Patents

Literature

1276 results about "Round table" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

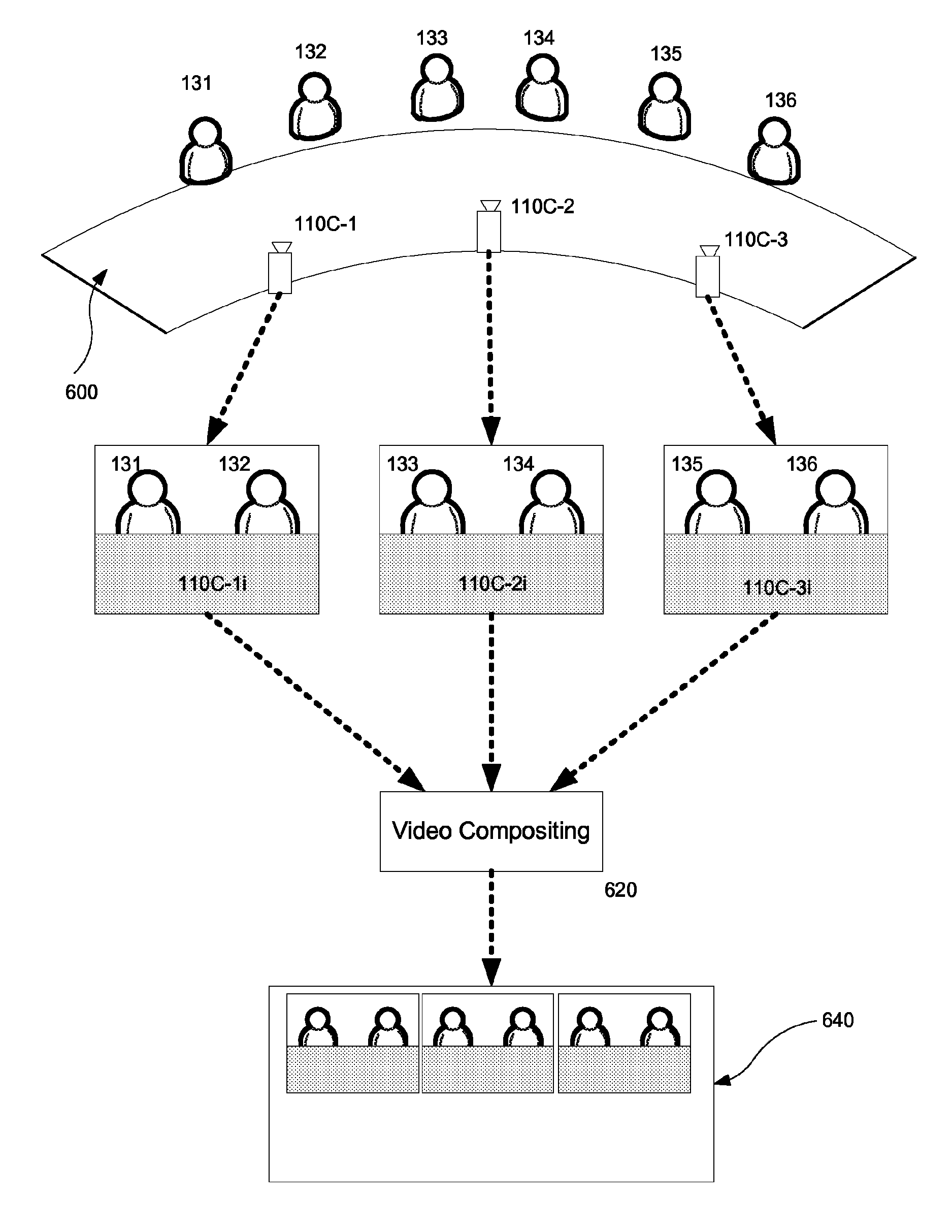

Virtual round-table videoconference

ActiveUS20090244257A1Television conference systemsTwo-way working systemsRound tableComputer graphics (images)

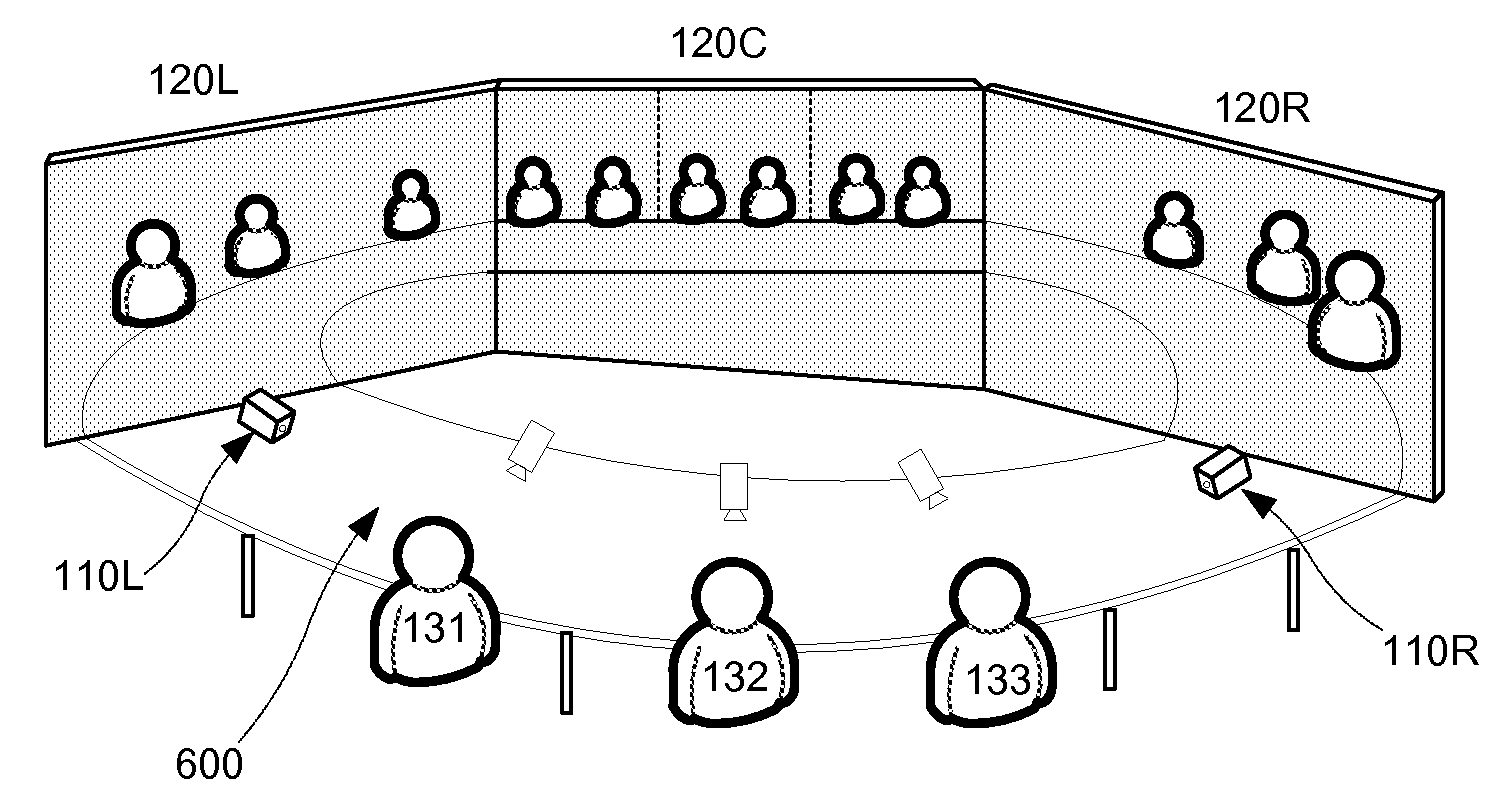

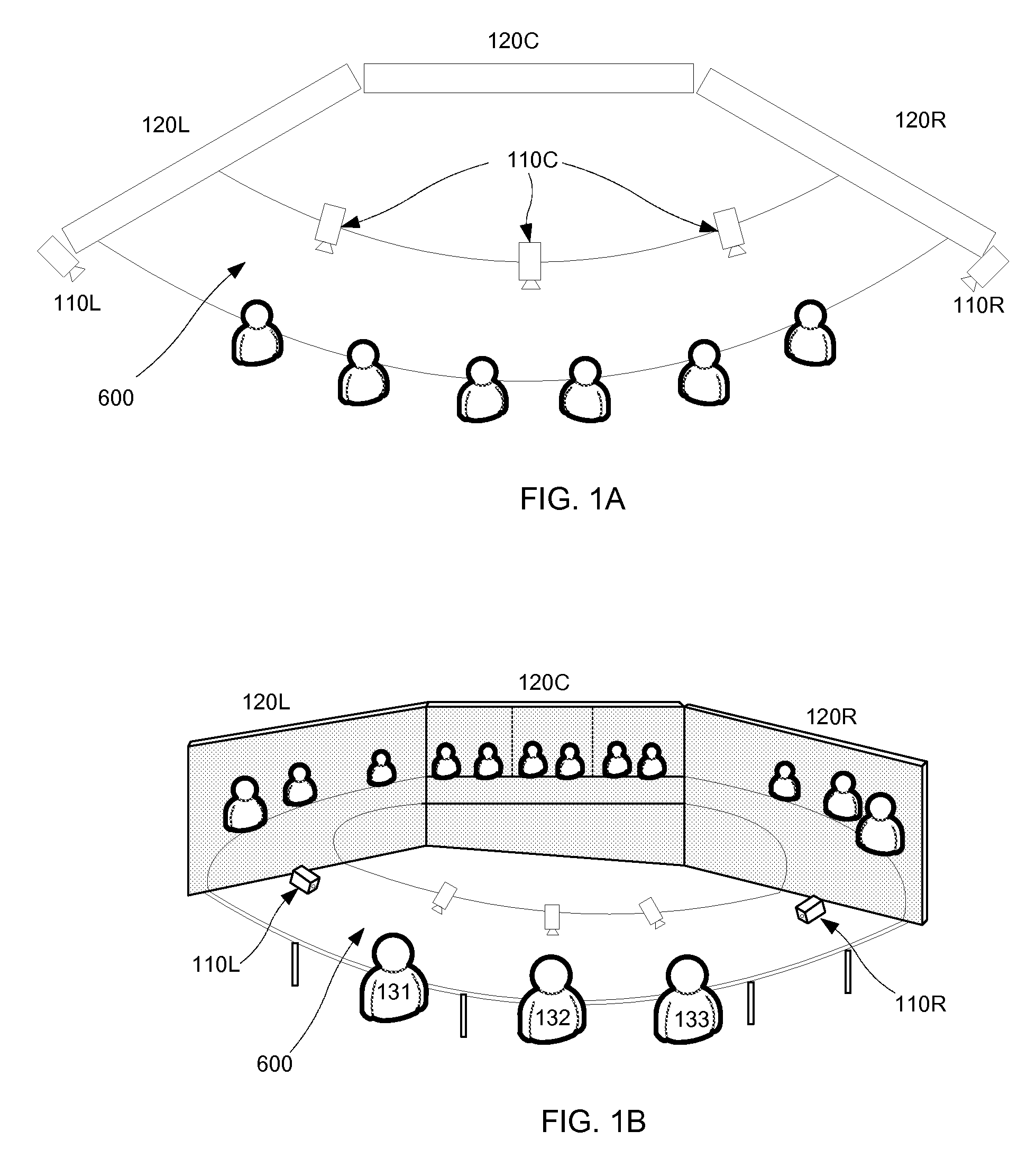

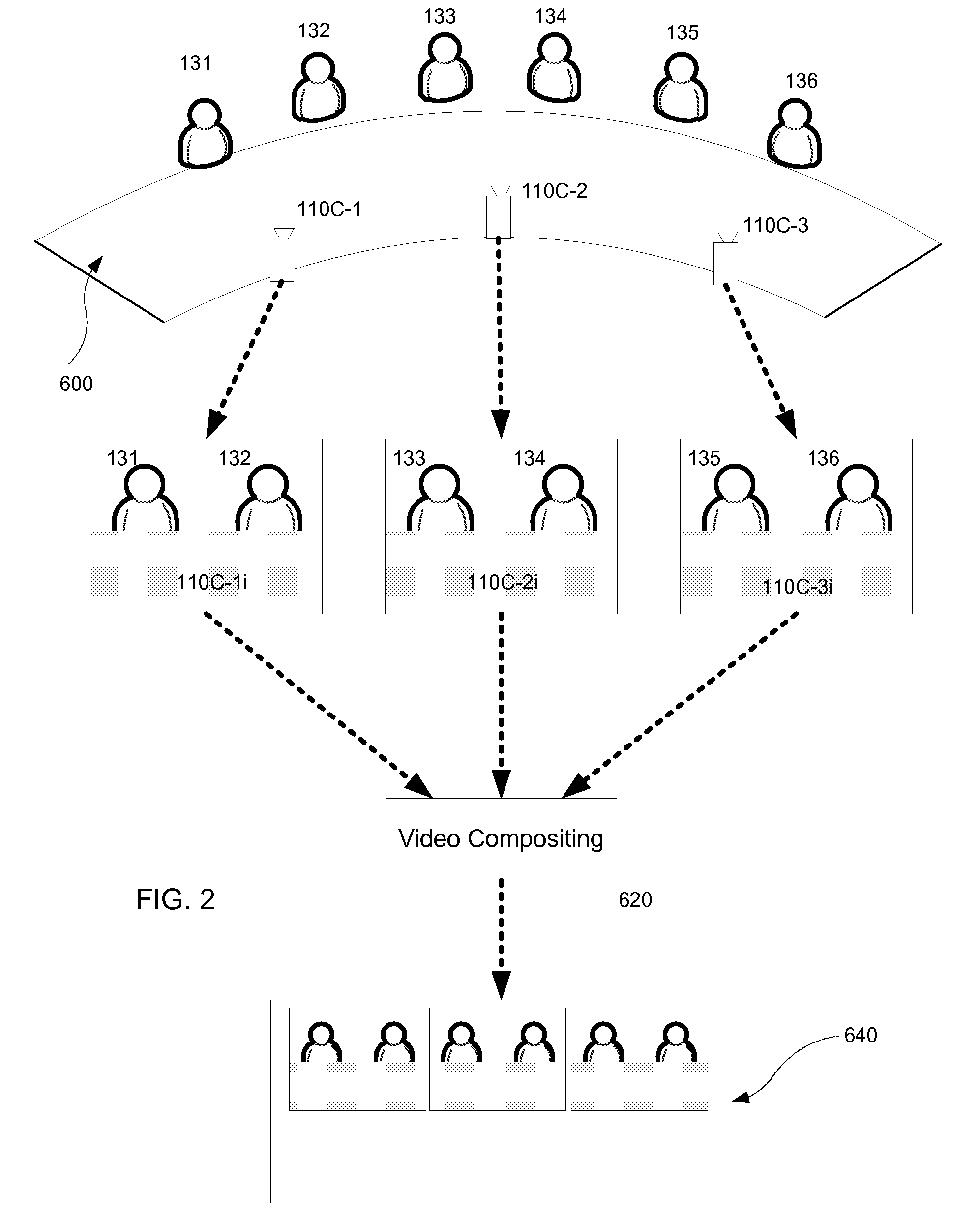

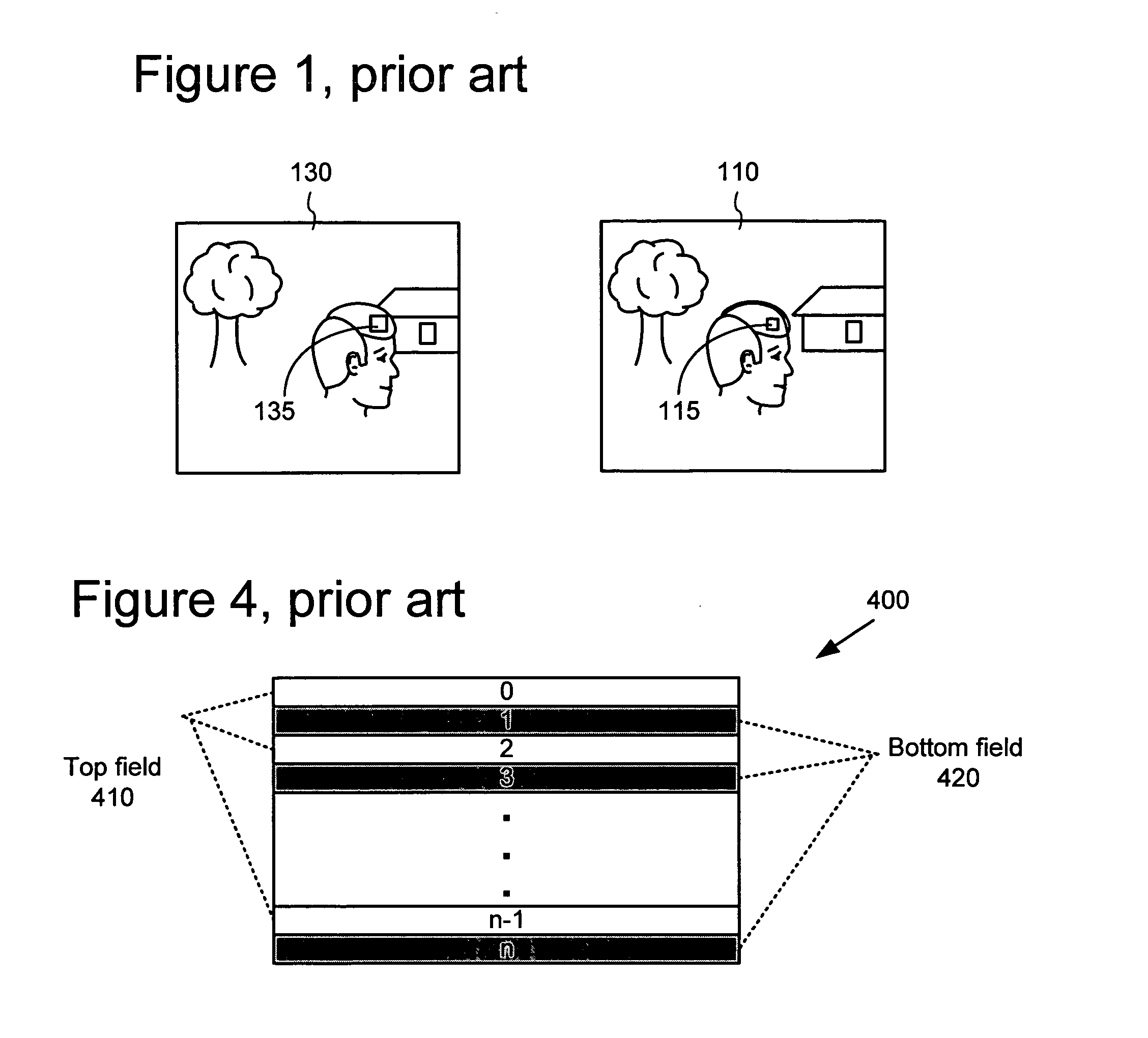

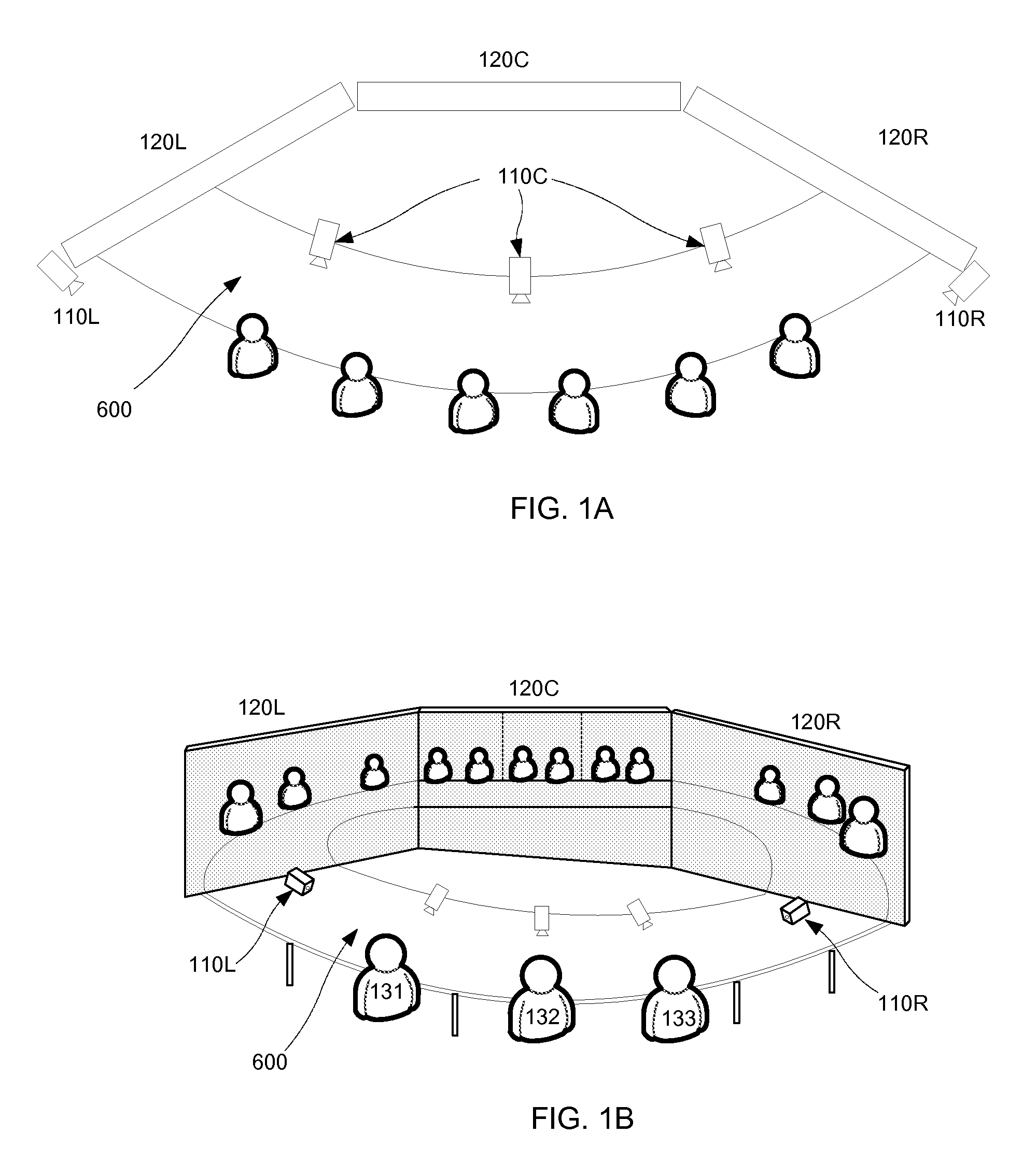

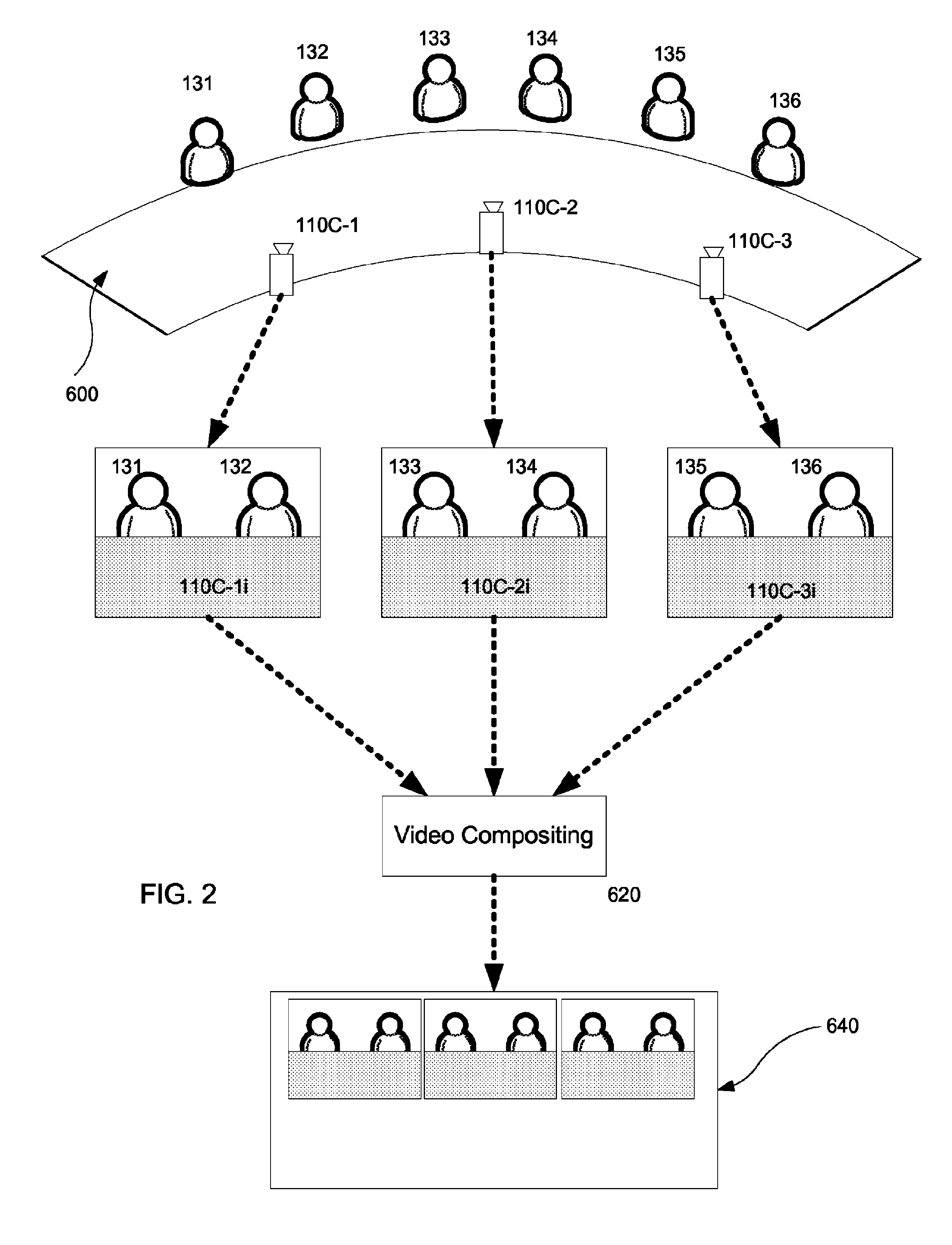

A system and method for creating a virtual round table videoconference is described. An embodiment of the system comprises a plurality of displays arranged in an arc configuration with a table to create a virtual round table. Cameras are arranged around the plurality of displays such that when a participant looks at a display with an image of a remote participant, the camera associated with the display captures an image of the participant's gaze, making eye contact with the camera. The image is displayed at the remote participant's endpoint creating the effect of eye contact between the participants. In another embodiment, audio speakers are arranged to provide directional sound such that the video source for a display and the audio source for the associated speaker are from the same endpoint.

Owner:CISCO TECH INC

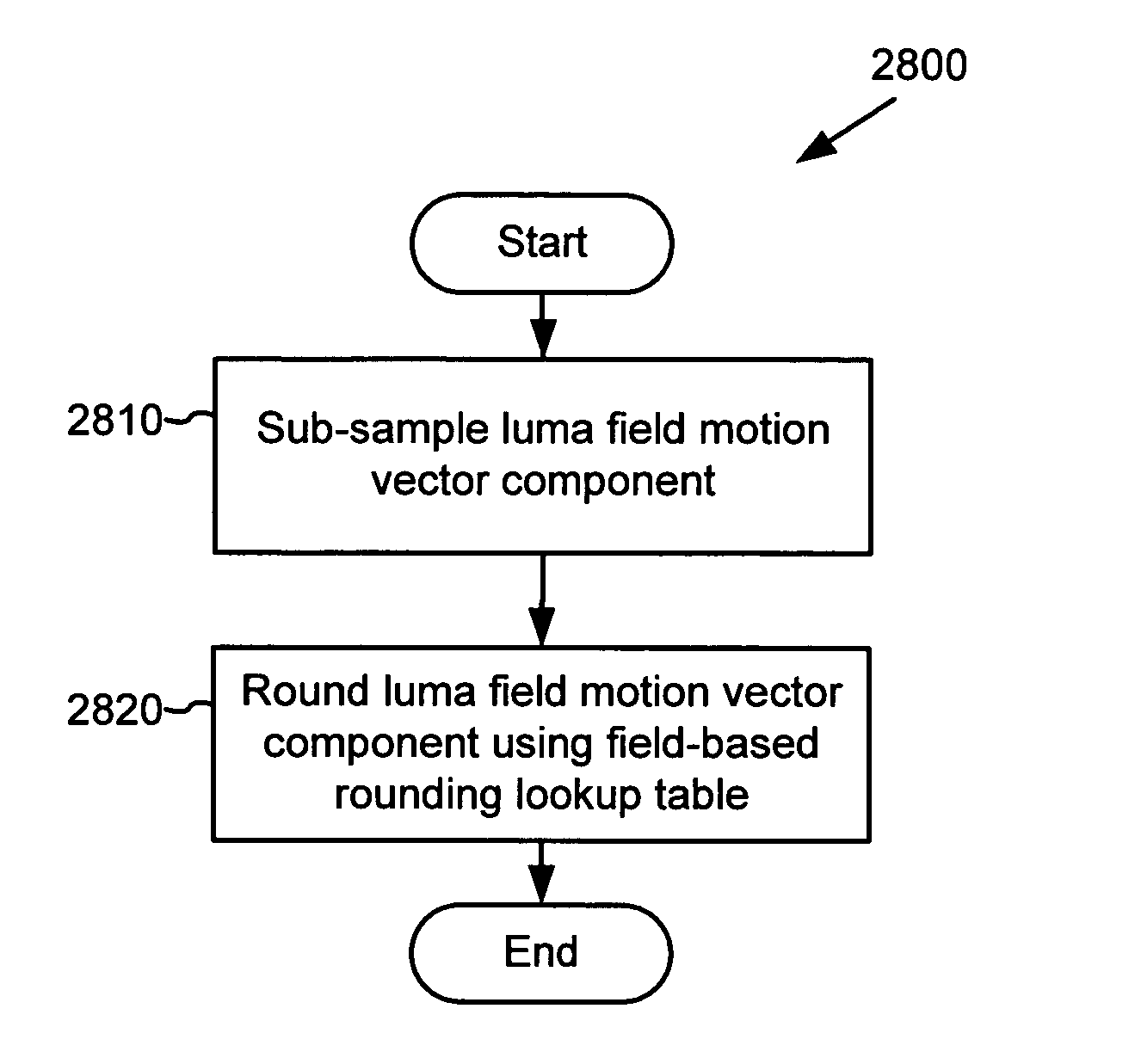

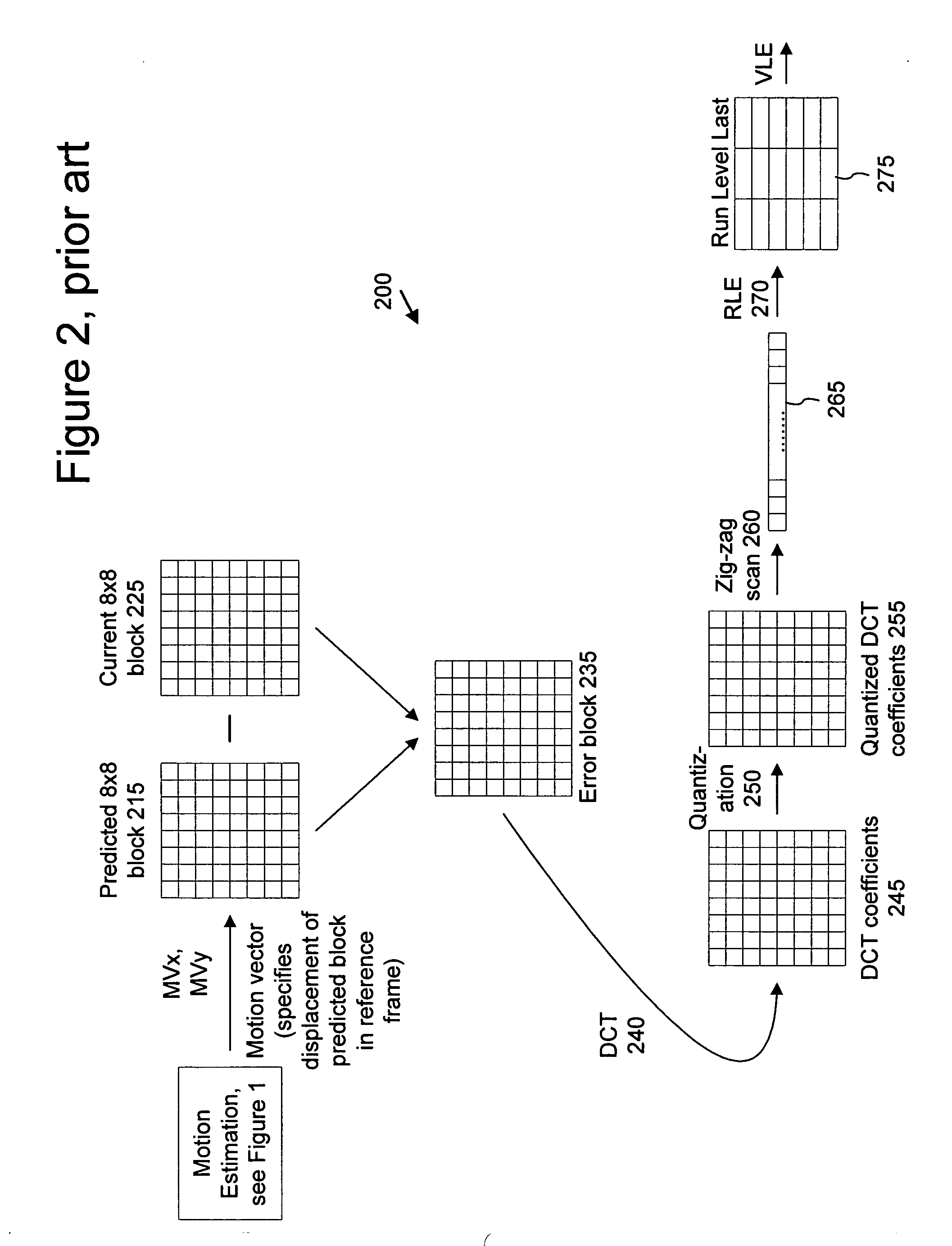

Chroma motion vector derivation

A decoder receives luma motion vector information for plural luma motion vectors for a macroblock (e.g., a 4:2:0 macroblock). The decoder derives a chroma motion vector for each of the plural luma motion vectors by performing at least one calculation on the luma motion vector information, maintaining a 1:1 ratio of chroma motion vectors to luma motion vectors for the macroblock. For example, the decoder receives four luma (frame or field) motion vectors for a macroblock and derives four chroma motion vectors for the macroblock. The deriving can comprise sub-sampling and / or rounding (e.g., using a field-based rounding table).

Owner:MICROSOFT TECH LICENSING LLC

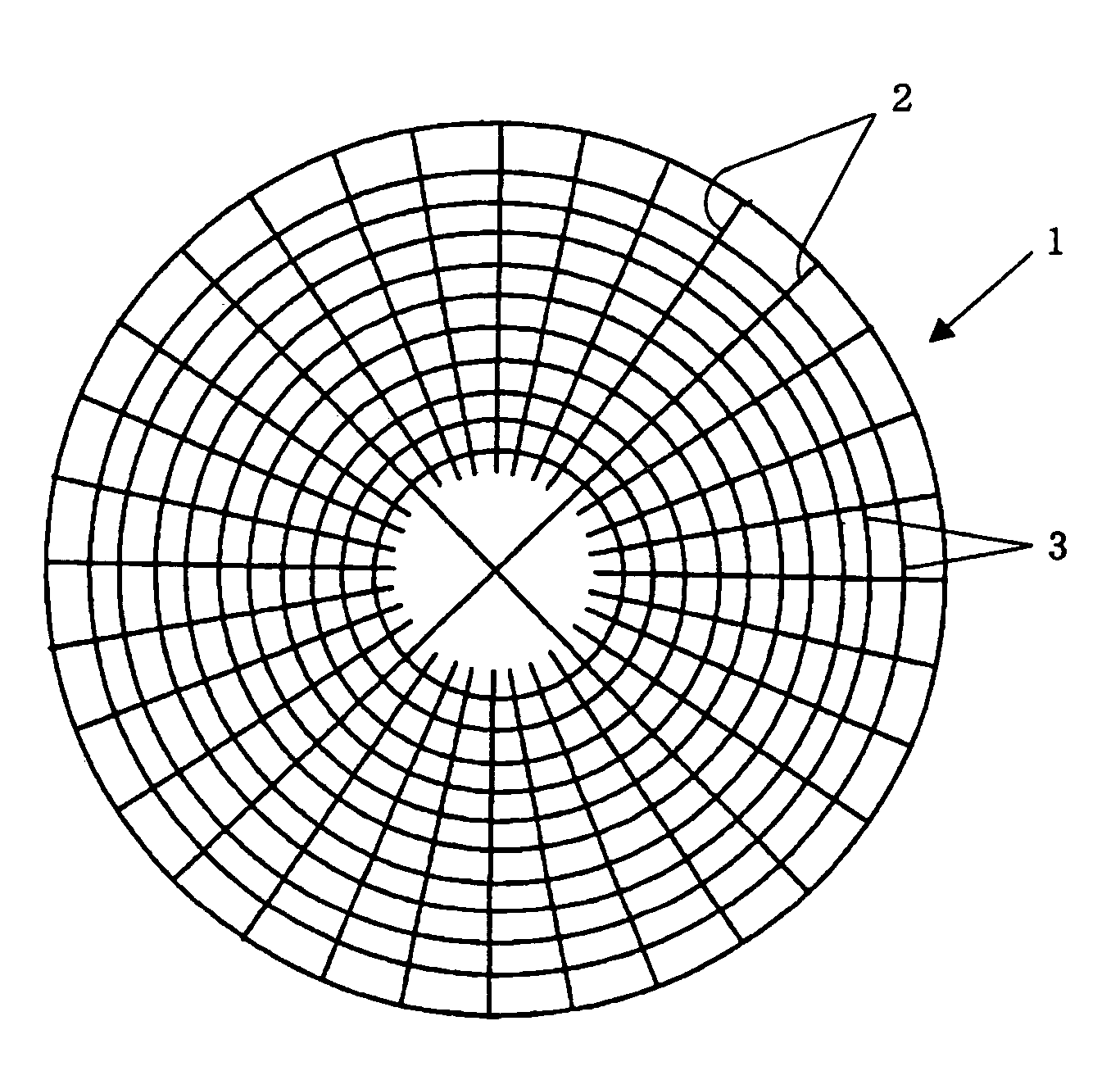

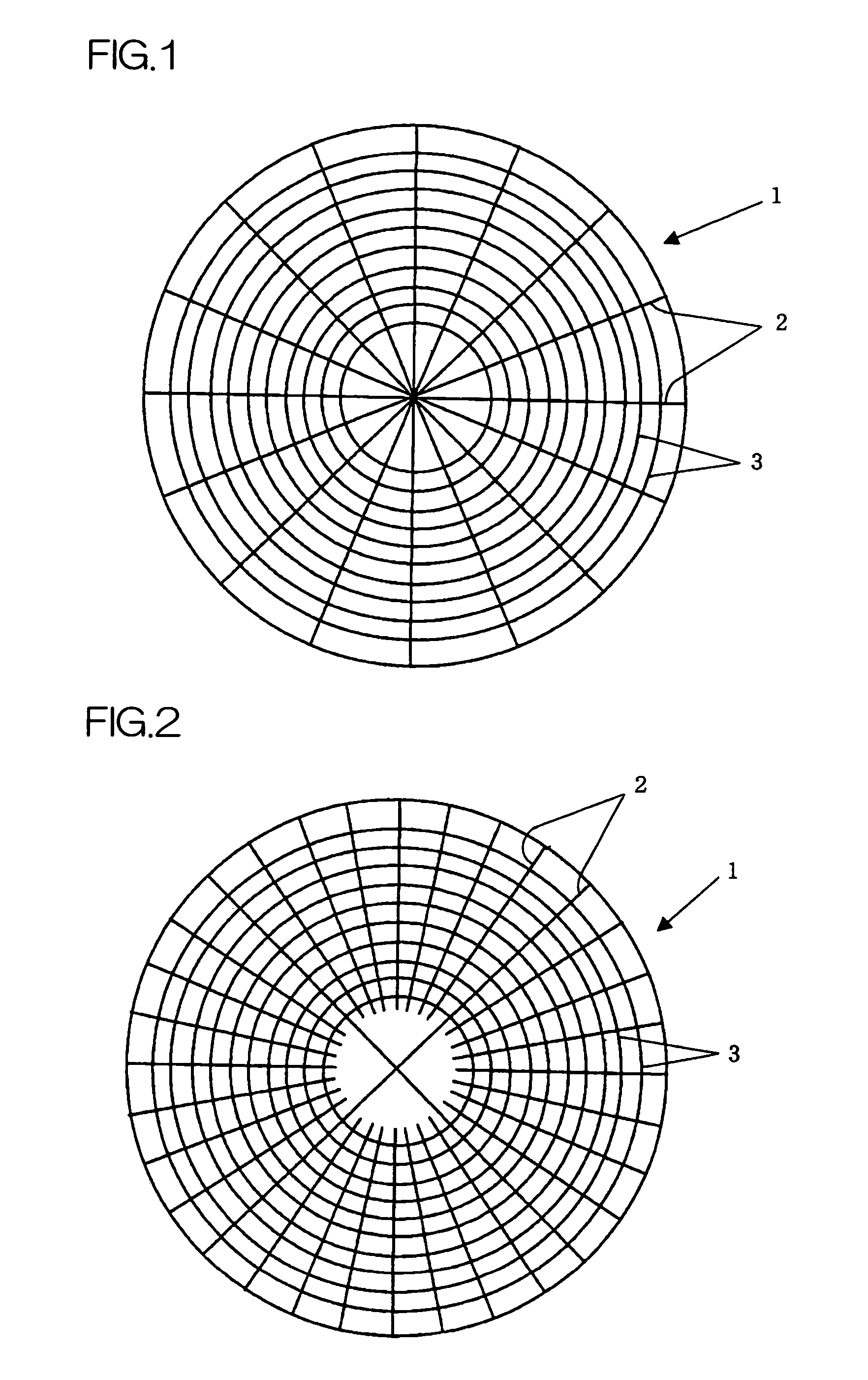

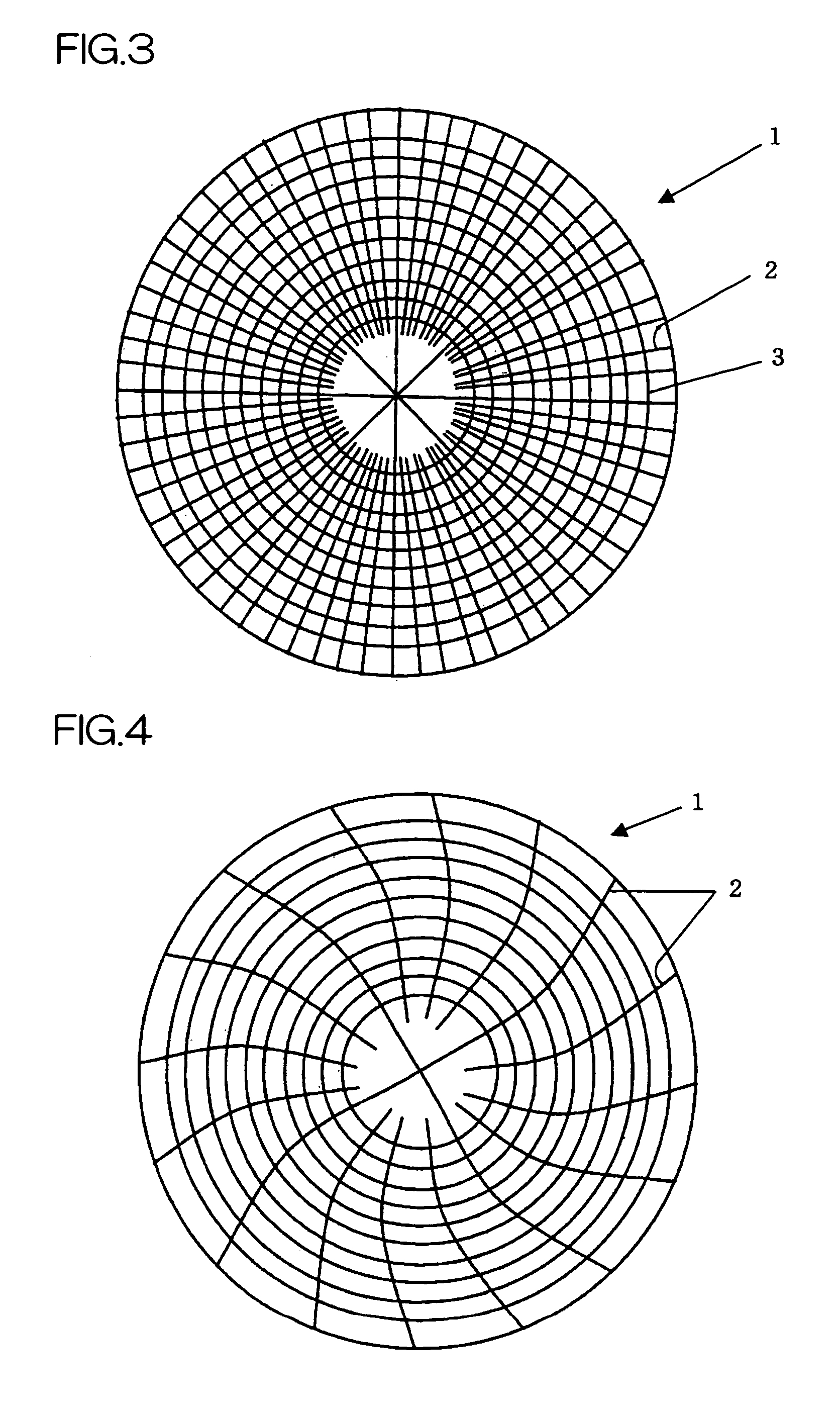

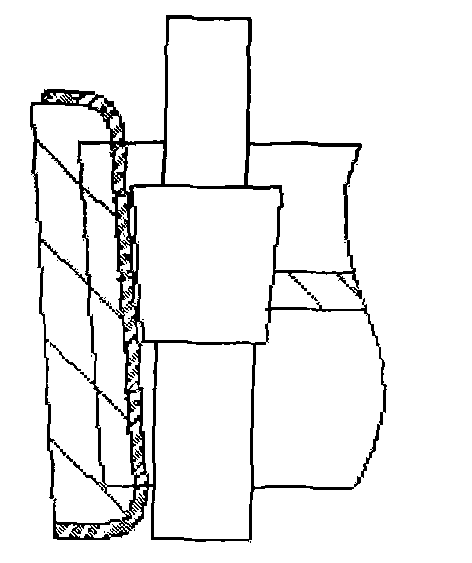

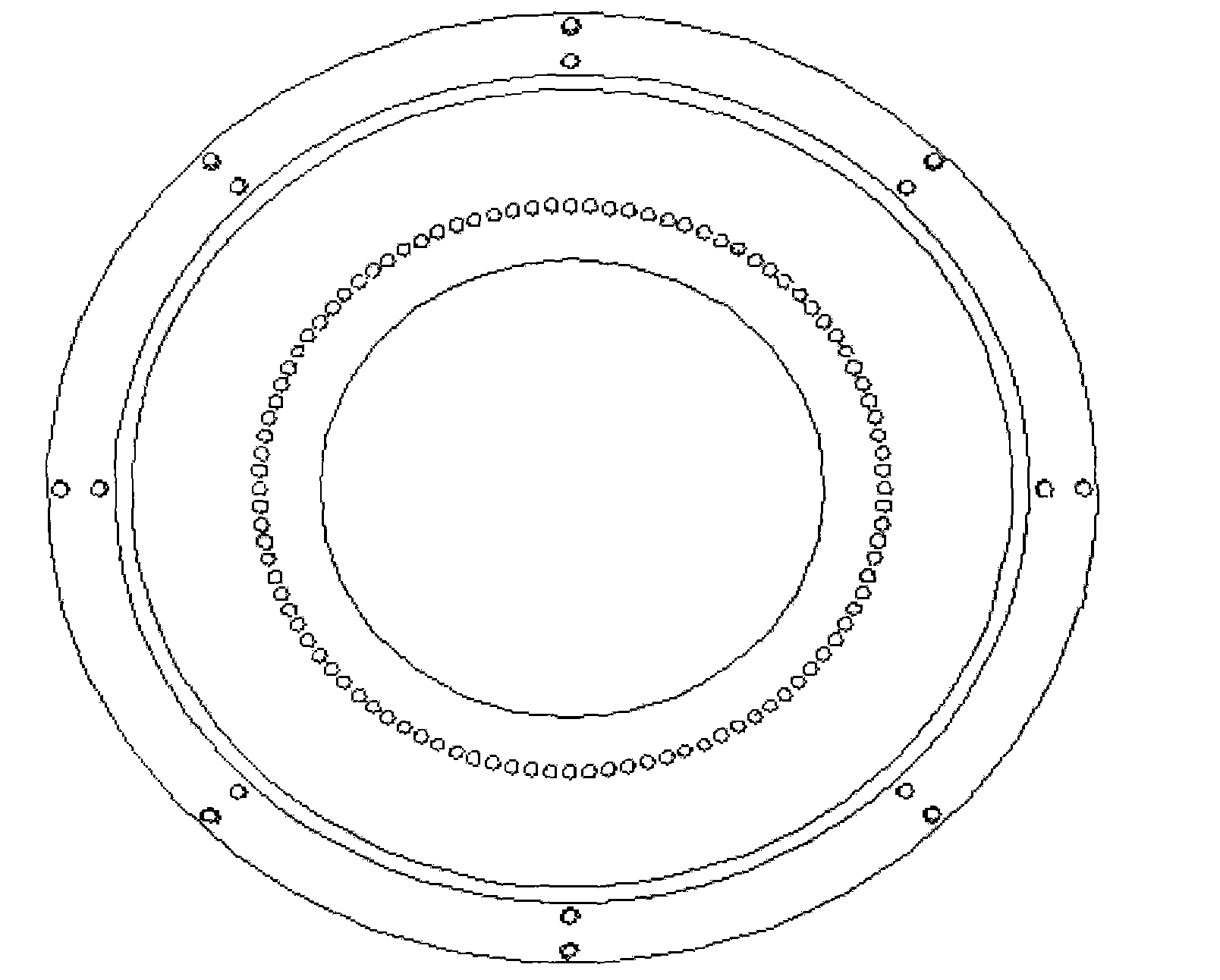

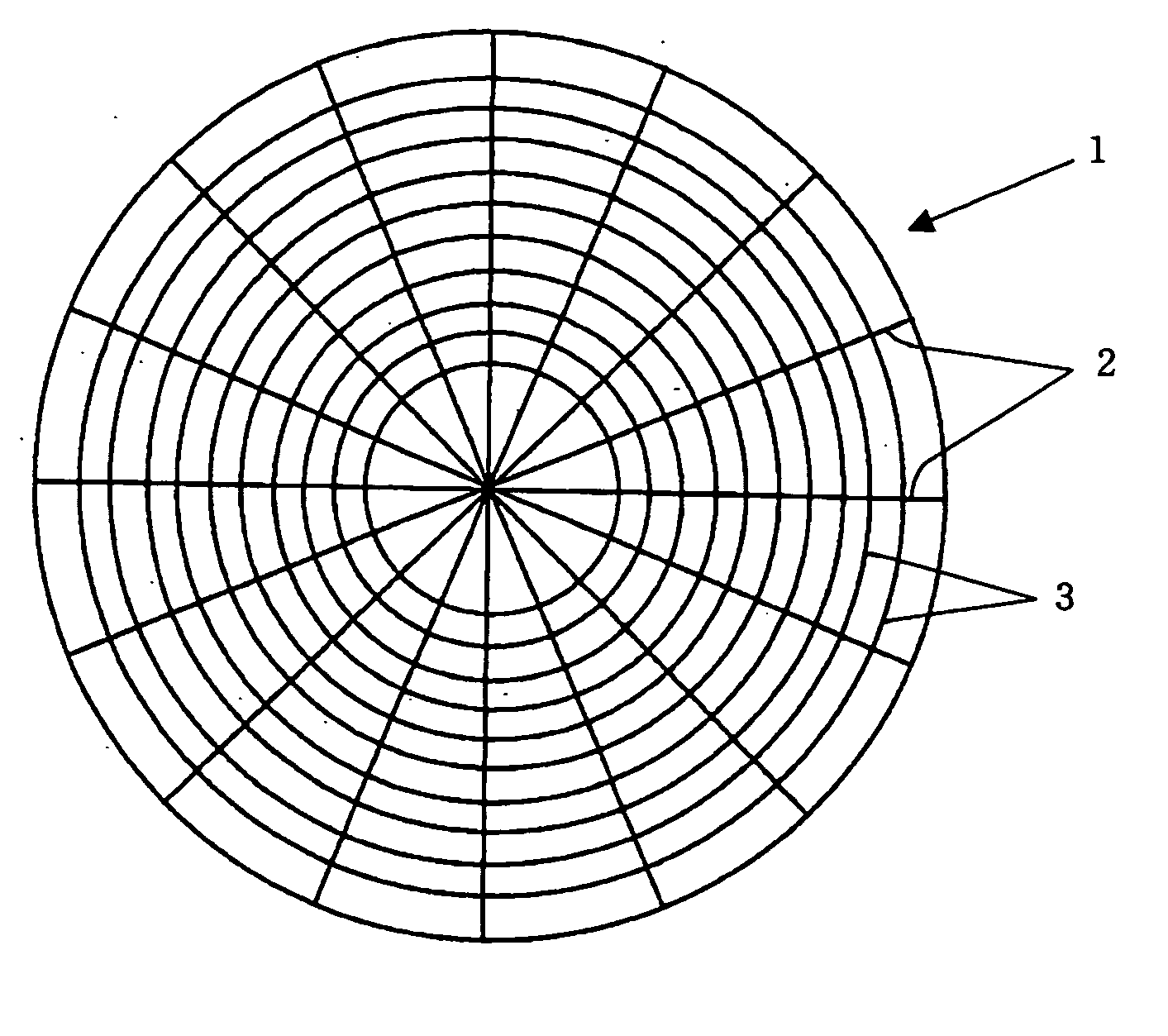

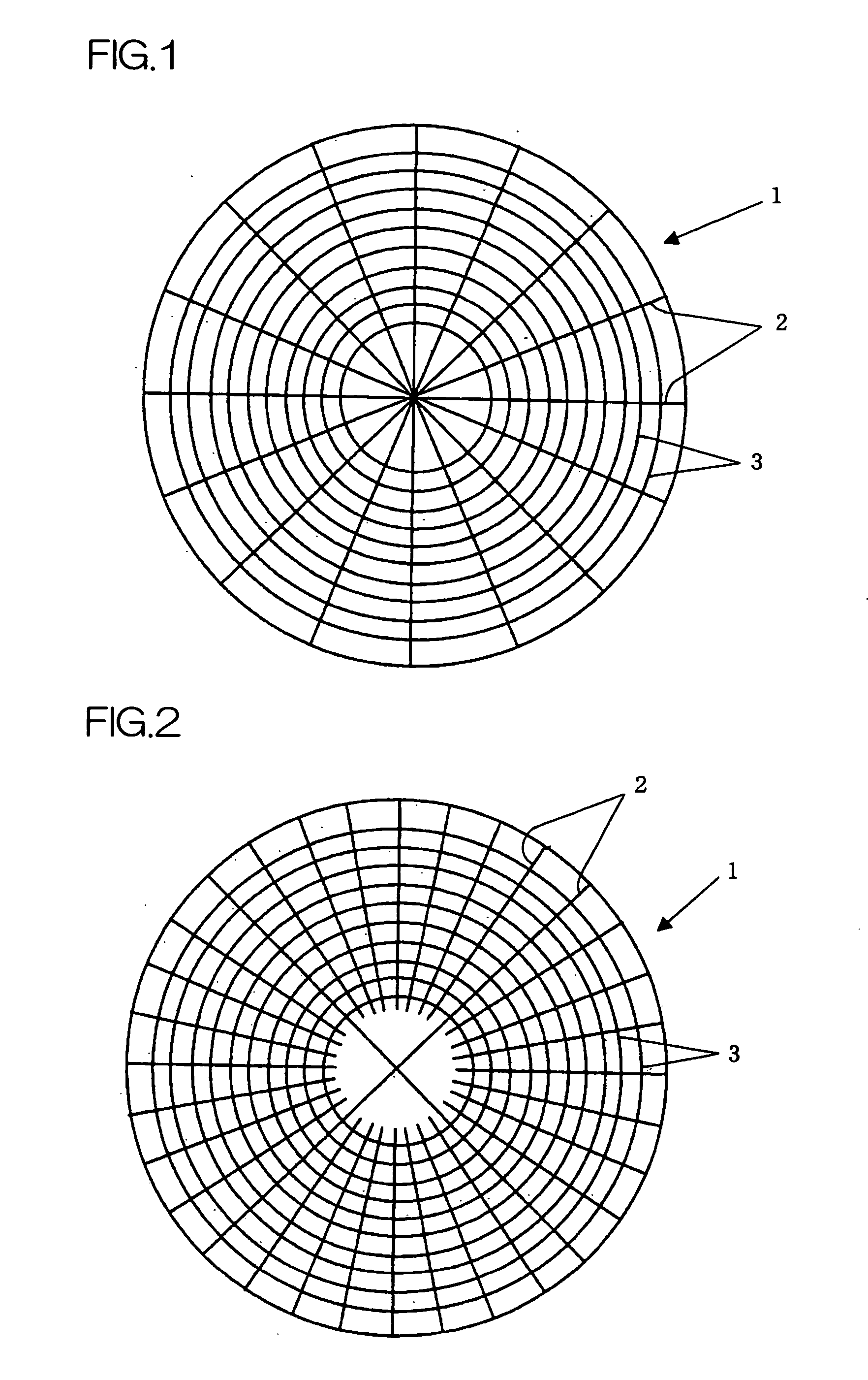

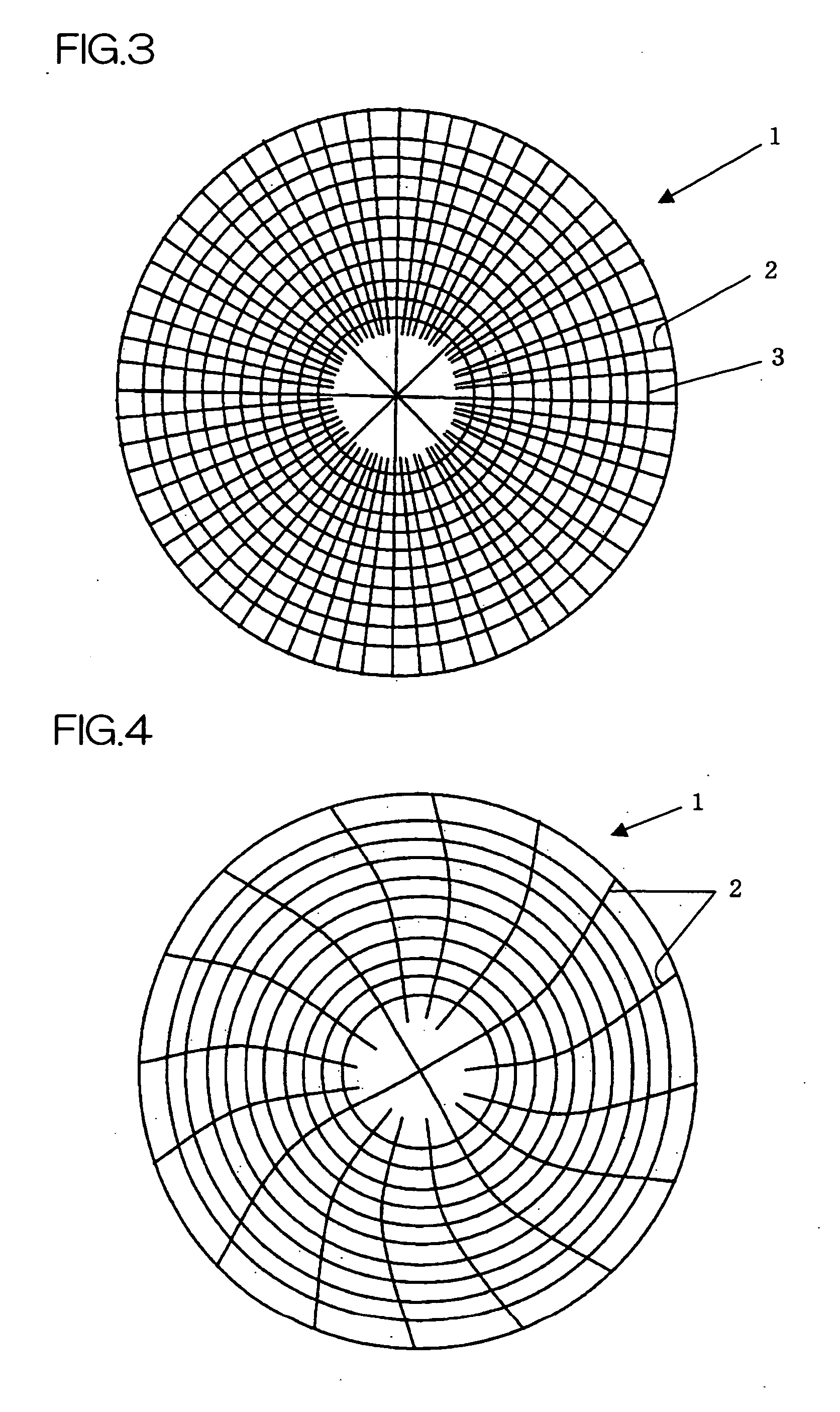

Method of manufacturing chemical mechanical polishing pad

ActiveUS7329174B2InhibitionIncrease ratingsFlexible-parts wheelsGrinding devicesRound tableMilling cutter

The present invention relates to a method of manufacturing a chemical mechanical polishing pad which provides a chemical mechanical polishing pad which fully suppresses the occurrence of a scratch on the polished surface and has an excellent polishing rate.The method comprising either one of a group of steps (A) and a group of steps (B), the group of steps (A) including(A1) the step of preparing a composition for forming a chemical mechanical polishing pad;(A2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form;(A3) the step of mounting the pad-like form on the round table of a cutting machine having at least a milling unit equipped with a milling cutter, a drive unit capable of angle indexing and positioning and a round table journaled by the drive unit;(A4) the step of forming the second group of grooves with the milling cutter; and(A5) the step of forming the first group of grooves, and the group of steps (B) including(B1) the step of preparing a composition for forming a chemical mechanical polishing pad;(B2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form having the second group of grooves by using a metal mold having projections corresponding to the shapes of the second group of grooves; and(B3) the step of forming the first group of grooves.

Owner:JSR CORPORATIOON

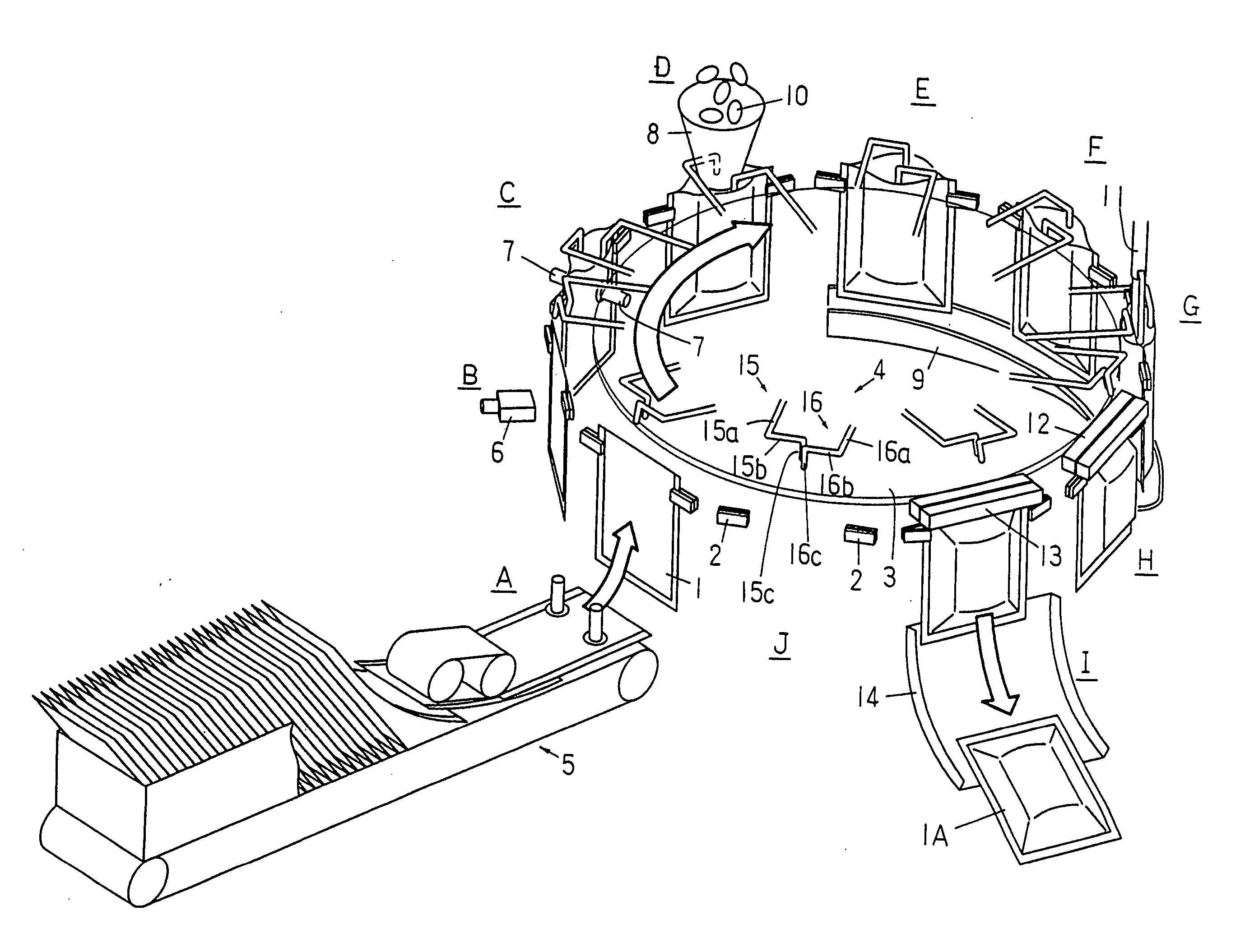

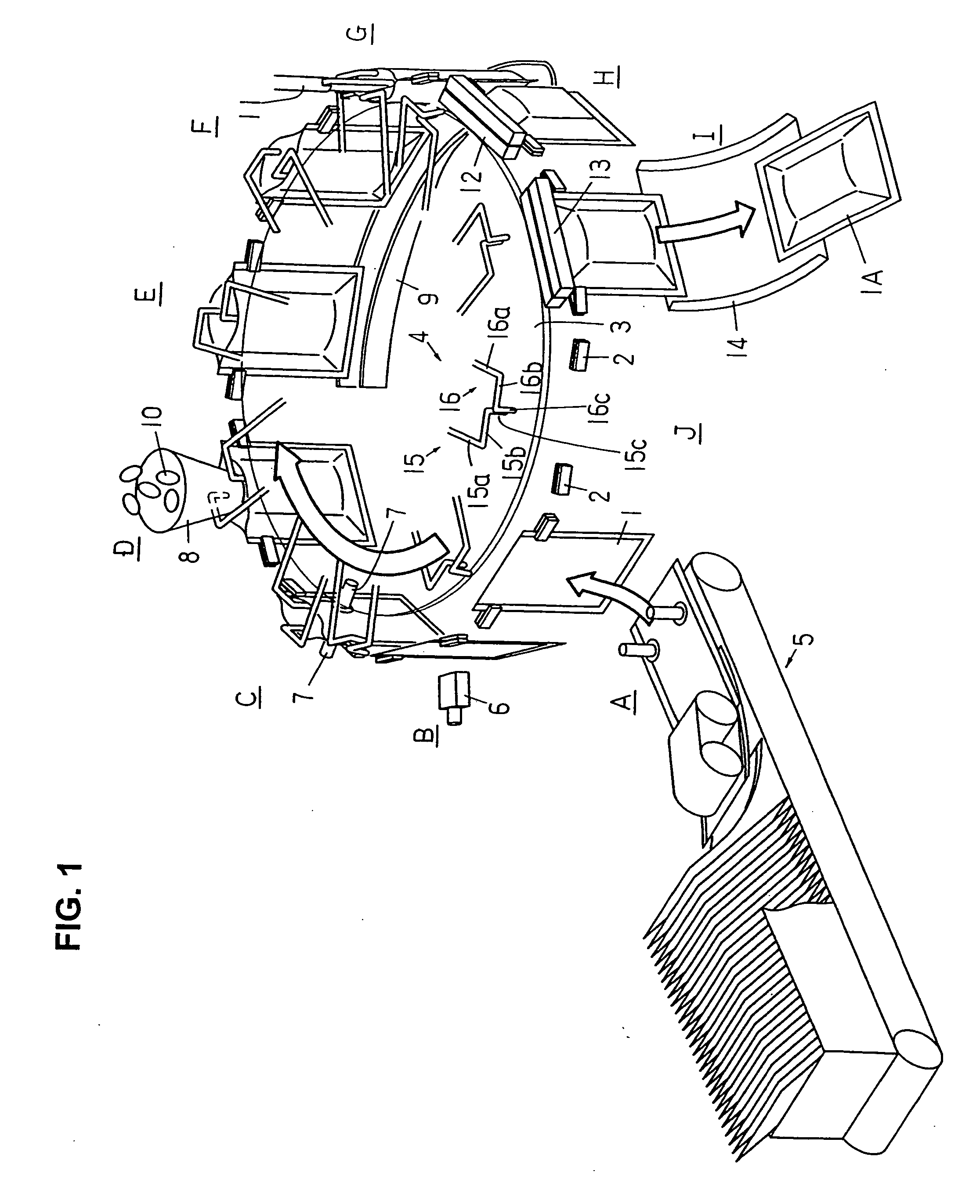

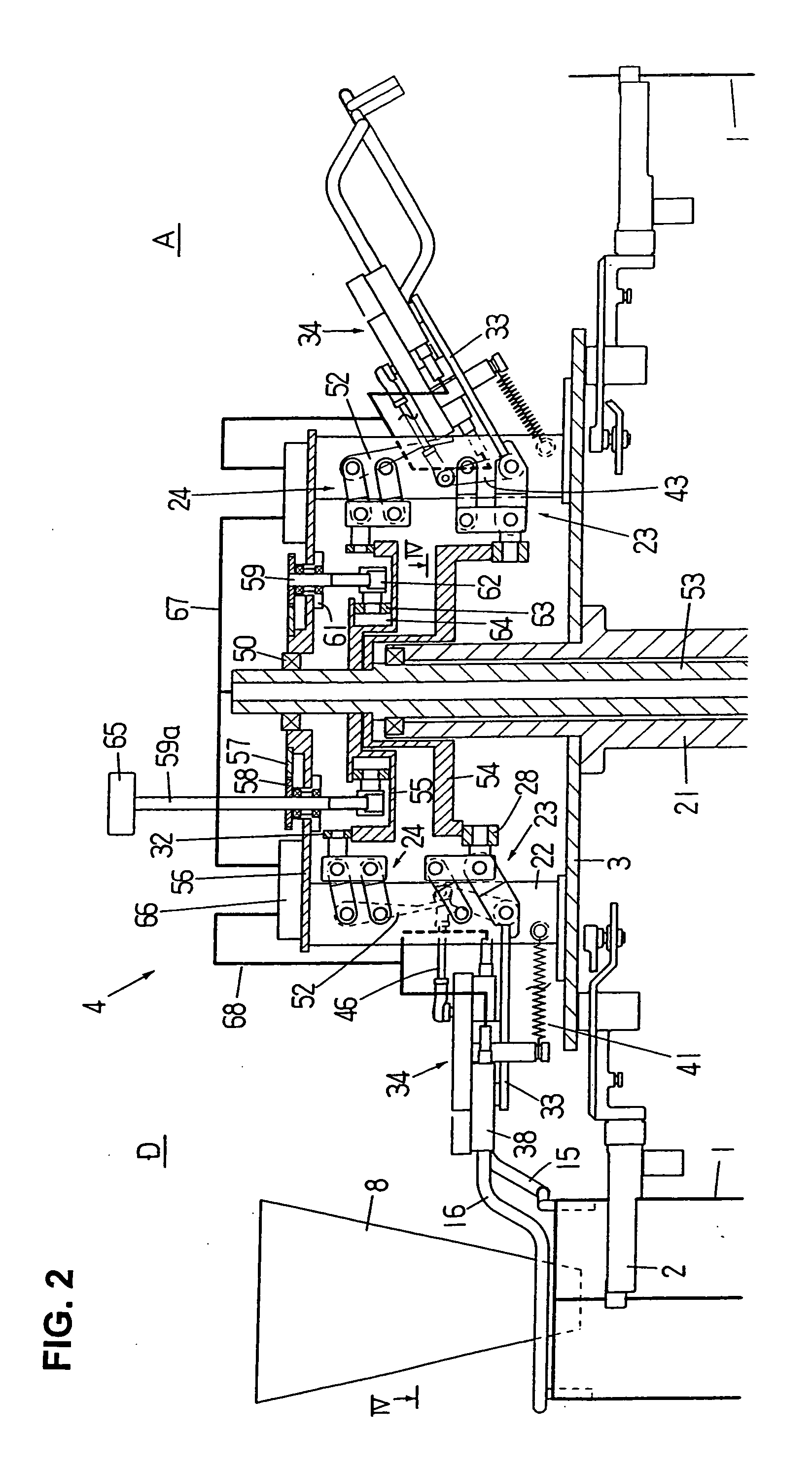

Bag-filling packaging machine

InactiveUS20070074492A1Stable fashionWithout compromising production efficiencySolid materialPackaging under special atmospheric conditionsRound tableEngineering

A bag-filling packaging machine in which supplied bags 1 are gripped by pairs of grippers 2 disposed on the periphery of an intermittently turning round table 3, and the bags, at stopping positions, are successively subjected to prescribed packaging operations with the gas inside the bags being replaced during that process, wherein a pair of guide members 15 and 16 for keeping the bag mouth opened is provided on the table 3 in correspondence with each of the gripper pair, and guide members 15 and 16 are connected to an inactive gas supply source and have gas blow-out ports at the tip ends that are inserted inside the bags, thus allowing the guide members 15 and 16 to not only keep the bag mouth opened but also function as gas blow-in nozzles.

Owner:TOYO JIDOKI CO LTD

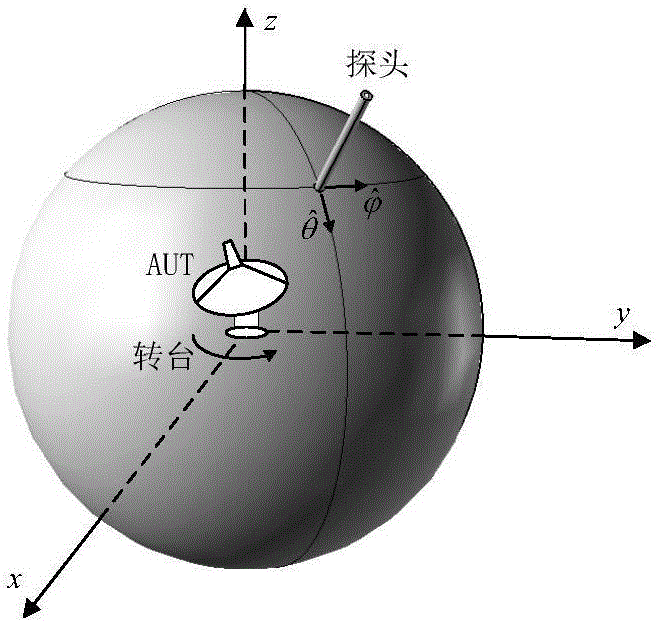

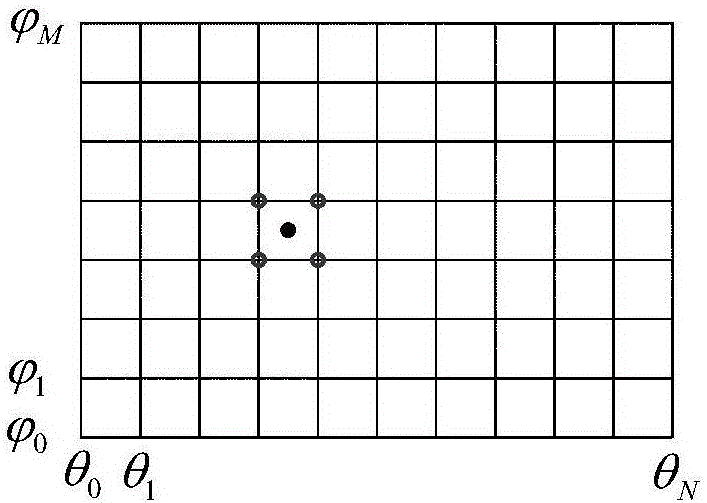

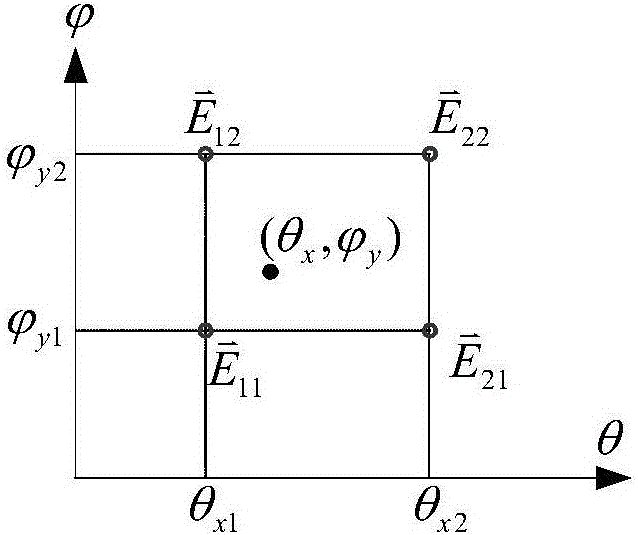

Near-field antenna measurement method for any curved surface scanning

ActiveCN106291130ASimple and convenient near and far field conversionEasy to implementAntenna radiation diagramsRound tableField transformation

The invention discloses a near-field antenna measurement method for any curved surface scanning. An antenna and a movable probe are driven to rotate through a rotary round table to perform scanning, and circular, linear and any curved surface motion ways can be adopted, so that the near-field test method can be suitable for any curved surface scanning; a scanning surface is not limited to a plane, a cylindrical surface or a spherical surface, and any curved surface can be adopted; various antennas can be measured. In the near-field antenna measuring method for any curved surface scanning, sampling points are taken as a plurality of points which are uniformly distributed in a parameter space, and then electric fields of any point are calculated through bilinear interpolation, so that a far electric field of the antenna can be calculated according to a Huygens equivalence principle, and near-field to far-field transformation is simple, convenient and easy to realize.

Owner:KUNSHAN HAMILTON COMM TECH CO LTD

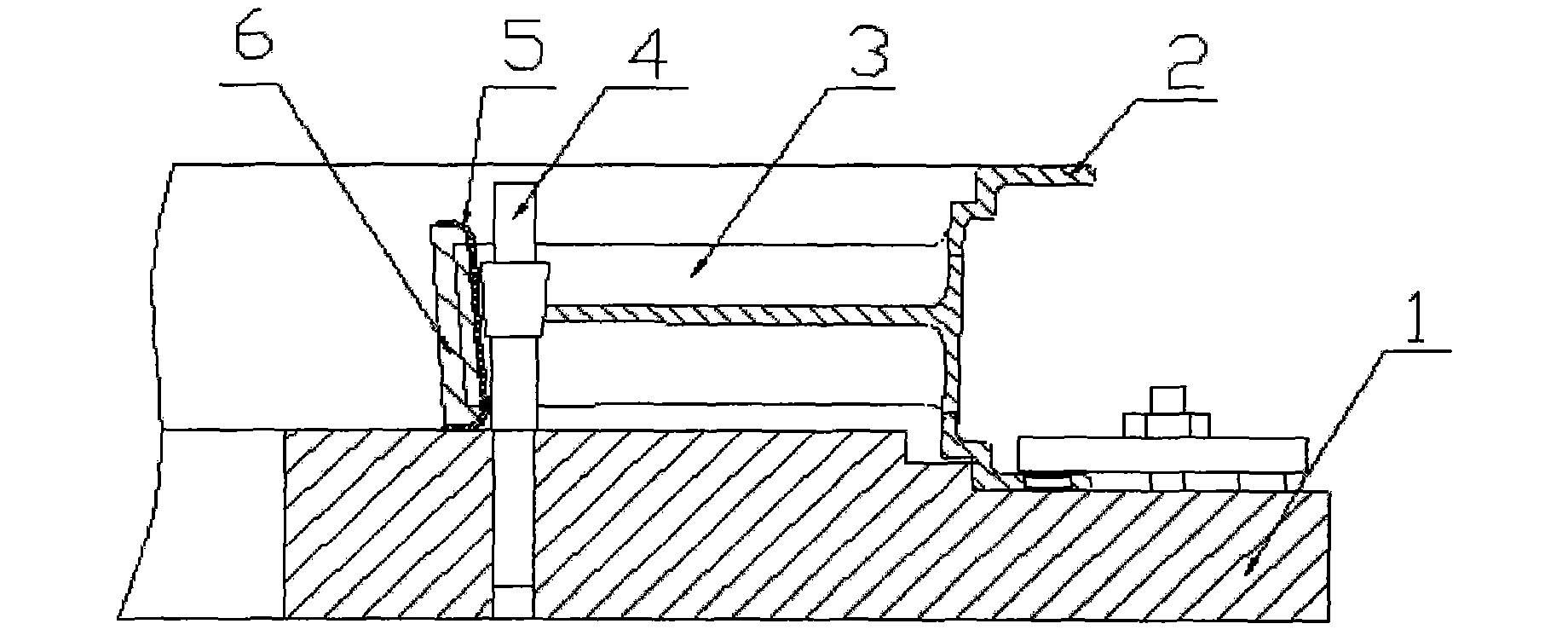

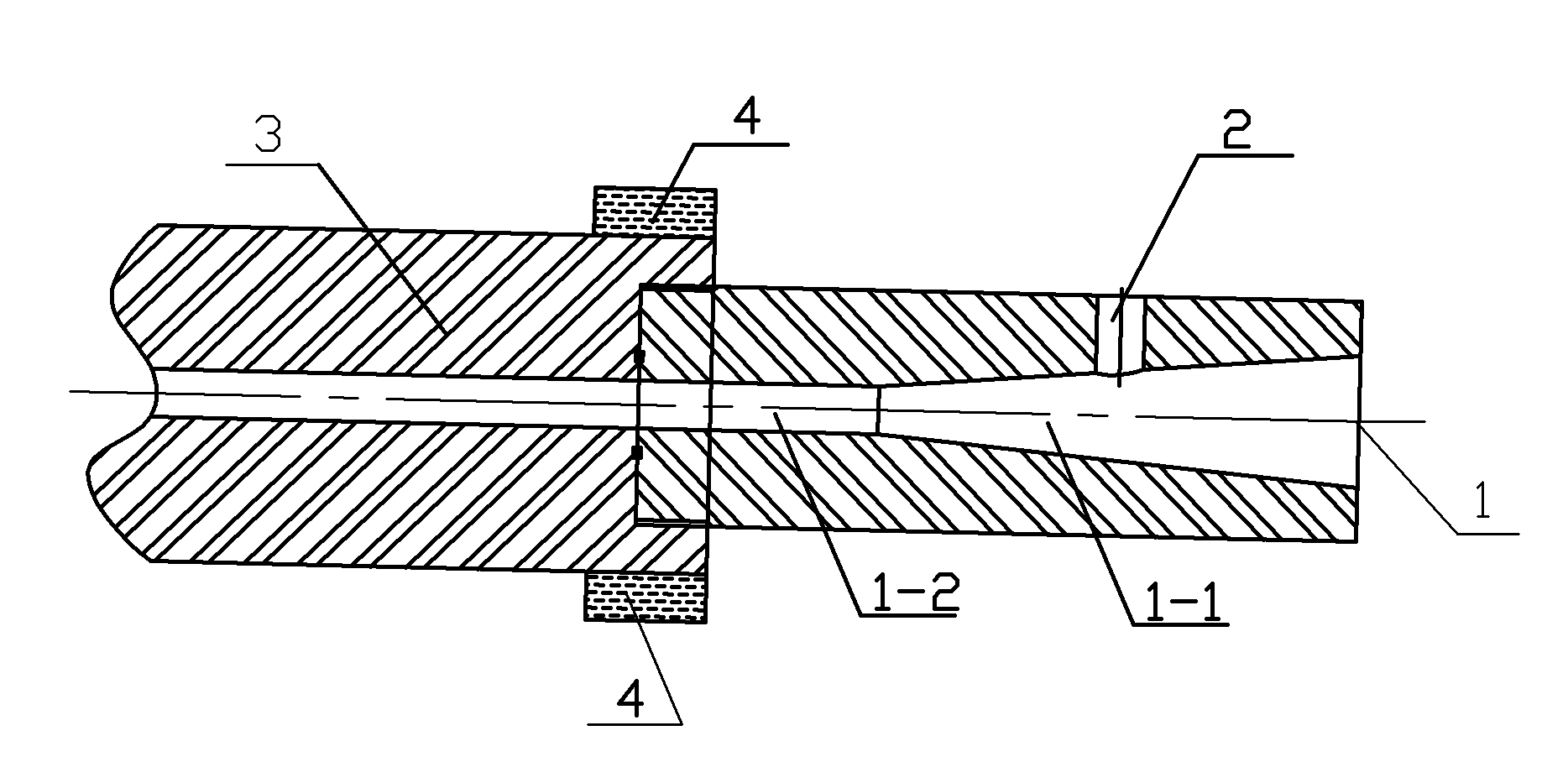

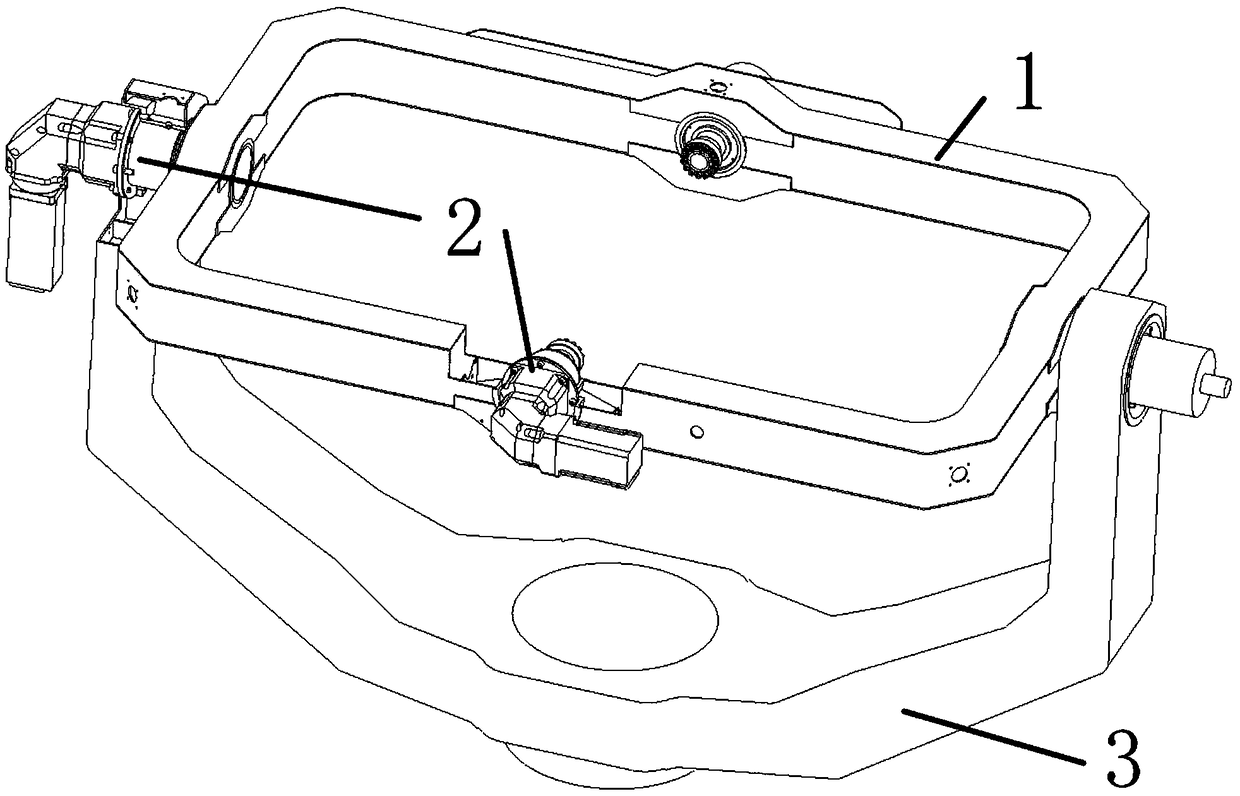

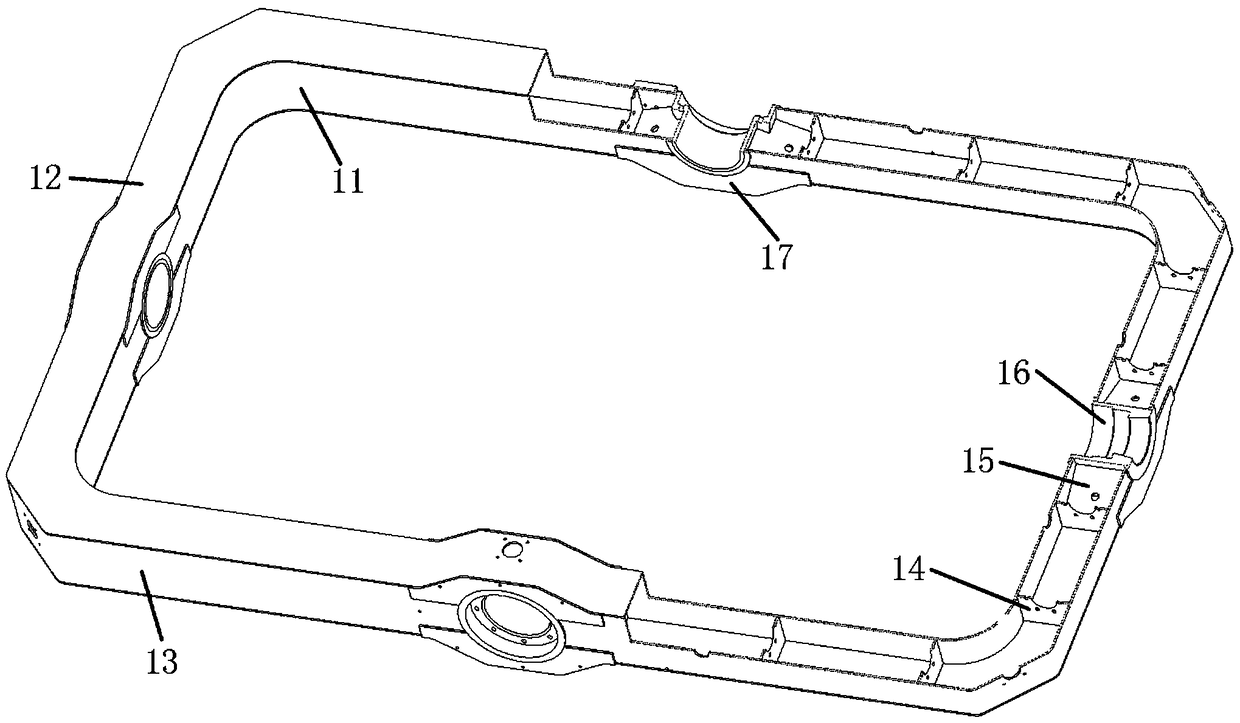

Correction device and correction method for inner ring of engine crankcase

The invention provides a correction device and a correction method for an inner ring of an engine crankcase. The correction device comprises a correction clamp base, positioning pins and a pressure plate; the tooling surface of the correction clamp base is provided with a circular seam allowance, and the inner side of the seam allowance is provided with a circle of uniform positioning pin holes; and the middle section of the positioning pin has a round table step-shaped columnar structure, the taper of the round table of the middle section is as same as that of the inner ring of the crankcase, and the maximum diameter of the positioning pin enables the positioning pin inserted into the positioning hole not to interfere with a blade of the crankcase. The correction method comprises the following steps of: jointing the seam allowance of the crankcase and the seam allowance on the correction clamp base; inserting the positioning pins into the positioning pin holes, positioning the positioning pins and the inner ring of the crankcase in a two-section contact mode, and then fixing the crankcase on the correction clamp base through the pressure plate; welding the inner ring and the blade of the crankcase; and finally, pouring a glue layer into the inner side of the inner ring of the crankcase, and gluing the inner ring and the blade of the crankcase. The device and the method ensurethe concentricity of the easily-deformed inner ring and the outer crankcase and the ellipticity of the inner ring.

Owner:AECC AVIATION POWER CO LTD

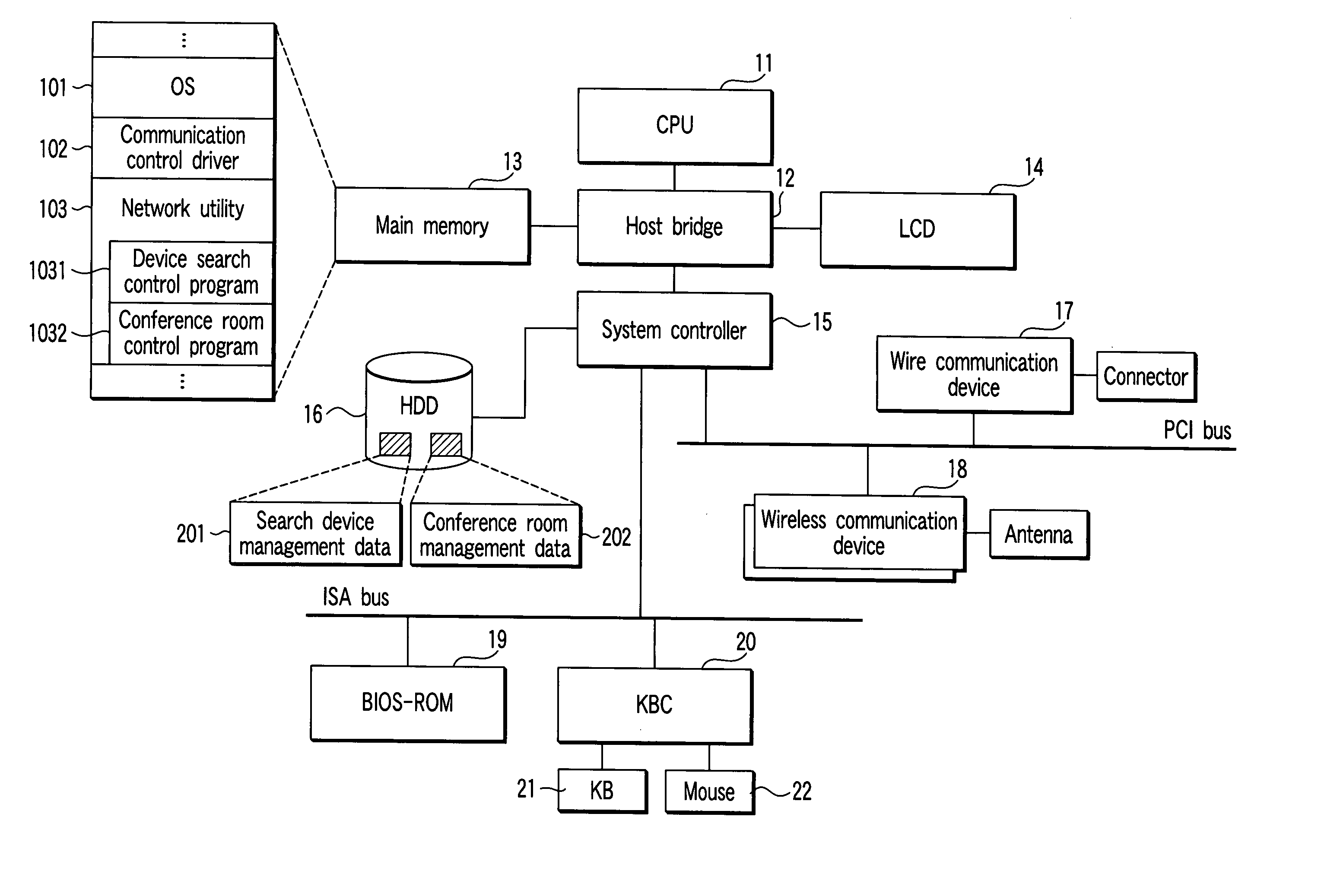

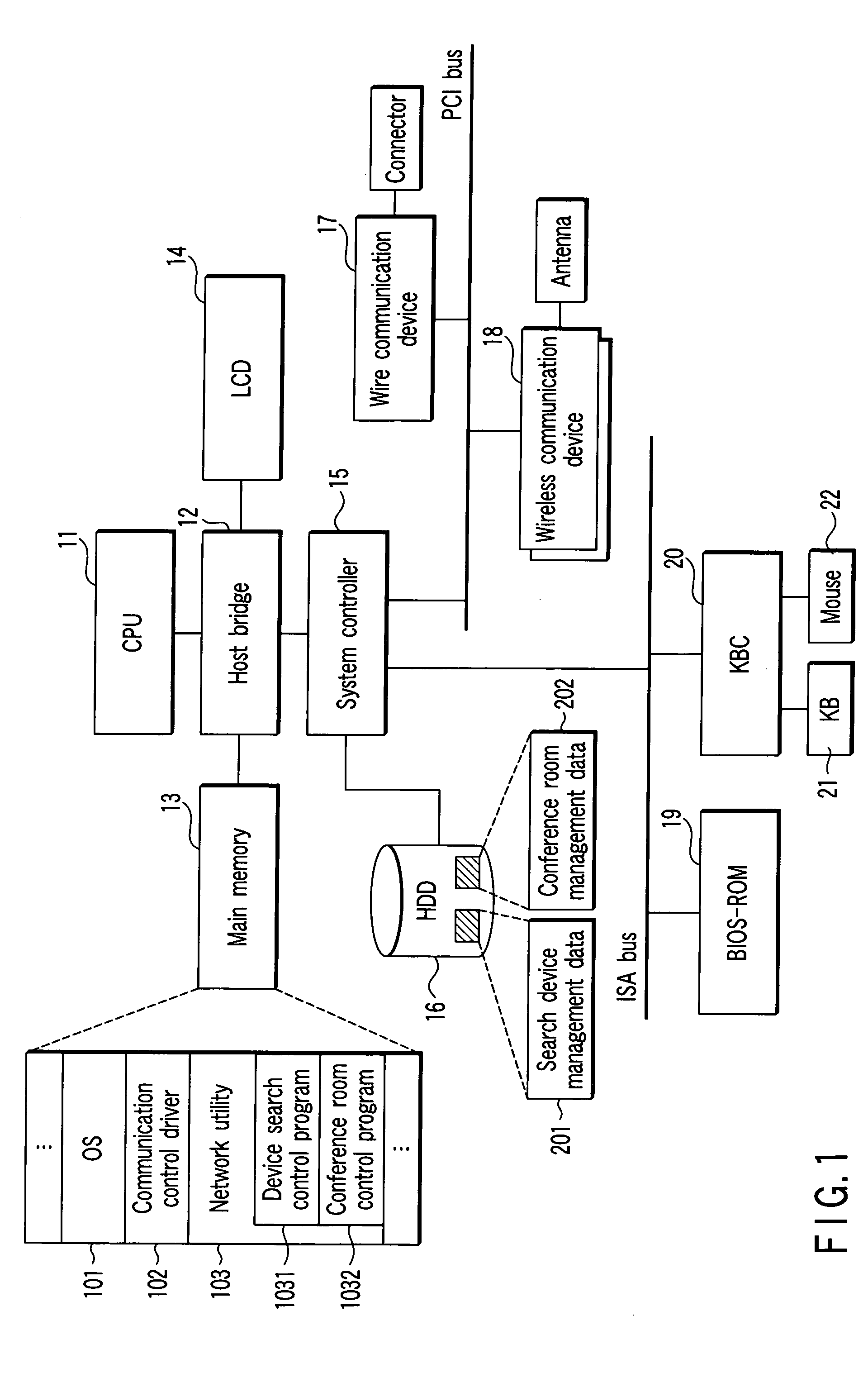

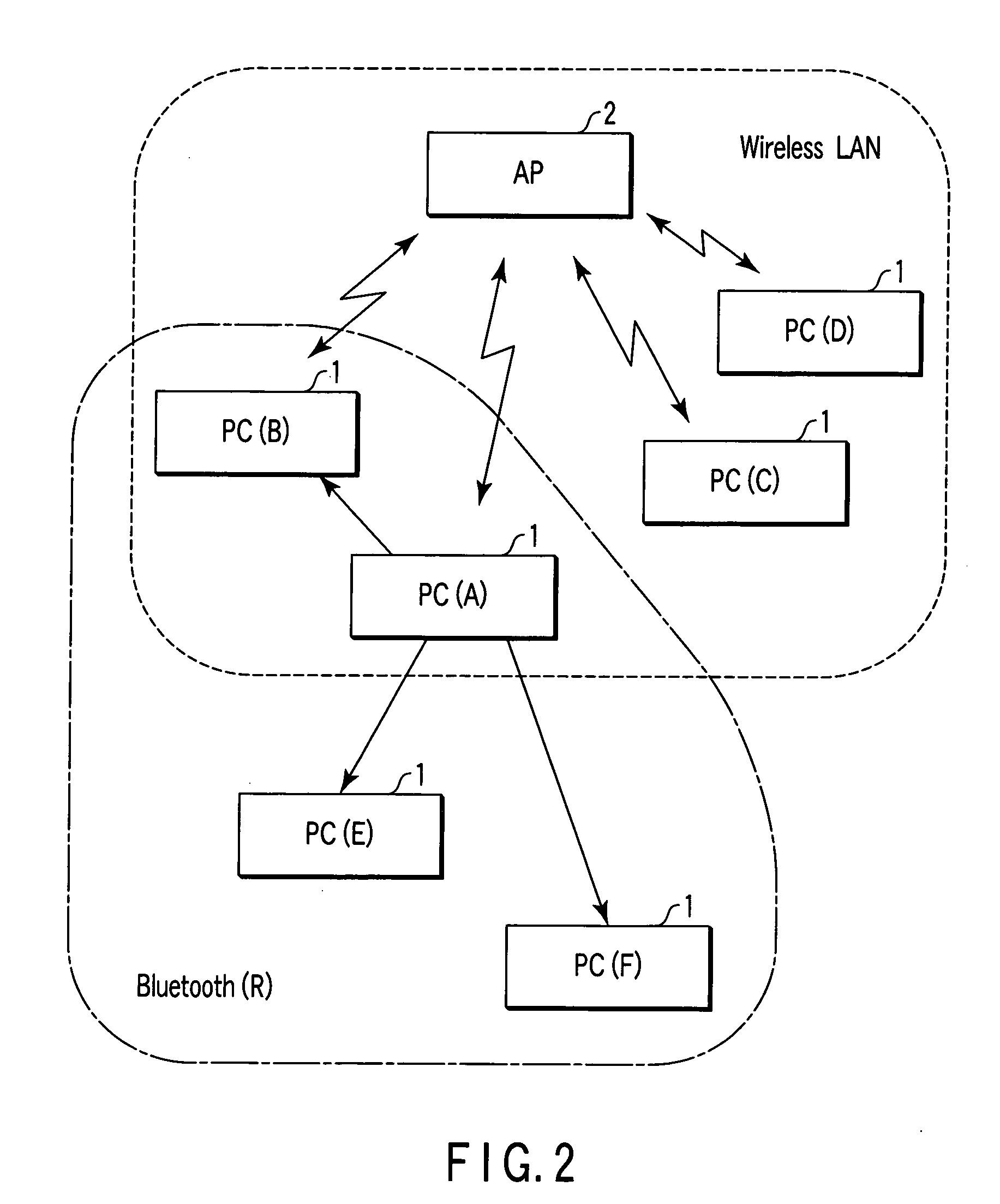

Electronic apparatus

An electronic apparatus of this invention is capable of performing wireless communication complying with, for example, Bluetooth(R), searches for wireless devices existing nearby, and displays a screen for selecting members to be summoned to a conference from the devices searched for. Then, objects representing the members selected on the screen and an object representing the present apparatus are arranged at equal intervals on a circle to cause these objects to be regarded as attendees sitting at a round table in the conference room. According to an operation performed on a displayed object (for example, the icon of a file to be transferred is dragged and dropped on the object of a destination member), data transmission and reception to and from each member is performed.

Owner:KK TOSHIBA

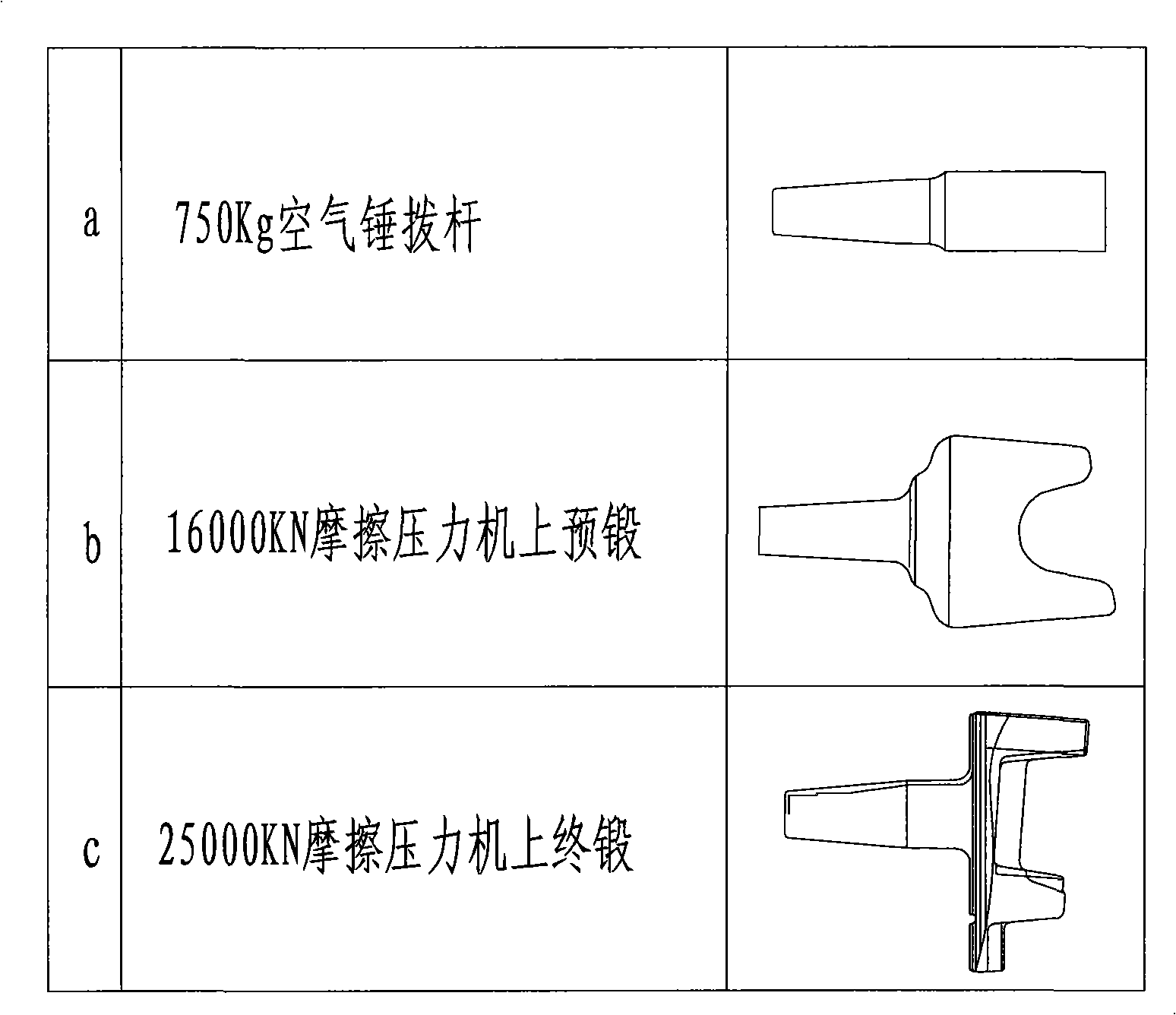

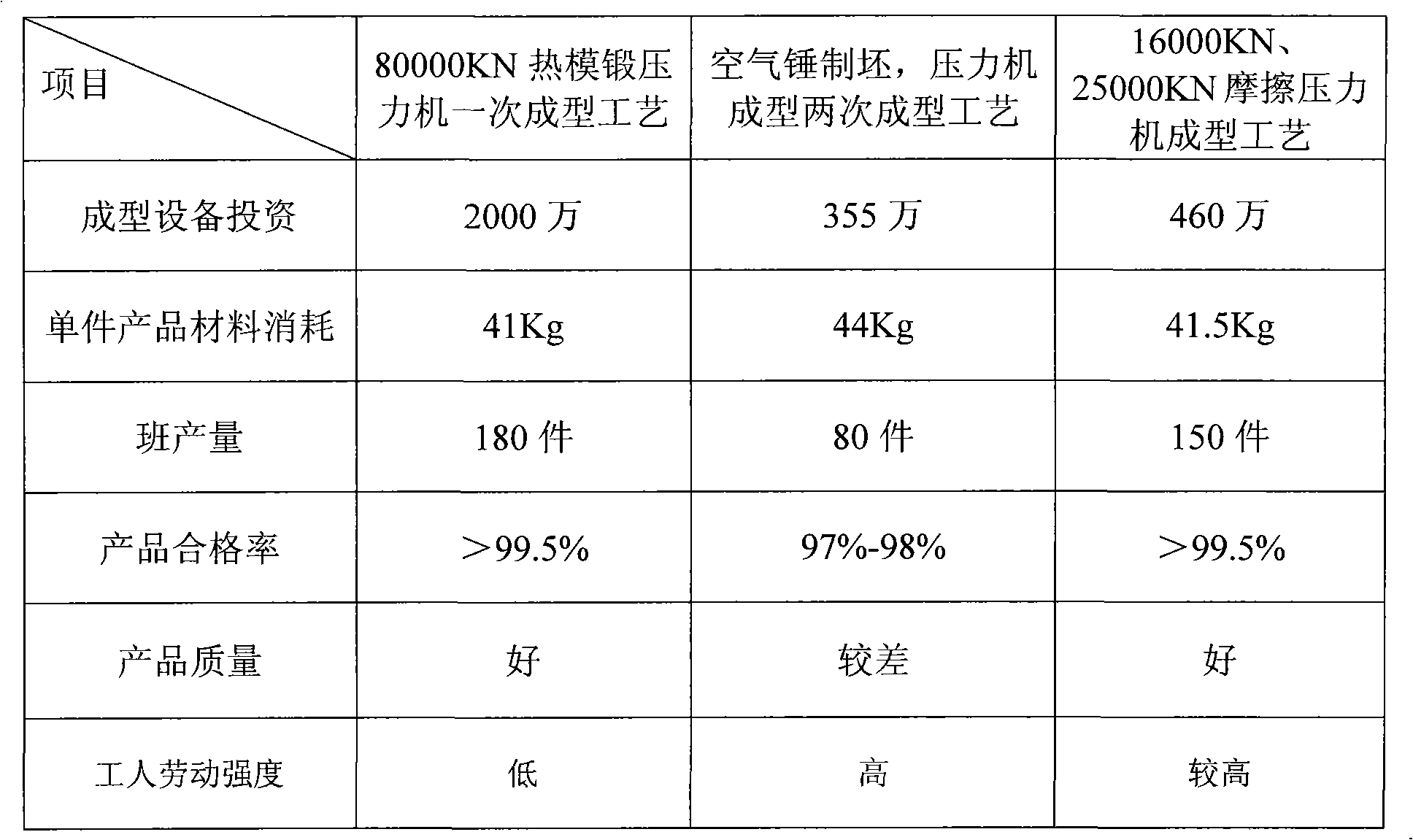

Steering knuckle forging molding process of heavy truck

ActiveCN101670417AImprove performanceShorten molding timeRailway componentsMetal-working apparatusRound tableEngineering

Owner:CHONGQING KAIEN MACHINERY MFG CO LTD

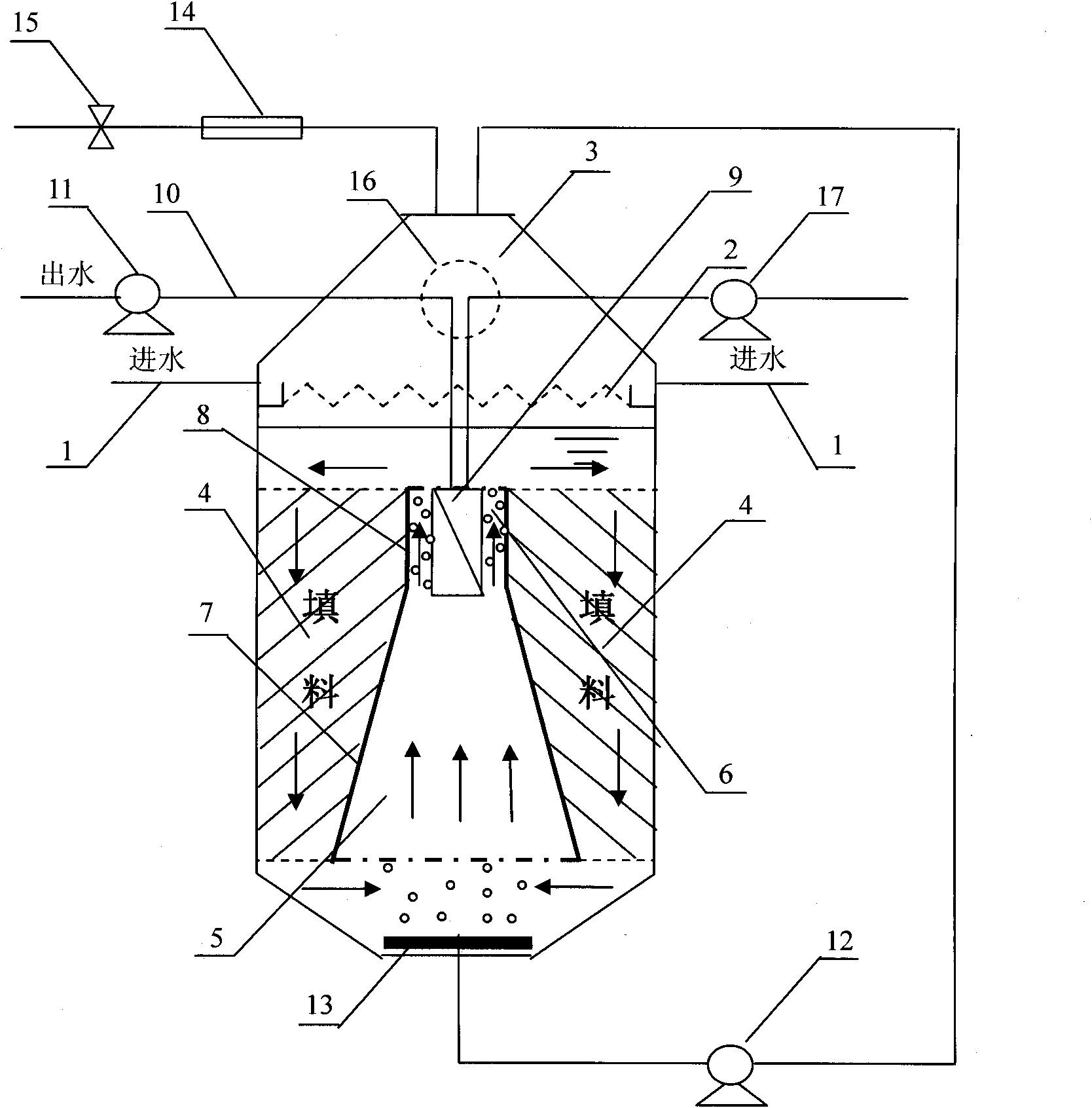

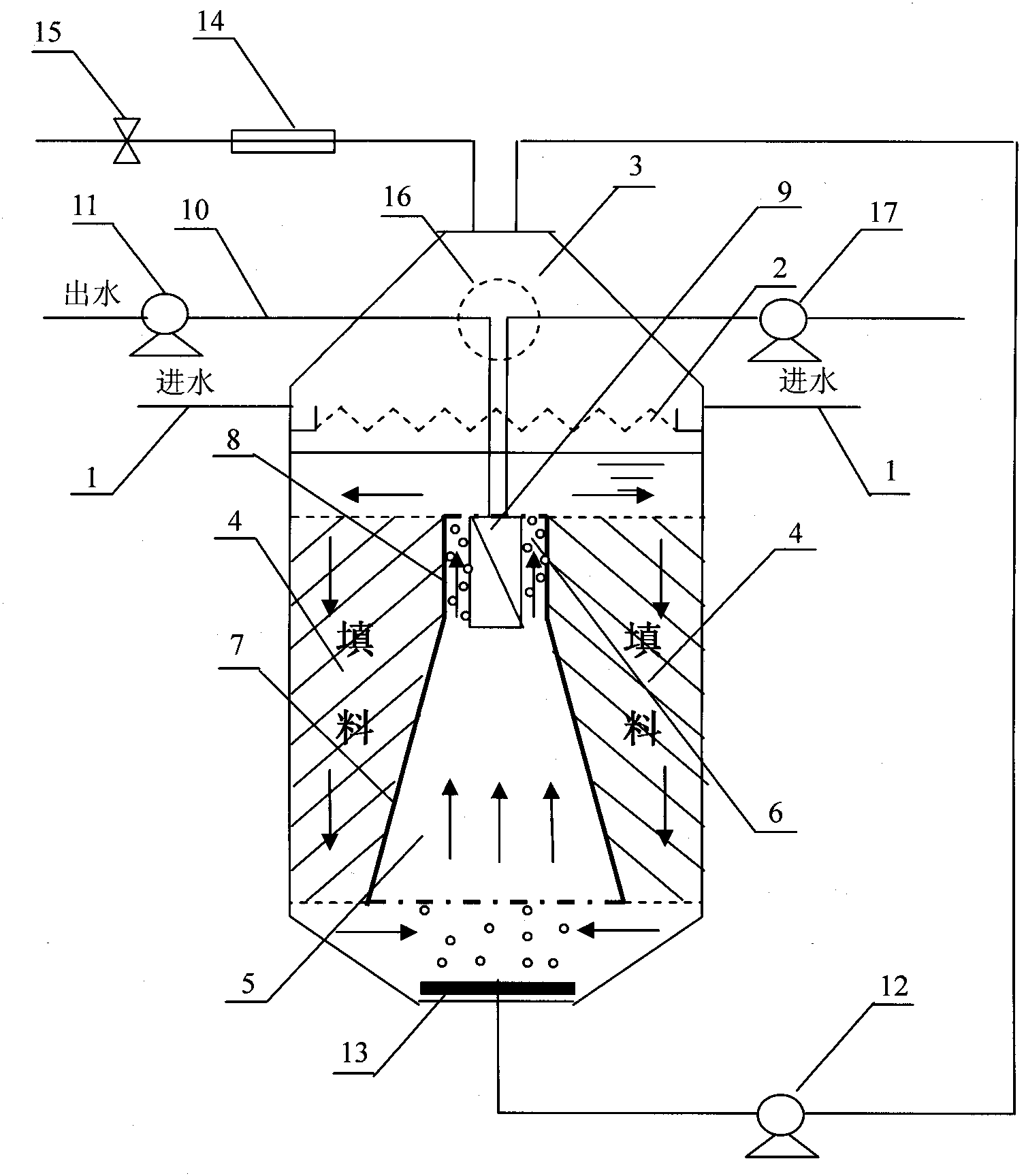

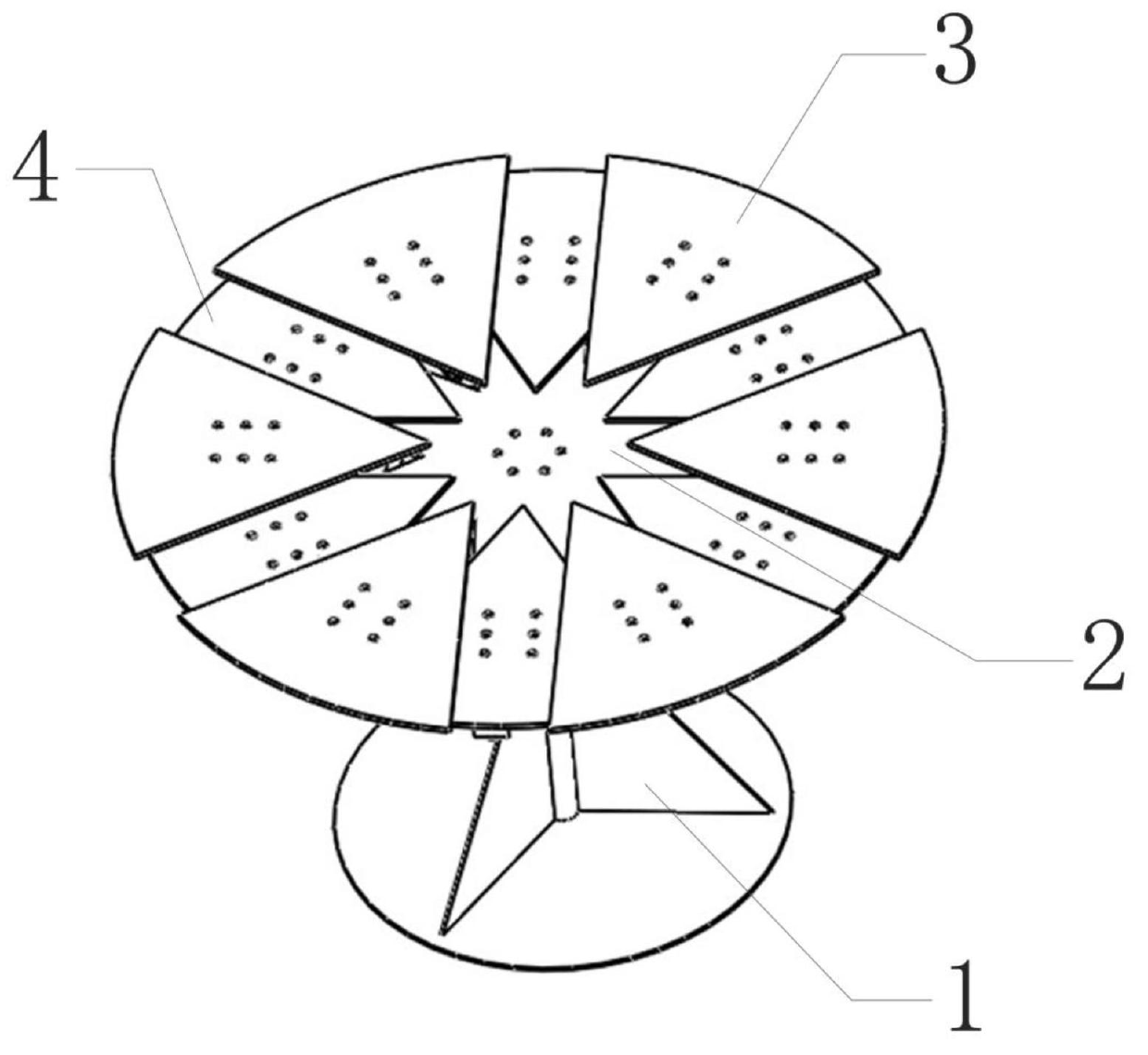

Novel anaerobic membrane bioreactor

InactiveCN101781059AReduce pollutionIncrease cross flow velocityTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisHigh concentrationActivated sludge

The invention discloses a novel anaerobic membrane bioreactor, which comprises an anaerobic biomembrane zone, an anaerobic activated sludge zone, a membrane disengagement zone and the like. Water inlet tubes of the novel anaerobic membrane bioreactor are positioned on the upper part of the novel anaerobic membrane bioreactor and uniformly distribute water through a triangular overflow weir. A gas collection chamber is positioned on the top and is connected with two pipelines, wherein one pipeline is used for exhausting and the other one is connected with gas recycle pump. An aerobic gas is recycled to the bottom of the reactor and is aerated through an aerator so that membrane fouling can be effectively reduced. A round table and a cylindrical separation plate are arranged in the middle of the reactor and divide the reactor into the anaerobic biomembrane zone, the anaerobic activated sludge zone and the membrane disengagement zone. A membrane module is arranged on the membrane disengagement zone in a form of immersion and water is pumped out of the membrane module by a pump. The device can be applied to treatment of high-concentration organic waste water in municipal engineering, food industry, industry and the like, and is in particular applied to the places where the land resource is in short supply because of a small occupied area.

Owner:HOHAI UNIV

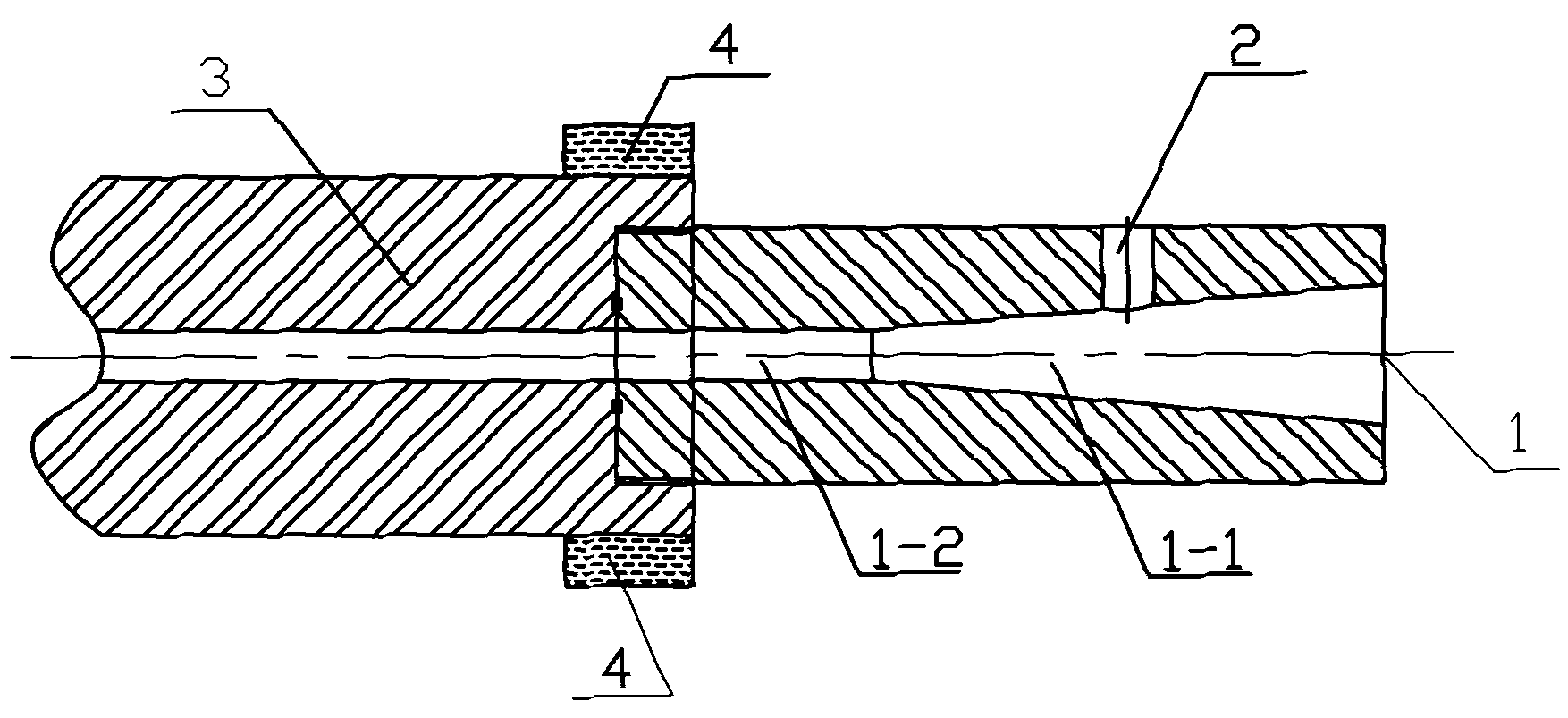

Novel extensible type round table driven by mechanical mechanism

The invention relates to a novel extensible type round table driven by a mechanical mechanism and belongs to the field of machine design and manufacture. The novel extensible type round table driven by the mechanical mechanism is characterized in that a tabletop of the round table is skillfully divided into three layers, and a three-dimensional linkage mechanism is arranged below the tabletop of the round table in the design; by means of the three-dimensional linkage mechanism, the radial reciprocating motion and lifting space omni-directional linkage of a middle-top layer and a middle layer of the three layers of tabletop boards are achieved, and synchronous revolution motion of the three layers of the boards is achieved; and by means of a linked mechanical device, furniture like the round table can be changed from small to big or from big to small, and during using, the round table can be changed into a bigger or into a smaller by moving one of the tabletop boards. By means of the mechanical device, the problem that tabletops of the furniture like the round table are hard to extend in space is solved, and a solution is provided for effectively utilizing space in sites of households, restaurants, meeting rooms and the like.

Owner:HOHAI UNIV CHANGZHOU

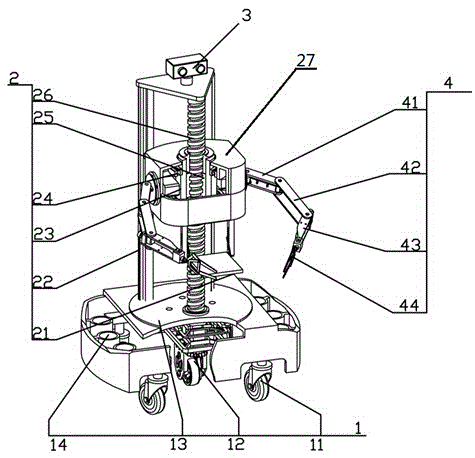

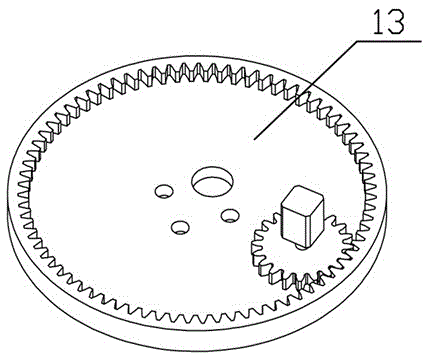

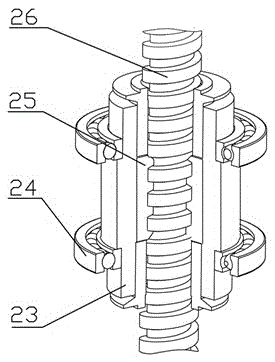

Automatic tallying robot for supermarket

The invention discloses an automatic tallying robot for a supermarket. The automatic tallying robot for the supermarket comprises a moving platform, an ascending and descending device, a grabbing mechanical hand, a scanning detection system and a controller, wherein the grabbing mechanical hand is connected with the ascending and descending device; the scanning detection system is arranged on the top of the ascending and descending device; the moving platform comprises a universal wheel, a driving wheel, a rotating round table and a mechanical hand claw base; the driving wheel realizes the reversing and the moving of the moving platform through being driven by a motor; a plurality of mechanical claws capable of being used for grasping different cargos are arranged in the mechanical hand claw base; the ascending and descending device comprises a material support frame, an I-shaped guide rail, a lead screw with a servo motor driver, a lead screw nut and an ascending and descending block; the material support frame is used for carrying cargos to be sorted; the lead screw nut is matched with the lead screw; the ascending and descending block is connected with the lead screw nut; the grasping mechanical hands move along with the ascending and descending block; the vertical movement of the ascending and descending block is realized through a lead screw nut mechanism; the controller controls the rotation stop and the sequences of all motors. The automatic tallying robot has the advantages that the fast sorting of various cargos can be realized; the labor and the materials are greatly reduced; the structure is stable and reliable; the efficiency is high.

Owner:HUBEI UNIV OF TECH

Virtual round-table videoconference

ActiveUS8319819B2Television conference systemsTwo-way working systemsRound tableComputer graphics (images)

A system and method for creating a virtual round table videoconference is described. An embodiment of the system comprises a plurality of displays arranged in an arc configuration with a table to create a virtual round table. Cameras are arranged around the plurality of displays such that when a participant looks at a display with an image of a remote participant, the camera associated with the display captures an image of the participant's gaze, making eye contact with the camera. The image is displayed at the remote participant's endpoint creating the effect of eye contact between the participants. In another embodiment, audio speakers are arranged to provide directional sound such that the video source for a display and the audio source for the associated speaker are from the same endpoint.

Owner:CISCO TECH INC

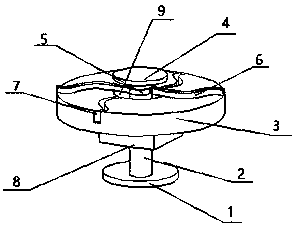

Medical breathing tube cleaning and disinfecting treatment system

InactiveCN108311483AEasy to cleanSolve the problem of manual cleaning inconvenienceHollow article cleaningChemicalsRound tableEngineering

The invention belongs to the technical field of medical instruments, and particularly discloses a medical breathing tube cleaning and disinfecting treatment system. The medical breathing tube cleaningand disinfecting treatment system comprises a box body, an adjusting module, a cleaning module, an outer wall cleaning module and an inner wall cleaning module; the box body is a cuboid with a cavityinside, a round table through hole is formed in the upper surface of the cuboid, a seal door is arranged on the round table through hole of the box body, the seal door is in contact with the throughhole of the box body, a handle is arranged on the seal door, the adjusting module is used for adjusting the position of the clamping module according to lengths of different breathing tubes, the clamping module is used for clamping two ends of the breathing tubes, and cleaning is facilitated; the outer wall cleaning module is used for achieving cleaning of the outer walls of the breathing tubes, and the inner wall cleaning module is used for achieving cleaning of the inner walls of the breathing tubes. The inner walls and the outer walls of the breathing tubes can be cleaned at the same time,and labor intensity is low.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

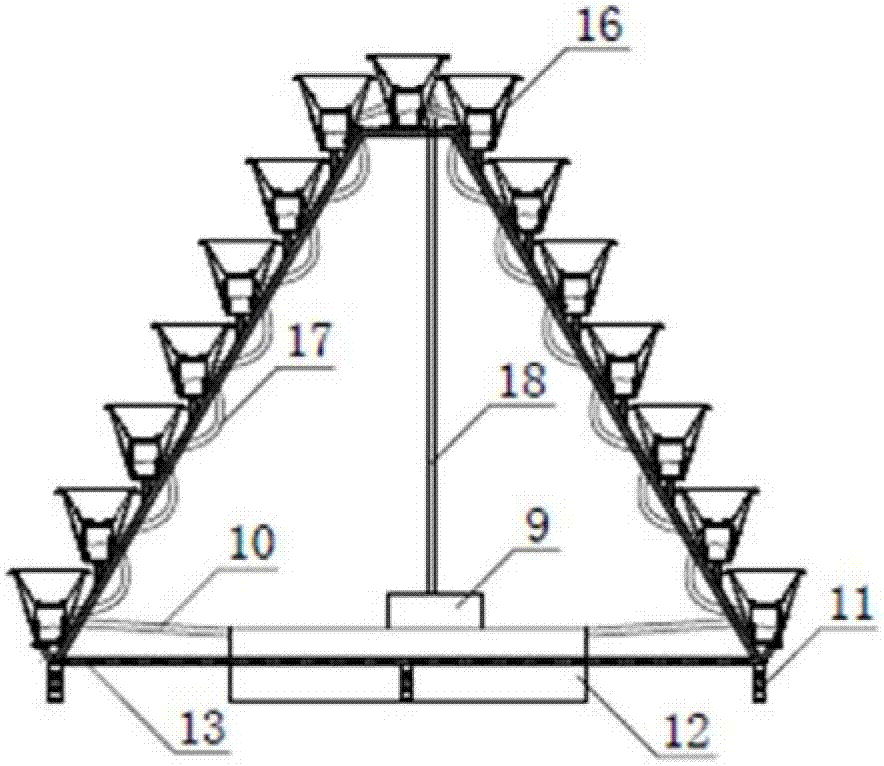

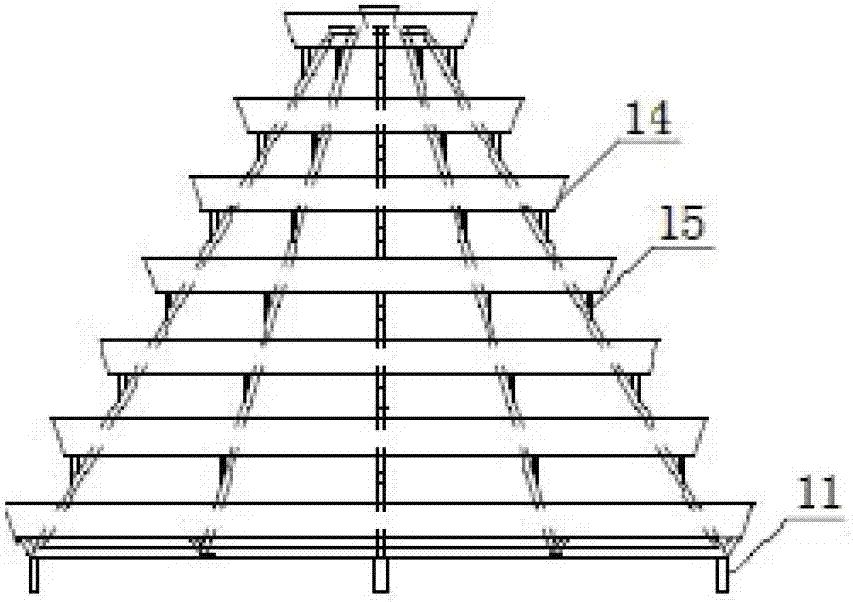

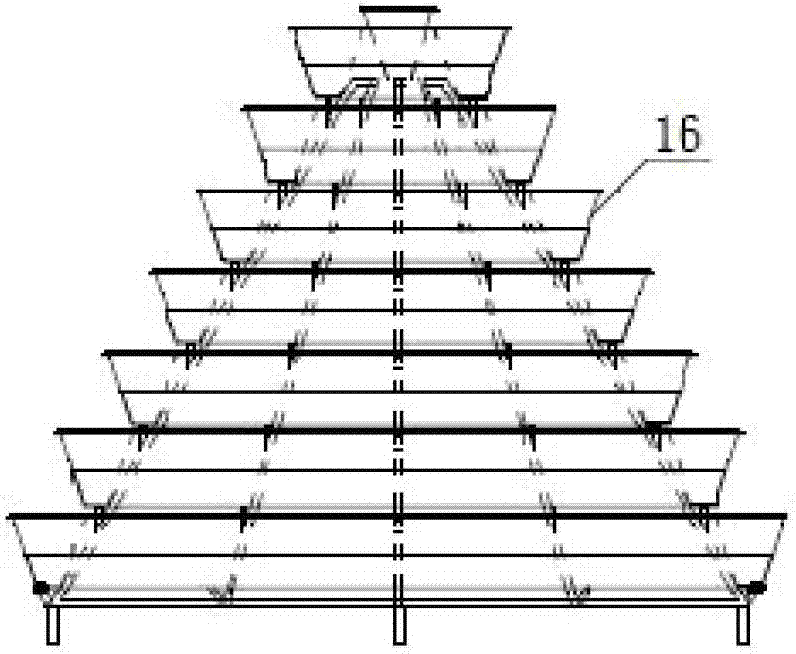

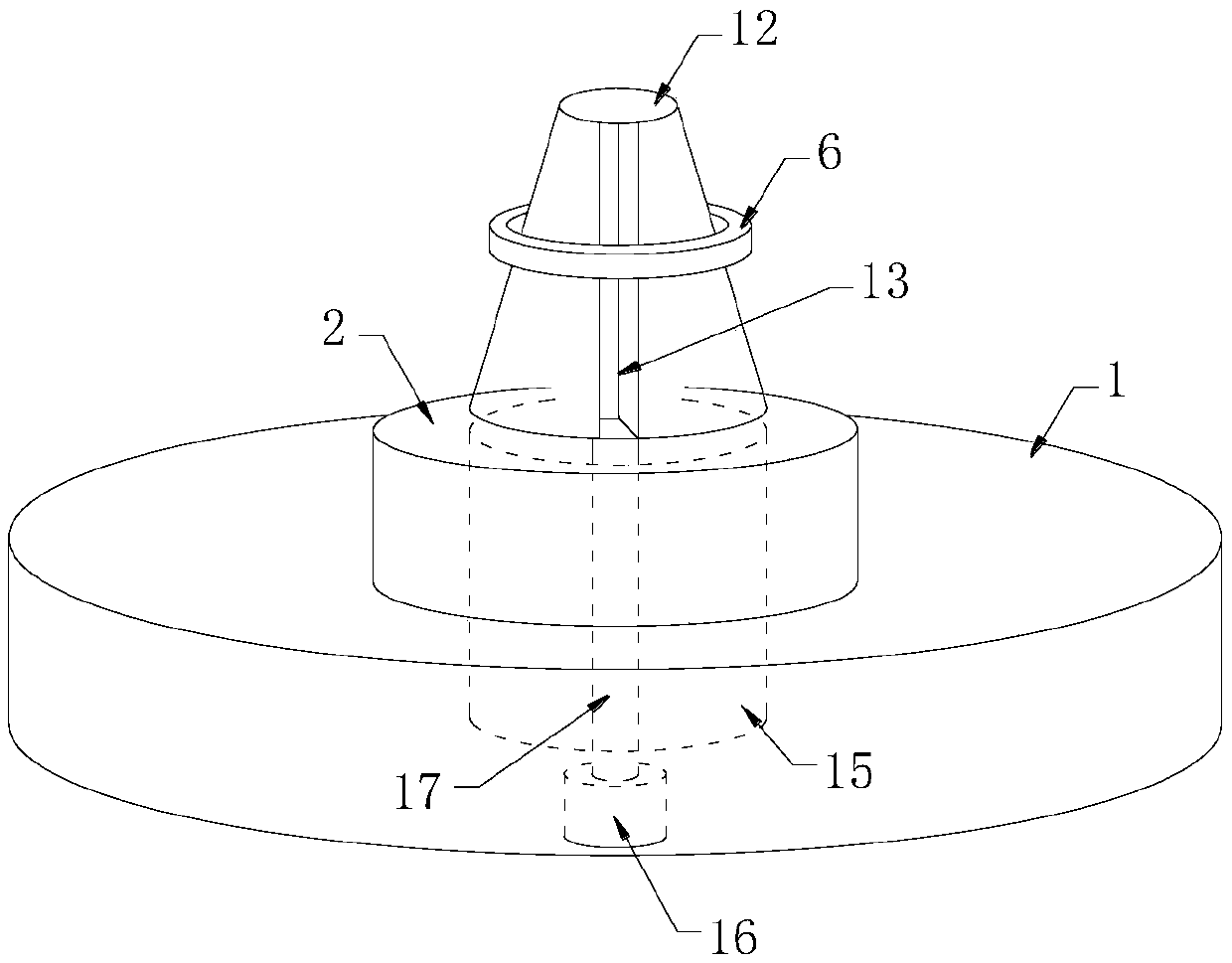

Conical air-storage liquid-storage culture system

InactiveCN102870663ASplit structure design is reasonableReasonable structural designAgriculture gas emission reductionCultivating equipmentsRound tableGreenhouse

The invention discloses a conical air-storage liquid-storage culture system, belonging to the technical field of agricultural facilities. The technical scheme comprises a conical or round-table shaped bracket (13), wherein multiple layers of ring-shaped culture grooves (16) are arranged on the bracket (13); each layer of ring-shaped culture grooves (16) are formed by an integral ring-shaped groove or a plurality of arc-shaped culture grooves with sealed ends which are connected end to end. The system has the following advantages: the system is reasonable in the split type structure design and is agile and convenient to assemble and transport, so that the cost spent on transporting, storing and the like are greatly reduced; the system is beautiful in shape and has very high ornamental value; the system is easy to move, and the two-side phenomenon is avoided; the system is reusable and long in service life; with the adoption of the system, leaf vegetables and fruit vegetables productions can be performed without destroying ground; the space use ratio is improved fully, and the yield of unit area is significantly improved; and the system is suitable for various greenhouse three-dimensional layer type culture, and also can be used as a landscape gardening facility and an indoor balcony planting device.

Owner:BEIJING CAU FUTONG GARDENING

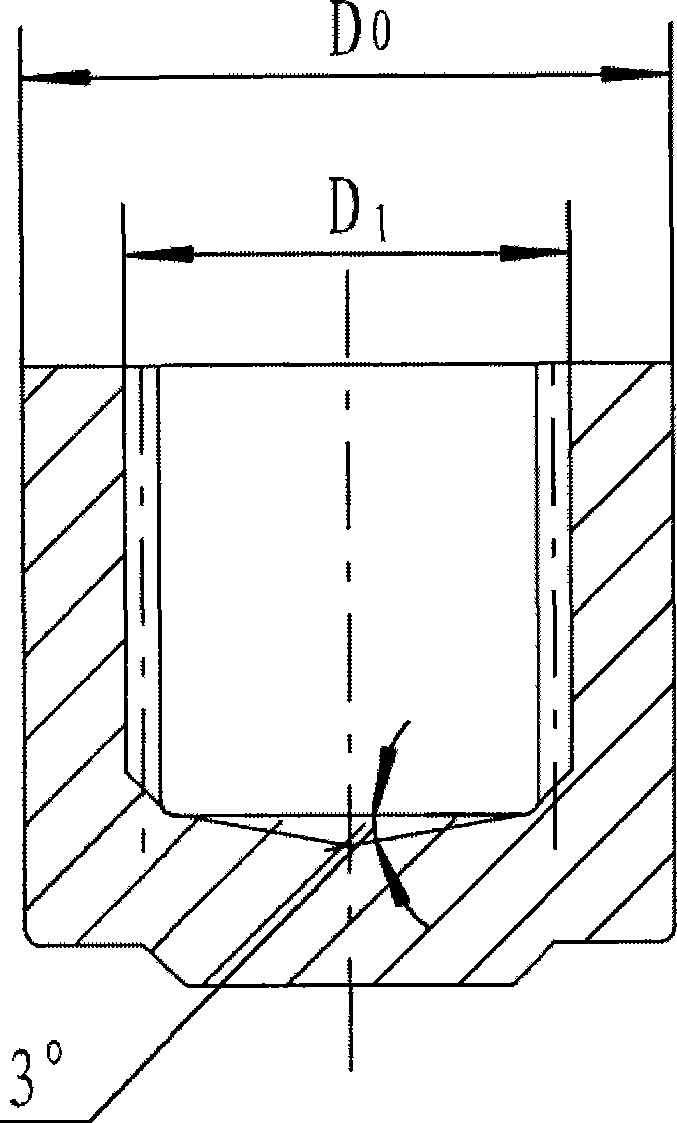

Injection die for injection and pull-extrusion process and method for preparing resin matrix composite by using same

The invention discloses an injection die for an injection and pull-extrusion process and a method for preparing a resin matrix composite by using the same, relating to an injection die and a method for preparing a resin matrix composite by using the same. Through the invention, the problem that the existing injection dies for the injection and pull-extrusion process are complicated in structure is solved. The injection die is provided with a die cavity and a glue injection hole, wherein the die cavity consists of a round table-shaped die cavity and a cylindrical die cavity; and the glue injection hole is located on the die wall of the round table-shaped die cavity. The method comprises the steps of: injecting a resin matrix into the round table-shaped die cavity through the glue injectionhole; causing continuous fibers to enter the die cavity of the injection die from a large-diameter end of the round table-shaped die cavity of the injection die under the traction of a traction device and then enter a die cavity of a pull-extrusion molding die through the cylindrical die cavity; and carrying out sizing and curing. The die cavity of the injection die is conical in front part and flat in rear part, the fibers of a solvent impregnated resin are stressed by a small-diameter end of the round table-shaped die cavity and the die wall of the cylindrical die cavity and then air bubbles are discharged, therefore, the void ratio of the composite is reduced and the mechanical property is improved. The injection die is simplified and the application range of the injection and pull-extrusion process is enlarged.

Owner:HARBIN FRP INST

Dining table with automatic cleaning function

InactiveCN107898149ASimple structureImprove efficiencyCarpet cleanersFloor cleanersEngineeringRound table

The invention belongs to the technical field of intelligent dining tables, and particularly relates to a dining table with an automatic cleaning function. The dining table comprises a base, a column,a round table body, a turntable, a lantern ring, a scraping plate, a groove, a garbage can and a garbage discharge port. The base is located on the ground; the column is located on the base; the roundtable body is located above the column; the turntable is located above the round table body; the lantern ring is located below the turntable and used for fixing the scraping plate below the turntable; the scraping plate is located on a round table top, connected with the lantern ring and used for scraping the table top completely; the groove is formed in the round table top, so that the scrapingplate falls into the round table body; the garbage can is located below the round table body and used for containing garbage which is discharged from the garbage discharge port; the garbage dischargeport is formed in the center of the round table body and used for making the turntable conveniently lift and rotate. The dining table with the automatic cleaning function is simple in structure, highin efficiency and convenient to use.

Owner:FOSHAN JIA YUN HANG TECH CO LTD

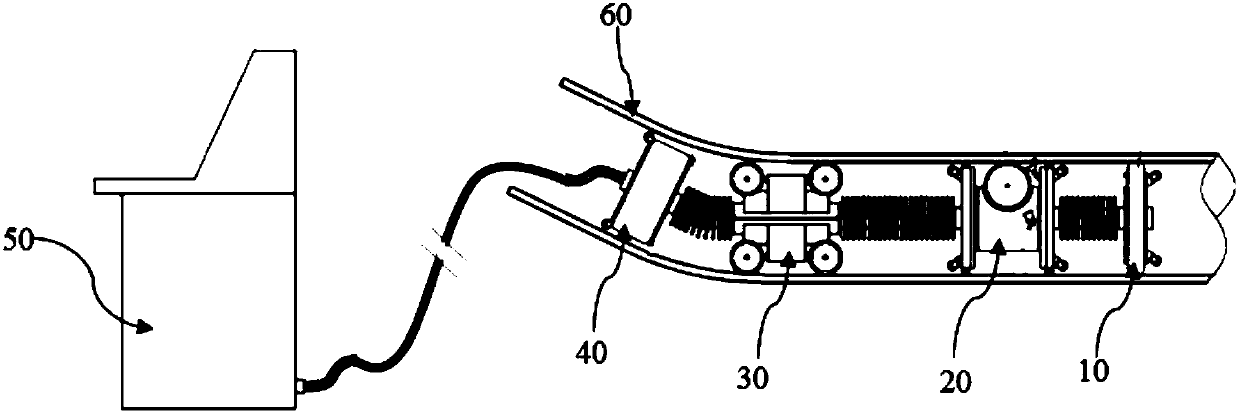

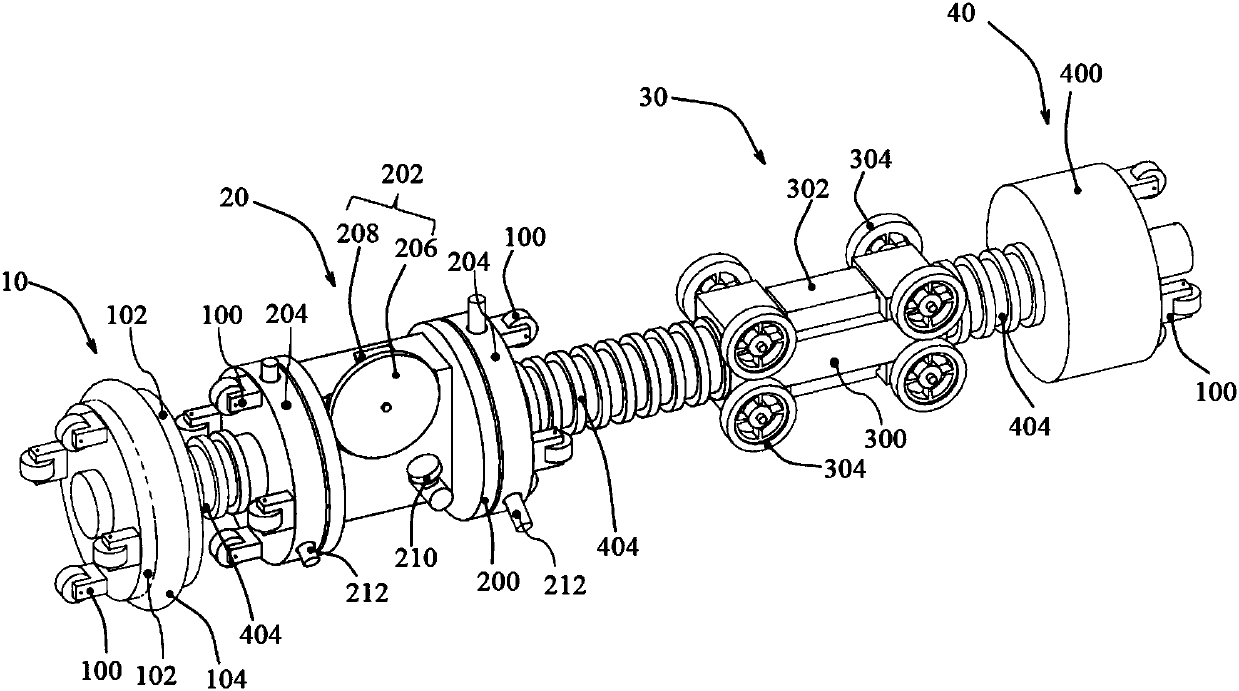

Nuclear power station pipeline weld inner wall grinding robot

InactiveCN107855859ASolve problems that cannot be polishedSolve the problem of weld stress concentrationEdge grinding machinesGrinding feed controlStress concentrationRound table

The invention discloses a nuclear power station pipeline weld inner wall grinding robot, which comprises a sealing unit, a grinding unit, a driving unit, and an electric element unit. The sealing unitcomprises a first round table and a rubber sealing plate arranged on the first round table; the grinding unit comprises a rotary holder and a grinding device arranged on the rotary holder; the driving unit is used for driving the grinding unit to enter and exit a pipeline; and the sealing unit, the grinding unit, the driving unit and the electric element unit are connected in a bending way. Compared with the prior art, the nuclear power station pipeline weld inner wall grinding robot provided by the invention has the following advantages that multiple functions of automatic grinding, polishing, cleaning and nondestructive testing of a steel-made pipeline weld inner wall are realized, the problem that the steel-made pipeline weld inner wall cannot be ground is solved, a turning and climbing problem of the robot on the pipeline inner wall is solved, the problem of weld stress concentration is solved, a heat fatigue effect is eliminated, the weld quality is ensured, and the weld potential quality hazard is eliminated.

Owner:中广核工程有限公司 +1

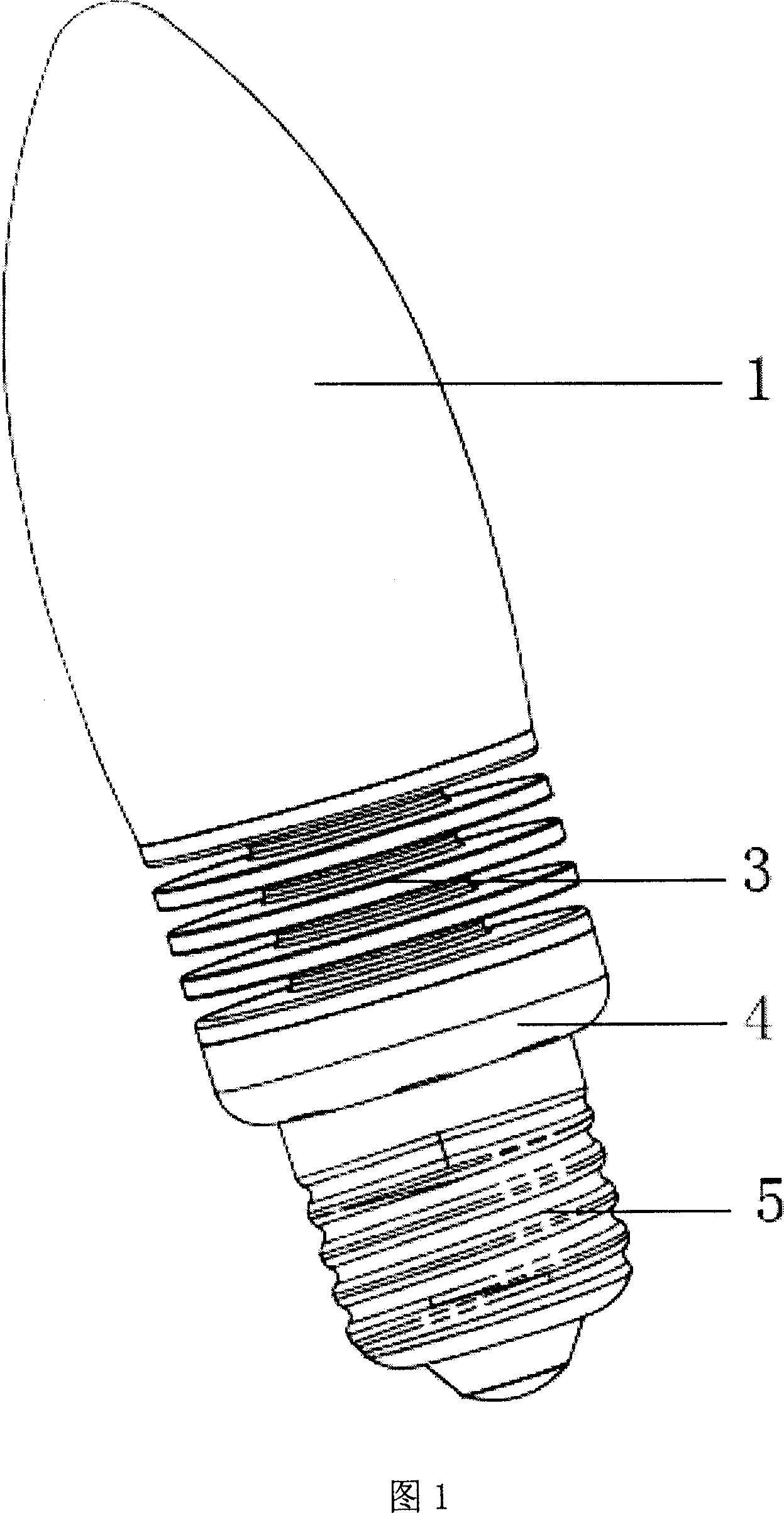

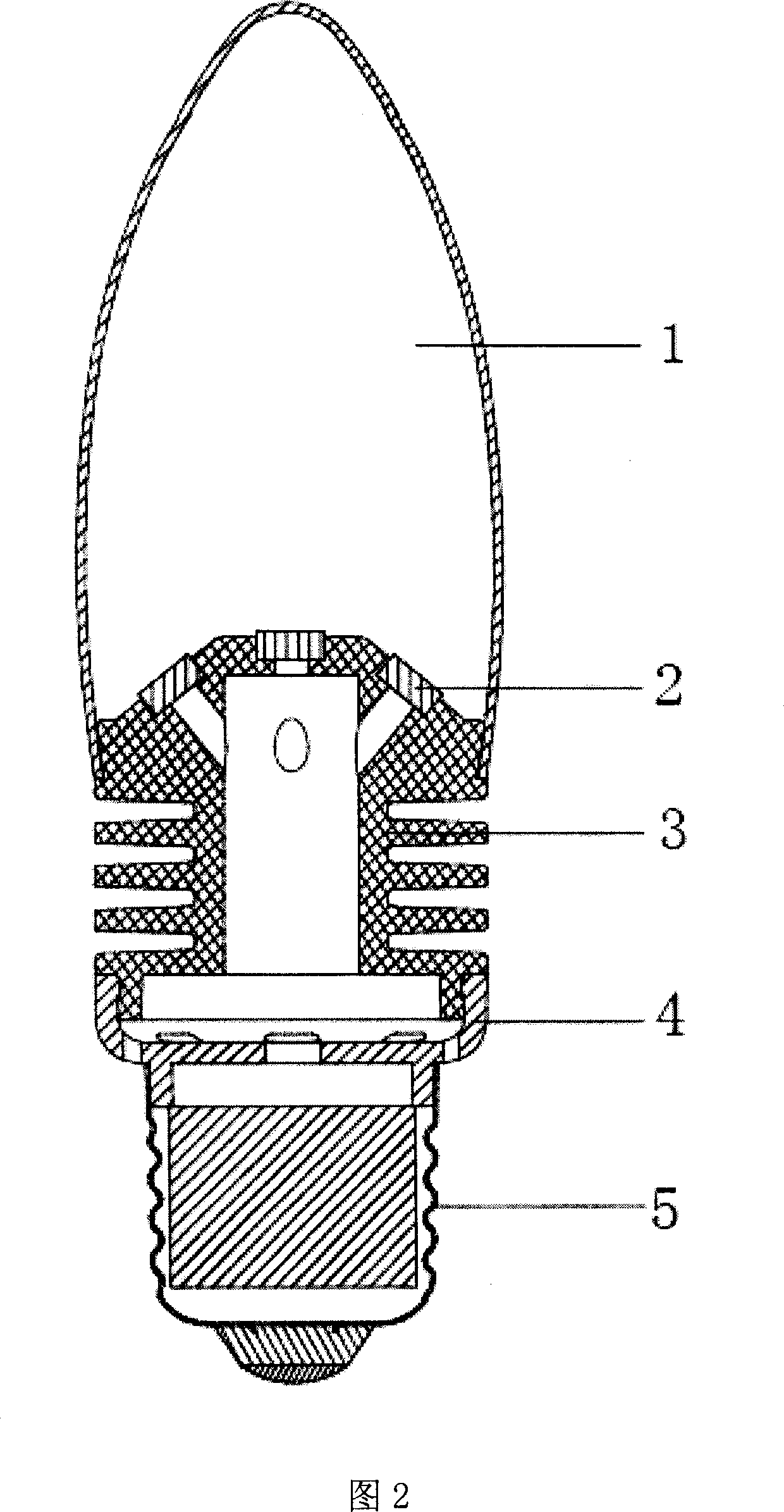

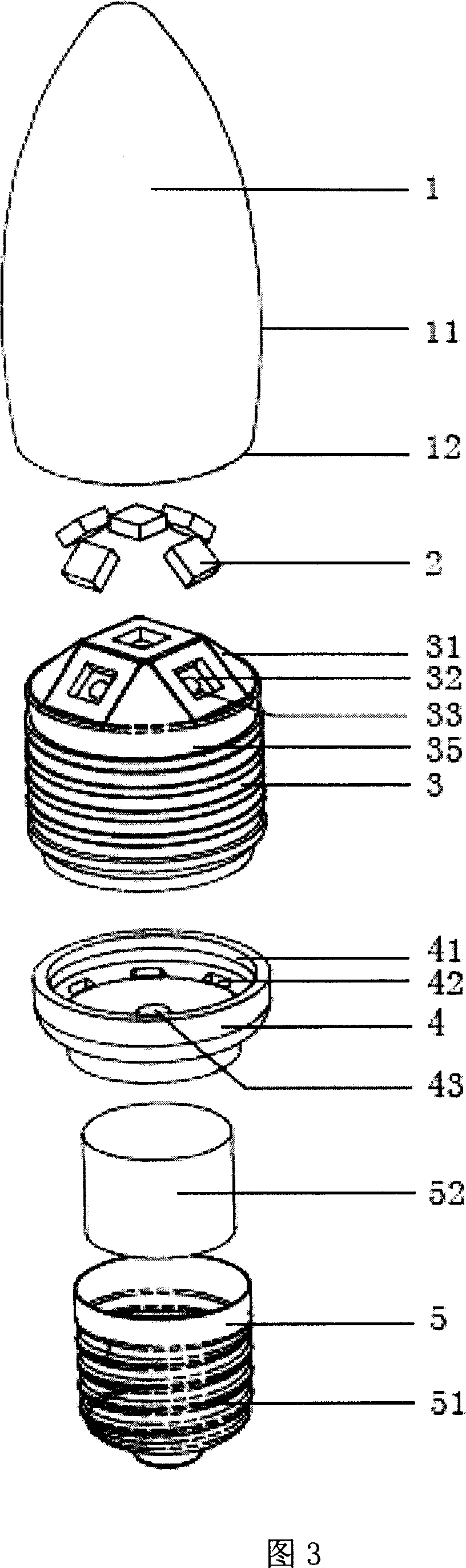

LED energy saving lump

InactiveCN1948819AEffective distributionExtended service lifePoint-like light sourceLighting heating/cooling arrangementsRound tableEffect light

An energy-saving lighting lamps and lanterns, especially a LED energy-saving lamp consists of a lampshade, an LED light source, a cooling body, an insulating piece and a lamp holder. The LED light source is inlaid on the round-table-like surface at the end of the cooling body and the round-table-like surface is coated with a reflecting layer. In the centre of the cooling body there is a hollow column, around which are uniformly distributed metal cooling fins. LED can let the heat out effectively through an integral cooling body. The insulating piece is used for separating the cooling body from the lamp holder to insulate the cooling body. The lampholder includes a lampholder casing and an LED drive power source mounted in the lampholder casing.

Owner:诸建平

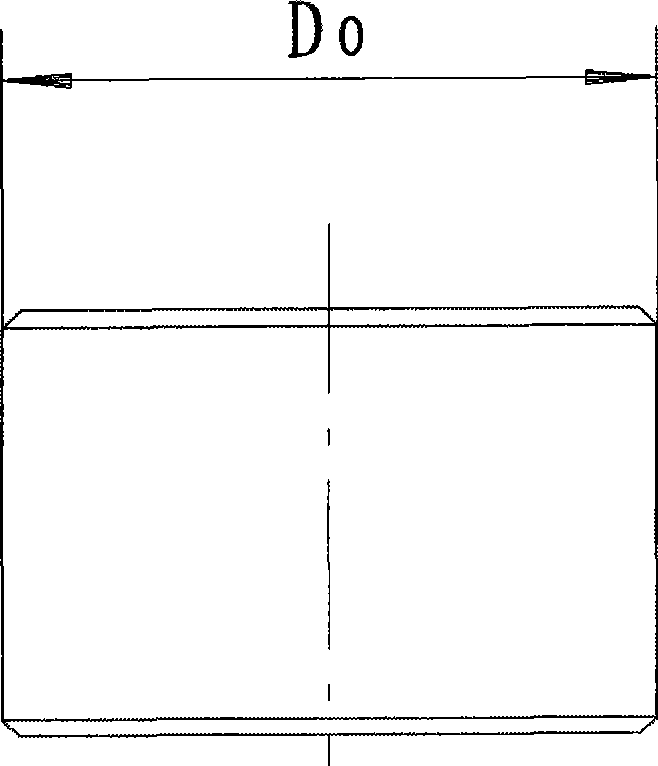

Method of manufacturing chemical mechanical polishing pad

ActiveUS20070082587A1InhibitionIncrease ratingsFlexible-parts wheelsGrinding devicesRound tableMilling cutter

The present invention relates to a method of manufacturing a chemical mechanical polishing pad which provides a chemical mechanical polishing pad which fully suppresses the occurrence of a scratch on the polished surface and has an excellent polishing rate. The method comprising either one of a group of steps (A) and a group of steps (B), the group of steps (A) including (A1) the step of preparing a composition for forming a chemical mechanical polishing pad; (A2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form; (A3) the step of mounting the pad-like form on the round table of a cutting machine having at least a milling unit equipped with a milling cutter, a drive unit capable of angle indexing and positioning and a round table journaled by the drive unit; (A4) the step of forming the second group of grooves with the milling cutter; and (A5) the step of forming the first group of grooves, and the group of steps (B) including (B1) the step of preparing a composition for forming a chemical mechanical polishing pad; (B2) the step of molding the composition for forming a chemical mechanical polishing pad into a pad-like form having the second group of grooves by using a metal mold having projections corresponding to the shapes of the second group of grooves; and (B3) the step of forming the first group of grooves.

Owner:JSR CORPORATIOON

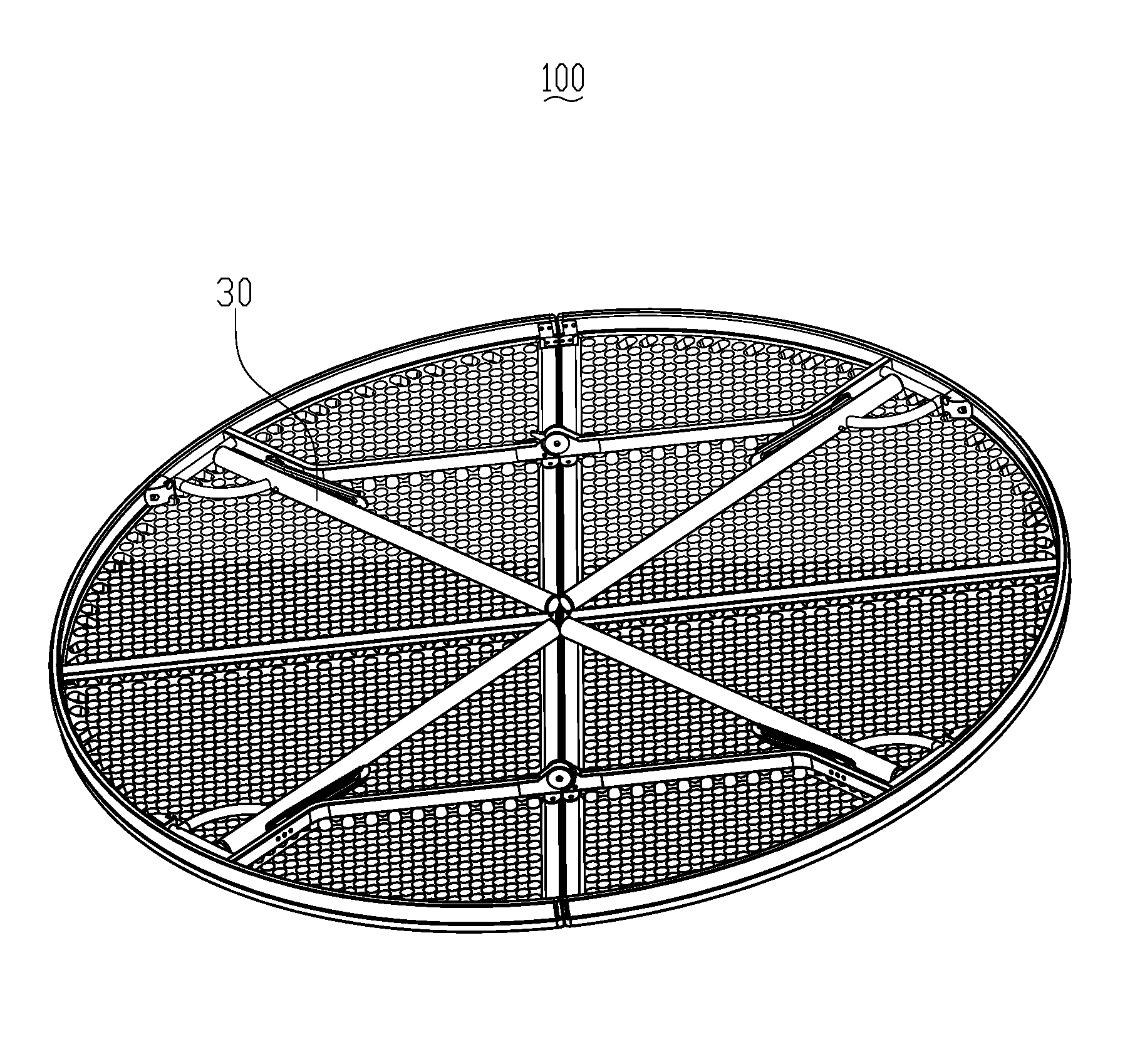

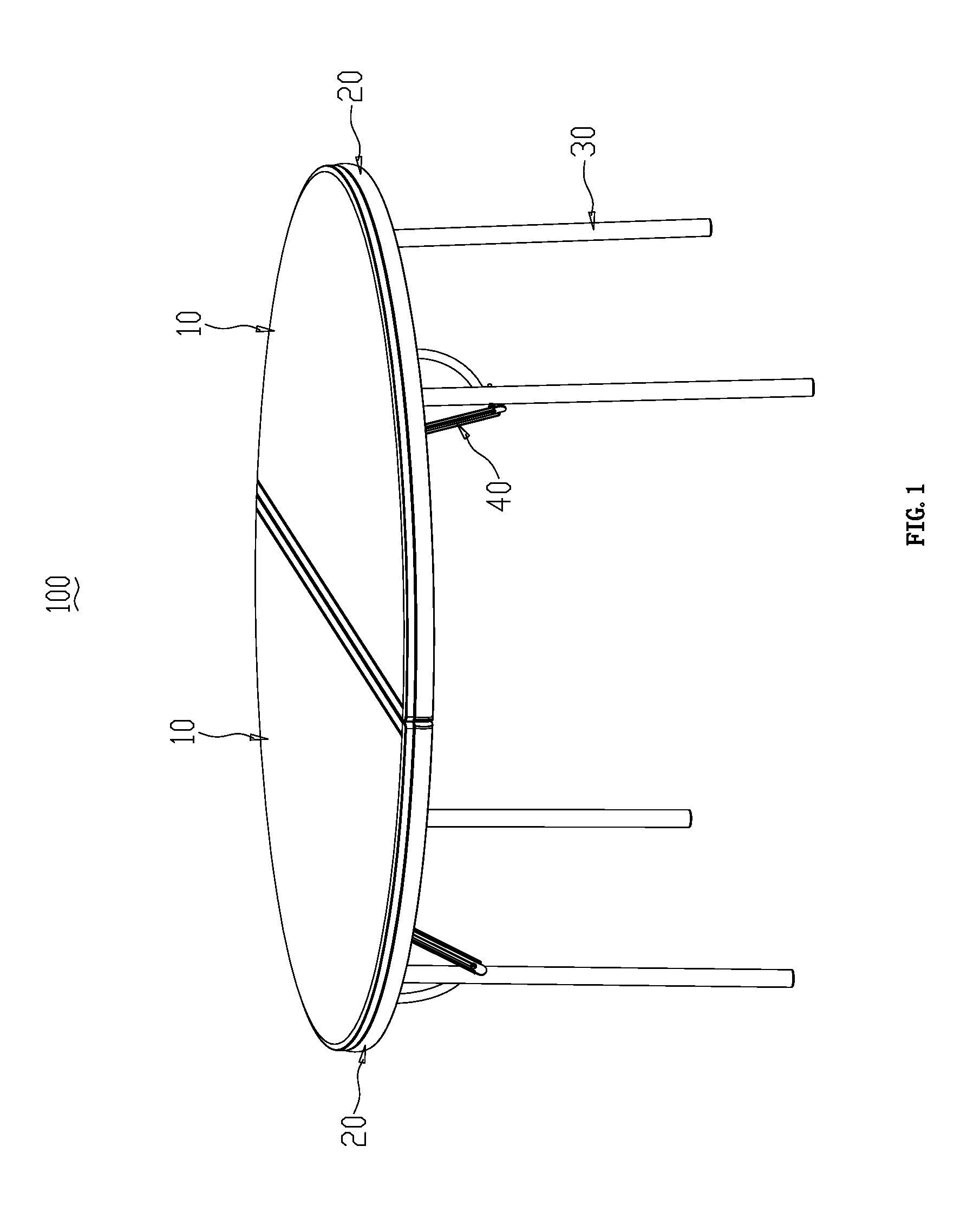

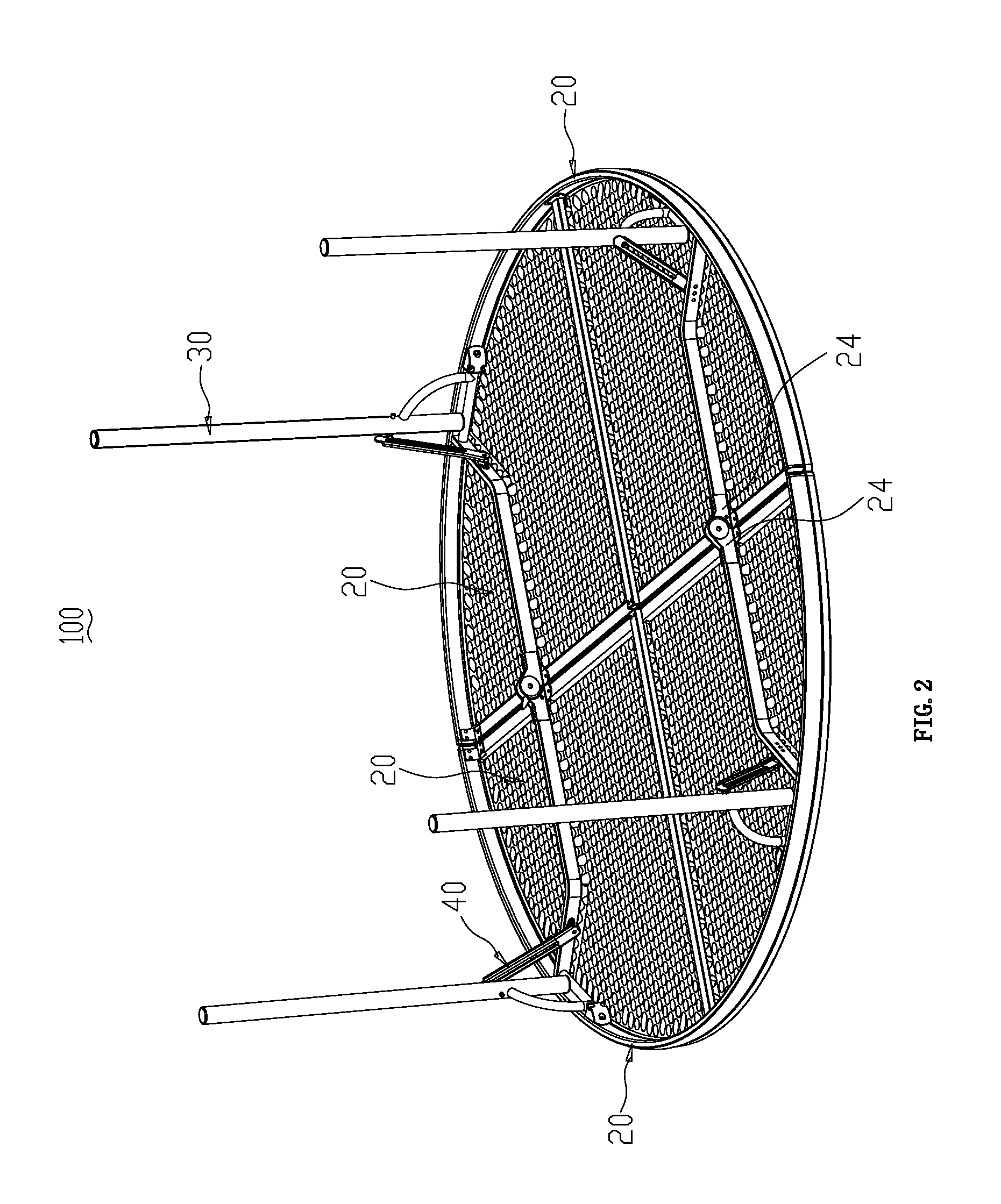

Folding round table

ActiveUS9504314B2Maximally lengthenReduce spacingFoldable tablesStowable tablesRound tableEngineering

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

Reverse cold extrusion mold for car rear transversal stabilizer bar casing tube

InactiveCN101502855ASave materialThe whole length of the working section is tooth-shaped, and the structure is simplePunchingRound table

A rear transverse stabilizer rod bushing reverse cold extrusion die is disclosed, belonging to plastic forming die of metallic material and solving the problems that the current extrusion convex die has complex structure, large variation of cross section, large processing difficulty, low service life, inconvenient installation and regulation, excessive required materials of the die and high expenditure. The invention comprises a reverse extrusion concave die, an ejection device, a reverse extrusion convex die and a guide device; a punching head of the reverse extrusion convex die is sequentially divided into a punching head lower end, a working section and a fixation section, the punching head lower end is a cone, the entire working section is tooth-shaped; the diameter, the spline module and the number of teeth thereof are equal to relative parameters of the bushing to be formed; the fixation section is cylindrical; a conical clamping ring of the reverse extrusion convex die is a round table having an inner hole, the side thereof has an axial incision, and the inner hole has annular channels that are distributed equidistantly. The invention is convenient in manufacturing, installation, regulation and usage, stable and reliable in operation, wide in application range of the technology and long in service life; the die expenditure is lowered due to quite few materials required for manufacturing the convex die.

Owner:湖北天轮机械有限公司 +1

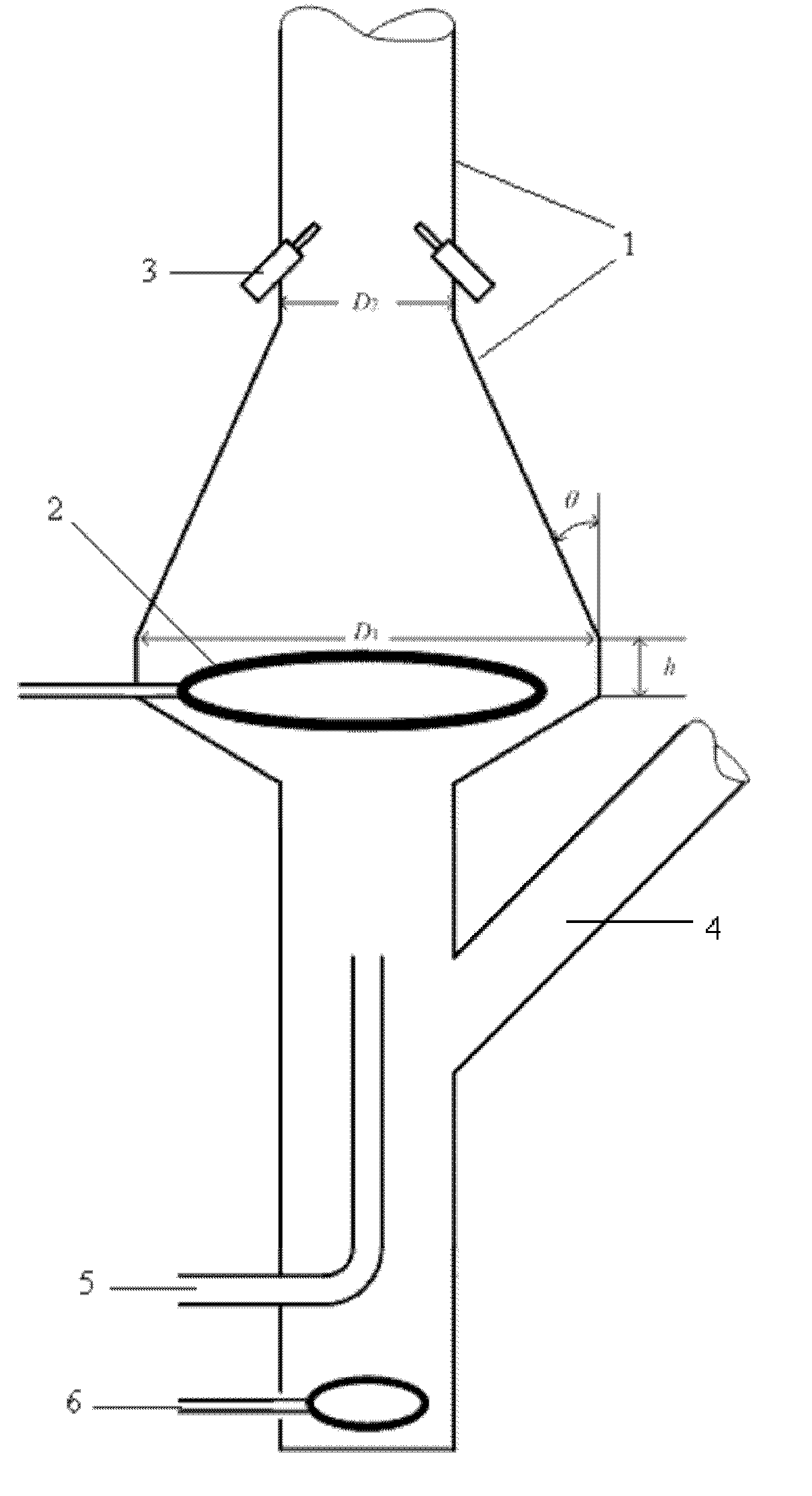

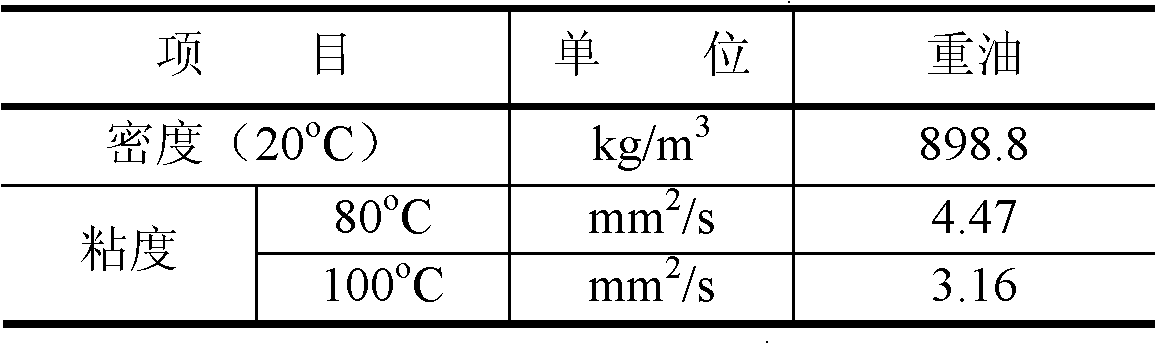

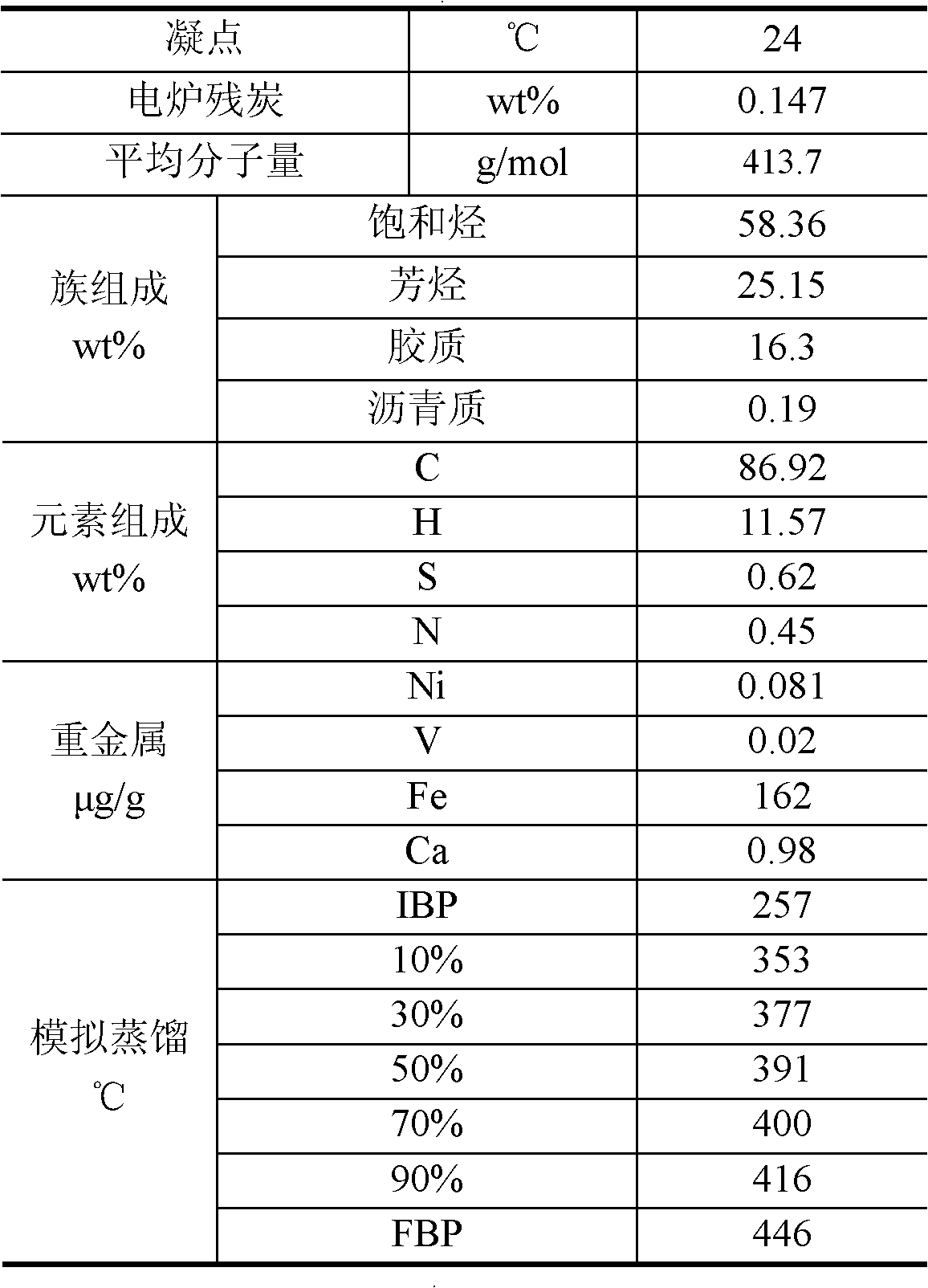

Reactor and method for preparing propylene by method of group feeding of heavy oil and light olefin

ActiveCN101838546AHigh yieldHigh fluidized densityCatalytic crackingChemical/physical processesRound tableGasoline

The invention discloses a riser reactor for preparing propylene, which comprises an upper section of pipeline and a lower section of pipeline. The upper section of pipeline is a straight pipe, while the lower section of pipeline is a diameter expanding section, of which the shape is of a pipeline of a round table; and an included angle between a bus and an axis of the round table is 1 to 60 degrees, wherein the diameter of the upper bottom surface of the round table is more than or equal to that of the straight pipe. The reactor is adopted for preparing the propylene by a method of group feeding of heavy oil and light olefin by catalytic cracking; and the axial average air speed in the straight pipe on the upper section of the riser is 3 to 25m / s, the axial average air speed in the diameter expanding section is 0.1-5m / s, the exit temperature of the riser is between 460 and 600 DEG C, and the light olefin accounts for no more than 50 percent weight of the raw oil, so that the yield andthe selectivity of the propylene are improved, and the reactor and the method can be used for the production of diesel oil and high-octane petrol.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

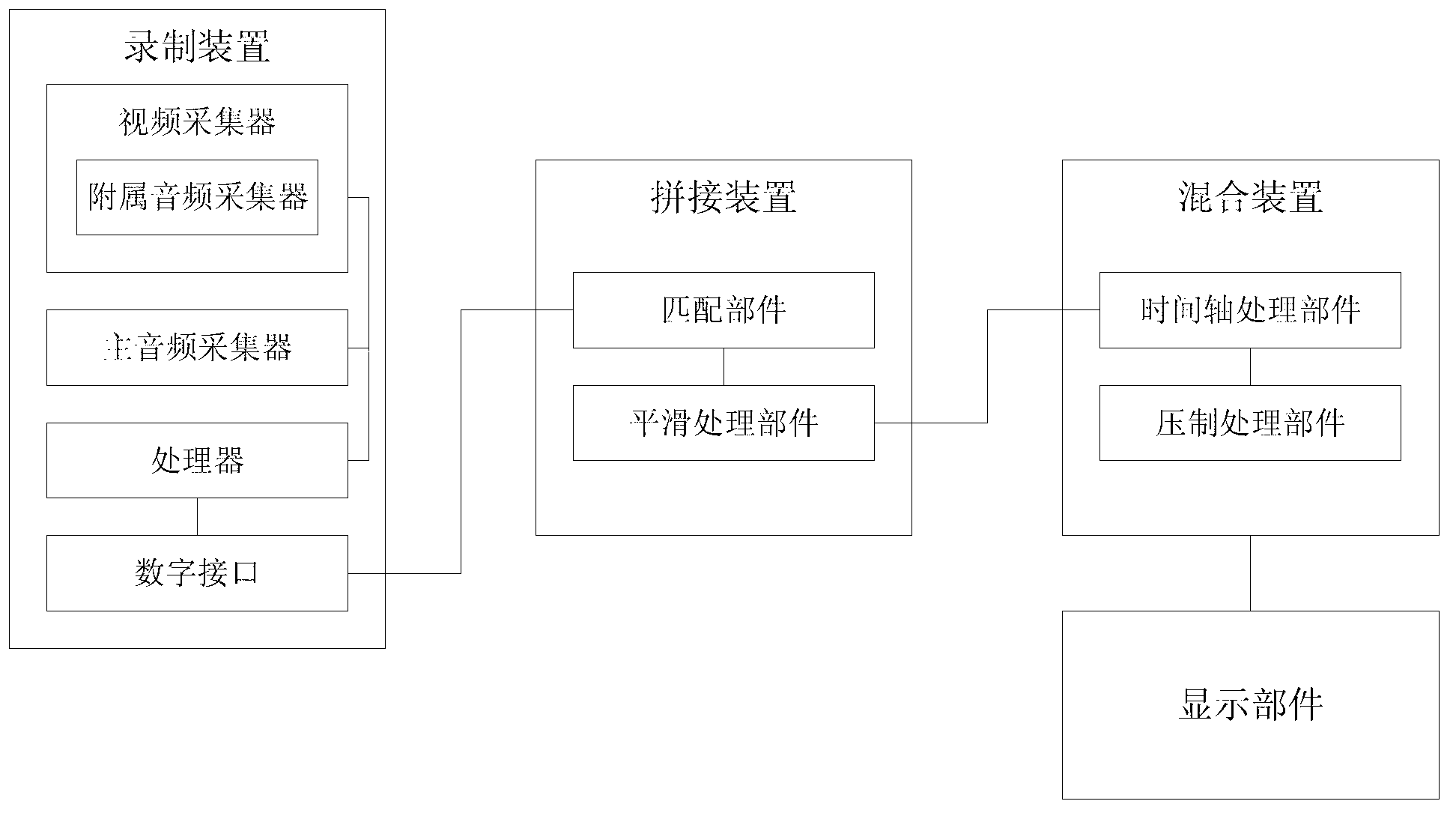

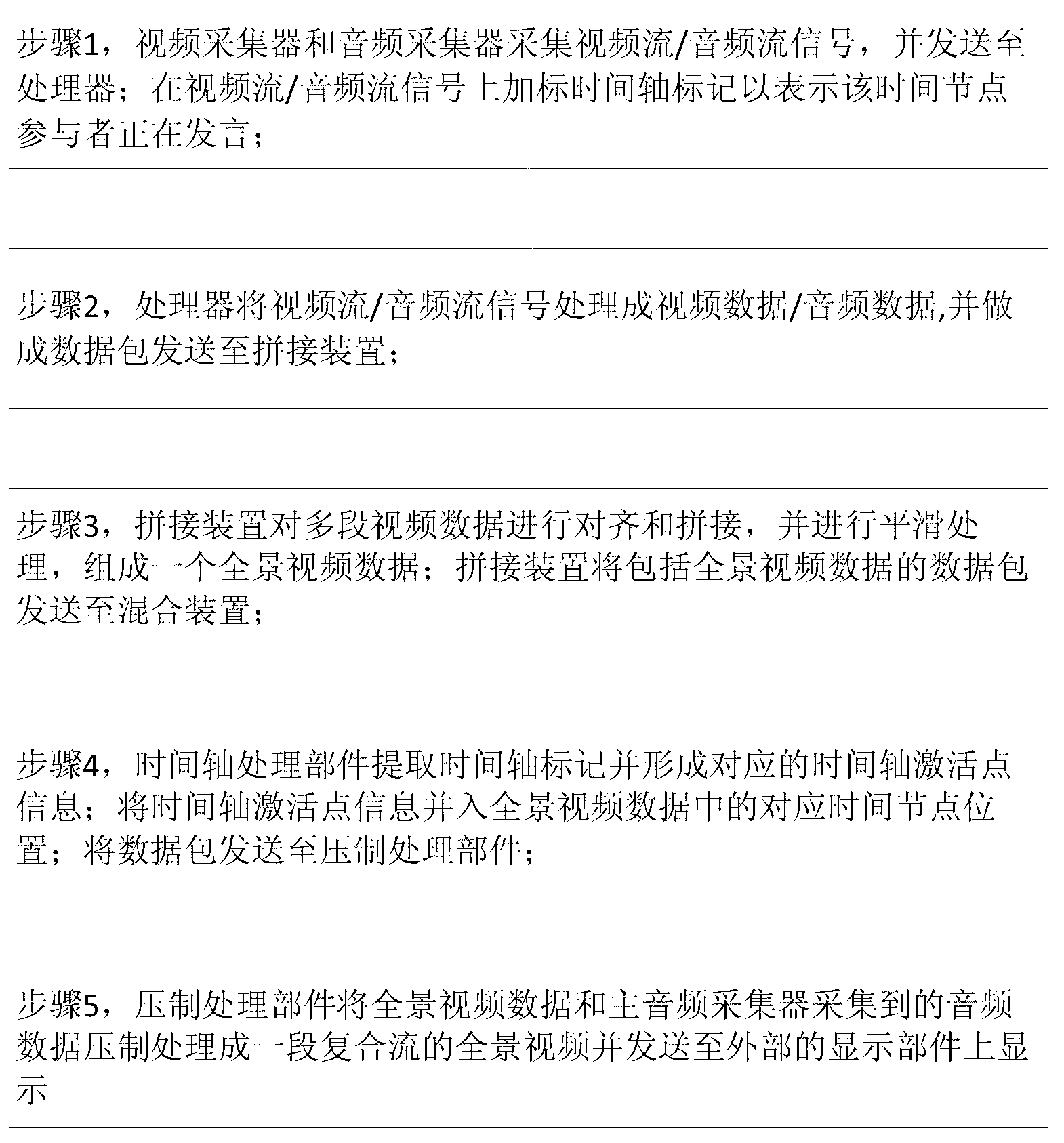

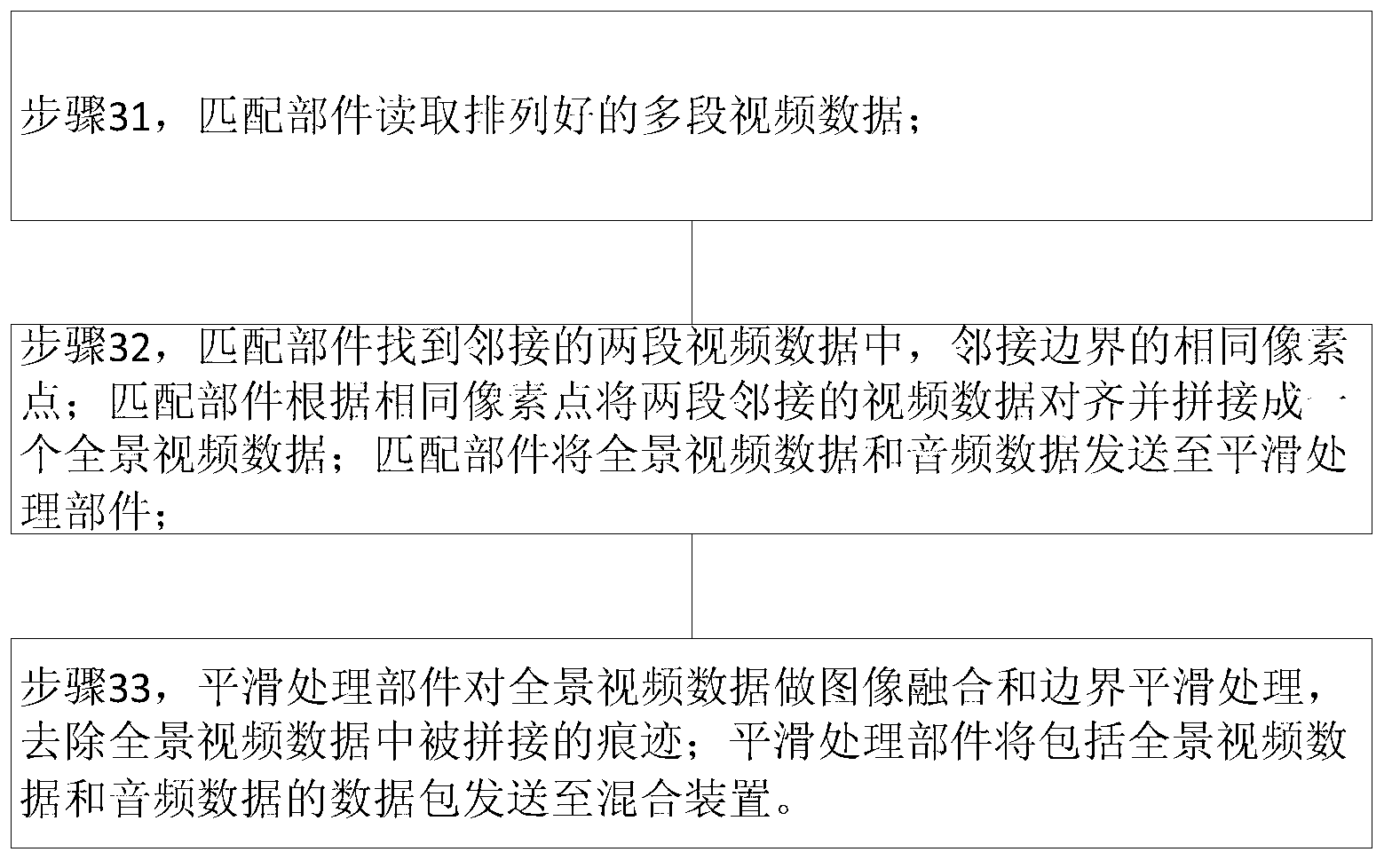

System and method for multi-media panorama recording

InactiveCN103297688AGood sense of substitutionComprehensive recording contentTelevision system detailsTelevision conference systemsRound tableComputer graphics (images)

The invention discloses a system and method for multi-medial panorama recording. The system comprises a recording device, a splicing device and a mixing device. The method comprises the steps of recording multi-segments of video data and voice frequency data, splicing the multi-segments of the video data into one segment of panorama video data, and adding time axis activation point information marking time nodes of speech of participators in the panorama video data; pressing the panorama video data and the voice frequency data into one segment of compound stream panorama video, and sending the panorama video to an outside display part for display. The technical scheme has the advantages of all-true simulating the information collecting process of an eye wide angle, realizing the mode of 360-degree panorama recording and playing, enabling recording contents to be more comprehensive, being capable of simulating on-site sense of round-table conference participators, and giving viewers better participating senses.

Owner:NINGBO SCI & TECH PARK DISTRICT JIETITECH

Process for forging rear axle shaft flange of automobile

ActiveCN101947634AUniform deformationIncrease productivityRailway componentsVehicle componentsRound tableDiameter ratio

The invention discloses a process for forging a rear axle shaft flange of an automobile. The process comprises the following steps of: heating a round bar to the temperature of between 1,150 and 1,250 DEG C; upsetting and blanking the round bar on a horizontal forging machine by using a mold cone cavity so as to form a rear axle shaft middle blank of the automobile, wherein the rear axle shaft middle blank of the automobile is provided with a round table-shaped part which has a thicker front part and a thinner rear part, the length-to-diameter ratio of the round table-shaped part is 0.9 to 1.5, and the diameter is an average diameter of the round table-shaped part; controlling time for an upsetting and blanking process; keeping the temperature of the rear axle shaft middle blank of the automobile to be between 1,000 and 1,100 DEG C; and performing pendulum grinding and molding on the rear axle shaft middle blank of the automobile directly on a pendulum grinding machine so as to obtain the rear axle shaft flange of the automobile. The process has the advantages of improving the production efficiency of forging the rear axle shaft flange of the automobile, along with small required blanking and forging equipment, a small amount of scale produced by heating a forging piece, better surface quality of the forging piece, and the uniform deformation and high dimensional accuracy of the forged rear axle shaft of the automobile.

Owner:DONGFENG COMML VEHICLE CO LTD

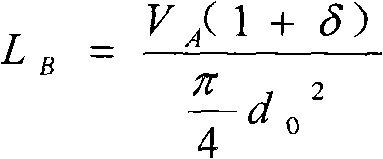

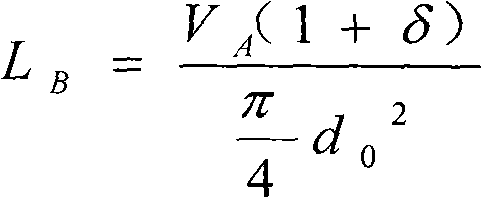

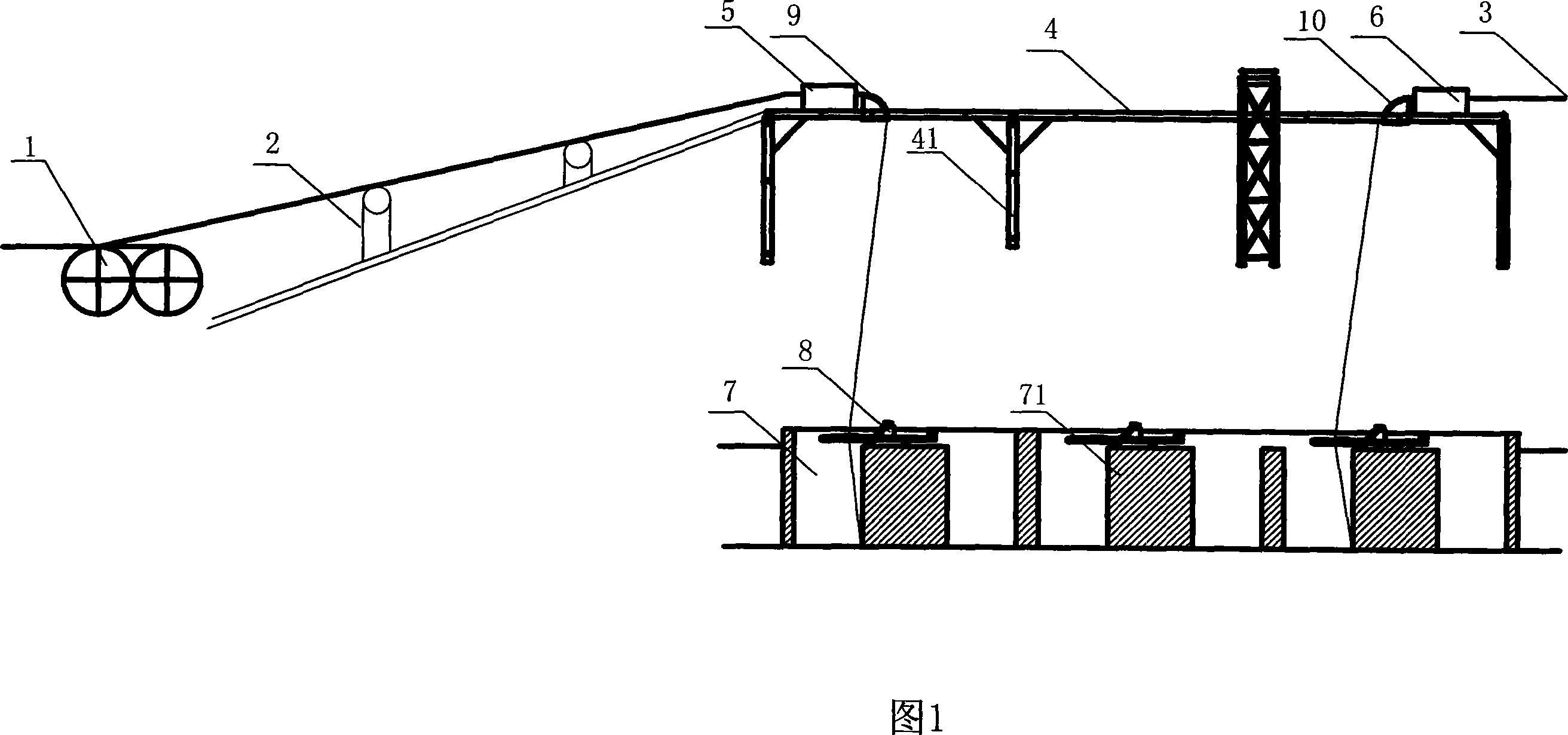

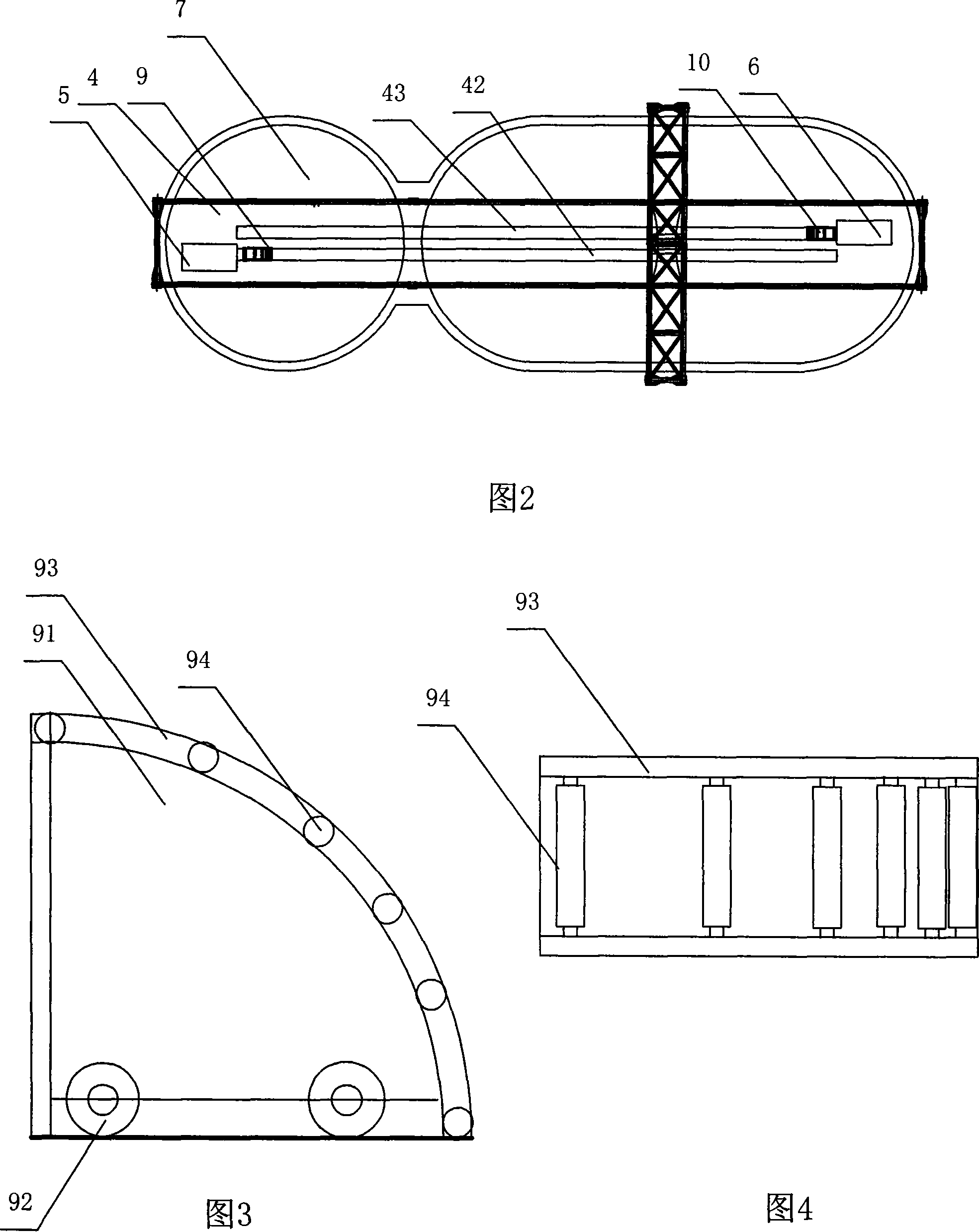

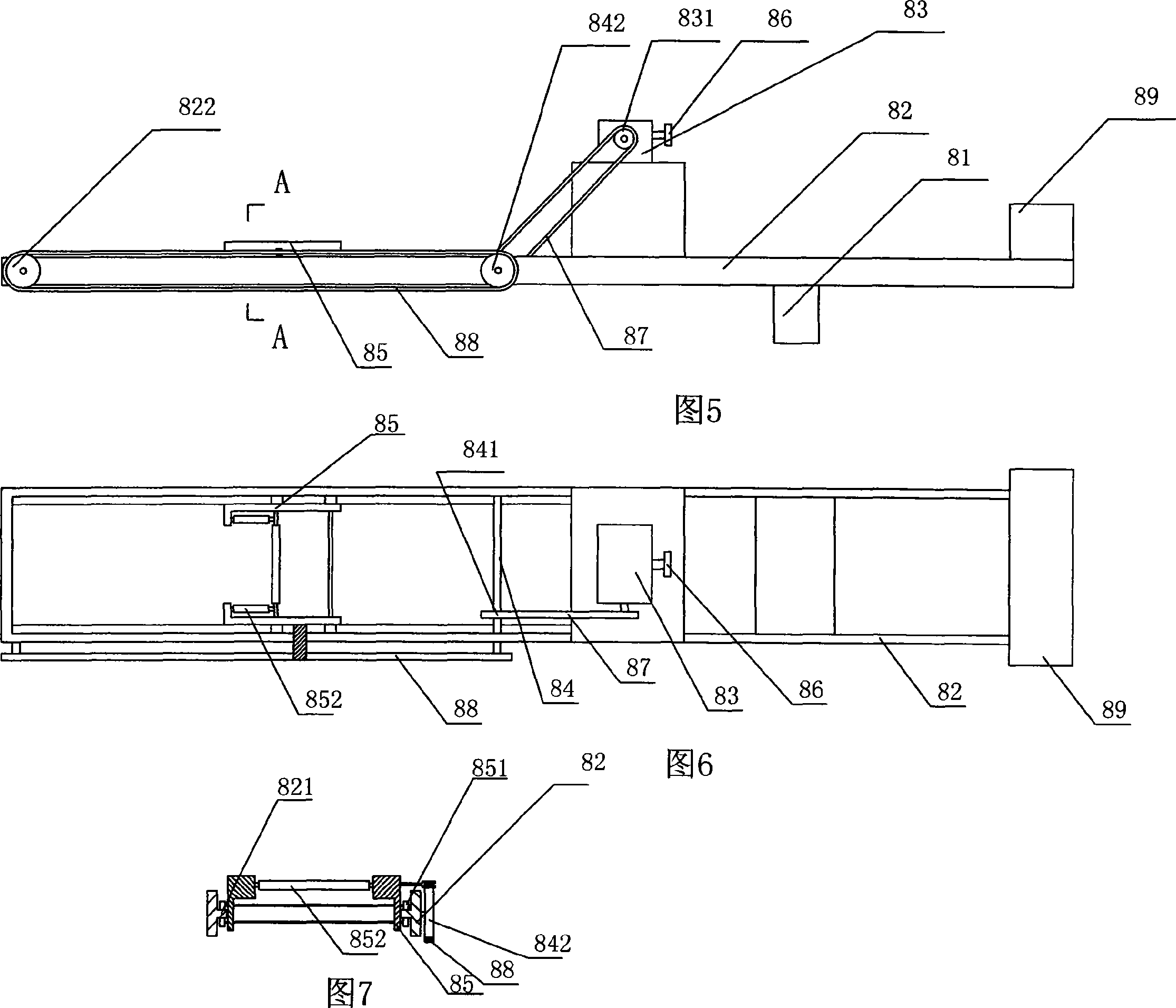

Submarine cable wire take-up and pay-off and boarding system

ActiveCN101071941AReduce labor intensityProtectCable installations on floatsCable-laying vesselsOcean bottomRound table

This invention discloses the board system and a submarine cable flaps Line, including the resumption of traction round, wire planes, cable embarkation devices and the supporting structures which set up a number of working platform, the working platform to set up a line traction installations and put online boat towing equipment, the working platform set up a number of cable beneath the pool, a cable winding circular pool set up Taiwan, characterized by at least two cable mutual Unicom is the pool, a round table set up wound a row of devices on the surface of the platform set up a parallel line to take line and missed trunkings leakage, or line leak trunkings and trunkings caving line leak on the same structure were set up with the first mobile arc frame and second mobile arc planes, Wound yen Taiwan counterparts at the top of the line leak trunkings next to a work platform, set up the first mobile location-arc structure, Taiwan counterparts Wound circle above the leakage trunkings caving line next to the work platform Arc set up a second mobile-positioning structure, the advantages can be stored longer submarine cable and at the same time cross-line operations conducted flaps.

Owner:宁波东方电缆股份有限公司

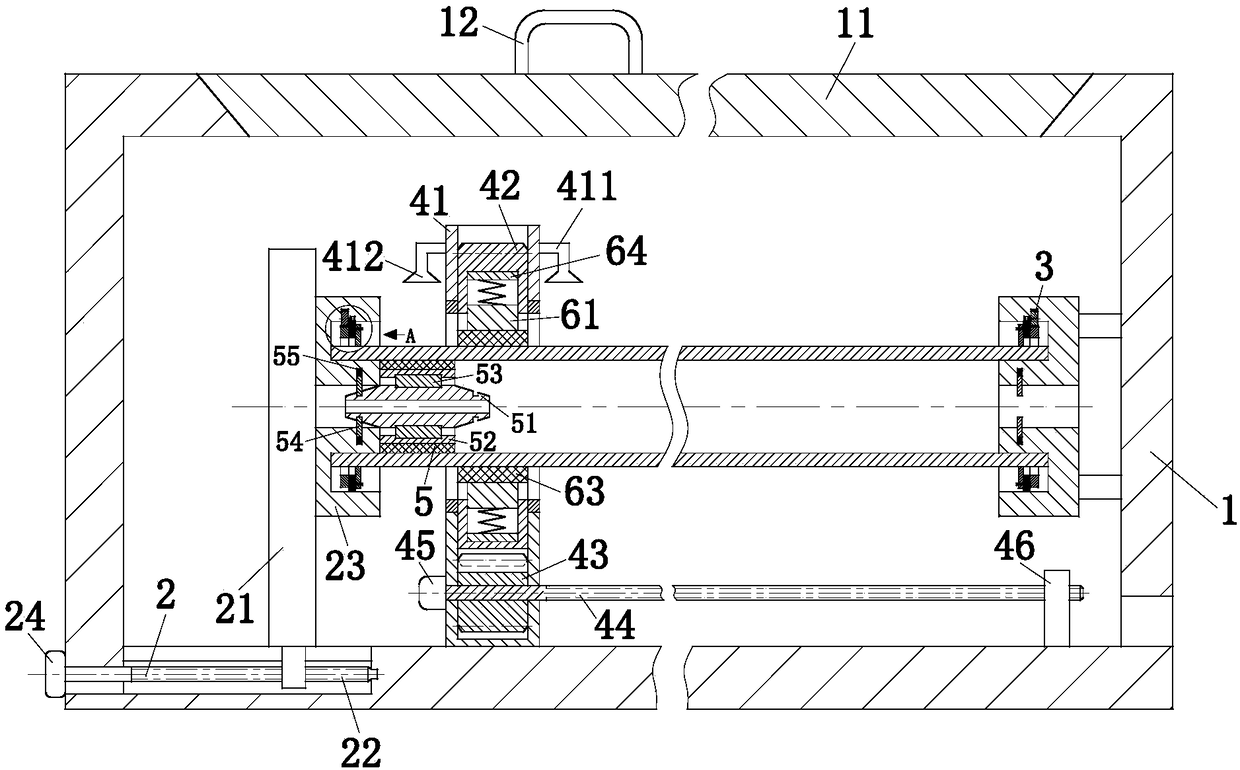

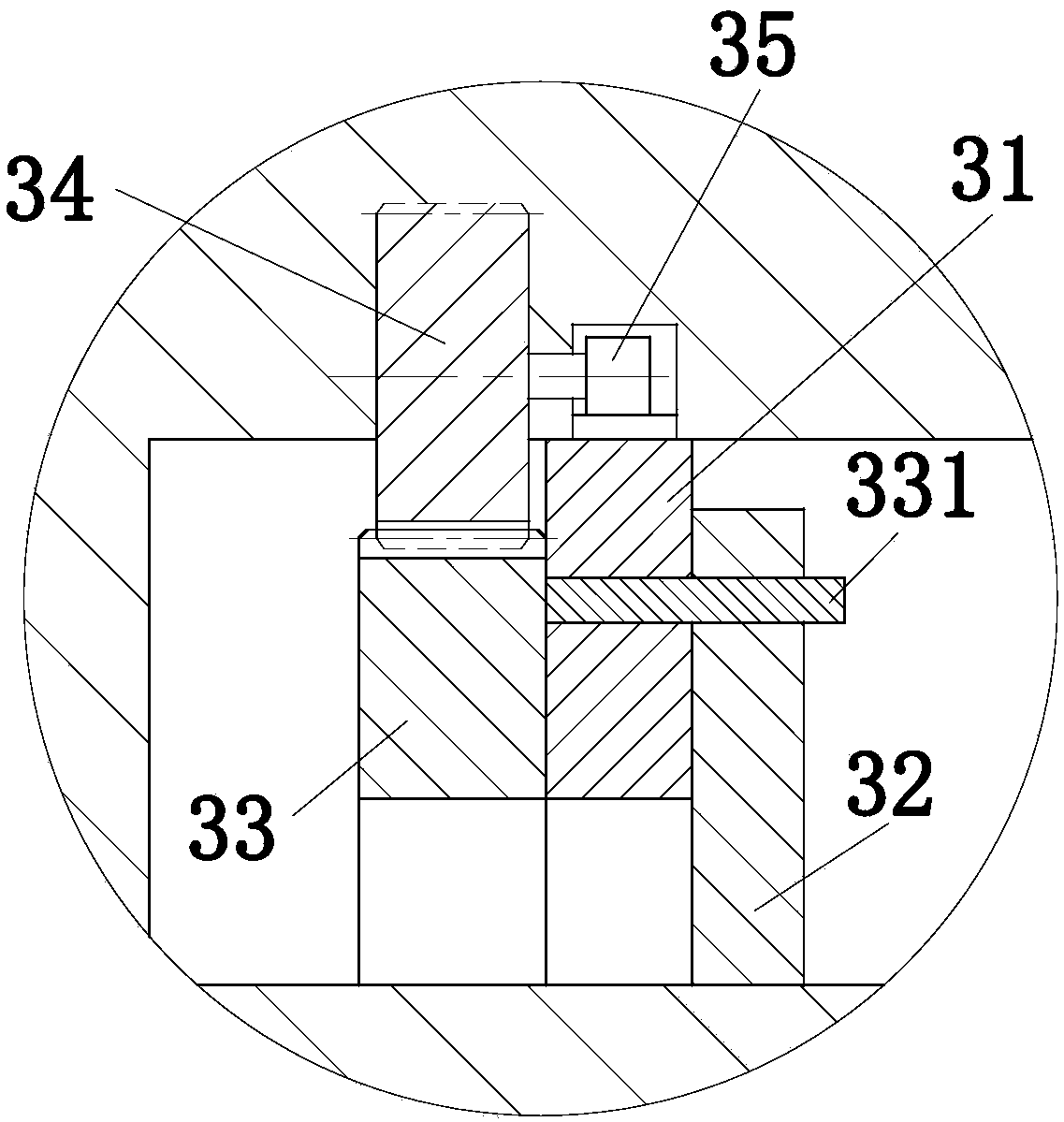

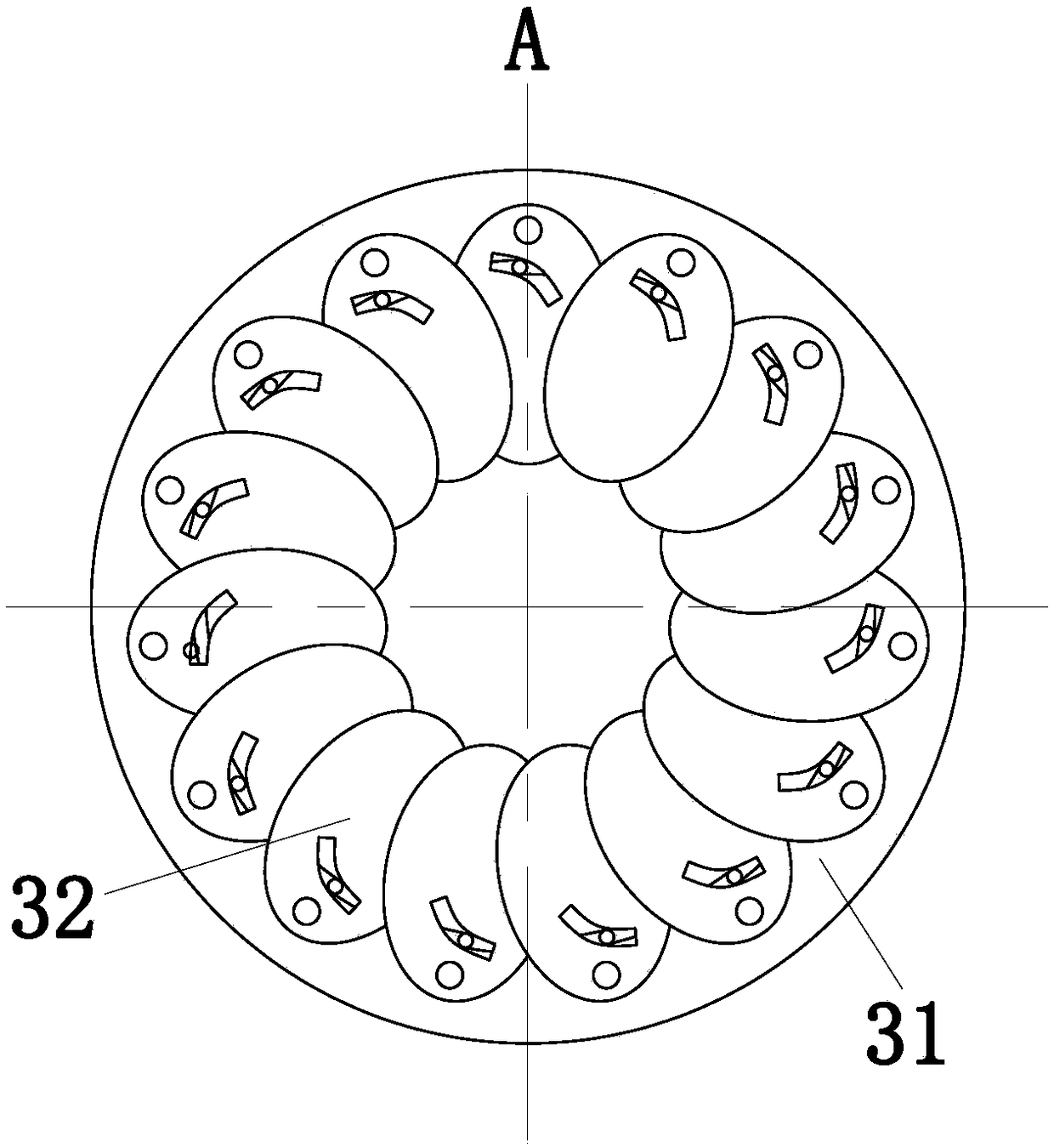

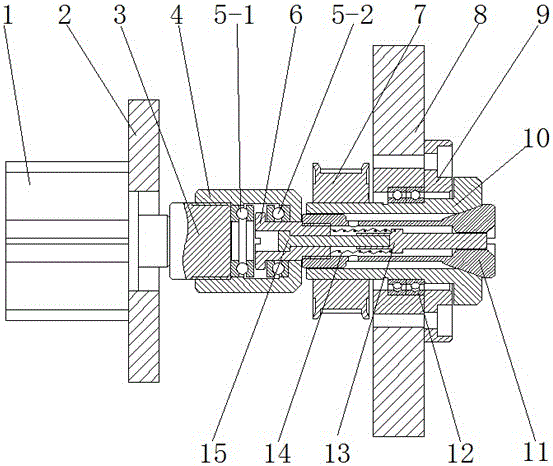

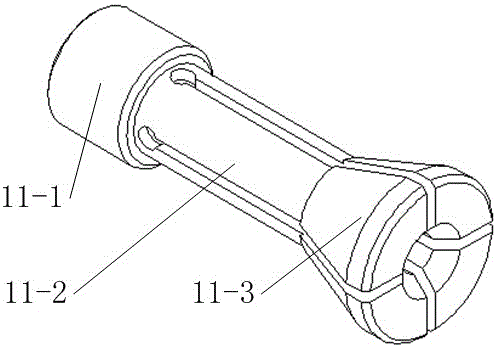

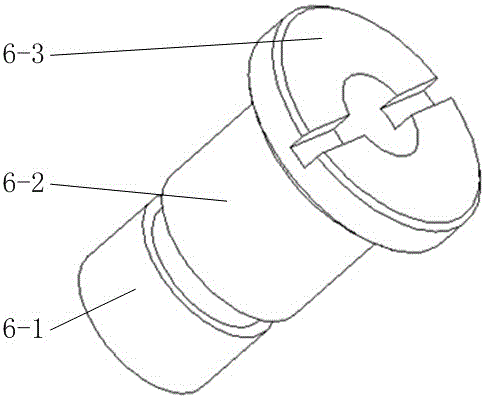

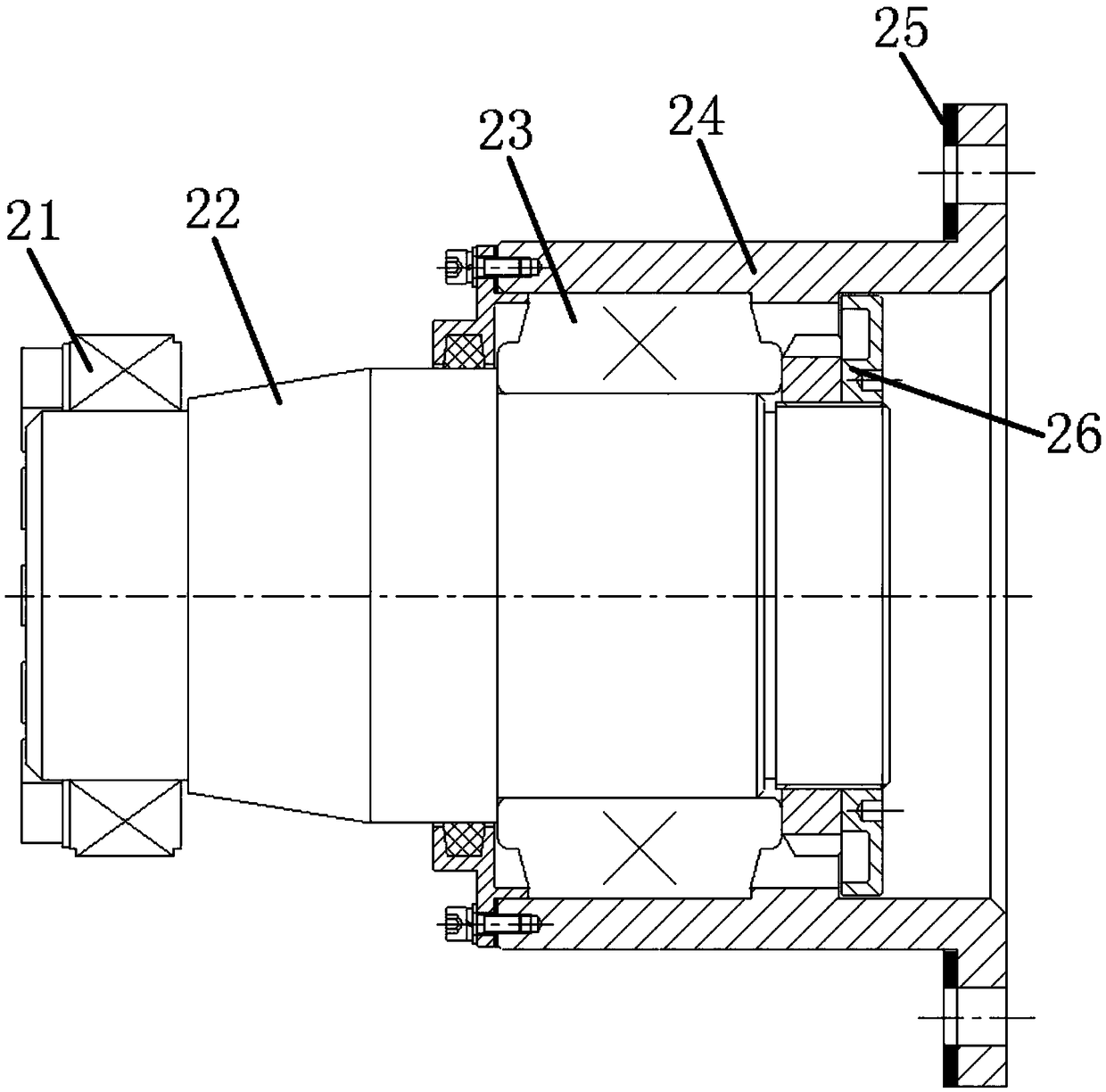

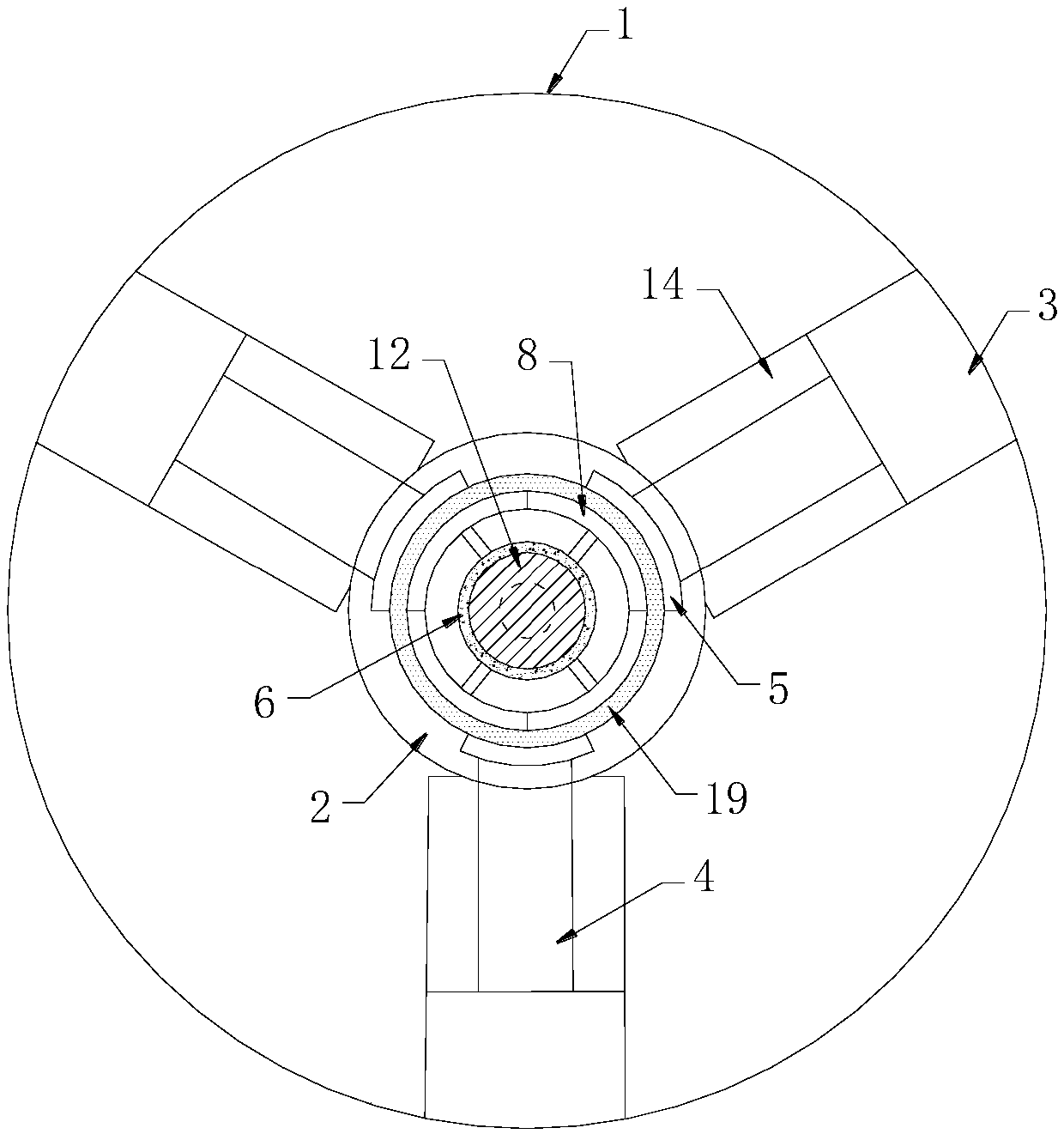

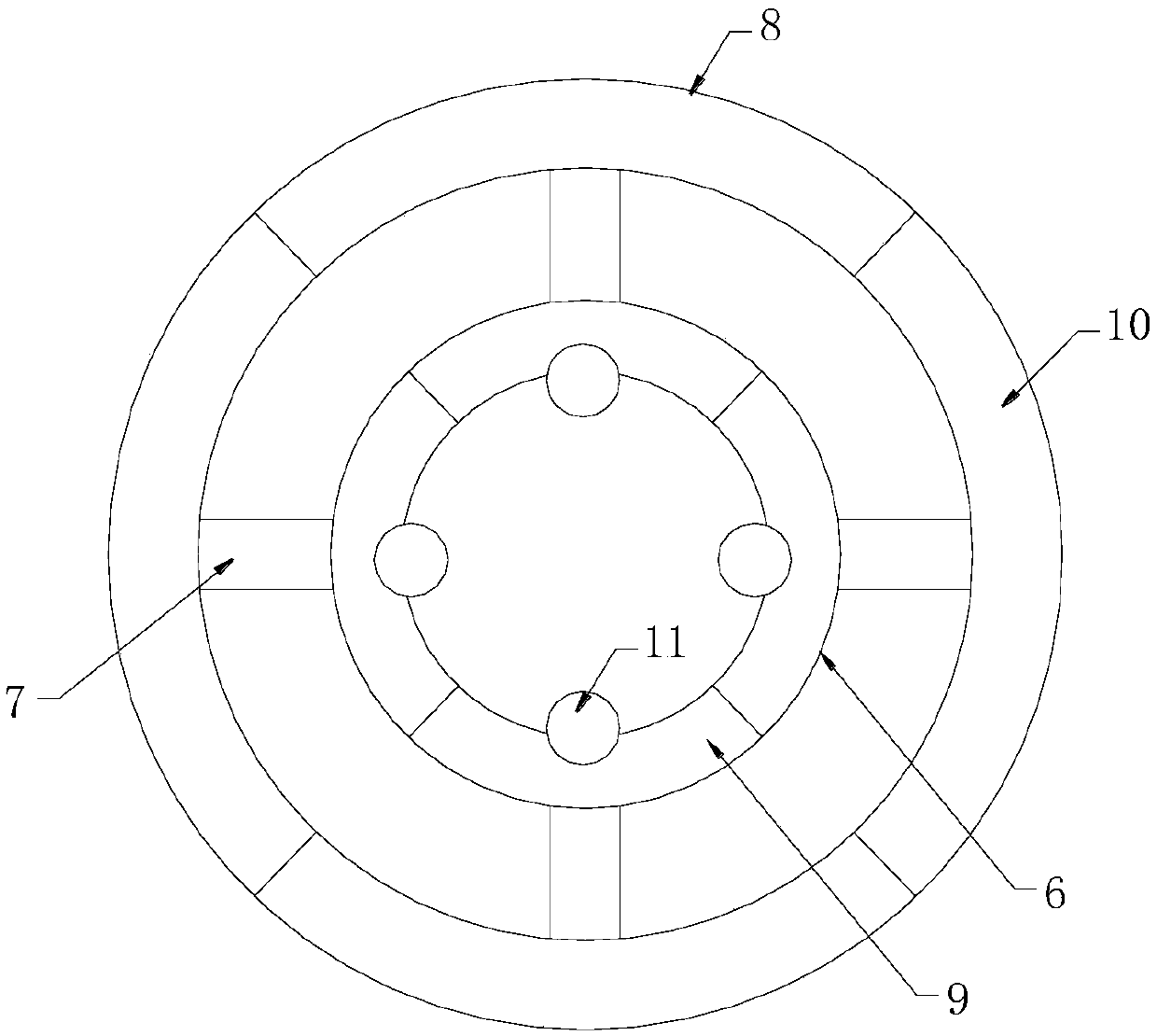

Clamping rotating device

The invention discloses a clamping rotating device. The device comprises a stretching mechanism, a clamping compressing mechanism and a rotating mechanism; during work, a workpiece is ejected in from a center through hole of a round table of an elastic clamping sleeve, a spring is compressed, an air cylinder is ventilated, the elastic clamping sleeve is forced to move along a bearing sleeve in the direction where the air cylinder is located, radial shrinkage is carried out, and the aim of clamping an object is achieved; a synchronous belt wheel does the rotation motion, and the elastic clamping sleeve and the workpiece are driven to jointly do the rotation motion; if the air cylinder carries out exhaust unloads, the elastic clamping sleeve is reset, and the spring is automatically reset and meanwhile ejects out the workpiece. Stable clamping and rotating of the workpiece can be achieved, the problem that due to double clamping grasping, clamping stability is poor, and clamping force is not enough is solved, the control manner that the air cylinder is combined with a mechanical mechanism is adopted in the device, operation is convenient, and the cost is saved.

Owner:NANJING UNIV OF SCI & TECH

External floating top vertical metal can volume measuring method based on three-dimensional laser scanning technology

ActiveCN103389136AEasy accessGuaranteed measurement accuracyContainer/cavity capacity measurementRound tableFast measurement

The invention discloses an external floating top vertical metal can volume measuring method. According to the method, firstly, complete three-dimensional point cloud data are obtained through adopting a multi-station scanning and splicing mode at the upper and lower parts of a floating disc; and then, the integral thought is utilized, the can wall point cloud data are cut and are divided into a plurality of small cylinders, and the volumes of the small cylinders are calculated and are superimposed for obtaining the total volume. Through fitting the point cloud coordinate data of each small cylinder at the height parts, the girth sheet radius is obtained, and further, the area of the bottom of the cylinder is calculated; the cylinder volume is calculated according to the obtained height; and meanwhile, the temperature and gradient correction is introduced. The bottom volume calculation adopts an equal-area circle dividing mode, the volume of each round table body and each middle cone is calculated, and the obtained total displacement is superimposed. The method has the advantages that the operation is simple, the safety is high, the work intensity is low, the fast measurement of large-sized external floating top vertical metal cans can be realized, the data processing is convenient, the accuracy is high, meanwhile, the metrological verification cost is greatly reduced, and certain economic benefits are brought.

Owner:CHINA JILIANG UNIV

Three-degree-of-freedom turning frame system applied to dynamic flight simulator of helicopter

ActiveCN108766101ARealize pitching motionRealize three degrees of freedom rotationCosmonautic condition simulationsSimulatorsRound tableThree degrees of freedom

The invention discloses a three-degree-of-freedom turning frame system applied to a dynamic flight simulator of a helicopter. A rolling and turning frame is connected with a manned cabin in a rotatable manner to realize pitching motion of the manned cabin; a yawing frame is connected with the rolling and turning frame in a rotatable manner to realize rolling and turning motion of the manned cabin;the yawing frame is connected with the tail end of a turning arm of a centrifugal machine through a bearing to realize yawing motion of the manned cabin, so that the manned cabin rotates in three degrees of freedom in a centrifugal field; the rolling and turning frame and the manned cabin as well as the rolling and turning frame and the yawing frame are respectively connected through expansion sleeves; furthermore, a power system is mounted on a shaft sleeve; the shaft sleeve is mounted in a shaft hole. The structural cooperation is relatively easy to mount and dismount; due to the design ofa round table structure on a pin shaft and a conical surface in the shaft hole, the pin shaft can be automatically guided and located during mounting, and the cooperation precision is high.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

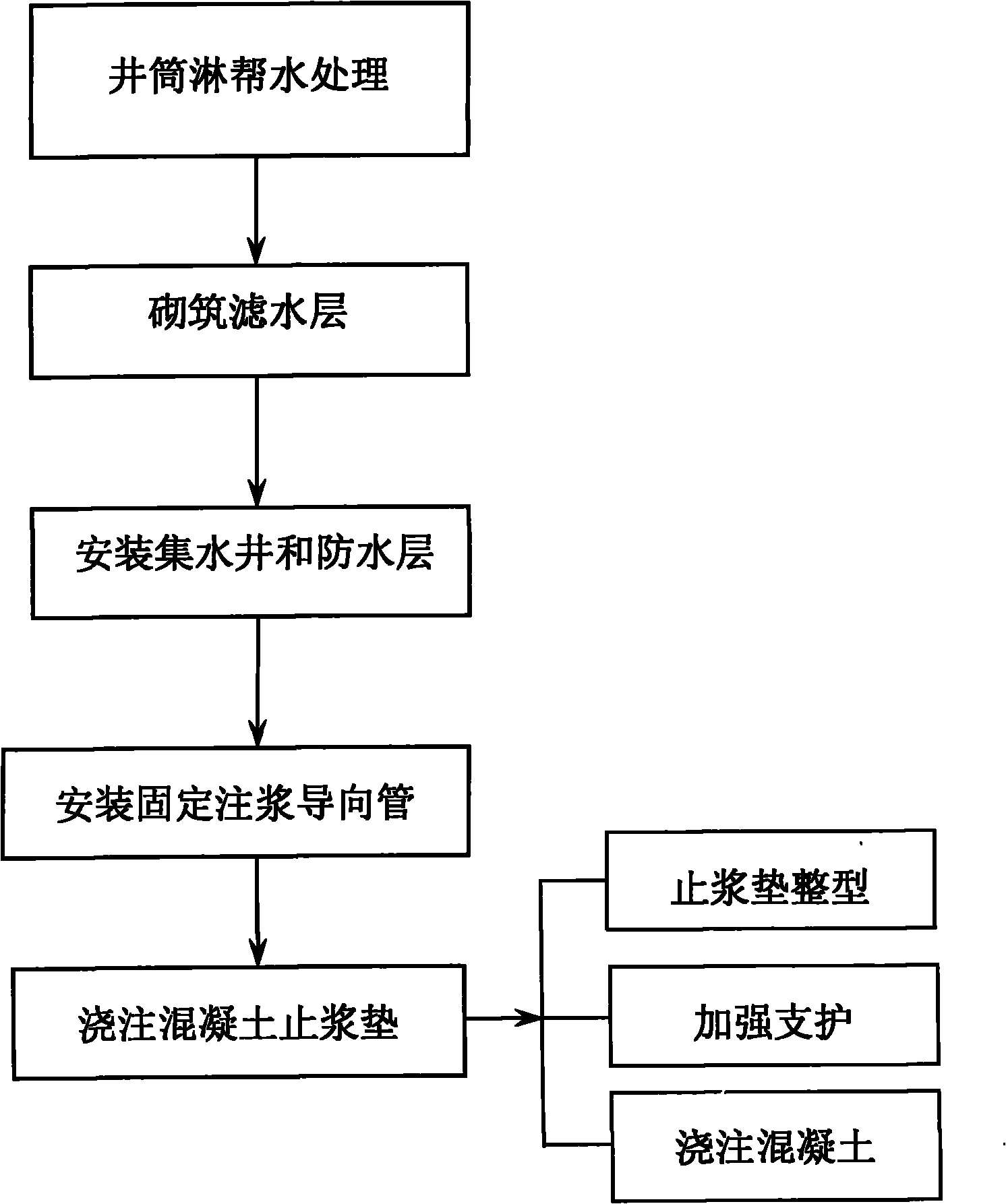

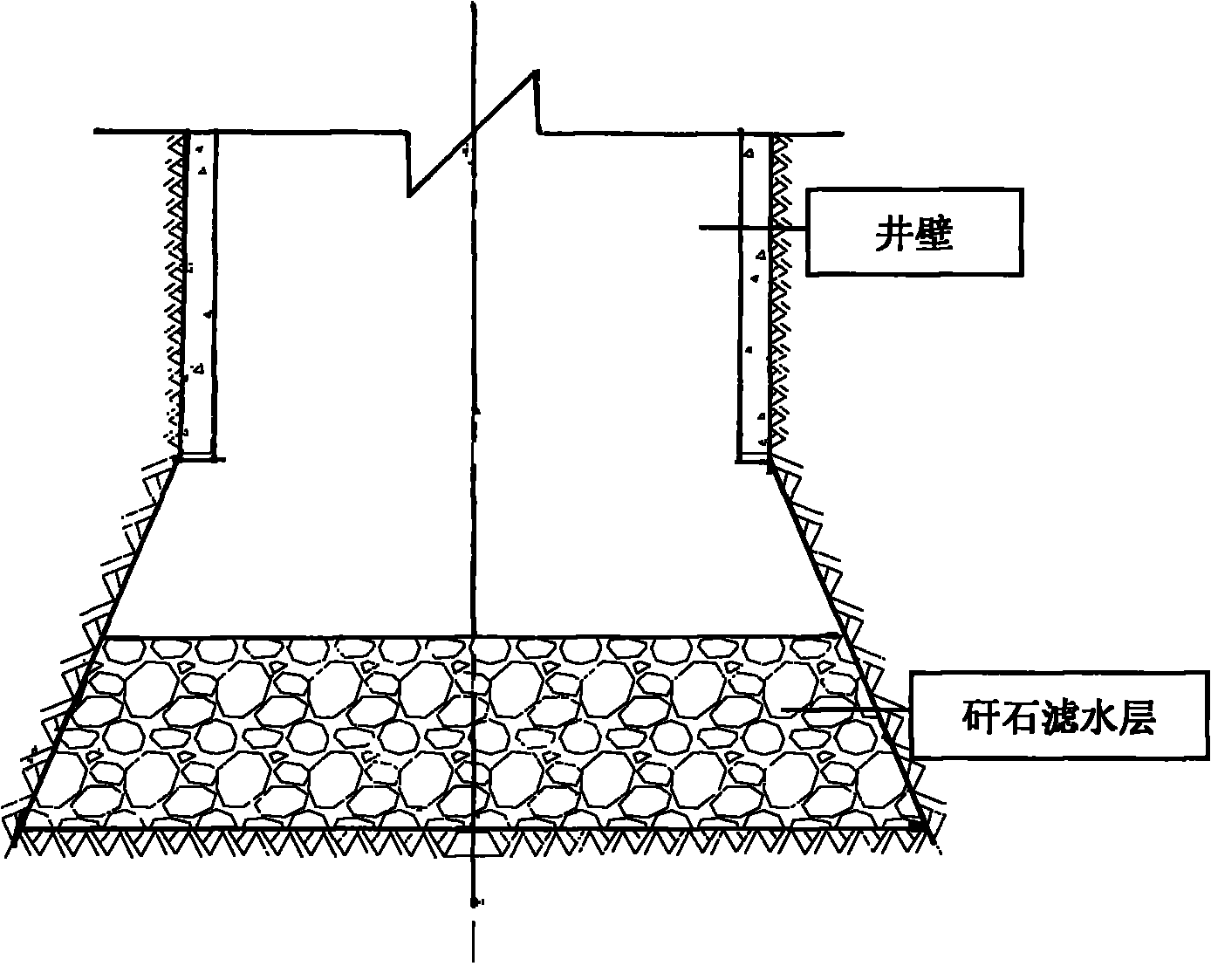

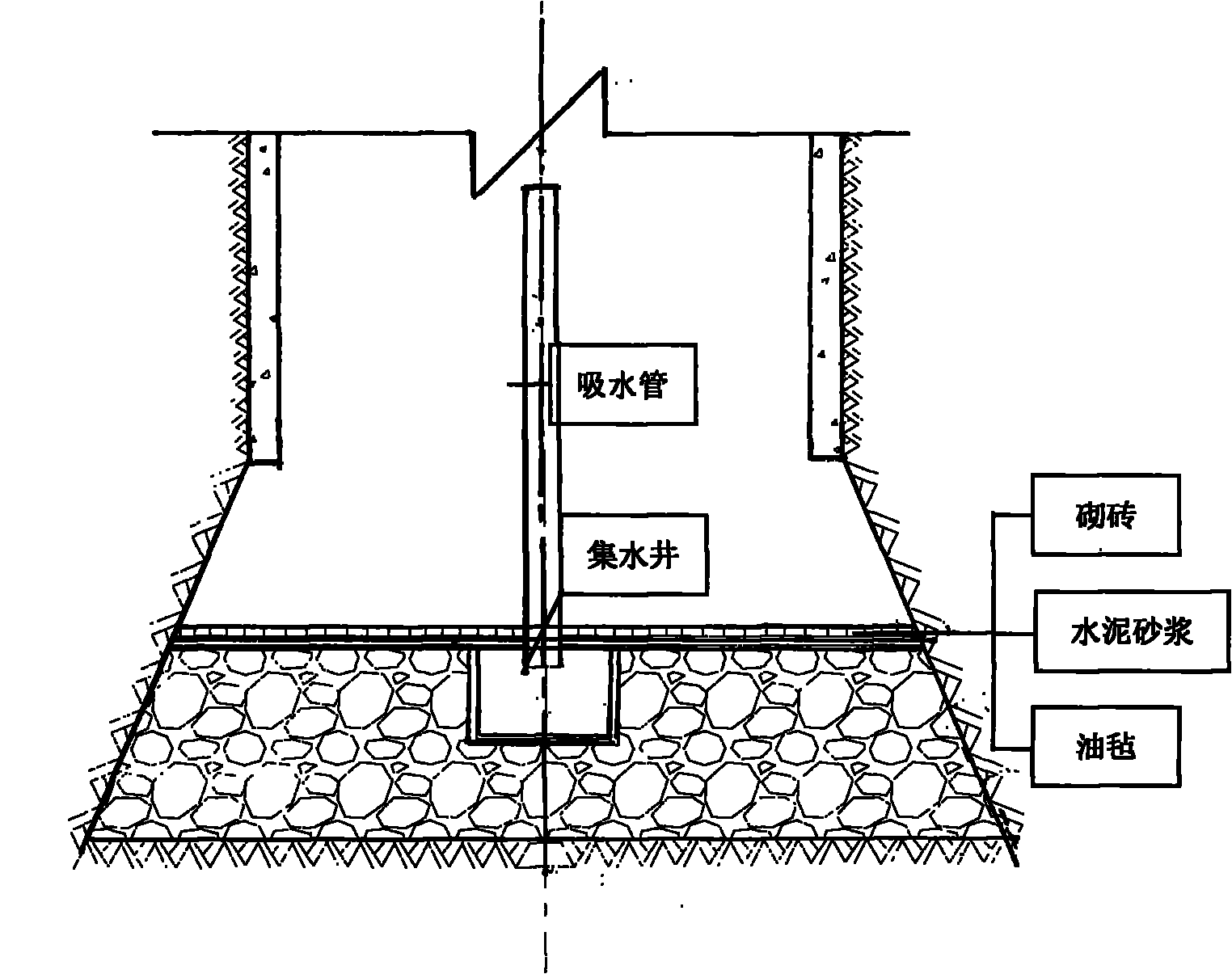

Grout stop pad construction method for kilometer vertical shaft grouting for water control

The invention discloses a construction method for pouring a round-table-shaped grout stop pad in kilometer vertical shaft grouting water-control construction process, comprising the following steps: shaft pouring water treatment, building a water filtering layer, installing a water collecting well and a waterproof layer, installing and fixing a grouting guiding pipe, and pouring a concrete grouting pad, wherein in the step of shaft pouring water treatment, grouting is carried out behind the wall; for the step of installing the water collecting well and the water filtering layer, a space with certain volume is preserved at the medium and upper part of the water filtering layer for installation of a bottomless water-filtering wood tank, then, the steps of paving felt, pouring cement mortar and building a layer of bricks are carried out at the upper part of the water filtering layer from bottom to top in sequence; and in the construction of pouring the concrete grouting pad, the grouting pad and the well wall are tightly fitted through pouring. In the whole construction process disclosed by the invention, the bearing capability of the well wall is fully utilized to confine an aquifer so as to ensure that grout is poured into fractures of the aquifer by using maximum grouting pressure, thus the grouting water-plugging effect under high water pressure and high grouting pressure is ensured in a kilometer vertical shaft construction process, the thickness of the grouting pad is reduced to the maximal extent, and the grouting construction speed is increased.

Owner:SHANDONG UNIV OF SCI & TECH

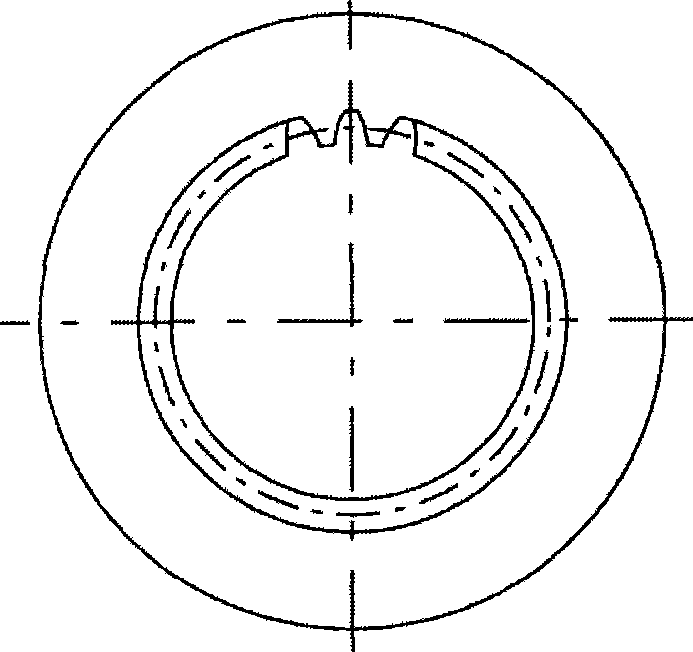

Thin part machining fixture

PendingCN109623447AReduce deformation rateSolve the deformationPositioning apparatusMetal-working holdersRound tableEngineering

The invention discloses a thin part machining fixture. The machining fixture comprises a main base, a machining table, a plurality of external clamping mechanisms and a cylinder clamp inside support;the machining table is arranged in the center of the main base; the plurality of external clamping mechanisms are arranged on mounting seats distributed around the main base; the cylinder clamp insidesupport is arranged in the center of the machining table; each external clamping mechanism comprises an air cylinder, an extendable shaft and an external clamping curved block, wherein one end of theextendable shaft is connected with the air cylinder, and the other end of the extendable shaft is fixedly connected with the external clamping curved block; the cylinder clamp inside support includesan inner extendable ring, a connecting shaft and an inner supporting ring; the inner extendable ring is composed of a plurality of inner curved clamps; the inner supporting ring is composed of a plurality of inner support curved blocks; the number of the inner curved clamps and the number of the inner support curved blocks are equal, and each inner curved clamp and each inner support curved blockare connected into a whole through the corresponding connecting shaft; and balls are arranged on the inner side of the plurality of the inner support curved blocks in a rolling mode, and the balls are matched with ball grooves embedded in a round table type regulating mechanism.

Owner:上海卢宏精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com