Biological aerated filter system with alkaline leaching excess sludge as filler, operating method of biological aerated filter system and preparing method of filler

A biological aerated filter and residual sludge technology, applied in the direction of water pollutants, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems of easy plugging of fillers and stable operation of the filter system, and achieve low production costs, Improve decontamination efficiency and good removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A method for preparing fillers in a biological aerated filter system using residual sludge from alkali leaching as fillers, the steps of which are as follows:

[0065] Step 1. Wash the excess alkali leaching sludge to neutrality; the surface of the excess alkali leaching sludge is rough, loose and porous, and the interior also has a relatively rich pore structure, and its light weight and fine particles have the potential to be used as water treatment fillers; alkali leaching The remaining sludge is alkaline, which is not conducive to the attachment and growth of microorganisms, so it needs to be washed to neutrality, and the prepared filler layer 4 is conducive to the attachment and growth of microorganisms;

[0066] Step 2: After the alkali leaching residual sludge is dried, it is ground and sieved; the particle size of the sludge is reduced, and it is pretreated for calcination heat treatment, in order to obtain better filler performance;

[0067] Step 3. Preheat the...

Embodiment 1

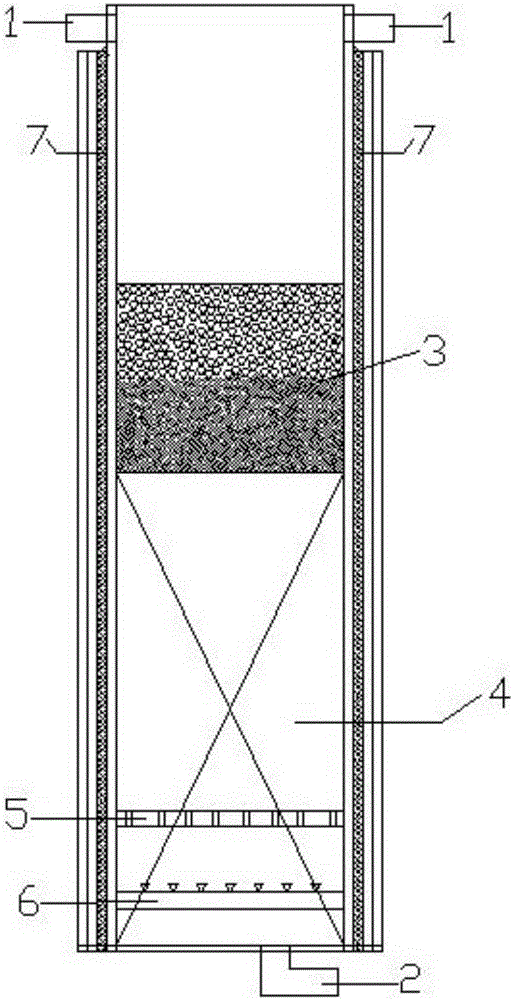

[0084] Such as figure 1 As shown, a biological aerated filter system using residual alkali leaching sludge as filler, the inner diameter of the double-layer column is 24cm, the outer diameter is 30cm, the height of the inner column is 100cm, the height of the outer column is 95cm, and the effective volume is about It is 36L, the effective height of packing layer 4 is 50cm, and the height of ceramsite filter layer 3 is 20cm.

[0085] The selection of the ratio of the height of the filter to the inner diameter of the bottom only needs to ensure that the flow rate during operation is suitable for the dissolved oxygen in the system, and this specific value has been found to meet the requirements through experiments. The height of the packing layer and the height of the filter material area such as the ceramsite filter layer are determined based on comprehensive consideration of factors such as the organic pollution load and the resistance of the filter material layer; the water di...

Embodiment 2

[0087] see figure 1 , a biological aerated filter operating system using residual alkali leaching sludge as filler, the BAF tank body includes a water inlet 1, a filter layer 3, a packing layer 4, and a microporous aeration device 5 arranged in sequence from top to bottom And backwashing device 6, insulating glass wool 7, water outlet 2. The inner diameter of the double-layer cylinder is 24cm, the outer diameter is 30cm, the height of the inner column is 100cm, the height of the outer column is 95cm, the effective volume is about 36L, the effective height of the packing layer 4 is 50cm, and the height of the ceramsite filter layer 3 is 20cm. The filling rate of the ceramsite particles is above 90%. The ceramsite filter layer 3 is set to be distributed in the upper and lower layers. The average particle size ranges of the upper and lower layers are 10-12mm and 4-6mm respectively. 10cm.

[0088] The implementation steps of the film-hanging of the biological aerated filter syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com