Patents

Literature

2165 results about "Soybean Proteins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Proteins which are present in or isolated from SOYBEANS.

Extended binder compositions

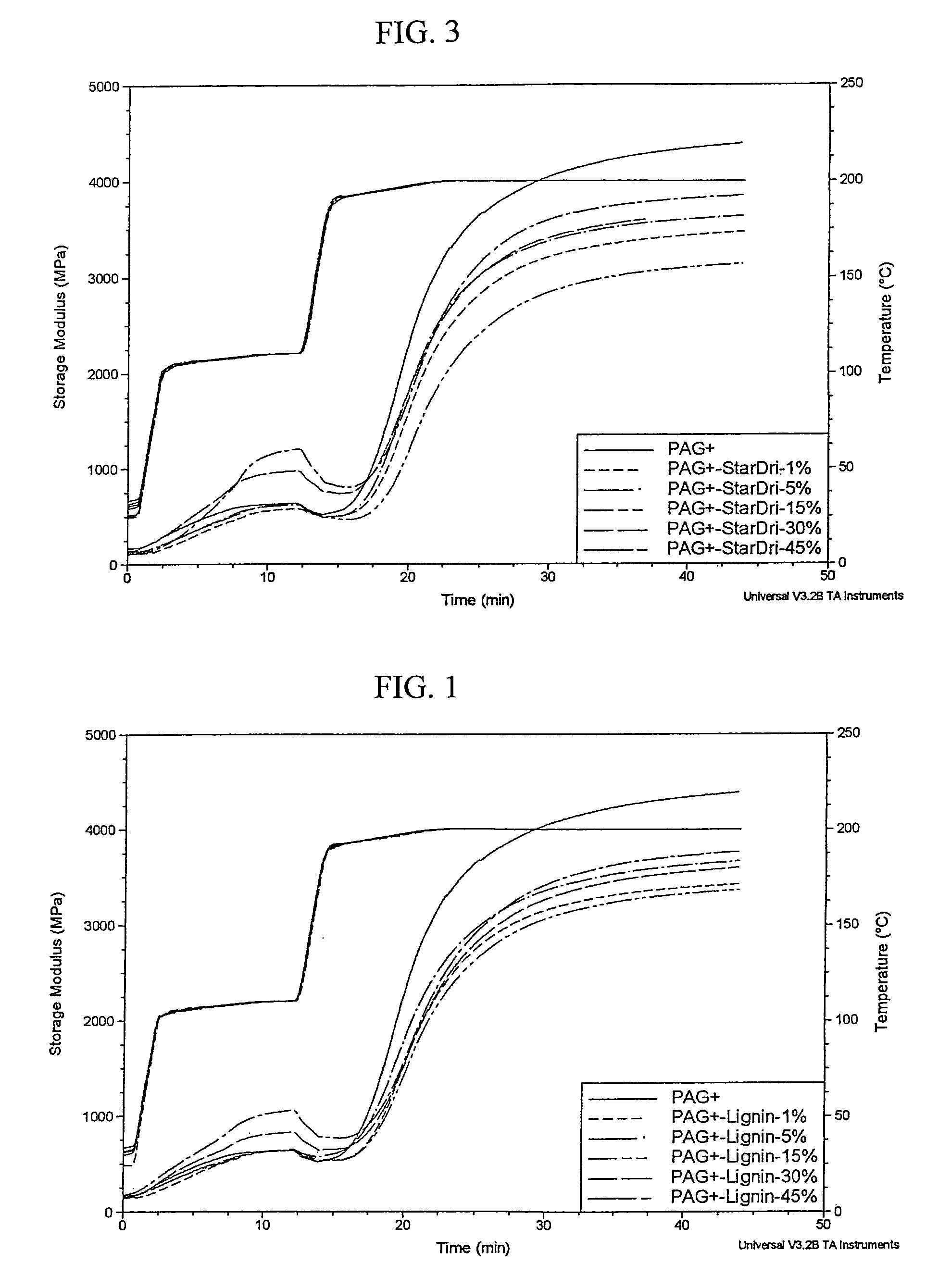

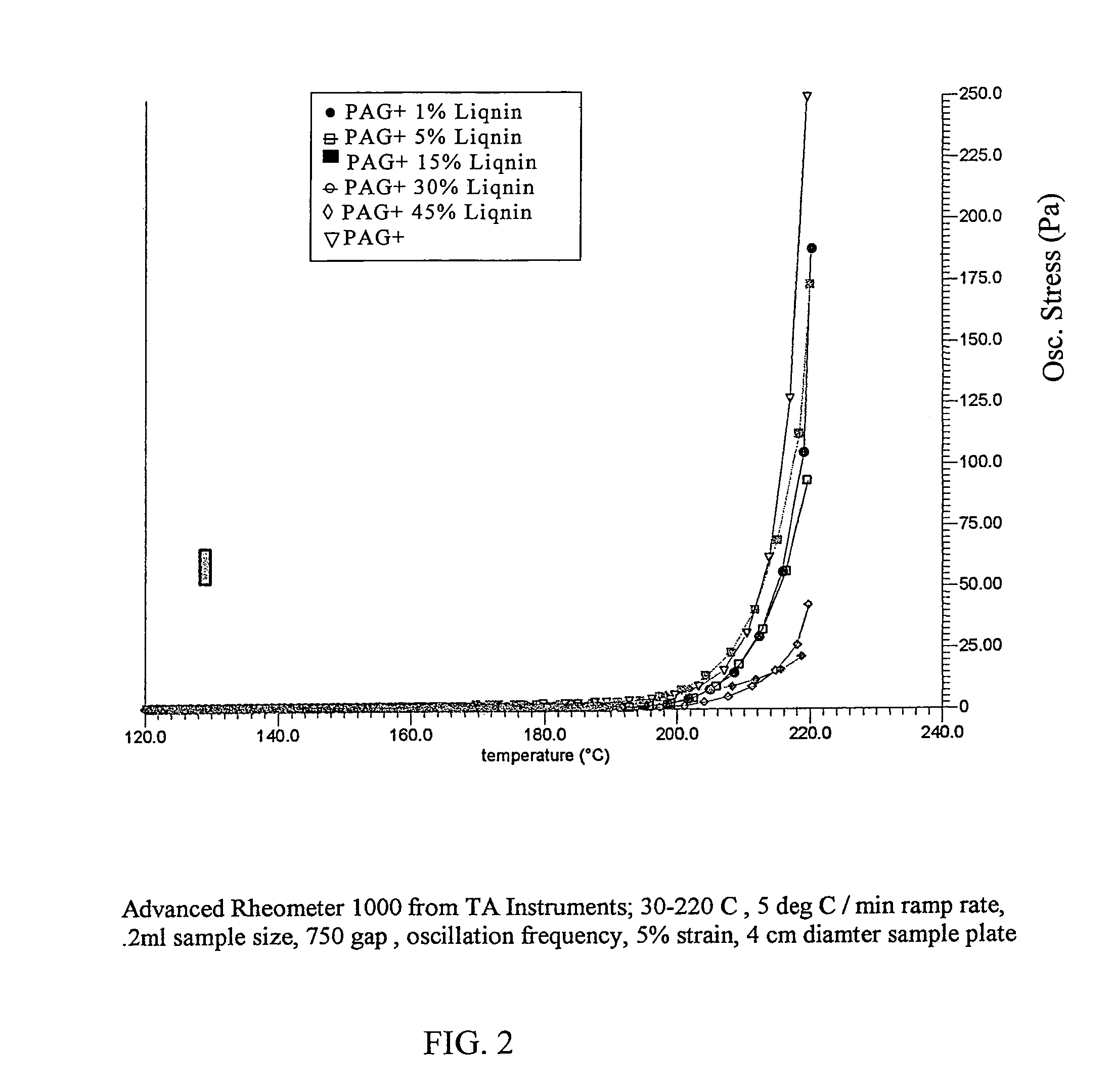

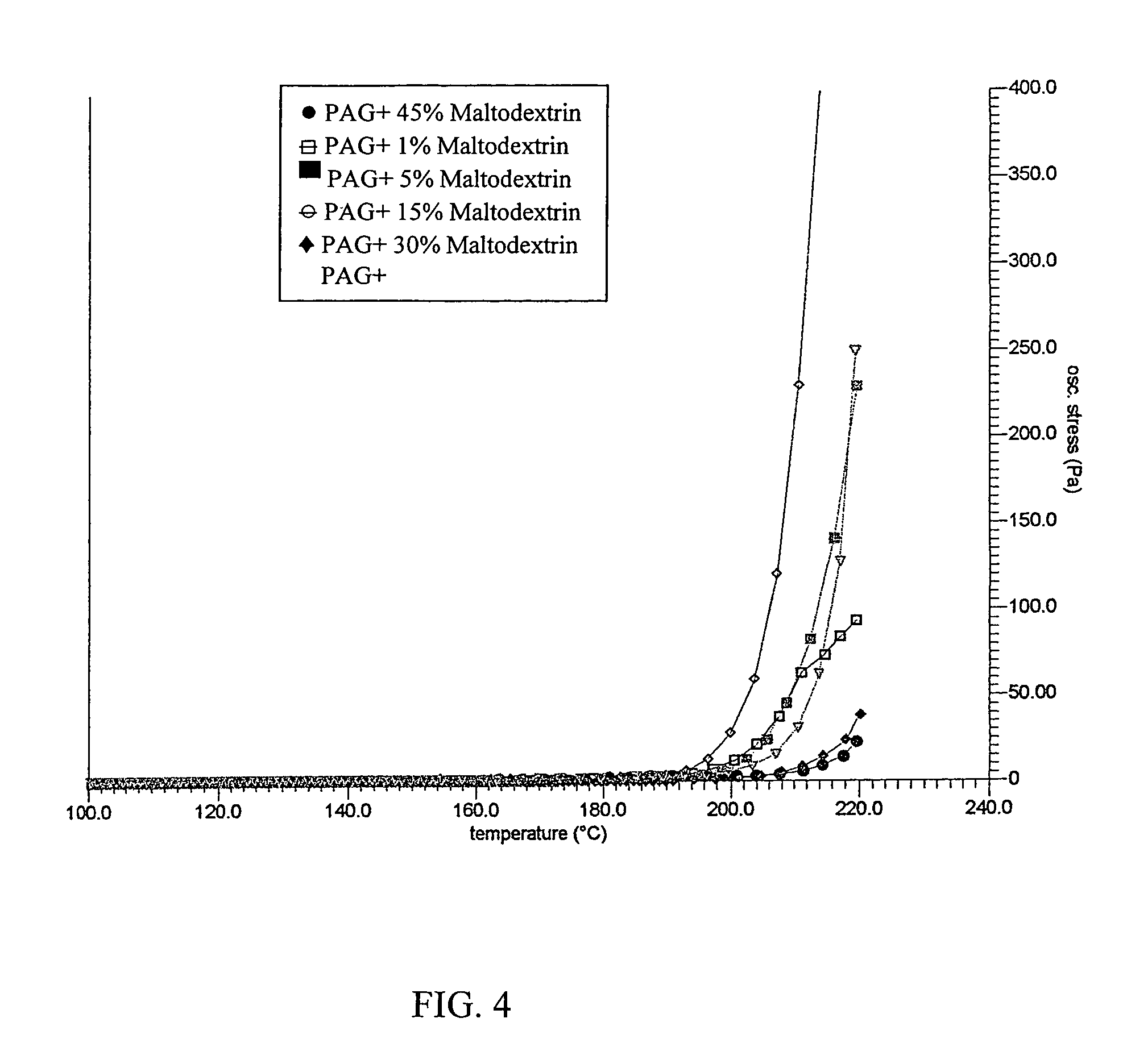

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for producing L-lactic acid and coagulate bacillus cereus special for the same

ActiveCN101173242AReduce consumptionReduce lossesBacteriaMicroorganism based processesBacillus cereusCulture mediums

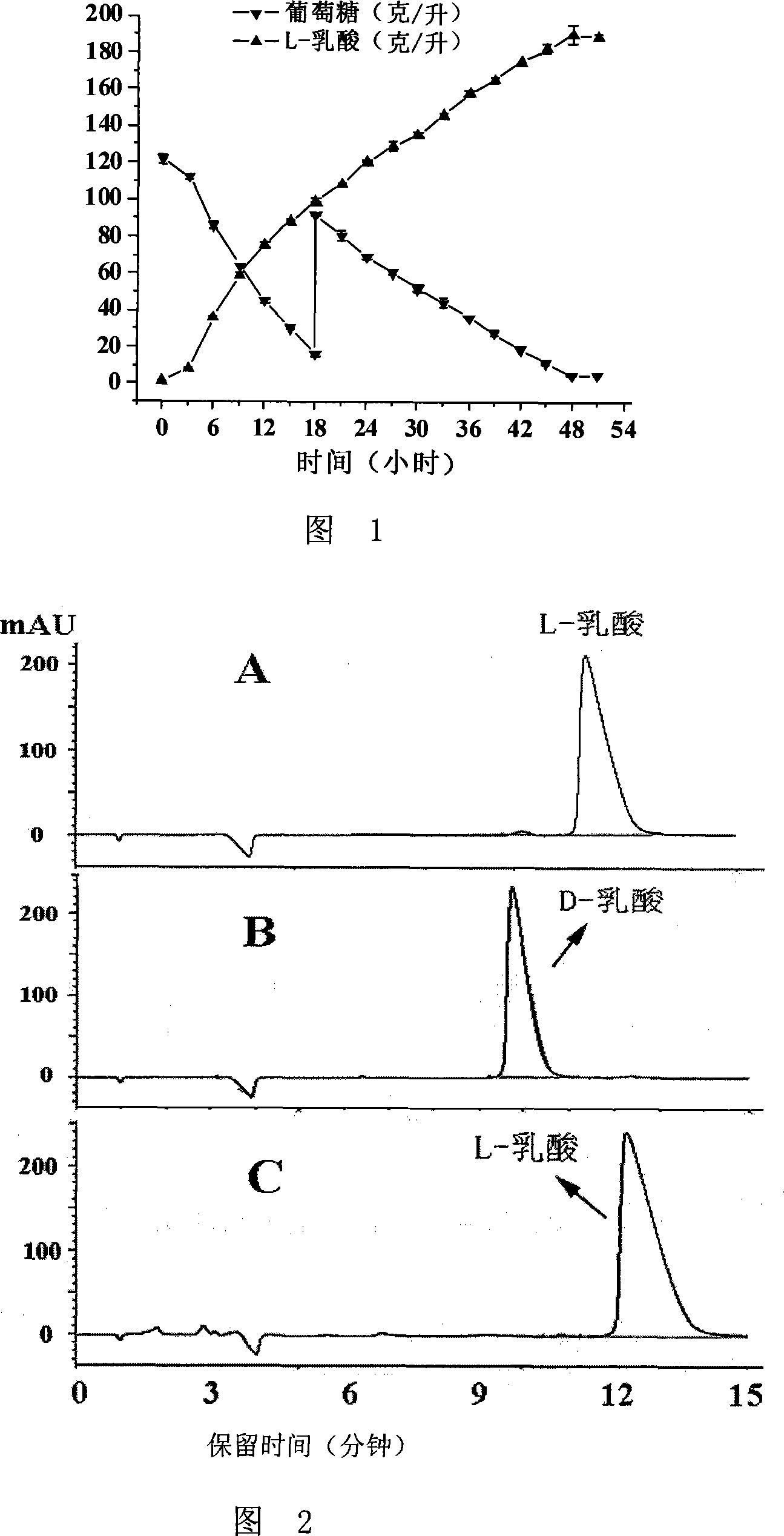

The invention discloses a production method of L-lactic acid and the special condensate bacillus CASH CGMCC No. 2184. L-lactic acid can be gotten by cultivating the special condensate bacillus CASH CGMCC No. 2184. Per litter of fermentation culture medium of the condensate bacillus comprises at least one of the following five nitrogen sources: yeast powder 5 to 15g, peptone 5 to 15g, soybean peptide 5 to 15g, soybean peptone 5 to 15g, and cottonseed protein 10 to 20g; in addition, the fermentation culture medium comprises glucose 80 to 170g (the content of initial glucose), calcium carbonate 50 to 100g and water; the pH of the fermentation culture medium is 5.5 to 7. With glucose as the substrate, under the condition of 45 to 60DEG C and with 98 to 99% of sugar acid conversion, the condensate bacillus CASH CGMCC No. 2184 efficiently ferments to produce L-lactic acid with optical purity of 99%; the concentration of the L-lactic acid maximum can attain 190 g / l and the volume production efficiency maximum can attain 5.7 g / l / h.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

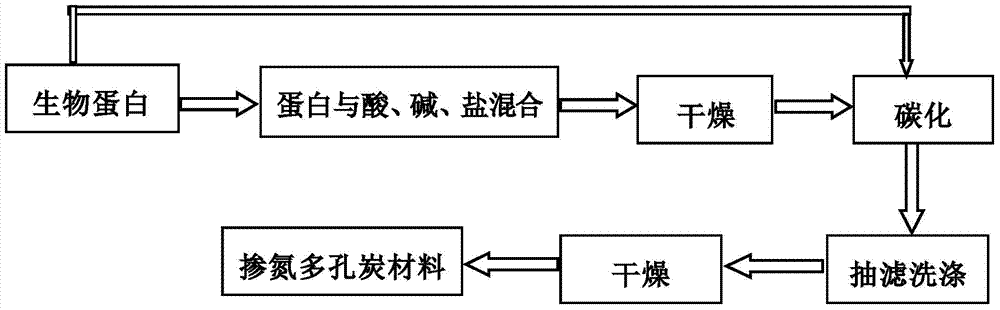

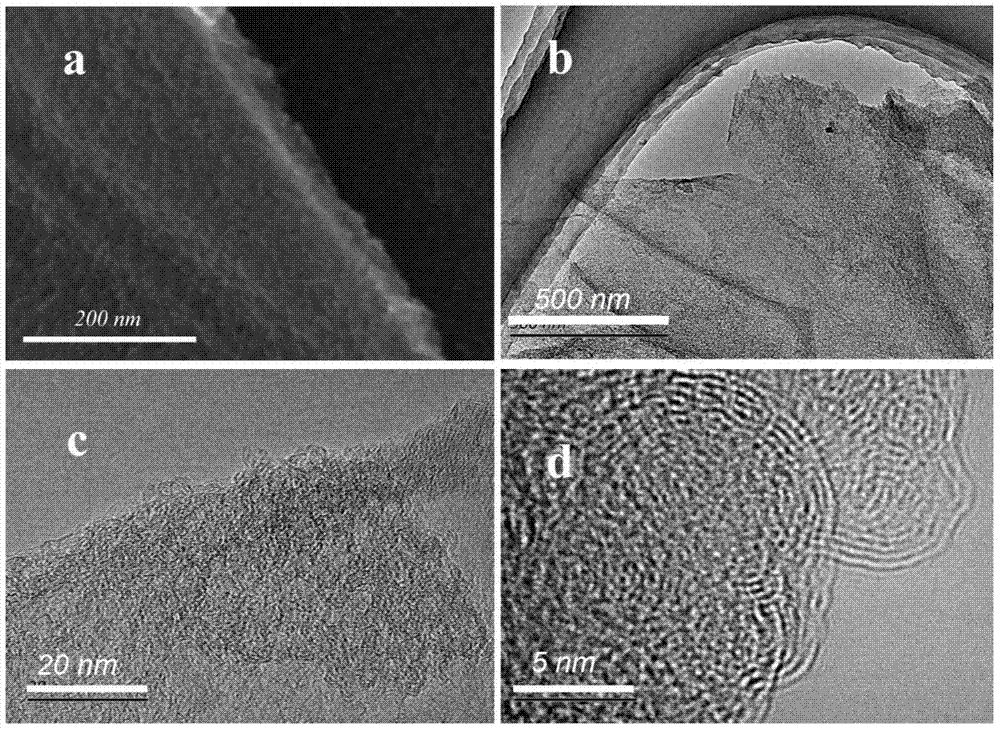

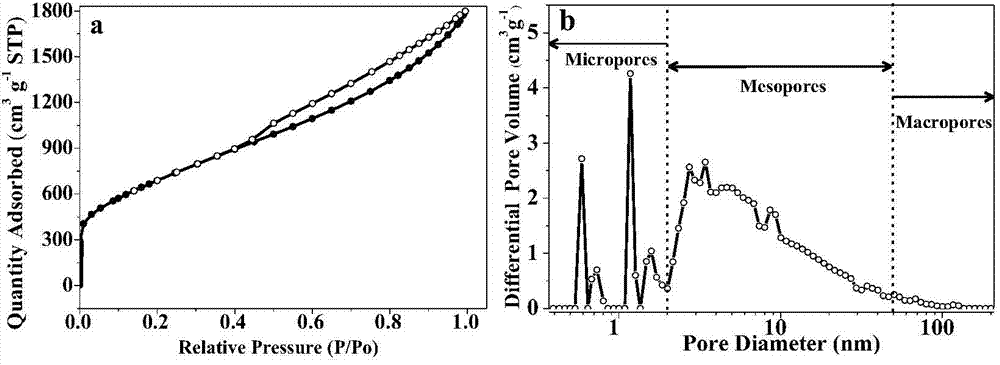

Method for preparing nitrogen doped porous carbon material by using biologic proteins

The invention provides a method for preparing a nitrogen doped porous carbon material by using biologic proteins. The method mainly comprises the following steps: 1, mixing the biologic proteins with an acid or alkali or salt solution; 2, carbonizing the above obtained dried mixture under the protection of inert gas; and 3, carrying out distilled water addition, pumping filtration and washing until the pH value is 6.4-7, and drying to obtain solid powder which is the nitrogen doped porous carbon material. The widely and easily available biologic proteins are adopted as raw materials, and the raw materials comprise silk fibroin, albumen and soybean proteins, so the method has the advantages of simple operating technology, convenient control, cleanness, environmental protection, and easy industrial realization. The prepared nitrogen doped porous carbon material has the advantages of large specific surface area, low ash content and good conductivity. The nitrogen doped porous carbon material can be used in lithium ion batteries, lithium sulfur batteries, super capacitors and other electrode materials, and fields of carbon dioxide capture, hydrogen storage, catalyst carriers, active carbon adsorbents and biologic applications.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultraviolet-preventing antibacterial fabric and preparation technology thereof

ActiveCN103255538AImproves UV protectionImprove breathabilityFibre treatmentWoven fabricsCarbon fibersAnti bacterial

Ultraviolet-preventing antibacterial fabric comprises, by weight percentage, 10-15% of adhesive anion functional fibers, 10-15% of soybean protein fibers, 20-30% of bast fibers, 5-10% of wool fibers, 5-10% of nanometer bamboo carbon fibers, 10-15% of chitin fibers, 2-5% of nano-silver-ion fibers, 4-6% of ultraviolet-preventing finishing agents, and 2-4% of mosquito-repellent finishing agents. The ultraviolet prevention performance and air permeability of the fabric are improved, and meanwhile the fabric has effects of preventing bacteria and repelling mosquitoes. The fabric is good in application effect in home textiles, sanitary products, sports goods, health care, bacteria prevention and mosquito repellent.

Owner:广州市缔造亿百儿童用品有限公司

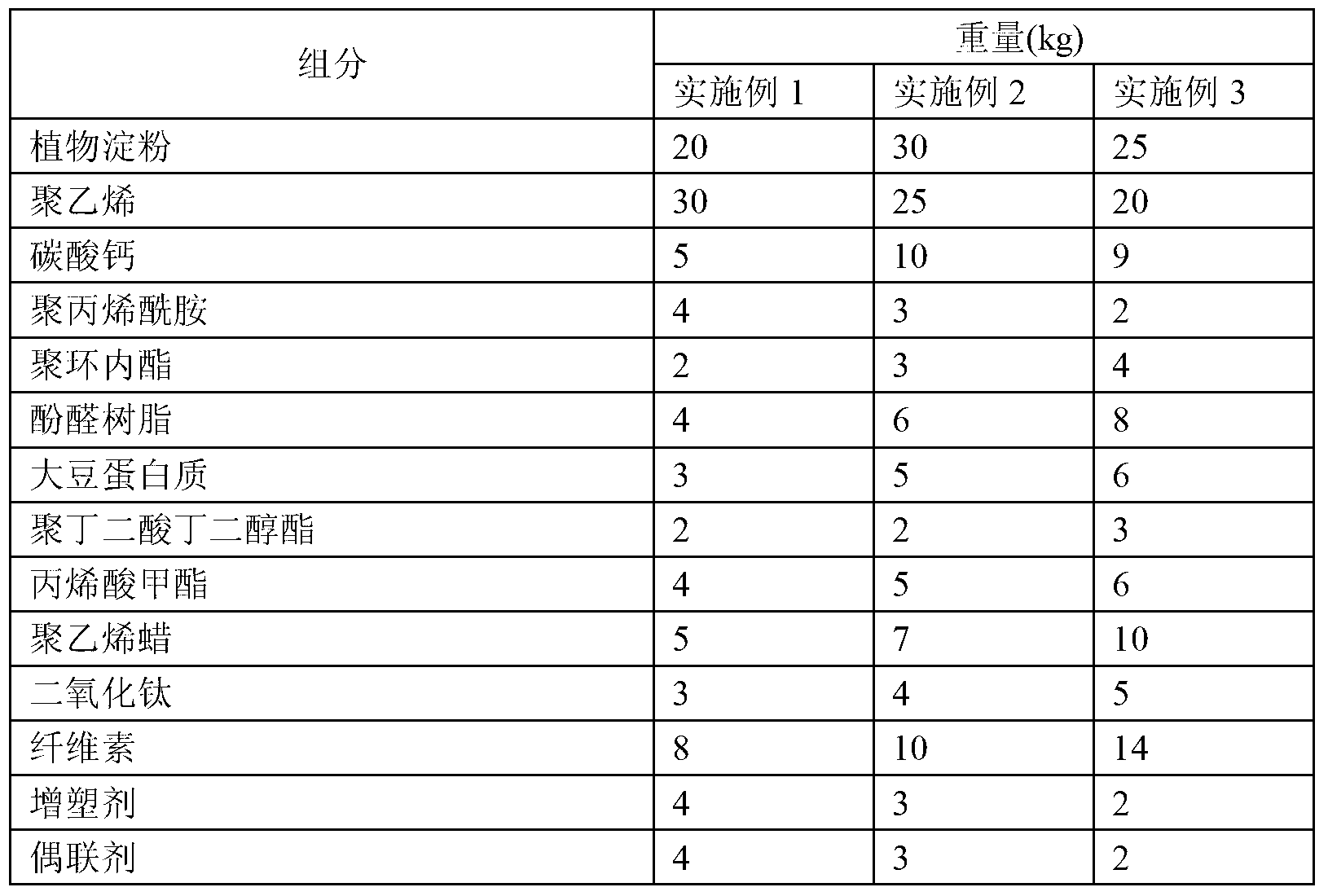

Degradable film containing starch and preparation method of degradable film

The invention provides an agricultural film material and particularly relates to a degradable film material containing starch serving as a raw material, belonging to the technical field of high molecular materials. The degradable film comprises the following raw materials in parts by weight: 20-30 parts of plant starch, 20-30 parts of polyethylene, 5-10 parts of calcium carbonate, 2-4 parts of polyacrylamide, 2-4 parts of poly cyclic lactone, 4-8 parts of phenol aldehyde resin, 3-6 parts of soybean protein, 2-3 parts of polybutylene succinate, 4-6 parts of methyl acrylate, 5-10 parts of polyethylene wax, 3-5 parts of titanium dioxide, 8-14 parts of cellulose, 2-4 parts of plasticizer and 2-4 parts of coupling agent. The degradable film provided by the invention has excellent strength, the tensile strength of the degradable film can be higher than 16MPa, the light transmittance can be higher than 88%, and the degradable film can be generally degraded within 4-6 months.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Method for producing antimicrobial calcium alginate fiber

ActiveCN101381907AEvenly distributedImprove antibacterial propertiesAlginate artificial filamentsAbsorbent padsCalcium alginateMechanical property

The invention discloses a method for manufacturing an antimicrobial calcium alginate fibre. A sodium alginate is used as spinning stock solution; in a solidification bath containing an antimicrobial agent, the antimicrobial calcium alginate fibre is obtained by a wet-method spinning process; and the antimicrobial agent is a cationic compound which is combined with large molecules of the calcium alginate fibre through ionic bonds. The antimicrobial calcium alginate fibre obtained by the method has no toxicity and no side effect on human body; the antimicrobial agent and the large molecules of the fibre are combined by the ionic bonds in order that the antimicrobial agent has long-lasting antimicrobial function; in addition, the fibre retains the excellent quality of the calcium alginate fibre, has excellent hygroscopic property and good mechanical property, can be used for manufacturing medical dressings, has the advantages of convenient use, comfortable application and good ventilation, the acceleration of the healing of wound, the relieving of the pains of patients and the like, can be also used for manufacturing clothing and industrial textiles by pure spinning or blended spinning with cotton, mucilage glue, bamboo pulp, fur, ramie, soybean protein fibre and the like.

Owner:山东康康新材料科技有限公司

Cereal meal replacement stick for fat loss and preparing method thereof

InactiveCN109645500AIncrease satietyEasy to chewVitamin food ingredientsLactobacillusIsomaltooligosaccharideSatiations

The invention relates to a cereal meal replacement stick for fat loss and a preparing method thereof. The cereal meal replacement stick is prepared from concentrated whey protein, calcium caseinate, soybean isolate protein, hydrolysis fish collagen, konjac flour, psylliumseedhusk powder, a white kidney bean extract, a potato extract, conjugated linoleic acid glyceride powder, DSM fabuless palm oilpowder, freeze-dried fruit powder, beet juice powder, mixed cereal powder, mixed tocopherol concentrate, active probiotic powder, a compound nutrient supplement, freeze-dried fruit particles, nut grains, chia seeds, puffing cereal particles, puffing soybean protein grains, isomalto-oligosaccharide, fructo-oligosaccharide, resistant dextrin, glycerinum and high-oleic-acid sunflower seed oil. The preparing method specifically comprises the following steps of syrup boiling, material mixing, forming, cooling, cutting and coating or non-coating. The meal replacement stick has the advantages of energy negative balance, strong satiation, low sugar increase and full nutrition, and the health and vigor of the body are guaranteed while dieters lose weight and fat.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

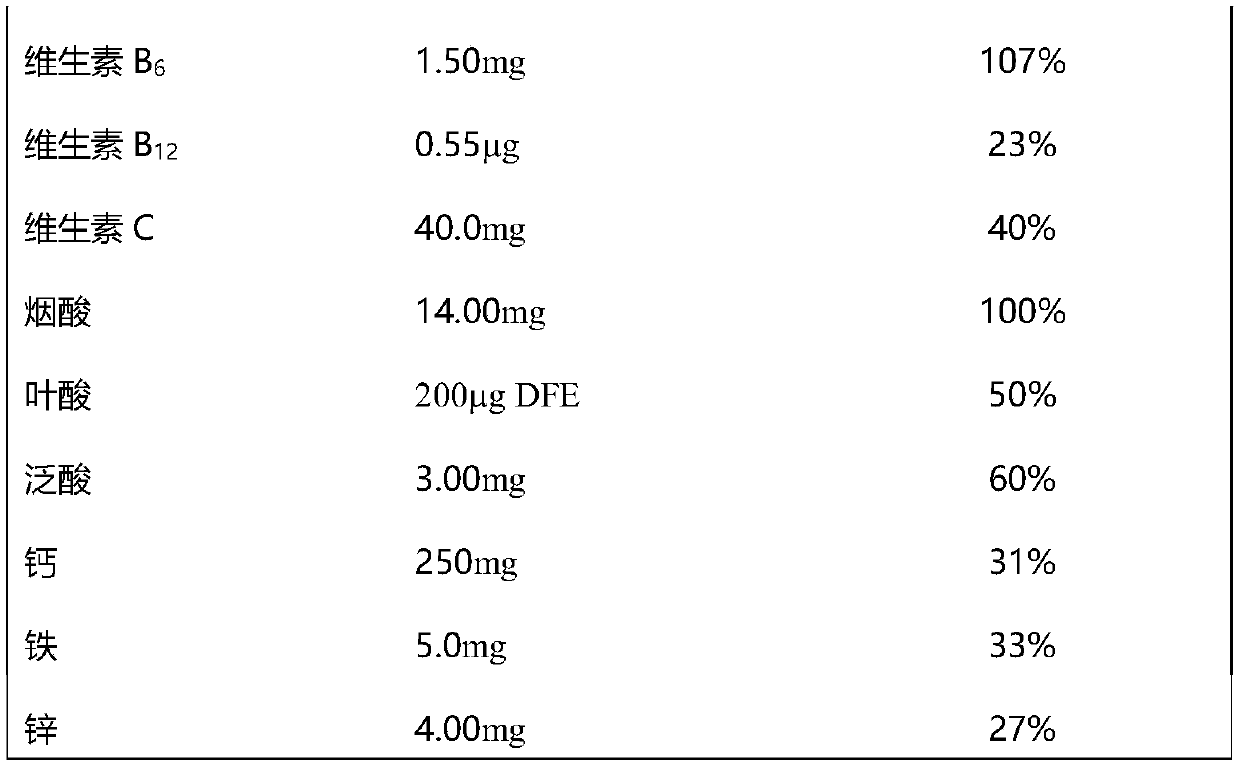

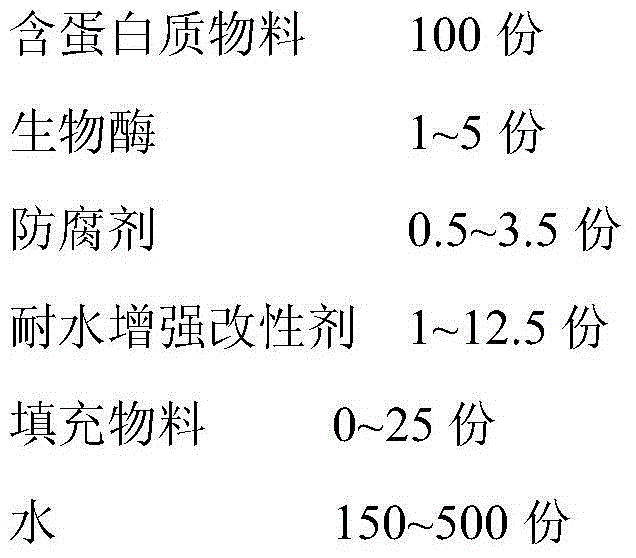

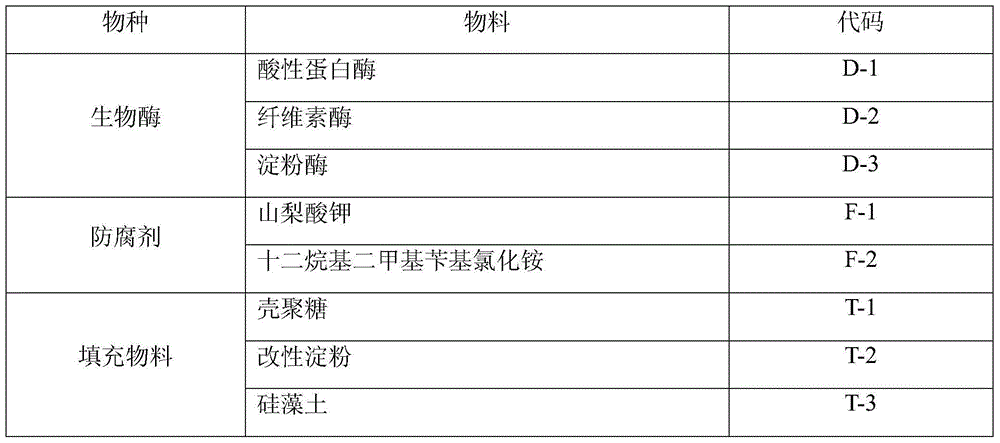

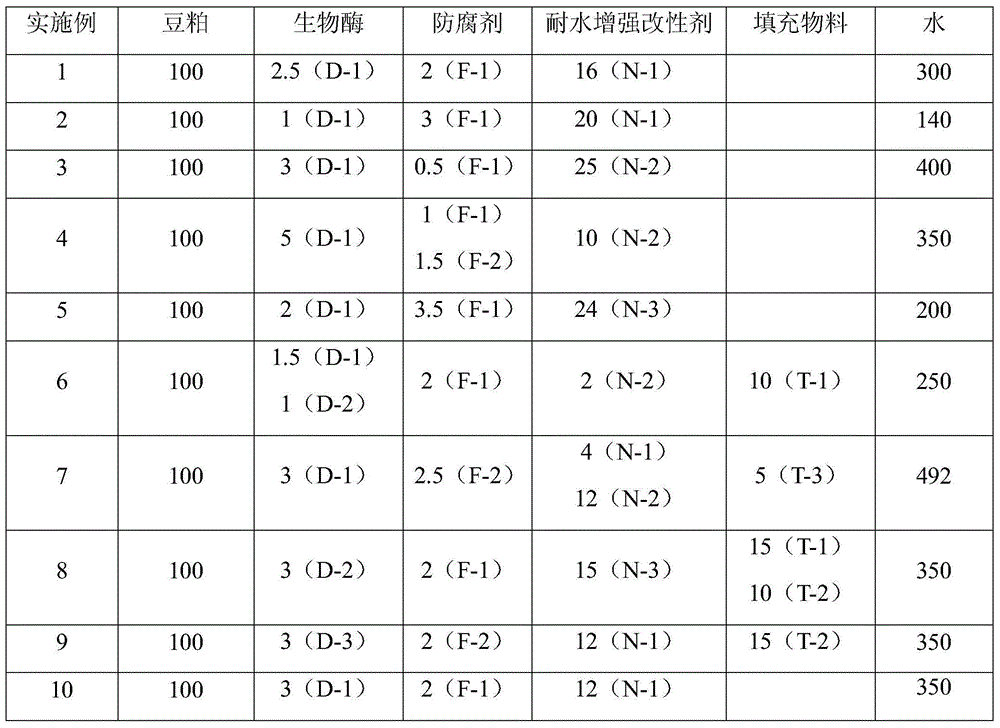

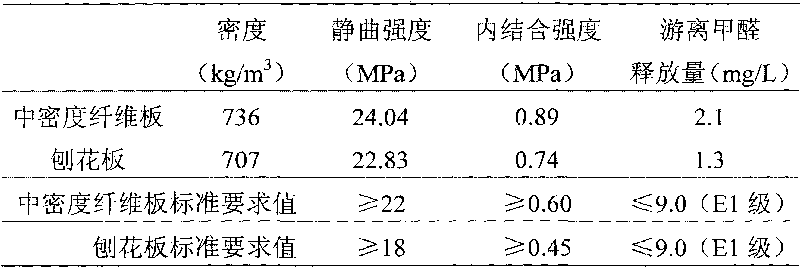

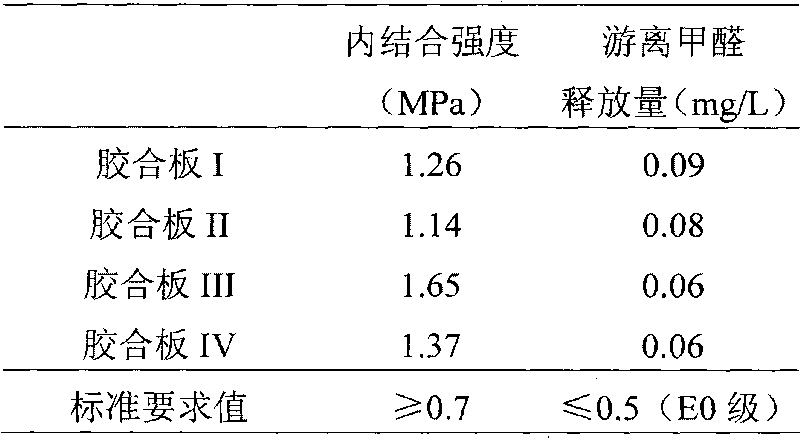

Water-resistant bio-based formaldehyde-free adhesive for wood and preparation method thereof

ActiveCN104629678AHigh solid contentLight weightNon-macromolecular adhesive additivesProtein adhesivesPreservativeSolid content

The invention discloses a water-resistant bio-based formaldehyde-free adhesive for wood and a preparation method thereof, belonging to the technical field of adhesives. The water-resistant bio-based formaldehyde-free adhesive comprises a protein-containing material, a biological enzyme, a preservative, a water-resistance enhancement modifier, water and the like. The preparation method comprises the following steps: adding the water into a reaction kettle while controlling the temperature at 30-55 DEG C; sequentially adding the biological enzyme and soybean protein, stirring uniformly, regulating the pH value to 4-6.5, and carrying out enzymolysis for 20-70 minutes; and regulating the pH value to 7.5-10, adding the preservative and water-resistance enhancement modifier, and stirring uniformly. The water-resistant bio-based formaldehyde-free adhesive for wood has the advantages of environment friendliness, high storage stability, high solid content, lower energy consumption, favorable adhesion strength and favorable water resistant; the consumption of the water-resistant bio-based formaldehyde-free adhesive for wood is obviously lowered; and the cost is obviously lowered.

Owner:茌平县金大通木业有限公司

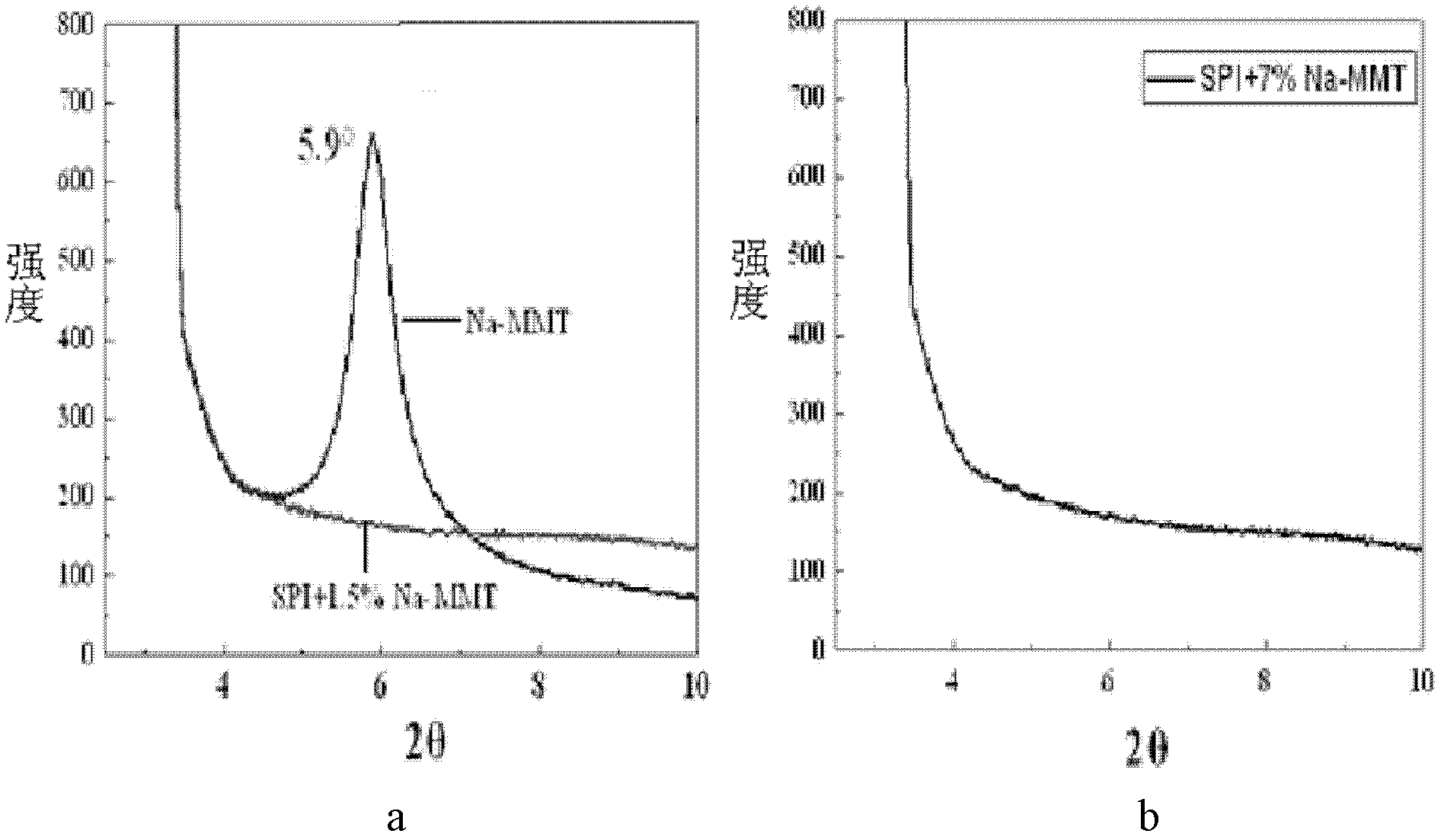

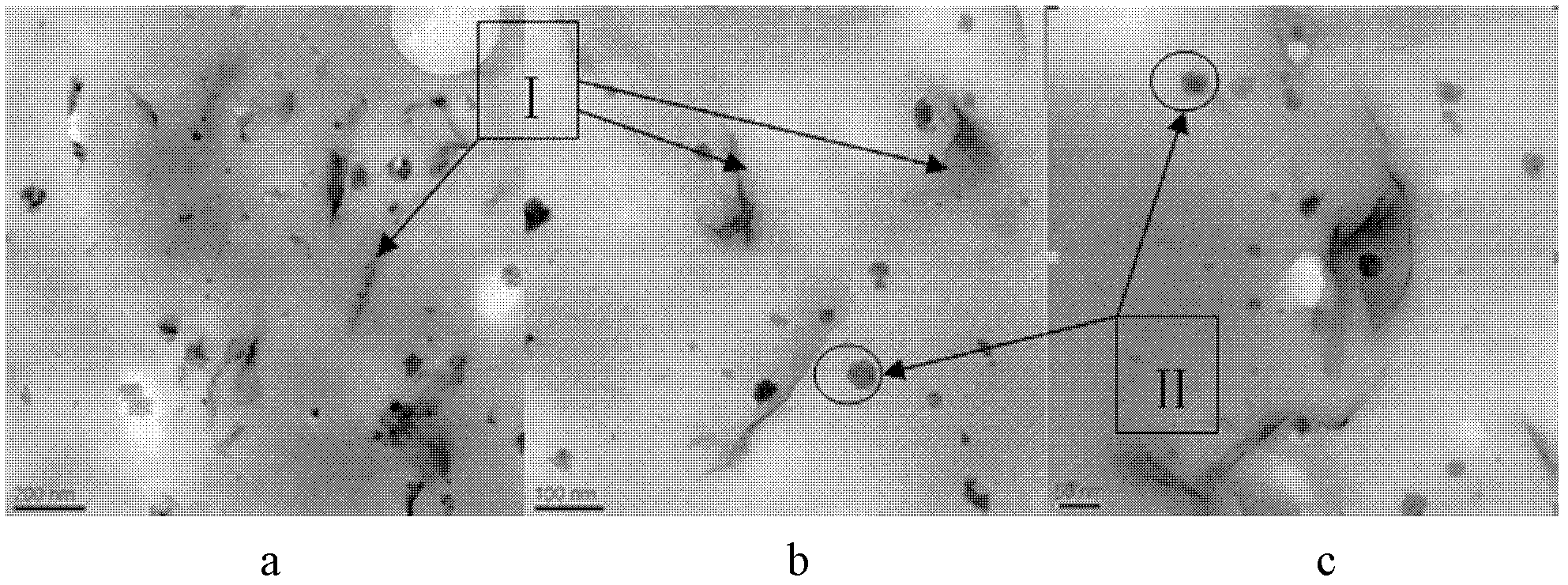

Layered silicate reinforced soybean adhesive, its preparation method and application

ActiveCN102516933AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveEconomic benefits

The invention discloses a layered silicate reinforced soybean adhesive, comprising 100 weight parts of water, 10-50 weight parts of soybean derivative, 0.1-10 weight parts of modifier, and 0.1-10 weight parts of layered silicate. The soybean adhesive disclosed herein comprises no formaldehyde as a raw material, thus the soybean adhesive belongs to an environmentally friendly adhesive. By using the modifier and layered silicate to modify soybean protein in the soybean derivative, the initial adhesion is raised, and simultaneously the bonding intensity and water resistance of the soybean adhesive are raised. The soybean adhesive is especially suitable for being used as a timber adhesive. The invention further provides a preparation method of the layered silicate reinforced soybean adhesive.The method has the advantages of simple preparation, good controllability, and low production cost, is easy to operate and is easy to industrialize, has good economic benefits, is beneficial for popularization and application, and has a wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

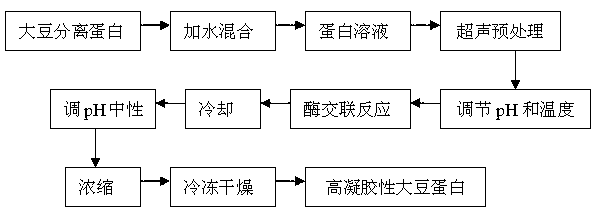

Preparation method of high-gelation soybean protein

InactiveCN102934731AReduce dosageImprove gel performanceVegetable proteins working-upProtein solutionFreeze-drying

The invention relates to a preparation method of a high-gelation soybean protein, and belongs to the technical field of soybean protein processing. The method comprises the following steps: (1) mixing soybean protein isolate and water to obtain a protein solution, and performing ultrasound preprocessing on the protein solution; and (2) adjusting the pH and temperature of the protein solution subjected to ultrasound preprocessing in the step (1), adding transglutaminase for cross linking reaction, cooling the product after cross linkage to room temperature, and then concentrating and freeze drying to obtain the high-gelation soybean protein. The method has the beneficial effects that the needed equipment is simple and safe to operate; the enzyme needed in production is small in amount, short in enzymolysis time, low in cost and environmentally-friendly; the obtained soybean protein is high in gel strength, and meanwhile the gel stability is good; and the application range of the soybean protein in foodstuff is expanded.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Natural green health care knitwear and its mfg. method

A health-care knitting fabric is made up of hemp fibre, color cotton fibre, bamboo fibre, soybean protein fibre, chitin fibre, and natural wooden pulp fibre through twisting, knitting, boiling, softening, baking and high-pressure ironing.

Owner:王新文

Composite modified soybean protein adhesive as well as production method and application thereof

InactiveCN101857792AImprove wettabilityNo pollution in the processProtein adhesivesWood veneer joiningCross-linkAlkaline water

The invention discloses a composite modified soybean protein adhesive as well as a production method and application thereof. The composite modified soybean protein adhesive comprises the following components: an alkaline water solution of surfactant, soybean protein products, a modifier, a cross-linking agent and fillers. In the invention, soybean protein molecules are modified by using a composite modifying method of degradation-crosslinking, the wetting property of the adhesive on wood surfaces is improved through degradation, and intermolecular cohesive forces of the solidified adhesive are improved through crosslinking. The composite modified soybean protein adhesive is water adhesive, which is nontoxic and pollution-free and has excellent glue joint strength and water resistant property, and can be used as the adhesive for processing man-made planks instead of traditional phenolic resin adhesives, urea-formaldehyde resin adhesives and melamine-formaldehyde resin adhesives.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

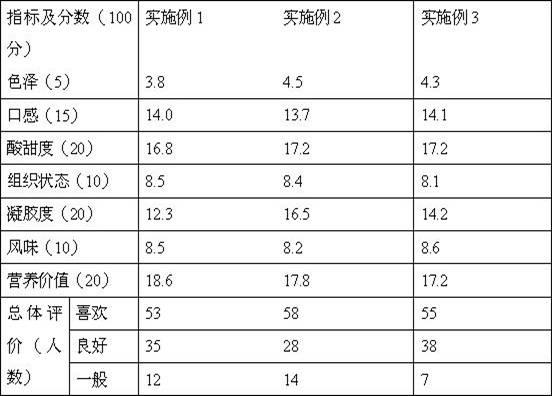

Soybean protein jelly and preparation method thereof

The invention discloses soybean protein jelly and a preparation method thereof. The jelly drink comprises the following formula components: 1 to 10 weight / volume percent of soybean protein, 6 to 12 percent of weight / volume percent of sugar, 0.05 to 2 weight / volume percent of stabilizer, 2 to 10 weight / volume percent of juice, 0.1 to 0.8 weight / volume percent of acidity regulator, 0.05 to 0.2 weight / volume percent of essence and the balance of water. The soybean protein jelly is nutritional edible jelly, can be directly poured out and eaten and is safer to eat.

Owner:EAST CHINA NORMAL UNIV +1

Method for producing modified soybean albumen adhesive

InactiveCN101255328AImprove bonding qualityImprove water resistanceProtein adhesivesGlue/gelatin preparationAlcoholOrganic solvent

The invention provides a preparation method of modified soybean protein adhesive. Any one selected from soybean protein concentrate, soybean protein isolate, defatted soybean flour, soybean pulp and soybean cake is used as raw material and then organic solvent alcohol is added. The hydrophobicity group of alcohol immerges into the soybean molecule to break the molecule structure and denature the soybean, the hydrophobicity amino acid residues of protein molecule are bare, therefore the bond strength and water resistance is increased. The object of the invention is to solve the problem that the bond strength of soybean protein adhesive is low and the water resistance is bad. The soybean protein adhesive has good bond strength without pollution and the alcohol has the same function of antifoaming agent, so that the soybean protein adhesive has higher bonding strength and water resistance, compared with the soybean protein adhesive which is not modified.

Owner:SHENYANG POLYTECHNIC UNIV

Compound protein fiber and preparation method thereof

ActiveCN102174720ASoft touchSoft lusterConjugated cellulose/protein artificial filamentsWet spinning methodsMoisture absorptionPVA - Polyvinyl alcohol

The invention relates to a compound protein fiber and a preparation method thereof. The compound protein fiber comprises the following components in percentage by mass: 10 to 45 percent of collagen, 10 to 45 percent of soybean protein and 10 to 80 percent of polyvinyl alcohol. The preparation method of the compound protein fiber comprises the following steps of: dissolving the collagen and the soybean protein in water, adding the polyvinyl alcohol, dissolving, and performing copolymerization modification to obtain spinning solution; and performing processes such as wet spinning, solidification molding, acetalation treatment and the like to obtain the compound protein fiber. The invention has the characteristics that: the compound protein fiber which has a high mechanical property, a high moisture absorption property, high air permeability, a high dyeing property, smooth handfeel, soft luster, skin intimate performance and health-care performance and is comfortably worn is manufactured by performing blending and copolymerization modification on the polyvinyl alcohol by using the collagen and the soybean protein; and the collagen and the soybean protein have wide raw material resources and low prices, a manufacturing process is relatively simple, and production cost is reduced.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Method for producing soybean peptide

ActiveCN102178028ALess quantityLow costProtein composition from vegetable seedsVegetable proteins working-upFiltrationMacroporous resin

The invention relates to a method for producing a soybean peptide. In the method, fermented soybean meal is taken as a raw material and then animal-derived protease is utilized to produce the soybean peptide. The method comprises the following steps of: 1) enzymolyzing liquid, namely mixing the fermented soybean meal and water in a weight ratio of 1:(4-8), adding trypsinase, and preserving heat and enzymolyzing; 2) killing enzyme at high temperature; 3) filtering, namely filtering and separating enzymatic hydrolysate to obtain crude soybean protein; 4) decolorizing and deodorizing; 5) refining; and 6) spray-drying, and sterilizing to obtain a finished product, wherein the decolorization and deodorization are realized through filtration by a pretreated macroporous resin. The method has theadvantages that: 1) the fermented soybean meal is taken as the raw material, so that a protease inhibitor in the raw material is eliminated; 2) the prehydrolysis of soybean protein in the fermented soybean meal can be completed; and 3) the amount of the additional enzyme is reduced greatly, so that the cost is effectively reduced and the higher hydrolysis rate is obtained.

Owner:武汉百安生物科技有限责任公司

Composition with functions of reducing hypertension, hyperglycemia and hyperlipidemia and preparation method of composition

InactiveCN105661521AReduce morbidityLower the three highsVitamin food ingredientsYeast food ingredientsAcute hyperglycaemiaSide effect

The invention provides composition with functions of reducing hypertension, hyperglycemia and hyperlipidemia. The composition comprises components in parts by weight as follows: 65 parts of soybean protein, 0.6 parts of fish collagen protein, 4.5 parts of dried skim milk, 11 parts of dietary fiber, 0.9 parts of whey protein, 0.5 parts of wheat albumin, 1.3 parts of cereal powder, 0.9 parts of sargassum fusiforme powder, 0.1 parts of beer yeast powder, 0.03 parts of rice germ / soybean fermentation extract powder, 0.01 parts of Chinese yam extract powder, 0.01 parts of hawthorn fruit extract powder, 0.01 parts of salmon milt extract powder, 3 parts of potassium chloride, 1 part of silicon dioxide, 0.7 parts of L-methionine, 0.2 parts of a sweetening agent, 0.7 parts of vitamins and 9.54 parts of cocoa extract powder. The invention further provides a preparation method of the composition. The composition has the good effects of reducing hypertension, hyperglycemia and hyperlipidemia and decreasing morbidity of fatty liver, diabetes mellitus and cardiovascular and cerebrovascular diseases and the like, is convenient to take and avoids side effects.

Owner:SHICHENG BIOLOGICAL ENG SHANGHAI CO LTD

Method for improving gelling performance of minced fish product by adding transglutaminase

InactiveCN1543840AHigh gel strengthImprove qualityFood preparationGlutamine aminotransferasePolyphosphate

The invention discloses a method for improving gel property of minced fish product through adding glutamine aminotransferase which comprises, adding into minced fish processed from fresh fish as raw material complex addition agent consisting soybean protein, polyphosphates and glutamine aminotransferase, adding addition agent, then kneading the minced fish 10-20 minutes, the gel property of the obtained minced fish product is increased to 400-500g from the previous 200g before addition.

Owner:JIANGNAN UNIV

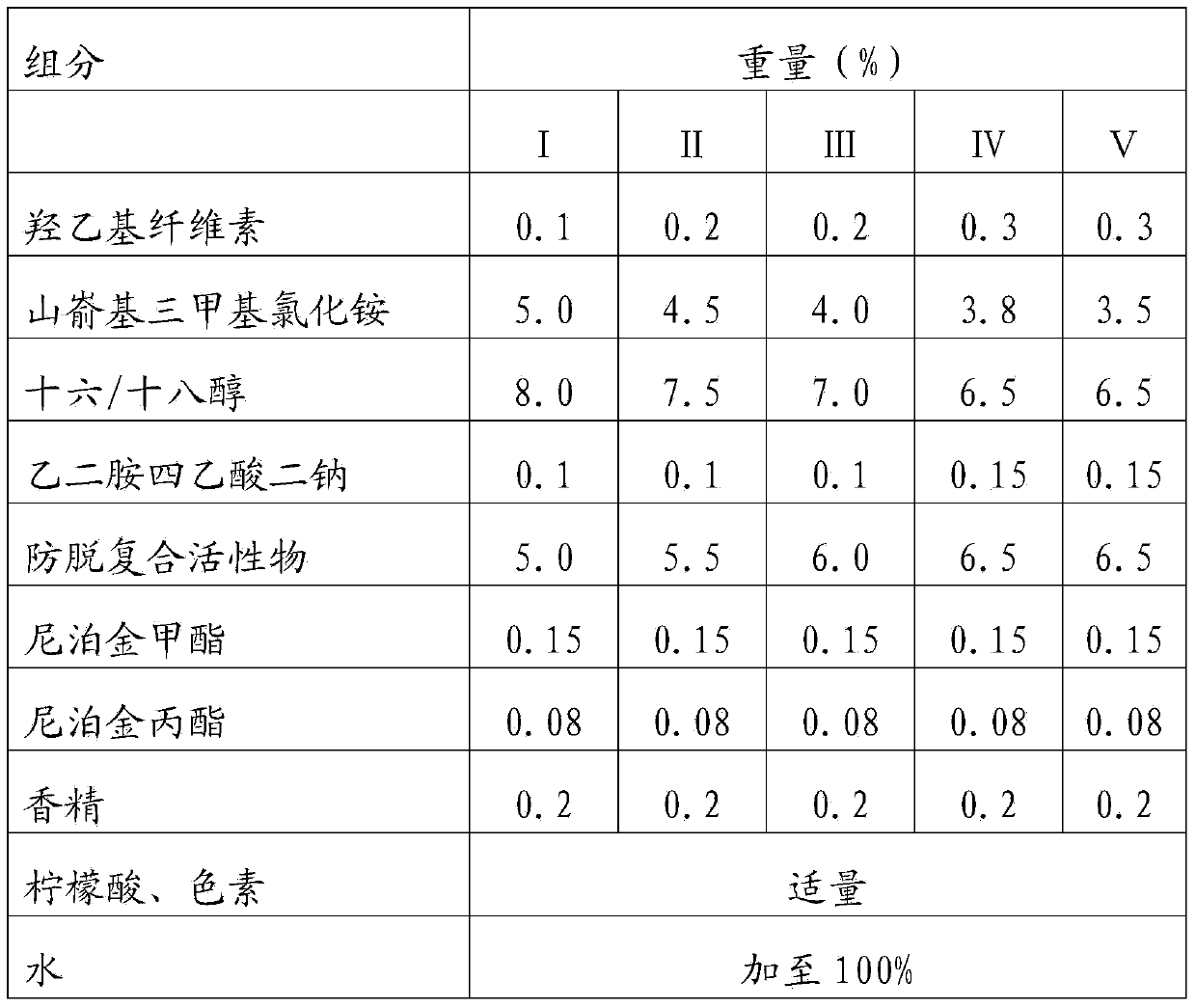

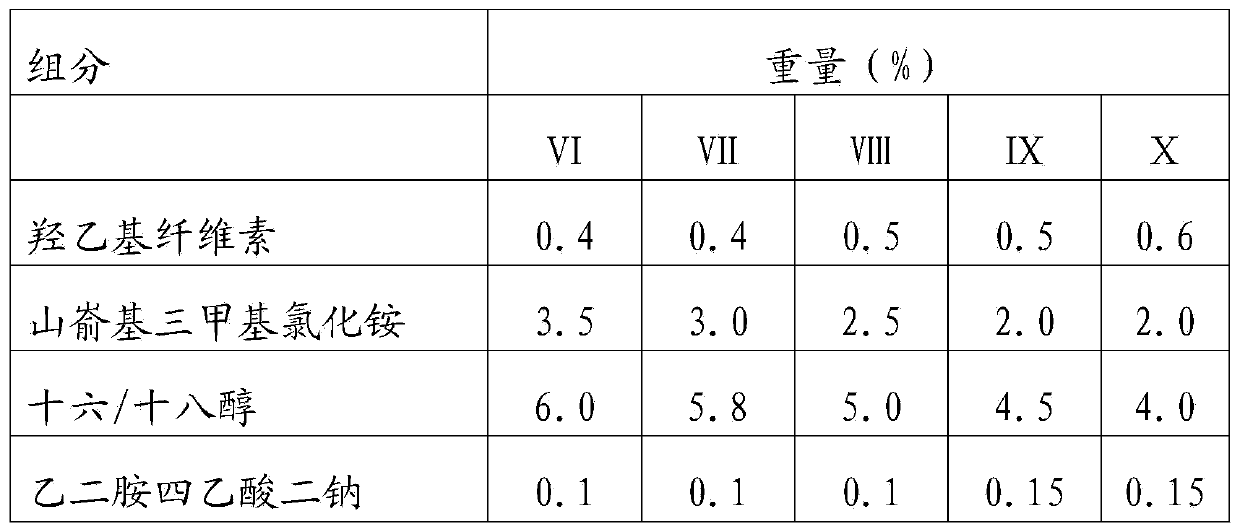

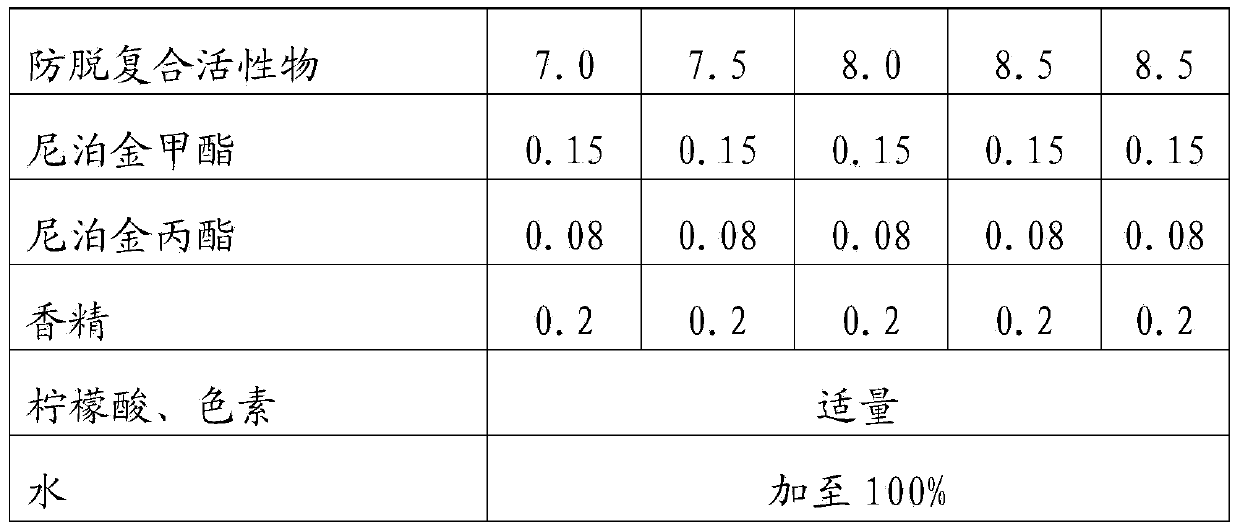

Hair-care composition containing efficient anti-hair-loss compound agent

ActiveCN103462844AReturn to normal ratioRestore hair loss speedCosmetic preparationsHair cosmeticsSugar amineRest period

The invention relates to a hair-care composition containing an efficient anti-hair-loss compound agent. The hair-care composition comprises long-chain alcohol, a cationic surface active agent, a thickening agent, essence, a preservative, a chelating agent, water and an anti-hair-loss compound active matter, wherein the anti-hair-loss compound active matter accounts for 0.1 to 10 percent of weight of the composition and is a composition of hydrolyzed soy protein, amino acid, amino sugar, vitamin B complex, zinc salt, ginseng essence, May burdock root essence, organic silicon and polyquaternium. By virtue of the hair-care composition, the hair growth can be promoted, the ratio of a growing period to a resting period of hair is improved, forming of healthy scalp and healthy hair is promoted, and the hair loss speed of a hair loss patient is returned to be normal.

Owner:LAFANG CHINA CO LTD

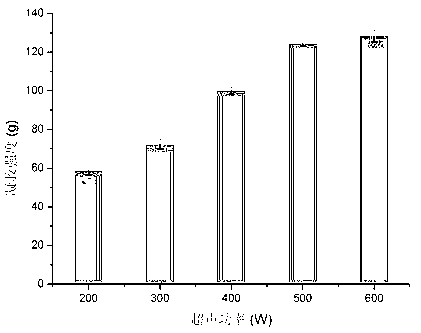

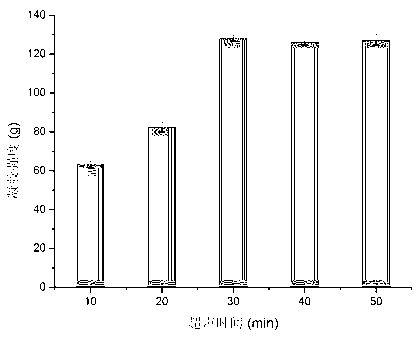

Process method for quickly preparing soybean antioxidant peptide

The invention discloses a process method for quickly preparing a soybean antioxidant peptide, belonging to the technical fields of deep processing of agricultural and sideline products and comprehensive utilization of byproducts thereof, and relating to the process method for quickly preparing the soybean antioxidant peptide by using a microwave technology. According to the process method, soybean protein concentrate powder with protein content of 70 percent is used as a raw material, the material passes through a microwave extractor through processes of preparing the soybean protein concentrate powder, pretreating soybean protein concentrate powder emulsion, performing microwave auxiliary enzymatic treatment on the soybean protein concentrate powder emulsion, deactivating enzymatic hydrolysate, centrifuging, performing ultrafiltration treatment and performing vacuum freeze drying treatment by using the microwave auxiliary enzymatic hydrolysis technology; the enzymatic hydrolysis time is shortened to 35-38 minutes; and compared with the conventional enzymatic hydrolysis, the efficiency is increased by 3-4 times, and the ABTS (2, 2'-azino-bis (3-ethylbenzthiazoline-6-sulfonic acid)) free radical clear rate is over 72 percent and is equivalent to that of the conventional enzyme. According to the process method, a new idea is provided for technical research for quickly preparing the soybean antioxidant peptide, and a new approach is provided for development and application of soybean series products of high antioxidant activity.

Owner:JILIN UNIV

Preparation method of high-load curcumin soybean protein nano product

InactiveCN104256048AImprove bindingGood water solubilityProtein composition from vegetable seedsVegetable proteins working-upFood industrySolubility

The invention discloses a preparation method of a high-load curcumin soybean protein nano product, belonging to the technical field of a production process of a functional food. The preparation method comprises the following steps: step 1: adding soybean protein into water; agitating and dispersing at a room temperature; hydrating for 6-12 hours to obtain a soybean protein dispersed solution; step 2: adding curcumin into absolute ethanol and agitating and dissolving to obtain a curcumin ethanol solution; and step 3: adding the curcumin ethanol solution into the soybean protein dispersed solution at a room temperature under an agitating condition; agitating and sufficiently mixing; and centrifuging and drying centrifugal liquid supernatant to obtain powder, namely the high-load curcumin soybean protein nano product. According to the preparation method of the high-load curcumin soybean protein nano product, through utilization of structural properties and thermal pretreatment moderate denaturation of the soybean protein, the soybean protein is urged to be combined with curcumin to form the high-load curcumin soybean protein nano product, and the water solubility and the stability of curcumin can be greatly improved; and the production process is simple and safe and can be applied to food industries.

Owner:SOUTH CHINA UNIV OF TECH

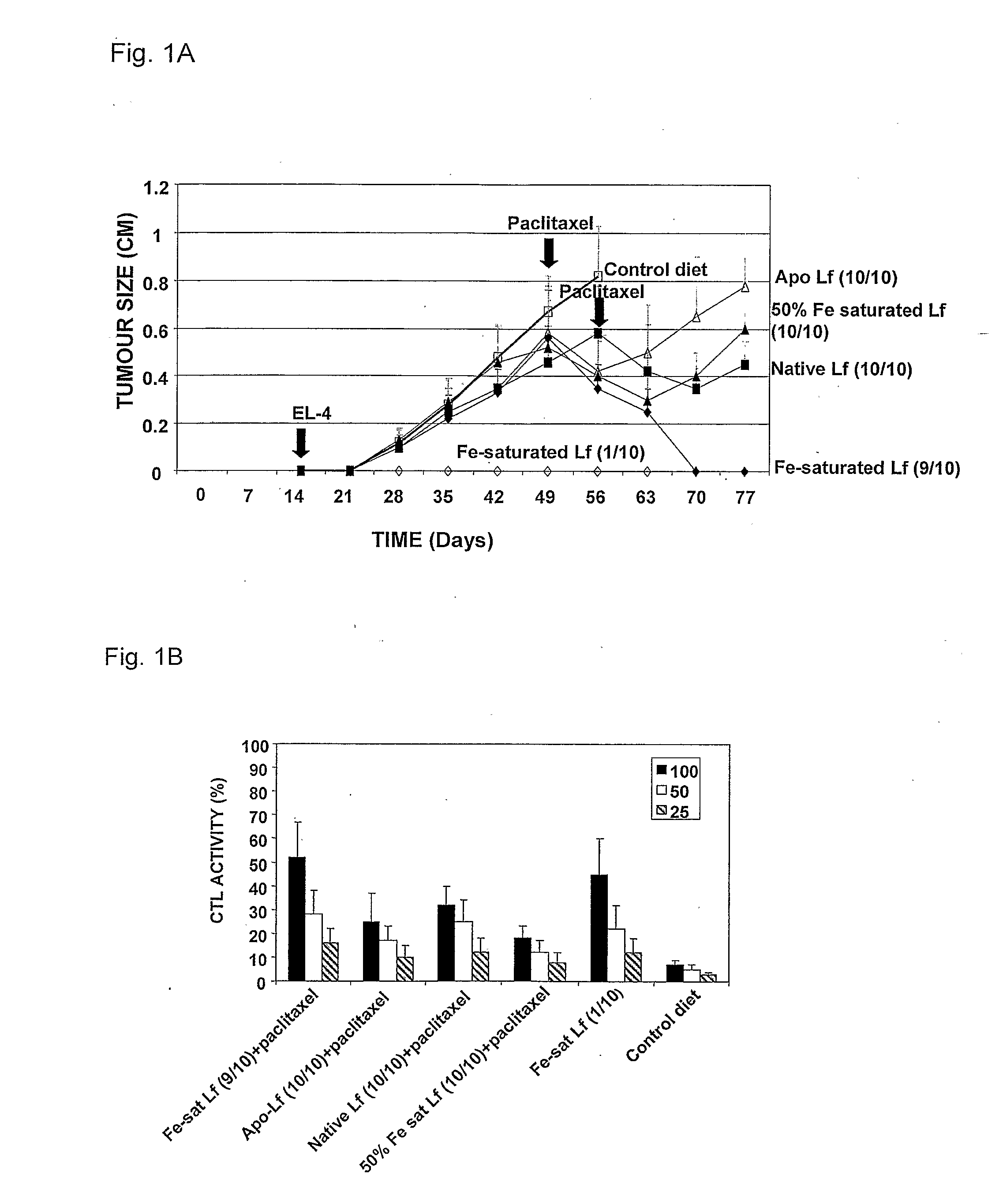

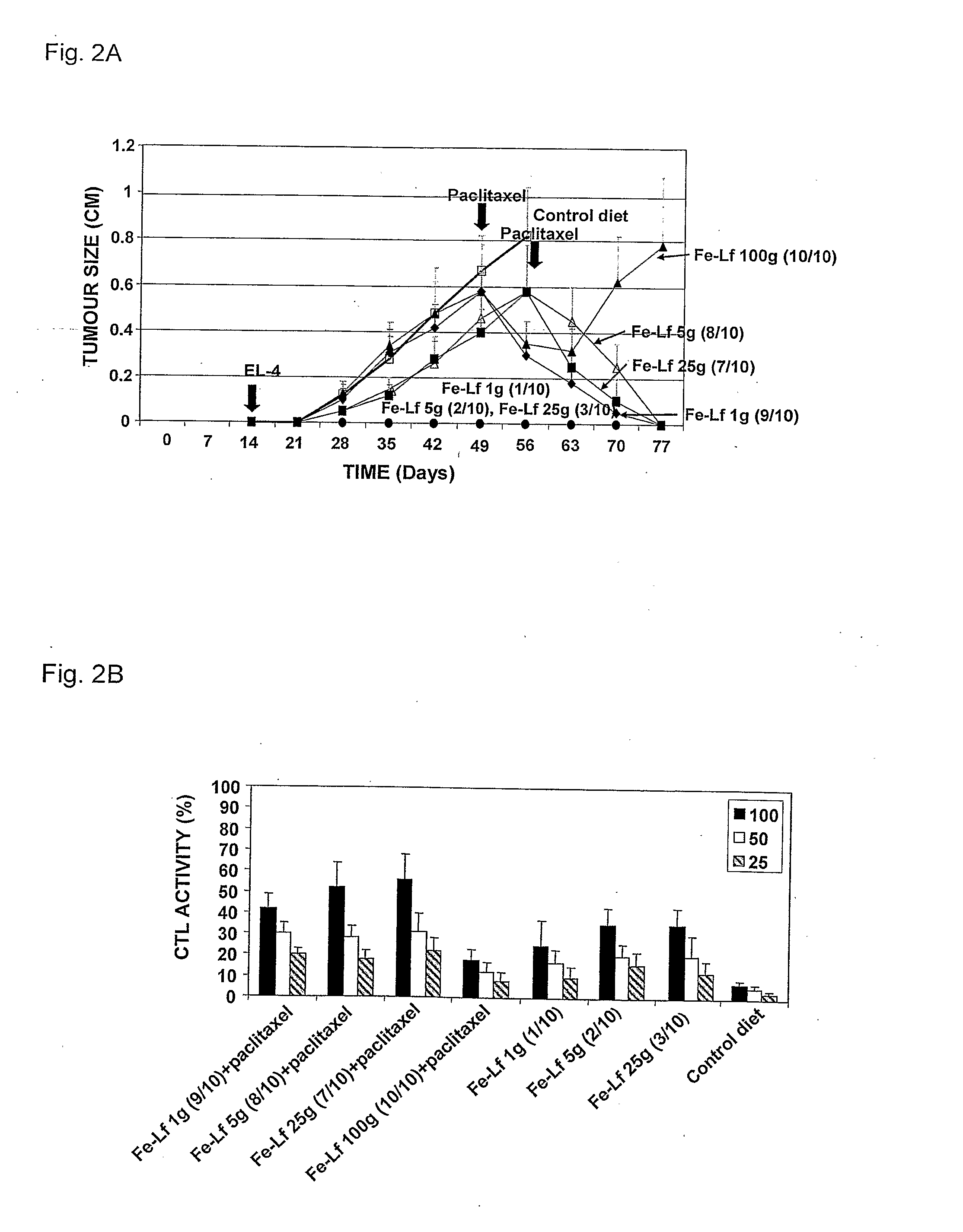

Methods of immune or haematological enhancement, inhibiting tumour formation or growth, and treating or preventing cancer

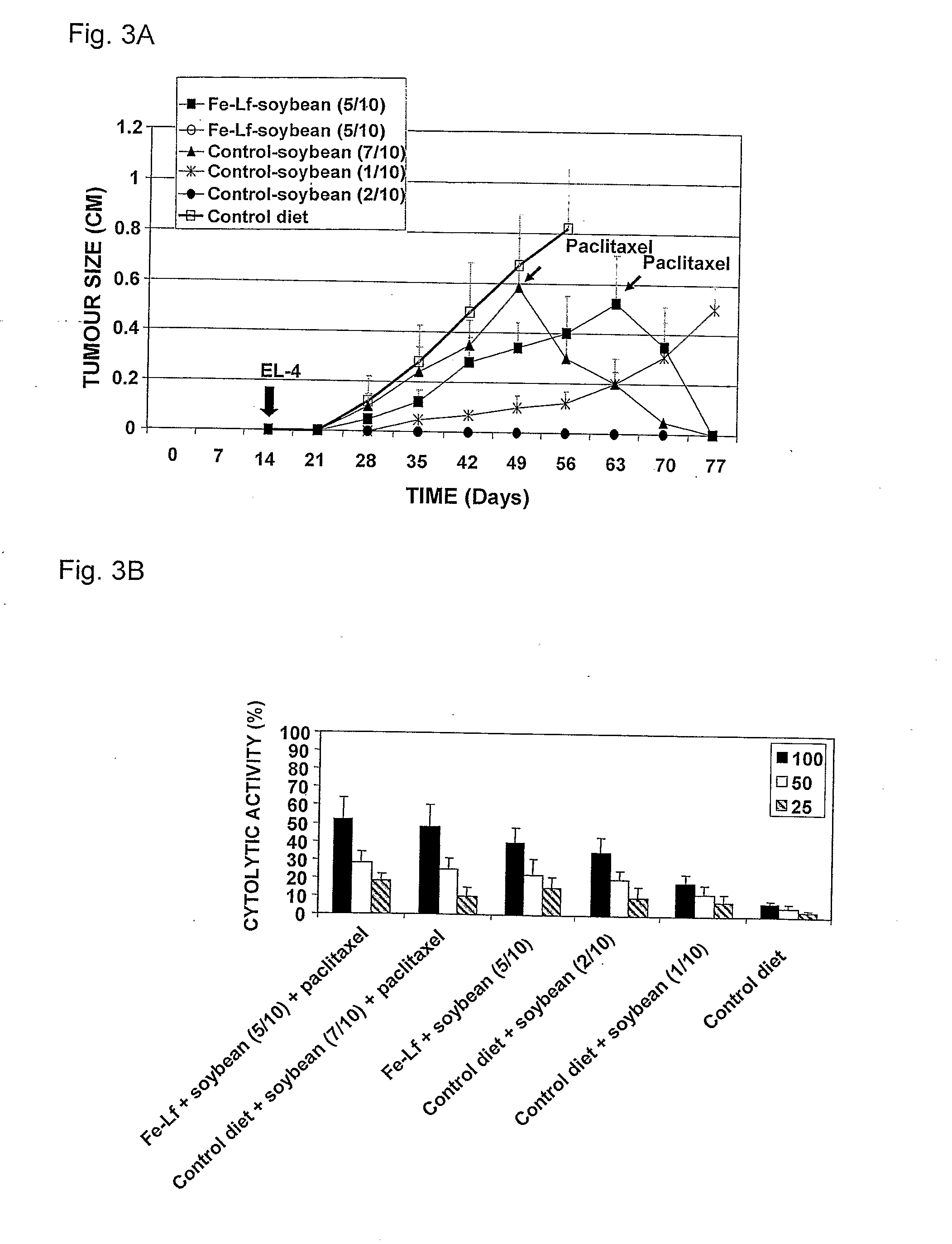

InactiveUS20100092497A1Small sizeImprove responsivenessBiocideOrganic active ingredientsCancer preventionPhysiology

Use of lactoferrin or metal ion lactoferrin, preferably iron lactoferrin, preferably bovine lactoferrin, preferably iron bovine lactoferrin, or a metal ion functional variant or functional fragment thereof and at least one anti-tumour food factor selected from soy protein and vitamin D inhibits tumour formation or growth, maintains or improves one or both of the white blood cell count and red blood cell count, stimulates the immune system, and / or treats or prevents cancer. Dietary (foods or food supplements), nutraceutical or pharmaceutical compositions may be used.

Owner:FONTERRA COOP GRP LTD

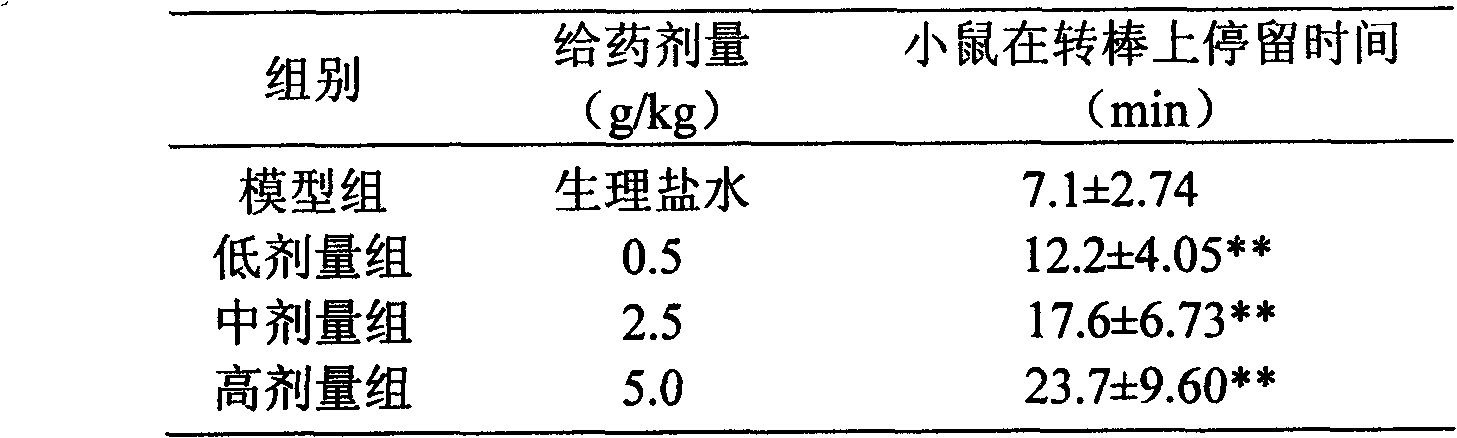

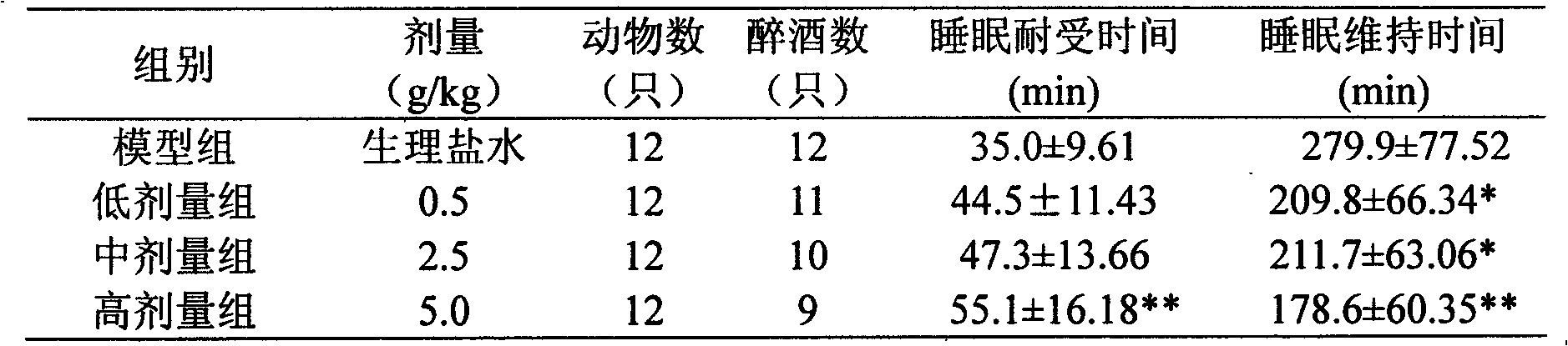

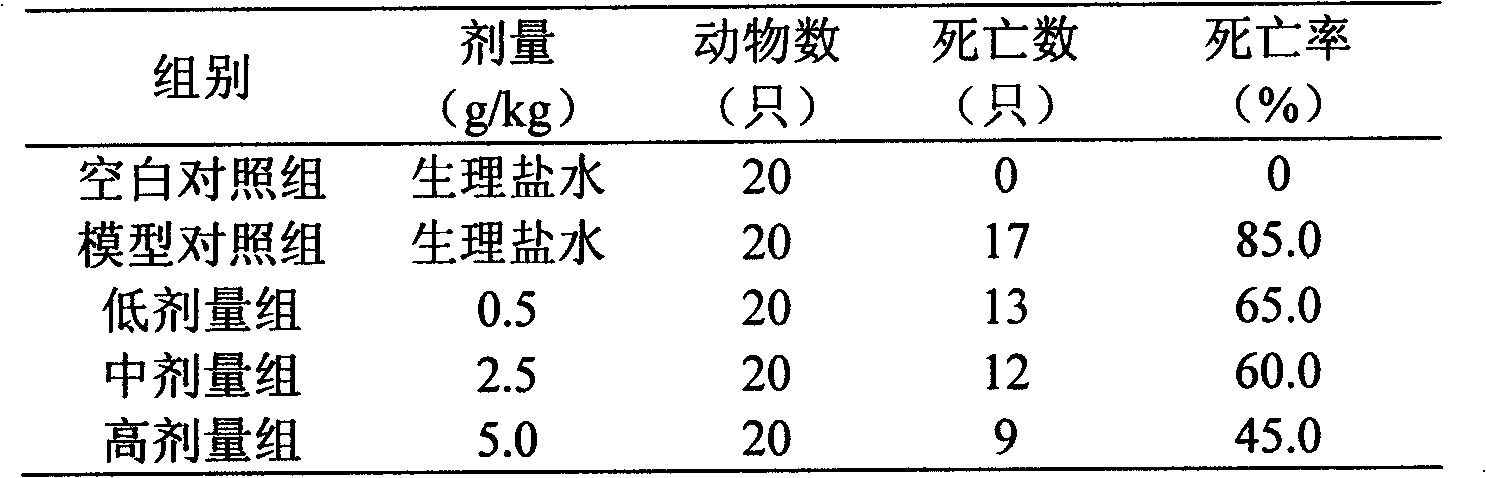

Composition for sobering up and protecting liver

The invention provides a functional product composition for sobering up and protecting the liver, comprising effective components and auxiliary materials which are acceptable in the medicine. The functional product composition for sobering up and protecting the liver is characterized in that the effective components are prepared by the following raw material medicines according to parts by weight: 5-60 parts of soybean protein, 4-50 parts of zein, 3-40 parts of ginseng, 2-40 parts of radix puerariae and 2-40 parts of raisin tree fruit. The composition can quickly lower the concentration of ethanol in blood after drinking, quickens the sobriety recovery of the brain and has very good functions of sobering up and restoring consciousness; the composition also can effectively treat acute alcoholism, prevents chronic alcoholism and lowers the injury of alcohol to liver cells.

Owner:SOUTHERN MEDICAL UNIVERSITY

Process for producing soybean protein peptide using soybean as raw material

InactiveCN1500881AIncrease methionine contentNutrition scienceFermentationGlycopeptideTherapeutic effect

The present invention is the technological process of preparing soybean protein peptide with soybean as material. The technological process includes dissolving soybean protein, the first enzymolysis, centrifugal separation to obtain supernatant and precipitate; separating and enzymolyzing the supernatant and the precipitate, with soybean glycopeptide being obtained via enzymolyzing the supernatant; centrifugally separating the precipitate enzymolyzing product to obtain supernatant and precipitate for the second time; separately drying the the supernatant and the precipitate to obtain amino acid balanced peptide and soybean polypeptide separately. The technological process is unique and low in cost, and the products have nourishing and auxiliary treatment effects and no toxic side effect and may be used widely in medicine and health food.

Owner:陆晓民

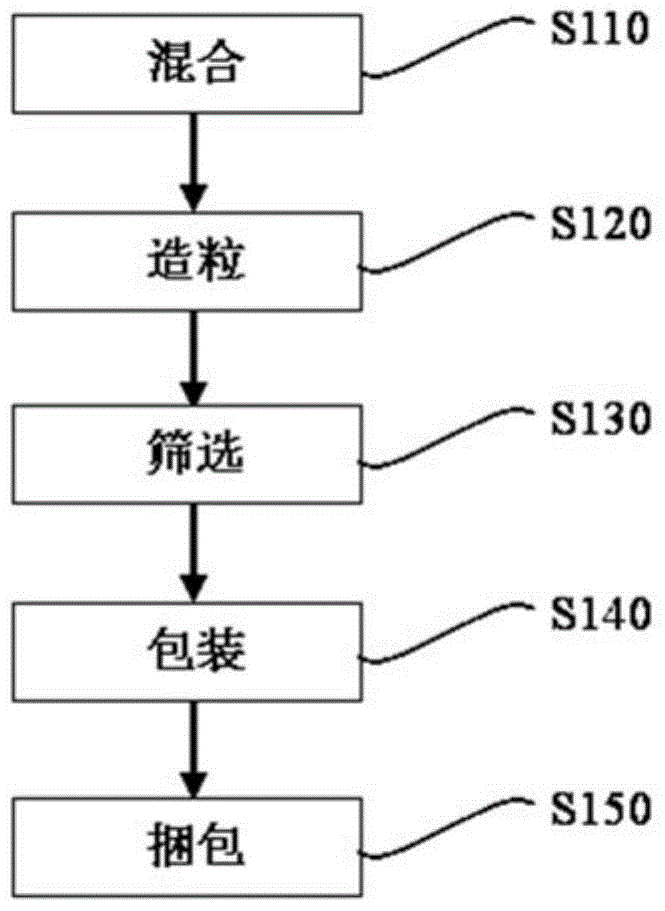

Compound protein powder and preparing method thereof

InactiveCN104770743ASuitable for large-scale productionThe formula is scientific and reasonableFood preparationYolkCooking & baking

The invention discloses compound protein powder and a preparing method thereof. The compound protein powder comprises soybean protein powder, whey protein powder, highland barley protein powder, potato protein powder, sweet potato protein powder, collagen protein powder, pea protein powder, walnut powder, egg white powder, yolk powder, soybean lecithin, rape pollen, sweetening agents and essence. The preparing method comprises the steps of raw material baking, cooling, mixing and packaging, and finished products are obtained. The raw material ratio accords with the modern health maintenance principle, the formula is scientific and reasonable, the good effect that nutrient needed by a human body is supplemented is achieved, taste is good, and flavor is unique.

Owner:威海御膳坊生物科技有限公司

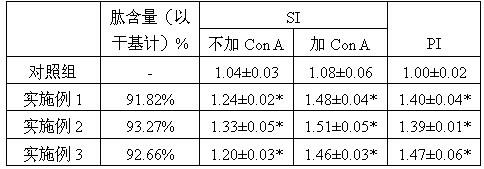

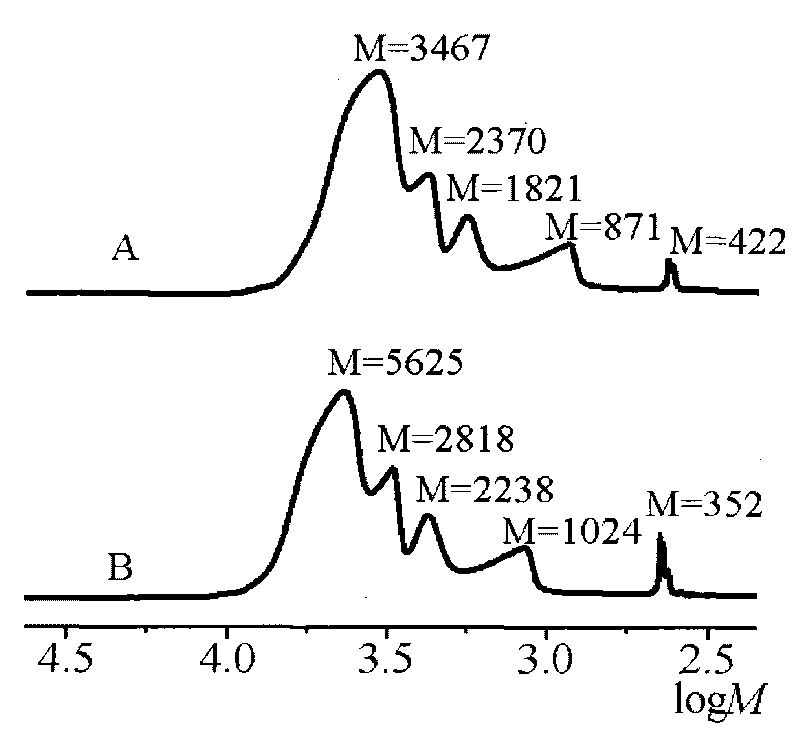

Method for preparing immunocompetent soybean peptide by enzymolysis and membrane separation

ActiveCN101974589AImprove the quality of immune activityPeptide preparation methodsFermentationImmunocompetenceHydrolysis

The invention relates to a method for preparing an immunocompetent soybean peptide by enzymolysis and membrane separation, belonging to the technical field of soybean protein deep processing. The method comprises the following steps of: by taking defatted soybean protein powder as a raw material, firstly, carrying out acid cleaning on the defatted soybean protein powder to obtain acid washed soybean protein; then carrying out enzyme hydrolysis by using an Alcalase protease under certain conditions to obtain coarse soybean peptide liquid; clarifying the prepared coarse soybean peptide liquid by adopting microfiltration; then carrying out enrichment and desalination treatment by adopting ultrafiltration and nanofiltration; and finally, drying to obtain the powdery immunocompetent soybean peptide. The activity of the soybean peptide is determined by adopting a neutral red phagocytosis test and a lymphopoiesis method, which proves that the prepared soybean peptide has high immunocompetence.

Owner:安徽盛美诺生物技术有限公司

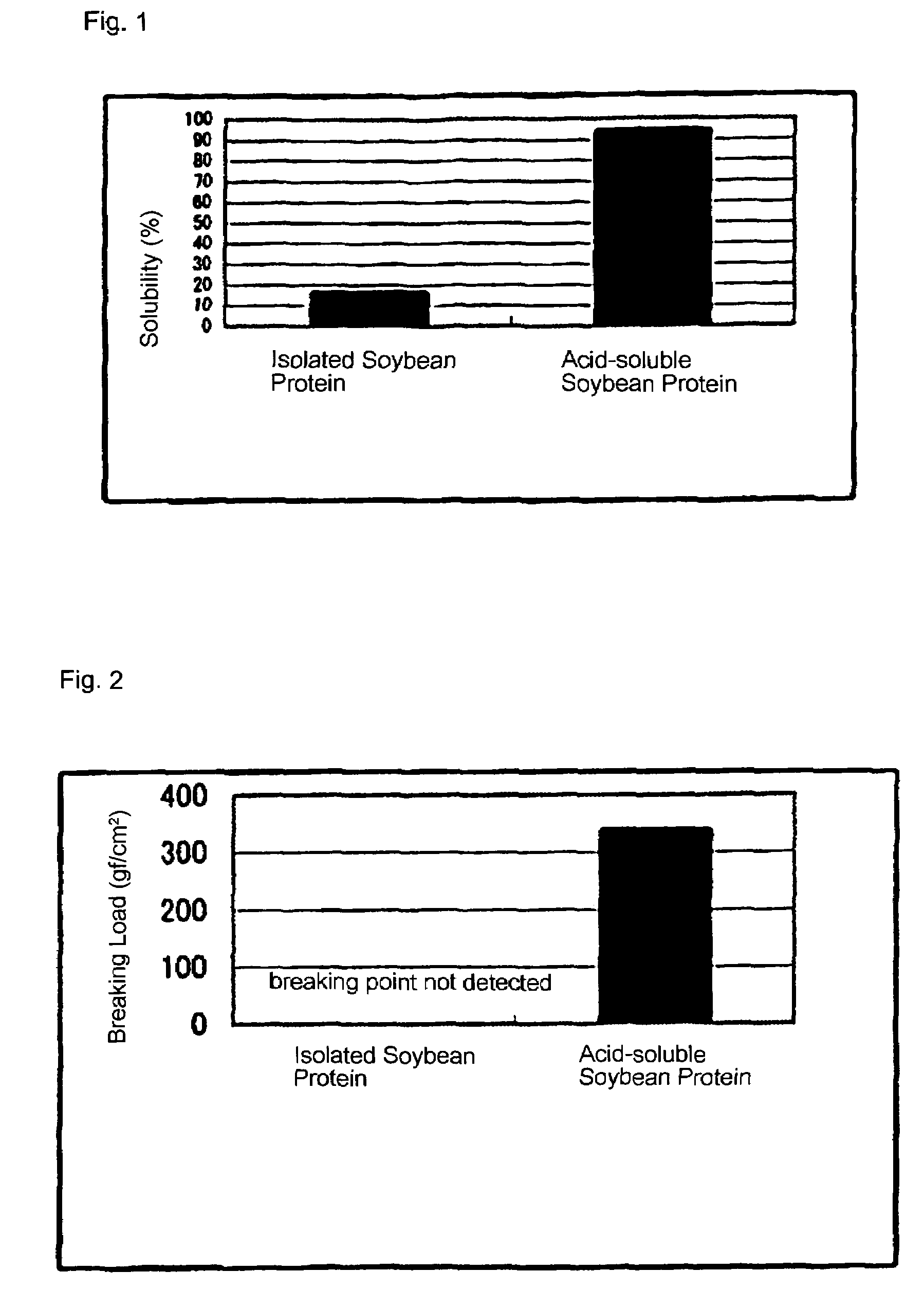

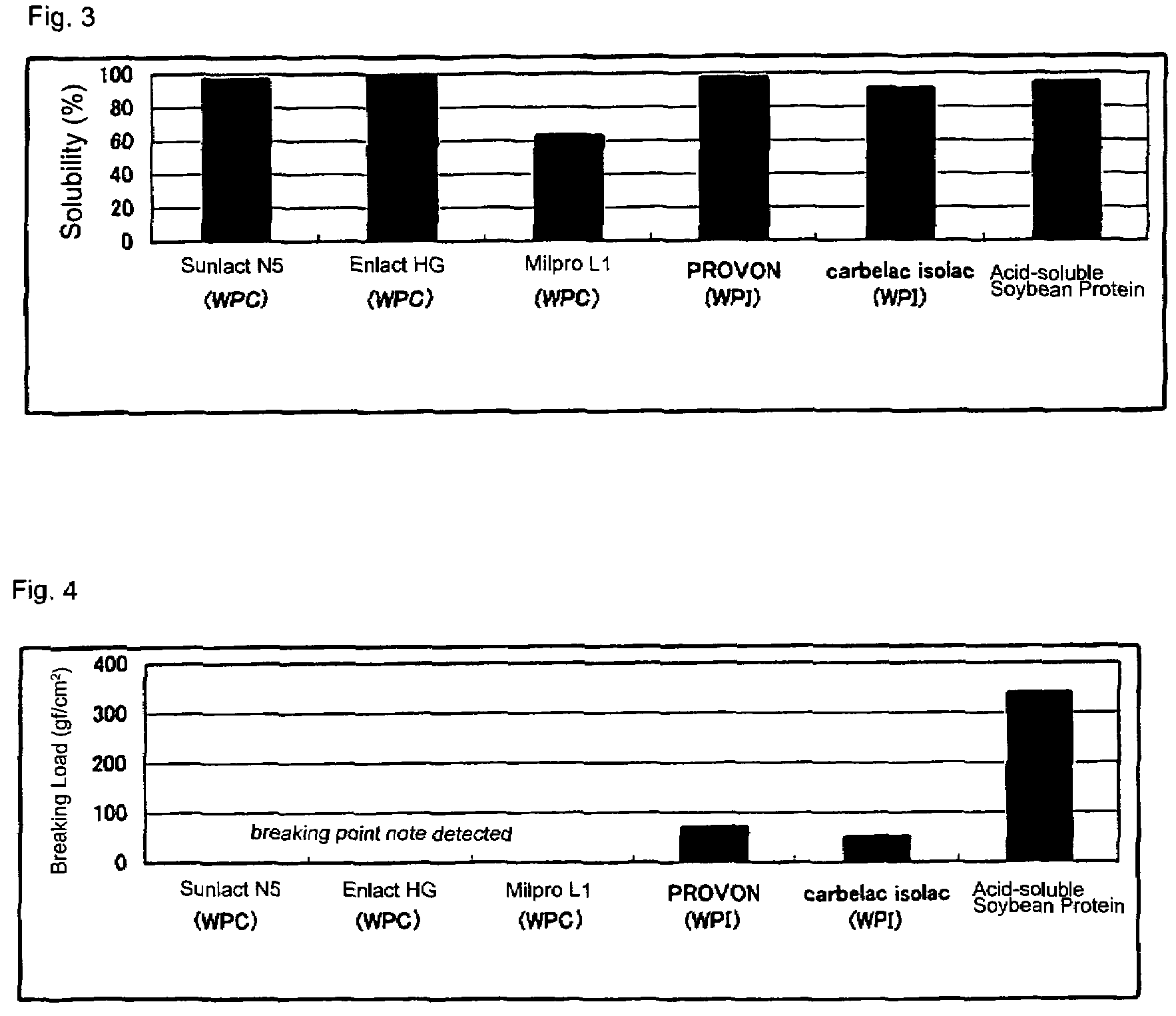

Acidic soy protein gel foods and process for producing the same

The present invention is intended to provide acidic gel foods containing soybean protein to diversify means of taking soybean protein in daily eating habits. Using the acid-soluble soybean protein as specified in the description, an aqueous solution or an alcohol-containing aqueous solution of the protein is adjusted to pH 3 to 4.5. Then an acid having 2 or more acid groups per molecule or its salt or a salt of another acid is added thereto and the mixture is heated to form a gel. Thus, acidic gel foods including a jelly-like food favorable as a food can be obtained.

Owner:FUJI OIL CO LTD

Method for graft modification of soyabean protein-sugar

The invention provides a method for graft modification of soyabean protein-sugar which consists of, subjecting the mixed solution of soybean protein and sugar to microwave radiation heating, cooling down, and separating and removing extra polysaccharides and by-products from the mixture.

Owner:JIANGNAN UNIV

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376AHigh viscosityImprove adsorption capacityProtein adhesivesGlue/gelatin preparationMedium densityAdhesive

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid to adjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

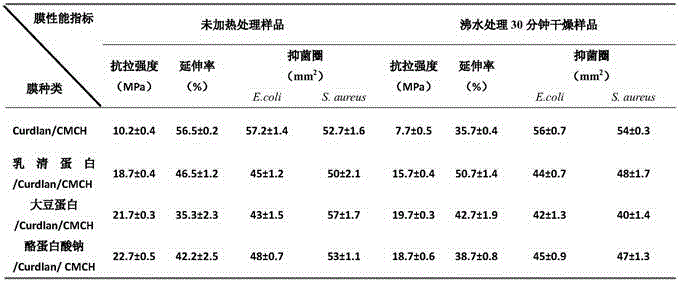

Edible protein/polysaccharide composite membrane and preparation method and application thereof

ActiveCN105802249AWide variety of sourcesGood film formingFlexible coversWrappersCross-linkProtein solution

The invention discloses an edible protein / polysaccharide composite membrane and a preparation method and application thereof.The composite membrane is prepared through the method that a Curdlan solution, a carboxymethyl chitosan solution and plasticizer glycerinum are added into a protein solution including one of soybean protein, casein and whey protein, the pH value of the mixed liquid is adjusted to be 5-8; ultrasonic degassing is conducted, MTG is added, and membrane-forming liquid is acquired; the membrane-forming liquid is poured into a polyfluortetraethylene plate, a reaction is conducted for 30-60 minutes at the temperature of 55-65 DEG C, sizing and sterilization are conducted, 4-DEG C cooling is conducted for 10-20 minutes, drying is conducted under the conditions that RH is 30-50% and the temperature ranges from 20 DEG C to 30 DEG C, and then membrane uncovering is conducted.The heat stability of the membrane is improved by adding Curdlan into the common edible protein solution, chitosan is added so that the membrane can have the antibacterial performance, microorganism source transglutaminase is added to catalyze the protein and cross linking between the protein and chitosan, and the chemical performance of the membrane is improved.

Owner:TAIXING DONGSHENG FOOD TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com