Oil catch

An oil block and oil intake technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor oil block sealing and easy oil leakage, and achieve good sealing effect, long service life, and reduce the effect of backflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

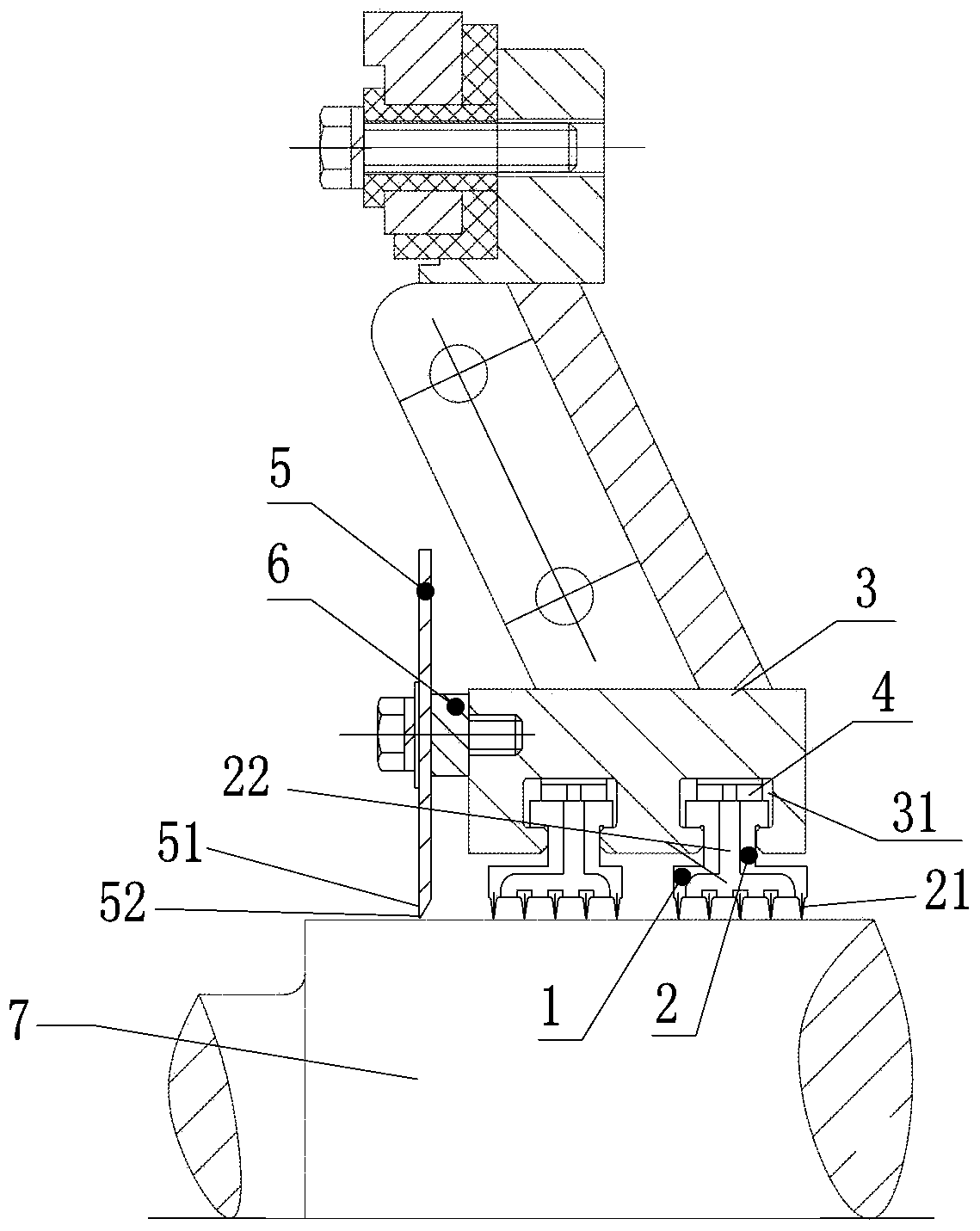

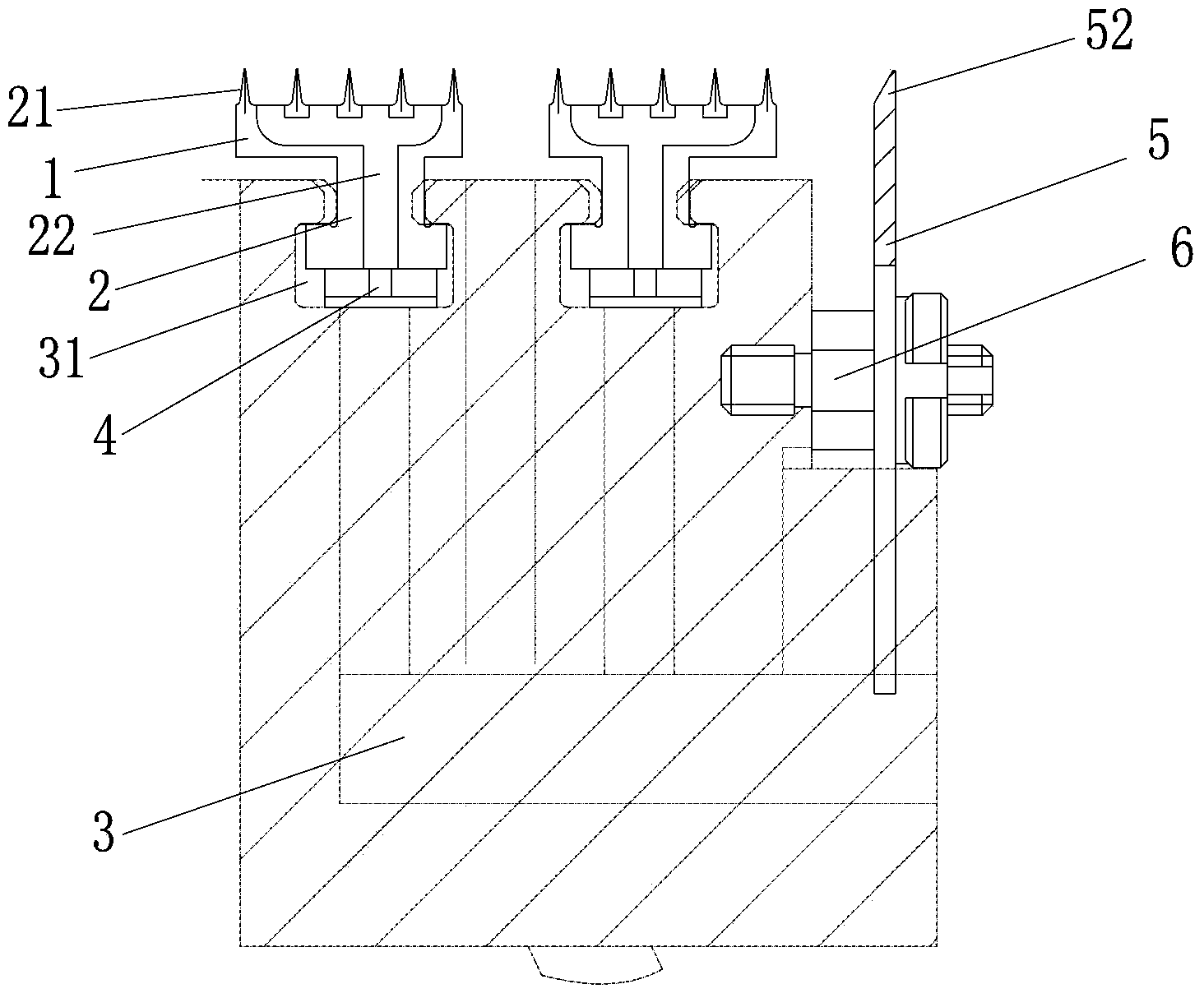

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

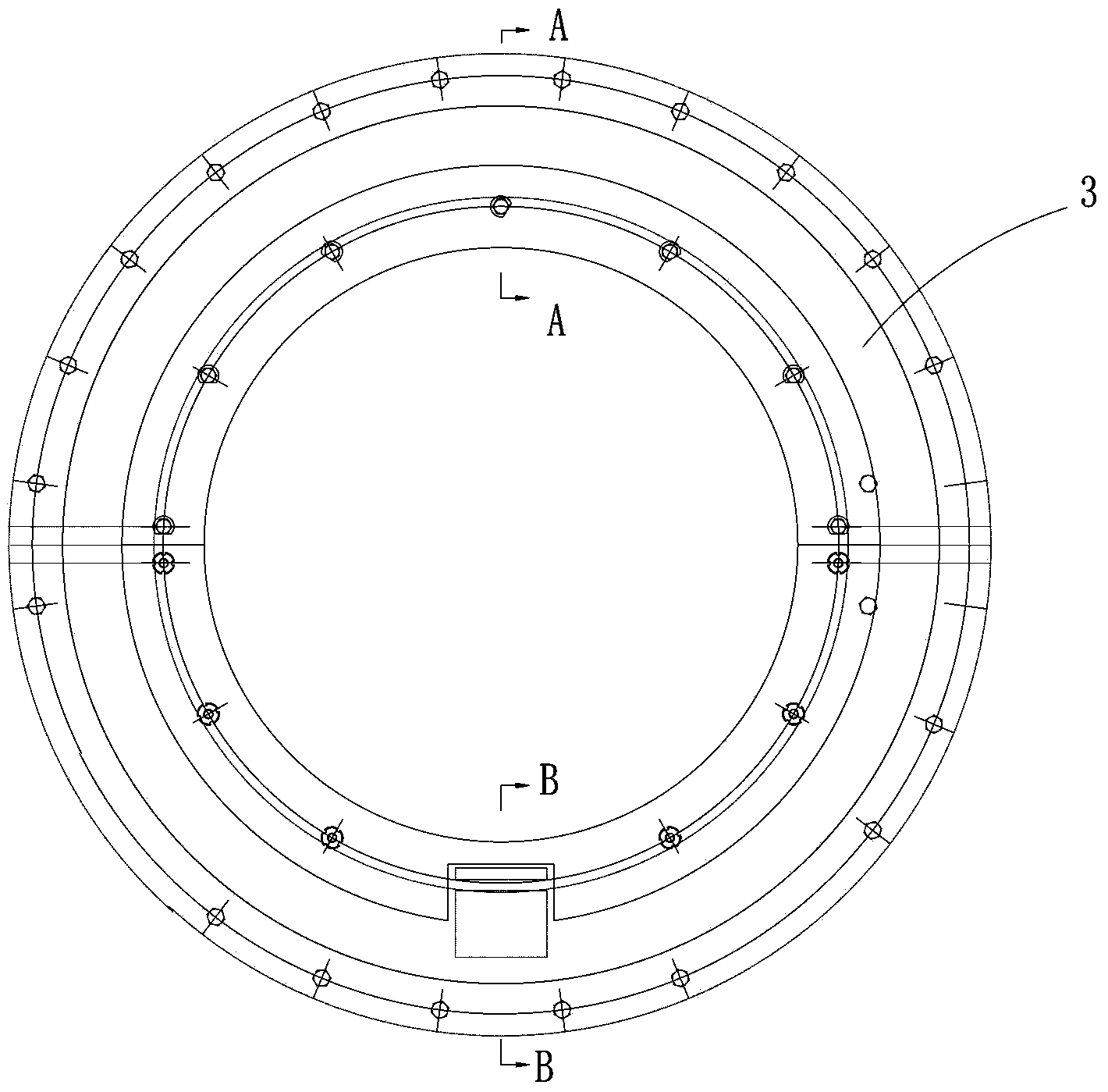

[0022] like figure 1 shown and combined with figure 2 . The oil baffle in this embodiment includes an oil baffle ring 3 sleeved on the rotating shaft 7, and an inner oil baffle plate 5 fitted on the outer periphery of the rotating shaft 7, and the inner oil baffle plate 5 is fixedly connected to the inner side of the oil baffle ring 3 , A gap is formed between the inner oil baffle 5 and the rotating shaft 7, the inner oil baffle 5 is used to block the oil attached to the rotating shaft 7 on the oil inlet path, and make the oil enter the oil baffle ring 3 below through the gap. The interval of the gap is L, 0.4≤L≤0.6 mm.

[0023] The oil retainer also includes an outer ring 1 and an inner ring 2. The inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com