Method for preparing aglycon of soybean isoflavone glycoside base by enzymatic method hydrolyzing soybean

A technology of isoflavone glycosides and isoflavone aglycones, which is applied in the field of preparing soybean isoflavone glycosides by enzymatic hydrolysis, and can solve the problems of serious pollution and large damage of soybean isoflavone aglycones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

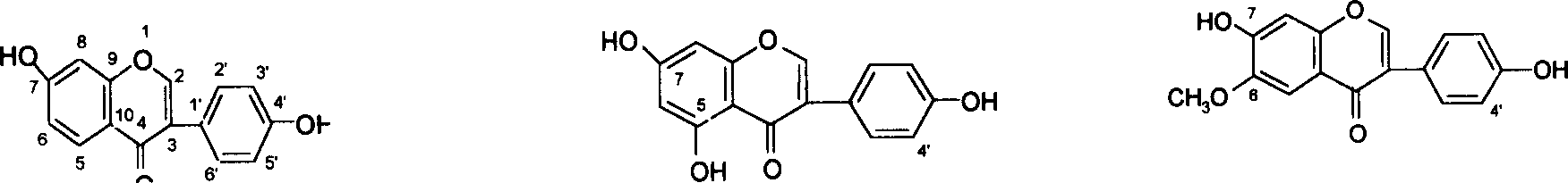

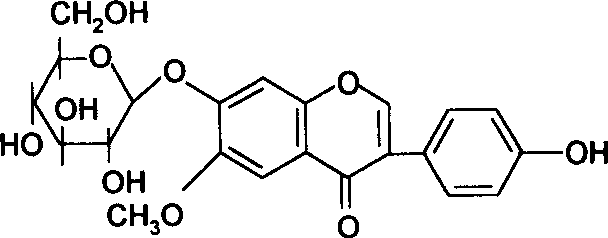

Image

Examples

Embodiment 1

[0026] a. Take the high-temperature aerobic bacteria Clostridium thermocopriea (document 1) in a medium containing 3% corn flour, 1% enzyme-producing inducer-soybean extract (dry matter), and shake culture at a temperature of 60°C for 30-60 hours , sterilize by centrifugation, add 65% saturated ammonium sulfate to precipitate the enzyme protein in the supernatant (containing the enzyme mixture), dialyze with 0.02M, pH5 acetic acid buffer solution, centrifuge to remove residue, and freeze-dry to obtain soybean isoflavone glycosides enzyme.

[0027] b. Mix 2 grams of soybean isoflavone glucosidase, 30 grams of genistin (Genistin), 1500 milliliters of acetate buffer (0.2M, pH5.0) and 150 milliliters of ethanol, so that genistin accounts for the total reaction volume 0.1-10% of the mixture, stirred and reacted for 1 hour at a temperature of 75°C.

[0028] c. add 6000 milliliters of ethanol after the reaction, filter and remove the protein precipitate, and the filtrate is evaporat...

Embodiment 2

[0032] a. Aspergillus niger (Aspegillus niger) was cultured with agitation and ventilation at a temperature of 28-30°C for 50-100 hours in a medium containing 4% malt extract, 1% enzyme-producing inducer-soybean extract, Centrifuge, use 60-75% saturated ammonium sulfate to precipitate enzyme protein in supernatant (containing enzyme mixture), collect protein, dissolve in phosphate buffer (0.02M, pH5. 0), the ammonium sulfate is removed by dialysis, and the residue is removed by centrifugation, which is the enzyme solution.

[0033] b. Mix 4 grams of soybean genistin (Genistin), 100 milliliters of phosphate buffer (0.02M, pH5.0) and 50 milliliters of the above-mentioned enzyme solution, so that genistin accounts for 0.1-10% of the total reaction volume, React at a temperature of 4°C for 40 hours.

[0034] c. adding 1 / 3 of the total reaction volume of n-butanol for extraction three times, and evaporating to dryness under reduced pressure to obtain crude aglycone. A silica gel ...

Embodiment 3

[0039] a. Using Aspergillus oryzae in a culture medium containing 5% wheat bran extract, 0.2% enzyme-producing inducer—soybean isoflavone or rutin, or 1% extract of its flavonoid-derived plant, Stirring and ventilating at a temperature of 28-30°C for 50-100 hours, centrifuging to obtain an enzyme-containing mixture, adding ethanol to 70% to precipitate the enzyme protein, collecting the protein, and freeze-drying to obtain the enzyme.

[0040] b. Treat three kinds of soybean isoflavone glycosides or mixed glycosides with the same method as in Example 1 and Example 2, and convert more than 80% of them into aglycones.

[0041] The above enzymes were separated and purified by the DEAE-Cellulose ion exchange resin column method and BioRed protein preparation chromatography (document 3), and the molecular weight was determined by SDS electrophoresis method (document 4). The molecular weight of the enzyme was 53,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com