Hydrophilic modification method of ultrafiltration membrane

A hydrophilic modification and ultrafiltration membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of difficult selection of grafted monomers, difficulty in maintaining hydrophilicity, and harsh reaction conditions and other problems, to achieve excellent separation performance, convenient operation, and stable hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

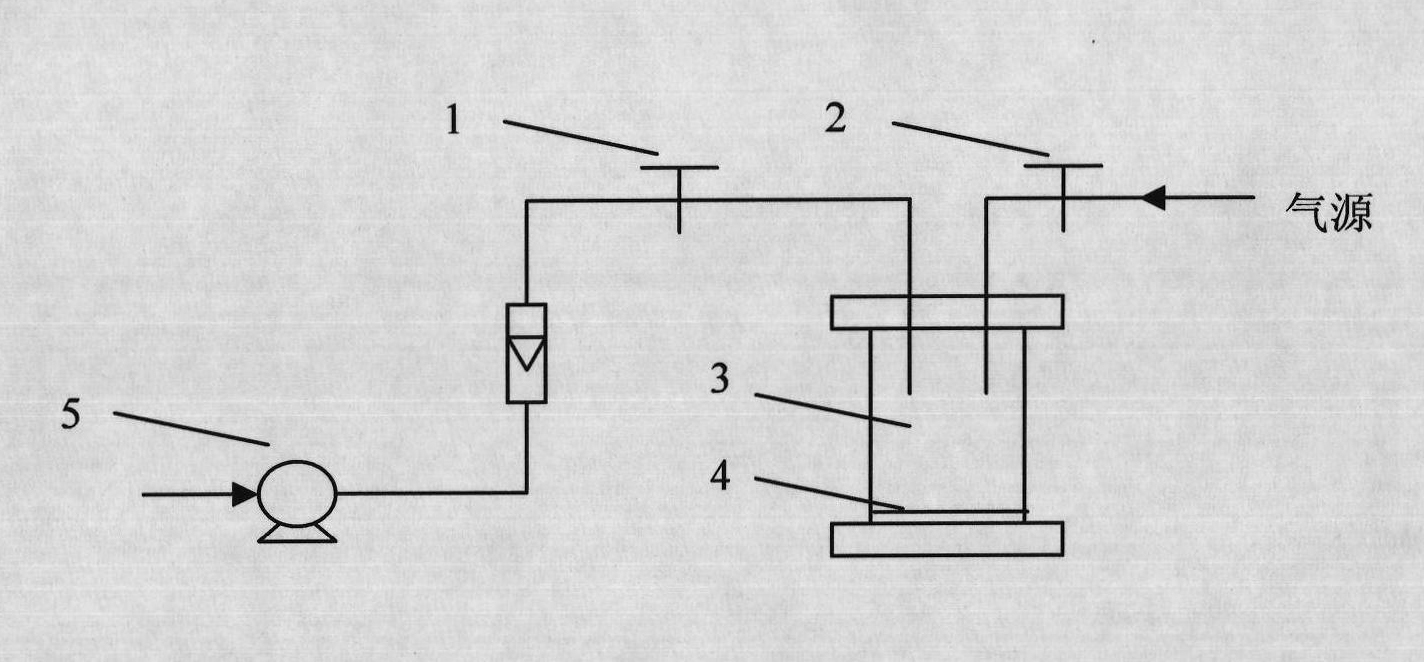

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the PVA hydrophilic modification ultrafiltration membrane (PES bottom membrane) that preparation deposition amount m is 0.4

[0026] Select polyethersulfone (PES) ultrafiltration membrane as the bottom membrane, the membrane area is 25cm 2 Concentration is that the PVA aqueous solution 50ml of 0.2 μ g / ml and the glutaraldehyde 25ml of 1.5% are mixed homogeneously and transported in the filter pool (concentration of solidifying agent in the mixed solution is 0.5%), under 0.1MPa air pressure, PVA is deposited on On the PES base film; curing at 20°C for 30 minutes;

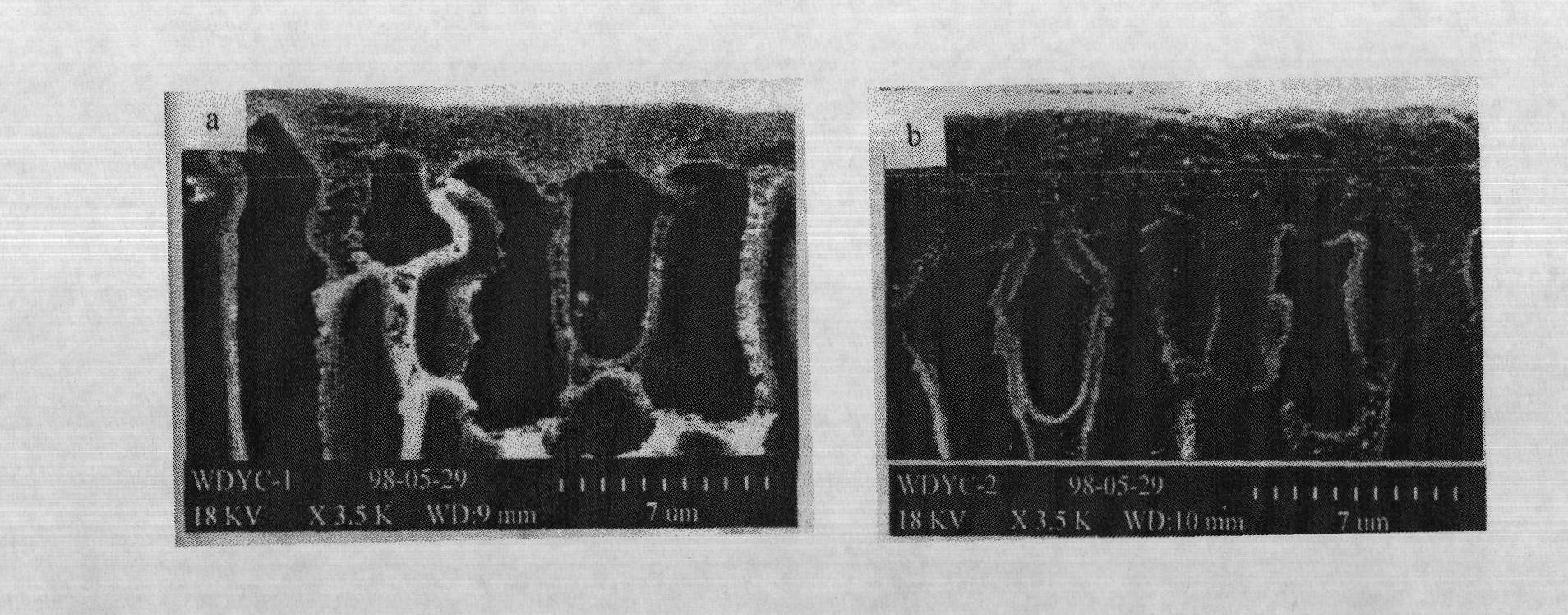

[0027] The pure water flux of the modified ultrafiltration membrane is 187.2L / hr.m 2 (25°C, 0.1MPa); the contact angle of the membrane surface is 22 degrees; the stable flux of 3000ppm oil-water emulsion filtration test is 110L / hr.m 2 , After repeated oil-water emulsion filtration tests and cleaning, the pure water flux can still recover to more than 90% of the initial pure water flux.

Embodiment 2

[0028] Embodiment 2: the PVA hydrophilic modification ultrafiltration membrane (PES bottom membrane) that preparation deposition amount m is 2

[0029] (1) Select polyethersulfone (PES) ultrafiltration membrane as the bottom membrane, and the membrane area is 25cm 2 50ml of PVA aqueous solution with a concentration of 1μg / ml and 25ml of 3% glutaraldehyde are mixed evenly and transported to the filter tank (the concentration of the curing agent in the mixed solution is 1%), and deposited on the PES ultrafiltration filter under 0.1MPa pressure. On the base film; curing at 40°C for 20 minutes;

[0030] The pure water flux of the modified ultrafiltration membrane is 156.8L / hr.m 2 (25°C, 0.1MPa); the contact angle of the membrane surface is 18 degrees; the stable flux of 3000ppm oil-water emulsion filtration test is 100L / hr.m 2 , After repeated oil-water emulsion filtration tests and cleaning, the pure water flux can still recover to more than 95% of the initial pure water flux. ...

Embodiment 3

[0031] Embodiment 3: the PVA hydrophilic modification ultrafiltration membrane (PES bottom membrane) that preparation deposition amount m is 8

[0032] (1) Select polyethersulfone (PES) ultrafiltration membrane as the bottom membrane, and the membrane area is 25cm 2 Be that the PVA aqueous solution 50ml of 4 μ g / ml and the glutaraldehyde 25ml of 6% are mixed uniformly and transported in the filter pool (concentration of curing agent in the mixed solution is 2%), transported in the filter pool after mixing uniformly, Deposited on the PES ultrafiltration bottom membrane under 0.1MPa pressure; cured at 40°C for 10 minutes;

[0033] The pure water flux of the modified ultrafiltration membrane is 149.8L / hr.m 2 (25°C, 0.1MPa); the contact angle of the membrane surface is 18 degrees; the stable permeation of 3000ppm oil-water emulsion filtration test is 95L / hr.m 2 , After repeated oil-water emulsion filtration tests and cleaning, the pure water flux can still recover to more than 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com