Patents

Literature

108results about How to "Improve lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

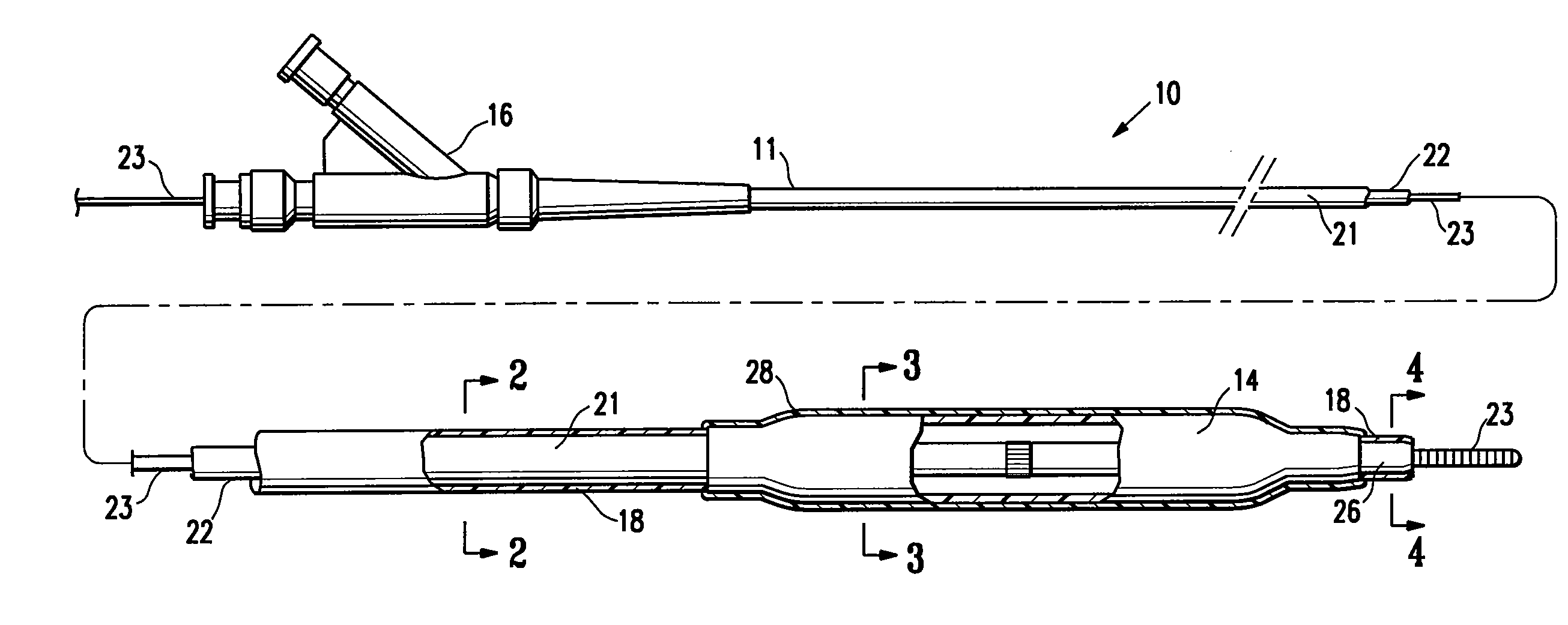

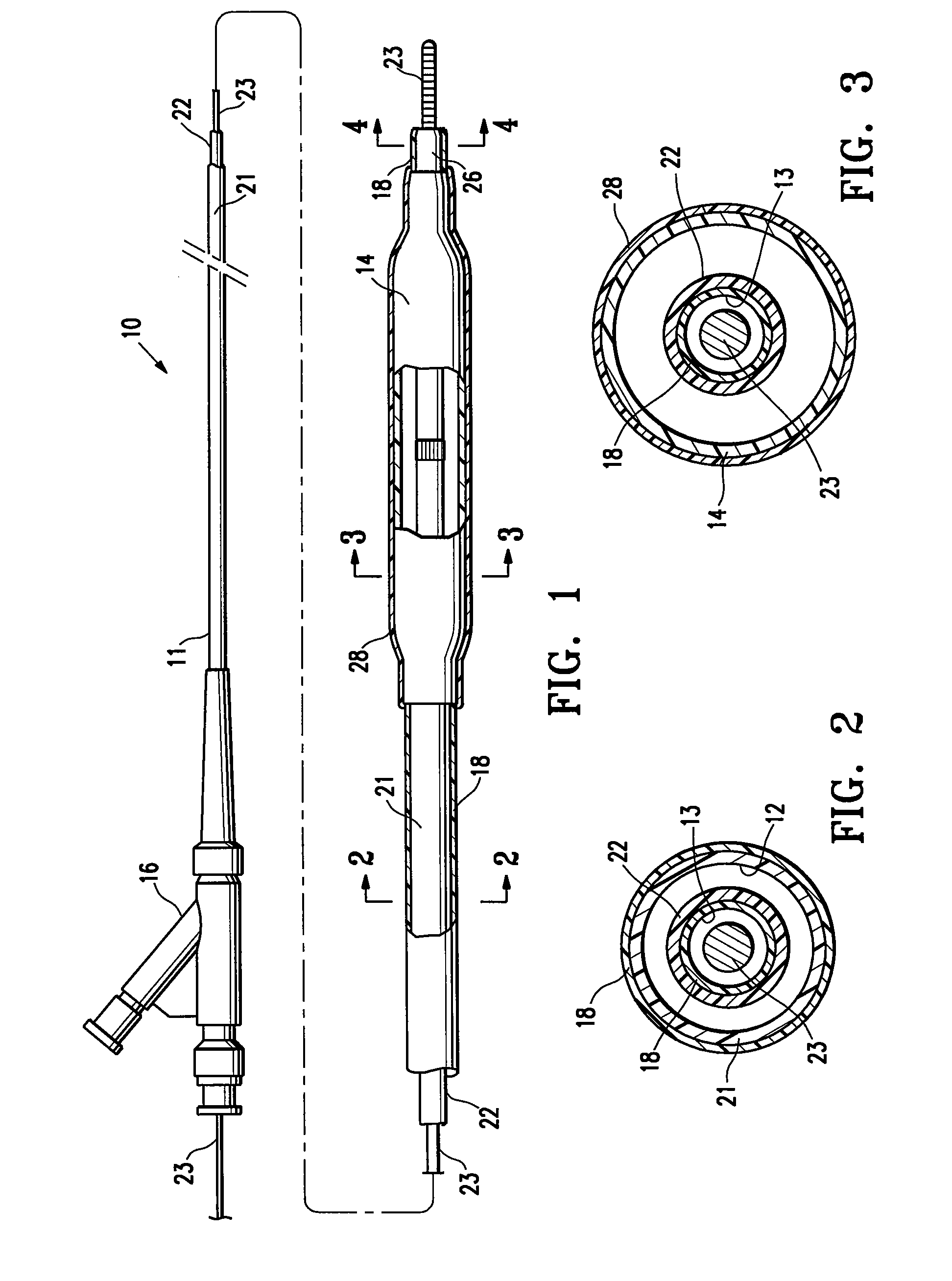

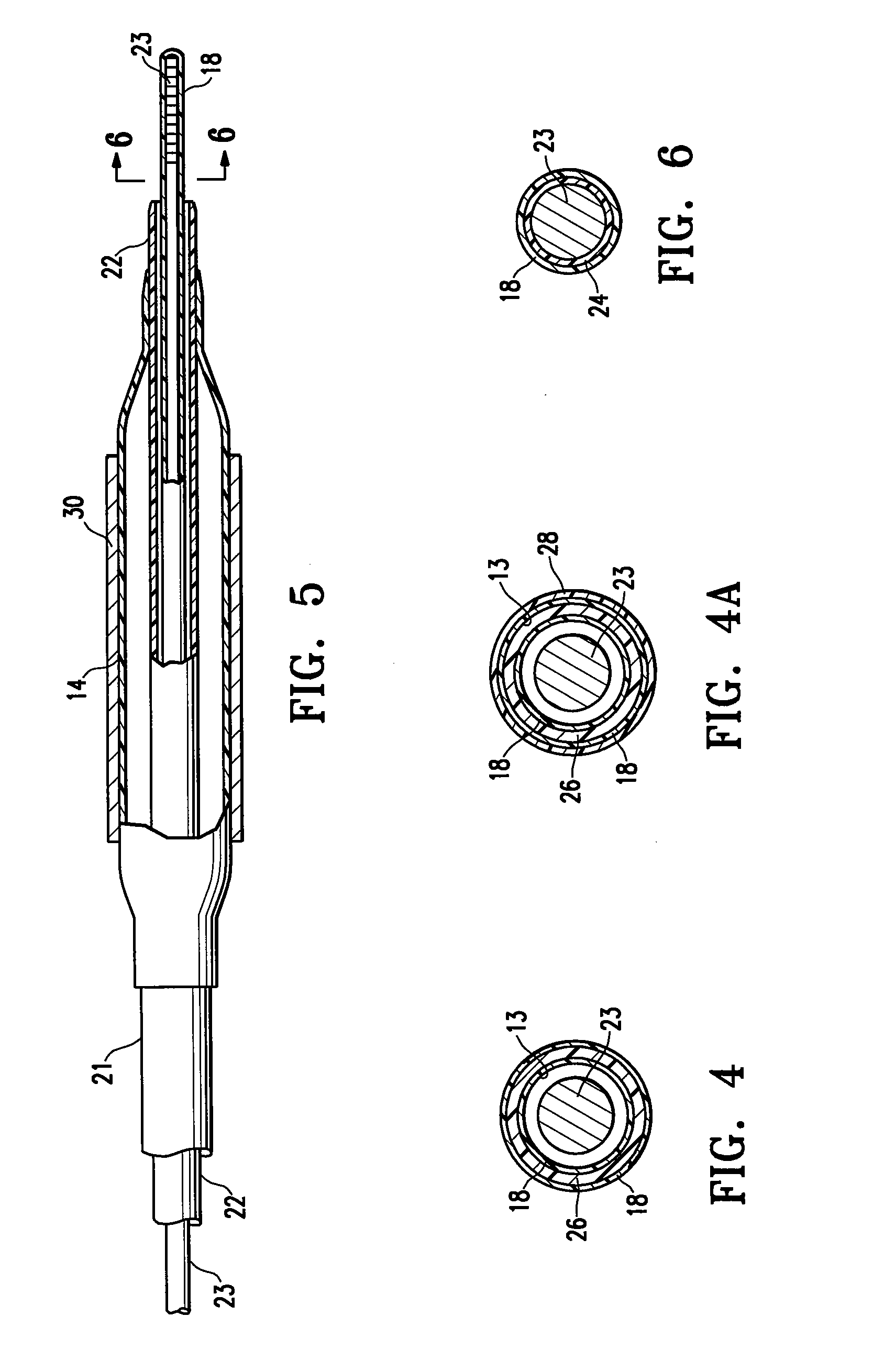

Medical device having a lubricious coating with a hydrophilic compound in an interlocking network

InactiveUS20090041923A1Enhance adhesionImprove lubricityBiocideSalicyclic acid active ingredientsBiomedical engineeringDiagnostic agent

A medical device having a lubricious coating on at least a section of the medical device, and a method of coating a medical device, the lubricious coating being a network of a hydrophilic compound cross-linked to itself and interlocked with a network of a cross-linked polymerized multifunctional monomer or polymer. The coating can include one or more agents which provide enhanced adhesion of the coating on the device, or which provide faster hydration of the coating and / or improved lubricity. Additionally, the lubricious coating can be provided with one or more therapeutic or diagnostic agents, and in one embodiment the agent elutes relatively quickly in a concentrated release from the lubricious coating upon hydration of the coating.

Owner:ABBOTT CARDIOVASCULAR

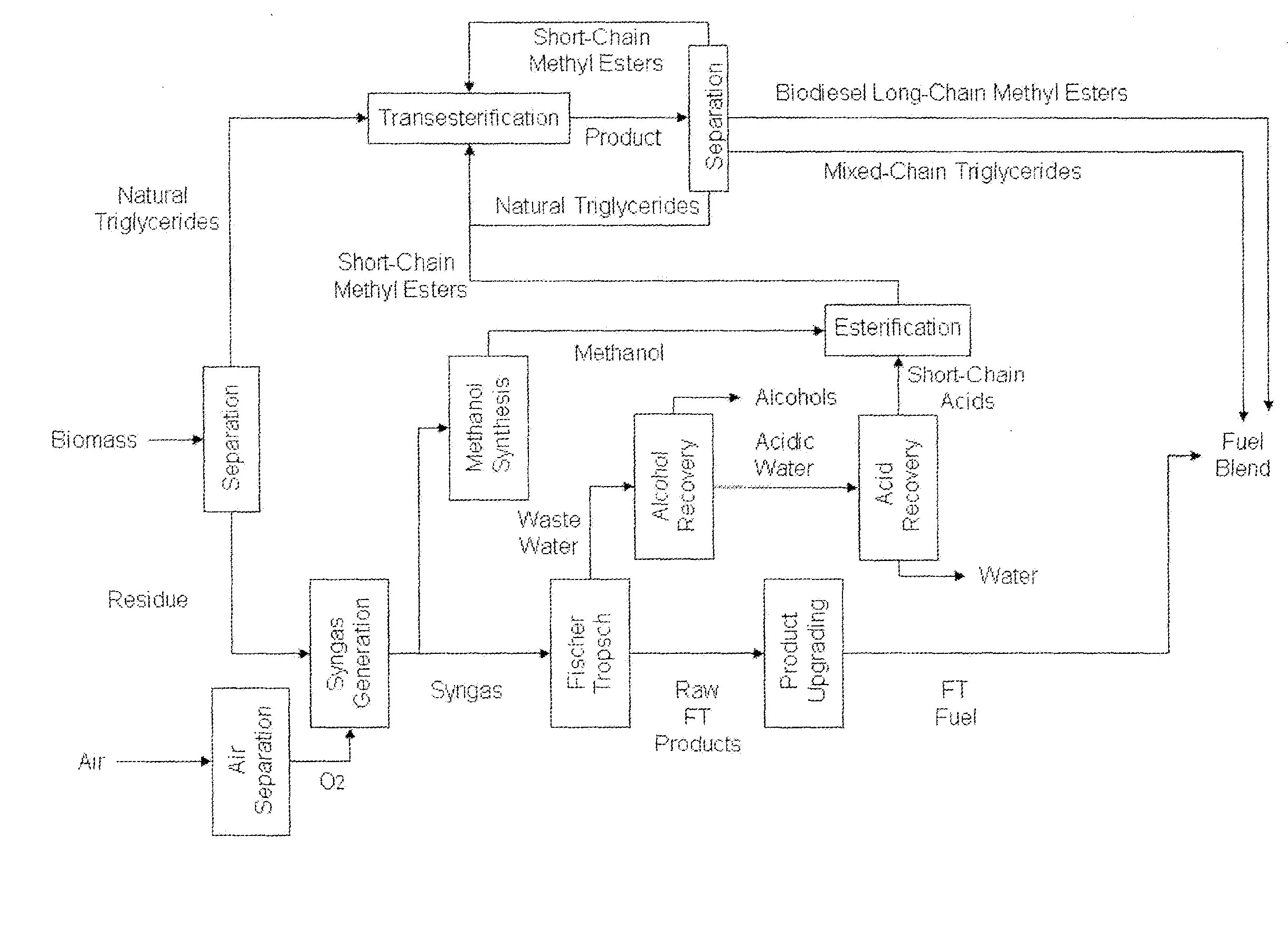

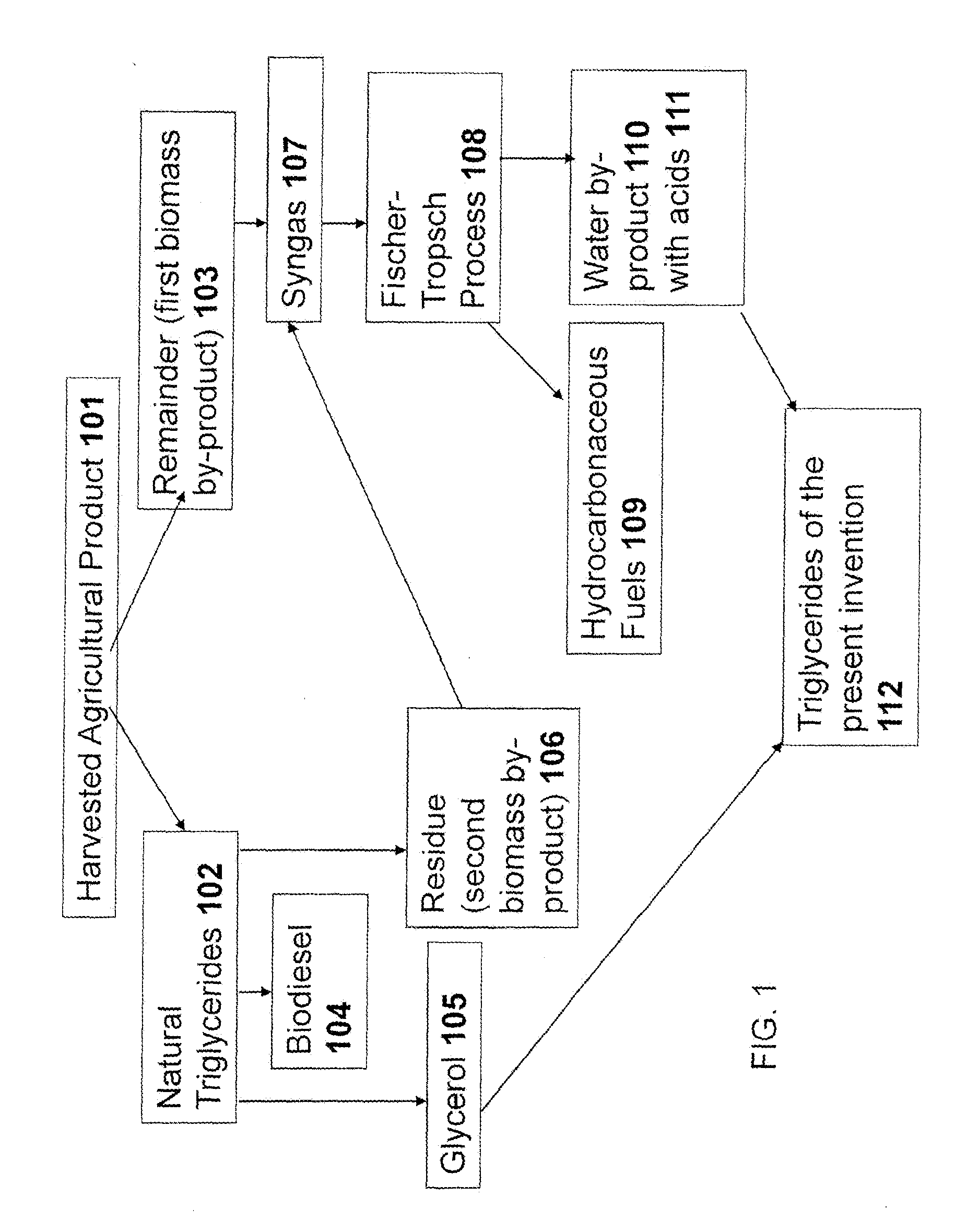

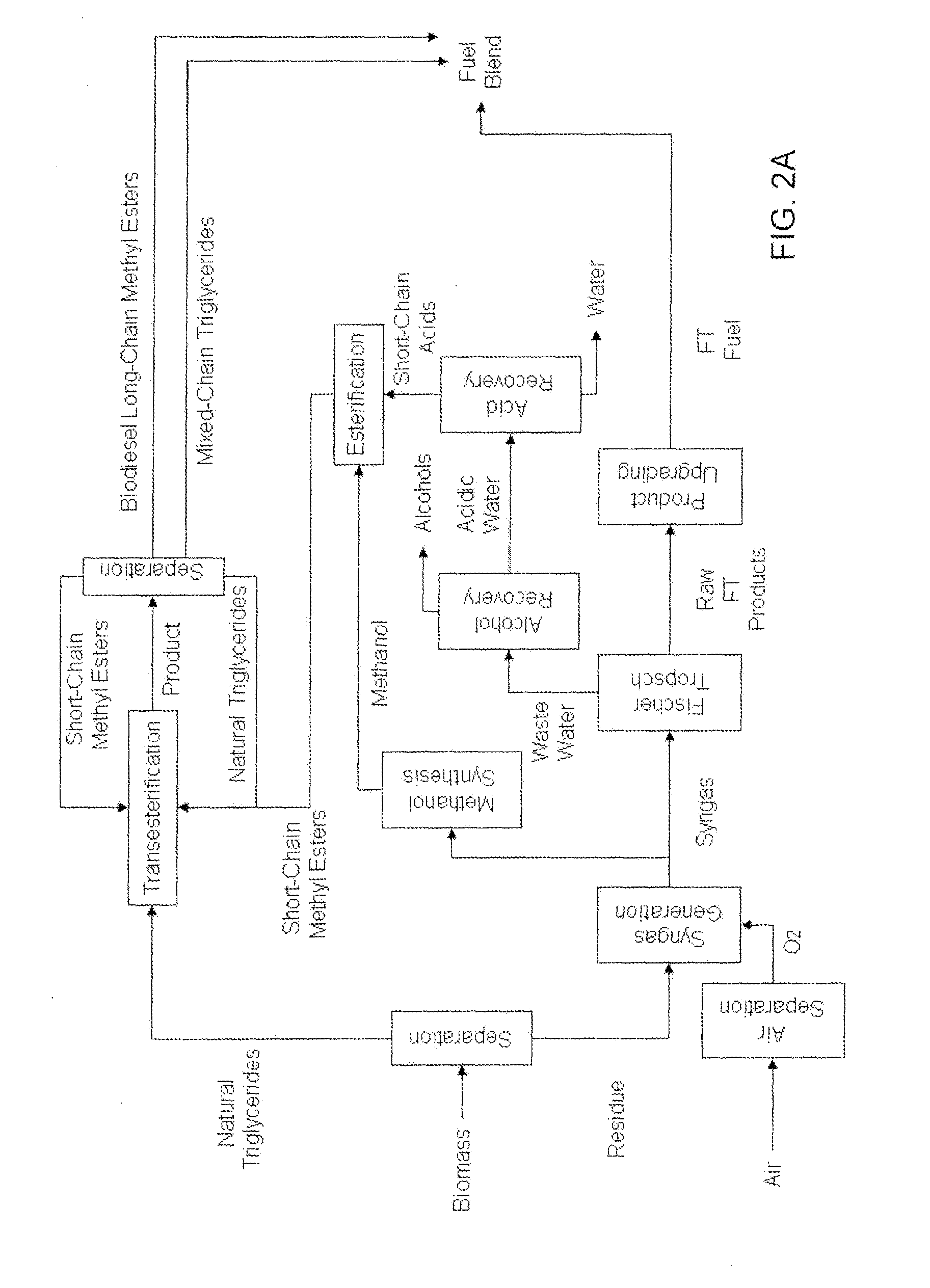

Low Melting Point Triglycerides for Use in Fuels

InactiveUS20100263263A1Improve efficiencyImprove lubricityFatty acid esterificationFatty acids production/refiningChemistryGlycerol

In the present invention, a fuel composition and a process for making the same are disclosed. Specifically, in the present invention, triglycerides useful for distillate fuels are described along with their method for preparation from Fischer-Tropsch acid by-products and the glycerol by-product from biodiesel generation. By using these two by-product streams, the overall efficiency of both processes is improved and a new source of distillate fuels is created. These triglycerides can be used to improve the lubricity of Fischer-Tropsch derived distillate fuels. In addition, these triglycerides also have low melting points and have viscosities compatible with distillate fuels.

Owner:TEXACO INC

Paste solder for hard soldering of SiCp/Al composite material and preparation method and use method thereof

InactiveCN103100800AReduce in quantityImprove automationWelding/cutting media/materialsSoldering mediaAdhesiveTubing types

The invention relates to a paste solder for the hard soldering of a SiCp / Al composite material and a preparation method and use method thereof, and relates to a solder for the hard soldering of the SiCp / Al composite material and a preparation method and use method thereof. The paste solder for the hard soldering of the SiCp / Al composite material aims at the problem that the traditional strip-shaped solder or foil-shaped solder is adverse to the automation in a hard soldering process and is not suitable to weld an irregular, small-sized or geometrical complicated part. The paste solder for the hard soldering of the SiCp / Al composite material is prepared by mixing solder alloy powder, a soldering flux and an adhesive. The preparation method comprises the following steps of: 1, preparing the solder alloy powder; 2, preparing the soldering flux; 3, preparing the adhesive; and 4, mixing to prepare the hard soldering of the paste solder for the SiCp / Al composite material. The use method comprises the following steps of: adopting coating type cloth or needle tube type cloth; and then carrying out vacuum heating treatment so as to complete welding. The preparation method disclosed by the invention is mainly used for preparing the paste solder for the hard soldering of the SiCp / Al composite material.

Owner:HENAN POLYTECHNIC UNIV +2

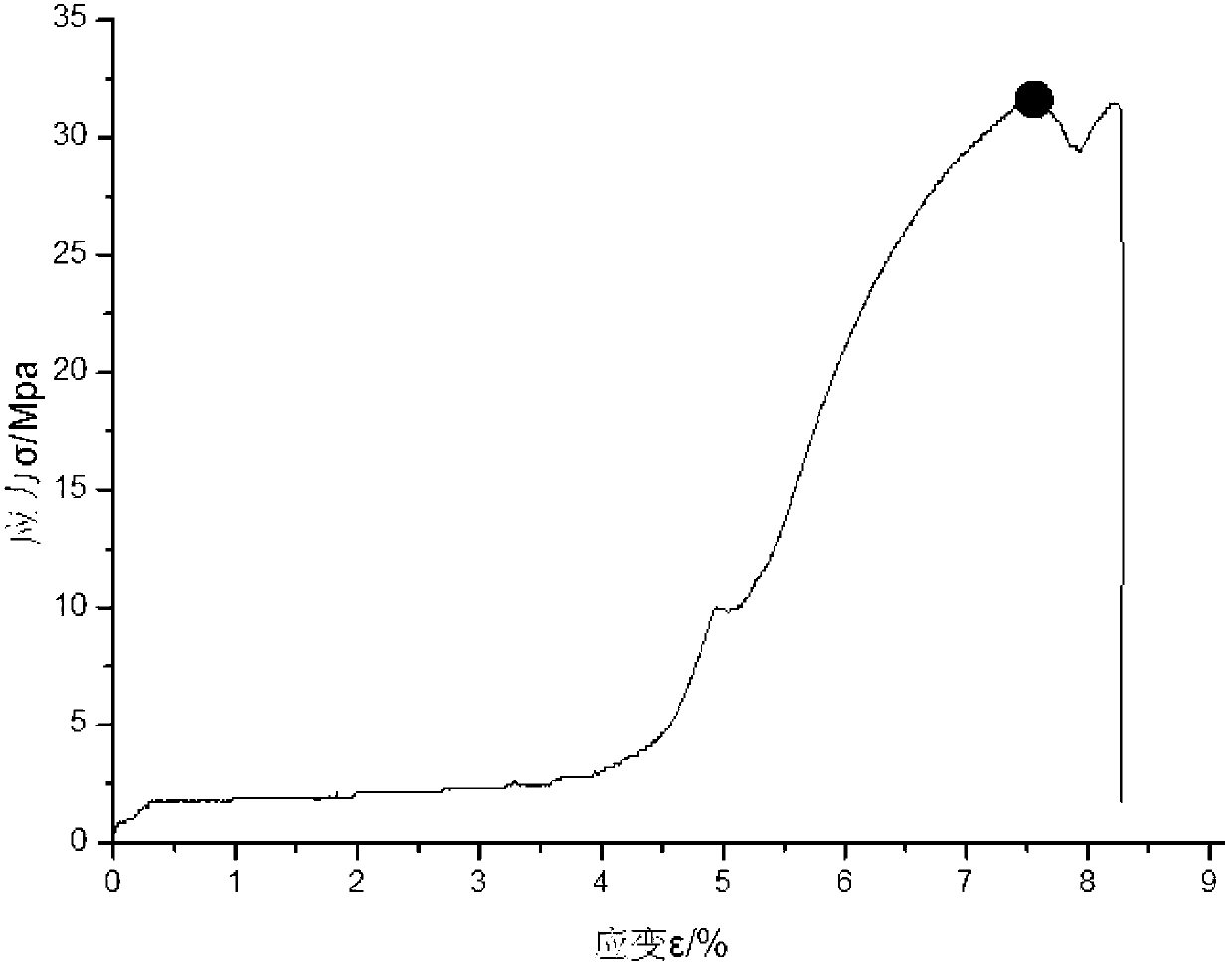

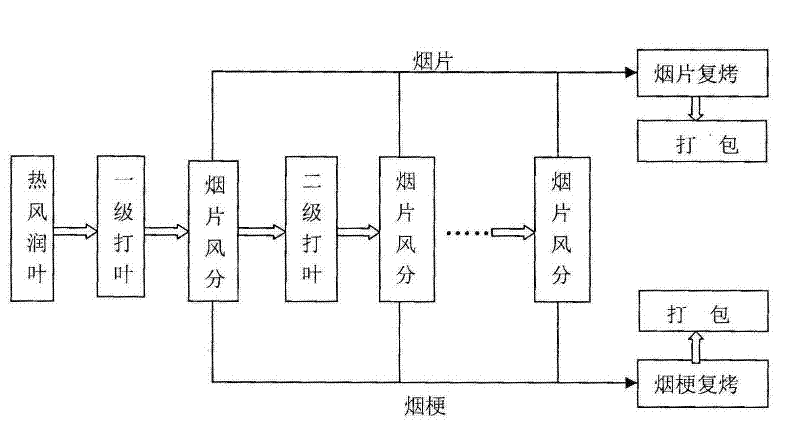

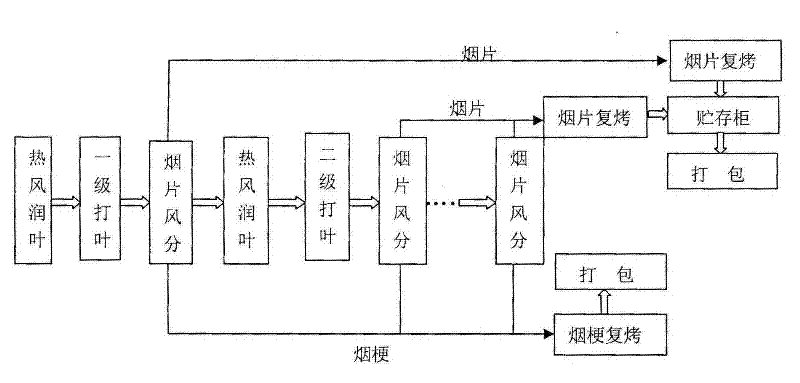

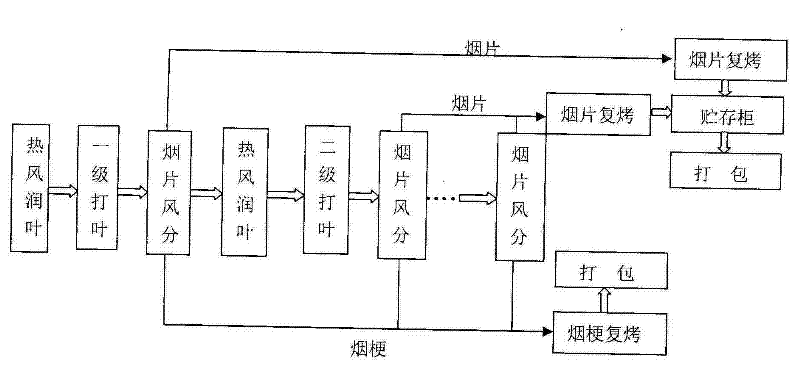

Novel threshing and redrying process based on tobacco mechanics characteristic differences

ActiveCN102488306AImprove lubricityGuaranteed pass rateTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

A threshing and redrying process based on tobacco mechanics characteristic differences comprise links of primary threshing, secondary threshing, tobacco air separating, tobacco redrying and packaging. The threshing and redrying process is characterized in that according to measured tobacco mechanics characteristic indexes, tobaccos are divided into a type I of tobaccos and a type II of tobaccos, a hot air humidifying link is added between the primary threshing link and the secondary threshing link for the type I of tobaccos, tobaccos produced from the primary threshing link, the secondary threshing link and follow-up various process links are respectively redried, moisture content of the type I of tobaccos is reduced before the type I of tobaccos enter the primary threshing link, and tobaccos produced from the primary threshing link are in low-strength redrying; and the type II of tobaccos are in threshing and redrying according to existing threshing and redrying process flow. The novel threshing and redrying process is based on the tobacco mechanics characteristic differences, is complete and feasible threshing and redrying process flow and control technology for resolving the problem of tar extrusion and caking of tobacco during processing, and by the aid of the threshing and redrying process flow and control technology, threshing and redrying processing technical level and comprehensive tobacco quality further can be improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

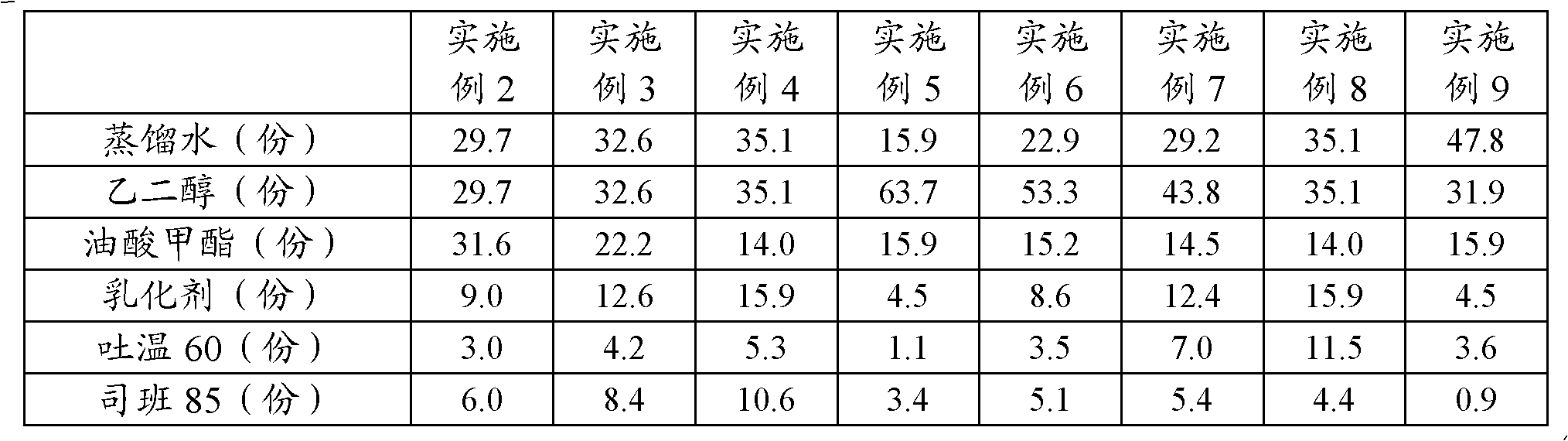

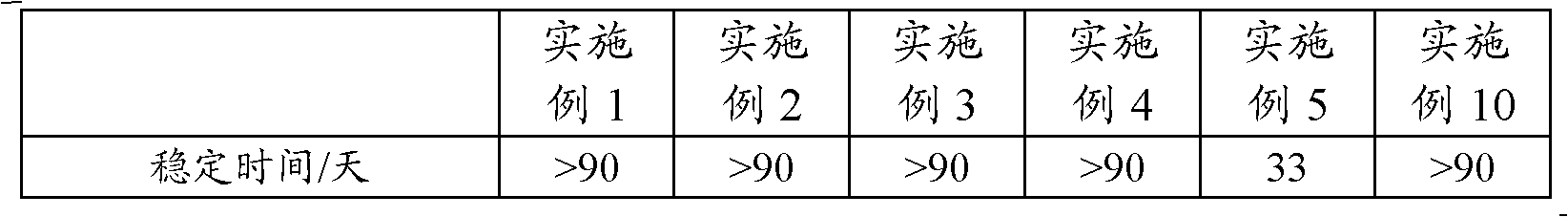

Water-based lubricant for drilling fluid as well as preparation and application of water-base lubricant

ActiveCN102676129ALow turning resistanceImprove lubricityDrilling compositionDrilling fluidMaterials science

The invention discloses a water-base lubricant for drilling fluid. The water-base lubricant comprises the following raw materials by part by weight: 7-80 parts of water, 0-72 parts of polyatomic alcohol, 6-64 parts of vegetable fat and 1-19 parts of emulsifying agent. The invention further discloses a preparation method and application of the water-base lubricant. The water-base lubricant is a biologically-gradable environment-friendly water-based lubricant; and when the water-base lubricant is applied to water-based drilling fluid, the wear resistance and the torque of a drilling tool can be remarkably reduced and the lubricating property of the drilling fluid is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Branched carboxylic acids as fuel lubricity additives

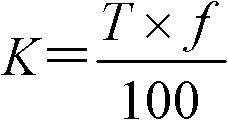

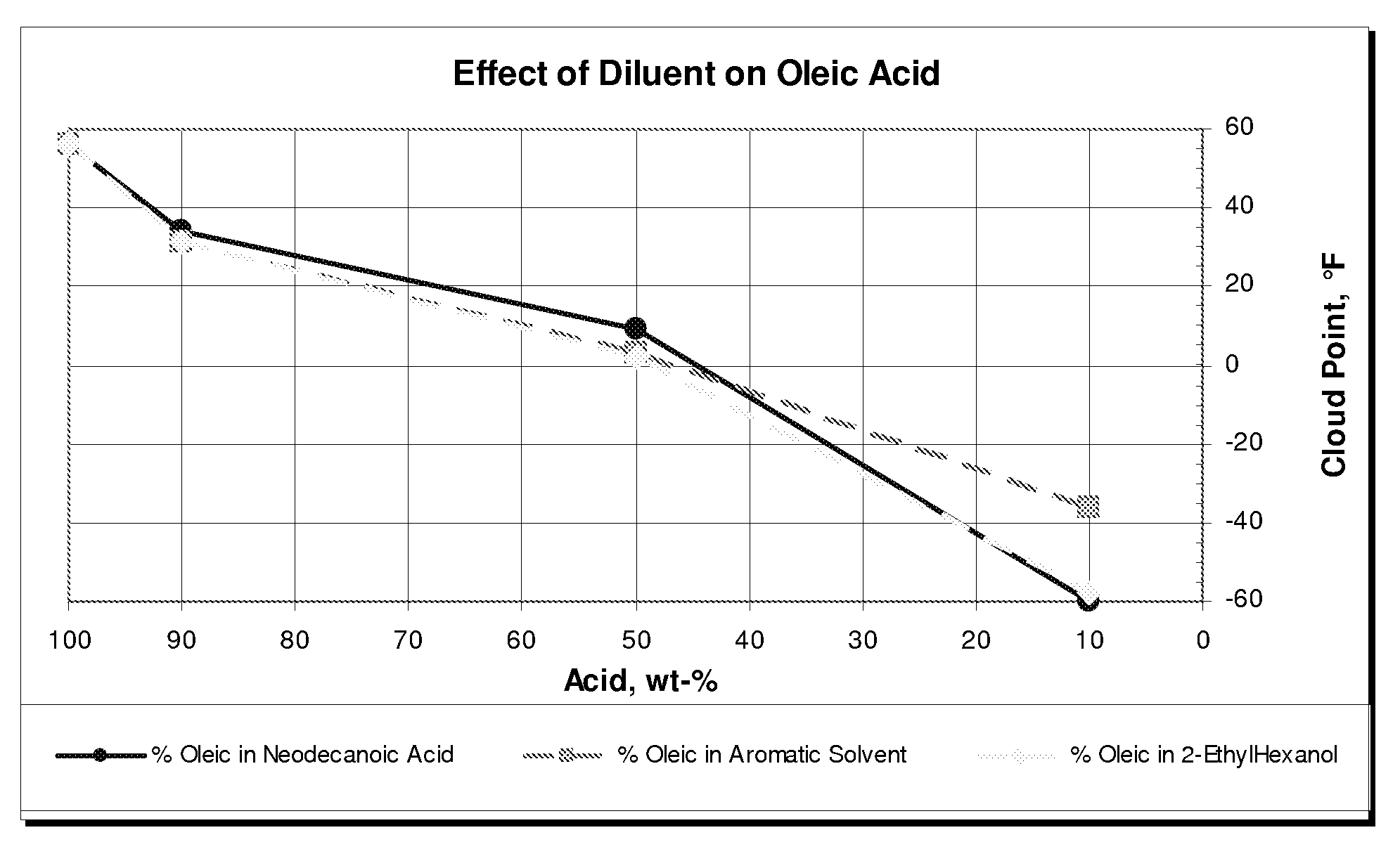

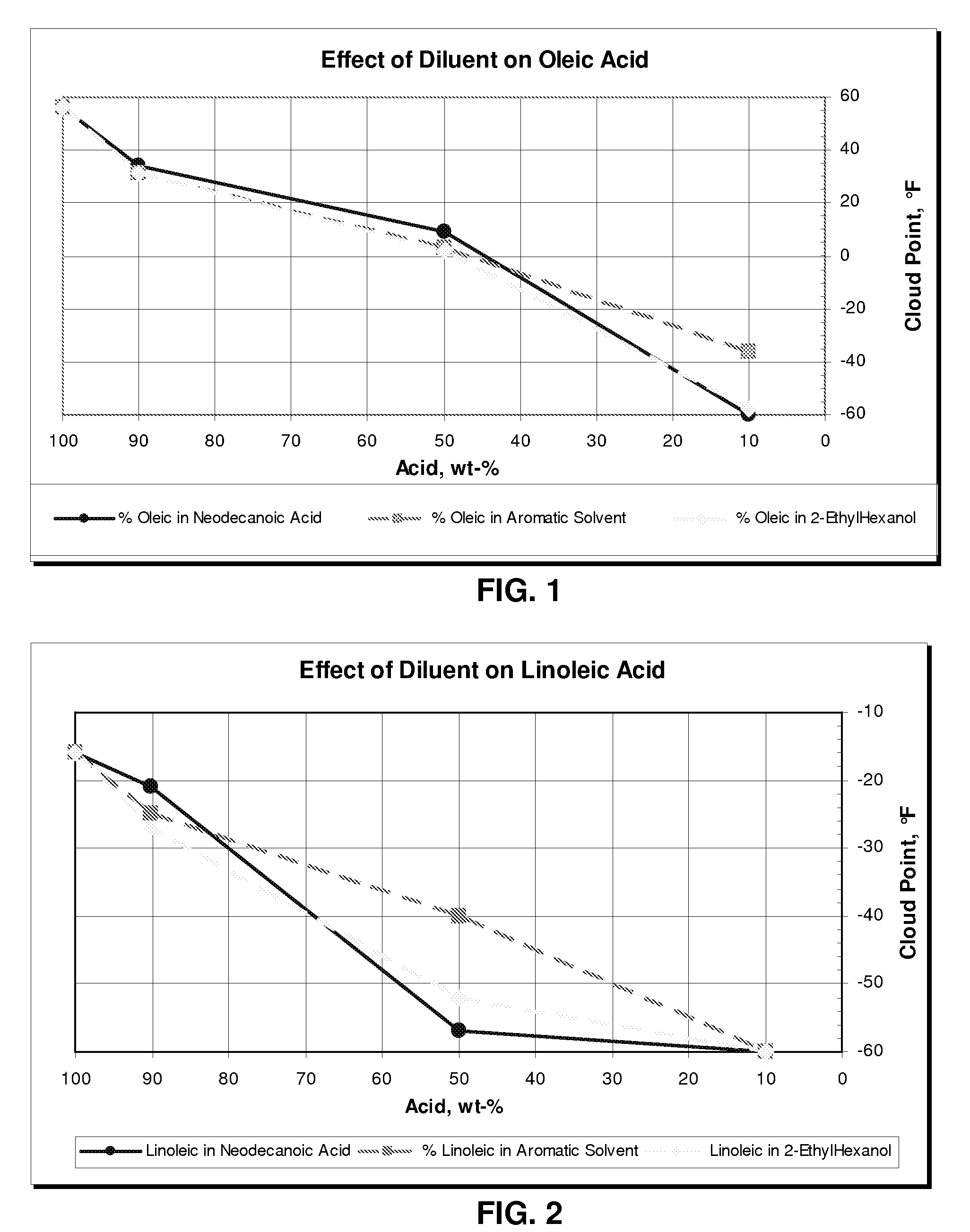

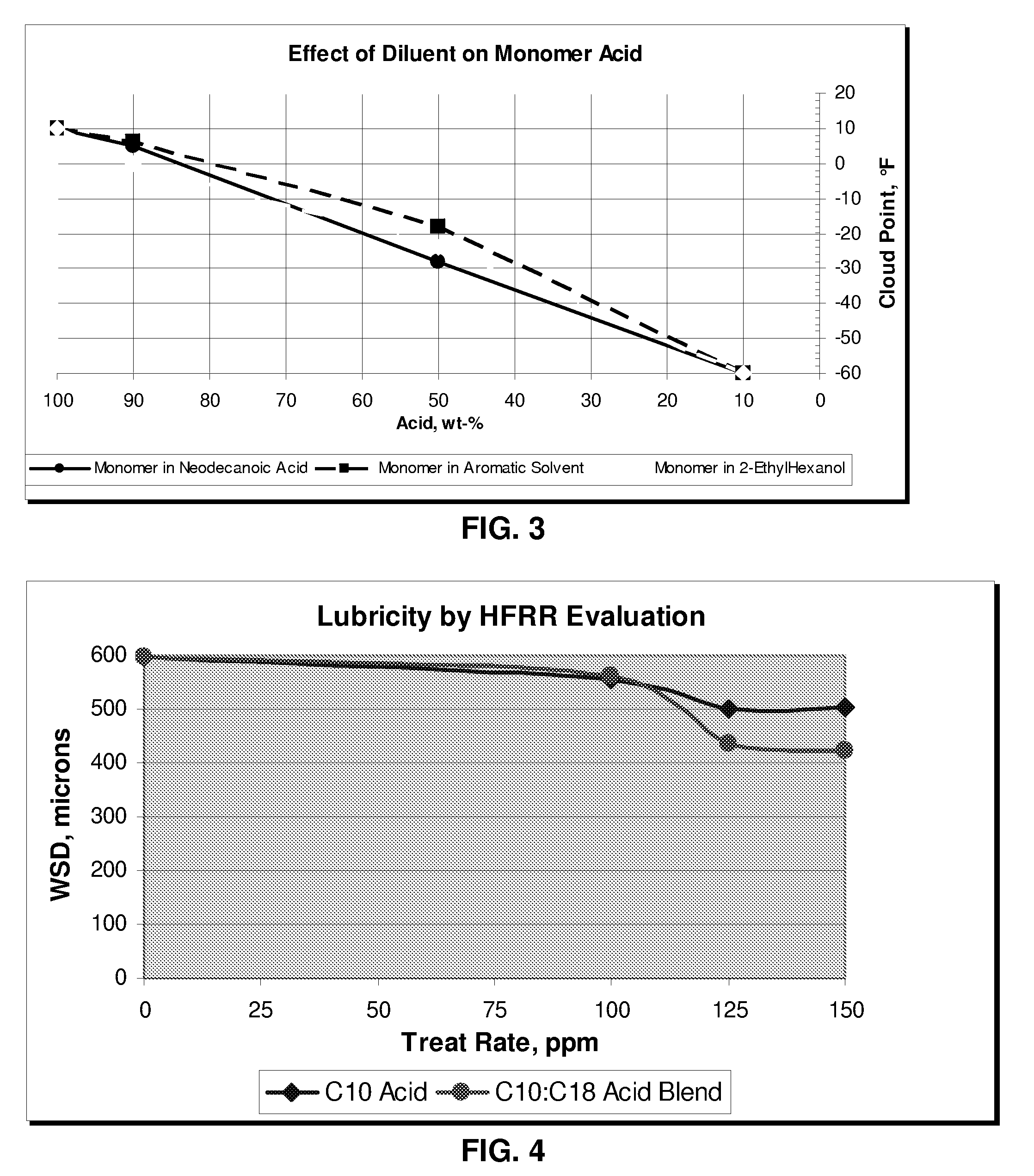

ActiveUS20090056203A1Improve lubricityImprove the lubrication effectLiquid carbonaceous fuelsFuel additivesChemistryNeodecanoic acid

Certain branched carboxylic acids may serve as improved lubricity additive compositions in distillate fuels, and in particular for cold weather applications. Suitable branched carboxylic acids may include, but are not necessarily limited to, isostearic acid, neodecanoic acid, isononanoic acid, neononanoic acid, neoundecanoic acid, isovaleric acid, pivalic acid, and the like and mixtures thereof. The branched carboxylic acids may be used alone or together with straight chain carboxylic acids, and optionally with an aromatic solvent.

Owner:BAKER HUGHES INC

Plant oil base medical instrument lubricating oil and preparation method thereof

The invention relates to a plant oil base medical instrument lubricating oil and a preparation method thereof. According to the mass ratio of (26-34) : (4-6) : (3-7) : (4-6) : (130-150) : (12-16), the lubricating oil comprises castor oil polyoxyethylene ether, a cellulose surface active agent, highalcohol, polyvinylpyrrolidone, deionized water and colza oil. The method comprises the following steps: firstly, uniformly emulsifying the castor oil polyoxyethylene ether, the cellulose kind of surface active agent, the highalcohol, the polyvinylpyrrolidone and the deionized water at the temperature of 45 DEG C, and forming emulsified liquid; secondly, adding colza oil into the emulsified liquid under the condition of stirring, then increasing the rotating speed, stirring and emulsifying for 20 min, and forming the plant oil base medical instrument lubricating oil. The vegetable oil and the surface active agent are adopted to prepare the water-soluble emulsified plant oil base medical instrument lubricating oil, a protecting film can be formed on the surface of the instrument, bubbles are less, the environment can be protected, and the lubricating oil has no influence on the sterilization effect.

Owner:SHAANXI UNIV OF SCI & TECH

Modified Leituoshi stone for drilling liquor and its production mehtod

The present invention uses calcium base leituoshi stone ore as raw material, and adopts semi-dry artificial modification process including the steps: breaking clay mineral, adding 1%-5% sodium salt, uniformly mixing them, water-spraying, shearing, pressing, piling and ageing for 7-10 days, drying so as to obtain modified leituoshi stone. Said invention is simple in production method, convenient for operation, less in dosage of modifying agent and low in energy consumption and cost. The phi-600 reading value of drilling fluid prepared with modified leituoshi stone is greater than or equal to 60, mud-making rate is greater than or equal to 18 cu.m / t, filter loss is less than or equal to 13.5 ml and dynamic shear force is less than or equal to 1.2XPVPa. It is superior to sodium base bentonite in all the properties, and is applicable for drilling in the fields of petroleum industry, natural gas engineering, geologic drilling engineering and building engineering, etc.

Owner:湖北名流累托石科技股份有限公司

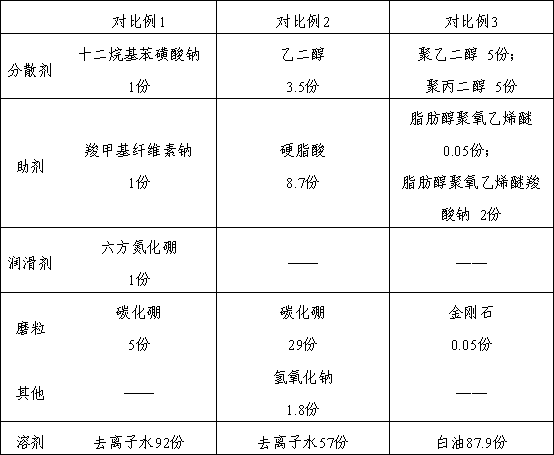

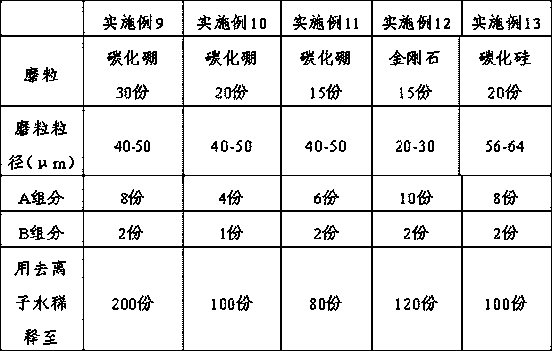

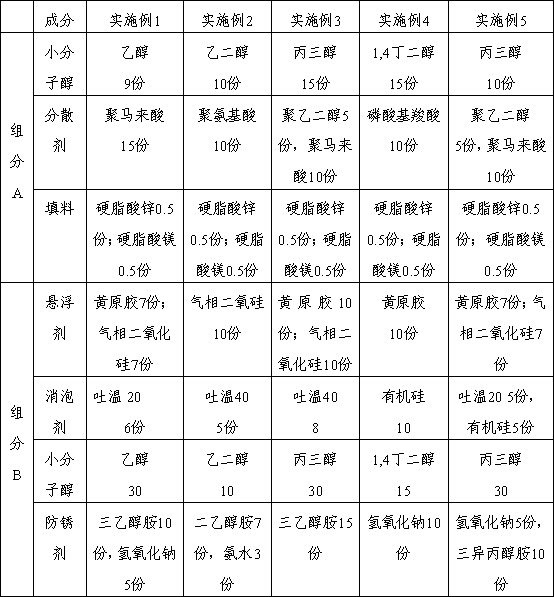

Grinding auxiliary and grinding liquid for coarse grinding of sapphire and preparation methods of grinding auxiliary and grinding liquid

The invention discloses a grinding auxiliary and a grinding liquid for coarse grinding of sapphire and preparation methods of the grinding auxiliary and the grinding liquid. The grinding auxiliary comprises a component A and a component B in a mass ratio of the component A to the component B being 3:1-5:1, wherein the component A is prepared from ingredients in parts by weight as follows: 5-10 parts of small molecular alcohol, 10-15 parts of an organic dispersing agent and 1-2 parts of filler; the component B is prepared from ingredients in parts by weight as follows: 10-20 parts of a suspending agent, 5-10 parts of a defoaming agent, 10-30 parts of the small molecular alcohol and 10-15 parts of an antirust agent. An appropriate quantity of the component A and an appropriate quantity of the component B are taken proportionally and are stirred and mixed uniformly at the normal temperature, a mixture is diluted with deionized water to 10-20 times by weight, abrasive particles are further added, and the grinding liquid for the coarse grinding of the sapphire is prepared. The grinding liquid prepared according to the technical scheme is good in dispersing stability and cannot layer after long-term storage; the lubricating performance is good, and large scratches caused when the grinding liquid is applied to the coarse grinding of the sapphire are reduced; the filler is added to the grinding liquid, so that the temperature of the grinding process is reduced, the surface of a substrate material of the sapphire is not prone to cracking, and the fragment rate is reduced.

Owner:BEIJING GRISH HITECH

High-strength environment-friendly wear-resistant coating for inner wall of internal combustion engine cylinder and preparation method of coating

InactiveCN105543762AImprove lubricitySmall dampingMolten spray coatingDimethyl formamideSodium silicate

The invention provides a high-strength environment-friendly wear-resistant coating for the inner wall of an internal combustion engine cylinder and a preparation method of the coating. The coating is characterized by being prepared from the following raw materials in parts by weight: 60-64 parts of 316 stainless steel powder, 5-5.2 parts of Mo powder, 3.5-3.7 parts of NiCr alloy powder, 20-22 parts of Ni60 powder, 5-10 parts of titanium dioxide, 4-9 parts of graphene, 1.3-1.5 parts of yttrium oxide, 2.3-2.5 parts of nano potassium-sodium niobate, 2.1-2.3 parts of phosphate carbonyl iron powder, 3.1-3.3 parts of lanthanum ferrite, 1.2-1.4 parts of molybdenum boride, 0.2-0.4 part of gallium chloride, 0.4-0.6 part of sodium silicate, 0.5-0.7 part of lithium titanate, 1.4-1.8 parts of TiH2, 9.2-9.6 parts of sodium molybdate powder, 4.3-4.7 parts of acetic anhydride, 85-89 parts of dimethyl formamide, 175-186 parts of concentrated hydrochloric acid and 9-13 parts of tetrabutylammonium bromide.

Owner:韩功篑

Formula and preparation method of human lubricant

InactiveCN104800894AMild in natureImprove lubricityOrganic active ingredientsSurgeryTremellaGlycerol

The invention belongs to the field of human lubricants, and relates to a formula and a preparation method of a human lubricant. The formula comprises the following components in parts by mass: 0.05-0.5 parts of tremella polysaccharide and 0.1-1.5 parts of preservative. The preparation method of the vaginal lubricant comprises the steps that polyacrylamide resin, glycerol, propylene glycol and 1,3-butanediol are sufficiently mixed; an aqueous medium is uniformly mixed; the preservative is added; and the human lubricant is obtained. Compounded agents used by the natural antibacterial lubricant are good in lubrication, mild in property, colorless and odorless, have no adverse effect on a human, have antibacterial and anti-inflammatory action, can be dissolved in water, are convenient to clean, and cannot remain on the surface of human skin, so that the lubricant is safe and effective.

Owner:海洁(重庆)卫生用品股份有限公司

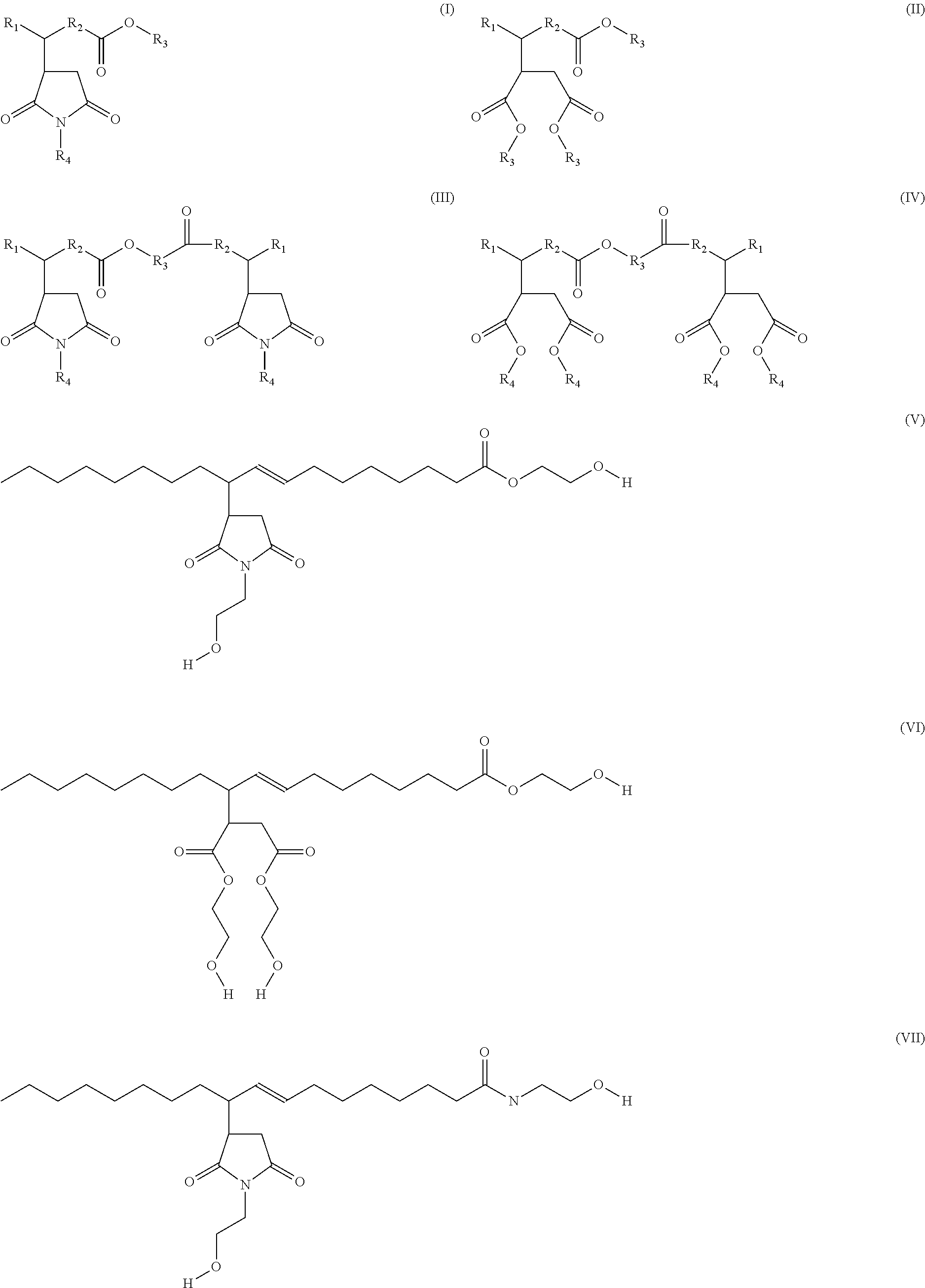

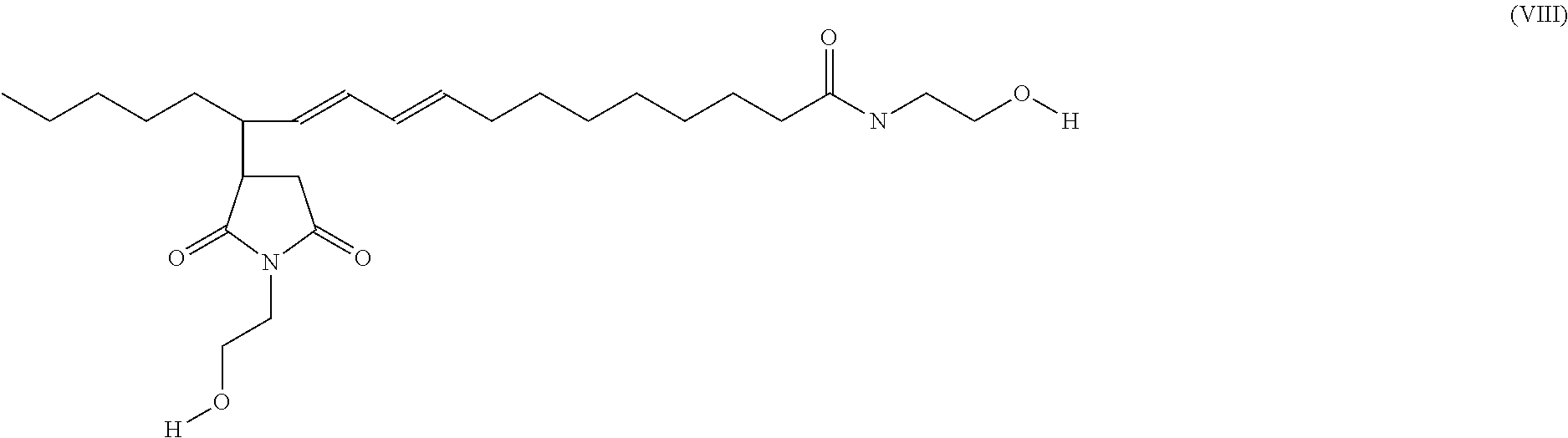

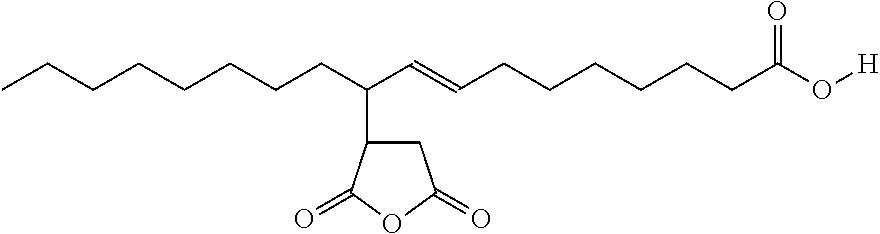

Functionalized Maleated Fatty Acids as Non Acidic Fluid Additives

InactiveUS20120053101A1Improve lubricityImprove the lubrication effectLiquid carbonaceous fuelsAdditivesAlkanolamineOxide

Maleated fatty acids that are functionalized with materials such as polyols, alkanolamines and / or alkylene oxides have been discovered to improve the properties of various fluids. In a non-limiting example, functionalized maleated fatty acids having acid numbers less than 10 may improve the lubricity of fuels and lubricants, such as hydrocarbon fuels and lubricants, when added thereto.

Owner:BAKER HUGHES INC

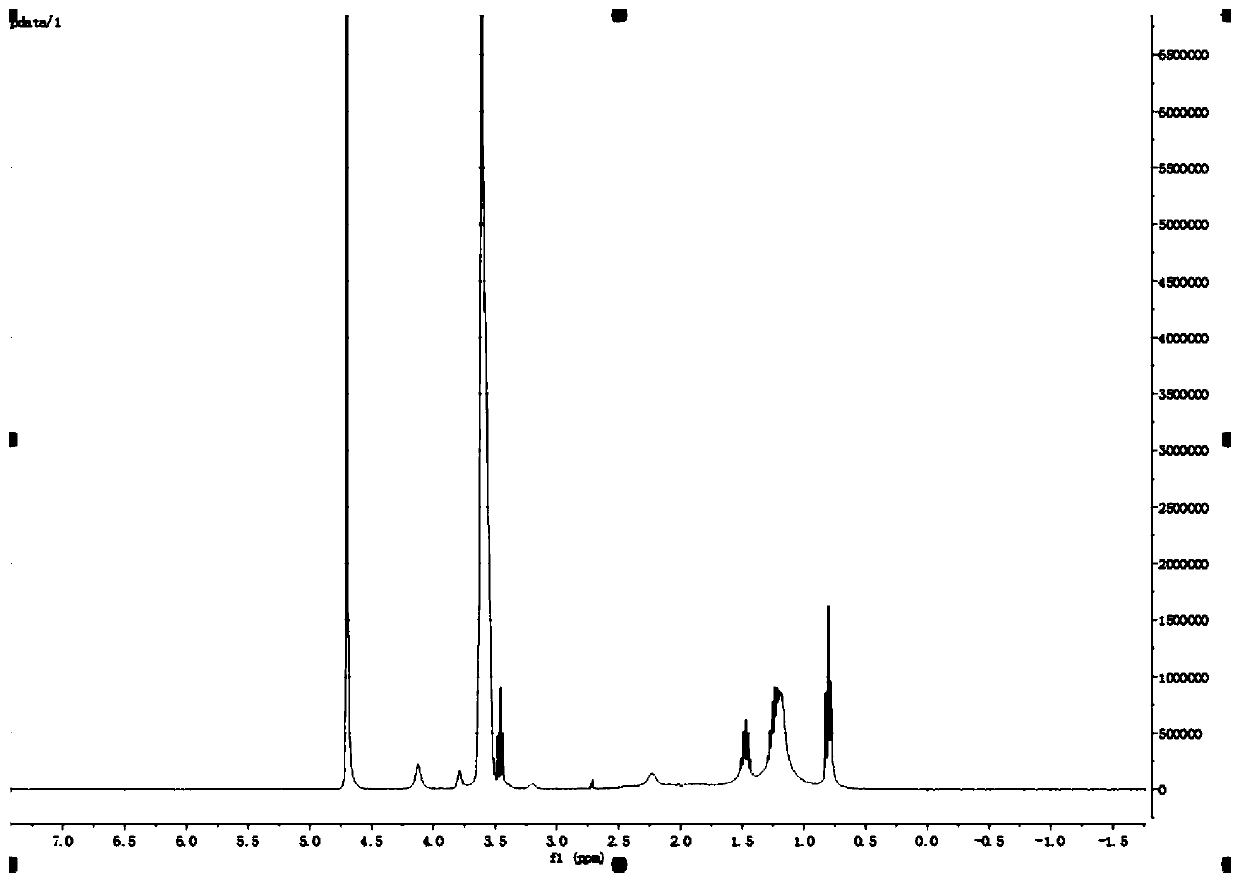

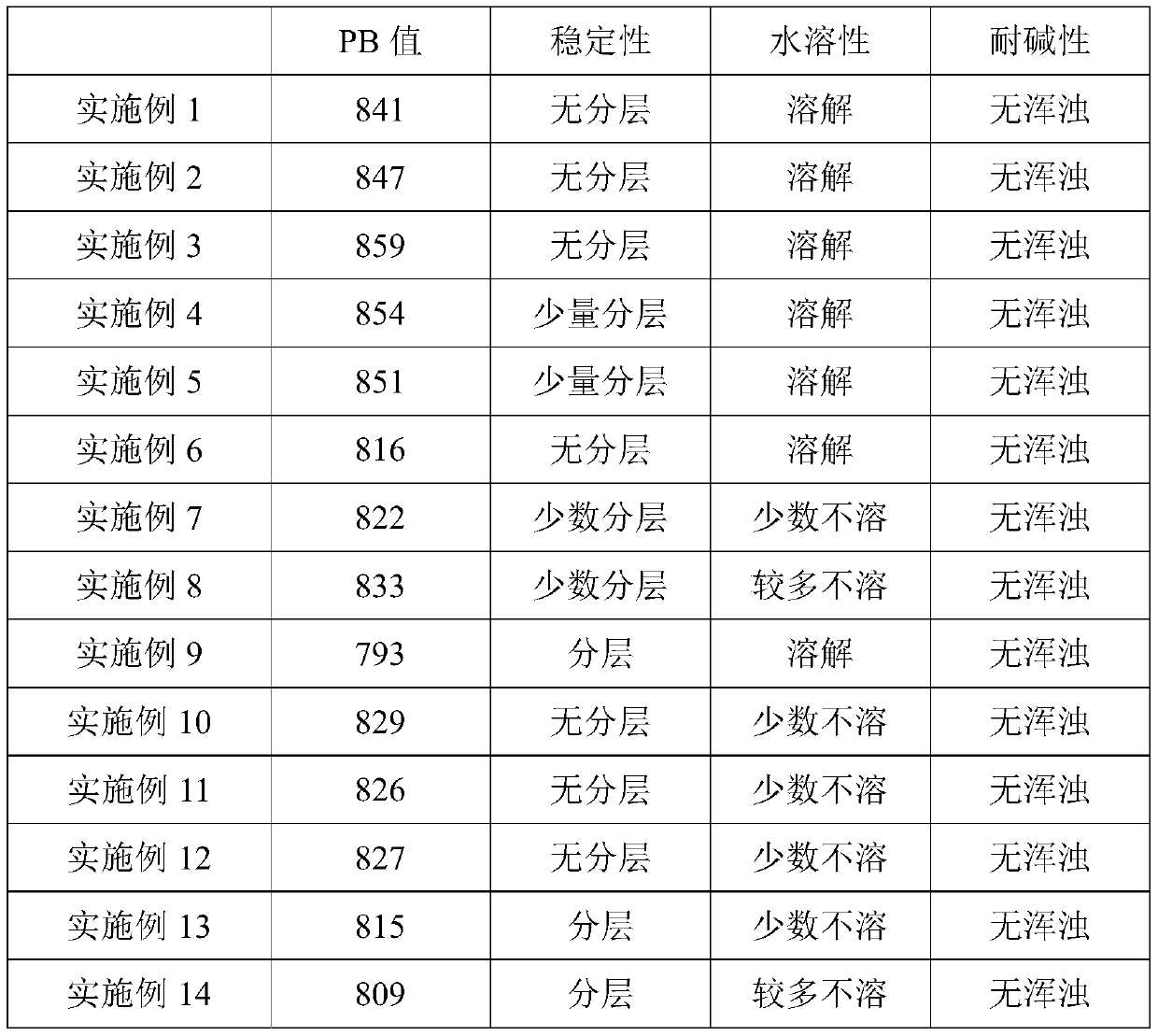

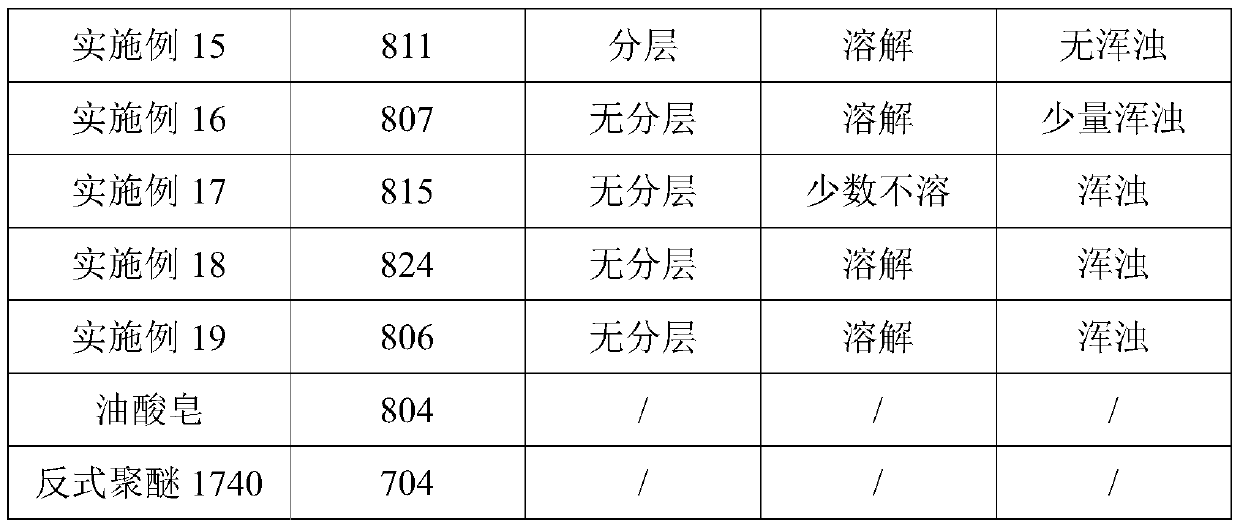

Novel polyether ester nonionic surfactant and preparation method thereof

ActiveCN111138655ANo "leaching out" problemDoes not cause "rejection" phenomenonTransportation and packagingMixingPolymer sciencePtru catalyst

The invention relates to the technical field of lubricants, particularly to a novel polyether ester nonionic surfactant and a preparation method thereof. The preparation method at least comprises thefollowing steps: mixing polyether and fatty acid, adding a catalyst, and carrying out a reduced pressure reaction to obtain the novel polyether ester nonionic surfactant. According to the invention, the novel polyether ester nonionic surfactant is extremely good in water solubility, has good intersolubility with other additives, cannot cause the direct rejection phenomenon of the additive, has good biodegradability, is non-toxic, belongs to an environment-friendly product, has good stability and good alkali resistance, does not have the problem of precipitation of a polyether lubricant in a cutting fluid, has the lubricating property far superior to that of the traditional polyether lubricant, and is a product with the most outstanding lubricating property in a water-soluble cutting fluidadditive at present.

Owner:上海创化科技服务有限公司

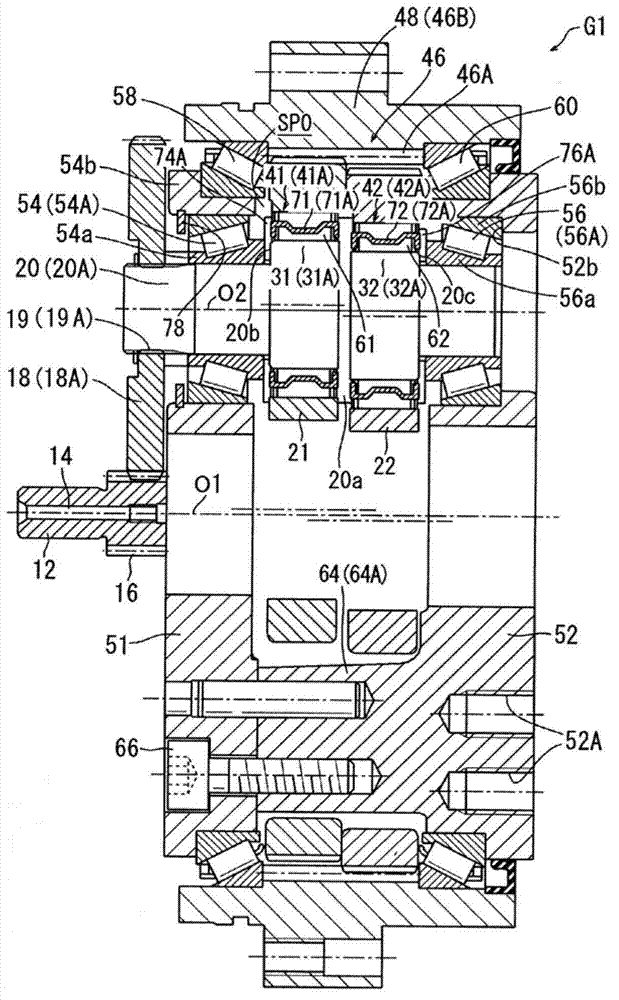

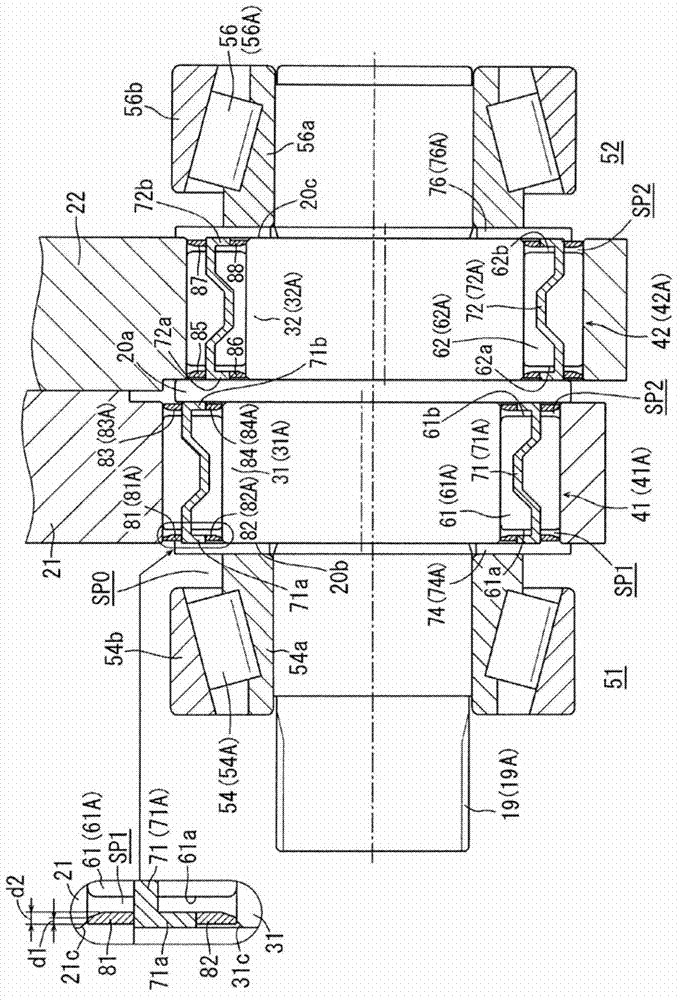

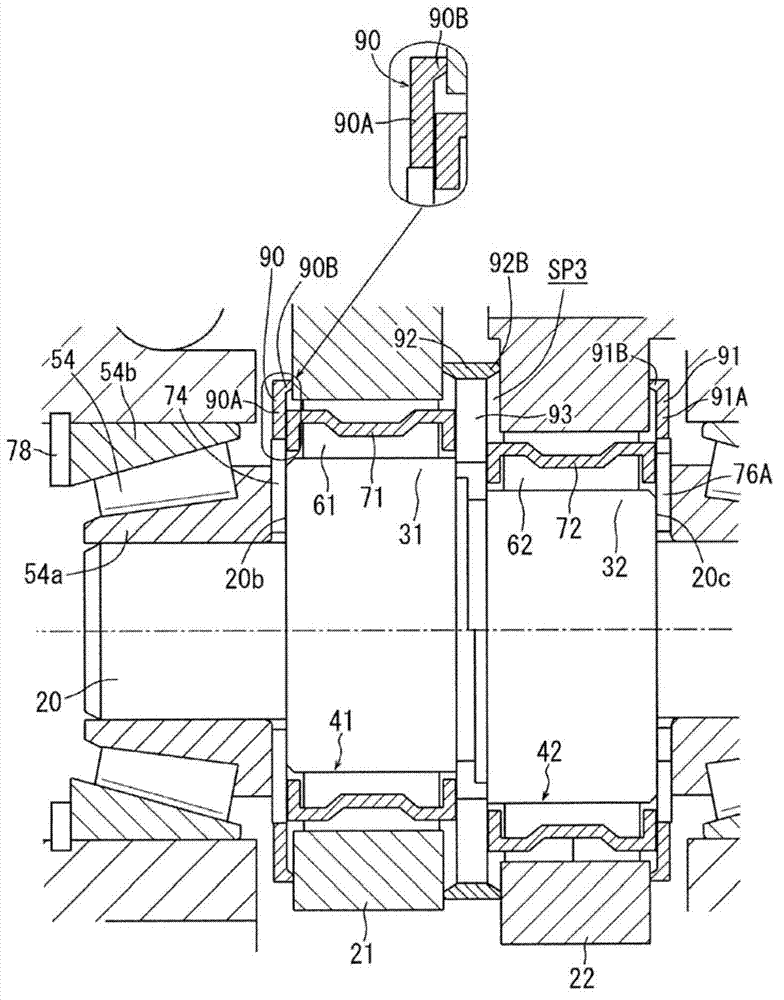

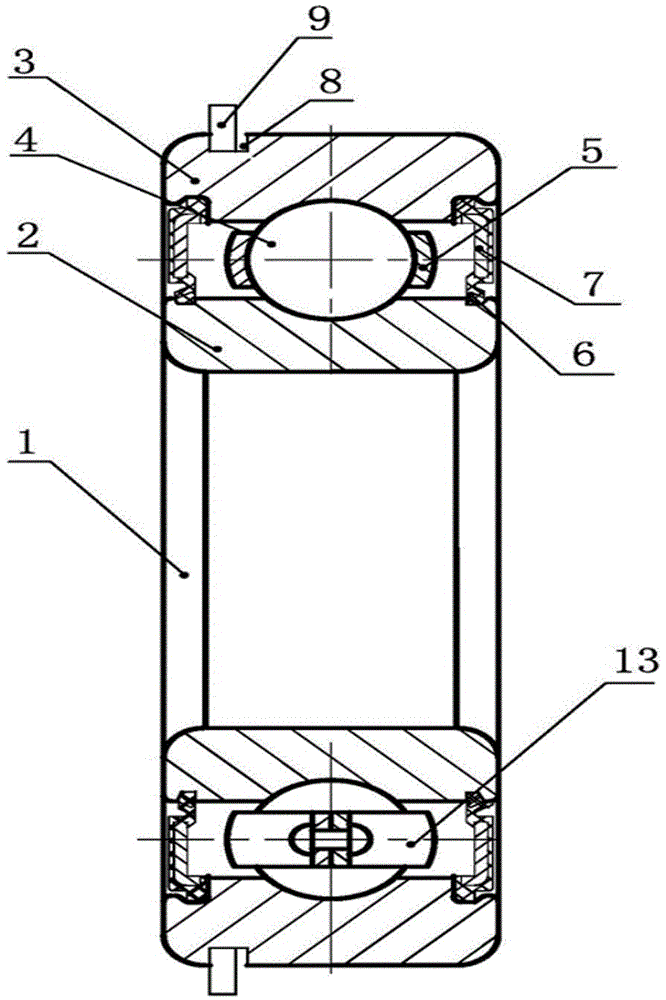

Eccentric swing type speed reduction device

ActiveCN102996721AImprove lubricityGuaranteed lubrication effectGear lubrication/coolingToothed gearingsLubricantSpeed reduction

The invention provides an eccentric swing type speed reduction device, which can better maintain lubricity of an eccentric body bearing without increase of cost. In the speed reduction device, first and second rollers (61, 62) form first and second eccentric body bearings (41, 42) disposed between first and second eccentric bodies (31, 32), and first and second external gears (21, 22), furthermore, spaces between the first and second eccentric bodies (31, 32), and first and second external gears (21, 22) are set to be first and second sealing spaces (SP1, SP2), lubricant is sealed in the sealing spaces (SP1, SP2), and the first and second rollers (61, 62) are disposed.

Owner:SUMITOMO HEAVY IND LTD

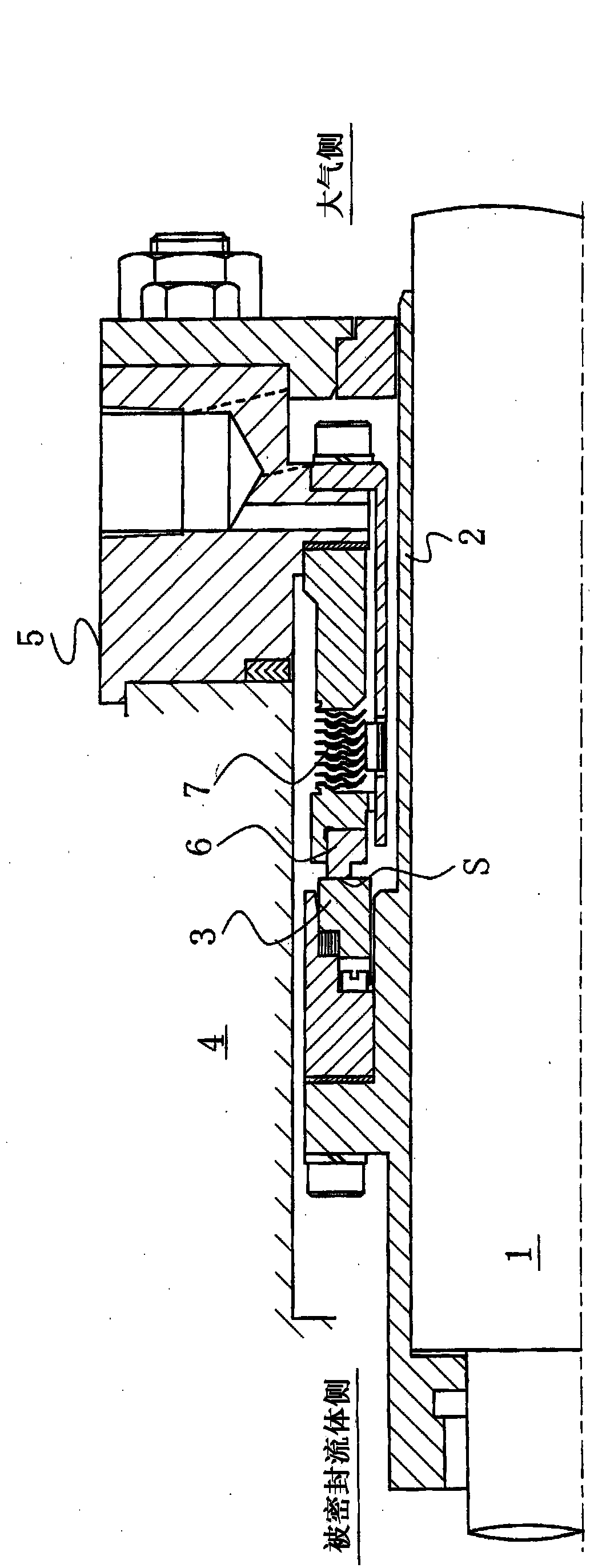

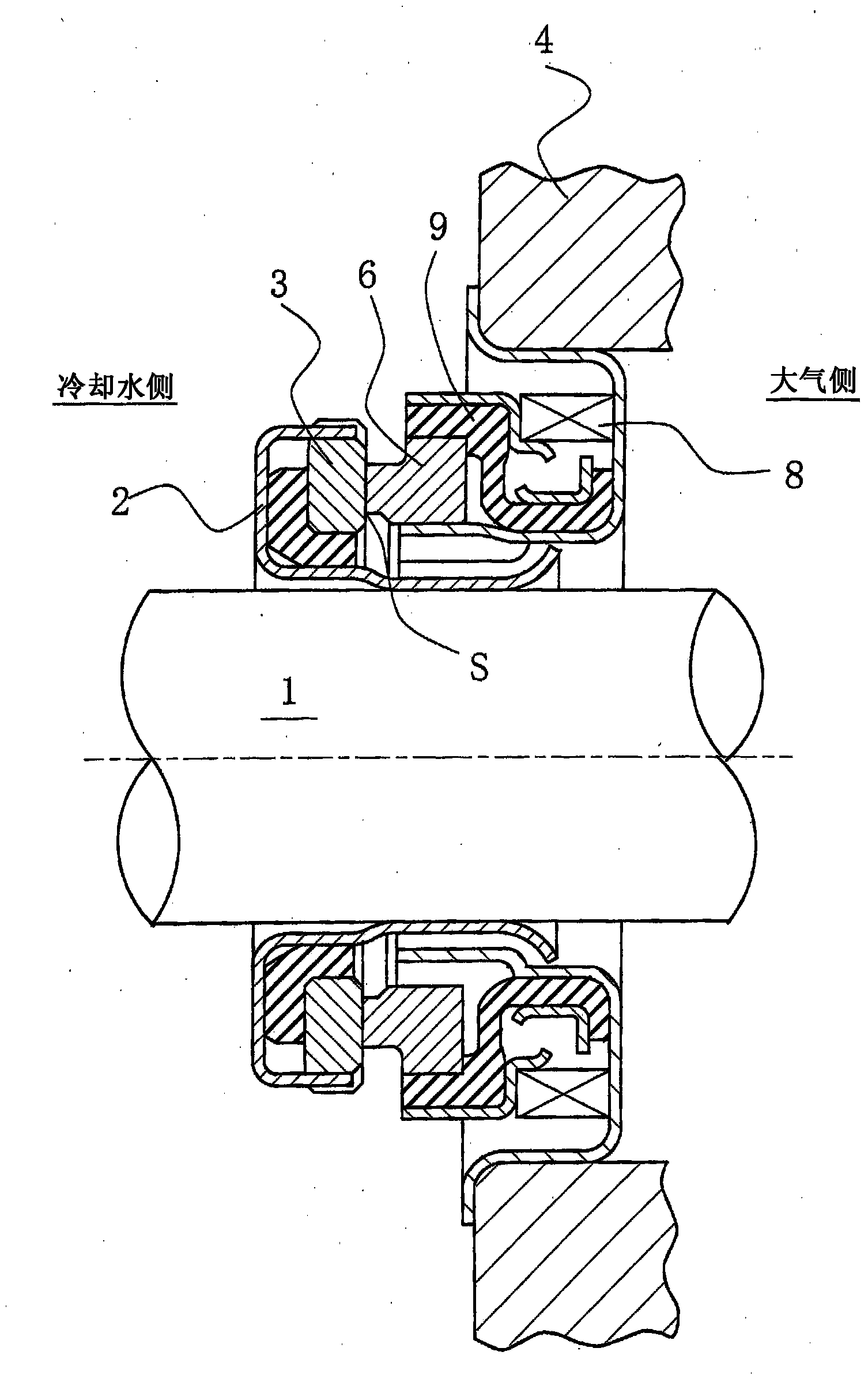

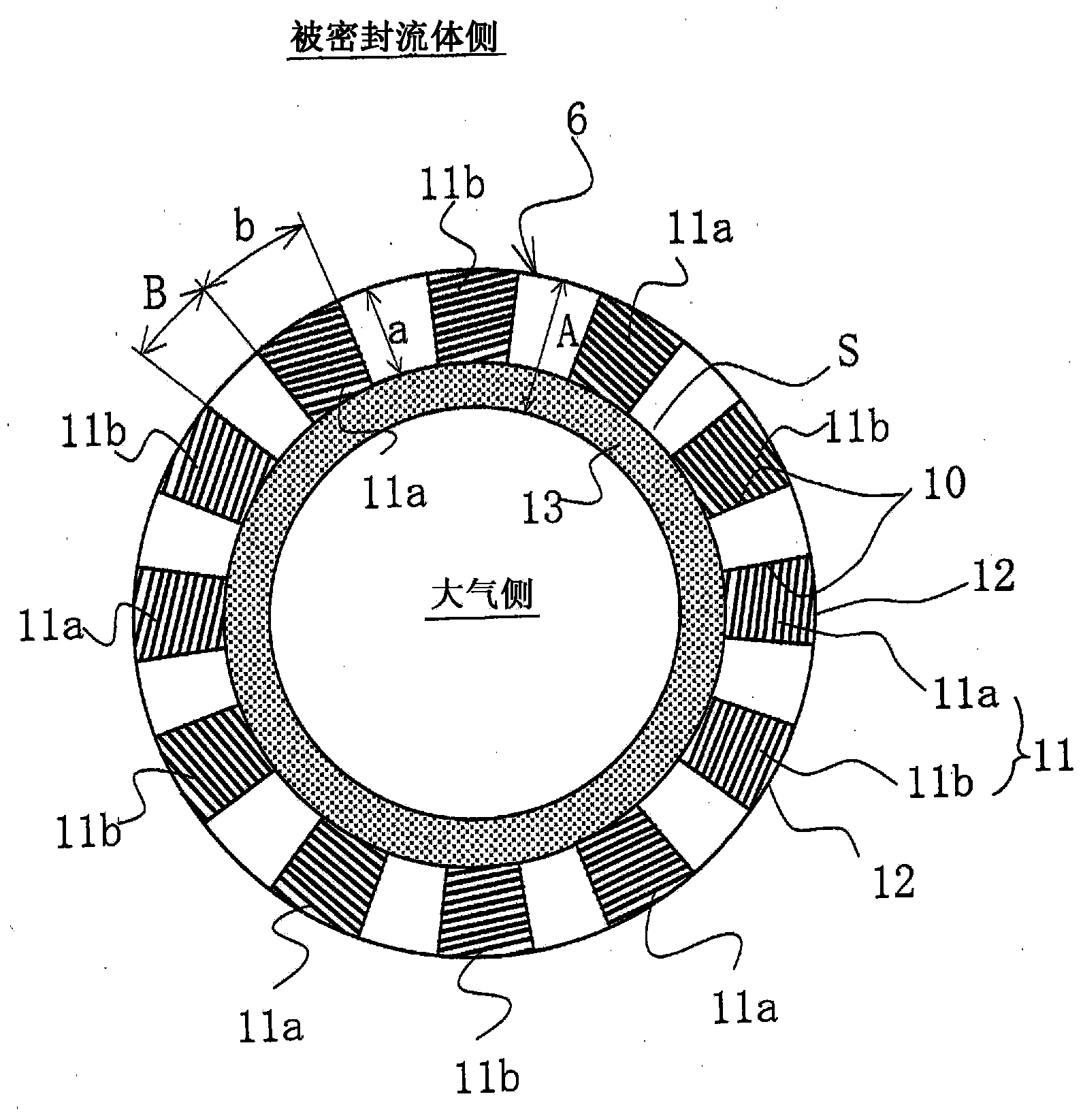

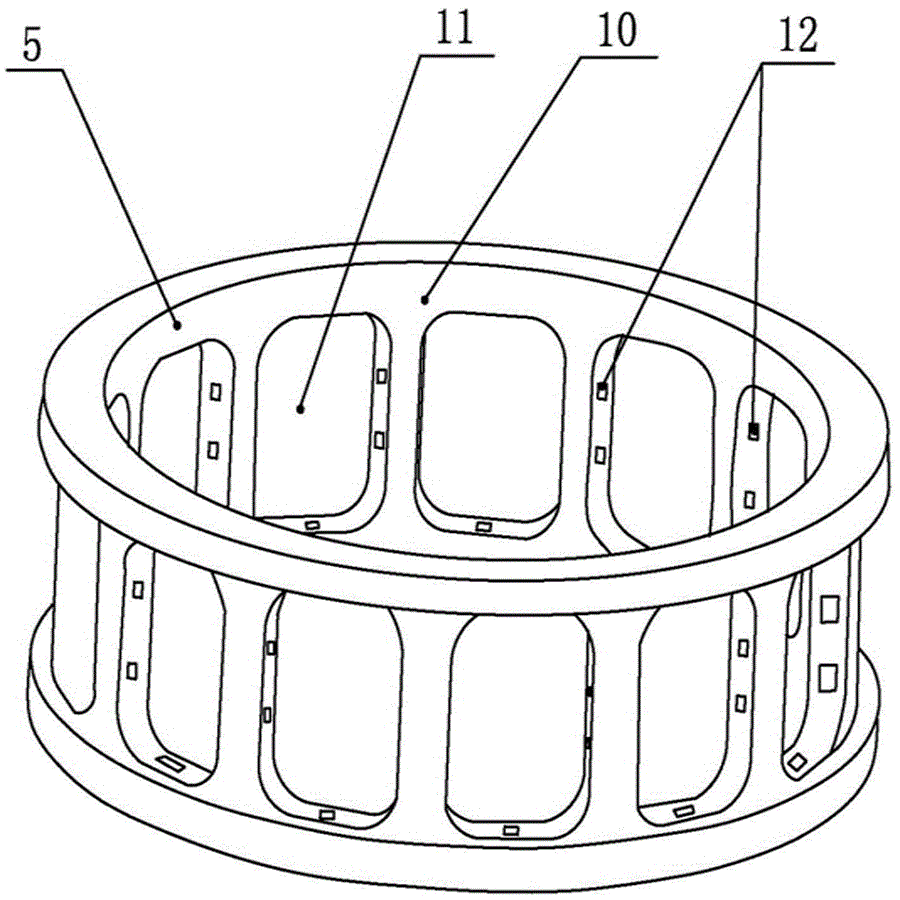

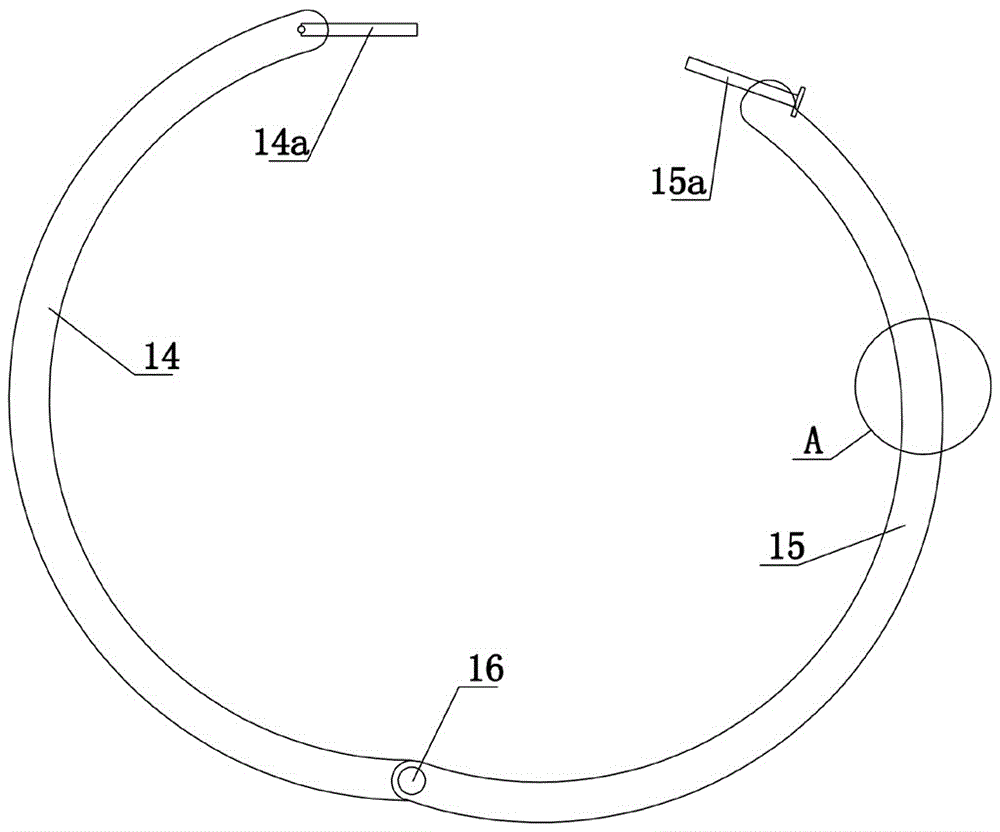

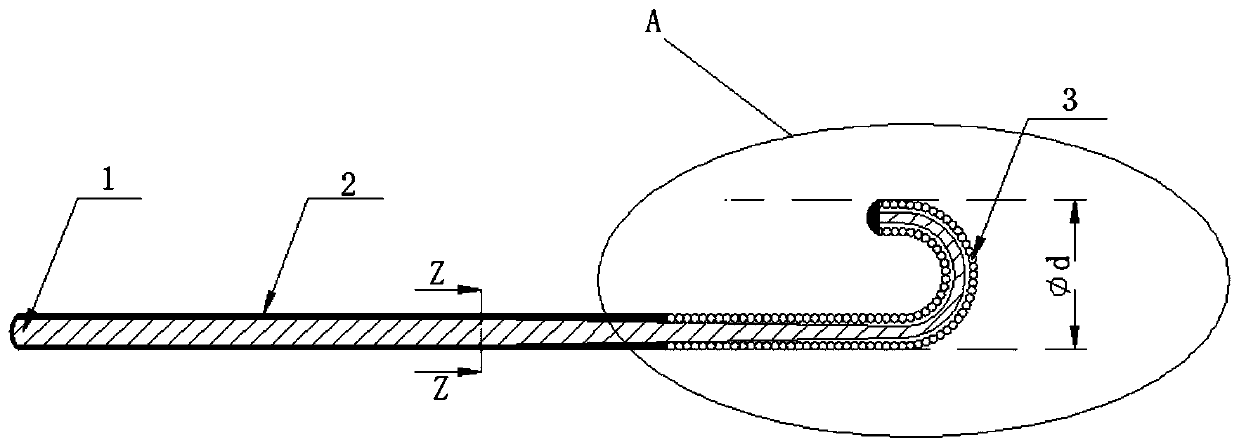

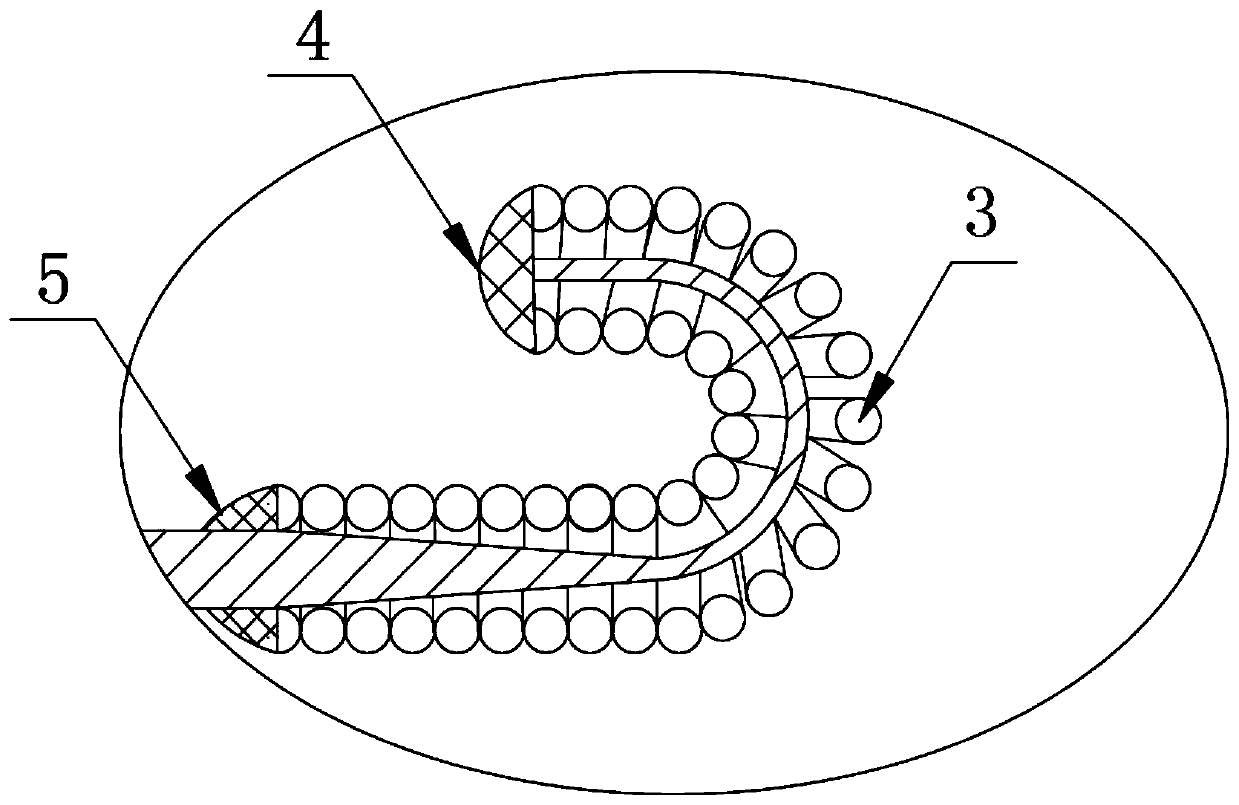

Sliding component

To provide a sliding component that does not leak when standing still, operates as well as prevents leakage by using fluid lubrication during rotation including the initial period of rotation, and can achieve both sealing and lubrication. A sliding component is characterized by: a plurality of housing blocks for fluid to be sealed, separated in the circumferential direction, being formed in either a fixed ring or a sliding surface of a rotating ring so as to communicate with a housing space for fluid to be sealed; a pumping unit that causes a pumping action by relative rotational sliding between the fixed ring and the rotating ring being formed in the floor section of the plurality of housing blocks for fluid to be sealed; the pumping unit formed in the floor section of the plurality of housing blocks for fluid to be sealed comprising a suction pumping unit that operates in the direction that the fluid to be sealed is sucked in and a discharge pumping unit that operates in the direction that the fluid to be sealed is discharged; and a seal dam unit, on the opposite side to the fluid to be sealed side of the sliding surface having the housing blocks for fluid to be sealed formed therein, being formed from a sliding material having excellent lubrication properties.

Owner:EAGLE INDS

Solvent-free silica nanofluid and application thereof

ActiveCN108085089AExcellent anti-friction and anti-wear propertiesImprove lubricityAdditivesBoundary lubricationSolvent

The invention discloses solvent-free silica nanofluid. The solvent-free silica nanofluid is characterized in that inorganic silica nanoparticles are modified by covalent bonds through a phosphonic acid functional group carrying surface modifying agent; amine-terminated block low polymer is grafted to the modified silica surface through an ionic bond; the grafted shell structure is capable of obviously inhibiting the agglomeration of nanoparticles, and thus a novel functional nano material with liquidlike fluid behavior and being stable in a long term can be obtained. The invention further discloses application of such fluid. The silica nanofluid can be used as a lubricating agent and a basic oil additive and is outstanding in friction reduction and abrasion resistance; the introduced phosphonic acid functional group is easily adsorbed to the surface of a friction substrate through electrostatic, thus an organic-inorganic hybrid structural double electrical layer can be formed, and thelubricating capacity of an adsorbing film is improved; meanwhile, the silica nanoparticles are accumulated on the interface, so that the bearing capacity of a frictional chemical reaction film is improved, and the boundary lubricating performance of a friction pair is improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Smooth dough sheet and method for producing the same

InactiveCN101371688AImprove lubricityIncrease moisture contentFood preparationAqueous solutionMechanical engineering

The invention discloses a slip dough cover and a manufacturing method thereof; the slip dough cover comprises elastic slip dough cover bodies and smooth outer layers, and the smooth outer layers are attached on the surfaces of the elastic slip dough cover bodies. The method for manufacturing the slip dough cover comprises: a. emulsifier is melted; b. aqueous solution is formed; c. flour and wheatgluten are mixed to make dough; d. the first rolling is carried out; e. the second rolling is carried out; f. the first rolling to the fifth rolling can be carried out according to the needs, finally, the smooth outer layers can be formed by spreading or sticking smooth powder on the surfaces of the elastic slip dough cover bodies; g. the elastic slip dough cover bodies are cut for moulding. The technique is scientific and reasonable, and the products not only have good smooth mouthfeel, but also have excellent chewiness as well as the advantages of convenience, nutrition, etc.

Owner:童伟雄

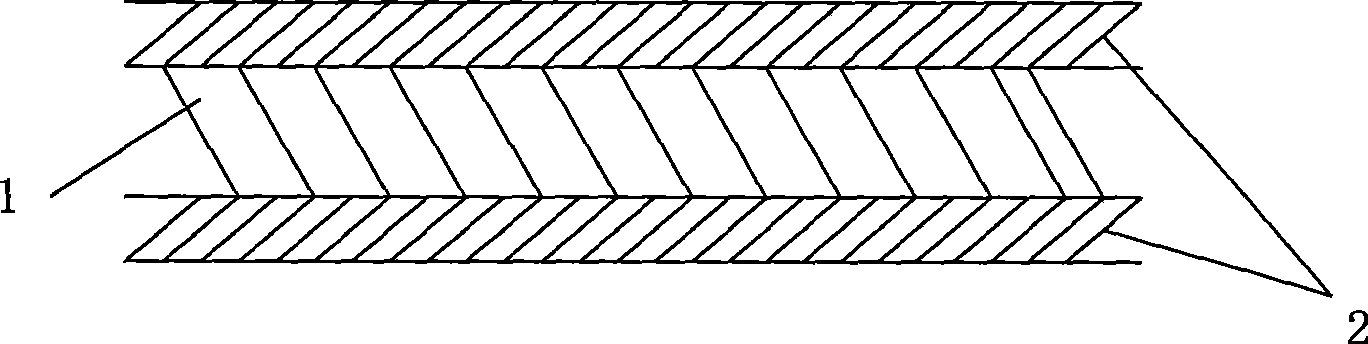

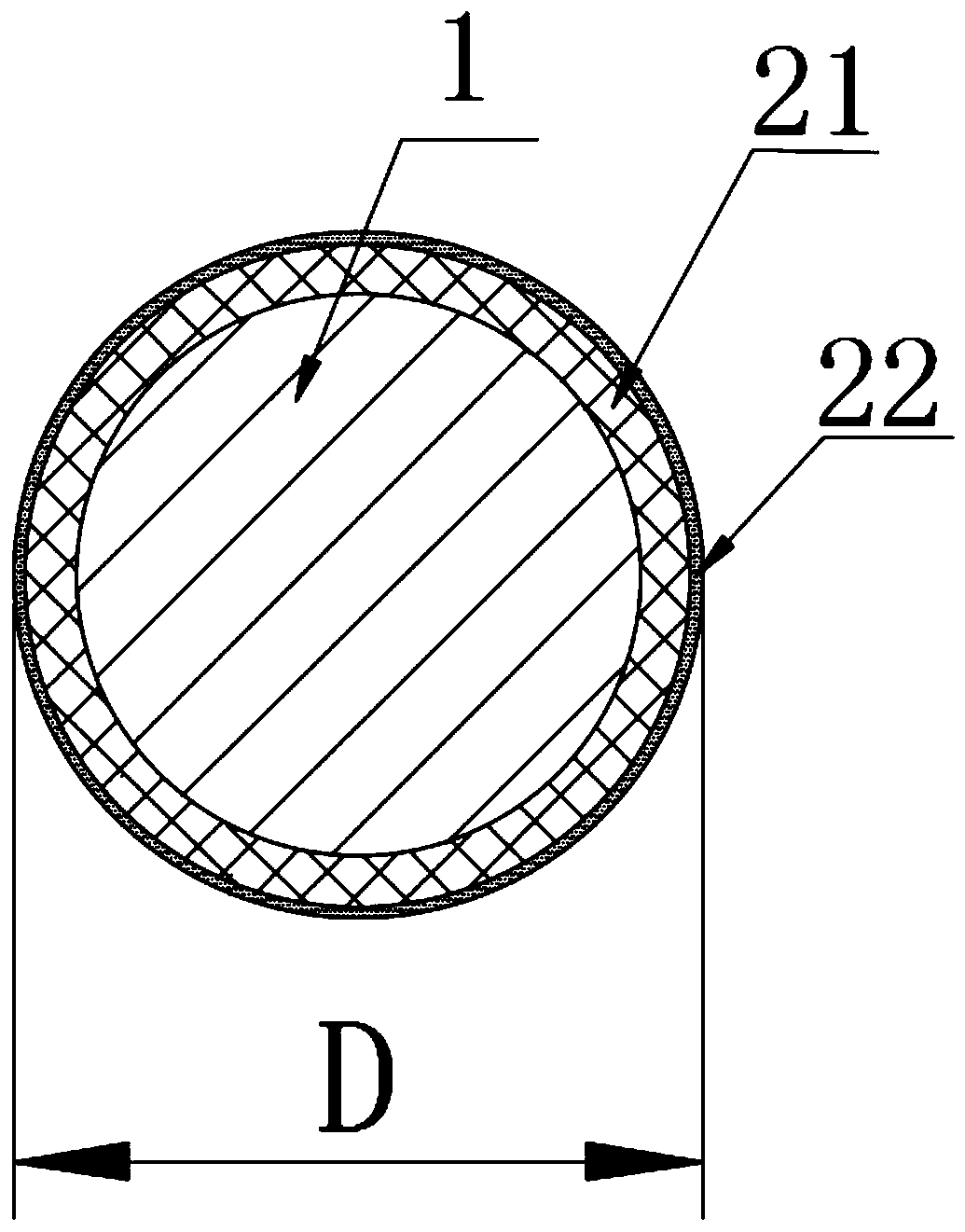

Single-row ball bearing with self-locking stop ring

InactiveCN106089990APrevent deviationImprove lubricityBall bearingsBearing componentsHollow cylinderSelf locking

The invention discloses a single-row ball bearing with a self-locking stop ring, and belongs to the field of bearings. The single-row ball bearing comprises a bearing body; the bearing body comprises an inner ring, an outer ring, a steel ball, a holding frame, a sealing ring and a framework; the outer wall of the outer ring is inwards sunken to form a stop slot; the stop ring is arranged in the stop slot; the stop ring is an open elastic part; the stop ring comprises a left half ring and a right half ring, which are in the shape of semi-circular arc; one end of the left half ring is hinged with the right half ring; the other end of the left half ring is hinged with a positioning post; one end of the right half ring is hinged with the left half ring; a bolt is arrange at the other end of the right half ring in a penetrating mode; the positioning post is a hollow cylinder; and inner threads are arranged on the inner wall of the cylinder. The inner wall of the stop ring can be always fitted to the outer wall of the bearing by regulating radius of the stop ring of the bearing, so that bearings with different radiuses can be used; and moreover, friction force between the stop ring and the bearing is reduced, and the service life of the stop ring is prolonged.

Owner:新昌县羽林街道君博机械厂

Beef fat hot pot condiment

PendingCN112042913AFatty fragranceGood lubricity and stabilityFood ingredient as thickening agentYeast food ingredientsChemistryAllium

The invention discloses a beef fat hot pot condiment, and belongs to the field of food. The beef fat hotpot condiment comprises 450-500 parts of edible beef fat, 80-100 parts of shortening, 70-90 parts of glutinous rice cake capsicum annuum L., 10-20 parts of dry capsicum annuum L., 10-20 parts of piperis Dahongpao, 10-20 parts of thick broad-bean sauces, 1-10 parts of fermented soya beans, 10-20parts of rhizoma zingiberis, 5-10 parts of allium cepa L., 5-10 parts of Allium. fistulosum L. var. gigantum Makino, 1-10 parts of foeniculi fructus, 1-5 parts of rock candies, 10-15 parts of chickenpowders, 1-5 parts of yeast extracts, 0.5-3 parts of ethyl maltol and 1-10 parts of liquor and spirits. The beef fat hot pot condiment is clear and bright, is free from impurities and has a thick fatfragrance and good oil wettability and stability, the taste of the beef fat hot pot condiment is natural and is emitted for a long time, the beef fat hot pot condiment is smooth to eat, has a good taste, is not greasy, is free from soup turbidity, is health to eat and is environmentally-friendly, and in addition, the beef fat hot pot condiment has few additives and small ingredients and has a lowcost.

Owner:糜富林

Contrast guide wire and preparation method thereof

InactiveCN110681031AEasy to useImprove lubricityWire articlesGuide wiresArterial bifurcationBiomedical engineering

The invention discloses a contrast guide wire and a preparation method thereof. The contrast guide wire includes an inner core wire, an outer distal spring coil sheath, and an outer proximal polymer sheath of which the surface is provided with a hydrophilic coating. The contrast guide wire provided by the invention is preformed as a J-shaped bent portion, so that the contrast guide wire is difficult to enter arterial bifurcations and prevents damage to inner walls of blood vessels. The J-shaped bent portion can be straightened when the spring coil sheath is squeezed, thereby facilitating the contrast guide wire to enter into and fit with instruments. The spring sheath at head end is designed to improve tactile feedback of an operator. Meanwhile, the hydrophilic coating on the surface of the contrast guide wire improves lubricity and allows the contrast guide wire to easily reach a target site of blood vessels.

Owner:APT MEDICAL HUNAN INC +1

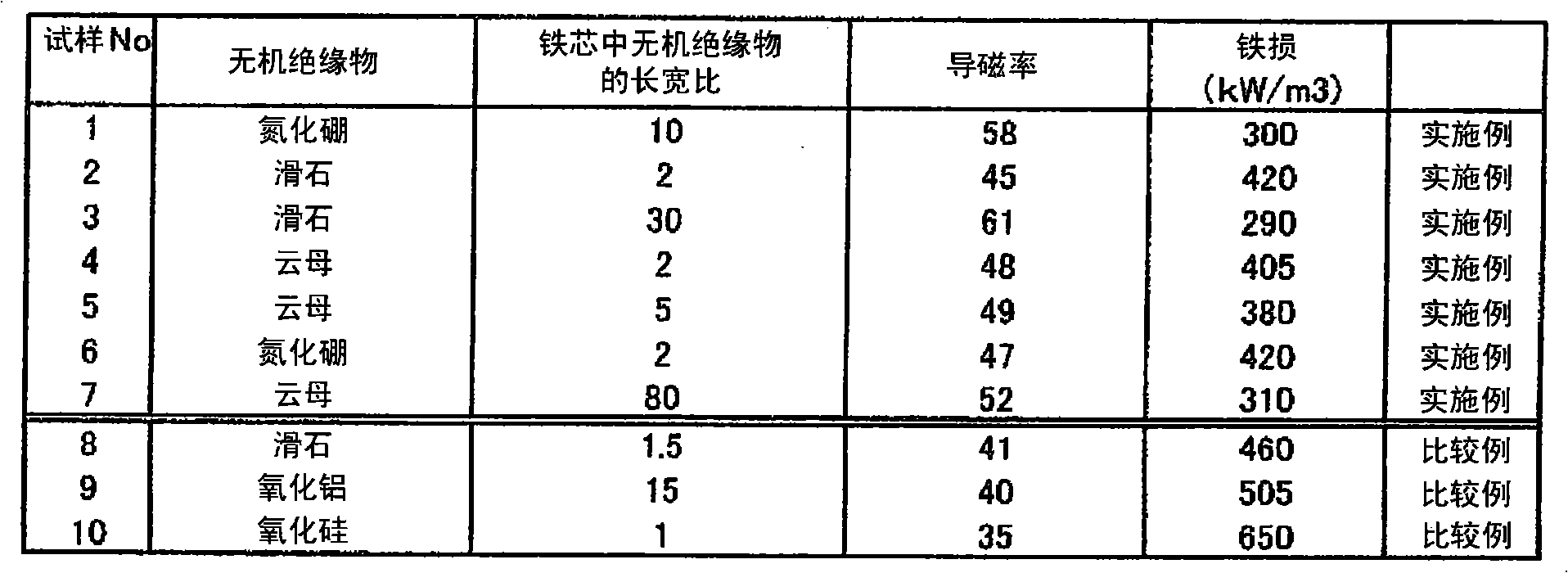

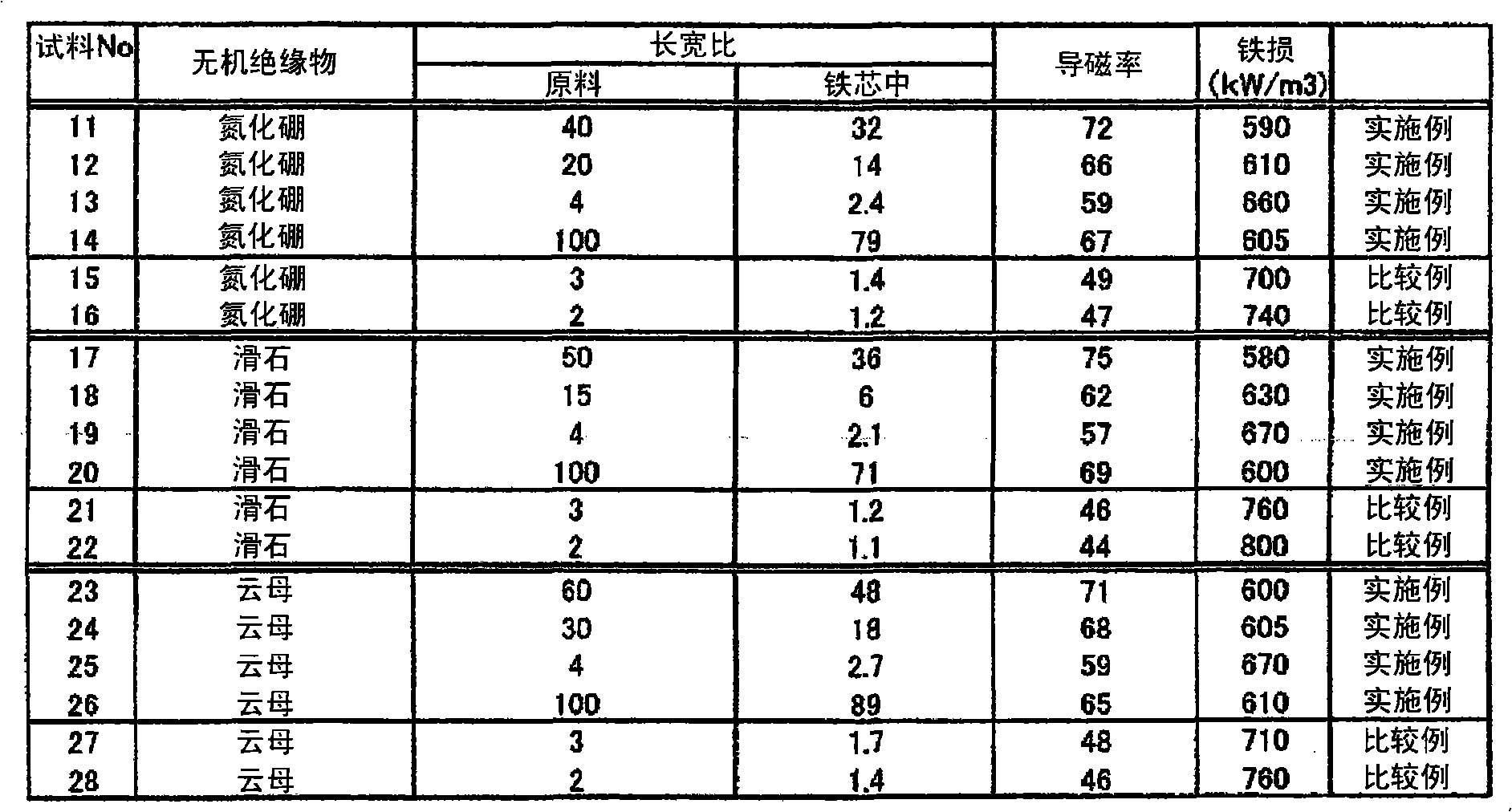

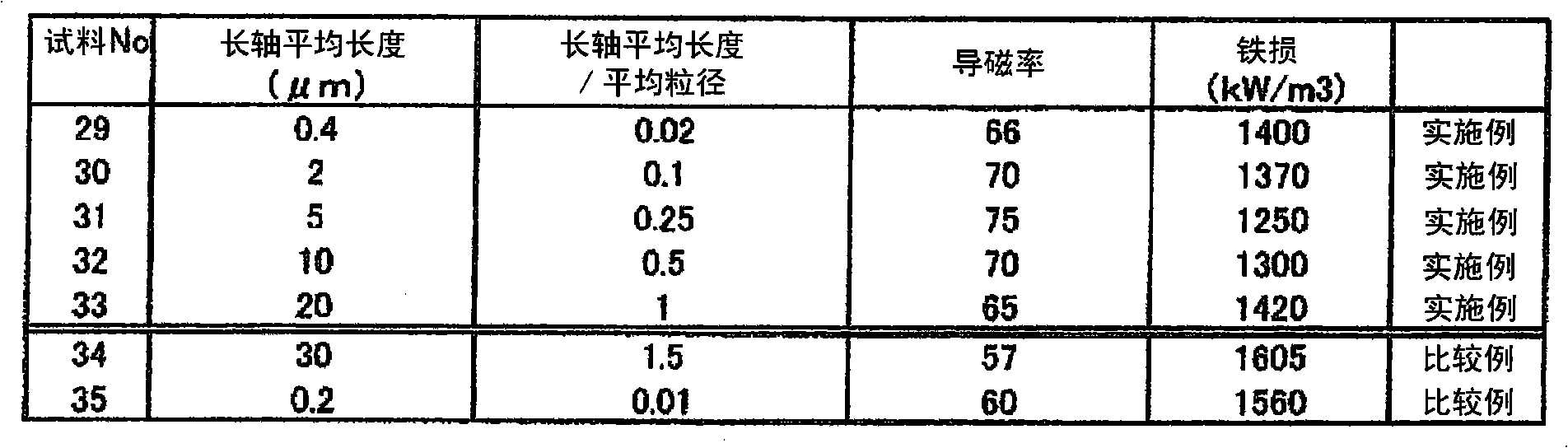

Composite magnetic material and process for producing the composite magnetic material

ActiveCN102171776AExcellent magnetic propertiesImprove lubricityInorganic material magnetismInductances/transformers/magnets manufactureTransformerMiniaturization

Disclosed is a composite magnetic material having excellent soft magnetic characteristics that can realize a reduction in size of electromagnetic components such as inductors, choke coils, and transformers and is usable in a high frequency range. The composite magnetic material is characterized in that the composite magnetic material comprises substantially spherical metallic magnetic powders, a flat inorganic insulating material interposed among the metallic magnetic powders, and a binder, the metallic magnetic powders have an aspect ratio of not more than 3, and the inorganic insulating material has an aspect ratio of not less than 2 and is cleavable. Also disclosed is a process for producing the composite magnetic material, which comprises performing a press molding step while crushing the inorganic insulating material.

Owner:PANASONIC CORP

Thermal oxidization resistant engine cylinder inner wall abrasion resistant coating and preparation method thereof

InactiveCN105441854AImprove lubricityHigh bonding strengthMolten spray coatingTransportation and packagingLubricationOff phenomenon

The invention discloses a thermal oxidization resistant engine cylinder inner wall abrasion resistant coating which is prepared from the following raw materials in parts by weight: 68-69 parts of 316 stainless steel powder, 6-6.5 parts of Mo powder, 25-26 parts of Ni60 powder, 5.8-6 parts of WC, 5.6-5.8 parts of B4C, 0.3-0.4 part of nano graphene, 2.5-2.8 parts of tetrabutyl titanate, 8.5-10 parts of sodium molybdate, 4.5-4.8 parts of acetic anhydride, 75-80 parts of dimethylformamide, a proper amount of concentrated hydrochloric acid and 10-12 parts of tetrabutylammonium bromide. According to the thermal oxidization resistant engine cylinder inner wall abrasion resistant coating, through utilizing sodium molybdate, nano molybdenum particles are formed on the surface of the metal powder, and nano molybdenum dioxide is adhered to the surface, so that the lubrication performance of the coating is improved, and the bonding strength of the coating is improved; and through utilizing WC, B4C, nano graphene and tetrabutyl titanate, the thermal oxidization resistance of the coating is improved, the friction coefficient is reduced, the bonding strength of the coating and a substrate is high, and the fracture and falling-off phenomena are reduced.

Owner:HEFEI ZHONGLAN NEW MATERIAL TECH CO LTD

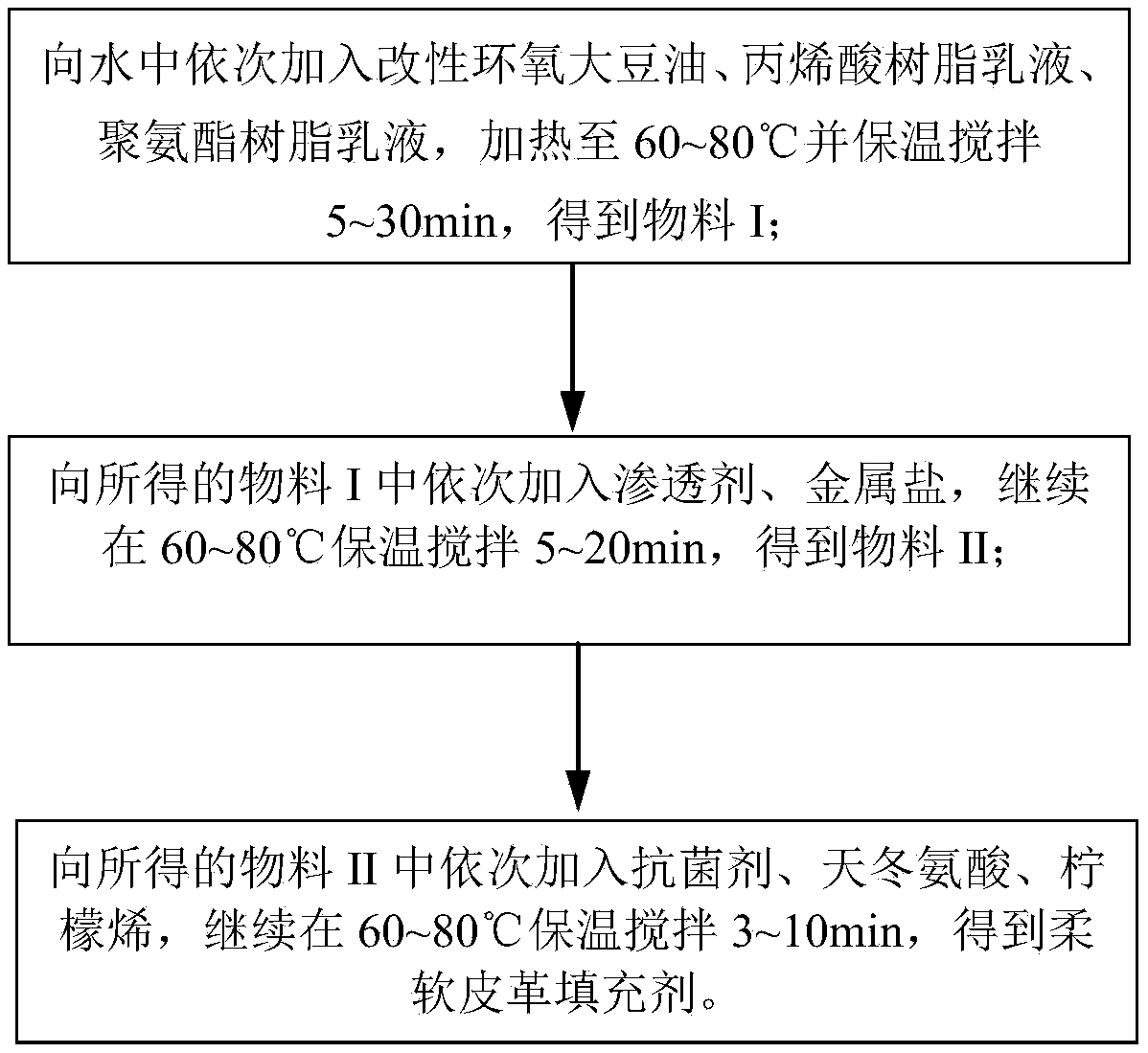

Soft leather filling agent and preparation method thereof

InactiveCN108659644AImprove permeabilityEasy to prepareAntifouling/underwater paintsPaints with biocidesFiberEmulsion

The invention discloses a soft leather filling agent and a preparation method thereof. The soft leather filling agent comprises the following raw materials in parts by weight: 20 to 50 parts of acrylic acid resin emulsion, 15 to 40 parts of polyurethane resin emulsion, 15 to 30 parts of modified epoxidized soybean oil, 2 to 8 parts of a penetrating agent, 1 to 5 parts of an antibacterial agent, 0.1 to 1 part of metal salt, 1 to 5 parts of aspartic acid, 1 to 5 parts of limonene and 15 to 50 parts of water. The soft leather filling agent has specific raw materials and proportion, has high penetrability, can rapidly penetrate into leather, is firmly combined with leather fiber and forms one layer of ultrathin lubricating film on the surface of the leather, so that the softness, the toughnessand the antibacterial and anti-mildew properties of the leather are improved and excellent lubricating effect on the leather is achieved; furthermore, the preparation method is simple, convenient andsuitable for large-scale production application.

Owner:江门市汇锦科技有限公司

Tap-hole filling material and filling method thereof

The invention discloses a tap-hole filling material, main raw materials of which are quartz sand, sintered magnesia clinker and waste and old magnesia-chromite bricks and auxiliary materials of which are a carburant and a sintering aid. The raw materials contain, by weight, 25-45% of quartz sand, 30-60% of sintered magnesia clinker, 10-35% of waste and old magnesia-chromite bricks, 0-2% of the carburant and 0-11% of the sintering aid. A filling method of the tap-hole filling material comprises the following step: more than one tap-hole filling material with different ratios undergoes layered filling according to contents of the carburant and the sintering aid from low gradient to high gradient, and the contents of the carburant and the sintering aid at the bottom layer are the lowest. Through compounding of the main raw materials and the auxiliary materials and layered gradient filling, fluidity, sintering property and pouring rate of the filling materials are raised, limitations such as poor fluidity, low free-opening rate and the like of existing tap-hole filling materials are overcome, and technological requirements of converter tapping are met. In addition, cost is low.

Owner:武汉钢铁有限公司

Coating for directional electromagnetic steel plate and preparation method of coating

ActiveCN109777160AImprove lubricityImprove heat resistanceMetallic material coating processesHeat resistancePhosphate

The invention discloses coating for a directional electromagnetic steel plate. The coating comprises 100 g of phosphate, 60-120 g of silica sol, 10-30 g of CrO3, 1-20 g of a titaniferous compound and1-30 g of boric acid, wherein the phosphate is counted by phosphate radical and the silica sol is counted by SiO2. The surface of the steel sheet is coated with the coating, and a coating layer is dried and is then thermally treated at 800-950 DEG C for 10-100 s. Compared with the prior art, the coating has the beneficial effects as follows: (1), the coating layer prepared from the coating for thedirectional electromagnetic steel plate has excellent slidability, heat resistance and anti-sticking performance; (2), the coating layer prepared from the coating for the directional electromagneticsteel plate has good covering power, the produced directional electromagnetic steel plate has a good appearance characteristic, namely uniform color and luster.

Owner:NANJING BAOCHUN NEW MATERIAL TECH CO LTD

Lubricating oil with graphene

The invention provides lubricating oil with graphene. The lubricating oil contains the following components in parts by weight: 190-250 parts of lubricating-oil base oil, 13-16 parts of glyceryl tristearate, 10-15 parts of polymethacrylate, 5-10 parts of polyisobutene, 10-13 parts of octyl phenol, 4-5 parts of fluorine surfacant, 14-18 parts of silane coupling agent, 7-10 parts of diisocyanate and 5-15 parts of oxidized graphene powder. The lubricating oil provided by the invention has the advantages that an additive and the base oil are better in compatibility; by the combined effect of polymethacrylate and polyisobutene, the viscosity index of the lubricating oil is obviously increased; simultaneously due to addition of the graphene, the stability of the lubricating oil is improved; and the anti-freezing and anti-rusting properties and the wearing-resistant and lubricating properties are better.

Owner:丁芸娉

Preparation method of anti-static carbon fibre functional composite paper

ActiveCN108035188AImprove surface activityImprove permeabilityCoatings with pigmentsPaper/cardboardCarbon fibersAdhesive

The invention discloses a preparation method of anti-static carbon fibre functional composite paper. The preparation method comprises the following steps: crushing wheat straw and waste paper, addingwater, standing, draining, soaking in a potassium hydroxide solution, steaming in a manner of insulating from water, drying, performing wet ball milling, concentrating, pulping, and performing papermaking to obtain blank paper; mixing waste paper and the potassium hydroxide solution, standing at a room temperature, then heating and stirring, performing suction filtration, washing a filter cake, drying to reach constant weight, adding a sepiolite powder, dodecyl ammonium chloride and silver nitrate solution, regulating the pH value of the system to be 6.4 to 6.8, stirring uniformly, adding a silane coupling agent KH-550, stirring uniformly, performing ultraviolet irradiation treatment, filtering, washing with deionized water, drying, and crushing to obtain a composite antibacterial agent; uniformly mixing graphite, carbon black, a coconut shell carbon powder and the composite antibacterial agent, adding an anti-static agent, a dispersing agent and an adhesive, mixing uniformly, concentrating, coating the surface of the blank paper with the mixture, drying, applying the adhesive to double surfaces, drying a finished product, and rolling paper.

Owner:安徽鑫光新材料科技股份有限公司 +1

Moistureproof material for Xuan paper

InactiveCN108411703AExtended service lifeImprove fire and flame retardant performanceInorganic fibres/flakesOrganic non-cellulose fibresVegetable fibersBasalt

The invention provides a moistureproof material for Xuan paper. The moistureproof material comprises, by weight, 9-14 parts of Pteroceltis tatarinowii bark fibers, 18-32 parts of Shatian straw fibers,6-11 parts of an antioxidant, 2-7 parts of a compatibilizer, 0.8-3.4 parts of a flame retardant, 26-43 parts of clover fibers, 22-35 parts of reed fibers, 14-29 parts of basalt fibers, 23-37 parts ofsoybean powder and 32-46 parts of glutinous rice slurry, wherein the content of soluble solids in the glutinous rice slurry is 42 to 52%, and the monofilament of the basalt fibers has a diameter of 0.35 to 0.65 [mu]m and a length of 3 to 9 mm. According to the invention, a combination of plant fibers and organic fibers is employed to replace a part of traditional raw materials for Xuan paper, socost is saved, good pulping effect is obtained, and the service life, fireproof performance and flame retardation performance of Xuan paper are improved.

Owner:霍文慧

Novel Chinese art paper material

InactiveCN108301250AImprove fire and flame retardant performanceExtended service lifeNon-macromolecular organic additionVegetable material additionGlass fiberAlkali free

The invention provides a novel Chinese art paper material including the following components in parts by weight: 11-17 parts of wingceltis bark fibers, 23-34 parts of sand field rice straw fibers, 6-11 parts of an antioxidant, 2-7 parts of a compatibilizer, 0.8-3.4 parts of a flame retardant, 18-31 parts of pineapple peel pomace fibers, 24-33 parts of sisal hemp fibers, 6-13 parts of alkali-free low-floating long glass fibers and 36-49 parts of glutinous rice slurry, wherein the soluble solid content of the glutinous rice slurry is 45%-55%, the monofilament diameter of the alkali-free low-floating long glass fibers is 28-35 [mu]m, and the monofilament length of the alkali-free low-floating long glass fibers is 9-18 mm. The plant fibers and the organic fibers are combined to replace a partof traditional raw materials of Chinese art paper, the cost is saved, the slurry making effect is good, and at the same time, the service life of the Chinese art paper is prolonged and fire preventionand flame retardancy are improved.

Owner:霍文慧

Surface hydrophilic layer modification method for implantable medical device and application

PendingCN113499484AImprove hydrophilic performanceImprove lubricitySurgeryPharmaceutical delivery mechanismAqueous solubilityEngineering

The invention discloses a surface hydrophilic layer modification method for an implantable medical device and application, and belongs to the technical field of medical devices, and the surface hydrophilic layer modification method comprises plasma hydrophilic modification, hydrogel hydrophilic modification and biological extract modification. The surface of the medical device is modified through plasma hydrophilic modification or hydrogel prepared from biocompatible water-soluble polymers and viscous components, or a biological extract, so that a hydrophilic layer is formed, the surface lubricity of the biological medical device can be improved, resistance generated in the use process of the medical device is reduced, the damage to tissues caused by implantation of medical instruments is reduced, complications are reduced, and the biocompatibility is improved. The method has the advantages that the method is simple, the lubricating effect is good, the operation is convenient, and the method is safe, environmentally friendly and the like. The invention further discloses the surface hydrophilic layer of the implantable medical device and the implantable medical device modified by the hydrophilic layer.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com