Patents

Literature

71results about How to "Improve hydrophilic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

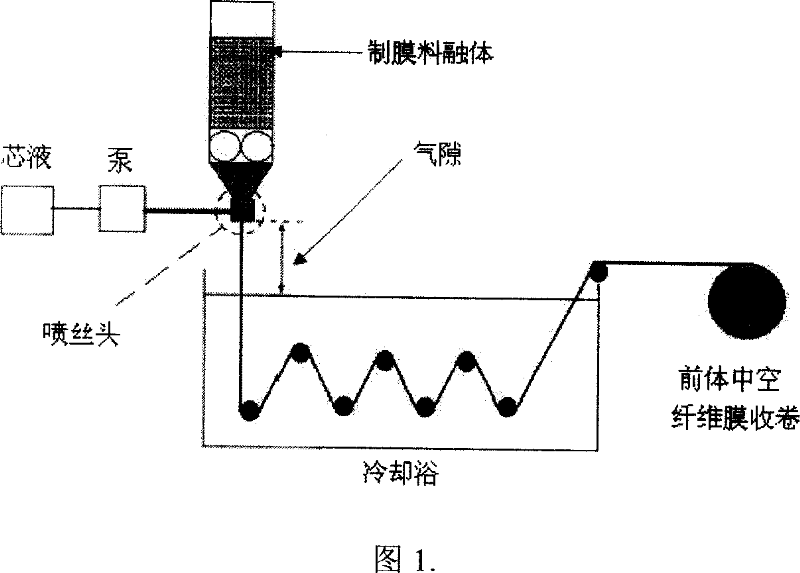

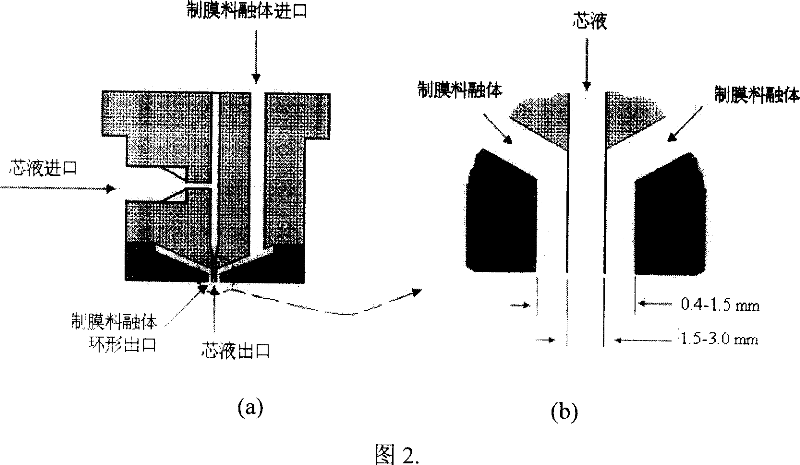

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

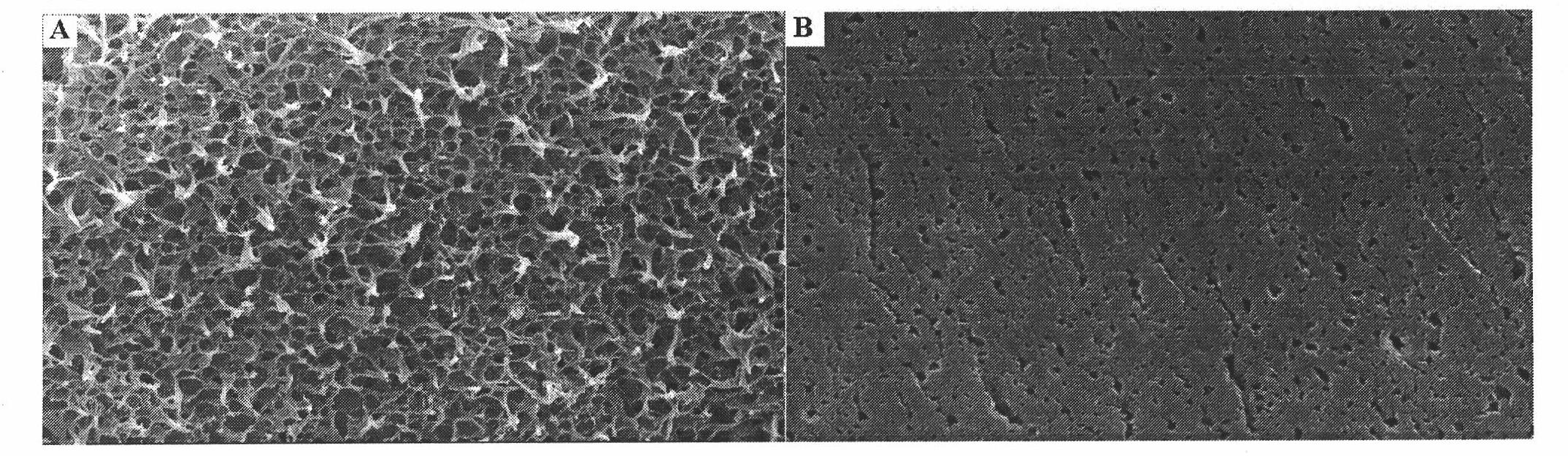

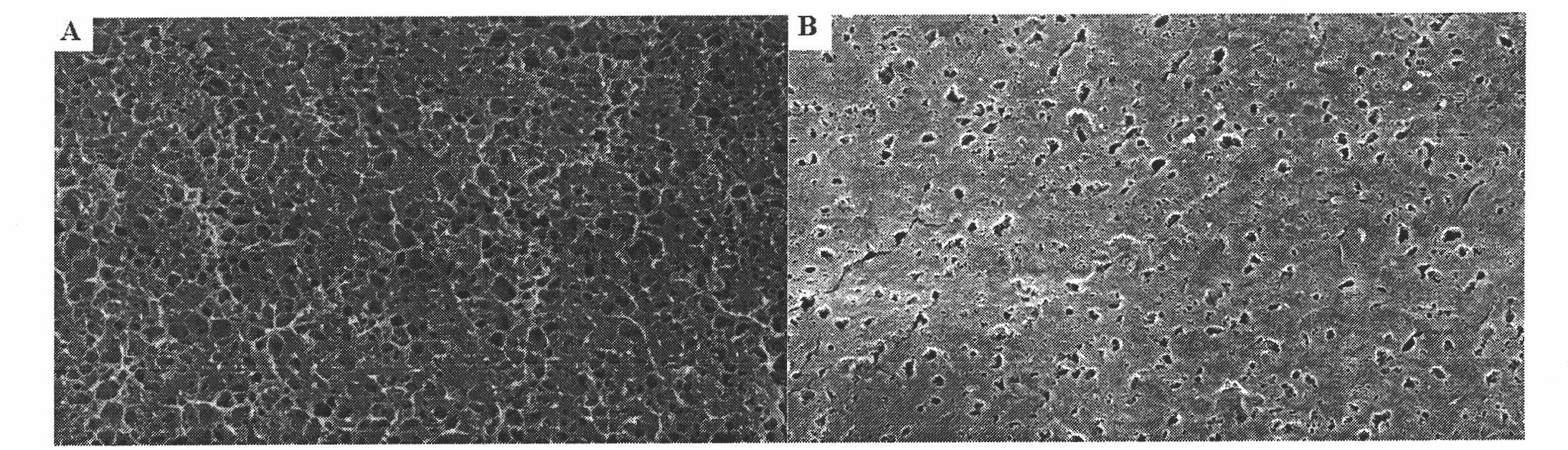

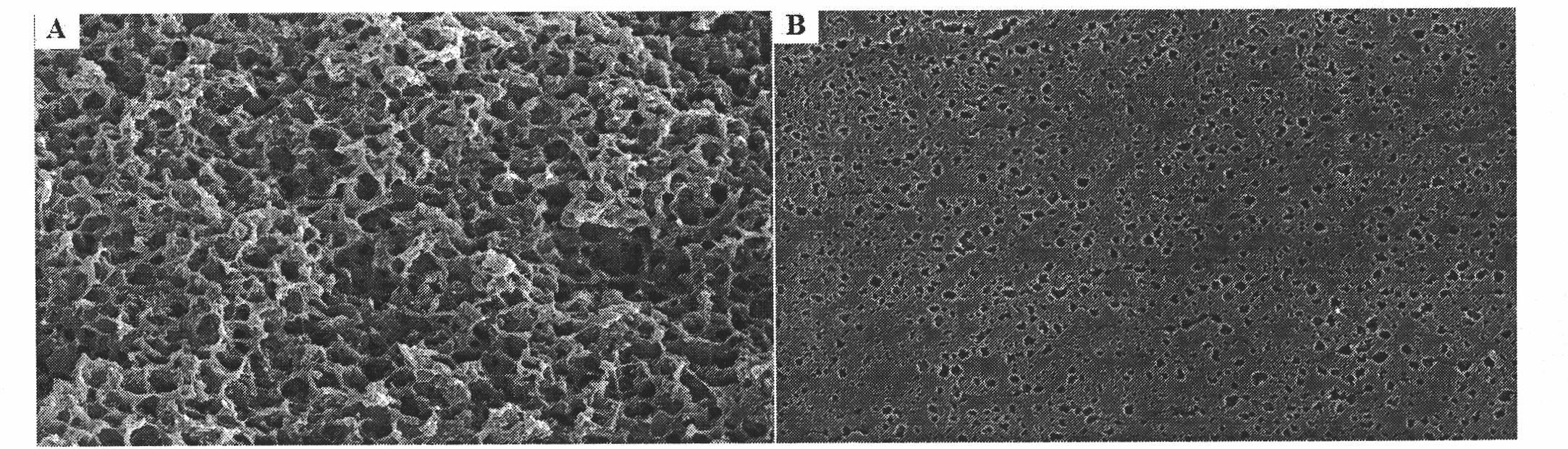

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

Process for preparing hydrophilic elastic plastic filler for treating water

InactiveCN1350984AGood hydrophilicityImprove hydrophilic performanceSustainable biological treatmentBiological water/sewage treatmentWater solubleTitanium dioxide

A process for preparing elastic hydrophilic plastic filler for treating water incldues such steps as proportionally mixing plastic particles of PP, PE or PVC or their mixture, powder of water-solublepolyvinyl alcohol, polyacrylamide, or their mixture, and power of quartz, TiO2, SiO2, or their mixture together, granulating, and shaping filler. Its advantages include simple process, high effect and high reliability.

Owner:SOUTH CHINA UNIV OF TECH

In-situ polymerization mico-crosslinking polyvinylpyrrolidone modified polyether sulfone hollow fiber membrane and preparation method and use thereof

ActiveCN103706266ALow elution rateStable hydrophilicitySemi-permeable membranesSuction devicesSolventCross-linked polyethylene

The invention discloses an in-situ polymerization mico-crosslinking polyvinylpyrrolidone modified polyether sulfone hollow fiber membrane and a preparation method and a use thereof. The preparation method is characterized by comprising the following steps: adding 10-25 parts of polyether sulfone and 90-75 parts of solvent into a reaction kettle, adding vinyl pyrrolidone accounting for 2-20% of mass of the polyether sulfone solution after the polyether sulfone is dissolved, carrying out a polymerization reaction for 2-24 hours at a temperature of 50-95 DEG C in the presence of a crosslinking agent and an initiator to obtain a polyvinylpyrrolidone modified polyether sulfone solution, stewing to cure the polyvinylpyrrolidone modified polyether sulfone solution to prepare modified polyether sulfone spinning dope, and directly mico-crosslinking polyvinylpyrrolidone between polyether sulfone lattice chains; and preparing a modified polyether sulfone hollow fiber membrane with hydrophilia, protein pollution resistance and anticoagulant function by utilizing a dry spraying-wet spinning method. The membrane is made into a filter and has excellent blood compatibility to be used for purifying blood, and the anti-protein pollution recovery rate is increased from 50% to 95%; the albumin adsorption is decreased from 20 micrograms / cm<2> to 5 micrograms / cm<2>; the activated partial thromboplastin time is increased from 50 seconds to 96 seconds.

Owner:SICHUAN UNIV

Polyester flat microporous membrane and preparation method thereof

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

Cement paste toughening agent and application of cement paste toughening agent in preparation of cementing flexible cement paste

ActiveCN103305197ADoes not change inherent performanceGood settlement stabilityDrilling compositionPolymer sciencePortland cement

The invention relates to a cement paste toughening agent and application of the cement paste toughening agent in preparation of a cementing flexible cement paste. The toughening agent is prepared by modification of rubber powder; the modification of rubber powder includes the steps of cleaning, activating, etching and grafting; the cementing flexible cement paste prepared by the toughening agent is prepared from the following components in parts by weight: 100 parts of portland cement, 5-50 parts of modified rubber powder, 10-40 parts of a toughing agent, 15-80 parts of a density regulator, 35-65 parts of water, 0.5-2 parts of a dispersing agent, 0.5-3 parts of a fluid loss agent, 1.5-4 parts of a retarder and 0.1-2 parts of a defoamer. The inherent performance of a substrate is not changed by plasma treatment on the rubber powder; no pollution is generated; the cement paste toughening agent is simple in process, convenient to operate, stable in hydrophilism through the grafted rubber powder, small in effect from timeliness, and low in handling expense; the flexible cement paste prepared from the modified rubber is good in sedimentation stability; the mechanical property is obviously improved; the cement construction requirements of the scene can be completely met.

Owner:SOUTHWEST PETROLEUM UNIV

Composition for preparing hollow capsule and starch-base hollow capsule thereof

The invention relates to a composition for preparing a hollow capsule and a starch-base hollow capsule prepared from the composition, belonging to the field of food, medicines and the like. The composition for preparing the hollow capsule is prepared by mixing hydroxypropyl starch or acid-treated hydroxypropyl starch with a reinforcing and toughening agent and a gelatinizer. The substitution degree DS of the hydroxypropyl starch or acid-treated hydroxypropyl starch is 0.007-0.93, and the gelatinization temperature is 30-70 DEG C. The composition can be heated in water to be gelatinated and colloidized to obtain the starch-base hollow capsule. The hydroxypropyl functional group is introduced to the starch molecules to modify the starch, thereby overcoming the intermolecular hydrogen bonding force of the starch, performing the toughening and reinforcing functions, effectively inhibiting starch from anabiosis, increasing the hydrophilicity of the starch molecules and lowering the gelatinization temperature; and thus, the starch-base hollow capsule has favorable disintegrability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

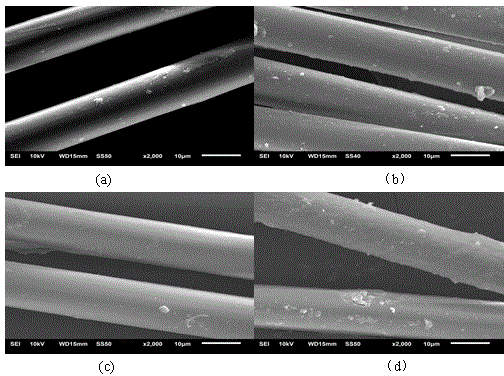

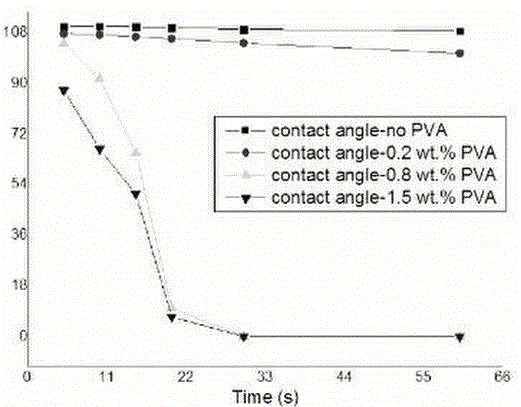

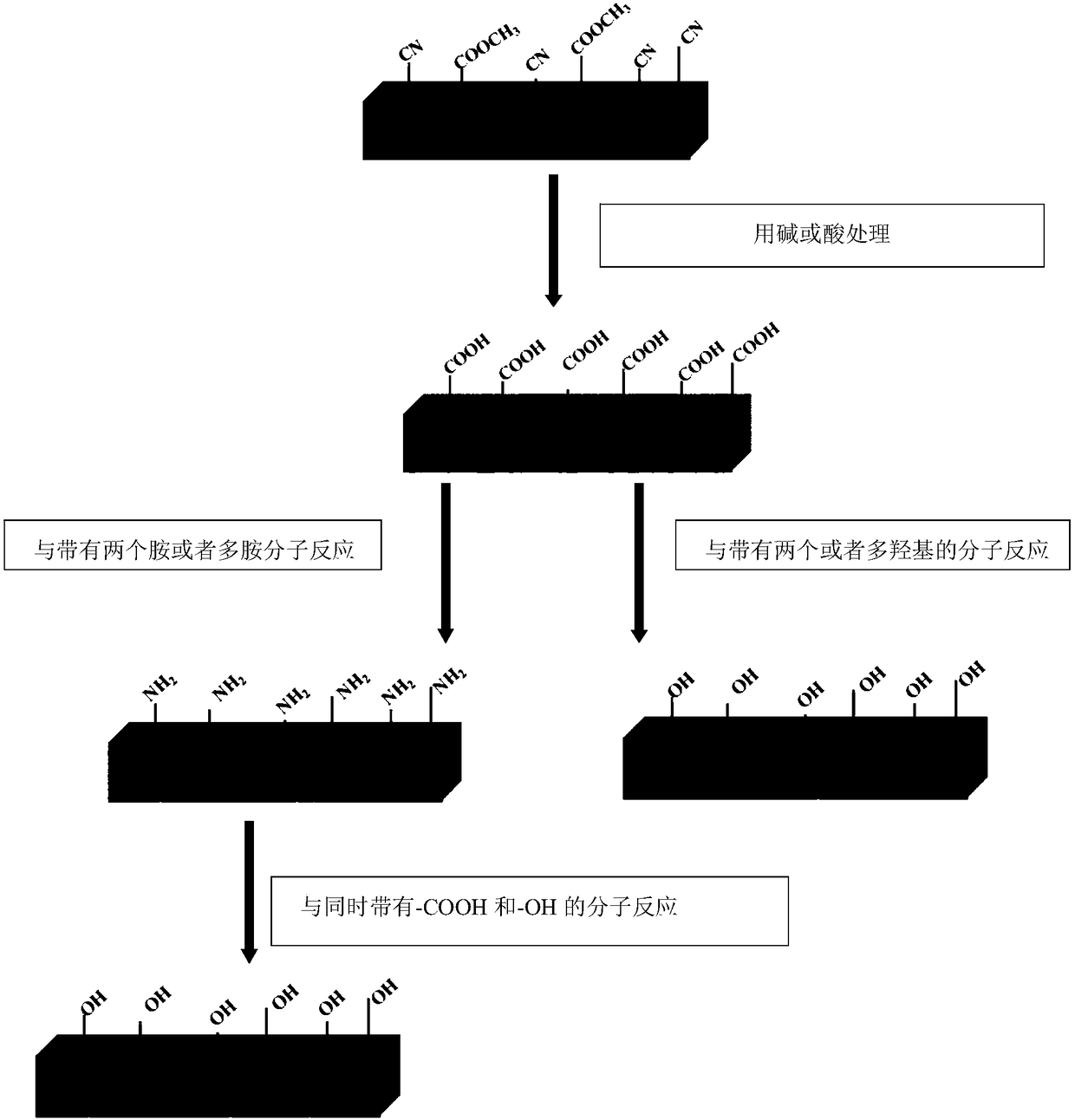

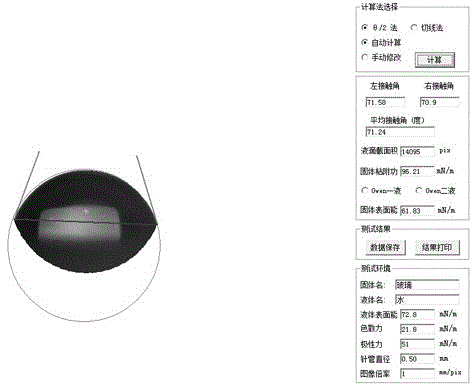

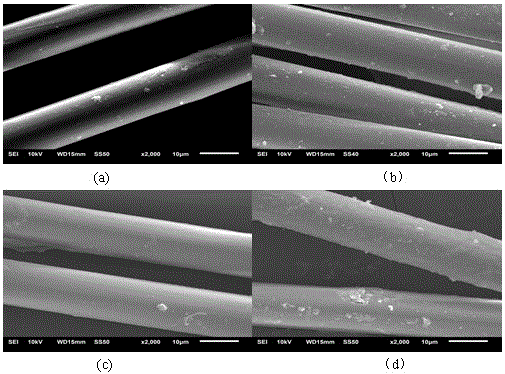

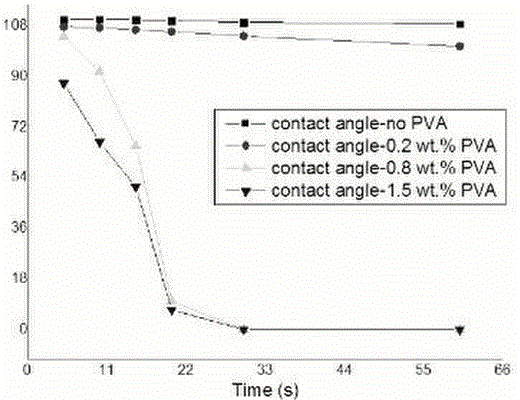

Hydrophilic modification method of PVA to polyester fiber

The invention provides a hydrophilic modification method of PVA to polyester fiber, which belongs to the high-molecular technical field. The method comprises the following steps: pretreating the polyester fiber by a sodium hydroxide solution with 3-10% of mass fraction for 1 hour, wherein the solid liquid ratio is 1: 50, flushing and drying the polyester fiber, then placing the polyester fiber in a reaction container filled with a PVA solution with 0.2-0.3% of mass fraction, then adding acetate, methanol and sulfuric acid according to volume ratio of 3: 2: 1 in the reaction container, wherein the volume fraction of acetate, methanol and sulfuric acid are 10% respectively, adding GA with 25% of mass fraction in the reaction container, wherein the mol ratio of GA to PVA is 1: 4, performing mechanical stirring and reacting for 1-2 hours under the temperature of 50-70 DEG C, washing by water after the reaction is completed, and drying. Through representation and determination, the surface of the modified polyester fiber uniformly contains PVA, the contact angle is less than 10-50 DEG, hydrophilcity of the polyester fiber is greatly improved, the effect is stable, and the polyester fiber can be widely used in the fields of regeneration resource papermaking, clothes, decoration and industry and agriculture.

Owner:WUHAN TEXTILE UNIV

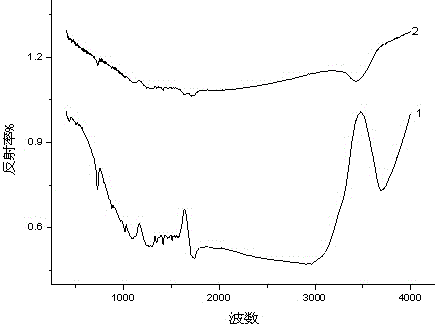

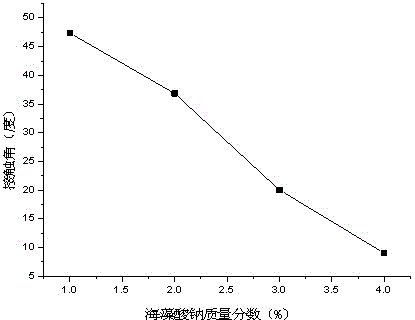

Hydrophilic modification method for polyester fiber by using sodium alginate

The invention provides a hydrophilic modification method for a polyester fiber by using sodium alginate, which belongs to the technical field of high polymer. The method comprises the following steps: stirring and pretreating the polyester fiber by using a sodium hydroxide solution with a mass fraction of 3 to 10% in a reaction container at a temperature of 70 to 90 DEG C for 1 h, wherein a solid-liquid ratio is 1: 50, then carrying out flushing with water after completion of a reaction and carrying out drying; and preparing a sodium alginate solution with a mass fraction of 1 to 4%, standing the sodium alginate solution at a temperature of 4 DEG C for 1 h, allowing sodium alginate to expand after sufficient water absorption, placing the sodium alginate solution in the reaction container, adding the dried polyester fiber into the reaction container, carrying out mechanical stirring at normal temperature for 1 to 2 h, adding a calcium chloride solution with a mass fraction of 2% during stirring and after completion of a reaction, successively carrying out flushing with water and then drying at 70 DEG C for 1 h. According to determination results, the contact angle of the modified polyester fiber is less than 10 to 60 DEG, hydrophilicity of the polyester fiber and products thereof are greatly improved, and the modified polyester fiber can be extensively applied to fields like papermaking with renewable resources, clothes, decoration, the industry and the agriculture.

Owner:WUHAN TEXTILE UNIV

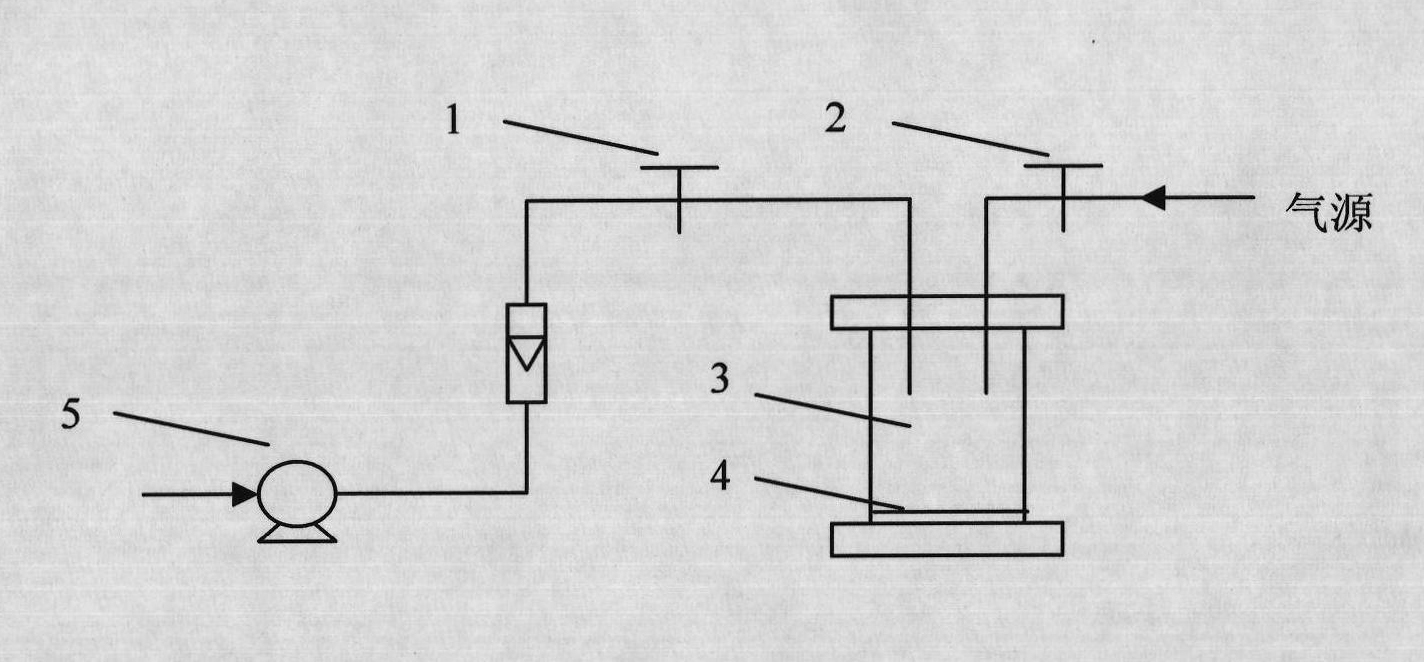

Hydrophilic modification method of ultrafiltration membrane

InactiveCN101966433AStrong combinationNot easy to loseSemi-permeable membranesUF - UltrafiltrationSeparation process

The invention provides a hydrophilic modification method of an ultrafiltration membrane, which can carry out hydrophilic modification on an ultrafiltration multiaperture separation membrane. According to the method, the method of air pressure deposition is employed to deposit hydrophilic macromolecule poval or polyvinylpyrrolidone on the surface of an ultrafiltration multiaperture basement membrane and at the inner walls of membrane pores in a uniform quantitation mode; after the immobilized treatment carried out, a polymer hydrophilic layer deposited on the surface of the basement membrane can greatly improve the hydrophily of the basement membrane; and meanwhile, the polymer macromolecules deposited on the inner surface of the membrane pores can mend defects of macropores of the basement membrane while strengthening the bonding strength of the basement membrane and the polymer hydrophilic layer. The modified hydrophilic ultrafiltration membrane of the invention can be applied to various separation processes.

Owner:大连先路科技发展有限公司

Preparation method of high-performance composite membrane used for water treatment

ActiveCN105169969AImprove hydrophilic performanceStable chlorine resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAnti bacterialAntibacterial property

The invention relates to a preparation method of a high-performance composite membrane used for water treatment. According to the preparation method, interfacial polymerization is adopted so as to prepare a functional layer on a porous support membrane. In preparation processes, an adopted water-phase reaction solution contains an in-suit generated inorganic nano hydroxide with excellent dispersity; interaction of the nano-scale hydroxide with groups in the functional layer enables that the nano-scale hydroxide can be coated by the network structure of the functional layer firmly, and the high-performance composite membrane is provided with long-term stable hydrophilic performance, chlorine resistance, pollution resistance, antibacterial properties, and excellent separation performance.

Owner:HENAN INST OF ENG

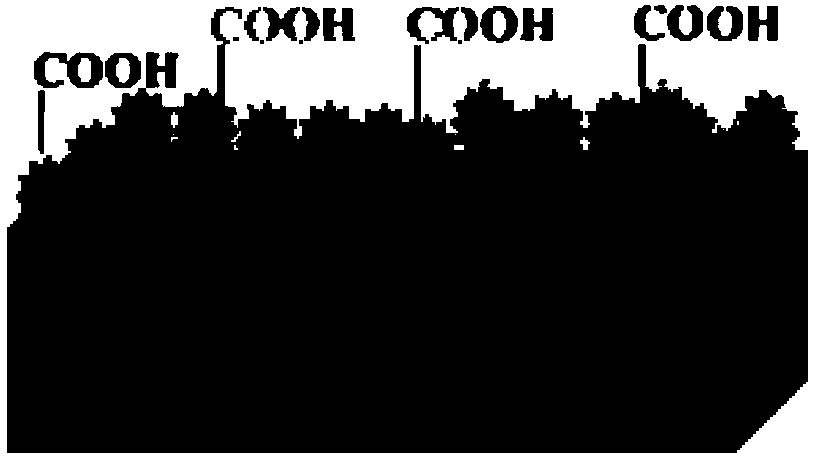

Preparation method of superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane

ActiveCN108246112ALow costUniform pore size distributionMembranesSemi-permeable membranesPorosityNano structuring

The invention provides a preparation method of a superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane. The preparation method comprises the following steps of: adopting acrylonitrile monomer as a main-body raw material, and adopting an aqueous-phase precipitated polymerization method to synthesize a polyacrylonitrile-based copolymer; selecting a crystalline diluting agent, combining with a thermally-induced phase separation method to construct a polyacrylonitrile-based microporous membrane with a micro / nano structure and high flux on the surface, and preparing the superhydrophilic and underwater-superoleophobic microporous membrane by simple modification and grafting, wherein the use of an organic solvent is avoided in synthesis and modification of the process. The oil-water separating membrane prepared by the preparation method has the advantages of high porosity, good pressure resistance, permanent hydrophilia and excellent underwateroleophobic property; in addition, the adhesion to oil drops is very low, the pollution resistance is good, long-time and stable operation can be achieved, and high-efficiency separation from an oil-water mixture to oil-in-water type oil-water emulsion can be realized only by means of gravity or lower pressure.

Owner:TIANJIN POLYTECHNIC UNIV

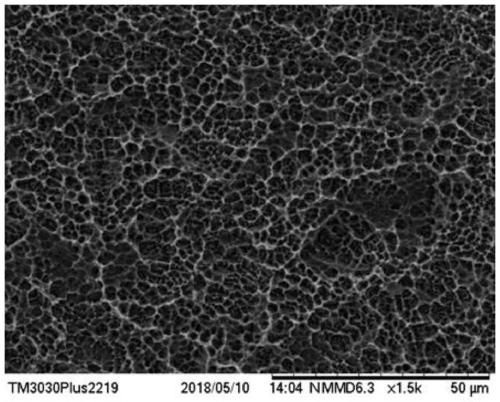

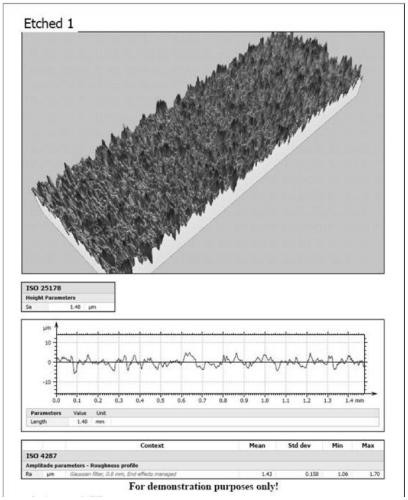

Treatment process for improving surface hydrophilicity of implant

ActiveCN109731135AHigh hardnessHigh strengthAbrasive feedersSolid state diffusion coatingAcid etchingSand blasting

The invention belongs to the technical field of implants and particularly relates to a treatment process for improving the surface hydrophilicity of an implant. The method comprises the following steps: firstly carrying out sand blasting and acid etching treatment on an implant, then carrying out alkali heat treatment and plasma oxidation treatment to enable secondary pits in the surface of the implant to be more uniform and compact, finally directly immersing the implant subjected to the plasma oxidation treatment into a mixed solution of MgCl2, CaCl2 and NaCl with an adjusted pH value, and carrying out hydrophilic treatment to obtain the implant with better hydrophilicity. The surface of the implant prepared by the method not only can improve the mechanical gomphosis of the implant and surrounding bone tissues, promote the adsorption effect of bioactive molecules and cells, facilitate the adhesion and proliferation of the cells, but also improve the surface energy and the wettabilityof the cells, accelerate the initial bone bonding speed of the implant and achieve rapid bone integration. The process is simple and suitable for commercial production.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Technology for preparing baking-free bricks with iron tailings, secondary aluminum ash and acid leaching magnesium residues

InactiveCN109133761AImprove hydrophilic performanceImprove mechanical propertiesMonocomponent polyolefin artificial filamentArtifical filament manufactureRiver sandMagnesium

The invention discloses a technology for preparing baking-free bricks with iron tailing-secondary aluminum ash-acid leaching magnesium residues. The iron tailings, aggregate river sand and gel materials are mixed with the pretreatment secondary aluminum ash and quick lime pretreatment acid leaching magnesium residues, uniform stirring is conducted, mixing water is added for pre-activation, then anadditive is added, stirring is conducted in advance, wheel-grinding mixing is performed, final stirring is conducted, after ageing, the mixture is injected into a forming mold, forming pressure is set, by the adoption of staged pressurizing, the mixture is pressed to be formed under constant pressure, and after steam curing maintaining is conducted in an autoclave, the baking-free bricks are obtained through natural maintaining. Quick lime is adopted for pretreating acid leaching magnesium residues and added into the acid leaching magnesium residues to form an alkaline environment, under alkaline conditions, part of heavy metal ions precipitate, meanwhile, a good adsorption effect on ammonium radical ions is realized, pollution of ammonium radical degradation to air is prevented, and a good excitation effect on acid leaching spiegel residues is realized; the active performance of the magnesium residues is excited, and after gel substances and aggregate are added for uniform mixing andstirring, the baking-free bricks are prepared through the method of pressing forming.

Owner:枞阳县天筑新型建筑材料有限公司

Nanofiber high-rate hydrophilic non-woven material and preparation method

ActiveCN106079761AImprove hydrophilic performancePrevent moisture lossLayered product treatmentSynthetic resin layered productsChemistryHigh rate

The invention provides a nanofiber high-rate hydrophilic non-woven material and a preparation method thereof. The nanofiber high-rate hydrophilic non-woven material comprises a nanofiber antibacterial layer, at least one side of the nanofiber antibacterial layer is provided with a nanofiber antibacterial retention layer and a nanofiber antibacterial hydrophilic layer in sequence from inside to outside, and the nanofiber antibacterial layer is a nanometer polypropylene fiber antibacterial layer. The nanofiber antibacterial hydrophilic layer can improve hydrophilic performance, the nanofiber antibacterial retention layer can further lock water, water loss is prevented, and the hydrophilic rate is increased; in addition, the nanofiber antibacterial layer is the nanometer polypropylene fiber antibacterial layer and has disinfection and sterilization functions. The nanofiber high-rate hydrophilic non-woven material has good hydrophilic performance, and the hydrophilic rate is smaller than or equal to 1,000%.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Compound finishing agent for improving antistatic performance of polyester fabrics

The invention discloses a compound finishing agent for improving the antistatic performance of polyester fabrics, and relates to the technical field of fabric finishing. The compound finishing agent is prepared from the following raw materials in parts by weight: 15 to 25 parts of cactus, 1 to 5 parts of polyaspartic acid / glucosamine, 1 to 5 parts of hydroxypropyl methyl cellulose, 0.5 to 1 part of cationic polyacrylamide, 0.5 to 1 part of rice bran wax, 0.05 to 0.5 part of polydimethyl diallyl ammonium chloride, and 0.05 to 0.5 part of sodium gluconate. The compound finishing agent is rich in natural components, and after polyester fabrics are processed by the finishing agent, the polyester fabrics have an excellent and stable hydrophilic property, good antistatic performance, and good durability.

Owner:安徽华锦柏亚纤纺科技有限公司

Polyester-cotton anti-static functional fabric

InactiveCN104389072AImprove hydrophilic performanceImprove wetting propertiesCarbon fibresBiochemical fibre treatmentWeft yarnEngineering

The invention discloses a polyester-cotton anti-static functional fabric, which is woven by warp yarns and weft yarns, wherein the weft yarns are polyester-cotton blended plied yarns, the weft yarns are formed by uniformly ranging polyester-cotton blended plied yarns and polyester-cotton blended yarns / carbon fiber filament fasciated yarns according to a certain proportion at intervals, and the polyester-cotton blended yarns / carbon fiber filament fasciated yarns are spun by using carbon fiber filaments as core yarns of an inner layer and using the polyester-cotton blended yarns as the fasciated yarns of an outer layer by a parallel spinning process. Compared with the prior art, the polyester-cotton anti-static functional fabric has the advantages and beneficial effects that 1, the fabric made of anti-static fasciated yarns has the effects that the intensity utilization rate is high, the abrasion-resistant performance is better, deformation cannot easily occur, the hand feeling is soft, the fabric is well-rounded and has the special luster, and in addition, the damage of machines to carbon fiber in the post processing process of the yarns can be effectively avoided; 2, after the fabric is washed for more than 50 times, the anti-static performance is only reduced by 1 percent to 5 percent, and the technical requirements of anti-static clothing standards (GB12014-2009) can still be met.

Owner:SWOTO PROTECTION & TECH CO LTD

Preparation method of highly hydrophilic polysulfone ultrafiltration membrane

InactiveCN105664739ALower contact angleImprove hydrophilic performanceSemi-permeable membranesMembranesUltrafiltrationPolyester

The invention discloses a preparation method of a highly hydrophilic polysulfone ultrafiltration membrane. The method comprises the following steps: uniformly dispersing graphene oxide in a polar organic solvent by ultrasonic waves, then adding polysulfone and additives to the organic solution, dissolving and stirring to form a uniform and stable casting solution, and adopting a phase inversion method to cast The membrane liquid undergoes phase inversion on the polyester non-woven fabric through the scraping membrane equipment to form a solid membrane, and finally a highly hydrophilic polysulfone ultrafiltration membrane is produced. In the present invention, graphene oxide rich in carboxyl, hydroxyl, carbonyl and other oxygen-containing functional groups is added to the polysulfone ultrafiltration membrane as a modifier to change the internal pore structure of the polysulfone ultrafiltration membrane and reduce the The contact angle significantly improves the hydrophilic performance of the prepared modified polysulfone ultrafiltration membrane, overcomes the problems of poor hydrophilic performance of the existing ultrafiltration membrane, and has a good industrial application prospect.

Owner:唐山海清源科技股份有限公司

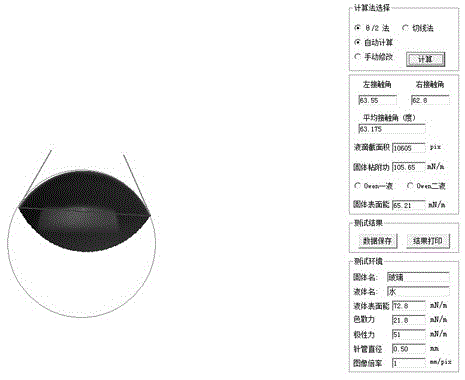

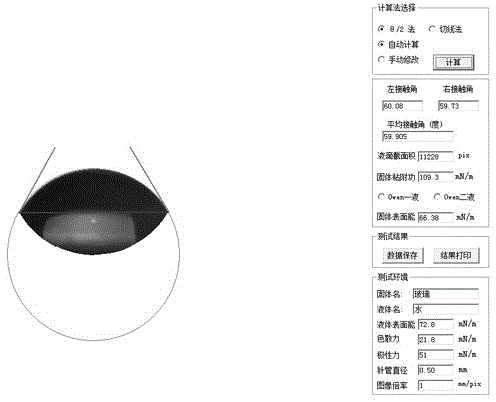

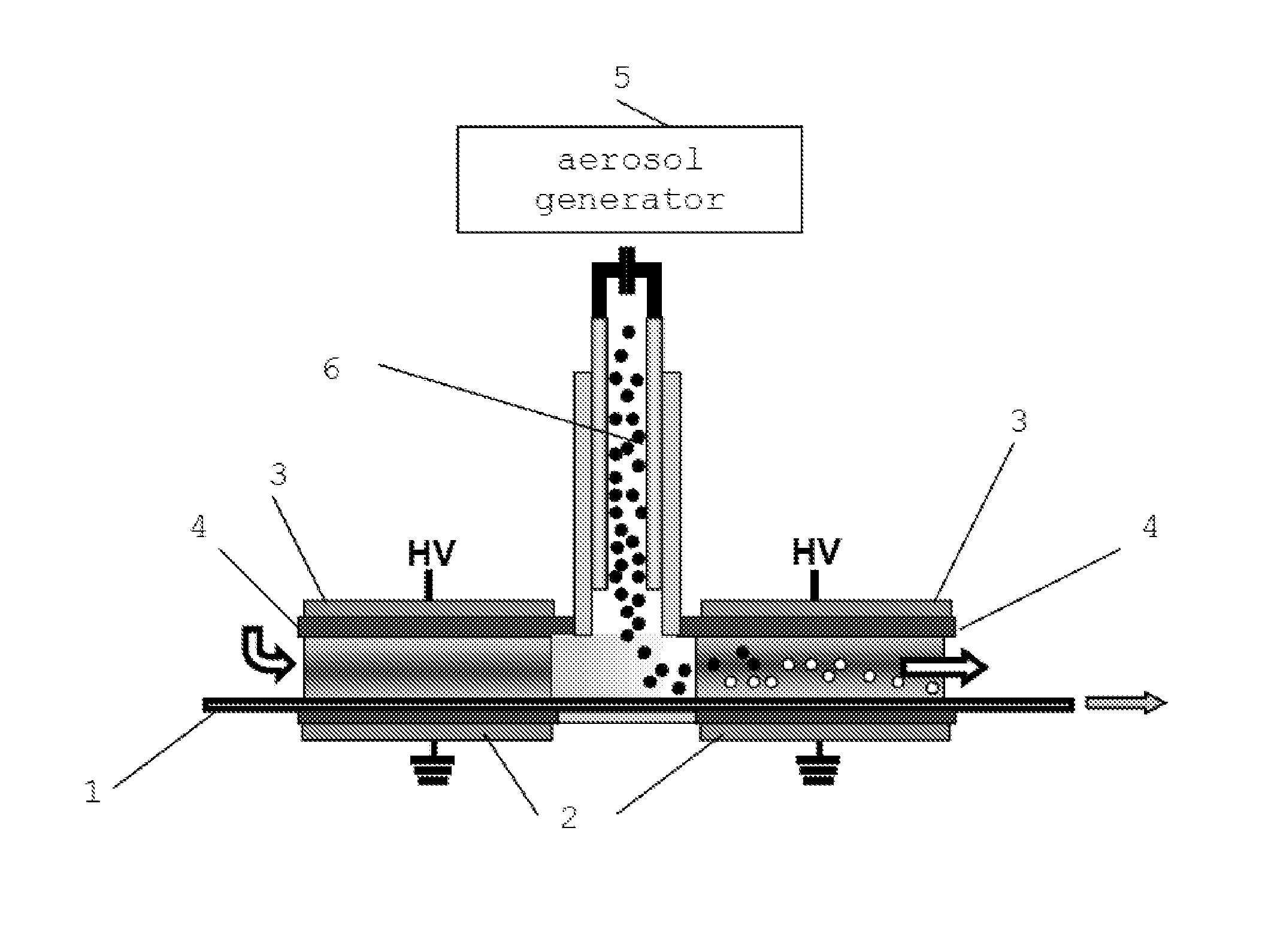

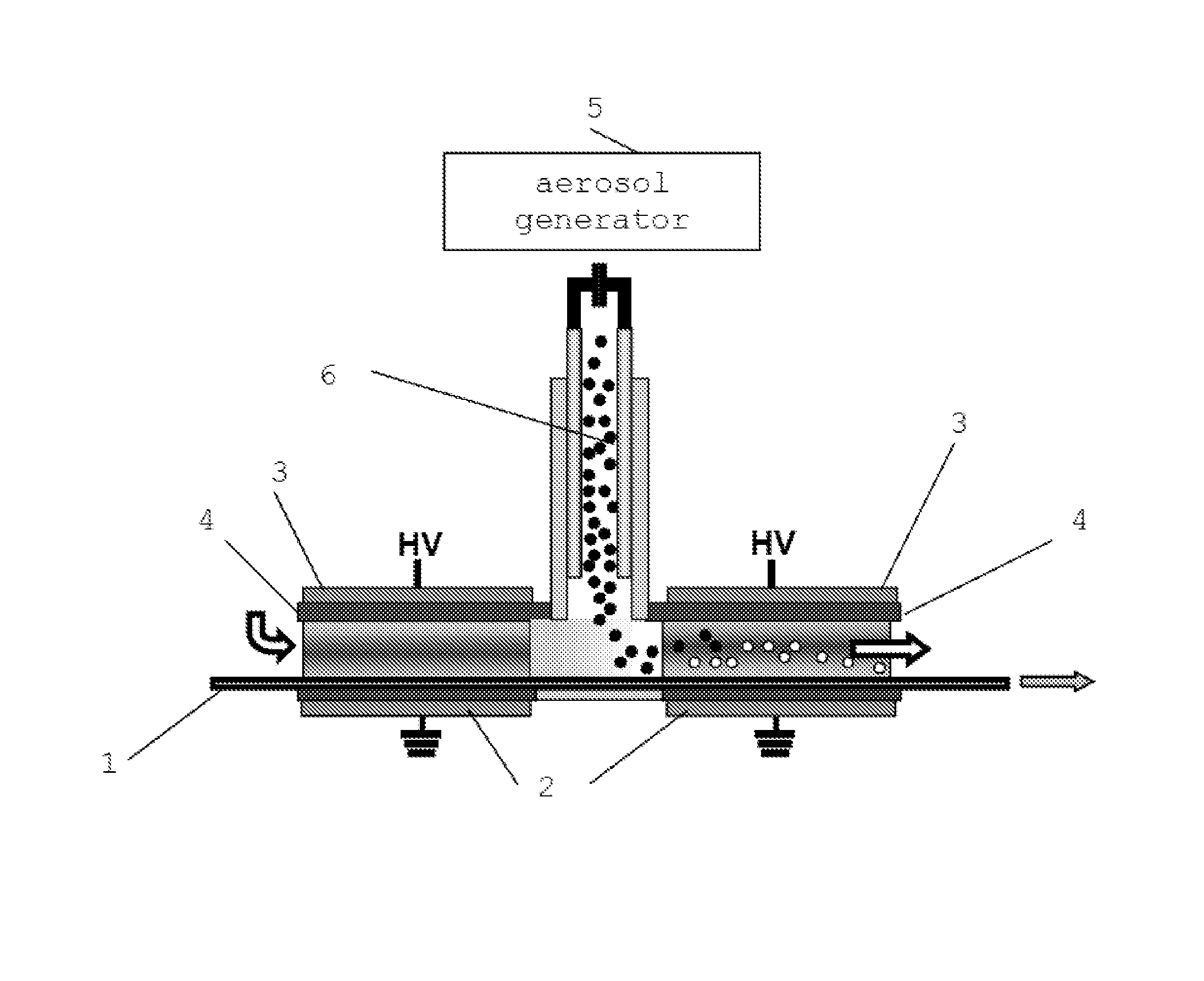

Method for stable hydrophilicity enhancement of a substrate by atmospheric pressure plasma disposition

ActiveUS8663751B2Improve aging resistanceImprove adhesionChemical vapor deposition coatingThin material handlingHydrophilic coatingEthyl acetate

A method for applying a hydrophilic coating on a substrate includes: providing a substrate (1), producing an atmospheric pressure plasma discharge in the presence of a gas, at least partially exposing the substrate to the atmospheric pressure plasma discharge. The method introduces a liquid aerosol (6) or a vapor of coating forming material into the atmospheric pressure plasma discharge, thereby forming a coating on the substrate. The coating forming material is a non-polymerizable acetate derivative, and is ethyl acetate in one embodiment.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

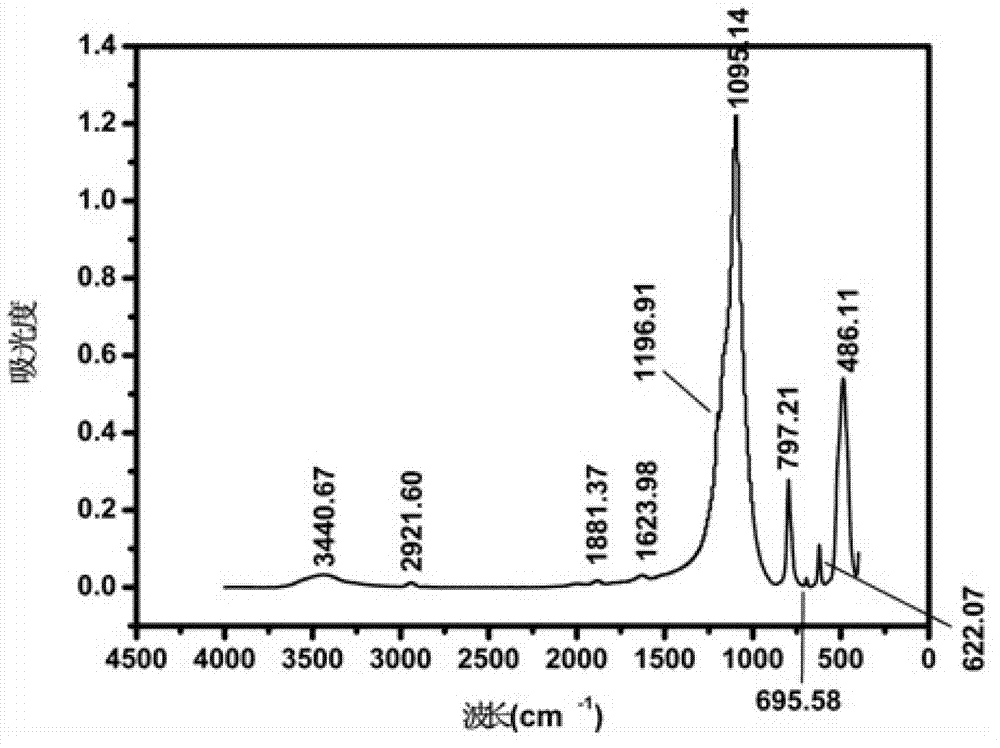

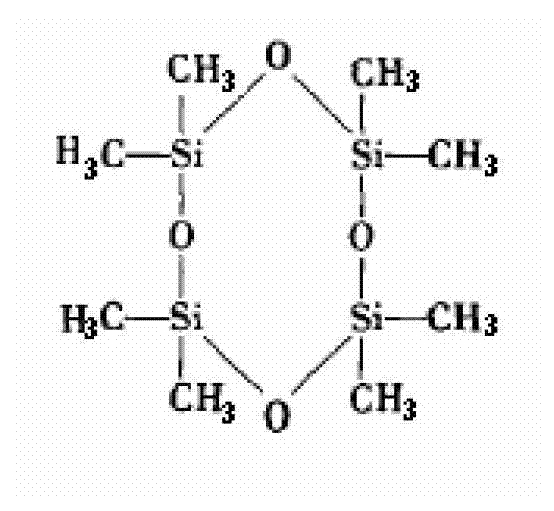

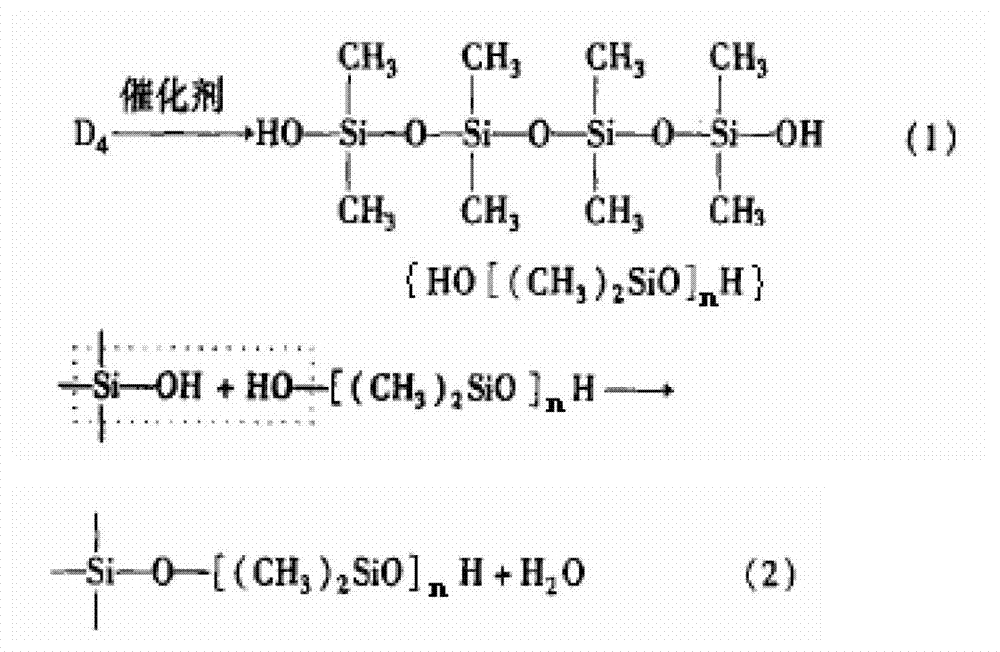

Curable elastomer impression material

ActiveCN103083192AImprove hydrophilic performanceImprove performanceImpression capsDentistry preparationsChemistrySurface finishing

The invention discloses a curable elastomer impression material. The curable elastomer impression material comprises the following components: (a) organic polysiloxane, (b) organic hydrogen polysiloxane, (d) a catalyst and (e) a filling material, wherein each molecule of the organic polysiloxane at least comprises two olefinic bond type unsaturated groups; each molecule of the organic hydrogen polysiloxane comprises at least three SiH groups; the catalyst is used for promoting the reaction between the component (a) and the component (b); and the filling material is subjected to surface treatment by using a siloxane type treatment agent which is linear siloxane or cyclic siloxane. The curable elastomer impression material has stable hydrophilicity and good overall properties. Moreover, a process for treating filling material powder in the impression material is relatively simple, no byproduct is generated, and pollution can not be caused to the environment.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Healthy environment-friendly paint for indoor wall

InactiveCN107699070AGood moisture absorption and air permeabilityGood anti-mold and antibacterial effectAntifouling/underwater paintsPaints with biocidesFiberCarboxylic salt

The invention discloses a healthy and environment-friendly coating for indoor walls. The proportioning ratio of each raw material component of the coating is: nano-titanium dioxide, 3-12 parts, vinyl acetate emulsion, 15-25 parts, acrylic emulsion, 10-20 parts Bamboo fiber powder, 8-15 parts, shell powder, 8-15 parts, zinc oxide, 3-10 parts, carboxymethyl cellulose, 0.1-0.9 parts, chitin, 2-10 parts, sodium carboxylate, 0.1-0.8 parts, polydimethylsiloxane, 0.3-1.0 parts of water, the ratio of the water to the total amount of the base material is 1:1.2-1:1.5. The photolysis of nano-titanium dioxide can completely decompose harmful organic substances such as indoor formaldehyde and toluene, pollutants, bacteria and other harmful organic substances, and the obtained environmentally friendly coating has good moisture absorption, breathability, anti-mildew and antibacterial effects.

Owner:张梦影

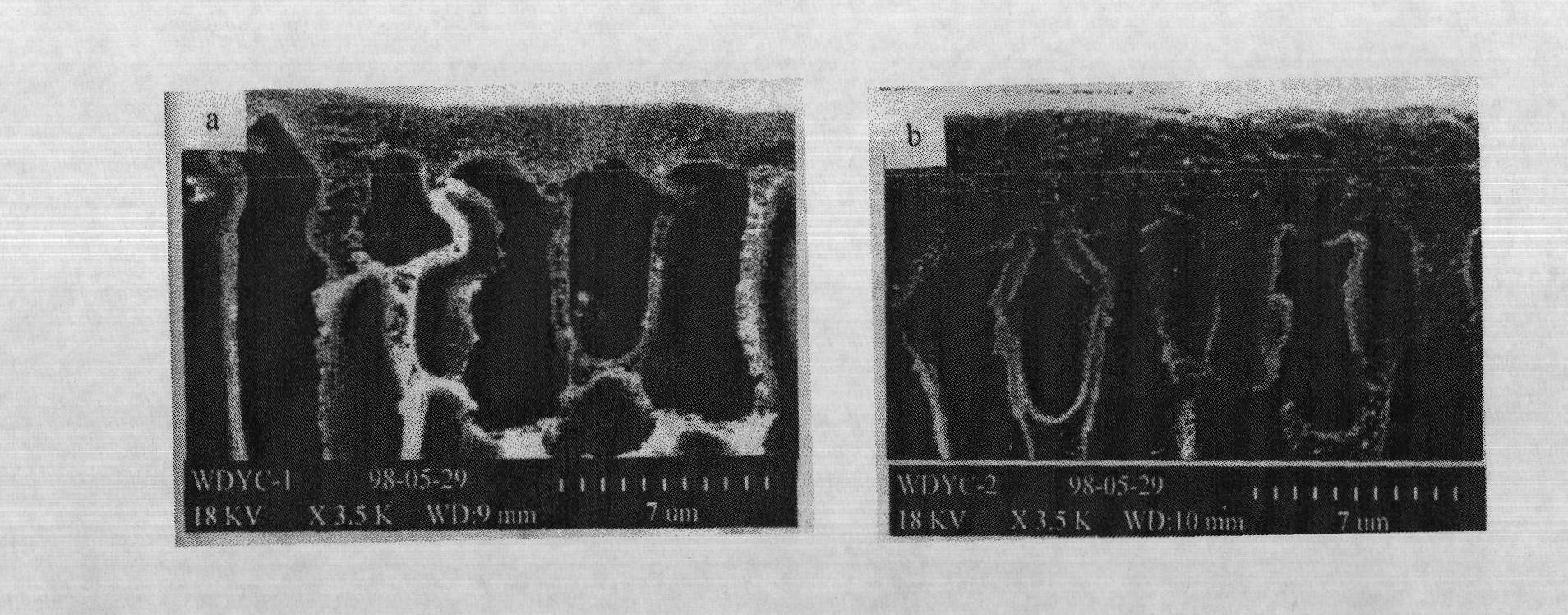

Pretreatment process for spinning of kapok loose fibers

InactiveCN103451911AImprove hydrophilic performanceReduce environmental pollutionPhysical treatmentKapok fiberMaterials science

The invention relates to a pretreatment process for spinning of kapok loose fibers. The pretreatment process comprises the following steps of impregnating with cyclopentasiloxane, prebaking to remove water, and carrying out low-temperature plasma treatment. The pretreatment process has the advantages that the low-temperature plasma treatment is carried out on the kapok fibers, so that the hydrophilic performance and the apparent morphology of the fiber material is improved, the technical advantages of saving water and energy are realized, the environmental pollution is less, and the operation is simple and is easy to control; the treatment with low-temperature plasmas on the kapok fibers only reaches the depth about 10nm from the surface of the fibers, on the premise of not damaging the self performance of kapok, the structure activity of a waxy outer layer of the kapok fiber treated by plasmas is changed, the hydrophilicity is enhanced, the appearance takes on etching morphology, the interfibrillar cohesive force is enhanced and the spinning is easy.

Owner:MAANSHAN YITENGYI TEXTILE ORNAMENT CO LTD

A method for hydrophilic modification of polyester fiber by pva

The invention provides a hydrophilic modification method of PVA to polyester fiber, which belongs to the high-molecular technical field. The method comprises the following steps: pretreating the polyester fiber by a sodium hydroxide solution with 3-10% of mass fraction for 1 hour, wherein the solid liquid ratio is 1: 50, flushing and drying the polyester fiber, then placing the polyester fiber in a reaction container filled with a PVA solution with 0.2-0.3% of mass fraction, then adding acetate, methanol and sulfuric acid according to volume ratio of 3: 2: 1 in the reaction container, wherein the volume fraction of acetate, methanol and sulfuric acid are 10% respectively, adding GA with 25% of mass fraction in the reaction container, wherein the mol ratio of GA to PVA is 1: 4, performing mechanical stirring and reacting for 1-2 hours under the temperature of 50-70 DEG C, washing by water after the reaction is completed, and drying. Through representation and determination, the surface of the modified polyester fiber uniformly contains PVA, the contact angle is less than 10-50 DEG, hydrophilcity of the polyester fiber is greatly improved, the effect is stable, and the polyester fiber can be widely used in the fields of regeneration resource papermaking, clothes, decoration and industry and agriculture.

Owner:WUHAN TEXTILE UNIV

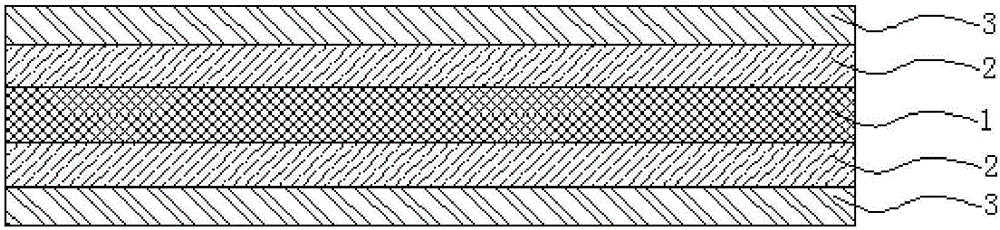

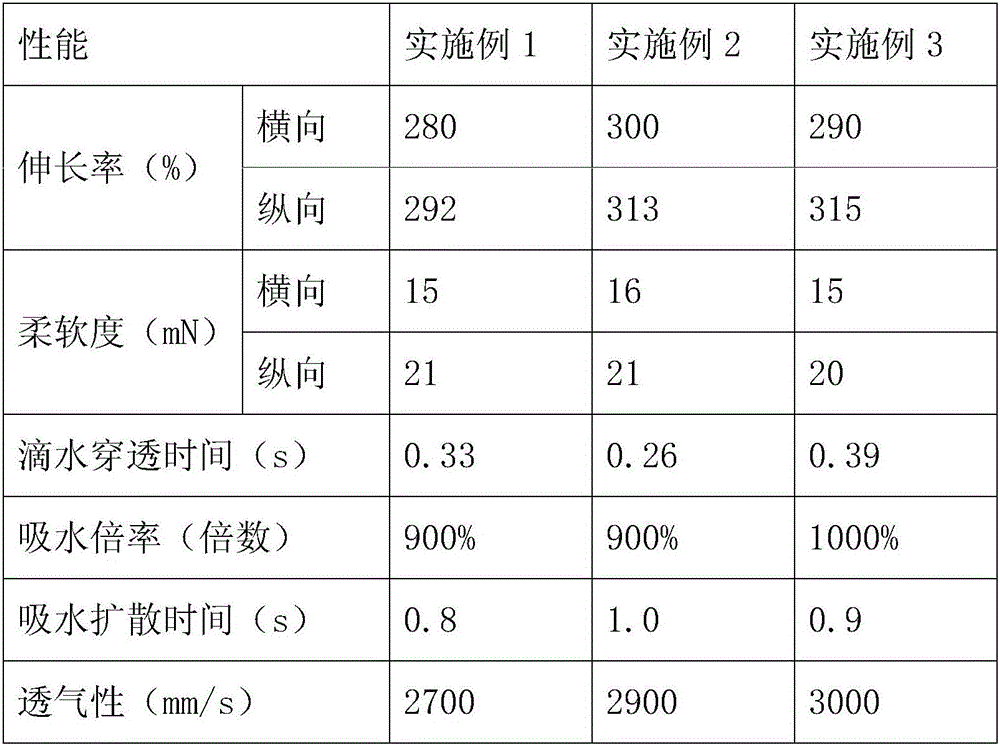

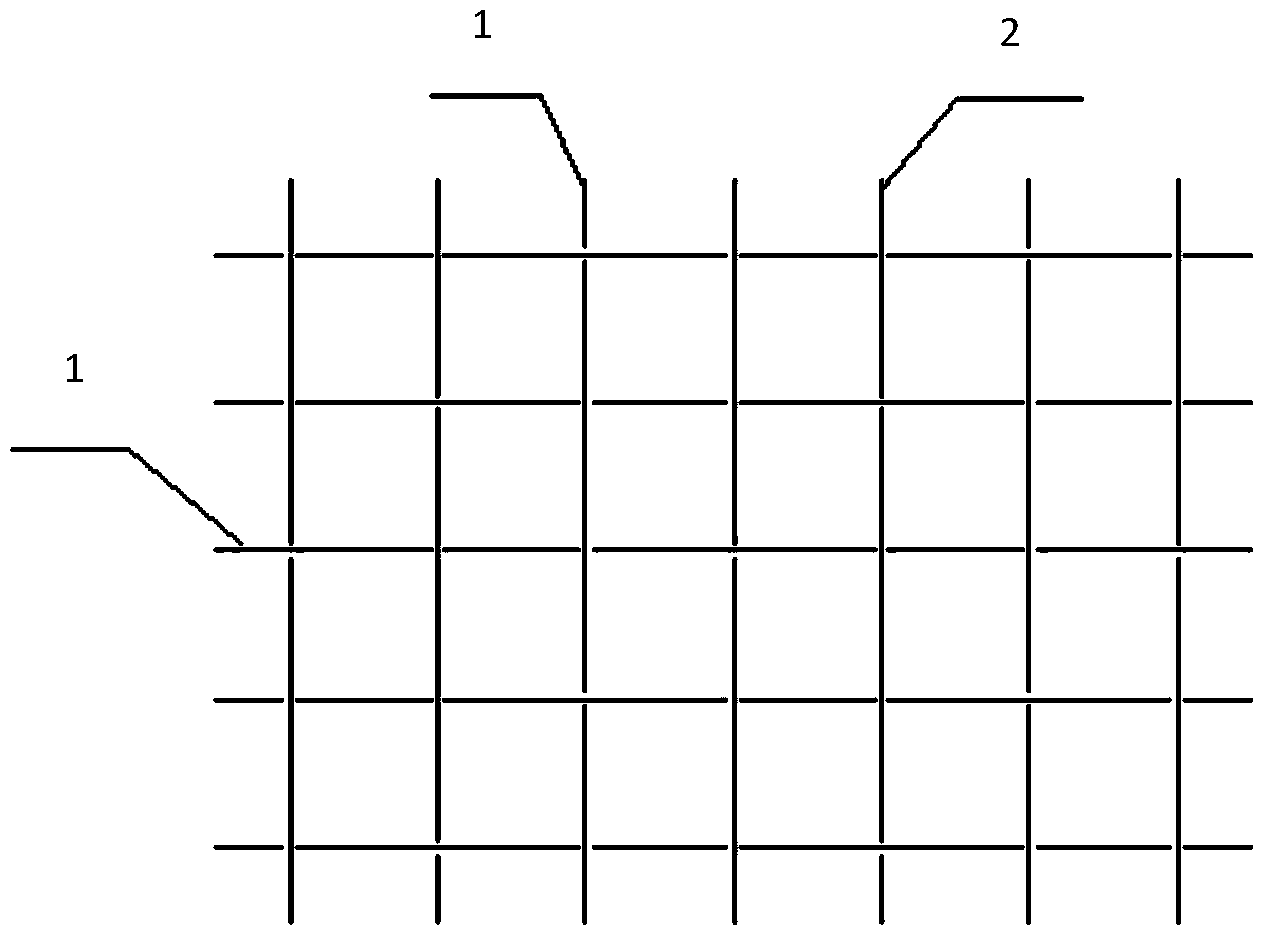

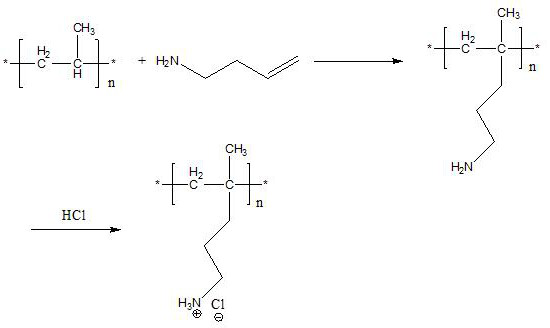

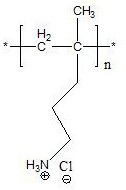

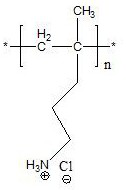

Hydrophilic melt-blown fabric and preparation method thereof

ActiveCN111748908AImprove hydrophilic performanceImprove the bactericidal effectAbsorbent padsMonocomponent synthetic polymer artificial filamentPolypropyleneAnti bacterial

The invention provides a hydrophilic melt-blown fabric. The hydrophilic melt-blown fabric is prepared from hydrophilic modified polypropylene, deionized water and tetraethoxysilane, wherein the hydrophilic modified polypropylene is prepared by polymerizing polypropylene and a 3-butenyl-1-amine monomer and reacting with hydrochloric acid, and the chemical structural formula is shown as a formula I.The preparation method is simple, the prepared melt-blown non-woven fabric has excellent hydrophilic performance and good antibacterial performance and can be applied to sanitary products such as sanitary towels, diapers, sanitary cleaning cloth and the like, and the hydrophilic performance of the melt-blown fabric is remarkably improved under the action of the hydrophilic modified polypropyleneand interlayer silicon dioxide; and meanwhile, chloride ions are dissociated under the action of water, and a good sterilization effect is achieved; the material can be repeatedly used after being subjected to chlorine bleaching again, and the service life of the material is prolonged. The formula I is shown in the specification

Owner:宣城广能非织造有限公司

Dry film hydrophilc agent

ActiveCN103437162AImprove hydrophilic performanceIncrease hydrophilic permeabilitySemi-permeable membranesFibre treatmentFilm materialGlycerol

The invention relates to a dry film hydrophilc agent which is prepared from the following components in parts by weight: 1000 parts of water, 20-60 parts of polyethyleneglycol-polyethylene phthalate block copolymer, 5-20 parts of silicon oil block terpolymer, 150-300 parts of ethanol or glycerol, 0-6 parts of n-hexyl alcohol, 5-10 parts of Tween-80, 3-30 parts of op-10 surfactant and 0-5 parts of sodium bisulfite. Compared with the traditional agent, the hydrophilc agent is reasonable in formula, and the film material is hydrophilc for a long time; after the film material is immersed by the hydrophilc agent, the film can be preserved in a dry state without being immersed in liquid, thereby reducing the possibility of bacterium breeding and mildewing on the film material surface; and the invention effectively prolongs the shelf life of the film product, prolongs the service life of the film product, and enhances the water output and stability of the film product.

Owner:SUZHOU EDGECROSS MEMBRANE TECH

Surface hydrophilic layer modification method for implantable medical device and application

PendingCN113499484AImprove hydrophilic performanceImprove lubricitySurgeryPharmaceutical delivery mechanismAqueous solubilityEngineering

The invention discloses a surface hydrophilic layer modification method for an implantable medical device and application, and belongs to the technical field of medical devices, and the surface hydrophilic layer modification method comprises plasma hydrophilic modification, hydrogel hydrophilic modification and biological extract modification. The surface of the medical device is modified through plasma hydrophilic modification or hydrogel prepared from biocompatible water-soluble polymers and viscous components, or a biological extract, so that a hydrophilic layer is formed, the surface lubricity of the biological medical device can be improved, resistance generated in the use process of the medical device is reduced, the damage to tissues caused by implantation of medical instruments is reduced, complications are reduced, and the biocompatibility is improved. The method has the advantages that the method is simple, the lubricating effect is good, the operation is convenient, and the method is safe, environmentally friendly and the like. The invention further discloses the surface hydrophilic layer of the implantable medical device and the implantable medical device modified by the hydrophilic layer.

Owner:SHENZHEN INST OF ADVANCED TECH

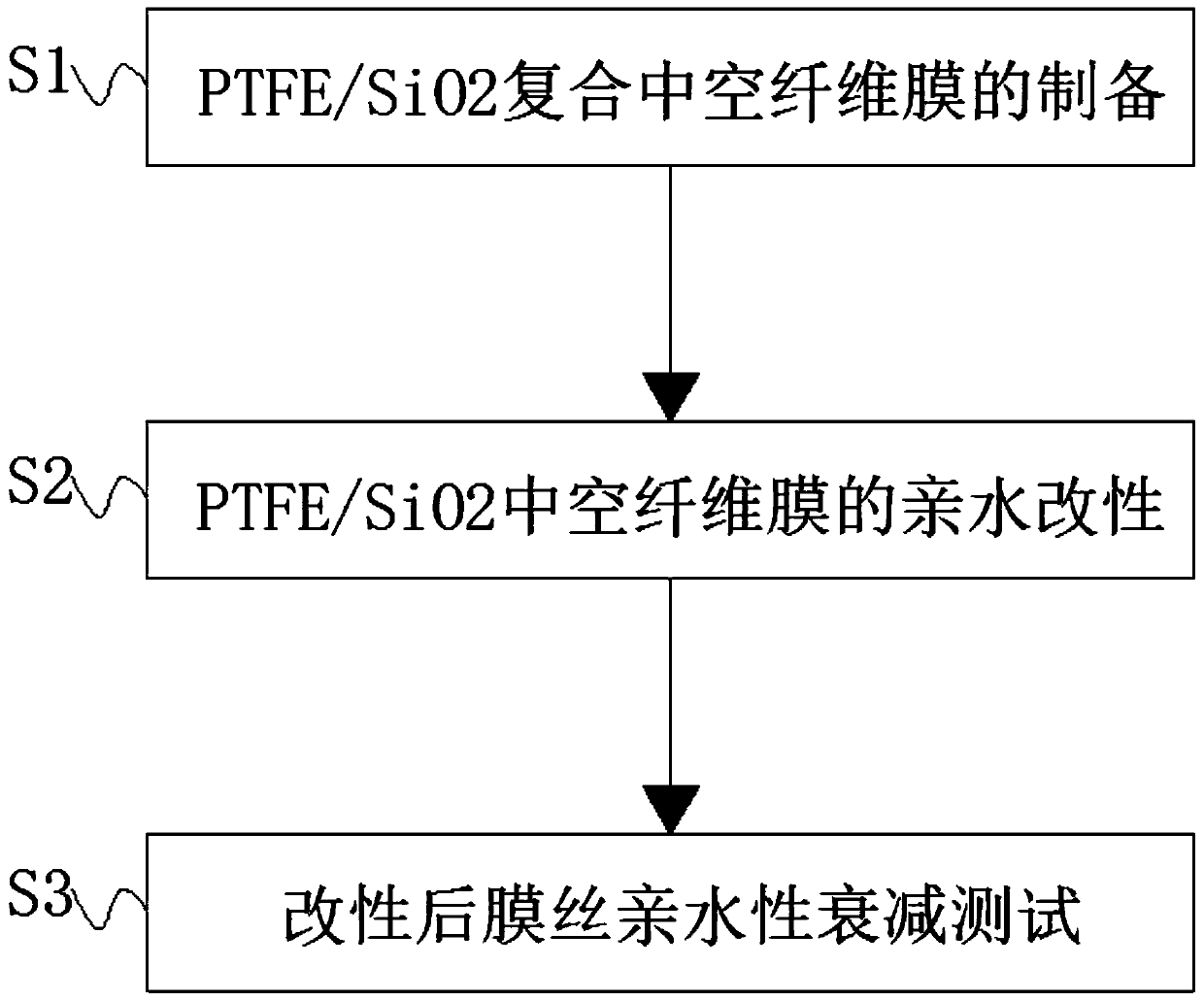

Preparation method of hydrophilic polytetrafluoroethylene hollow fiber membrane

InactiveCN110523299AImprove hydrophilic performanceEnhanced advantageMembranesSemi-permeable membranesCross-linkFiber

The invention discloses a preparation method of a hydrophilic polytetrafluoroethylene hollow fiber membrane. The preparation method specifically comprises the following steps: S1, preparing a PTFE / SiO2 composite hollow fiber membrane; S2, performing hydrophilic modification on the PTFE / SiO2 composite hollow fiber membrane; and S3, performing a hydrophily attenuation test on modified membrane yarns. The invention belongs to the technical field of water treatment of PTFE hollow fiber membrane. The invention discloses a preparation method of the hydrophilic polytetrafluoroethylene hollow fiber membrane. According to the preparation method, physicochemical cross-linking method is adopted; under the action of a coupling agent and a cross-linking agent, hydroxyl (-OH) is introduced onto the surface of the membrane to prepare the PTFE microporous membrane with stable hydrophilic performance; the hydrophilic performance of the composite microporous membrane is obviously improved; the stabilityof the hydrophilic performance of the PTFE hollow fiber membrane is ensured; the pure water flux of the modified membrane filaments can reach 3500L / m<2>*h, the water contact angle is 60 degrees, theadvantages of the PTFE hollow fiber membrane products are improved, the surface of the PTFE hollow fiber membrane has stable hydrophilic performance, and the application range of the PTFE hollow fibermembrane in the fields of membrane separation and water treatment is expanded.

Owner:XINJIANG DELAND

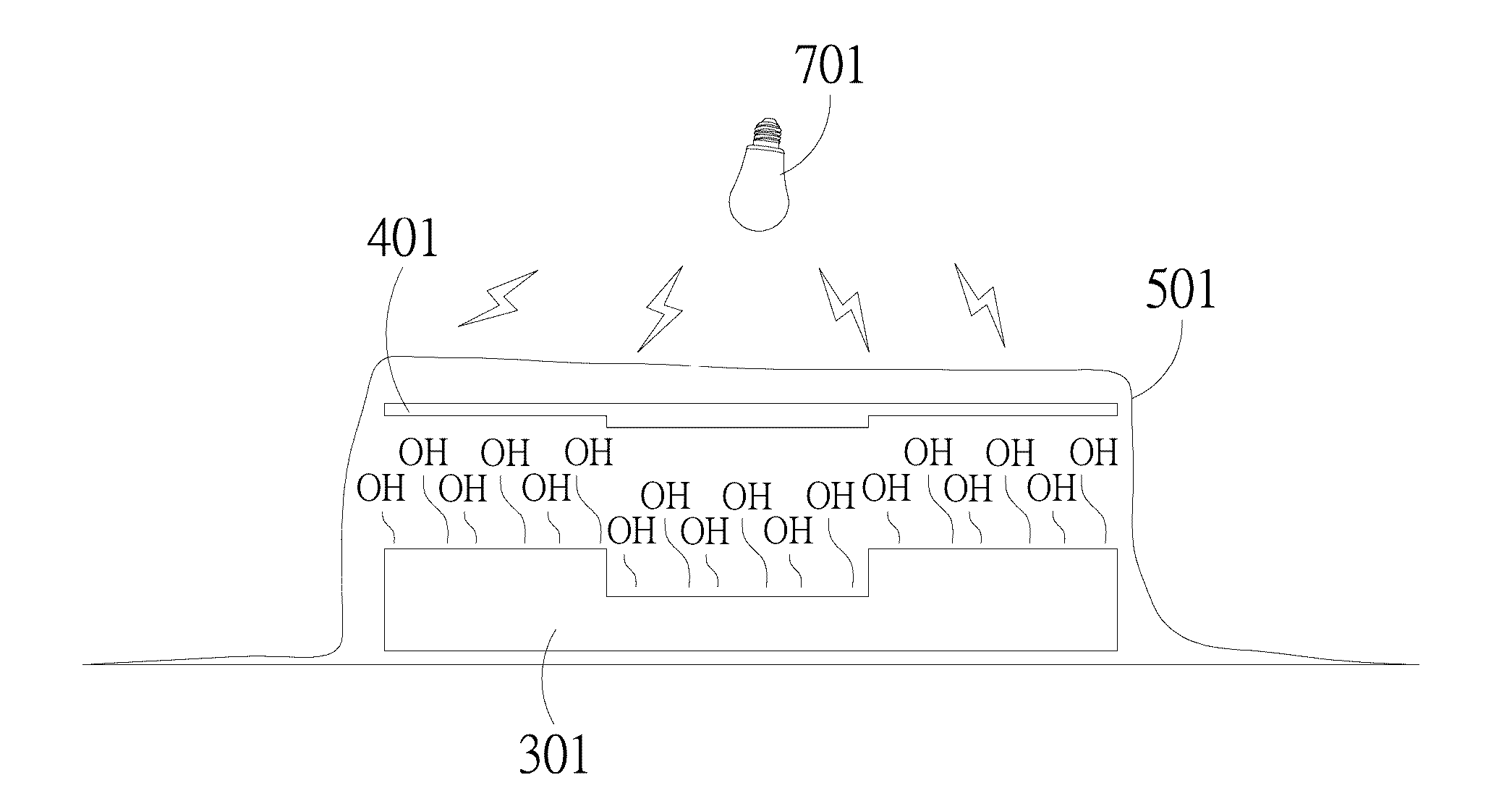

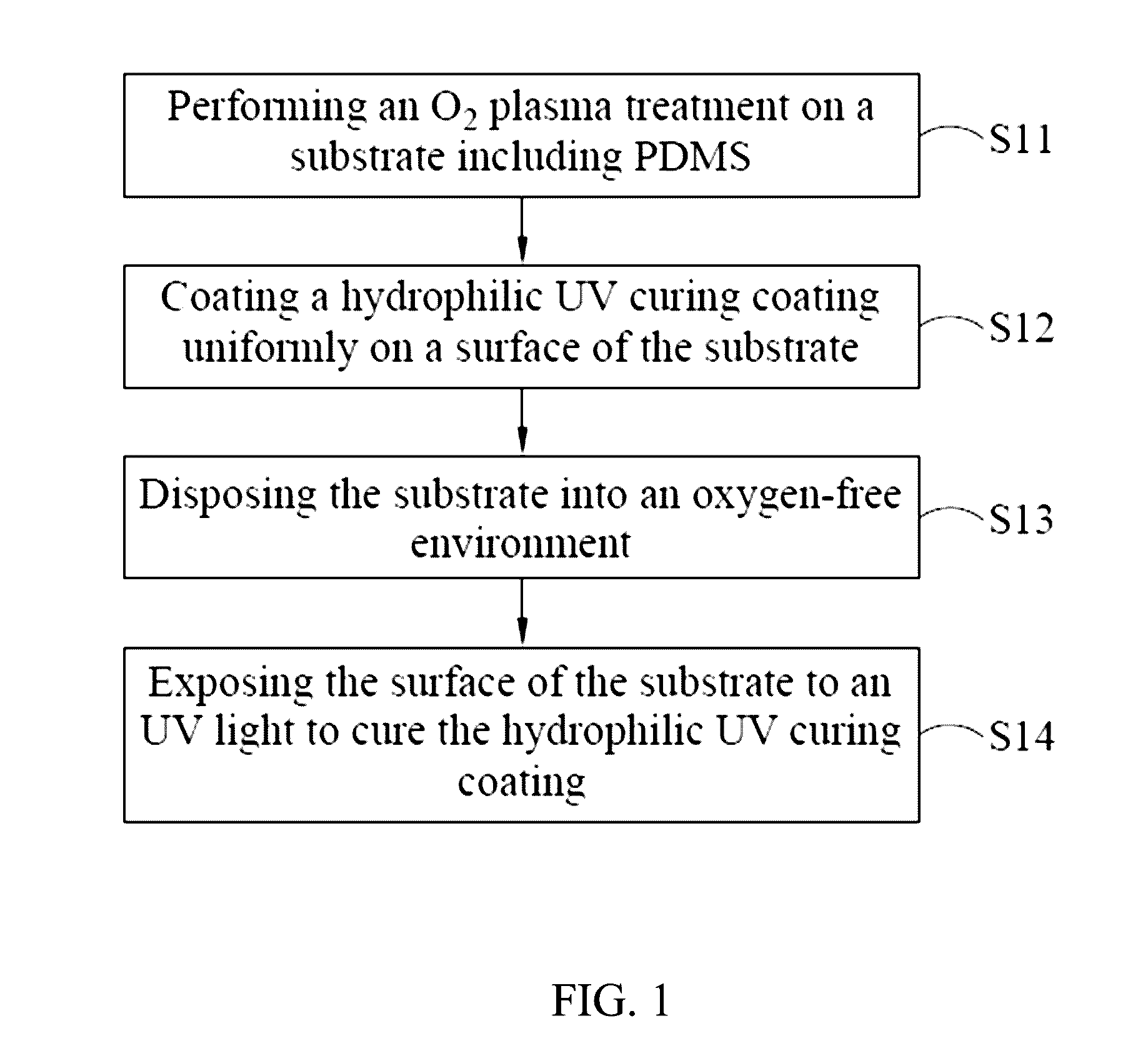

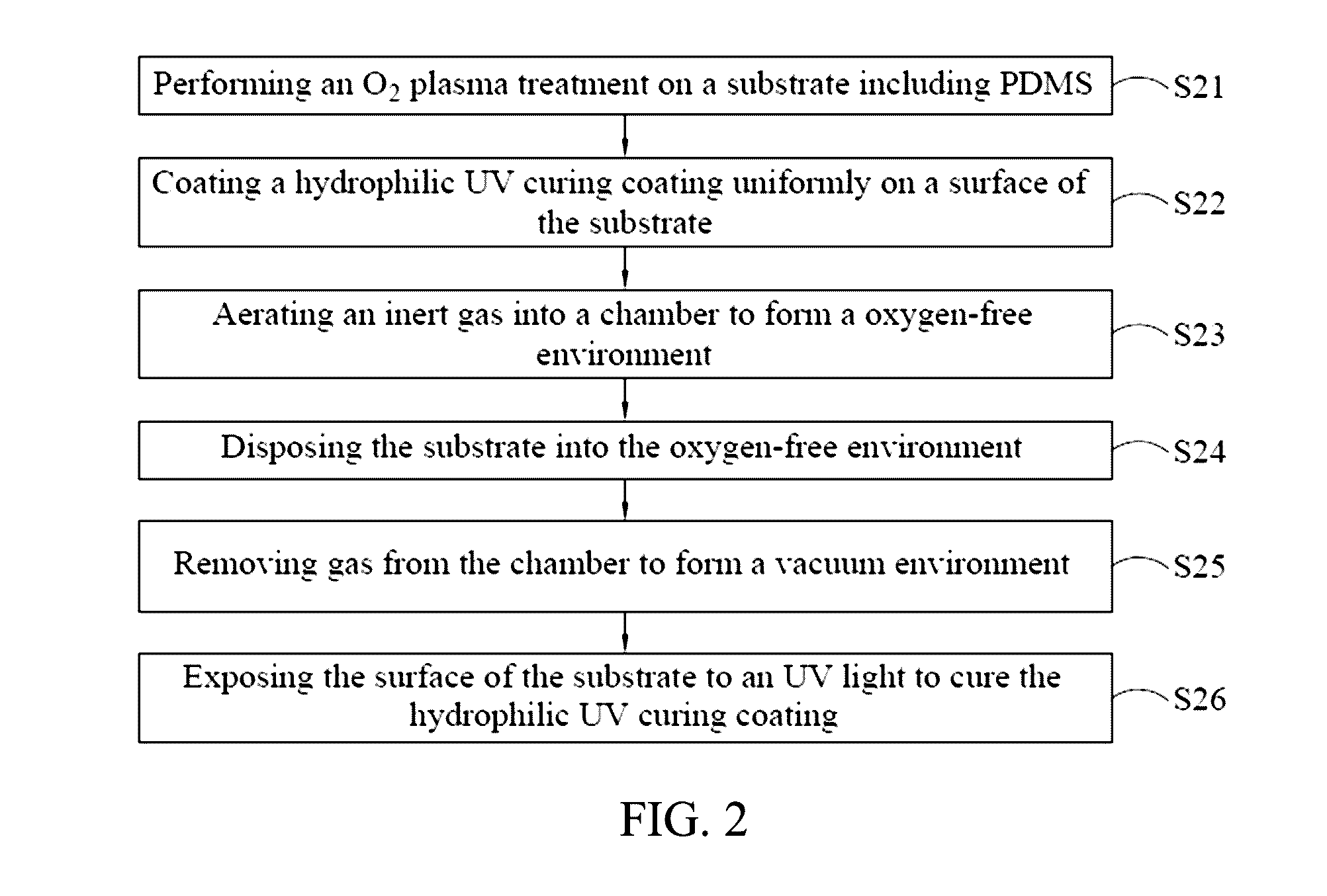

Method of modifying substrate surface

ActiveUS20160362781A1Low costImprove hydrophilic performancePretreated surfacesSpecial surfacesUV curingUltraviolet

A method of modifying substrate surface includes: performing an O2 plasma treatment on a substrate including polydimethylsiloxane (PDMS); coating hydrophilic UV curing coating uniformly on the substrate; disposing the substrate into an oxygen-free environment; and exposing to an UV light to cure the hydrophilic UV curing coating. The method of modifying substrate surface may greatly enhance the hydrophilicity and the stability of the PDMS substrate.

Owner:NATIONAL TSING HUA UNIVERSITY

Method capable of enhancing hydrophilic performance of cotton fibers

ActiveCN111485427AReduce crystallinityBig gapBiochemical treatment with enzymes/microorganismsGrip property fibresCotton fibreAcetic acid solution

The invention discloses a method capable of enhancing hydrophilic performance of cotton fibers. The method comprises the following steps of activating the cotton fibers to obtain pre-treated cotton fibers; swelling the pre-treated cotton fibers fully in a sodium hydroxide solution, successively adding epichlorohydrin and a phase change catalyst to react for 10-20 hours at 70-80 DEG C, filtering, washing and drying the solution, adding isopropanol into the solution, adjusting the pH value of a system with alkali liquor to 9.2-9.8, adding 2-6 parts of 0.6-0.8% HBP-NH2 solution under nitrogen protection to react for 2-4 hours at 50-60 DEG C, and washing and drying the solution to obtain amino cotton fibers; dissolving chitosan in an acetic acid solution, adding soyabean proteins, stirring thesolution for 20-40 min at 70-80 DEG C, cooling the solution to 40-46 DEG C, adjusting the system to be neutral, carrying out enzymolysis and enzyme deactivation, adding the amino cotton fibers, stirring the solution for 20-40 min at 75-85 DEG C, and filtering and washing the solution and vacuum drying the solution to obtain the hydrophilic cotton fibers.

Owner:安徽省农业科学院棉花研究所

Preparation method of anti-crack low-shrinkage cement mortar

InactiveCN110467396AImprove dispersion performanceImprove hydrophilic performanceConstruction aggregateSulfonic acid ester

The invention belongs to the field of cement mortar materials, and particularly relates to a preparation method of anti-crack low-shrinkage cement mortar. According to the invention, waste straw is used as a raw material; carbonized wood fibers, mixed aggregate, coarse wood powder, hydroxymethyl cellulose, triethylamine and sodium sulfite are added into water and then stirred and dispersed to obtain the anti-crack low-shrinkage cement mortar. An organic viscosity reducer used in the invention is quaternary ammonium type cationic cyclodextrin, so the shrinkage amount of the cement mortar is reduced, and cracking of the cement mortar is avoided. The coarse wood powder recovered from straw residues contains a large amount of lignin; on one hand, as a modifying substance for cyclodextrin, thecoarse wood powder improves the dispersion performance of cyclodextrin; on the other hand, sulfonic acid groups are introduced into lignin molecules, so high dispersion of cement particles and uniformdensity of slurry can be kept, and shrinkage amount in a later solidification period is reduced; in addition, since a certain amount of lignin is added, the deposition density of cyclodextrin duringbonding of a construction surface is improved, the compressive strength of the cement mortar is enhanced, and the cement mortar has wide application prospects.

Owner:李魁

Method for realizing uniform liquid separation on hydrophobic polymer trace porous carrier

ActiveCN108341988AImprove hydrophilic performanceImprove hydrophilicityAnalysis by subjecting material to chemical reactionCoatingsSurface modificationRadio frequency plasma

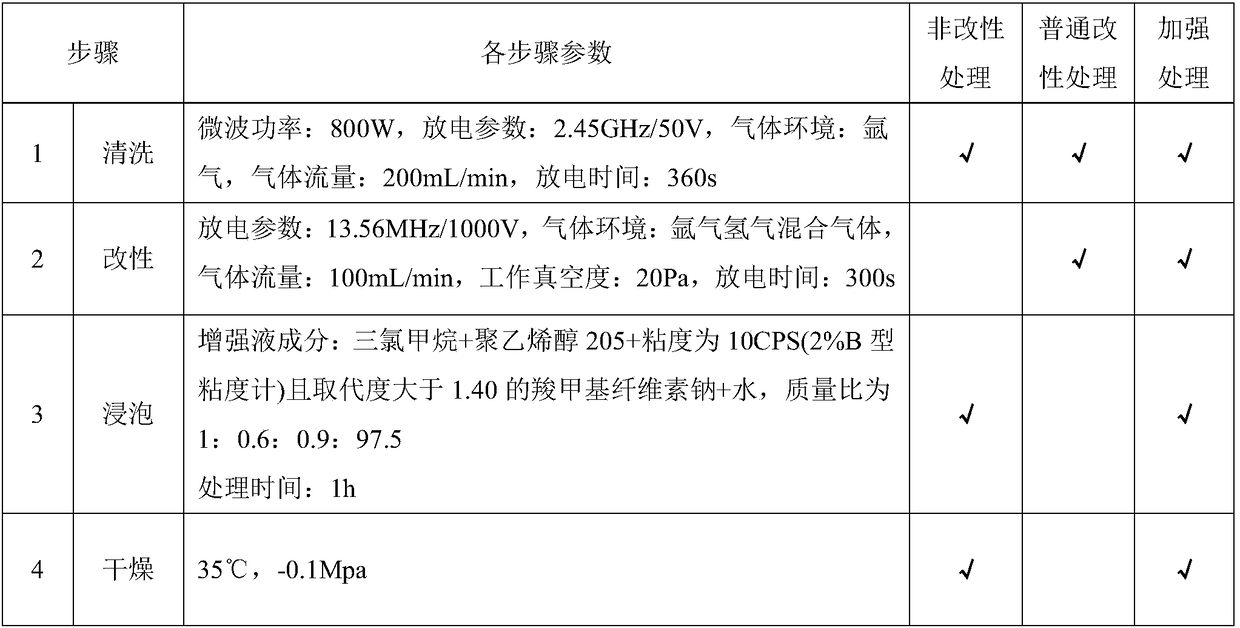

The invention discloses a method for realizing uniform liquid separation on a hydrophobic polymer trace porous carrier. The hydrophilic modification method of the hydrophobic polymer trace porous carrier comprises the following steps: 1) cleaning a hydrophobic polymer trace porous carrier injection molded part; 2) placing the cleaned injection molded part into a generation cavity of a radio frequency plasma generator for surface modification treatment; 3) putting the surface-modified injection molded part into a hydrophilic modification enhancing liquid for soaking treatment; 4) taking out thesoaked injection molded part, draining off, and drying to obtain the hydrophilic trace porous carrier injection molded part. The obtained injection molded part has relatively high hydrophilicity, sothat the hydrophilic culture medium which is subpackaged or borne on the surface of the injection molded part can be rapidly and uniformly dispersed in each micro-hole under the small sub-packaging amount. A trace biochemical identification strip with the liquid separation function is treated by using the technology, after the trace biochemical identification strip is placed for 360 days, even liquid separation can still be carried out, and correct identification results can be guaranteed.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com