Patents

Literature

76 results about "Glutamine aminotransferase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving gelling performance of minced fish product by adding transglutaminase

InactiveCN1543840AHigh gel strengthImprove qualityFood preparationGlutamine aminotransferasePolyphosphate

The invention discloses a method for improving gel property of minced fish product through adding glutamine aminotransferase which comprises, adding into minced fish processed from fresh fish as raw material complex addition agent consisting soybean protein, polyphosphates and glutamine aminotransferase, adding addition agent, then kneading the minced fish 10-20 minutes, the gel property of the obtained minced fish product is increased to 400-500g from the previous 200g before addition.

Owner:JIANGNAN UNIV

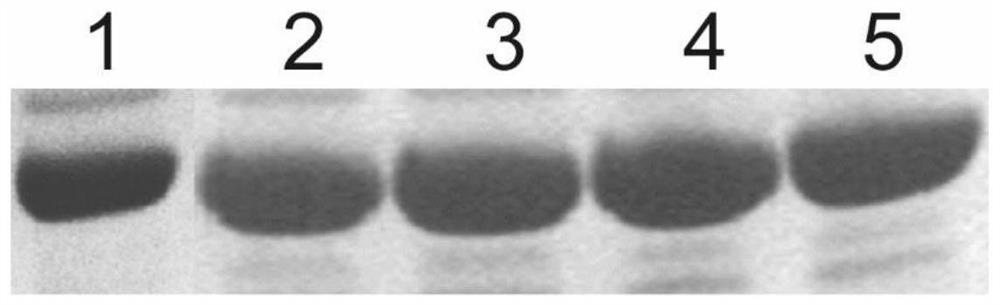

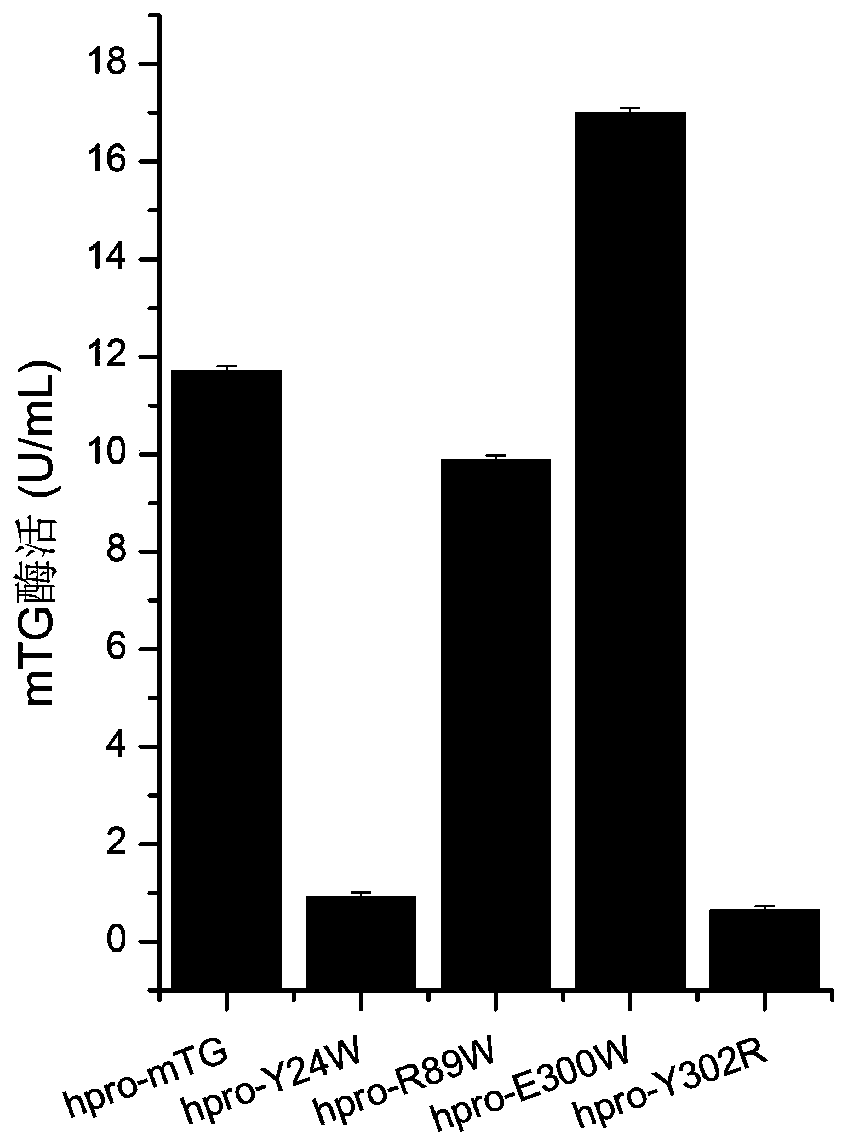

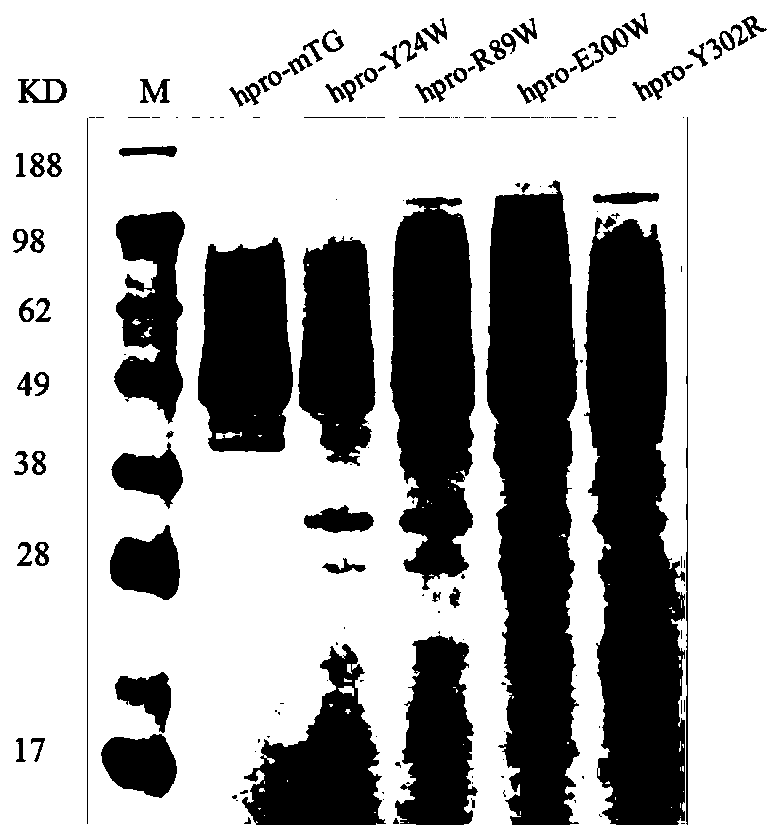

Mutant of glutamine transaminase expressed by active form

ActiveCN107574159AAchieve active expressionSimplify production stepsFungiTransferasesBacterial strainMutant

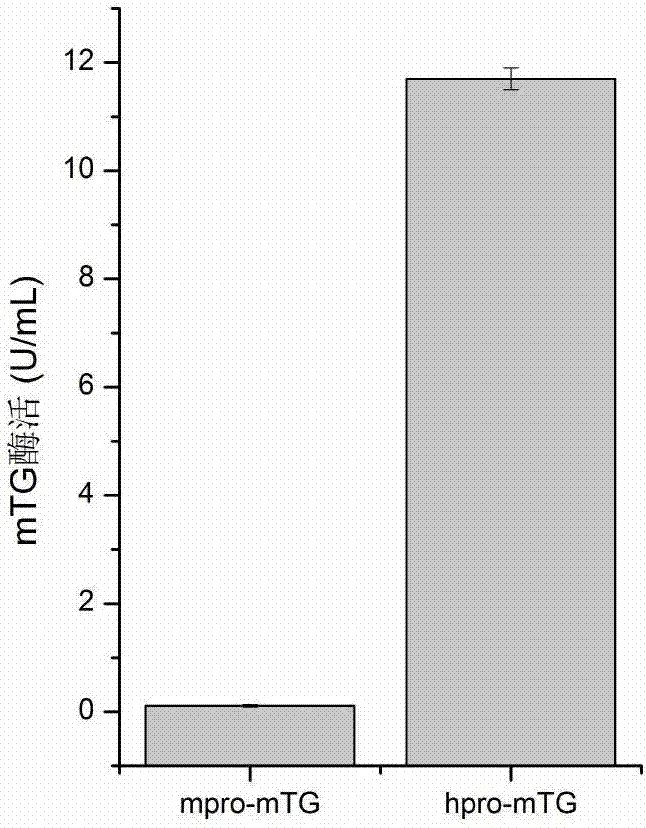

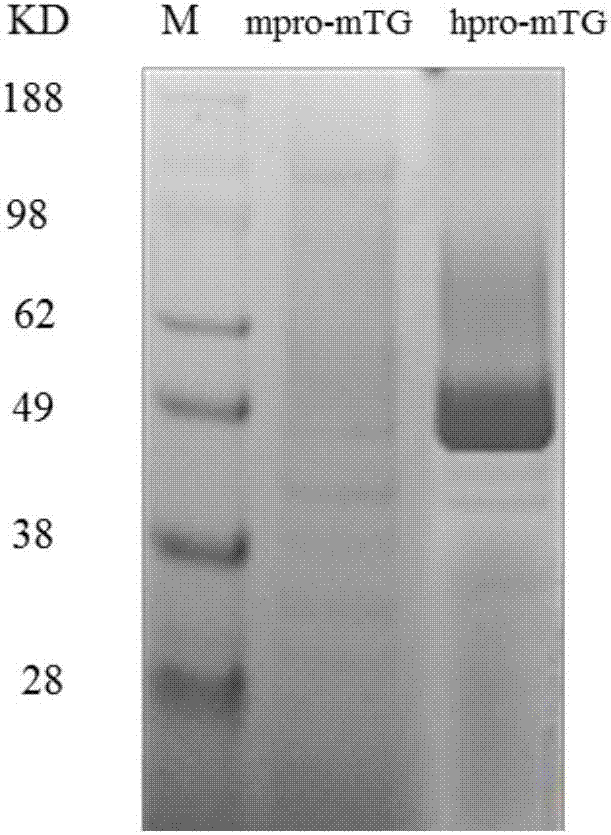

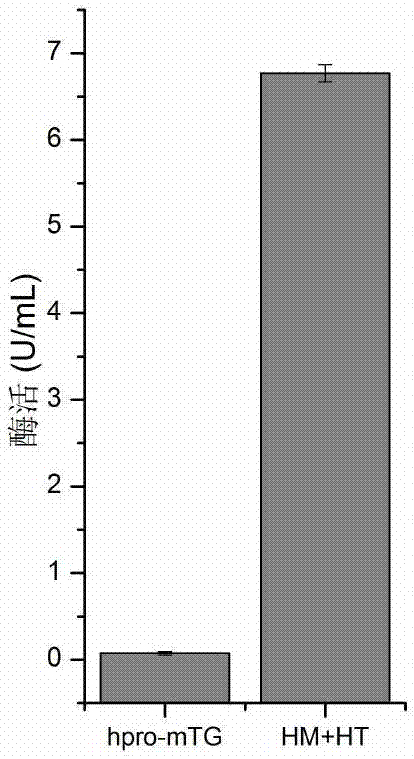

The invention discloses a mutant of glutamine transaminase expressed by an active form, and belongs to the field of gene engineering and fermentation engineering. A genetically engineered bacterium po1h / hpro-mTG of high-output glutamine transaminase is structured by using yarrowia lipolytica as a host. The bacterial strain is high in enzyme production level; the fermenting enzyme activity of a shake flask is up to 11.7 U / mL, and improved by 106 times in comparison to that before transformation; the fermenting enzyme activity of a fermenting tank is up to 43.7 U / mL. Through co-expressing proteases TAMEP and hpro-mTG, the activity expression of glutamine transaminase is realized; the fermenting enzyme activity of the shake flask can reach 6.7U / mL, and the fermenting enzyme activity of the fermenting tank can reach 21.4U / mL. The fermenting enzyme production level of the recombinant bacteria is high, the production cost of the glutamine transaminase is reduced; the mutant is good for the industrial production of the glutamine transaminase.

Owner:JIANGNAN UNIV

Glutamine transaminase with improved heat stability and application thereof

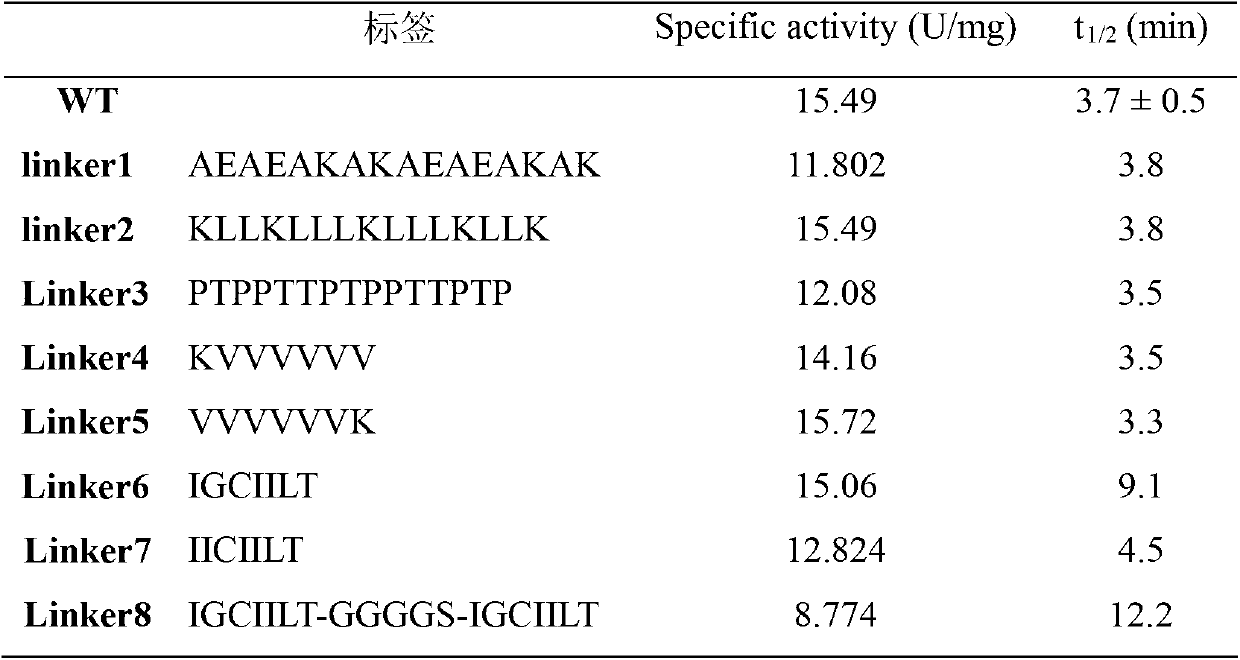

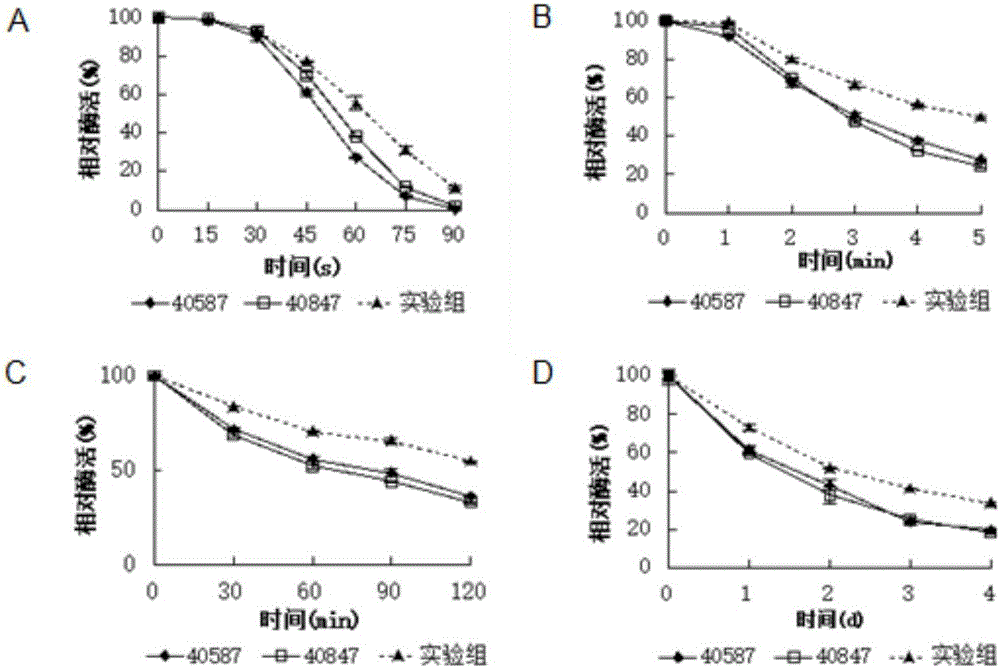

ActiveCN102994469AGood enzymatic propertiesImprove thermal stabilityBacteriaTransferasesEscherichia coliMicrobial transglutaminase

The invention discloses a glutamine transaminase with improved heat stability and application thereof. High-efficiency expression of microbial transglutaminase (MTG) in escherichia coli serves as a modification platform, a label facilitating improvement of heat stability is added at the C end of MTG maturase, preference is given to IGCIILT to obtain a mutant strain with good enzymatic property, and the heat stability is improved by 2.5 times and 3 times. Modified enzyme is suitable for industrial application, the production cost can be reduced, and the production efficiency can be improved.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Gluten protein colloid granules and preparation method and application of gluten protein colloid granules

ActiveCN104664044AInhibition of deamidation reactionImprove stabilityVegetable proteins working-upFood preparationHigh surfaceGlutamine

The invention discloses gluten protein colloid granules and a preparation method and application of the gluten protein colloid granules. The preparation method comprises the following steps: gluten protein is subjected to crosslinking reaction under the effect of glutamine transaminase so as to form gluten protein colloid granules; micro hydrophilic molecules with primary amine groups are added into the reaction system, and are at least one of L-lysine, glucosamine and L-glutamic acid, and the mass ratio of micro hydrophilic molecules with primary amine groups to the gluten protein is 1 to (10-100). According to the invention, the micro hydrophilic molecules with primary amine groups are added into the reaction system; the gluten protein is subjected to crosslinking among molecules and within molecules, and crosslinking reaction is performed together with the micro hydrophilic molecules with primary amine groups; on one hand, glutamine or asparaginate in the gluten protein can be prevented from being subjected to deamidation reaction by glutamine transaminase, and on the other hand, because the micro hydrophilic molecules with the primary amine groups contains electrified groups, relatively high surface electric charge is given to the gluten protein.

Owner:ZHEJIANG UNIV +1

Method for using glutamine aminotransferase catalyzing exogenous protein to clean wool fabric

InactiveCN101302714AGood felt shrinkageReduce COD valueBiochemical fibre treatmentAnimal fibresEcological environmentBiological macromolecule

Owner:JIANGNAN UNIV

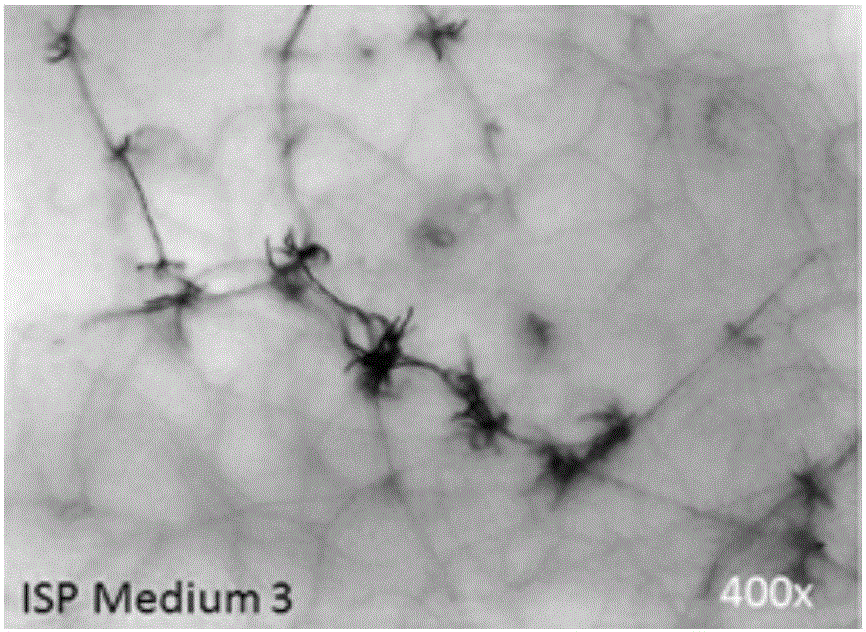

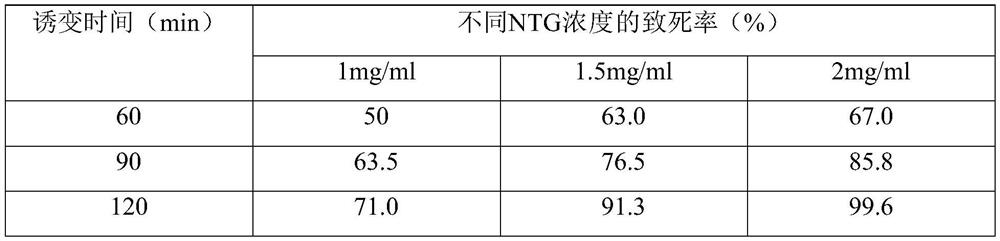

Glutamine transaminase high-yielding strain and application thereof

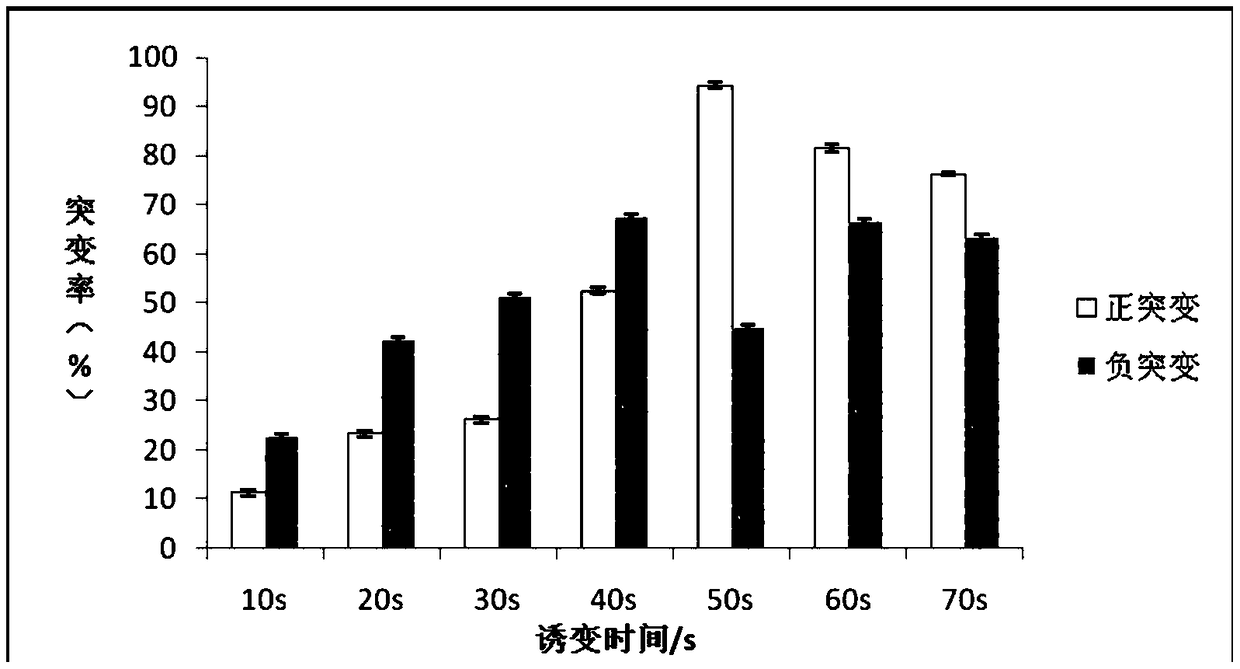

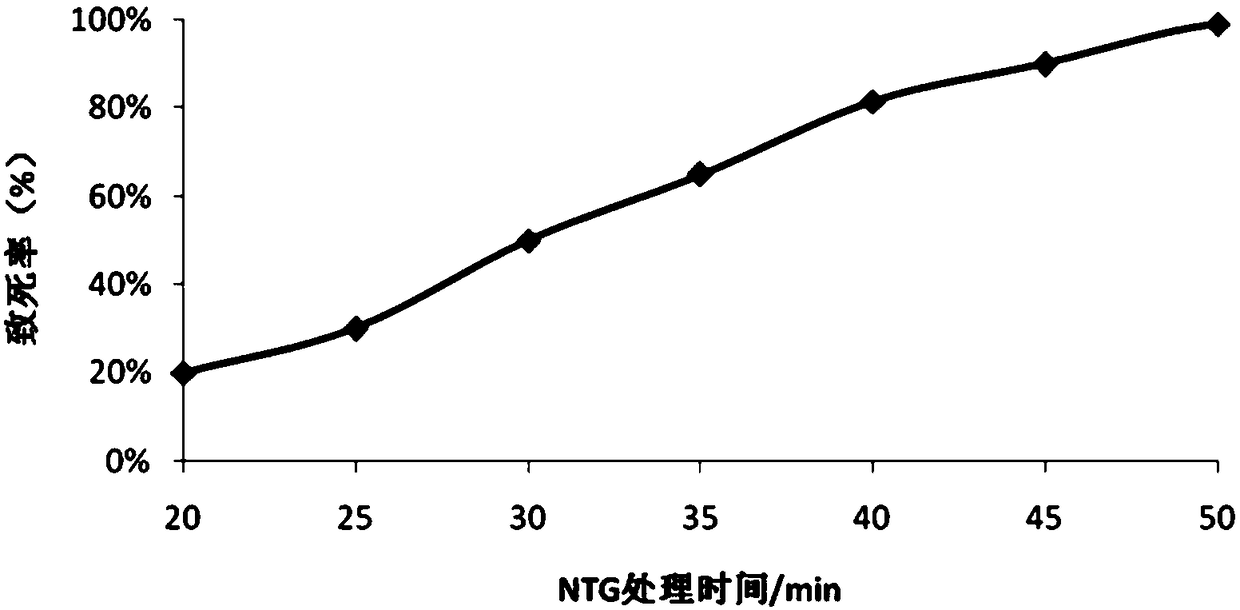

InactiveCN103981130AGood genetic stabilityHigh transglutaminase activityBacteriaTransferasesStreptomyces hygroscopicusHigh activity

The invention discloses a glutamine transaminase high-yielding strain and application thereof. The strain is named as streptomyces hygroscopicus NYU-70 according to classification and naming, and has been preserved in China Center for Type Culture Collection and preservation number of CCTCCM2014121. Streptomyces hygroscopicus NY-1 is used as a starting strain for low energy ion implantation mutagenesis, activity of the enzyme of the strain after mutagenesis is measured through casein gel method and colorimetric method, mutant strains with high activity in producing glutamine transaminase are screened out as the starting strains for the next round of mutagenesis, and the above steps are repeated to obtain the glutamine transaminase high-yielding strain. The strain has high activity and good genetic stability in fermentation production of glutamine transaminase. The mutant strain can be used in liquid shake flask fermentation to obtain glutamine transaminase, and has enzyme activity of 16.9U / mL.

Owner:虞龙

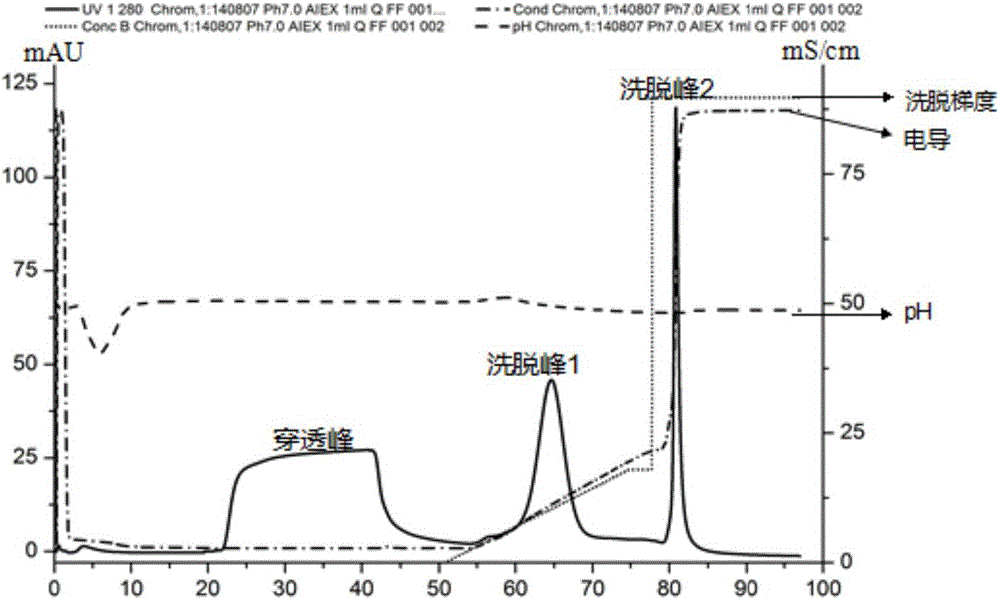

Separation and purification method of microbial transglutaminase

ActiveCN105754892AHigh purityStable in natureBacteriaMicroorganism based processesSpecific enzymePurification methods

The invention discloses a separation and purification method of new microbial transglutaminase. The method comprises the following steps of carrying out alcohol precipitation on new streptomyces mobaraensis fermentation liquor with the strain number being CGMCC No.10804 obtained through natural screening, carrying out anion exchange chromatography, desalting, freezing and drying to obtain the microbial transglutaminase. The obtained transglutaminase has the purity being larger than or equal to 90 percent, the plasma endotoxin level being less than or equal to 0.02EU / mL, the specific enzyme activity being 25 to 30U / mg, and the recovery rate being larger than or equal to 70 percent. The separation and purification method of the new microbial transglutaminase is simple in process, low in cost, and high in enzyme recovery; the obtained transglutaminase is high in purity; the microbial transglutaminase obtained through fermenting the strain is stable in property, so that the industrial production is convenient; a feasible method is provided for satisfying medical grade MTGase scale production.

Owner:EAST CHINA NORMAL UNIV +1

Immobilized glutamine transaminase preparation method

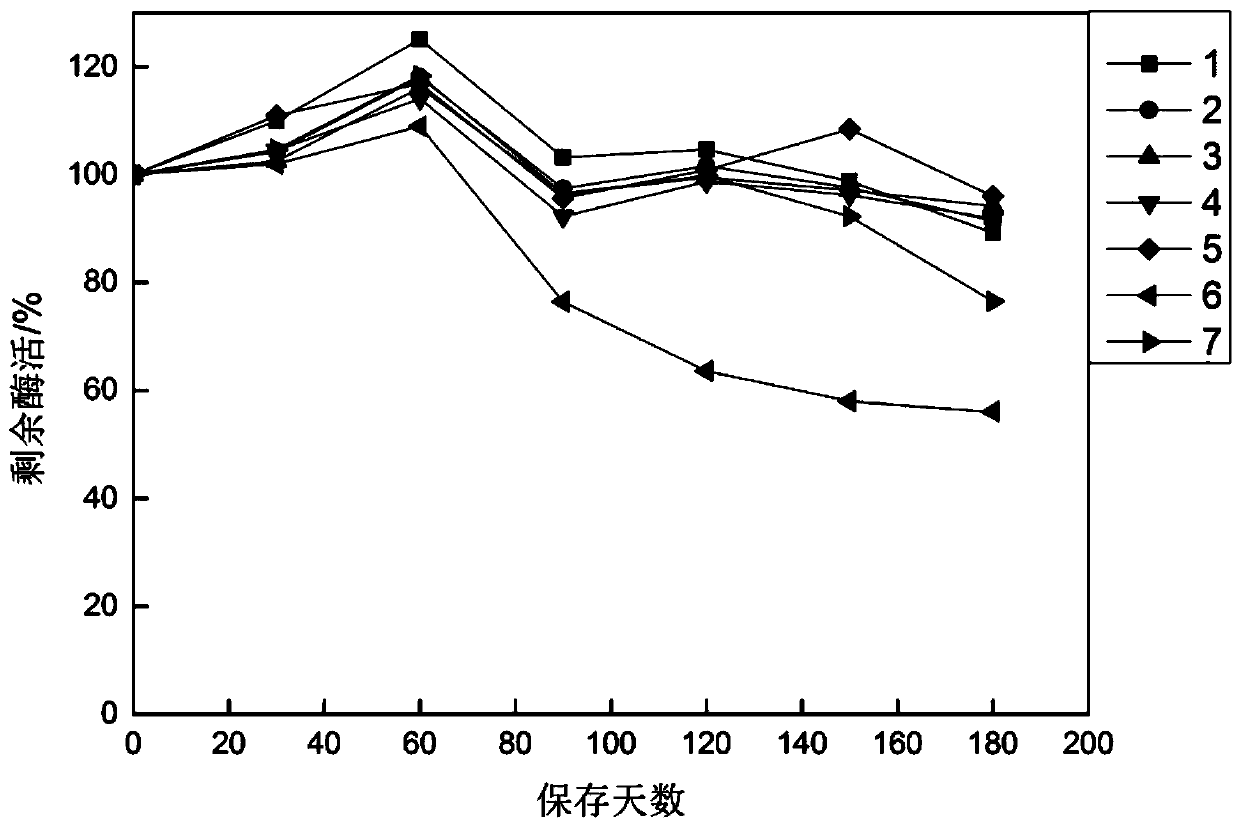

ActiveCN110373406AImprove stabilityLow priceEnzyme stabilisationAcyltransferasesCarrageenanGlutamine transaminase

The invention discloses an immobilized glutamine transaminase preparation method. The method includes that natural macromolecular compounds such as sephadex, agarose gel, carrageenan and gelatin are adopted for enzyme immobilization, an immobilized embedded substance is immersed into a liquid mixture of alcohols, carbohydrates, an antioxidant and the like, and accordingly stability of an immobilized enzyme preparation is greatly improved. The immobilized glutamine transaminase preparation method has advantages that preservation time of glutamine transaminase at a low temperature, the normal temperature and a high temperature is greatly prolonged, and stability of glutamine transaminase is remarkably improved.

Owner:TAIXING DONGSHENG FOOD TECH +1

Bean curd and its production process

ActiveCN101161100ALuscious tasteWhite and delicate tasteFood preparationGlutamine aminotransferaseBiotechnology

The present invention relates to a kind of bean curd as well as its preparing method. The present invention provides a bean curd, which is characterized in that the bean curd contains glutamine aminotransferase. The present invention also provides a method for preparing the bean curd. The bean curd has the characteristics of traditional bean curd that taste lubricating and candour exquisite, also has the hardness and elasticity of the traditional bean curd, which ensures the bean curd obtain unprecedented taste and texture.

Owner:BEIJING ERSHANG GROUP

Transglutaminase mutants as well as genes, engineering bacteria and preparation method thereof

The invention belongs to the technical field of bioengineering and particularly relates to transglutaminase mutants as well as genes, engineering bacteria and a preparation method thereof. The mutantsare obtained from target genes through mutation with a sequential error-prone PCR method and screening, specific enzyme activity of the mutants expressed in a Bacillus subtillis expression system isincreased by 19% and 27% respectively compared with that of wild type transglutaminase, and the application prospect is broad.

Owner:TIANJIN UNIV OF SCI & TECH

Method for conserving jelly salted pork

InactiveCN1806569AExtended shelf lifeEasy to useMeat/fish preservation using chemicalsFood preparationGlutamine aminotransferaseBiochemistry

Owner:NANJING YURUN FOOD

Lactobacillus casei stain mutant strain for producing glutamine transaminase and use thereof

The invention provides a mutagenic Lactobacillus casei strain and a biological preparation thereof. The mutant strain is Lactobacillus casei strain KJY14(KJY-HN001-01-04), CGMCC No.15424, deposited onMarch 7, 2018. The invention also provides a biological preparation containing Glutamine transaminase prepared by the mutagenic bacterium. The invention also provides the use of the mutant strain alone or in combination with other lactic acid bacteria for preparing coagulant for soy yoghurt, yoghurt tofu, soybean albumen beverage and soybean albumen acid soup.

Owner:湖南肯基因科技有限公司

Glutamine transaminase production bacterium

ActiveCN111690570AEfficient accumulationHigh enzyme productionBacteriaMutant preparationBiotechnologyGlutamine aminotransferase

The invention relates to a glutamine transaminase production bacterium which is obtained by mutagenesis screening and preserved in China Center for Type Culture Collection, wherein the preservation No. is CCTCC NO:M 2020194, CCTCC NO:M 2020195, CCTCC NO:M 2020196 or CCTCC NO:M 2020197. Compared with the glutamine transaminase of an original strain, the glutamine transaminase production bacterium disclosed by the invention has the advantages that the yield of the glutamine transaminase production bacterium is increased by at least 3.5 times, the enzyme activity of fermentation liquid can achieve 33U / mL or above, and the industrial application prospect is broad.

Owner:TAIXING DONGSHENG FOOD TECH

Novel milk custard and preparation method thereof

ActiveCN101288435ANo bitternessGreat tasteMilk preparationFrozen sweetsWarm waterAdditive ingredient

The invention relates to a food taking powdered milk and white sugar as main ingredients, that is, novel milk custard, and a preparation method thereof. The invention is characterized in that: the provided novel milk custard contains no egg white and renninum, or glutamine aminotransferase and has rich nutrition, good taste and health care function. The novel milk custard is mainly prepared with the following raw materials by weight proportion: 35-70 parts of powdered milk, 15-50 parts of white sugar, 1.0-2.5 parts of calcium carbonate, 0.5-2.5 parts of compound carrageenan, 0.5-2.5 parts of glucomannan and 1-10 parts of other materials. Compound carrageenan and glucomannan are both gelling agents which belong to dietary fiber and have health care function; the preparation method of the invention is as follows: the raw materials are evenly blended, added with 4-5 times of warm water by weight proportion, and then heated to 80-90 DEG C, and the temperature is kept for 10-30 minutes; filling, cooling, standing still and consolidation forming are carried out to obtain the edible milk custard. The novel milk custard has the advantages of no bitter flavor, good mouthfeel, rich nutrition and health care function, and the preparation method can facilitate large-scale production and the improvement of production efficiency.

Owner:GUANGZHOU JIANWEI BIOLOGICAL TECH CO LTD

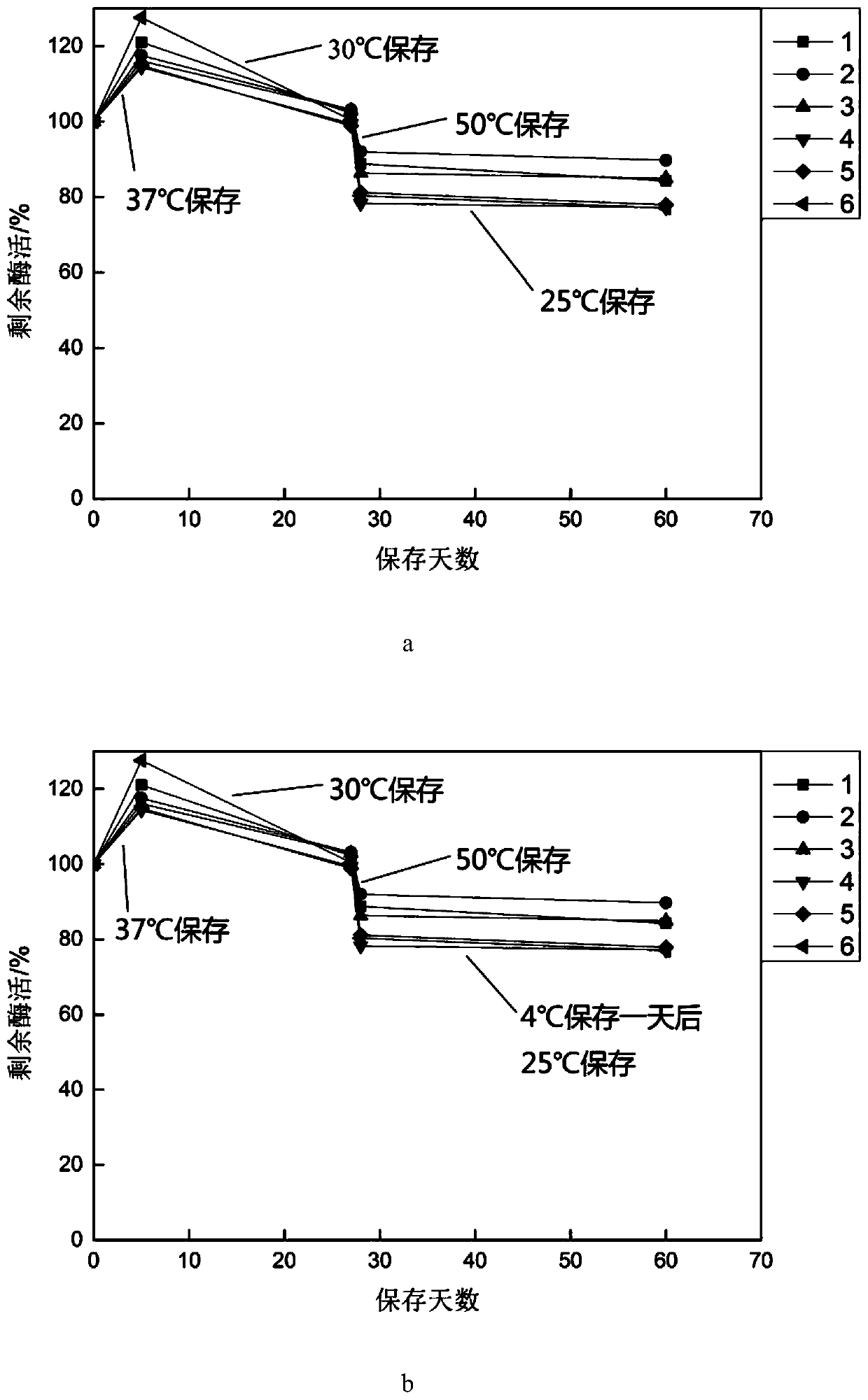

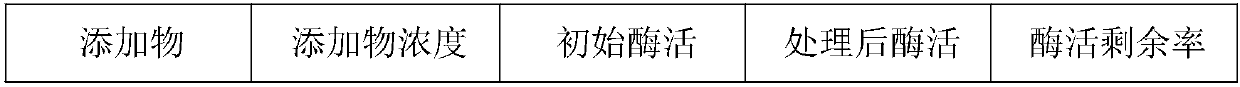

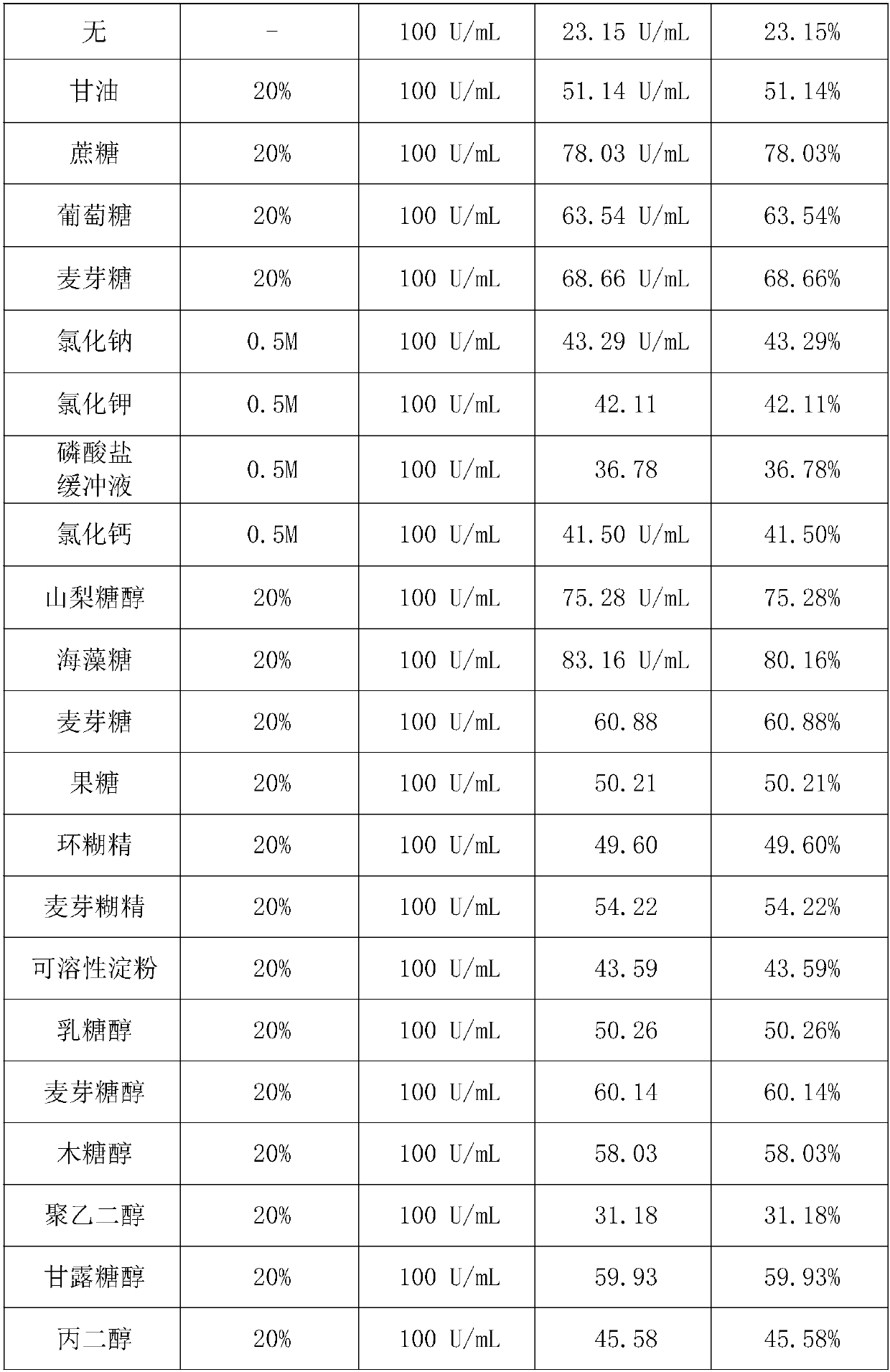

Preparation for stabilizing activity of liquid glutamine transaminase

InactiveCN110205309AStable traitsQuality is not affectedEnzyme stabilisationAcyltransferasesGlutamine aminotransferaseAnti oxidant

The invention discloses a preparation for stabilizing the activity of liquid glutamine transaminase. The compositions of the preparation include glutamine transaminase, carbohydrates and / or alcohols,an anti-oxidant, a water activity regulator and an acidity regulator. The technical problems of extremely unstable liquid enzyme of the glutamine transaminase at high room temperature (30 DEG C) and hard preservation for a long time can be solved; the enzyme activity of the liquid glutamine transaminase preparation preserved 3 months under 30 DEG C can remain more than 85%, the enzyme activity preserved 6 months under normal temperature can remain more than 90%, and the state of a solution is stable; and the preparation has wide application prospects and great meanings on popularizing, applying and developing.

Owner:TAIXING DONGSHENG FOOD TECH

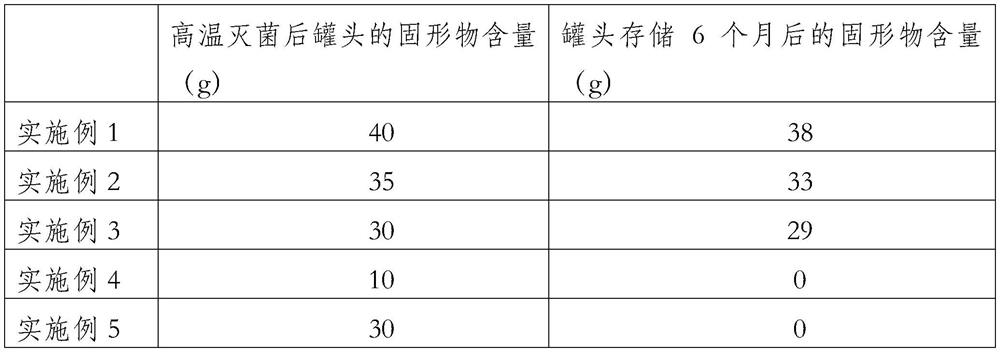

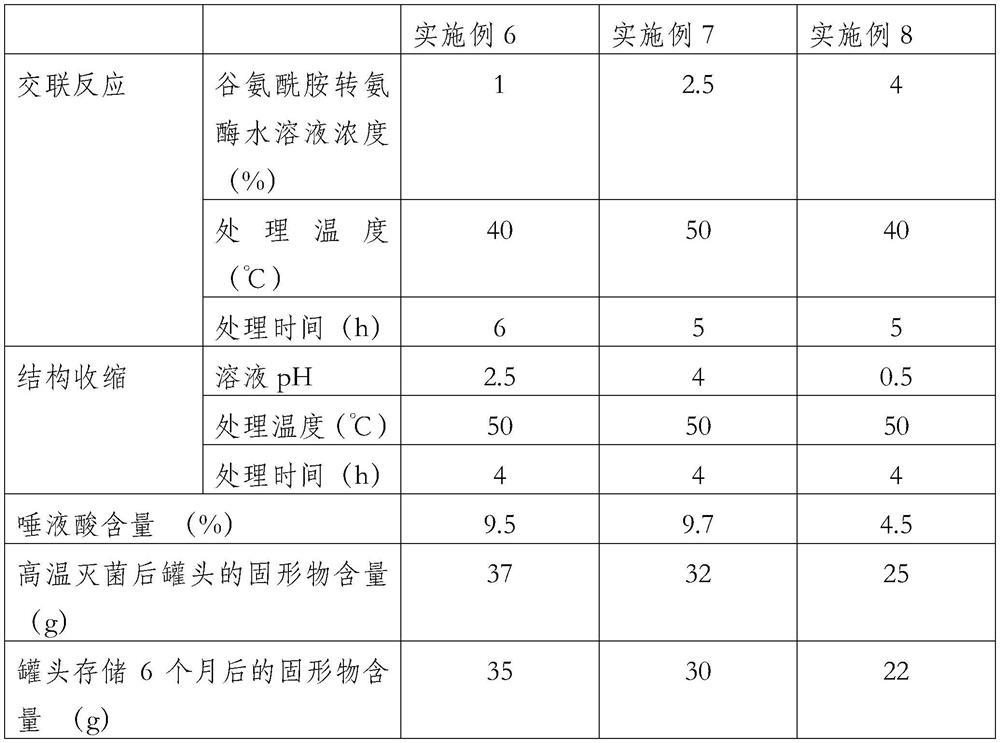

Preparation method of convenient instant bird's nest and product thereof

PendingCN111838657AHigh nutritional valueIncrease the degree of cross-linkingClimate change adaptationFood scienceGlutamine aminotransferaseProtein molecules

The invention discloses a preparation method of convenient instant bird's nest and a product thereof. The method comprises the following steps: pretreating bird's nest; adding into a glutamine transaminase water solution for soaking; draining the material, immersing the drained bird's nest shreds into water; and adding acid to adjust the pH value of the system to 0-5, soaking at 30-100 DEG C for 20-600 minutes, draining the material, cleaning with clean water at normal temperature, fishing out the bird's nest shreds, draining, drying, mixing with water or sweet water, sub-packaging, sealing, sterilizing in a high-temperature pressure cooker, cooling, inspecting and packaging to obtain the convenient instant bird's nest. After the bird's nest shreds are treated by glutamine transaminase, the bird's nest shreds are subjected to enzymolysis; the protein denaturation further enables the internal structure of the bird's nest shreds to be more compact, and the protein denaturation and the bird's nest shreds have a synergistic effect, so that the thermal stability during high-temperature sterilization is improved, the bird's nest shreds are insoluble during high-temperature sterilizationand later storage, and the phenomenon of water melting of the bird's nest shreds is avoided.

Owner:JIANGNAN UNIV

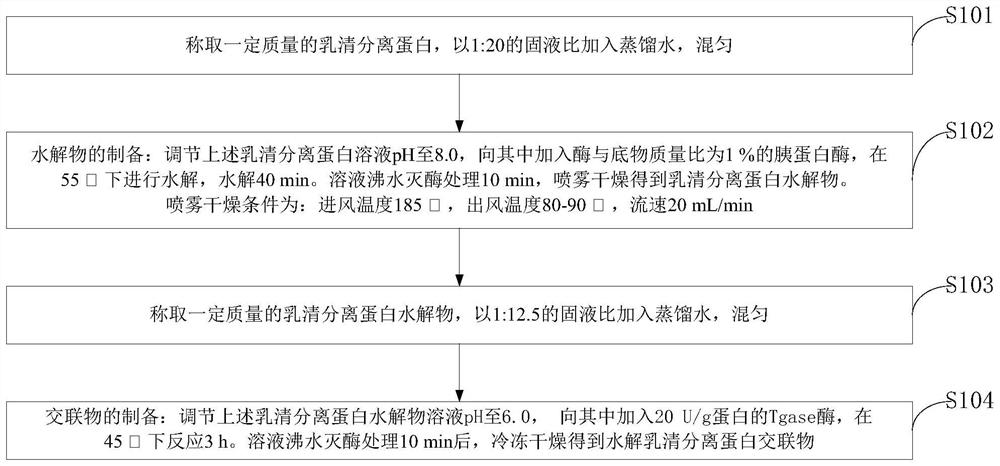

Preparation method of hydrolyzed whey protein cross-linked product

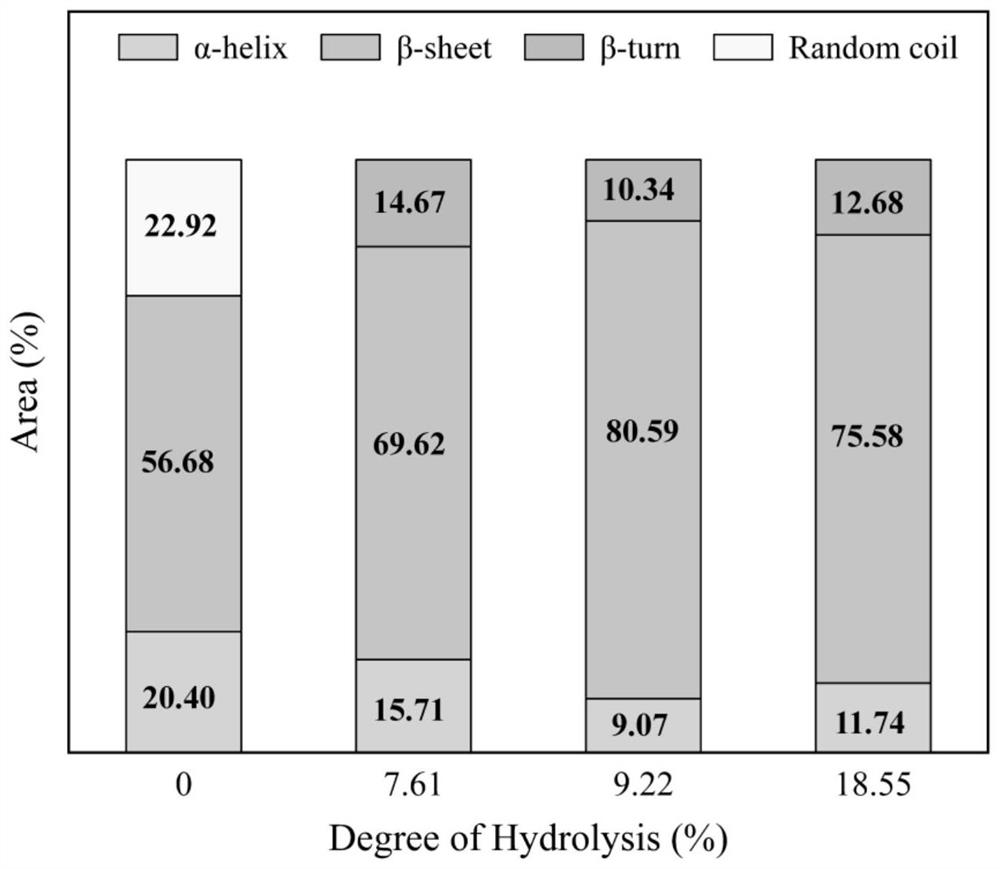

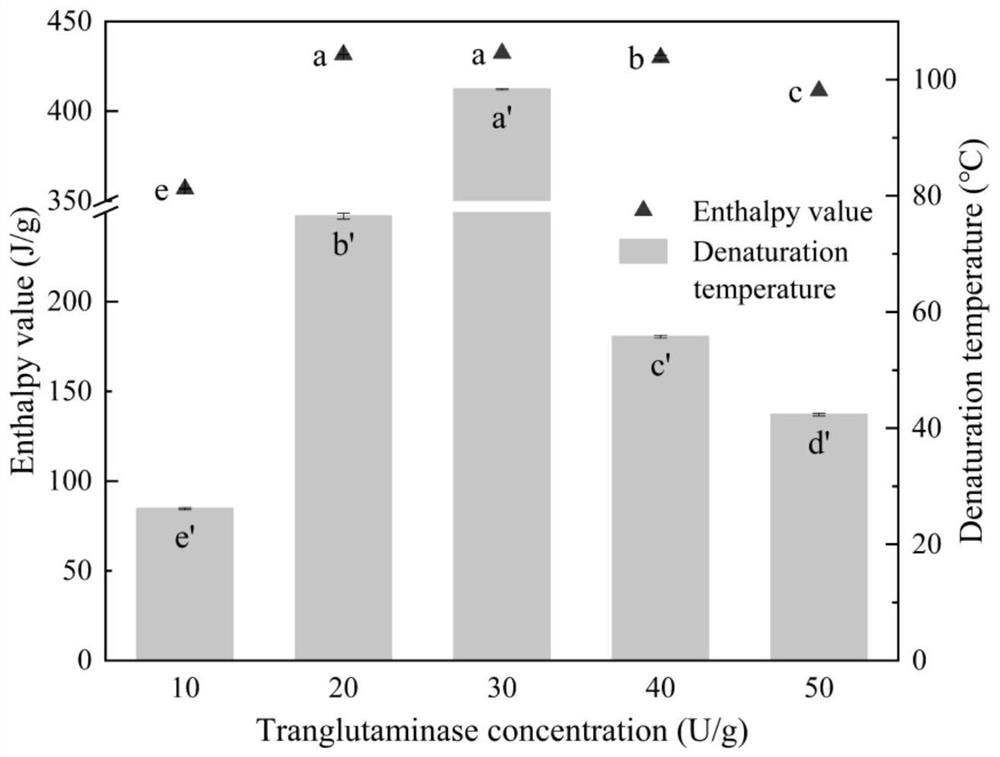

PendingCN114106357AImprove thermal stabilityHigh apparent viscosityFermentationGlutamine aminotransferaseHydrolysate

The invention discloses a preparation method of a hydrolyzed whey protein cross-linked product, and belongs to the technical field of cross-linked protein preparation, and the method comprises the following steps: carrying out enzymolysis on whey protein isolate by utilizing trypsin to obtain a whey protein isolate hydrolysate. And carrying out cross-linking on the hydrolysate by using glutamine transaminase to obtain the hydrolyzed whey protein isolate cross-linked substance. Specifically, enzyme hydrolysis and glutamine transaminase cross-linking are combined to modify the whey protein, the thermal stability of the whey protein with high thermal stability is obtained, and cross-linking after hydrolysis can further increase the apparent viscosity of the whey protein at the same time. According to the invention, the whey protein is treated by using a method of combining enzyme hydrolysis and enzyme crosslinking, the influence of change factors in two modification processes on the structure and functional characteristics of a final product is analyzed, and the hydrolyzed whey protein cross-linked product with good thermal stability and high apparent viscosity is obtained, thereby providing a theoretical basis and technical support for modifying the whey protein. The wide application of the whey protein is promoted.

Owner:NANCHANG UNIV

Chicken powder and composite preparation method of chicken powder based on low-salt fermentation process

PendingCN110521998AShort fermentation timeImprove hydrolysis efficiencyFood scienceMinced chickenFermentation

The invention belongs to the field of seasonings, and discloses a composite preparation method of chicken powder based on a low-salt fermentation process, which comprises the following steps: mincingchicken, killing miscellaneous enzymes, carrying out enzymolysis, and carrying out post-treatment after enzymolysis. Wherein the specific enzymolysis process comprises the following steps: step 1, adding a compound enzyme into the minced chicken subjected to impurity enzyme deactivation, wherein the compound enzyme consists of protease and glutamine transaminase, the enzymolysis temperature is 50+ / -2 DEG C, and the enzymolysis time is 2-2.5 hours; and step 2, after the step 1 is finished, adding papain into a mixture, wherein the temperature is increased to 65 + / -2 DEG C, and the enzymolysistime is 0.8-1.2 h; wherein the weight ratio of the protease to the glutamine transaminase to the papain is 7: (1.4 to 1.6) : (1.5 to 1.7); wherein the protease, the glutamine transaminase and the papain account for 1.9-2.1% of the total weight of the chicken. The method is short in fermentation time and high in product yield, and meanwhile, the invention further provides chicken powder.

Owner:GUANGDONG YA ROAD BIOTECH

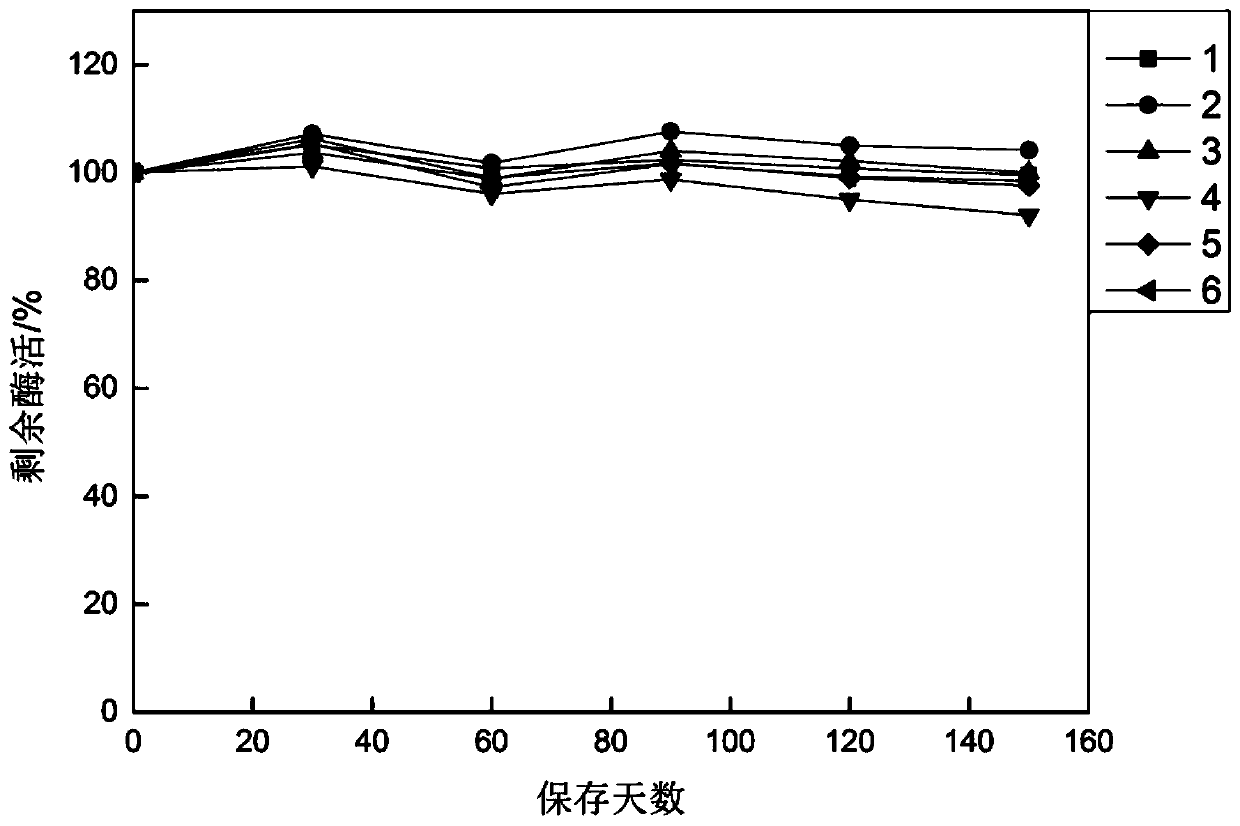

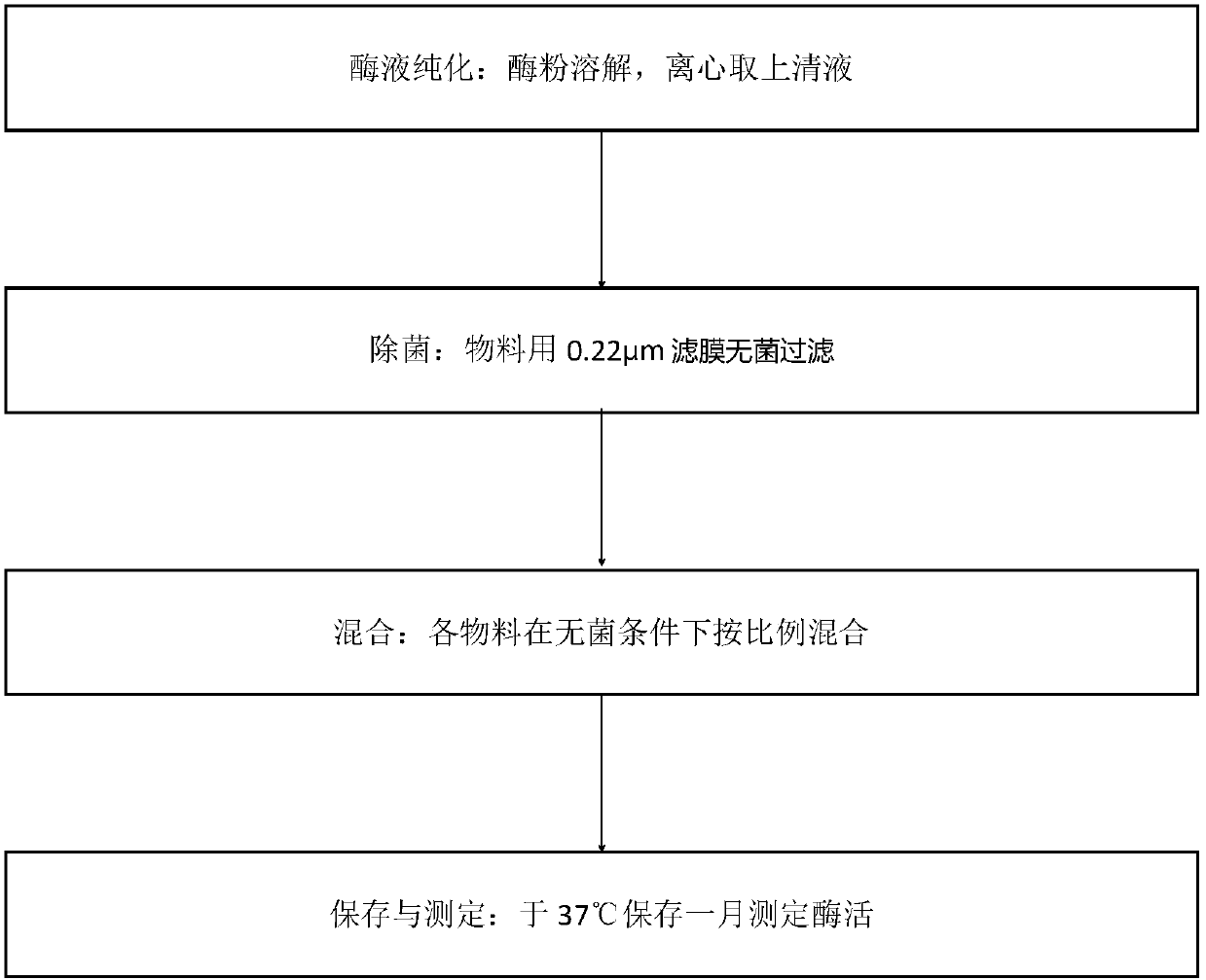

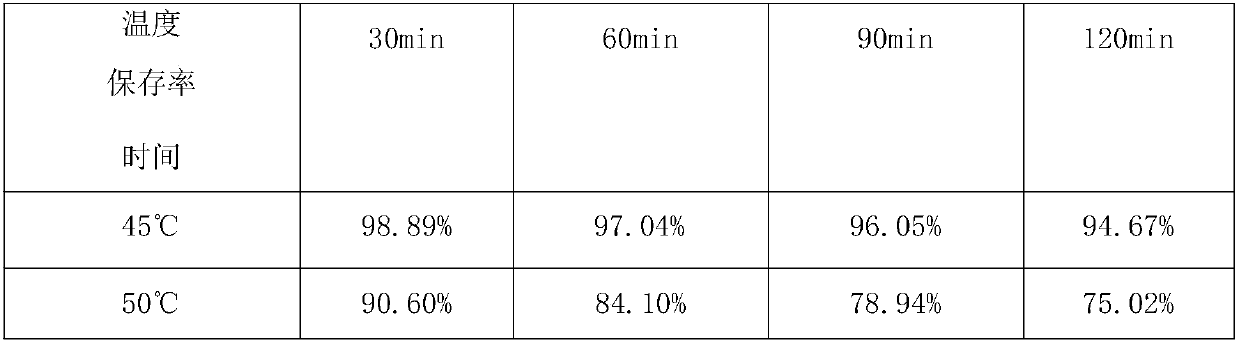

Preparation method for transglutaminase liquid enzyme activity stable preparation

InactiveCN110205317AAchieve retention rateEnzyme stabilityEnzyme stabilisationAcyltransferasesMicroorganismWater activity

The invention discloses a preparation method for a transglutaminase liquid enzyme activity stable preparation. The preparation method includes the following steps: step 1) a step of enzyme powder dissolution, namely the step of mixing transglutaminase powder and water, dissolving and performing centrifugation to take supernatant; step 2) a step of degerming, namely the step of adopting a film of 0.22 [mu]m to filter a degerming enzyme liquid and a reagent; and step 3) a step of mixing, namely the step of quantitatively measuring or weighing an enzyme liquid, a water activity regulator and a redox potential agent, performing mixing, using a pH conditioning agent to supplement 100% volume, and performing uniform mixing so that the transglutaminase liquid enzyme activity stable preparation can be obtained. The stability of the enzyme activity of a transglutaminase liquid enzyme in the preparation prepared by the method can be enhanced, and the corruption of microorganisms cannot occur; and the technical problems in the prior art that the enzyme activity of the transglutaminase liquid enzyme is hard to preserve for a long time can be solved, so that the preparation method can have wideapplication prospects.

Owner:TAIXING DONGSHENG FOOD TECH

Method for improving gelling performance of minced fish product by adding glutamine transferase

InactiveCN1232191CHigh gel strengthImprove qualityFood preparationGlutamine aminotransferaseGlutamine transferase

The invention discloses a method for improving gel property of minced fish product through adding glutamine aminotransferase which comprises, adding into minced fish processed from fresh fish as raw material complex addition agent consisting soybean protein, polyphosphates and glutamine aminotransferase, adding addition agent, then kneading the minced fish 10-20 minutes, the gel property of the obtained minced fish product is increased to 400-500g from the previous 200g before addition.

Owner:JIANGNAN UNIV

Method for improving morphological condition of animal cell-derived artificial meat

The invention discloses a method for improving the morphological condition of animal cell-derived artificial meat, and belongs to the technical field of food engineering. Meat paste obtained by culturing animal stem cells in different parts by weight, salt, phosphate, water, casein meal and glutamine transaminase are mixed. Meanwhile, the invention provides a treatment method for a finished product of animal cell culture. The glutamine transaminase is added to promote large-scale crosslinking of the animal cells, a reaction condition is provided by a mixture of the phosphate, the salt and thewater, and a bridge is provided for adhesion of the glutamine transaminase by adding casein, so that the crosslinking degree is deepened. The artificial meat treated with the method has high compactness and good taste.

Owner:JIANGNAN UNIV

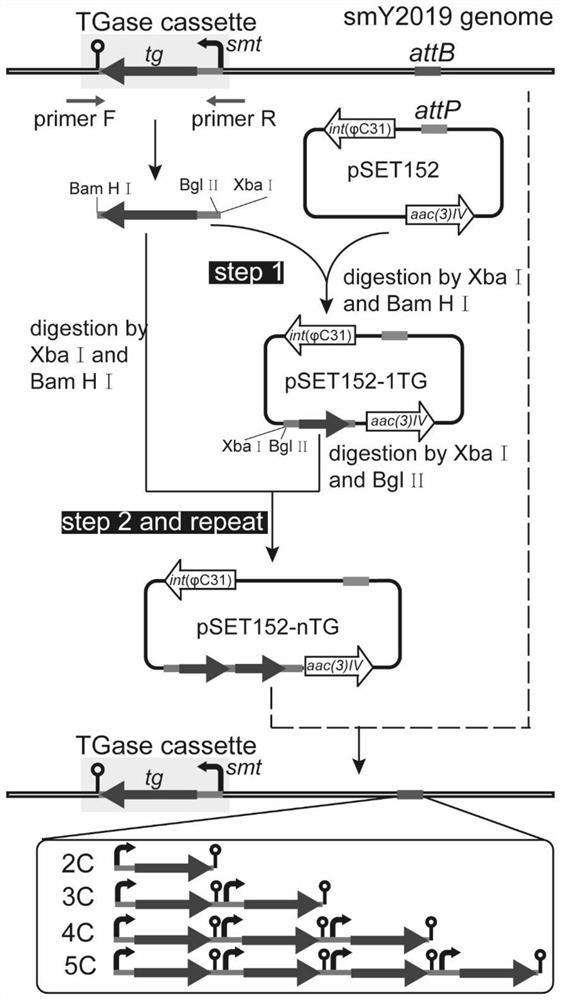

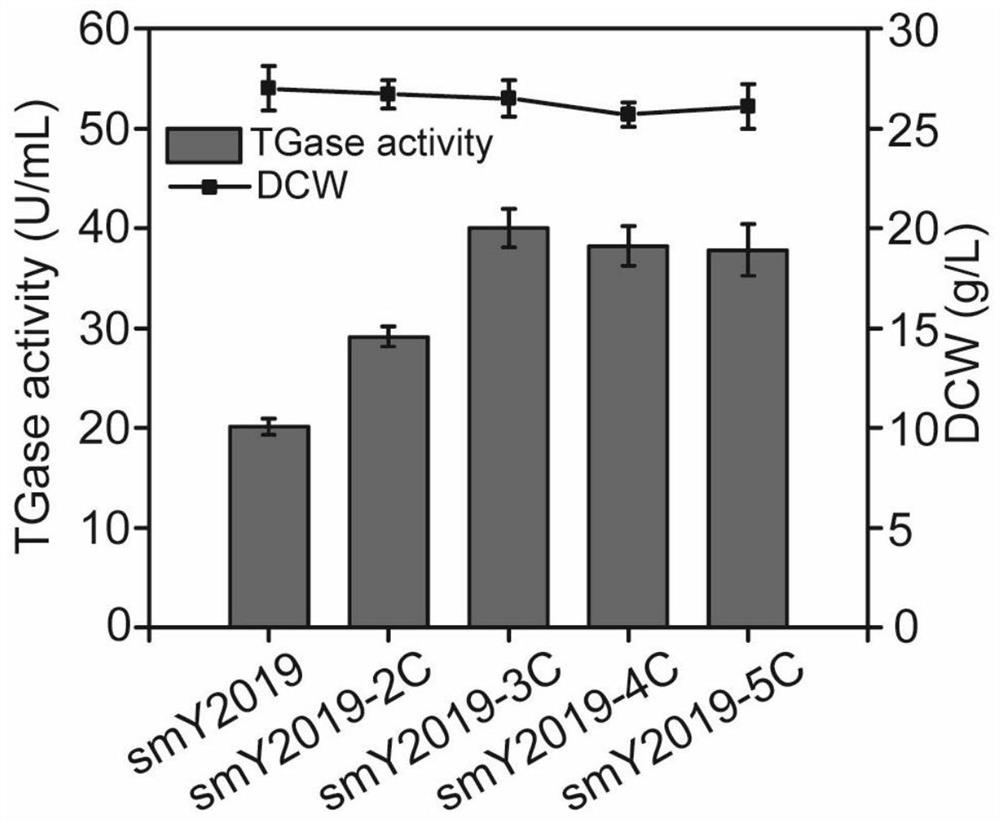

Recombinant streptomyces mobaraensis and application thereof in production of transglutaminase

ActiveCN112126613AIncrease enzyme activityBacteriaMicroorganism based processesStreptomyces mobaraensisNucleotide

The invention discloses a recombinant streptomyces mobaraensis and application thereof in production of transglutaminase, and belongs to the technical field of biology. The invention provides a recombinant streptomyces mobaraensis smY2019-nC capable of producing transglutaminase at high yield. The recombinant streptomyces mobaraensis smY2019-nC is obtained by integrating a plurality of nucleotidesequences such as transglutaminase gene expression cassettes shown in SEQ ID NO.1 on a genome of streptomyces mobaraensis smY2019. The recombinant streptomyces mobaraensis smY2019-nC is inoculated into a fermentation medium to be fermented for 72 hours, so that the enzyme activity of transglutaminase in the fermentation liquor can be up to 40 U / mL and is increased by 100% compared with that of wild streptomyces mobaraensis smY2019, and therefore, the recombinant streptomyces mobaraensis smY2019-nC has an extremely high application prospect in production of transglutaminase.

Owner:JIANGNAN UNIV

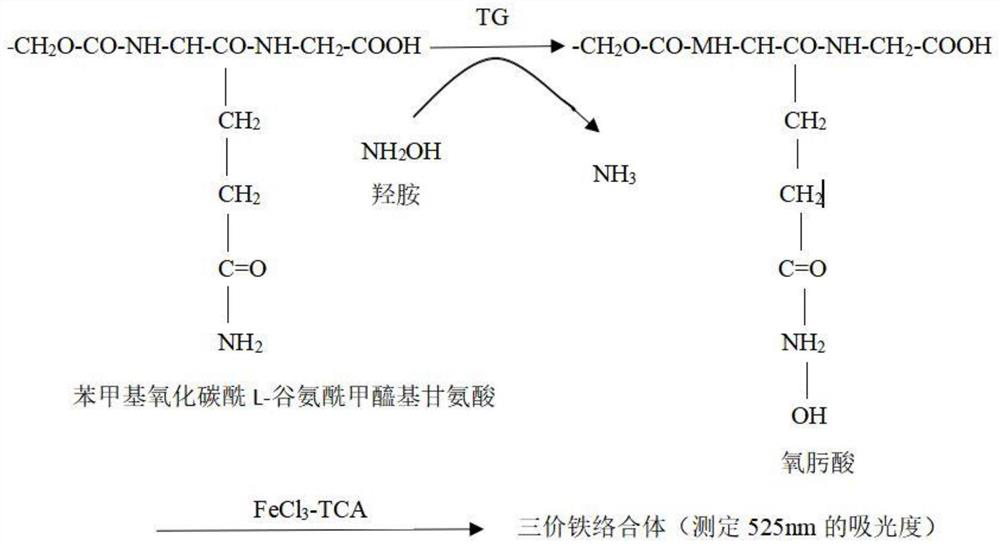

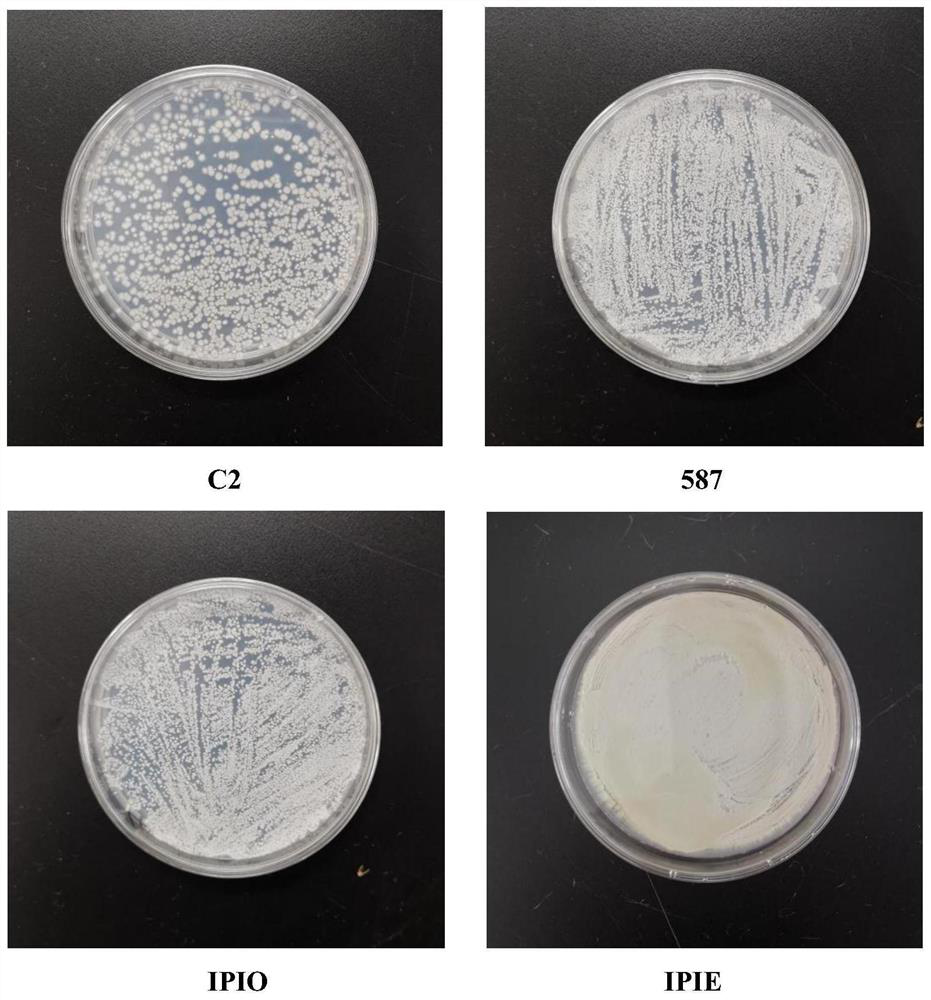

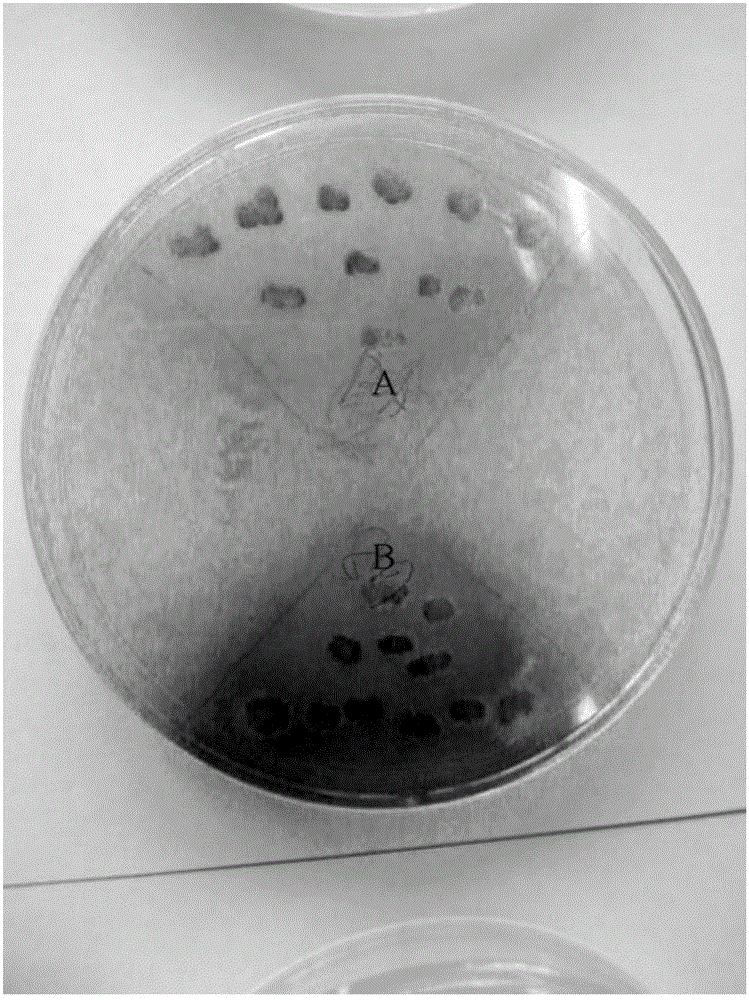

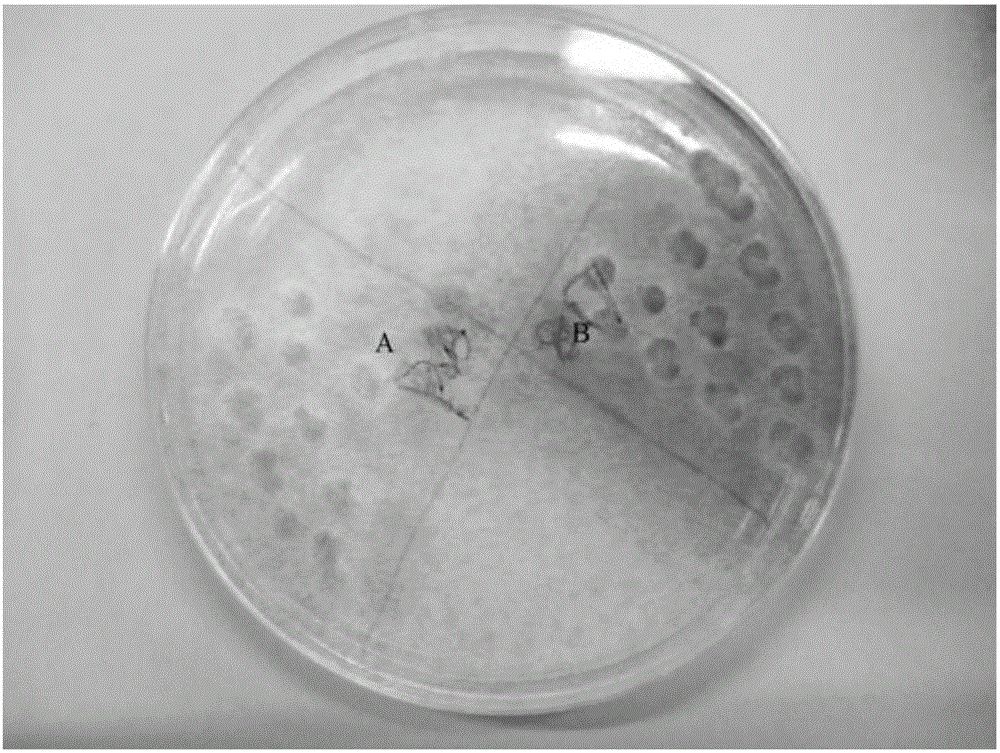

Culture medium for screening high-yield glutamine transaminase strain in high-throughput mode

ActiveCN105820955AAvoid missingShort cycleBacteriaMicroorganism based processesIron sulfateDipotassium phosphate

The invention relates to the field of microbial breeding and screening and discloses a novel culture medium for screening high-yield glutamine transaminase strains in a high-throughput mode. The culture medium comprises, by weight, 0.1-2% of glutamine transaminase substrates, 1.5-4% of agar, 2% of starch, 1% of nitrate of potash, 0.5% of dipotassium phosphate, 0.5% of sodium chloride, 0.5% of magnesium sulfate heptahydrate, 0.01% of iron sulfate heptahydrate, 0.0001-0.01% of an acid-base indicator. The pH ranges from 6 to 8. The culture medium has the advantages of being short in cycle, capable of screening a great number of bacterial strains at the same time and free of any mark so that the high-yield glutamine transaminase strains can be obtained through direct screening when used for screening the high-yield glutamine transaminase strains. The invention further discloses a use method of the culture medium, and the bacterial strains to be selected are cultured for 3-5 days on the culture medium and used for screening high-yield bacterial strains.

Owner:EAST CHINA NORMAL UNIV +1

A transglutaminase mutant with improved enzyme activity

ActiveCN107739734BEasy to separate and purifyEasy to trainFungiAcyltransferasesGlutamine aminotransferaseSite-directed mutagenesis

The invention discloses a glutamine transaminase mutant with improved enzymatic activity, which belongs to the field of enzyme engineering. The site-specific mutagenesis is performed on glutamine transaminase, an amino acid residue close to an active site of the glutamine transaminase is changed, so that the catalytic efficiency of the glutamine transaminase is improved, and the enzymatic activityof the glutamine transaminase is further improved. Recombinant yarrowia lipolytica with improved enzymatic activity is established by the glutamine transaminase mutant, the enzymatic activity of theglutamine transaminase is improved by 1.45 times compared with an original strain, the enzymatic activity of the shake flask fermentation can reach 16.995U / mL, and the enzymatic activity of the fermenting tank fermentation can reach 59.85U / mL which is the highest fermentation value reported at present.

Owner:TAIXING DONGSHENG FOOD TECH

A high-producing bacterium of transglutaminase and its application

InactiveCN103981130BGood genetic stabilityBacteriaTransferasesGlutamine aminotransferaseStreptomyces hygroscopicus

The invention discloses a strain of high-yield transglutaminase and its application, which is classified as a Streptomyces hygroscopicus NYU-70, and has been preserved in CCTCC, China's Type Culture Collection Center, with the preservation number CCTCC? M? 2014121. Using Streptomyces? hygroscopicus NY-1 as the starting strain, low-energy ion implantation mutagenesis was carried out. After mutagenesis, the enzyme activity of the strain was further measured by casein gel method and colorimetry, and the activity of producing glutamine transaminase was screened out. Higher mutant strains, as the starting bacteria for the next round of mutagenesis, were obtained by repeating the above steps for screening. The strain produces high activity of transglutaminase through fermentation and good genetic stability. The mutant strain was used for liquid shake flask fermentation to obtain transglutaminase, and the enzyme activity was 16.9 U / mL.

Owner:虞龙

Method for producing fish paste product, and enzyme preparation for fish paste products

InactiveUS20100323058A1Suppress mutationElasticityMilk preparationAnimal feeding stuffFish pastePhysical property

In the process of producing a fish paste product, adding a defined amount of a transglutaminase and ascorbic acid or a related compound thereof are added to material surimi can suppress changes in the physical properties of nerimi during the process of producing a fish paste product and a fish paste product having a preferable firmness and elasticity can be obtained even in the case of reducing the amount of material surimi.

Owner:AJINOMOTO CO INC

Method for continuously extracting glutamine transaminase from fermentation liquor

ActiveCN103966181ASolve the problem that the steps are cumbersome and not conducive to amplificationEasy to implementMicroorganism based processesAcyltransferasesBiotechnologyGlutamine aminotransferase

The invention discloses a method for continuously extracting glutamine transaminase from fermentation liquor, and belongs to the field of bioengineering. The method comprises the following steps: introducing sterile compressed air into a fermentation tank after fermentation is ended; leading out the fermentation liquor to ceramic composite membrane equipment from the fermentation tank, feeding the fermentation liquor from which thallus and impurities are removed into membrane separation equipment, and carrying out ultra-filtration concentration; connecting all the equipment by a pipeline with a flow control valve; continuously running after setting parameters in absence of people involvement; adding auxiliary materials to the fermentation liquor after concentrating, and then sequentially carrying out solvent participation and centrifugal separation; and adding auxiliary materials again and drying in vacuum, so as to obtain glutamine transaminase powder. The method has the advantages of being reasonable and continuous in process, simple in equipment, simple and convenient to operate, low in cost, and easy to industrially amplify. By adopting the method, the technical problem that the steps such as salt precipitation, dialysis, ion exchange column separation and the like in traditional extraction are not needed, resulting in easy industrial application is solved.

Owner:长握生物科技(江苏)有限公司

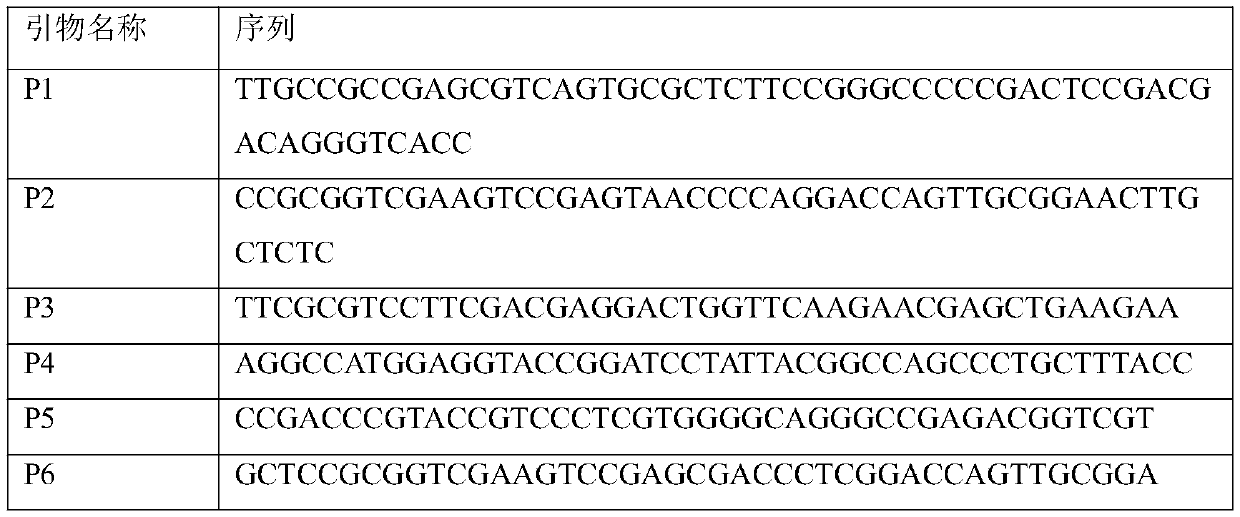

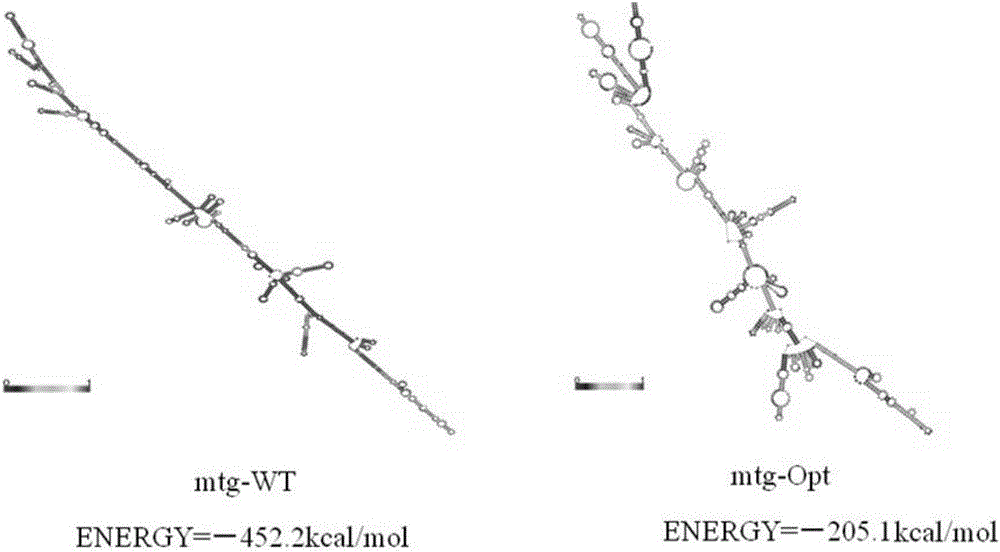

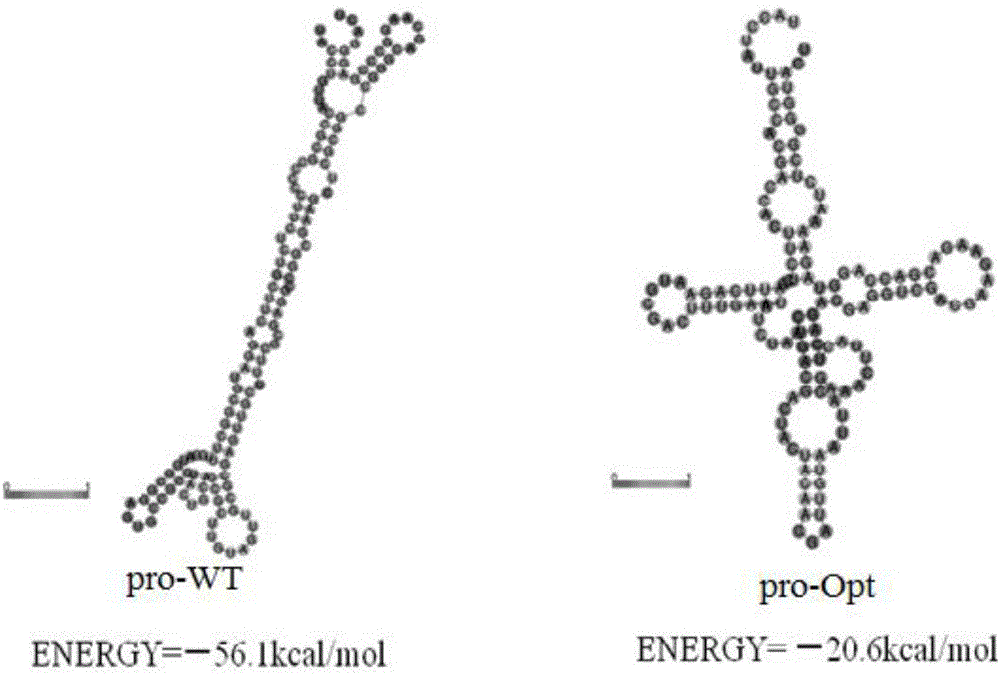

Optimized glutamine transaminase gene and leader sequence as well as secretory expression thereof

InactiveCN106755000AIncrease secreted expressionNucleic acid vectorAcyltransferasesStreptomyces mobaraenseSecretory protein

The invention relates to a gene sequence optimized glutamine transaminase as well as a secretory expression method and application thereof. A streptomyces mobaraense-derived glutamine transaminase gene and a leader sequence thereof are reformed according to optimal codons of pichia pastorris to obtain an optimized glutamine transaminase gene and an optimized leader sequence thereof. A recombinant pichia pastoris system co-expressed by the optimized glutamine transaminase gene and the optimized leader sequence thereof is constructed, and a strain of high-expression recombinant glutamine transaminase is obtained by screening. The optimized glutamine transaminase gene and the optimized leader sequence thereof can be stably and efficiently expressed in the pichia pastoris, the activity of the expressed recombinant glutamine transaminase is up to 0.5 U / mL and is 4 times that of the original glutamine transaminase, and a foundation is laid for further industrial expanded production of the glutamine transaminase.

Owner:ANHUI MEDICAL COLLEGE

Glutamine transaminase separation and purification method

InactiveCN106244567AImprove enzyme production efficiencyReduce solubilityMicroorganism based processesAcyltransferasesWater bathsPhytase

The invention discloses a glutamine transaminase separation and purification method which comprises the following steps: coating preserved Bacillus subtilis in a NA slant culture medium, culturing, centrifugating, discarding the supernate, washing the obtained bacterium with a pH-7.0 phosphoric acid buffer solution, and preparing a bacterium suspension; carrying out microwave treatment on the bacterium suspension, inoculating in a seed culture medium, inoculating the bacterium into a fermentation culture medium according to the inoculum size of 5%, culturing for some time, carrying out ultrasonic treatment, putting in a water bath shaking table, and culturing for 48 hours to obtain a fermentation culture fluid; and centrifugating the fermentation culture fluid, filtering through a microfiltration membrane, collecting the enzyme solution, and carrying out freeze-drying to obtain the glutamine transaminase. The phytase is added into the soybean protein extracting solution to cut off the phytic acid connecteed between the soybean 7S globulin and soybean 11S globulin; the whole separation process is carried out under normal temperature conditions, thereby avoiding the problem of longer globulin separation process time caused by the addition of the reducer; and the separated soybean 11S globulin and soybean 7S globulin have higher yield and purity.

Owner:ANHUI ZHENGWEIQI SEASONING FOOD LIMITED

Preparation method of cross-linking enzyme

ActiveCN111849960ALittle chemical damageMild reaction conditionsOxidoreductasesAcyltransferasesGlutamine aminotransferaseOxidative enzyme

The invention discloses a preparation method of cross-linking enzyme. The preparation method comprises the following steps: mixing polyphenol oxidase with a glutamine transaminase solution for a reaction; the cross-linked enzyme microparticles with a particle size of several micrometers to tens of micrometers and different vigor sizes can be obtained,the cross-linked glutamine transaminase prepared by the method can be separated from a solution by means of filtration, centrifugation and the like, and the prepared cross-linked glutamine transaminase is used for polyethylene glycol (PEG) modification and the like of protein drug molecules. The cross-linked glutamine transaminase is easy to recover and can be repeatedly used in the use process, no burden is caused to product separation, and the production cost is greatly reduced. According to the method, the crosslinking process is environmentally friendly, mild and efficient, the reaction is controllable, a carrier is not needed, glutamine transaminase does not need to be purified, and multiple enzymes can be crosslinked and immobilized together.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com