Method capable of enhancing hydrophilic performance of cotton fibers

A cotton fiber and hydrophilic technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of poor water absorption and softness, and achieve good softness, fast moisture dissipation and stable hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

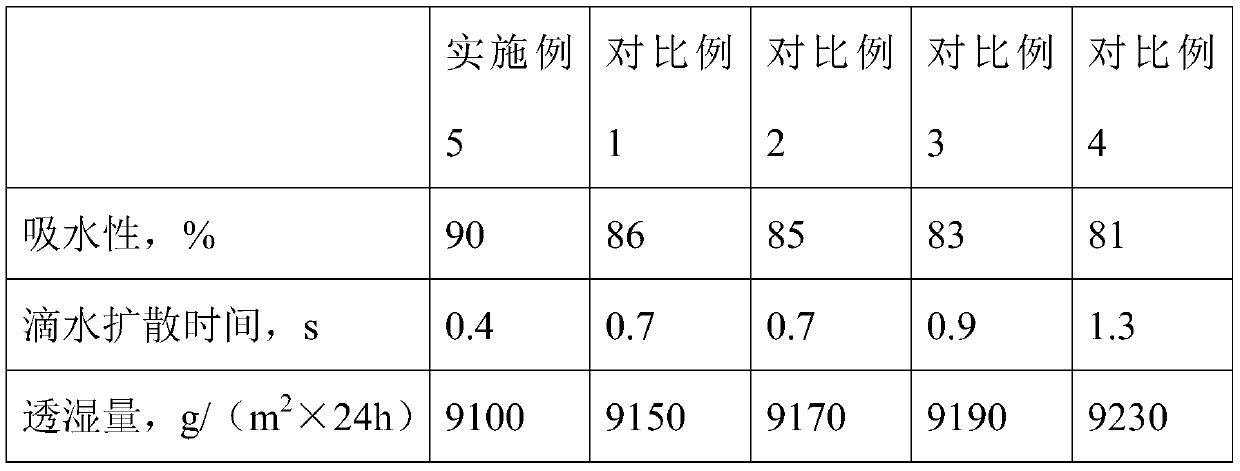

Examples

Embodiment 1

[0027] A method capable of enhancing the hydrophilic properties of cotton fibers, comprising the steps of:

[0028] S1, the cotton fiber is ultrasonically washed in a 50wt% ethanol aqueous solution, the number of washings is 4 times, dried, then sent to a concentration of 0.8mol / L sodium hydroxide solution and soaked at room temperature for 15h, filtered, washed until neutral, and obtained pre-treated cotton fibers;

[0029] S2. Fully swell 10kg of pretreated cotton fibers in 80kg of 1moL / L sodium hydroxide solution, and then add 10kg of epichlorohydrin, 0.05kg of dodecyltrimethylammonium chloride, and 0.05kg of tetradecane Trimethylammonium chloride, reacted at 80°C for 10h, filtered, washed with water and absolute ethanol, dried, then added 80kg of isopropanol to adjust the pH of the system to 9.2-9.8, and added 2kg of %HBP-NH 2 Solution, reacted at 50°C for 4h, washed with ethanol, and dried to obtain amino cotton fiber;

[0030] S3. Dissolve 4kg of chitosan in 150kg of ...

Embodiment 2

[0032] A method capable of enhancing the hydrophilic properties of cotton fibers, comprising the steps of:

[0033] S1, the cotton fiber is ultrasonically washed in a 70wt% ethanol aqueous solution, the number of washings is 2 times, dried, then sent to a concentration of 1.2mol / L sodium hydroxide solution and soaked at room temperature for 5h, filtered, washed until neutral, and obtained pre-treated cotton fibers;

[0034] S2. Fully swell 20kg of pretreated cotton fibers in 40kg of 2moL / L sodium hydroxide solution, and then add 2kg of epichlorohydrin, 0.01kg of benzyltriethylammonium chloride, and 0.01kg of tetradecyltriethylammonium chloride. Methyl ammonium chloride, reacted at 70°C for 20 hours, filtered, washed with water and absolute ethanol, dried, then added 40kg of isopropanol to adjust the pH value of the system to 9.2-9.8, and added 6kg of 0.6% of the mass fraction under nitrogen protection HBP-NH 2 solution, reacted at 60°C for 2h, washed with ethanol, and dried ...

Embodiment 3

[0037] A method capable of enhancing the hydrophilic properties of cotton fibers, comprising the steps of:

[0038] S1, the cotton fiber is ultrasonically washed in 55wt% ethanol aqueous solution, the number of times of washing is 3 times, dried, then sent into the concentration of 1.1mol / L sodium hydroxide solution and soaked at room temperature for 8h, filtered, washed until neutral, obtained pre-treated cotton fibers;

[0039]S2. Fully swell 18kg of pretreated cotton fibers in 50kg of 1.8moL / L sodium hydroxide solution, add 4kg of epichlorohydrin and 0.018kg of dodecyltrimethylammonium chloride in sequence, and react at 73°C for 18h , filtered, washed with water and absolute ethanol respectively, dried, and then added 50kg of isopropanol to adjust the pH value of the system to 9.2-9.8, and added 5kg of HBP-NH with a mass fraction of 0.65% under nitrogen protection 2 solution, reacted at 58°C for 2.5h, washed with ethanol, and dried to obtain amino cotton fiber;

[0040] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com