Method for producing L-lactic acid and coagulate bacillus cereus special for the same

A technology of Bacillus coagulans and lactic acid, which is applied in the field of producing L-lactic acid, can solve the problems of low acid production rate, achieve the effects of less chance of polluting miscellaneous bacteria, reduce the loss of nutrients, and reduce the consumption of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Isolation, mutagenesis, screening and identification of Bacillus coagulans CASH CGMCC № 2184

[0035] 1. Isolation, mutagenesis and screening

[0036] The composition of the medium used in this example is as follows:

[0037] Nutrient liquid medium: glucose 150 g / liter, yeast powder 10 g / liter, calcium carbonate 50 g / liter, pH 6.

[0038] Nutrient agar medium: glucose 50g / L, yeast powder 10g / L, calcium carbonate 20g / L, agar powder 10g / L, pH 6.

[0039] Fermentation medium: glucose 150 g / liter, yeast powder 20 g / liter, calcium carbonate 90 g / liter, pH 6.

[0040] Nutrient broth medium: glucose 50 g / l, yeast powder 10 g / l, calcium carbonate 10 g / l, pH 6.

[0041] The specific operation process of this embodiment is as follows:

[0042] A soil sample was obtained from near a milk factory in Mentougou District, Beijing, and every 2 grams of soil sample was put into 50ml nutrient liquid medium, and enriched and cultured at 55°C for 6-10 hours. Then, it was diluted and s...

Embodiment 2

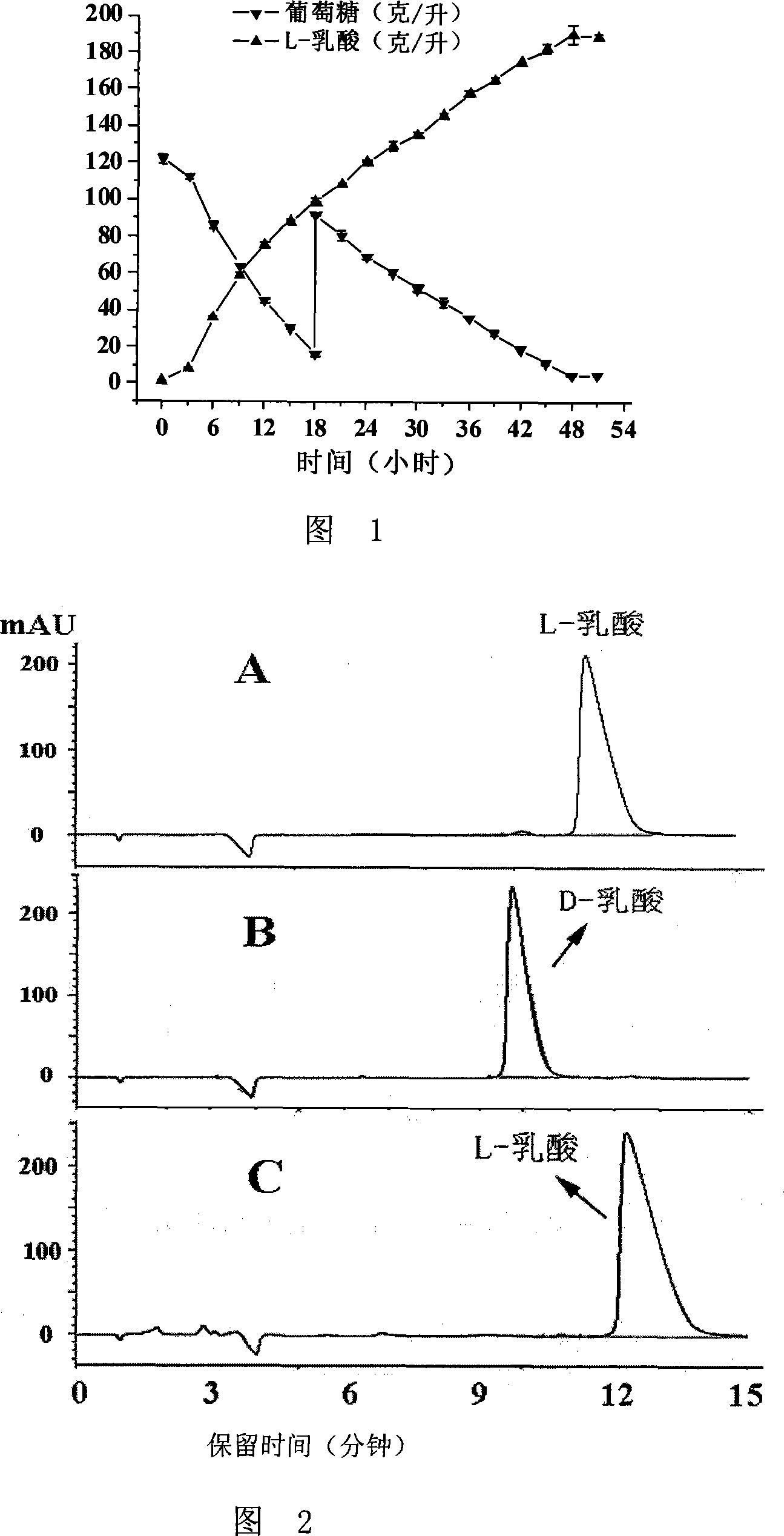

[0047] Example 2: Using Bacillus coagulans CASH CGMCC №2184 to ferment to produce L-lactic acid in a triangular flask

[0048] The composition of the medium used in this example is as follows:

[0049] Slant medium: glucose 20g / l, yeast extract 5g / l, peptone 10g / l, beef extract 10g / l, magnesium sulfate heptahydrate 0.58g / l, manganese sulfate tetrahydrate 0.25g / l, carbonic acid Calcium 15g / L, agar powder 15g / L. The initial pH of the medium was 6.5. Sterilized at 115°C for 20 minutes.

[0050] Seed culture medium: glucose 70 g / l, yeast powder 10 g / l, soy peptone 5 g / l, calcium carbonate 30 g / l. The initial pH of the medium was 6.5. Sterilized at 115°C for 20 minutes.

[0051] Fermentation medium: glucose (Zibo Hongyu Industrial Sugar Co., Ltd.) 170 g / liter, yeast powder (Beijing Aoboxing Biotechnology Co., Ltd., catalog number 01-013) 15 g / liter, calcium carbonate 80 g / liter. The initial pH of the fermentation medium was 6.5. Not sterilized.

[0052] The method for producing L-lacti...

Embodiment 3

[0063] Example 3. Using Bacillus coagulans CASH CGMCC №2184 to ferment to produce L-lactic acid in a triangular flask

[0064] The culture temperature of Bacillus coagulans CASH CGMCC №2184 is 55°C. The composition of the fermentation medium is: glucose (Zibo Hongyu Industrial Sugar Co., Ltd.) 118 g / l, soy peptone (Beijing Aoboxing Biotechnology Co., Ltd., catalog number 01-004) 15 g / l, calcium carbonate 80 g / Rise. The initial pH of the fermentation medium was 5.5. The fermentation time is 24 hours. The other methods are the same as in Example 2.

[0065] At the end of fermentation, the concentration of glucose is 3.2 g / liter ± 1.1 g / liter (mean ± standard deviation), the concentration of L-lactic acid is 113.5 g / liter ± 1.9 g / liter (mean ± standard deviation), and the sugar-acid conversion rate is 98.9 %±0.3% (average value±standard deviation), volume production efficiency 4.7 g / l / hr±0.2 g / liter / hr (average value±standard deviation), L-lactic acid optical purity 99.3%±0.2% (aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com