Spiral continuous stirring device for paste filling material and paste material preparation method

A mixing device and paste technology, which is applied to cement mixing devices, unloading devices, and raw material supply devices for sales, etc., can solve the problems of uneven mixing of slurry and sand, unstable material properties, and low conveying efficiency, and achieve increased activation. effect, material cost reduction, simple device structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a paste material preparation method of the above-mentioned spiral continuous stirring device for paste materials, the method comprising the following steps:

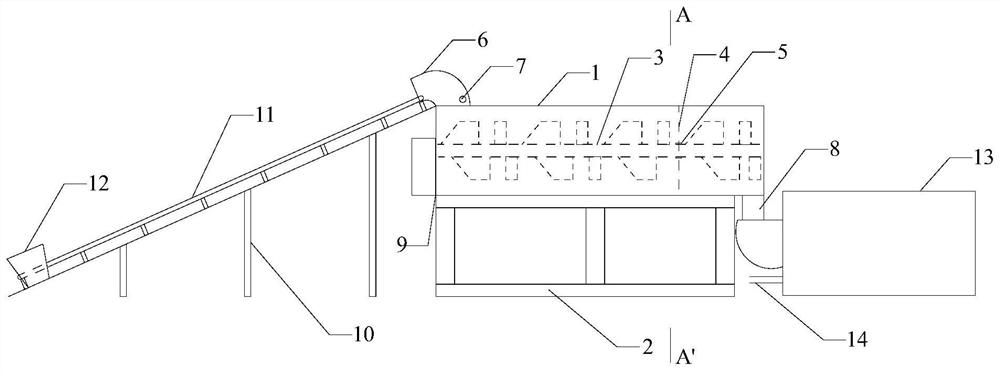

[0045] Step 1: Assemble the spiral continuous mixing device for the paste material and place it in the goaf treatment area, separation layer treatment site or water interception curtain construction position.

[0046] Step 2: Through the crushing equipment, materials such as building solids, coal gangue, pebbles and gravels are crushed into fine aggregates of 0-10 mm, which are used to prepare paste materials.

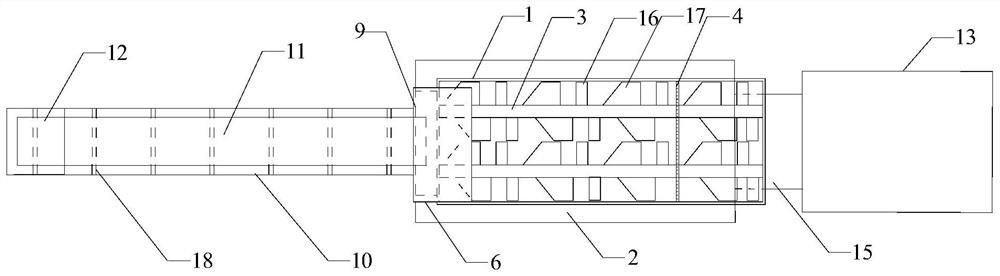

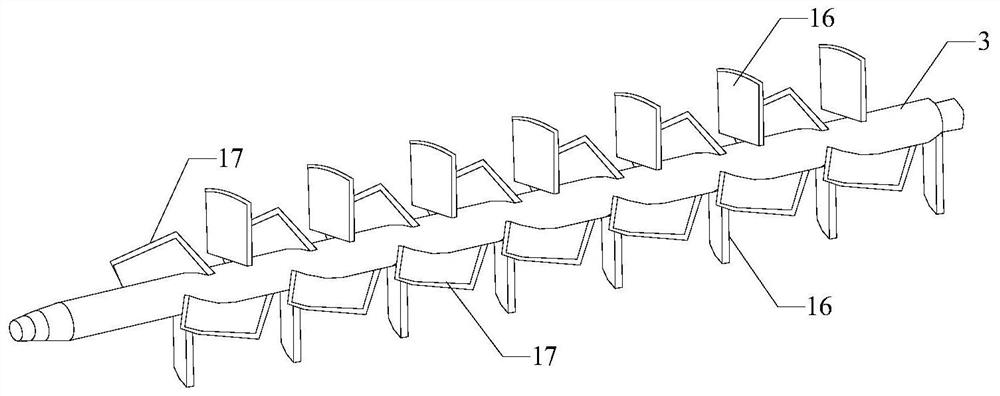

[0047] Step 3: Transfer fine aggregates such as sand or crushed construction solids, coal gangue, pebbles and gravels to the receiving hopper 12 of the conveying device by an excavator or a forklift, and the transmission roller shaft 18 drives the conveyor belt 11 to drive, and the conveyor belt 11 Send fine aggregates such as sand or broken building solids, coal gangue,...

Embodiment 1

[0054] Step 1: Assemble the conveying device, stirring device and pumping device into a set of spiral continuous stirring device for paste material, and place the device on the site of the gob treatment project.

[0055] Step 2: Through the crushing equipment, the construction waste solid waste materials are crushed into fine aggregates with an average particle size of 5mm, which are used to prepare paste materials.

[0056] Step 3: Transfer the construction waste solid waste material fine aggregate with an average particle size of 5 mm to the receiving hopper 12 by a forklift, and the transmission roller shaft 18 drives the conveyor belt 11 to drive, and the conveyor belt 11 solidifies the construction waste with an average particle size of 5 mm. The waste material fines are conveyed to the mixer 6 .

[0057] Step 4: Prepare cement at the pulping station: fly ash with 3:7 and water-cement ratio of 1:1, transport the slurry to the mixer 6 through the slurry delivery pipe, and ...

Embodiment 2

[0065] Step 1: Assemble the conveying device, stirring device and pumping device into a set of spiral continuous stirring device for paste material, and place the device on the site of the gob treatment project.

[0066] Step 2: Screen the medium sand as the fine aggregate of the paste material for the preparation of the paste material.

[0067] Step 3: The medium sand is transferred to the receiving hopper 12 by a forklift, the transmission roller shaft 18 drives the conveyor belt 11 to drive, and the conveyor belt 11 transports the medium sand to the mixer 6 .

[0068] Step 4: Prepare cement at the pulping station: fly ash is 3:7, and the slurry with a water-cement ratio of 1:1 is transported to the mixer 6 through the slurry delivery pipe, and enters the mixer 6 and 80% through the slurry delivery hole 7 The amount of medium sand is mixed to preliminarily prepare a paste material, and the preliminarily formed paste material falls into the barrel 1 of the stirring device.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com