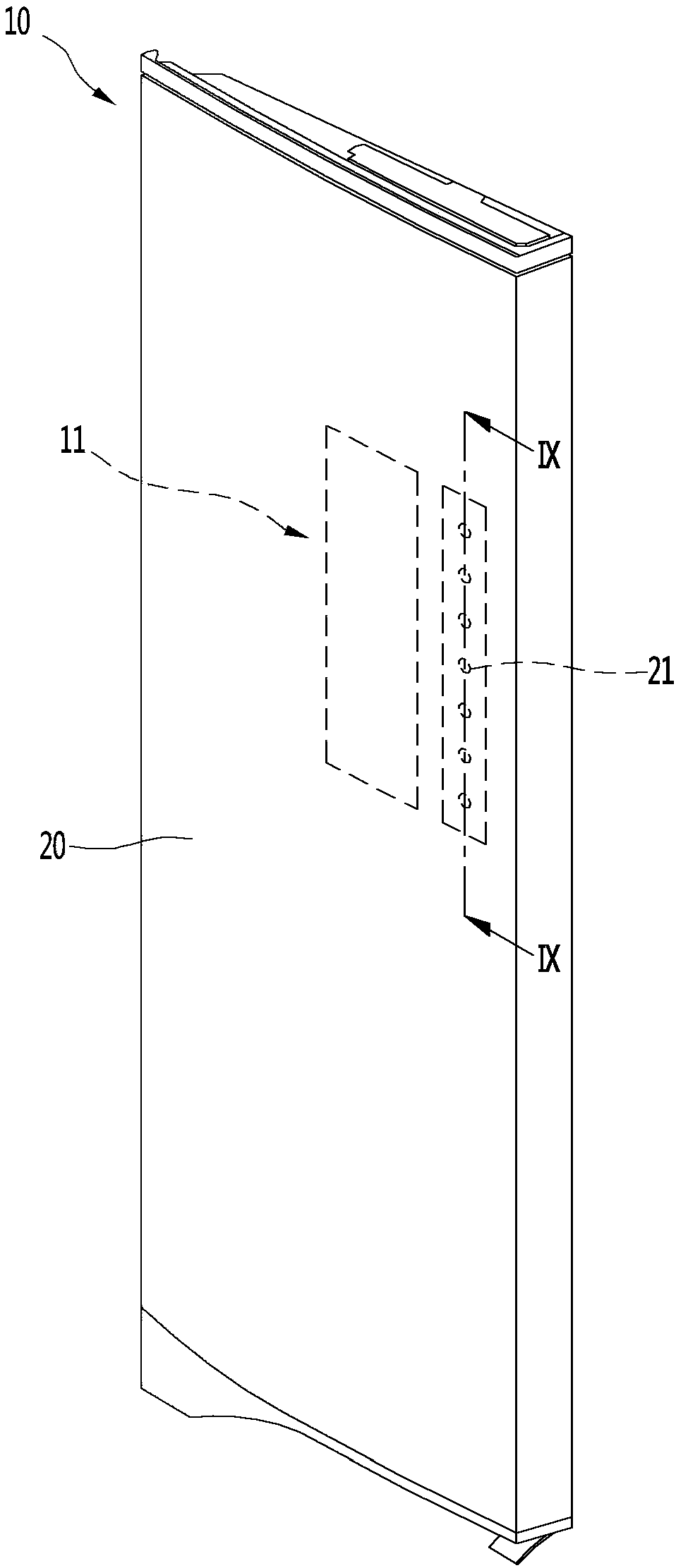

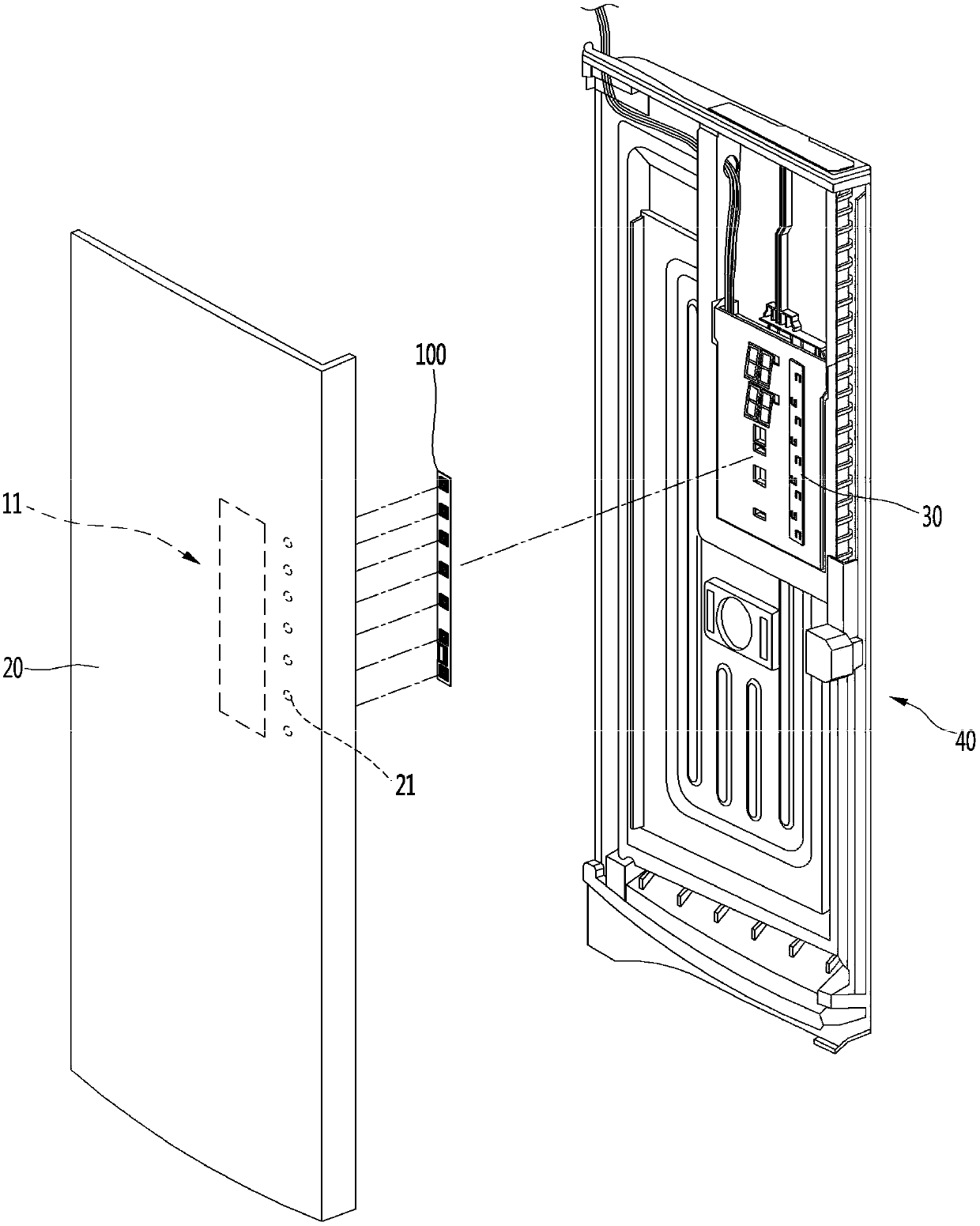

Appliance having touch sensor assembly

ActiveCN107782061AReduce the numberSimple structureLighting and heating apparatusElectronic switchingTouchpadElectrical and Electronics engineering

The invention relates to an appliance having a touch sensor assembly. The appliance according to the embodiment of the invention includes: a front panel forming the external shape of the appliance and having a touch point; a touch board including: a first side attached to a location on a rear surface of the front panel, the location corresponding to the touch point; a second side opposite to thefirst side; a pressing portion; and one or more holes defined around the pressing portion; a holder that is arranged in a position covering the pressing portion and the holes and attached to the second side of the touch board, the holder having a receiving portion; a piezo disc configured to be inserted in the receiving portion of the holder and have a first electrode and a second electrode used for contact with the pressing portion; a guide board having a seating hole configured to receive the holder and the piezo disc and arranged on the second side of the touch board; and a first adhesive member attached to the first side of the touch board.

Owner:LG ELECTRONICS INC

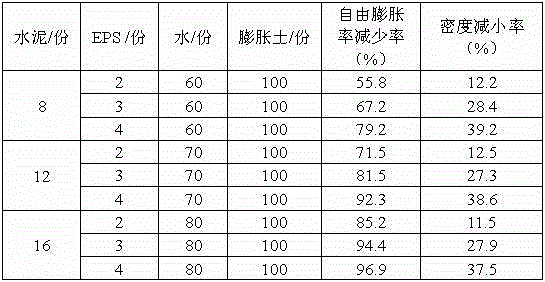

EPS (expandable polystyrene) improved soil for treating expansive soil slopes and construction method thereof

The invention discloses an EPS (expandable polystyrene) improved soil for treating expansive soil slopes and a construction method thereof. The EPS improved soil is prepared by the following step: uniformly stirring 2-4 wt% of polystyrene foam particles, 8-16 wt% of cement and water and 60-80 wt% of excavated expansive soil to form the mixed soil. The EPS improved expansive soil has the advantages of low density, high strength, small swelling-shrinkage deformation, short construction period and the like, can use local materials, can utilize wastes, can effectively solve the problem of destabilization of the expansive soil slopes, and can be widely used in the fields of civil engineering, hydraulic engineering, traffic engineering and the like.

Owner:NANJING UNIV OF TECH

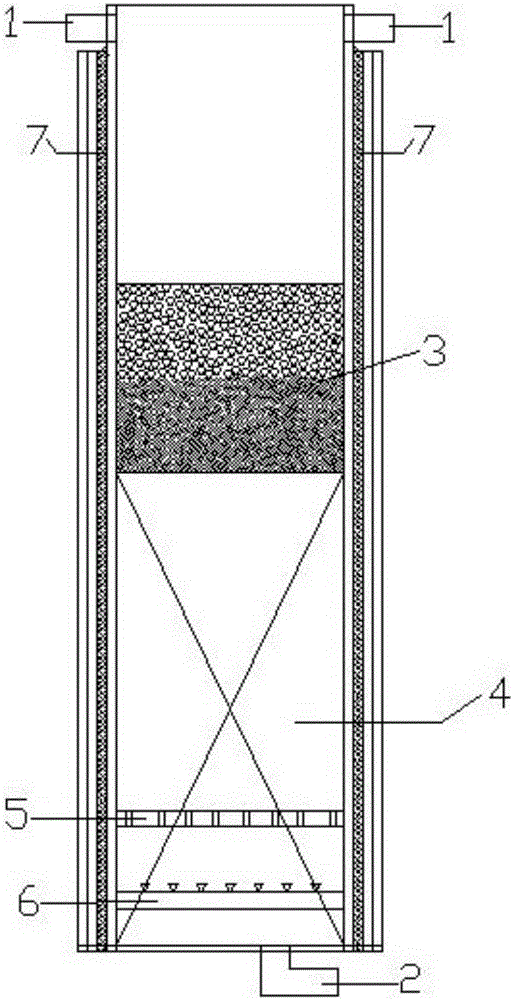

Biological aerated filter system with alkaline leaching excess sludge as filler, operating method of biological aerated filter system and preparing method of filler

InactiveCN106082428ARealize the harmless utilization of resourcesLarge emissionsWater treatment parameter controlTreatment using aerobic processesSludgeGlass wool

The invention discloses a biological aerated filter system with alkaline leaching excess sludge as filler, an operating method of the biological aerated filter system and a preparing method of the filler, and belongs to the technical field of sewage disposal. The biological aerated filter system comprises a water inlet and a water outlet, and further comprises a filter layer, the filler, a microporous aeration device and a backwash device. The biological aerated filter system is provided with the filter layer, the microporous aeration device and the backwash device in sequence from top to bottom, the space between the filter layer and the microporous aeration device in the biological aerated filter system is filled with the filler, the water inlet is located in the top of the biological aerated filter system, the water outlet is located in the bottom of the biological aerated filter system, the space between an inner column layer and an outer column layer of the biological aerated filter system is sealed to be vacuum, and the outer surface of the inner column layer is closely wrapped with a heat insulation glass wool layer. Due to the heat insulation arrangement, the biological aerated filter system still has high ammonia nitrogen and phosphorus removing efficiency in cold winter. By the adoption of the up-to-bottom water inlet mode, the problem that filler is likely to cause blockage is relieved; meanwhile, the purpose of recycling the industrial waste alkaline leaching excess sludge is achieved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

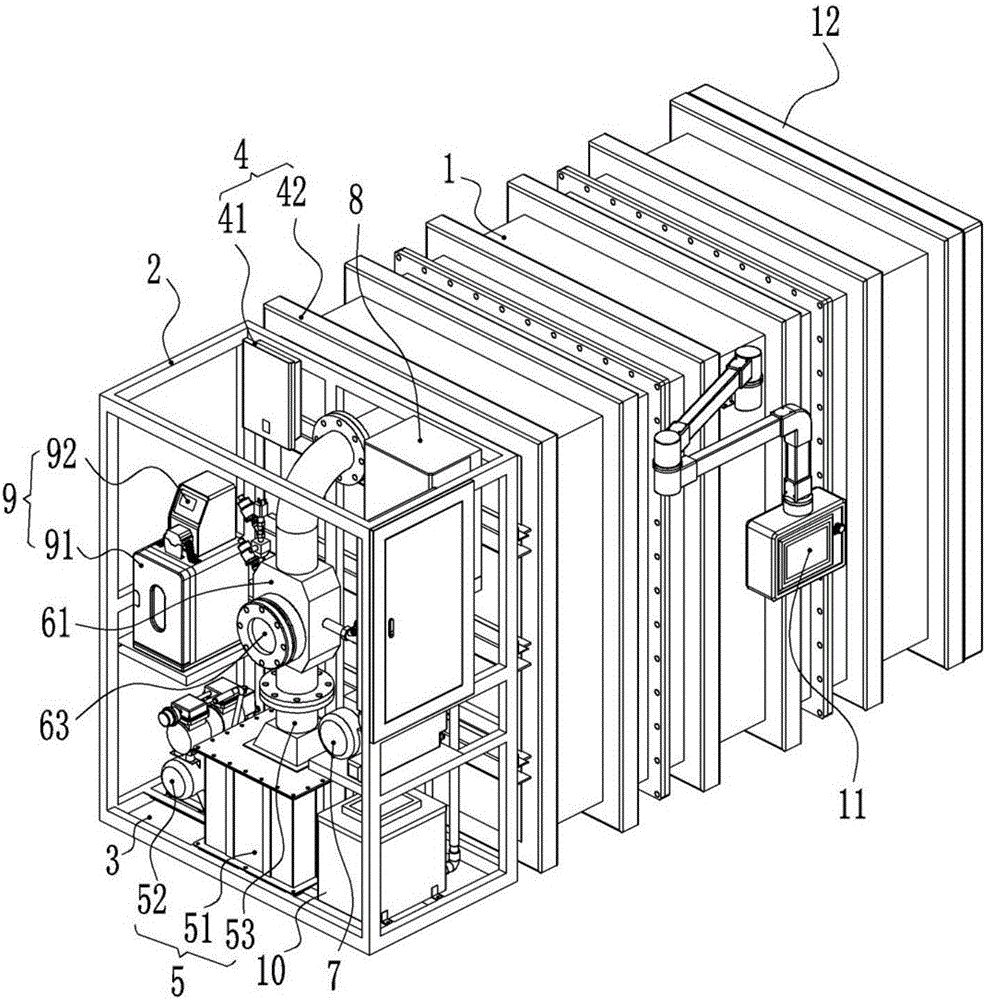

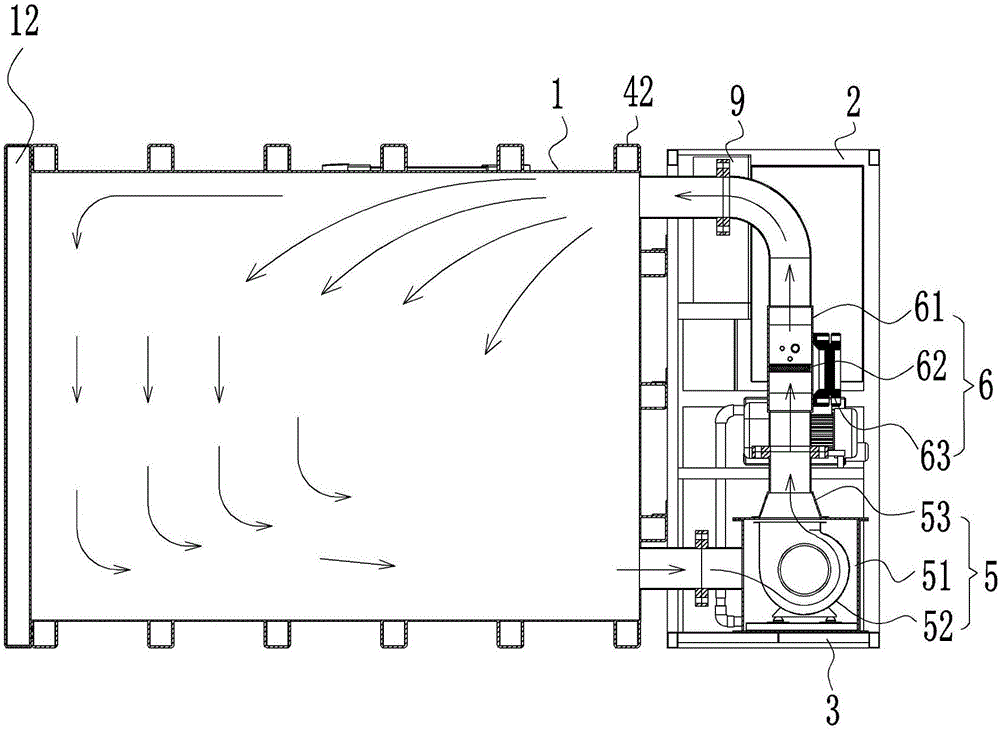

Fumigation disinfection machine and disinfection method

PendingCN106512044ADisinfect and sterilize thoroughlyGood disinfection and sterilization effectHeatChemicalsDisinfectantEngineering

The invention discloses a fumigation disinfection machine. The fumigation disinfection machine comprises a sterilization cabin, wherein a mounting rack is arranged on the side wall of the sterilization cabin, a vacuum device, a heating device, a humidification device, a disinfectant supply device, a gasification device, a gasification circulating device and a residual gas treatment device are mounted on the mounting rack, the vacuum device is communicated with a pipeline of the gasification circulating device and the residual gas treatment device, the gasification circulating device, the gasification device and the sterilization cabin are sequentially communicated to form a circulating loop, and the disinfectant supply device is communicated with the gasification device. The disinfectant supply device is used for conveying a disinfectant quantitatively, the gasification circulating device, the gasification device and the sterilization cabin are communicated to form the circulating loop, secondary heating is performed on the inside of the sterilization cabin, humidity adjustment is performed, so that the sterilization effect on cultural relics is better, no damage can be caused to the cultural relics in the sterilization process, the safety of the cultural relic sterilization and disinfection process is guaranteed, disinfected gas is recovered, and harm to the environment and workers is prevented.

Owner:CHONGQING SHENGGUANGDIAN ZHILIAN ELECTRONICS CO LTD

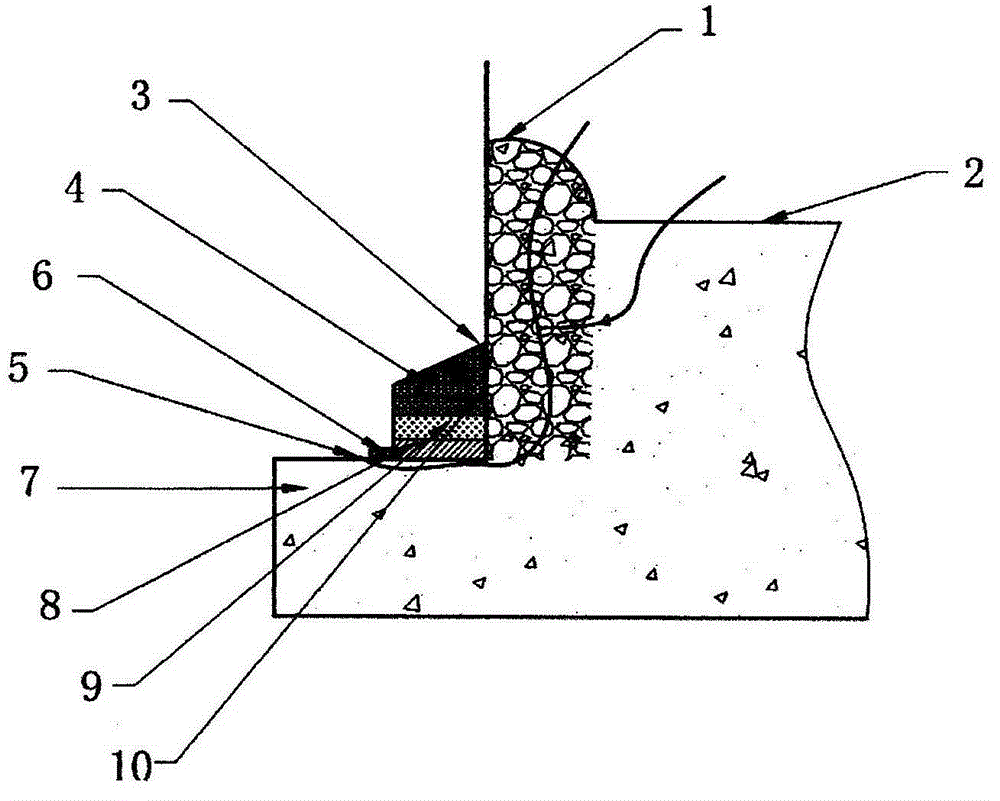

Technological method for plugging treatment of blow-by under-pressure coal gas of blast furnace foundation sealing plate

ActiveCN105238894AHigh bonding strength and toughness and stiffnessEliminate hidden dangers of personal safety accidentsBlast furnace componentsBlast furnace detailsResin compositeBonding strength

The invention relates to a technological method for plugging treatment of blow-by under-pressure coal gas of a blast furnace foundation sealing plate. The technological method is characterized by comprising the following steps: three composite materials with different performances namely solid dedicated resin composite material, plastic dedicated colloid material and high-strength castable are adopted as the plugging material in a blast furnace foundation sealing plate cavity, and after the technological method for plugging treatment of blow-by under-pressure coal gas of the blast furnace foundation sealing plate is carried out, the plugging sealing material tightly combines with the blast furnace foundation sealing plate and cement foundation pier surface material in a protective box of the blast furnace foundation sealing plate, does not generate cracks, gaps or holes, has high bonding strength, tenacity and rigidity, and absolutely changes the internal structure of the protective box of the blast furnace foundation sealing plate, so that the defects generated at the joint part of the blast furnace foundation sealing plate and the blast furnace foundation cement foundation pier are fully repaired and fitted, the problem that the blast furnace foundation sealing plate leaks under-pressure coal gas is solved, and safe operation of blast furnace production and energy conservation are ensured.

Owner:BEIJING RUIPU TONGCHUANG TECH DEV

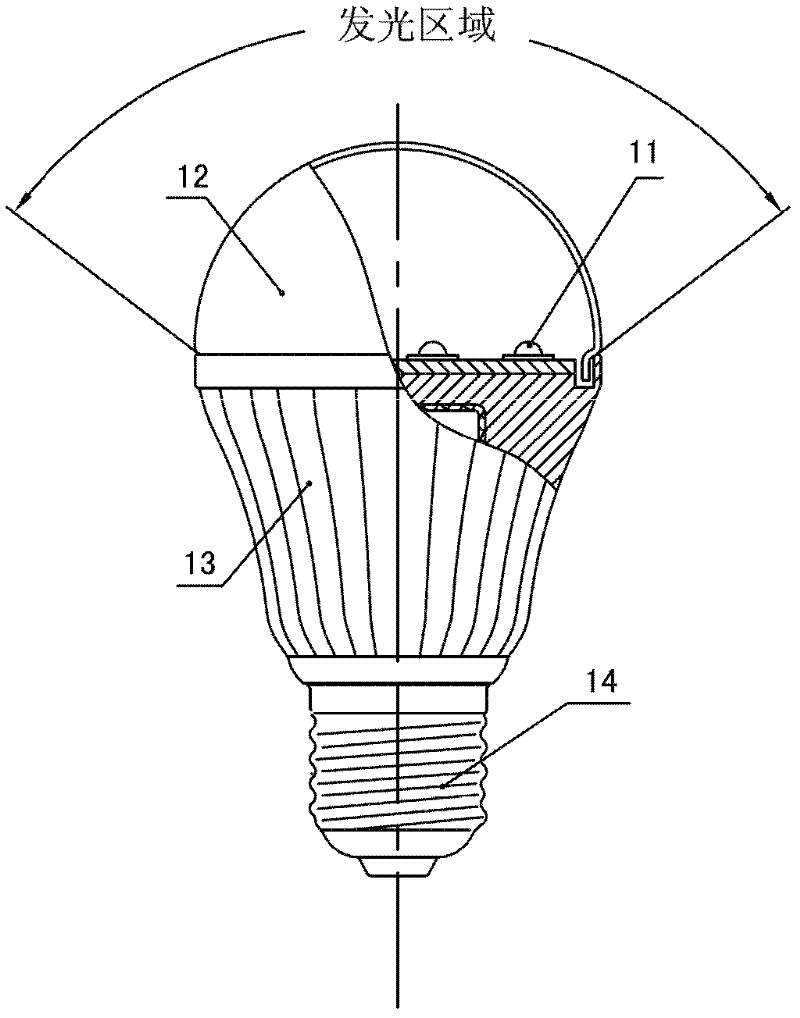

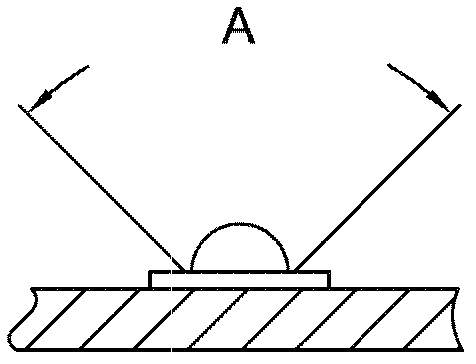

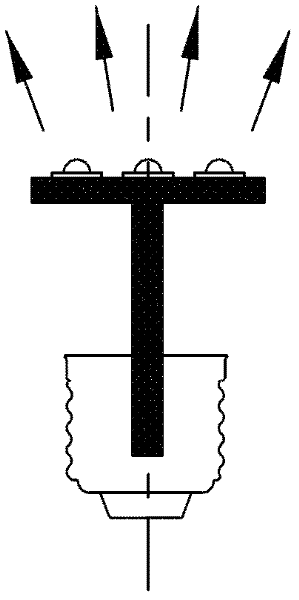

Reverse glowing led lights

InactiveCN102261591AChange internal structurePoint-like light sourceElectric lightingHeat sinkEngineering

The invention relates to a reverse luminous LED lamp. Traditional LED lamps have axial light emission and cannot be used in wall lamps, desk lamps and other occasions. The LED lamp of the present invention comprises: a lamp holder; an electronic drive assembly connected to the lamp holder; a bulb shell whose lower end is connected to the lamp holder and encloses the electronic drive assembly; an upper shell arranged on the bulb The upper end of the shell; the heat sink, which is arranged in the upper shell; and the LED light emitting device, which is arranged under the heat sink and connected with the heat sink. The invention enables the LED lamp to irradiate in the reverse direction under the condition that the shape and the structure of the lamp cap are compatible with the traditional lamp, and is suitable for wall lamps, chandeliers, chandeliers and other application occasions that require reverse emission of light.

Owner:戴培钧

Novel multifunctional PVC hanging plate for product storage

InactiveCN106366494AImprove adsorption capacityImprove bindingBuilding insulationsMicrocrystalline waxBenzoyl peroxide

The invention discloses a novel multifunctional PVC hanging plate for product storage. The novel multifunctional PVC hanging plate is prepared from, by weight, 15-25 parts of Makrolon, 8-16 parts of high density polyethylene, 25-40 parts of PVC resin, 15-25 parts of lignin, 20-40 parts of montmorillonoid, 12-18 parts of wollastonite, 10-20 parts of modified composite particles, 1-2 parts of zinc stearate, 1.5-2.5 parts of N,N-m-phenylenedimaleimide, 2-4 parts of ammonium-potassium dichromate, 1-2 parts of benzoyl peroxide, 0.5-0.8 part of zinc oxide, 2-4 parts of tributyl citrate, 1-2 parts of microcrystalline wax, 2-3 parts of coal tar, 3-4 parts of stabilizer, 1.5-2.5 parts of foaming agent and 2-3 parts of antioxygen 264. The novel multifunctional PVC hanging plate for product storage has excellent abrasion resistance and aging resistance.

Owner:安徽优丽普科技有限公司

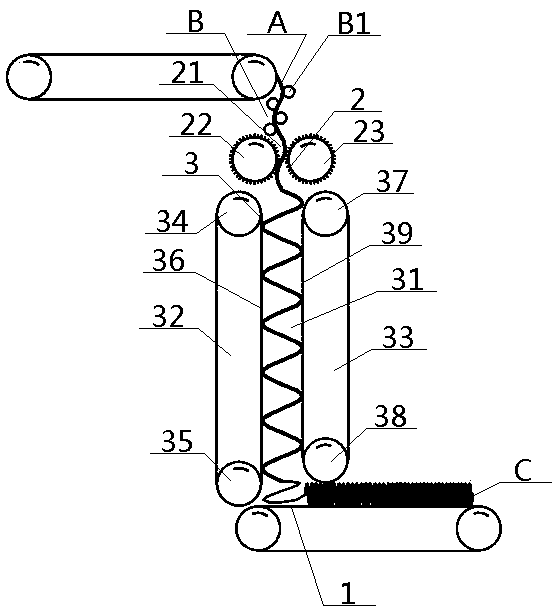

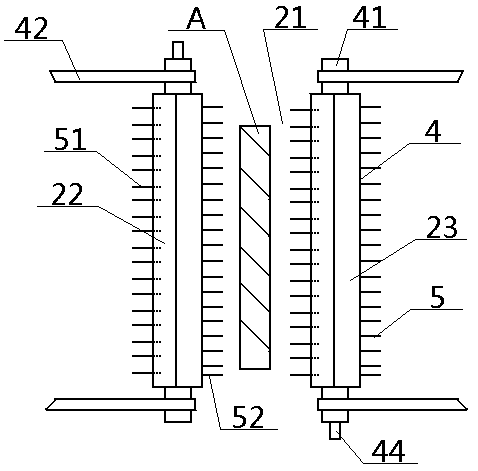

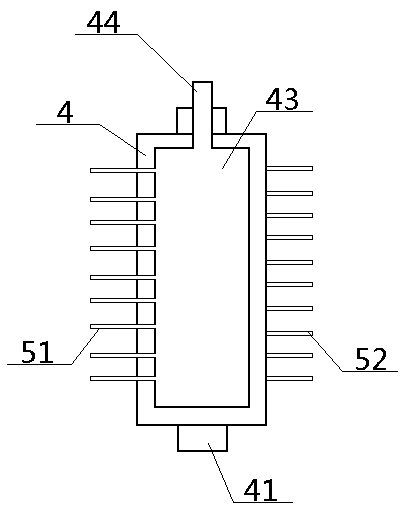

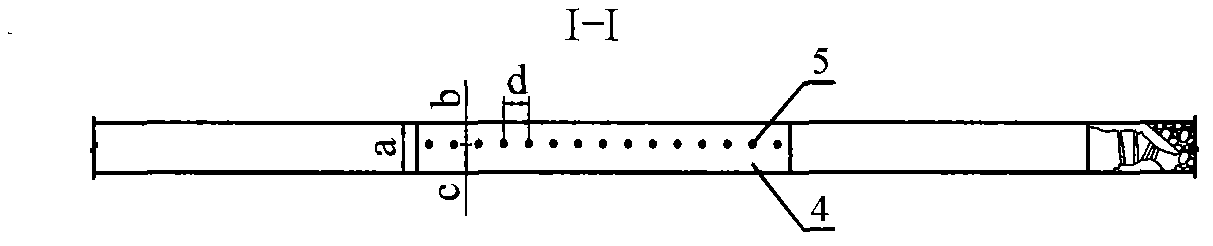

Vertical net laying system for honeycomb porous structure cotton and using method thereof

The invention discloses a vertical net laying system for honeycomb porous structure cotton. A top inlet of a cotton supply channel is communicated with a filament introduction region, forward and reverse filaments introduced in the filament introduction region are perpendicular to weaving bodies passing through the cotton supply channel, a bottom outlet of the cotton supply channel is communicatedwith the top face of a horizontal conveyor belt under the channel through a cotton discharge channel, left and right reciprocating rollers at the two sides of the cotton supply channel include reciprocating roller bodies and multiple reciprocating needles arranged on the roller bodies, the reciprocating needles can include breathable needles so as to be communicated with roller inner cavities inside the reciprocating roller bodies, and left and right cotton discharging portions on the two sides of the cotton discharge channel are each composed of multiple needle rollers sequentially distributed from top to bottom. Due to the design, the weaving and crossing effect is high, the internal structure of weaving bodies can be changed, the functionality is high, the weaving bodies of the porousstructure are formed, the arranging effect on the interiors and exteriors of the weaving bodies is high, and the structure uniformity and surface flatness of the weaving bodies can be improved.

Owner:平邑经发科技服务有限公司

Anti-corrosion and anti-ageing adhesive for paperboard

InactiveCN106047215AIncrease viscosityImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesPolyesterPolymer science

The invention discloses an anti-corrosion and anti-ageing adhesive for a paperboard. The anti-corrosion and anti-ageing adhesive for the paperboard comprises the following raw materials in parts by weight: 25-35 parts of aromatic isocyanato, 5-15 parts of polypropylene glycol, 15-20 parts of polyester diol, 40-60 parts of gelatinized starch, 5-15 parts of oxhide gelatin, 1-6 parts of bone glue, 5-15 parts of modified whey protein composite microparticles, 5-15 parts of soy protein, 1-2 parts of bis (dioctylpyrophosphate) ethylene titanate, 1-2 parts of sodium dodecyl sulfate, 0.5-1.2 parts of tebuconazole, 1-2 parts of tea polyphenol, 0.2-1 part of chitosan, 1-5 parts of ricinoleic acid, and 20-40 parts of water. The anti-corrosion and anti-ageing adhesive for the paperboard is good in anti-corrosion property and anti-ageing property and excellent in toughness and heat stability.

Owner:HEFEI DONGCAI PRINTING TECH

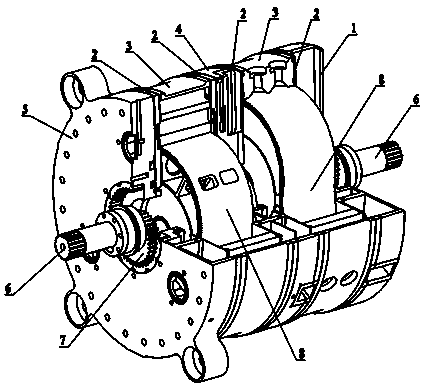

Wear-resistant environment-friendly low-energy-consumption 8-shaped rotor engine as well as rotor and acting method thereof

InactiveCN108757167AHigh popularityIncrease varietyInternal combustion piston enginesWear resistantEnvironmental resistance

The invention relates to the field of machinery, in particular to a wear-resistant environment-friendly low-energy-consumption 8-shaped rotor engine as well as a rotor and an acting method thereof. The engine comprises a cylinder body, an inner shell space with three arc-shaped surfaces being in butt joint is contained in the cylinder body; the engine further comprises a rotor capable of rotatingin the inner shell space, and the rotor is of a structure similar to an 8-shape; the engine further comprises a shaft penetrating through a hole inside the 8-shaped rotor, and the shaft is an eccentric shaft; the rotating part of the eccentric shaft can drive a rotating structure of the structure similar to the 8-shape in the inner shell space; and the inner shell space comprises an oil hole. Firstly, the problem that a traditional rotor engine is unreasonable in structure is solved; secondly, the problems that the traditional rotor engine is low in compression ratio and limited in types of available fuels are solved; thirdly, the problems that for the traditional rotor engine, the combustion is incomplete, due to oil burning, pollution is serious, and emission does not reach the standardare solved; and fourthly, the problems that the traditional rotor engine is serious in abrasion and short in service life are solved.

Owner:SHAANXI XIN NIAN POWER TECH GRP CO LTD

Flame-retardant rubber toughened nylon corrugated-pipe material used for rail transit and preparation method thereof

InactiveCN107698969AImprove impact resistanceIncrease the degree of cross-linkingPolymer scienceStearic acid

The invention discloses a flame-retardant rubber toughened nylon corrugated-pipe material used for rail transit and a preparation method thereof. The flame-retardant rubber toughened nylon corrugated-pipe material comprises the following raw materials in percentages by weight: 65 to 80% of nylon resin, 5 to 10% of toughening rubber, 10 to 20% of flame retardant loaded polymer vesicles, 1 to 2% ofstearic acid, 0.1 to 0.5% of an anti-oxidant, 1 to 5% of an inorganic filling material and 0.1 to 0.5% of a vulcanizing agent PDM.

Owner:滁州远方车船装备工程有限公司

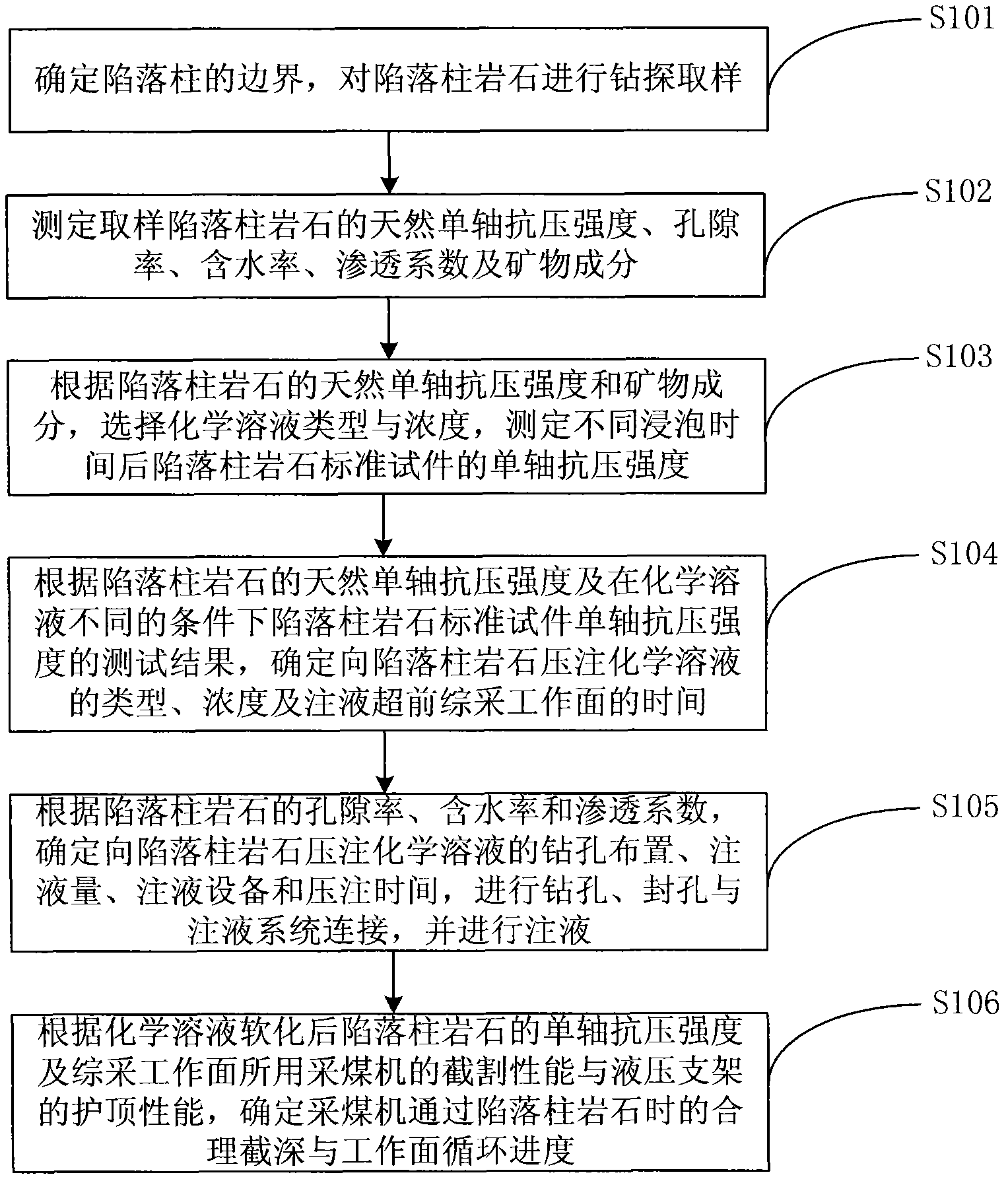

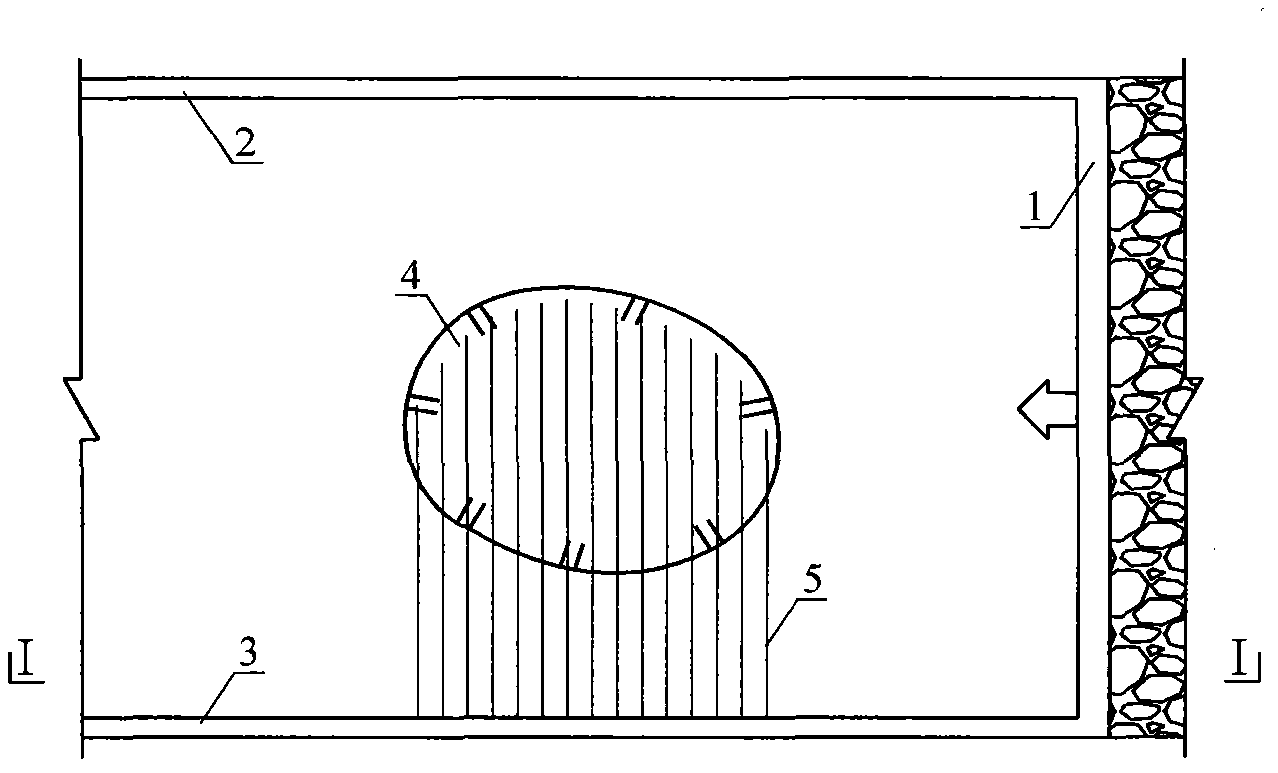

Method for chemically softening rock to allow fully mechanized coal face to pass collapsed column

InactiveCN102720497BWeakened mechanical strengthGuarantee normal progressUnderground miningSurface miningChemical solutionUltimate tensile strength

The invention discloses a method for chemically softening rock to allow a fully mechanized coal face to pass a collapsed column. The method includes: drilling rock of the collapsed column, and filling chemical solution to dissolve and corrode mineral components of the rock of the collapsed column, thereby changing internal structure of the rock of the collapsed column, reducing inter-particle action of the rock of the collapsed column, lowering internal cohesion of the rock of the collapsed column and weakening mechanical strength of the rock of the collapsed column to soften the rock of the collapsed column; and selecting reasonable coal cutter web and work face cycle advance to allow the fully mechanized work face to pass the collapsed column. By the method, tunneling and supporting amount, coal loss amount and conveyance amount when the fully mechanized work face is subject to skipping, bypassing and directly passing through the collapsed column are reduced, difficulty in moving and replacement of a support and abutting of work faces, equipment damage caused by direct passage and the like are eliminated, and normal advance of the fully mechanized work face is guaranteed. The method is economic, practical, simple, quick, safe and reliable, guarantees low coal loss and has high popularization and application value.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com