Patents

Literature

216results about "Cable-laying vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

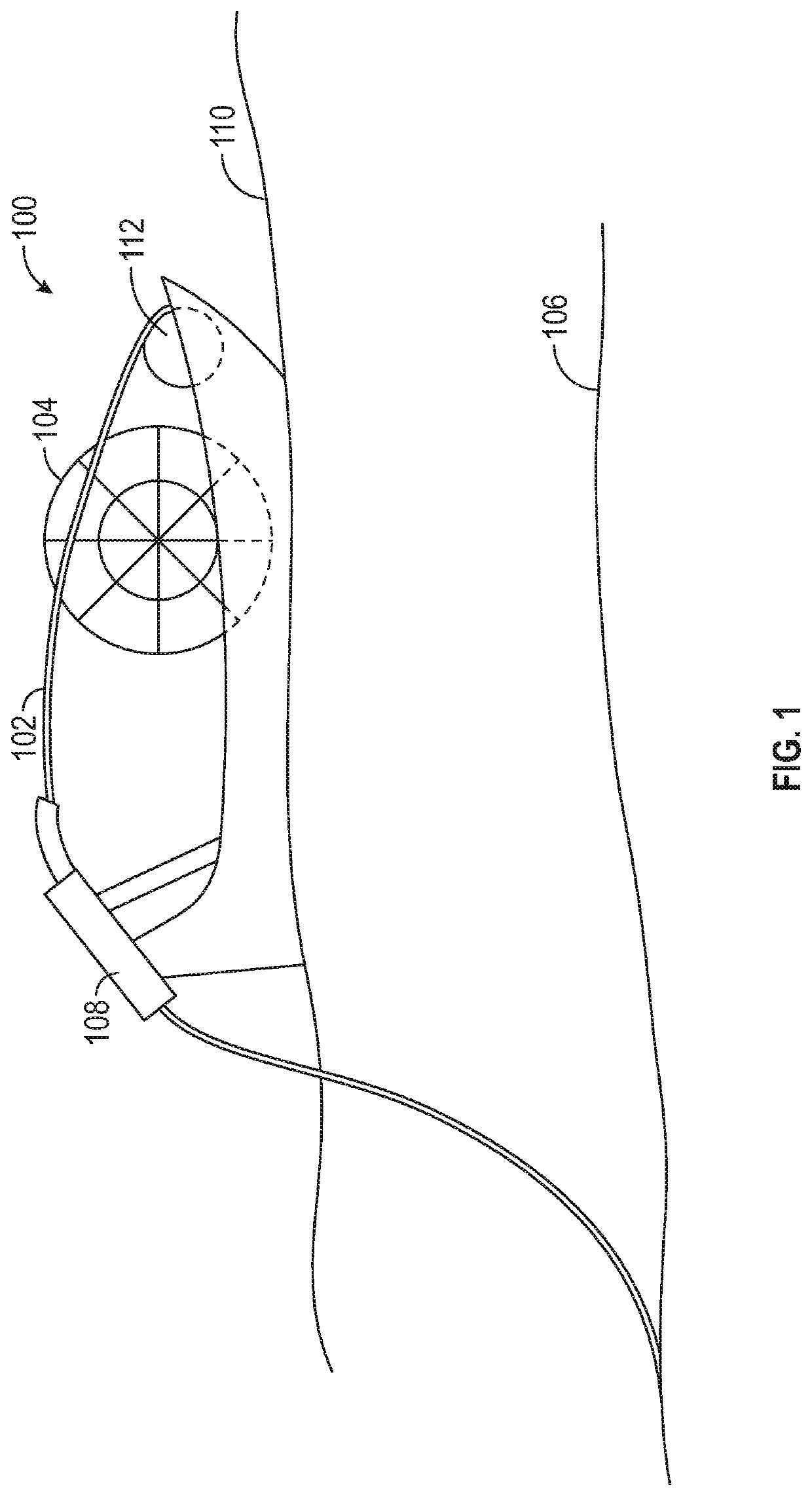

Cable deployment system and method of using same

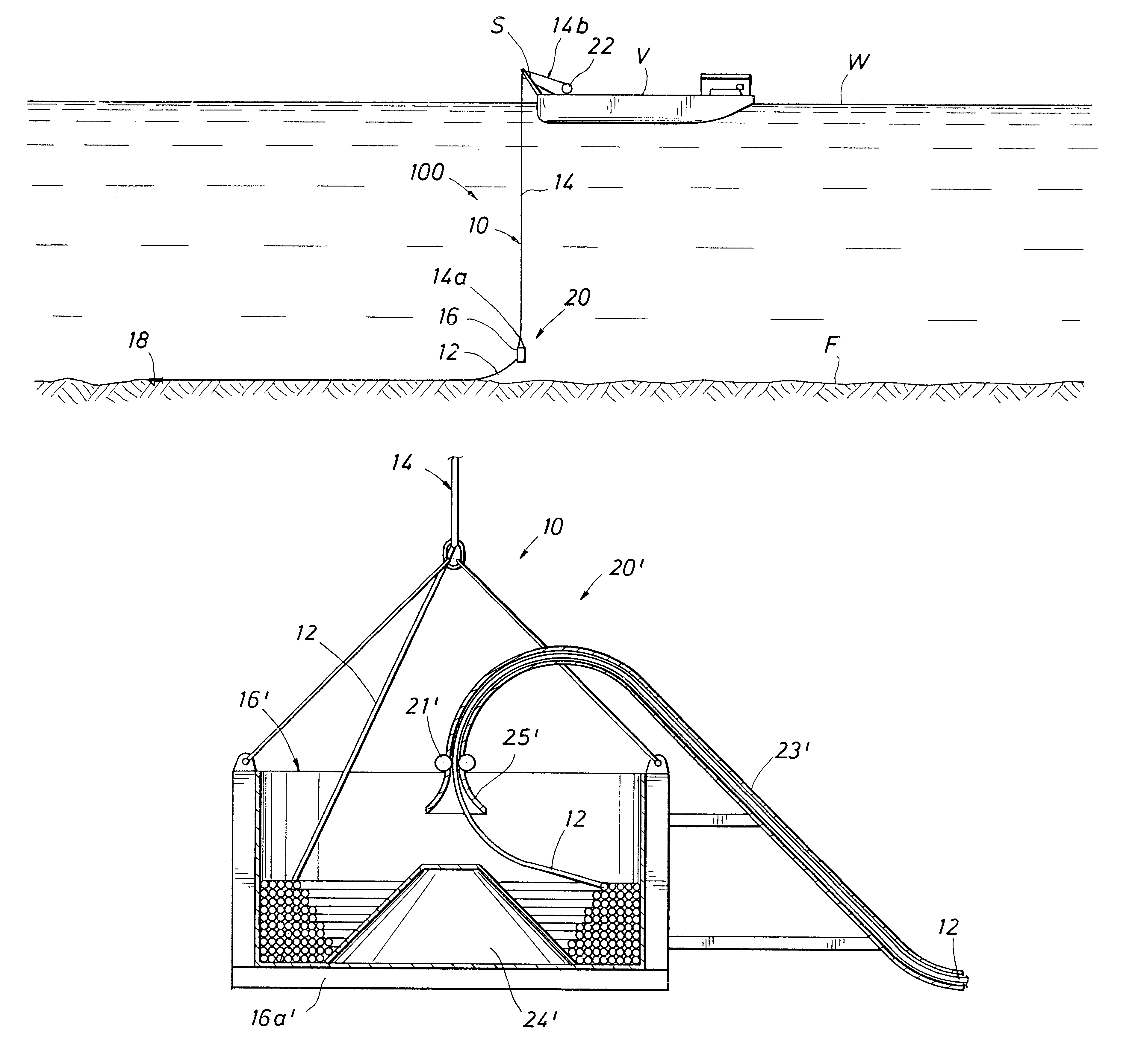

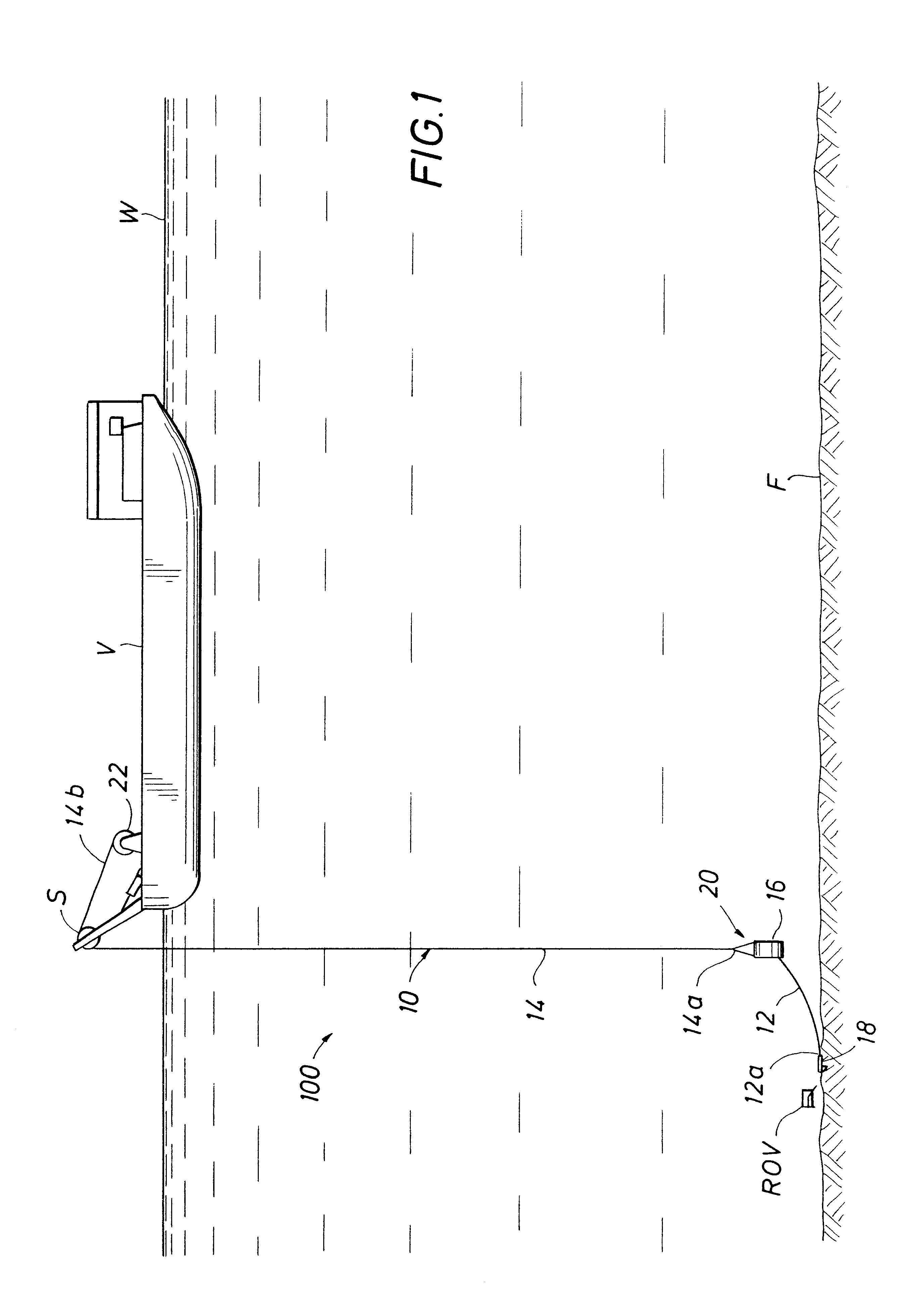

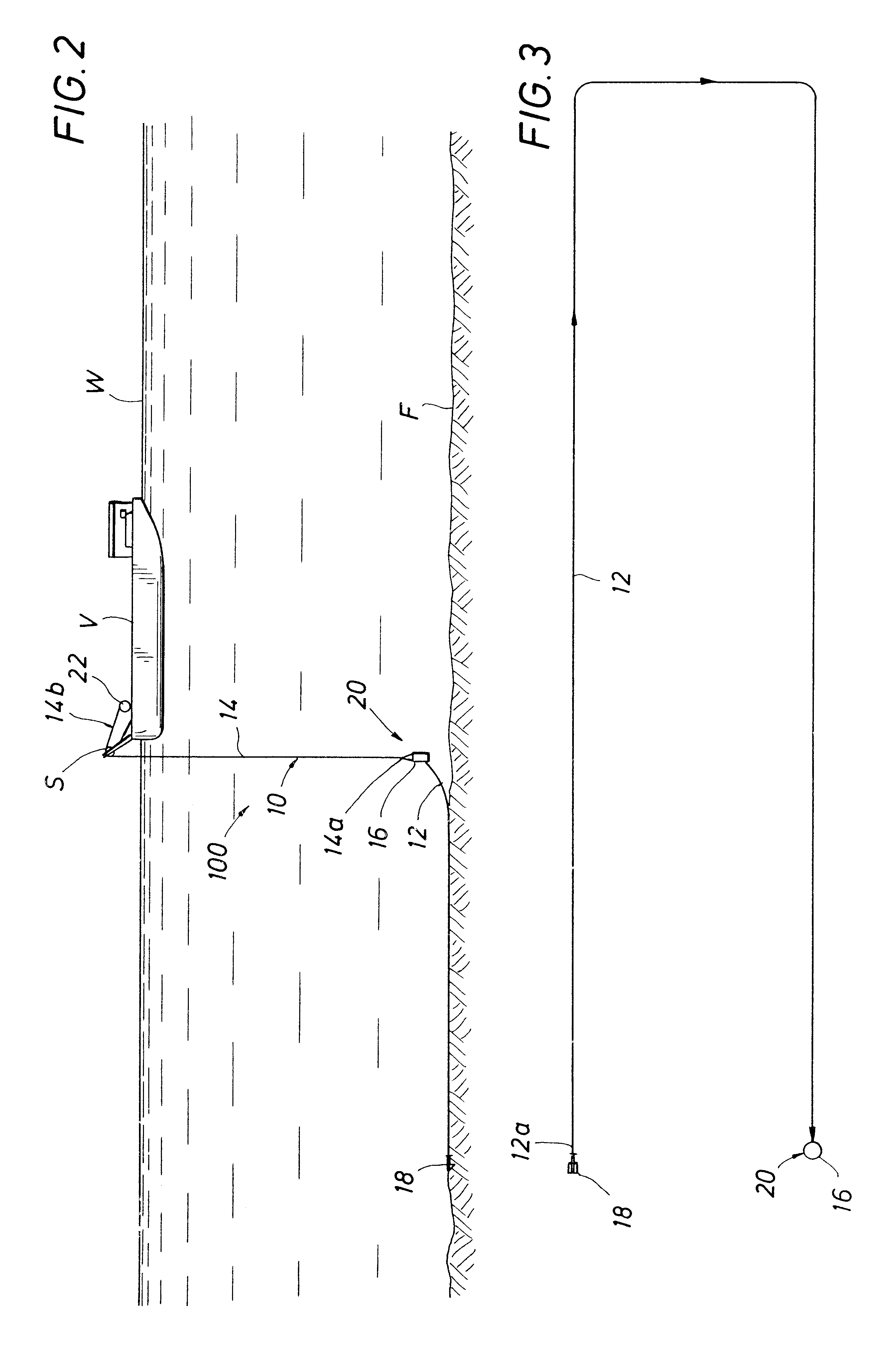

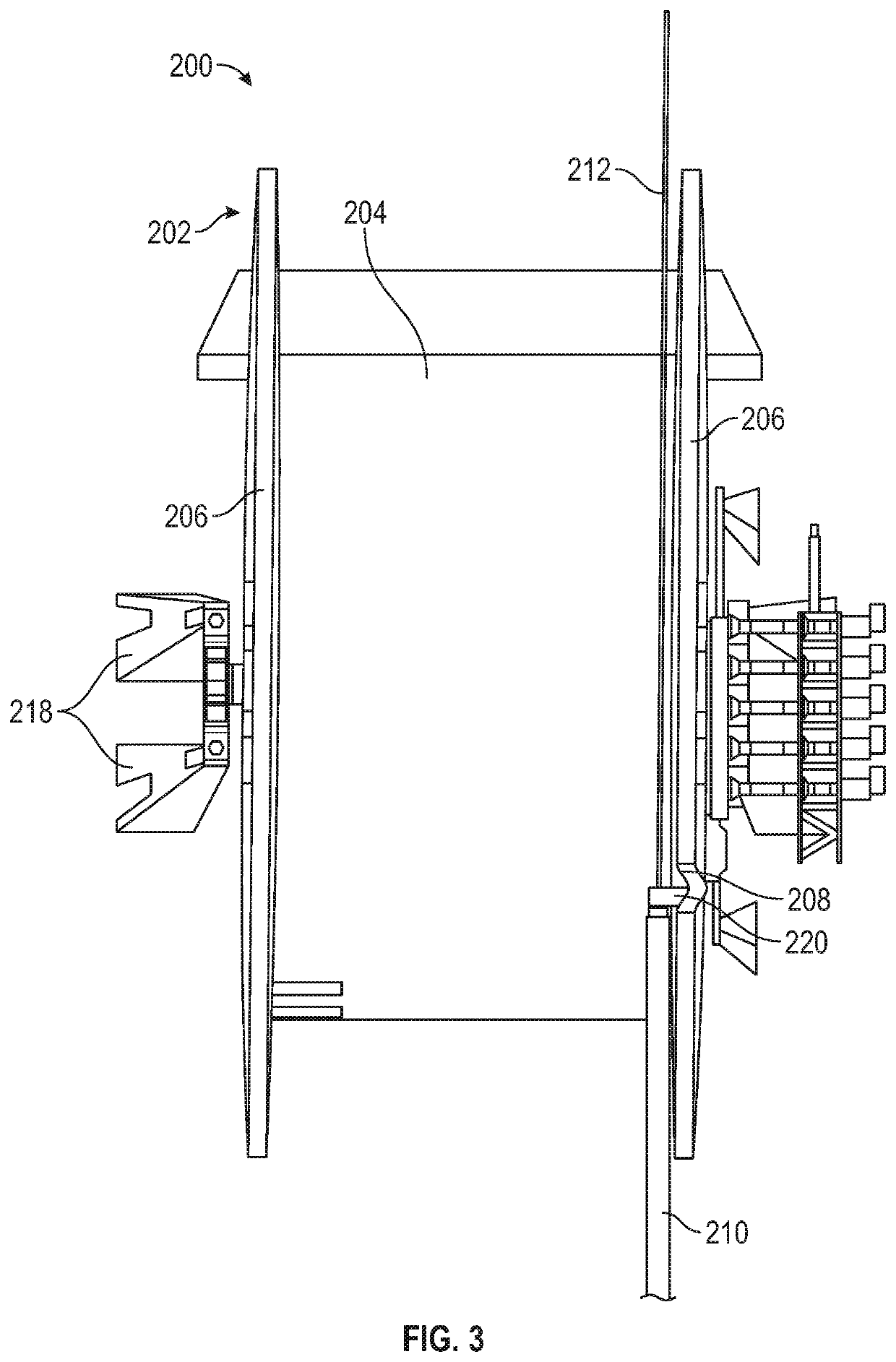

A cable deployment system and method for laying a cable on the sea floor. The cable deployment system includes a cable having a first cable section connected to a riser cable section. The riser cable section includes an armor that is connected to a drum capable of containing a required length of the first cable section. A stinger is attached to the drum and shaped to allow the first cable section to exit the drum. The cable deployment system also includes a tensioning device attached to the drum. The tensioning device is capable of maintaining a tension in the first cable section during deployment of the first cable section from the drum. The method of deploying the cable in deep water from a surface vessel includes the steps of containing the first cable section within the drum and lowering the drum from the surface vessel. An end of the first cable section is secured to the sea floor and the first cable section is deployed from the drum onto the sea floor.

Owner:SAIPEM AMERICA

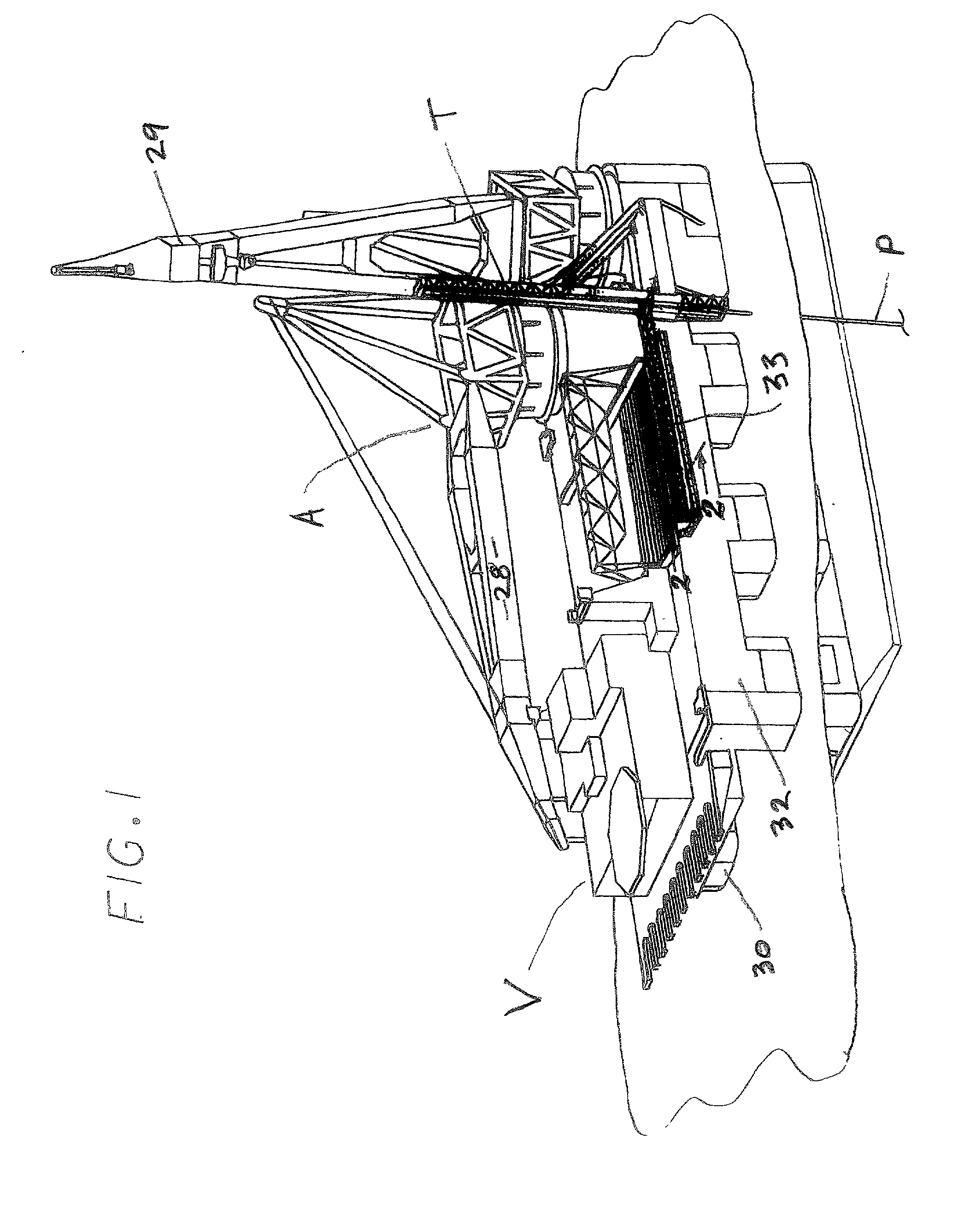

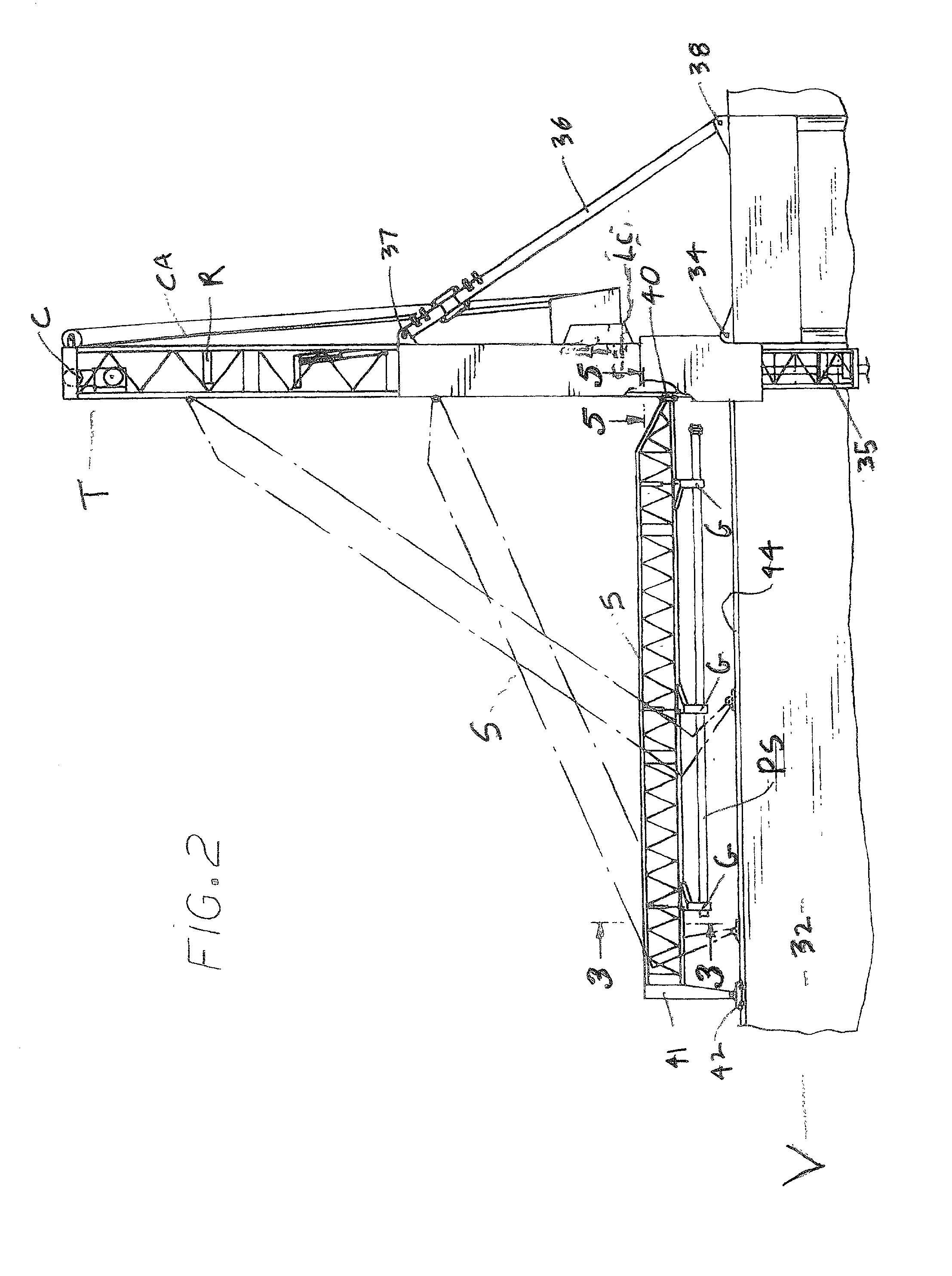

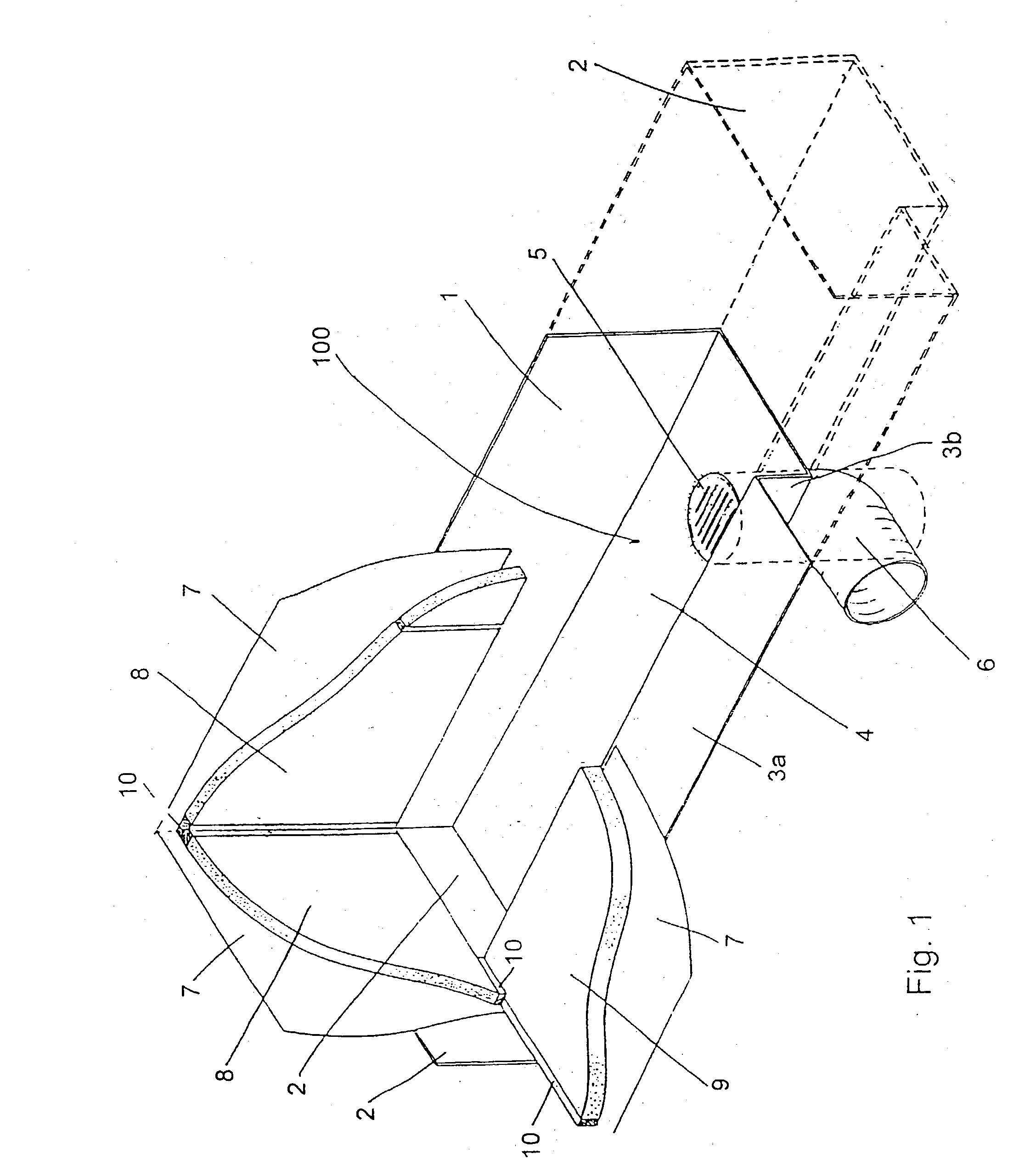

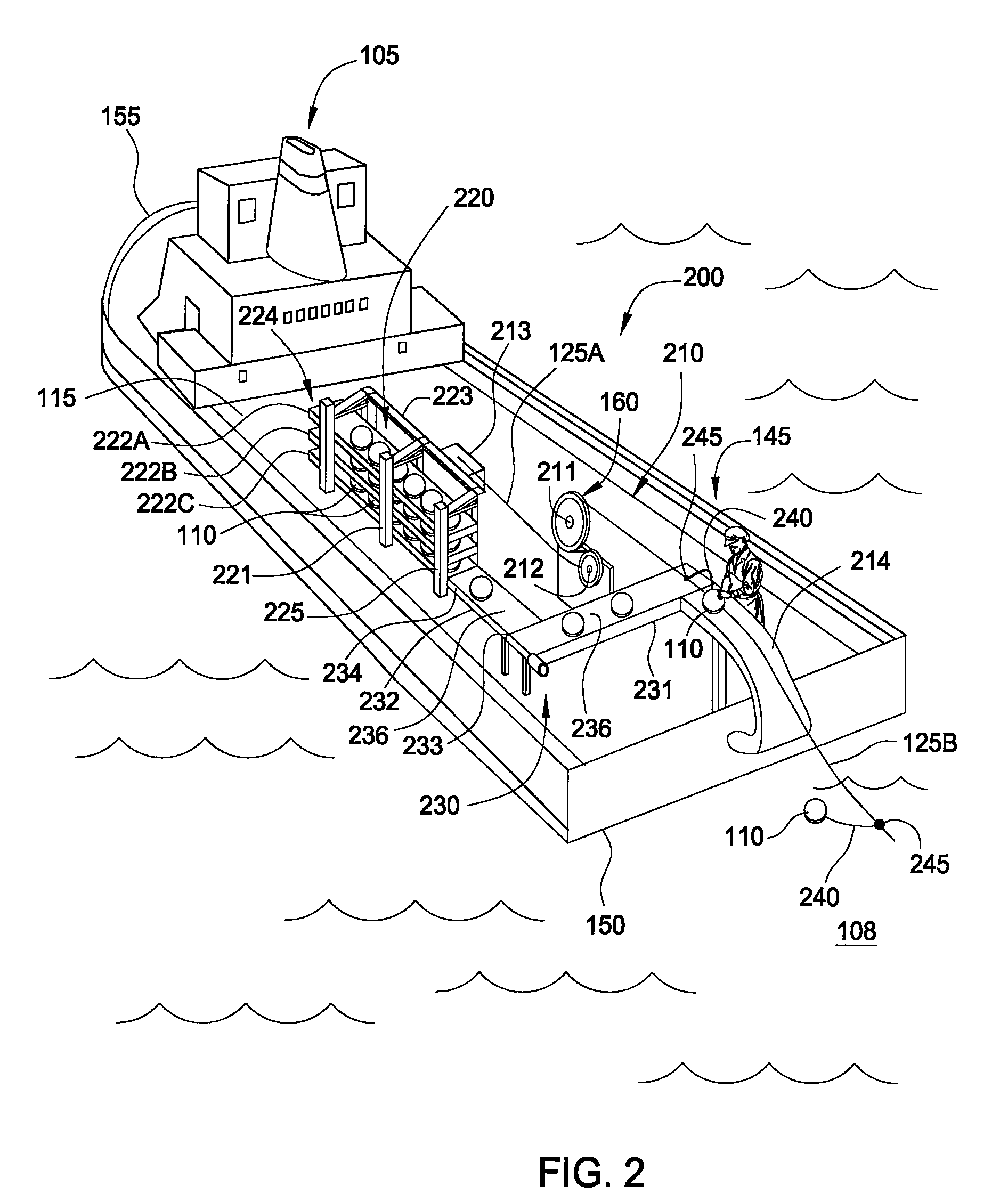

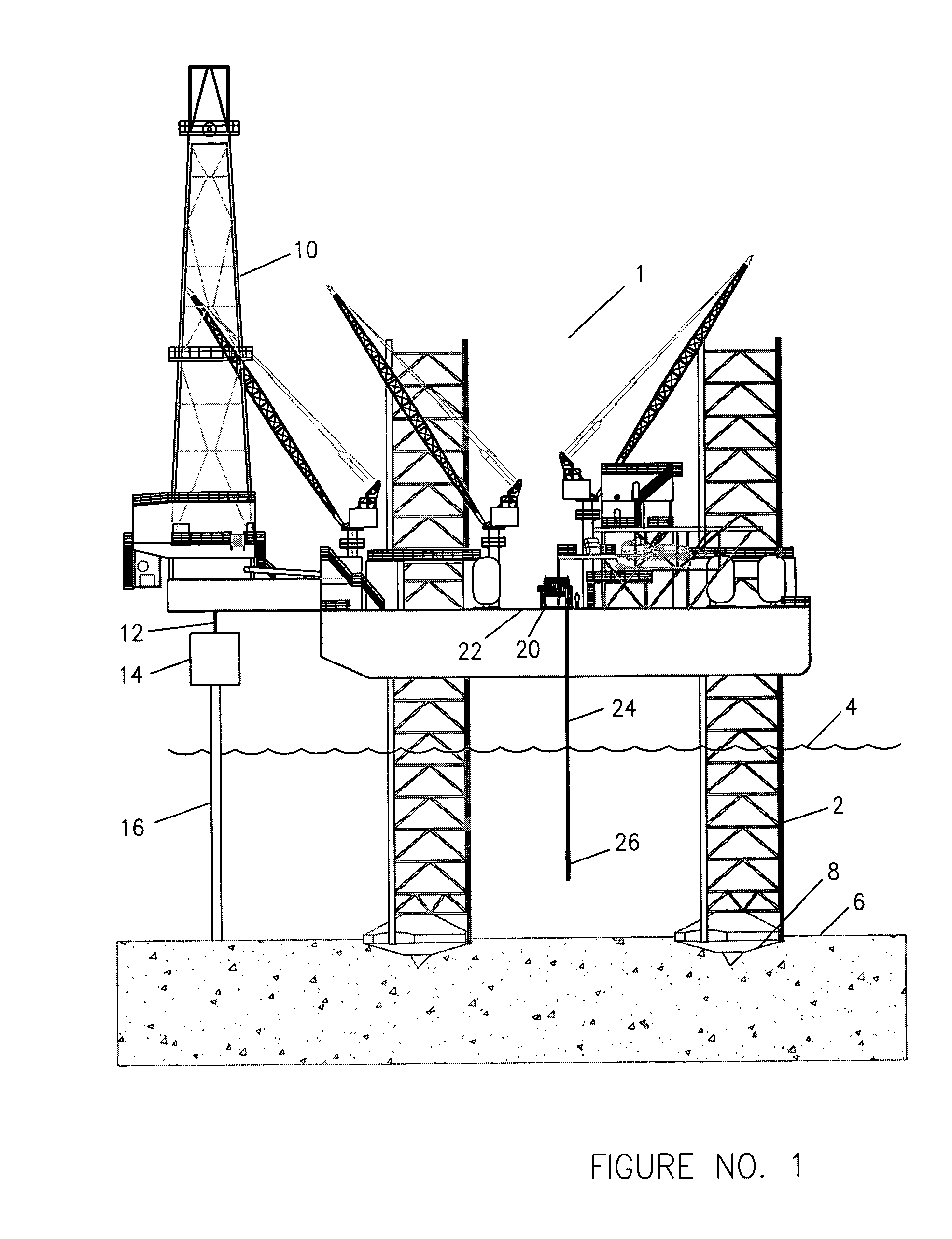

Underwater pipe laying method and apparatus

InactiveUS20020159839A1Quick addReduce necessityPipe laying and repairWaterborne vesselsMarine engineeringTower

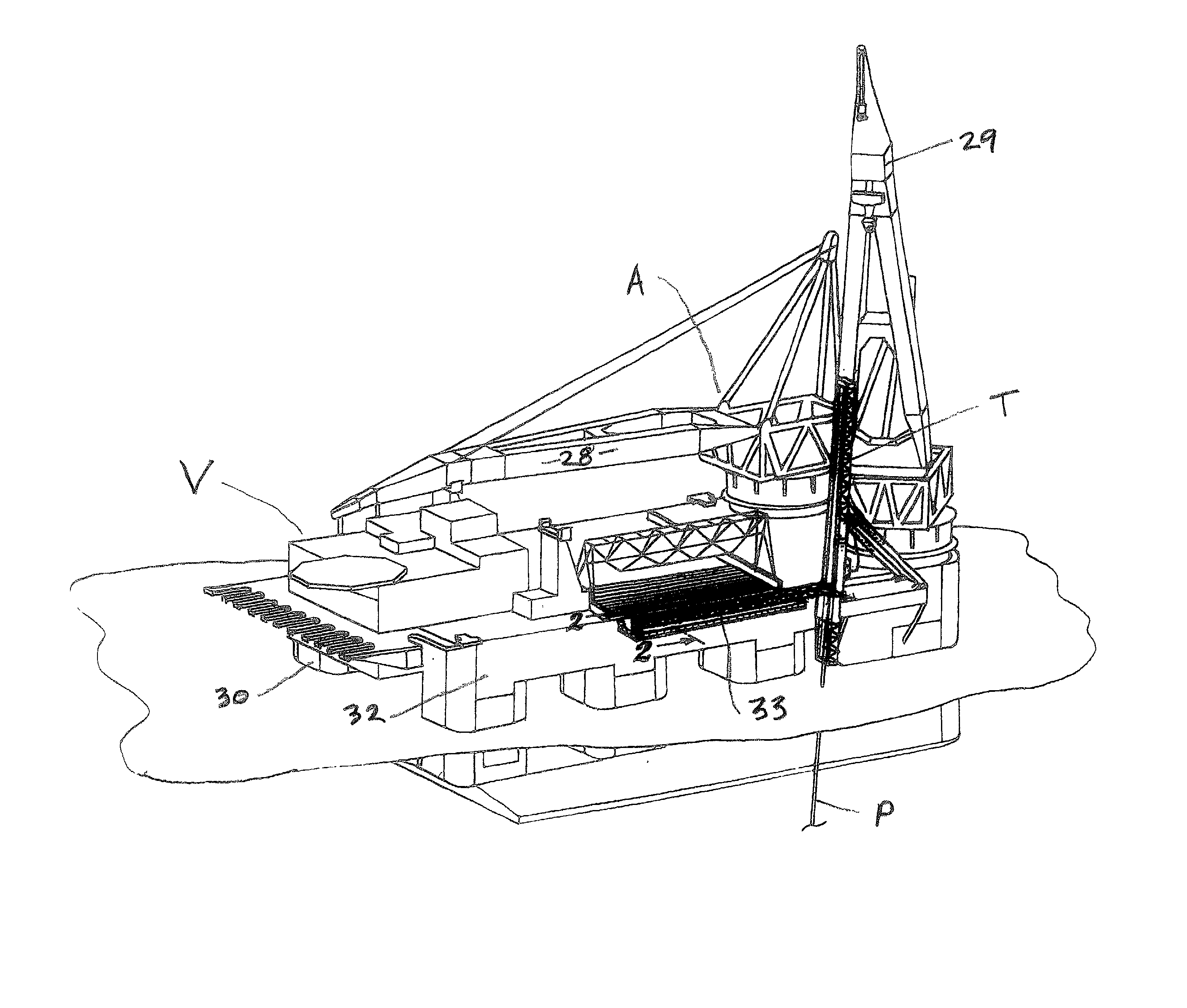

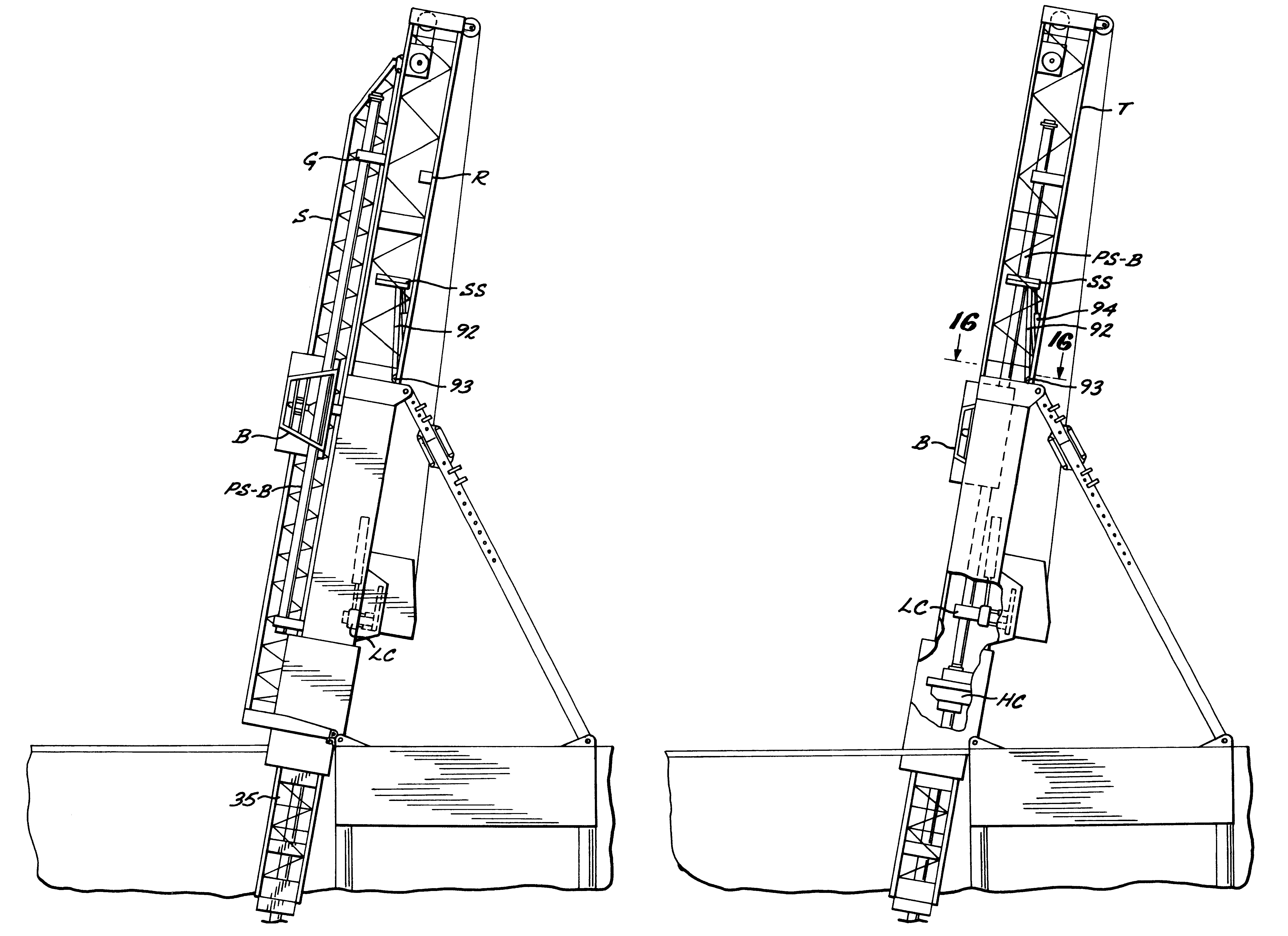

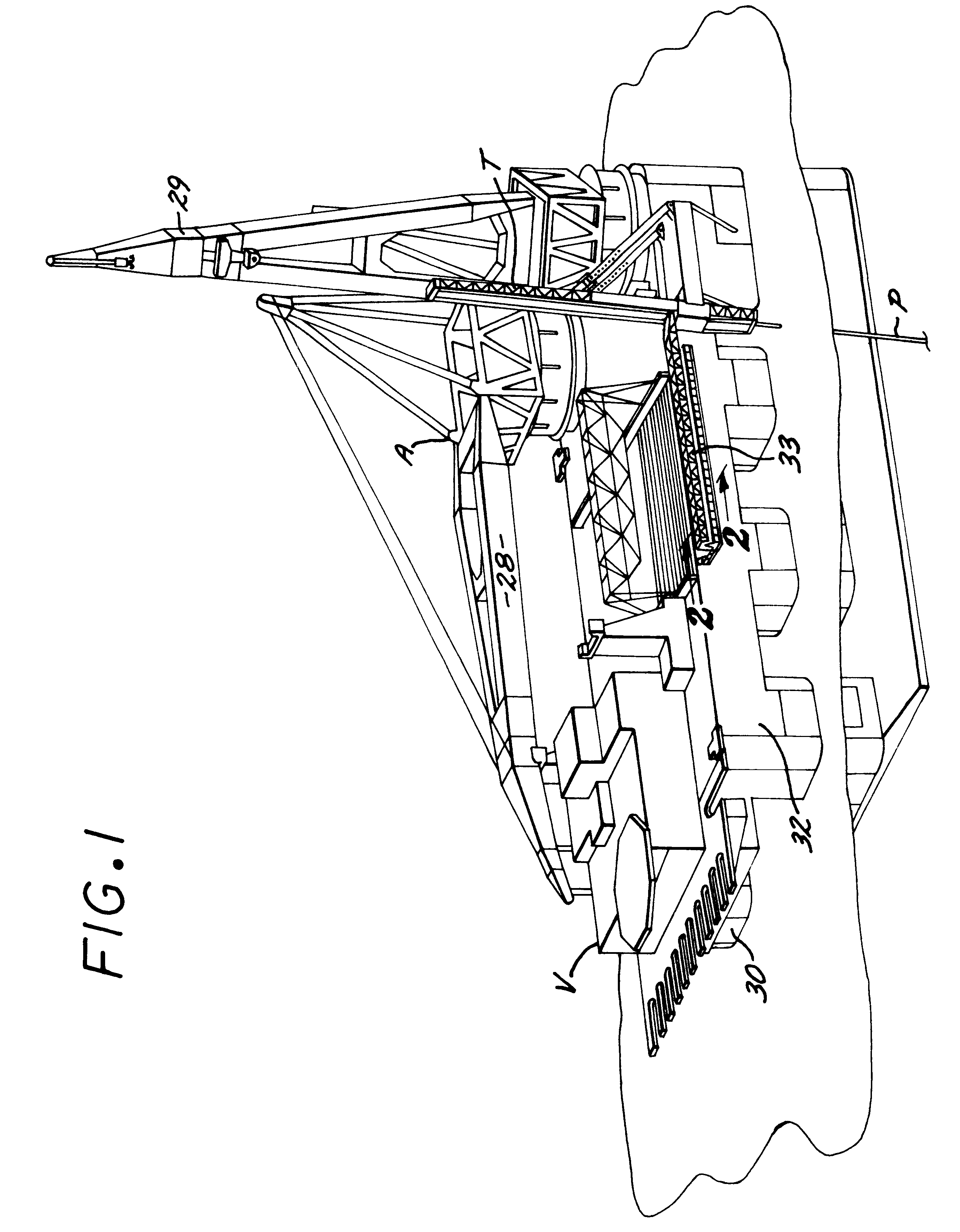

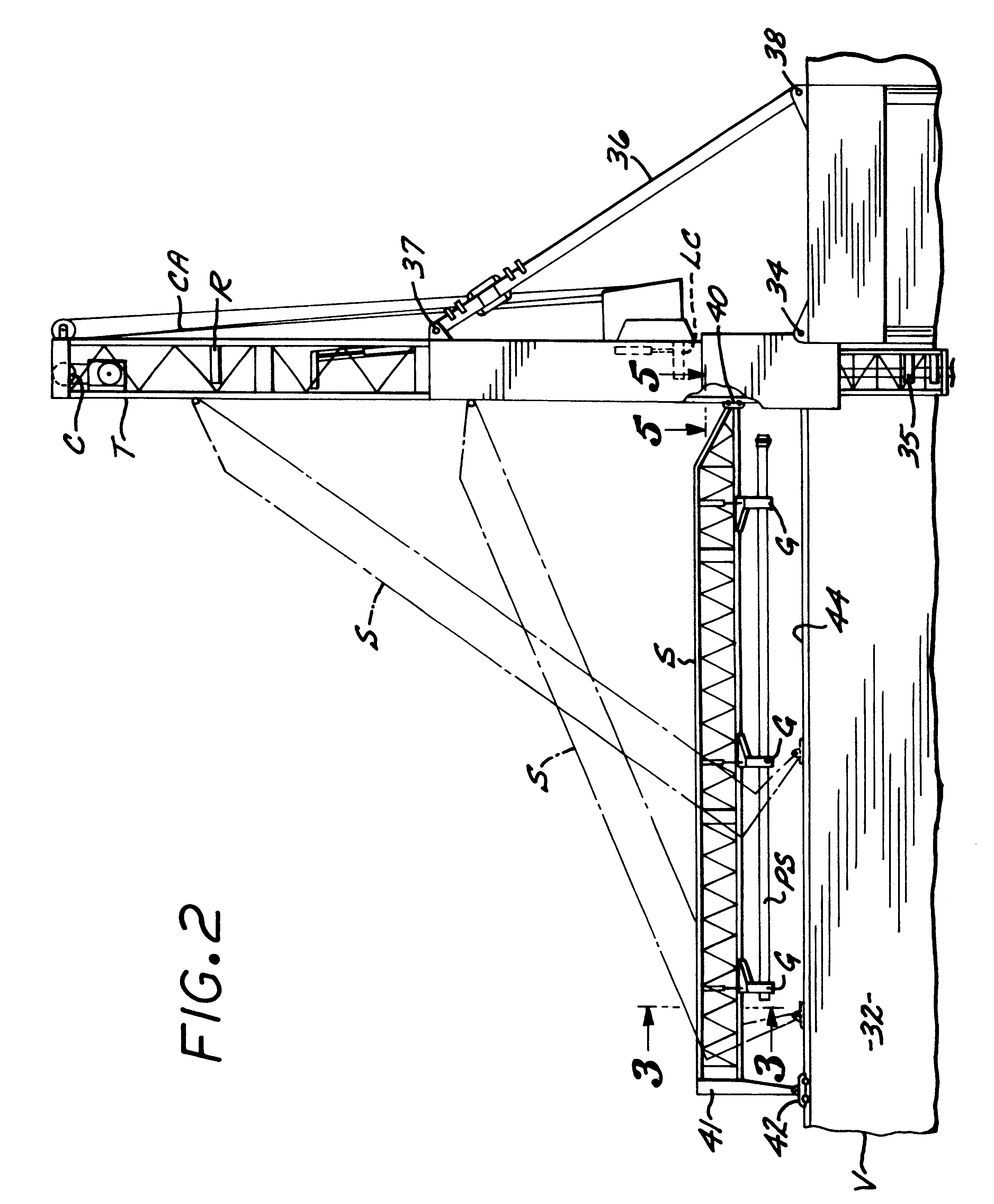

A method and apparatus for near vertical laying of a pipeline offshore by a pipe laying vessel includes a tower to which is attached a strongback that load pipe sections from a supply point on the vessel into the tower where the lower end of the pipe section is welded onto the upper end of a pipe line that extends into the sea while the strongback returns to the supply point for a second pipe joint. Where the pipe section includes a bulky item such as a valve assembly box, after the pipe section has been welded to the pipeline the pipe section is moved generally horizontally out of the tower and a hoisting cable lowers the pipe section to a predetermined depth below the tower. The hoisting cable then returns the pipe section and attached pipeline to their original position.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND SE

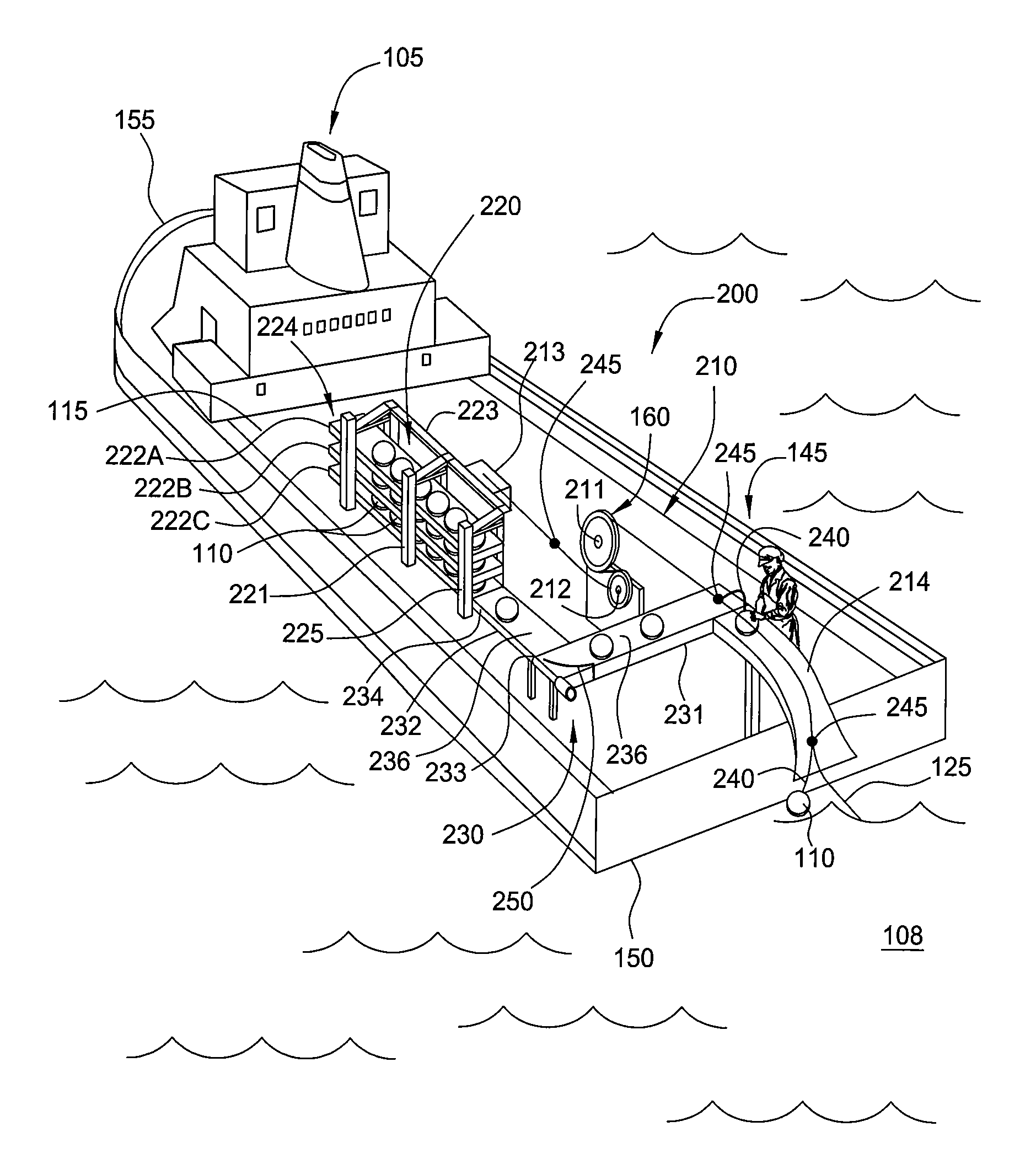

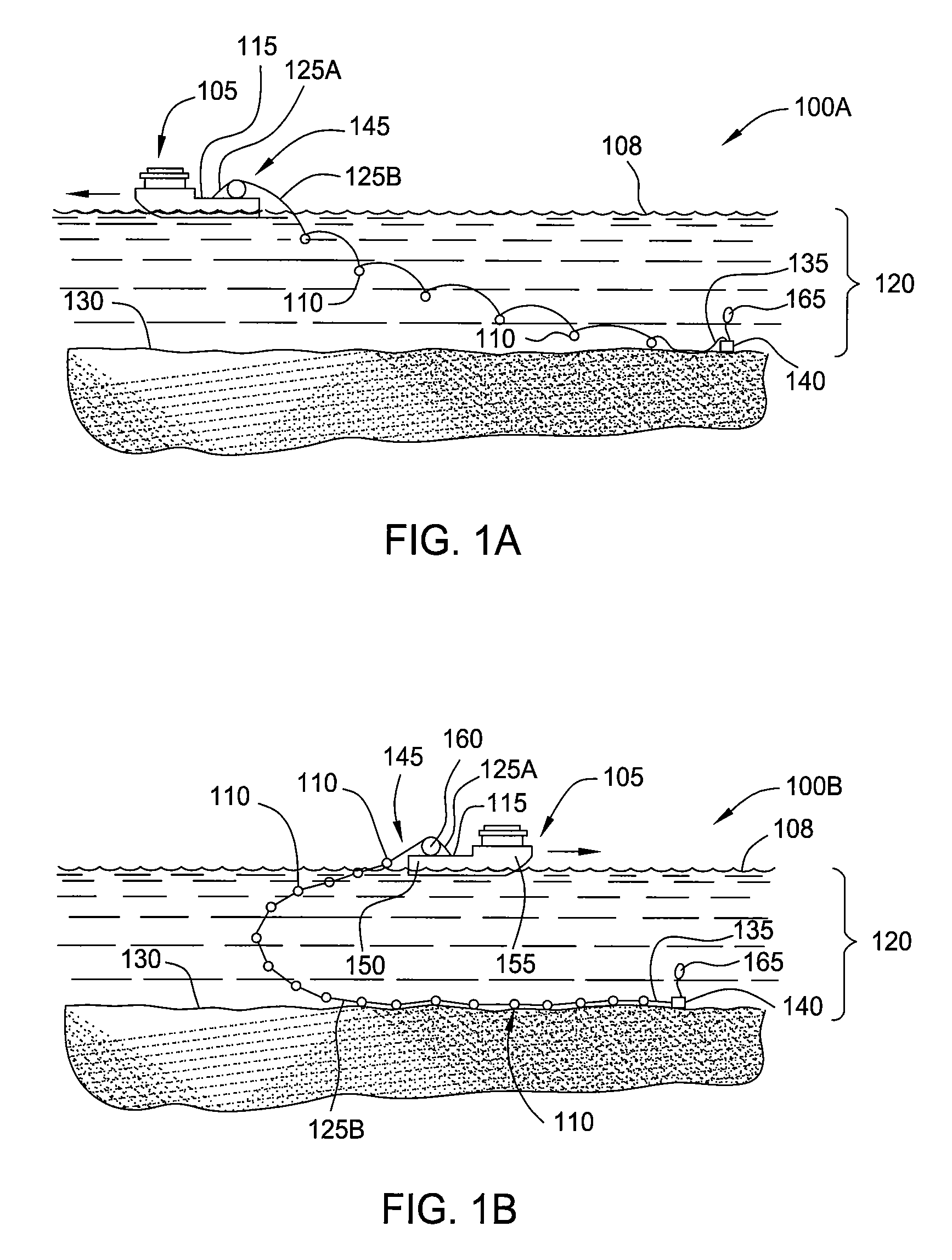

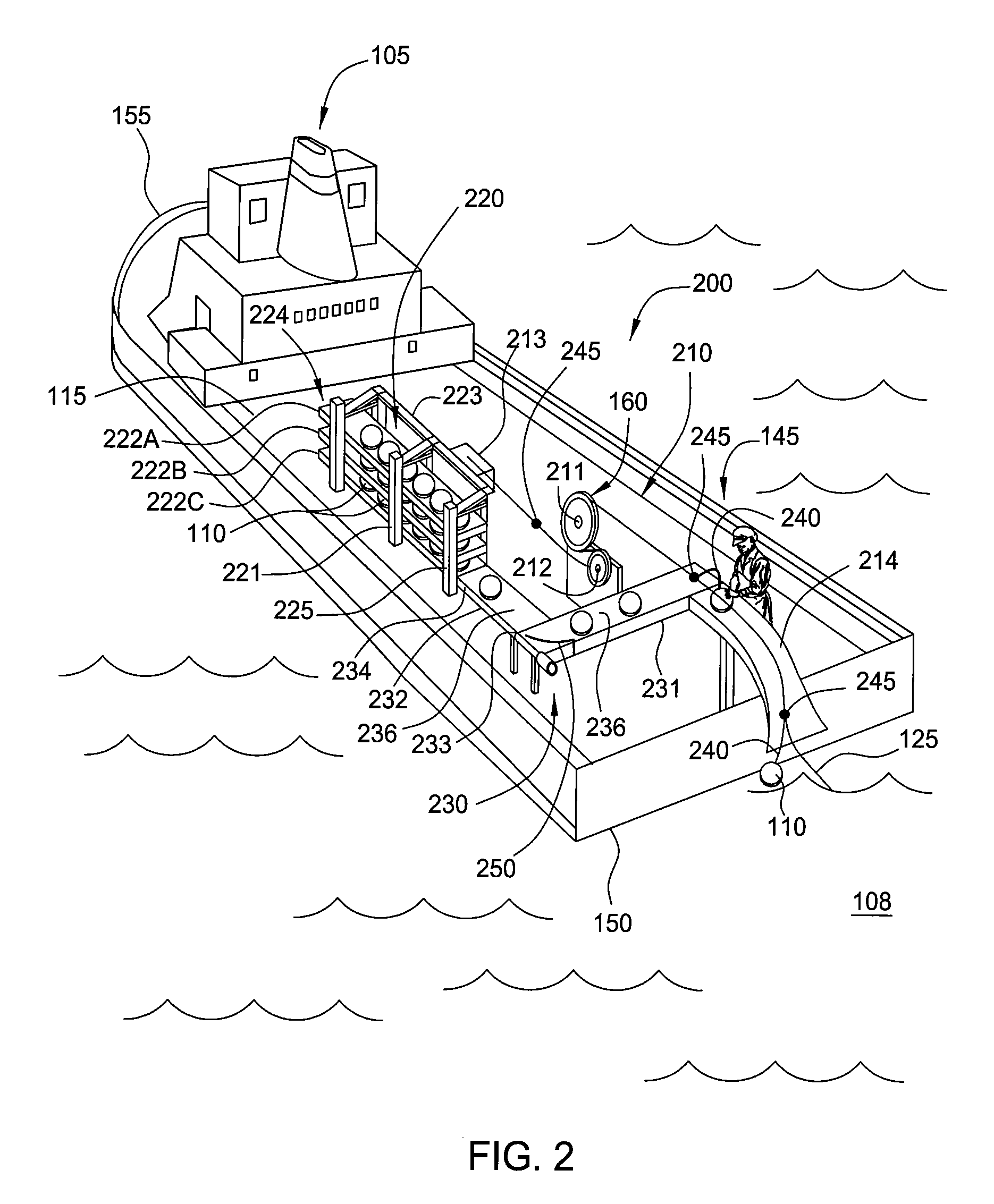

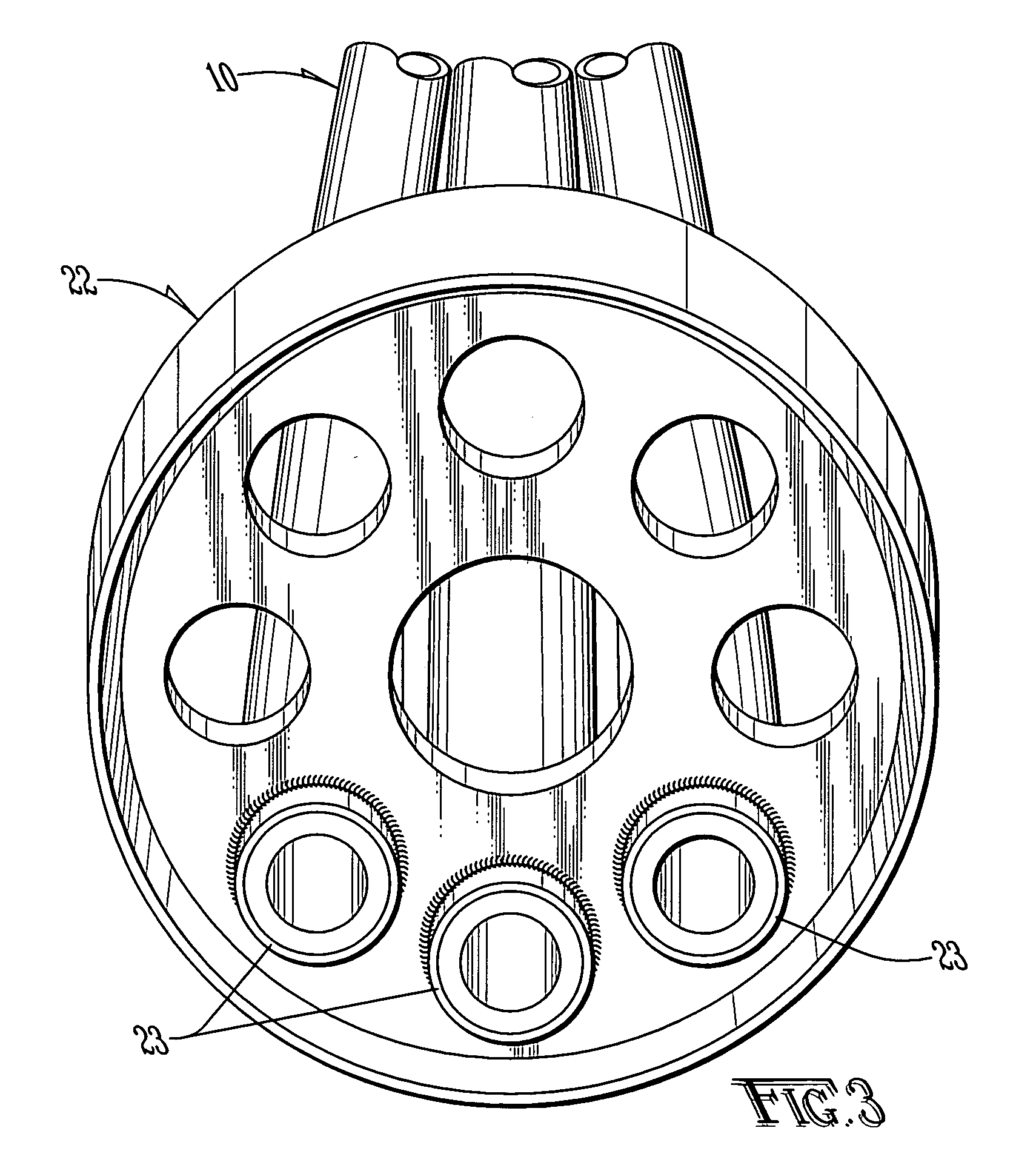

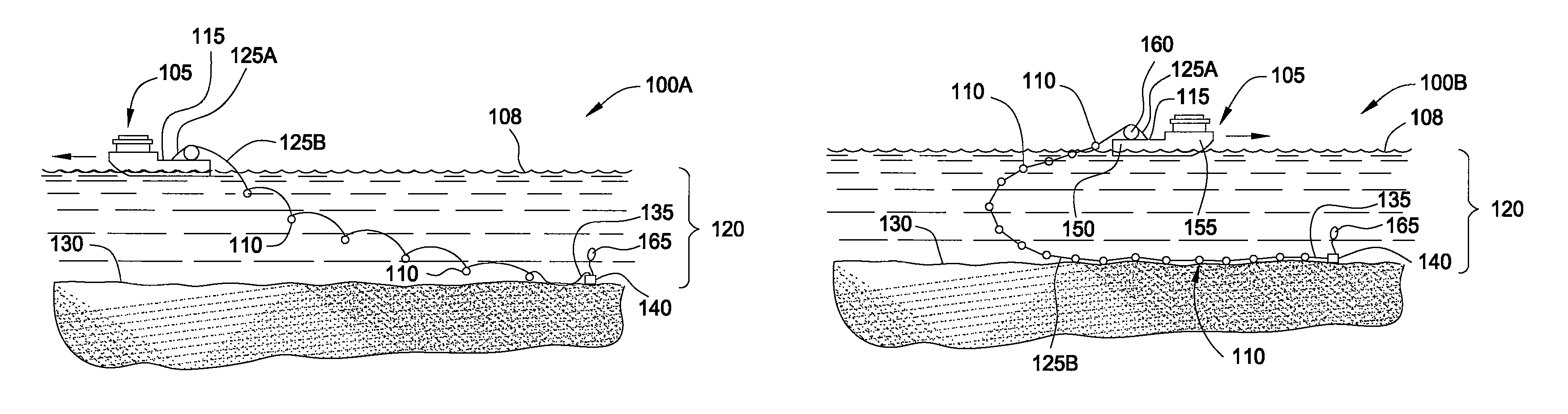

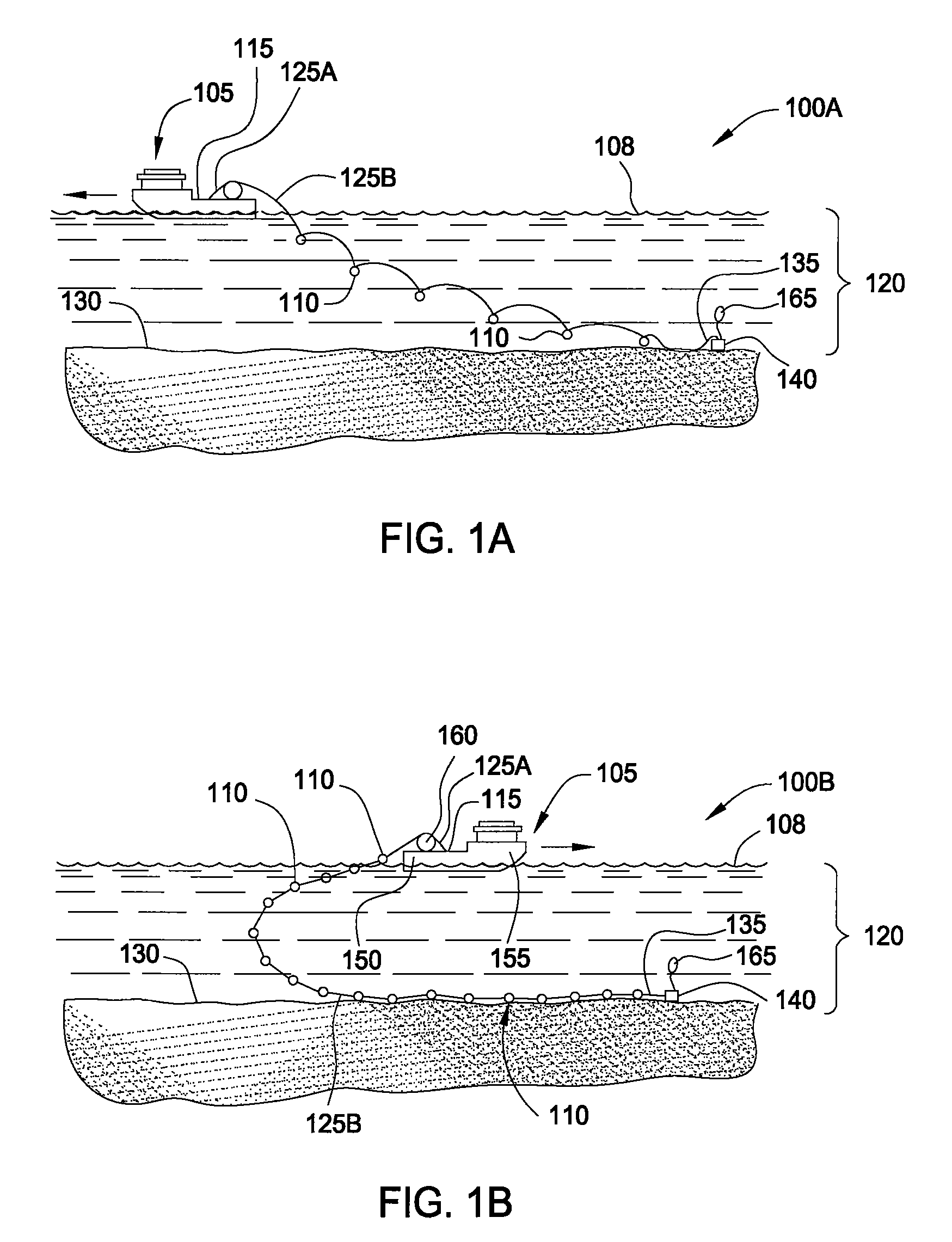

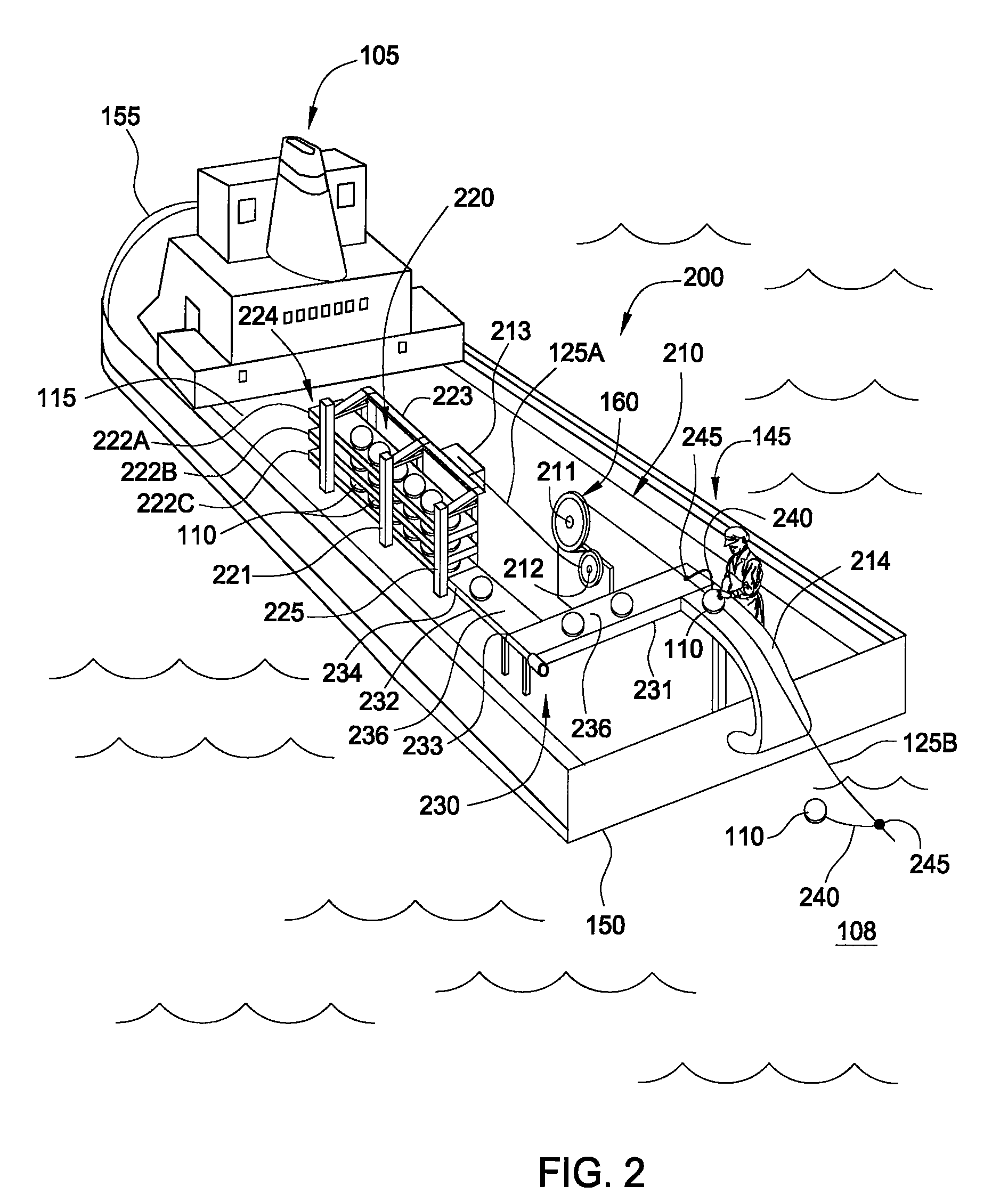

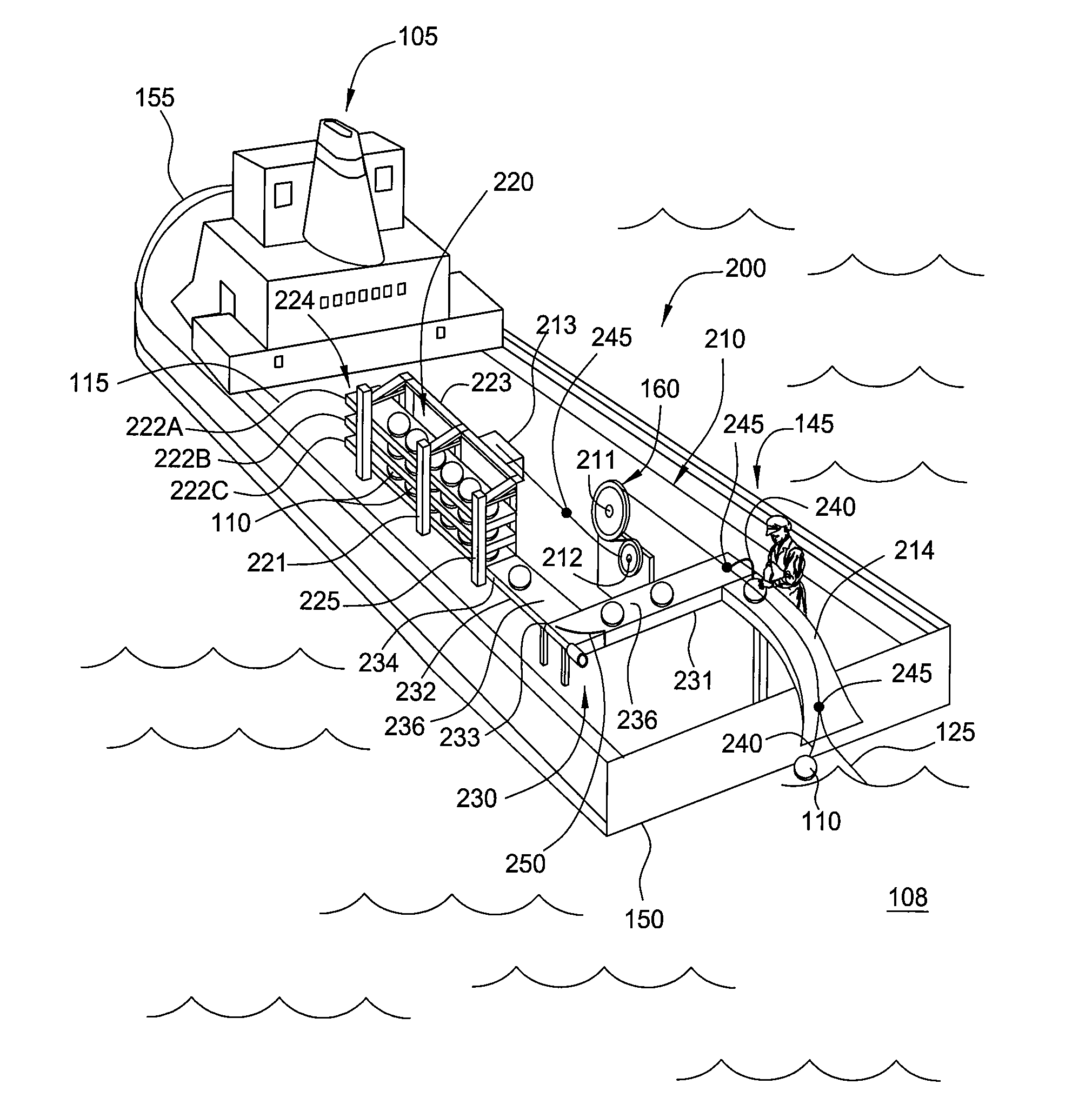

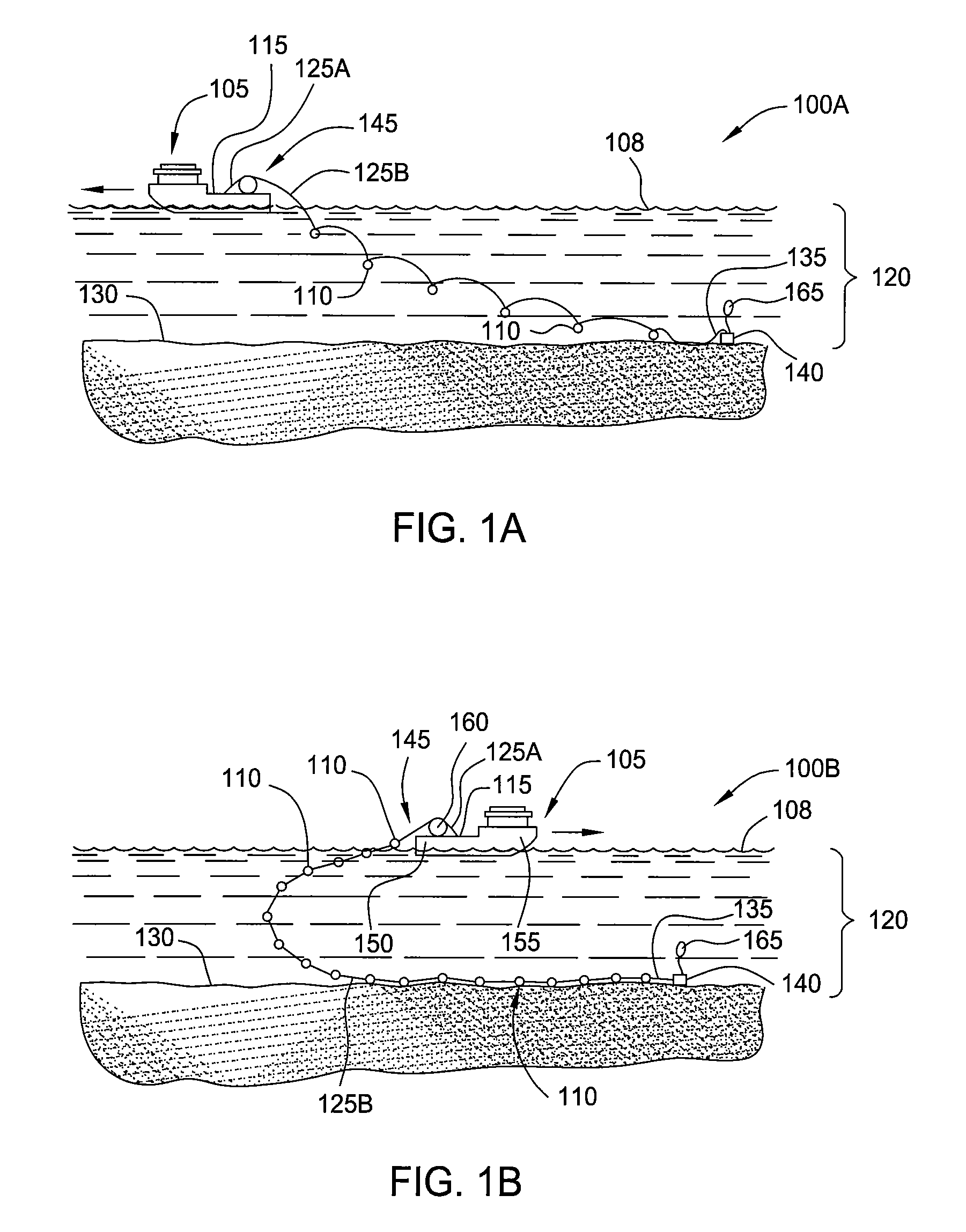

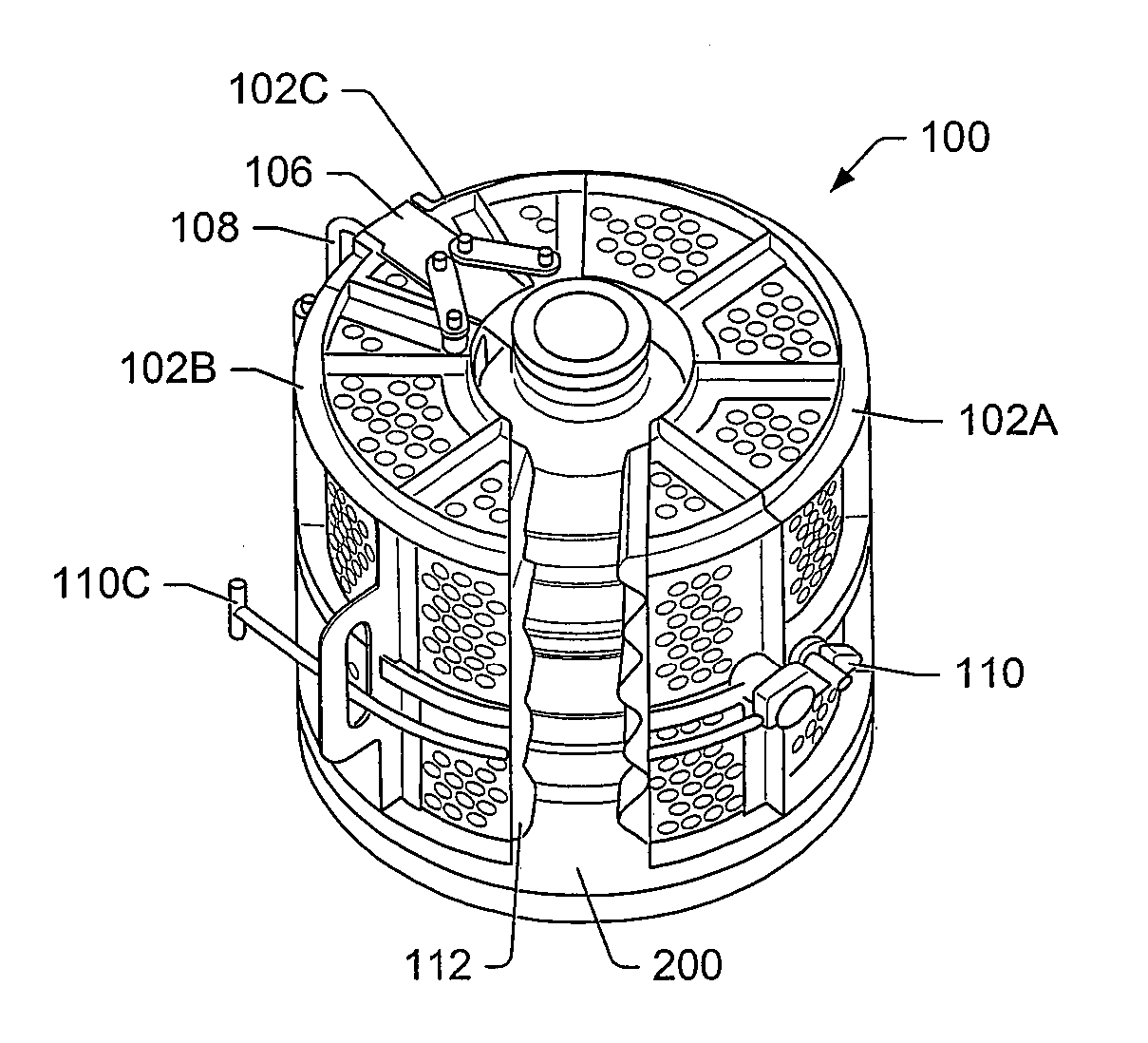

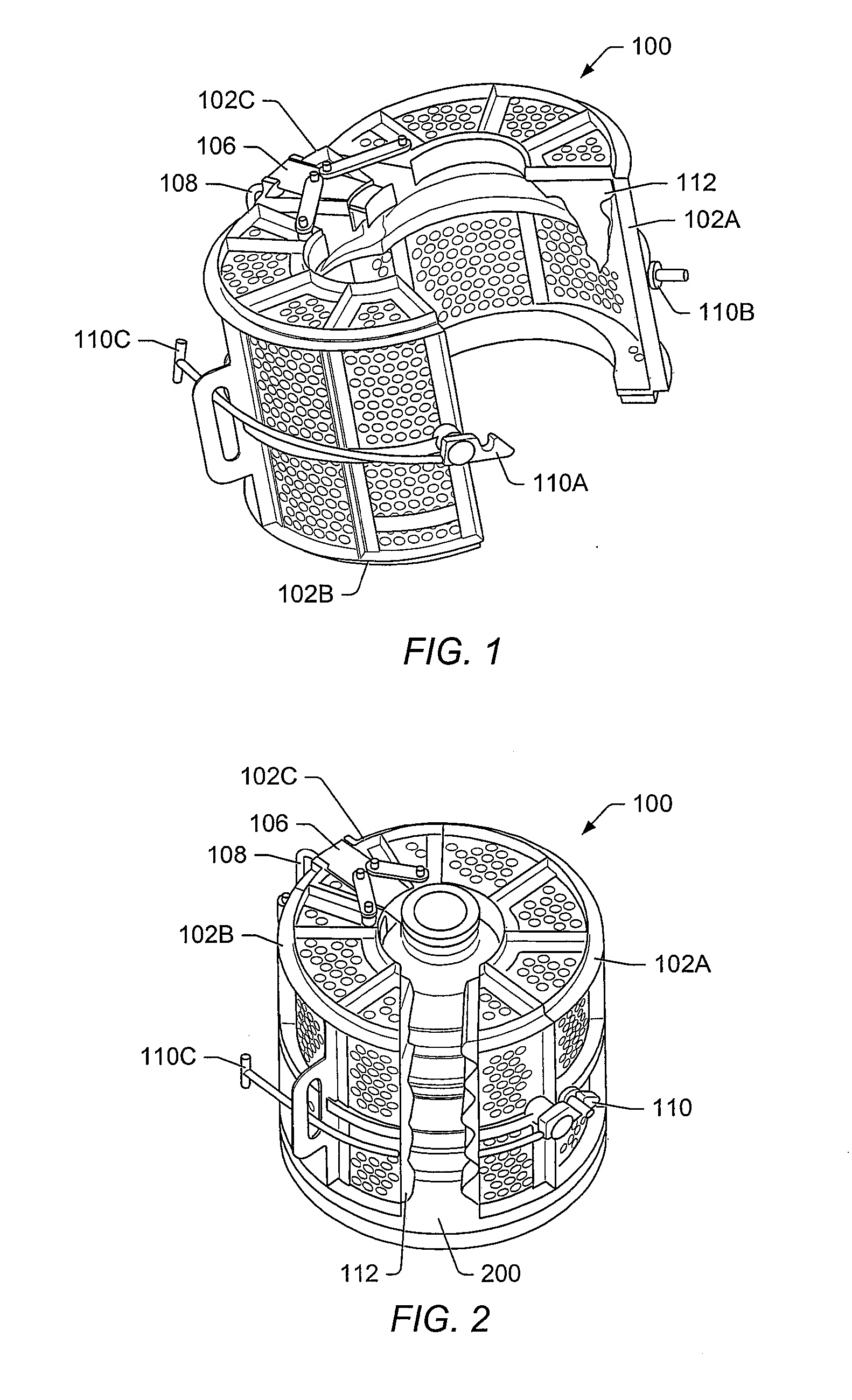

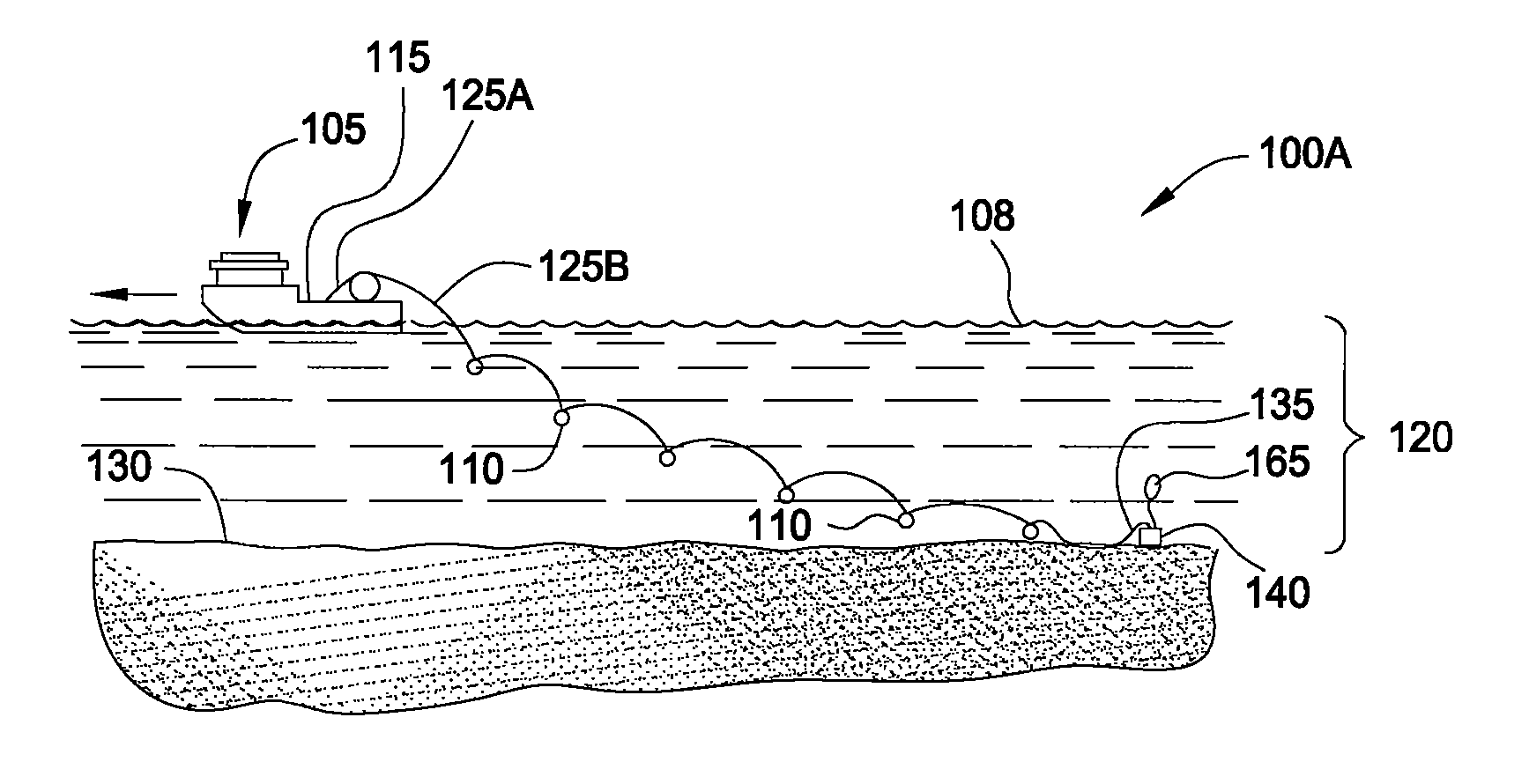

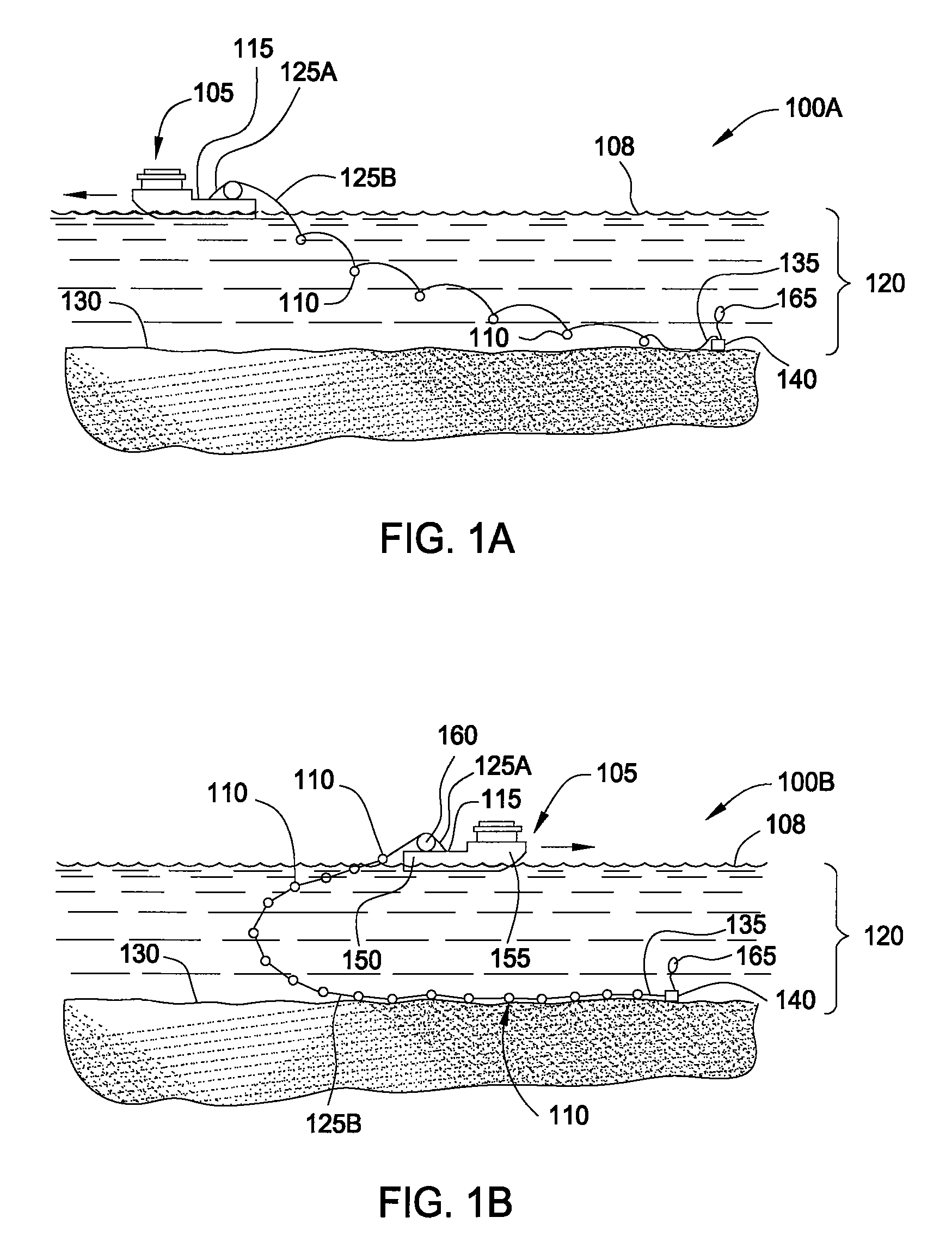

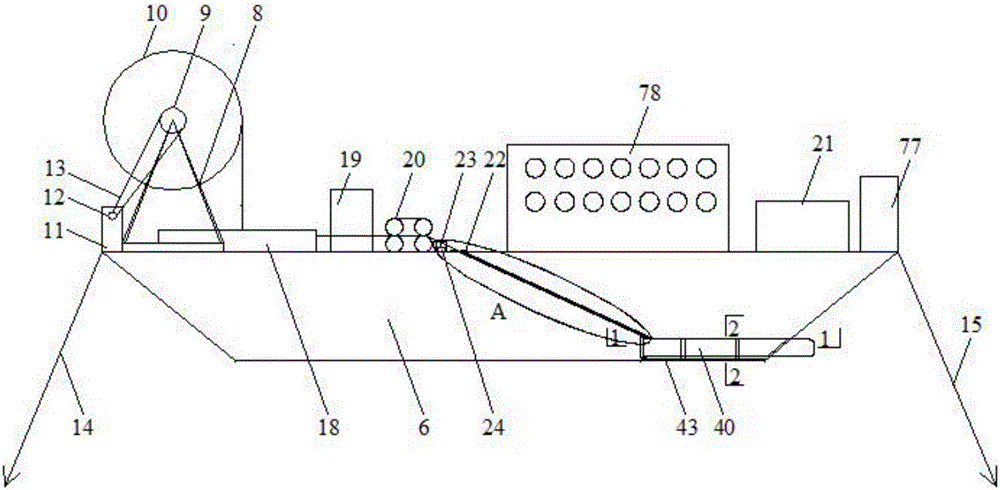

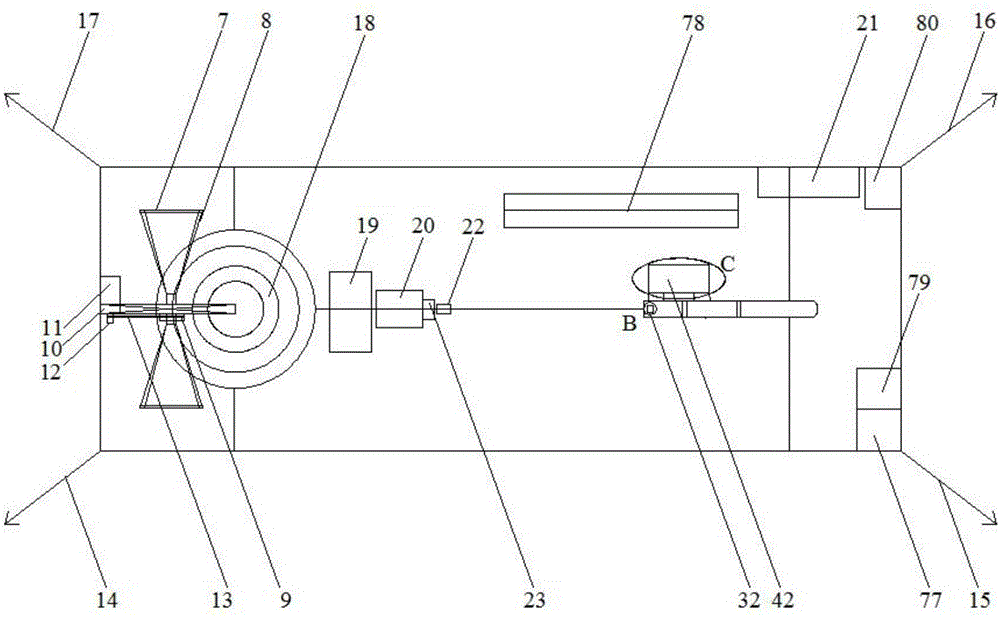

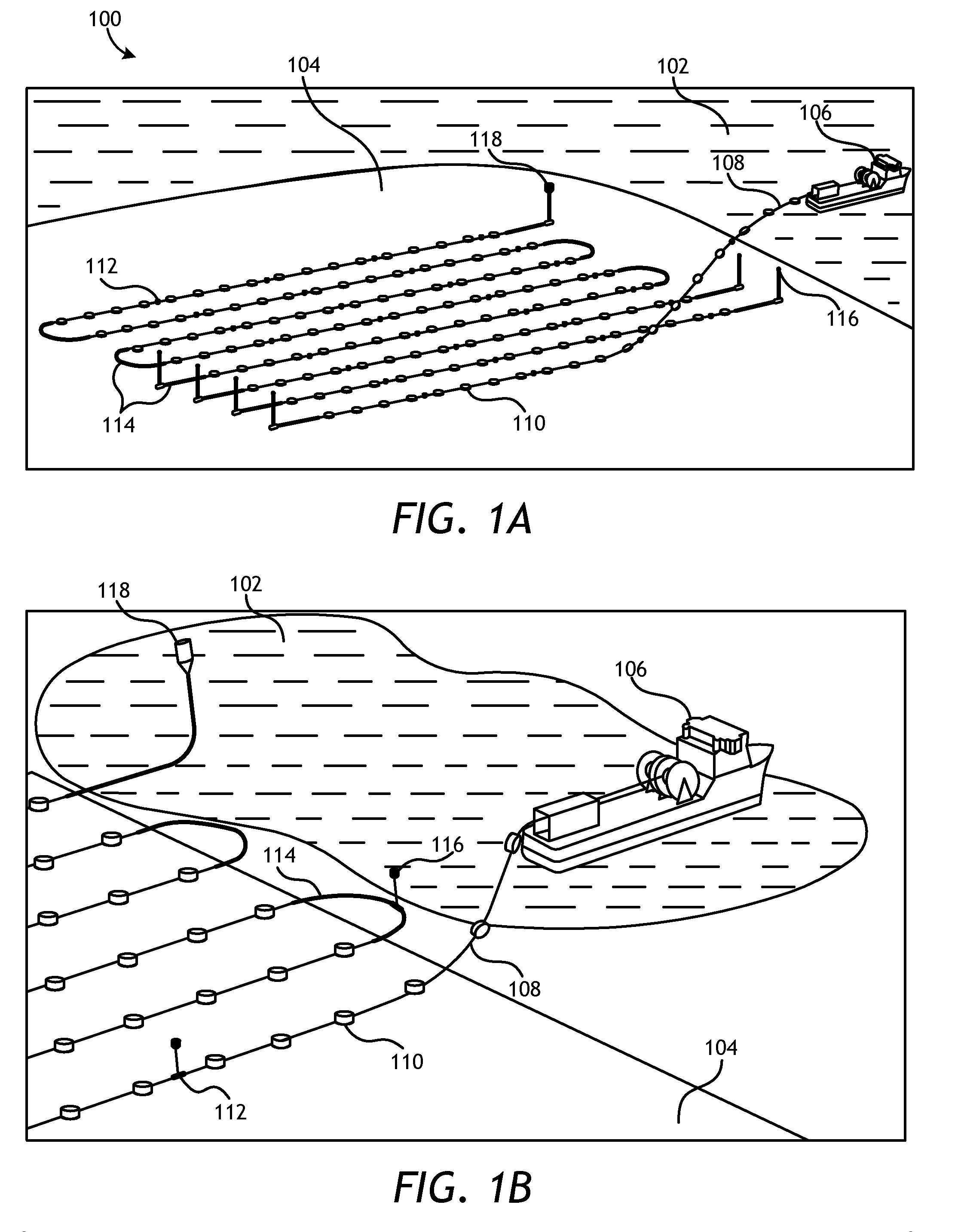

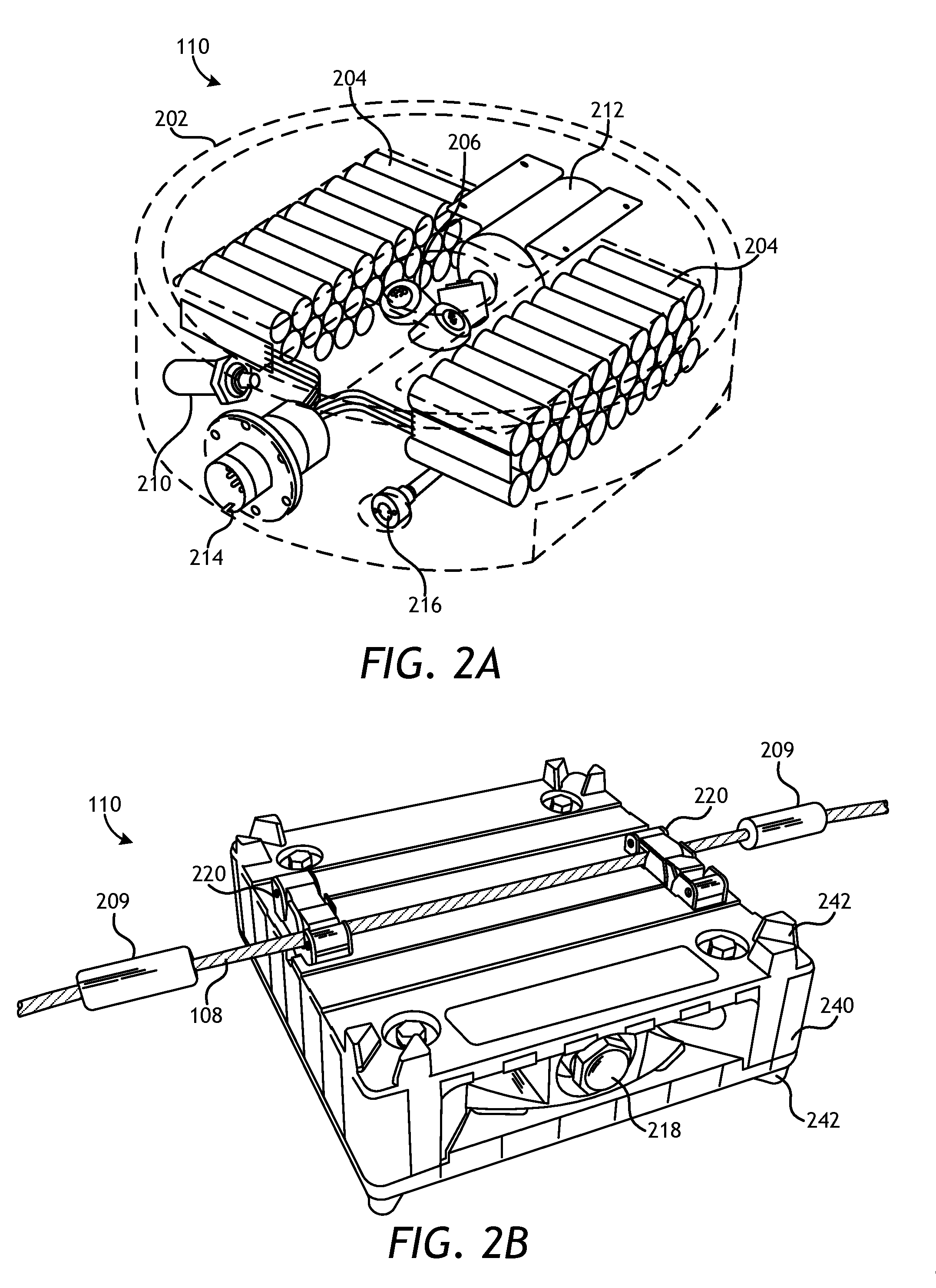

Node storage, deployment and retrieval system

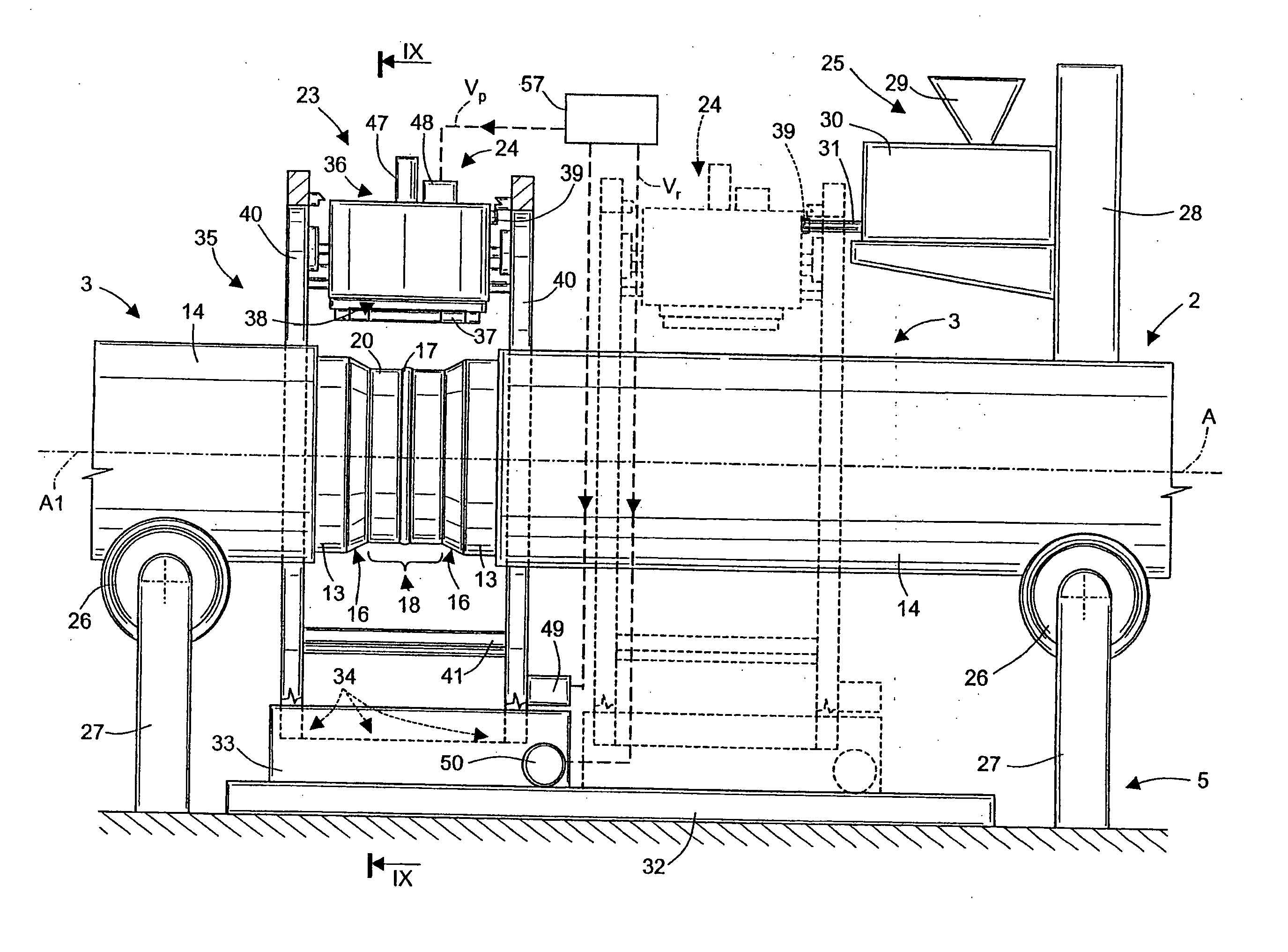

A method and apparatus for storing, deploying and retrieving a plurality of seismic devices is described. The apparatus includes a ramp device coupled to a portion of a trailing end of a vessel, a cable handling device positioned between the ramp device and a leading end of the vessel to define a cable path across the ramp device, and at least one conveyor system having a first end located adjacent the ramp device and a second end extending toward the leading end of the vessel. A deployment method includes providing nodes from a storage area to a workstation where the nodes may be attached to a cable. A retrieval method includes routing a cable through a workstation to detach nodes from the cable section and transfer the detached nodes to the storage area.

Owner:MAGSEIS FF LLC

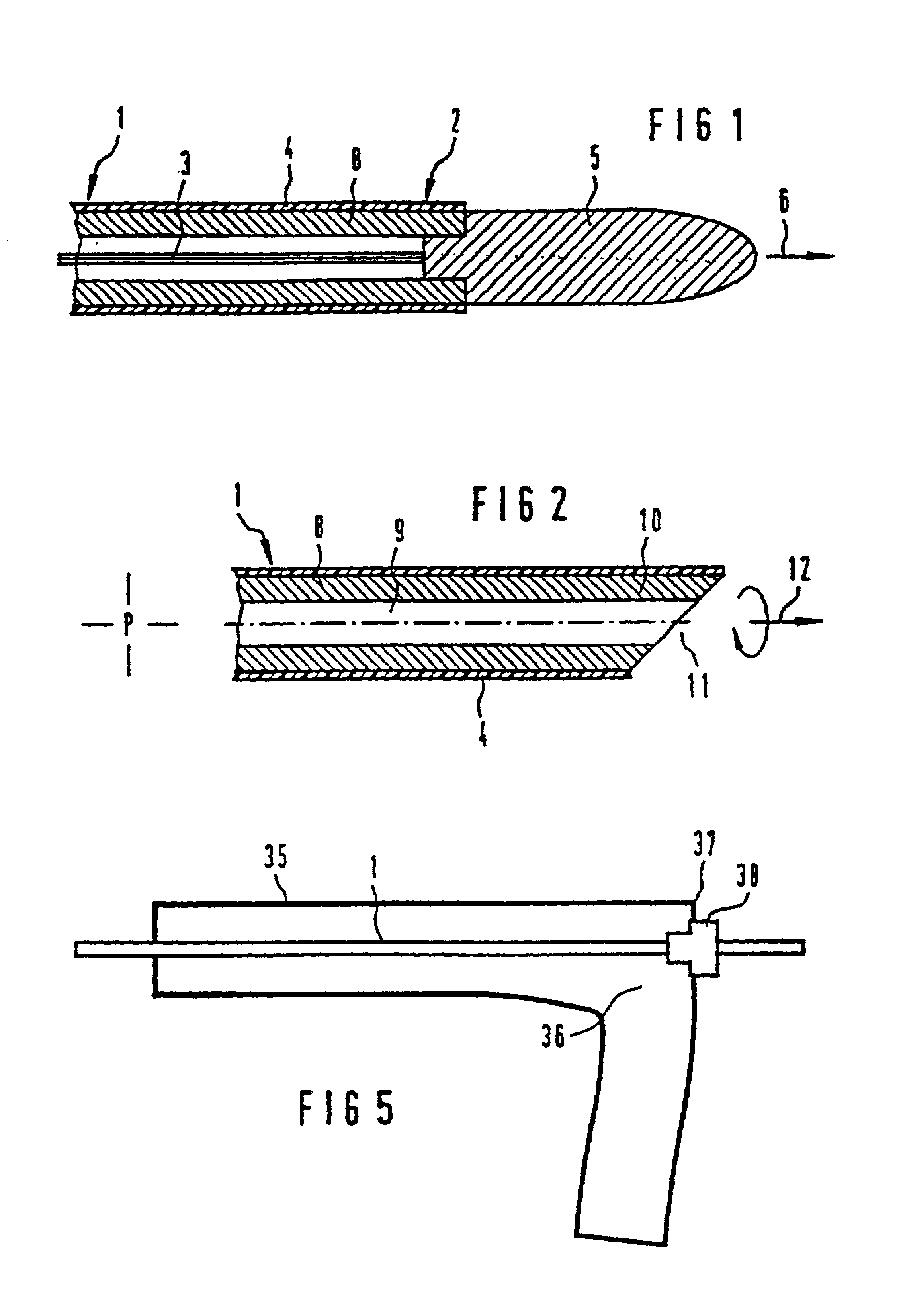

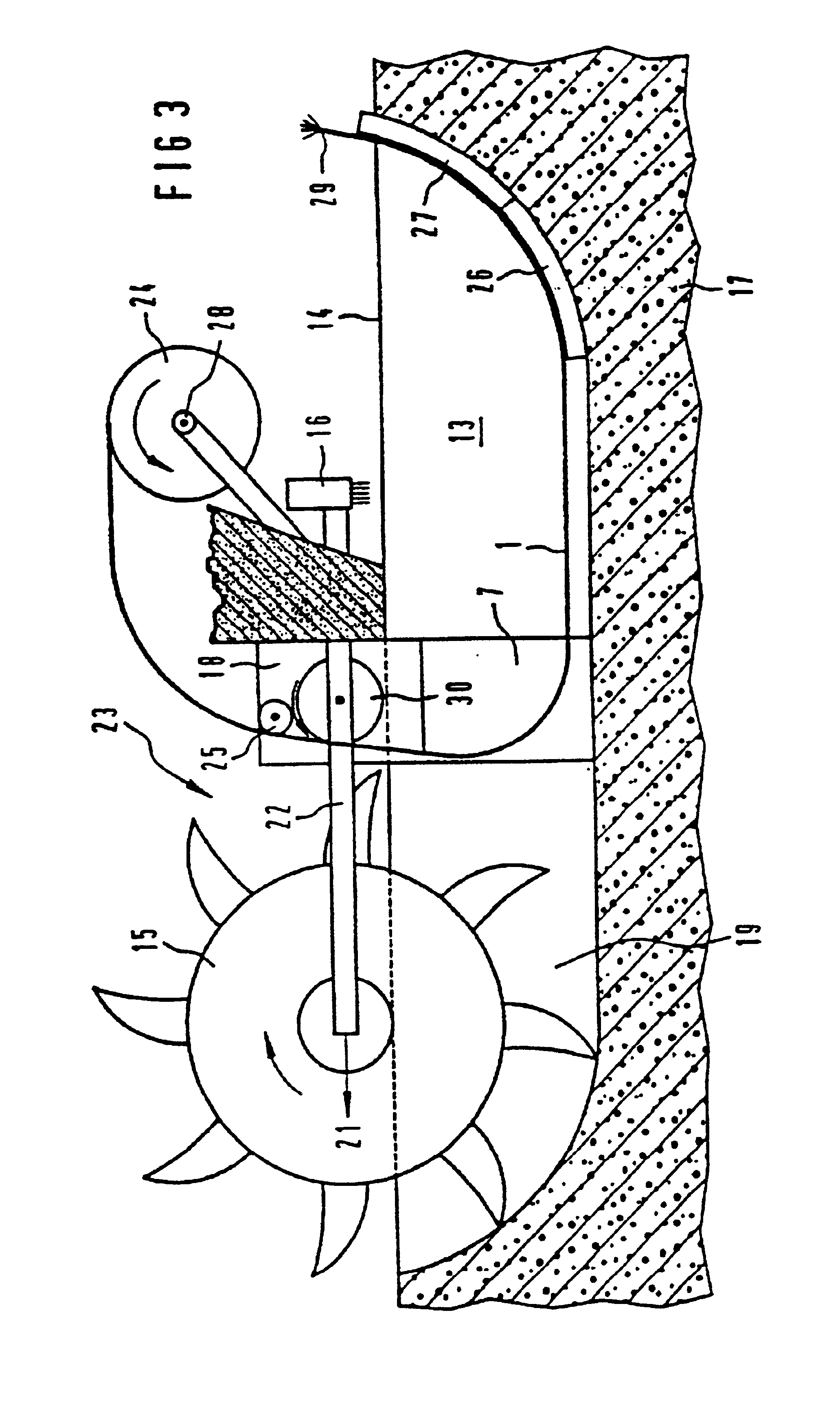

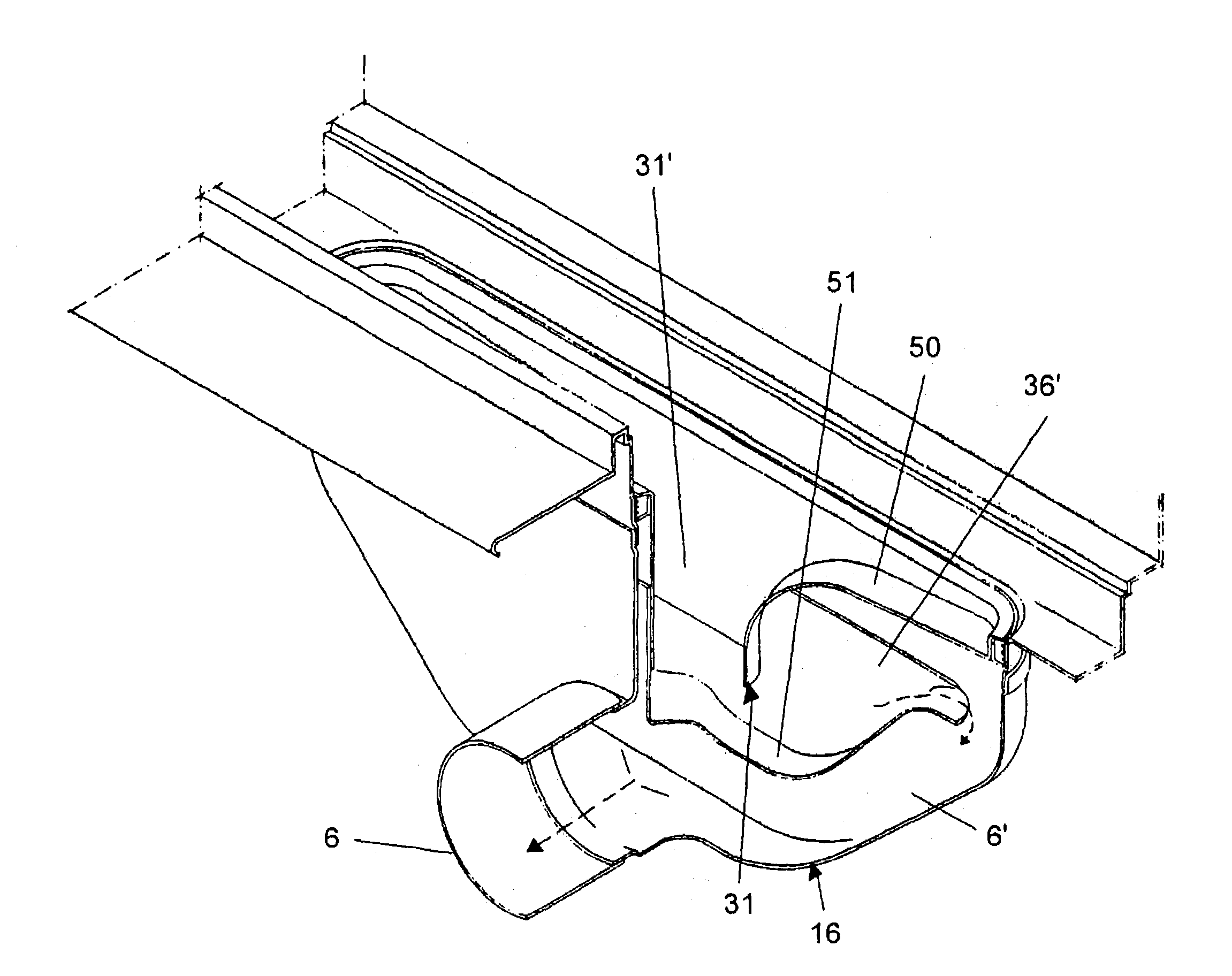

Fiber optic installation

InactiveUS6866448B2Short amount of timeIncrease flexibilitySoil-shifting machines/dredgersService pipe systemsFiberWaveguide

The invention relates to a process for introducing an optical cable, in the form of a microcable or minicable (1), in solid ground (17) with the aid of a laying unit (23). The microcable or minicable (1) used for this purpose comprises a homogeneous and pressurized-water-tight tube (8) which has an external diameter of from 2.0 to 10 mm and into which optical waveguides (3) are introduced.

Owner:CCS TECH INC

Underwater pipe laying method and apparatus

InactiveUS6592297B2Quick addReduce necessityPipe laying and repairWaterborne vesselsMarine engineeringTower

A method and apparatus for near vertical laying of a pipeline offshore by a pipe laying vessel includes a tower to which is attached a strongback that load pipe sections from a supply point on the vessel into the tower where the lower end of the pipe section is welded onto the upper end of a pipe line that extends into the sea while the strongback returns to the supply point for a second pipe joint. Where the pipe section includes a bulky item such as a valve assembly box, after the pipe section has been welded to the pipeline the pipe section is moved generally horizontally out of the tower and a hoisting cable lowers the pipe section to a predetermined depth below the tower. The hoisting cable then returns the pipe section and attached pipeline to their original position.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND SE

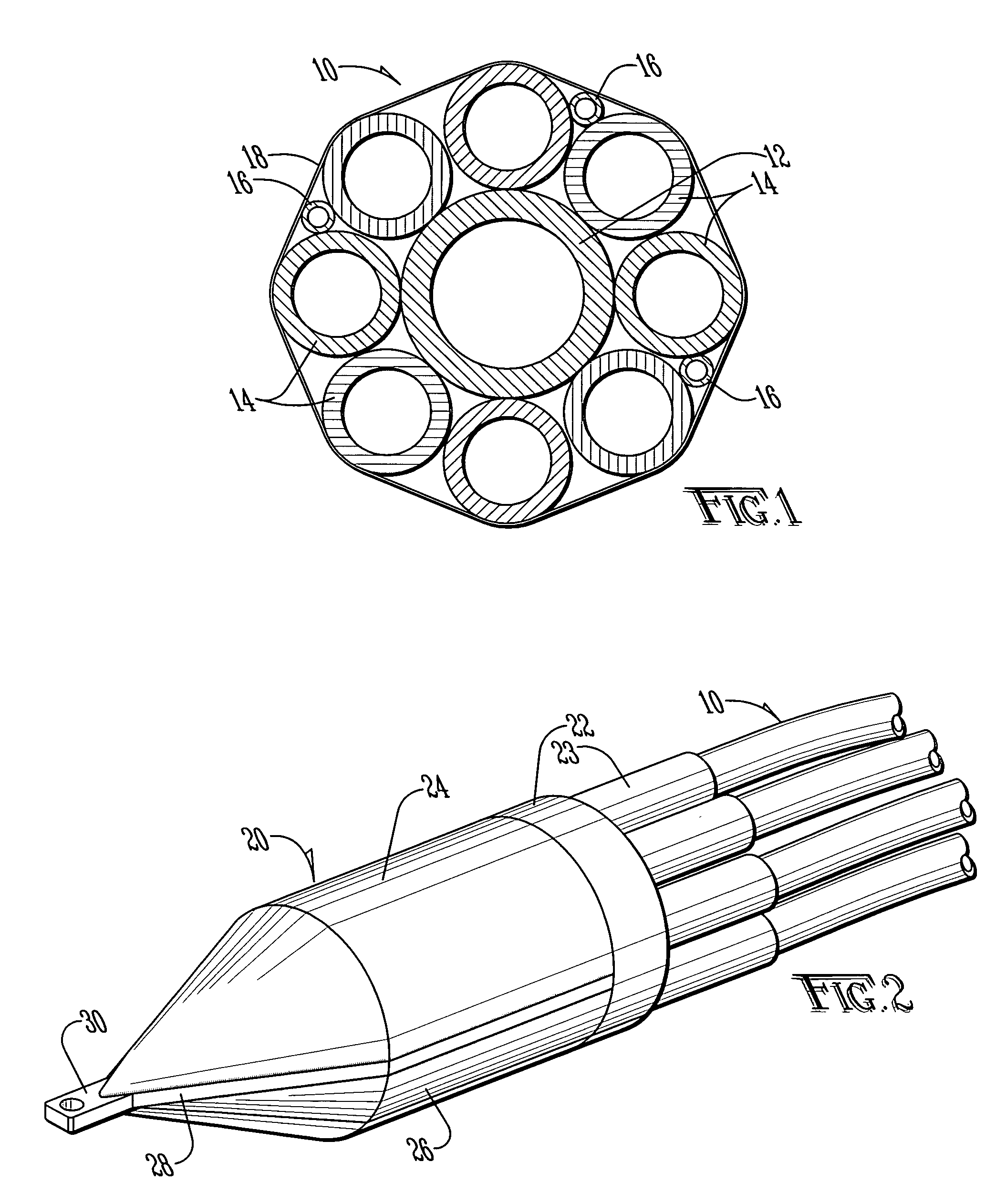

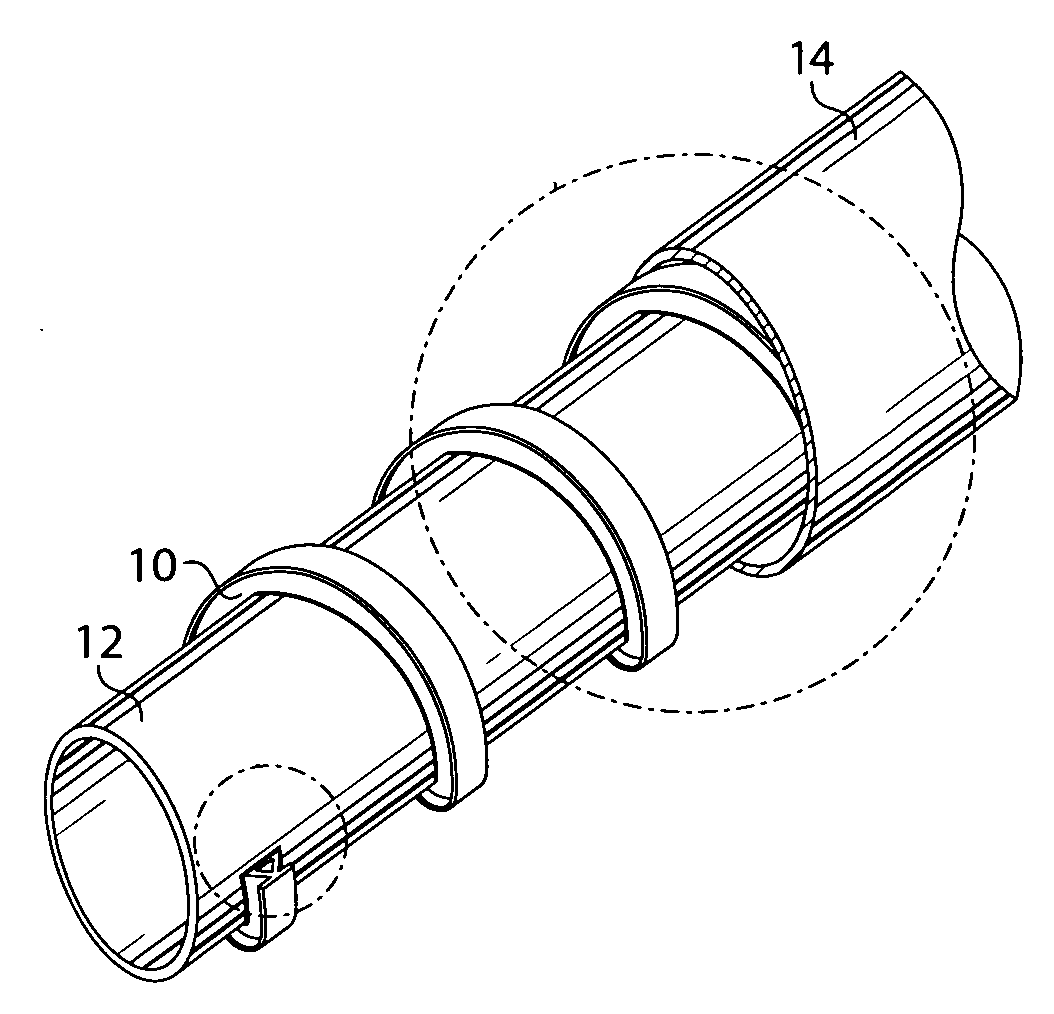

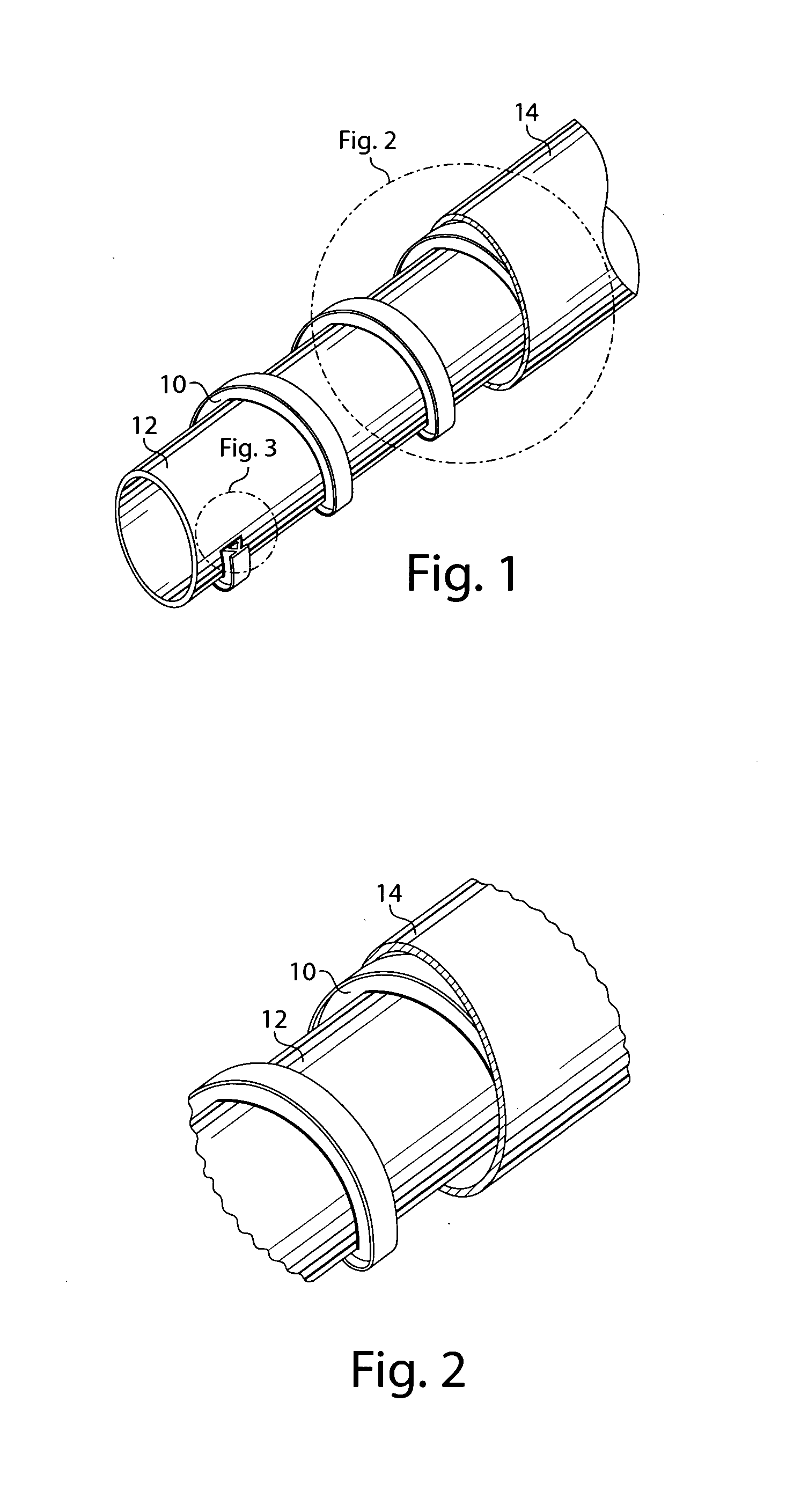

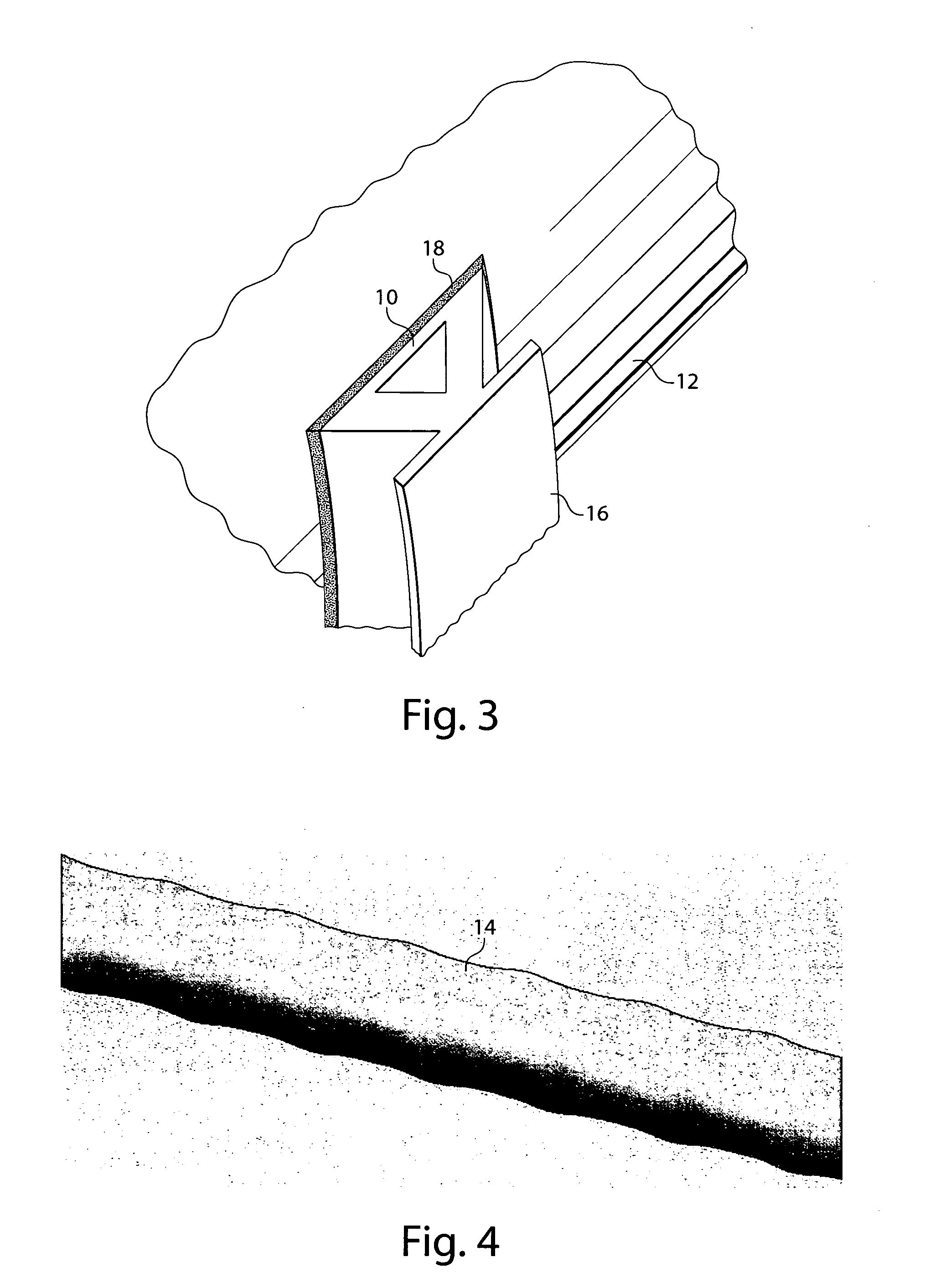

Pipe bundle for underground installation

InactiveUS6979776B1Optimizing electrical/magnetic characteristic of designLittle strengthPipe laying and repairWaterborne vesselsEngineeringMechanical engineering

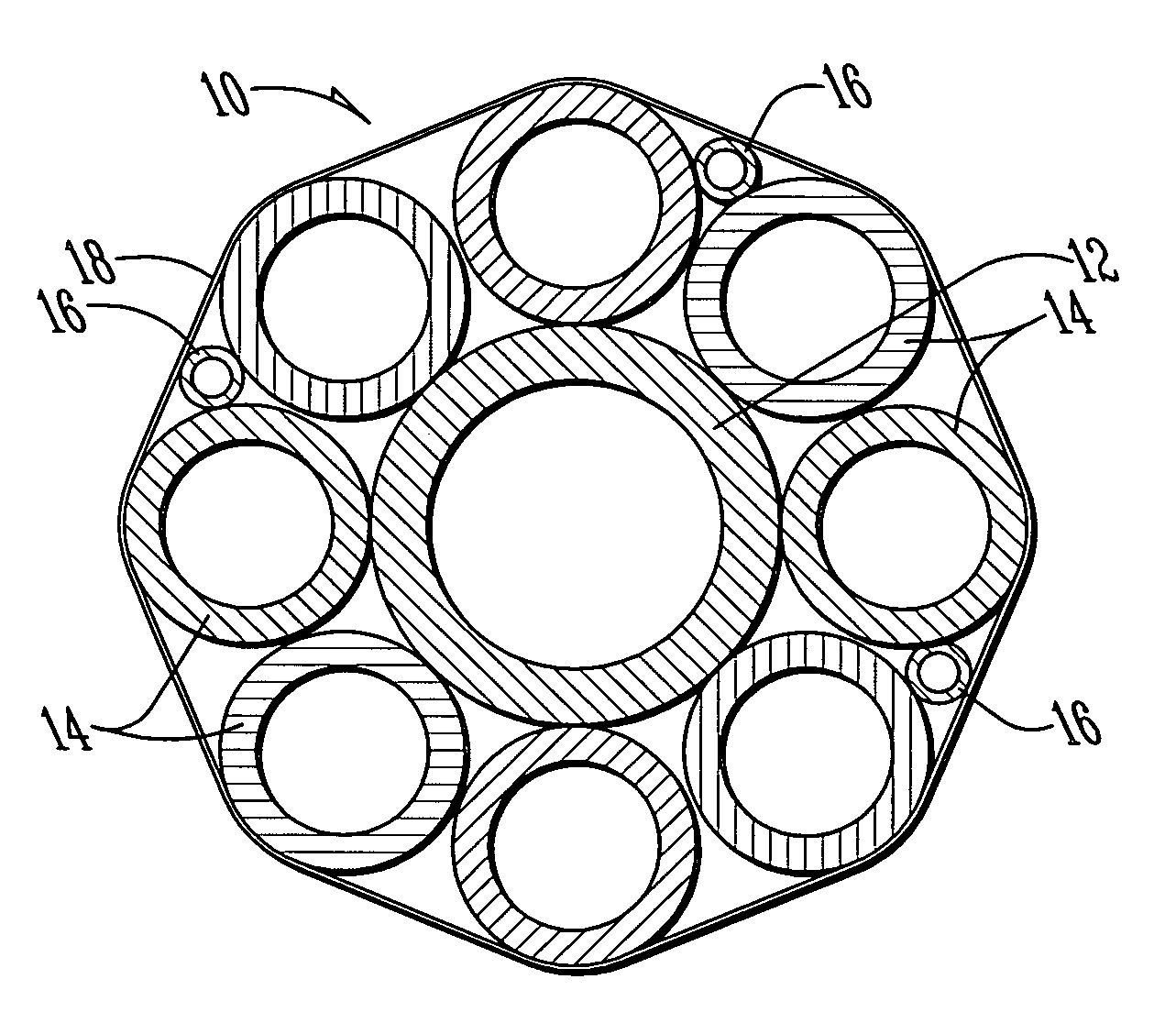

A pipe conduit bundle for installation into a wellbore using horizontal drilling techniques is disclosed. The pipe conduit does not require an outer casing for construction. The pipe bundle configuration is formed by pipes of varying sizes in a particular configuration, with bindings interspaced along the length of the pipes such that the pipe bundle deflects as a single unit during installation. A pulling head is attached to the bundle, which is hollow to allow liquid entering one pipe to be distributed to other pipes. Liquids such as water may be used to fill the pipes to reduce buoyancy, and thereby reduce drag, during installation of the bundle.

Owner:ENTERGY LOUSNA

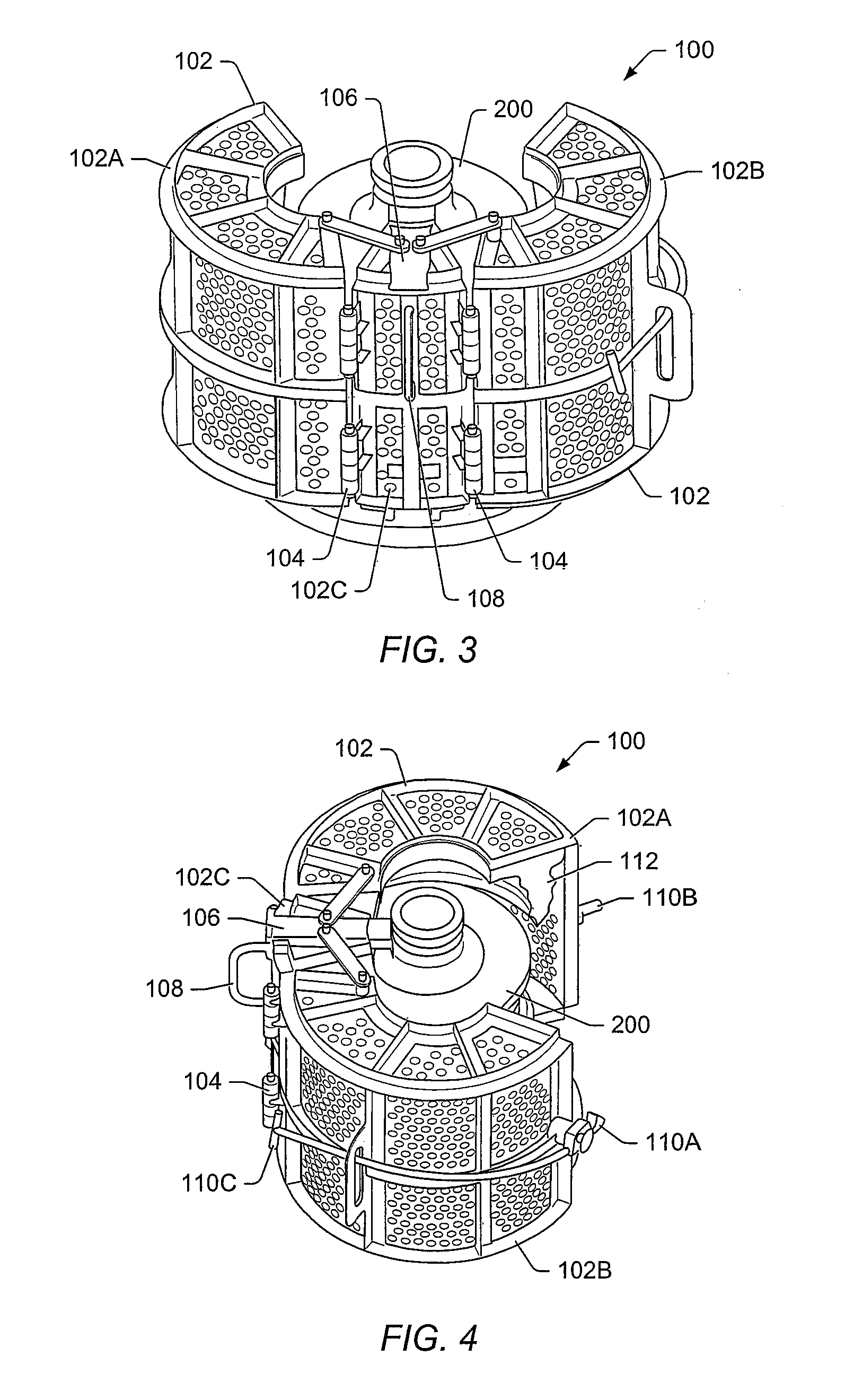

Powered sheave for node deployment and retrieval

Owner:MAGSEIS FF LLC

Node storage, deployment and retrieval system

A method and apparatus for storing, deploying and retrieving a plurality of seismic devices is described. The apparatus includes a ramp device coupled to a portion of a trailing end of a vessel, a cable handling device positioned between the ramp device and a leading end of the vessel to define a cable path across the ramp device, and at least one conveyor system having a first end located adjacent the ramp device and a second end extending toward the leading end of the vessel. A deployment method includes providing nodes from a storage area to a workstation where the nodes may be attached to a cable. A retrieval method includes routing a cable through a workstation to detach nodes from the cable section and transfer the detached nodes to the storage area.

Owner:MAGSEIS FF LLC

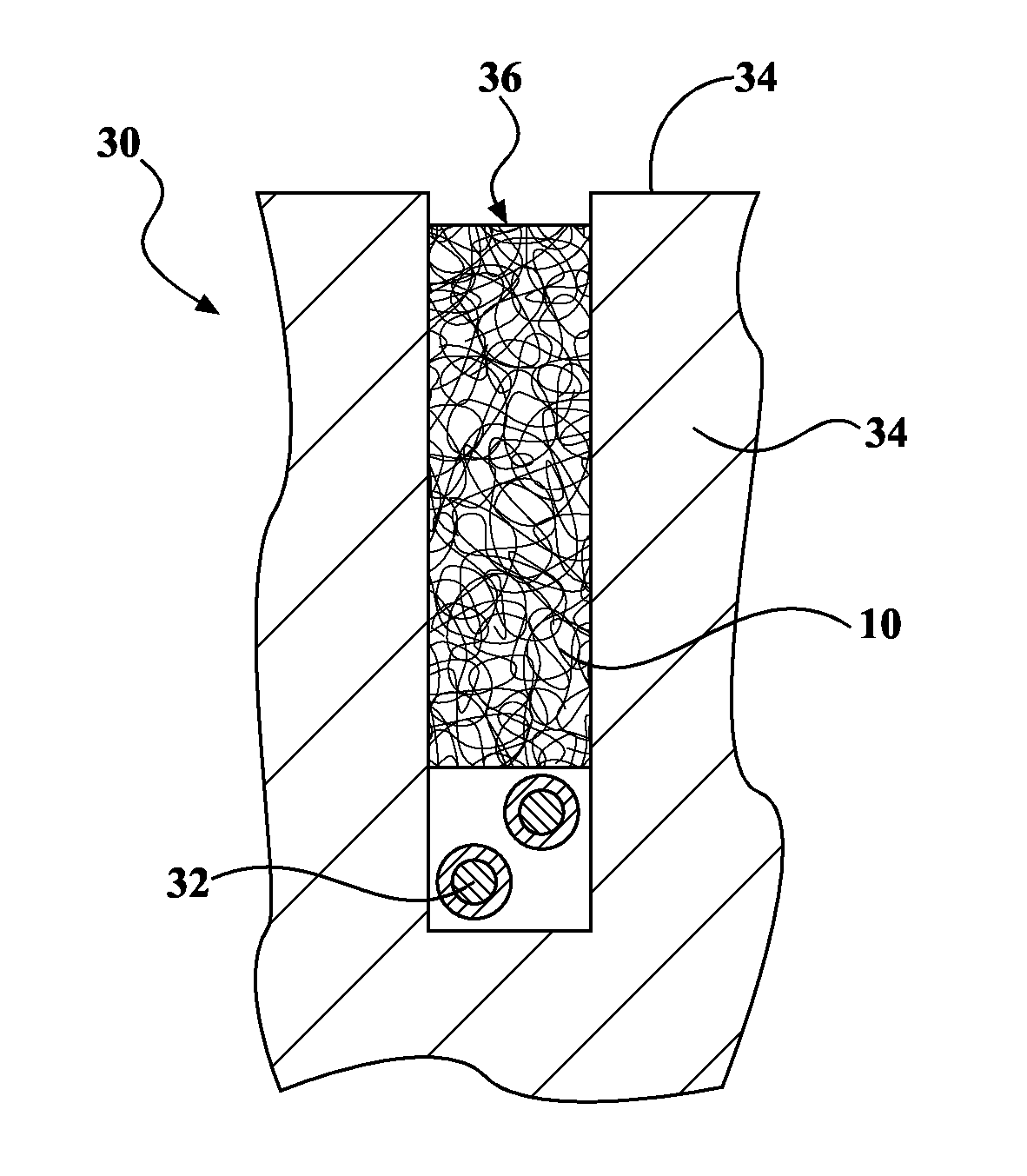

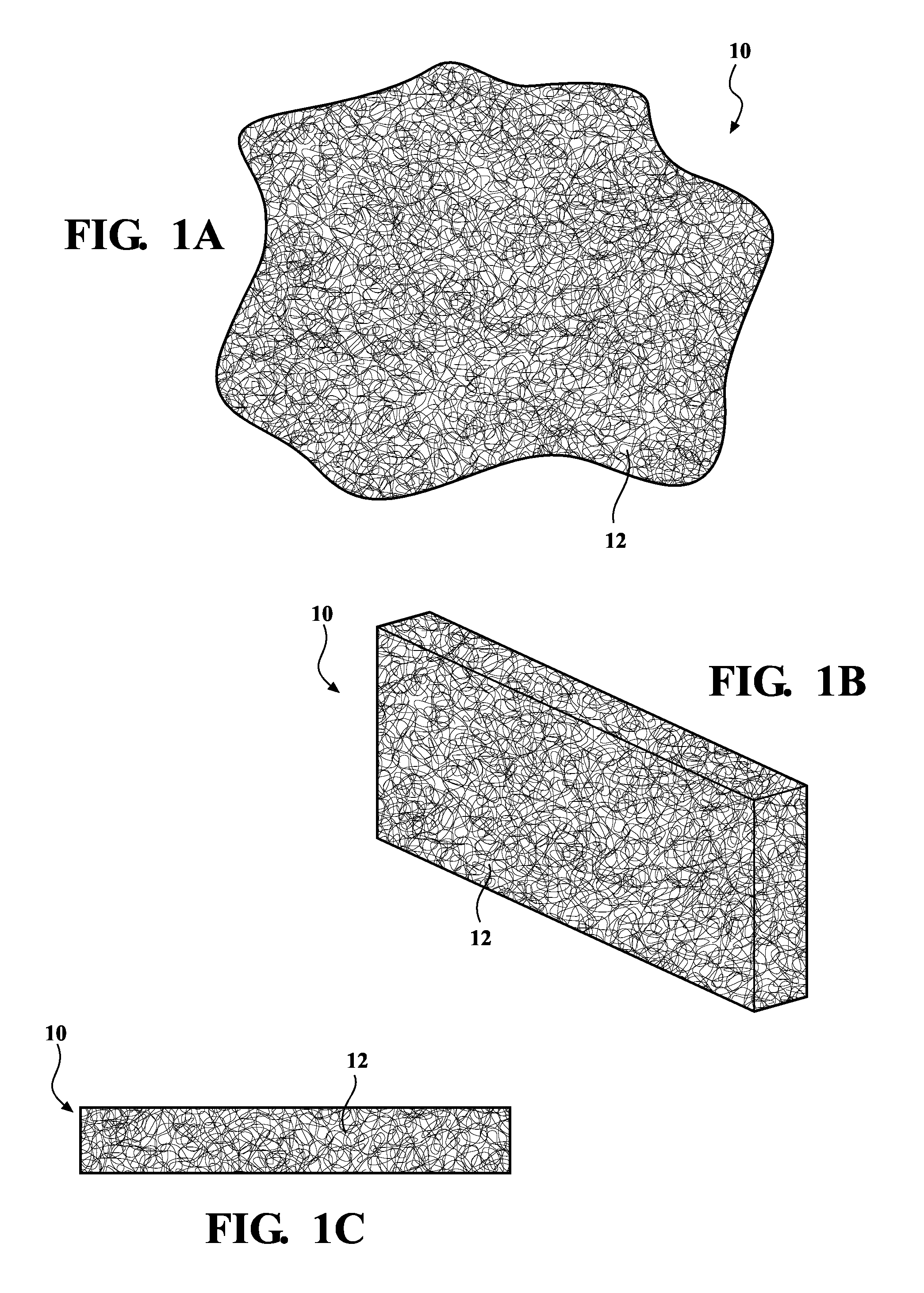

Multi-purpose micro-trench insert

InactiveUS20150300527A1Easy to installHigh strengthPipe laying and repairWaterborne vesselsEngineeringMechanical engineering

A micro-trench filling system and method of filling a trench holding a conduit is provided. The micro-trench filling system includes a trench formed into a covering surface, a conduit disposed in the bottom of the trench, a structural filler disposed on the conduit in the bottom of the trench, the structural filler made of a mesh material and having a plurality of openings; and a flowable filler poured into the trench and over the structural filler and surrounding the conduit. The flowable filler flows through the plurality of openings of the structural filler creating a bond between the flowable filler and structural filler, the flowable filler cures after a predetermined amount of time, and the structural filler and the flowable filler hold the conduit in place.

Owner:SUPERGROUT PRODS

Drain and a building structure having a drain

Owner:UNIDRAIN

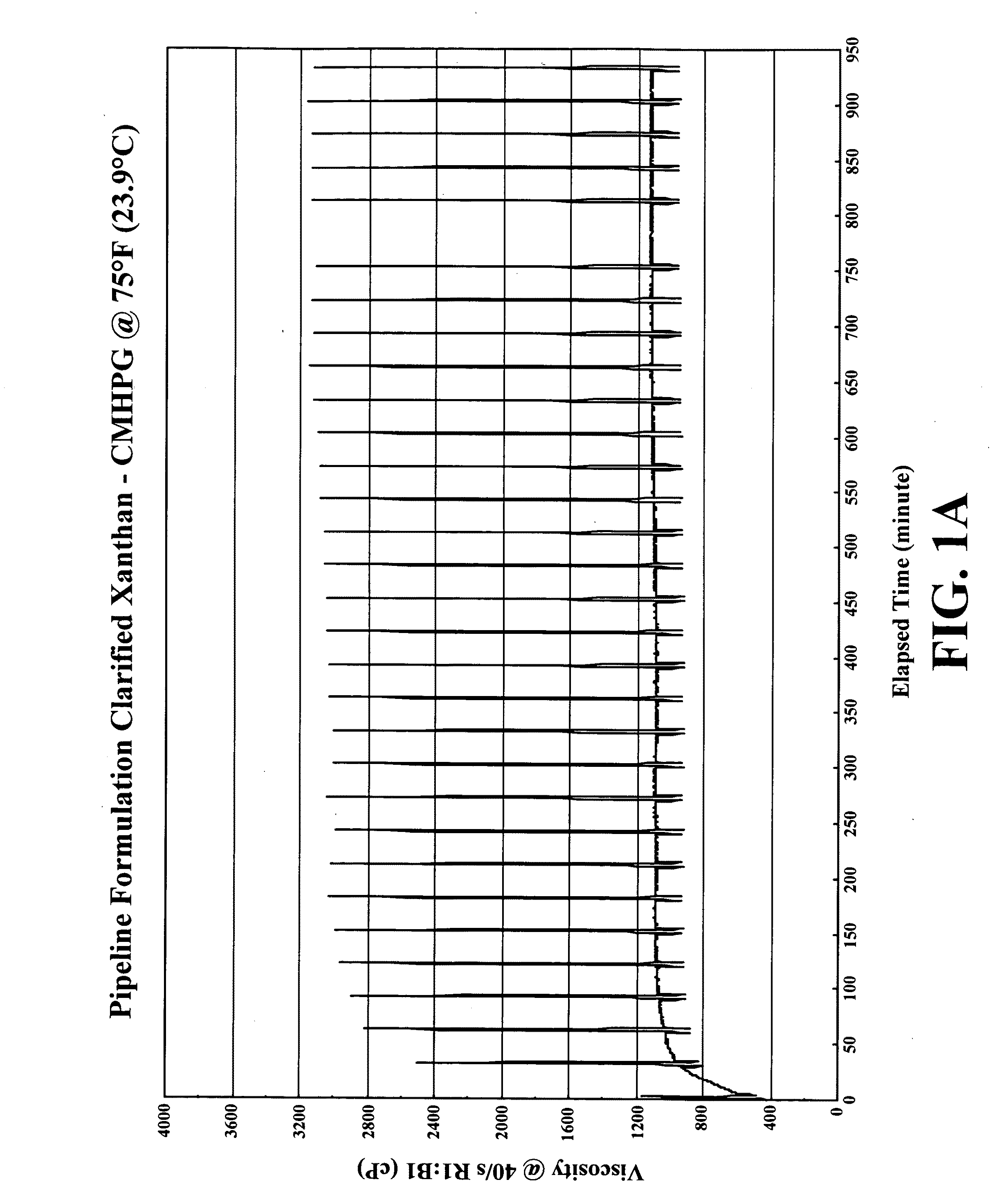

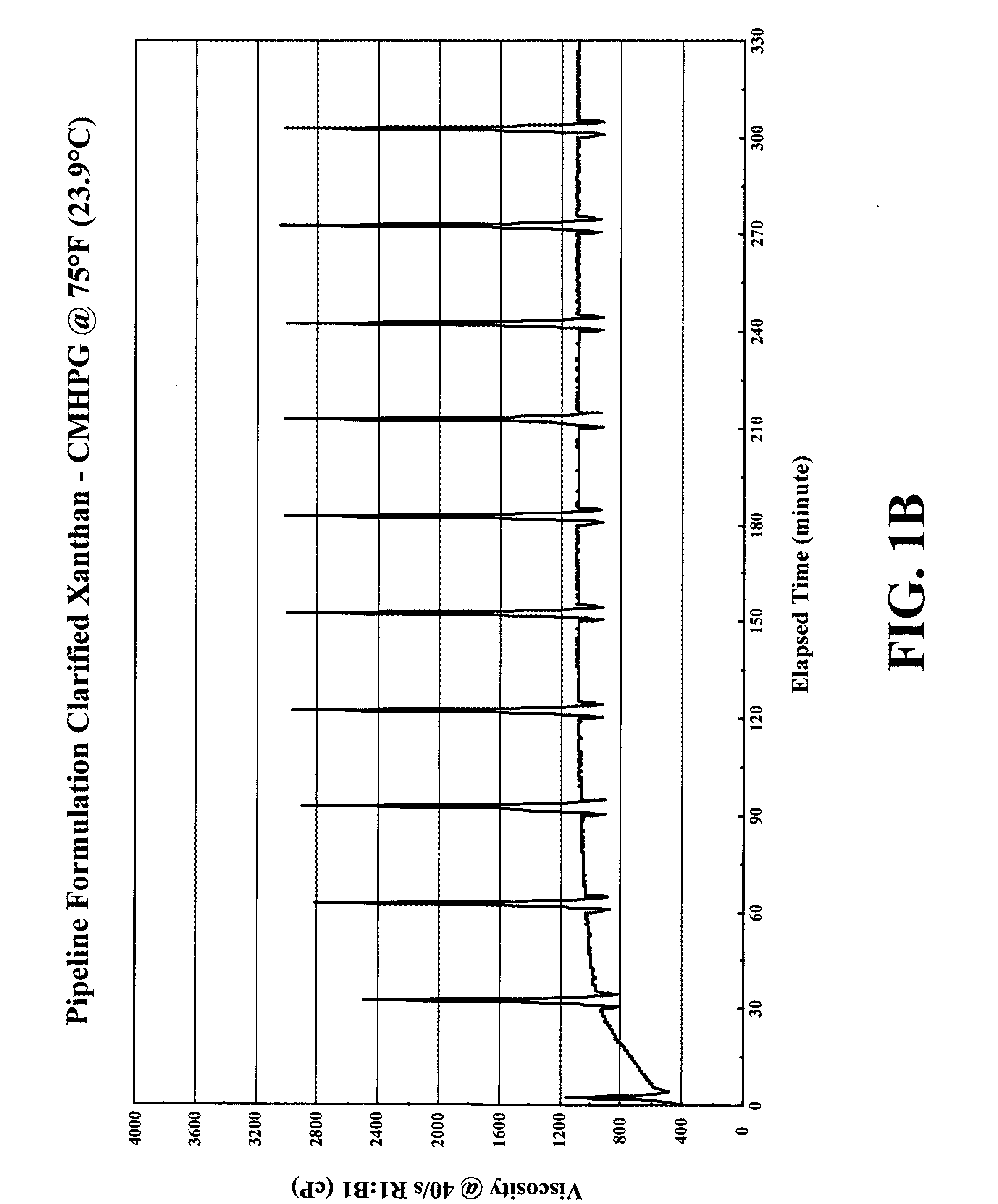

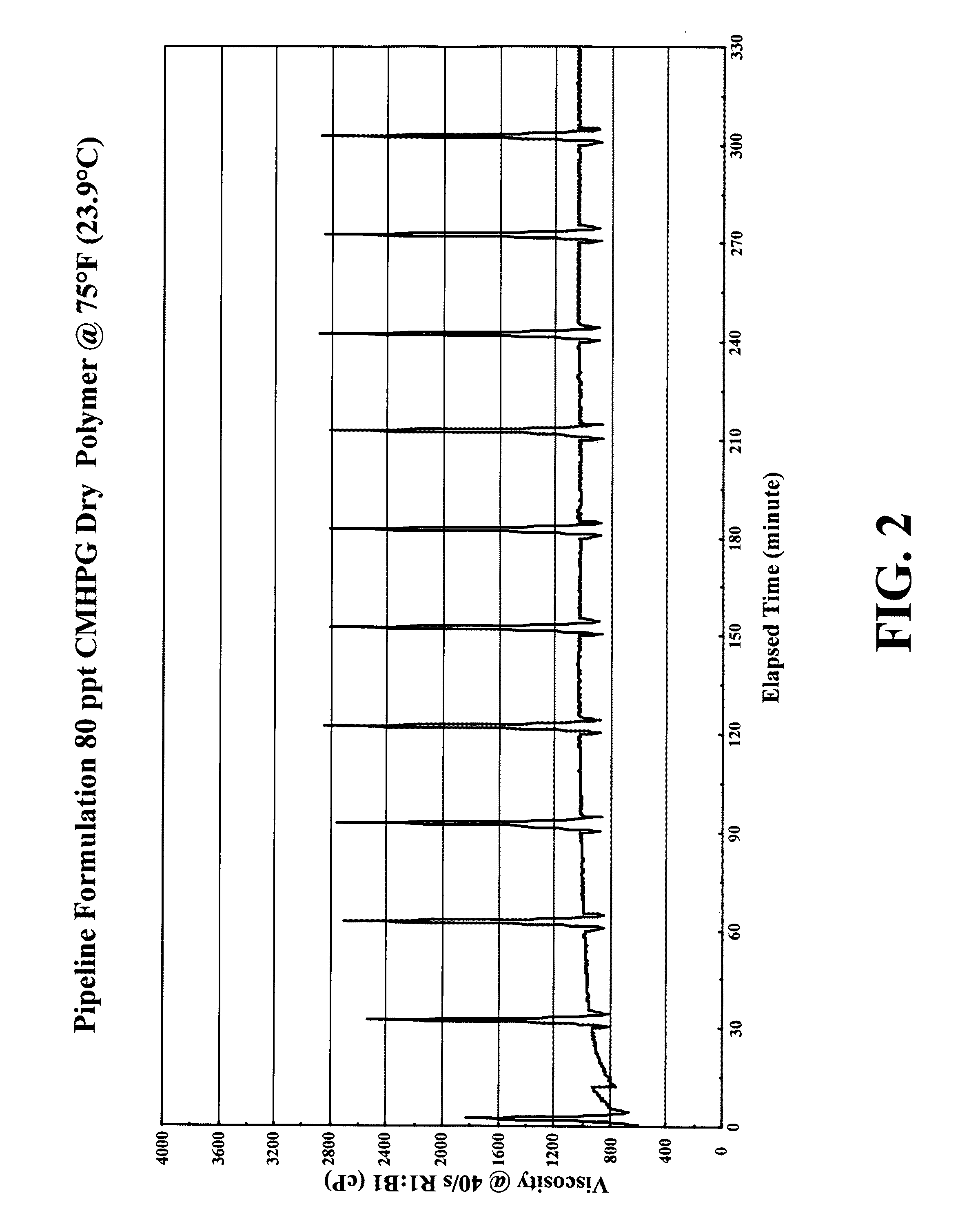

Potassium formate gel designed for the prevention of water ingress and dewatering of pipelines or flowlines

InactiveUS20090067931A1Reduce the amount requiredDetection of fluid at leakage pointPipe laying and repairOcean bottomPotassium formate

A gelled composition for pipeline, flowline, pipeline jumper or flowline jumper dewatering or preventing ingress of seawater into open pipeline systems or components during tie-in operations of jumpers or additional pipe, valving, manifolds, subsea pipeline architecture or flow conduits operations is disclosed, where the composition includes a concentrated metal formate solution and a hydratable polymer. The gelled formate compositions have improved dewatering properties with 100% or 360 pipe coverage. The gelled formate compositions have can also be reused by breaking and reformulation.

Owner:BAKER HUGHES INC

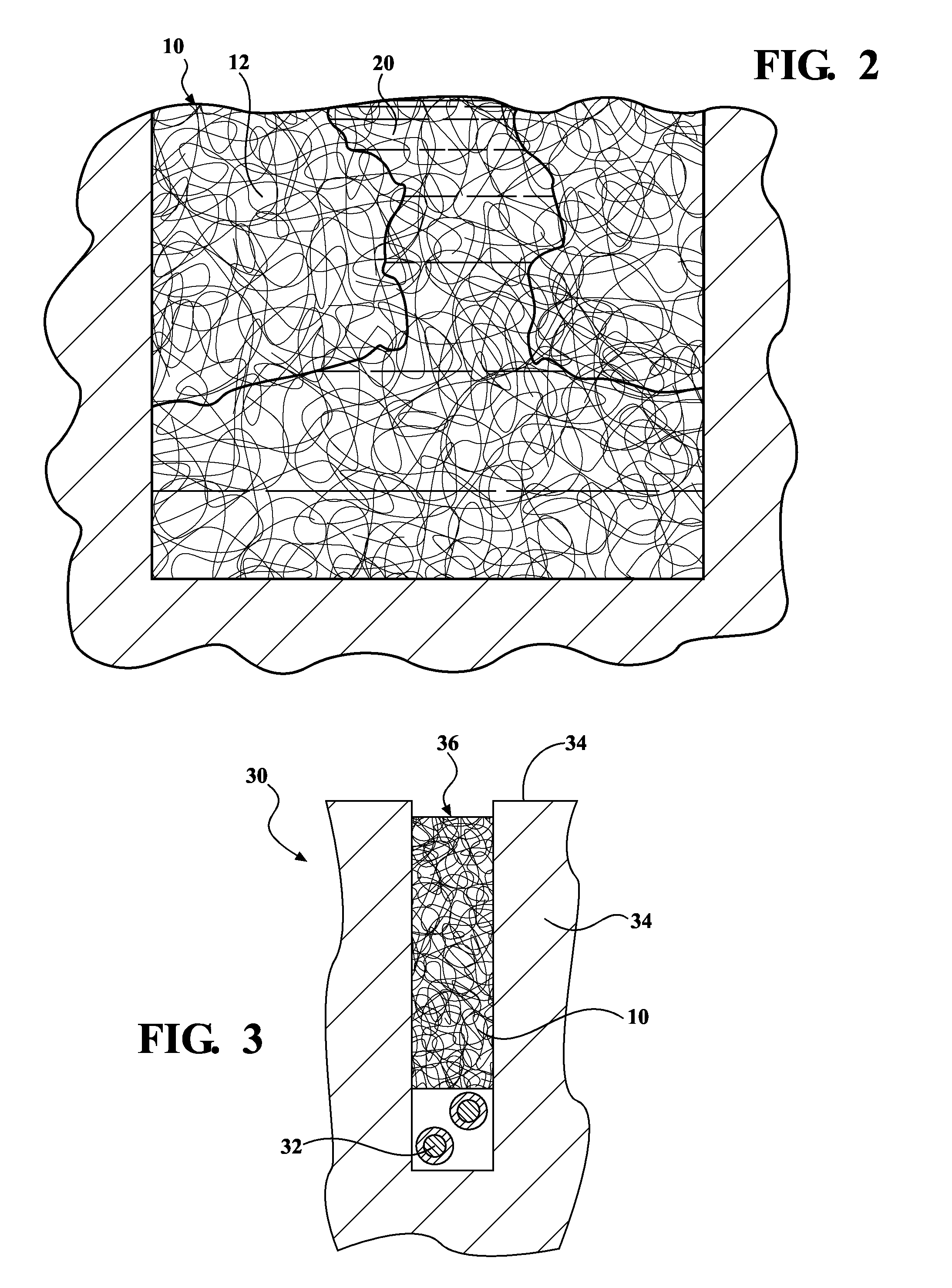

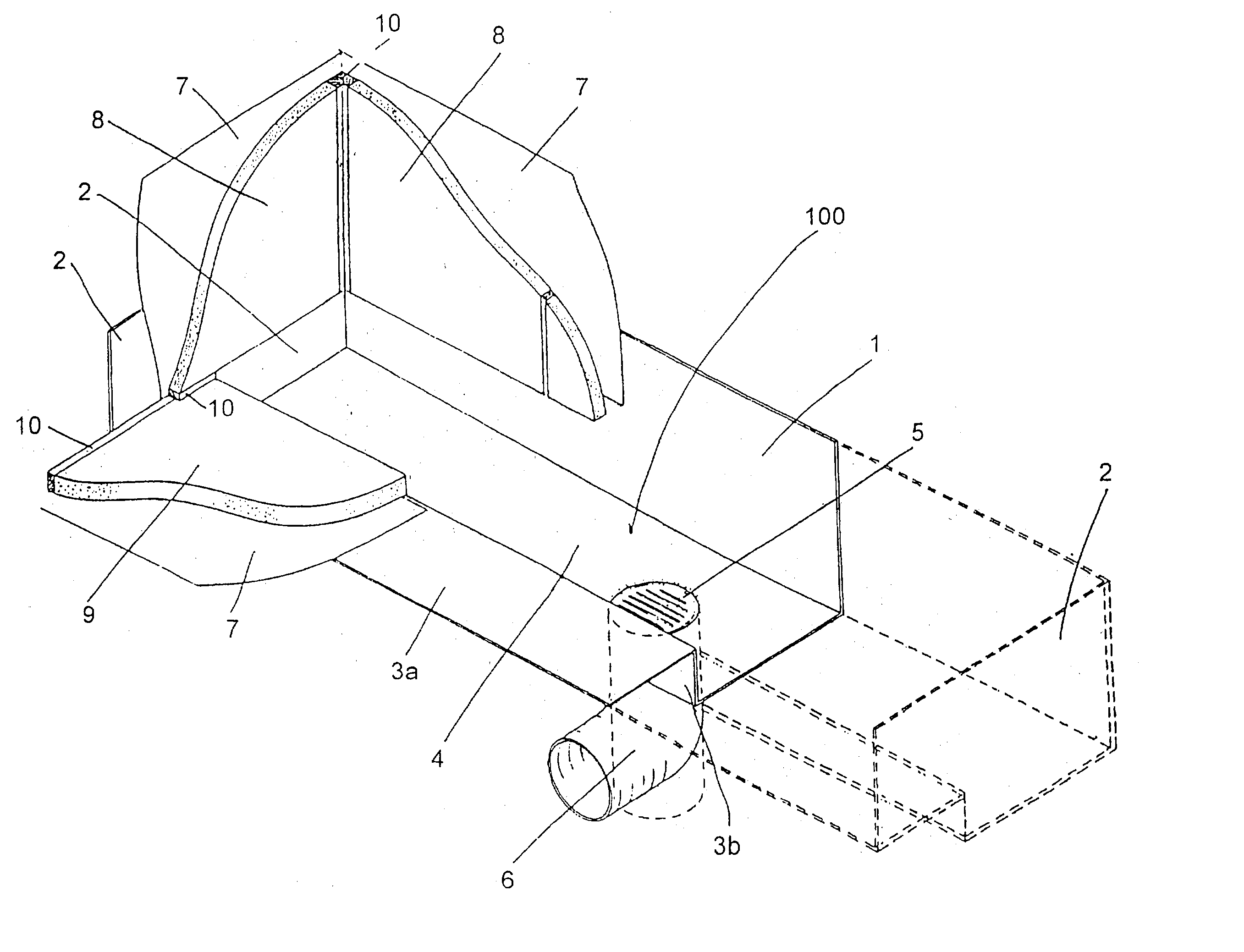

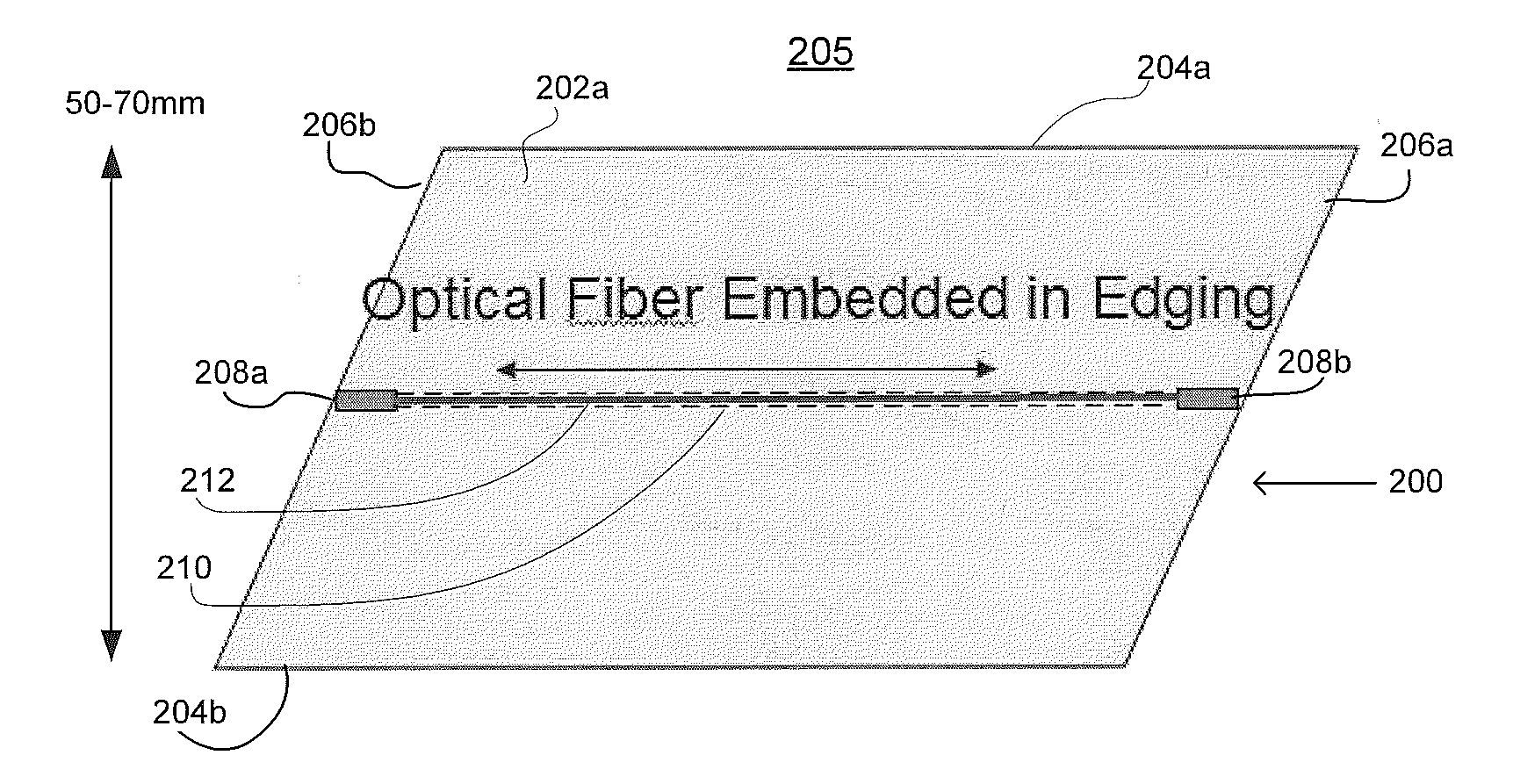

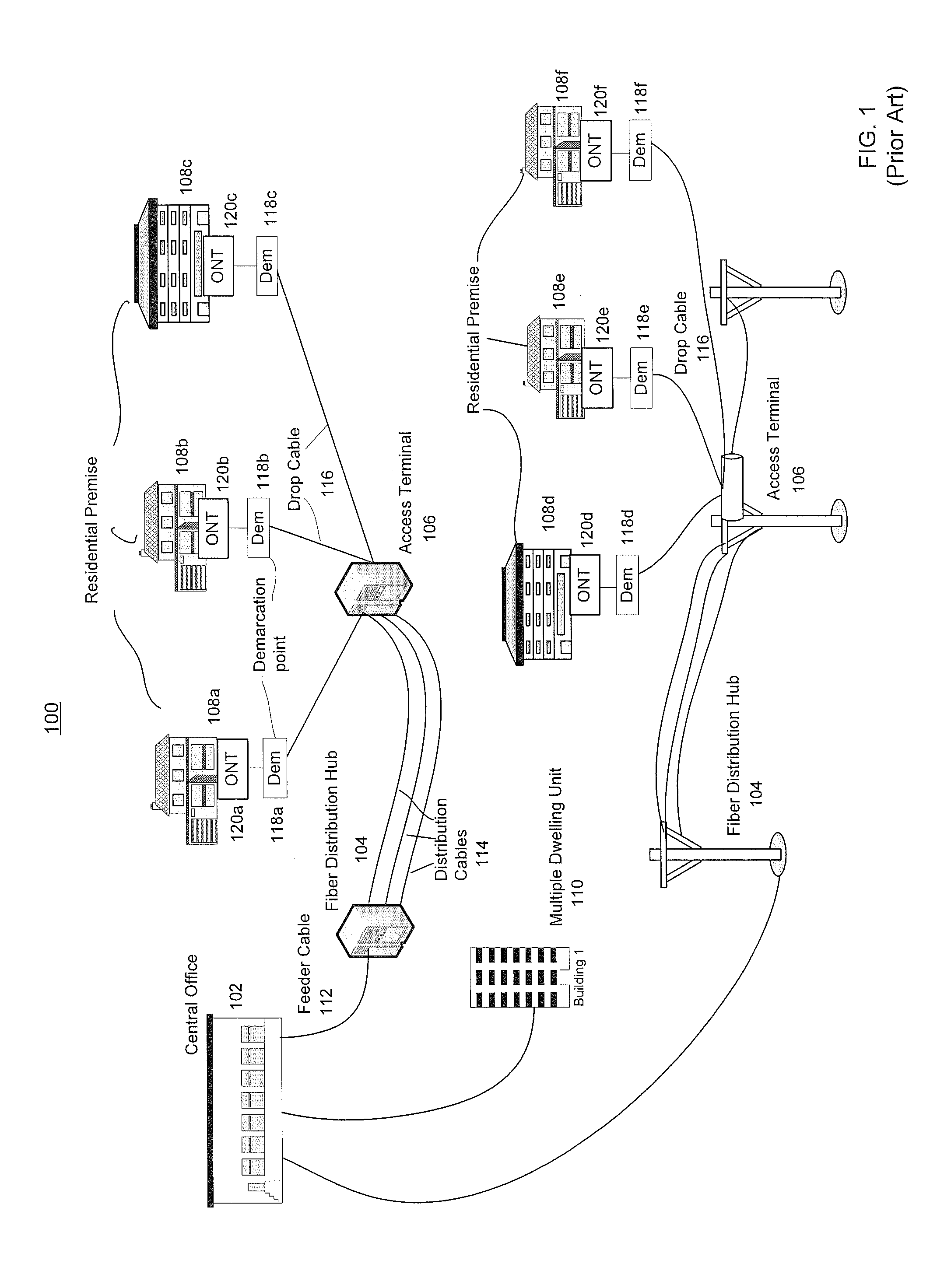

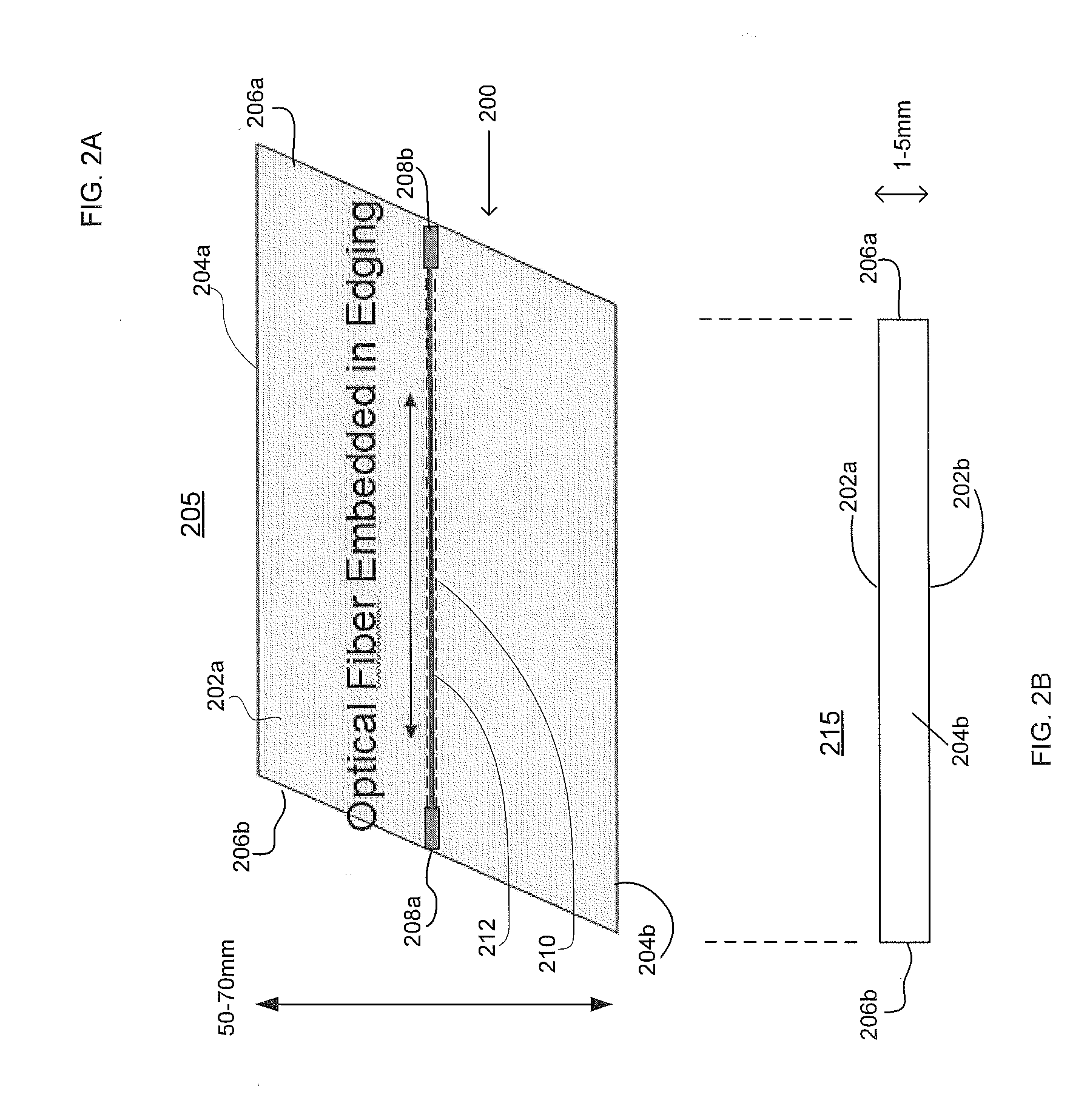

Cable edging systems and methods

InactiveUS20110315259A1Reduce impactImprove time savingPipe laying and repairPlanting bedsFiberHigh bandwidth

Devices and methods are provided for deploying optical fiber-optic cables or other cables. A general planar device is formed with a conduit disposed along the device. One or more fiber-optic cables or other types of communication cables are inserted through the conduit. The device with the embedded cables is pressed into the ground and can be used to provide high-bandwidth communications to a user's home from a service provider.

Owner:GOOGLE LLC

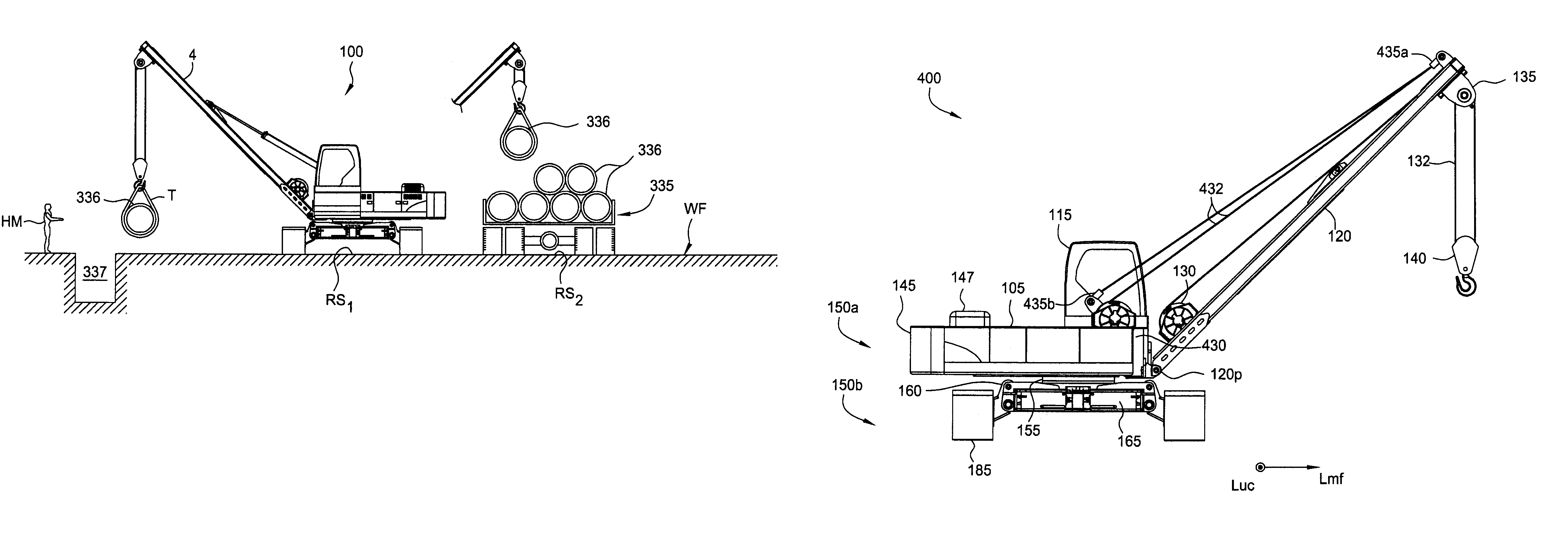

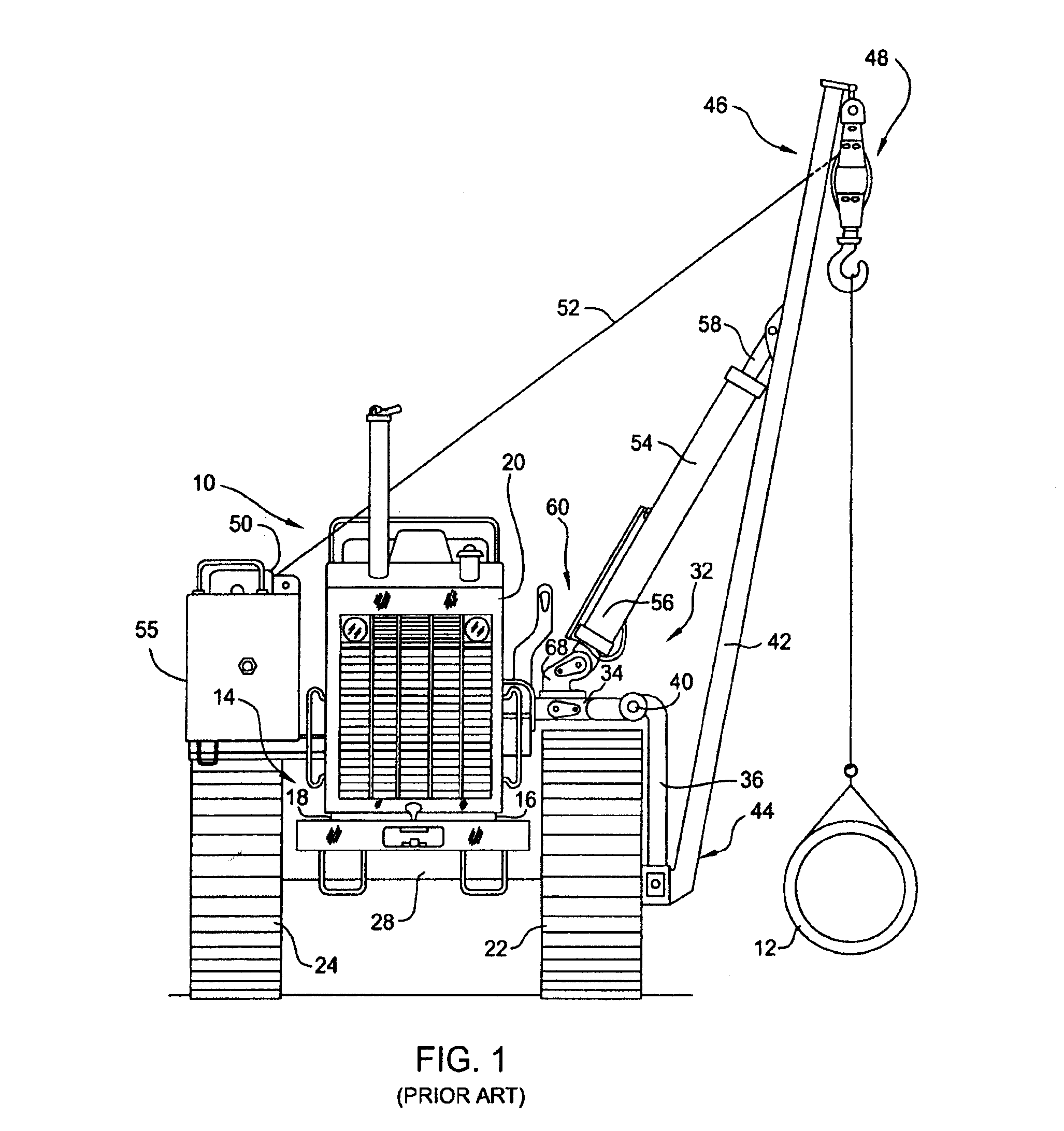

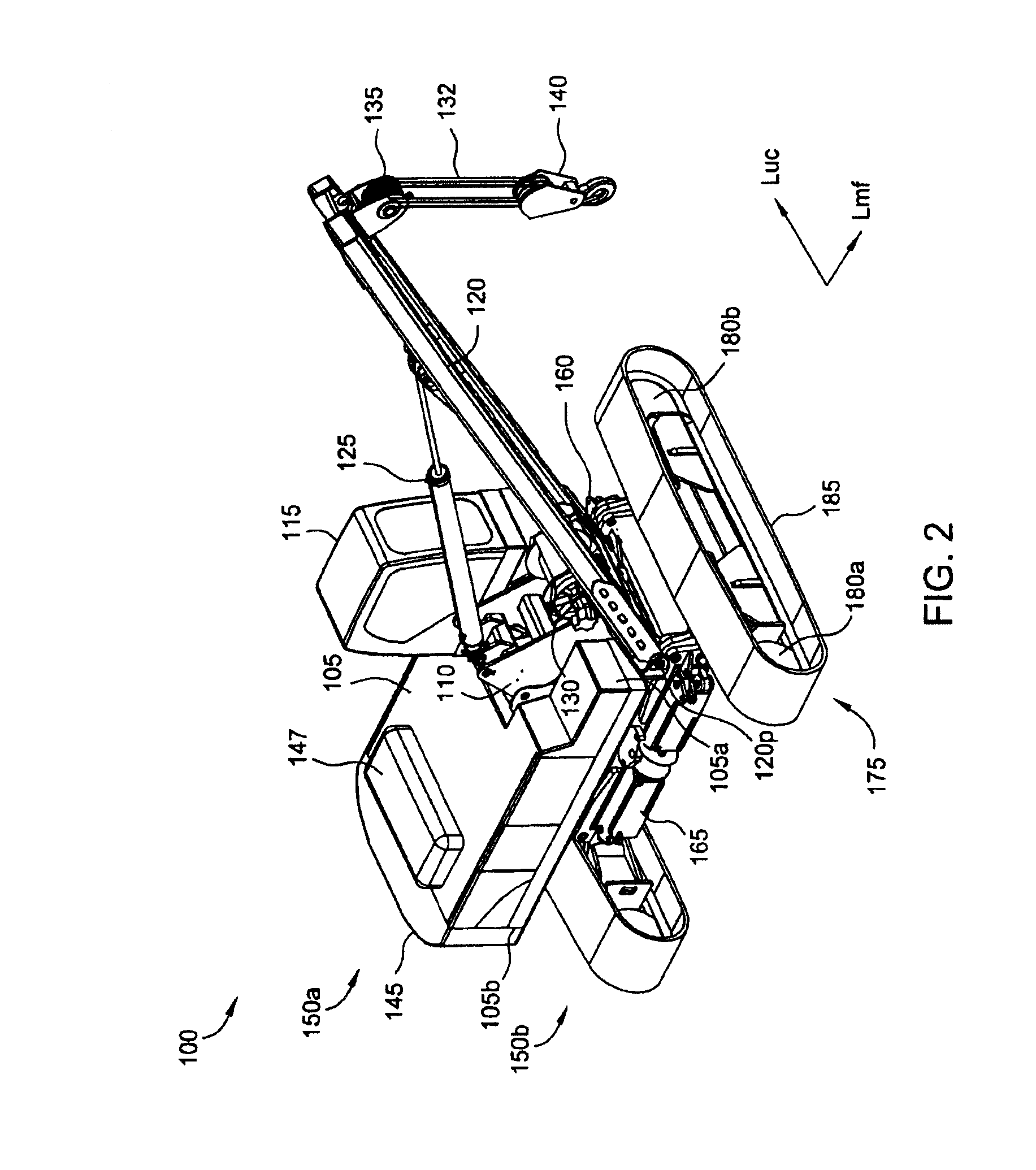

Pipelayer With Cab Riser

A pipelayer having an undercarriage with at least two tracks and a main assembly. Each track has a track frame coupled to the undercarriage and a track shoe supported by and movable around the track frame. The main assembly is supported by and rotatable relative to the undercarriage, and has a main frame, a boom pivotally mounted to the main frame, an operator cab, and a cab riser connecting the operator cab to the main frame. The cab riser is operable to selectively raise and lower the operator cab relative to the main frame. Also provided is a movable cab assembly having an operator cab, an adjustment mechanism to connect the cab to a vehicle frame and move to change the operator's view, and a guide to align the cab. A method for laying pipe using a pipelayer having a movable cab is also provided.

Owner:VOLVO CONSTR EQUIP

Subsea connector insulation device

ActiveUS20080063478A1Reduce convective heat lossReliable and cost-effective and easily implemented substantial sealPipe heating/coolingPipe elementsOcean bottomBiomedical engineering

A subsea insulation device is described. The device includes a frame coupled to and at least partially enclosing a subsea component. A bag may be at least partially enclosed in the frame. The bag may substantially seal against at least one surface of the subsea component when the bag is at least partially inflated. A port may be attached to the bag. The port may allow the bag to be coupled to a fluid provider connector so that fluid can be provided into the bag to inflate the bag.

Owner:DEEP SEA TECH

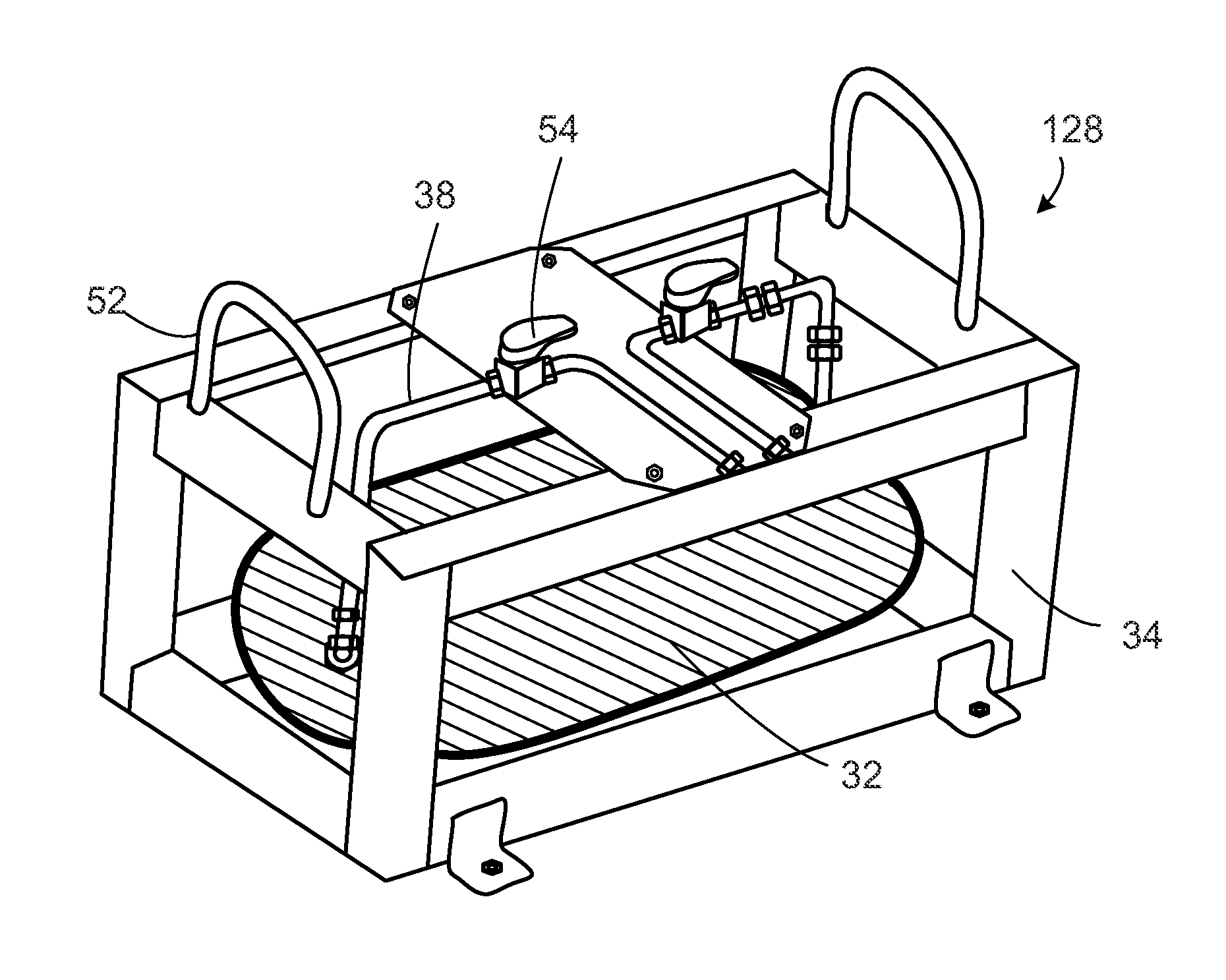

Subsea pipeline service skid

InactiveUS8381578B2Reduce pressureDetection of fluid at leakage pointPipe elementsMarine engineeringSubmarine pipeline

Owner:VALKYRIE COMMISSIONING SERVICES

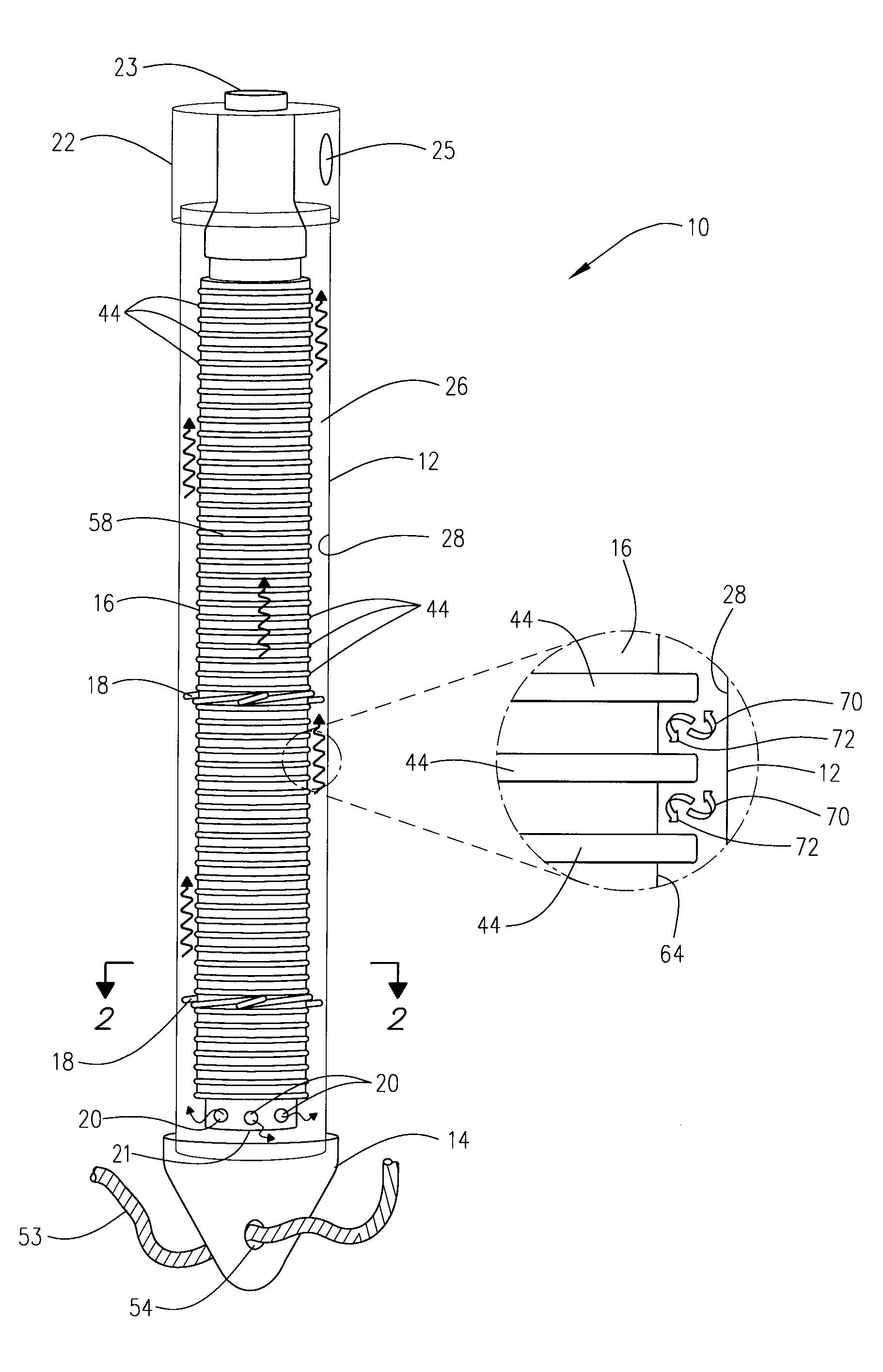

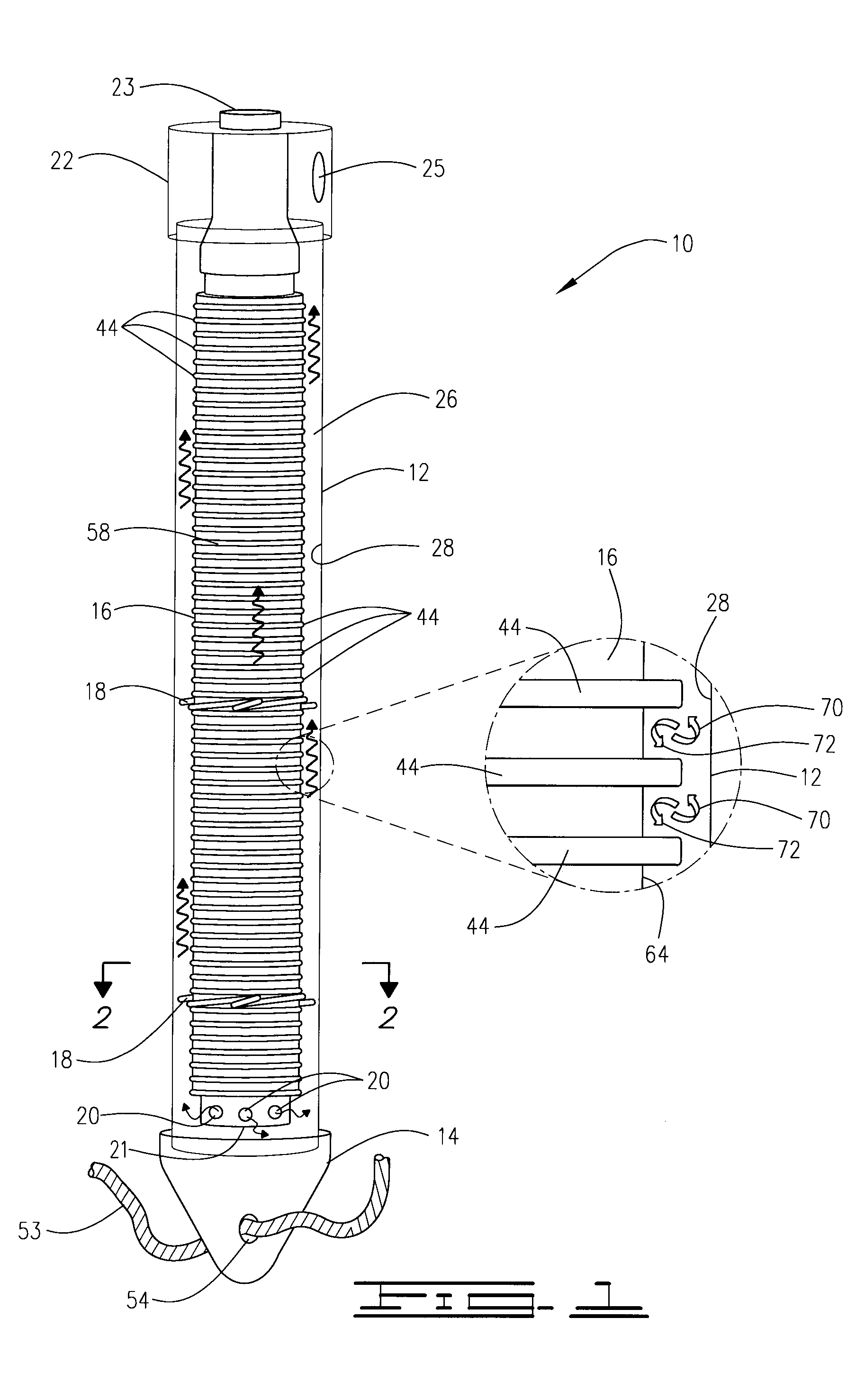

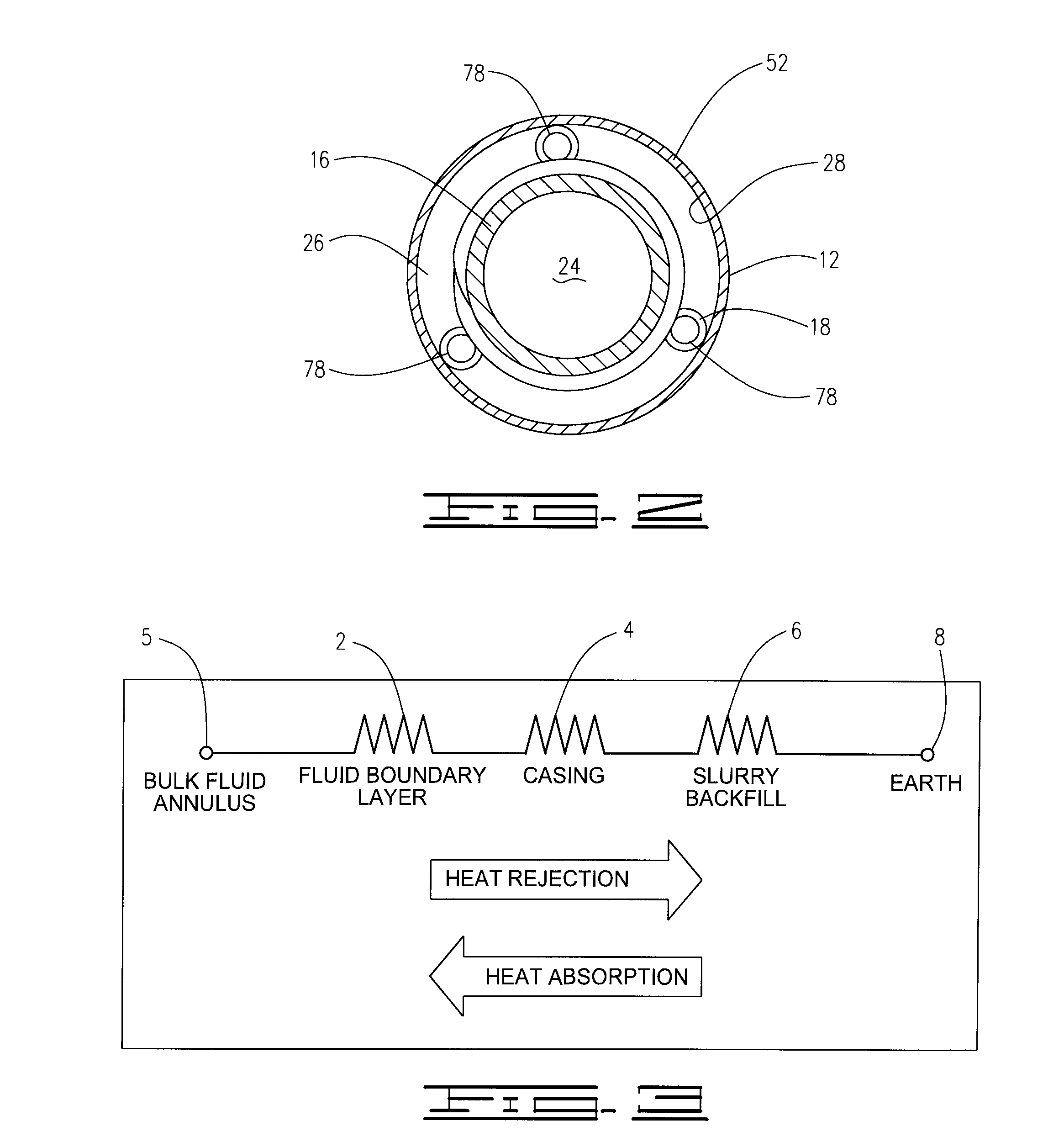

Method, apparatus, header, and composition for ground heat exchange

ActiveUS20100218912A1Solution to short lifeFine surfacePipe laying and repairCollector components/accessoriesSodium BentoniteSlurry

A subterranean ground heat exchange system, a method of installation, and a grout composition therefor. The grout composition is a pumpable slurry formed of from about 70 to about 85 parts by weight natural flake graphite and from about 30 to about 15 parts by weight bentonite. The solids content of the pumpable grout slurry is preferably at least 35% by weight and is more preferably at least 40% by weight. The ground exchange apparatus preferably utilizes an improved supply and return header comprised of supply and return ports which are provided through the vertically extending outer wall of a header housing. The header also includes an interior supply conduit which extends from the supply port into the interior of the header housing and includes a bend positioned in the interior of the housing for directing the heat transfer fluid downwardly.

Owner:RYGAN CORP

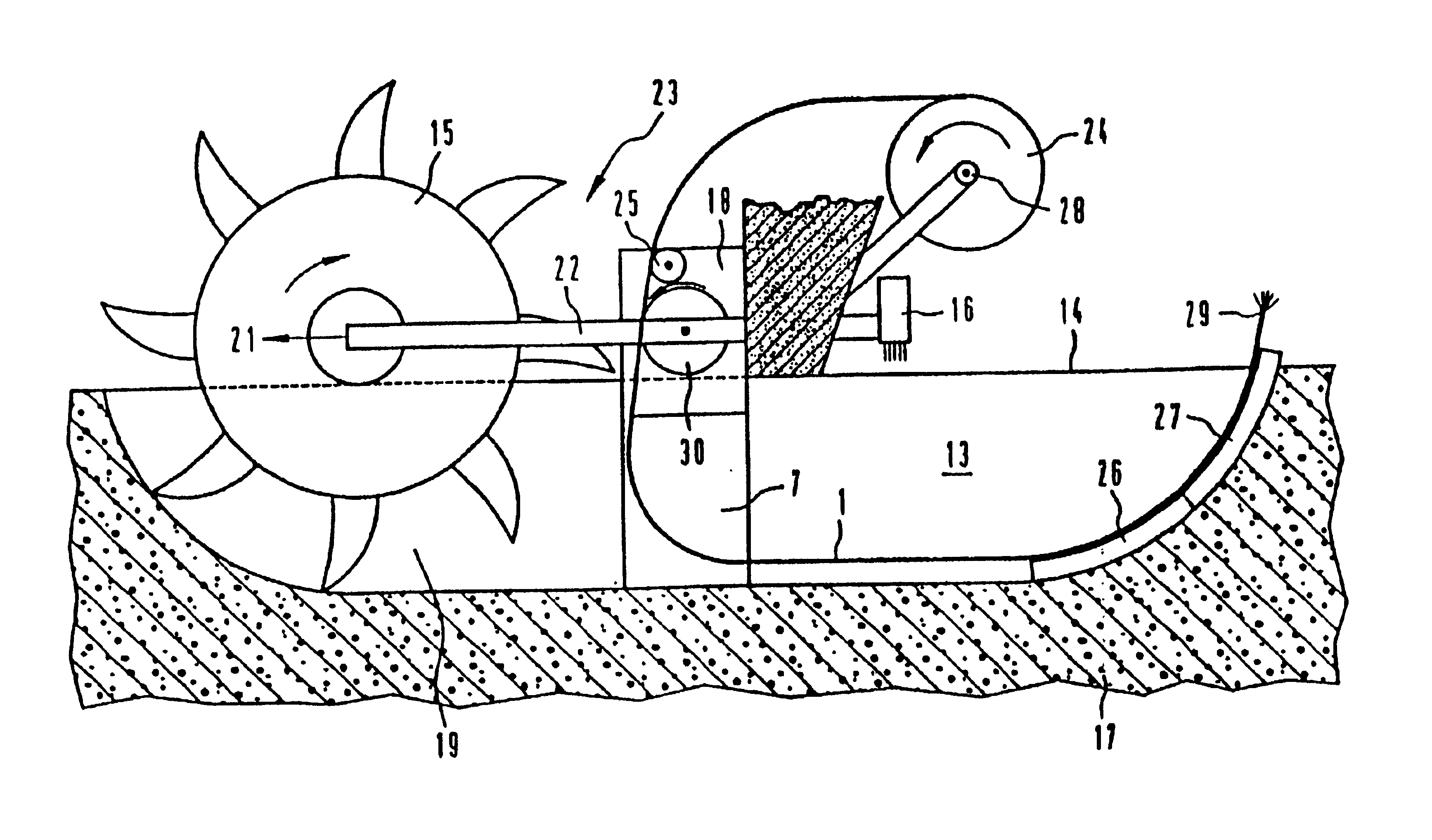

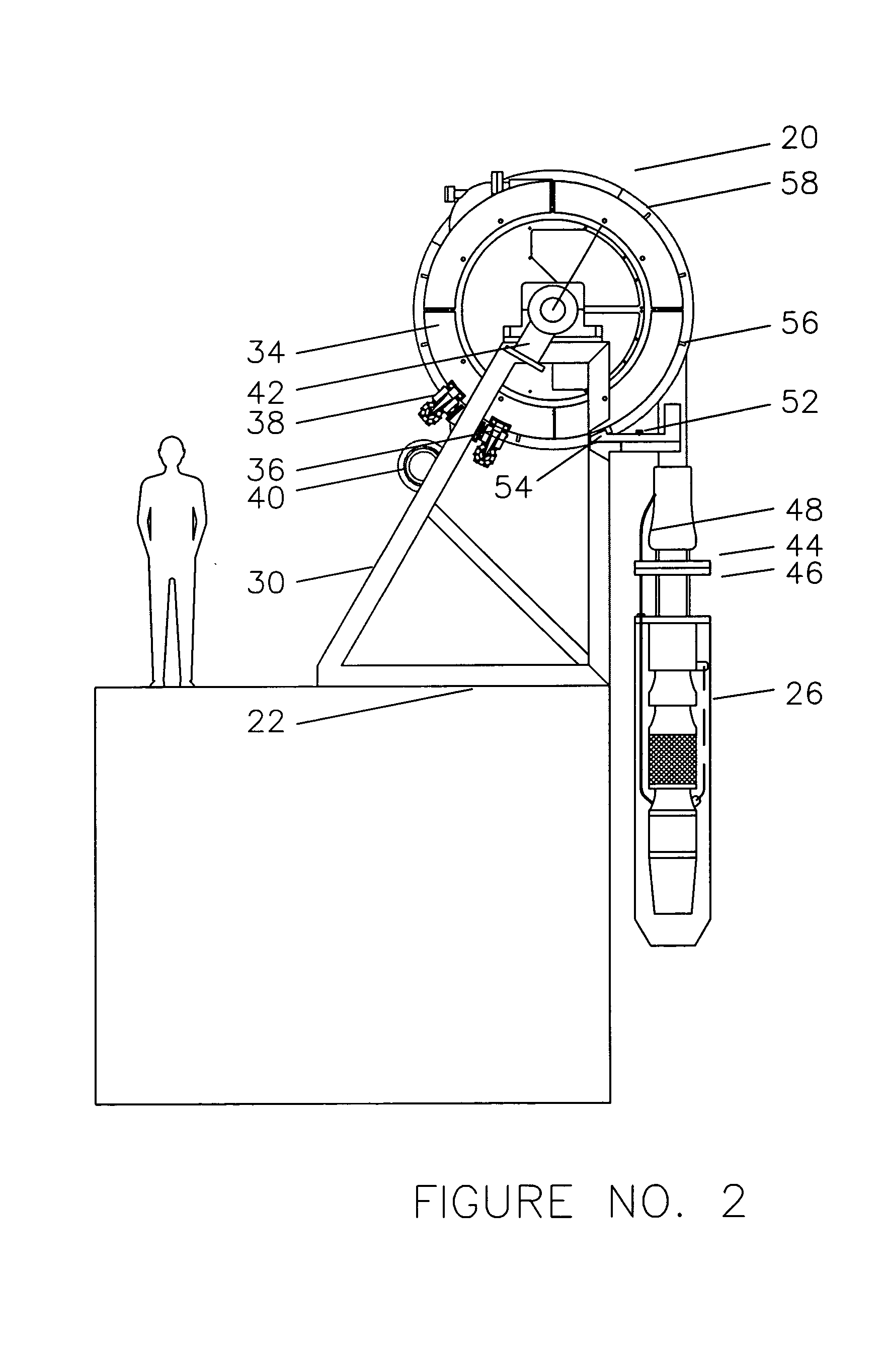

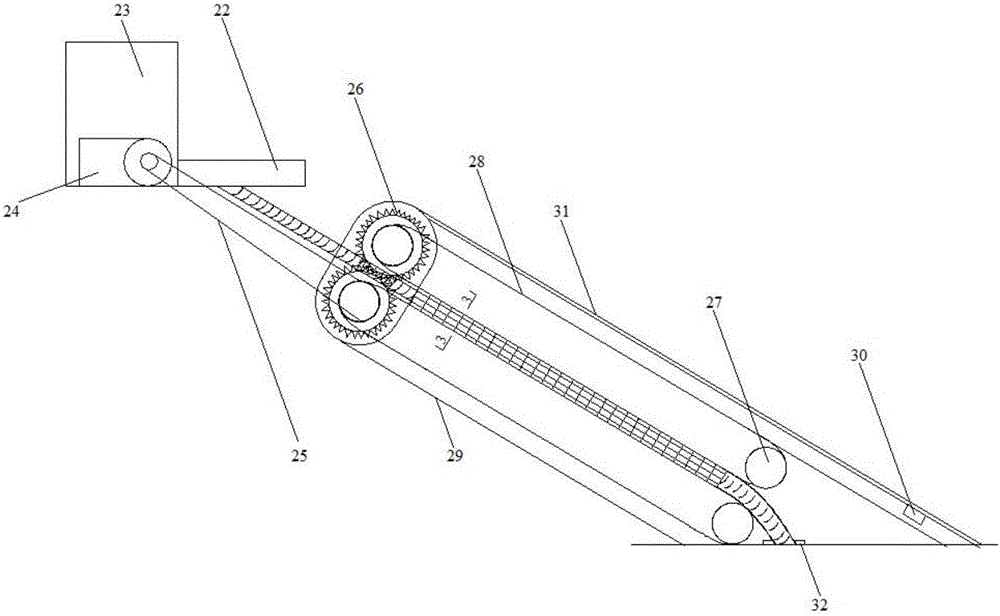

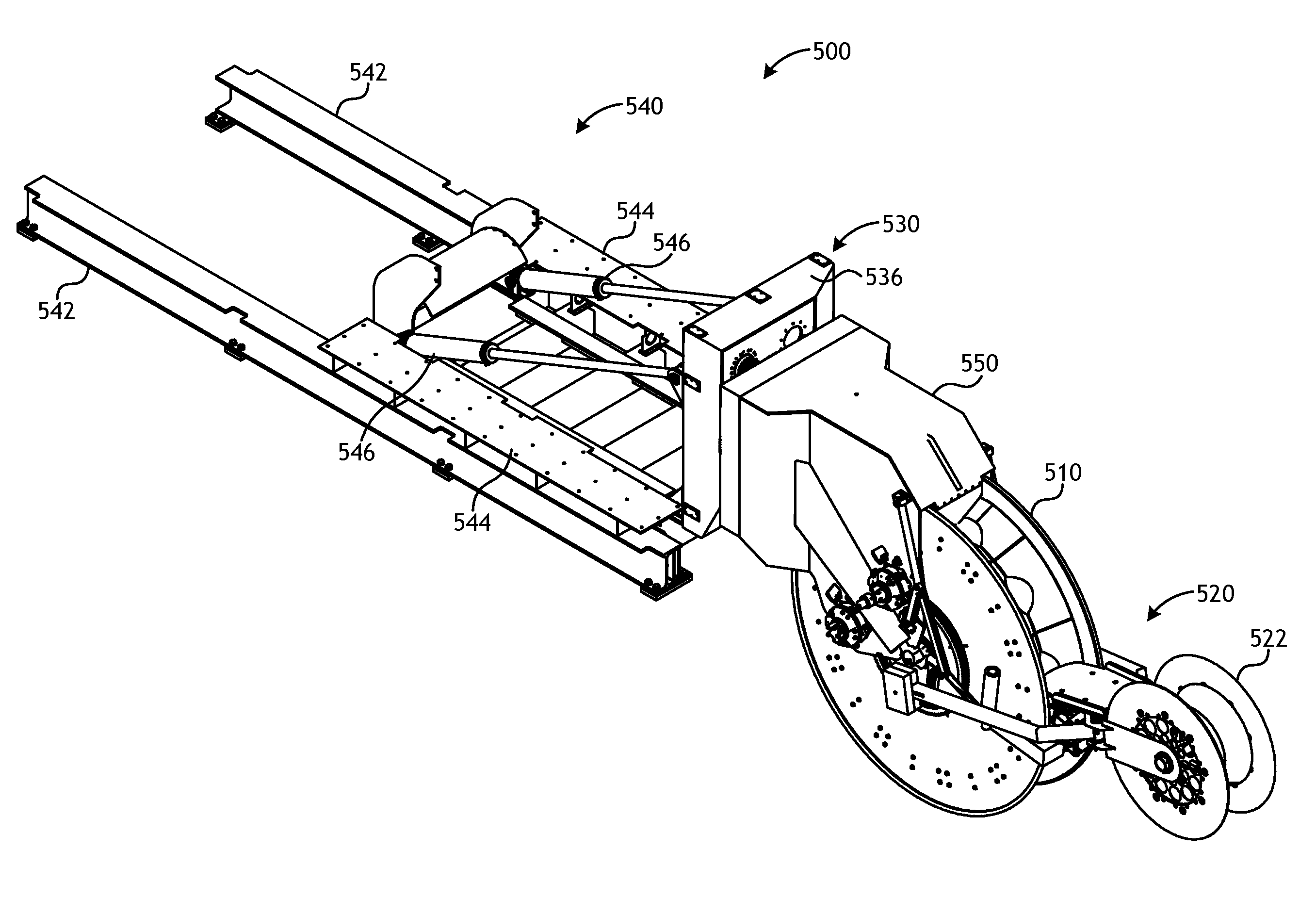

Powered sheave for node deployment and retrieval

ActiveUS20100054078A1Increase relative motionKeep movingTowing/pushing equipmentPipe laying and repairMarine engineeringNode deployment

A method and apparatus for deploying a plurality of seismic sensor units into a water column is described. The method includes providing a length of flexible cable from a cable storage device disposed on a vessel to a powered sheave, the cable having a plurality of spaced apart attachment points, routing the cable from the powered sheave to pass adjacent a workstation disposed on the vessel, deploying a free end of the cable into the water column while increasing the motion of the vessel to a first speed, operating the vessel at the first speed while providing a deployment rate of the cable at a second speed, the second speed being greater than the first speed, decreasing the second speed of the cable as an attachment point approaches the work station, and attaching at least one of the plurality of seismic sensor units to the attachment point at the workstation.

Owner:MAGSEIS FF LLC

Deepwell reel

A method of providing for seawater supply to an offshore jackup rig comprising suspending a pump from a hose which is unreeled from a reel on the jackup rig, the hose comprising fluid flow capacity for allowing seawater to be pumped from ocean depths up to the jackup rig, axial tensile capacity members within the wall of the hose to support the pump and the column of pumped water, and electricity carrying members within the wall of the hose to power the pump, a gland for the insertion of an electrical umbilical within the internal bore of the hose, and laying the hose horizontally on the deck of the jackup to insert the electrical umbilical within the hose.

Owner:BAUGH BENTON F

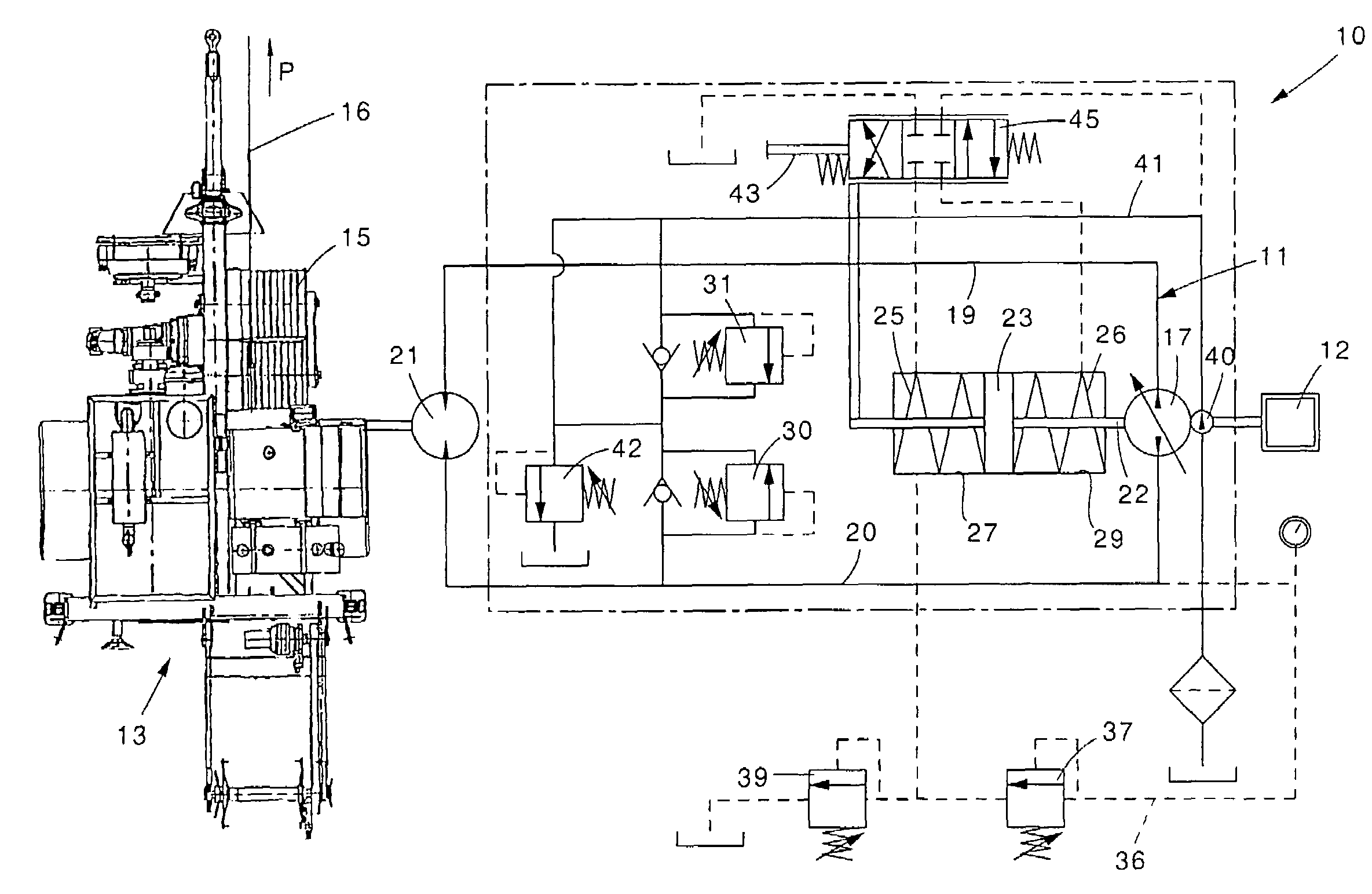

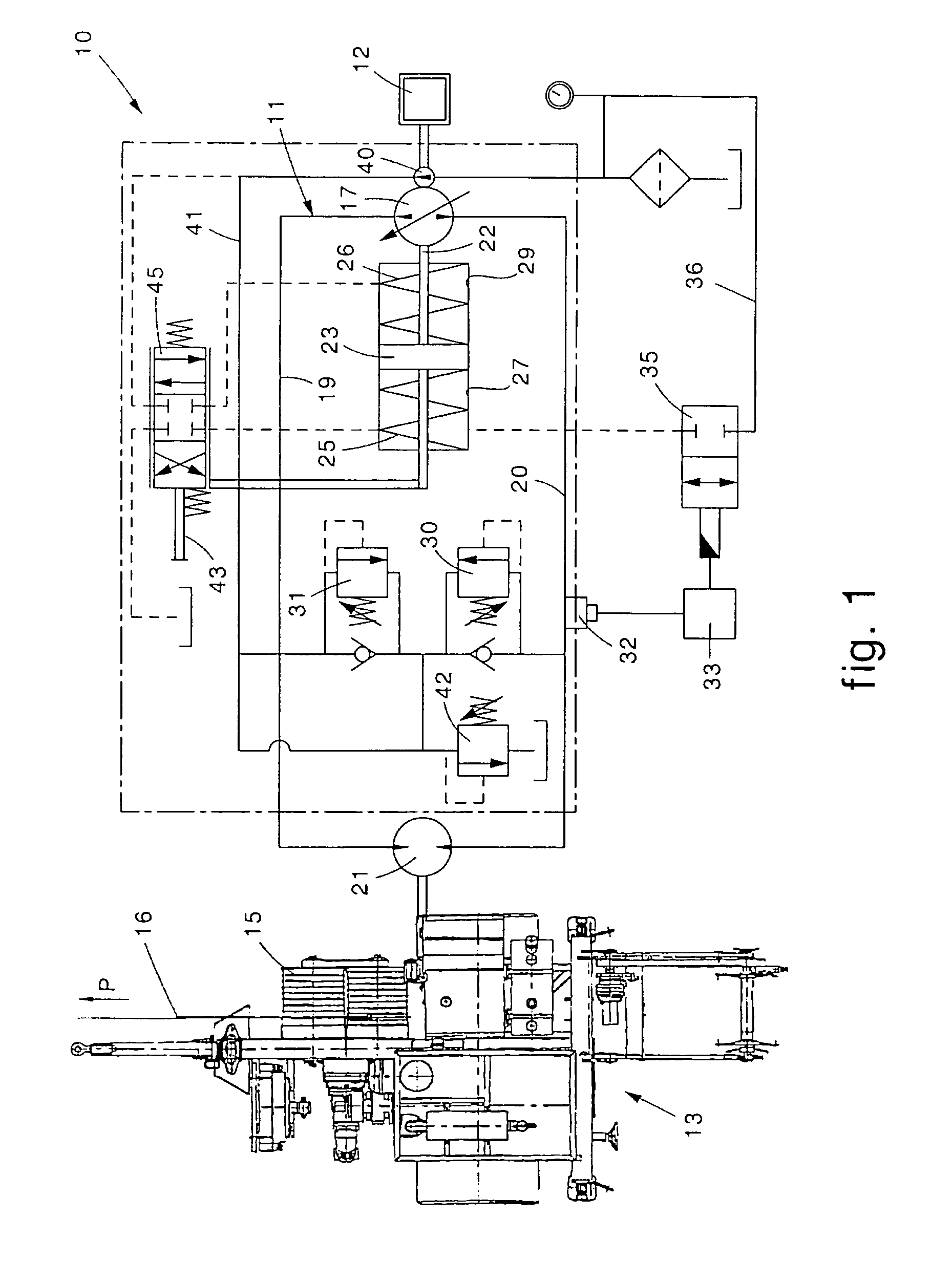

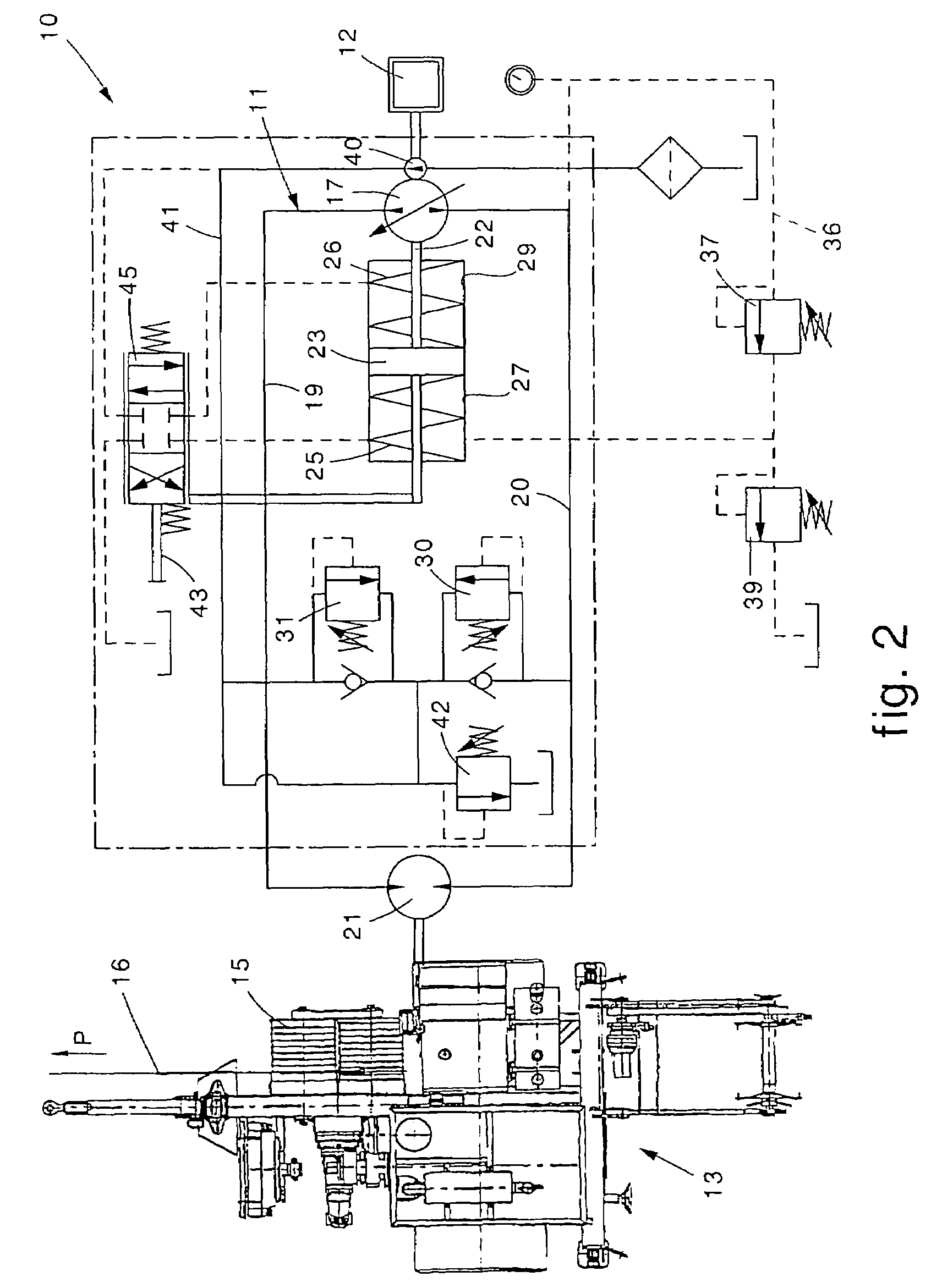

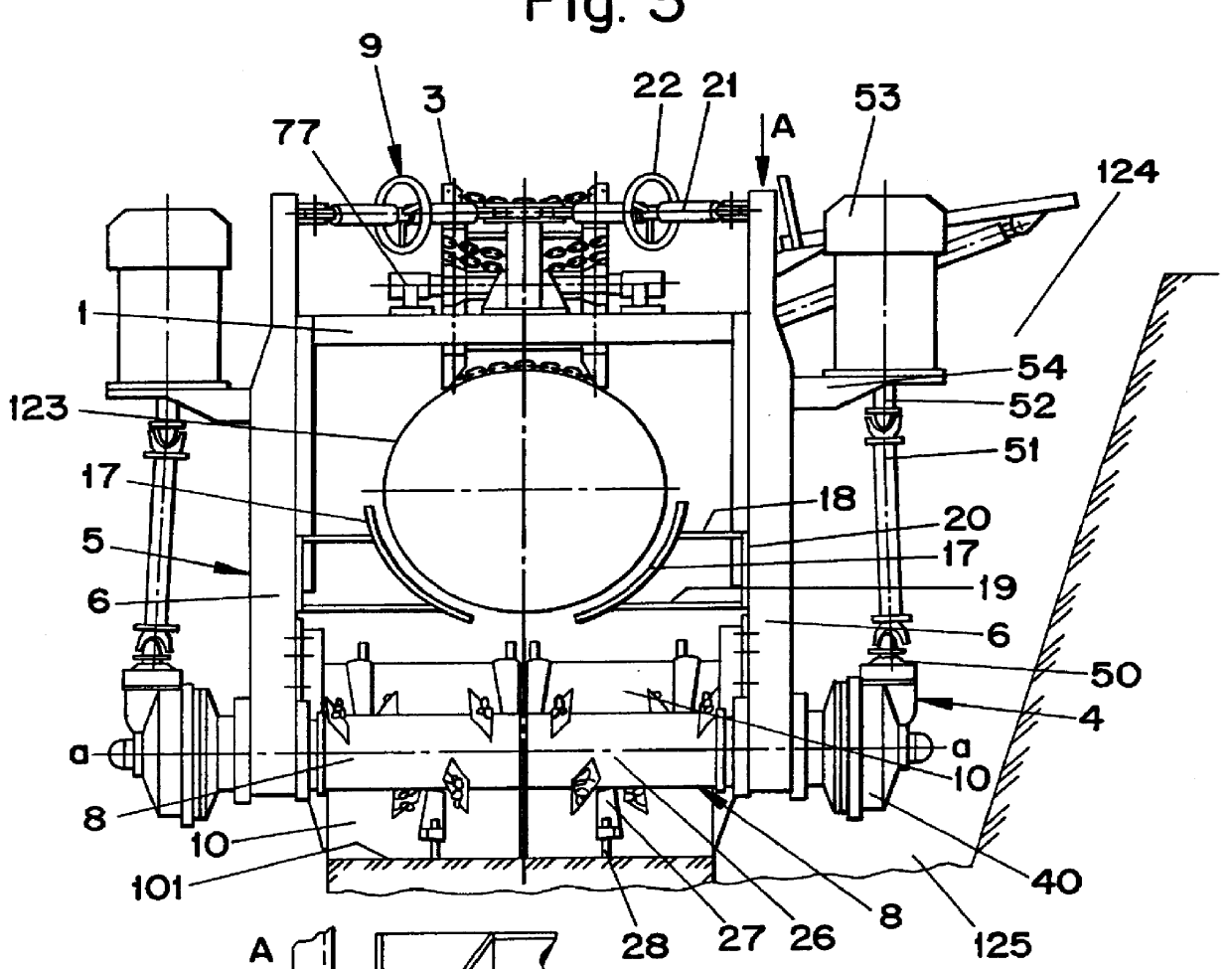

Laying apparatus for cables, lines, conductors or suchlike, and relative laying method

InactiveUS7093433B2Reduce deliveryReduce oil pressurePipe supportsPipe laying and repairHydraulic circuitEngineering

Laying apparatus and method for cables, lines, conductors or suchlike. The apparatus comprises at least a hydraulic circuit provided with a variable delivery feed pump and with a motor connected to the feed pump in order to drive laying members for the cables and suchlike. The hydraulic circuit comprises detectors able to detect the value of pressure of the oil inside the hydraulic circuit and to compare it with a pre-determined pressure value, and valves connected to the detectors and able to reduce the delivery of the feed pump in the event that the pressure measured exceeds the pre-determined pressure value.

Owner:TESMEC

Drain and a building structure having a drain

Owner:UNIDRAIN

Load-bearing, lightweight, and compact super-insulation system

ActiveUS20050047871A1Easy to installEasy maintenanceDrilling rodsService pipe systemsEngineeringInsulation system

A lightweight and compact super-insulation system that is also capable of supporting a high level of compressive load is described. The system utilizes spacers to provide structural support and utilize controlled buckling of a thin protective outer skin supported by spacers to form strong catenary surfaces to protect insulation material underneath. The spacers may comprise an aerogel, or an aerogel may provide insulation separate from the spacer yet contained within the thin outer skin. The system will be useful for thermal management of variety of deep underwater structures such as pipe-in-pipe apparatus, risers or subsea trees for ultra-deep water oil-and-gas exploration.

Owner:ASPEN AEROGELS INC

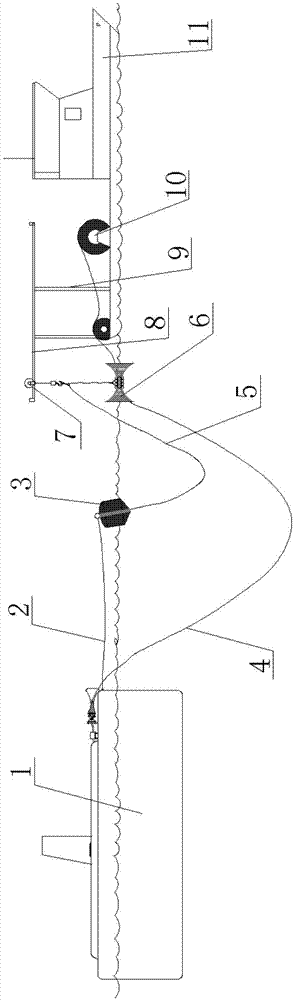

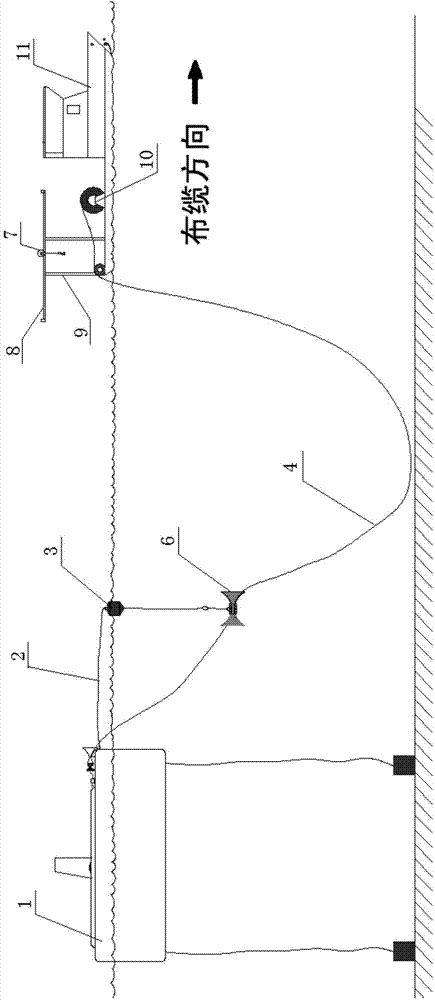

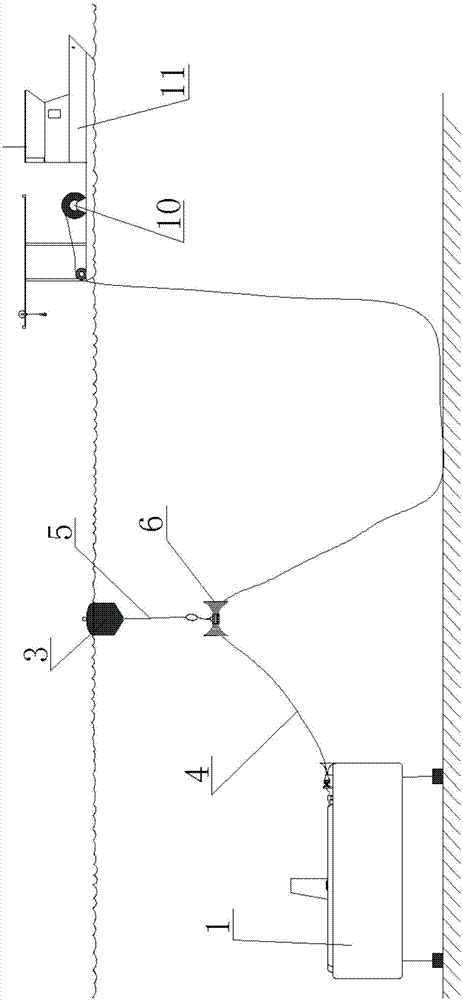

Device and method for laying and recycling cables

The invention relates to a device and a method for laying and recycling cables. The device comprises a floating drum, a steel cable and a suspension component. A cable storage disc is arranged on the upper portion of the floating drum, and a cable outlet pipeline is arranged in the floating drum. One end of the steel cable is wound and fixed to the cable storage disc, the other end of the steel cable penetrates through the cable outlet pipeline and is fixedly connected with the suspension component, a locating component is fixedly connected to the outer wall of the middle of the suspension component, the locating component is connected with the steel cable, and the suspension component clamps the cable and fixes the cable in a through hole. The method comprises the steps that the initial distance between the suspension component and a device platform is determined according to a catenary analytical calculation formula; a crane places the floating drum, the suspension component and the cable into water at the position with the initial distance away from the device platform; a cable laying ship carries out line navigation at a low speed in the direction away from device platform; a cable winch releases cables continuously along with moving of the cable laying ship. The device and method can lay cables rapidly and conveniently, can recycle cables effectively for reutilization, cost is lowered greatly, and economic performance is improved greatly.

Owner:WUCHANG SHIPBUILDING IND

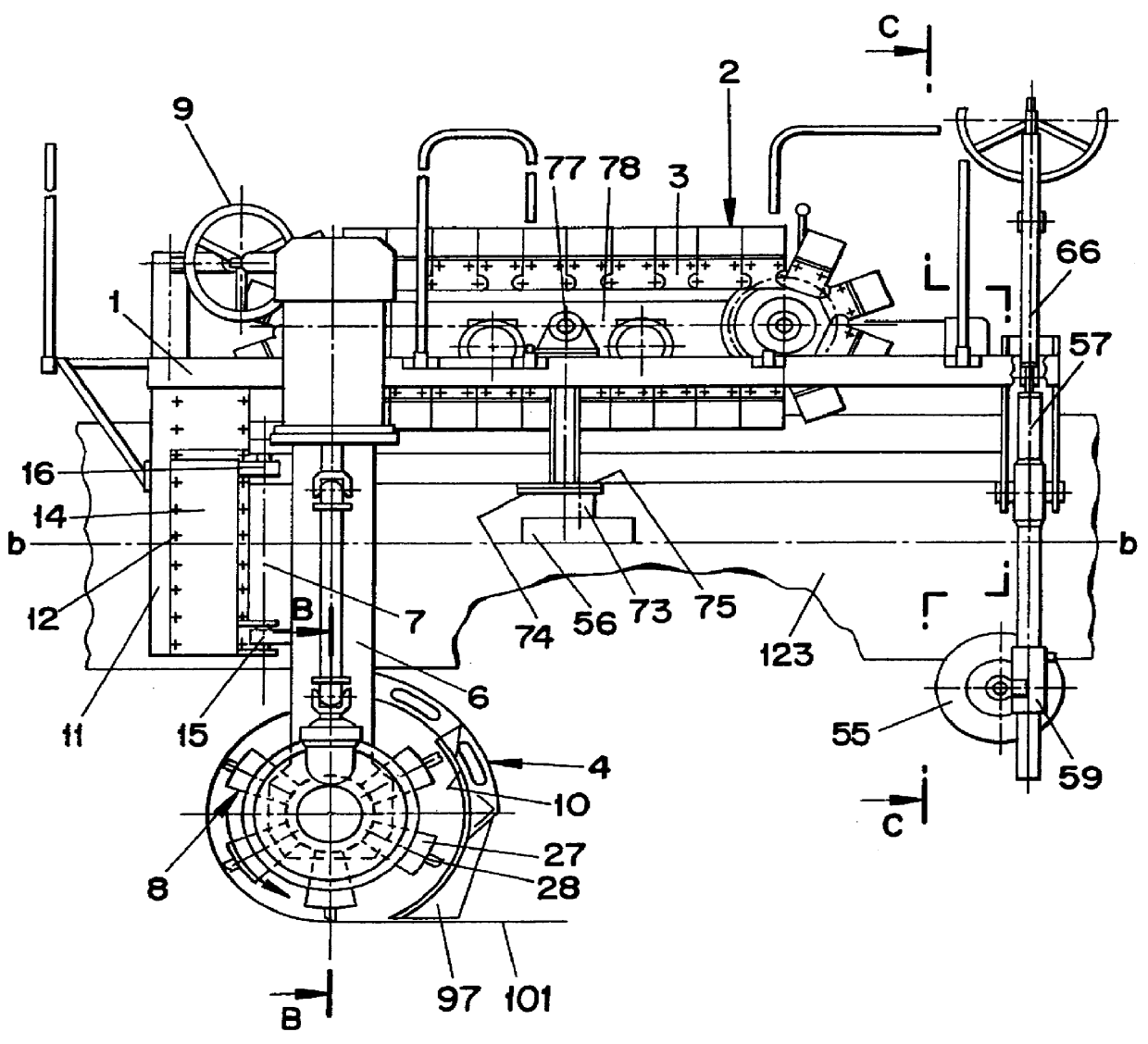

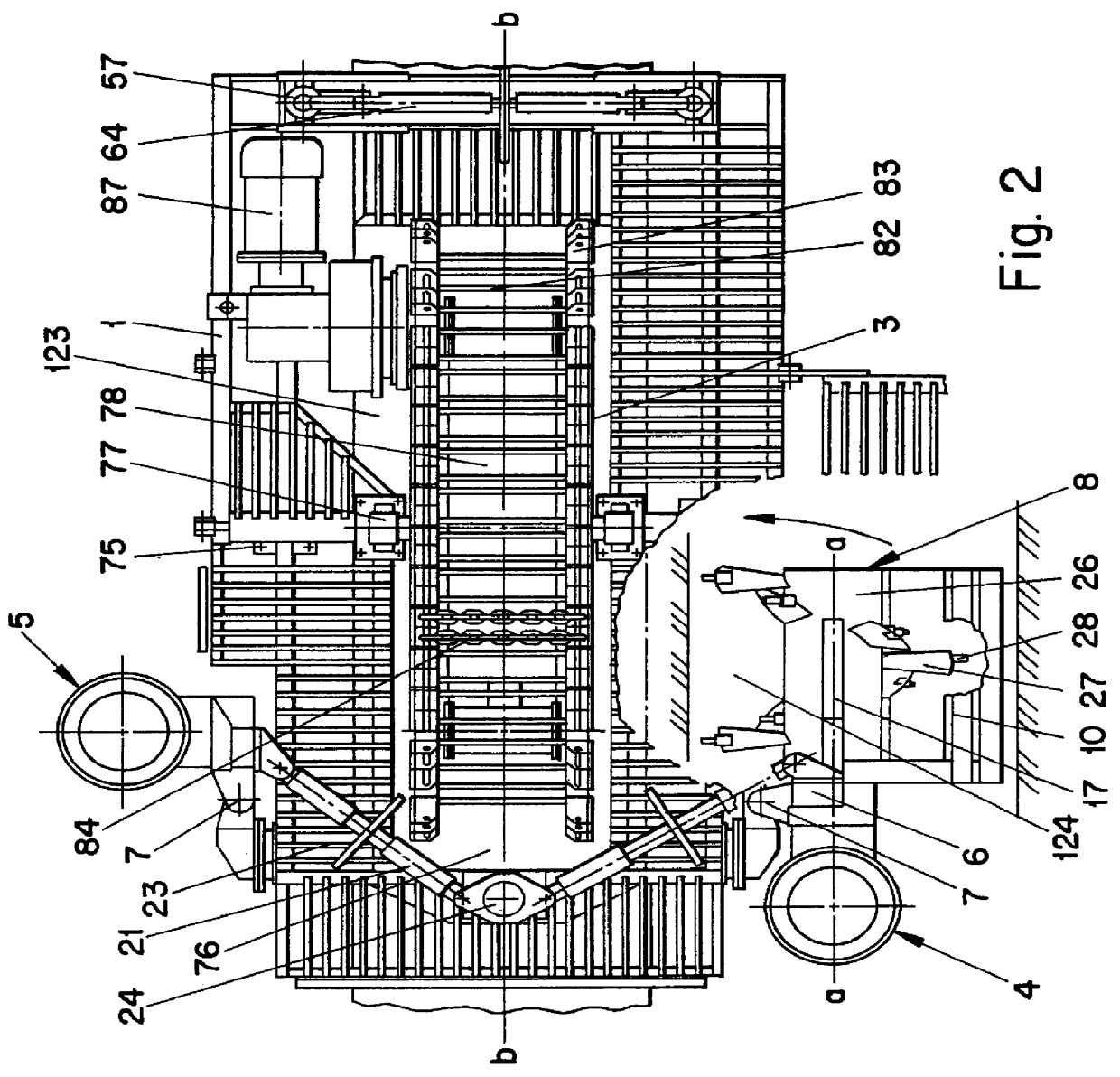

Machine for digging under pipes and caterpillar traction device

InactiveUS6154988ASmaller resistance to machine displacementPipe laying and repairConveyorsEngineeringActuator

PCT No. PCT / UA97 / 00012 Sec. 371 Date Jun. 3, 1999 Sec. 102(e) Date Jun. 3, 1999 PCT Filed Sep. 25, 1997 PCT Pub. No. WO98 / 15165 PCT Pub. Date Apr. 16, 1998The present invention is for a machine for digging under pipes, wherein the machine comprises a frame having a caterpillar drive traction device mounted thereon, as well as left and right end effectors. The end effectors are each made in the shape of a mount which is attached to the frame and capable of forced rotation about the vertical axis. These end effectors also comprise a cylindrical endless-screw-type driving cutters as well as a cylindrical blade attached to the mount coaxially behind the cutter. The cutter is mounted at a lower end and on the side of the mount so that its rotation axis is horizontal. The machine further includes a transversal stabilization device comprising two stabilization mechanisms, wherein each mechanism comprises an adjustable-height support member that rests on the bottom of the trench. The traction device includes a frame as well as a caterpillar that comprises rigid brackets and flexible support members. The brackets extend outwardly from the external surface of the caterpillar central part. The flexible support members are connected to the brackets so as to be incapable of linear displacement and are made short enough so as to stretch about the profile of the pipe cross-section.

Owner:NAT PRYDNIPROVSKI MAIN OIL PIPELINES 25 +2

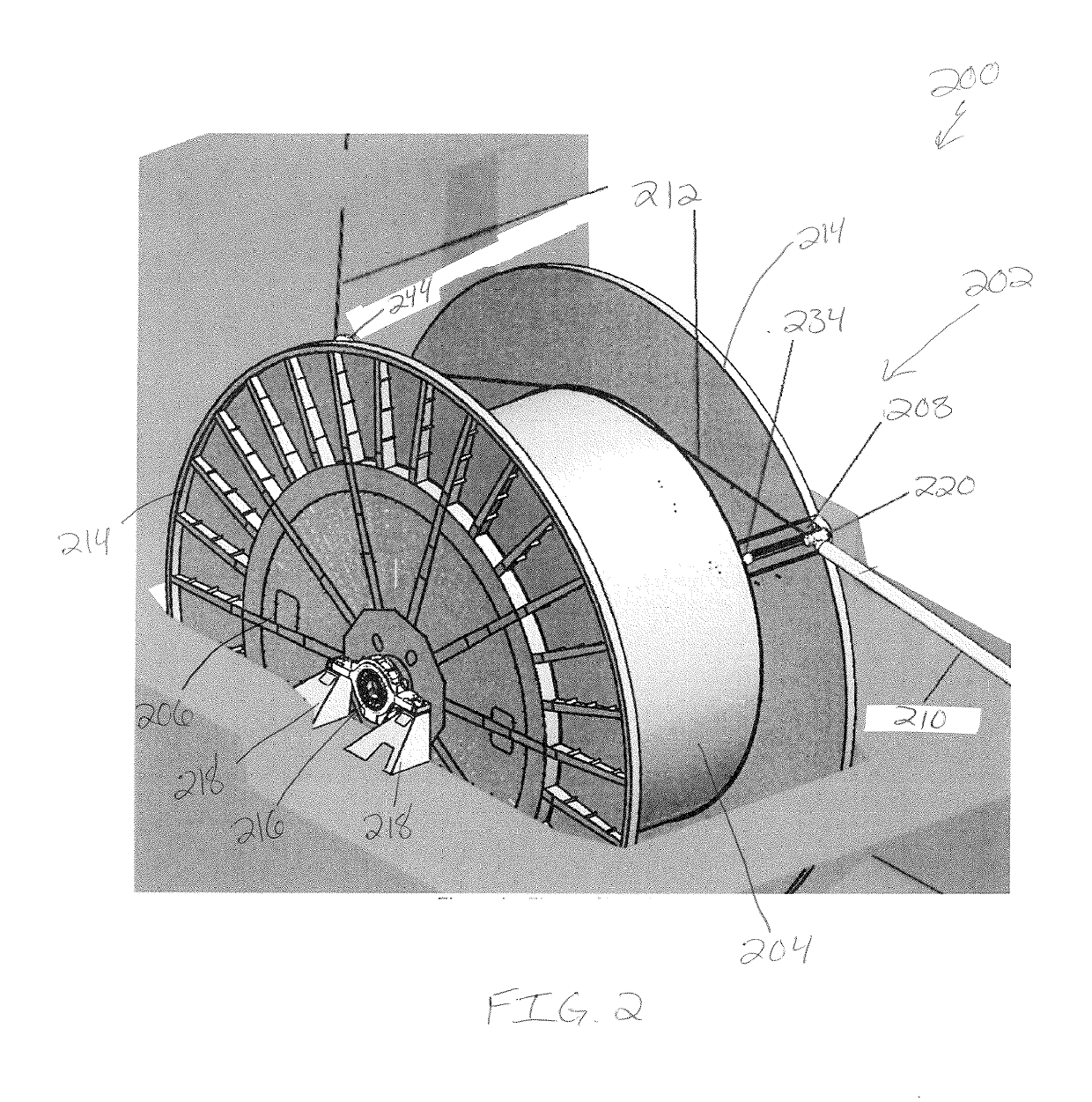

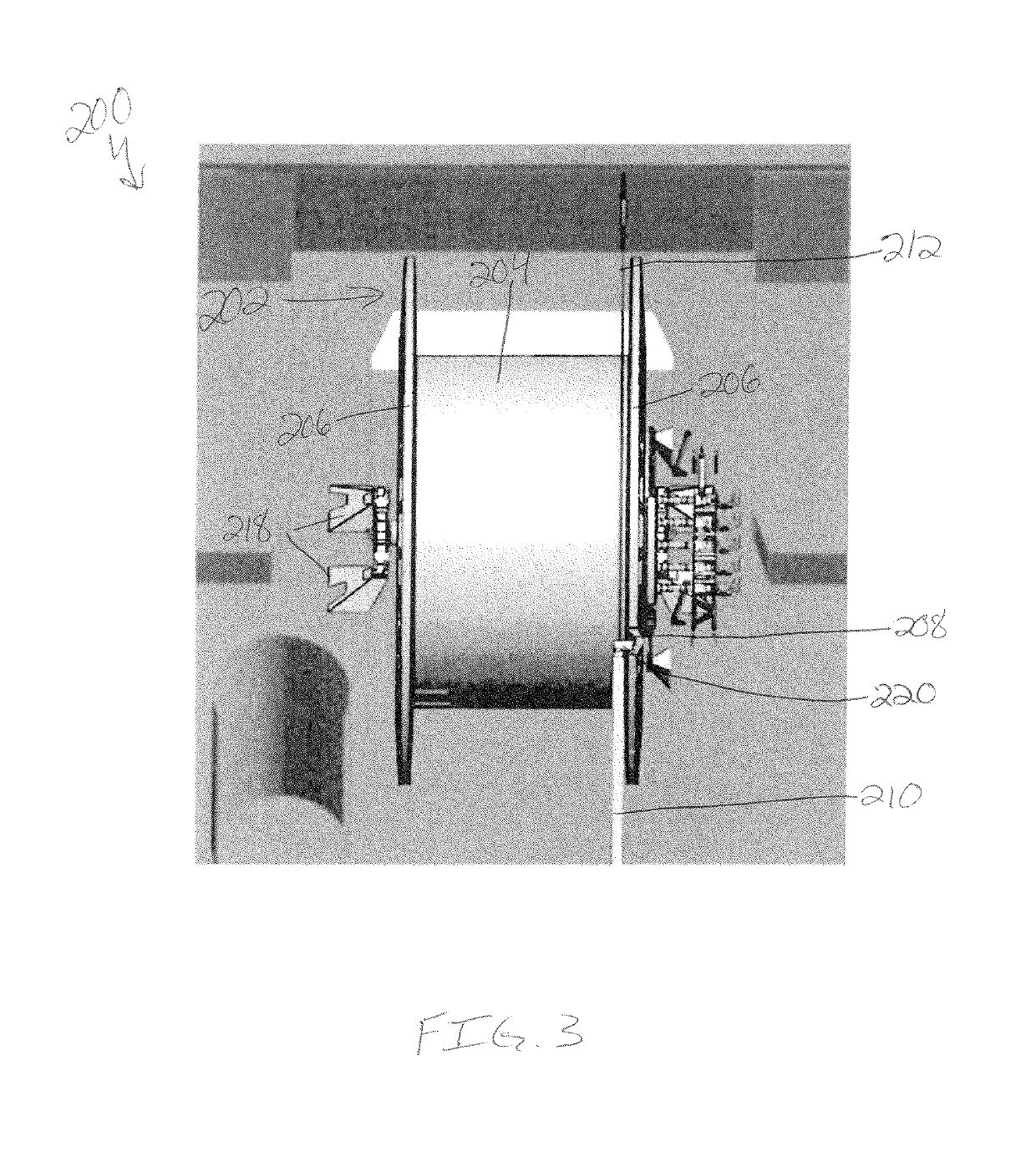

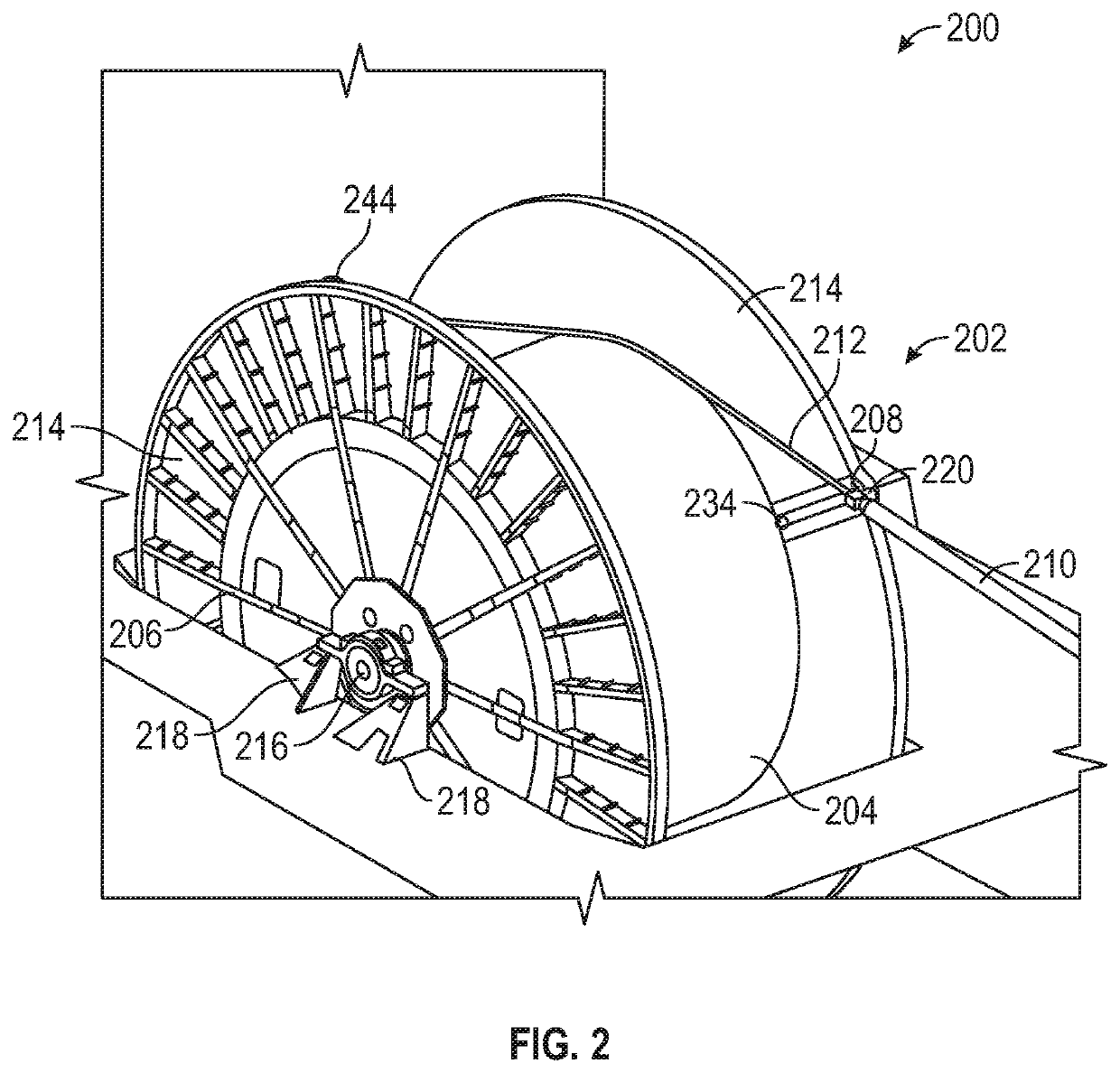

Pipelay reel with flange chute

Novel and advantageous pipelay reel systems and methods for use in laying flexible or rigid pipe or tubing in on and offshore operations. The pipelay reel system may have a pipelay reel having a drum arranged between two flanges. At least one flange of the reel may have a chute configured to receive an adapter coupled to a starting end of the pipe to be spooled on the reel. An initiation line coupled to a winch and intersecting the flange chute may be used to position the adapter with respect to a receiving end of the flange chute, and the reel may be rotated to pull the adapter down the chute to a latching end of the chute. Moreover, a latch may be used to secure the adapter in the chute such that the pipe may be spooled onto the reel.

Owner:NAT OILWELL VARCO LP

Submarine cable underwater synchronous paying-off underwater vehicle

ActiveCN106080987AReduce in quantityHigh degree of automationTransmission systemsCable-laying vesselsOcean bottomFirst aid

The invention discloses a submarine cable underwater synchronous paying-off underwater vehicle which is characterized by comprising a shipborne mechanical system, a synchronous pushing system, a pneumatic launching system, a calculation center control system and a dragging and underwater-moving system. The technologies of electric automatization, aerodynamics, mechatronics and single chip microcomputer control and the like are integrated, underwater operation can be achieved, and the underwater vehicle is less affected by stormy waves; automatic detection and real-time paying-off can be achieved, the positioning precision is 0.5-3 m, the course accuracy is 0.01 degree, and a cable line corridor can be accurately controlled; cable laying is high in speed and can be controlled in real time, and the highest cable laying speed can reach 50 KM / h; the automation degree is high, and the number of construction staff is greatly decreased; the integration degree is high, and the whole process can be monitored; construction obstacles for the cable line corridor do not need to be cleared away, so that the environment is protected; all the systems can be recycled, and secondary investment is low; the systems operate synchronously, and the tension force of submarine cable laying is reduced; the line first-aid repair capability is high, and the submarine cable underwater synchronous paying-off underwater vehicle is suitable for line reconstruction work after seaquakes; and the structure is reasonable, and the performance is reliable.

Owner:NORTHEAST DIANLI UNIVERSITY

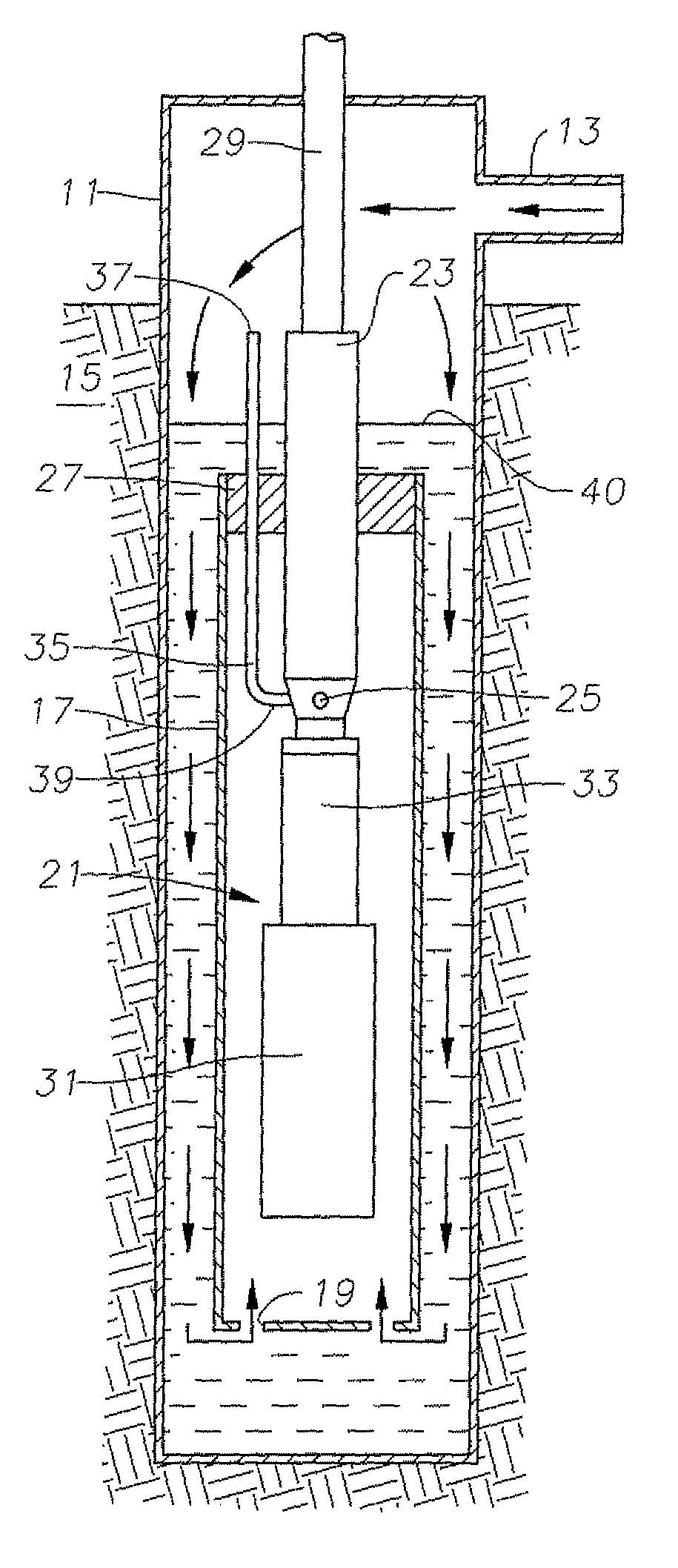

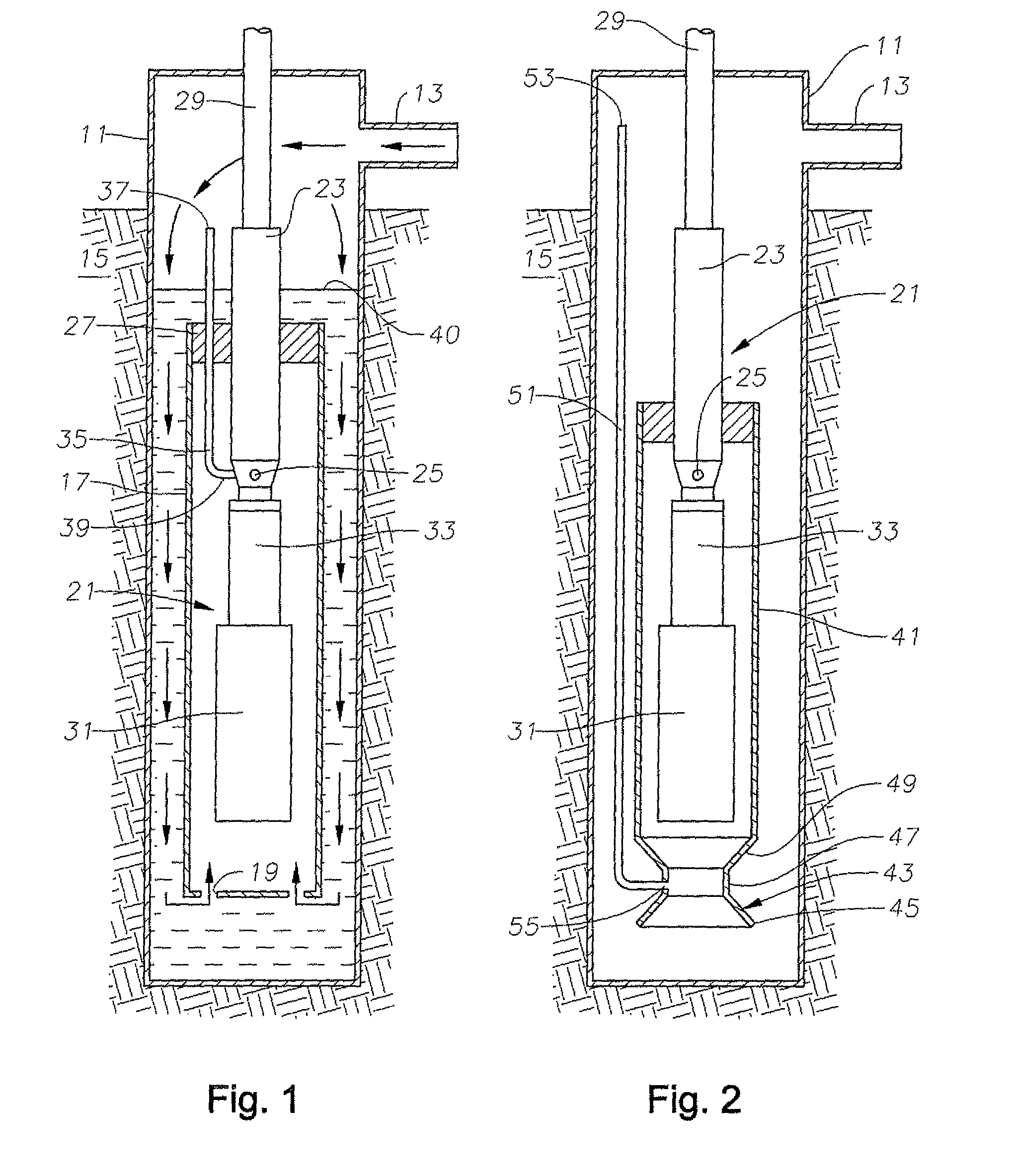

Gas eduction tube for seabed caisson pump assembly

A seafloor pump assembly is installed within a caisson that has an upper end for receiving a flow of fluid containing gas and liquid. The pump assembly is enclosed within a shroud that has an upper end that seals around the pump assembly and a lower end that is below the motor and is open. An eduction tube has an upper end above the shroud within the upper portion of the caisson and a lower end in fluid communication with an interior portion of the shroud. The eduction tube causes gas that separates from the liquid and collects in the upper portion of the caisson to be drawn into the pump and mixed with the liquid as the liquid is being pumped.

Owner:BAKER HUGHES INC

Pipelay reel with flange chute and method of use

Novel and advantageous pipelay reel systems and methods for use in laying flexible or rigid pipe or tubing in on and offshore operations. The pipelay reel system may have a pipelay reel having a drum arranged between two flanges. At least one flange of the reel may have a chute configured to receive an adapter coupled to a starting end of the pipe to be spooled on the reel. An initiation line coupled to a winch and intersecting the flange chute may be used to position the adapter with respect to a receiving end of the flange chute, and the reel may be rotated to pull the adapter down the chute to a latching end of the chute. Moreover, a latch may be used to secure the adapter in the chute such that the pipe may be spooled onto the reel.

Owner:NAT OILWELL VARCO LP

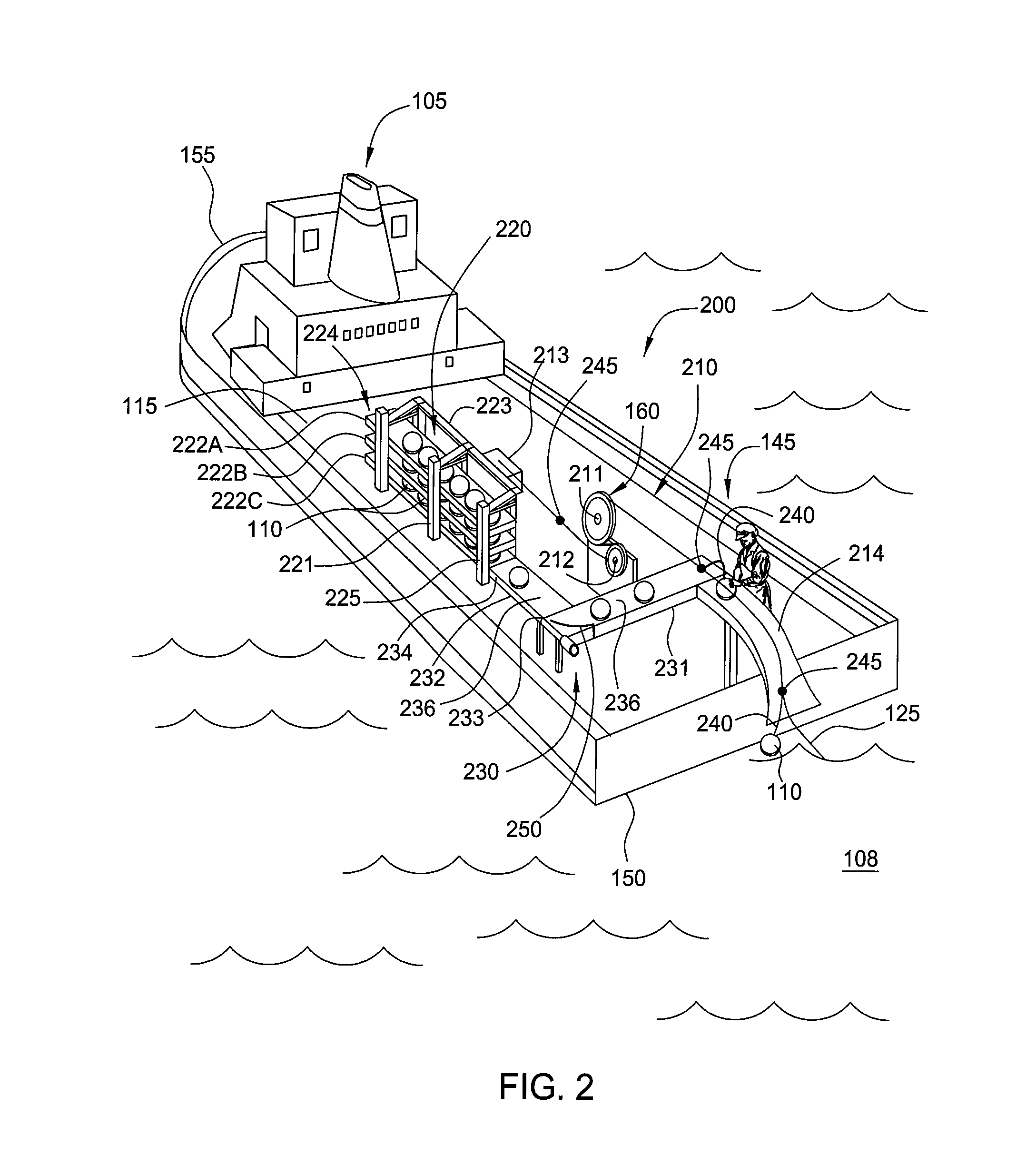

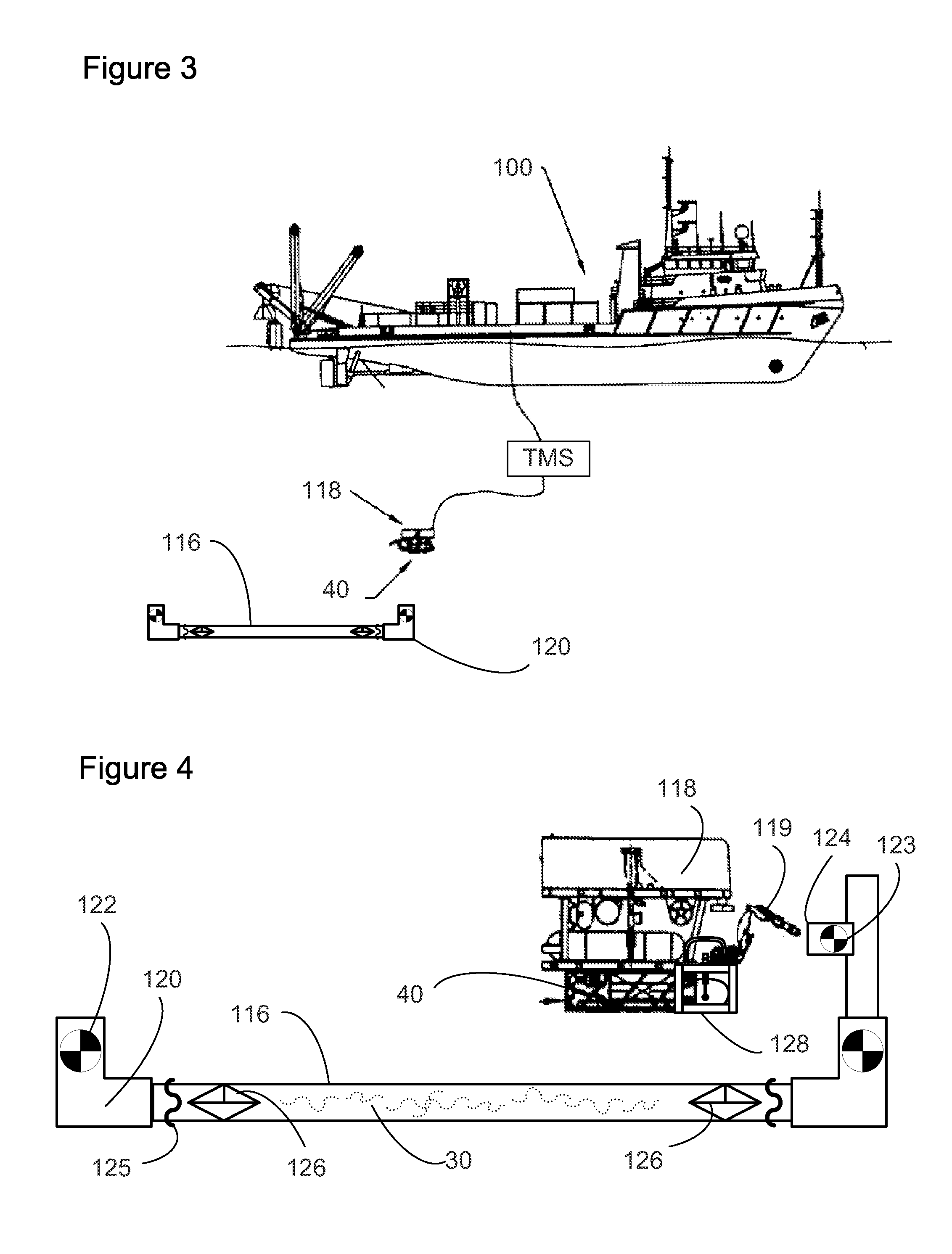

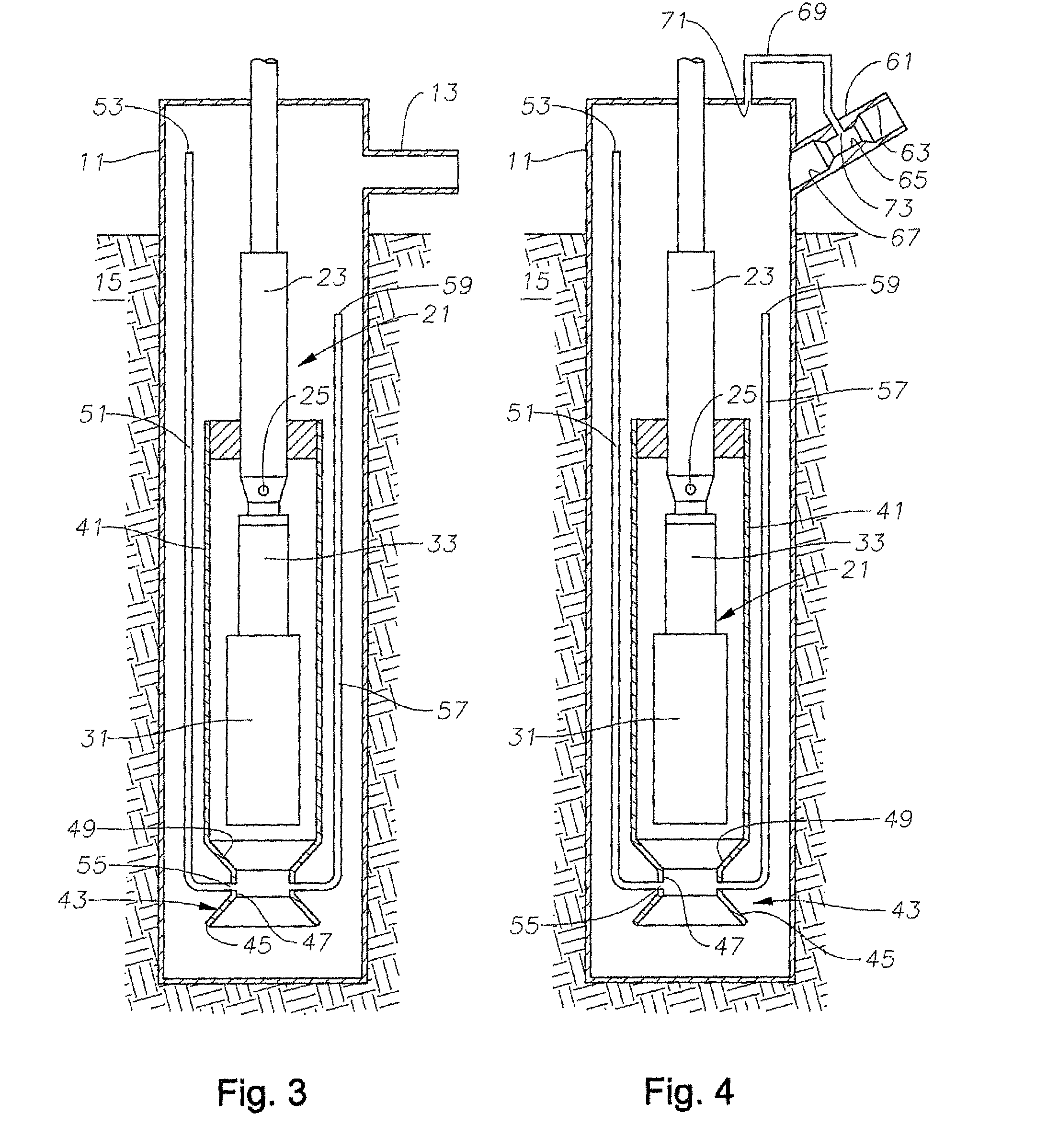

Overboard system for deployment and retrieval of autonomous seismic nodes

Embodiments of systems and methods for deploying and retrieving a plurality of autonomous seismic nodes from the back deck of a marine vessel using an overboard node deployment and retrieval system are presented. The overboard system may comprise one or more overboard wheels that are actively powered to move in response to changes in movement of the deployed cable. The overboard system may comprise a first overboard wheel with a plurality of rollers and a second overboard wheel configured to detect movement and / or changes in a position of the deployment line. The overboard system may be configured to move the first overboard wheel in response to movement of the second overboard wheel. In addition, the first overboard wheel may comprise at least one opening or pocket configured to hold a node while the node passes across the wheel. Other seismic devices may also pass through the overboard system, such as transponders and weights attached to the deployment cable.

Owner:PXGEO UK LTD

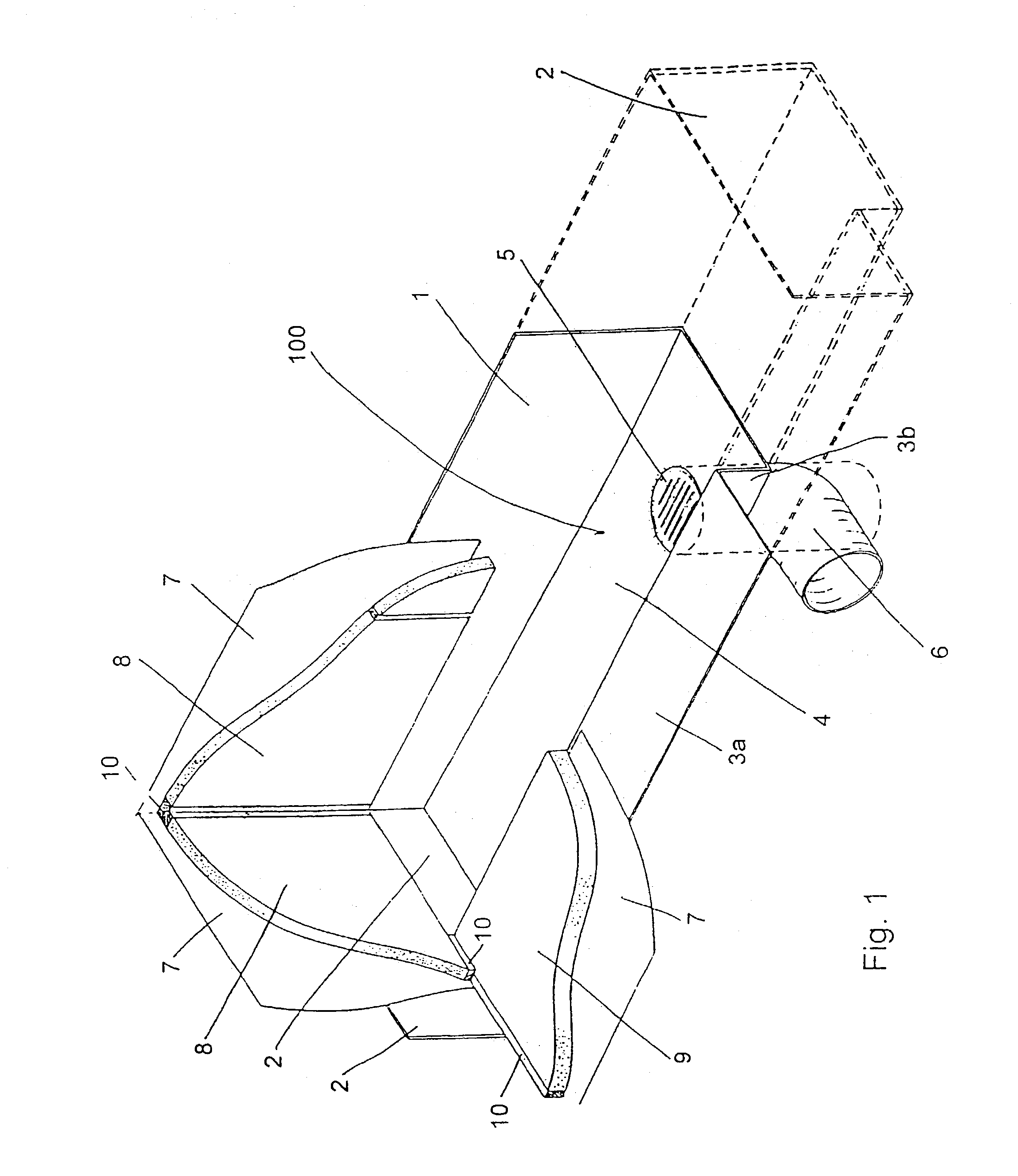

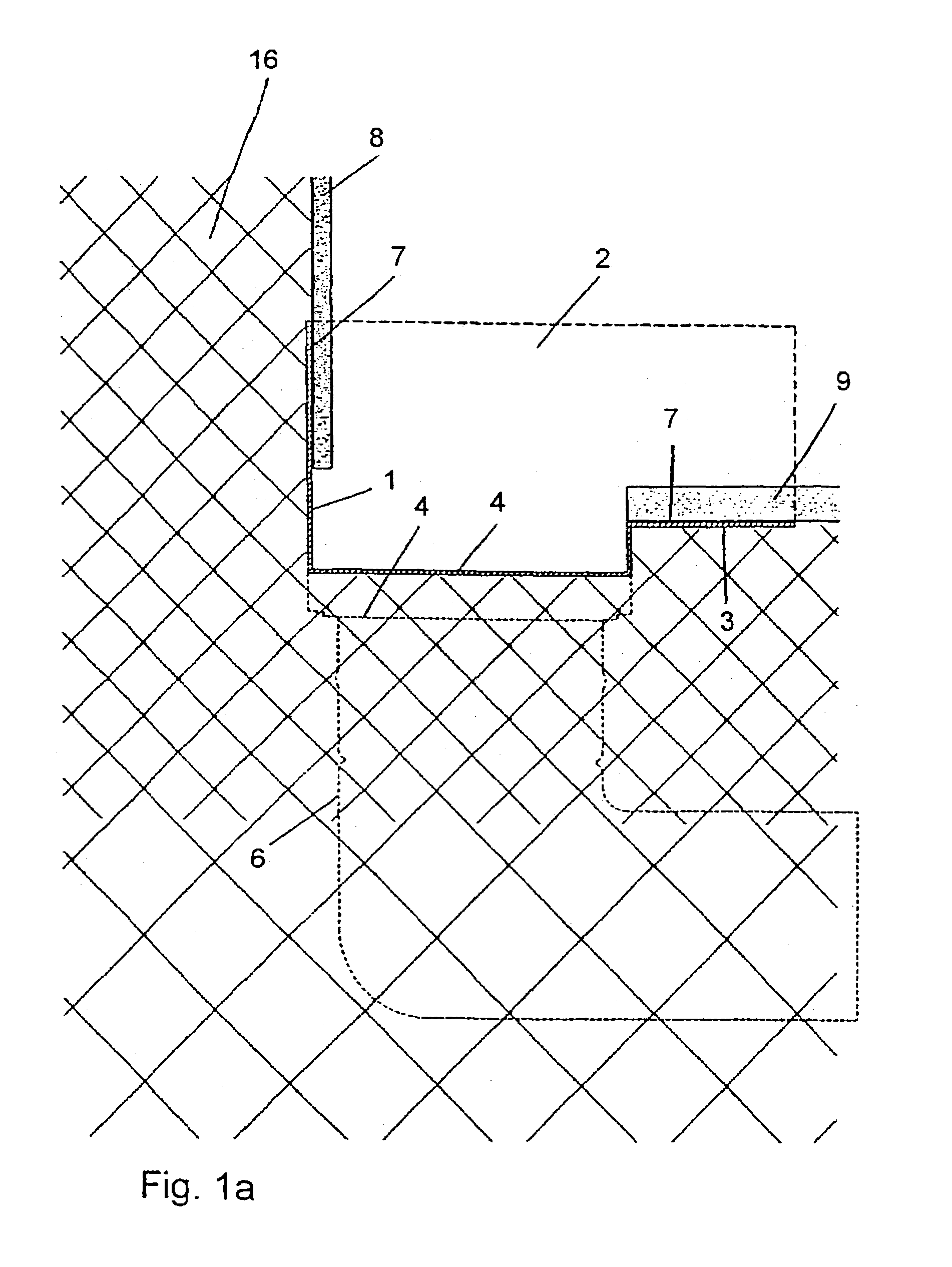

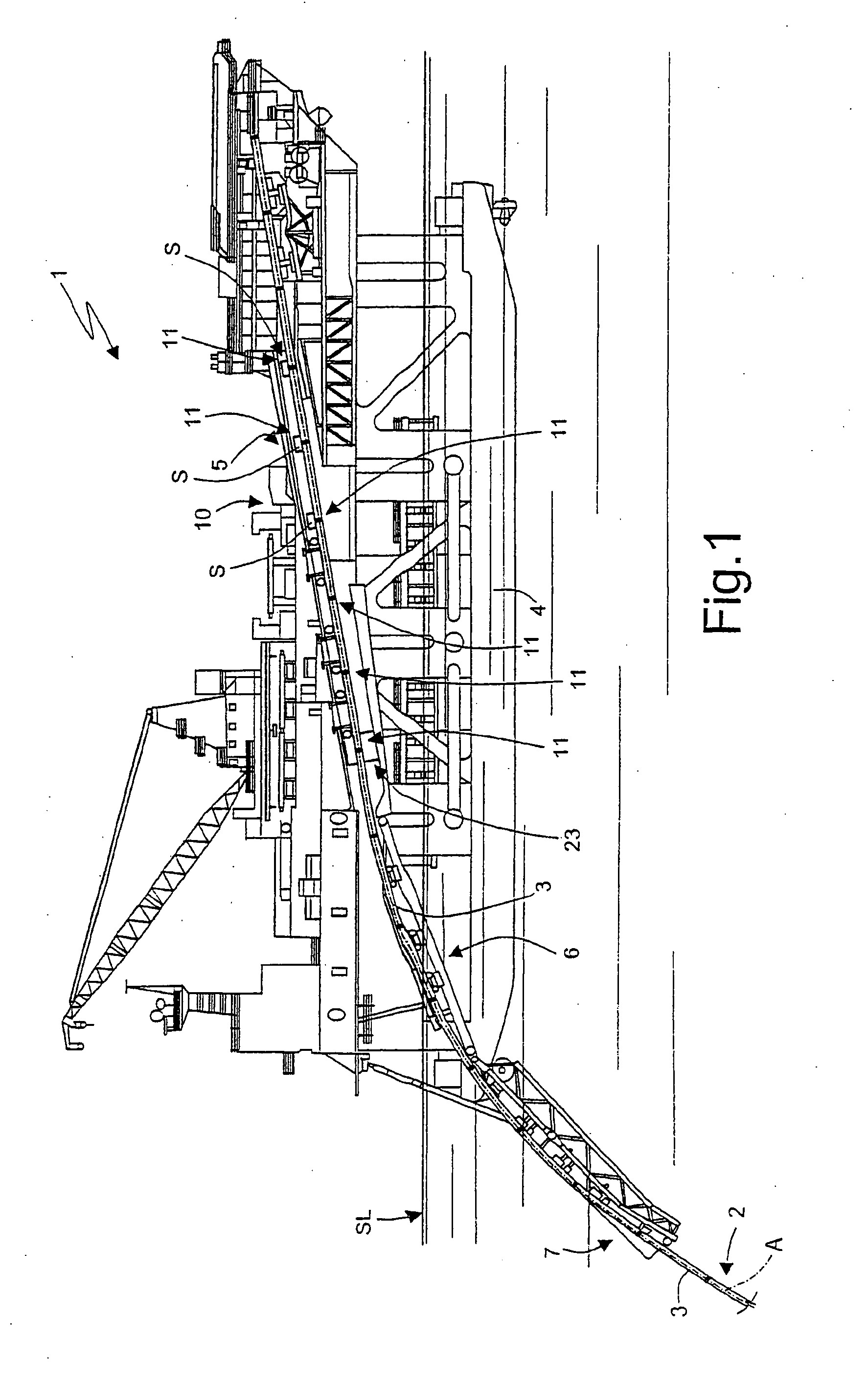

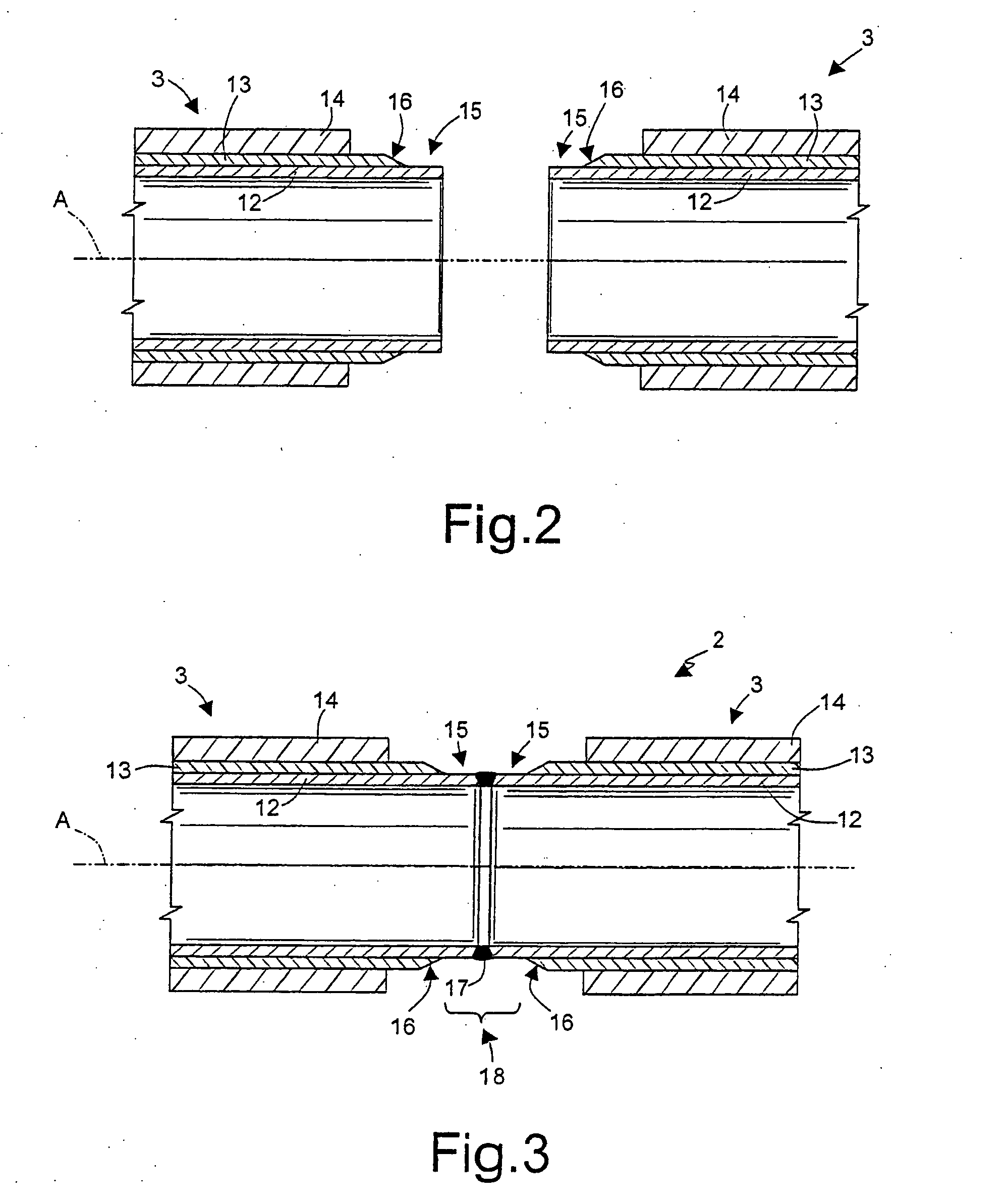

Pipe-joining method and apparatus for producing underwater pipelines, and underwater-pipeline-laying vessel comprising such an apparatus

ActiveUS20100065614A1Appropriate thicknessExhaust apparatusWelding/cutting auxillary devicesPlastic materialsBiomedical engineering

A method of joining pipes (3) to produce underwater pipelines (2), wherein the facing free ends (15) of two adjacent pipes (3), aligned along an axis (A), are welded to define a cutback (18); a protective sheet (22) of plastic material is extruded close to the cutback (18); and the protective sheet (22) is wound about the cutback (18).

Owner:SAIPEM SPA

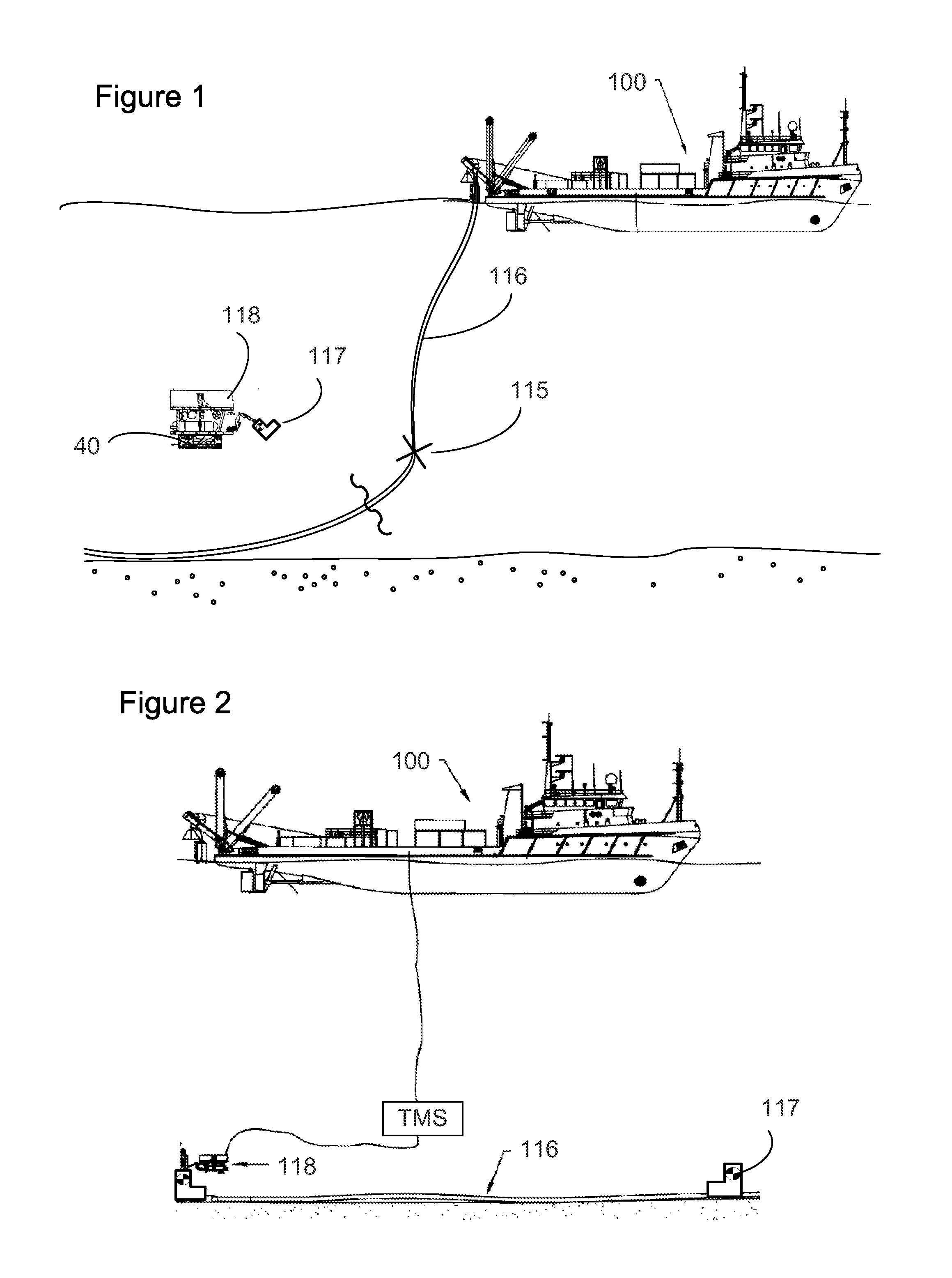

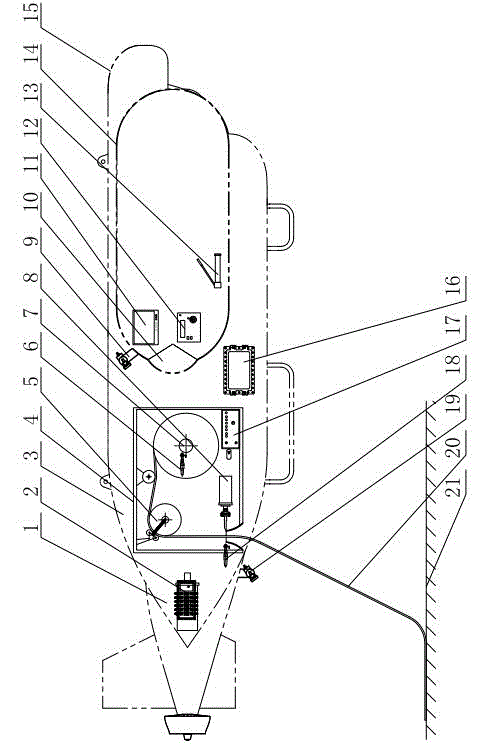

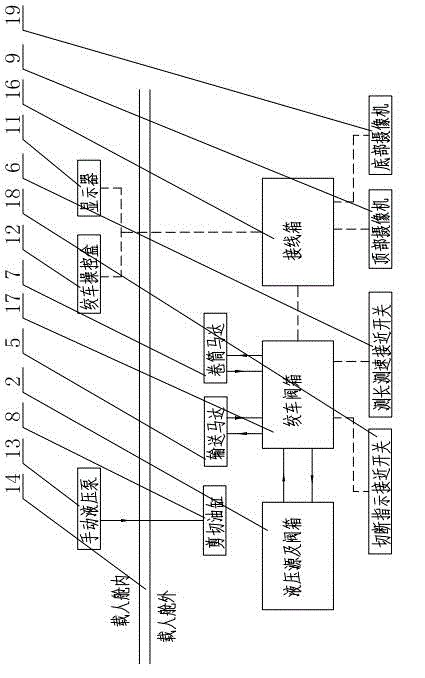

Deep-sea cable laying system of manned submersible

ActiveCN104875867AImprove concealmentEnsure safetyCable-laying vesselsUnderwater vesselsMotor driveInformation networks

A deep-sea cable laying system of a maned submersible comprises a manned submersible. A hydraulic source and a valve box are mounted in the tail of the submersible, a cable laying winch is mounted in an operation cabin of the submersible and comprises a box body, a reel motor driving a reel to rotate and a conveying motor driving a conveying wheel to rotate are mounted in the box body, a length and speed measuring approach switch is mounted on the reel, a shearing oil cylinder with a shear knife is assembled at one end of the box body, a winch valve box is mounted at the other end of the box body, a cutoff indication approach switch is mounted on the outer wall of the box body corresponding to the shearing oil cylinder, and cables are conveyed to the sea bottom by sequentially winding the reel and the conveying wheel. A wiring box is mounted in the operation cabin of the submersible arranged at the outer end of the box body, an observation window is mounted at the end of a manned cabin, a top camera is arranged mounted at the top of the manned cabin, and a monitor, a winch control box and a manual hydraulic pump are mounted in the manned cabin; a bottom camera is mounted at the bottom end of the outer side of the tail of the manned submersible. Safety of sea bottom information network is guaranteed.

Owner:中国船舶重工集团公司第七〇二研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com