Preparation method of superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane

A polyacrylonitrile-based oil, underwater super-oleophobic technology, applied in separation methods, immiscible liquid separation, liquid separation, etc., can solve the problems of complex modification, complicated experimental process, small material size, etc., and achieve permanent Stable hydrophilicity, uniform pore size distribution, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add acrylonitrile-based binary copolymer acrylonitrile-methyl acrylate (molar ratio 4:1), crystalline compound diluent caprolactam and acetamide (mass ratio of caprolactam and acetamide is 3:1) into the stirred tank, propylene The mass percentage of nitrile-methyl acrylate (molar ratio: 4 / 1) binary copolymer is 20wt%, raise the temperature to 150°C, fully stir for 2h, stop stirring, defoam at this temperature for 20min, and make cast film liquid; preheat the mold in an oven with a set temperature of 155°C for 6 minutes, pour the casting solution into a mold with a thickness of 200 μm in the middle, and then place it in the oven, keep it at 150°C for 10 minutes, and quickly take out the mold And place it at 20-30°C to cool naturally in the air, after the casting liquid crystallizes and solidifies; open the mold, extract the diluent in the nascent film in deionized water, and obtain the acrylonitrile-based copolymer flat microporous film. After drying the prepared polyacr...

Embodiment 2

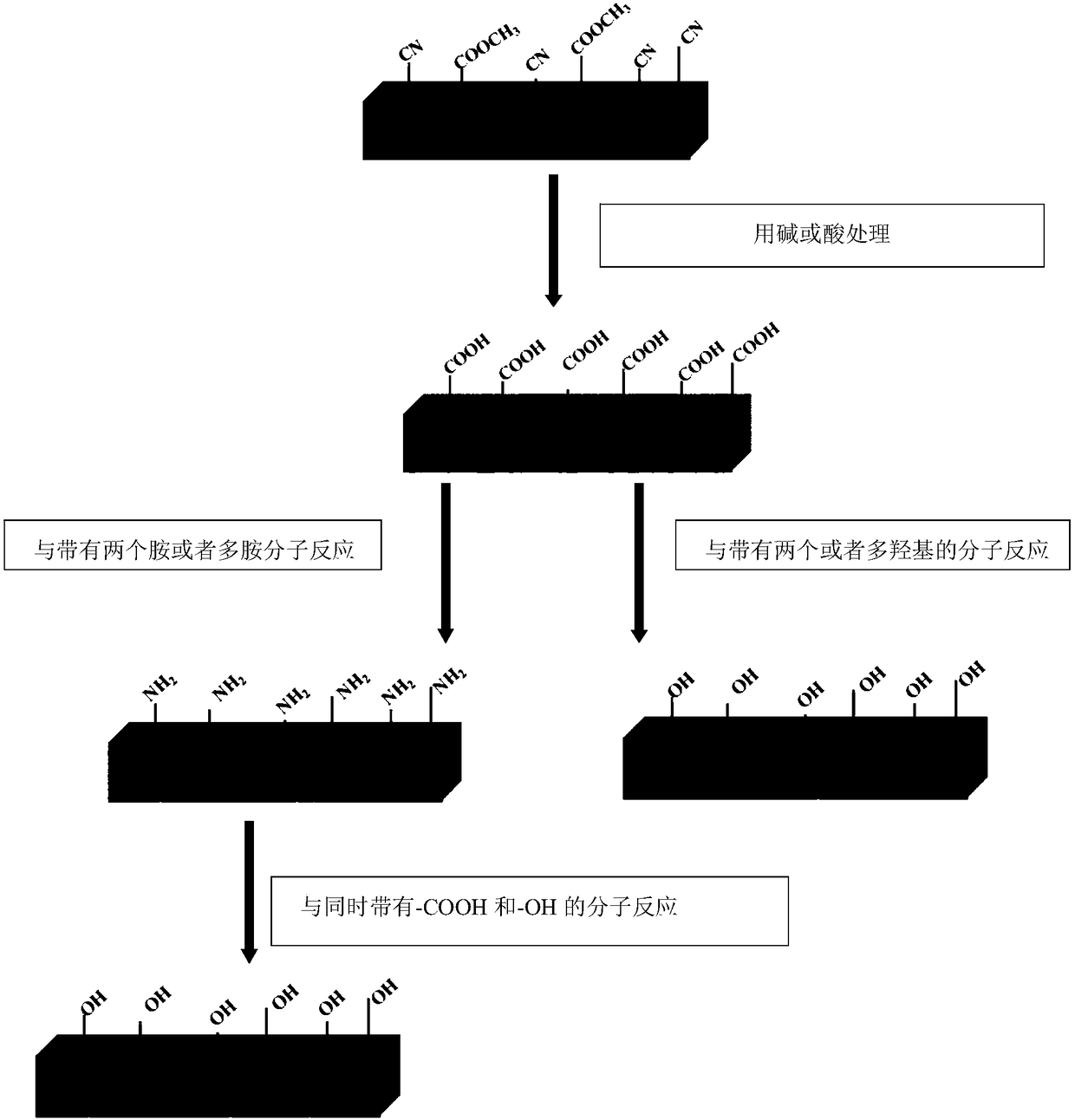

[0046] Such as figure 1 As shown, the carboxyl-rich microporous membrane prepared in Example 1 is directly immersed in a polyethyleneimine solution with a mass fraction of 2wt.% and a molecular weight of 600 at 40°C for 2 hours to prepare a superhydrophilic membrane rich in a large number of amine groups on the surface. Underwater superoleophobic polyacrylonitrile-based microporous membrane. The molecular structure of polyethyleneimine is

[0047]

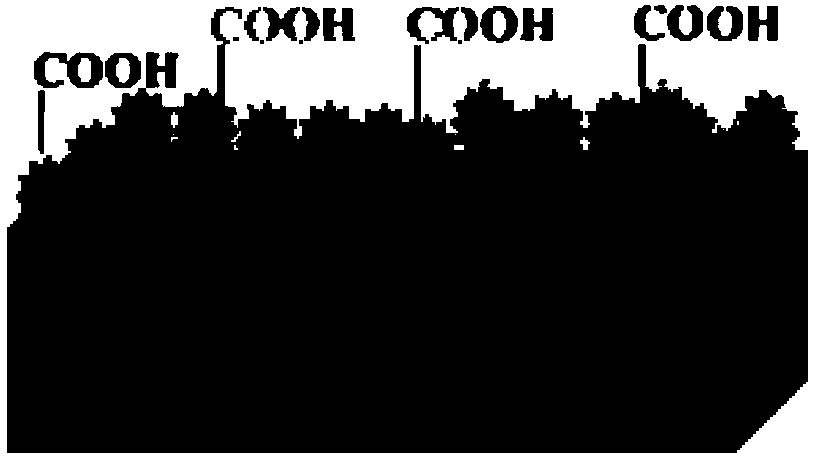

[0048] After testing, the amine-rich acrylonitrile-based copolymer flat microporous membrane obtained in this example has a pore size distribution of 0.18-0.27 μm, and the cross-section presents a symmetrical double-connected dendritic structure with a porosity of up to 77.5% and a fracture strength of 2.6Mpa, the elongation at break is 17%, the surface has a micro-nano structure, the roughness is 3-8μm, the water droplets in the air quickly infiltrate the microporous membrane, the air-water contact angle is 0°, and the underwa...

Embodiment 3

[0050] Such as figure 1 As shown, the carboxyl-terminated microporous membrane prepared in Example 1 is directly soaked in a solution of 10wt.% glycerol and 2wt.% hydrochloric acid (catalyst) at 40°C for 2 hours to prepare a surface rich in a large number of hydroxyl groups. Hydrophilic, underwater superoleophobic polyacrylonitrile-based microporous membrane. The molecular structure of glycerol is

[0051]

[0052] After testing, the hydroxyl-rich acrylonitrile-based copolymer flat-plate microporous membrane obtained in this example has a pore size distribution of 0.18-0.27 μm, a symmetrical double-connected dendritic structure in cross-section, a porosity of up to 78.0%, and a breaking strength of 2.8 Mpa, the elongation at break is 16%, the surface has a micro-nano structure, and the roughness is 3-7μm. In the air, water droplets quickly infiltrate the microporous membrane, the air water is 0°, and the underwater oil contact angle is 163°. Flat microporous membrane. Sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com