Patents

Literature

440 results about "Kapok fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kapok is an all-natural fiber pulled from the seed pods of the kapok tree. A sustainable, completely natural and pesticide-free product sourced from South Pacific growers, Kapok is resilient, lightweight and water resistant, which means it also resists mold.

Green totally degradable warming material and producing method thereof

InactiveCN101509175AHigh strengthImprove stabilityHollow filament manufactureFilament/thread formingCardingKapok fiber

A green completely-degradable warm-keeping material and a production method thereof are disclosed, the weight percent of components thereof are: 40-60 parts of kapok fiber, 10-40 parts of polylactic bi-component fiber and 15-40 parts of polylactic hollow fiber; the material is formed by pre-needling at first and then the procedures of hot-melt shaping, cooling, winding, etc. after a fluffy three-dimensional netlike structure fiber net is formed by cotton plucking, cotton mixing, weighting, opening, mechanical carding and disordering. The inventive warm-keeping material employs the completely-degradable raw materials and has no pollution in the entire production process, the product has multiple functions of excellent strength, fluffiness, warm keeping, bacteriostasis and the like, which belongs to green environmentally-friendly products.

Owner:JIAXING UNIV

Process for manufacturing kapok fiber blended yarns

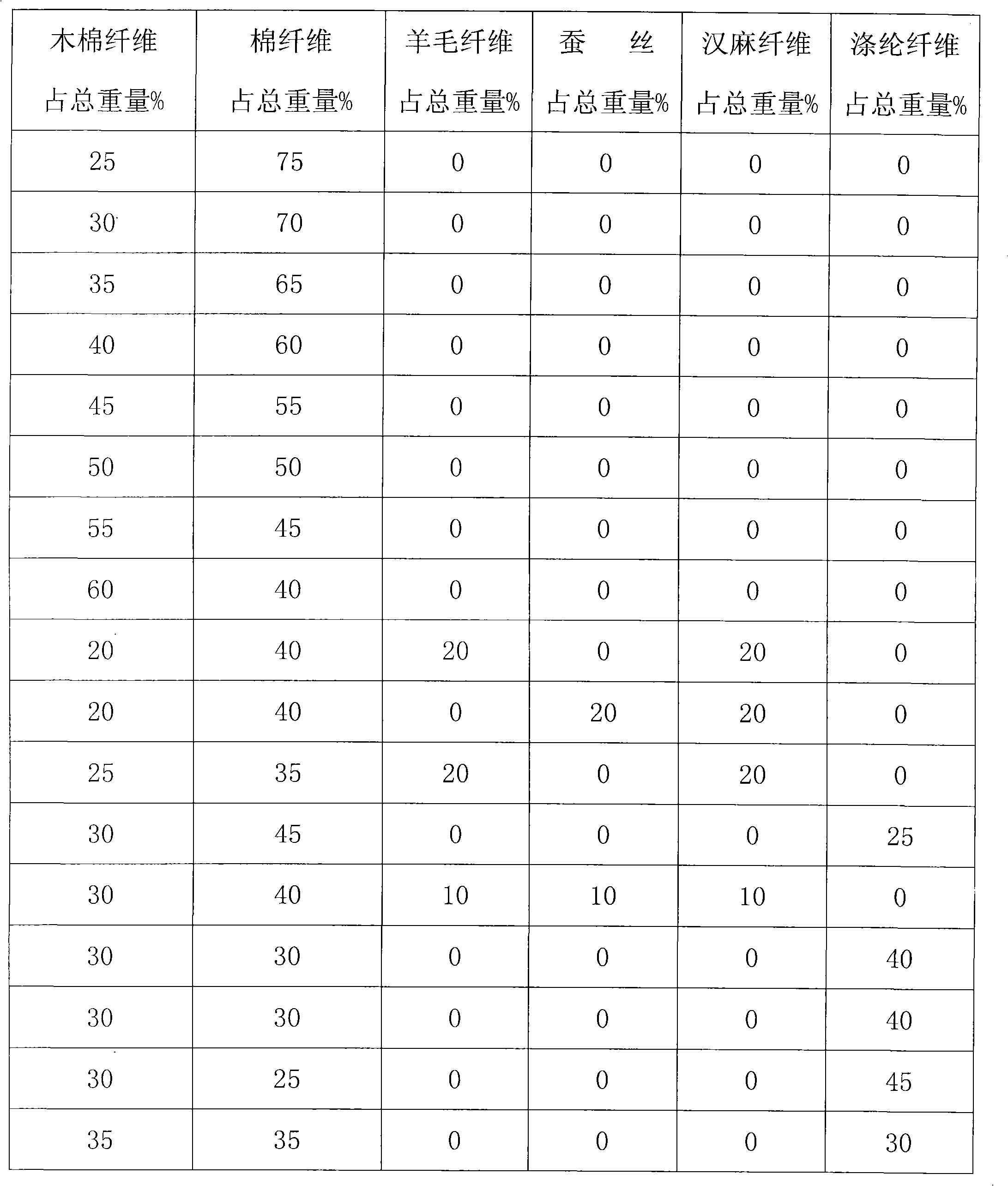

The invention discloses a process for manufacturing kapok fiber blended yarns, comprising the steps of selecting a plurality of kapok fibers, cotton fibers, wools, silks, hemp fibers and terylene fibers, wherein the content of the kapok fibers is 25-60% of the total blended yarns; the content of the cotton fibers, wools, silks, hemp fibers and terylene fibers is 40-75% of the total blended yarns; weighing the kapok fibers and other spinning fibers, dividing the fibers into small stacks, and obtaining multi-component blended yarns by mixing, blowing, cotton carding, drawing, roving and spinning, wherein the relative humidity of the production environment of each process is 60-65%; the products produced by the invention can be manufactured to be kinds of blended fabric materials; a fabric product which is pure natural, green, environment-friendly, soft and warming is increased in the spinning field.

Owner:JIHUA 3542 TEXTILE CO LTD

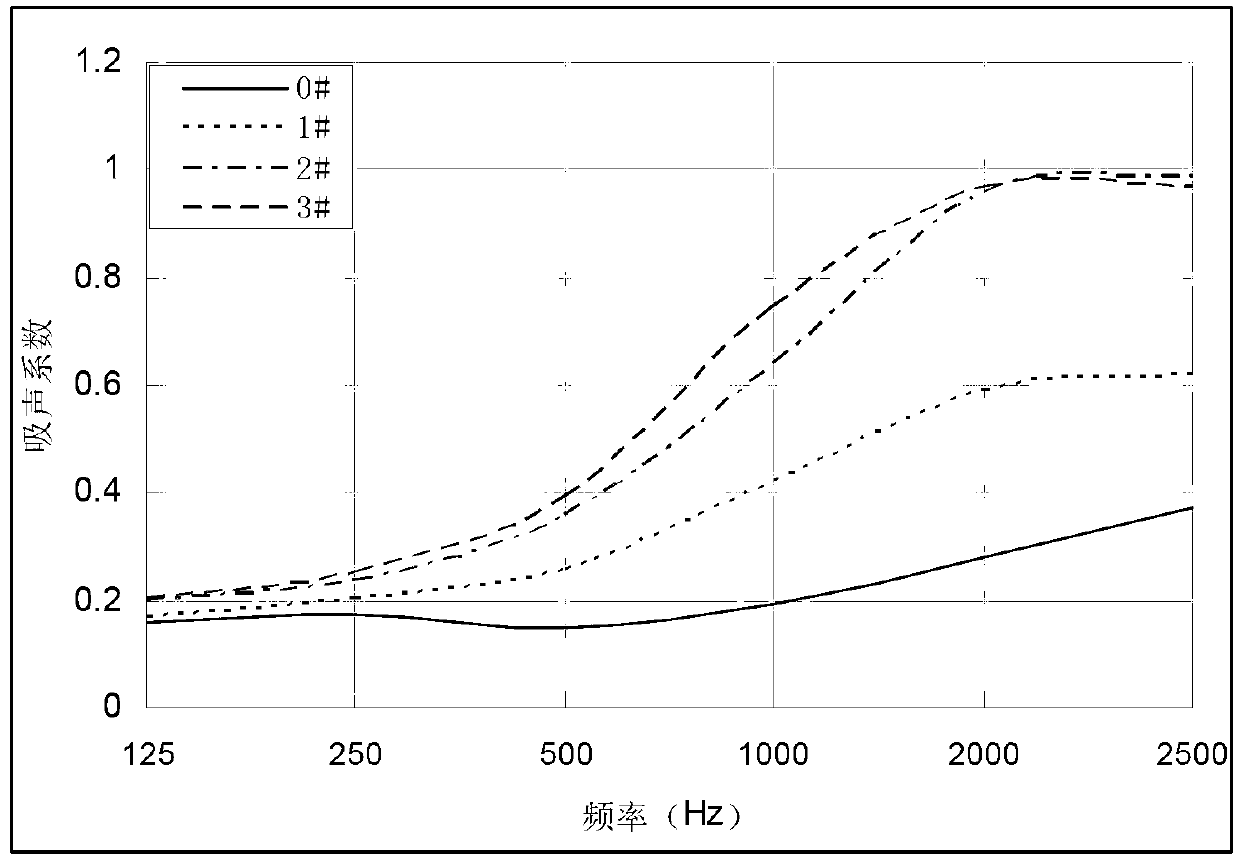

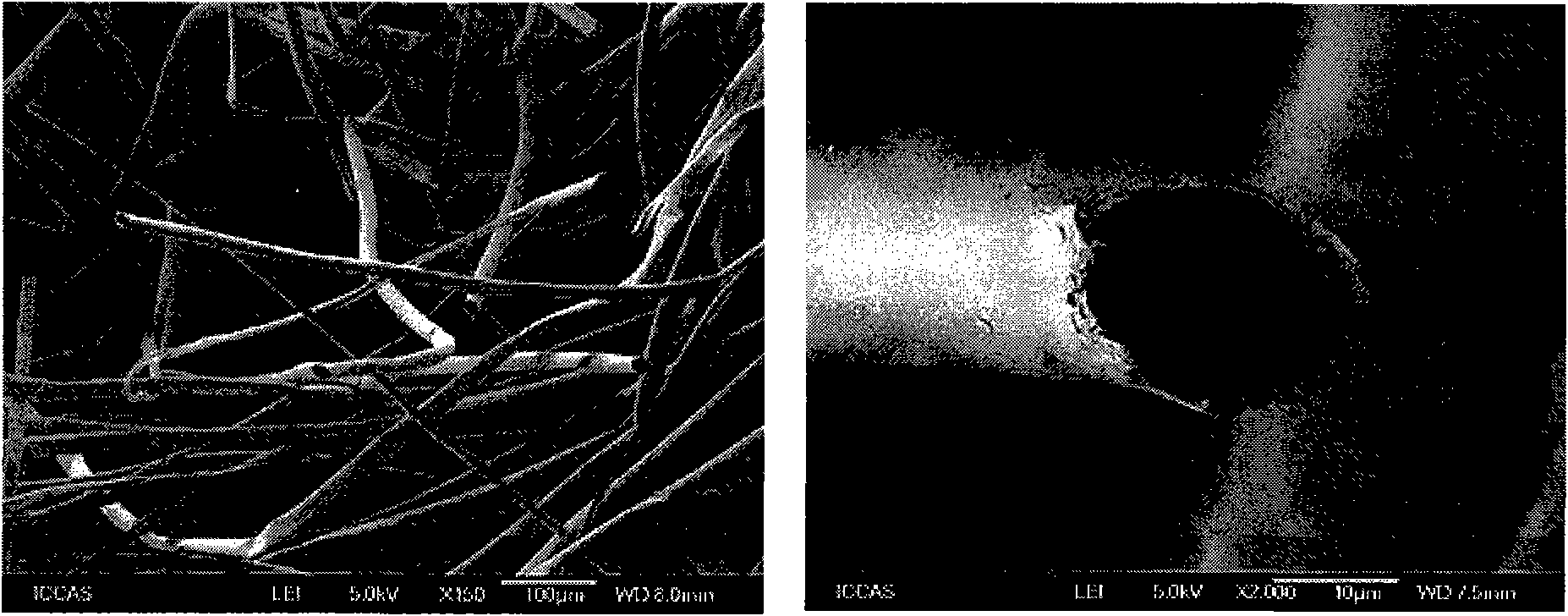

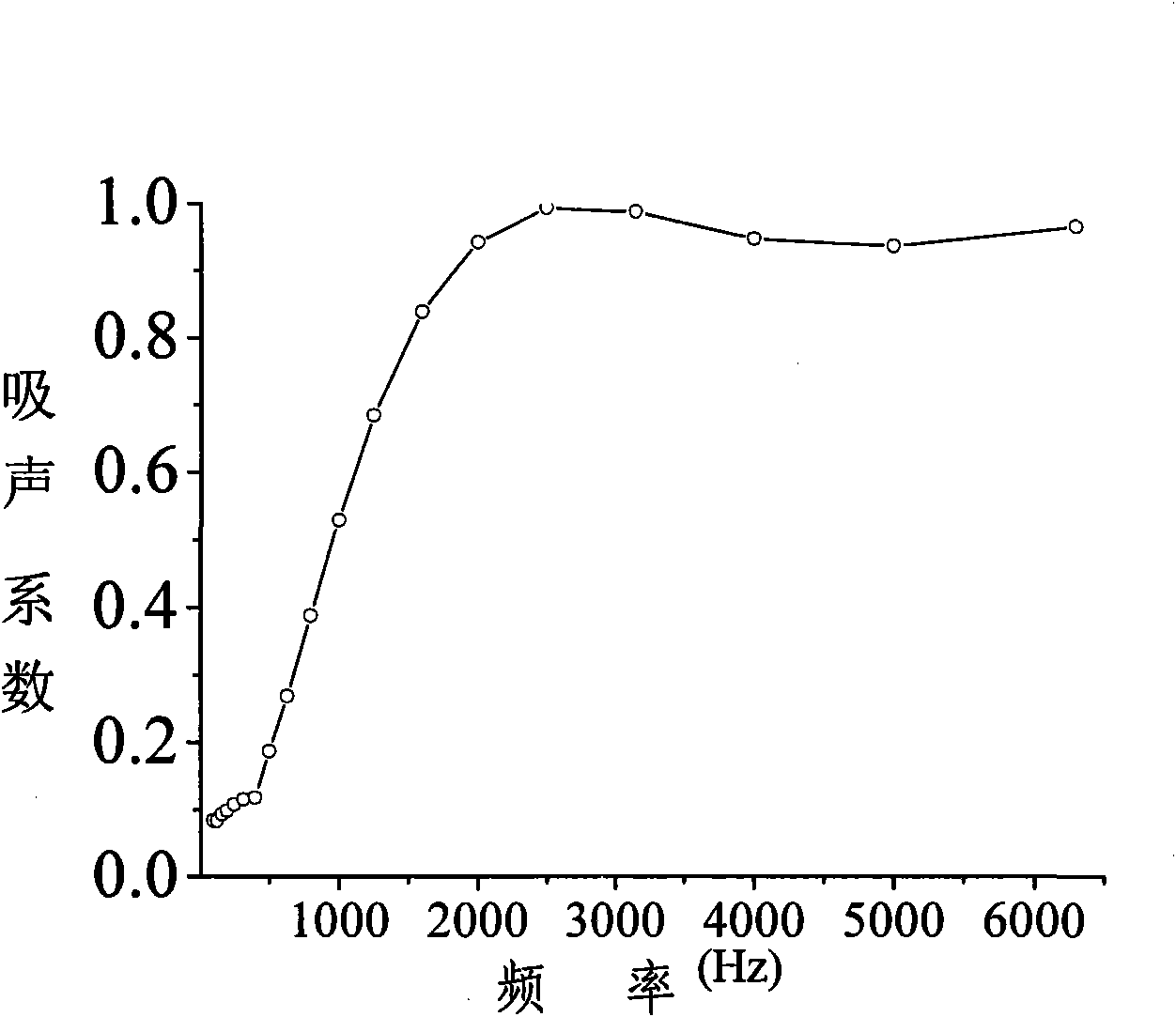

Low-frequency sound absorption needling non-woven composite materials and preparation method thereof and application thereof

InactiveCN103106898AImproved sound absorptionImprove sound absorptionSound proofingSound producing devicesKapok fiberEconomic benefits

The invention relates to low-frequency sound absorption needling non-woven composite materials and a preparation method of the low-frequency sound absorption needling non-woven composite materials and application of the low-frequency sound absorption needling non-woven composite materials. The composite materials comprise kapok fibers or hollow Dacron non-woven fabric and polyethylene films. The preparation method comprises: mixing, opening, carding and meshing are conducted to 60%-90% kapok fibers and 40%-10% hollow Dacron non-woven fabric according to mass percent; a fiber mesh is inputted in a needling machine so as to conduct needling reinforcement, the fiber mesh is reeled and cut off so as to obtain kapok or hollow Dacron needle non-woven fabric; the polyethylene films in 0.06mm-0.10mm are smoothly placed on one side of the needle non-woven fiber mesh, and are composited, taken out and cooled, and then the low-frequency sound absorption needling non-woven composite materials are obtained. The composite materials can be applied to the field of automotive trim, construction, high-speed rail and the like. The sound absorption materials have the advantages of being light in weight, simple in operation of the preparation method, good in economic benefit and suitable for industrial production.

Owner:DONGHUA UNIV

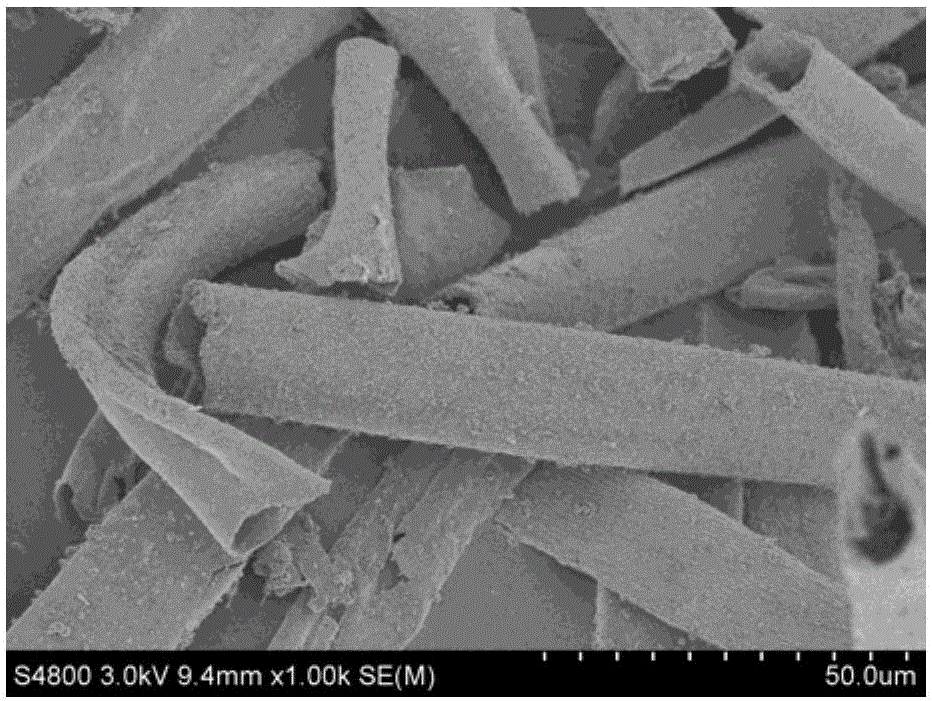

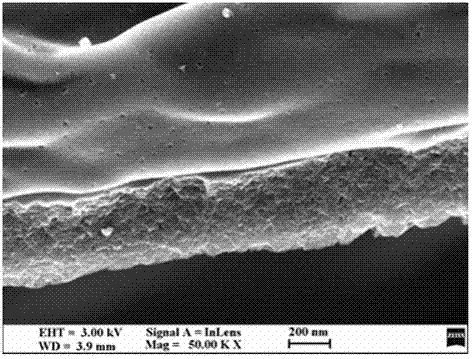

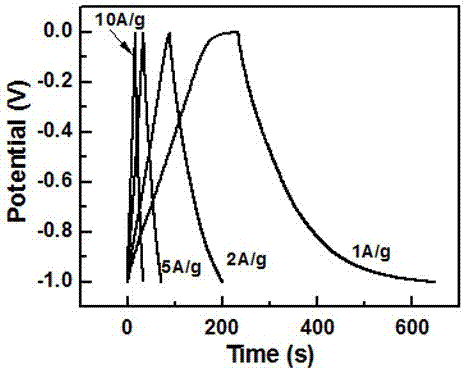

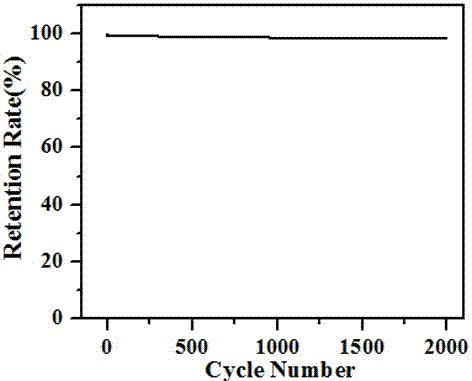

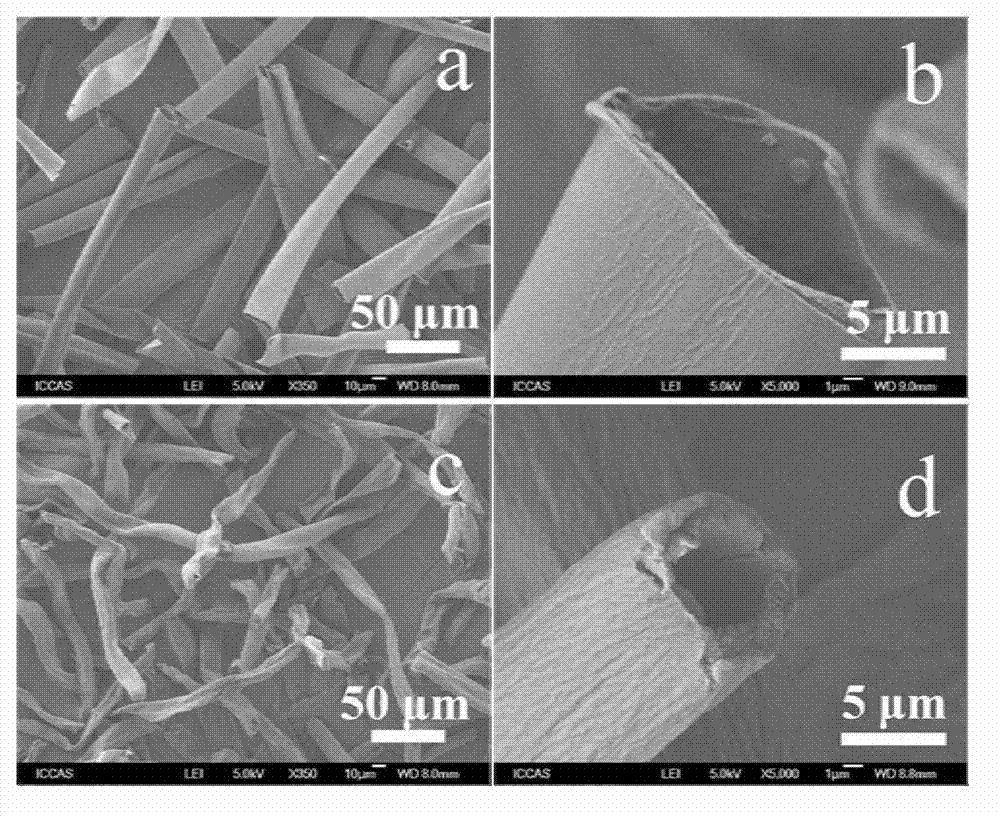

Preparation method and application of hollow tubular biochar

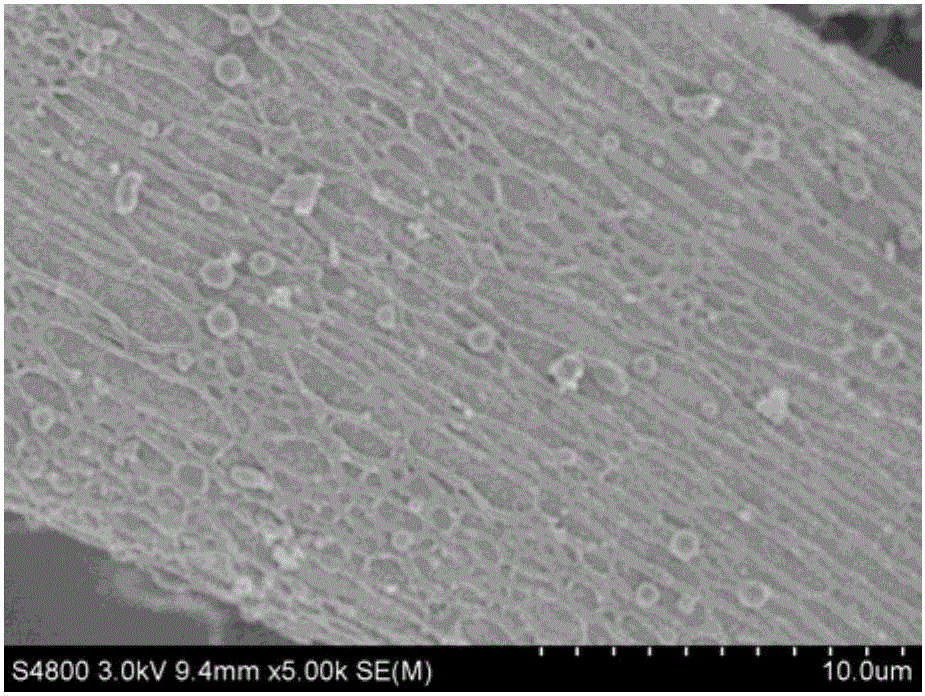

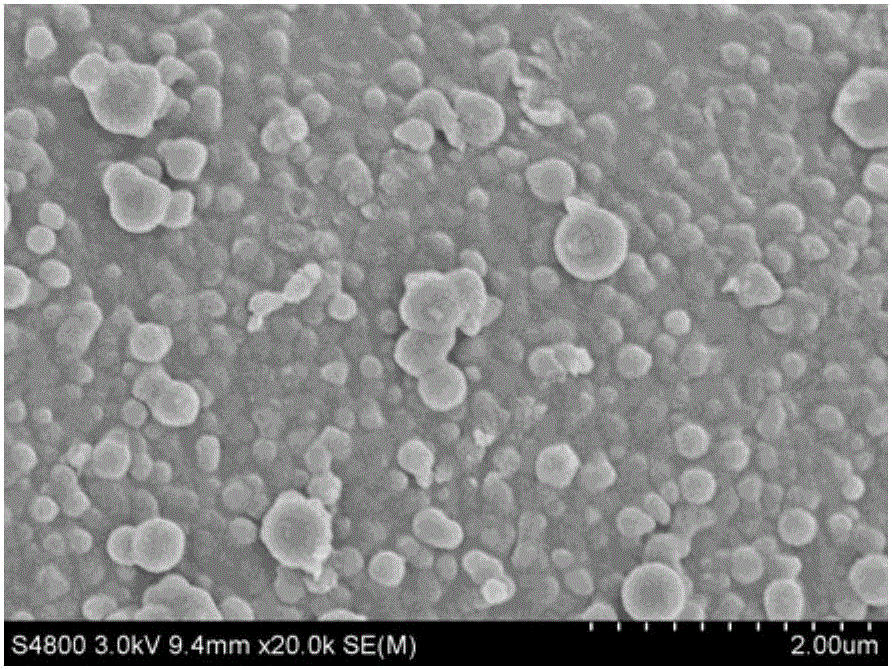

InactiveCN105776182ALow carbonization temperatureLarge specific surface areaHybrid capacitor electrodesCell electrodesSorbentKapok fiber

The invention discloses a preparation method and application of hollow tubular biochar. The preparation method includes: dispersing kapok fiber in a sulfuric acid solution for hydrothermal reaction to obtain carbonized kapok fiber; calcining the carbonized kapok fiber under protection of inert gas, cooling, washing, collecting and drying the calcined kapok fiber to obtain the hollow tubular biochar. The preparation method is simple and easy to control, carbonization and activation of the kapok fiber can be well realized on the premise that original structure of the kapok fiber is maintained, and distribution of balls in the inner surface and the outer surface of a hollow tube can be realized by controlling hydrothermal temperature and calcining temperature. In addition, the biochar prepared by the method can be applied in lithium / sodium ion batteries and supercapacitors and can be used as a carbon matrix in adsorbents, template agents and composite materials. Especially, the hollow tubular biochar presents excellent electrochemical performance when being applied in the lithium / sodium ion batteries.

Owner:SHAANXI UNIV OF SCI & TECH

Sound absorption and noise reduction material and application thereof

InactiveCN101593515AUnique anti-mildewGood sound absorption and noise reduction effectSound producing devicesSocial benefitsKapok fiber

The invention discloses a sound absorption and noise reduction material and application thereof in preparation of sound absorption and noise reduction products. The sound absorption and noise reduction material provided by the invention mainly comprises natural kapok and can also comprise natural organic fiber, inorganic fiber and synthetic fiber. The total content by mass percentage of the natural organic fiber, inorganic fiber and synthetic fiber is 0-95% of the sound absorption and noise reduction material. As the kapok fiber has the characteristics of high degree of hollowness, dampproof and mothproof, low price and easy availability, the kapok fiber can be made into sound absorption and noise reduction products such as kapok sound absorption batting filling material, kapok acoustic felt, kapok sound absorption non-woven fabrics and the like, the sound absorption and noise reduction has favourable effect, simple preparation technology, low cost, thus having great economic benefit and social benefit.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Cowboy plus material containing kawo fiber and producing technique thereof

InactiveCN101165245ABreathableMoisture-wickingWoven fabricsLiquid/gas/vapor textile treatmentHigh humidityKapok fiber

The present invention discloses jean fabric containing kapok fiber and its production process. The jean fabric contains kapok fiber in 20-100 % and other fiber in 0-80 %, and the other fiber is natural fiber and / or chemical fiber. It is produced through the steps of pre-treating material, scutching, high temperature and high humidity carding to form sliver, drawing, spinning, bleaching, weaving, post-treatment, etc. The jean fabric has the advantages of light weight, high air permeability, high moisture permeability, good warming performance, mothproofing and moldproofing.

Owner:晏国新 +1

Kapok fiber-based three-dimensional network oil absorption material

The invention discloses a kapok fiber-based three-dimensional network oil absorption material. According to the invention, activation-treated kapok fibers are used as base materials, and the three-dimensional network oil absorption material is prepared by grafting copolymerization, crosslinking, washing, drying, and crushing in the presence of an initiator. The dry oil absorption material can absorb diesel oil with a mass being 40-50 times of the mass of the material, can absorb gasoline with a mass being 40-47 times of the mass of the material, and can absorb chloroform with a mass being 60-67 times of the mass of the material. The oil absorption material of the invention is simple in preparation operation, is characterized by high oil absorption rate and high oil absorption speed, and is applicable to fields such as sea, river, lake surface oil pollution, kitchens, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

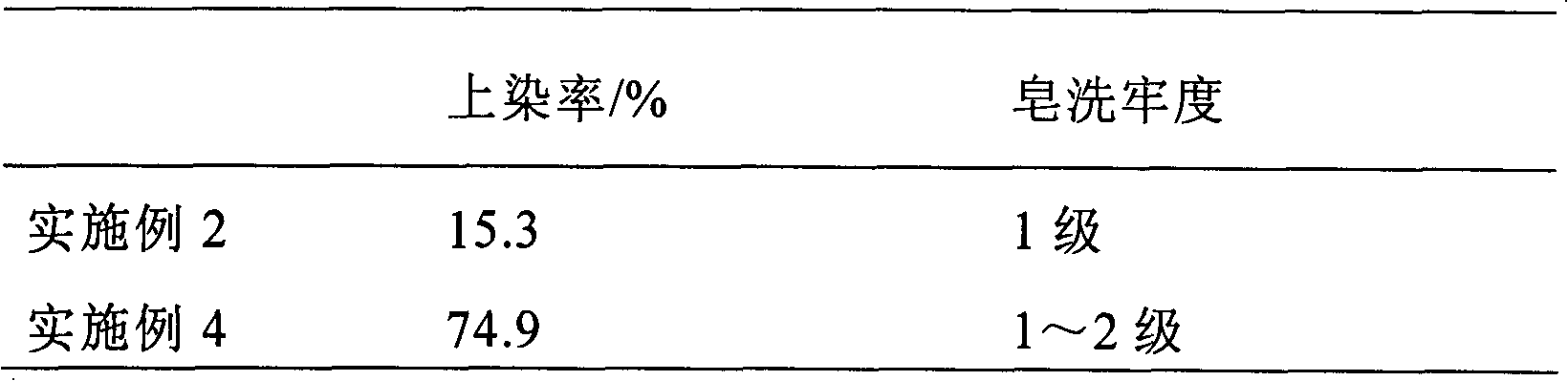

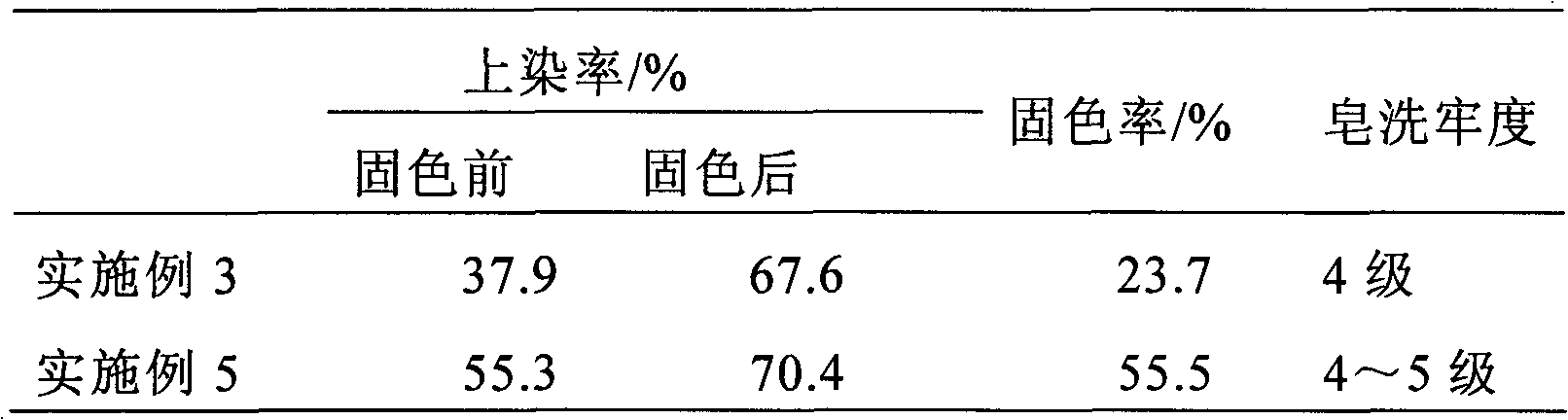

Rare earth mordant dyeing method for kapok fiber and textile thereof

InactiveCN102561063AImprove dyeing effectPromote infectionBleaching apparatusDyeing processState of artKapok fiber

The invention relates to a rare earth mordant dyeing method for kapok fibers and textiles thereof. The method comprises the following steps: pre-treating kapok textile so as to remove some waxy xubstances, impurities and the like on the surface of the kapok fiber and achieve certain whiteness; and then adding a complexing rare earth mordant into a dye bath of the pretreated kapok textile, and mordant dyeing the kapok textile. Compared with the prior art, according to the dyeing method of the invention, the dyeing of the kapok fibers and textiles thereof is not limited to direct dyes and can also be used for other anionic dyes such as reactive dyes and the like, and the problems of low rate of dye-uptake, poor level-dyeing property, poor deep-color dyeing effect, poor dyeing fastness and the like are overcome.

Owner:SHANGHAI UNIV OF ENG SCI

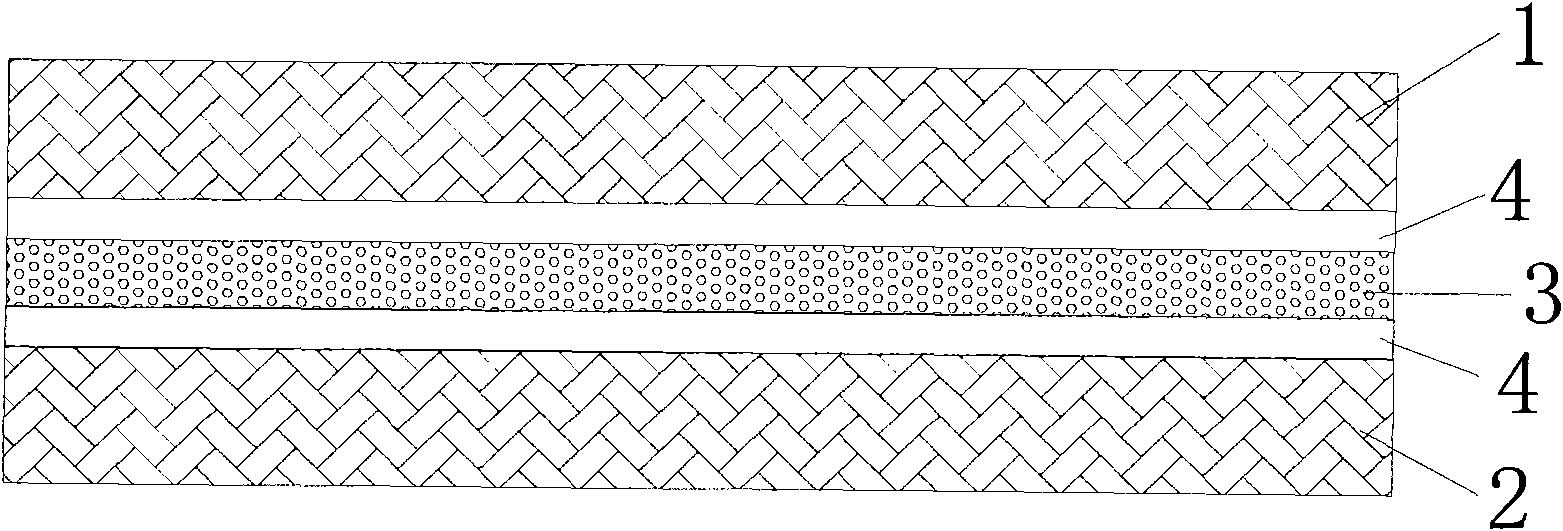

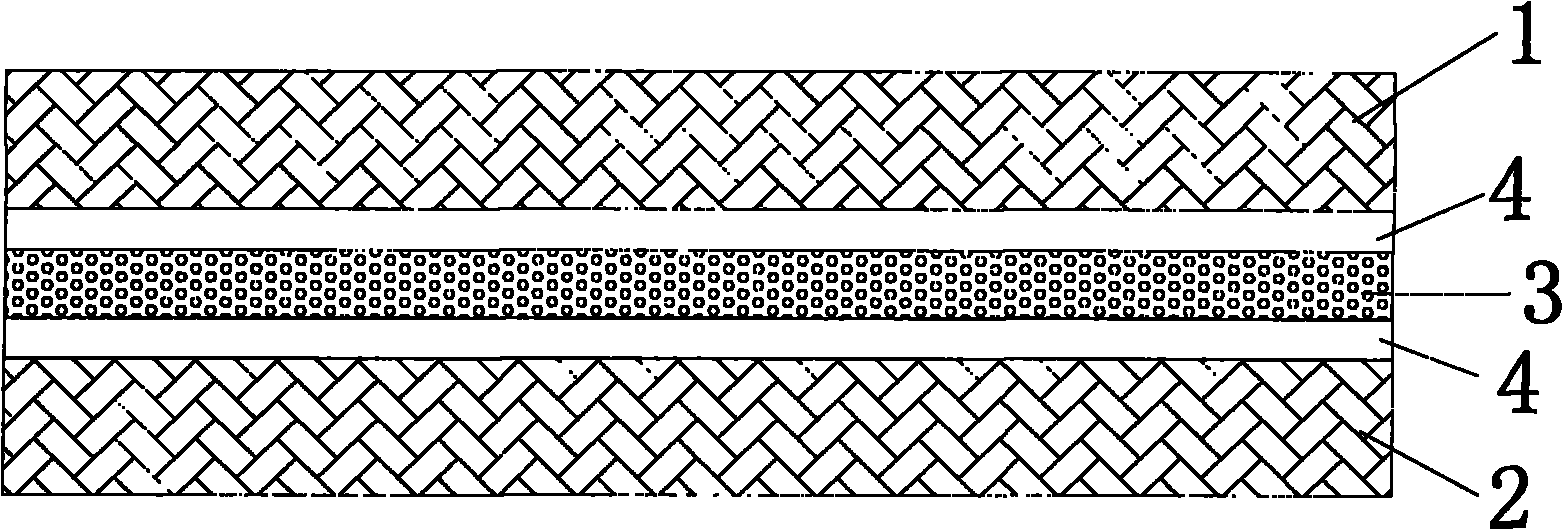

Mildewproof and mothproof composite fabric

InactiveCN102058189AImprove breathabilityKeep warmLayered productsProtective garmentKapok fiberEngineering

The invention discloses a mildewproof and mothproof composite fabric, which comprises an outer layer, an inner layer and a middle layer, wherein both the outer layer and the inner layer are made of fabric blended with kapok fibers and other fibers; the middle layer is a membrane layer; and the two sides of the membrane layer are combined with the outer layer and the inner layer through glue layers. The composite fabric disclosed by the invention is a kapok fiber-containing fabric, has excellent breathing, warming, dampness conducting, mildewproof and mothproof effects, is environmentally-friendly, has the characteristic of being softer, lighter and more environmentally-friendly than fabrics made of other fibers, and mainly solves the problem that the mildewproof and mothproof effects of other fibers are undesirable.

Owner:CHANGSHU HUABO WOOLEN TEXTILE

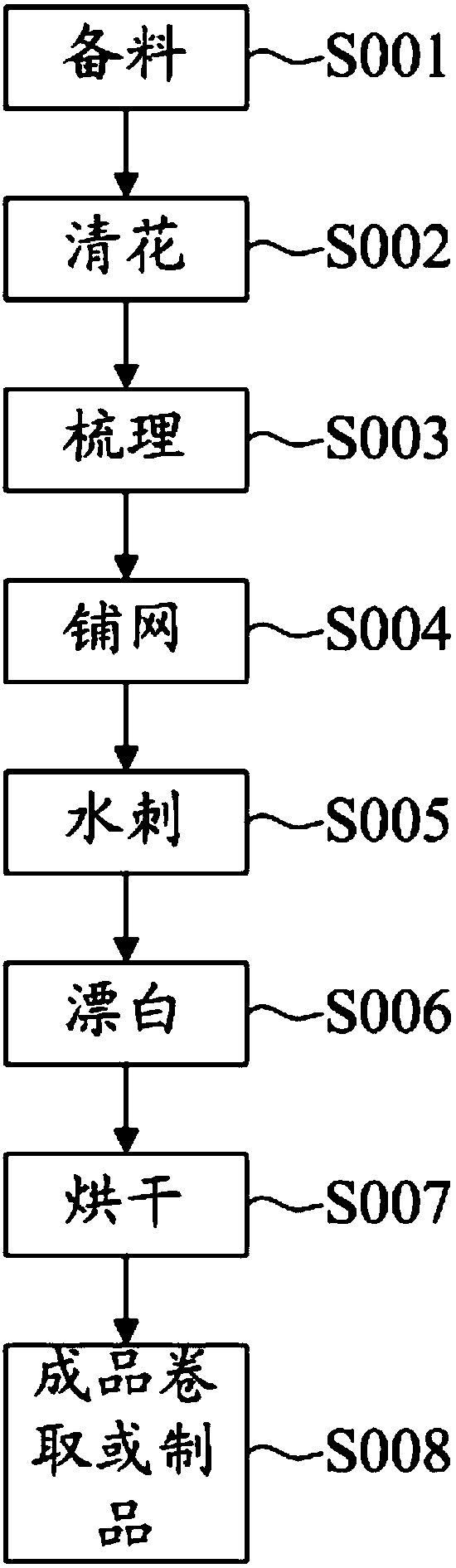

Production method of kapok fiber spunlaced nonwoven fabric

InactiveCN103205862AKeep natural propertiesMaintain propertiesNon-woven fabricsVegetal fibresKapok fiberPulp and paper industry

The invention belongs to the technical field of weaving, in particular to a production method of kapok fiber spunlaced nonwoven fabric. The method includes: pretreating kapok fiber to improve spinnability; using a weighing curtain feeder to feed kapok fiber into a blowing-carding device for opening, blending and purification; using an induced fan to collect web in a blowing-carding machine to feed into a tiny dust removing device for further dust removing and opening; connecting the tiny dust removing device with a spunlaced line carding machine, carding the fiber into web on the spunlaced line carding machine, cross lapping, spunlacing to form fabric, coiling, degreasing and bleaching, drying and slitting to obtain the finished product. The method is safe, environment-friendly, energy-saving, efficient, high in automation level, and advanced in spunlaced kapok nonwoven fabric weaving, and various characteristics of fiber raw materials are protected effectively.

Owner:蒋海彦

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

Bombax cotton thermal shell fabric and its manufacturing method

The invention discloses a kapok warm face material. The fiber ingredients and the ratio are: natural kapok fiber 10-100%, cotton or other fiber 0-90%, urethane elastic fiber and other elastic fiber 0-50%. The invention also discloses the manufacture method including the following steps: selecting the fiber ingredients; spinning after mixing the raw material; weaving on the knitting great circle machine; dyeing and after processing. The advantage of the invention is good warm effect, soft tactility and comfort.

Owner:DONGHUA UNIV

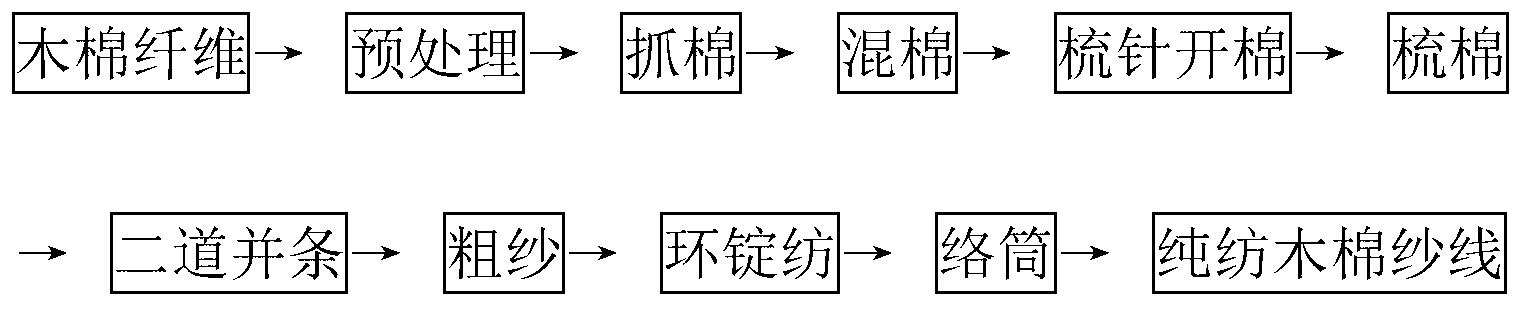

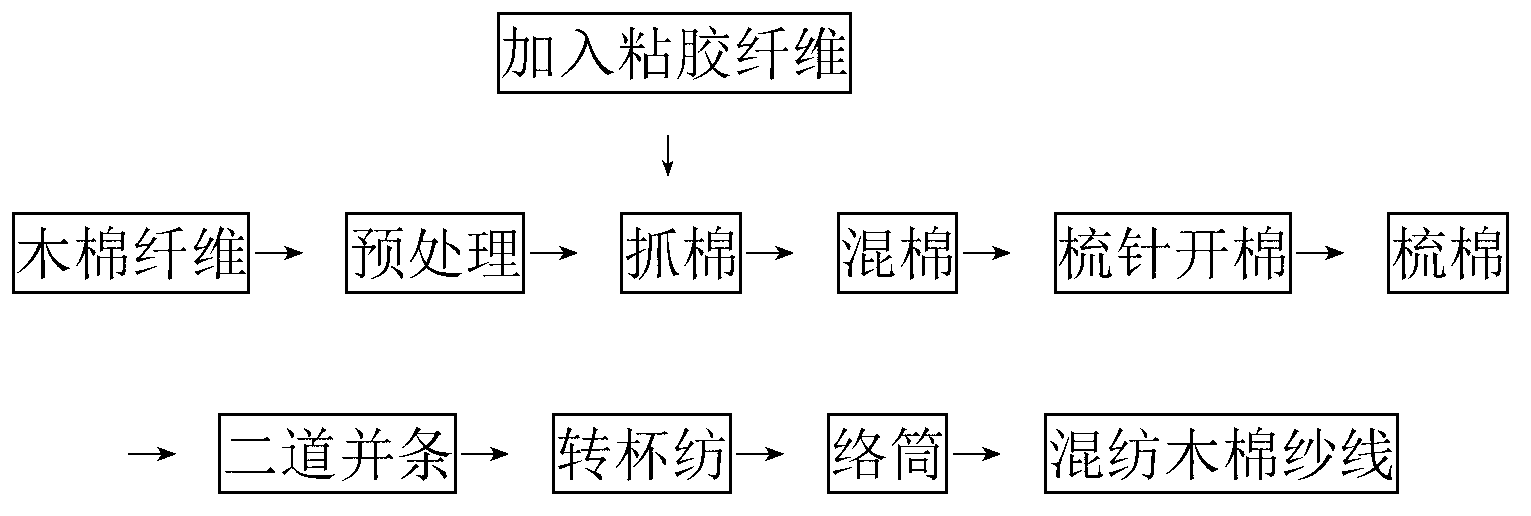

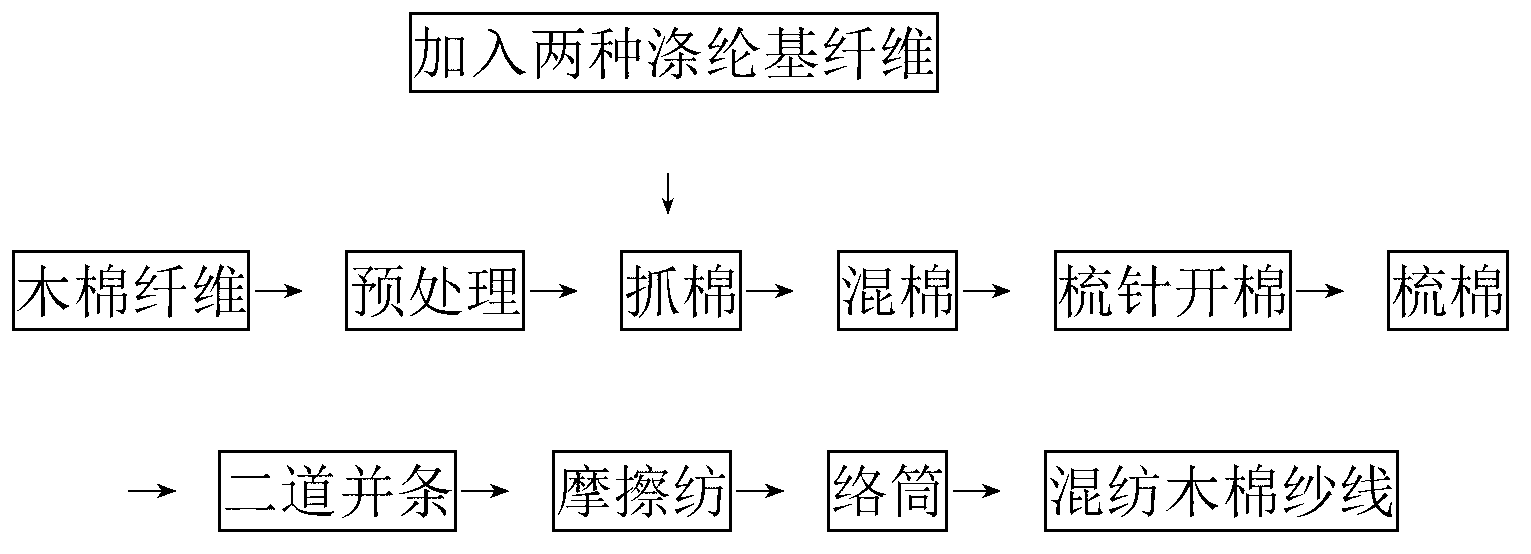

Method for processing kapok fiber yarns

The invention discloses a method for processing kapok fiber yarns. The method comprises the following steps of: pretreating kapok fibers, and then spinning the kapok fibers, wherein the spinning comprises the following steps of: sequentially performing cotton catching, cotton mixing, cotton carding and opening, dust removal, cotton feeding, cotton carding and twice strip drawing on the kapok fibers, and the kapok fiber yarns can be obtained by directly performing friction spinning and winding or rotary cup spinning and winding on the drawn kapok fibers, or the kapok fiber yarns can be obtained by performing roving and then ring spinning and winding on the kapok fibers; treatment liquid in the pretreatment working procedure comprises the following components in parts by weight: 3-10 parts of corn starch, 2-10 parts of carboxymethylcellulose and 80-95 parts of water; and the pretreatment method comprises the steps of uniformly spraying the treatment liquid with the temperature of 50-80 DEG C on the kapok fibers which is 30-50 times heavier than the treatment liquid, then covering a thin film on the kapok fibers, and standing for 24 hours.

Owner:SHENZHEN ZHONGSHENG LIDA TRADE CO LTD

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Kapok flocculus and production method thereof

InactiveCN101177844AImprove insulation effectMaintain propertiesNon-woven fabricsPolyesterKapok fiber

The invention relates to kapok wadding sheets and a production method thereof. The components selected fiber raw materials of the kapok wadding sheets and the weight percentage thereof are that 40 to 68 percent of kapok fiber, 8 to 12 percent of cellulose fiber, 13 to 32 percent of polyester porous fiber and 7 to 20 percent of polyester 3-D crimped fiber. The processing steps of the raw materials are opening picking, opening and cotton blending, feeding hopper vibrating, combing, laying, pulling and extending of the disordered, powdering, thermal melting, ironing and cooling and so on. Indexes of the kapok wading sheets of the invention, such as bulkiness, compression elasticity, heat retaining property, etc., are better than standards of the industry, and the invention provides the textile market with wadding sheets that are light, heat-retaining efficient and more environment friendly.

Owner:SHANGHAI RISOO TECH TEXTILE

Underclothes, underdrawers, bra and swimsuit made by ceiba fiber

An underwear, a drawer, a bra and a bathing suit are prepared by the kapok fiber, wherein the constituent and the mass percent content of the fiber material is that 5-100% of fiber is the kapok fiber and 0-95% of fiber is the other fiber, and the other fiber can be the natural fiber and the chemical fiber, in particular to one of or a plurality of or total of the plant fiber, the animal fiber, the mineral fiber, the artifical fiber, the synthetic fiber and the inorganic fiber, which is one of or a plurality of or total of the chemical fiber, the synthetic fiber, the fiber of the cotton, the fur, the silk, the hemp, the soybean, the milk, the jade and so on more particularly. A gasket made of the kapok fiber is arranged at the position of the drawer positioned on the pudendum. The kapok fiber or the other fiber is made into the face fabric by carding, drawing and spinning after being mixed and loosed. The face fabric is made into the underwear, the drawer, the bra and the bathing suit by cutting and sewing. The invention has the advantages of electrostatic resistance, balling resistance, bacterium resistance, softness, moisture absorption, moisture conductivity, green, thermal retention and teredo protection.

Owner:晏国新 +1

Preparation method and application of ceiba fiber in non-weave non-woven fabrics field

InactiveCN1990947AAchieve preparationRealize comprehensive applicationFibre treatmentNon-woven fabricsNatural fiberPre treatment

The invention relates to an additive, an assistant agent for pre treatment to ceiba fiber and a method for non-woven cloth by the ceiba fiber, belonging to non-woven technology area. Said method is that the additive is used to pre-treat the ceiba fiber; the ceiba fiber after pre-treatment is mixed with all kinds of natural fiber, man made fiber and synthetic fiber and is carded to net; the fiber net is strengthened; after that assistant agent with 1.5-5% wt of ceiba fiber stock weight is added in the sizing groove to mucilage so as to strengthened the intensity; after the formation under high temperature the product is produced. The invention not only realizes the non-woven production of ceiba fiber and all kinds of natural fiber, man made fiber in different proportion but also realizes the fabrication of all kinds of non-woven production with acupuncture and water jet, which uses the 100% ceiba fiber as the stock. It creates the precedent of non-woven area and novel industry chain is formed by producing novel non-woven environmental protection product. The grade of non-woven production is improved.

Owner:戴建荣 +1

Method for extracting fiber from oil palm fruit bundle and fiber obtained thereby

The invention discloses a method for extracting fiber yarns from palm fruit clusters of oil palm. The palm fruit clusters of the oil palm are cooked by steam with a temperature of between 100 and 200 DEG C for 0.5 to 1.5 hours, oil palm fruit pericarps are separated to obtain empty fruit clusters, then the empty fruit clusters are extruded and torn to obtain fiber blocks, the fiber blocks are washed and then are extruded to ensure that the water content of the fiber blocks is between 30 and 80 percent, then the selection is performed, the selected fiber blocks are subjected to silk fetching treatment to obtain the fiber yarns, and then the fiber yarns are dried, screened and bagged. The applicator aims at the requirement on an elastic material to process and select the fiber yarns in the palm fruit clusters so as to be suitable to process natural oil palm silk mattresses. Natural fiber yarns of the palm fruit clusters obtained by the method can substitute mountain palm fiber yarns to produce various natural palm mattresses, cushions, and products such as fiberboards and sound insulation boards for buildings and so on.

Owner:GUIZHOU DAZIRAN TECH

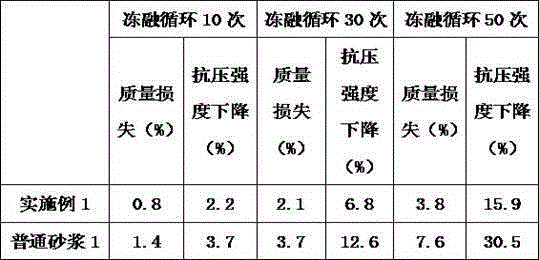

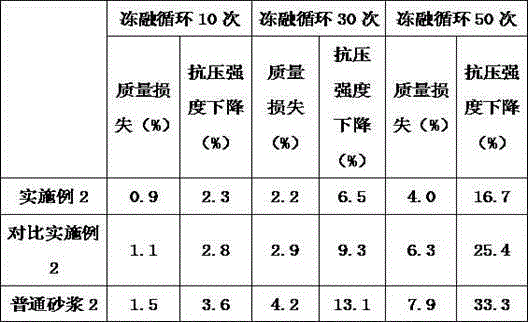

Anti-freezing mortar special for aerated bricks

The invention discloses anti-freezing mortar special for aerated bricks, made from, by weight, 30-40 parts of mineral residue, 30-35 parts of cement, 25-30 parts of river sand, 0.5-1 part of a water reducing agent, 0.5-1 part of an air entraining agent, 1-2 parts of an anti-freezing agent, 4-6 parts of vitrified micro bubbles, 3-5 parts of Kapok fiber, 2-4 parts of rare-earth oxide, and 5-8 parts of modified attapulgite. Unique components are selected, their contents are reasonably matched, and the mortar and its products are good in strength, cracking resistance, water permeation resistance and temperature resistance and excellent in anti-freezing performance, are applicable to cold areas and areas having great temperature differences and have excellent performance, and potential safety hazards are decreased.

Owner:ANHUI KUNLONG BUILDING MATERIALS CO LTD

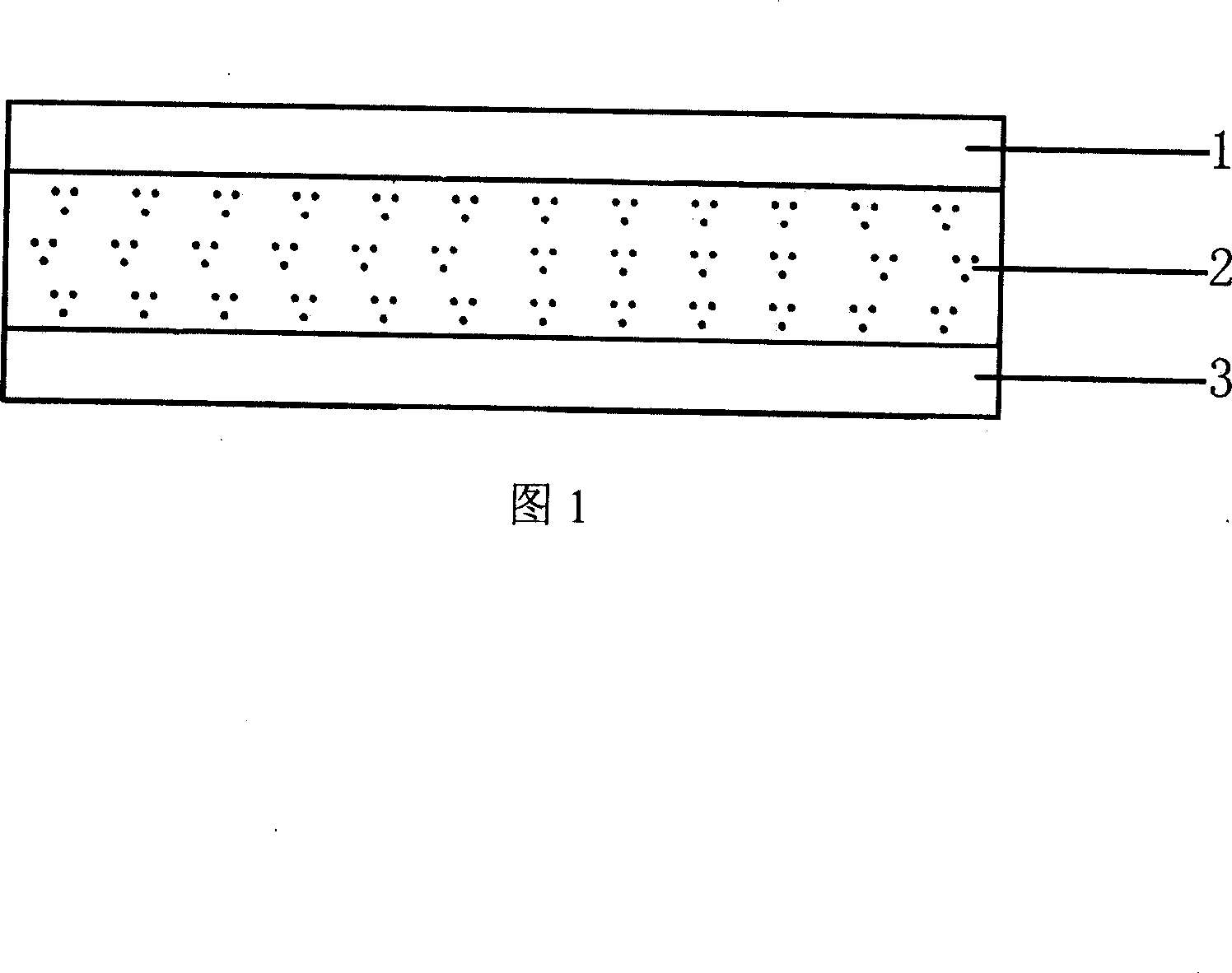

Sanitary towel, protecting pad, diaper, pants pad and medical protection pad for many kinds of persons that are all made of kapok fiber

The present invention relates to a sanitary napkin, pad, diaper, pant pad or medical protection pad for various people, which is prepared by kapok fiber and at least includes a surface layer, a middle layer and a bottom layer; the present invention is characterized in that the components and weight percentage contents of the fiber materials used for the surface layer, the middle layer and the bottom layer are: 5 to 100 percent kapok fiber and 0 to 95 percent other fibers. Each layer of the surface layer, the middle layer and the bottom layer is a one-layer or multi-layer structure. The present invention can use anti-inflammatory and bactericidal medicine for soaking, or, a Chinese herb medicine pad is lined between the surface layer and the bottom layer. The sanitary napkin, pad, diaper, pant pad and medical protection pad for various people of the present invention which is prepared by kapok fiber has the following advantages of anti-static, anti-pilling, antibacterial, soft and near skin, moisture absorption and guide, green and thermal insulation, anti-moth and anti-pest.

Owner:晏国新 +1

Preparation method and application of biomass porous carbon plate based on kapok fibers

InactiveCN107098327AAltitudeMake full use of spaceHybrid capacitor electrodesCarbon preparation/purificationBiomass carbonMaterials preparation

The invention provides a preparation method and an application of a biomass porous carbon plate based on kapok fibers and belongs to the technical field of biomass carbon material preparation. The preparation method comprises the following steps: after pre-treatment on the kapok fibers with an alkaline solution, firstly pre-carbonizing the kapok fibers at a relatively low temperature; then adding an activating agent and deionized water; performing ultrasonic treatment and drying to obtain a carbonized precursor mixture; and finally, performing normal pressure high-temperature pyrolysis to obtain the biomass porous carbon plate. The biomass porous carbon plate prepared by the preparation method is large in specific surface area and excellent in electrochemical property, can be used for preparing a supercapacitor electrode material, is simple in preparation method and provides a novel path for preparing the biomass carbon material.

Owner:FUZHOU UNIV

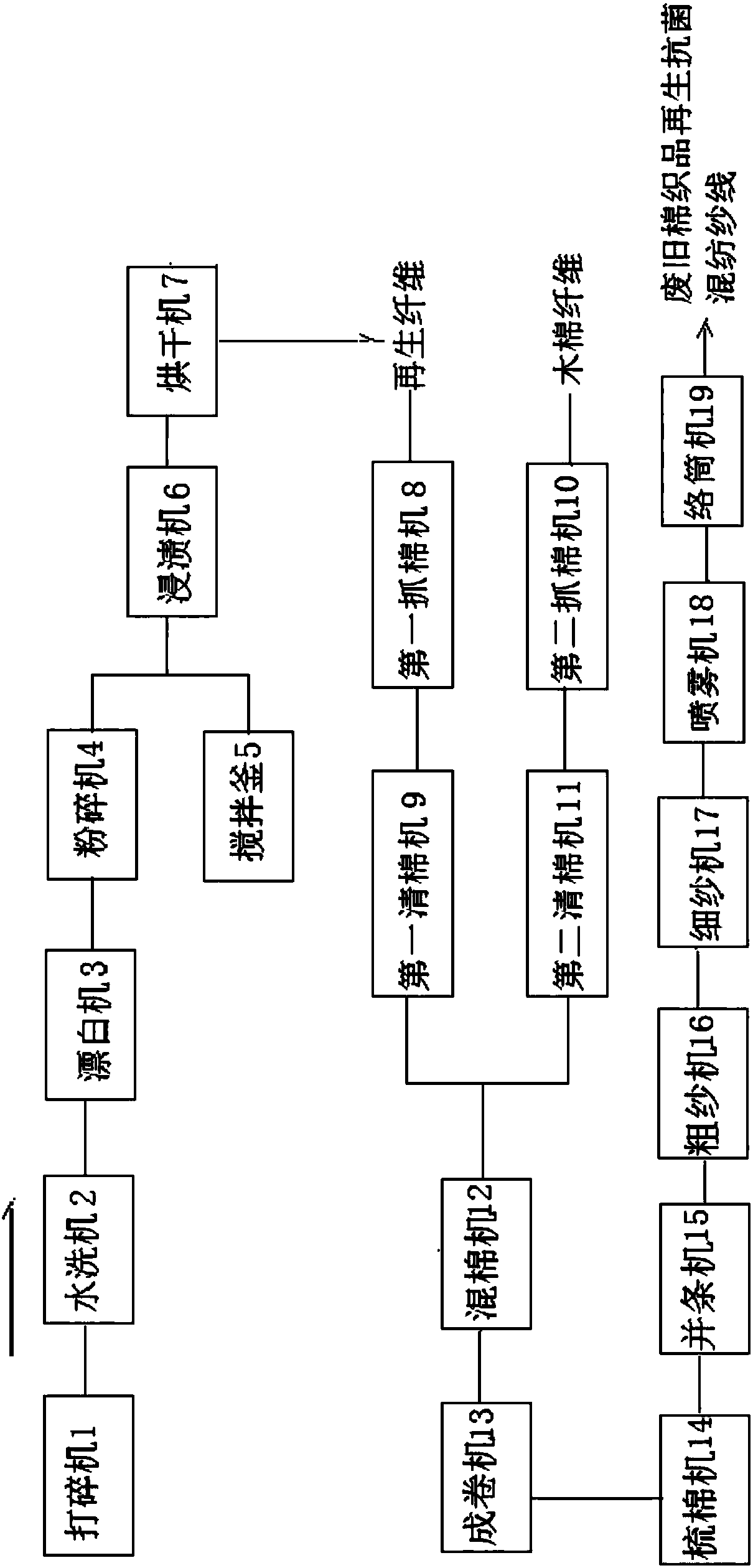

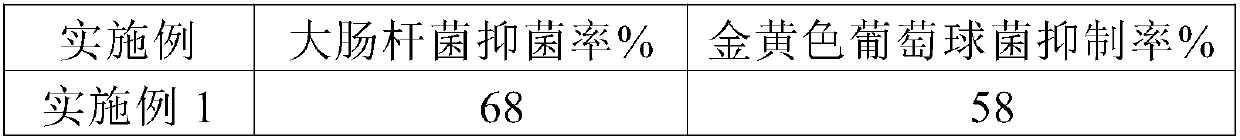

Waste cotton textile recycled antibacterial blended yarn for waste cotton texture and preparing method and system thereof

PendingCN107761209AImprove mechanical propertiesImprove wear resistanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsYarnCarding

The invention relates to waste cotton textile recycled antibacterial blended yarn and a preparing method and system thereof. According to the waste cotton textile recycled antibacterial blended yarn,waste cotton textile and impregnated sizing agent are adopted for preparing recycled fiber, wherein the impregnated sizing agent comprises multiple functional components, the functional components areevenly spread in slits in the surface of the prepared recycled fiber, and thus the recycled fiber is better modified; the recycled fiber is further subjected to opening and cleaning, and the recycledfiber obtained after cleaning and bombax cotton fiber obtained after opening and cleaning are sufficiently mixed and then subjected to lapping, cotton carding, drawing, roving, spinning, mist spraying and coning in sequence. The prepared waste cotton textile recycled antibacterial blended yarn has good mechanical performance, anti-abrasion performance and stability, is durable, natural, environmentally friendly and harmless to the human body, and has good mildew-proof and antibacterial performance, the quality of recycled cotton yarn is improved, and the use range of the recycled cotton yarnis broadened.

Owner:深圳恒锋资源股份有限公司

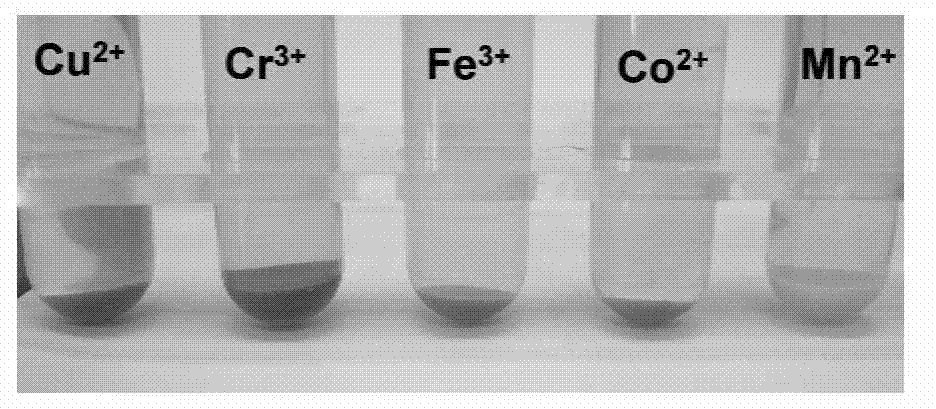

Kapok fiber adsorbent, preparation method and application thereof

ActiveCN102921382AEfficient removalImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesHigh absorptionOrganic solvent

The invention discloses a kapok fiber adsorbent, a preparation method and application thereof. The method comprises the following steps: (1) putting the kapok fiber in organic solvent to soak, then drying to obtain hydrophilously treated kapok fiber; (2) putting the hydrophilously treated kapok fiber in alkaline aqueous solution to implement alkaline treatment and obtain alkaline kapok fiber; and (3) reacting alkaline kapok fiber with a chelating agent to obtain the kapok fiber adsorbent instantly. The invention has the advantages of the adoption of kapok fiber having natural thin-wall hollow structure as raw material, great specific surface area and good modification effect. Compared with the prior art, the invention also has the advantages of fast absorption speed (the absorption balance for lead ion and cadmium ion can be reached in 2 minutes), high absorption capacity (the maximum absorption quantity of the lead ion can be reached 311mg / g, and the maximum absorption quantity of the cadmium ion can be reached 164mg / g), convenience for desorption and high re-adsorption quantity and is especially suitable for sewage treatment with high initial concentration.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Flannelette blanket containing kawo fiber and manufacturing technique thereof

InactiveCN101165247ABreathableMoisture-wickingWoven fabricsLiquid/gas/vapor textile treatmentHigh humidityKapok fiber

The present invention discloses thread blanket containing kapok fiber and its production process. The thread blanket contains kapok fiber in 20-100 % and other fiber in 0-80 %, and the other fiber is natural fiber and / or chemical fiber. Preferably, it contains kapok fiber in 50-95 % and other fiber in 5-50 %. It is produced through the steps of pre-treating material, scutching, high temperature and high humidity carding to form sliver, drawing, spinning, bleaching, weaving, gigging and post-treatment. The thread blanket has the advantages of light weight, high air permeability, high moisture permeability, good warming performance, mothproofing and moldproofing.

Owner:晏国新 +1

Dual-blended woven plant fiber yarn for men clothing

The invention discloses a dual-blended woven plant fiber yarn for men clothing. The dual-blended woven plant fiber yarn is formed by blending-weaving first plant fiber yarns, second plant fiber yarns and third plant fiber yarns, wherein the first plant fiber yarns are formed by blending and weaving Kapok woolen fibers and coconut fibers, the second plant fiber yarns are formed by blending and weaving kapok fiber fibers and rabbit fur keratin transgene cotton fiber, the third plant fiber yarns are formed by blending and weaving tea fibers and soybean protein fibers, and the weight percentages of the first, second and third plant fiber yarns are respectively 17%-25%, 48%-52% and 27%-31%. The dual-blended woven plant fiber yarn are formed by double blending and weaving, the woven yarns are compact in textures and have the characteristics that natural plant fibers are good in hygroscopicity, excellent in air permeability, fast in moisture liberation, and soft and comfortable, and also has antibacterial and deodorized and healthy effects.

Owner:苏州利森服饰贸易有限公司

Method for producing kapok scribbled by ring spinning

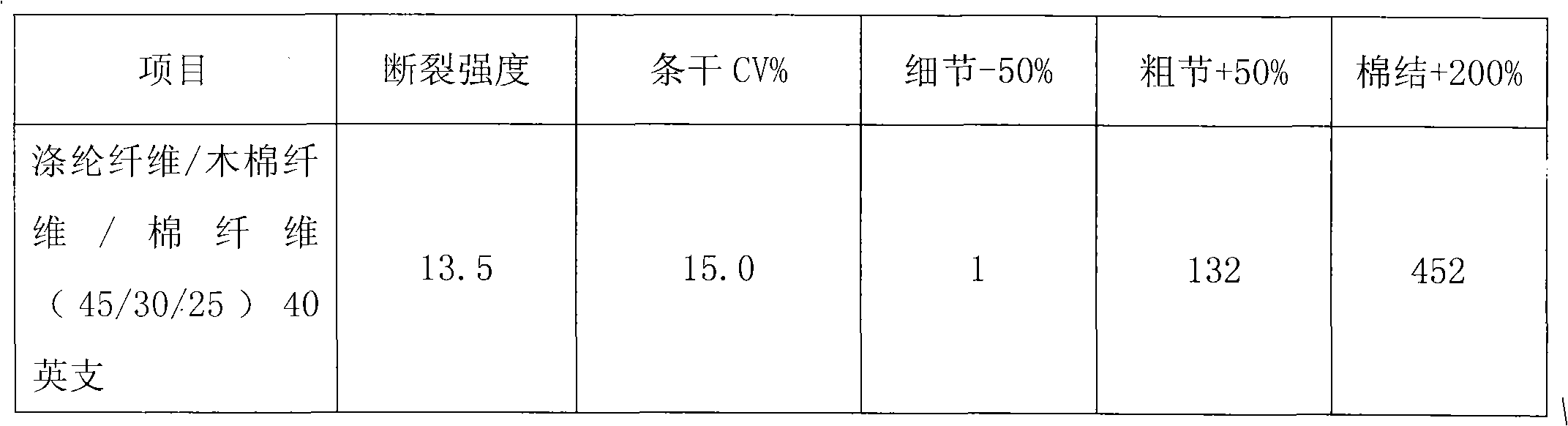

InactiveUS20070283676A1Effectively improve slivering of the resultant yarnsEffectively reduces the roller gaugeContinuous processingYarnBreaking strengthPolyester

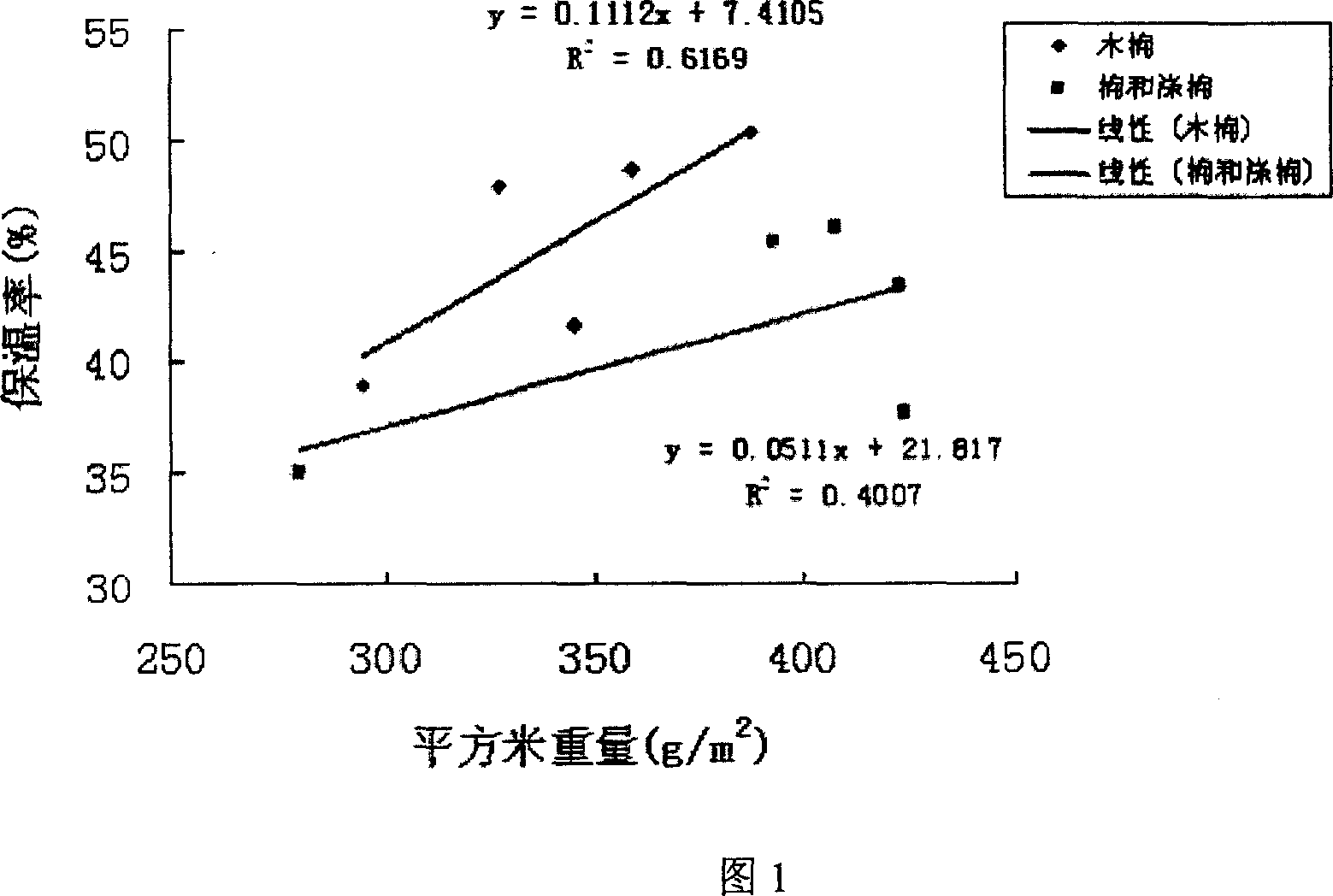

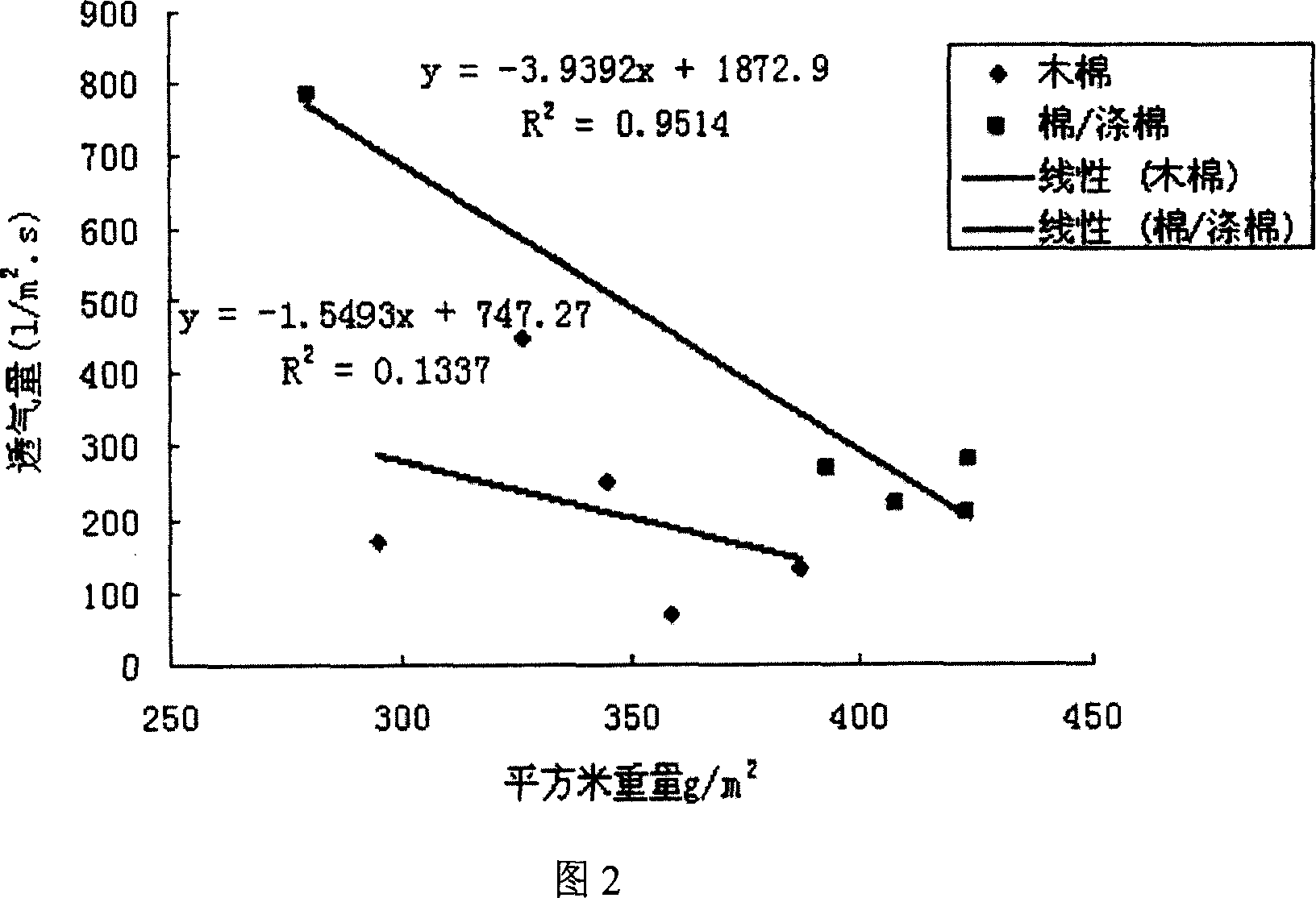

The present invention discloses a method for producing kapok scribbled by ring spinning, in which the mixed raw materials of kapok fibers and other fibers are subjected to the processes of opening and scutching, carding, drawing, roving, spinning, etc., and a device of guiding cotton sliver is provided after a carding procedure, wherein the said spinning adopts a double-short-apron drafting mode, the said carding is performed twice, and the said drawing is performed twice. The blended yarns produced according to the inventive method have the superior technical indexes in terms of the single yarn breaking tenacity, single yarn elongation at break, etc. which are better than the industrial standard of cotton berber yarn. And the shell fabric produced from the product of the invention has the superior technical indexes in terms of the fabric heat retention, fabric moisture vapour transmission, fabric touching cold-warm feeling, fabric bulking intensity, fabric compressive elastic recovery ratio and fabric soft draping property, etc. which are better than those of the similar products such as the pure cotton and polyester cotton, etc.

Owner:SHANGHAI RISOO TECH TEXTILE

Antibacterial kapok blend fiber, antibacterial filling flocculus, antibacterial kapok yarn and fabric

InactiveCN107641871AHelp cohesionHigh strengthBiochemical fibre treatmentNon-woven fabricsYarnKapok fiber

The invention discloses an antibacterial kapok blend fiber, an antibacterial filling flocculus, an antibacterial kapok yarn and a fabric. The invention further discloses preparation methods of the antibacterial kapok filling flocculus, the antibacterial kapok yarn and the fabric. By modifying the kapok fiber and mixing the kapok fiber with cashmere or tencel or down in a specific proportion, the antibacterial kapok filling flocculus is obtained. Compared with the prior art, the obtained antibacterial filling flocculus has good compression and resilience performance, and the antibacterial filling flocculus and the antibacterial kapok yarn have good antibacterial performance.

Owner:张伟夫

Kapok fiber pre-treating method

InactiveCN102182065AIncrease labor intensityImprove the mixing effectTextile treatment by spraying/projectingVegetal fibresPretreatment methodKapok fiber

The invention provides a kapok fiber pre-treating method. The method comprises the following steps of: spraying an auxiliary agent onto a raw material, namely kapok fibers; and then placing the kapok fibers in an environment of which the humidity is 55 to 60 percent and the temperature is 25 to 32 DEG C and balancing for 20 to 26 hours to obtain the pre-treated kapok fibers. The auxiliary agent comprises the following components in part by weight: 70 to 80 parts of water, 2 to 6 parts of silicone oil and 20 to 25 parts of crude oil. The spinning property of the kapok fibers can be obviously improved by treating the raw material, namely the kapok fibers, and then blending the kapok fibers and other fibers by the method; the labor intensity is reduced to a large extent; and the yield and the quality are approved by clients.

Owner:SHANGHAI HEYE TEXTILE +1

Moisture-absorption-and-sweat-releasing terylene/kapok blended yarn and production method and application thereof

InactiveCN106801279ASolve the problem of inability to produce medium and high count yarnReduce driftAbsorbent padsYarnYarnCarding

The invention belongs to the field of spinning, and particularly relates to a moisture-absorption-and-sweat-releasing terylene / kapok blended yarn and a production method and application thereof. The blended yarn is blended from the moisture-absorption-and-sweat-releasing terylene and kapok fibers in the weight ratio of 70:30. The production method of the blended yarn includes the steps of health maintenance pretreating, blowing, cotton carding, drawing, roving, spinning, spooling and the like. The blended yarn of the moisture-absorption-and-sweat-releasing terylene and the kapok fibers belongs to a middle-and-high count yarn, and the content of the kapok fibers in the blended yarn is 30%; the problems that in the prior art, when the content of the kapok fibers is high, blending is difficult, and the middle-and-high count yarn cannot be generated are solved. Fabric prepared with the moisture-absorption-and-sweat-releasing terylene / kapok blended yarn has the excellent gloss, extremely-excellent antibacterial performance, high fiber strength, the good antistatic performance, the natural and mild hand feeling and the excellent wearing performance, and can be used for producing high-end thermal underwear or high-end towels or infants apparels.

Owner:JIHUA 3509 TEXTILE

Medical protective pad

InactiveCN107789659AImprove water absorptionImprove water locking abilityAbsorbent padsBandagesCarbon fibersKapok fiber

The invention mainly relates to the technical field of medical products and discloses a medical protective pad. The medical protective pad is prepared from the following raw materials: kapok fibers, cotton fibers, chitosan fibers, bamboo fibers, alginate fibers, polylactic acid fibers, carbon fibers and an antibacterial agent; the medical protective pad is prepared from various fibers and is softand comfortable, does not slip off, is safe and poisonless and has no irritation, and the bacterium inhibition rate reaches 92.8 percent; after the carbon fibers are immersed into antibacterial liquid, the carbon fibers are frozen and dried so that the antibacterial property and the air permeability of the carbon fibers are improved, the breeding of bacteria is inhibited and the health of patientsis ensured; the kapok fibers and the cotton fibers are blended to form relatively thin fibers and the fibers can be uniformly distributed on the protective pad, so that the protective pad is comfortable and soft and the water absorption performance and the water locking performance of the protective pad are improved; the chitosan fibers and the bamboo fibers are blended to form relatively thick fibers, so that the stability of chitosan can be kept and the water absorption performance and the antibacterial performance of the protective pad are increased; unhairing and pilling of the protectivepad are avoided and the durability is improved.

Owner:安徽斯麦特医学技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com