Moisture-absorption-and-sweat-releasing terylene/kapok blended yarn and production method and application thereof

A technology of moisture absorption and perspiration production method, applied in the textile field, can solve the problems of low dry breaking strength, short fiber length, poor cohesion, etc., and achieve the effects of excellent antibacterial properties, high strength and excellent gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

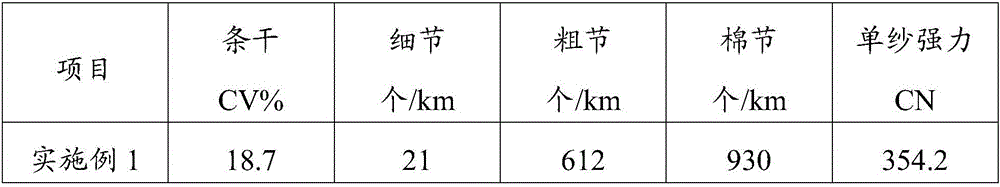

Embodiment 1

[0034] A moisture-wicking polyester kapok blended yarn, which is produced through the following processes:

[0035] 1) Pretreatment process

[0036] Weigh the moisture-wicking polyester and kapok fibers according to the weight ratio of 70:30, spray the kapok fibers evenly with the well-prepared health oil, and then cover the kapok fibers with a plastic cover cloth for more than 24 hours to treat the good kapok. The fiber is placed on the inner side of the cotton-grabbing round table, and the moisture-absorbing and sweat-wicking polyester is evenly placed on the outside of the cotton-grabbing round table. The moisture-absorbing and sweat-wicking polyester is surrounded by a circle on the outside of the kapok fiber. At the same time, kapok fiber and moisture wicking polyester can be grabbed at the same time; the health oil is mixed with environmentally friendly antistatic agent FK-305, cohesion enhancer CTA-1886B and water in a weight ratio of 1:1:8. The sprayed health oil is 3% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com