Functionalized Maleated Fatty Acids as Non Acidic Fluid Additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

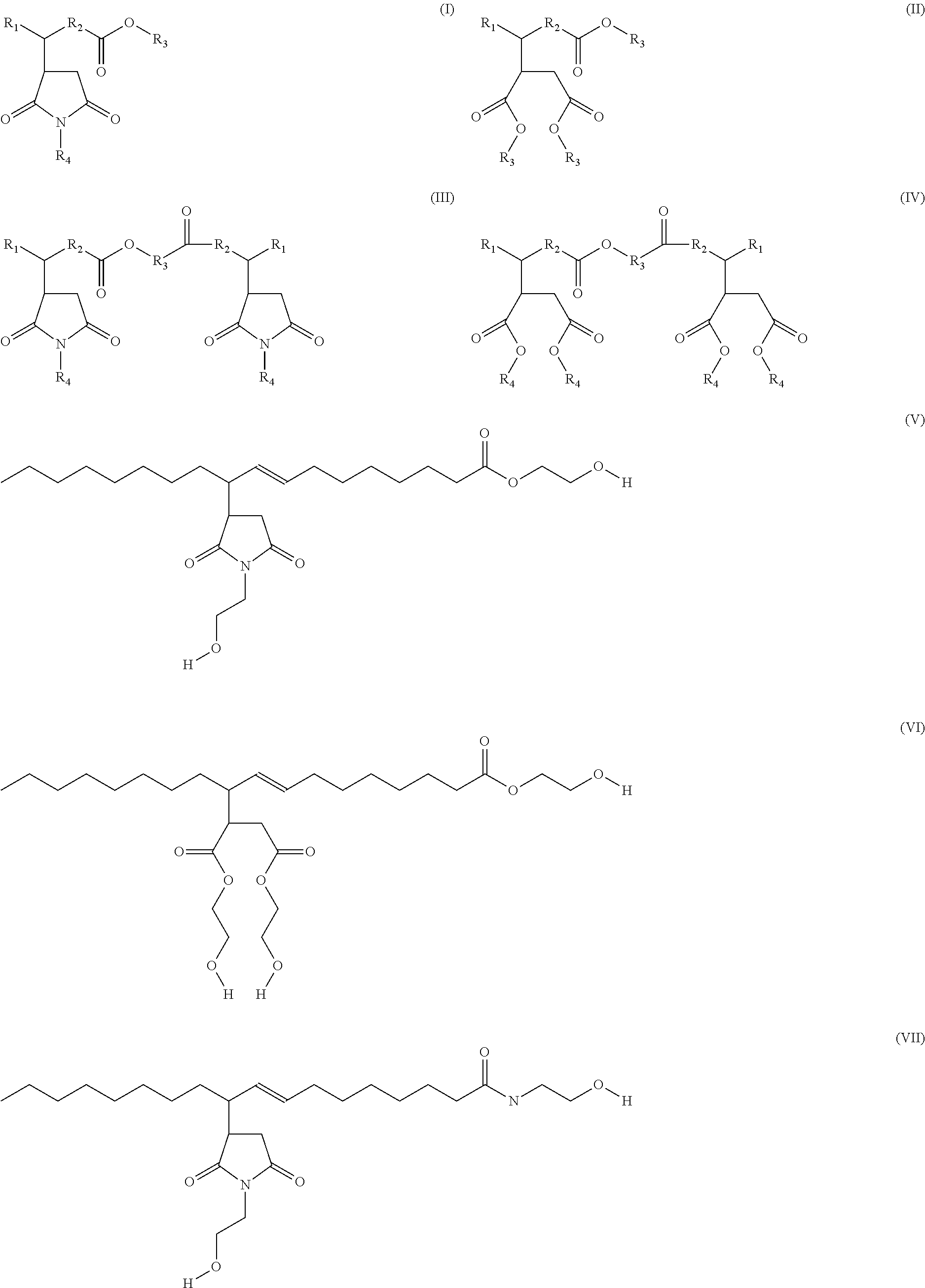

Image

Examples

examples 1-5

Preparation of Functionalized Maleated Fatty Acid Products

example 1

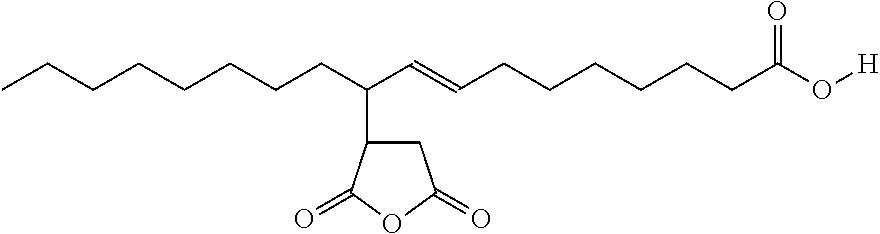

[0029]The preparation of maleated fatty acid: In a typical reaction, oleic acid (100 g) and maleic anhydride (25 g) were charged into a 250 ml 3-neck flask under nitrogen. The mixture was heated sequentially up to 240° C. for 30 hrs until the reaction was completed. The reaction was monitored by FT-infrared spectroscopy (FT-IR) as is known to those skilled in the art. The final product was diluted by aromatic solvent to a concentration of 90% active and marked as Example 1.

[0030]Above is a representative structure of Example 1 material.

example 2

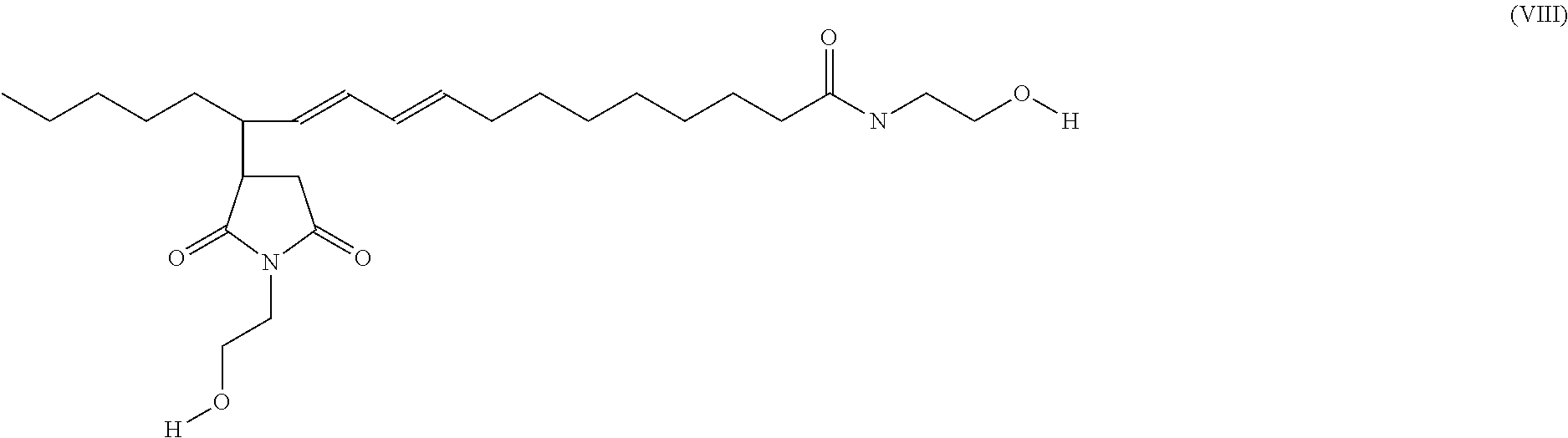

[0031]Oleic acid (100.1 g) and maleic anhydride (25.3 g) were mixed in a 3-neck flask. The mixture was heated sequentially up to 240° C. until the reaction is completed as monitored by FT-IR. The reaction mixture was first cooled to room temperature, and then ethanolamine (38.0 g) was added drop-wise while stirring. After the addition was completed, the reaction temperature was first set at 80° C., and then raised to 180° C. sequentially in 2 hours. The reaction process was monitored by FT-IR and acid number analysis. A second batch of ethanolamine (6.0 g) was added after 8 hrs reaction time. The reaction was stopped when the acid number is below 3. The final product was diluted with aromatic solvent to a concentration of 80% active and marked as Example 2.

[0032]Above is a representative structure of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com