Method for realizing uniform liquid separation on hydrophobic polymer trace porous carrier

A hydrophobic polymer, porous carrier technology, applied in the direction of chemical reaction of materials for analysis, coating, etc., can solve the problems of short hydrophilicity, insufficient hydrophilicity, waste of energy, etc., and achieve high hydrophilicity. The effect of water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

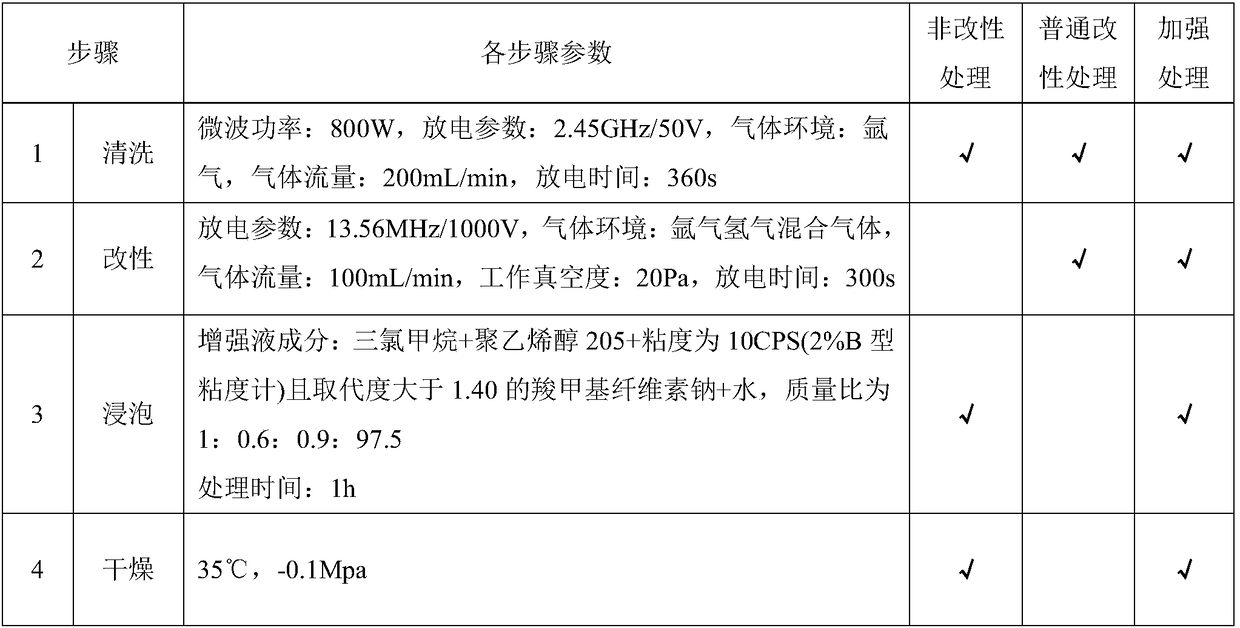

[0027] A method for hydrophilic modification of a hydrophobic macromolecule microporous carrier, comprising the steps of:

[0028] 1) cleaning the injection molded part of the hydrophobic polymer trace porous carrier;

[0029] 2) Place the cleaned injection molded part in the generation cavity of the radio frequency plasma generator for surface modification treatment;

[0030] 3) Soak the surface-modified injection molded part in a hydrophilic modification enhancement solution;

[0031] 4) Take out the injection molded part after soaking treatment, drain and dry to obtain the injection molded part of hydrophilic trace porous carrier.

[0032] As a further improvement of the above-mentioned hydrophilic modification method, the hydrophilic modification enhancement liquid is an aqueous solution containing chloroform, polyvinyl alcohol 205 and sodium carboxymethyl cellulose, and the mass concentration ratio of the three components is 3:(1 ~2.5): (1~3), and the total mass concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com