Hydrophilic modification method of PVA to polyester fiber

A polyester fiber and hydrophilic modification technology, which is applied in the field of polymers, can solve the problems of poor hydrophilicity of polyester fiber, and achieve the effects of low cost, small usage and simple source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

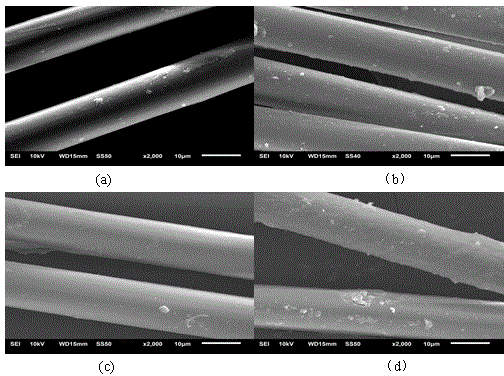

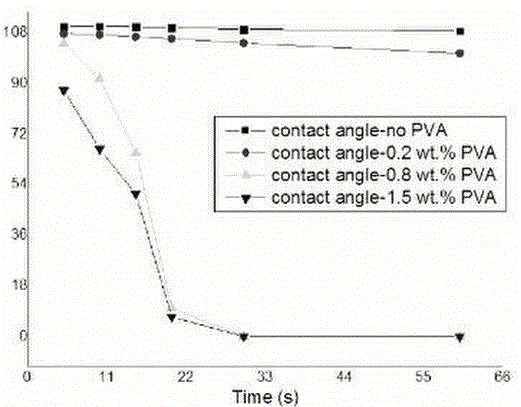

Image

Examples

Embodiment 1

[0021] 1 Accurately weigh 3g of sodium hydroxide solid, add 97ml of water to prepare a sodium hydroxide solution with a mass fraction of 3%, put it into a stirring container, then add 2g of polyester fiber to the container, and put it in the reaction container at 70°C Stirring pretreatment for 1 hour, the mechanical stirring speed is 100 rpm, the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50, after the reaction, wash and dry the polyester fiber with water.

[0022] 2 Accurately weigh 1.0g of PVA with an electronic weighing instrument, add 499ml of deionized water, dissolve at 70°C, and prepare a PVA solution with a mass fraction of 0.2%, and the solute is evenly distributed in the solution.

[0023] 3 Put the above-mentioned dried polyester fiber and the prepared PVA solution with a mass fraction of 0.2% into the reaction vessel, then add 30ml of acetic acid, 20ml of methanol, and 10ml of sulfuric acid to the reaction vessel. The volume...

Embodiment 2

[0027] 1 Accurately weigh 5g of sodium hydroxide solid, add 95ml of water to prepare a sodium hydroxide solution with a mass fraction of 5%, put it into a stirring container, then add 2g of polyester fiber to the container, and put it in the reaction container at 70°C Stirring pretreatment for 1 hour, the mechanical stirring speed is 250 rpm, the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50, after the reaction, wash and dry the polyester fiber with water.

[0028] 2 Accurately weigh 2.0g of PVA with an electronic weighing instrument, add 98ml of deionized water, dissolve at 70°C, and prepare a PVA solution with a mass fraction of 2%, and the solute is evenly distributed in the solution.

[0029] 3 Put the above-mentioned dried polyester fiber and the prepared PVA solution with a mass fraction of 2% into the reaction vessel, then add 30ml of acetic acid, 20ml of methanol, and 10ml of sulfuric acid to the reaction vessel. The volume frac...

Embodiment 3

[0033] 1 Accurately weigh 10g of sodium hydroxide solid, add 90ml of water to prepare a sodium hydroxide solution with a mass fraction of 10%, put it into a stirring container, then add 2g of polyester fiber to the container, and put it in the reaction container at 70°C Stirring pretreatment for 1 hour, the mechanical stirring speed is 400 rpm, the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50, after the reaction, wash and dry the polyester fiber with water.

[0034] 2 Accurately weigh 3.0g of PVA with an electronic weighing instrument, add 97ml of deionized water, dissolve at 70°C, and prepare a PVA solution with a mass fraction of 3%, and the solute is evenly distributed in the solution.

[0035] 3 Put the above-mentioned dried polyester fiber and the prepared PVA solution with a mass fraction of 3% into the reaction vessel, then add 30ml of acetic acid, 20ml of methanol, and 10ml of sulfuric acid to the reaction vessel. The volume fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com