Patents

Literature

181results about How to "Reduce oil pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

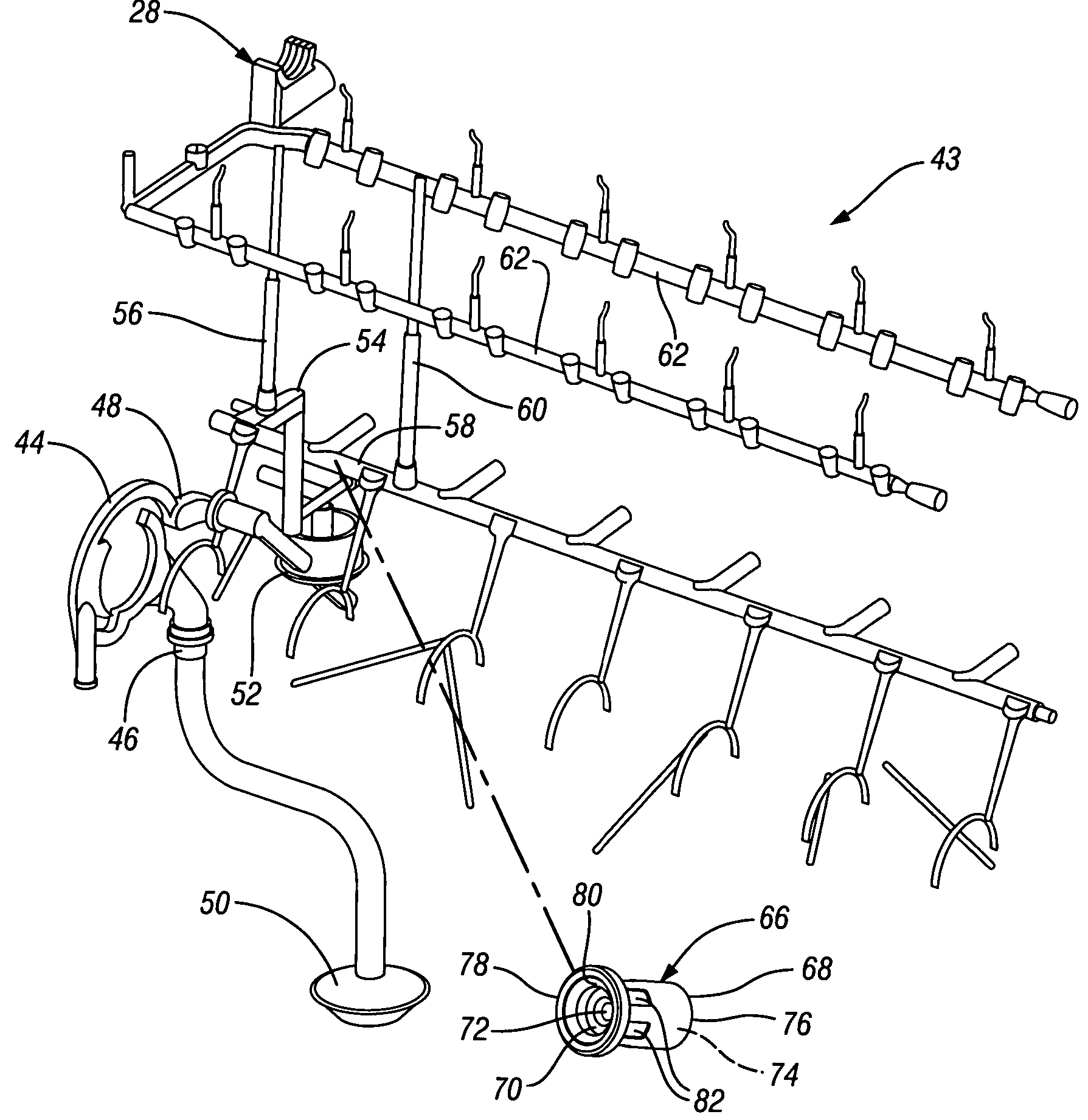

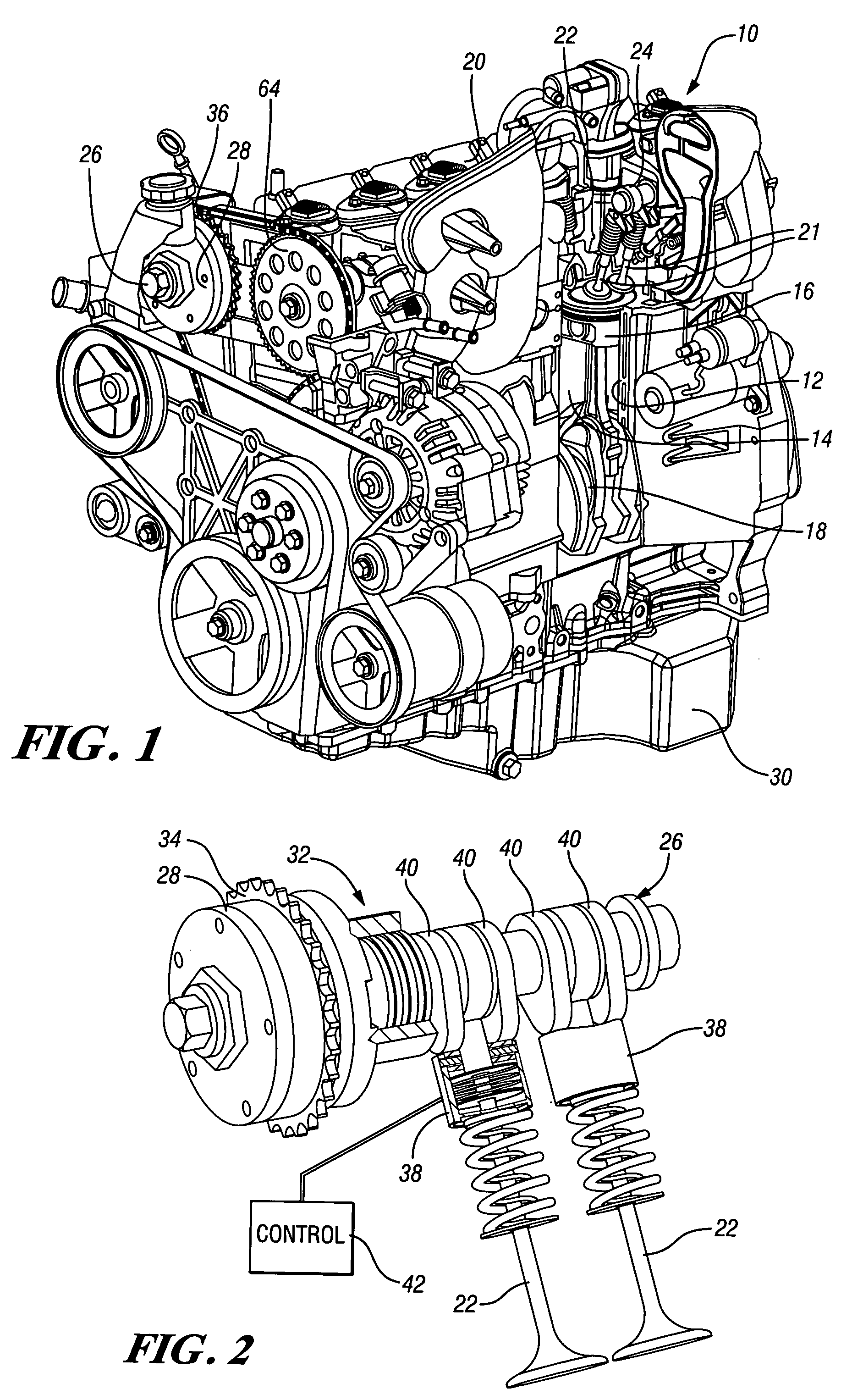

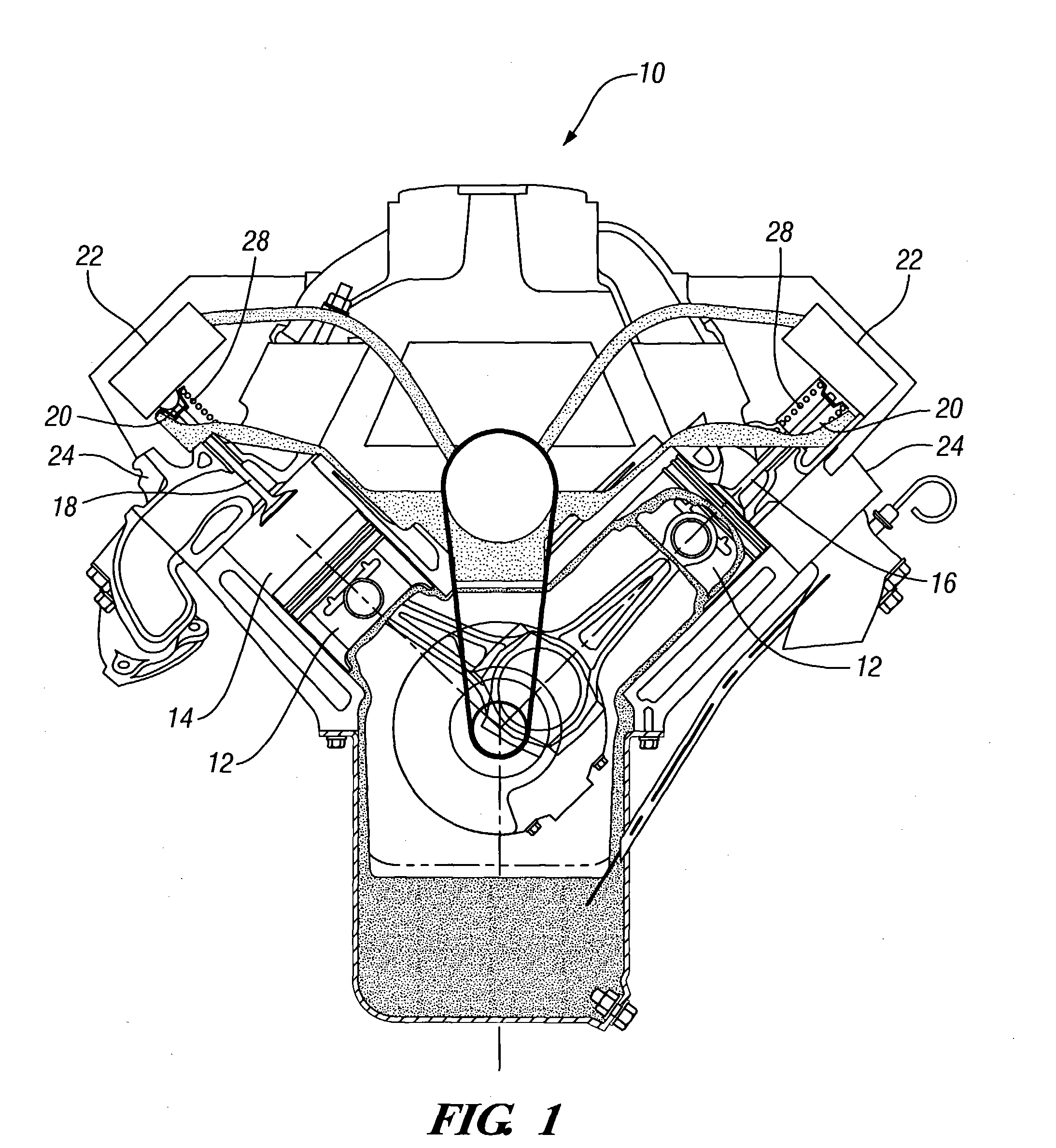

Engine oil system with oil pressure regulator to increase cam phaser oil pressure

InactiveUS20050061289A1Increase engine efficiencyIncrease amount of oilValve arrangementsLubrication of auxillariesLubricationPressure regulator

A lubrication system for an internal combustion engine having a pressure regulator to optimize oil flow through an engine to increase engine efficiency. The lubrication system includes an engine driven oil pump connected to supply pressurized oil through a main oil feed to a main bearing gallery, a cam gallery and a hydraulically actuated device such as a cam phaser or switching valve lifters. A pressure regulator connected between the main oil feed and the galleries selectively restricts oil flow to the galleries to raise oil pressure supplied to the hydraulically actuated device. The increased oil pressure to the cam phaser allows the engine to use a smaller oil pump and thereby increase engine efficiency while providing for actuation of the cam phaser over the full engine speed range. The increased oil pressure to the switching lifters allows the engine to reduce valve lift or disable cylinders over the full engine speed range.

Owner:GENERAL MOTORS CORP

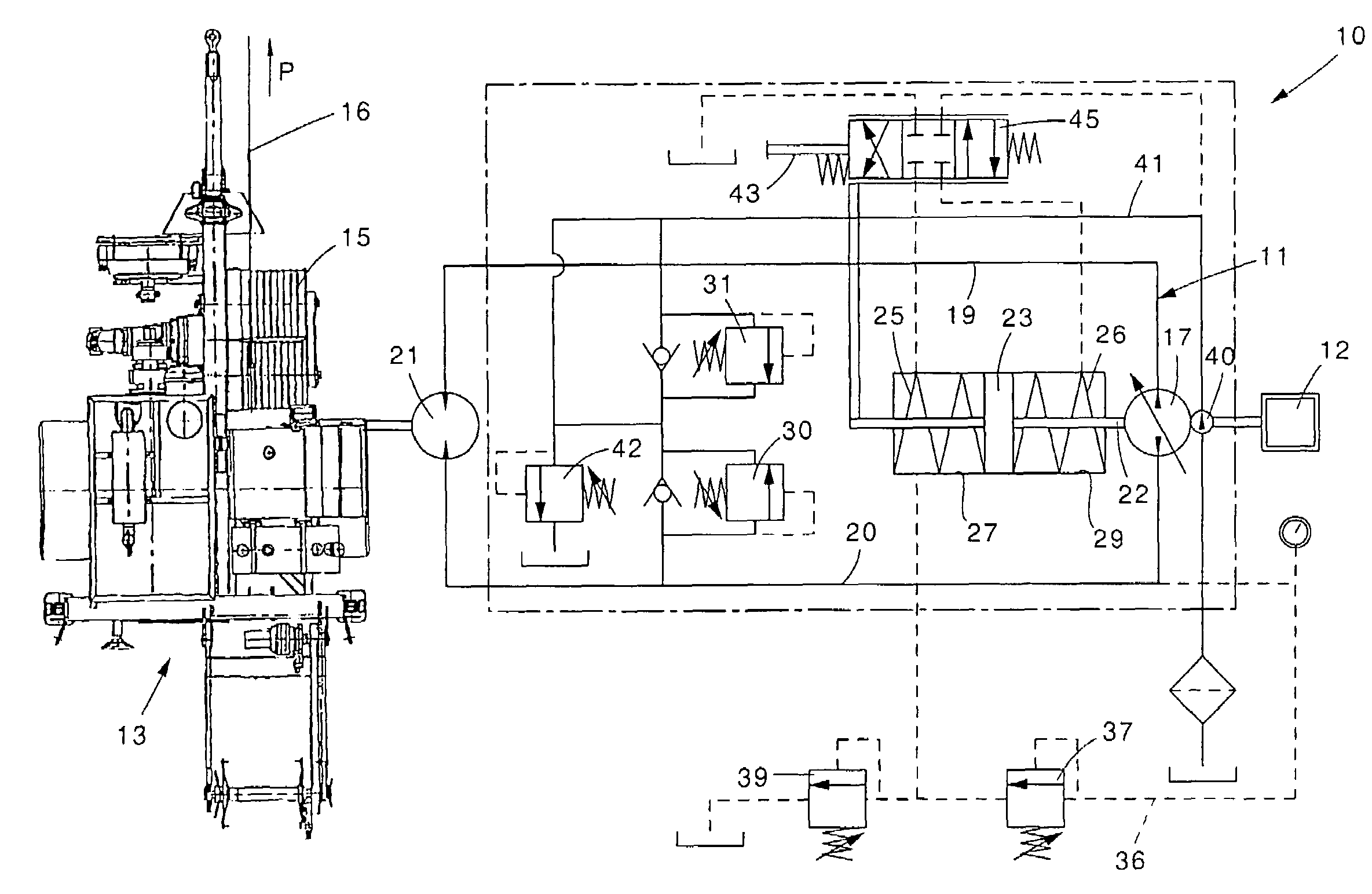

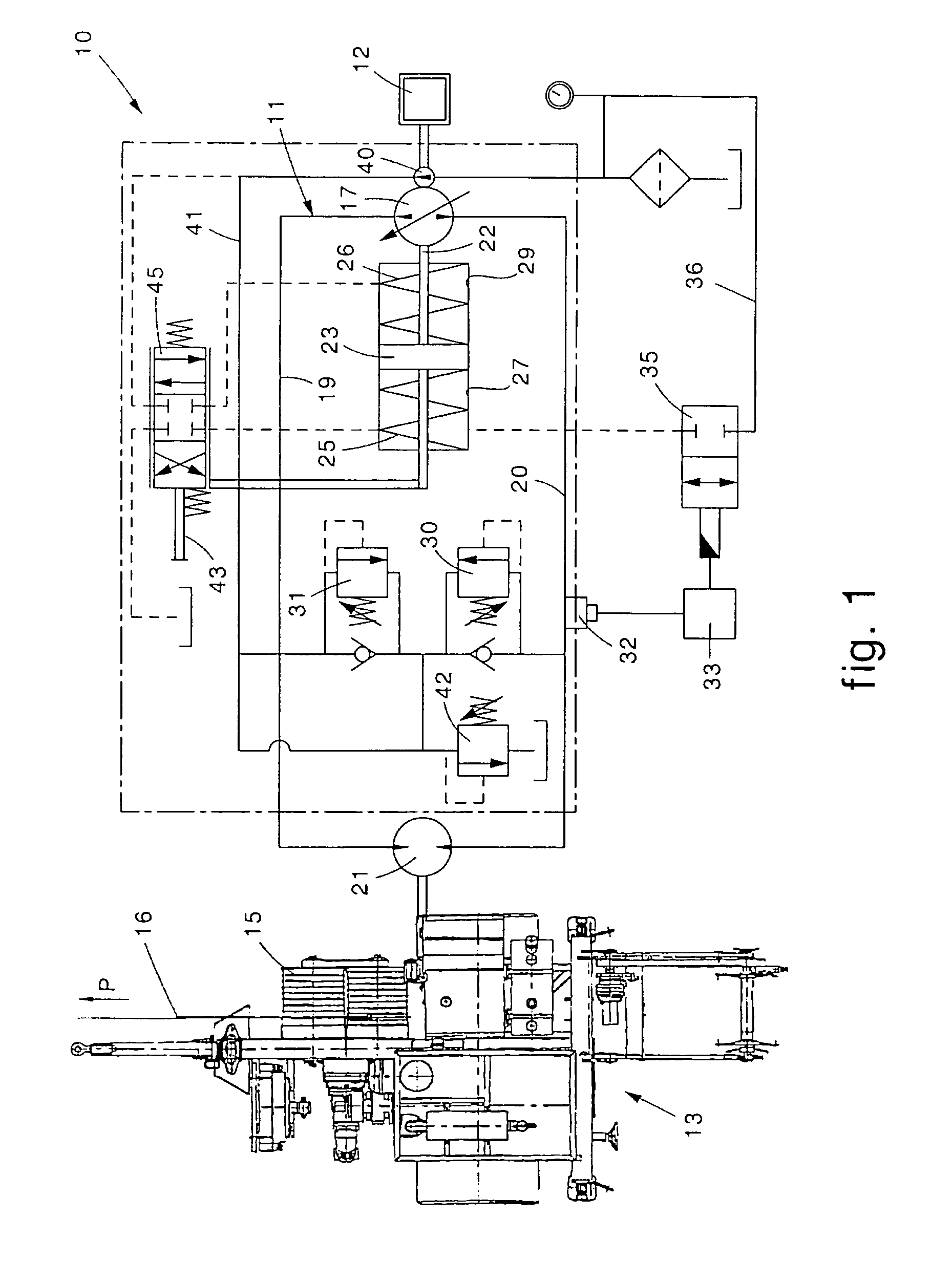

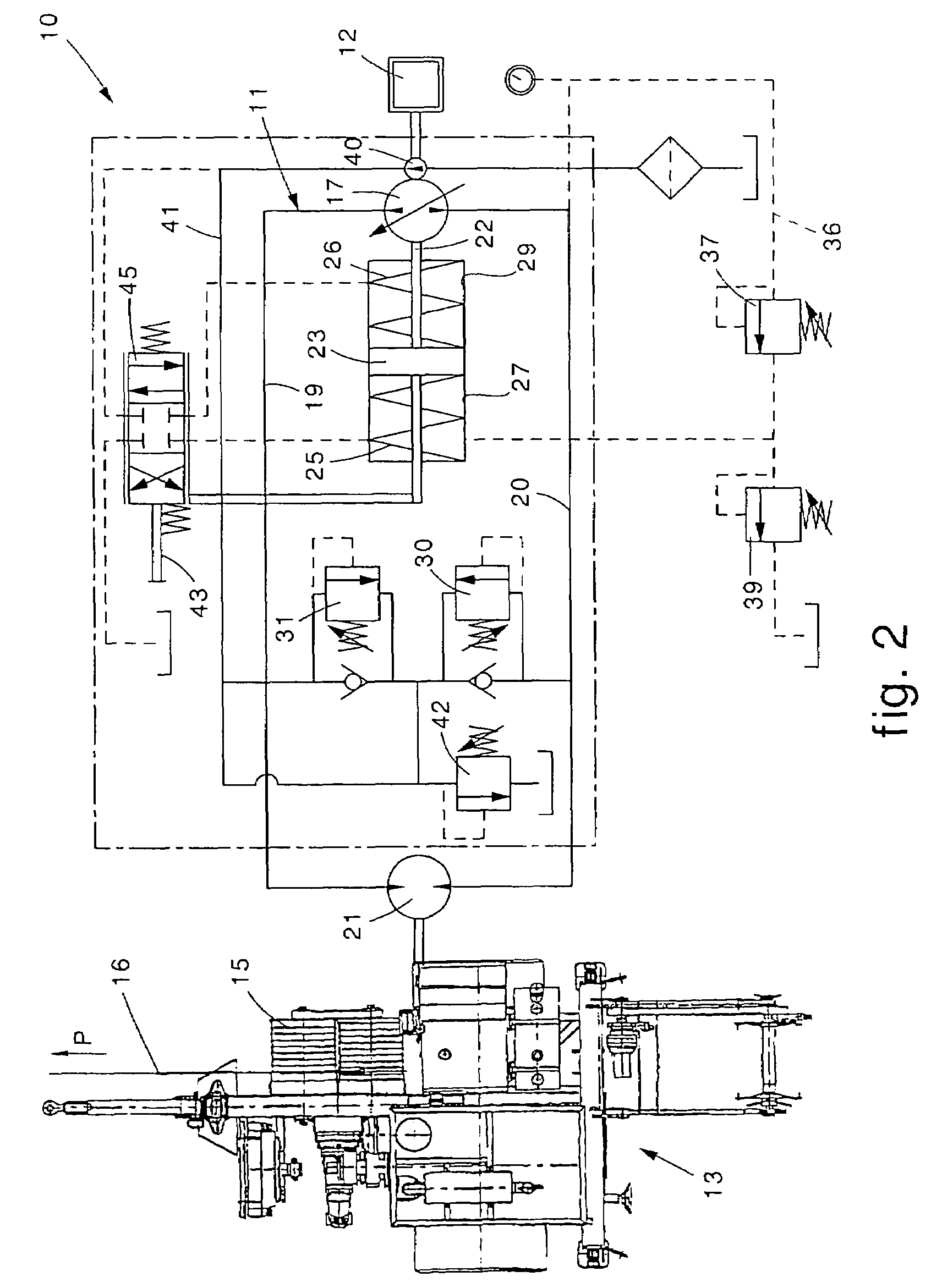

Laying apparatus for cables, lines, conductors or suchlike, and relative laying method

InactiveUS7093433B2Reduce deliveryReduce oil pressurePipe supportsPipe laying and repairHydraulic circuitEngineering

Laying apparatus and method for cables, lines, conductors or suchlike. The apparatus comprises at least a hydraulic circuit provided with a variable delivery feed pump and with a motor connected to the feed pump in order to drive laying members for the cables and suchlike. The hydraulic circuit comprises detectors able to detect the value of pressure of the oil inside the hydraulic circuit and to compare it with a pre-determined pressure value, and valves connected to the detectors and able to reduce the delivery of the feed pump in the event that the pressure measured exceeds the pre-determined pressure value.

Owner:TESMEC

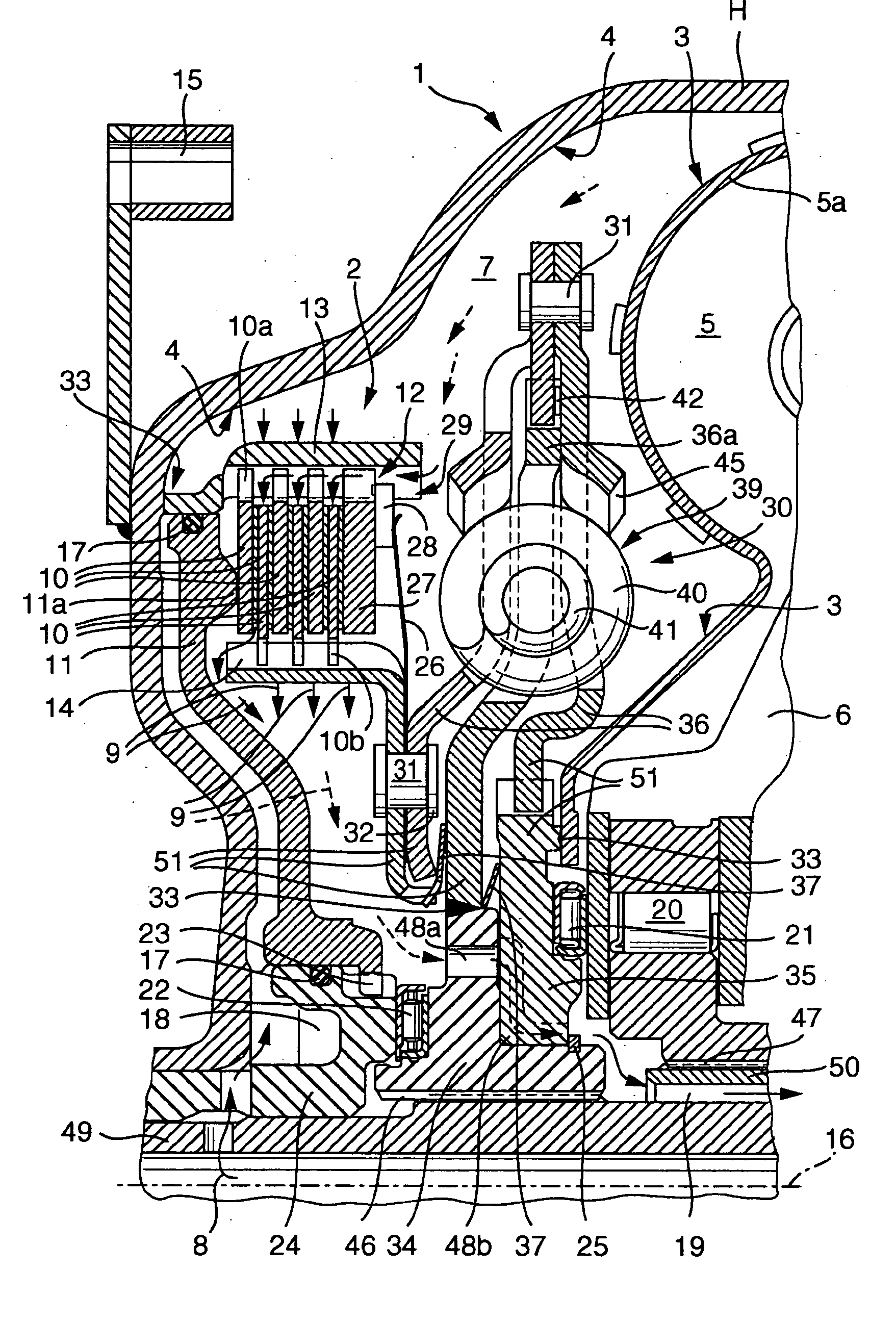

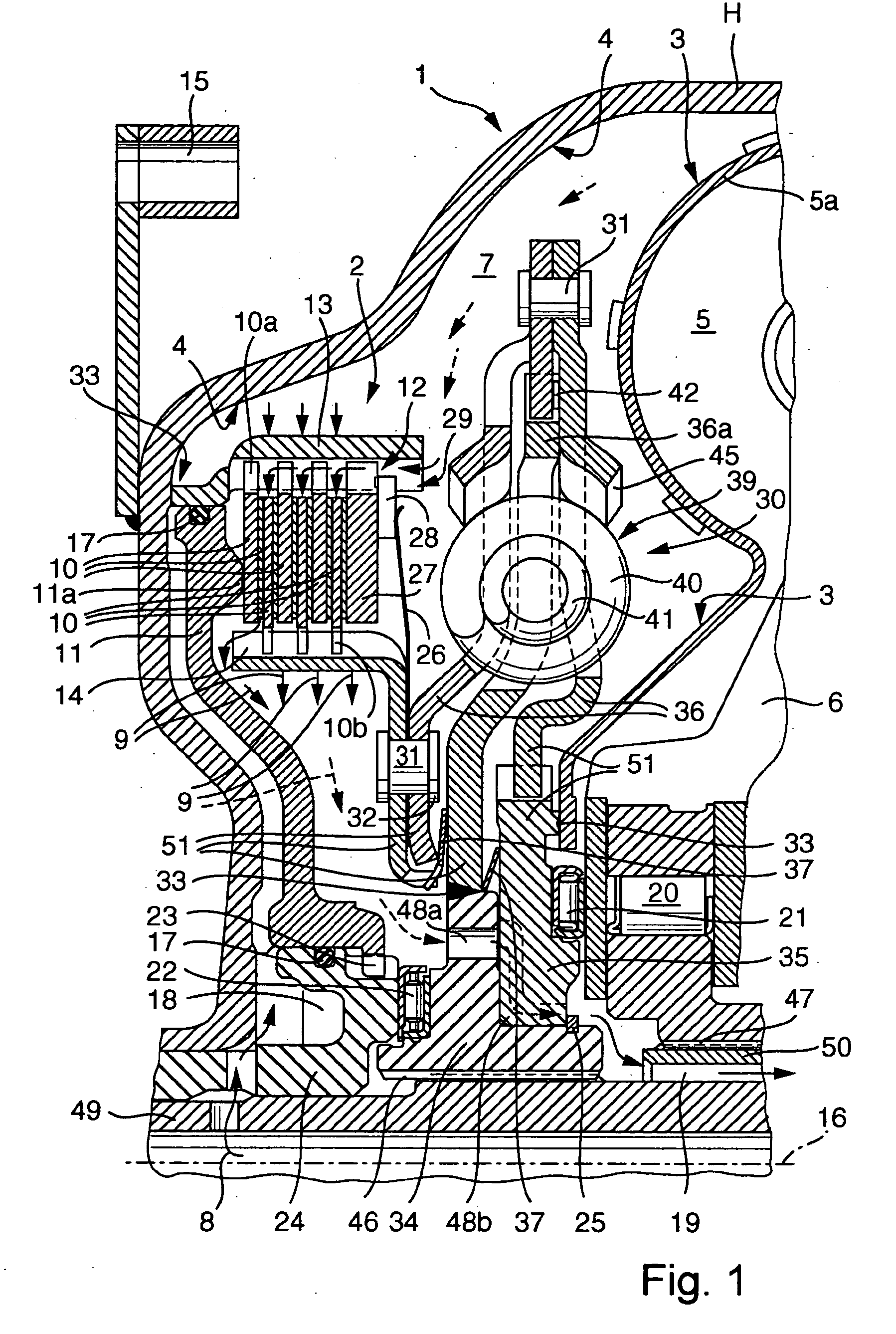

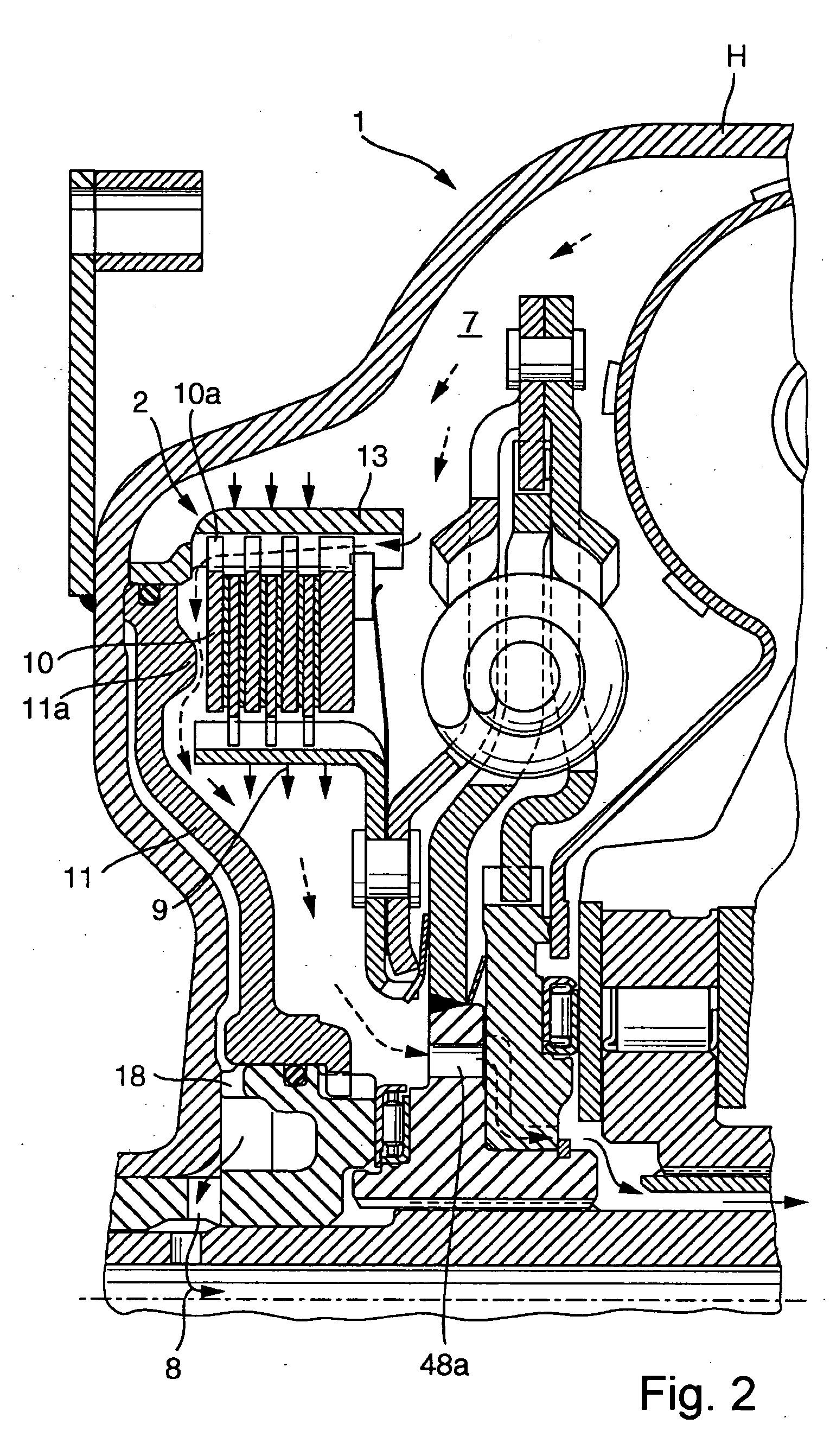

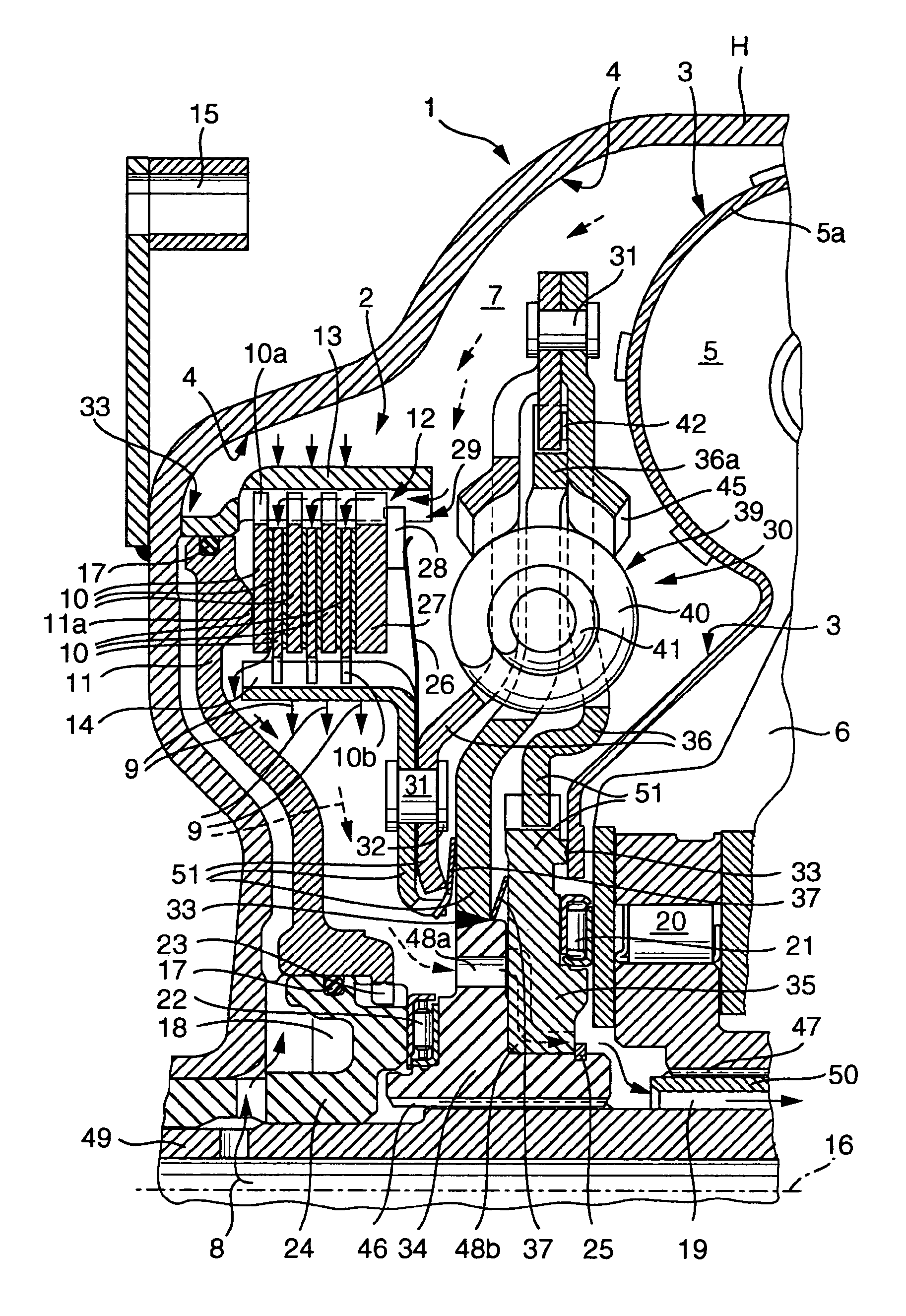

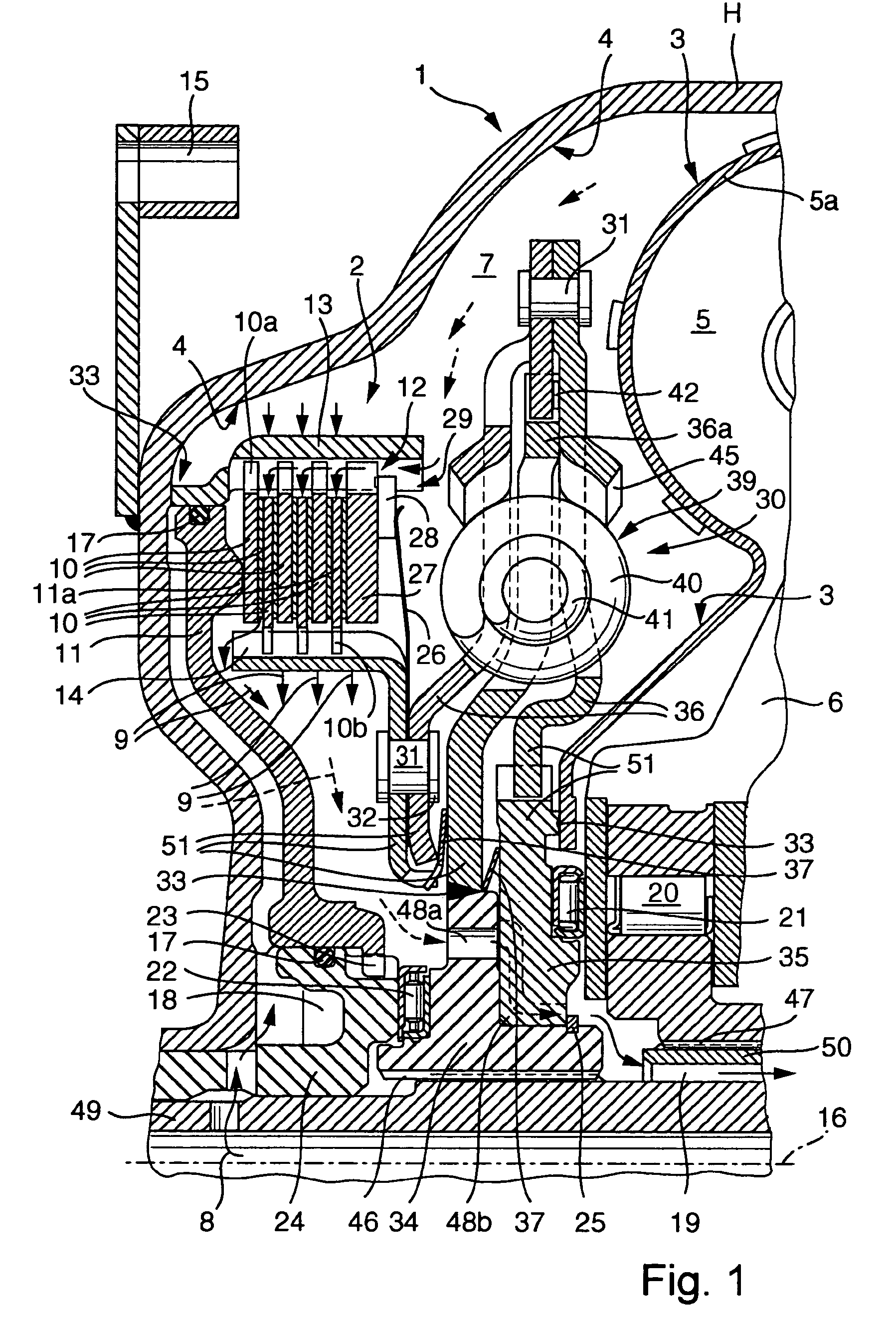

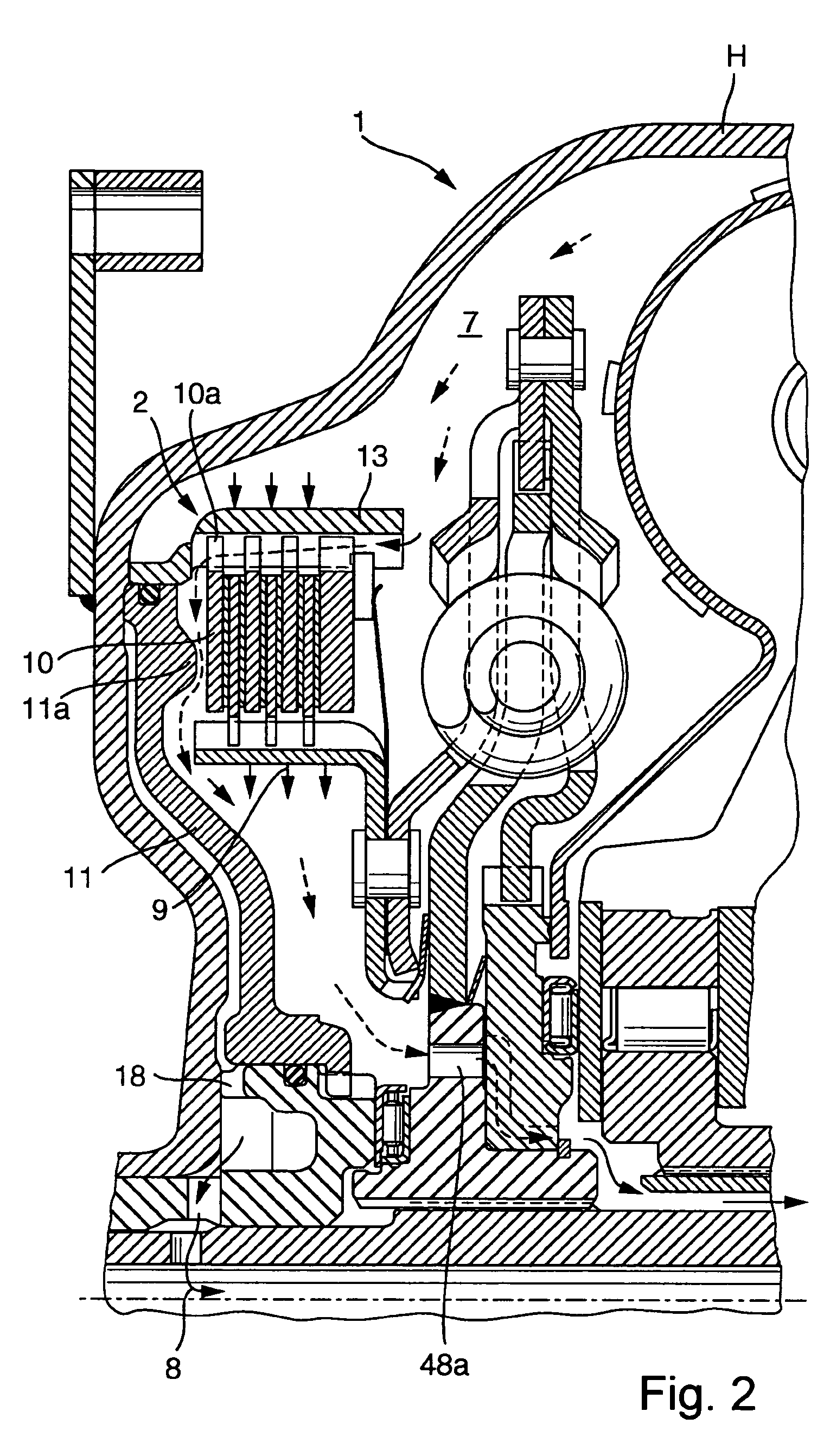

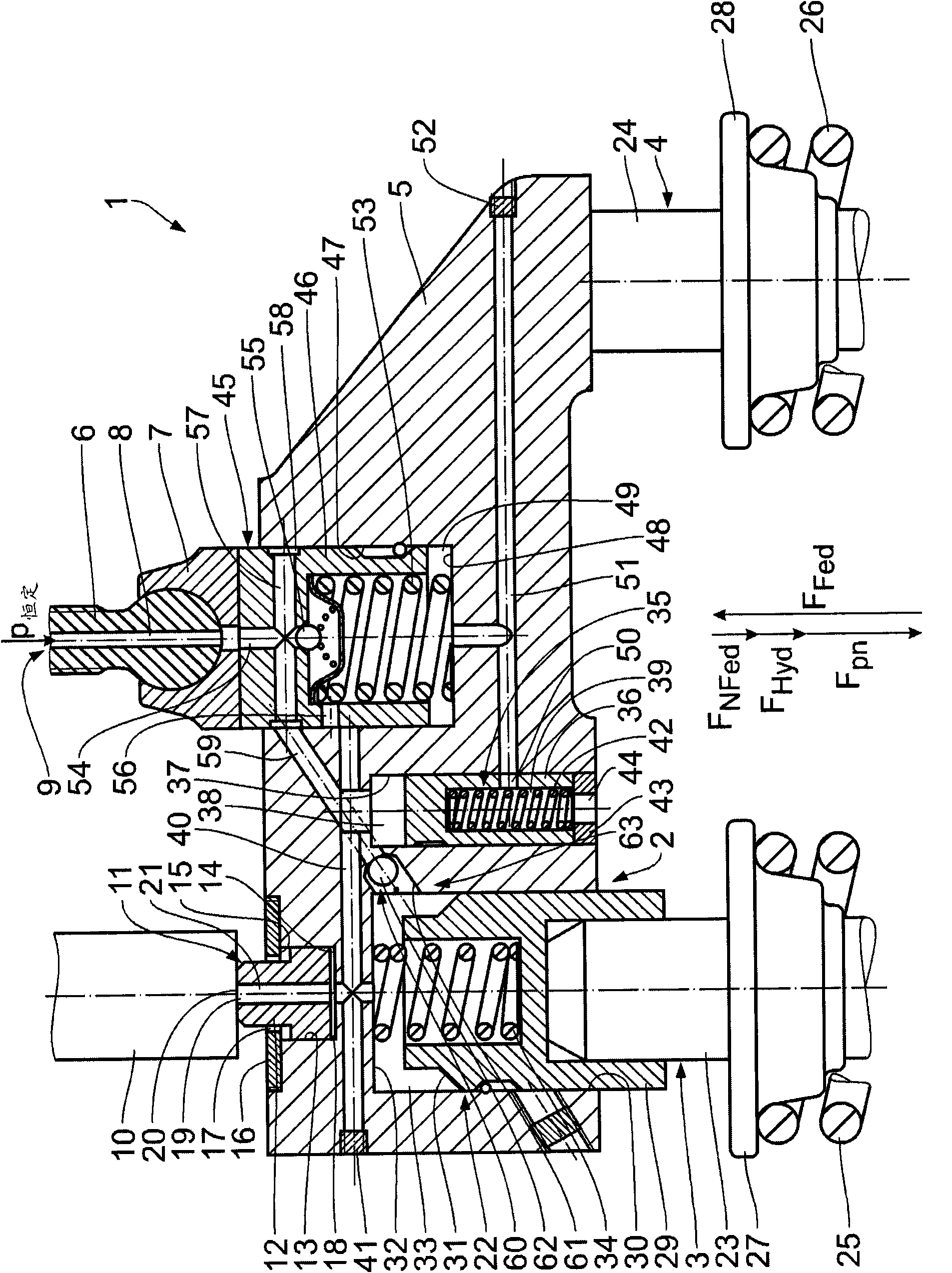

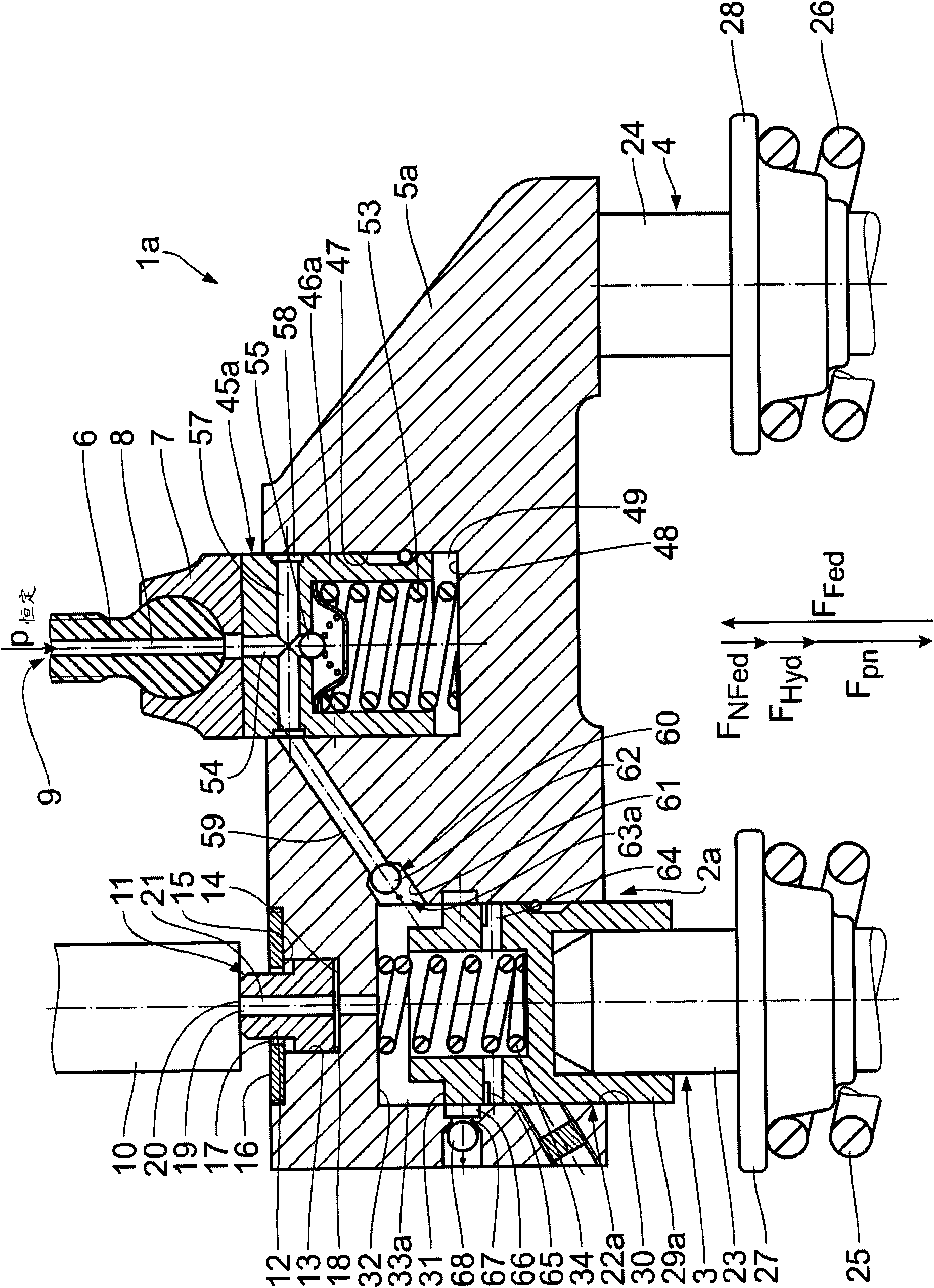

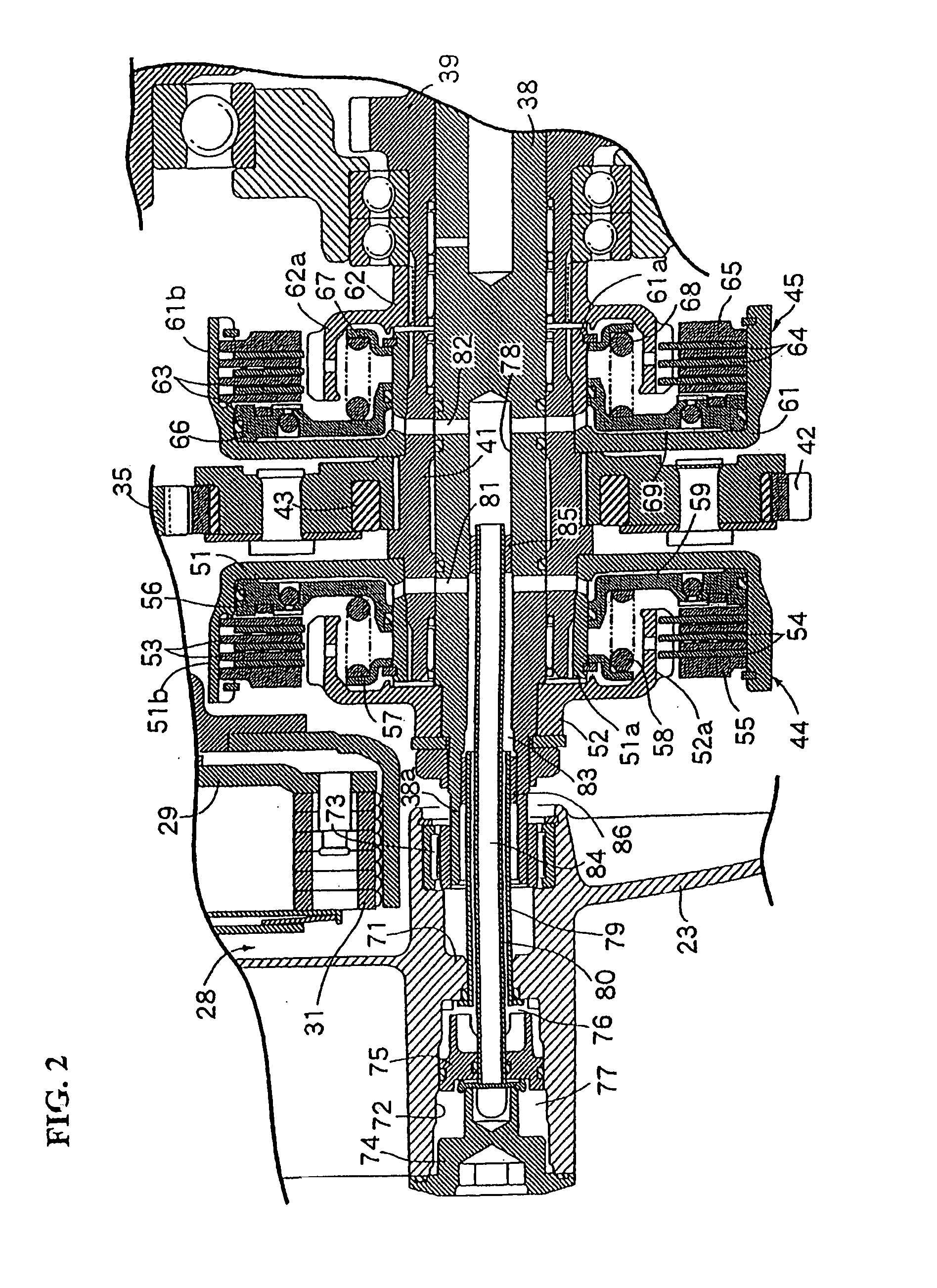

Method of operating hydrokinetic torque converters in the power trains of motor vehicles and torque converter for the practice of the method

ActiveUS20040144607A1Reduce oil pressureReduce pressureRotary clutchesFriction clutchesMobile vehicleHydraulic fluid

The hydrokinetic torque converter between the prime mover and the transmission in the power train of a motor vehicle is designed to promote and / or otherwise regulate the flow of hydraulic fluid therethrough. The fluid is circulated between the friction linings on the laminations of the bypass clutch in the housing of the torque converter. In a first embodiment of the method, the flow of fluid in certain parts of the torque converter is opposed or interfered with in such a way that a larger quantity of fluid flows between the laminations of the bypass clutch. In a second embodiment, the resistance to fluid flow through the bypass clutch of the torque converter is reduced. It is also possible to resort to both solutions in one and the same torque converter.

Owner:SCHAEFFLER TECH AG & CO KG

Method of operating hydrokinetic torque converters in the power trains of motor vehicles and torque converter for the practice of the method

ActiveUS7036643B2Reduce oil pressureReduce pressureRotary clutchesFriction clutchesMobile vehicleHydraulic fluid

Owner:SCHAEFFLER TECH AG & CO KG

Crankshaft lubrication system

Owner:HONDA MOTOR CO LTD

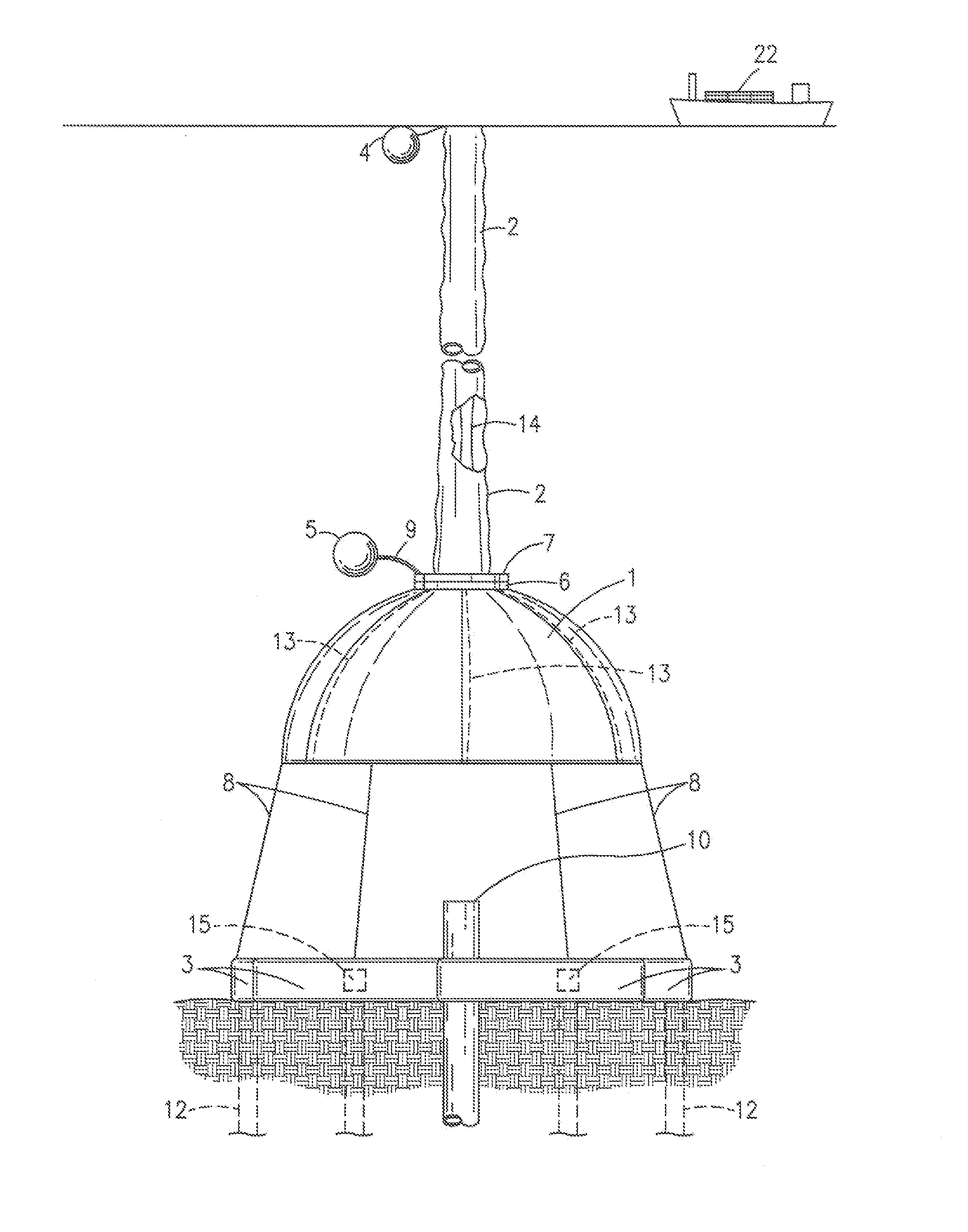

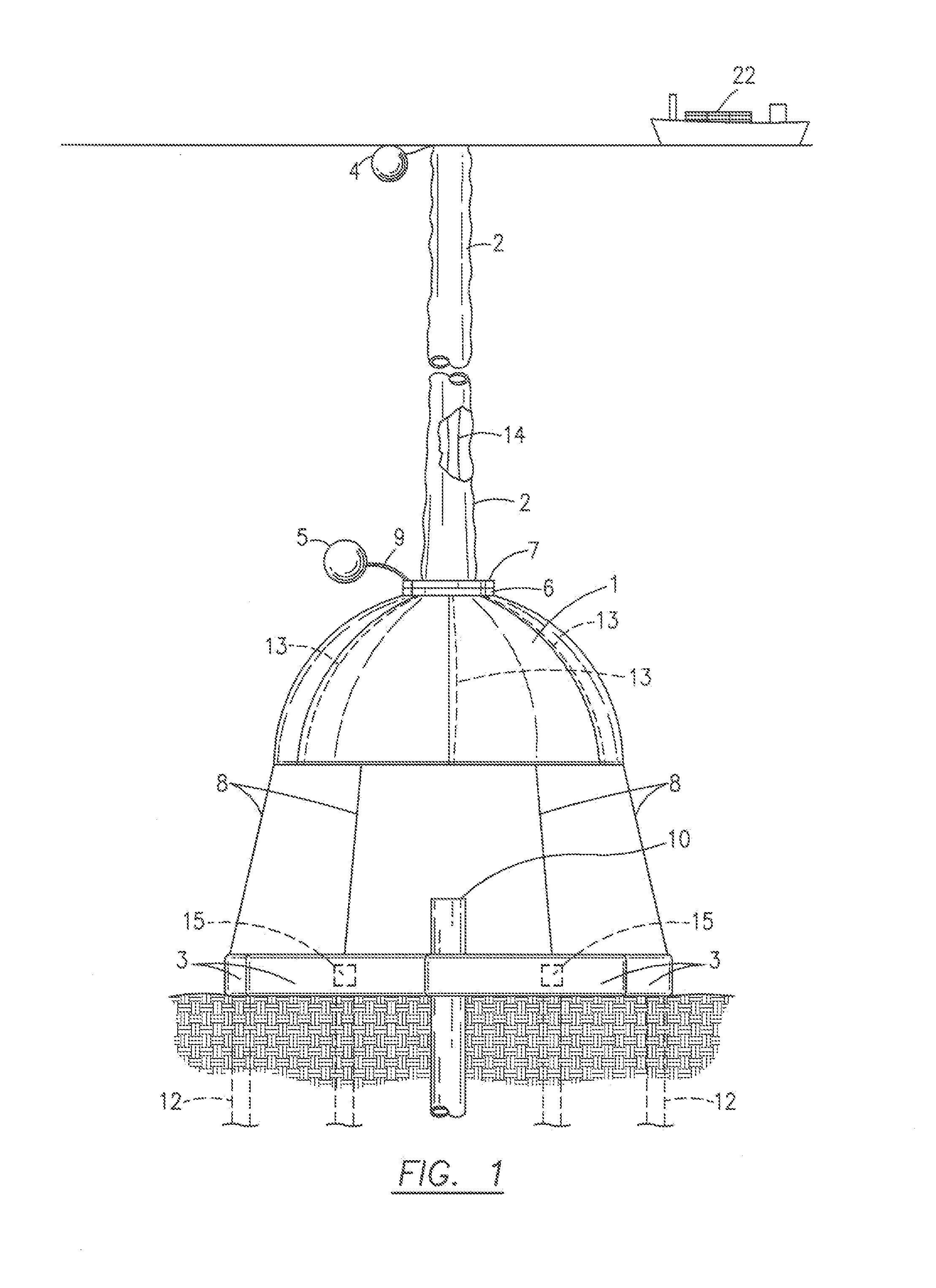

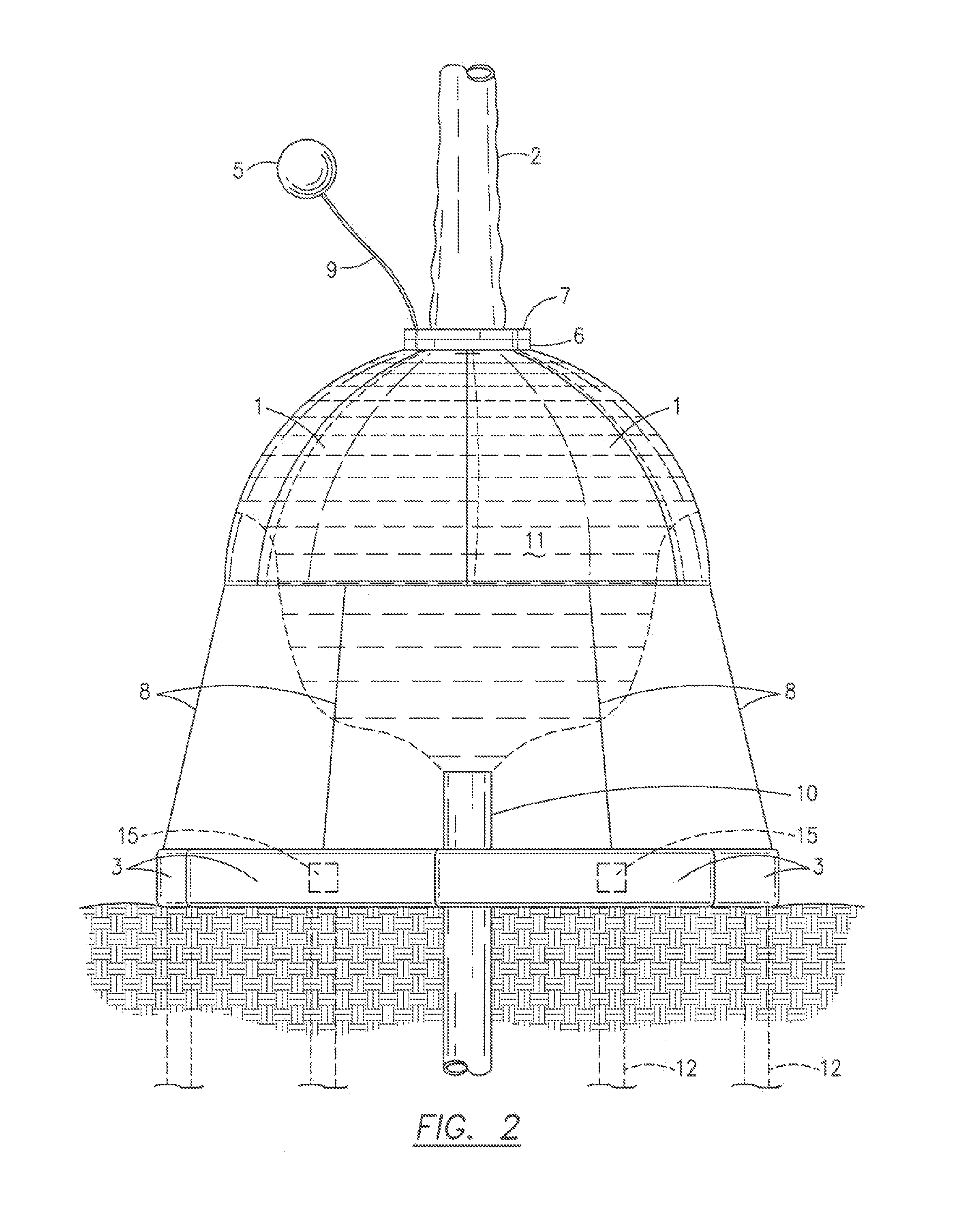

On demand non-rigid underwater oil and gas containment and retrieval system and method

An underwater oil and gas containment and retrieval system comprising a collapsible deployable oil and gas containment canopy including a dome comprised of several separately stored dome panels (1), a discharge vent tube (2) including inflatable air chambers (14) to provide some rigidity and shape, dome panel storage containers (3) for storing the dome panels (1) on the ocean floor, and a separate discharge vent tube storage container (16) for storing the discharge vent tube separately on the ocean floor. The system is especially useful for deep water wells below 500 feet deep.

Owner:WATSON SR MICHAEL RAY

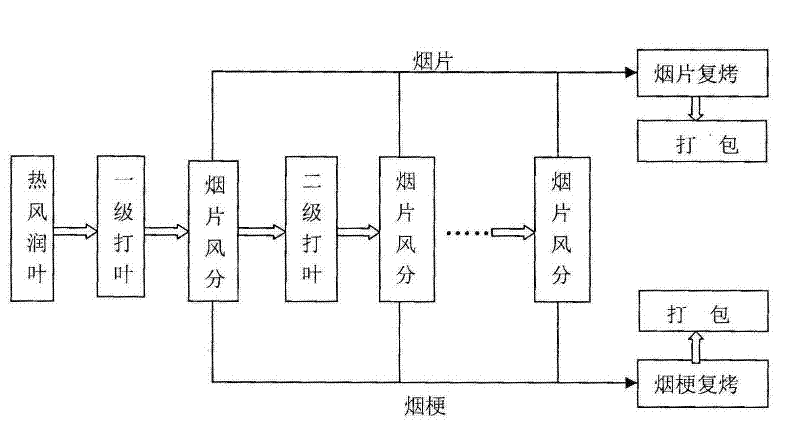

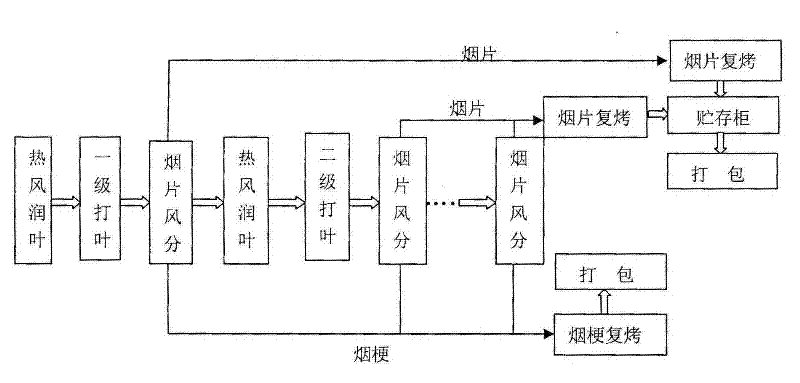

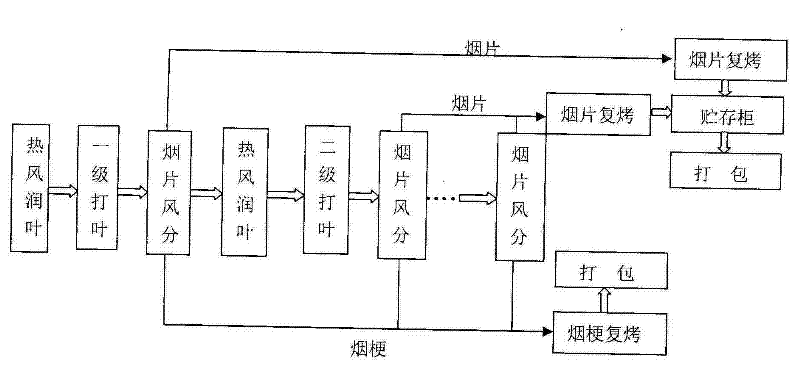

Novel threshing and redrying process based on tobacco mechanics characteristic differences

ActiveCN102488306AImprove lubricityGuaranteed pass rateTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

A threshing and redrying process based on tobacco mechanics characteristic differences comprise links of primary threshing, secondary threshing, tobacco air separating, tobacco redrying and packaging. The threshing and redrying process is characterized in that according to measured tobacco mechanics characteristic indexes, tobaccos are divided into a type I of tobaccos and a type II of tobaccos, a hot air humidifying link is added between the primary threshing link and the secondary threshing link for the type I of tobaccos, tobaccos produced from the primary threshing link, the secondary threshing link and follow-up various process links are respectively redried, moisture content of the type I of tobaccos is reduced before the type I of tobaccos enter the primary threshing link, and tobaccos produced from the primary threshing link are in low-strength redrying; and the type II of tobaccos are in threshing and redrying according to existing threshing and redrying process flow. The novel threshing and redrying process is based on the tobacco mechanics characteristic differences, is complete and feasible threshing and redrying process flow and control technology for resolving the problem of tar extrusion and caking of tobacco during processing, and by the aid of the threshing and redrying process flow and control technology, threshing and redrying processing technical level and comprehensive tobacco quality further can be improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

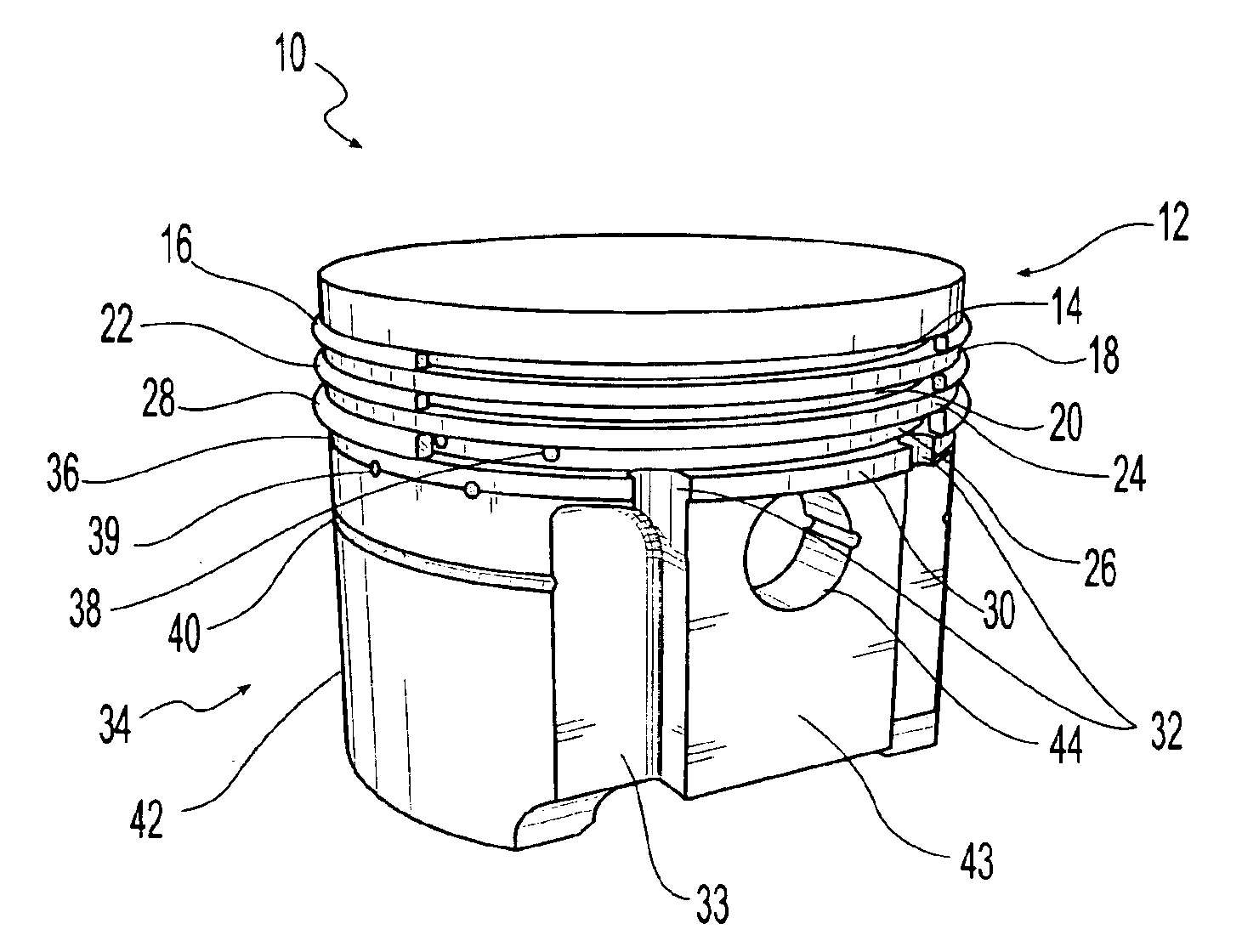

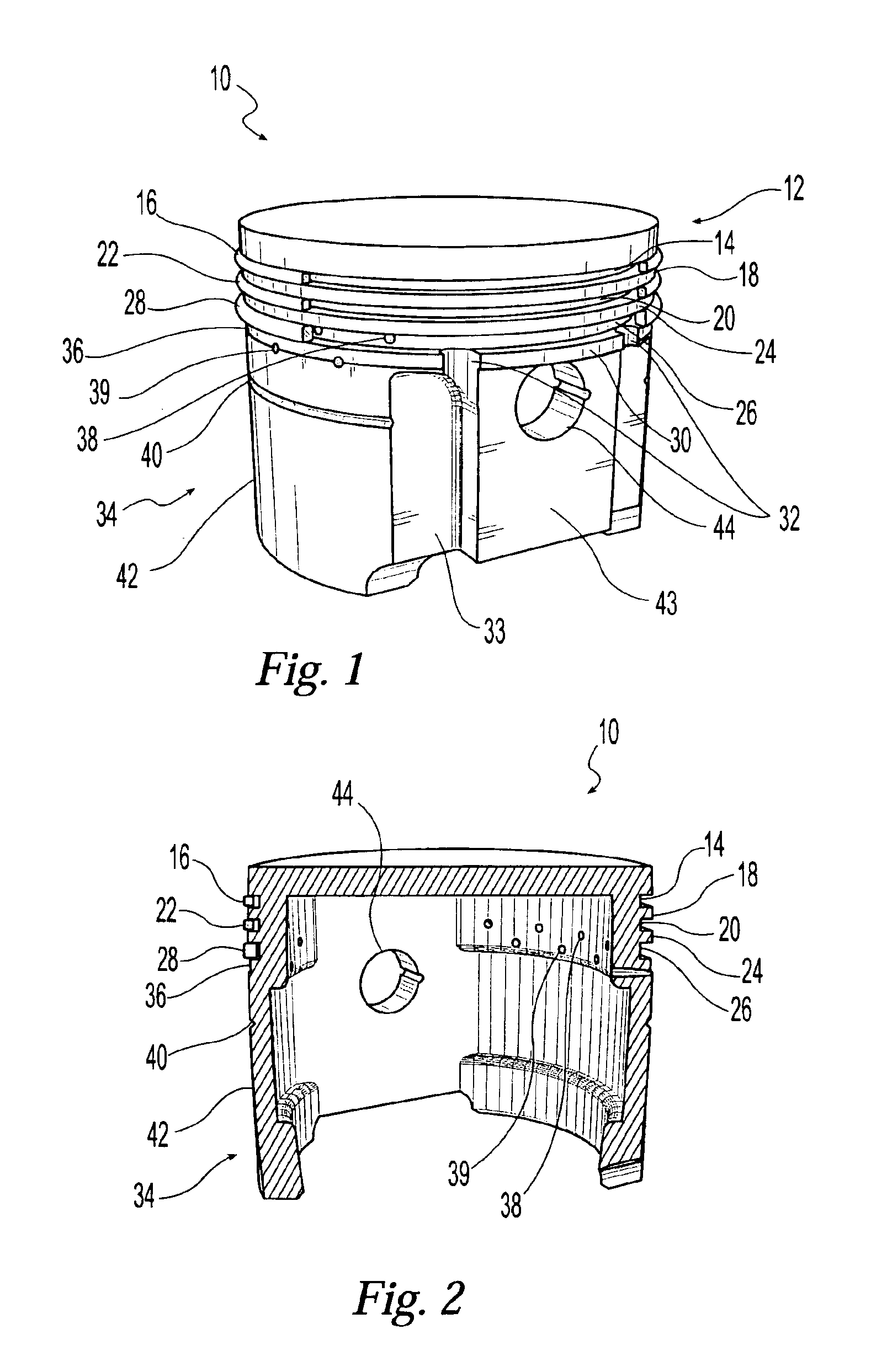

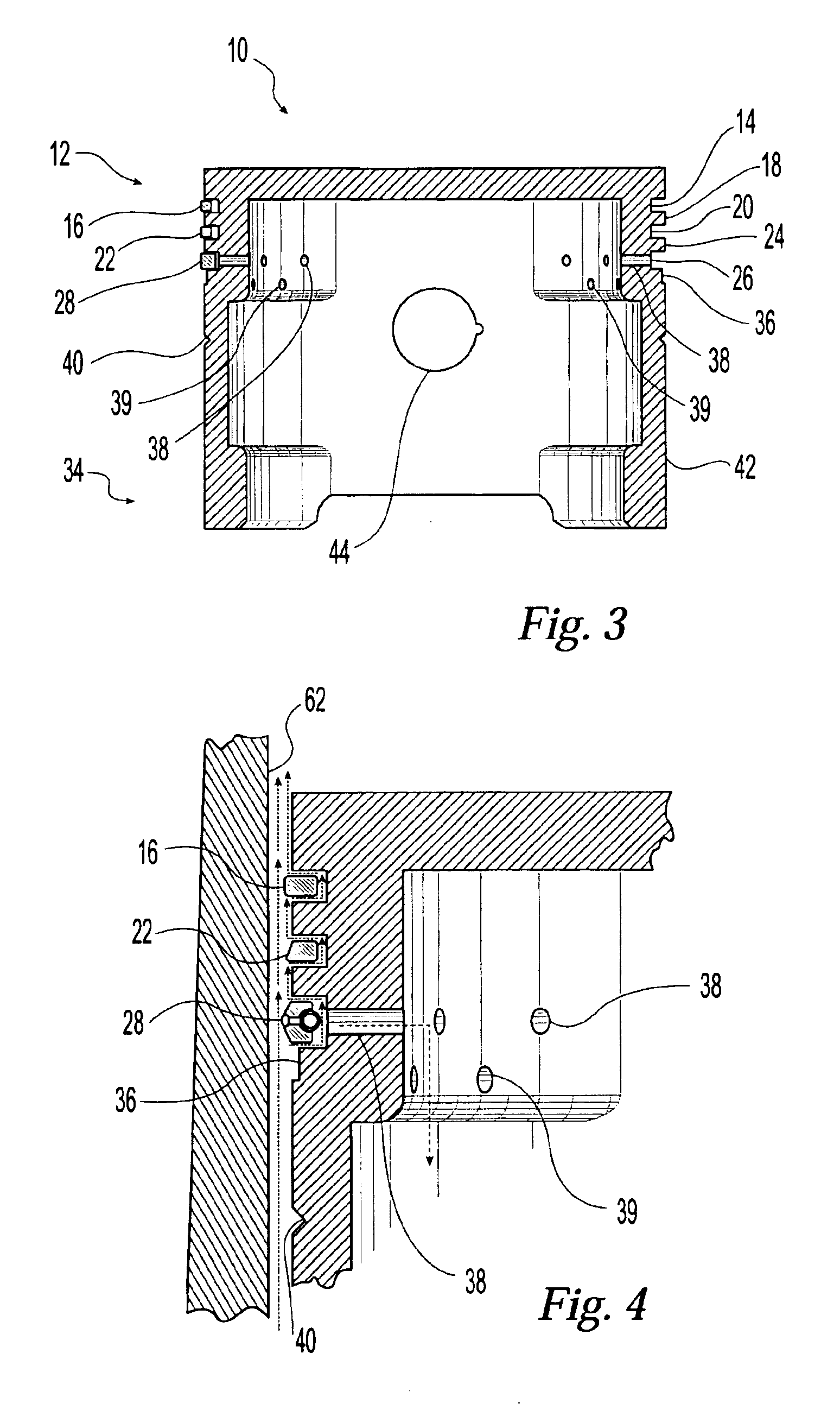

Contoured piston

InactiveUS6935220B2Reduce oil-pressureReduce any excessive oil pressurePiston ringsPlungersOil pressureEngineering

A piston for use in internal combustion engines or reciprocating compressors such as those utilized in air-brake systems for heavy duty freight vehicles. The body of the piston of the present invention is contoured in manner to reduce the undesirable build-up of oil pressure that frequently occurs at the oil control ring or rings when the piston is in operation. The crown portion of the piston body includes a series of piston ring groove and piston ring lands, one of which is modified to include drainage notches. The skirt portion of the piston body includes a plurality of furrows near the face of the piston, a horizontal channel recessed into the surface of the piston skirt, and a horizontal groove formed in the outer skirt wall of the piston. These structures function individually and in combination to provide multiple means by which excess lubricating oil may be directed away from the oil control rings and back toward the crankcase or oil reservoir within the engine or compressor.

Owner:BENDIX COMML VEHICLE SYST LLC

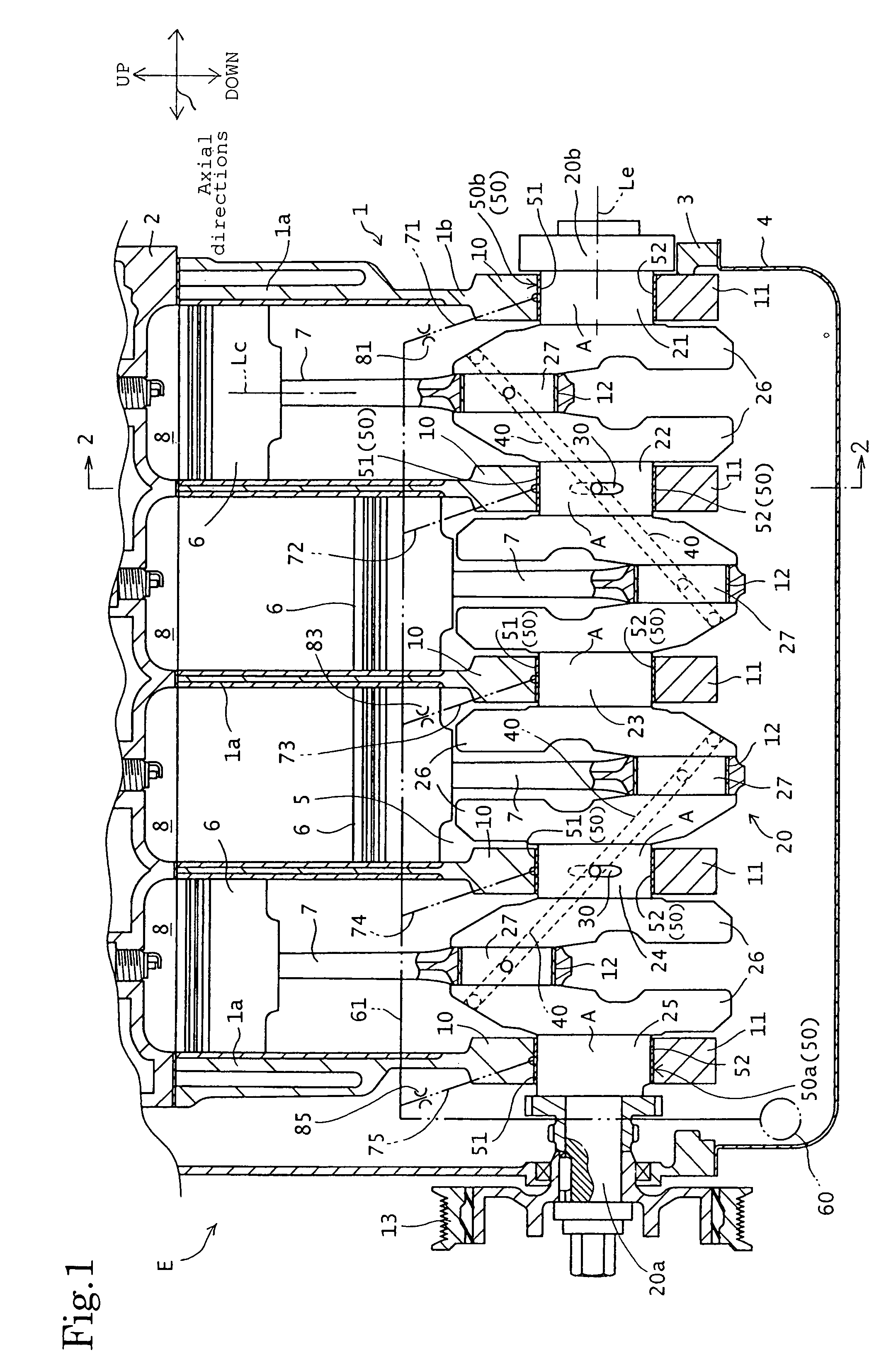

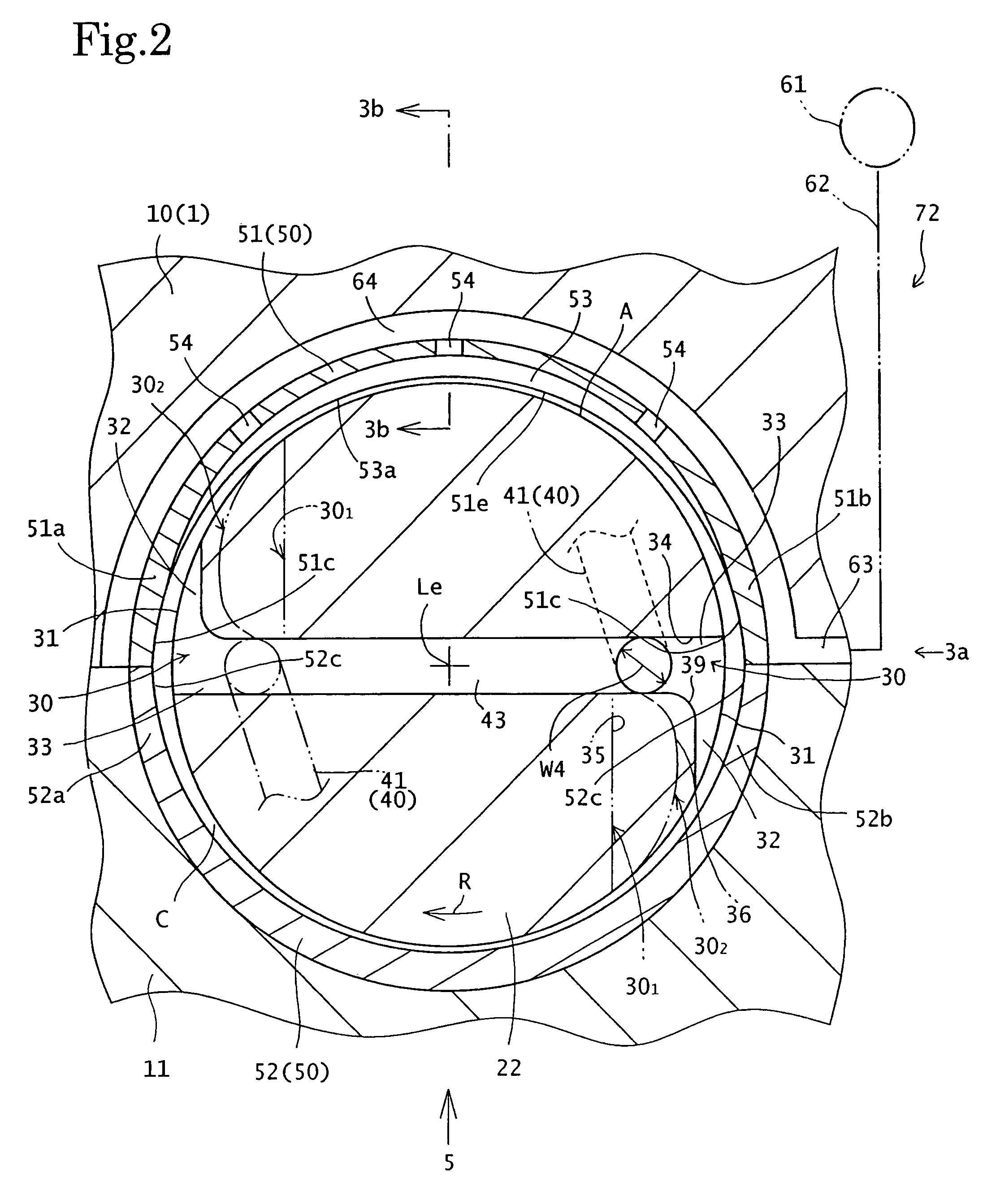

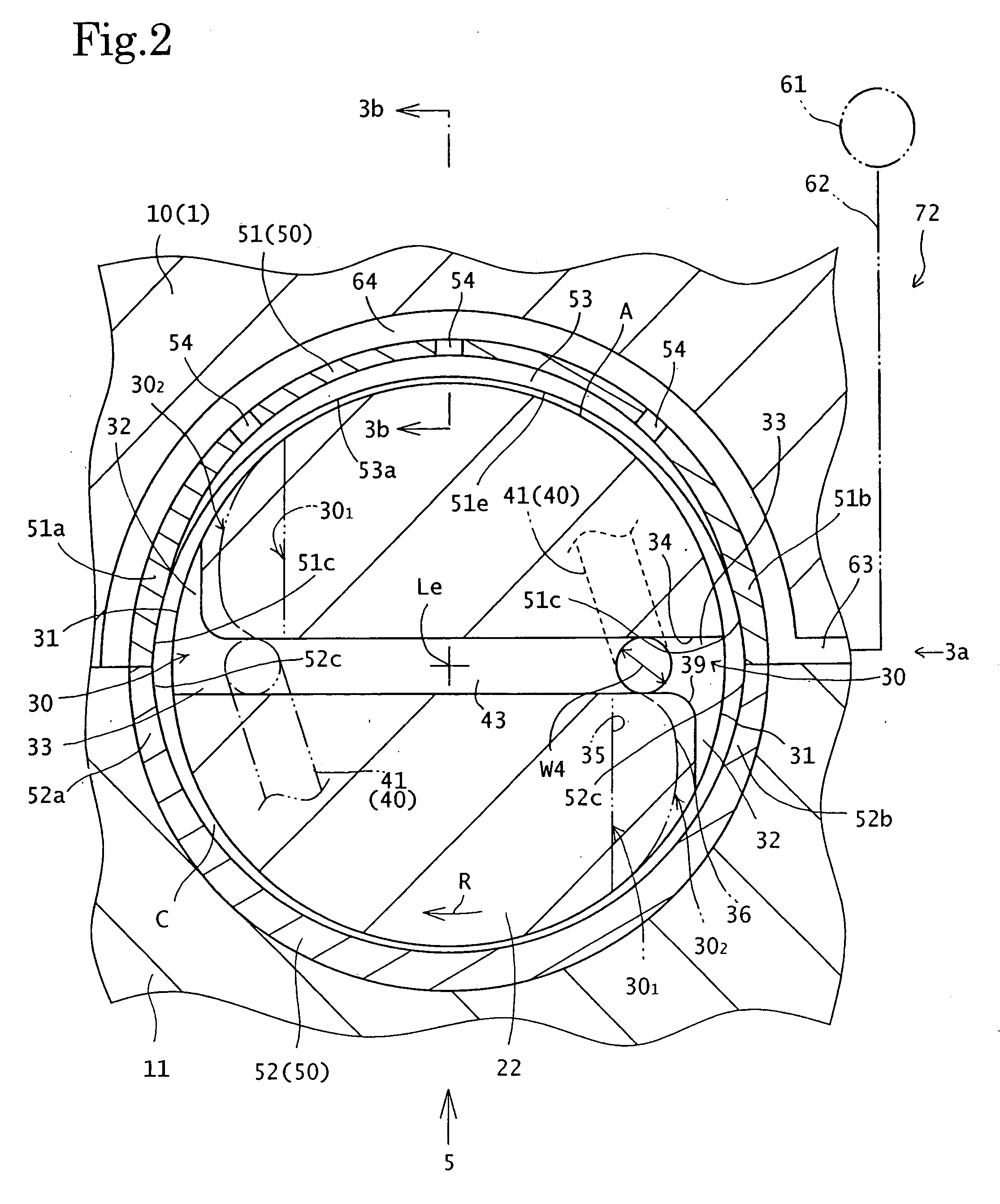

Crankshaft lubrication system

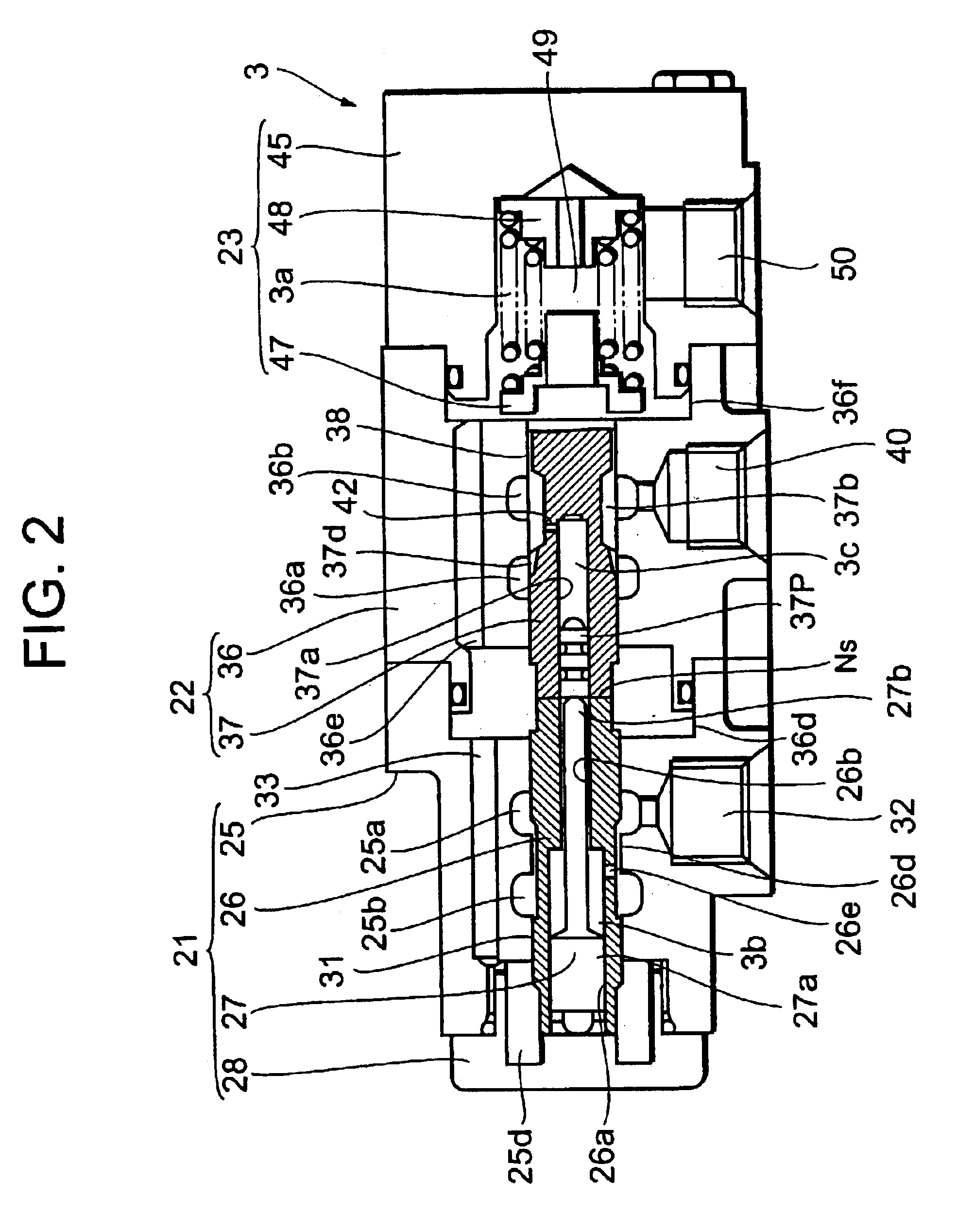

InactiveUS20080190699A1Reduce leakageJournal is reducedCrankshaftsConnecting rodsInternal combustion engineCrankpin

A crankshaft of an internal combustion engine has journals provided with shaft oil passages for carrying the oil to crankpins, and guide grooves having parts in which the shaft oil passages open, respectively, and opening in the cylindrical surfaces of the journals, respectively. The guide grooves has downstream end parts into which the shaft oil passages open, respectively, and extend in a circumferential direction in which the crankshaft rotates from the downstream end parts, respectively. First half bearing members of bearings are provided in their bearing surfaces with oil grooves through which the oil is supplied to the guide grooves, respectively. Each of the oil grooves are diametrically opposite to each of the guide grooves. The oil grooves have an axial width (W5) smaller than the axial width (W3) of the guide grooves. Thus oil leakage from gaps between each of the bearings and each of the journals of the crankshaft is reduced and hence an oil pump having a small capacity can be used.

Owner:HONDA MOTOR CO LTD

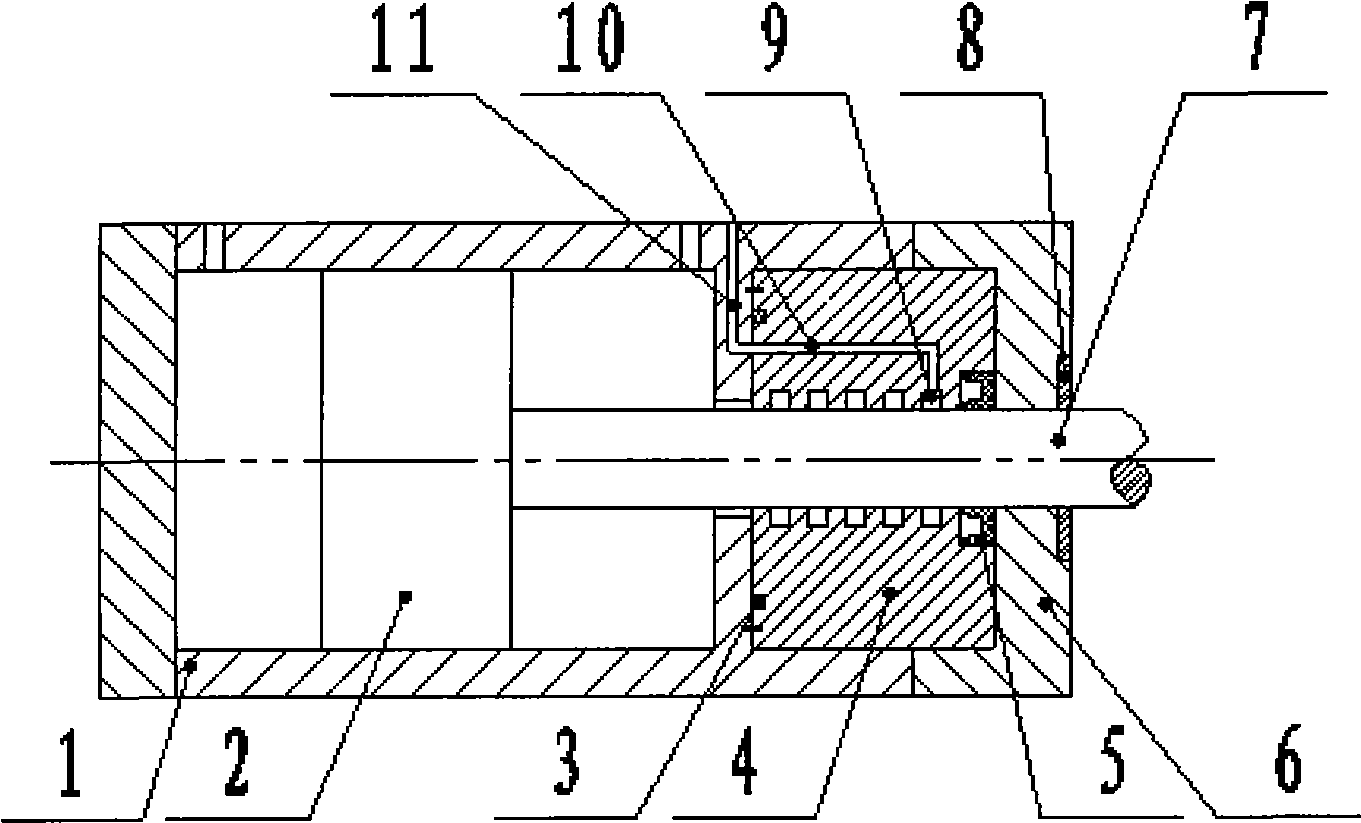

Oil film supporting servo hydraulic cylinder

The invention relates to a servo hydraulic cylinder supported by an oil film, which adopts the technical scheme that the servo hydraulic cylinder comprises a cylinder body (1), a piston (2), a piston rod (7), a guide sleeve (4) and a press cover (6), wherein the guide sleeve (4) passes through the piston rod (7) and is fixedly arranged at the shoulder position inside the cylinder body (1), a sealing ring (3) is arranged at the contact position of the guide sleeve (4) and the shoulder position of the cylinder body (1), three to seven balancing grooves (9) are arranged at the contact position of the guide sleeve (4) and the piston rod (7), the rightmost balancing groove (9) is communicated with a second oleophobic passage (11) through a first oleophobic passage (10), the press cover (6) tightly presses the guide sleeve (4) and is fixed on the small cavity end of the cylinder body (1), and the contact position of the right side of the guide sleeve (4) and the piston rod (7) is provided with a U-shaped sealing ring (5). The invention has the advantages of long service life, little friction, good dynamic response and little leakage.

Owner:WUHAN UNIV OF SCI & TECH

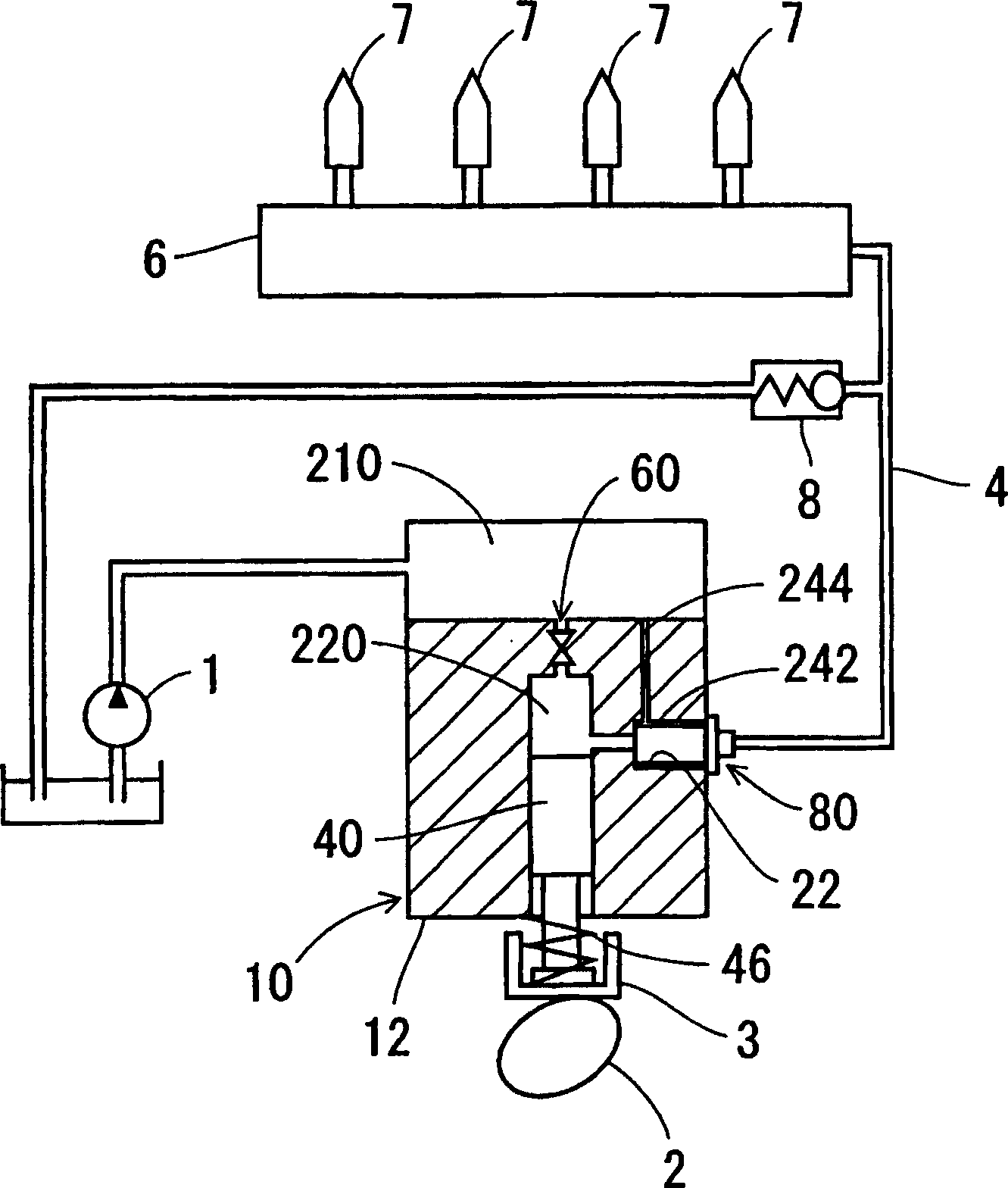

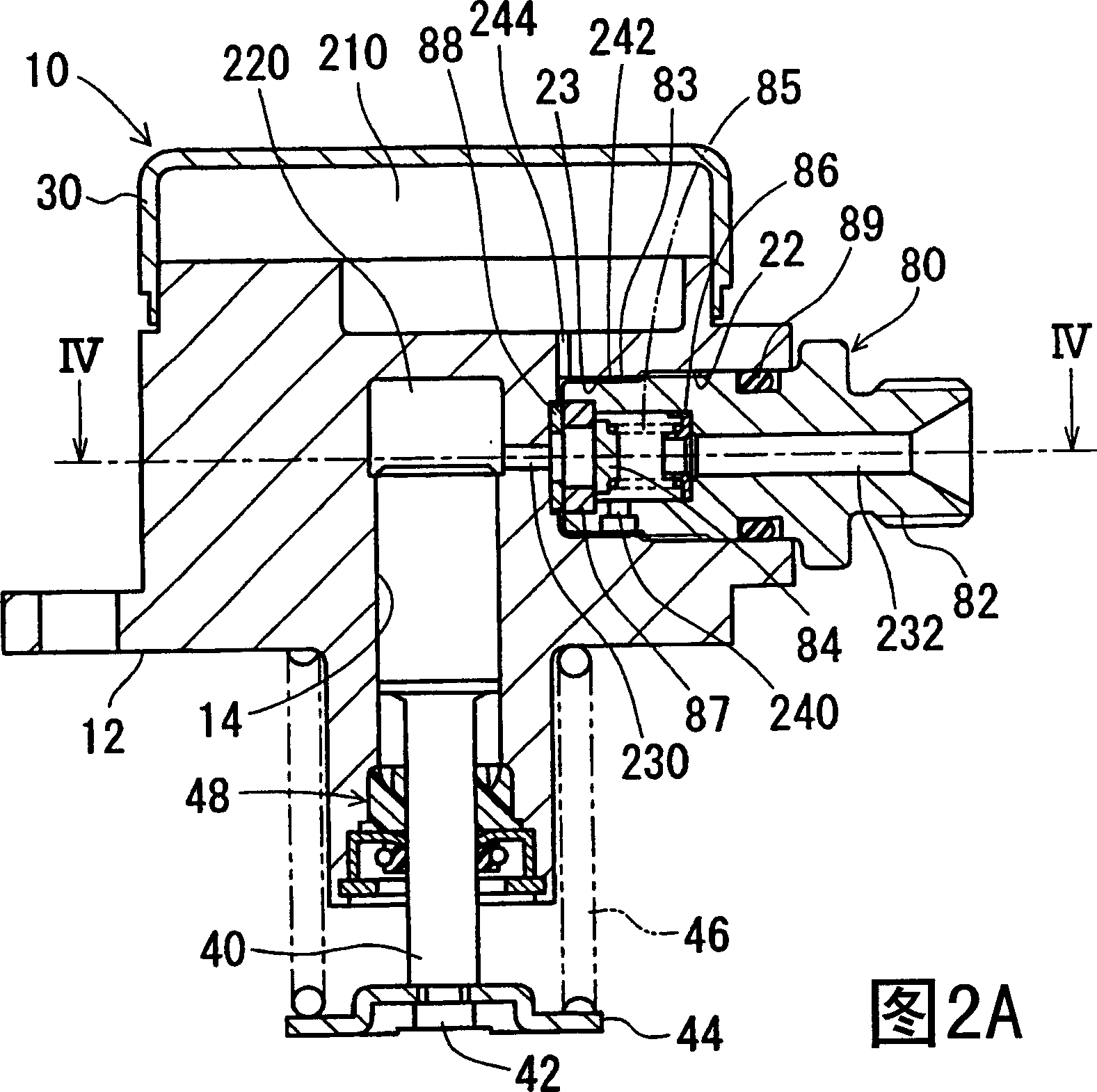

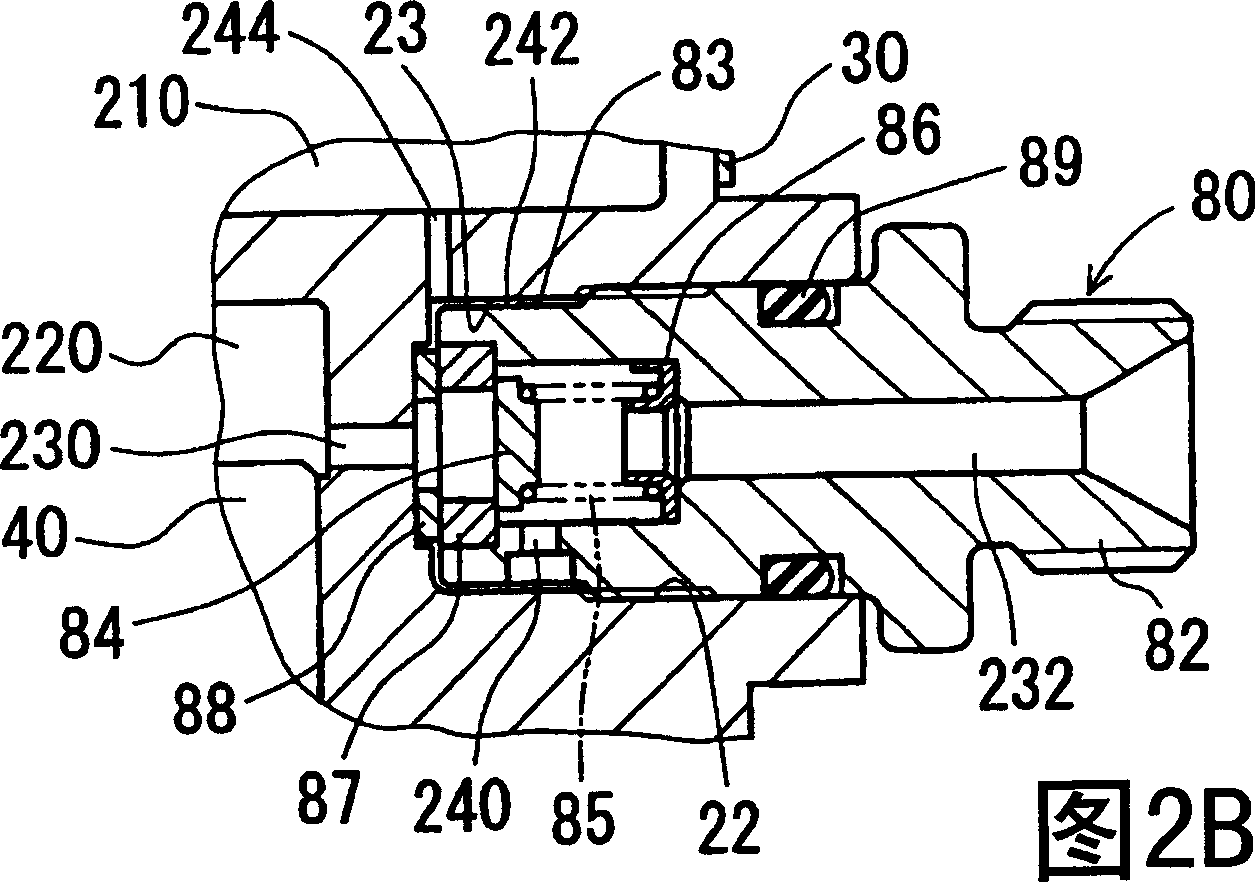

Fuel pump having plunger and fuel supply system using the same

A delivery valve (80) is connected to a discharge passage (230), through which fuel in a compression chamber (220) is discharged. The delivery valve (80) is screwed to a mount hole (22) formed in the cylinder (12). A communication passage (240) is formed in a body (82) to extend through the sidewall between a screwed part, in which the mount hole (22) and the body (82) are screwed to each other, and a gasket (88). A small clearance (242) is formed between an inner peripheral surface (23) of the mount hole (22) and an outer peripheral surface (83) of the body (82). The communication passage (240) provides communication between a fuel passage (232) downstream of a valve seat member (87) and the clearance (242). The clearance (242) communicates with the suction chamber (210) through a return passage (240, 270, 290) formed in the cylinder (12).

Owner:DENSO CORP

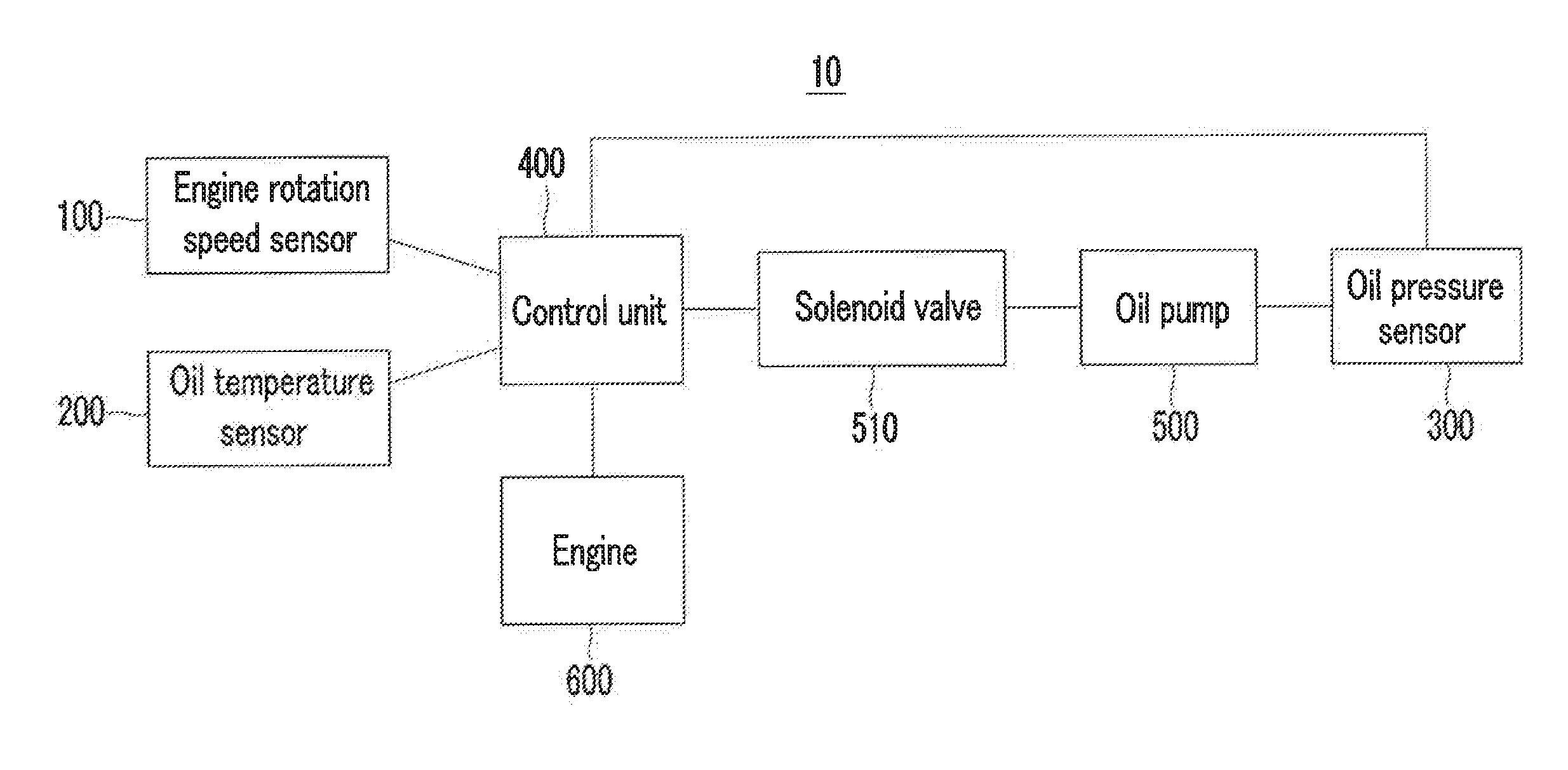

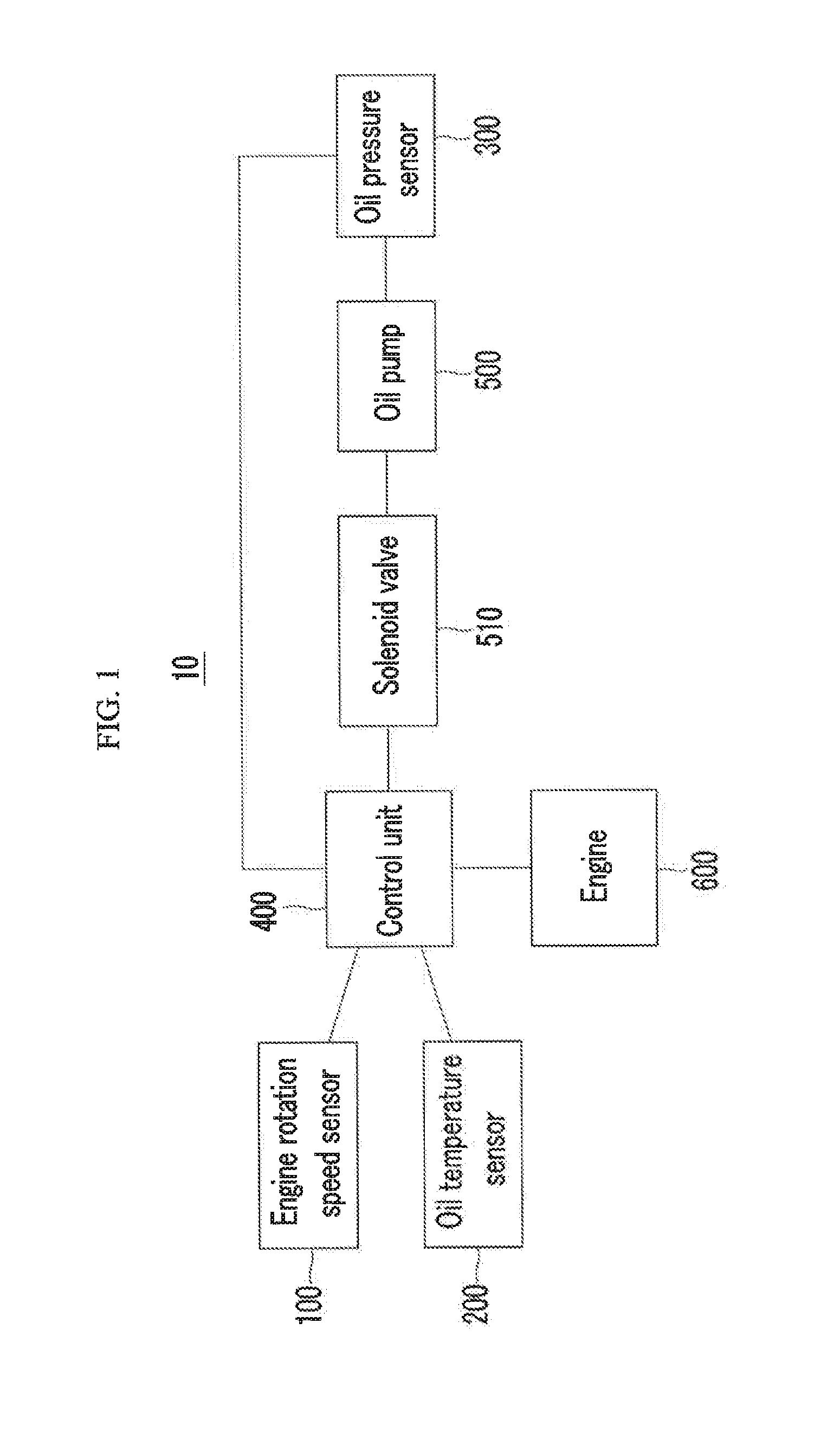

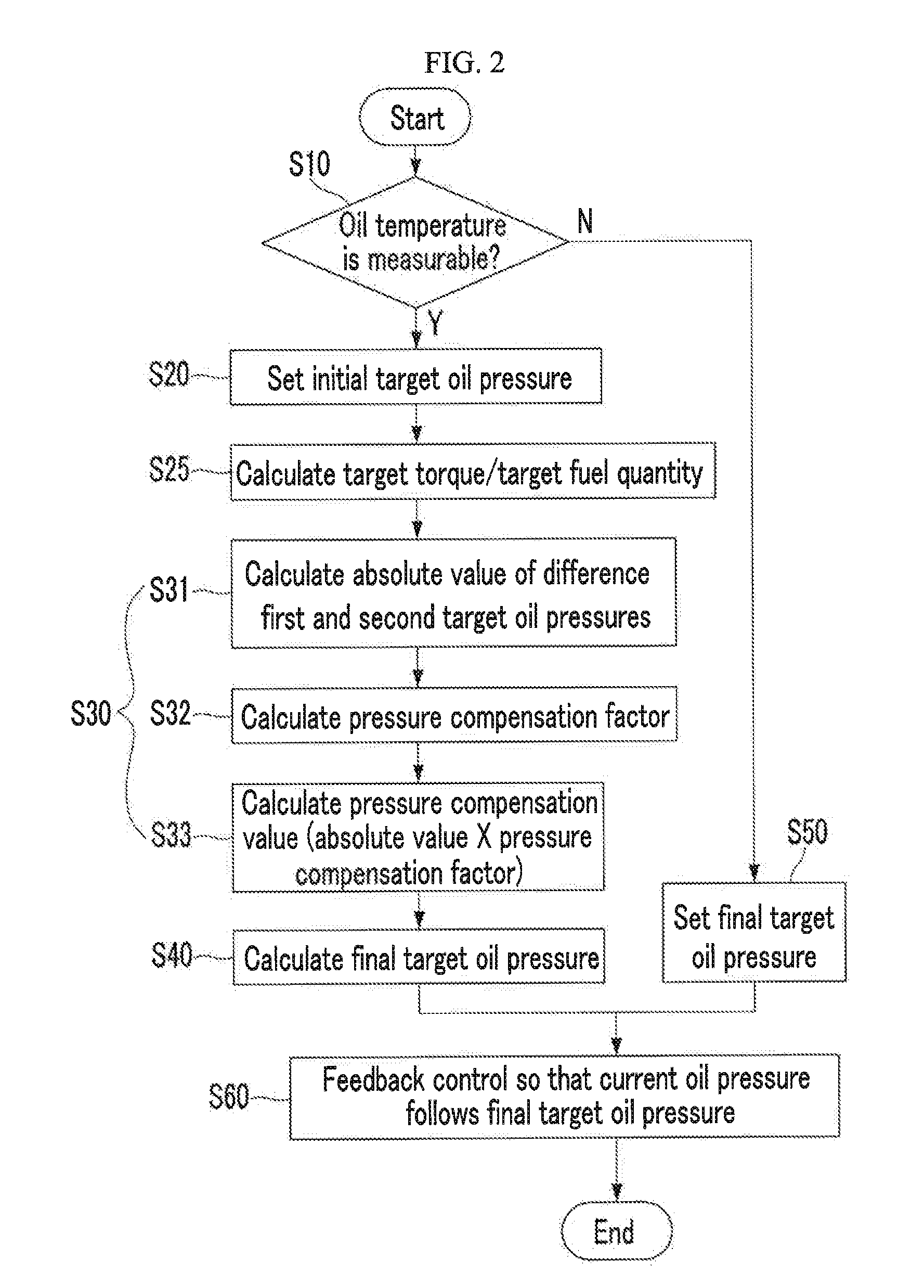

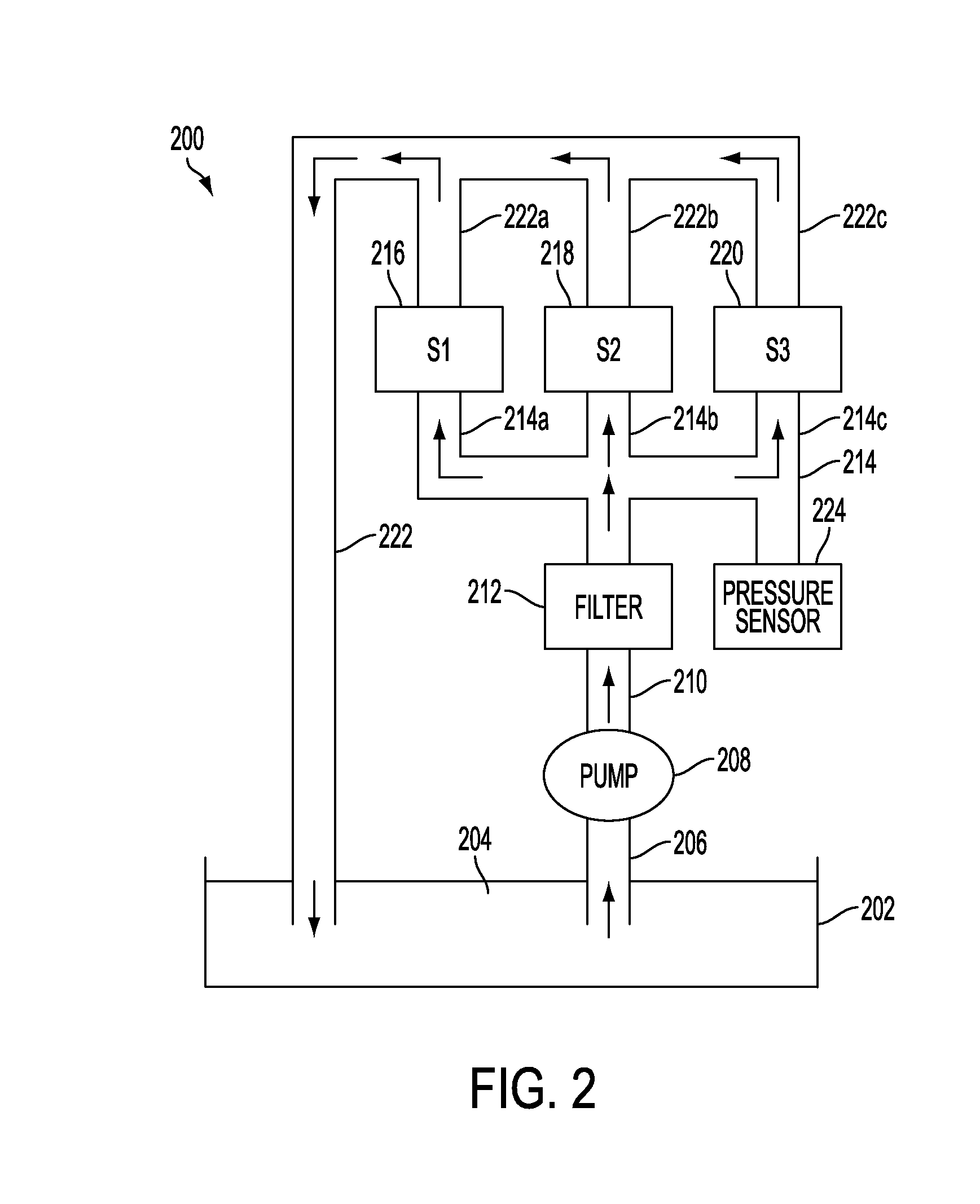

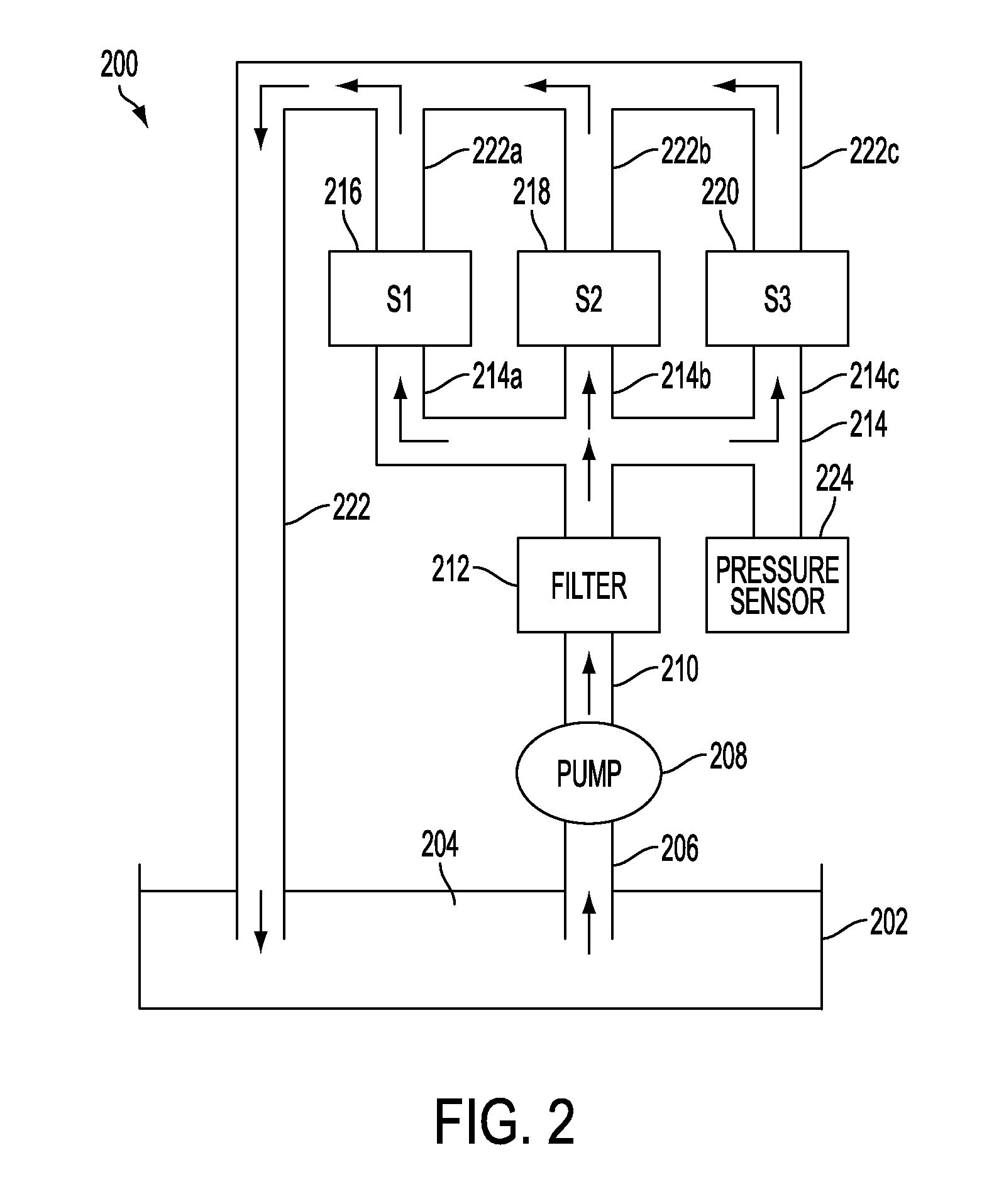

System and method for controlling oil pump

ActiveUS20140100739A1Improve fuel efficiencyReduce oil pressureDigital data processing detailsEngine revolutionsControl systemOil temperature

Disclosed are an oil pump control system and method, the oil pump control method including setting an initial target oil pressure of the oil pump based on a rotation speed of an engine or an oil temperature, determining a pressure compensation value by considering the target torque or target fuel quantity of the engine based on the initial target oil pressure, determining a final target oil pressure by adding the pressure compensation value to the initial target oil pressure, and feedback-controlling the oil pump so that current oil pressure measured in real time follows the final target oil pressure.

Owner:HYUNDAI MOTOR CO LTD +1

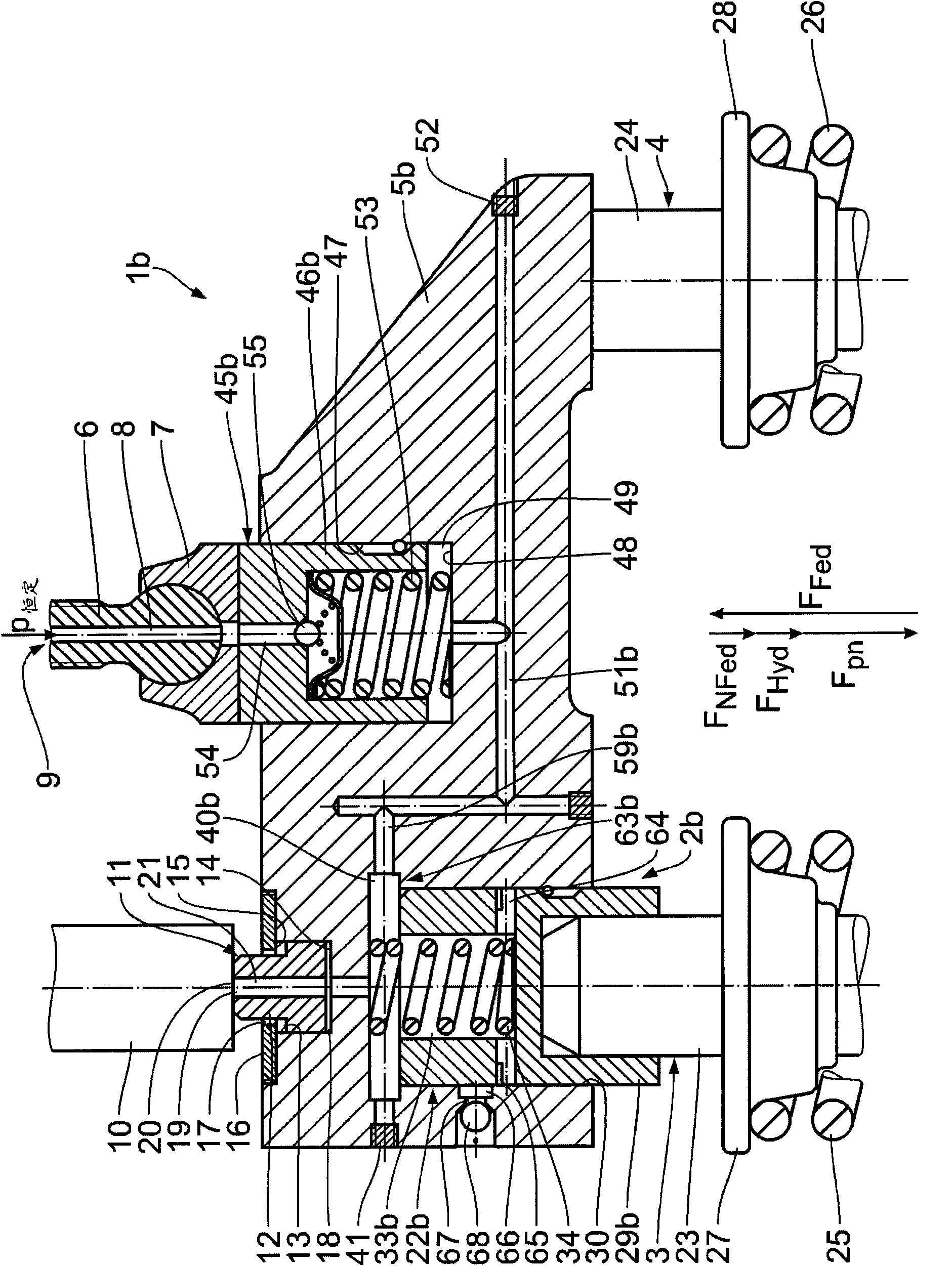

Combustion engine with a motor brake device

ActiveCN101624926AOptimization of exhaust gas characteristicsReduce noiseValve arrangementsOutput powerExhaust valveCombustion chamber

The invention relates to an internal combustion engine with an engine brake device. The internal combustion engine includes has at least a combustion chamber, from which exhaust gas can be discharged by means of at least an exhaust valve (3, 4) as well as an a hydraulic valve auxiliary control unit (22) of an engine brake device (2), and the valve (3) is held in the middle opened position by means of a hydraulic valve auxiliary control unit (22) when operating the engine brake device (2). Furthermore, the internal combustion engine (1) includes a hydraulic valve clearance compensation mechanism (45) for a valve (3,4) and a oil groove (59), and the oil groove (59) is equipped between the hydraulic valve auxiliary control unit (22) and the valve clearance compensation mechanism (45) for supplying oil for the hydraulic valve auxiliary control unit (22), and is closed by a closure unit (63) for compensating the valve clearance of the exhaust valve (3, 4).

Owner:MAN TRUCK & BUS AG

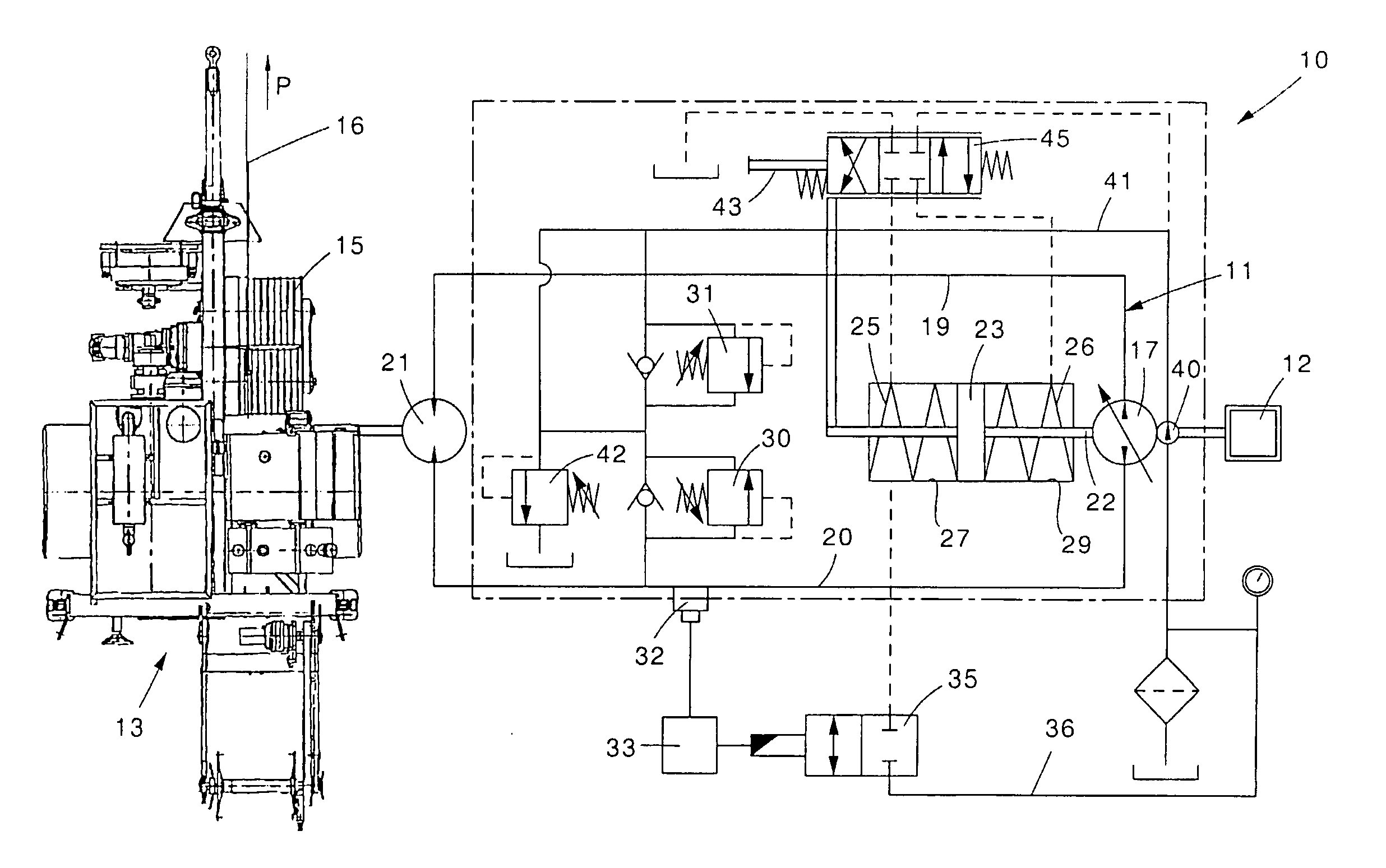

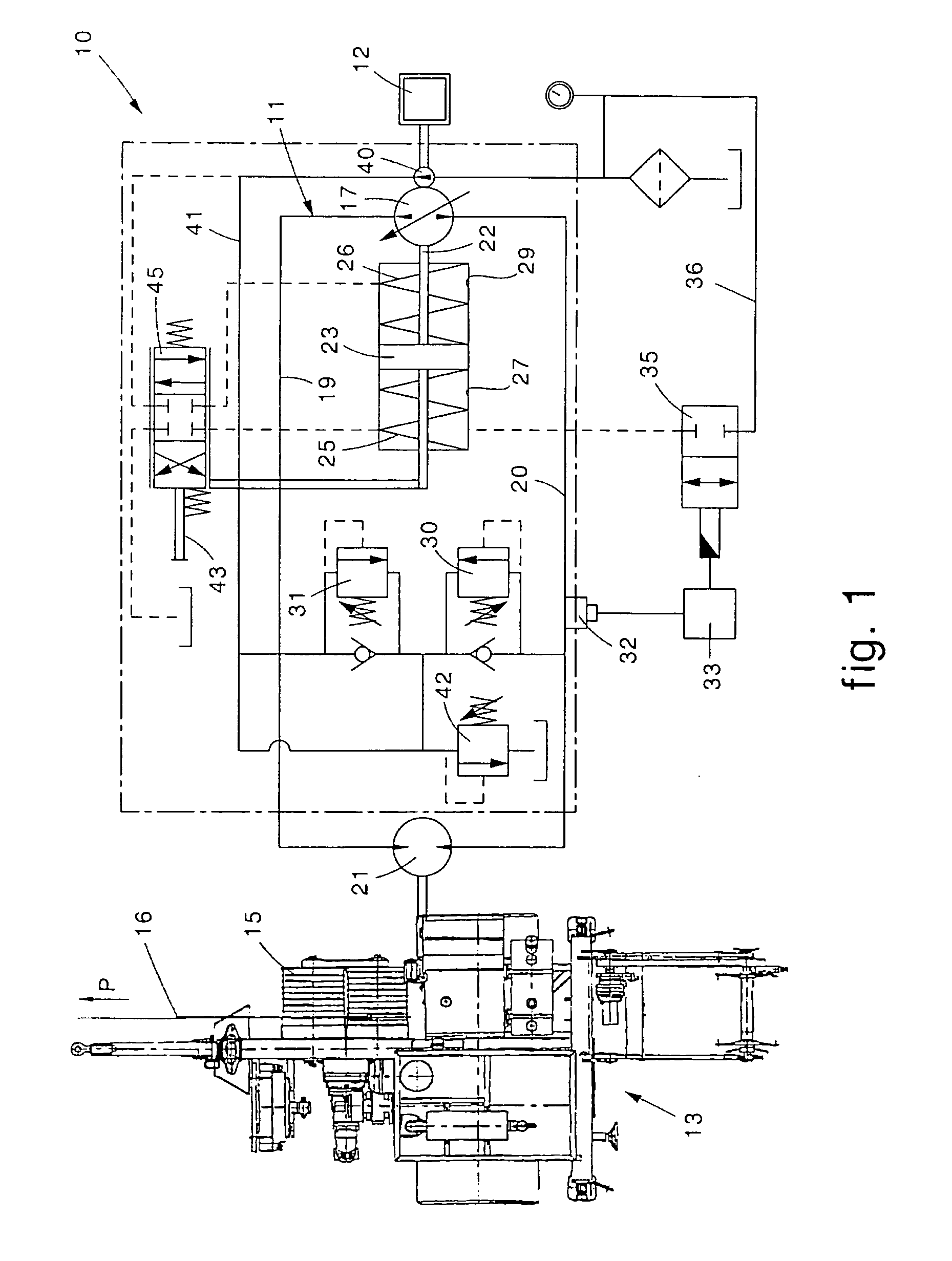

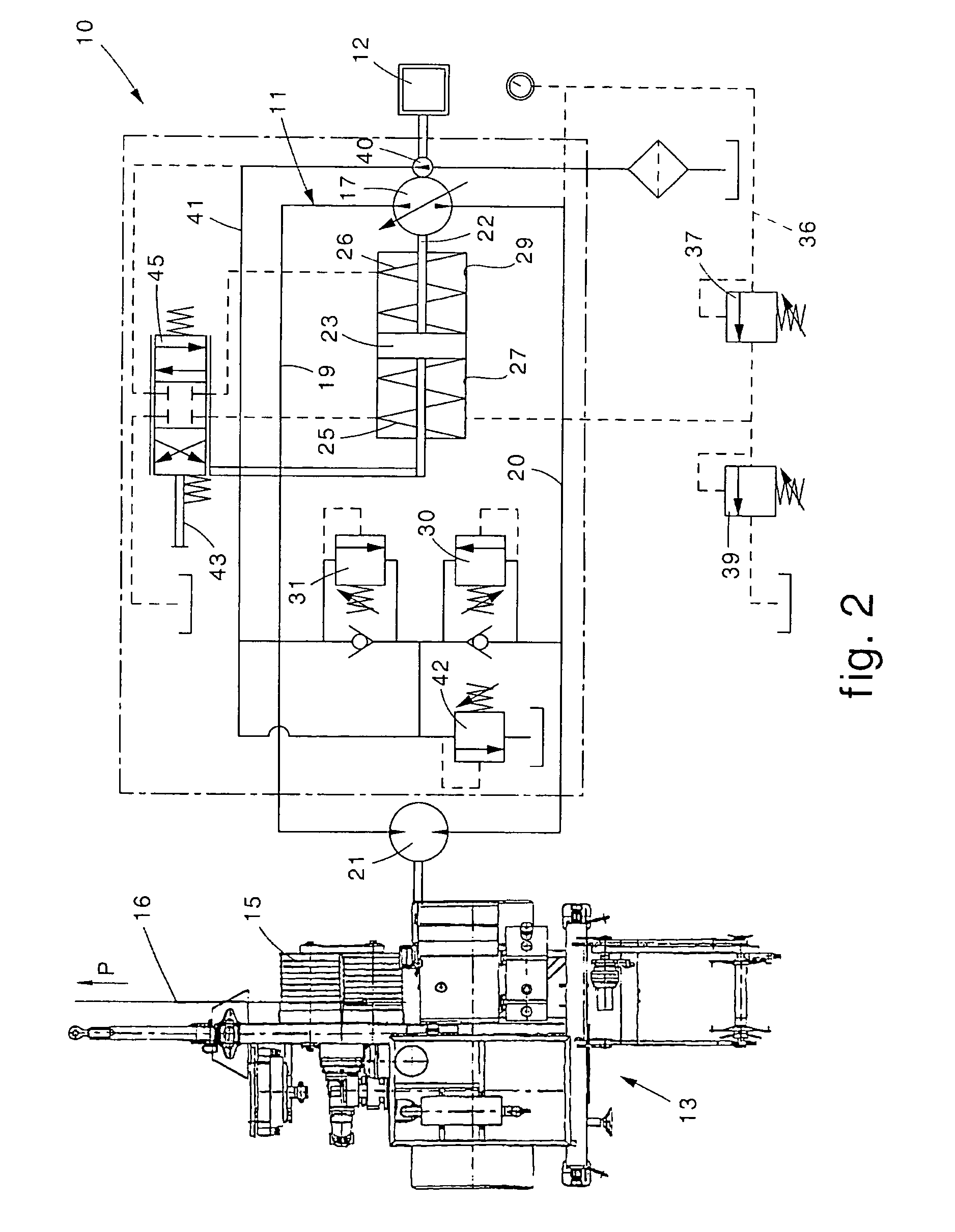

Laying apparatus for cables, lines, conductors or suchlike, and relative laying method

ActiveUS20050089374A1Reduce internal pressureControlling the riskPipe supportsPipe laying and repairElectrical conductorHydraulic circuit

Laying apparatus (10) and method for cables, lines, conductors or suchlike (16). The apparatus (10) comprises at least a hydraulic circuit (11) provided with a variable delivery feed pump (17) and with a motor (21) connected to the feed pump (17) in order to drive laying members (13) for the cables and suchlike (16). The hydraulic circuit (11) comprises detectors (32, 33) able to detect the value of pressure of the oil inside the hydraulic circuit (11) and to compare it with a pre-determined pressure value, and valves (35, 37) connected to the detectors (32, 33) and able to reduce the delivery of the feed pump (17) in the event that the pressure measured exceeds the pre-determined pressure value.

Owner:TESMEC

Engine with hydraulic variable valve timing

ActiveUS8127725B2Improve economyImprove performanceYielding couplingInternal combustion piston enginesSpool valveVariable valve timing

Owner:FORD GLOBAL TECH LLC

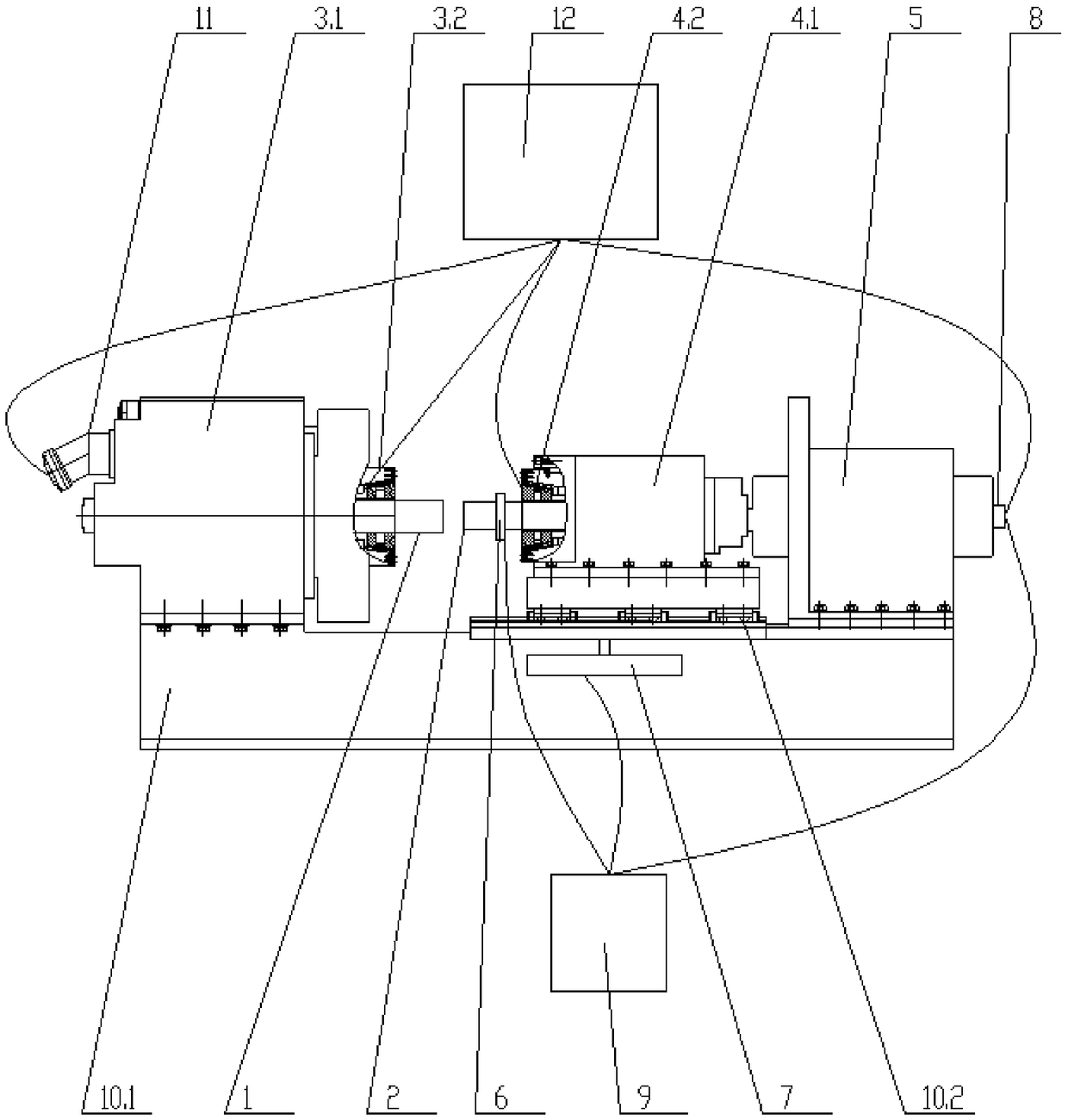

Friction welding axial deformation precision control process

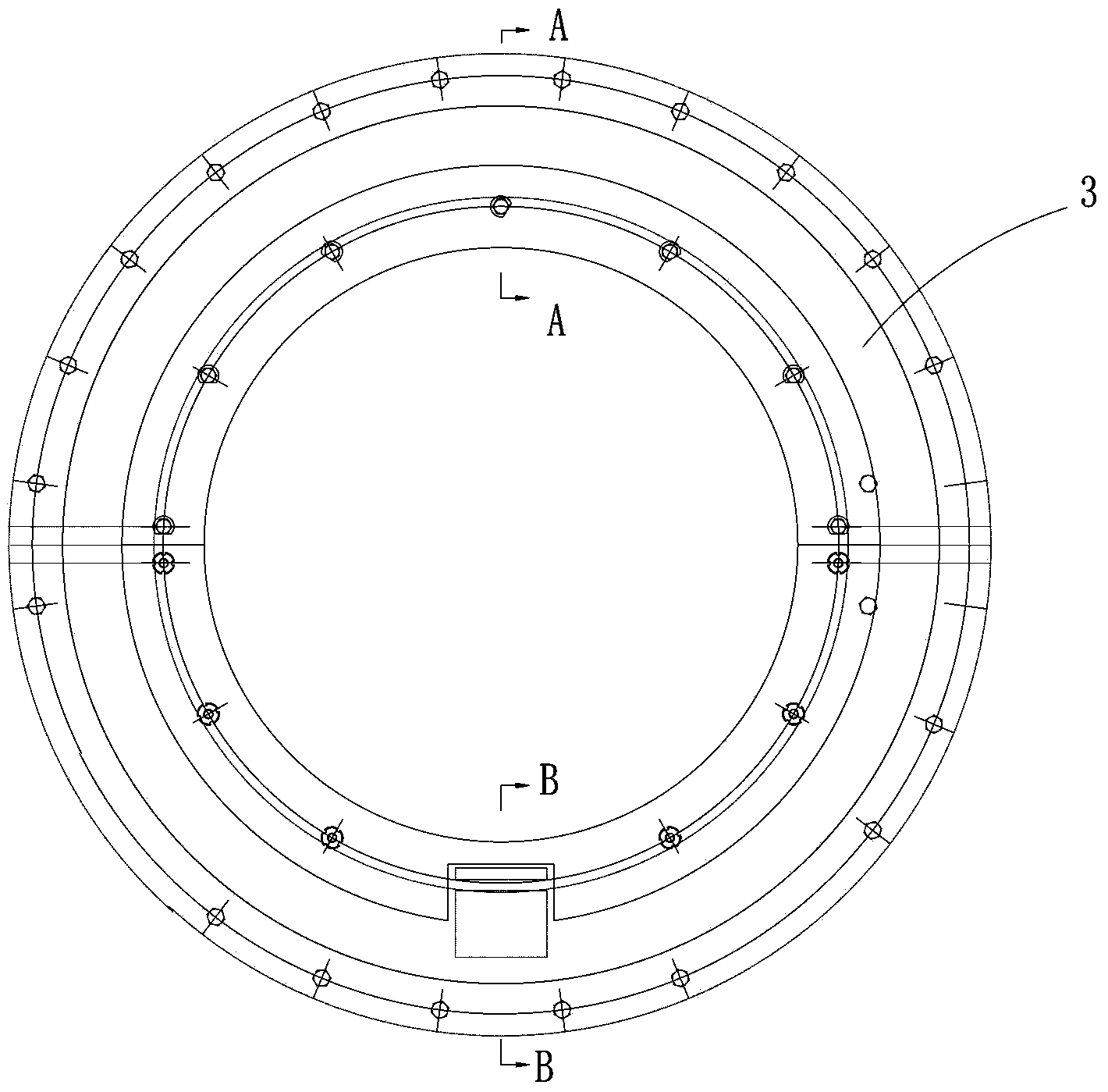

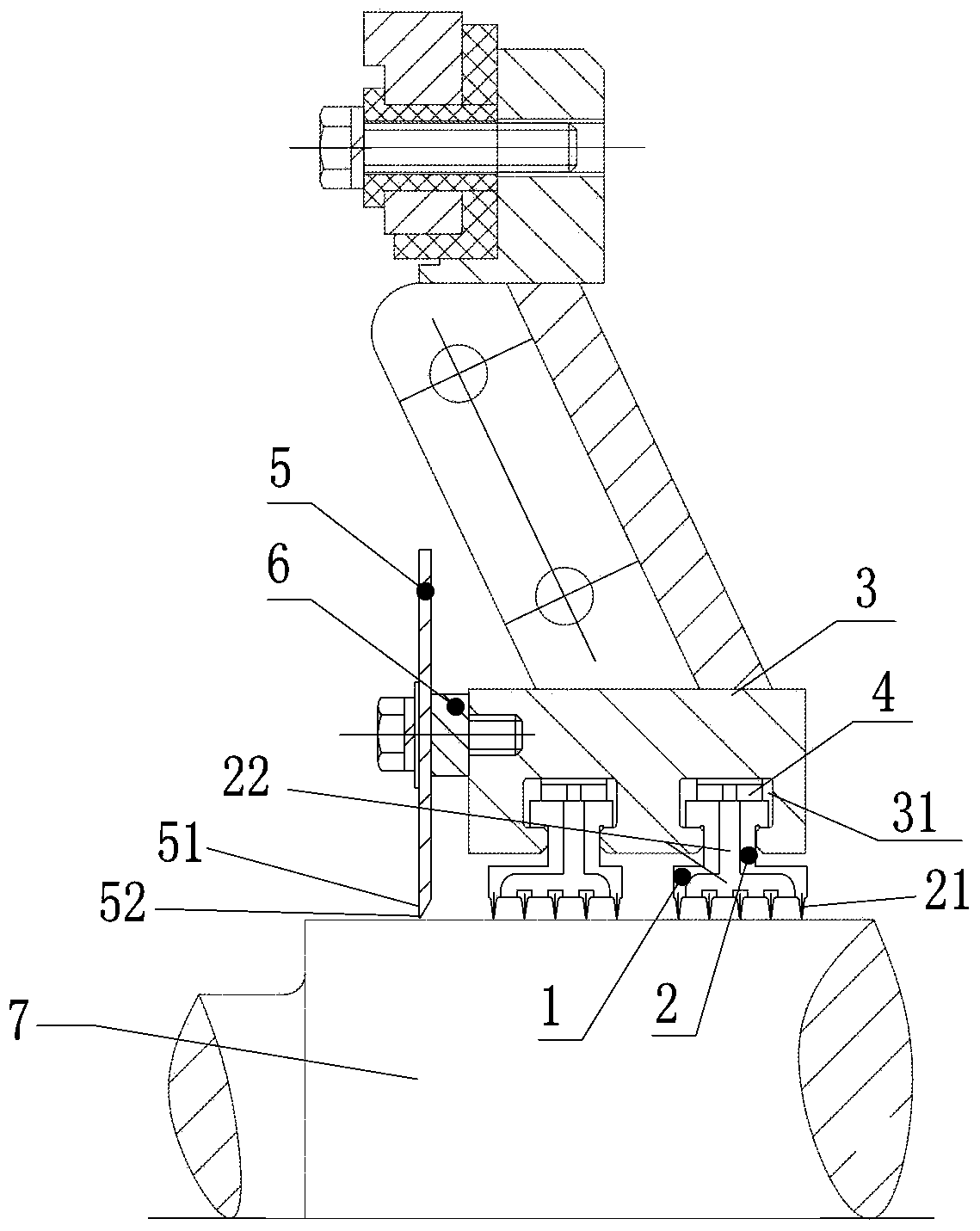

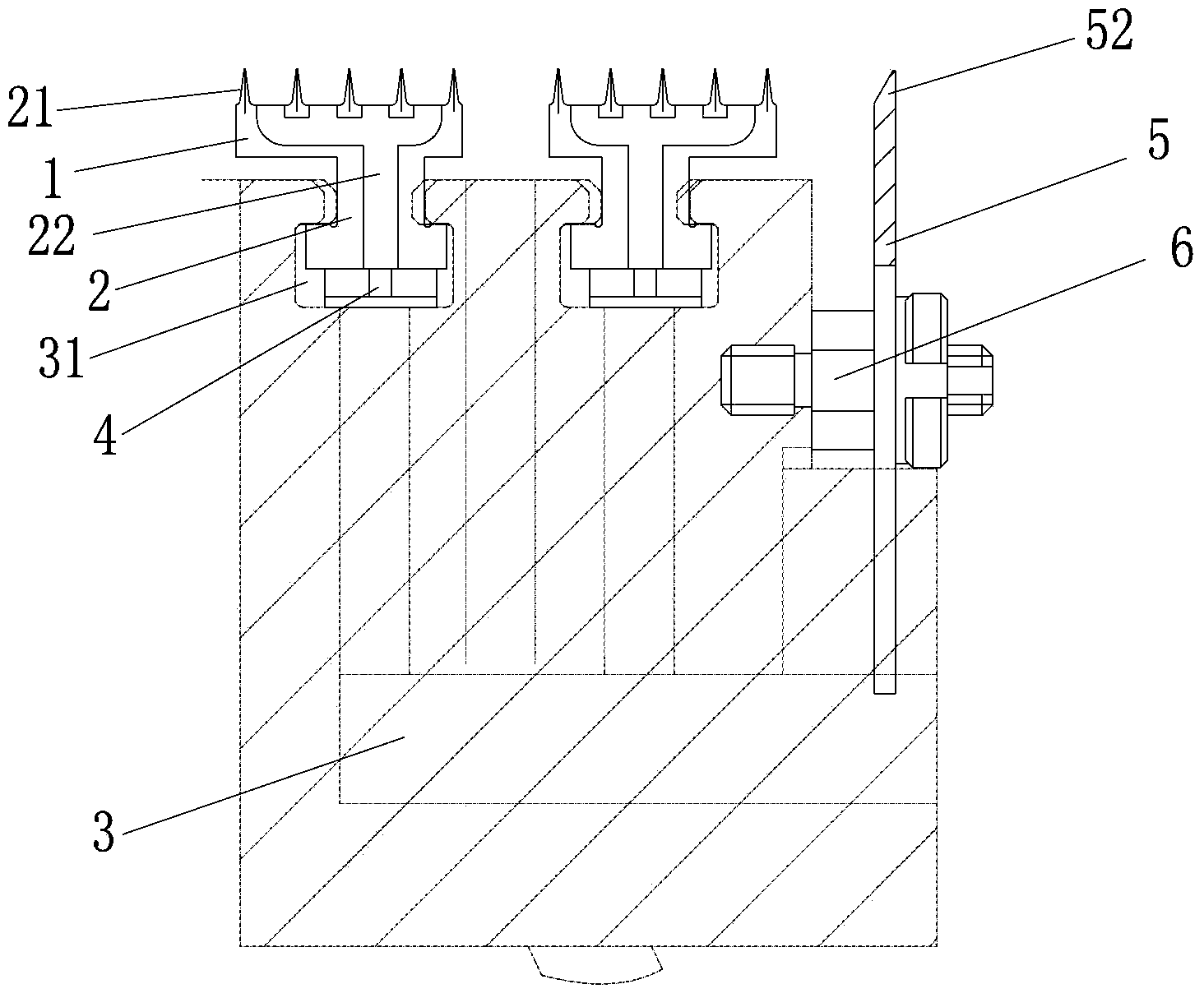

ActiveCN109483041AReduce oil pressureDimensional accuracy deviation eliminationNon-electric welding apparatusTorque sensorPressure jump

The invention relates to a friction welding axial deformation precision control process. The friction welding axial deformation precision control process includes a rotating workpiece 1, a moving workpiece 2, a spindle system 3.1, a rotating member fixture 3.2, a moving sliding table system 4.1, a moving member fixture 4.2, a welding loading mechanism 5, a lathe bed 10.1, a guide rail moving pair10.2, a power-driven system 11, a hydraulic system and connecting line 12, a torque sensor 6, a displacement sensor 7, a pressure sensor 8 and a friction welding control system 9. Based on friction torque jump / axial welding pressure jump determination conditions, the problem of automatic measurement of workpiece axial dimensional precision in the welding preparation process and the problem of accurate compensation of the spacing generated by the rotating workpiece and the moving workpiece in the welding process are solved, the accurate control over the axial shortening amount of the friction welding is realized, and the axial dimensional precision of an axial friction welding workpiece and the quality of friction welding products are improved.

Owner:HARBIN WELDING INST LTD

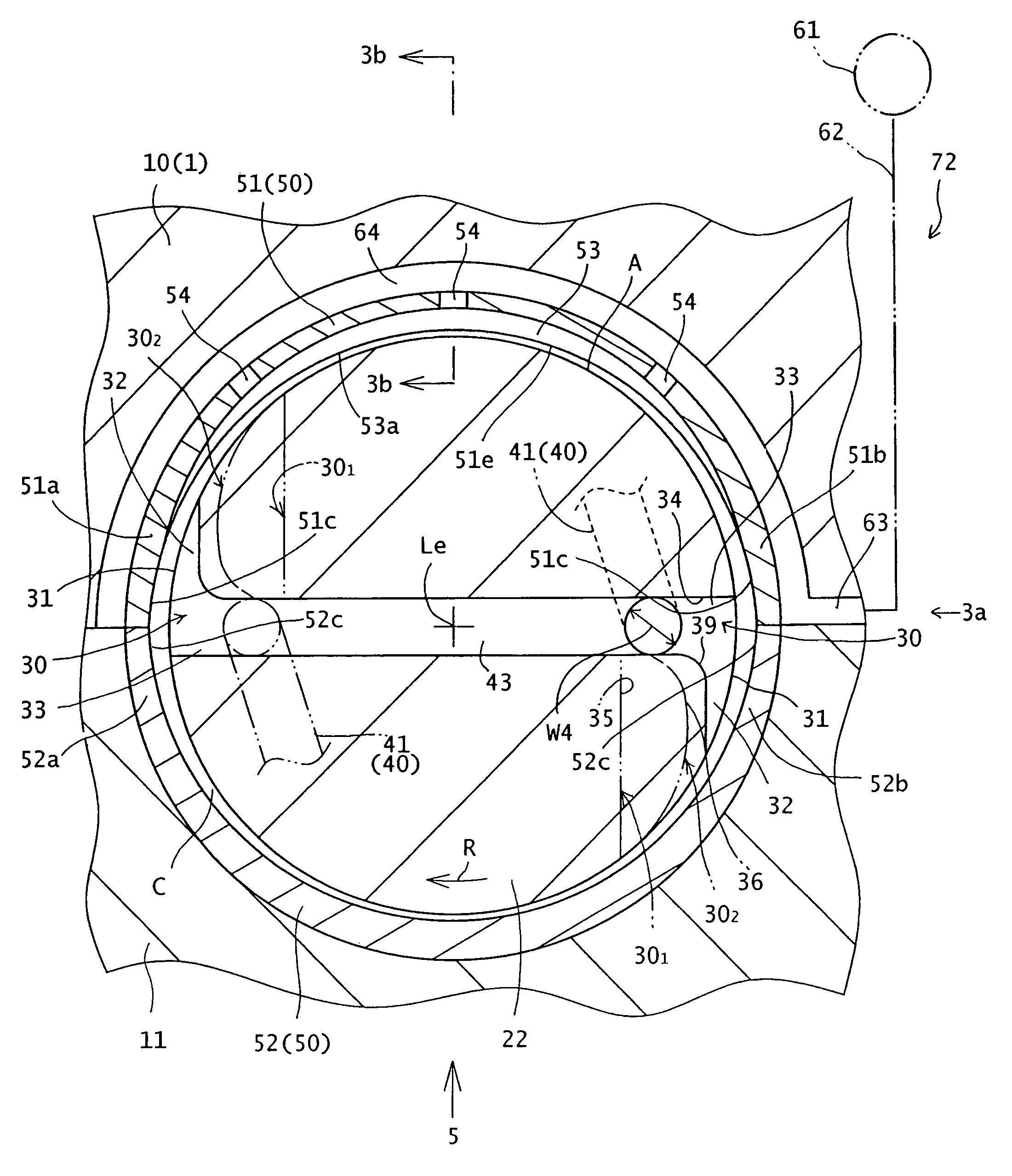

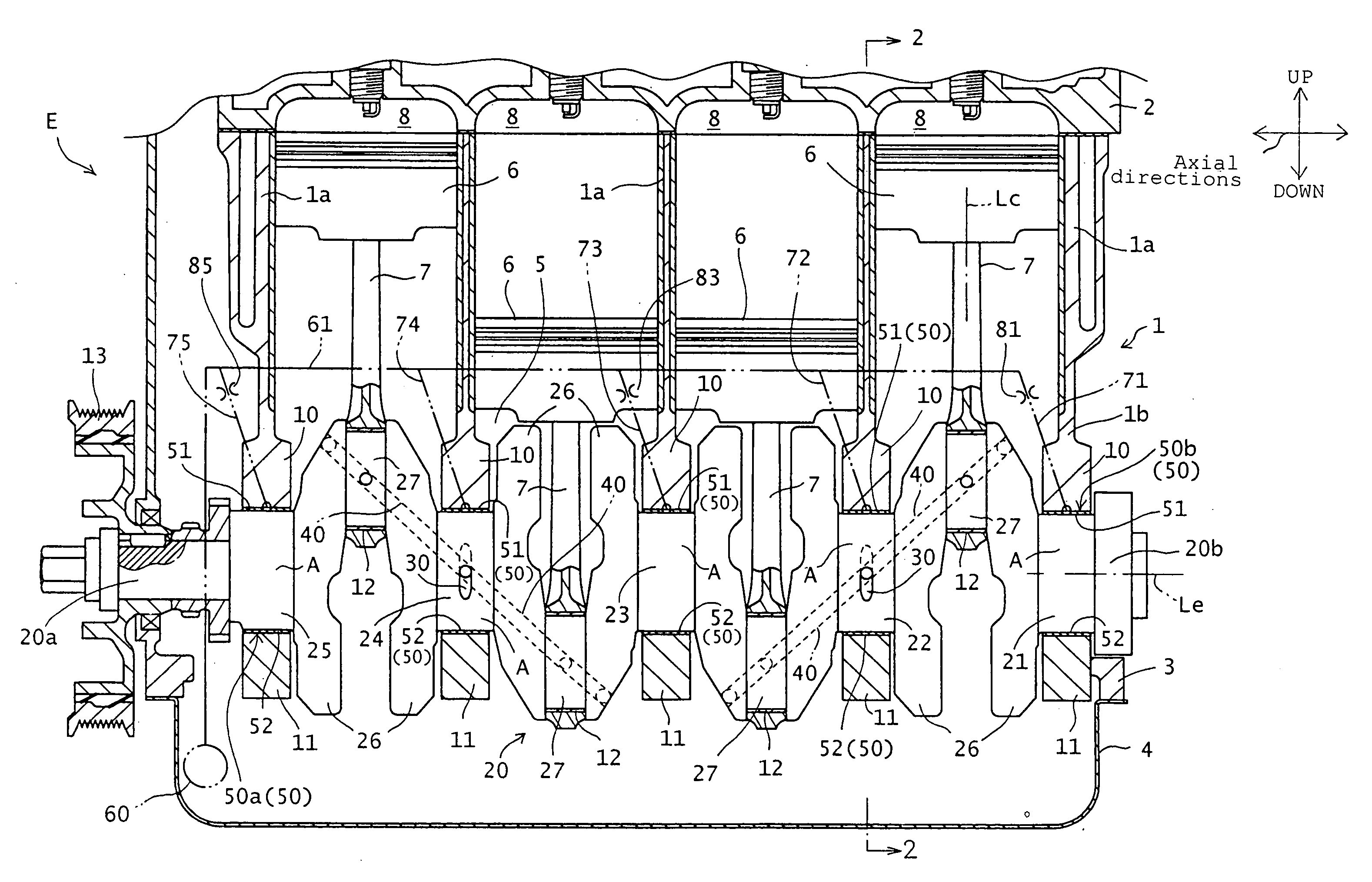

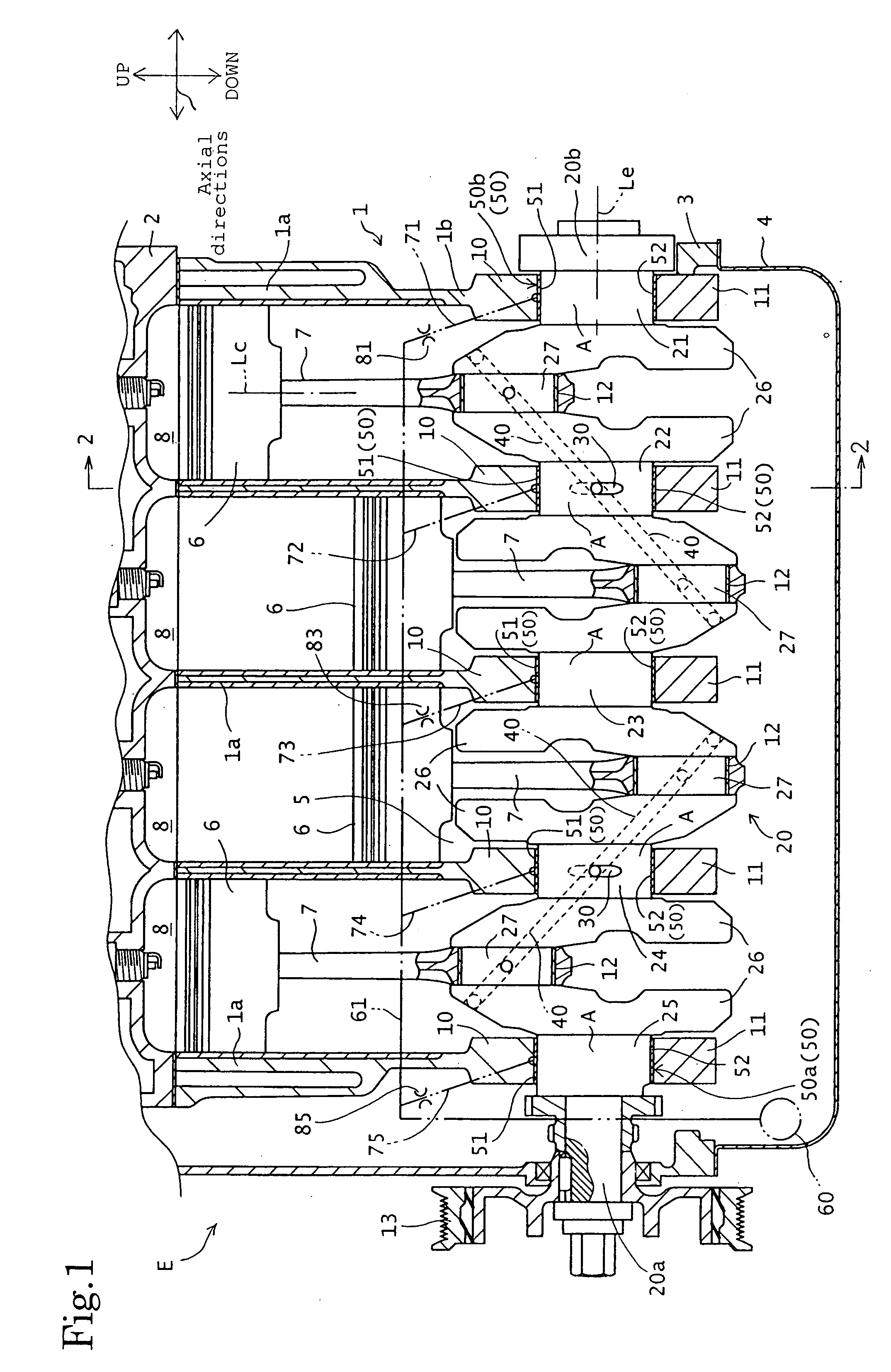

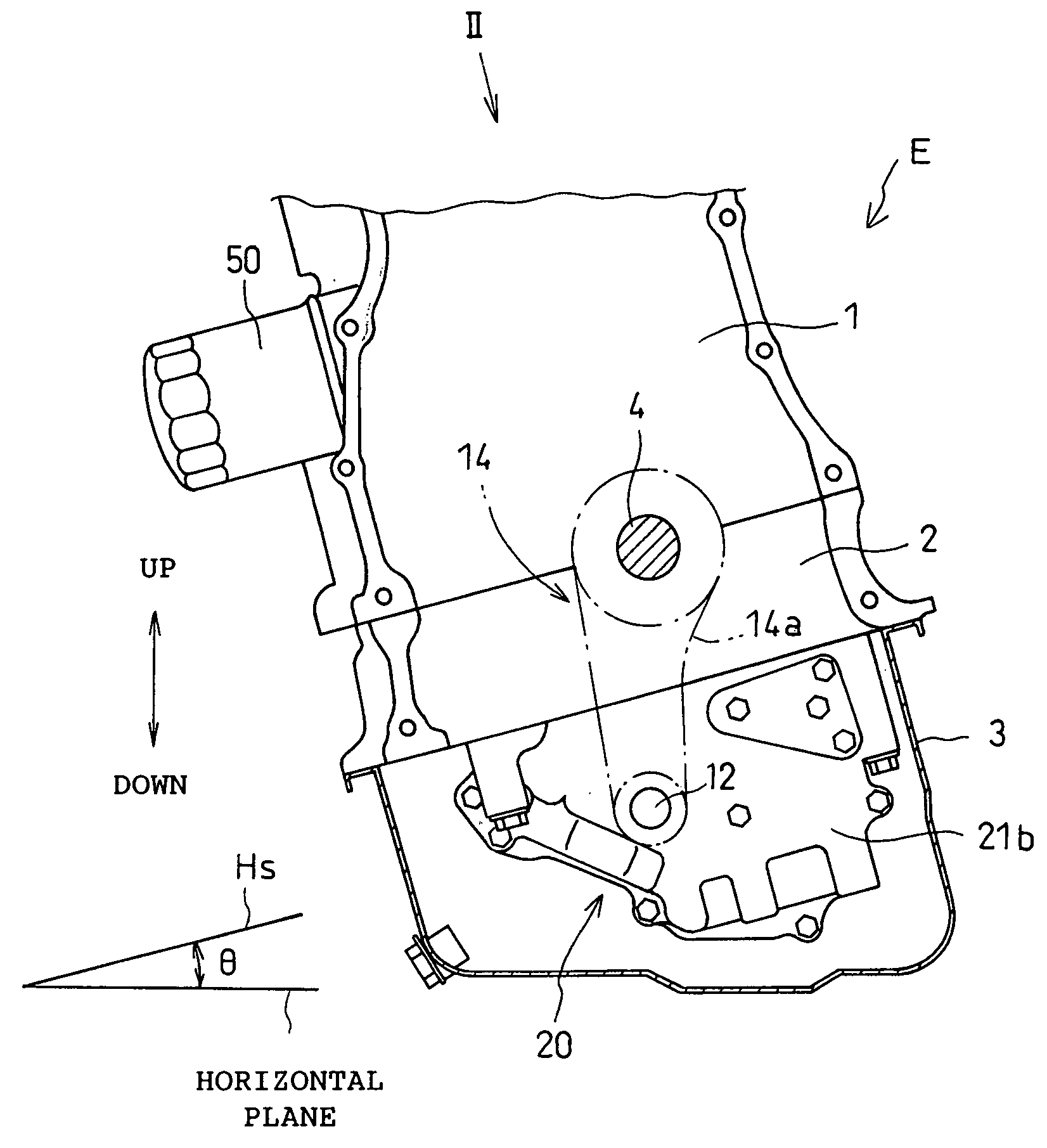

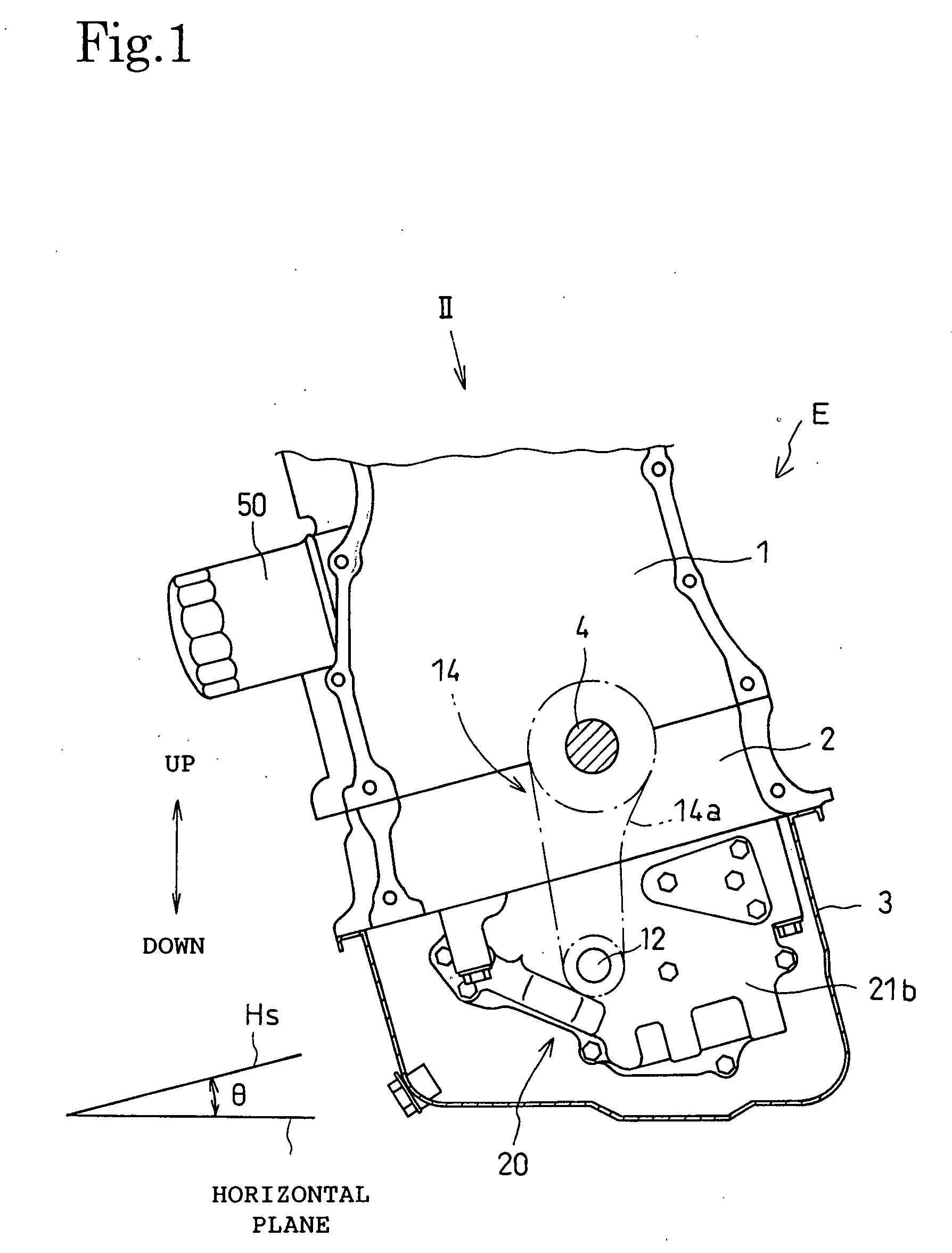

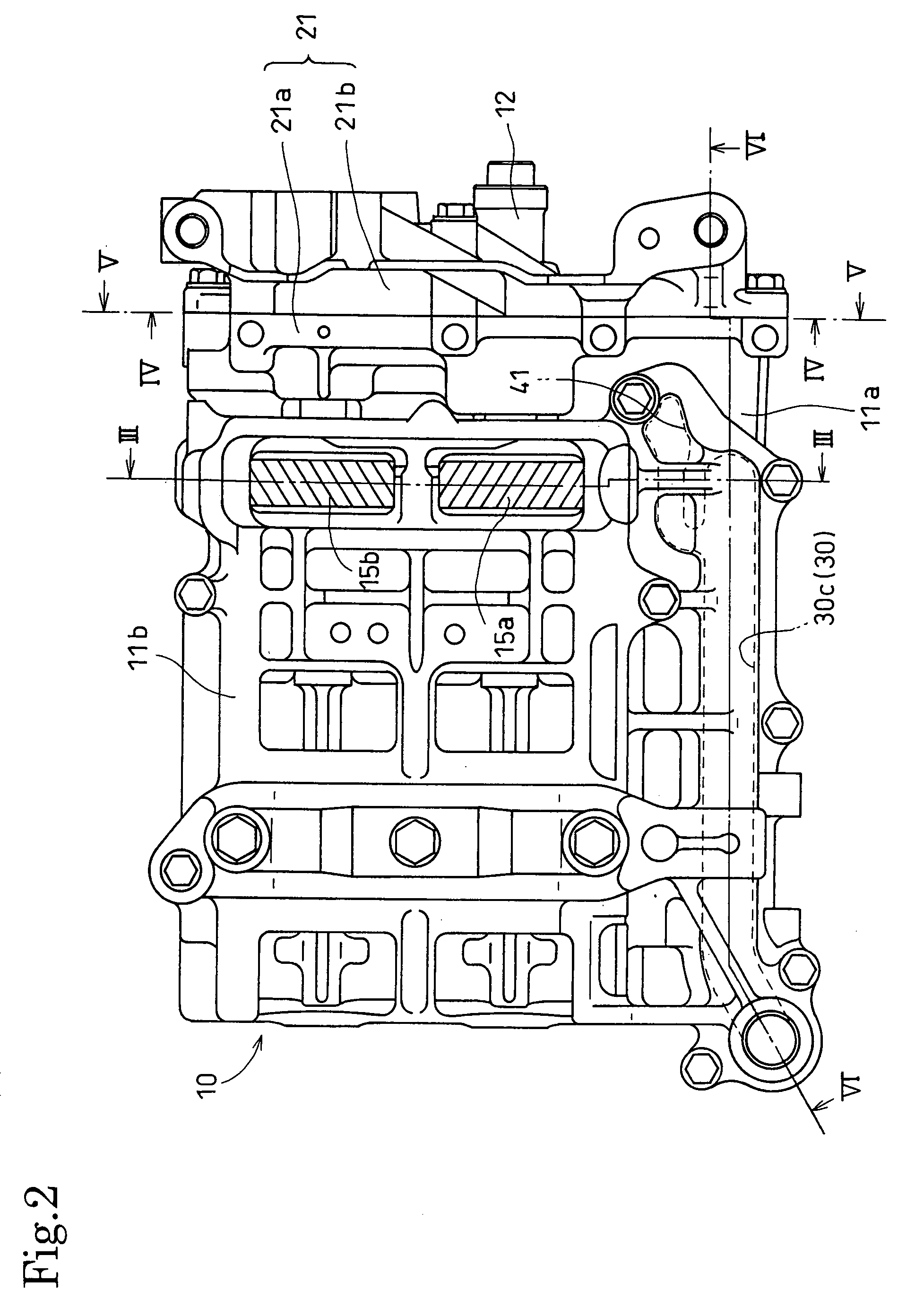

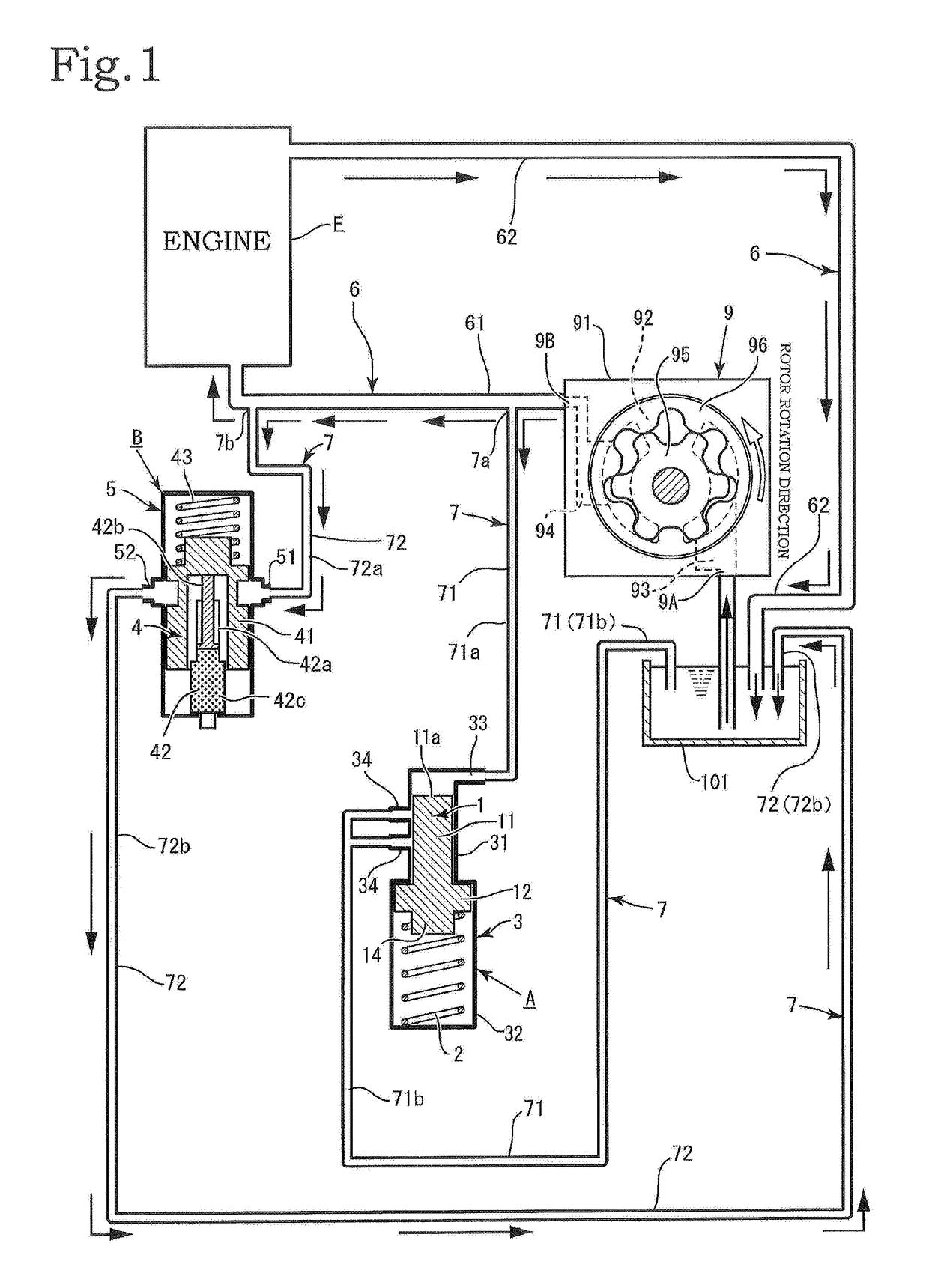

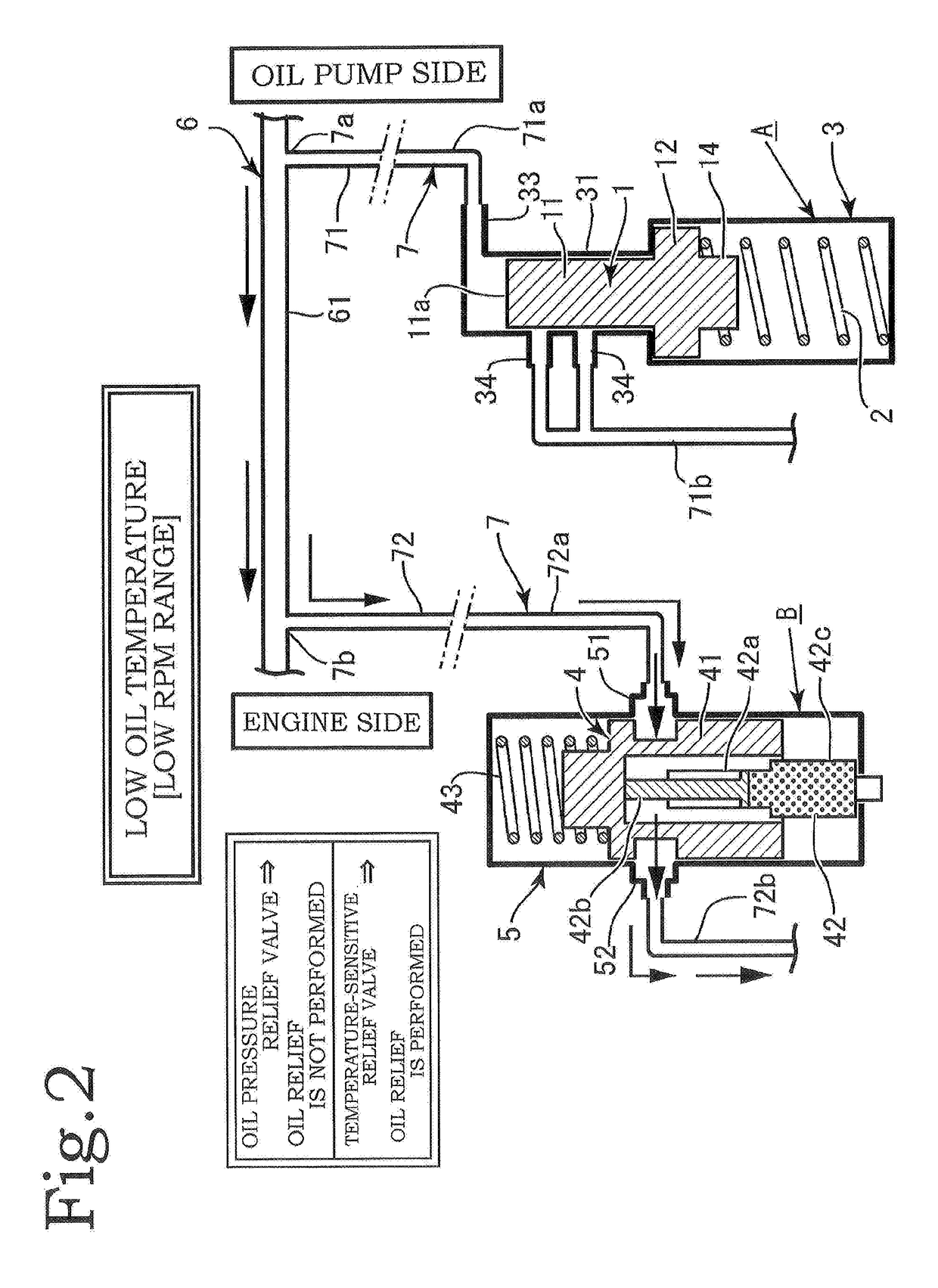

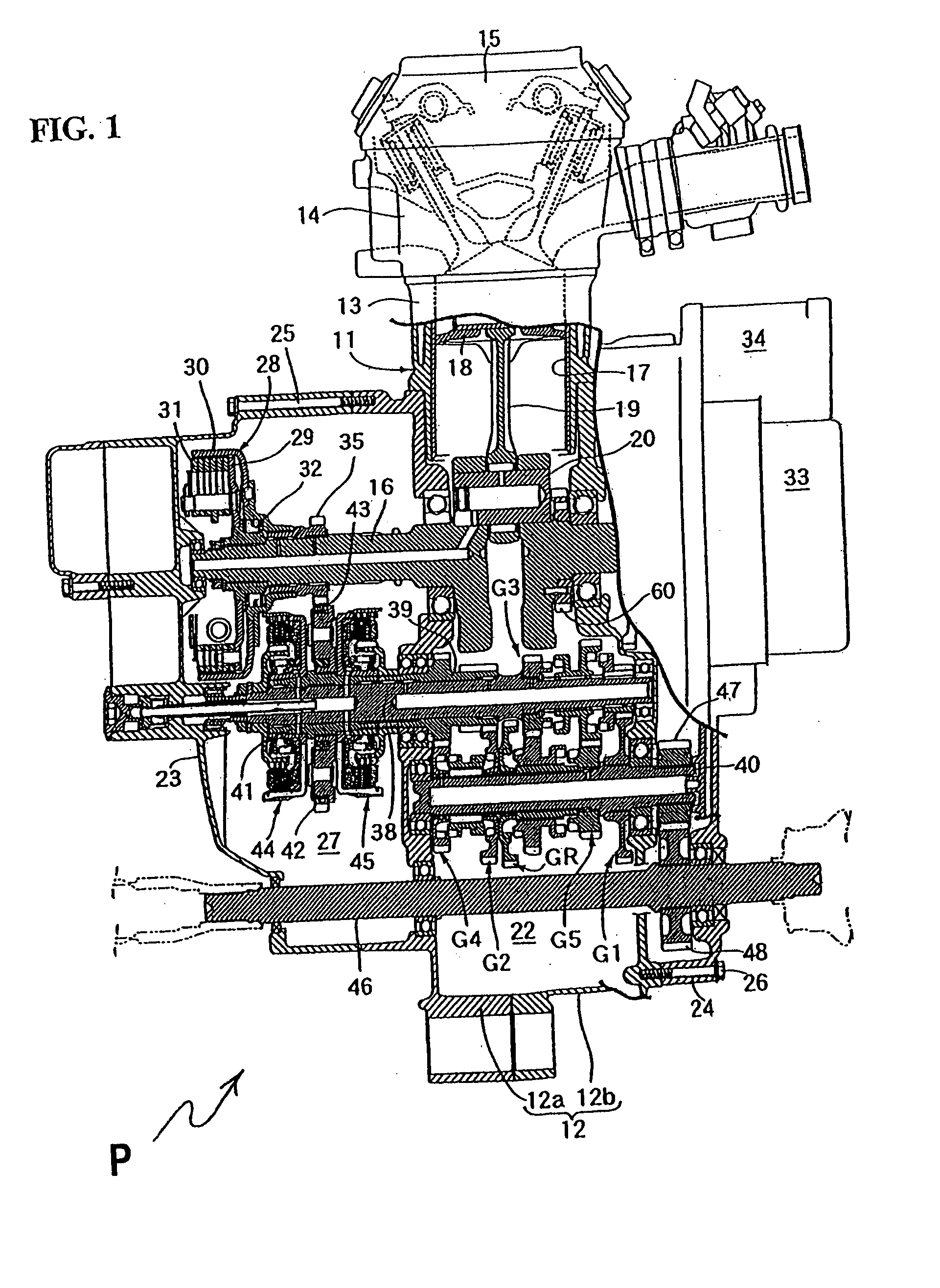

Machine provided with pulsating oil pressure reducing device

InactiveUS20070227476A1Increase freedomEasy constructionLubrication of auxillariesCombustion enginesInternal combustion engineOil pressure

A pulsating oil pressure reducing device 40 for an internal combustion engine has an oil chamber 41 for reducing pulsating oil pressure in a discharge passage 30 for carrying oil discharged from an oil pump 20. The oil chamber 41 communicates with the discharge passage 30 by way of a connecting port 41a1 and makes the oil stagnate therein. The oil chamber 41 is connected to the discharge passage 30 by an air vent passage 45 through which air is discharged from the oil chamber 41 into the discharge passage 30. The air vent passage 45 has an inlet port 45a opening into a top part 41a of the oil chamber 41 and a discharge port 45b opening into the oil passage 30 at a level above the inlet port 45a. Since the pulsating oil pressure reducing device 40 having the air vent passage separately from the connecting port, air can be efficiently discharged from the oil chamber and the degree of freedom of placement of the oil passage and the oil chamber is increased.

Owner:HONDA MOTOR CO LTD

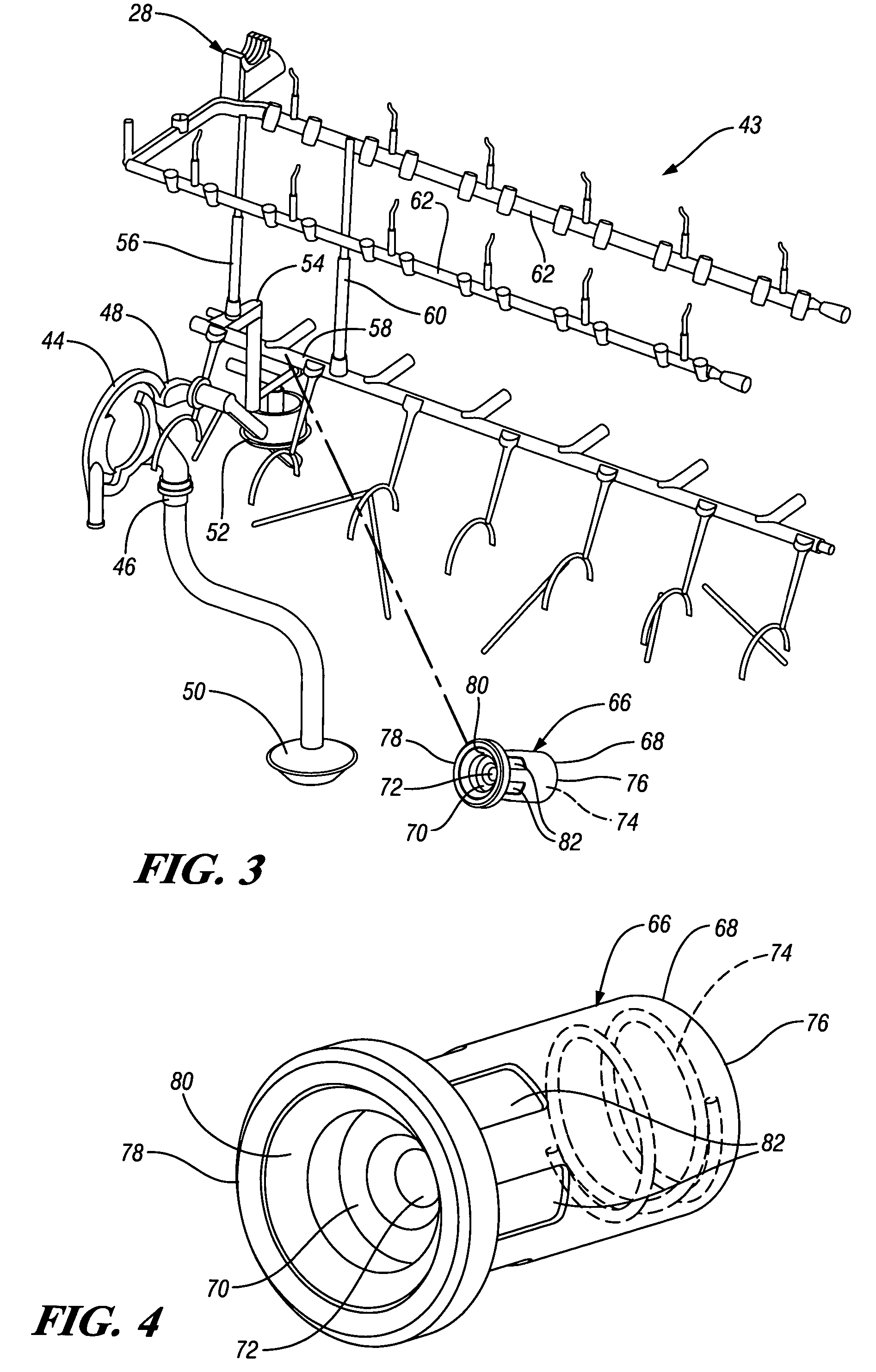

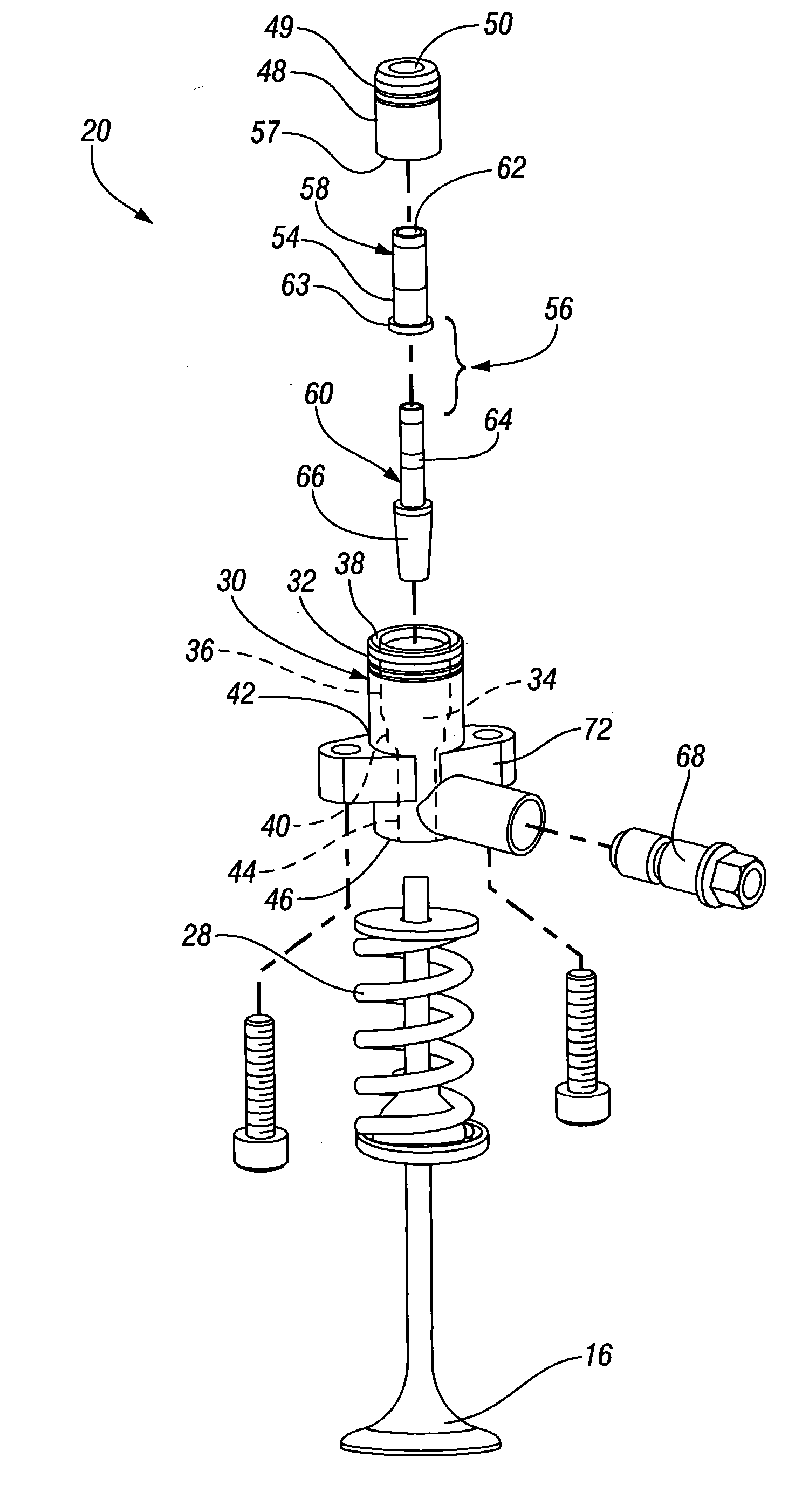

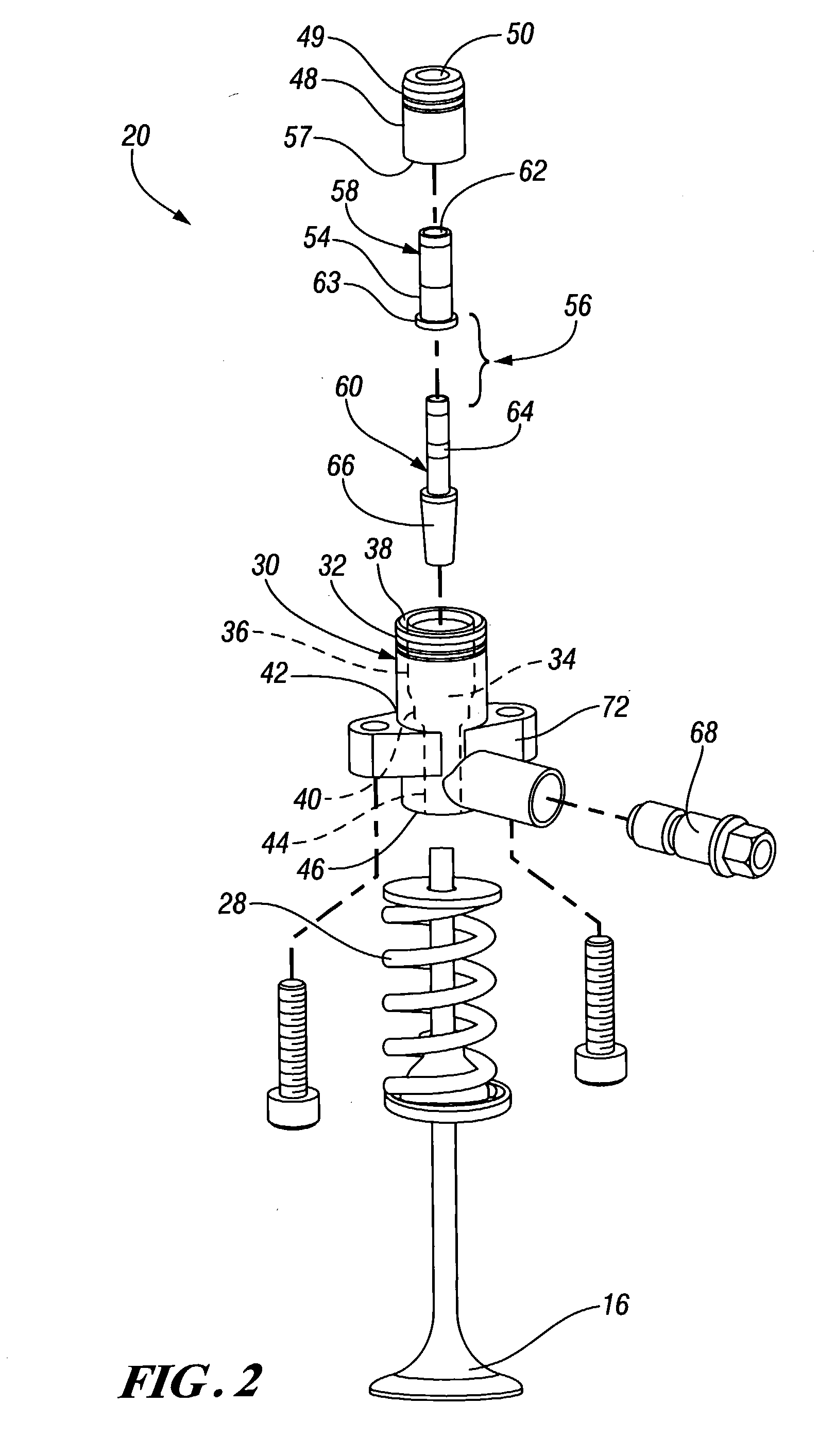

Hydraulic engine valve actuator

InactiveUS20050028767A1Reduce oil pressureMachines/enginesNon-mechanical valveExternal combustion engineCylinder head

An integrated hydraulic valve actuator for use in a camless internal combustion engine. The valve actuator includes a separate bolt-on housing defining a through opening receiving a cylindrical liner. The liner internally defines an internal cylinder providing a riding surface, which coaxially surrounds an outer surface of a tubular boost piston. The boost piston defines an inner cylinder, which provides a riding surface for a drive piston fitted within the inner cylinder of the boost piston. The pistons are axially reciprocable within the liner cylinder. A piston position sensor extends radially into the housing and engages a cam on the drive piston to relay the position of the drive piston to a controller. The actuator is preassembled and the housing is attached to an engine cylinder head or cylinder head supply manifold to operate an associated exhaust or intake valve.

Owner:GM GLOBAL TECH OPERATIONS LLC

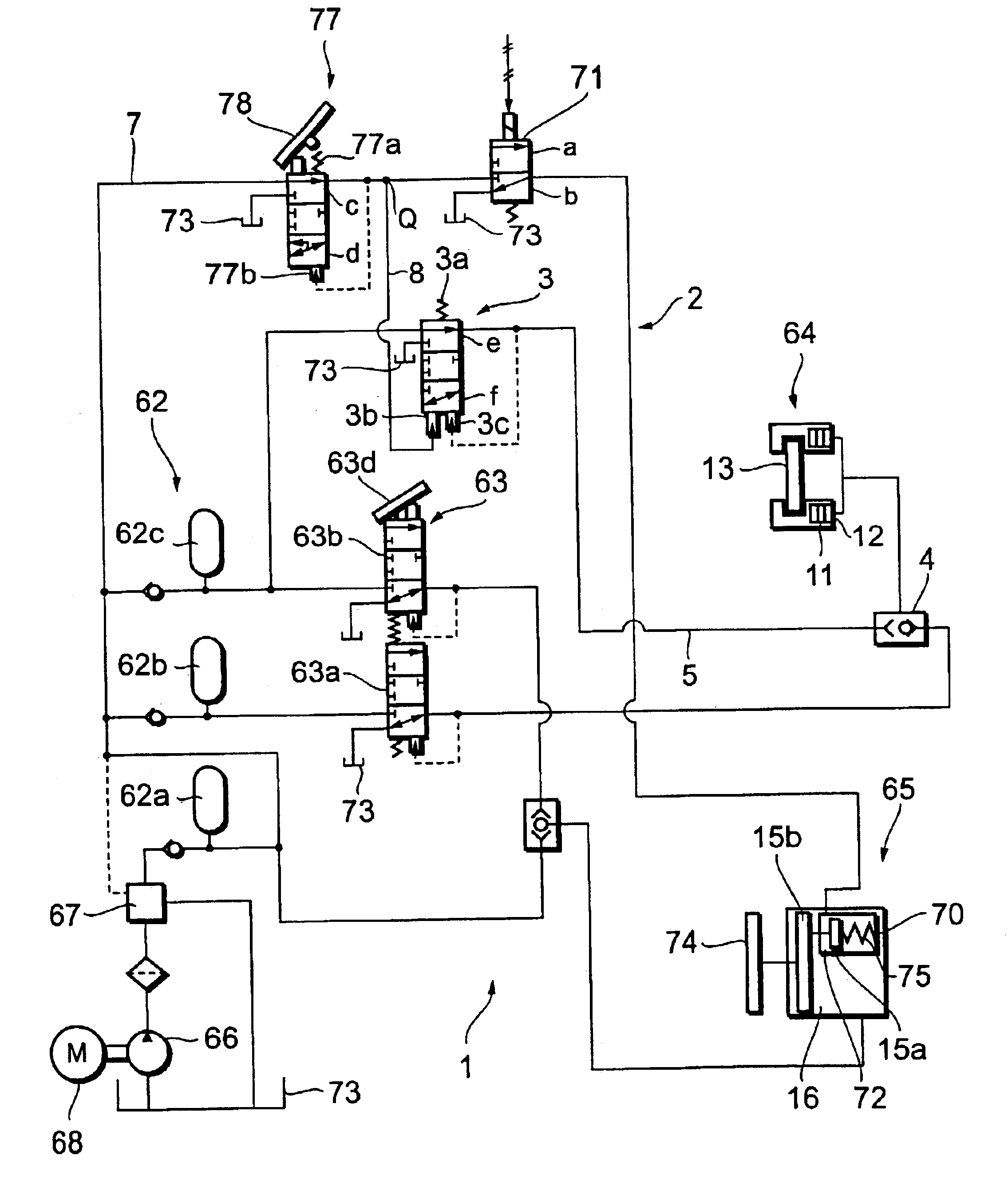

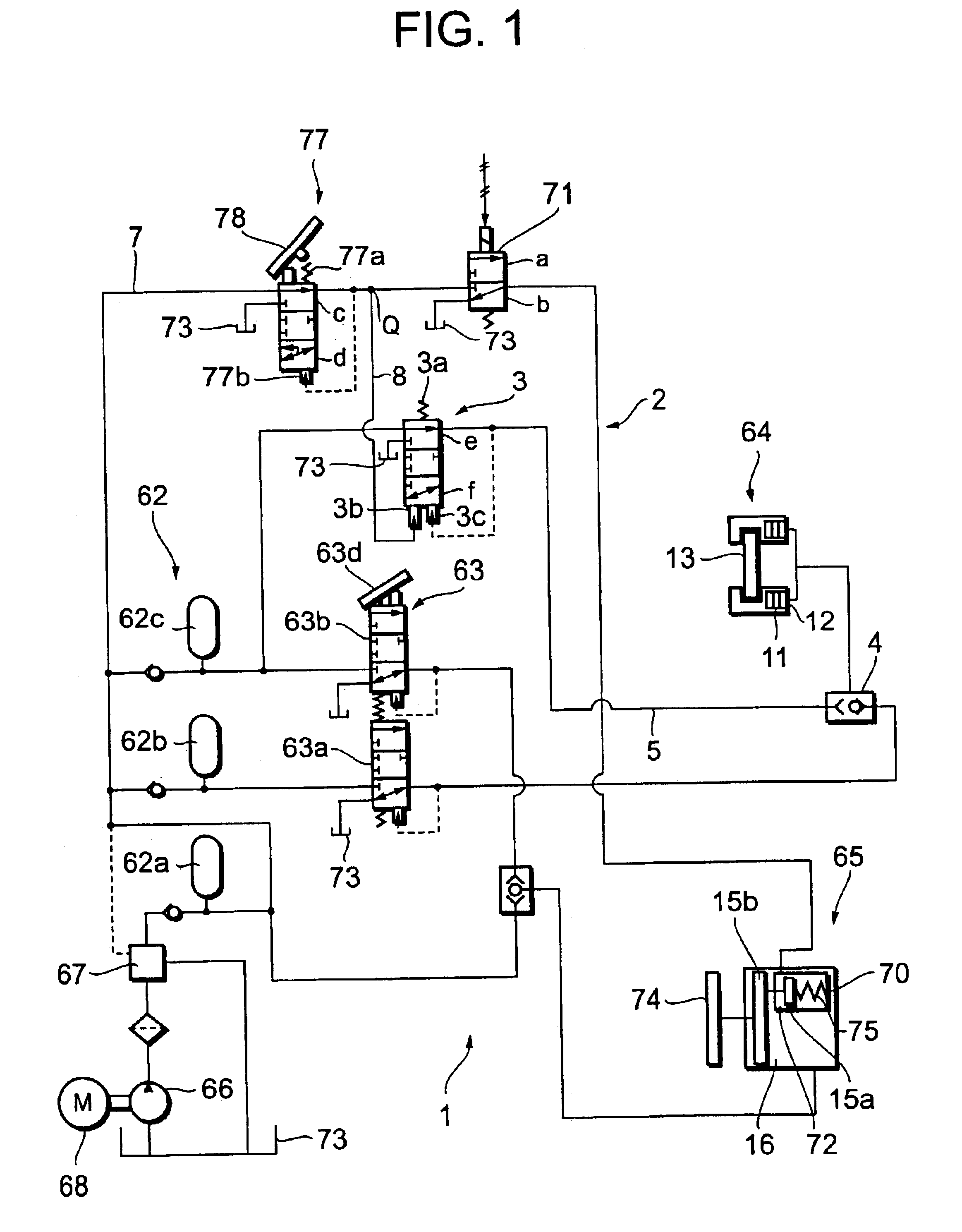

Emergency brake apparatus for vehicle

InactiveUS6848753B2Improve reliabilitySimple structureBraking action transmissionSoil-shifting machines/dredgersRelay valveHigh pressure

The invention provides an emergency brake apparatus for a vehicle which can brake both of front and rear tire wheels of a vehicle by using an oil pressure, at an emergency time. For this purpose, a pressure oil of a hydraulic power source is changed to a pilot oil pressure which is reduced from a high pressure to a low pressure in correspondence to an operation amount of an emergency brake valve (77) operated at the emergency time, and this pressure is output to a relay valve (3). The pressure oil of the hydraulic power source is increased in an inverse proportional manner from a low pressure to a high pressure in correspondence to the pilot oil pressure, and this pressure is output to a front tire wheel brake (64), thereby urgently braking the front tire wheel.

Owner:KOMATSU LTD

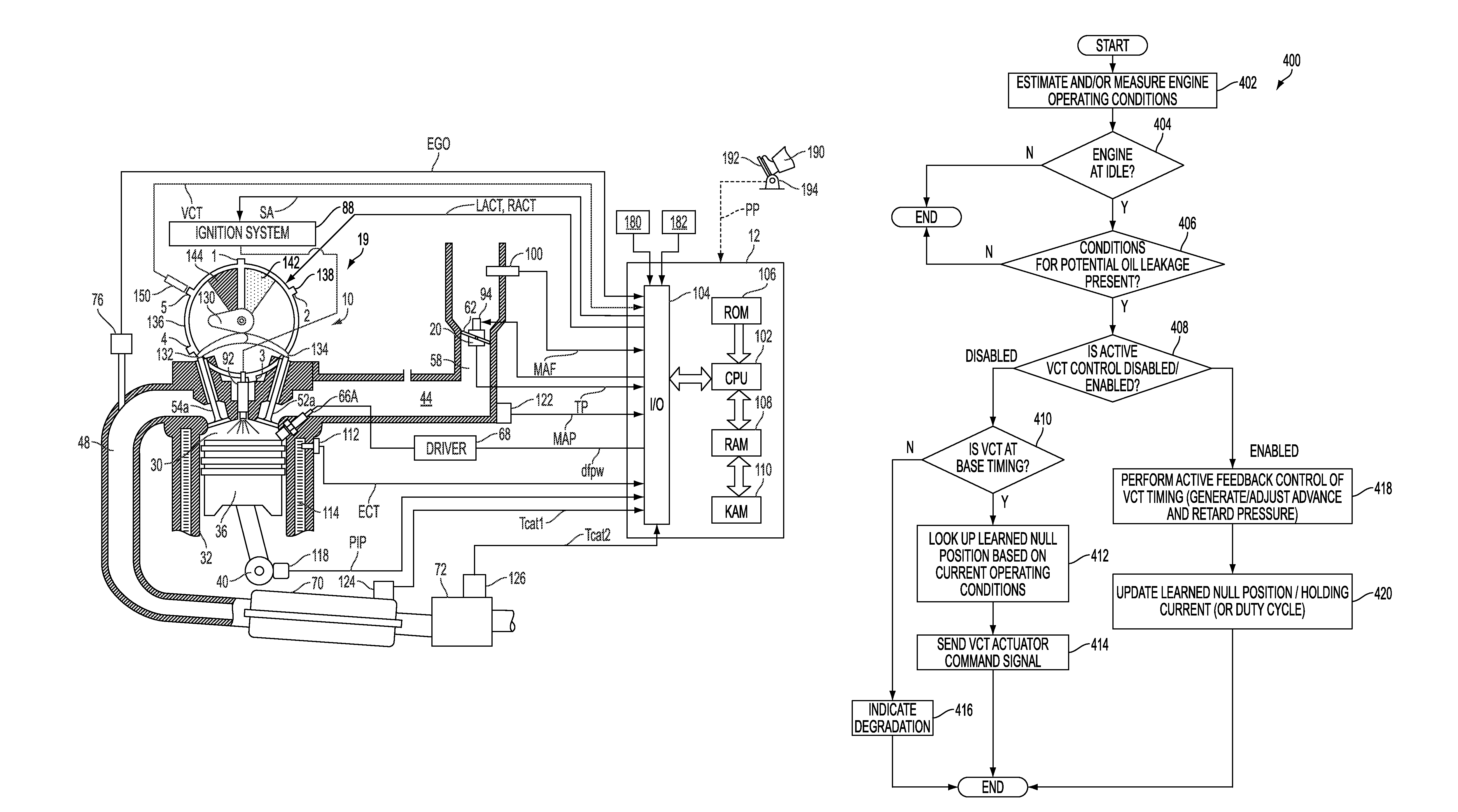

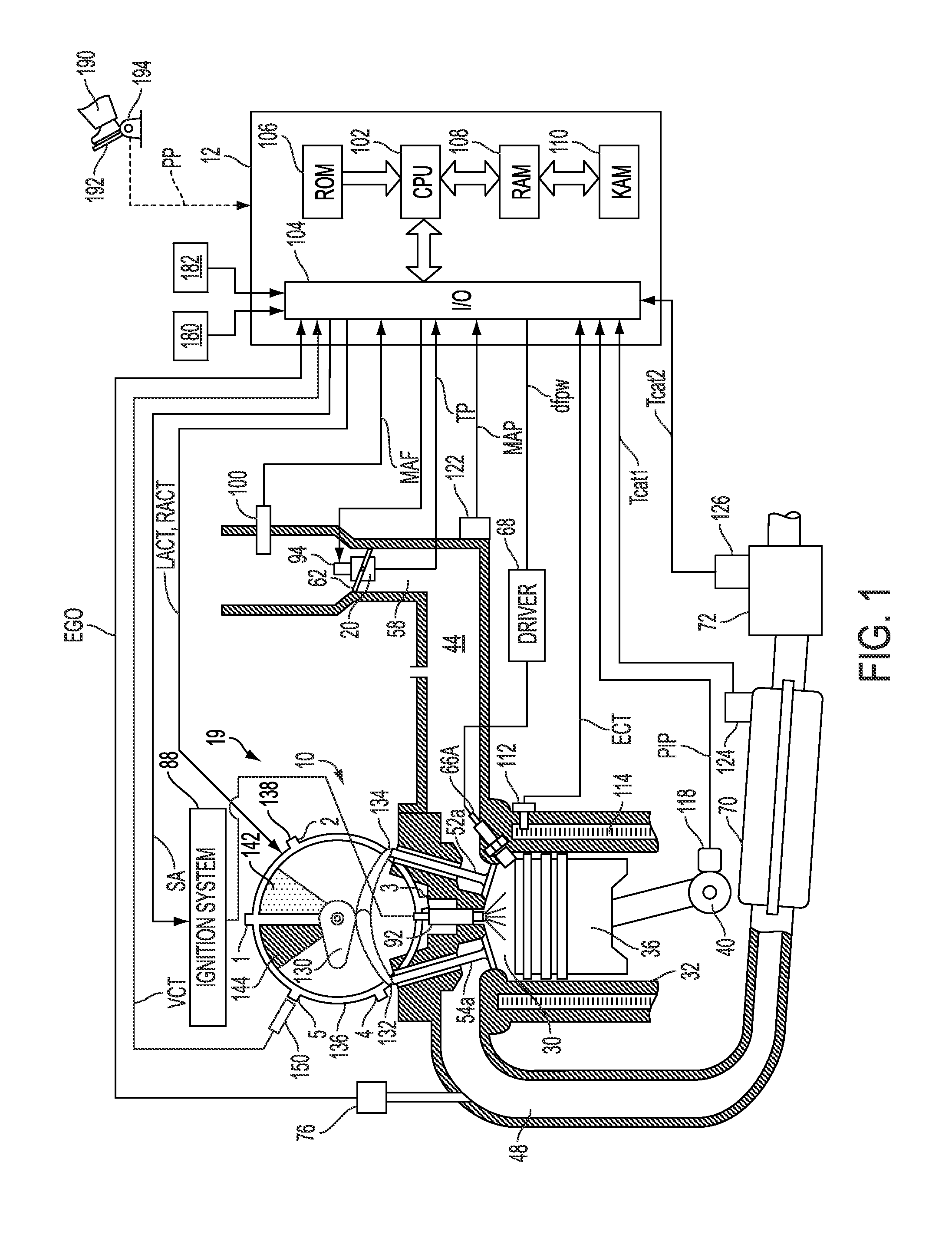

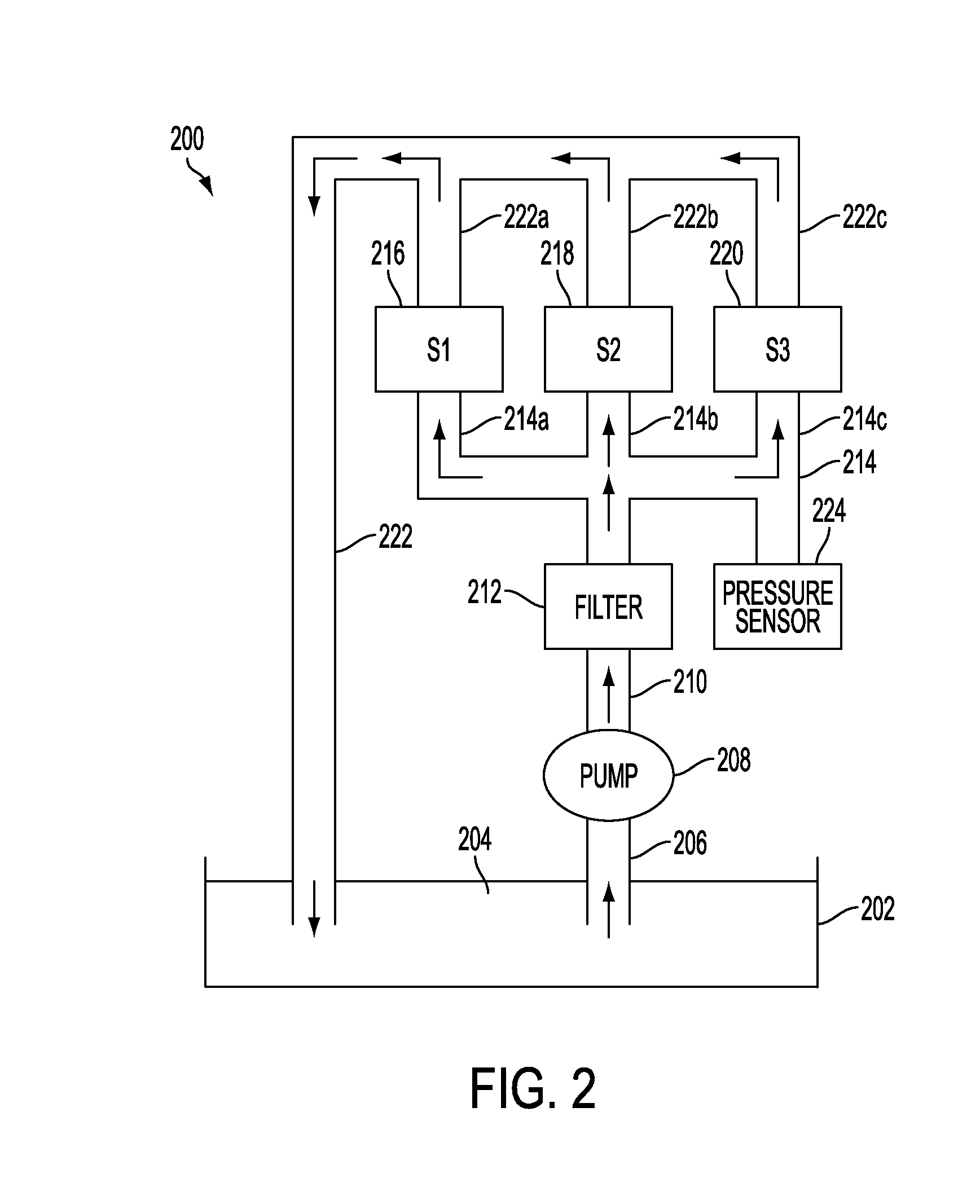

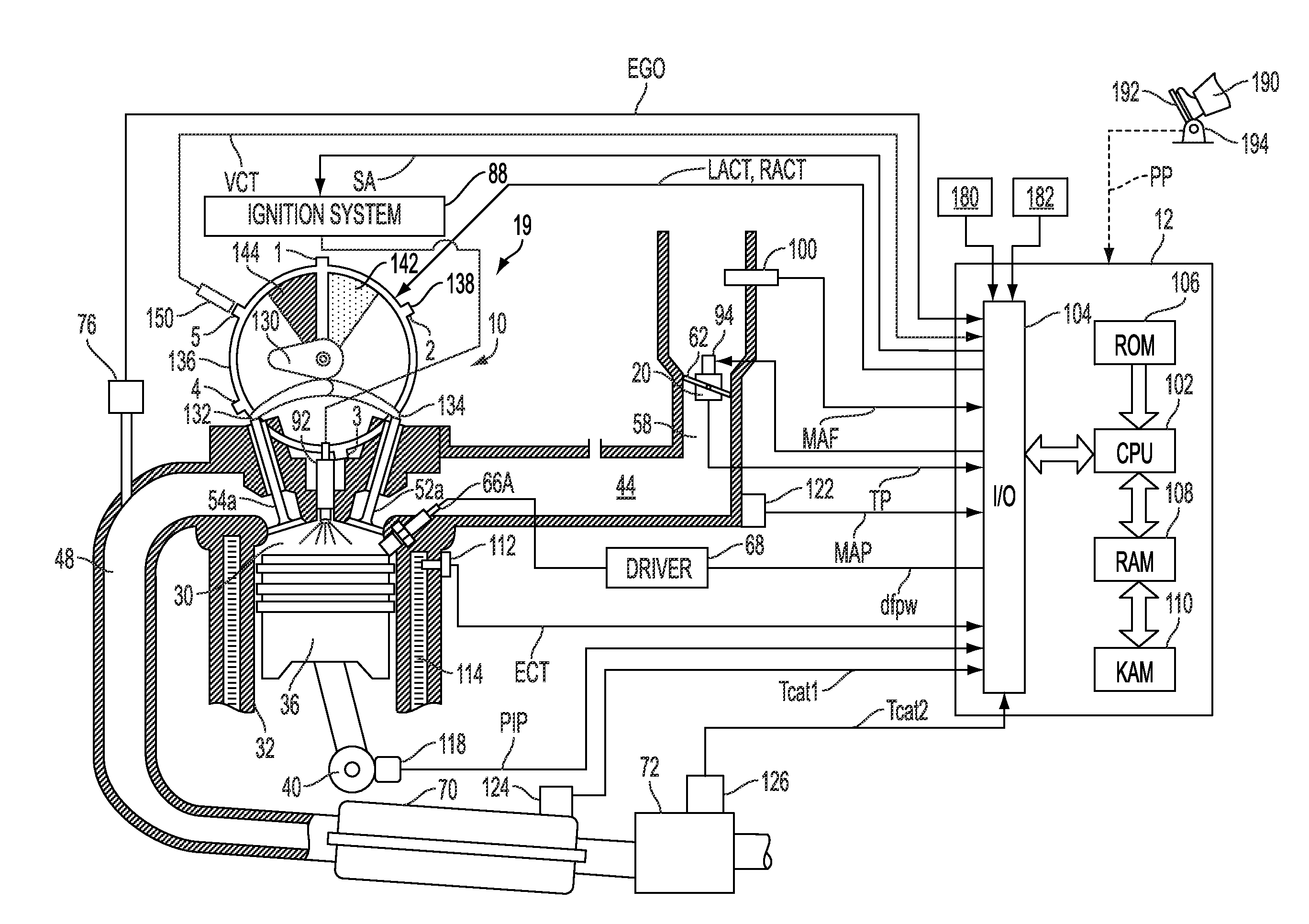

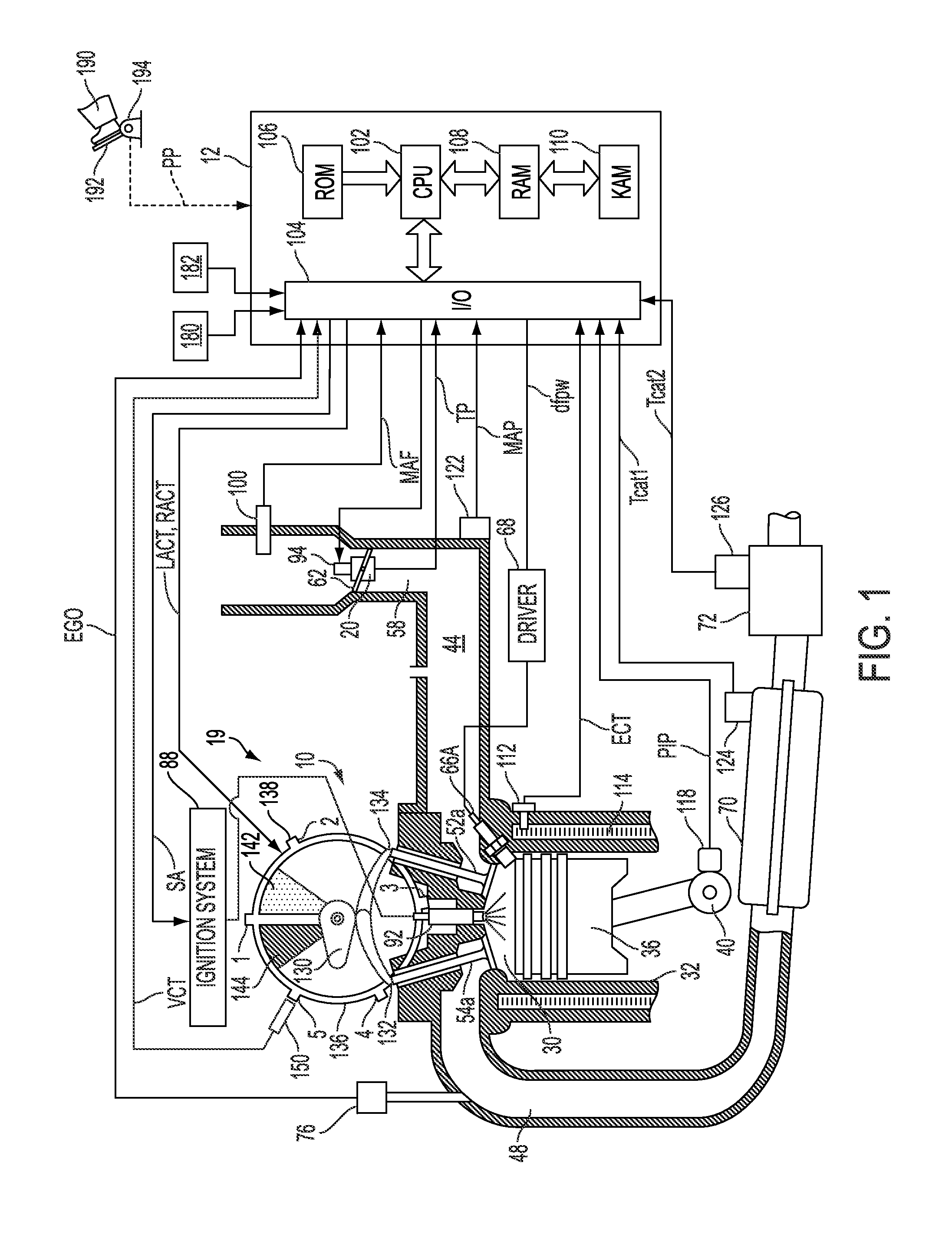

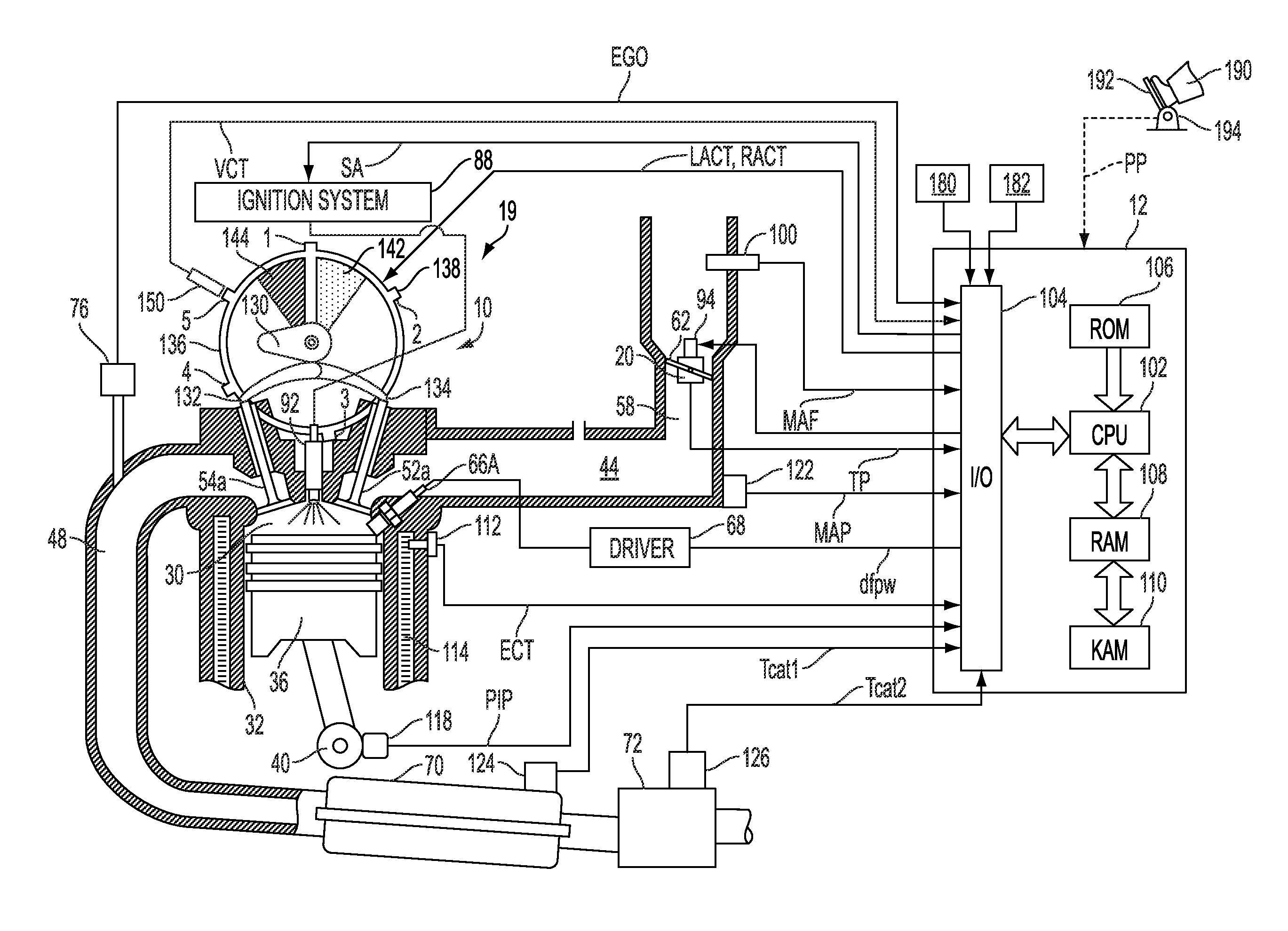

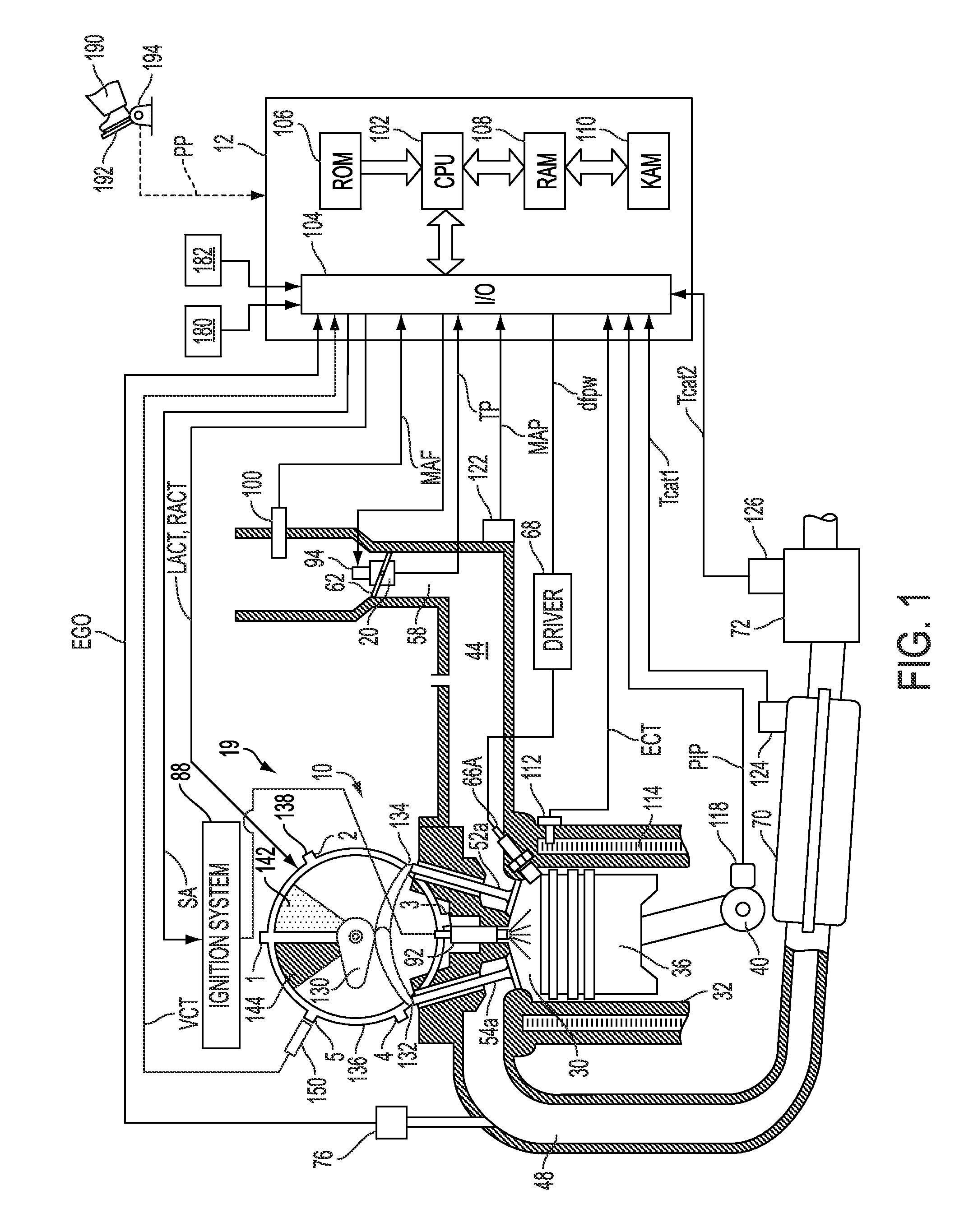

Engine with Hydraulic Variable Valve Timing

ActiveUS20110048346A1Improve emission performanceImprove fuel economy performanceYielding couplingInternal combustion piston enginesSpool valveVariable valve timing

In one example, a method is described for an engine with a hydraulically actuated phaser for adjusting cam timing. The phaser is controlled by a hydraulic spool valve, for example, having a de-energized position that results in hydraulic force urging the phaser to a base timing. When it is desired to operate the cam timing at base timing, rather then leave the spool valve in a de-energized position that can generate leakage, the spool valve is adjusted to near a null position to reduce the hydraulic pressure drop across the cam journal and thus reduce oil leakage. In this way, it is possible to maintain base timing, while also reducing leakage.

Owner:FORD GLOBAL TECH LLC

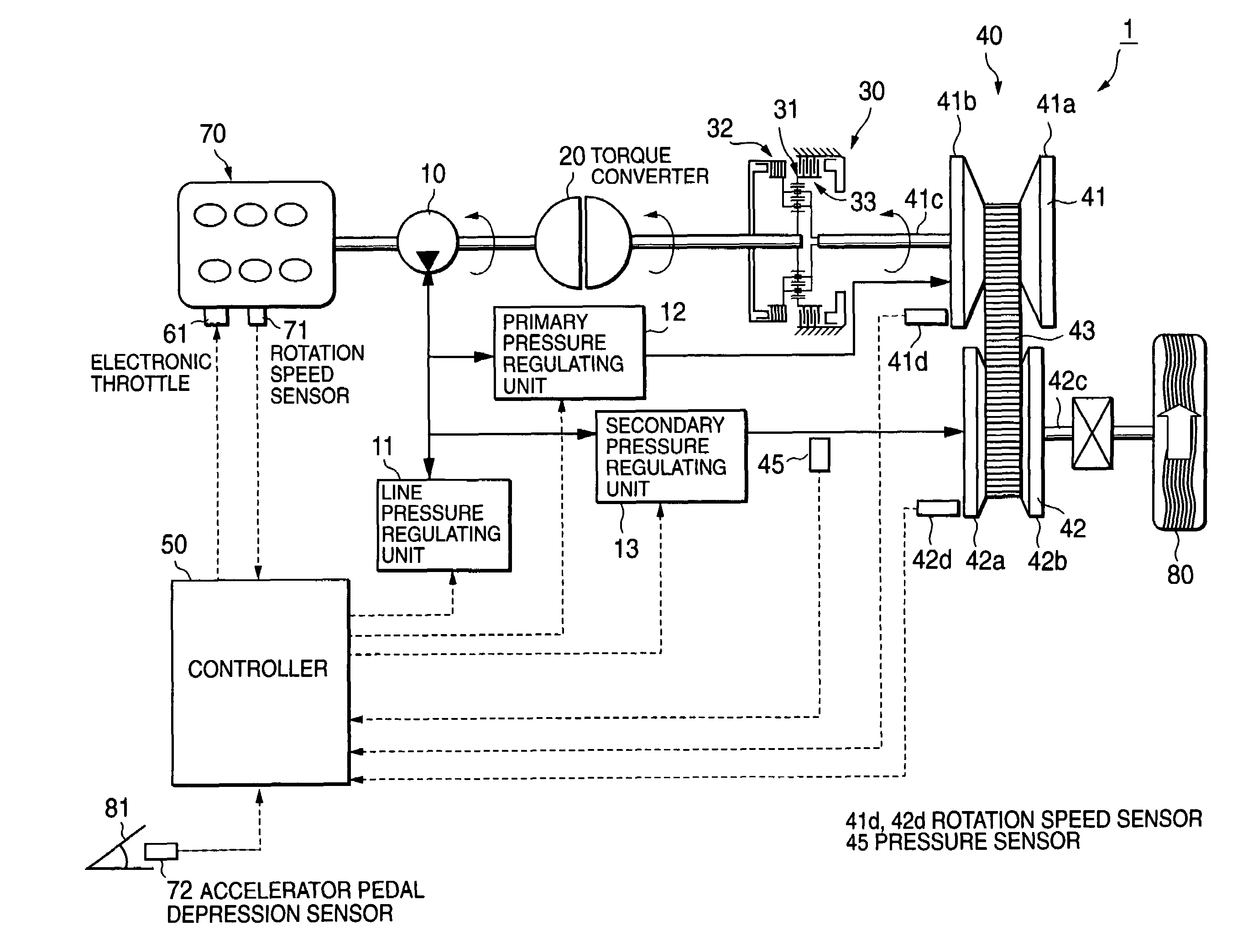

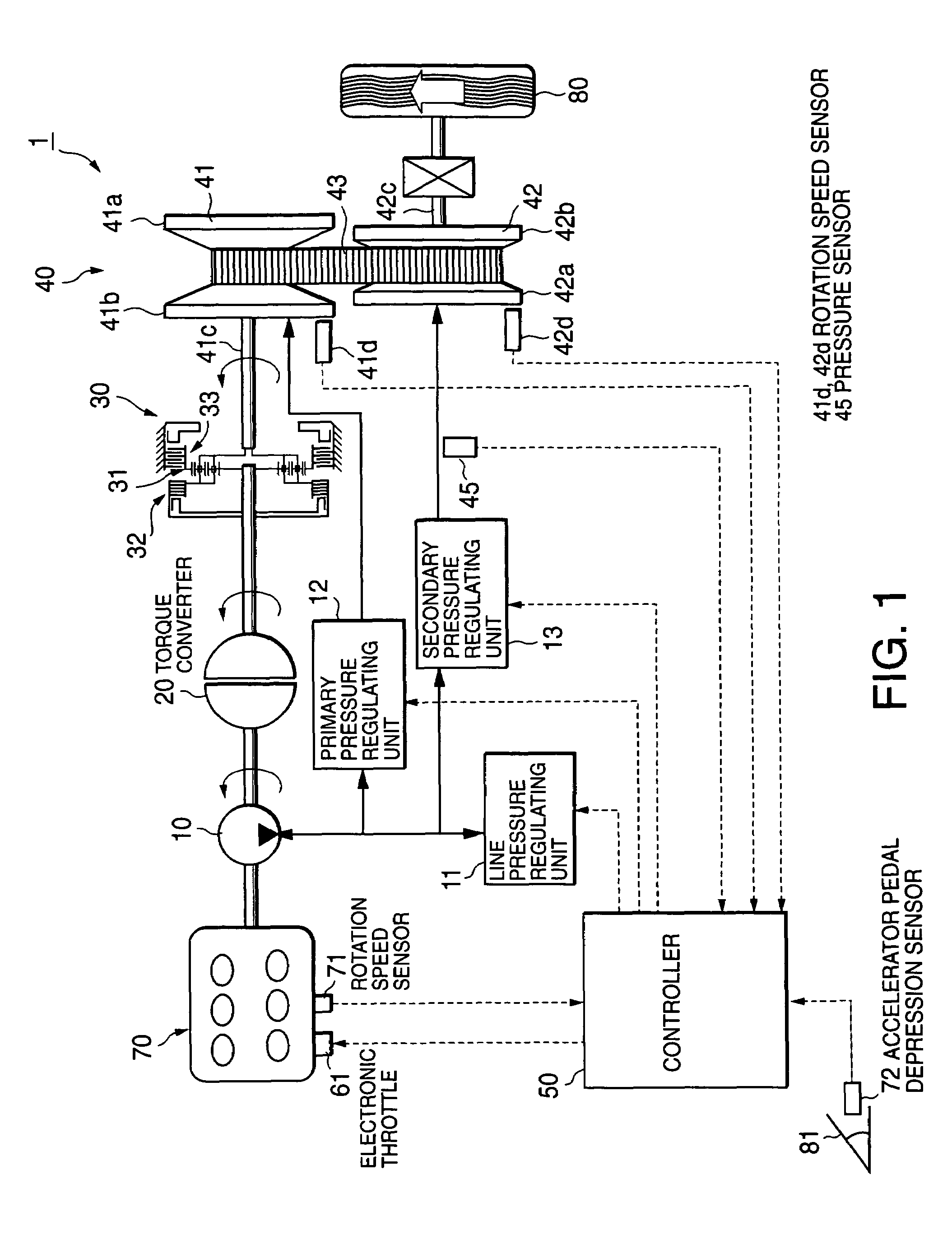

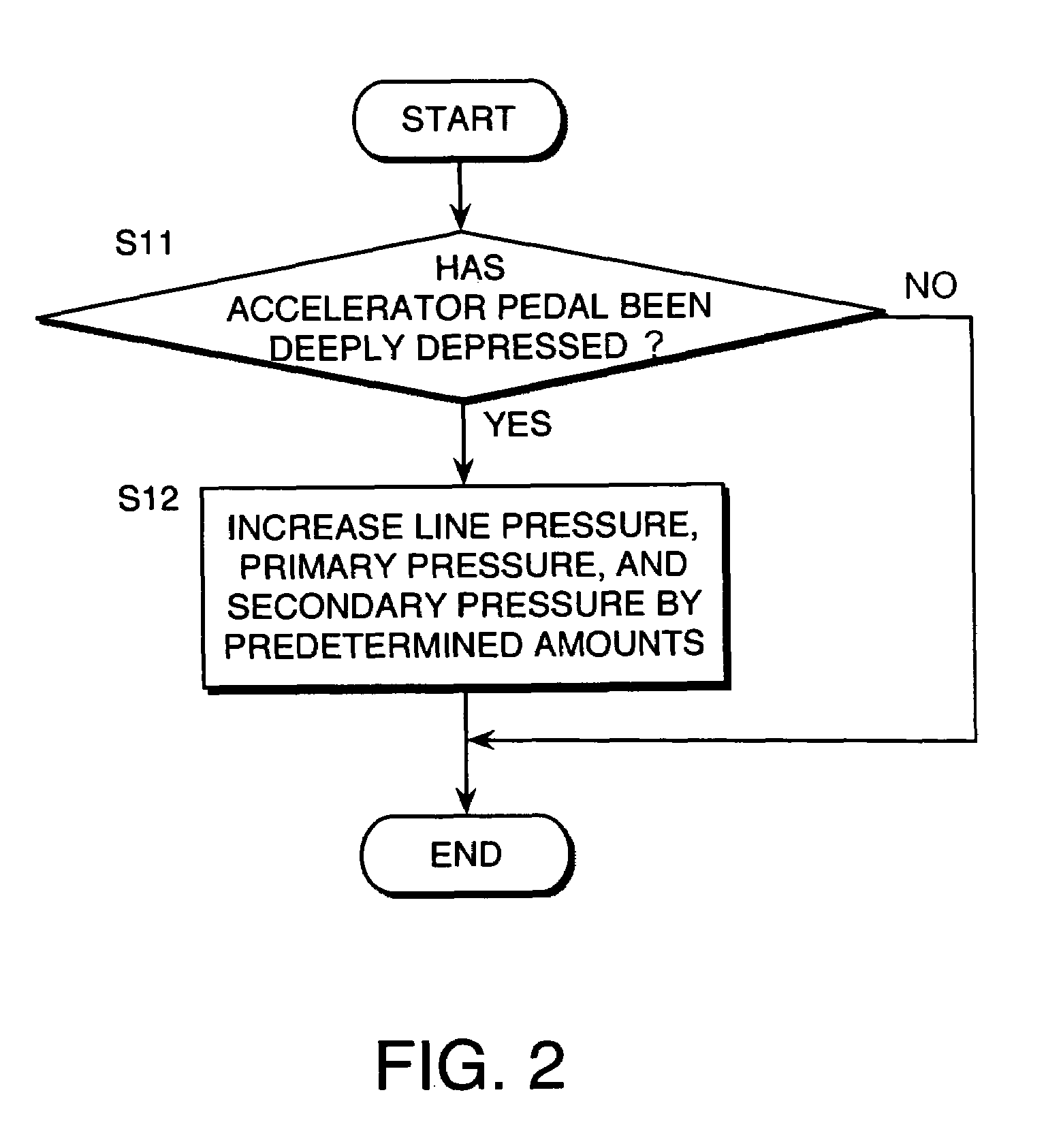

Control of belt-drive continuously variable transmission

InactiveUS7267632B2Improve retentionIncrease manufacturing costGearingGearing controlControl theoryPulley

A controller (50) controls the supply of oil pressure to a primary pulley (41) and a secondary pulley (42) of a belt-drive continuously variable transmission (1) in accordance with the depression amount of an accelerator pedal (81) of a vehicle. When slippage is detected in a V-belt (43) that is wrapped around the primary pulley (41) and secondary pulley (42), the controller (50) reduces the output torque of an engine (70) of the vehicle to stop the V-belt (43) from slipping. Meanwhile, damage to the V-belt (43) caused by slippage is prevented by reducing the oil pressure supply to the secondary pulley (42).

Owner:JATCO LTD

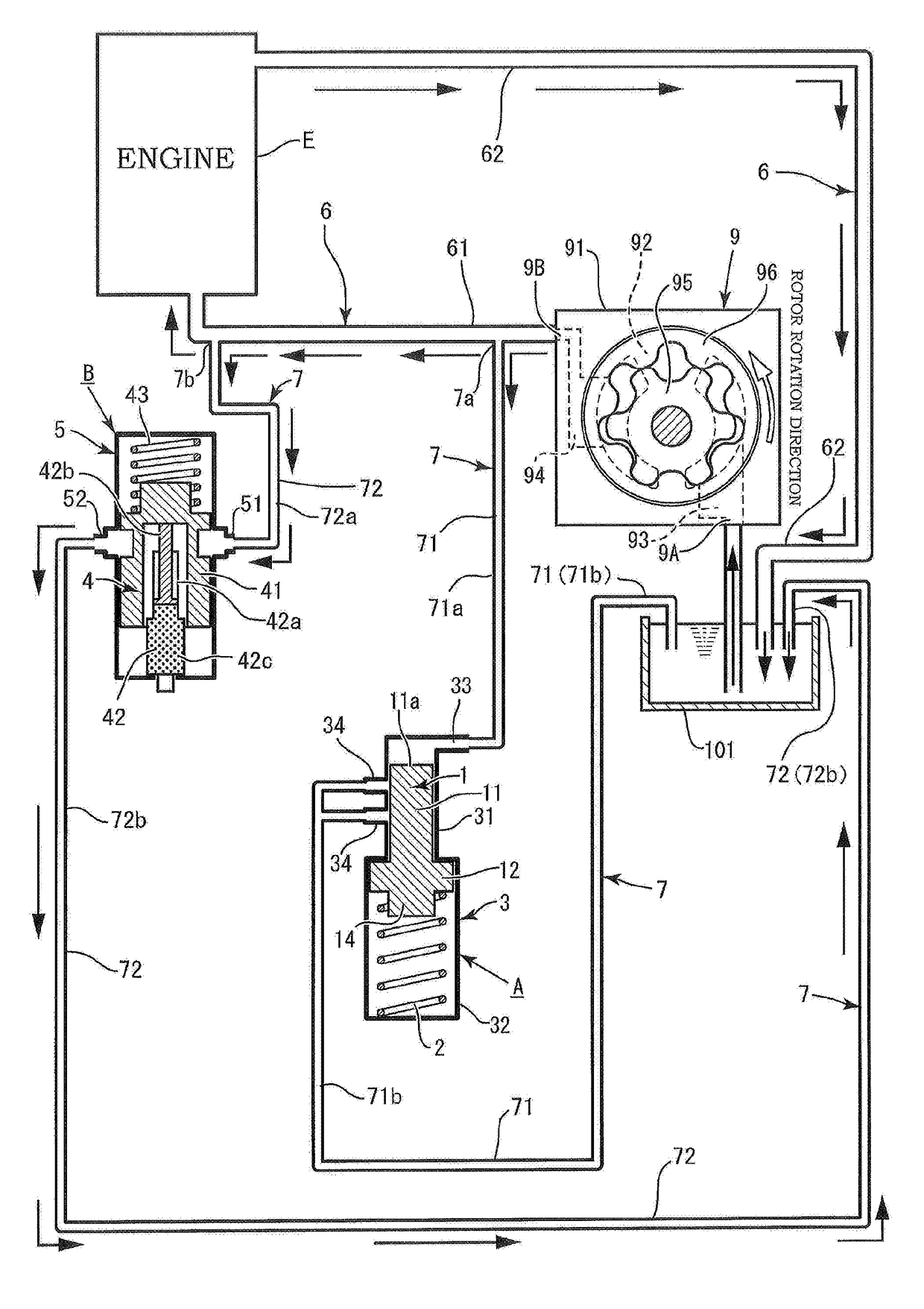

Relief device of oil circuit of engine

ActiveUS20170114682A1Accurately controlReduce oil-pressurePump componentsRotary piston pumpsOil pressureRelief valve

[Problem] To provide a relief device for an oil circuit of an engine provided with an oil pressure relief valve and a temperature-sensitive relief valve, with which it is possible for oil to be relieved (expelled) at the intended pressure regardless of the oil temperature, and with which it is possible to simplify the configuration. [Solution] The relief device comprises an oil pump (9), an upstream channel (61) provided from a discharge side of the oil pump (9) to an engine (E), an oil pressure relief valve (A) for relieving oil due to the valve body being moved by oil pressure, and a temperature-sensitive relief valve (B) for relieving oil by sensing the oil temperature and continuously opening and closing. The oil pressure relief valve (A) and the temperature-sensitive relief valve (B) are arranged in parallel in the upstream channel (61).

Owner:YAMADA SEISAKUSHO KK

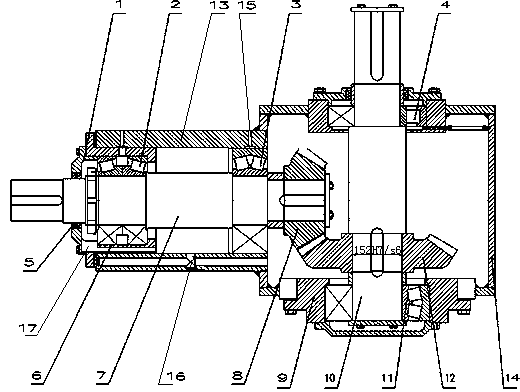

Gear box for petroleum drilling rotary table

InactiveCN104165209AReliable lubricationRelieve pressureToothed gearingsGear lubrication/coolingLubricationEngineering

The invention relates to a gear box for a petroleum drilling rotary table. The gear box for the petroleum drilling rotary table comprises a box body, an input shaft, an input bevel gear, an output bevel gear and an output shaft. The box body comprises an input shaft box body and an output shaft box body, and the combination part of the input shaft box body and the output shaft box body is connected into a whole in a welding mode after seamless butt joint is conducted. The input end of the input shaft box body is provided with a bearing sleeve, one end of the input shaft is arranged on the bearing sleeve in a supported mode through a bearing, and the other end of the input shaft is arranged on the input shaft box body in a supported mode through a bearing. The output shaft box body is provided with a bearing base, and the two ends of the output shaft are arranged on the bearing base in a supported mode through a bearing. One end of the input shaft and one end of the output shaft stretch out of the box bodies and are provided with a transparent cover and an oil seal. One end of the input shaft penetrates through the input shaft box body and enters the output shaft box body, the end of the input shaft is provided with the input bevel gear, the output bevel gear is arranged on the output shaft, and the input bevel gear and the output bevel gear are meshed with each other. The input shaft box body is at least provided with a forced lubrication oil inlet, lubrication oil enters the bearing supporting the input shaft through the forced lubrication oil inlet and an oil duct, and an oil return opening is formed in the position below the input shaft box body.

Owner:NANJING NINGJIA ELECTROMECHANICAL

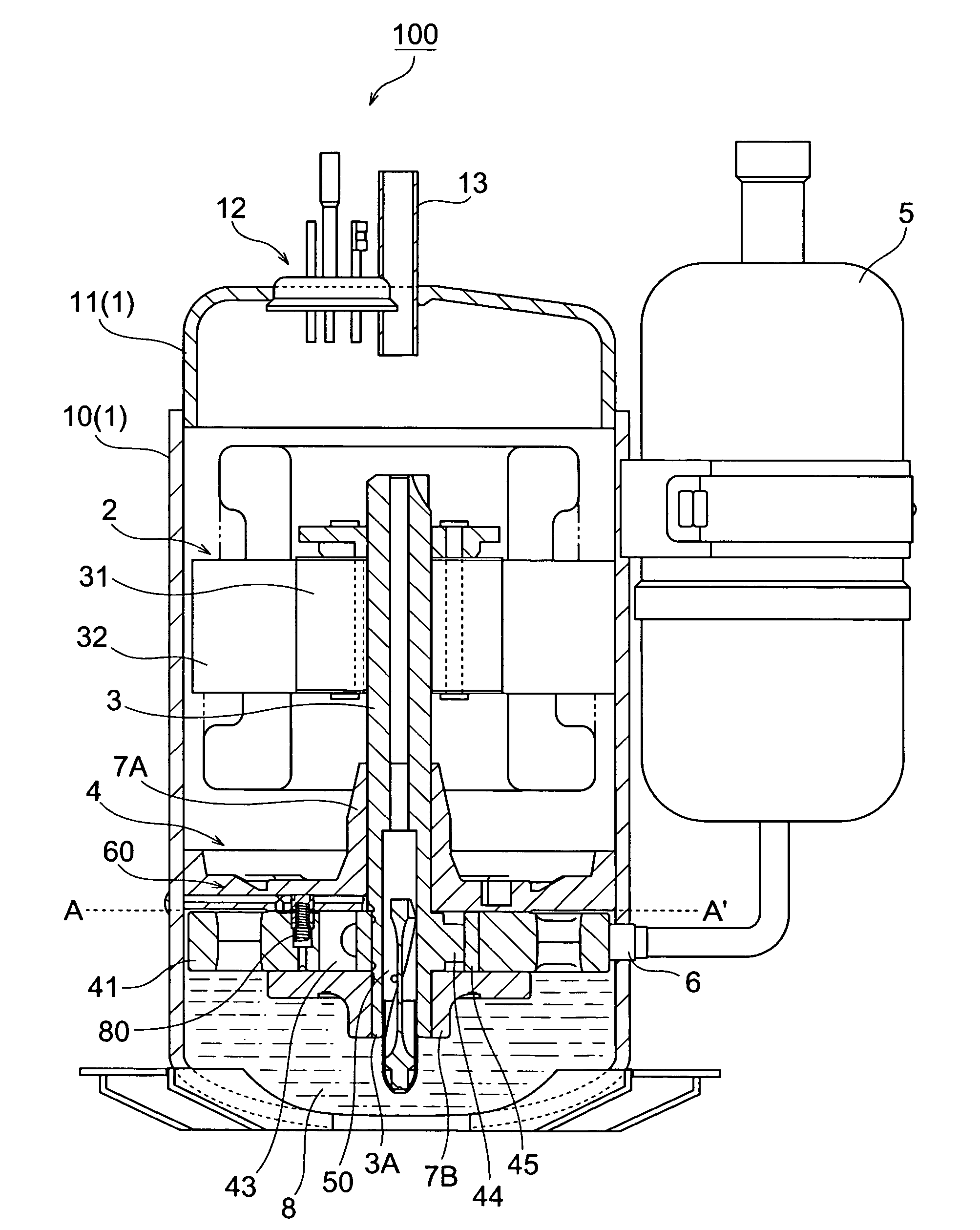

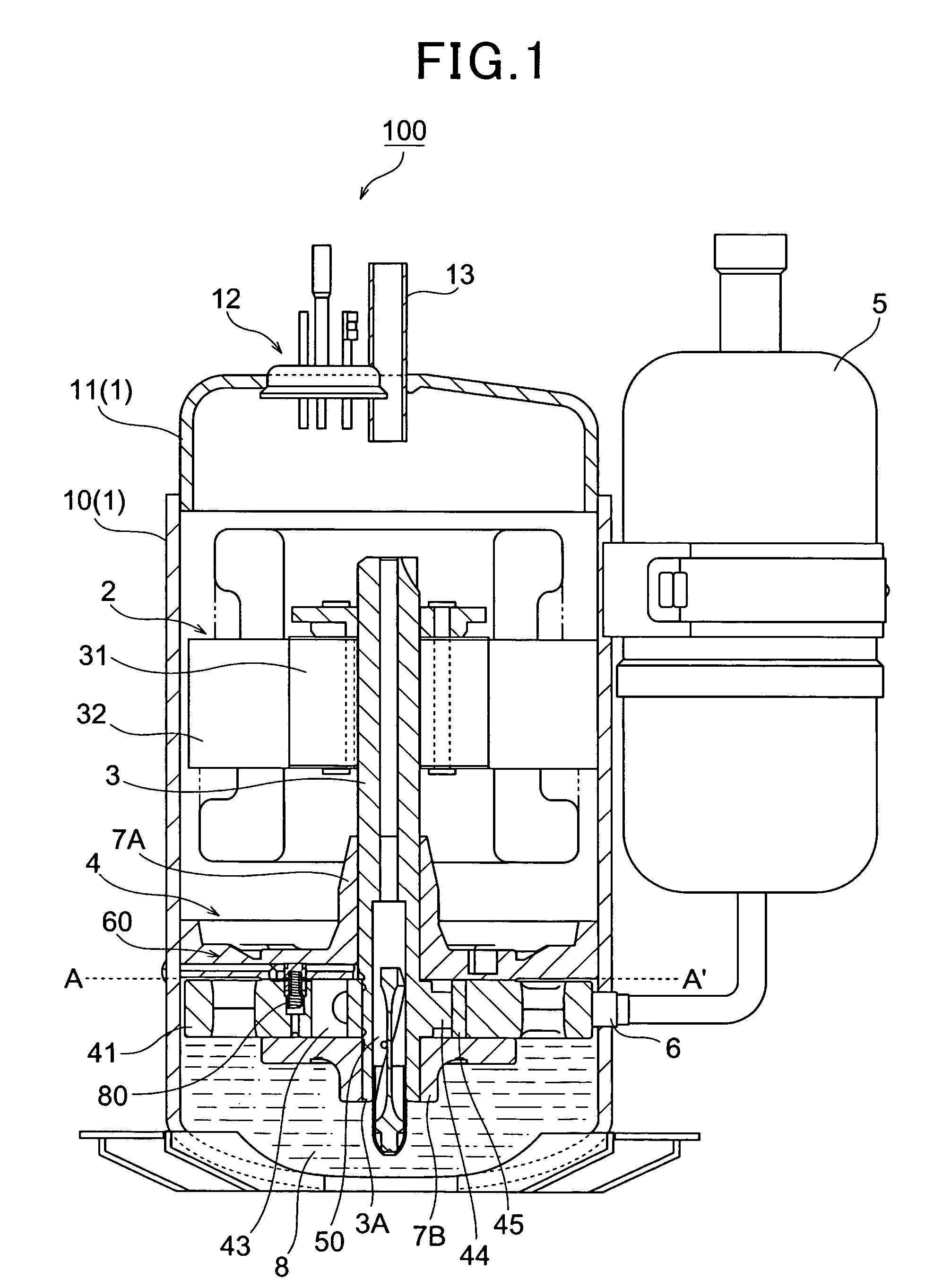

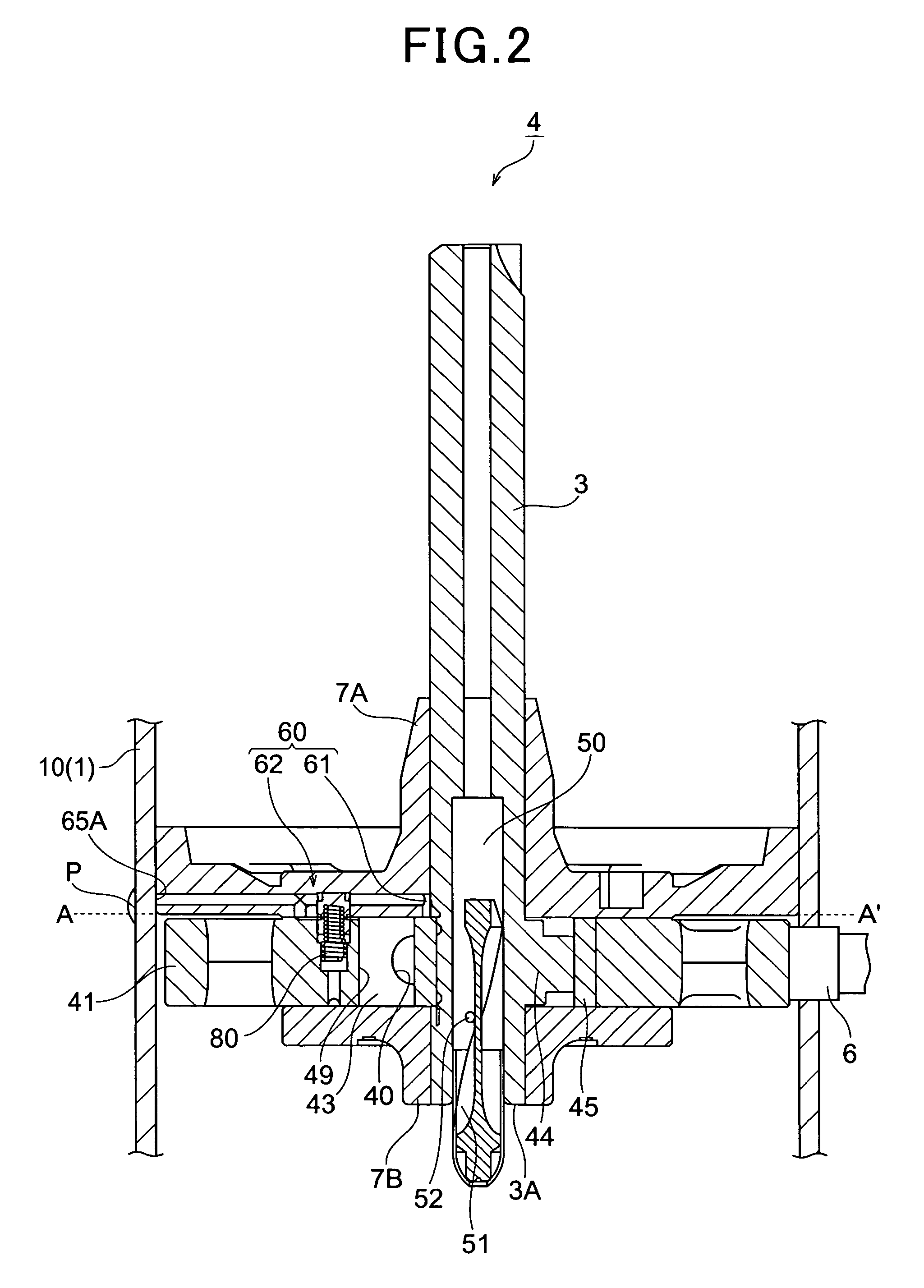

Hermetically sealed compressor having oil supply mechanism based on refrigerant pressure

ActiveUS7581936B2Sealing performanceImprove cooling efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A hermetically sealed rotary compressor 100 including an electrically-driven element 2, a rotary compressing element 4 equipped with a cylinder 41 having a compression chamber 43 and a hermetically sealed container 1 in which oil 8 is stocked, is equipped with an oil path 62 for injecting the oil 8 into the compression chamber 43 when refrigerant is sucked into the compression chamber 43, and an opening / closing valve 80 for opening / closing the oil path 62 in accordance with the discharge pressure of the rotary compressing element 4 of the pressure of the compressed refrigerant compressed by the rotary compressing element 4.

Owner:SANYO ELECTRIC CO LTD

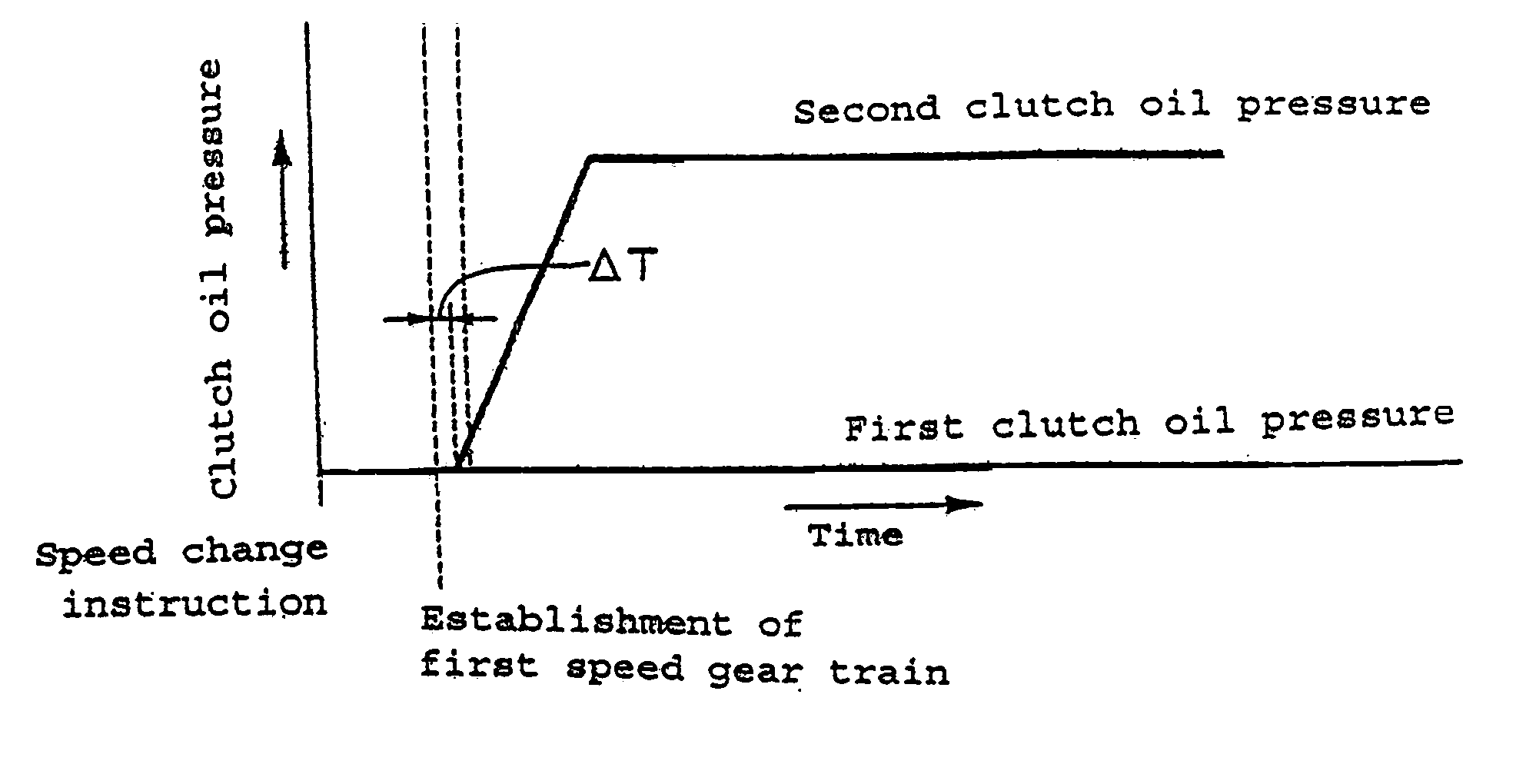

Oil pressure controlled vehicle transmission, power unit incorporating same, and method of using same

ActiveUS20070199782A1Reduce oil pressureIncrease oil pressureMechanical actuated clutchesGearing controlClutchVariator

A transmission for a vehicle is provided which prevents generation of a speed change shock at the time of starting the vehicle from a neutral condition. In the transmission, hydraulic clutches are each put into a connected state according to an action of an oil pressure, and a plurality of selectively engageable speed-stage gear trains are provided so that a neutral condition can be obtained. At the time of shifting from the neutral condition, where the oil pressures in hydraulic clutches are in a lowered state, to a starting condition in which a starting gear train is engaged, pressure in the hydraulic clutch corresponding to the starting gear train is controlled by a control valve, so that the oil pressure in the hydraulic clutch is maintained in the lowered state during and immediately after a shifting operation, and is subsequently increased in response to complete engagement of the starting gear train.

Owner:HONDA MOTOR CO LTD

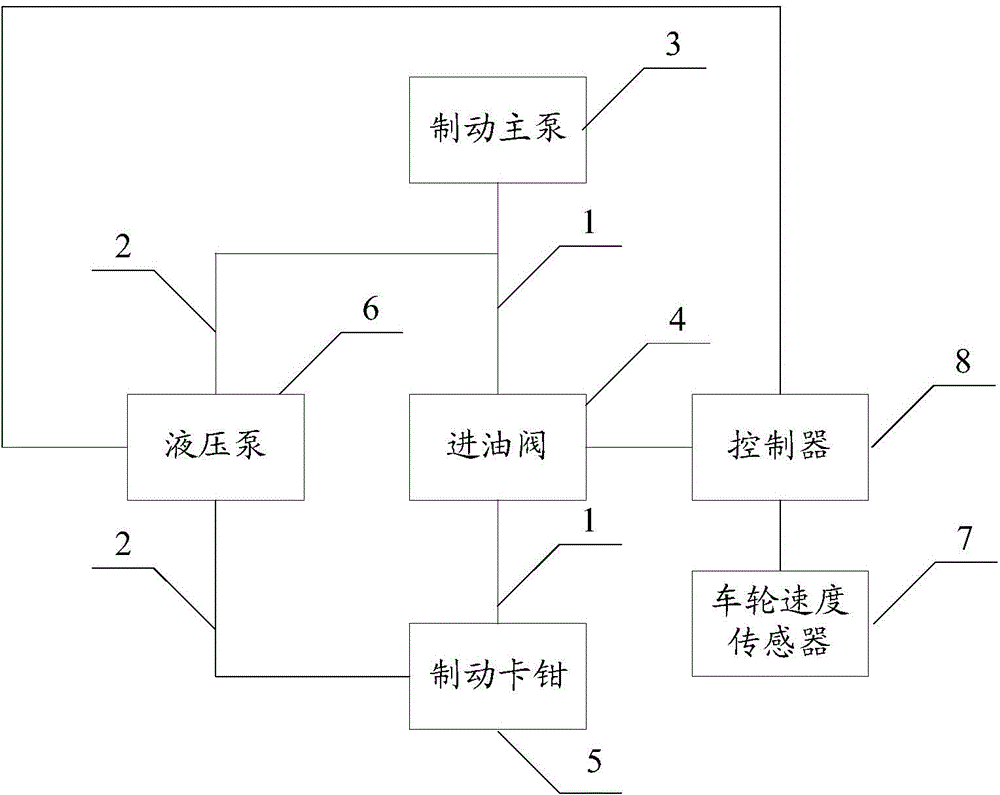

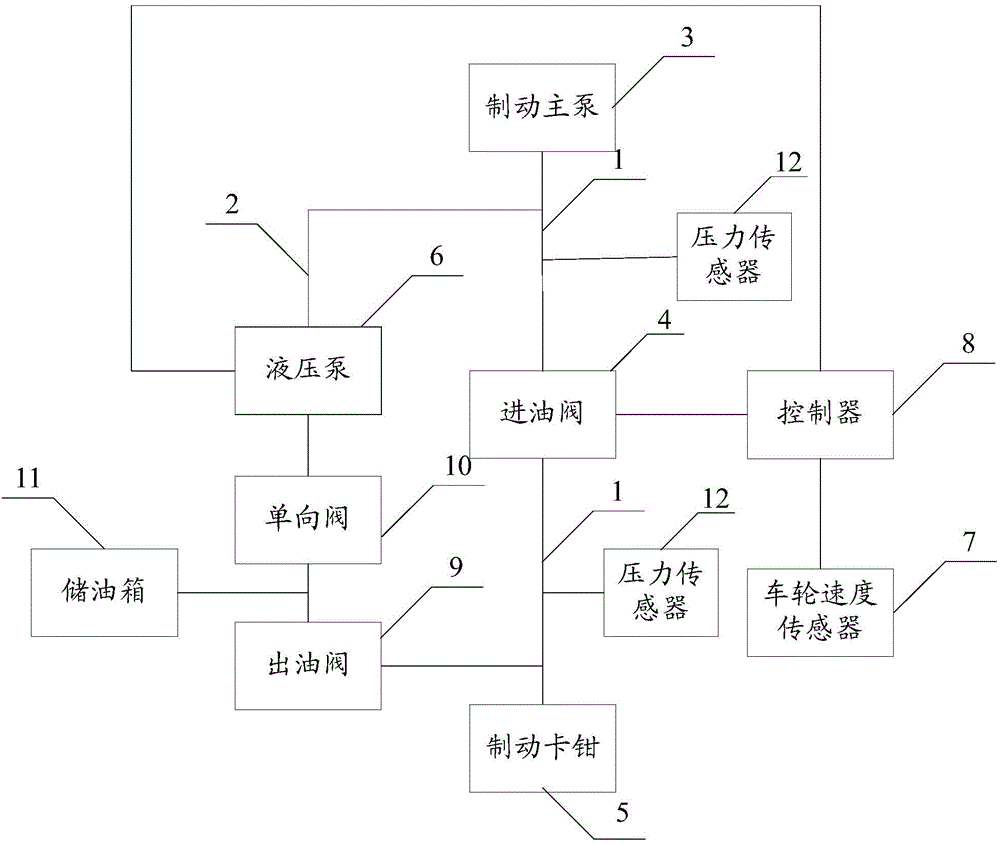

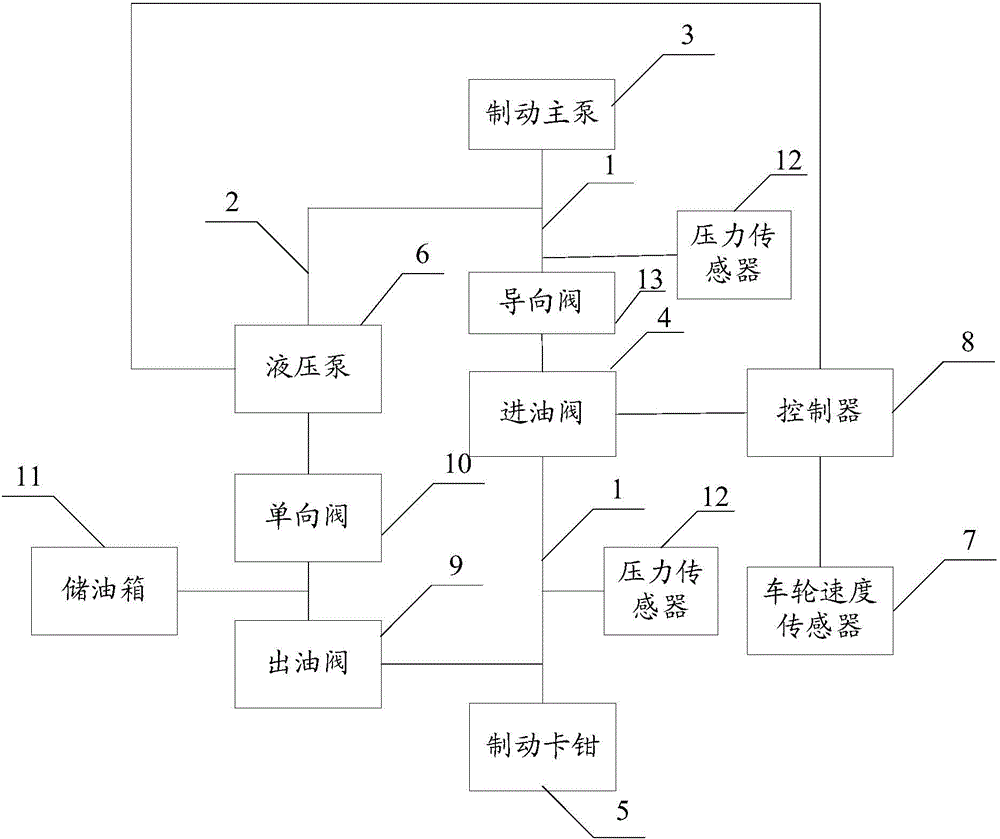

Anti-lock braking system of motorcycle

InactiveCN104401443AReduce oil pressurePrevent lockApplication and release valvesCycle brakesAutomotive engineeringOil pressure

The invention discloses an anti-lock braking system of a motorcycle. The system mainly comprises a main circulating oil path and a secondary circulating oil path, wherein brake fluid output by a brake main pump flows by an oil inlet valve into a pair of brake calipers through the main circulating oil path during normal brake; the pair of brake calipers realizes hydraulic brake under the action of oil pressure; when a controller determines that wheels are in a to-be-locked state through a wheel speed sensor, the controller controls the oil inlet valve to be closed, the brake fluid does not flow into the brake calipers, then the controller controls a hydraulic pump to be turned on, and the hydraulic pump pumps the brake fluid in the brake calipers back into the brake main pump through the secondary circulating oil path, so that the oil pressure in the brake calipers is reduced and the locking of the wheels is prevented.

Owner:ZHEJIANG CFMOTO POWER CO LTD

Oil catch

Owner:SUZHOU NUCLEAR POWER RES INST +2

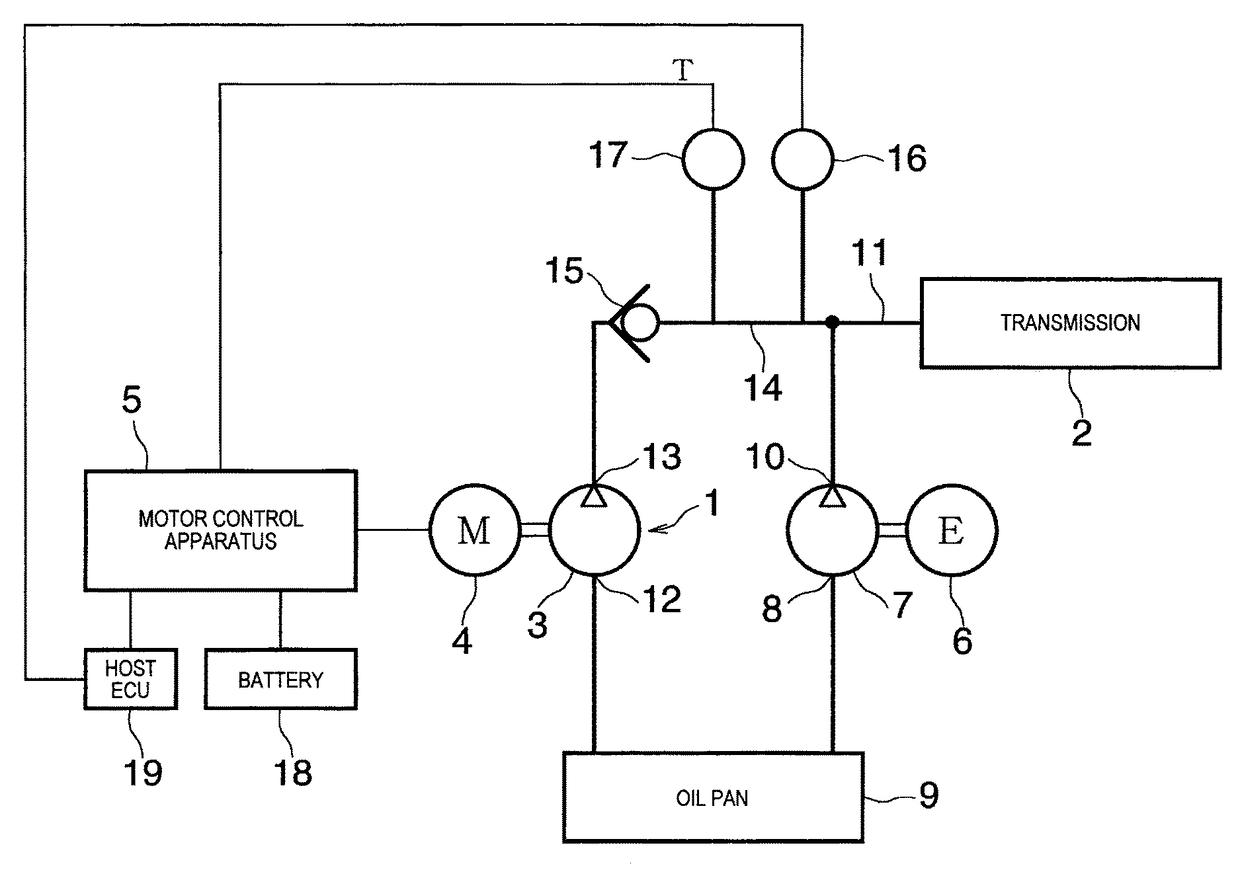

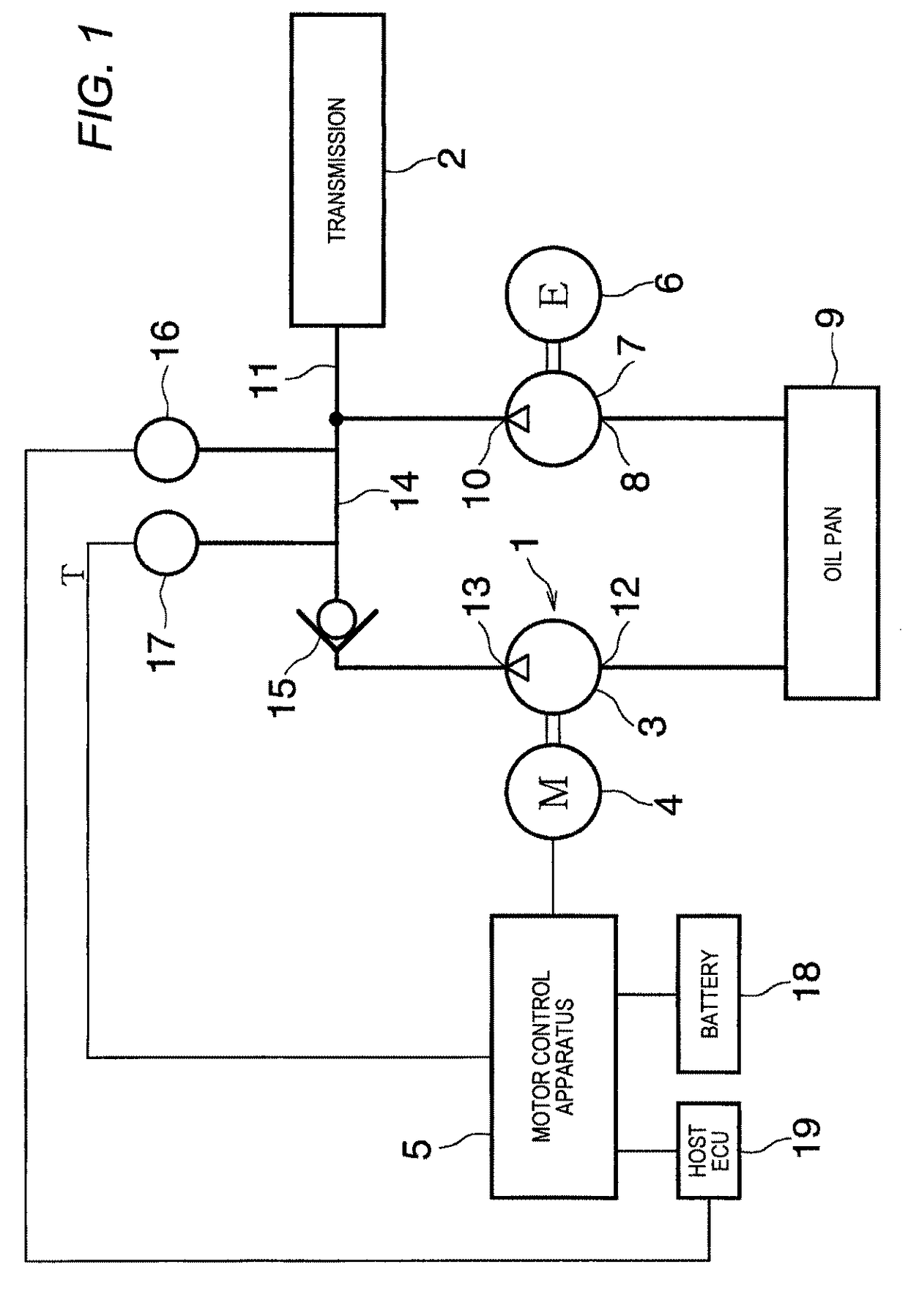

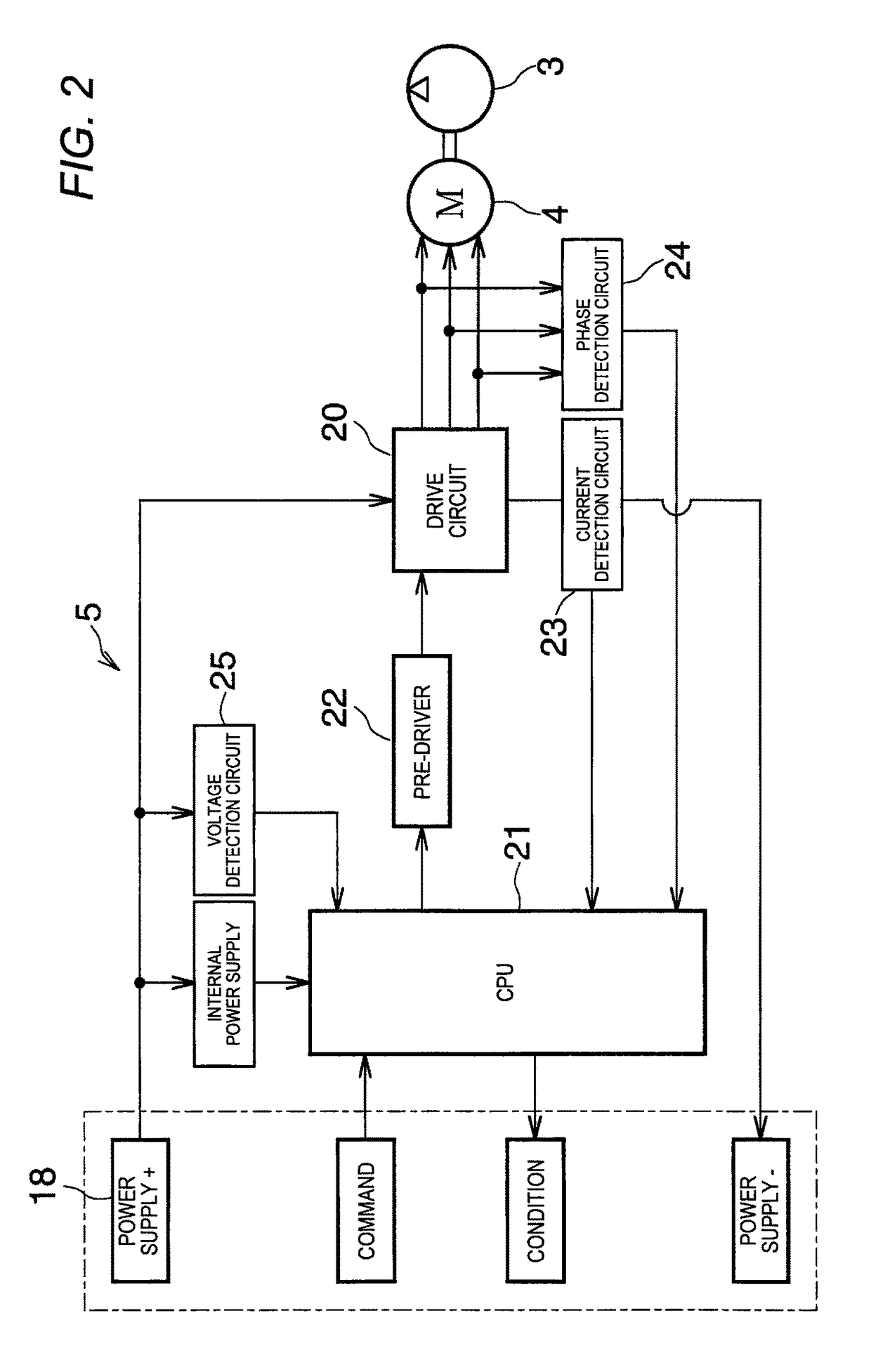

Motor control apparatus and electric pump unit

ActiveUS9683573B2Suppress generationImprove accuracyFluid parameterGearing controlChair control unitControl signal

A control unit includes an excessive output suppression control unit which suppresses an excessive output by reducing a current command value from a host control apparatus. A control signal output unit obtains a motor control signal by adding a reduction amount of the current command value to the current command value. The excessive output suppression control unit includes: an oil pressure estimating unit which estimates oil pressure based on a current and a rotating speed of the electric motor; and a current command value correction amount calculating unit which compares outputs the reduction amount of the current command value if the estimated oil pressure is higher than target oil pressure. One of the target oil pressure and the estimated oil pressure compared by the current command value correction amount calculating unit is corrected based on oil temperature information.

Owner:JTEKT CORP

Engine with Hydraulic Variable Valve Timing

InactiveUS20120145098A1Improve economyImprove performanceInternal combustion piston enginesOutput powerSpool valveVariable valve timing

In one example, a method is described for an engine with a hydraulically actuated phaser for adjusting cam timing. The phaser is controlled by a hydraulic spool valve, for example, having a de-energized position that results in hydraulic force urging the phaser to a base timing. When it is desired to operate the cam timing at base timing, rather then leave the spool valve in a de-energized position that can generate leakage, the spool valve is adjusted to near a null position to reduce the hydraulic pressure drop across the cam journal and thus reduce oil leakage. In this way, it is possible to maintain base timing, while also reducing leakage.

Owner:FORD GLOBAL TECH LLC

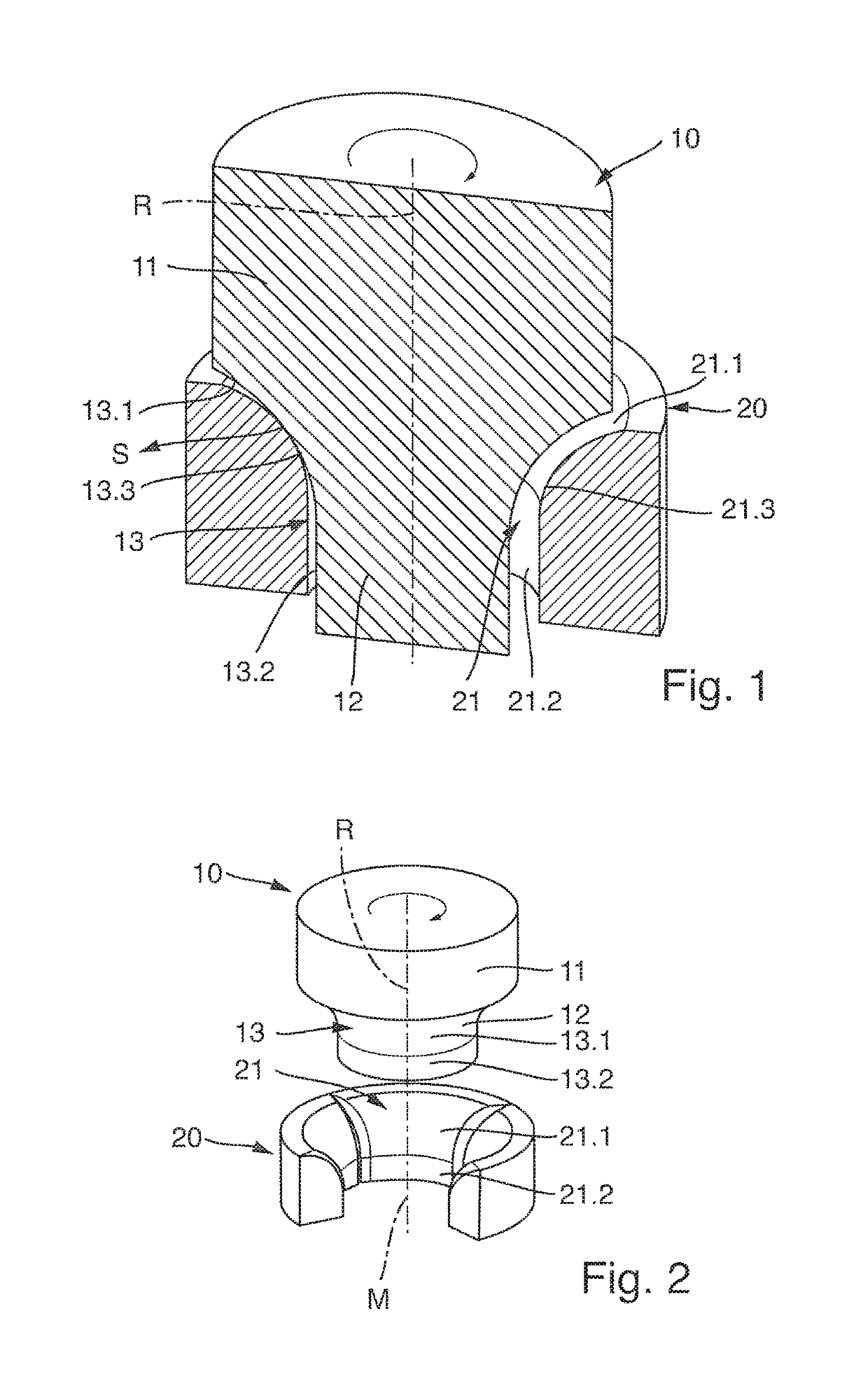

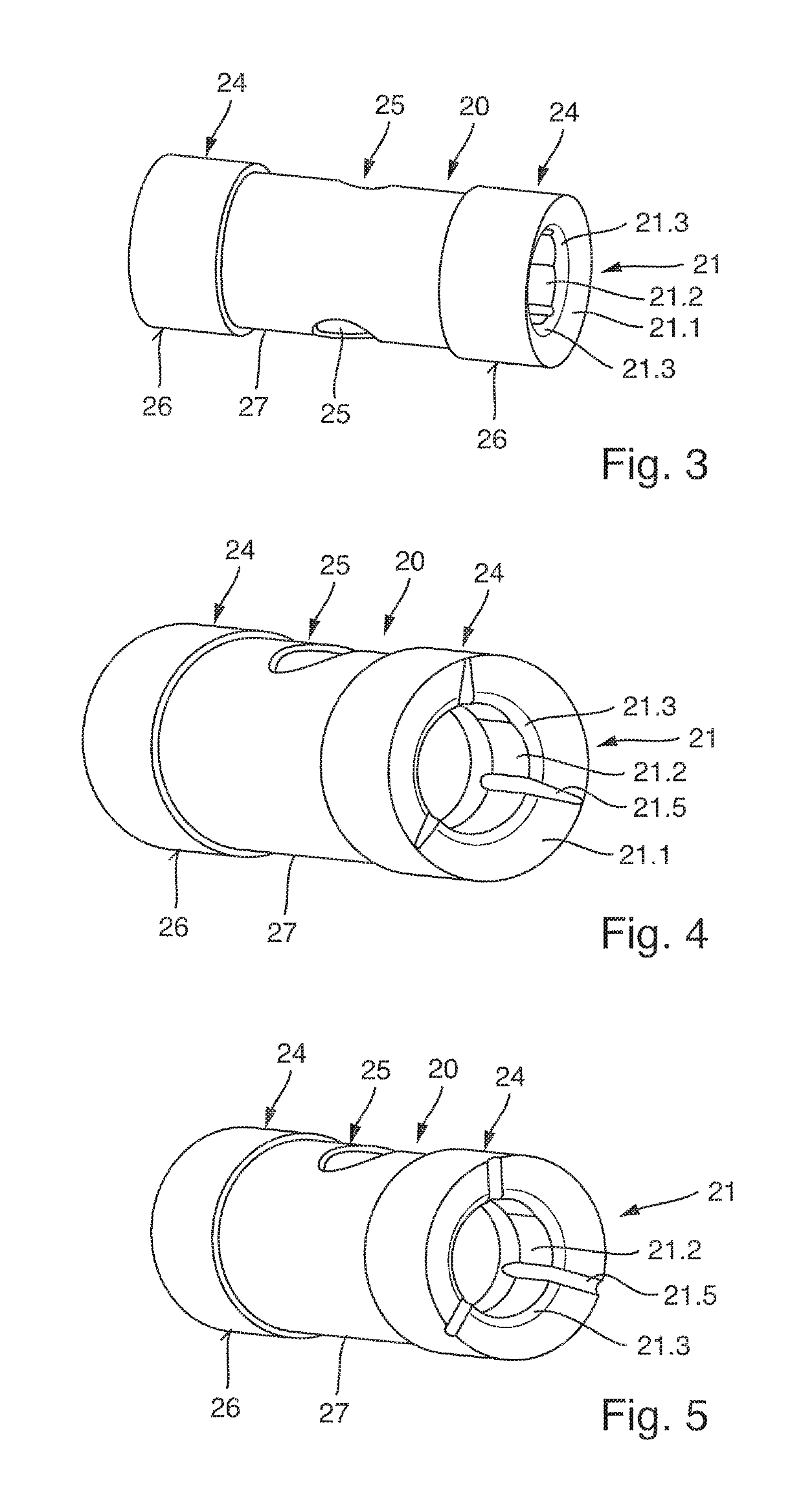

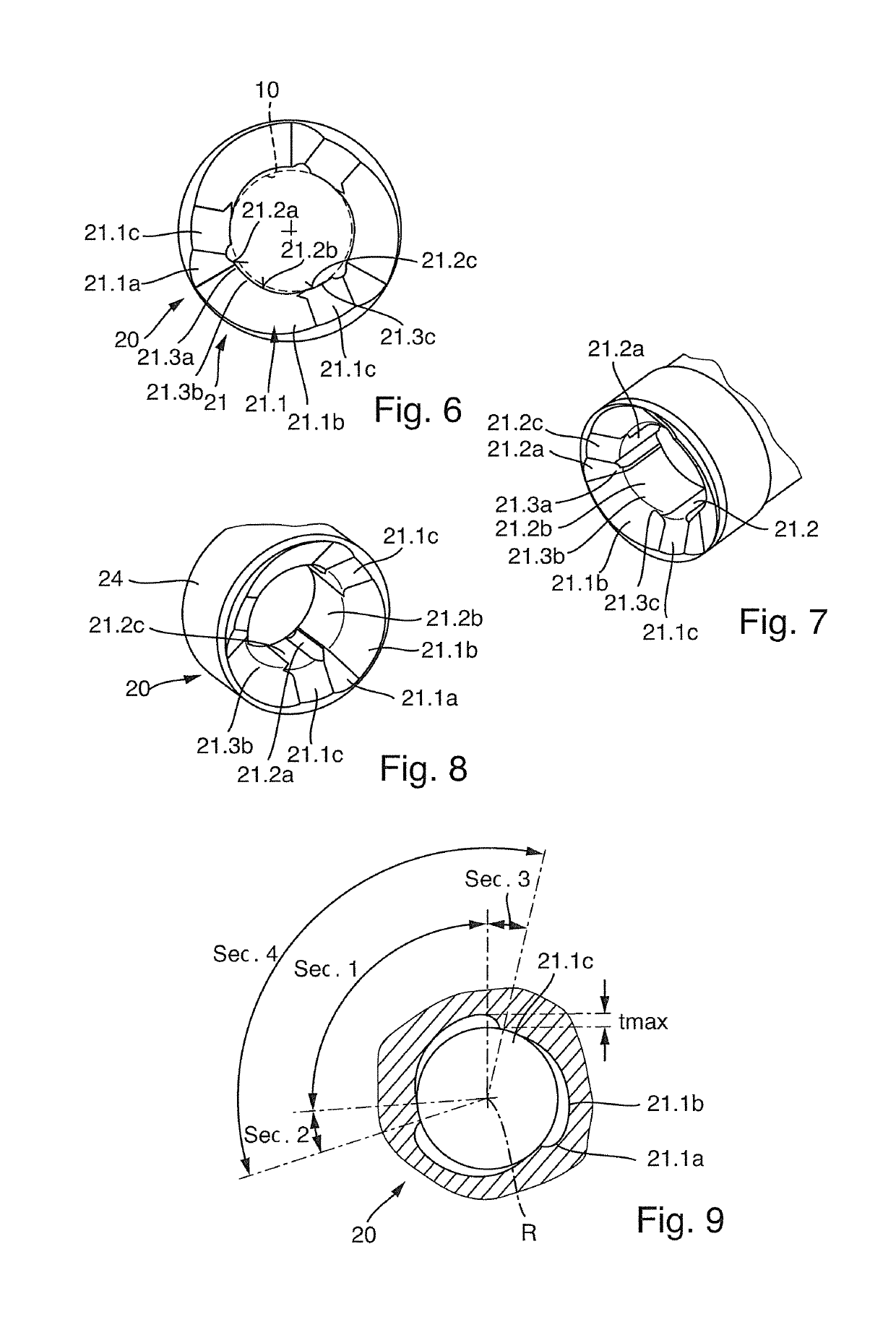

Hydrodynamic plain bearing and exhaust-gas-driven turbocharger

A hydrodynamic plain bearing having a stator and a rotor rotatable with respect to the stator, a rotor bearing surface being located opposite a counter-surface of the stator in order to generate hydrodynamic pressure. The rotor bearing surface and / or the counter-surface constitutes in a section view, in the context of a section along and through the rotation axis, a continuous bearing contour that is constituted from at least two contour segments. The contour segments are suitable for generating hydrodynamic load capacity in a radial and axial direction. The contour segments are led into one another, by at least one transition segment, in such a way that hydrodynamic load capacity is generatable via the contour segments and the transition segment. The plain bearing is embodied as a multiple-surface plain bearing having two or more lubrication wedges in the region of the contour segments and of the transition segment.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com