Patents

Literature

119results about How to "High enzyme production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing algin oligosacchride by using algin lyase

The invention relates to a method for preparing algin oligosaccharide by using algin lyase Agarivorans albus YKW-34, which is characterized by comprising the following steps: firstly preparing enzyme liquid of the algin lyase Agarivorans albus YKW-34, dissolving algin in water, adding the prepared enzyme liquid into the solution, decomposing the algin for 2 to 180 hours in a water bath at a temperature of 20 to 55 DEG C, raising the temperature to between 60 and 100 DEG C, inactivating the algin, filtering the algin by a film, and condensing, freezing and drying the algin to obtain the algin oligosaccharide. The method has the advantages that a culture medium for preparing the algin lyase has economic and simple compositions; the algin lyase has high yield, unique Na<+> / K<+> ion dependence, superior temperature and pH stability and high specific activity, and can degrade seminose half aldehyde and guluronic acid fragments of the algin at the same time; and the produced algin oligosaccharide with the polymerization degree of 2 to 12 has favorable application prospect.

Owner:OCEAN UNIV OF CHINA

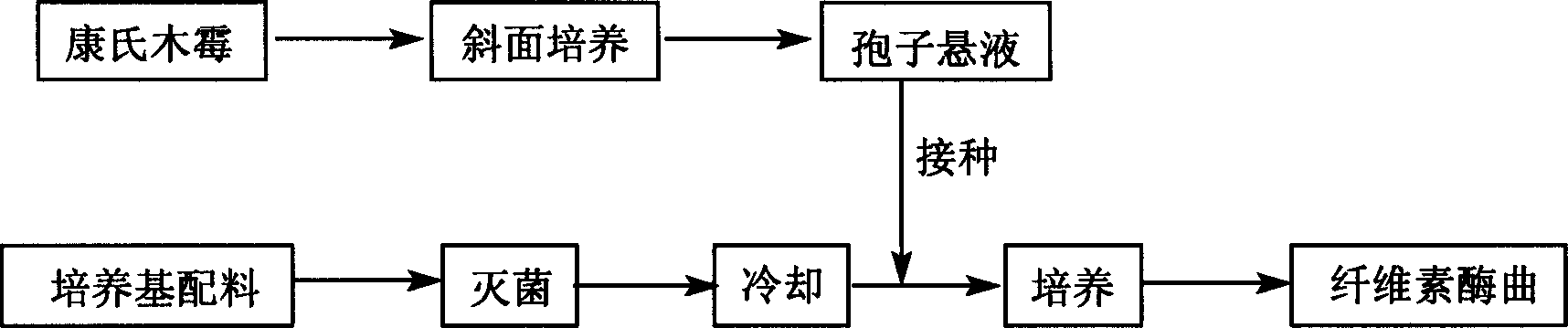

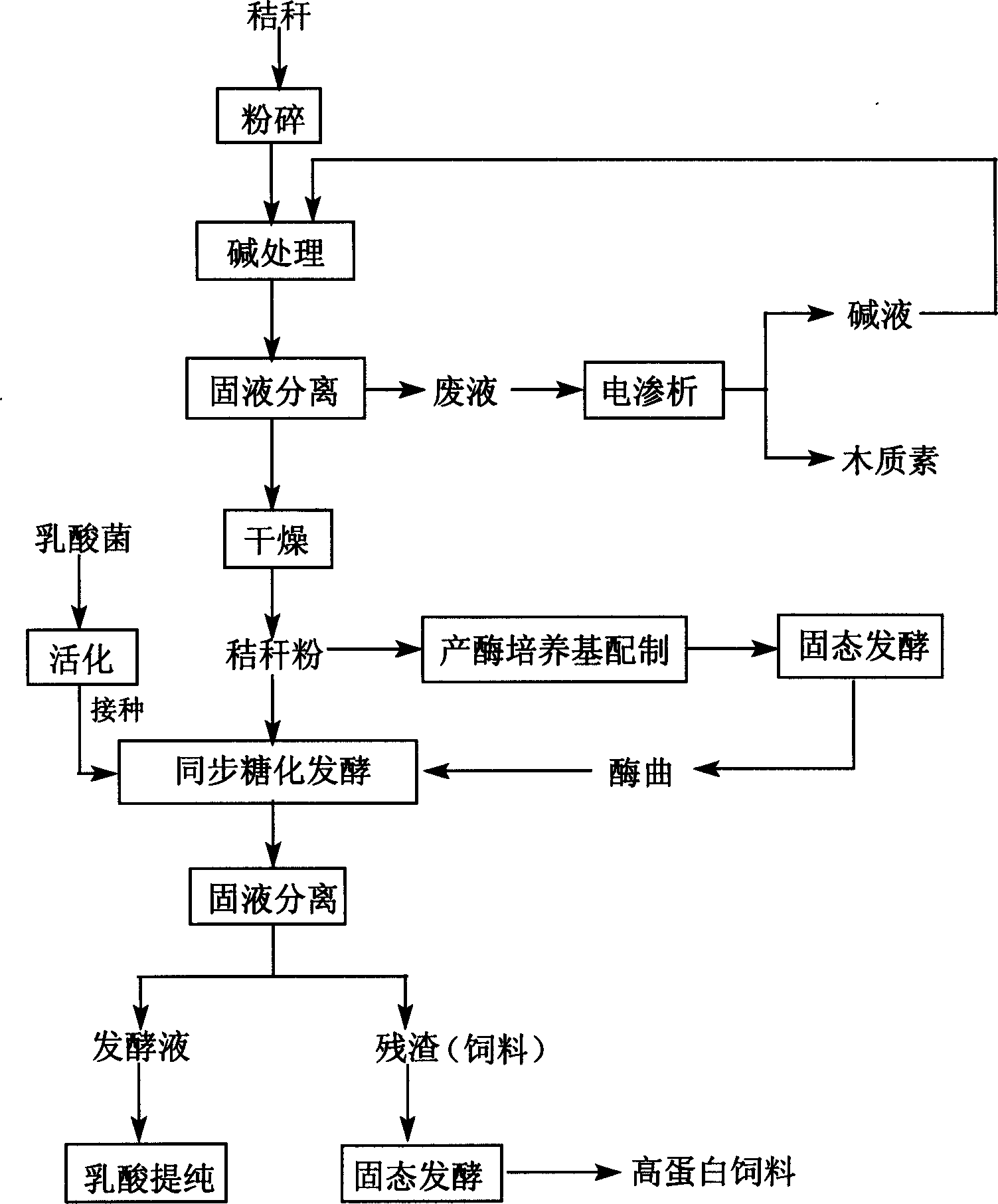

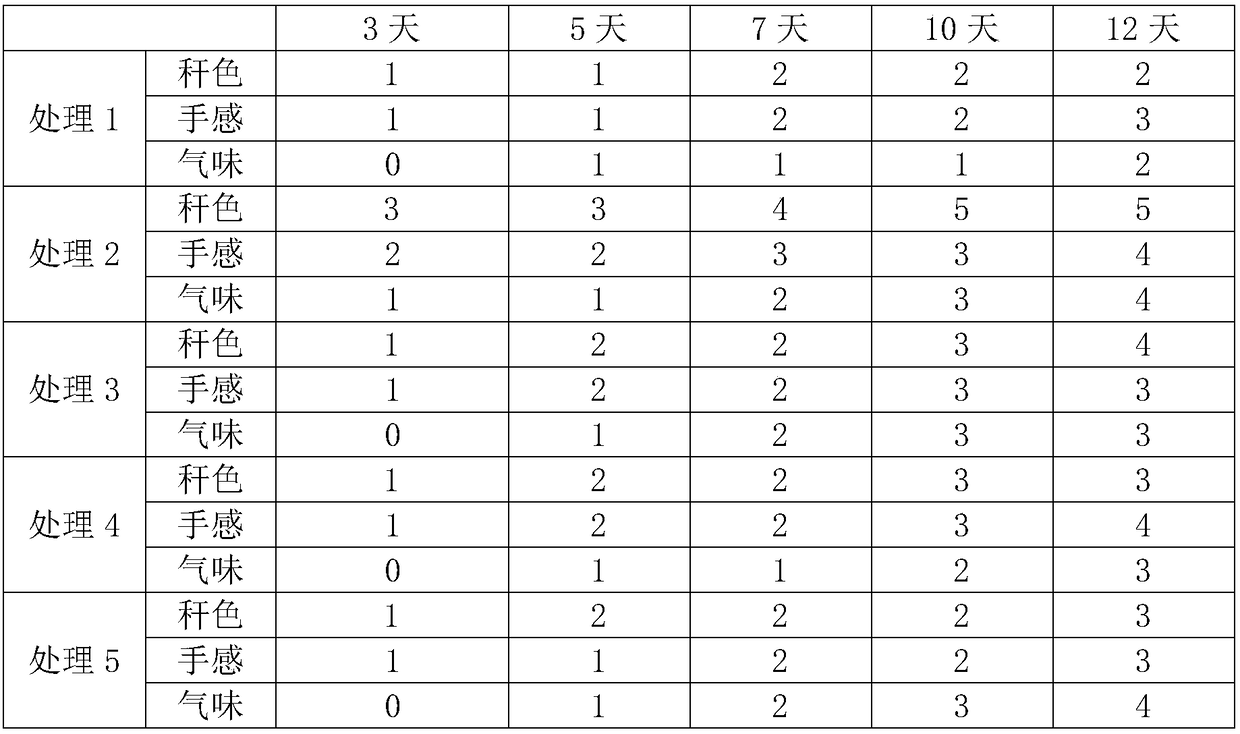

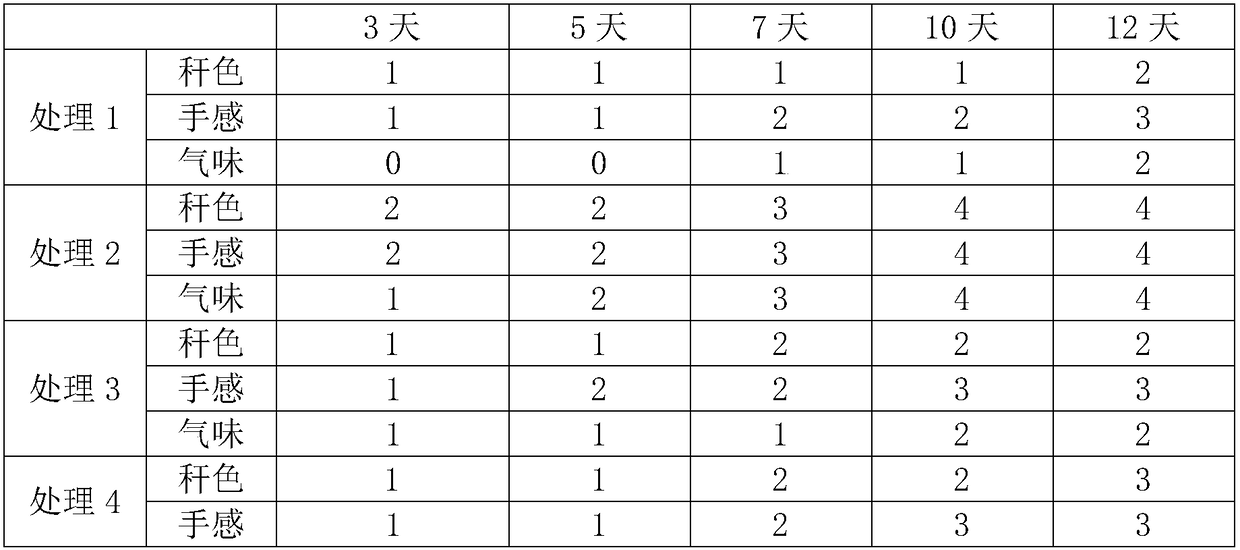

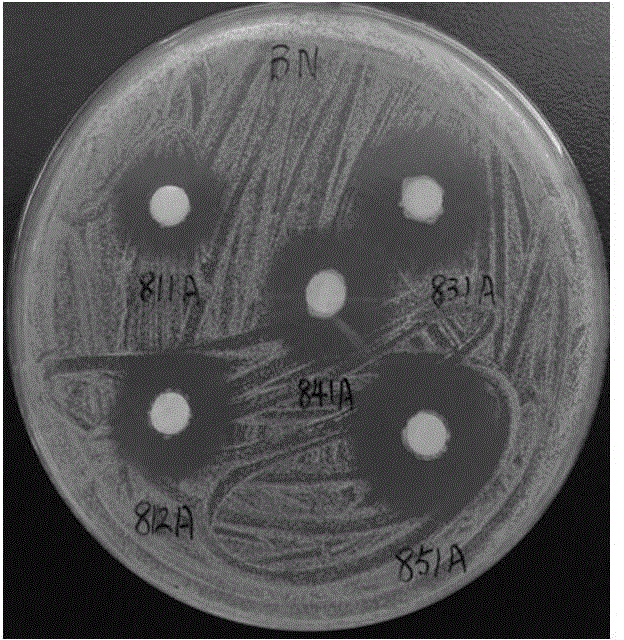

Method for preparing lactic acid and feedstuff concurrent with crop straw fermentation

InactiveCN1594584AReduce manufacturing costReduce energy consumptionFood processingAnimal feeding stuffCelluloseFilter paper

The invention relates to crop stalk fermentation and lactic acid and quality fodder preparation method. The synchronous diastatic fermentation provided by the invention is: adding in pretreated stalk of 2-3 times water in weight, 121 DEG C sterilizing, adding cellulase leaven (step 2 prepared), enzyme activity of cellulase leaven of total substrate amounting to 42-50IU / g in cellulose filter paper enzyme activity, inoculating activated high temperature resistant lactobacillus, inoculating volume is 5-10% of total substrate, fermenting 72-108 hours in 45-50 DEG C condition, adjusting substrate pH to 5.0-6.0 during fermenting. The invention shortens greatly of fermentation time, promotes the fermentation effiency. The 72-108 hours synchronous fermentation can produce 6-8g lactic acid and 60-70g quality fodder every 100g dry stalk. The invention has merits of low cost, low investment, no pollution, little energy consumption, high resource exploitation.

Owner:HARBIN INST OF TECH

Aspergillus niger WZ001 capable of producing naringinase and cirmtimase simultaneously and its application

The present invention provides one kind of Aspergillus niger WZ001 capable of realizing industrial production of producing naringinase and cirmtimase simultaneously in high yield and its application. The Aspergillus niger WZ001 has the preservation number of CCTCC No.206047. It has high yield of naringinase and cirmtimase over 14000 U / g in liquid fermentation culture or over 6000 U / g in solid fermentation culture.

Owner:北京京正源科技有限公司

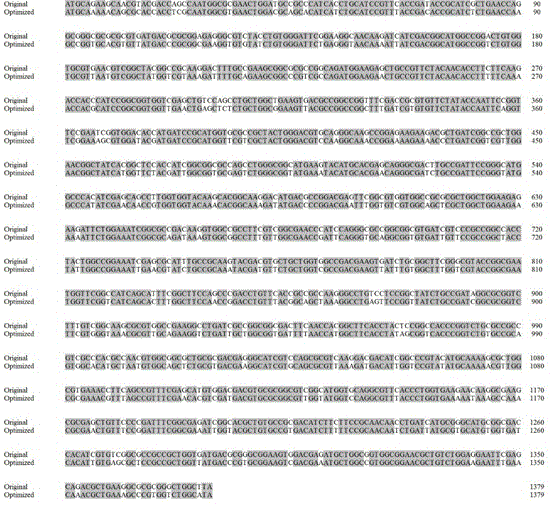

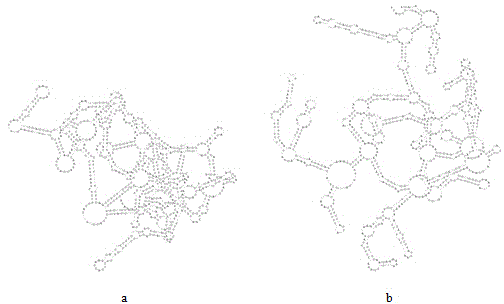

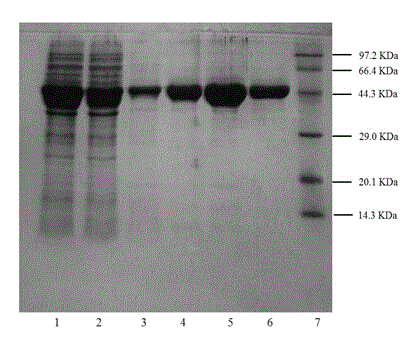

Omega-aminotransferase mutant gene and application thereof

InactiveCN104894148AHigh enzyme productionHigh catalytic efficiencyTransferasesGenetic engineeringPropylamineNucleotide sequencing

The invention discloses an omega-aminotransferase mutant gene and an application thereof, and belongs to the field of the molecular biological technology. The nucleotide sequence of the omega-aminotransferase mutant gene is shown as SEQ ID NO.1. The omega-aminotransferase amino acid sequence embodied by the code of the omega-aminotransferase mutant gene is shown as SEQ ID NO.2. The omega-aminotransferase mutant gene is firstly provided, and the omega- aminotransferase corresponding to the code of the omega-aminotransferase mutant gene has a high enzyme amount, so that the biological catalysis and conversion efficiency is improved in industrial production. The invention further provides the application of the omega-aminotransferase embodied by the code of the omega-aminotransferase mutant gene in preparation of trifluoro-propylamine. The trifluoro-propylamine is added to a buffer solution to serve as the substrate for the reaction, and then products of trifluoromethyl amine compounds are collected from the reaction liquid. The method for preparing the trifluoro-propylamine has the obvious advantages that the reaction conditions are mild, no pollution is caused, and the process is simple.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Microorganism polyzyme additive agent for improving pigling growth and development

The invention relates to a microorganism multienzyme additive for promoting the growth and development of baby pigs, which is characterized in that the additive is formed by composite synchronizing solid fermentation of a composite strain stock solution, carbon source, nitrogen source, inorganic salt and enzyme revulsant. A manufacturing method is that all the strains adopt a composite inducing technology to carry through filtering; a method of synchronizing liquid culture and solid composite culture is adopted to lead all the strains to be cultivated in the same culture medium; the total number of live bacterium reaches 3 billion / g and simultaneously a fermented product is kept completely. The product comprises massive physiological metabolism substances like active enzyme, small peptide, oxidation resistance substances, FAA, vitamins, etc. A specific type for feed preparing particles carries through a double-layer microcapsule peridium treatment on the strains that can not resist heat. The invention has the advantages of promoting the digestive absorption on the feed by the baby pigs, promoting the compound of organism protein and full utilization, increasing the disease resistance and immunological competence of the baby pigs, improving the feed switching rate and the production capacity of cultivated animals, reducing the pollution to the environment caused by animal dejecta. The invention is a green and safe agrotechnical product.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Bacillus subtilis high in nattokinase secretion and application thereof

ActiveCN107099487AImprove metabolic activityHigh activityBacteriaMicroorganism based processesPollutionMicrobiological culture

The invention discloses Bacillus subtilis high in nattokinase secretion and application thereof. The strain is named as Bacillus subtilis gs-11061 and is preserved in China General Microbiological Culture Collection Center, and the collection number of the Bacillus subtilis gs-11061 is CGMCC No. 13932. The invention further discloses a method using the Bacillus subtilis high in nattokinase yield to produce nattokinase. Compared with other fermentation methods, the method has the advantages that the Bacillus subtilis can be fermented under high temperature, and the fermentation cycle is shortened evidently; in terms of a culture medium, a xylose mother liquor coarse raw material is used to lower cost, and low energy consumption and low pollution are achieved; compared with original bacteria, the secretion of the nattokinase is increased evidently, fermentation products can be processed easily, and few byproducts are produced.

Owner:NANJING UNIV OF TECH

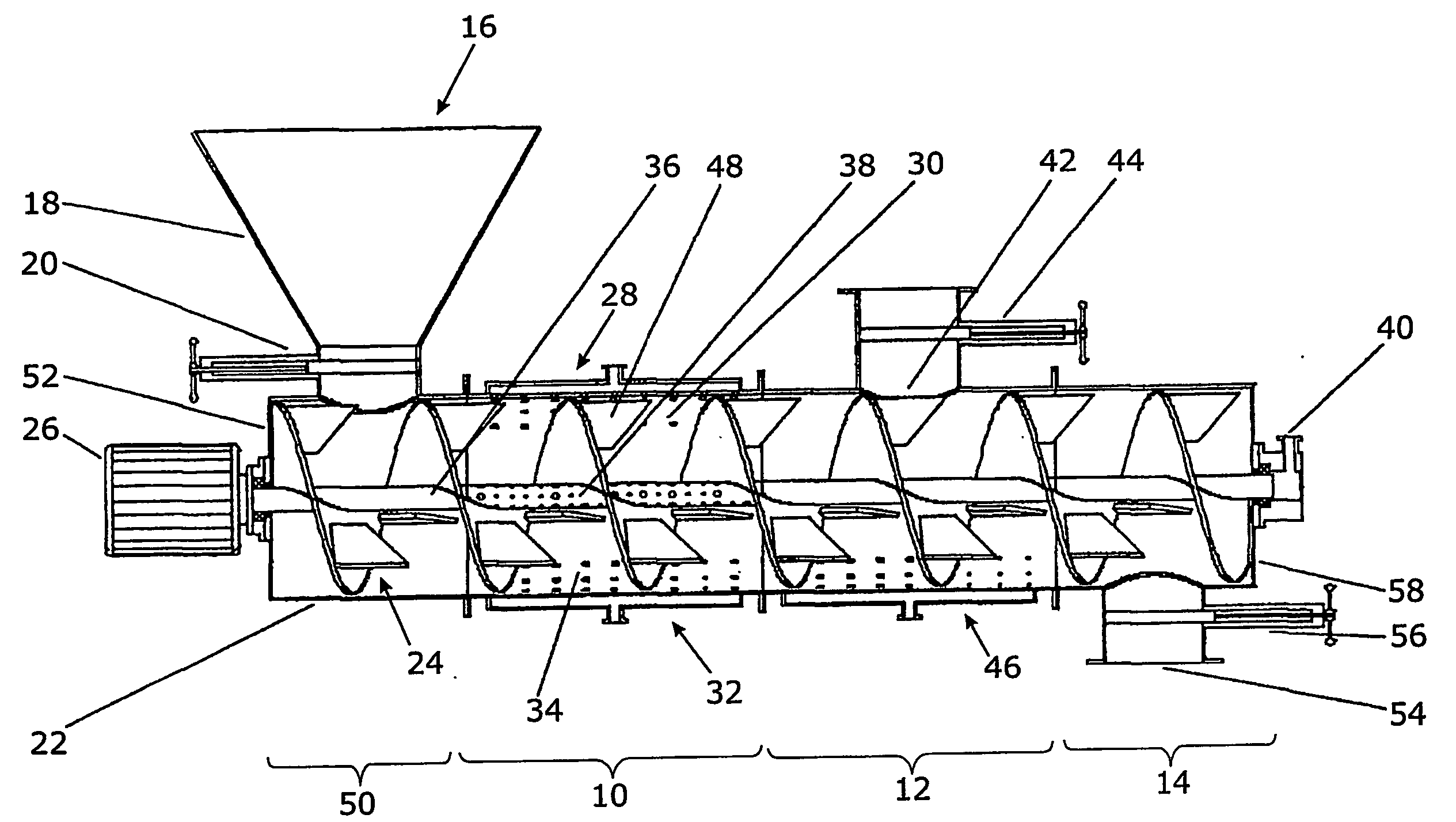

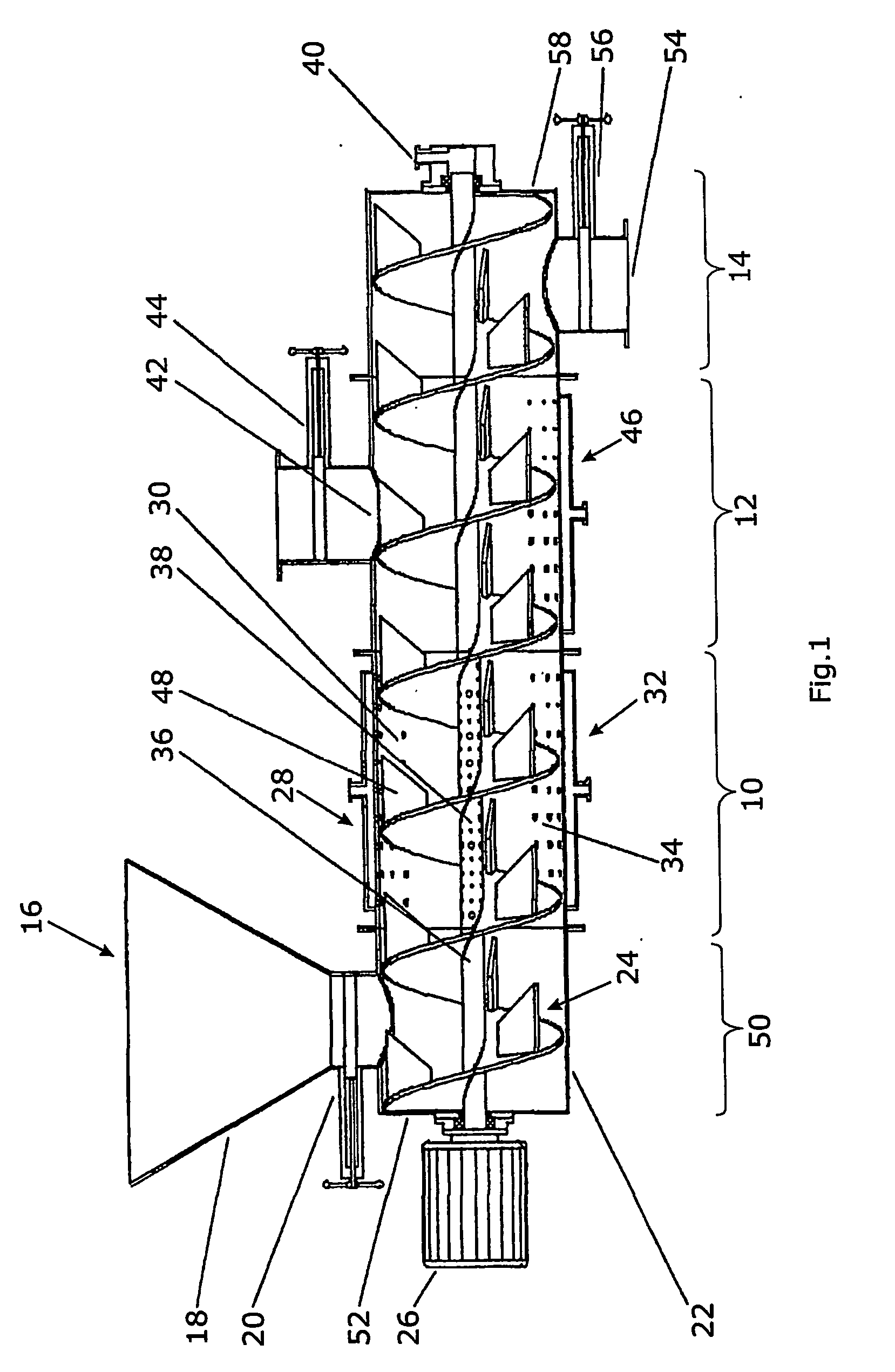

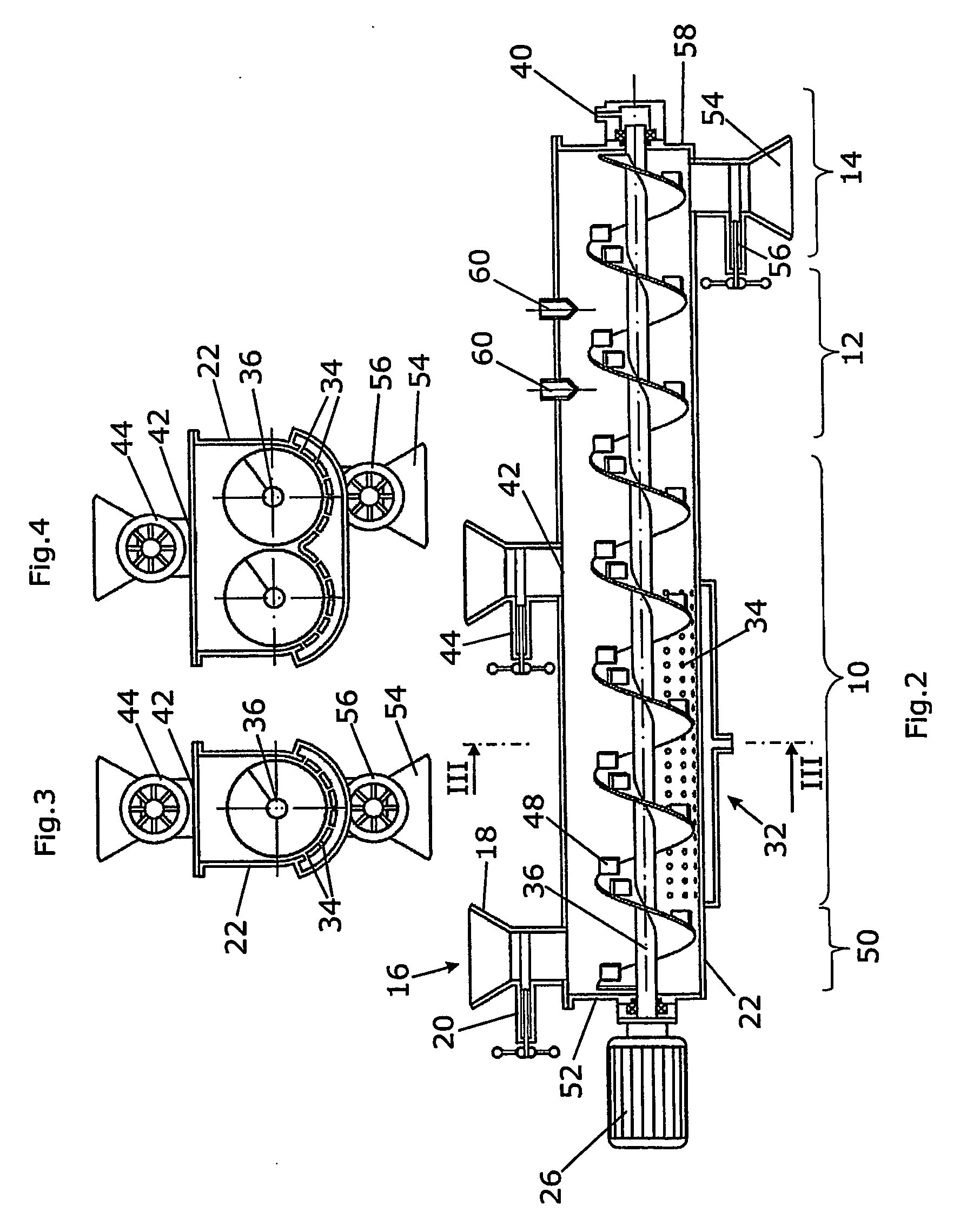

Directed selective solid-phase culturing of stable microbial mixed populations for the continuous preparation of defined enzyme and metabolite mixtures

ActiveUS20070048852A1High enzyme productionShortened growth timeBioreactor/fermenter combinationsFungiMicroorganismMetabolite

The present invention provides a method for directed selective solid-phase culturing of stable microbial mixed populations for the continuous preparation of defined enzyme and metabolite mixtures, enzyme and metabolite materials obtained by such method and suitable devices therefore.

Owner:SENZYME

High-yield 'cellulose, hemicelluloses and lignin enzyme' straw decomposition additive and preparation method thereof

InactiveCN108315275AEfficient decompositionEfficient recyclingFungiBio-organic fraction processingDecompositionRhizopus oryzae

The invention relates to a high-yield 'cellulose, hemicelluloses and lignin enzyme' straw decomposition additive and a preparation method thereof. The high-yield 'cellulose, hemicelluloses and ligninenzyme' straw decomposition additive comprises the following preparation raw materials: a cellulose, hemicelluloses and lignin enzyme mixture, plant materials, sugar and urea, wherein the cellulose, hemicelluloses and lignin enzyme mixture consists of cellulase bacillus subtilis fermentation liquor, a rhizopus oryzae fermentation substance and ligninase white-rot fungi fermentation liquor; the weight ratio of the cellulase bacillus subtilis fermentation liquor to the rhizopus oryzae fermentation substance to the ligninase white-rot fungi fermentation liquor is 3-7 to 5-10 to 5-10. By adoptingthe high-yield 'cellulose, hemicelluloses and lignin enzyme' straw decomposition additive provided by the invention, different bacterial florae can harmoniously coexist and be mutually promoted, an effect of complementary advantages can be achieved, the effective viable count can be increased, the enzyme yield can be increased, cellulose, hemicelluloses and lignin in crop straw can be rapidly andeffectively decomposed, and rapid treatment and circulation of straw biomass resources can be achieved.

Owner:三门峡龙飞生物工程有限公司

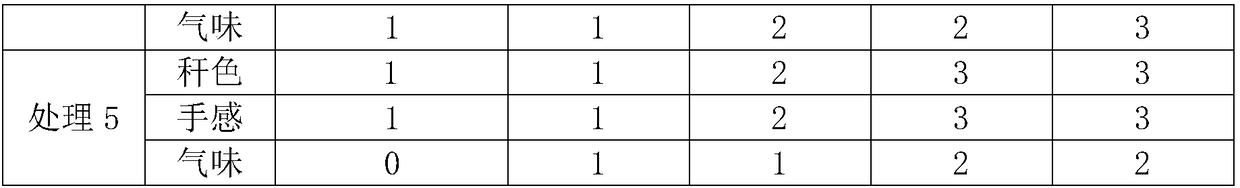

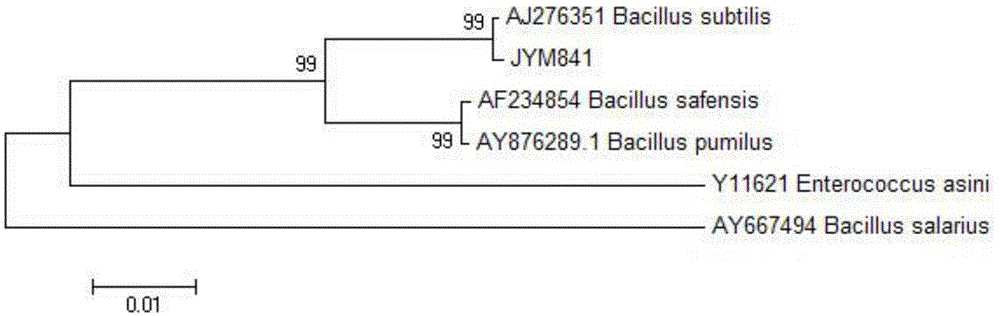

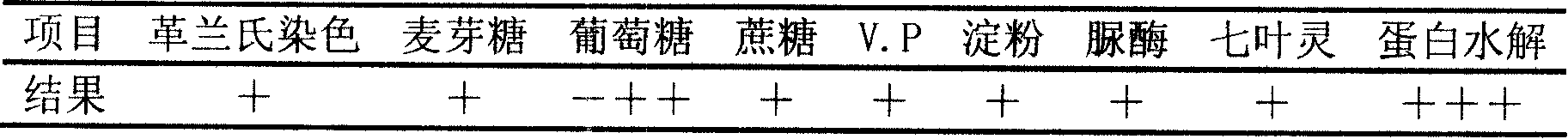

Bacillus subtilis with antibacterial activity and application of bacillus subtilis

ActiveCN104450590AStrong antibacterialBroad antibacterial spectrumAntibacterial agentsAntimycoticsStaphylococcus capraeCandida sanitii

The invention discloses bacillus subtilis JYM841 with antibacterial activity. The bacillus subtilis is preserved in a China center for type culture collection in January 10, 2014, and the preservation number is CCTCC NO: M 2014012. The bacillus subtilis JYM841 has a strong inhibitory effect on staphylococcus aureus and candida albicans, is high in antibacterial activity, wide in antibacterial spectrum, high in enzyme production, sensitive to bacterial antibiotic, drug-resistant to fungal antibiotic, high in heat-resisting ability and tolerant to acid and alkaline, has high antibacterial activity after treated at the temperature of 100 DEG C for 20min, and has tolerance to various enzymes such as trypsin, papain and protease K. An acid and alkali resistant pH (potential of hydrogen) value ranges from 6 to 10, and metabolite is stable, so that the bacillus subtilis can be applied to preparation of medicines for treating genital tract infection.

Owner:山东宝来利来生物工程股份有限公司

Yeast gene engineering fungus and beta mannosan enzyme preparation and production method of manna oligose

InactiveCN1478887AHigh purityReduce manufacturing costFungiHydrolasesBiotechnologyTransformation efficiency

A genetically engineered yeast Pichia pastoris (GS115 / HBMO47) able to effectively express beta-mannase is prepared through screening beta-mannase gene from the environmental microbes, cloning it to the expression carrier of Pichia yeast, introducing the carrier to Pichia yeast, and screening. The process for preparing the high-activity beta-mannase and the high-purity oligomannosan from said Pichia pastoris is also disclosed.

Owner:HUBEI UNIV

Cooperative fermentation process of bacterial enzyme prepn used as feed additive

InactiveCN1375216AHigh enzyme productionHigh synergistic effectAnimal feeding stuffAccessory food factorsFood additiveBiotechnology

The invention relates to a associated fermentation technique of germzymin acted as fodder additive. Its process flow is as follows: to plant multiple bacterial spawn of enzyme production and multipleready produced bacterial spawn on the slope respectively, after ripeness to be developed into spore suspension; then mixing said of each kind respectively according to proportion; hence seed culture medium to be led into enzyme production and spore suspension of ready produced and mixed bacteria spawn; finally through developing seed culture medium sets up full spore, mixing seed disinfectant of enzyme production germ and of ready produced bacterium, developing into mixture transfer agent of germ and enzyme, thereafter ferment breeding, products after ferment to be treated and become germzymin.

Owner:浙江省农业科学院微生物研究所 +1

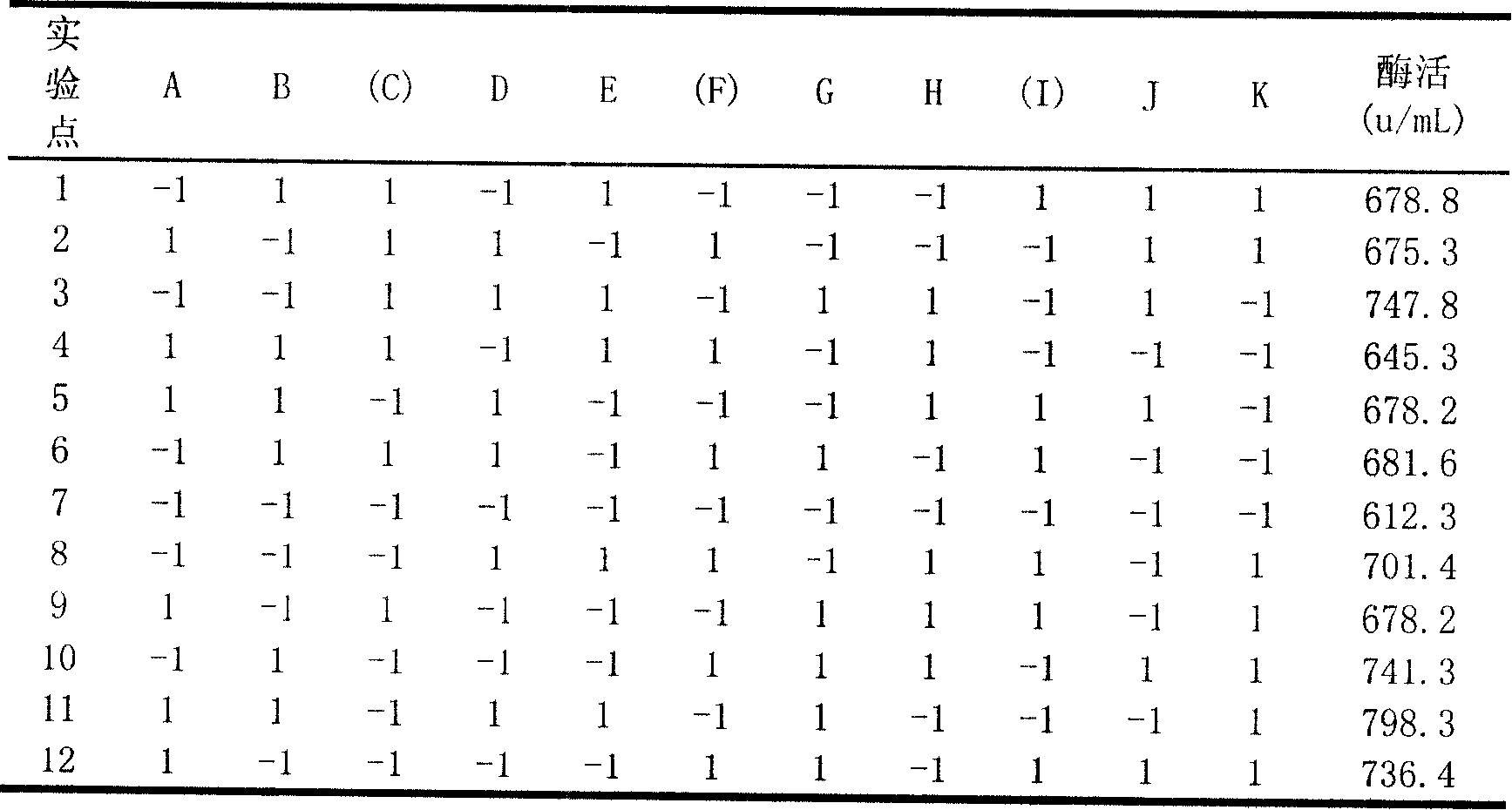

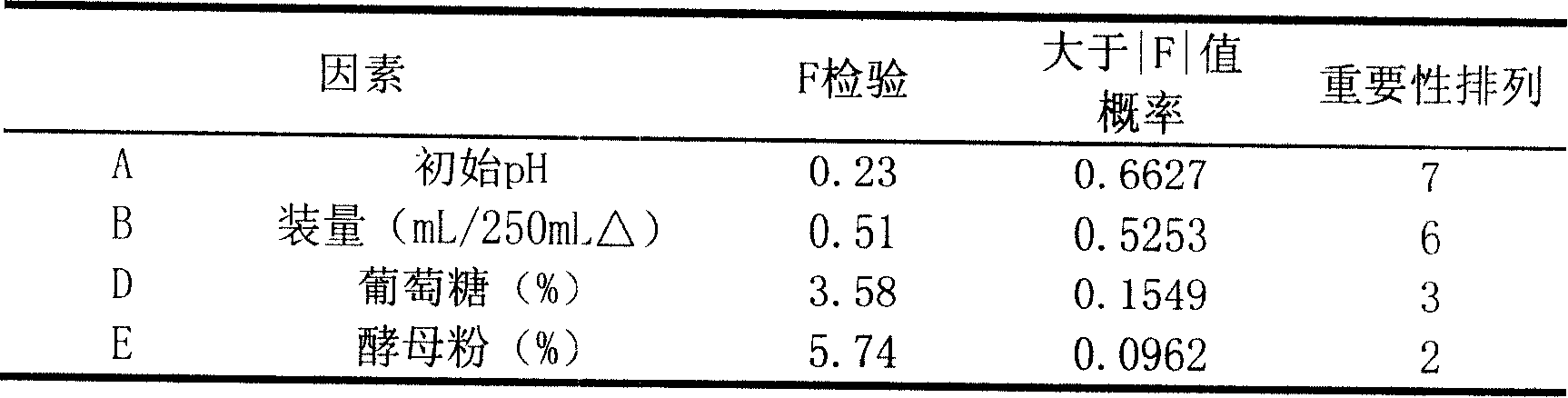

Method for sifting and cultivating bacillus thuringiensis of high-yield thermostable proteinase

ActiveCN101161811AOptimizing Fermentation ConditionsHeat resistantBiocideBacteriaSporeAureobasidium sp.

A screening and cultivation method for Bacillus thuringiensis of high-yield high temperature resisting protease includes the following steps: high-yield high temperature resisting protease Bacillus thuringiensis Bt140 is obtained through adopting casein substrate agar to identify flat primary screen and fermenting enzyme activity measuring secondary screening; Plackett-Burman design and response surface analytical method are adopted to obtain optimal fermentation zymogenic formula and fermentation condition for Bt140 quickly; finally, shaking fermentation level reaches to 918.56U / mL. During adopting Bt140 to produce high temperature resisting protease, spore collection for producing pesticide after fermentation is not influenced; therefore, the Bacillus thuringiensis combines the production capacity of protease and pesticide. For example, when 1 ton Bacillus thuringiensis is used for fermentation, corresponding Bt pesticide is obtained along with 60 to 90 Kg / megaunit enzyme powder.

Owner:LIFECOME BIOCHEM

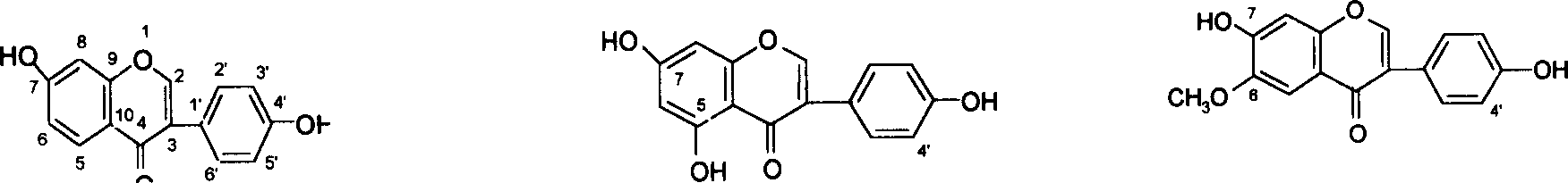

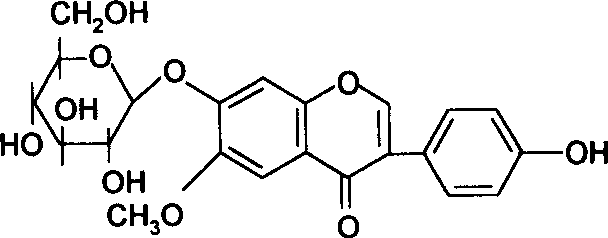

Method for preparing aglycon of soybean isoflavone glycoside base by enzymatic method hydrolyzing soybean

InactiveCN1483826AFully hydrolyzedNo pollution in the processFermentationMicroorganismGlycoside formation

The method for preparing soybean isoflavone aglycone by using enzyme method to hydrolyze soybean isoflavone glycoside glycosyl includes the following steps: using the enzyme capable of hydrolyzing soybean isoflavone glycoside glycosyl, mixing said enzyme, soybean isoflavone glycoside and buffer solution to make reaction for 1-40 hr., its reaction temp. is 4-75 deg.C and pH value is 3-9, so as to extract soybean isoflavone aglycone. Said invention not only can use enzyme to hydrolyze monoglycoside-soybean glycoside and genistein glycoside and convert them into correspondent aglycone, but also can use enzyme to hydrolyze soybean glycoside and genistein glycoside mixed glycoside and convent them into the mixed aglycone. Said product can be used as raw material for making medicine and health-care product.

Owner:沈阳天乐保化品有限公司

Novel vibrionaceae vibrio bacterial strain and application thereof

The invention relates the vibrionaceae vibrio strain and its application. The invention relates the vibrionaceae vibrio strain from sea-tangle, and the output of algin lyase made by the vibrionaceae vibrio strain is 2-5 times than that of algin lyase made with now technology. The algin lyase can be used to make algin oligosaccharide.

Owner:OCEAN UNIV OF CHINA

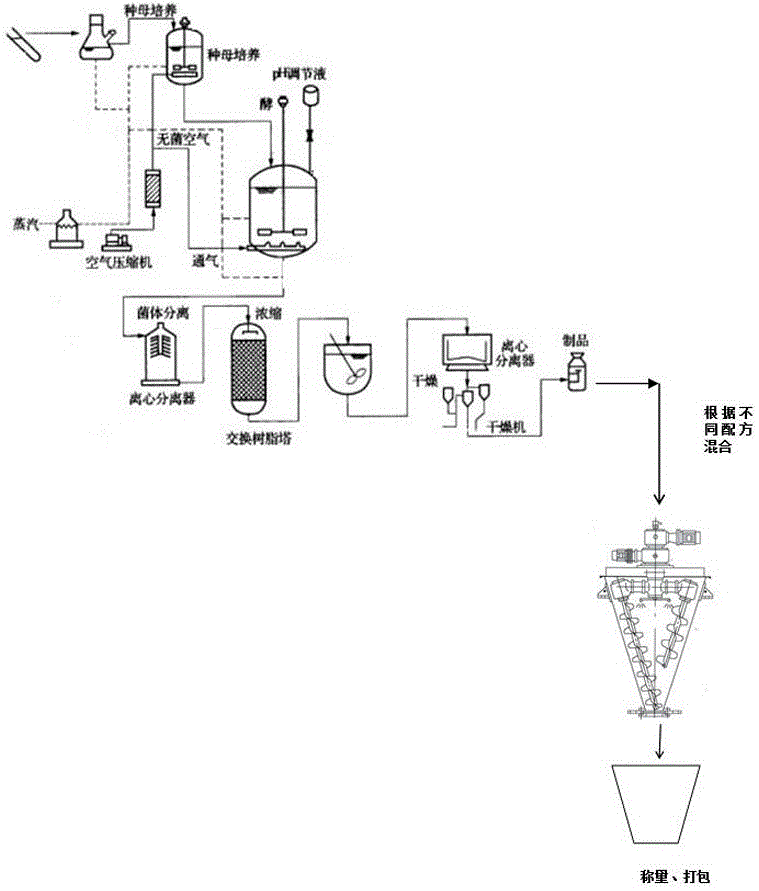

Detoxifying agent for biologically degrading ochratoxin A in feeds and preparation technology of detoxifying agent

InactiveCN106472961ATo achieve the purpose of removing toxinsStrong stress resistanceAnimal feeding stuffAccessory food factorsBiological activationOrganism

The invention relates to a detoxifying agent for biologically degrading ochratoxin A in feeds and a preparation technology of the detoxifying agent. The detoxifying agent comprises 40-60 parts of bentonite, 20 parts of immune polysaccharides, 10-20 parts of a free-radical scavenger and 20-30 parts of bacillus subtilis powder for degrading the ochratoxin A, wherein the bacillus subtilis powder is prepared through the following steps of (1) performing seed liquor activation on original strains, and performing mother seed culturing in a first-class fermentation tank loaded with culture mediums; (2) performing amplified culturing on mother seed culturing liquor in a second-class fermentation tank loaded with LB culture mediums; and (3) separating thalli from fermentation liquor, performing concentration, and performing drying so as to prepare the bacillus subtilis powder for biologically degrading the ochratoxin A. The bacillus subtilis powder, a first-time mixture and a second-time mixture in parts by weight are compounded so that a finished product of the detoxifying agent is obtained. According to the detoxifying agent disclosed by the invention, the degradation rate of the detoxifying agent for the ochratoxin A is as high as 92% or above, the degradation efficiency is high, and defects of an adsorbent are overcome; and besides, immune polysaccharide and free-radical removing ingredients are added to products, so that the functions of protecting the liver and enhancing the immunity of organisms can be achieved, and the effects are obvious.

Owner:北京科润生科技发展有限公司

Method for degradation of feather by using microorganism

InactiveCN1860904AImprove utilizationGreat application potentialBacillus licheniformisBiological cell

A process for degradating feather by use of microbes includes such steps as preparing the substrate of feather to be transformed, obtaining the Bacillus licheniformis ZJUEL31410 (CGMCC 1397), and microbial transforming of the feather to obtain forage.

Owner:ZHEJIANG UNIV

Glucose oxidase gene GOD, protein coded by GOD, pichia pastoris transformed by GOD and preparation method of pichia pastoris

InactiveCN105420252AAccurate and efficient productionImprove fermentation enzyme activityFungiMicroorganism based processesHeterologousSecretion expression

The invention belongs to the preparation of a new gene, and in particular discloses a glucose oxidase gene GOD, protein coded by the GOD and pichia pastoris transformed by the GOD. The glucose oxidase gene GOD is prepared by taking 5'-ATGAAGTCCACTATTATCACCTCCA and 3'-CTAGGCACTTTTGGCATAGTCTTCA as specific primers and penicillium notatum as a template through polymerase chain reaction (PCR) amplification. According to the invention, the problem of an existing recombinant glucose oxidase gene in heterologous expression is solved; the total-length GOD gene and a shuttle expression vector constructed by the gene are obtained and the gene and the shuttle expression vector thereof are further transformed to the pichia pastoris, and upon screening and identification, a strain, which is higher in secretion expression of the glucose oxidase than an original strain, is obtained. The invention can greatly save cost and expense for further industrialized production and can improve the economic benefits of the glucose oxidase.

Owner:河北省微生物研究所有限公司 +1

Feed enzymic preparation prepared by using soy sauce residues and preparation method of feed enzymic preparation

ActiveCN102524544AIncrease enzyme activityNo side effectsAnimal feeding stuffInorganic saltsGlucoamylase activity

The invention discloses a feed enzymic preparation prepared by using soy sauce residues. The feed enzymic preparation is prepared by adopting a preparation method comprising the following steps of: (1) preparing materials: taking desalted and dewaterd soy sauce residues as the main raw materials of a culture medium, adding inorganic salts into the culture medium, and adding water and evenly mixing to form a zymogenic material, wherein the dosage of the added inorganic salts is 0-0.25% of the total dry weight of the culture medium; (2) steaming: steaming the zymogenic material; (3) inoculating: inoculating strains into the steamed zymogenic material, and evenly mixing to form a fermenting material; and (4) fermenting: fermenting the fermenting material at the temperature of 28-35 DEG C until the fermenting material is mature, so as to obtain the feed enzymic preparation. The feed enzymic preparation has the advantages of higher acid protease activity, glucoamylase activity and cellulase activity and is suitable for being used as an animal feed. The invention further discloses the preparation method of the feed enzymic preparation.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

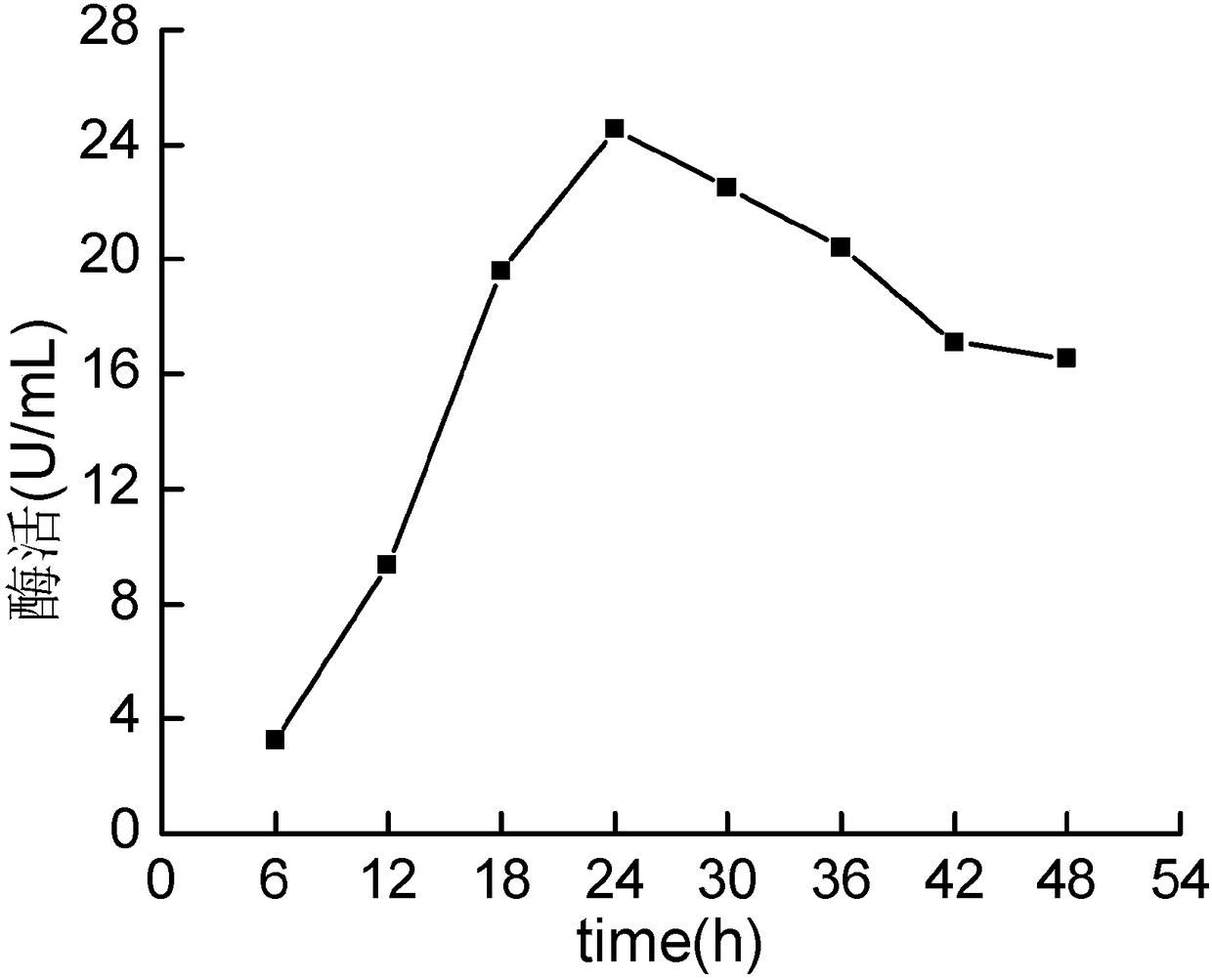

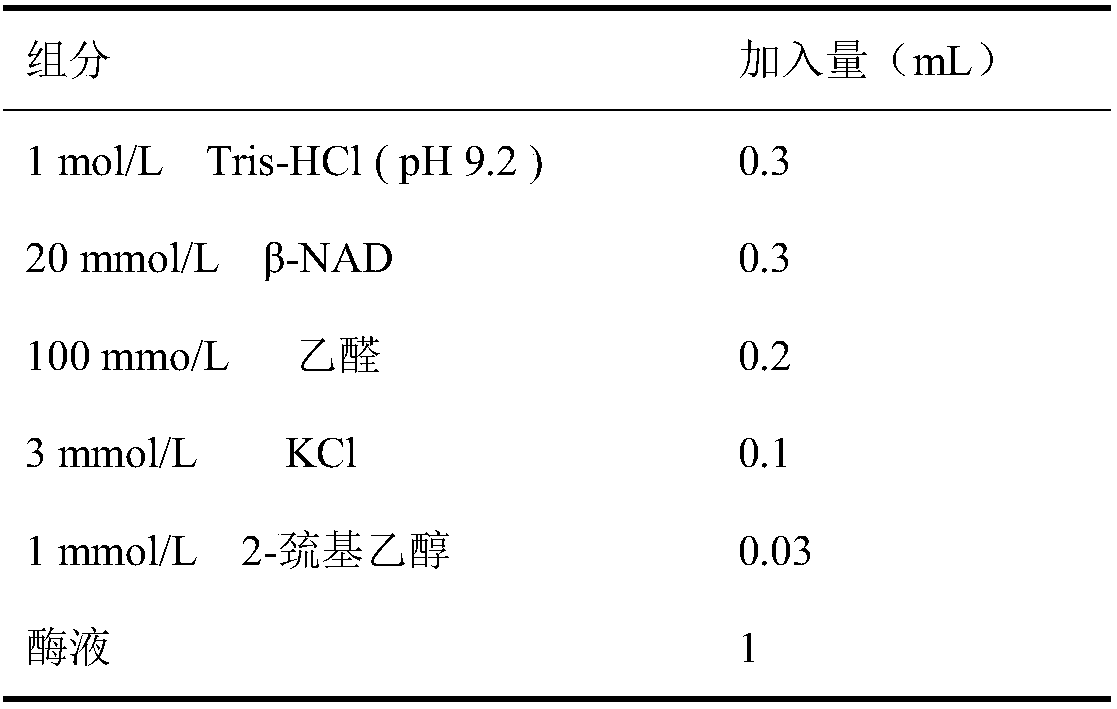

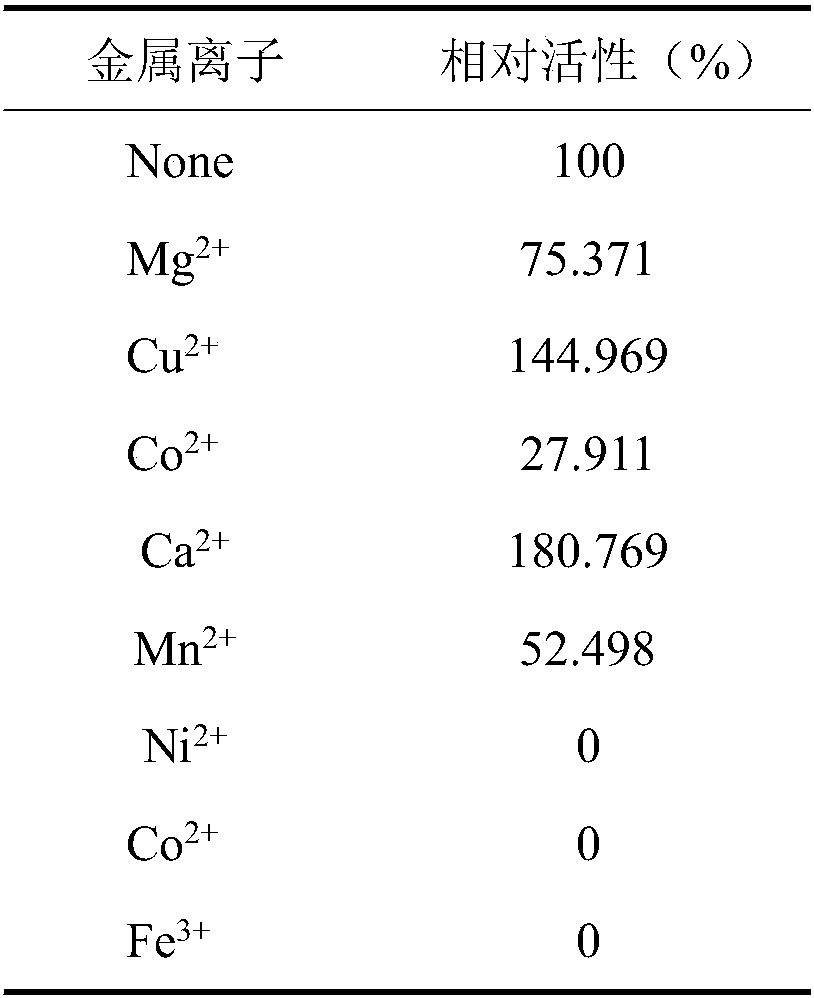

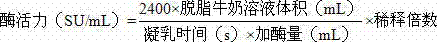

Acetaldehyde dehydrogenase and application thereof in aspect of anti-alcoholic health-care products

ActiveCN108103081AHigh enzyme productionBacteriaMicroorganism based processesMicrobiologyAcetaldehyde

The invention discloses acetaldehyde dehydrogenase and an application thereof in an aspect of anti-alcoholic health-care products, and belongs to the technical field of enzyme engineering. The invention provides an engineering bacterium for high-efficiency expression of a human acetaldehyde dehydrogenase gene and a construction method of the engineering bacterium; the expression of the humanized acetaldehyde dehydrogenase gene, which is shown as SEQ ID NO.1, in bacillus subtilis is achieved; and an enzyme yield by fermenting the recombinant bacterium for 24h can reach 24.52U / L or above. By improving a fermentation medium, the yield of the acetaldehyde dehydrogenase is improved, and an enzyme yield of a culture medium which is added with CaCl2 salt and CuSO4 is improved to 140-180% in comparison with an original enzyme yield; therefore, a new way and a theoretical basis are provided for research and development of anti-alcoholic drugs.

Owner:ZIBO VOCATIONAL INST

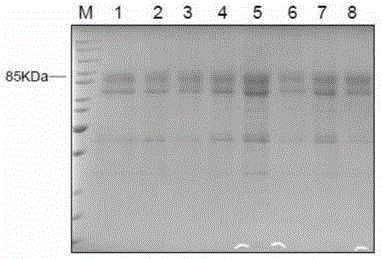

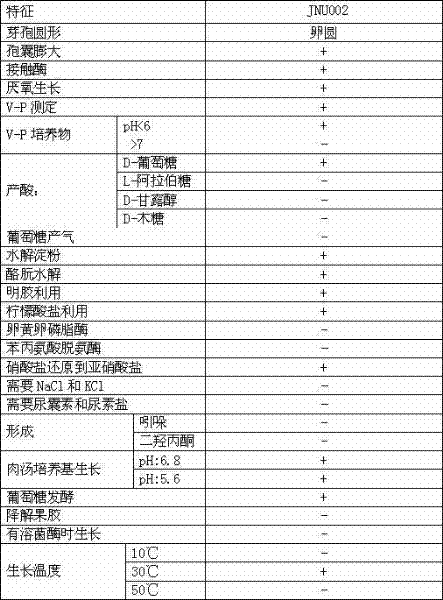

Bacillus amyloliquefaciens and method for producing chymosin by fermenting using same

ActiveCN102191203AHigh enzyme productionShort fermentation timeBacteriaHydrolasesBiotechnologyMicroorganism

The invention relates to Bacillus amyloliquefaciens and a method for producing chymosin by fermenting using the same and belongs to the technical field of microbial fermentation. The invention discloses a bacterial strain for producing the chymosin. The bacterial strain is named as Bacillus amyloliquefaciens JUN002 and is collected in China Center for Type Culture Collection, wherein the collection number is CCTCC No:M2011045. The method for producing the chymosin by using the bacterial strain through liquid fermentation comprises the following steps of: performing slant culture; (2) performing seed culture; and (3) performing liquid fermentation culture, namely inoculating cultured seeds into a fermentation culture medium according to the inoculation quantity of 0.1 to 0.2 percent to culture the seeds at the temperature of between 32 and 36 DEG C for 60 to 72 hours. The Bacillus amyloliquefaciens and the method for producing the chymosin by fermenting using the same have the advantages that: the chymosin is produced by using the Bacillus amyloliquefaciens CCTCC No:M2011045 through liquid fermentation, so the enzyme production level is high, the fermenting time is short, growth conditions are easy to control and the like; and the method is completely suitable for application to industrialized production.

Owner:四川生力源生物工程有限公司

Acid protease and preparation method thereof

InactiveCN101638647AHigh enzyme productionImprove performanceHydrolasesPeptide/protein ingredientsMicroorganismYeast

The invention provides acid protease which is derived from microorganism sources and a preparation method thereof. The acid protease is characterized in that a. enzymology characteristics: the optimumpH is 2.5-3.5, the stable pH is 2.5-6.0, the optimum temperature is 40-50 DEG C, and the temperature stability ranges from 30 DEG C to 50 DEG C; b. with A. niger as an enzyme producing strain and wheat bran as main materials, the acid protease is prepared by solid fermentation process; the fermenting and enzyme producing capabilities are more than or equal to 47000u / g (based on dry yeast), the yield of liquid enzyme is more than or equal to 85% and that of solid enzyme is more than or equal to 80%, which all reach the food grade hygienic standards. The acid protease takes grain processing by-products as main raw materials and has high fermentation enzyme activity, high enzyme extraction purification yield and low production cost. The acid protease is suitable for serving as the preparation raw material or the additive of the products in such industries as tanning, medicine, brewing and feed.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

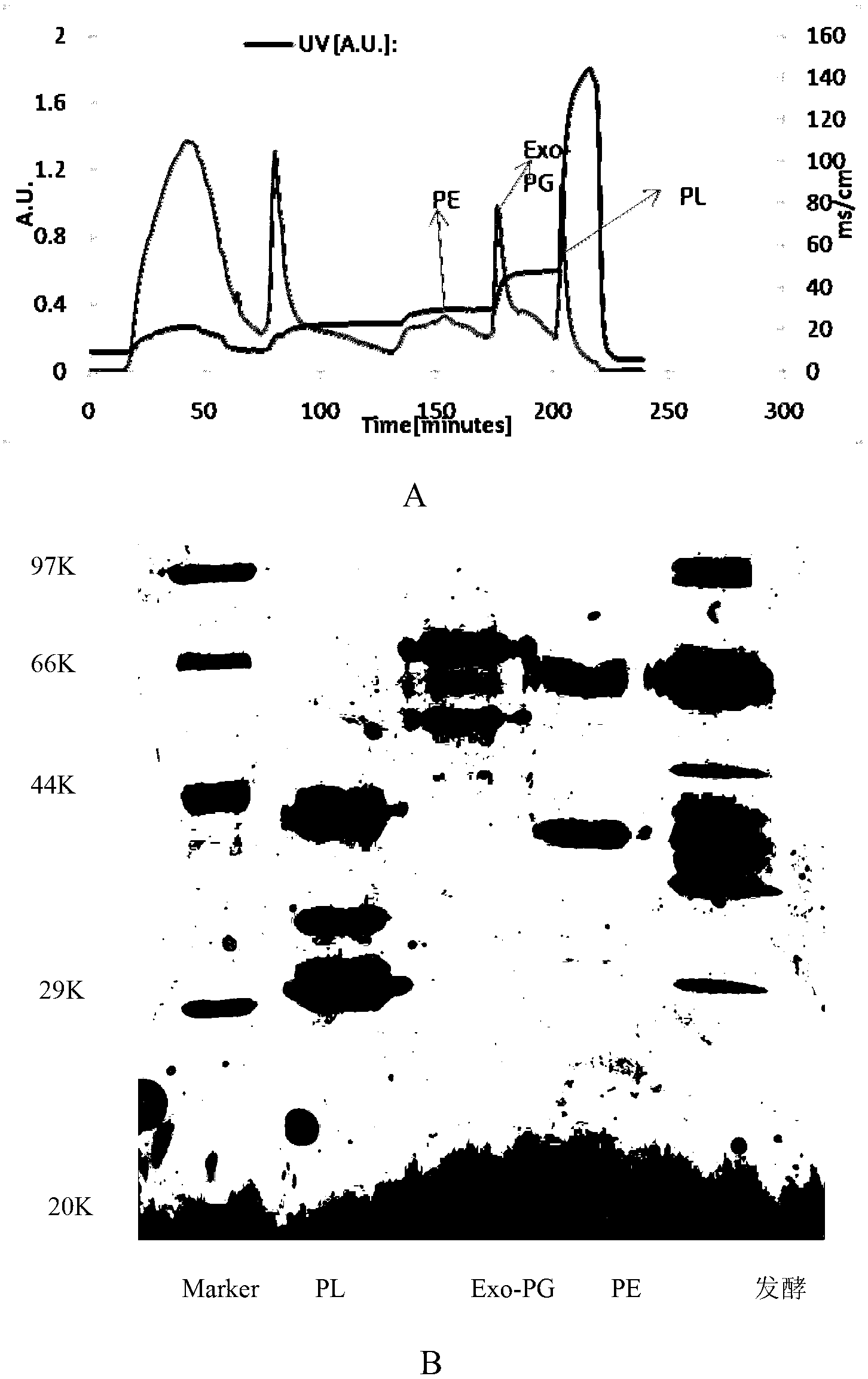

Pectinase producing bacterial strain and application in preparation of peeled citrous complex enzyme

The invention provides a pectinase producing bacterial strain, namely Asperillus niger WZW001, and an application in preparation of pectinase and peeled citrous complex enzyme. The strain is preserved in the CCTCC (china center for type culture collection) on Oct. 12, 2012, and the preservation No. is CCTCC No: M2012399. The peeled citrous complex enzyme prepared by the Asperillus niger WZW001 has the advantages of low production cost, specificity and efficiency, stable application and the like; during the application, as long as the Asperillus niger WZW001 strain fermentation liquor is used for preparing solid pectinase or is separated and purified to obtain PL, Exo-PG, and PE single enzyme elements, and one or more of the solid pectinase or the single enzyme elements is compounded with marketed cellulose without adding other enzymes, so that the orange capsule can be efficiently removed. According to the pectinase producing bacterial strain and the application, the problem of high cost of enzyme for an enzyme-method capsule removing process at present is solved, the replacement of the process to an acid-alkali chemical method is facilitated, and the energy-saving, emission-reduction, green and efficient production of the orange deep processing industry in the country has practical significance.

Owner:重庆檬泰生物科技有限公司

Method for preparing phosphoglyceric oxidase using inducing culture substrate chain coccus

InactiveCN101070529AImprove stabilitySimple extraction processBacteriaMicroorganism based processesPolyethylene glycolPotassium

This invention is with the guide hammer bacterium of culture medium preparation Lin the method of sour glycerine oxidize enzyme. The group of culture medium divides and cultivates condition: Bevel guides culture medium, draw thing by yeast , egg white Dong , glucose , Lin the mixture salt solution of 2 sour hydrogen potassiums, glycerines, agars, the magnesiums of sulphuric acid, chlorination manganese, common salts and pH6.8s forms; Seed culture medium draws thing and egg white by yeast Dong , glucose , Lin the mixture salt solution of 2 sour hydrogen potassiums, glycerines, the magnesiums of sulphuric acid, chlorination manganeses, common salts and pH6.8s forms; Seed culture medium draws thing and egg white by yeast Dong , glucose , Lin the mixture salt solution of 2 sour hydrogen potassiums, glycerines, the magnesiums of sulphuric acid, chlorination manganeses, common salts and pH6.8s forms; Ferment culture medium draws thing and egg white by yeast Dong , Lin the mixture salt solution of 2 sour hydrogen potassiums, glycerines, the magnesiums of sulphuric acid, chlorination manganeses, common salts and pH6.8s forms. Bacterial strain is cultivated by bevel, seed is cultivated , revolving shaking table ferments to train , enlarging again collect bacterium body after training , adoption assembles glycol - the two water of ammonium sulphate appearance extraction and the layer of two steps Xi purification gets Lin sour glycerine oxidize enzyme.

Owner:王腾 +1

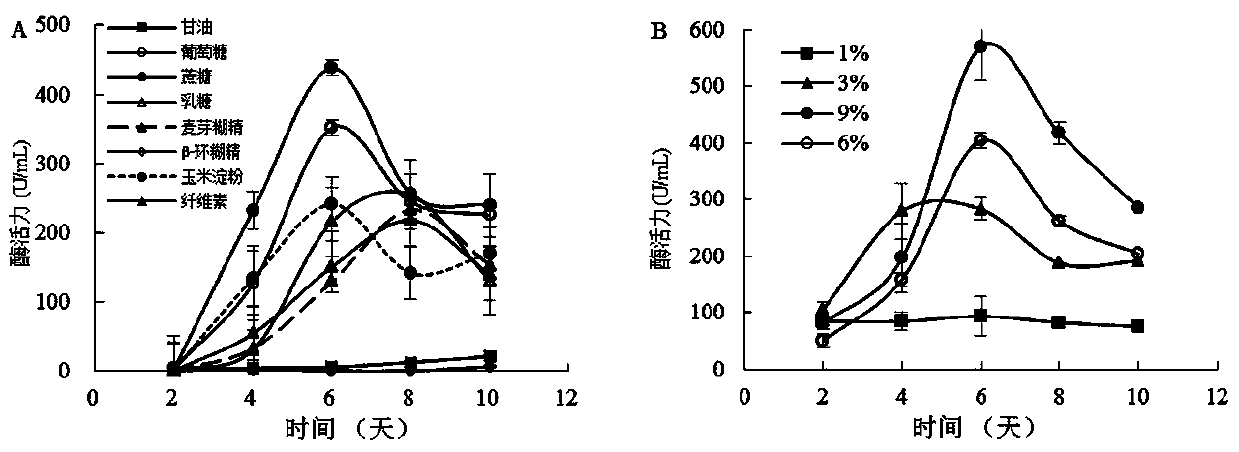

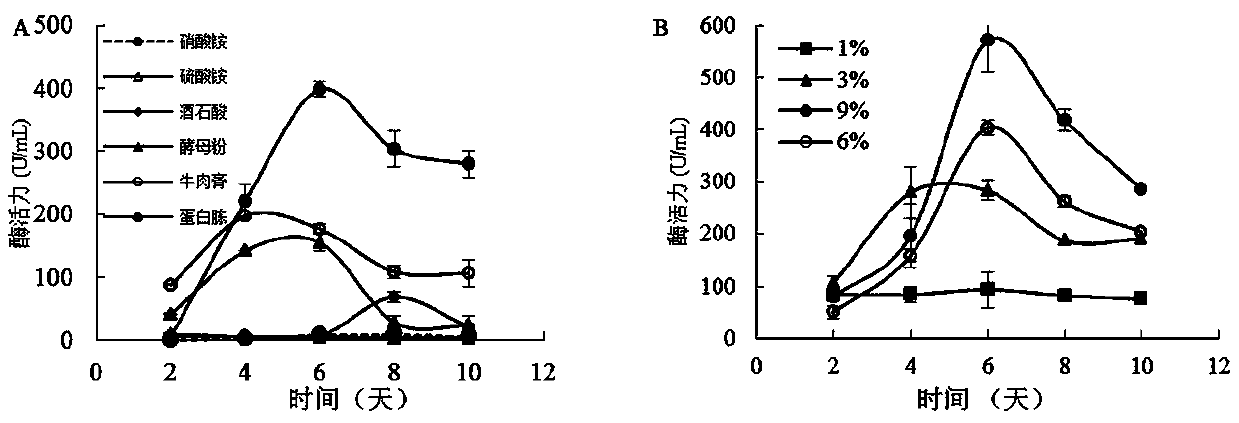

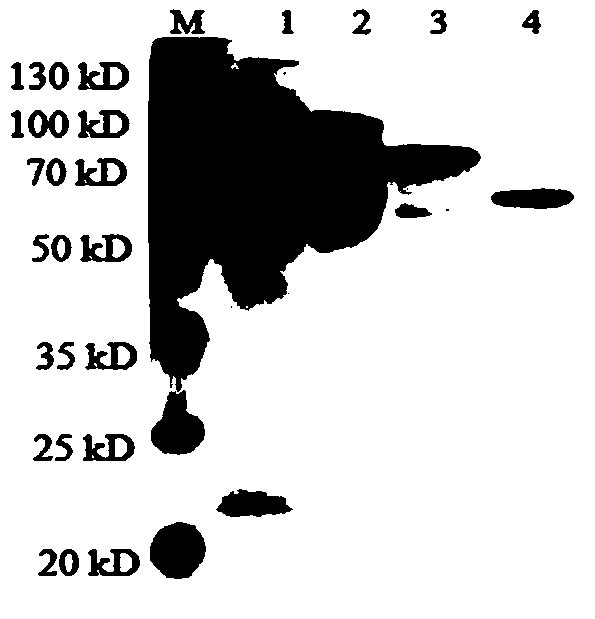

Cerrena unicolor derived laccase and gene and application thereof

ActiveCN110643583AReduce manufacturing costGood value for moneyFungiMicroorganism based processesBiotechnologyDienestrol

The invention provides cerrena unicolor derived laccase and a gene and application thereof, and belongs to the field of biotechnology. The amino acid sequence of the cerrena unicolor derived LacB laccase provided by the invention is as shown in SEQID NO.3, the overall-length sequence of the gene of the cerrena unicolor derived LacB laccase is as shown in SEQID NO.1, and the cDNA sequence is as shown in SEQID NO.2. The invention further discloses a fermentation production method of the LacB laccase. The LacB laccase is produced through fermentation of the cerrena unicolor, after the sixth day of fermentation culture, the laccase yield can reach 652 U / mL, and the fermentation production method has the advantages of being high in yield and short in enzyme production cycle. The LacB laccase has significant effects in environmental hormone degradation, and the degradation rate on diethylstilbestrol, hexestrol, dienestrol, beta-estradiol, bisphenol a and hydroprednisone is 98% or above. TheLacB laccase provides a new way for environmental pollutant government, and has good economic benefits and social benefits.

Owner:FUZHOU UNIV

Application of Haloferula sp. beta-N-acetylhexosaminidase to synthesis of breast milk oligosaccharide

ActiveCN111534503AExcellent transglycosidic activityHigh enzyme productionFermentationVector-based foreign material introductionHydrolysisOligosaccharide

The invention discloses an application of Haloferula sp. beta-N-acetylhexosaminidase to synthesis of breast milk oligosaccharide. The invention provides an application of HaHex74 protein or other relevant biomaterials to any of the following respects: (a1) synthesis of the breast milk oligosaccharide; and (a2) synthesis of lactose-N-tri-saccharide II and / or lactose-N-neotetraose, wherein HaHex74 protein is from Haloferula sp., and an amino acid sequence is shown as SEQ ID No.1. The beta-N-acetylhexosaminidase is high in enzyme production level, excellent in hydrolysis characteristics and highin glucoside transformation activity, and has important application value in synthesis of the breast milk oligosaccharide by an enzyme method.

Owner:CHINA AGRI UNIV

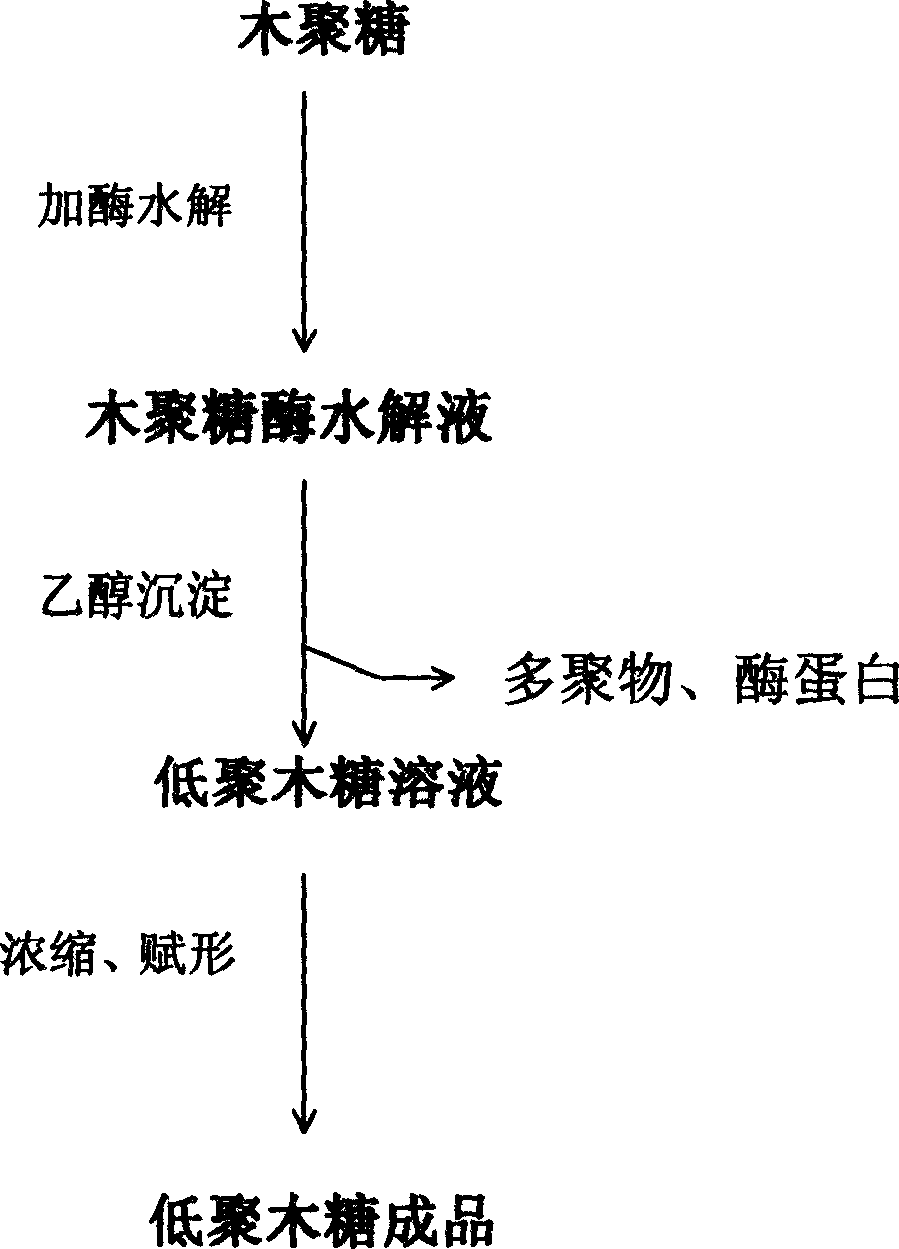

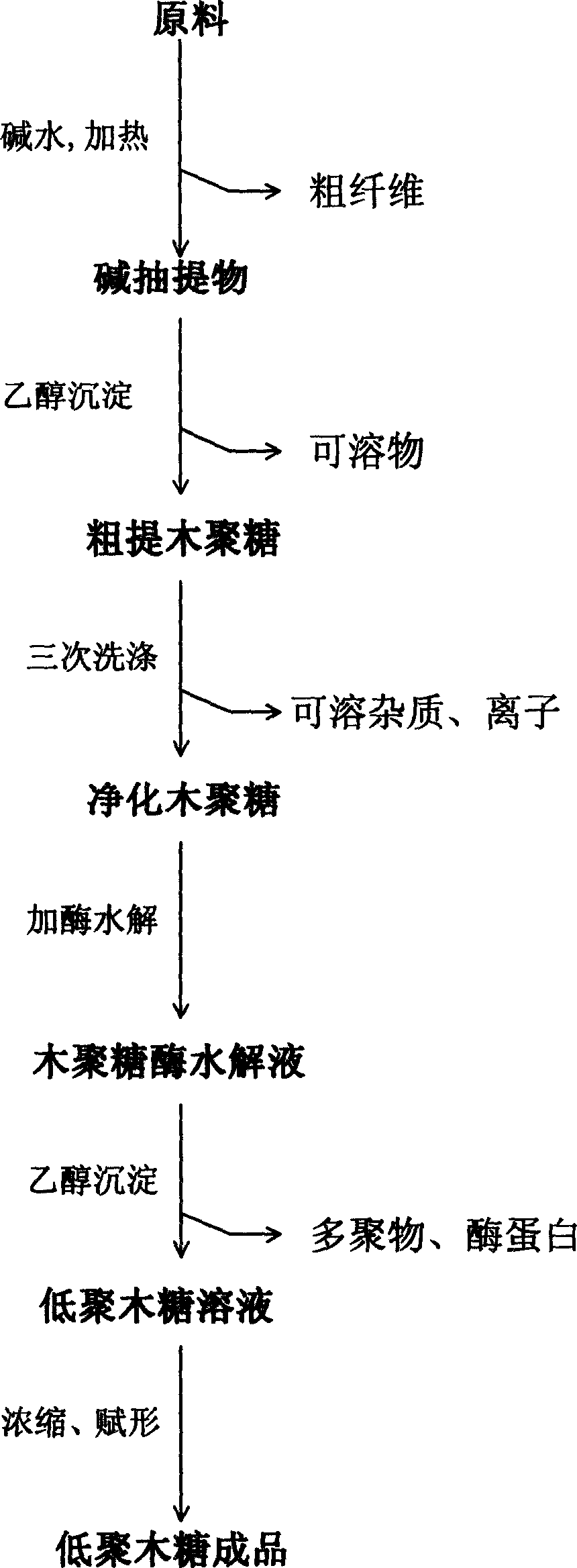

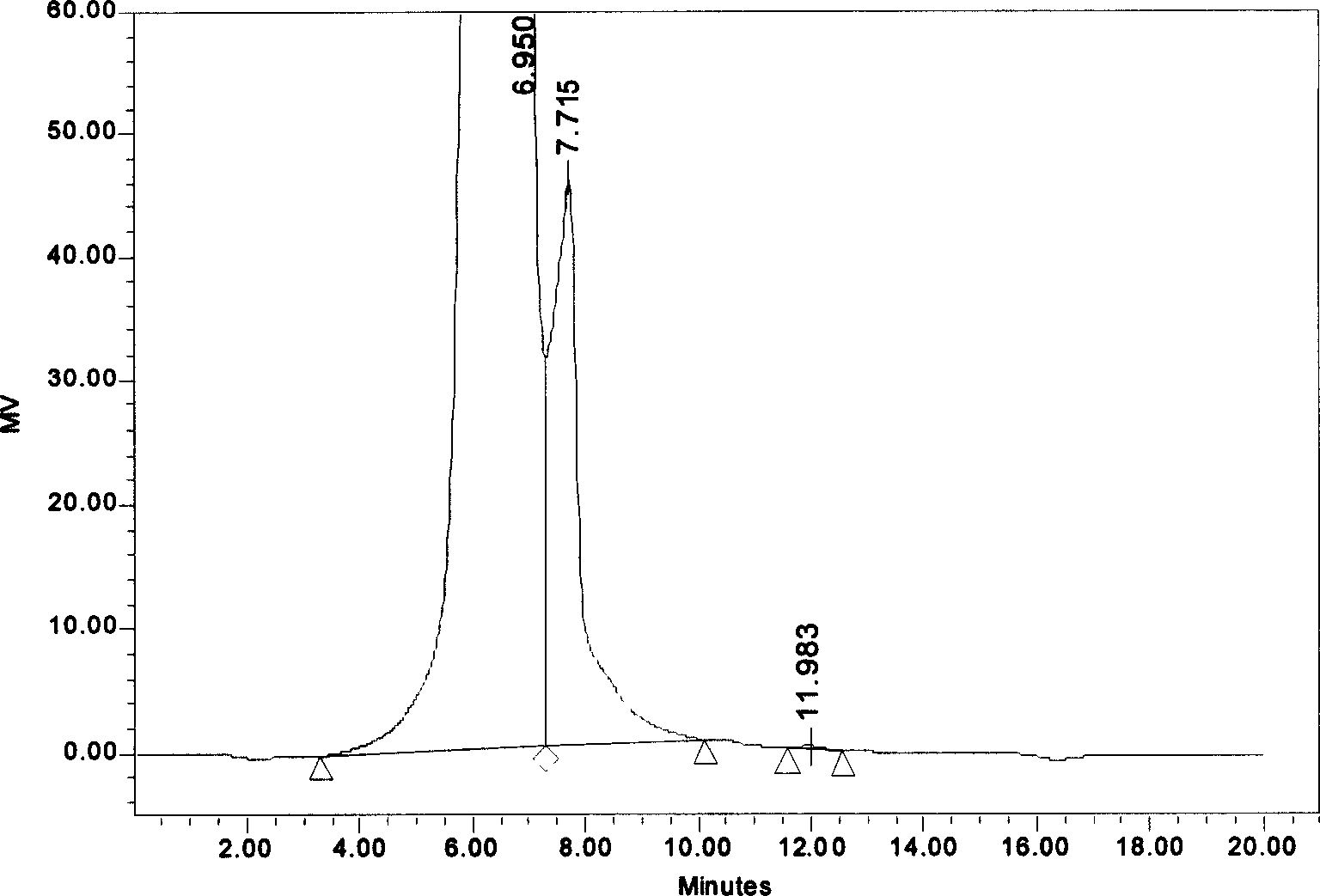

Clean and effective preparation of oligoxylose

InactiveCN1613879AImprove efficiencyStrong production capacityOligosaccharidesFermentationChemistryXylanase

A clean an effective preparation of oligoxylose is carried out by: making xylan solution bydissolving xylan in water or buffering liquid, adding xylanase into it to obtain an enzyme hydrolystic liquid, adding alcohol, centrifuging to obtain supernatant, separating to obtain oligoxylose. It costs low, has no pollution, and is effective. Its product likes natural one.

Owner:NANJING NORMAL UNIVERSITY

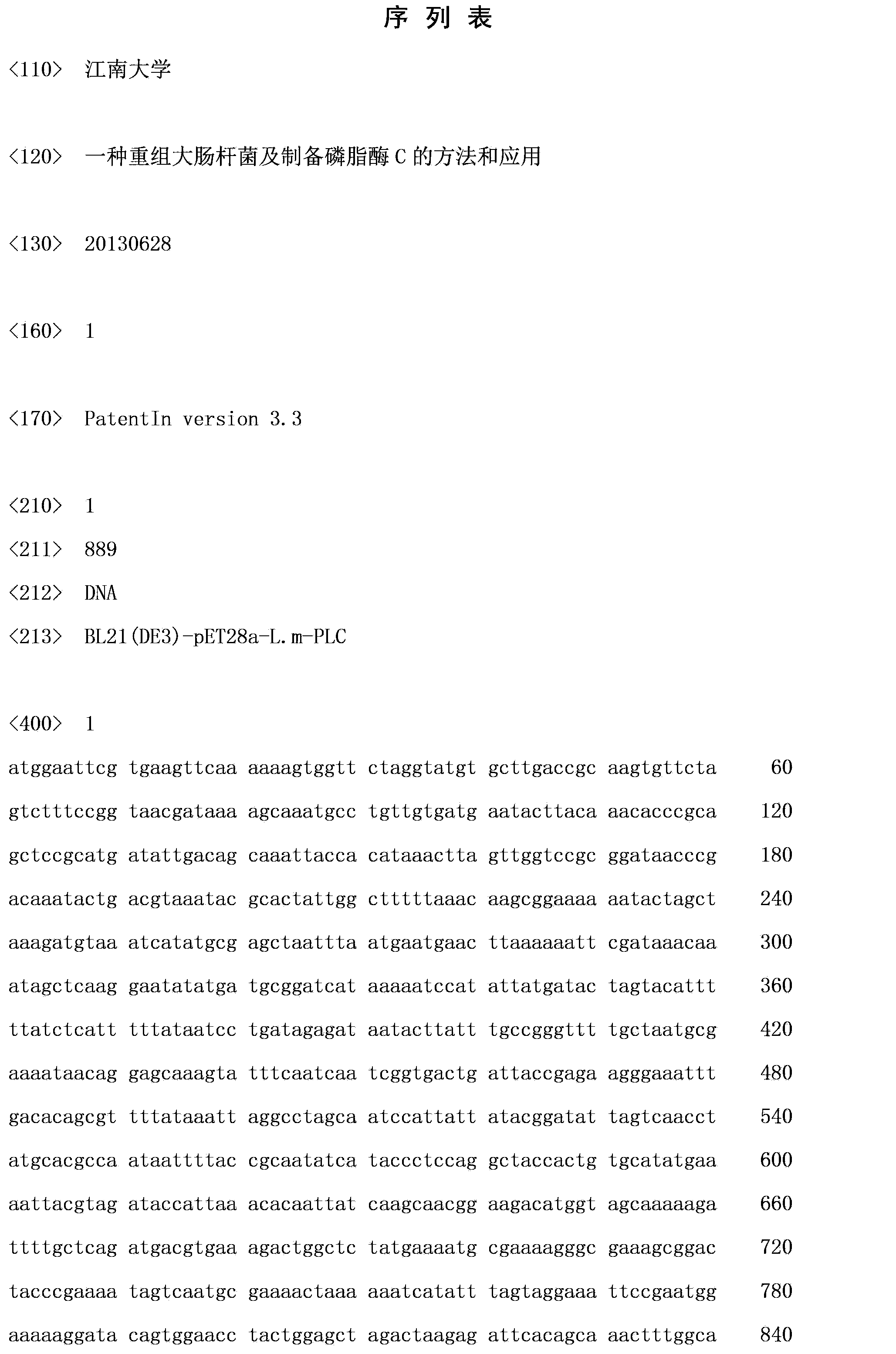

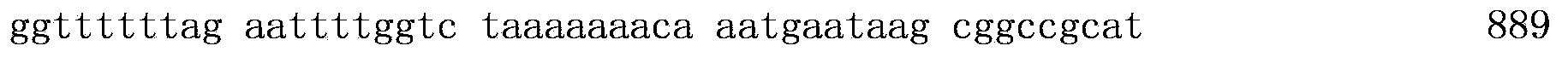

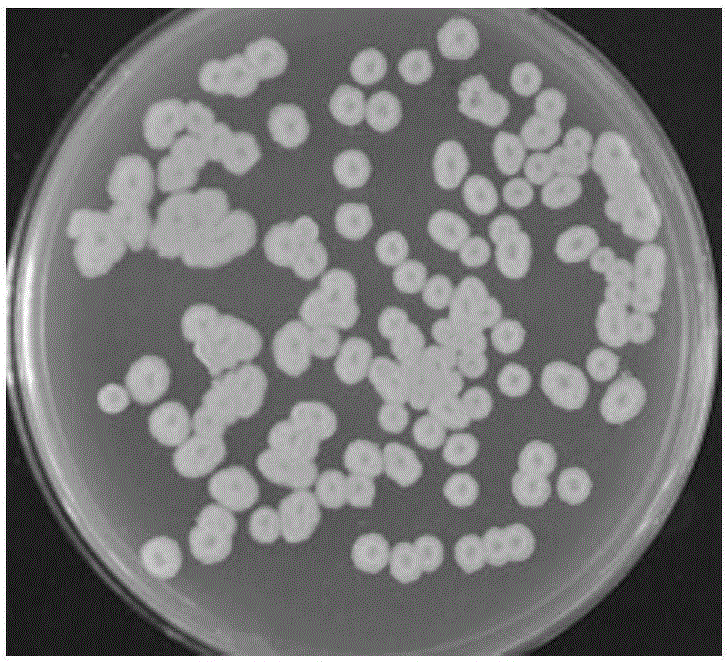

Recombinant escherichia coli, method for preparing phospholipase C and application

InactiveCN103525744ASimple production processShorten the production cycleBacteriaHydrolasesMononucleosisCompanion animal

The invention discloses recombinant escherichia coli, a method for preparing phospholipase C and application. The recombinant escherichia coli BL21(DE-3)-pET-28a-L.m-phospholipase C (PLC) of which the target gene is from listeria monocyogenes (L.monocytogenes) is utilized as a fermentation strain to carry out liquid fermentation, so as to prepare phospholipase C. The method disclosed by the invention is simple in enzyme production process, short in production cycle and low in cost. A glycerophosphate bond on glyceryl phosphatide C3 can be specifically hydrolyzed to produce diglyceride (DAG) by using recombinant phospholipase C; plant crude oil (soybean oil, colleseed oil, rice bran oil and the like) is degummed by phospholipase C.

Owner:JIANGNAN UNIV

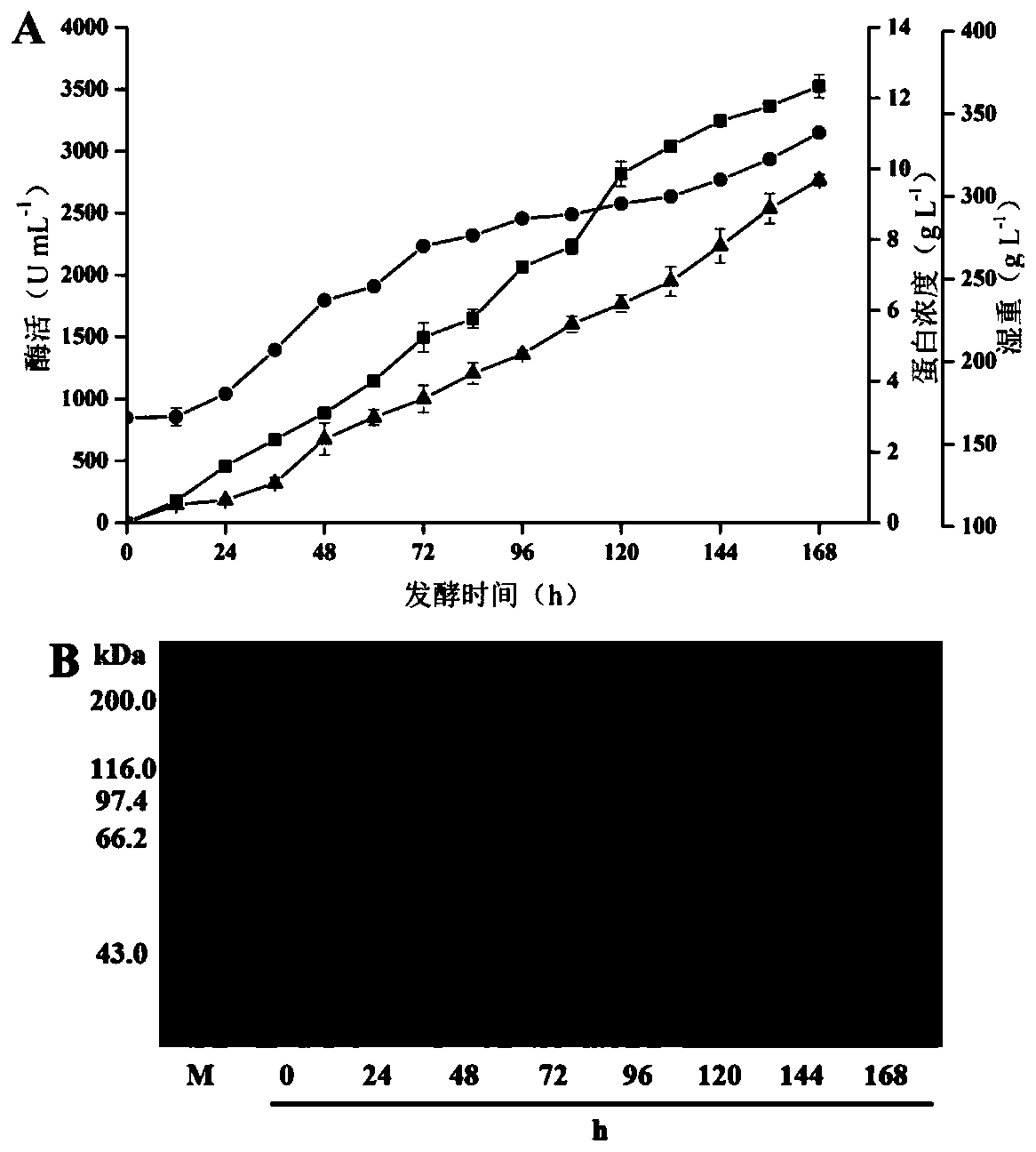

Fibrinolytic enzyme-producing Bacillus subtilis and fermentation method and application thereof

ActiveCN105238720AImprove securitySimple recipeBacteriaPeptide/protein ingredientsMicrobiologyBacillus subtilis

The invention discloses a fibrinolytic enzyme-producing Bacillus subtilis and a fermentation method and application thereof. The Bacillus subtilis is isolated and sieved from a traditional Chongqing fermented food, i.e., fermented soya beans. The Bacillus subtilis DC27 is collected in China Center for Type Culture Collection under CCTCC NO: M 2015573. The invention further provides a liquid fermentation method of the Bacillus subtilis, and the fibrinolytic enzyme in obtained fermentation broth has an activity of up to 4506 IU / ml. The Bacillus subtilis is from foods and can secrete the high-activity fibrinolytic enzyme; the Bacillus subtilis is safe and nontoxic, and is applicable to the development of functional foods or drugs for preventing or relieving thrombotic diseases; and the Bacillus subtilis has a promising application prospect.

Owner:HUAZHONG AGRI UNIV

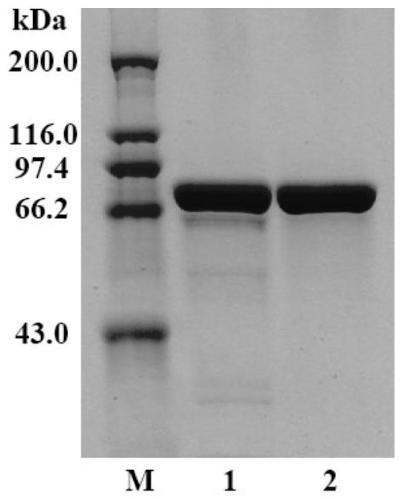

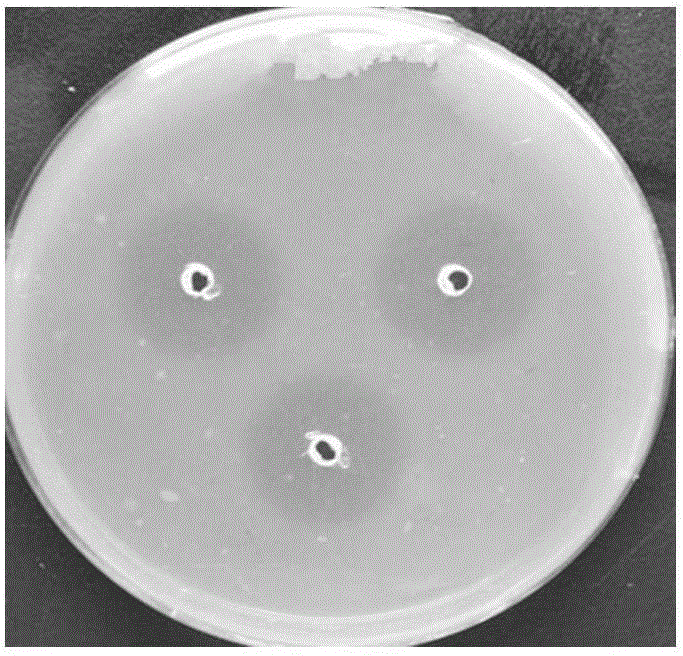

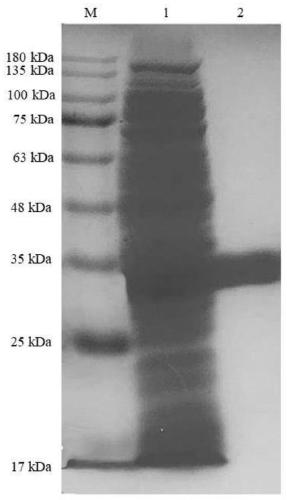

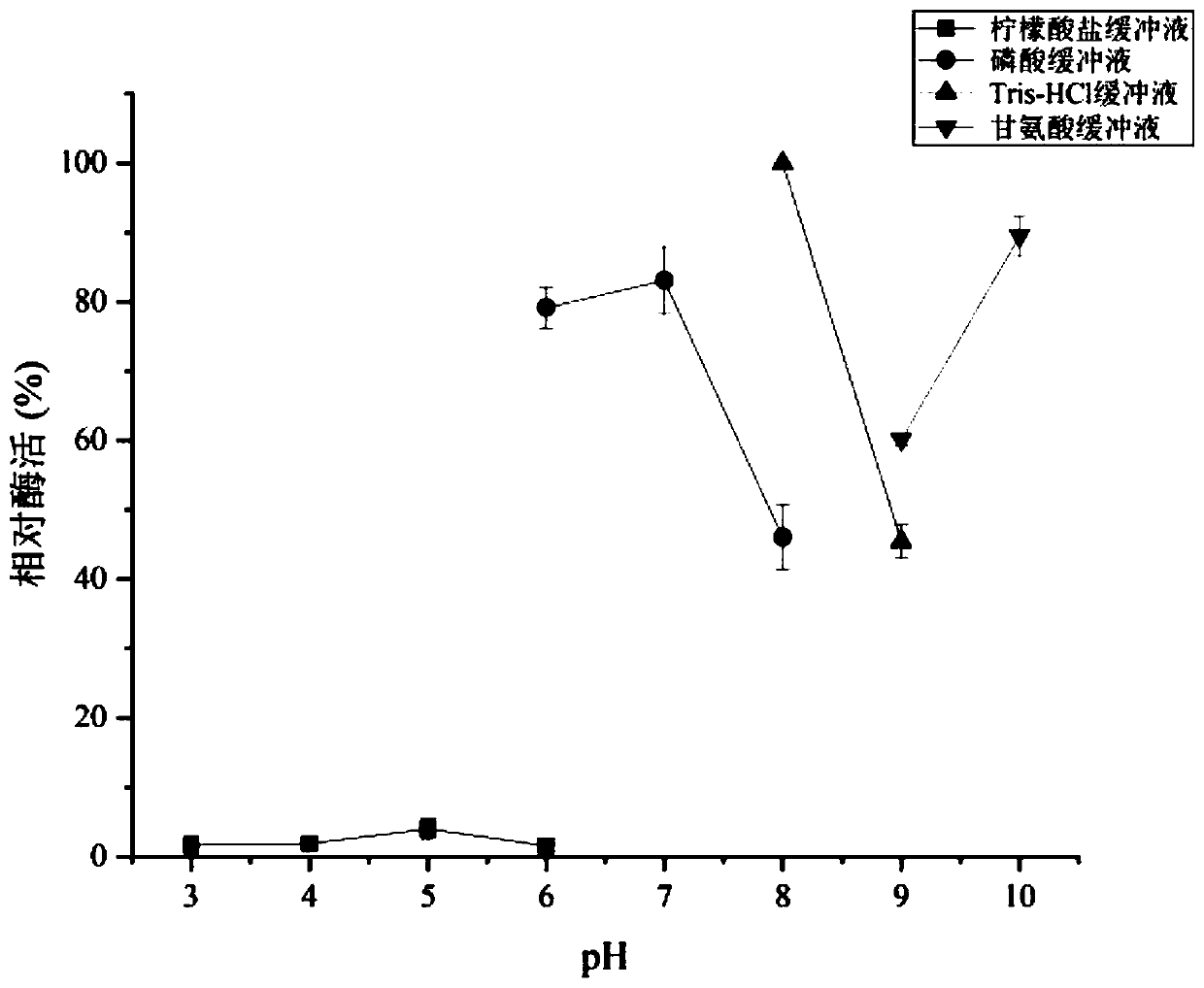

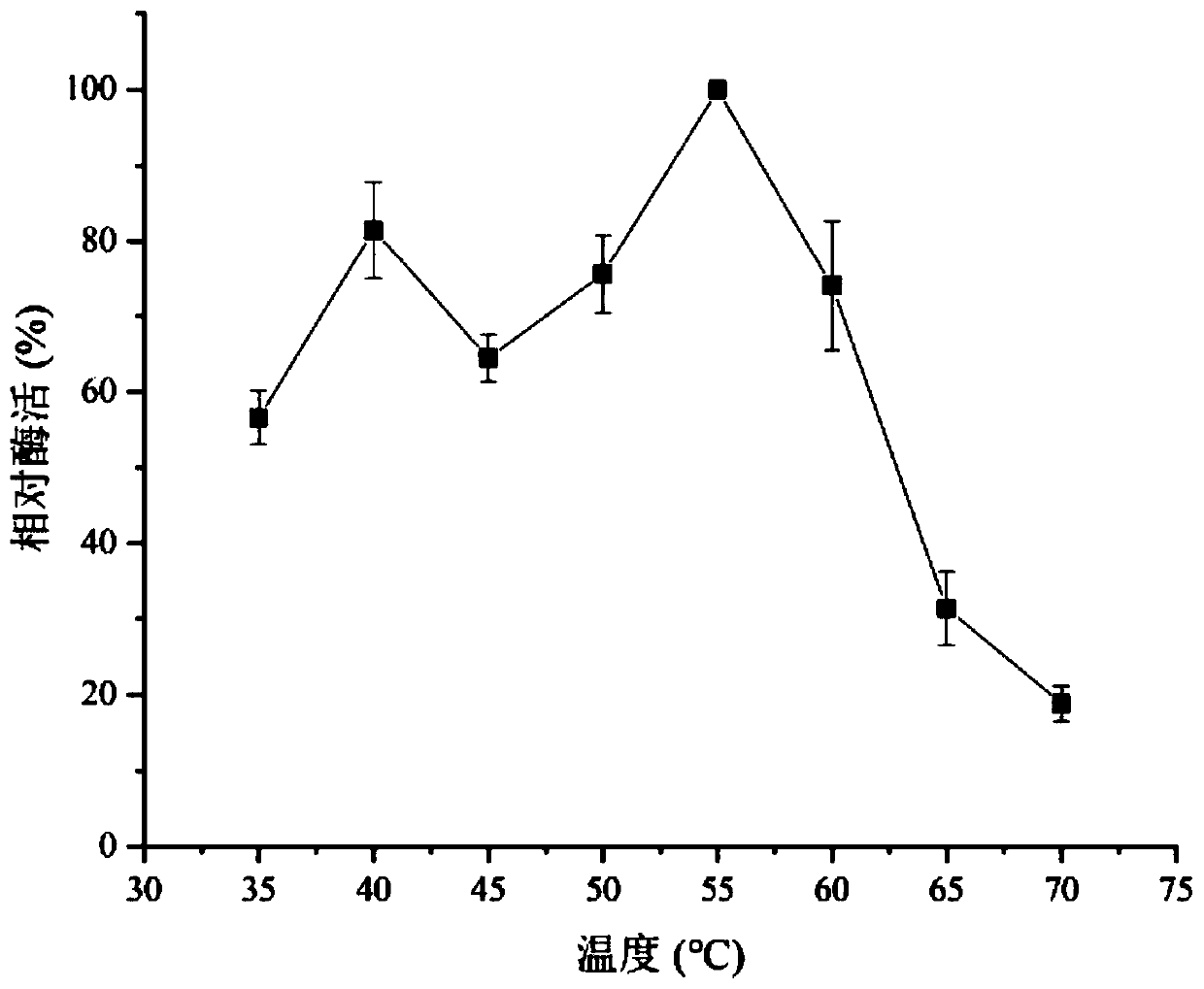

Chitosanase OUC-CsnCA and application of chitosanase OUC-CsnCA

ActiveCN111500555AIncrease enzyme activityHigh enzyme productionBacteriaMicroorganism based processesSpecific enzymeNucleotide

The invention discloses chitosanase OUC-CsnCA. The amino acid sequence of the chitosanase OUC-CsnCA is as shown in SEQ ID NO. 1. The invention also discloses a gene for encoding the chitosanase OUC-CsnCA, and the nucleotide sequence of the gene is shown as SEQ ID NO.2. The invention also discloses a preparation method of the chitosanase OUC-CsnCA. The invention also discloses application of the chitosanase OUC-CsnCA in degradation of chitosan / preparation of chitosan oligosaccharide, and further relates to application of the chitosanase OUC-CsnCA in preparation of an enzyme preparation for degrading chitosan. The chitosanase OUC-CsnCA disclosed by the invention is used for degrading chitosan to generate chitosan oligosaccharide, the optimum pH value of the chitosanase OUC-CsnCA is 8.0, theoptimum reaction temperature of the chitosanase OUC-CsnCA is 55 DEG C, and the specific enzyme activity of the chitosanase OUC-CsnCA is 1786.227 U / mg; in addition the enzyme activity and the enzyme production level are high, wherein the protein concentration after purification is 1.284 mg / ml, and compared with reported chitosanase, the chitosanase has certain advantages. The chitosanase OUC-CsnCAdisclosed by the invention has important industrial application value and economic value.

Owner:OCEAN UNIV OF CHINA

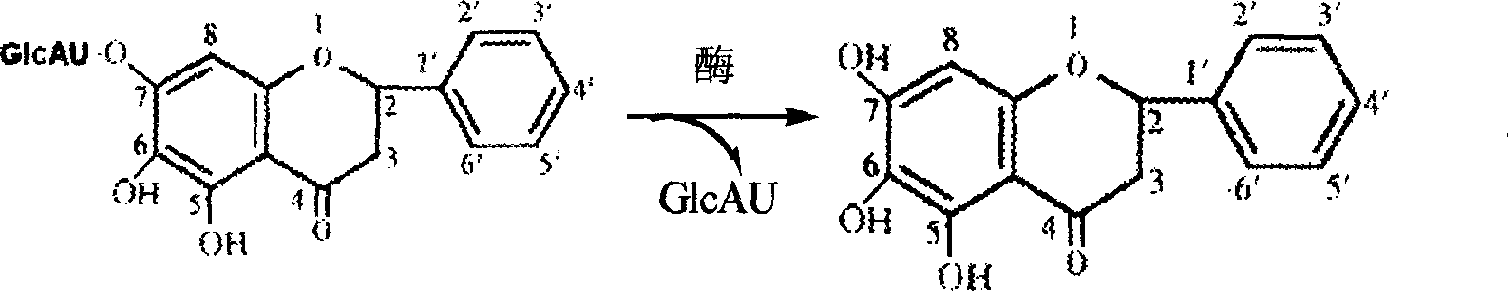

Preparation of scutellarin from scullcaposide glucuronyl by enzyme hydrolysis

ActiveCN1584039AImprove conversion rateOvercoming destructiveFermentationMicroorganismEnzymatic hydrolysis

A method for preparing scutellarin by enzymatic hydrolysis skullcap glycoside glucose aldehydic acid is disclosed. Its advantages include no pollution, high percent conversion and high enzyme output.

Owner:SUNFLOWER PHARM GRP (TIANJIN) DRUG RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com