Hydrophilic modification method for polyester fiber by using sodium alginate

A technology of polyester fiber and sodium alginate, which is applied in the field of polymers, can solve the problems of poor hydrophilicity of polyester fiber, and achieve the effect of easy operation, small dosage and high hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

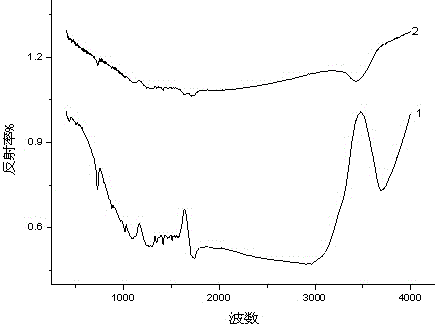

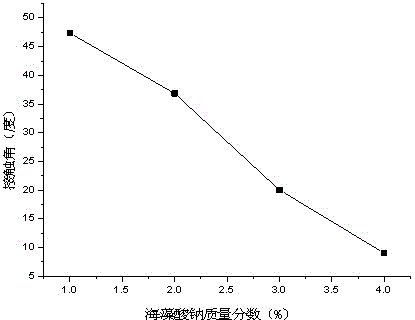

Image

Examples

Embodiment 1

[0022] 1. Accurately weigh 3g of sodium hydroxide solid, add 97ml of water to prepare a 3% sodium hydroxide solution, and put it in a stirring vessel, then add 2g of polyester fiber to the vessel, and place it in the reaction vessel at 70℃. The medium stirring pretreatment is 1 hour, the mechanical stirring speed is 200 rpm, and the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50. After the reaction, the polyester fiber is rinsed and dried with water.

[0023] 2. Accurately weigh 4g of sodium alginate solids, add 96ml of deionized water to prepare a 4% sodium alginate solution, stir it fully, the mechanical stirring speed is 200 rpm, and then place it at 4°C Let it stand for 1 hour to make the sodium alginate fully absorb water and swell to obtain a viscous solution of sodium alginate.

[0024] 3. Accurately weigh 2g of calcium chloride solids, add 98ml of deionized water to prepare a calcium chloride solution with a mass fraction of 2% for use, and put ...

Embodiment 2

[0028] 1. Accurately weigh 5g of sodium hydroxide solid, add 95ml of water to prepare a 5% sodium hydroxide solution, and put it in a stirring vessel, then add 2g of polyester fiber to the vessel, and place it in the reaction vessel at 80℃. The medium stirring pretreatment is 1h, the mechanical stirring speed is 300 rpm, and the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50. After the reaction, the polyester fiber is rinsed and dried with water.

[0029] 2. Accurately weigh 3g of sodium alginate solids, add 97ml of deionized water to prepare a 3% sodium alginate solution, stir it fully, the mechanical stirring speed is 300 rpm, and then place it at a temperature of 4 ℃ Let it stand for 1 hour to make the sodium alginate fully absorb water and swell to obtain a viscous solution of sodium alginate.

[0030] 3. Accurately weigh 2g of calcium chloride solids, add 98ml of deionized water to prepare a 2% calcium chloride solution for use, and put the treated...

Embodiment 3

[0034] 1. Accurately weigh 10g of sodium hydroxide solid, add 90ml of water to prepare a 10% sodium hydroxide solution, and put it into a stirring vessel, then add 2g of polyester fiber to the vessel, and place it in the reaction vessel at 90℃. The medium stirring pretreatment is 1h, the mechanical stirring speed is 400 rpm, and the solid-liquid ratio of the polyester fiber and the reaction solution is 1:50. After the reaction, the polyester fiber is rinsed and dried with water.

[0035] 2. Accurately weigh 2g of sodium alginate solids, add 98ml of deionized water to prepare a 2% sodium alginate solution, stir it fully, the mechanical stirring speed is 400 rpm, and then place it at 4°C Let it stand for 1 hour to make the sodium alginate fully absorb water and swell to obtain a viscous solution of sodium alginate.

[0036] 3. Accurately weigh 2g of calcium chloride solids, add 98ml of deionized water to prepare a calcium chloride solution with a mass fraction of 2% for use, and put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com