Patents

Literature

75results about How to "Increase reaction strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for reducing neurodegeneration in amyotrophic lateral sclerosis

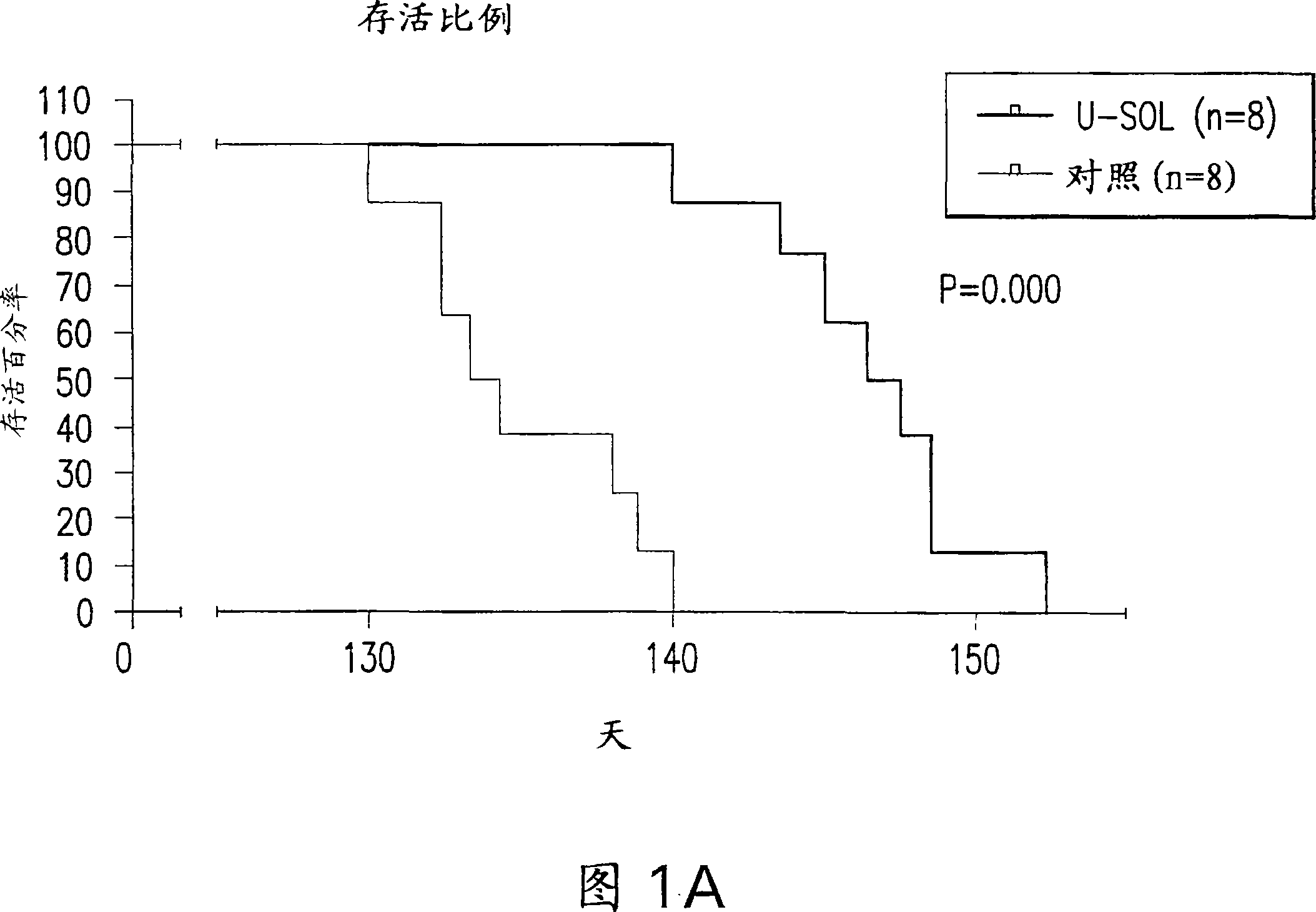

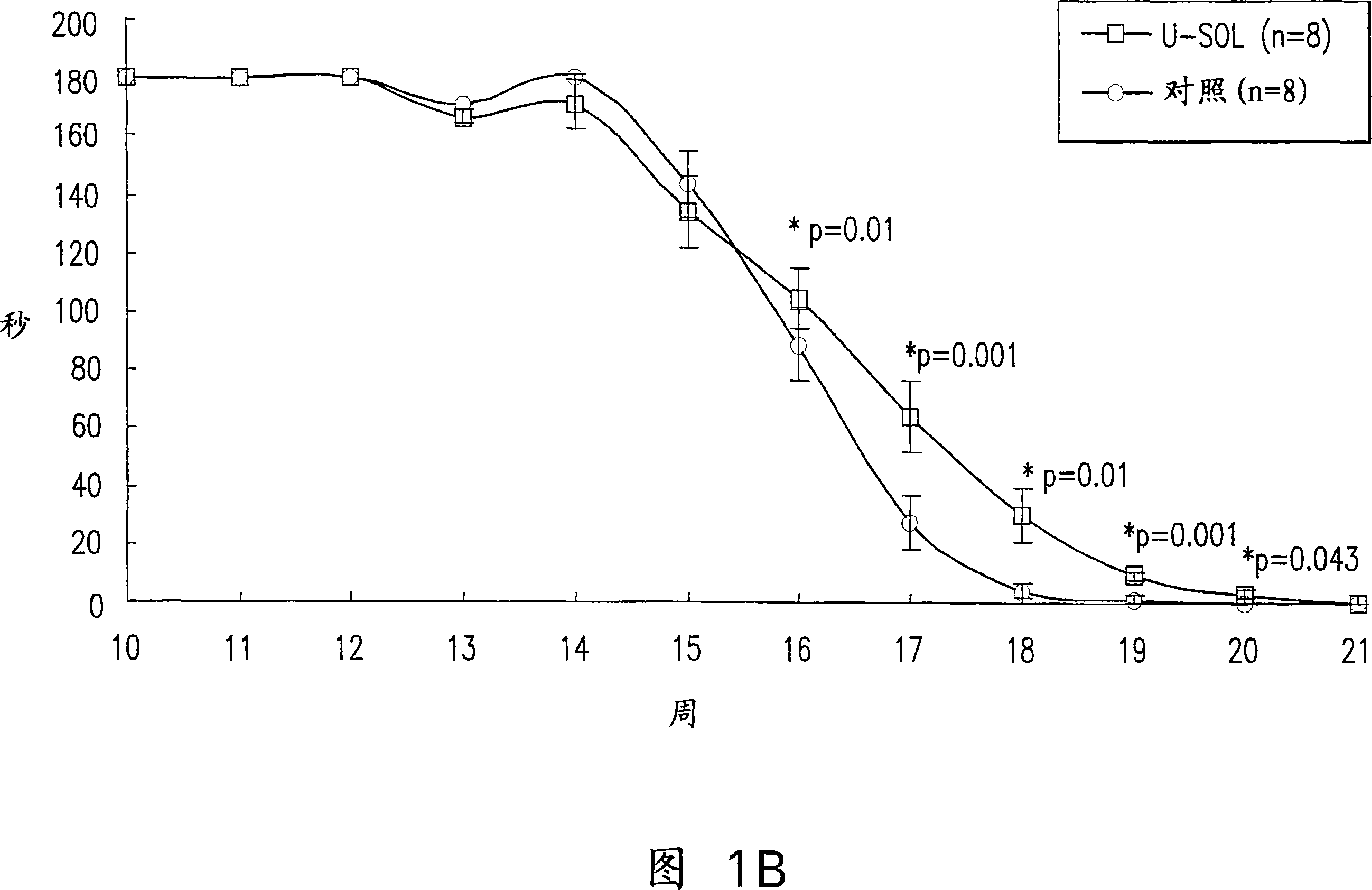

InactiveCN101048164AIncrease reaction strengthOrganic active ingredientsNervous disorderTherapeutic effectPrimary motor neuron

The present disclosure is related to clear aqueous solutions of one or more bile acids and either an aqueous soluble starch conversion product or a non-starch polysaccharide. Solutions of the disclosure may be administered to a subject in conjunction with a pharmaceutical compound having a therapeutic effect in subjects with a neurodegenerative disease and / or a motor neuron disease. In some embodiments, the disease is amyotrophic lateral sclerosis.

Owner:柳署弘

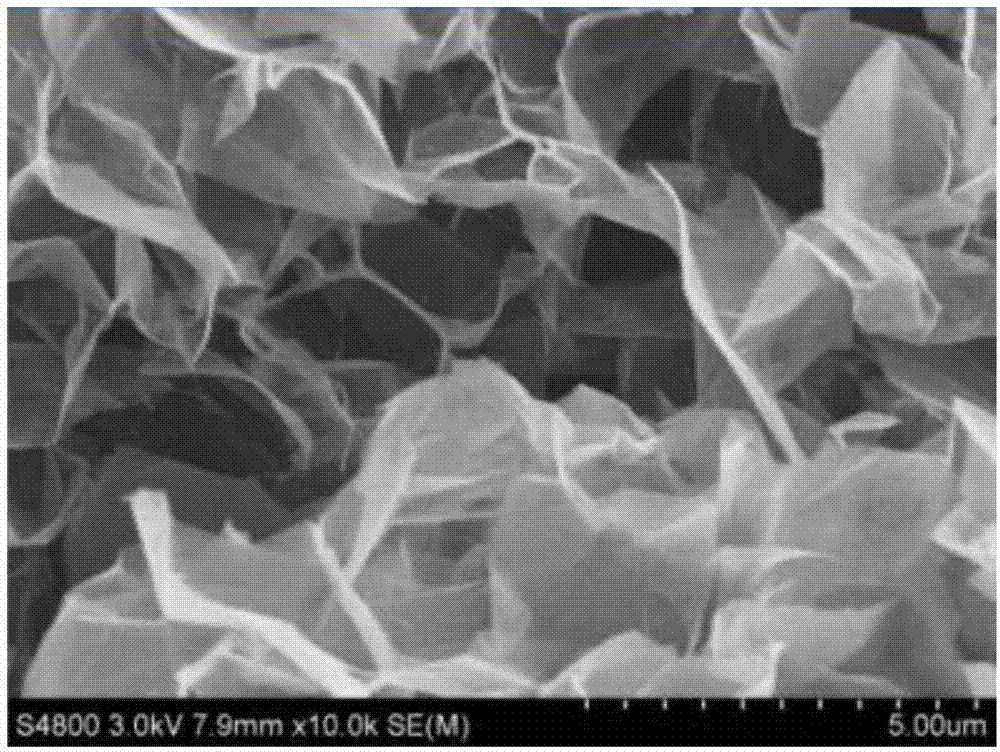

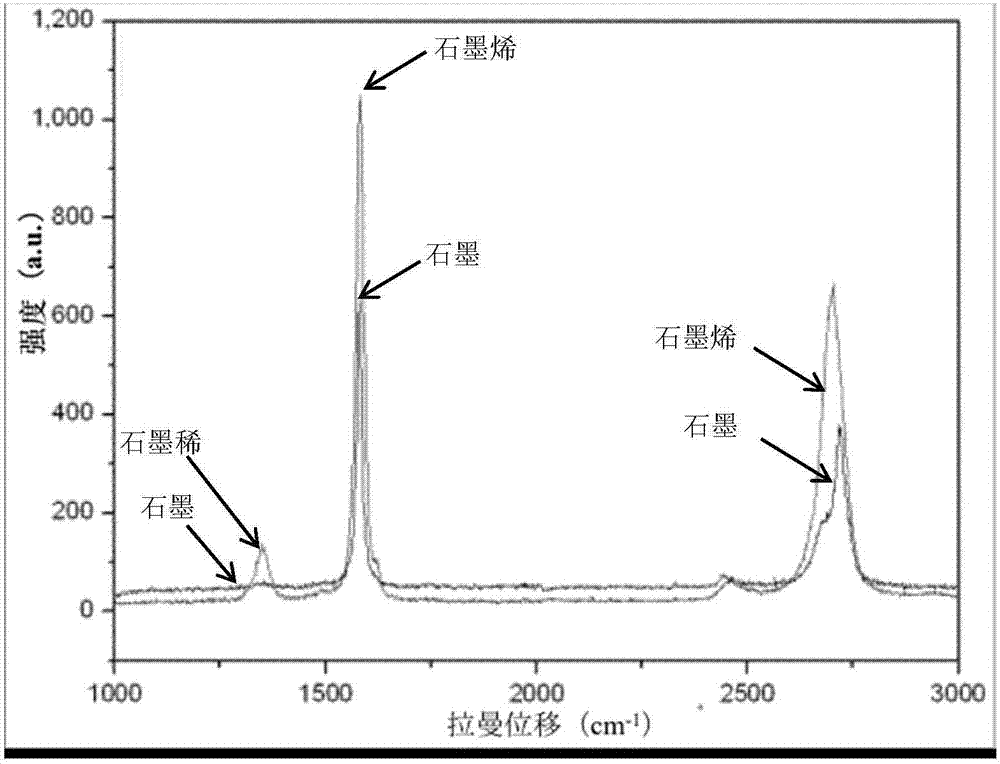

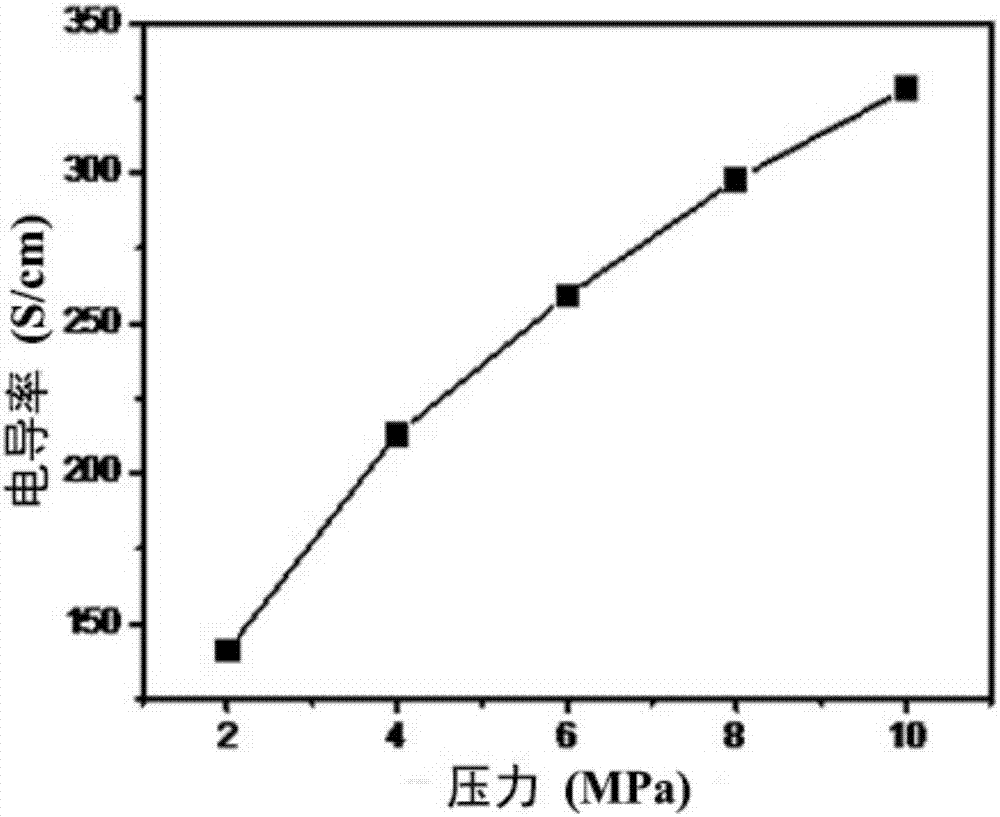

Peeling method of layered material and high-quality peeling material obtained by peeling

The invention discloses a peeling method of a layered material and a high-quality peeling material obtained by peeling. The method comprises the following steps: 1) mixing the layered material and anintercalating agent to achieve infiltration of the layered material by the intercalating agent; 2) adding an activating agent to allow the activating agent reacted with the intercalating agent, so that the physical impact of a generated gas flow on the layered material causes the sheet layers of the layered material to peel, thereby resulting in a dispersion solution of a peeling material precursor; and 3) mixing the obtained dispersion solution of the peeling material precursor with a dispersion medium, and performing physical disintegration on the obtained dispersion system so as to obtain adispersion solution of the peeling material. According to the peeling method, the gas flow compact generated by the violent reaction of the intercalating agent and the activating agent which are intercalated on the sheet layer surfaces and at the interlaminations is used to overcome a force between the sheet layers to realize expansion peeling, so that the peeling material with less layer and high quality is obtained; and the process is simple, the production cycle is short, and high efficiency mass production of the peeling material can be realized.

Owner:哈尔滨万鑫石墨谷科技有限公司

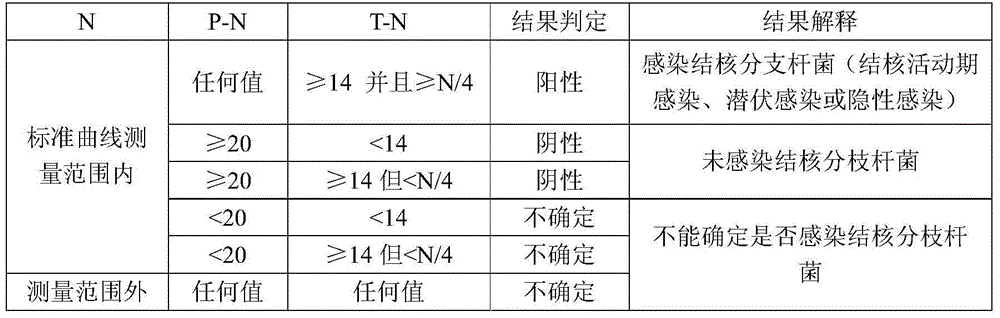

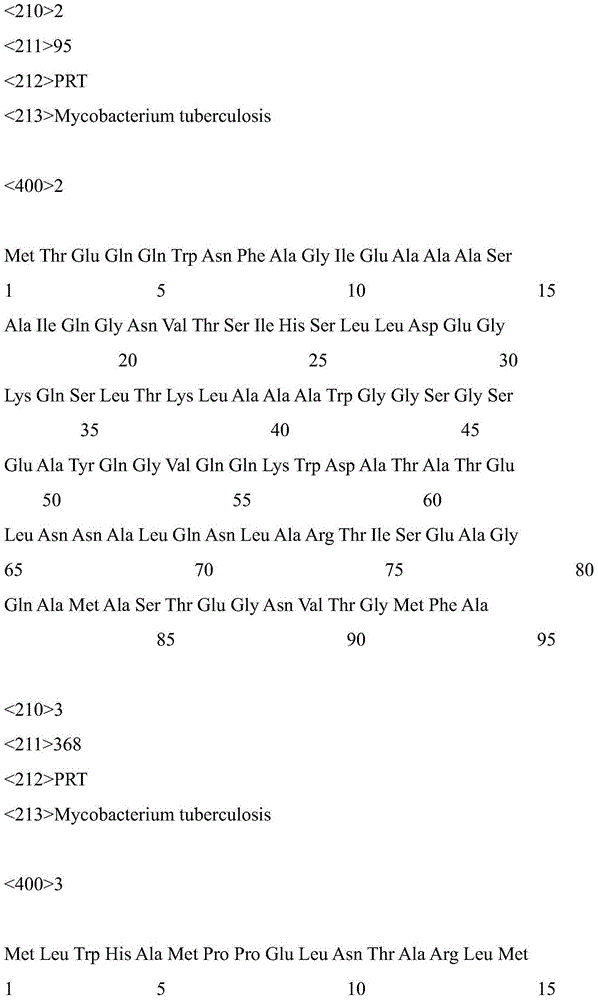

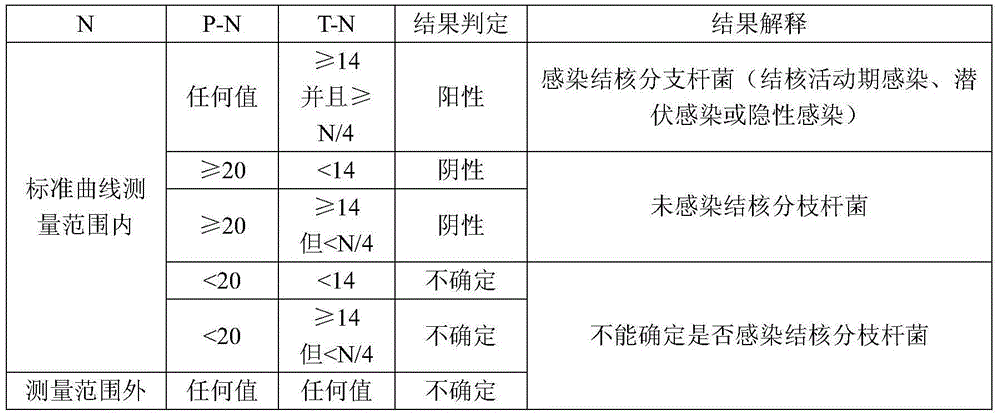

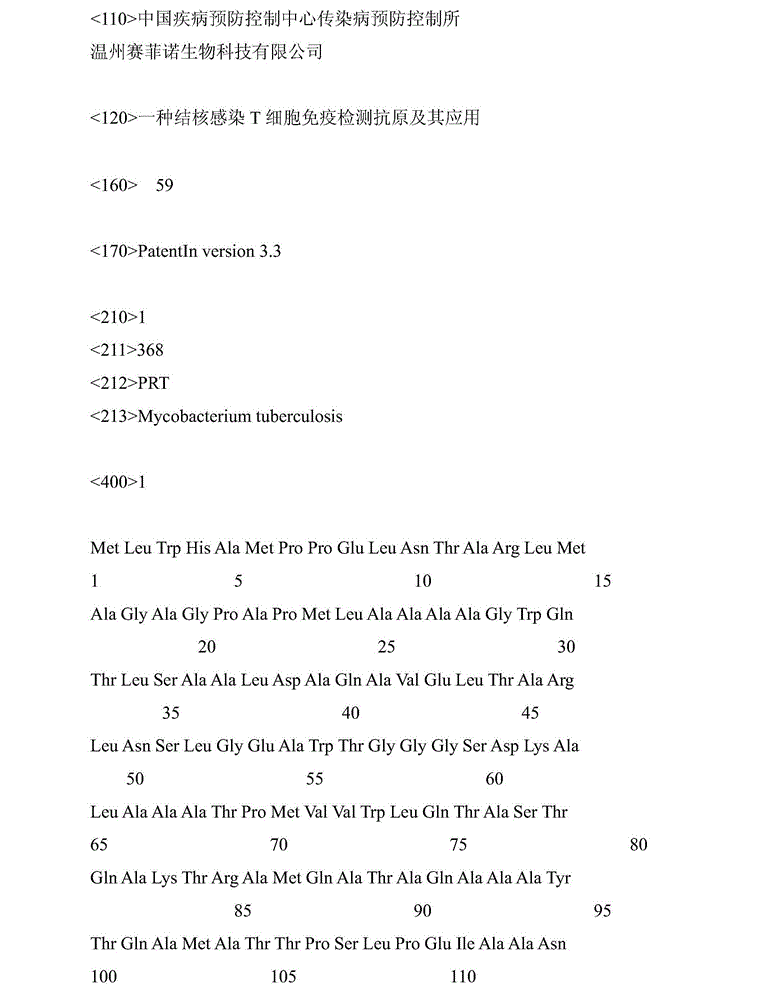

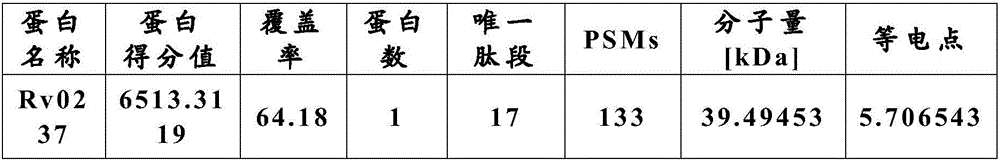

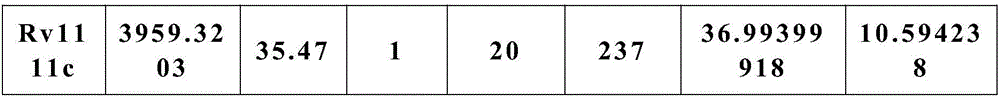

Antigen composition used for immunodetection of tuberculosis infected cell and application thereof

ActiveCN104628833AIncrease reaction strengthHigh strengthAntibacterial agentsBacterial antigen ingredientsInfected cellEpitope

The invention provides an antigen composition used for immunodetection of a tuberculosis infected cell. The antigen composition comprises mycobacterium tuberculosis CFP-10, ESAT-6 and Rv3873 antigens and / or antigen epitope peptides derived from the antigens. In an optimized embodiment, the antigen composition comprises all the antigen epitope peptides contained in the mycobacterium tuberculosis CFP-10, ESAT-6 and Rv3873 antigens. The invention also provides an application of the antigen composition to preparation of detection reagents used for detecting specific T cell immune response caused by tuberculosis infection in vitro. After lymphocytes of human or animals are stimulated by the antigen composition, cell factors secreted by a tuberculosis specific T cell are detected.

Owner:ICDC CHINA CDC +1

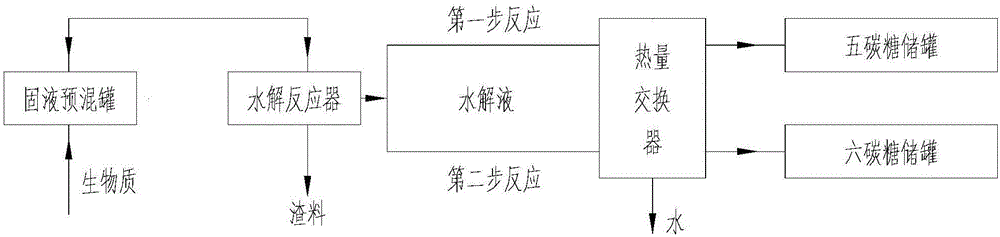

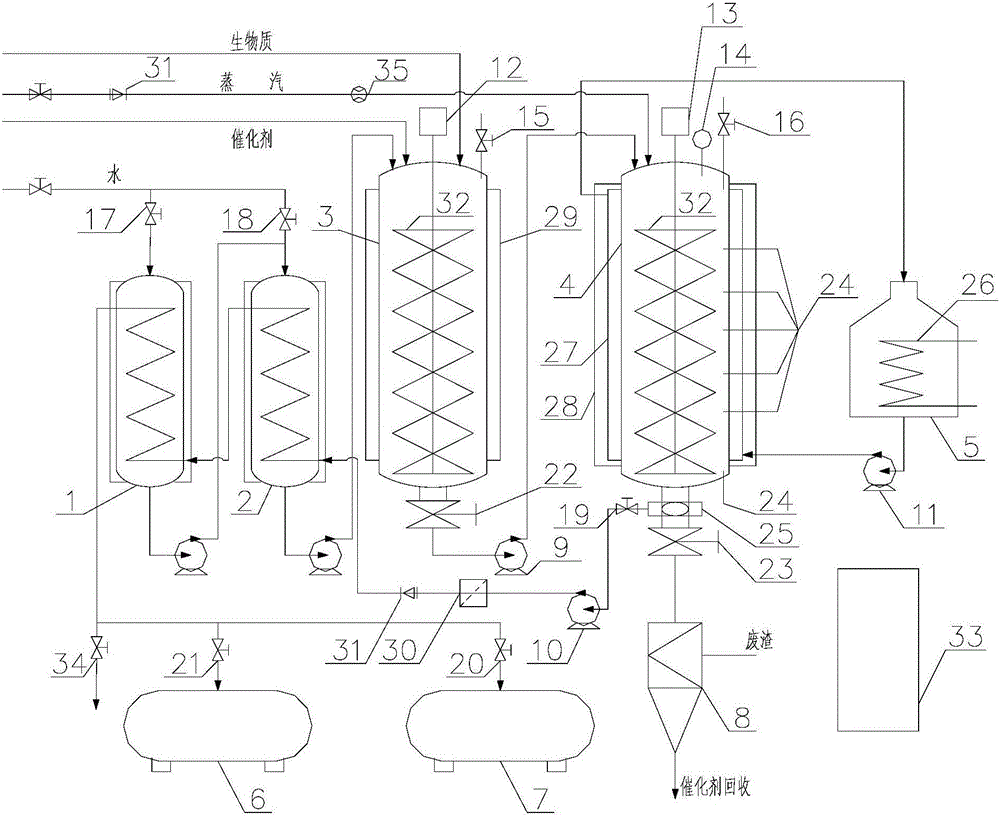

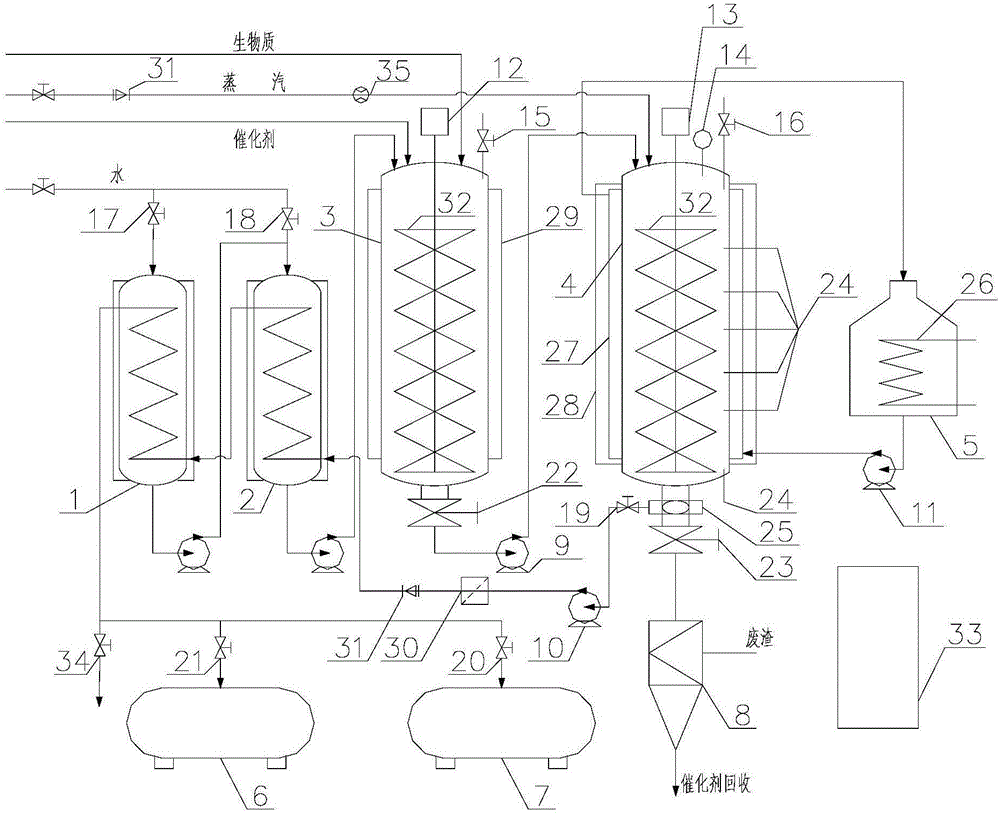

Method for hydrolyzing biomasses in two steps by utilizing carbon-based solid acid catalyst

ActiveCN106222314AFully hydrolyzedIncrease reaction strengthXylose productionGlucose productionHydrolysateSolid acid

The invention discloses a method for hydrolyzing biomasses in two steps by utilizing a carbon-based solid acid catalyst. The method comprises the following steps: (1) putting the carbon-based solid acid catalyst and biomass materials into a reactor at the mass ratio of (2 to 5) : 1; adding water into the reactor at the mass ratio of the biomass materials of the water of 1 to (10 to 40); after heating a mixture to 120 DEG C to 150 DEG C, reacting for 2 to 3 hours; separating hydrolysate, discharging the hydrolysate into a storage tank for storing pentose, and storing; (2) adding water into the reactor at the mass ratio of the biomass materials of the water of 1 : (10 to 40); after heating the mixture to 140 DEG C to 180 DEG C, reacting for 2 to 4 hours; separating hydrolysate, discharging the hydrolysate into a storage tank for storing hexose, and storing; (3) emptying the materials in the reactor and preparing for the next reaction cycle. According to the method disclosed by the invention, hemicellulose and cellulose in the biomass materials can be effectively catalyzed and be subjected to a hydrolysis reaction, and the method has the characteristics of high hydrolysis rate and high sugar yield.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Dewatered sludge curing agent and preparing method and using method thereof

ActiveCN105254166AHigh compressive strengthWide variety of sourcesSludge treatment by de-watering/drying/thickeningSlagDewatered sludge

The invention discloses a dewatered sludge curing agent and a preparing method and using method thereof and belongs to the technical field of environment engineering. The mass ratio of phosphate ore, carbide slag, tailing slag and marble slag in the dewatered sludge curing agent is (1-3) : (1-3) : (1-3) : (1-3). The preparing method comprises the steps of washing, drying, breaking and ball-milling phosphate ore, carbide slag, tailing slag and marble slag and then mixing phosphate ore, carbide slag, tailing slag and marble slag evenly in proportion. According to the using method of the dewatered sludge curing agent, dewatered sludge and the added dewatered sludge curing agent are evenly stirred in proportion to achieve curing. The compressive strength of cured dewatered sludge can reach 78 KPa after cured dewatered sludge is cured under a membrane for three days at normal temperature and normal pressure, and pH of leachate is 5-10. According to the dewatered sludge curing agent, solid waste is taken as the raw material, the sources of the raw material are wide, the cost of the raw material is low, and curing stability of dewatered sludge is realized by means of the chemical property of solid waste and mutual active excitation.

Owner:LIAONING TECHNICAL UNIVERSITY

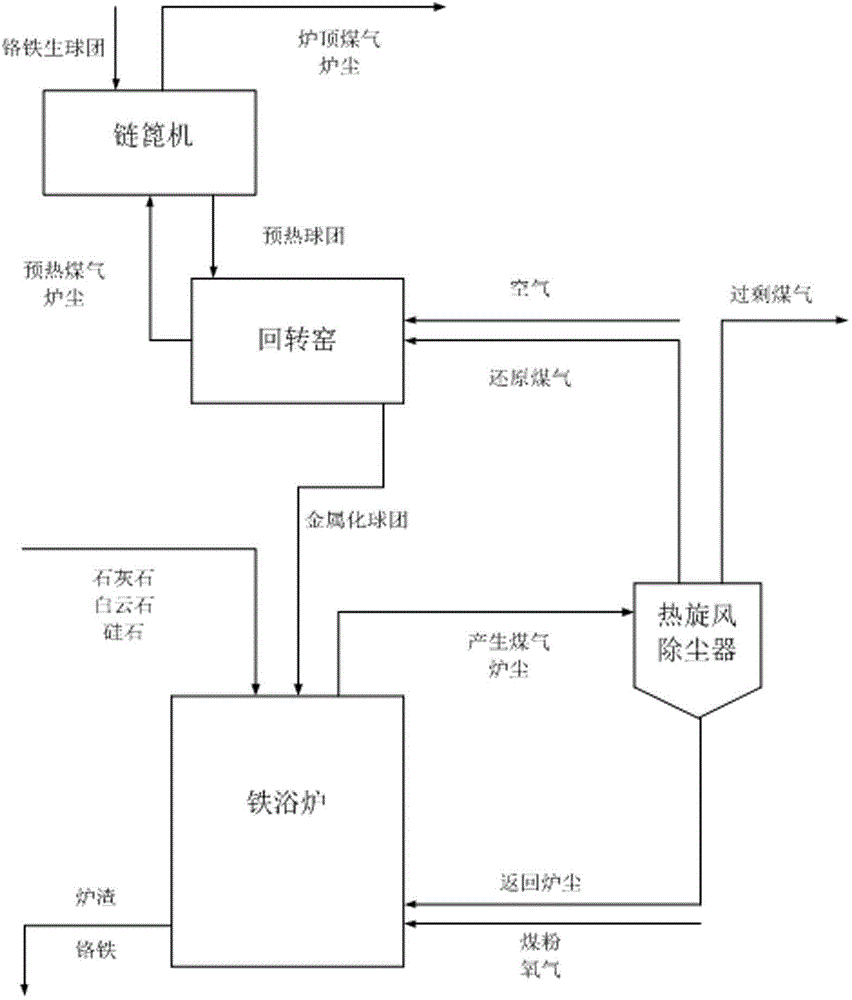

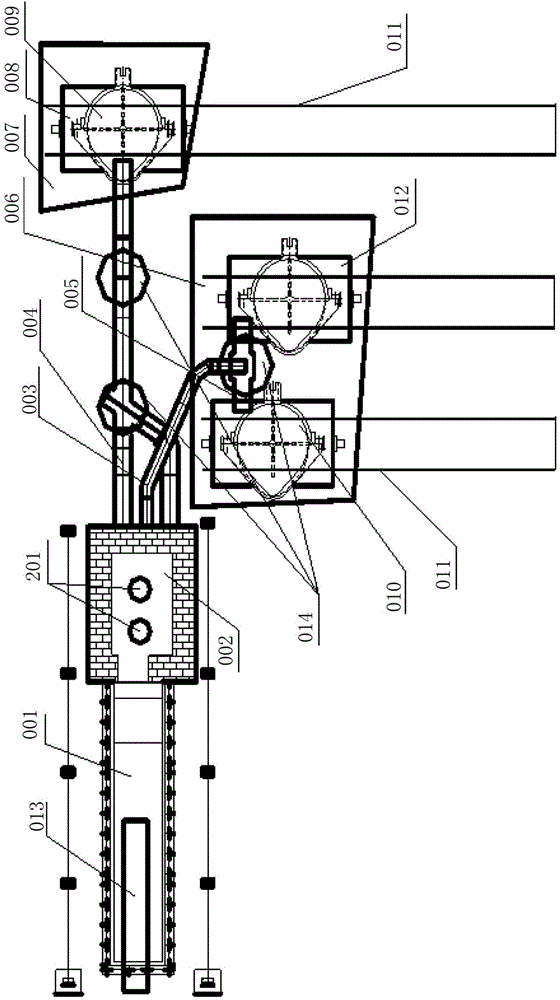

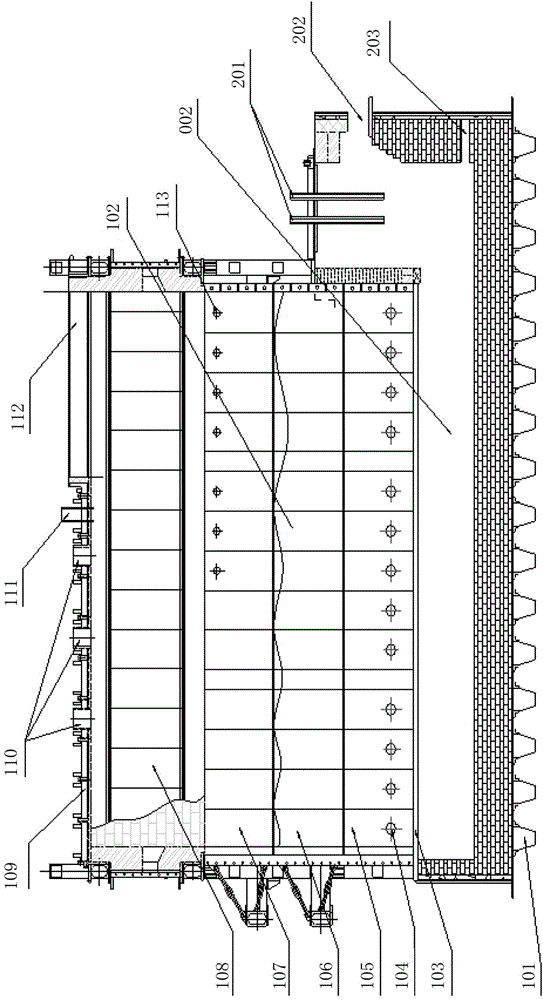

Method for producing ferrochromium alloy by two-step-process smelting reduction of ferrochromium mineral powder

The invention discloses a method for producing a ferrochromium alloy by two-step-process smelting reduction of ferrochromium mineral powder. The method comprises the following steps: (1) preparing raw materials, namely uniformly mixing the ferrochromium mineral powder with coke powder, and pelletizing on a disk pelletizing machine; (2) performing pre-reduction, namely uniformly distributing green pellets on a chain grate, preheating and drying the green pellets, loading the green pellets which are preheated and dried into the rotary kiln for pre-reduction, and burning by using coal gas generated by a final reduction section iron bath furnace for heat supply, wherein an adopted heat source is kiln tail waste gas from a rotary kiln; (3) performing final reduction, namely adding high-temperature pre-reduction pellets from the top of the iron bath furnace through a spiral discharger, thermally loading the pellets into the iron bath furnace for melt separation, spraying coal powder and oxygen into an iron bath by utilizing a coal oxygen spraying gun, burning the coal powder and the oxygen in the iron bath, supplying heat needed by the melt separation, after the melt separation is completed, performing slag iron separation, and discharging iron and slag. According to the method, the ferrochromium mineral powder can be largely treated, and utilization of powder mines is improved, so that the production cost of the ferrochromium alloy is reduced, and large-scale production is facilitated.

Owner:WISDRI ENG & RES INC LTD

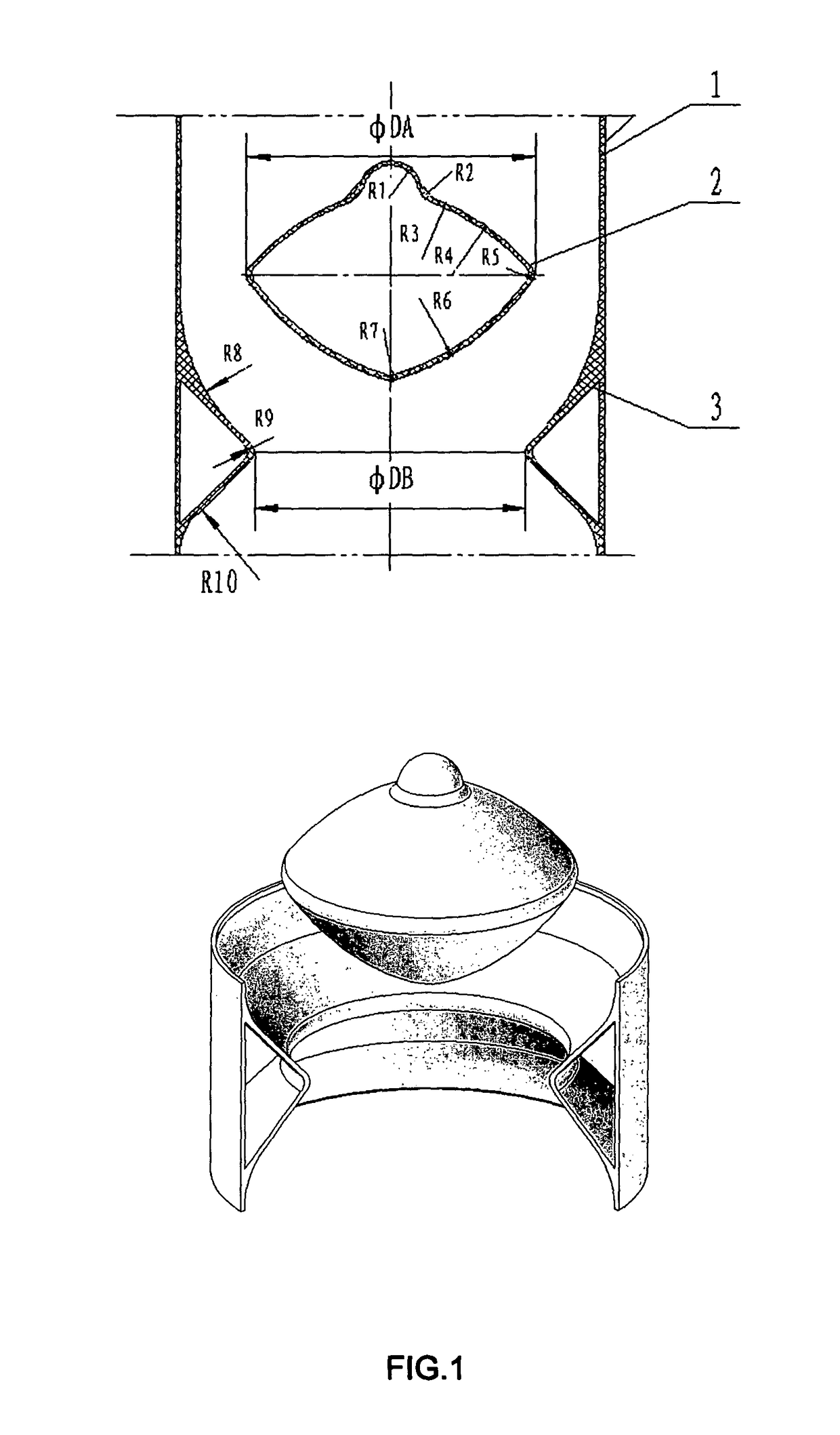

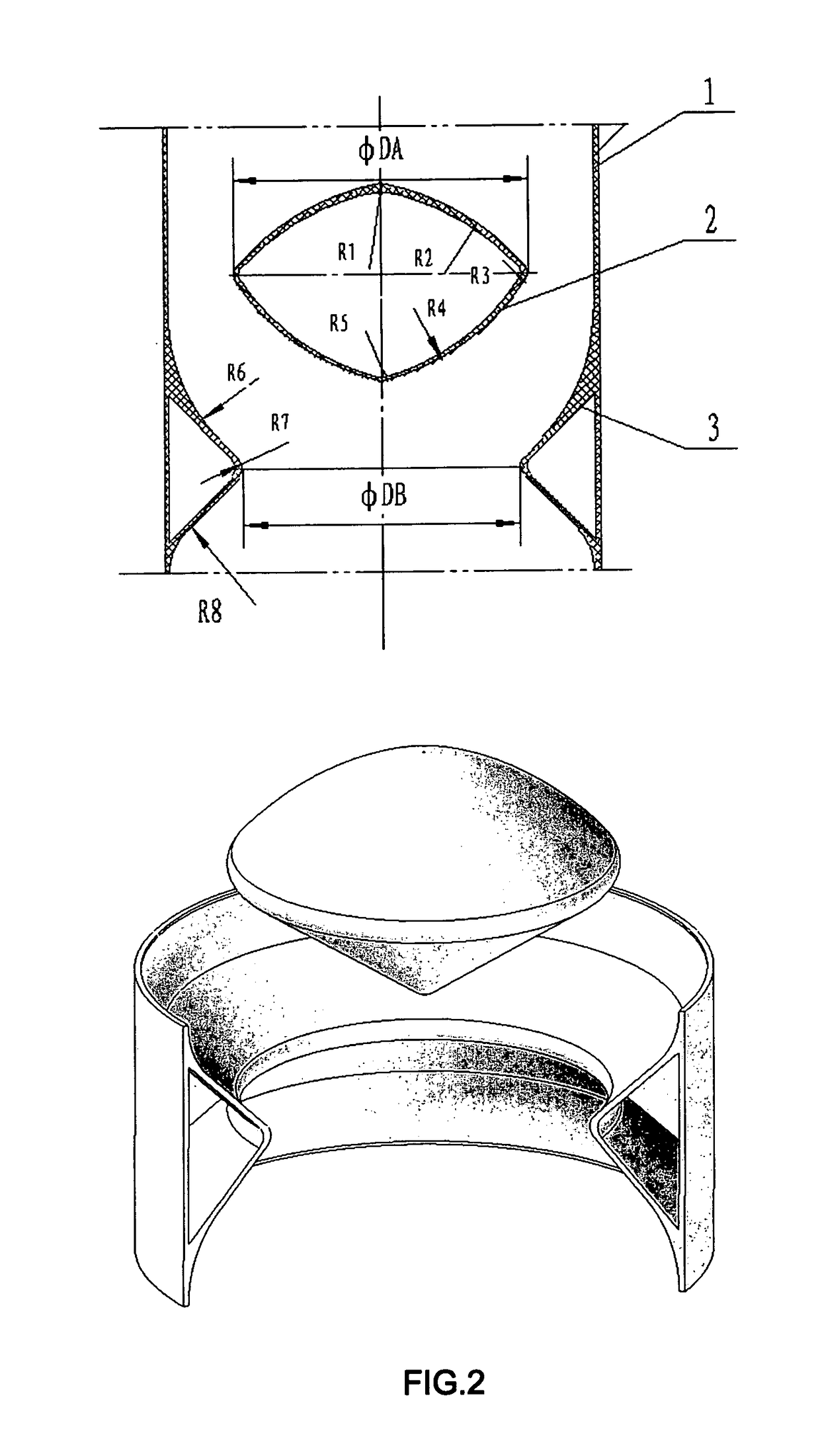

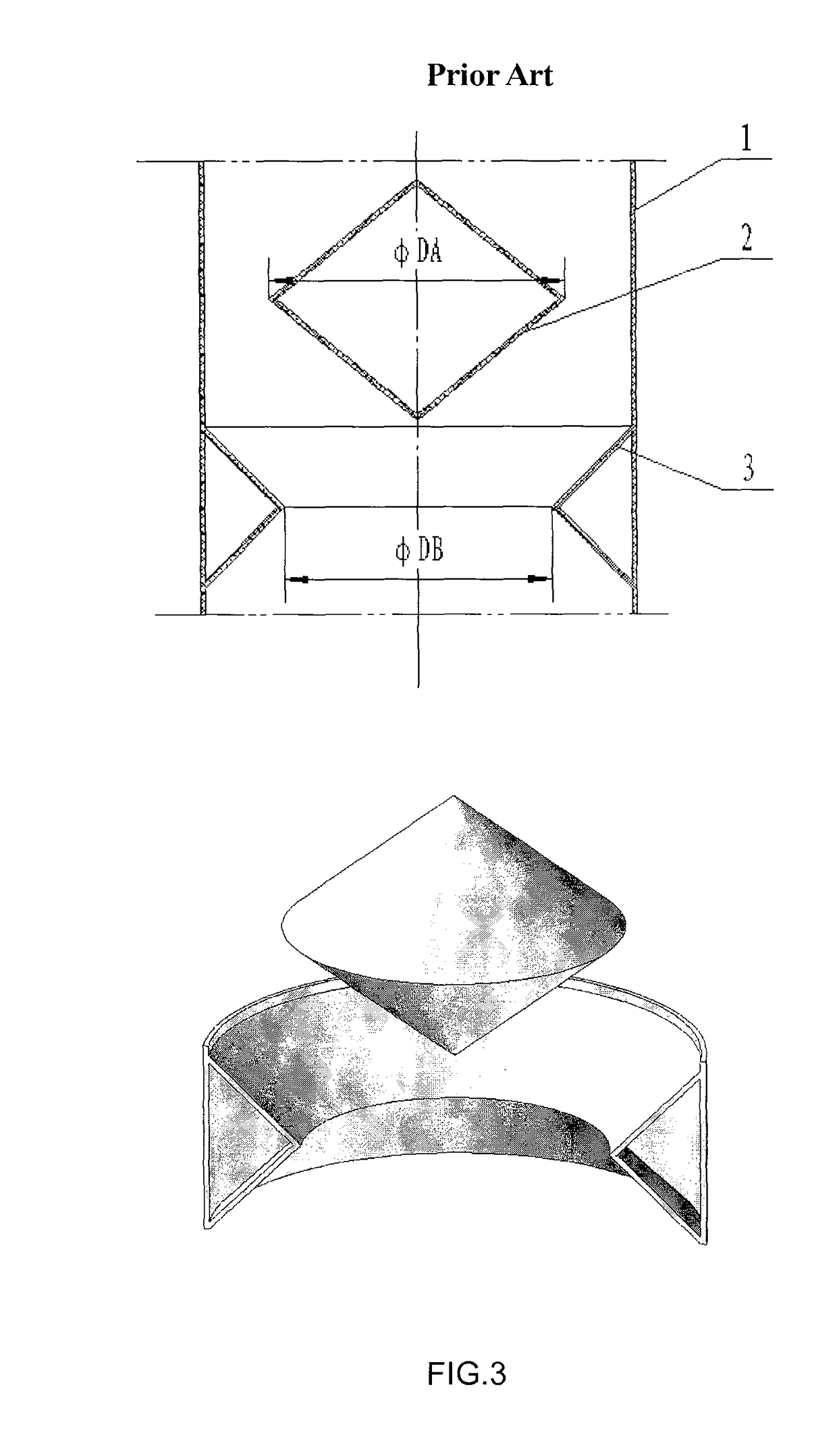

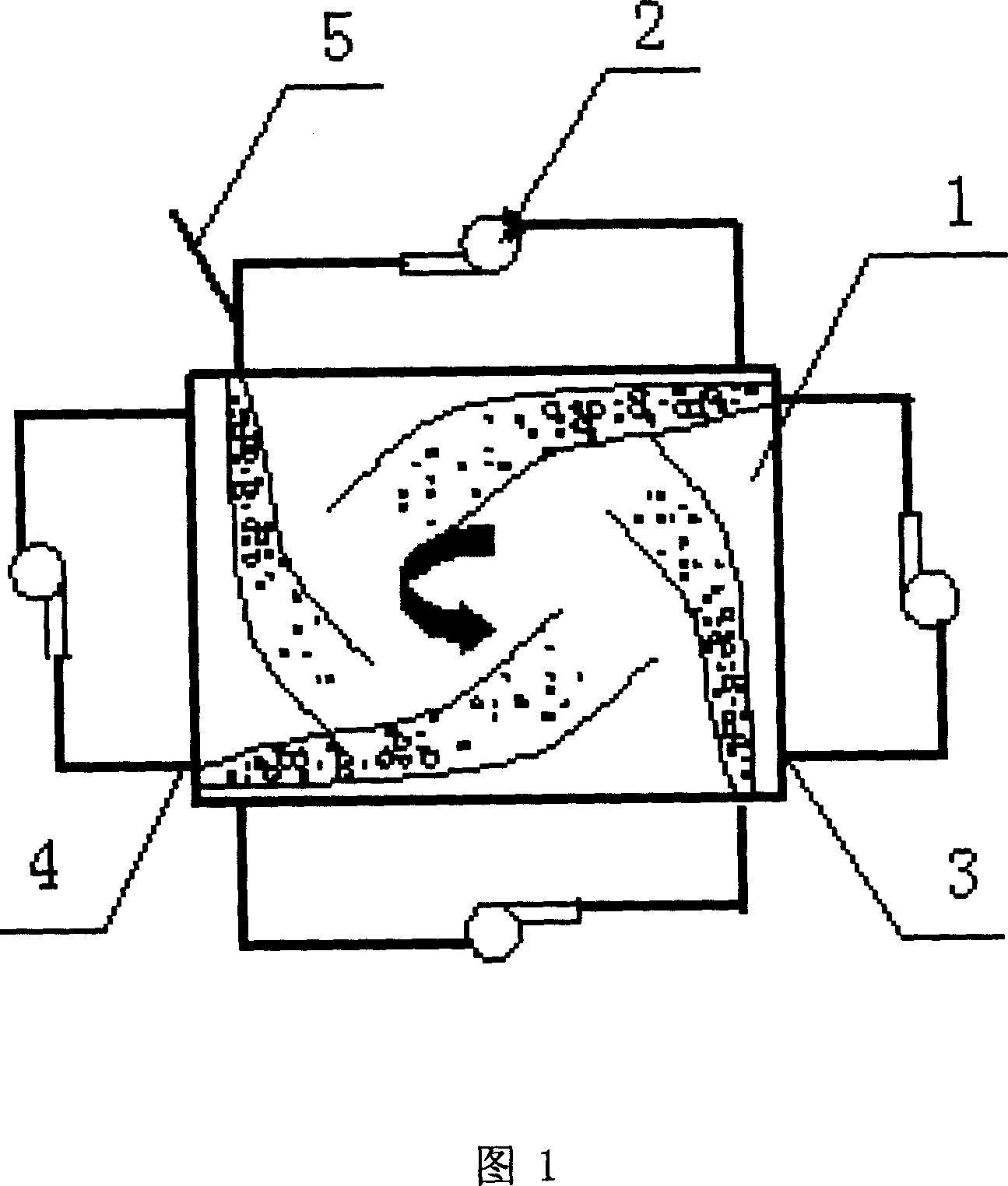

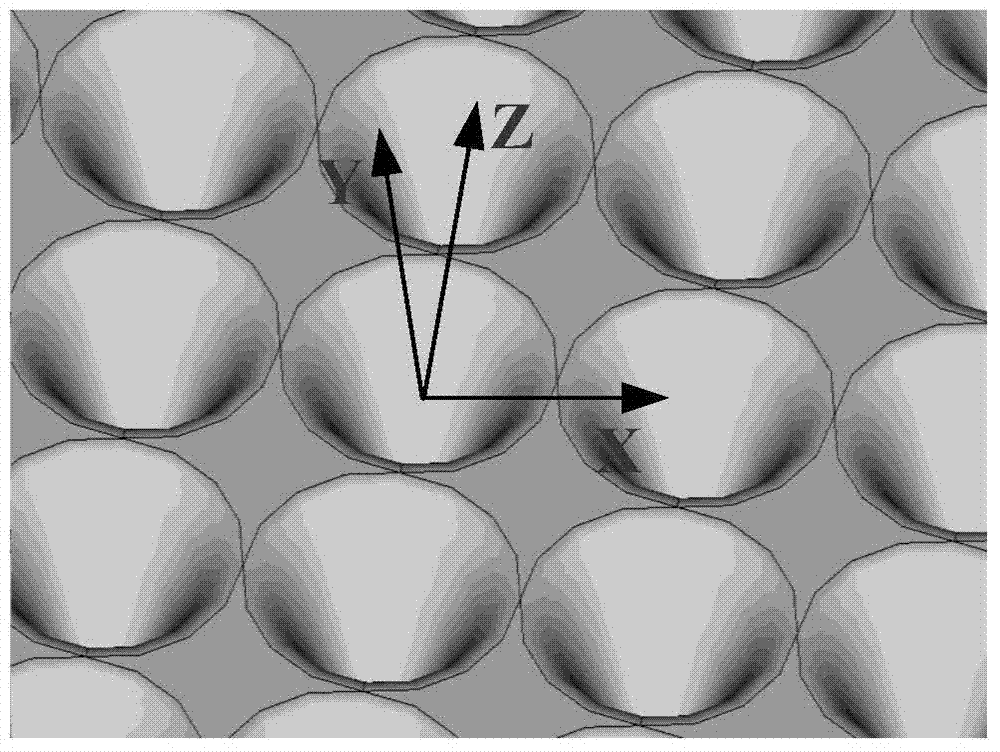

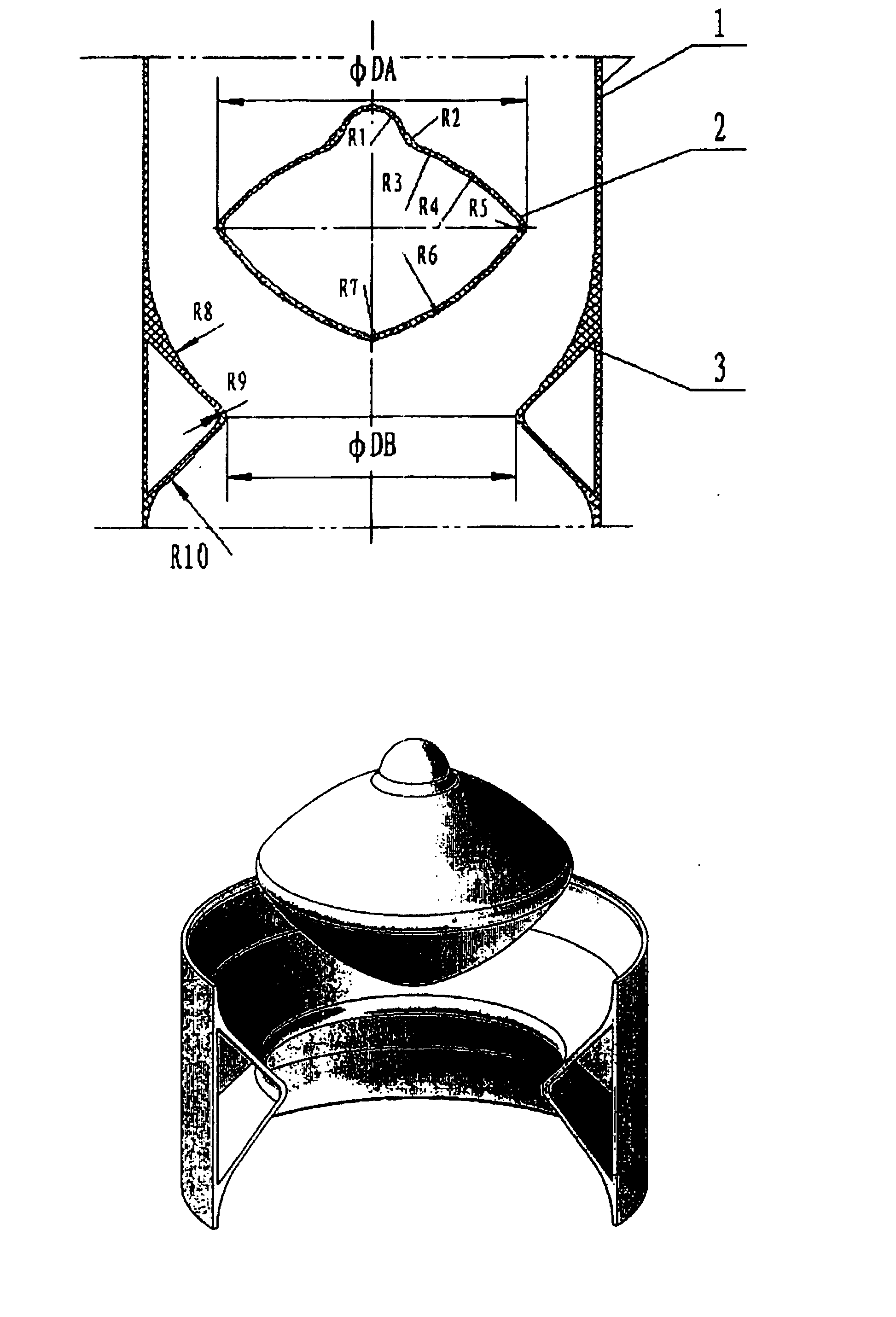

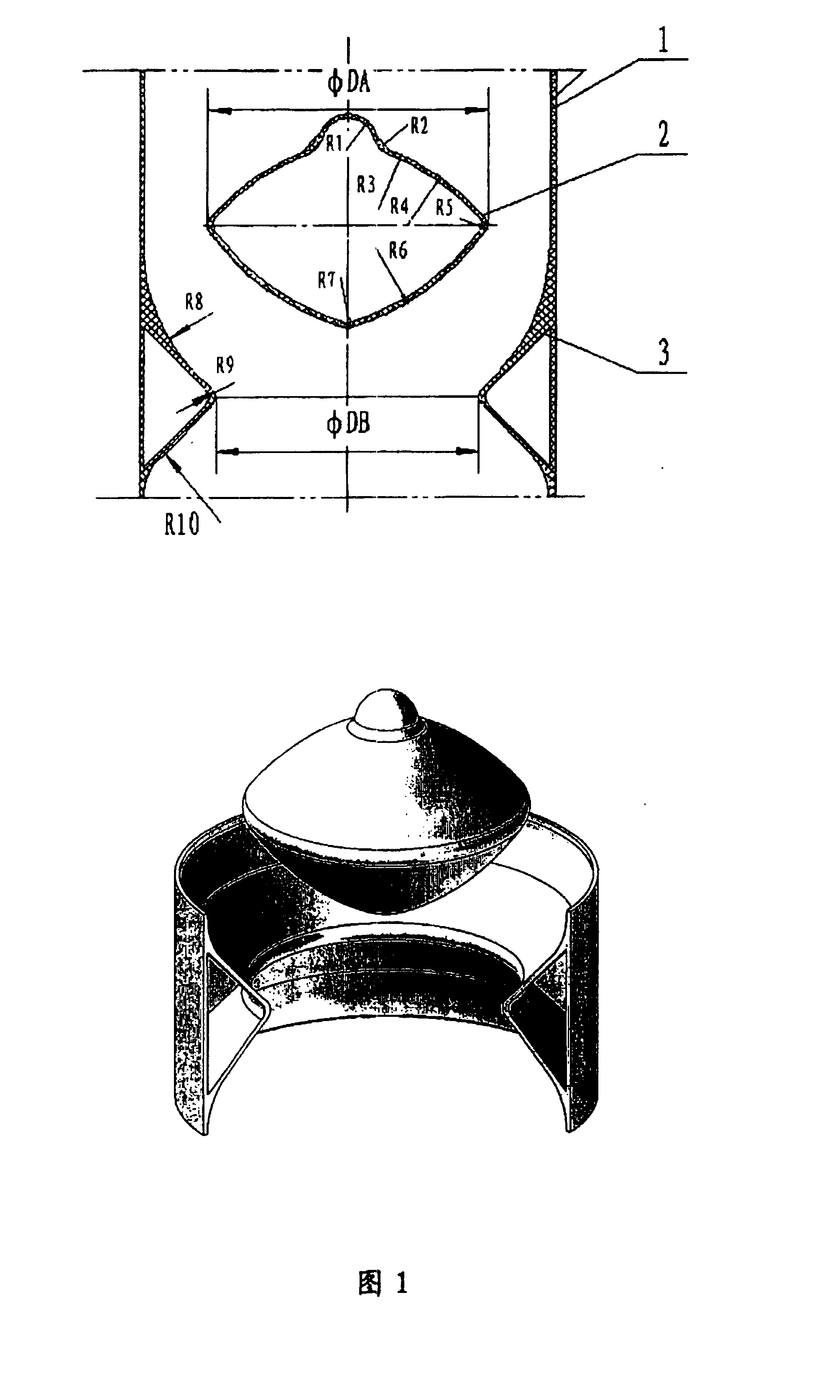

Multiphase reactor

ActiveUS8119083B2Simple structureIncrease reaction strengthFlow mixersDispersed particle separationFlue gasMaximum diameter

This invention relates to a multiphase reactor which is especially suitable for desulfurization of flue gas. A rotary build-in member comprising a axisymmetric body and an annular axisymmetric body is fixed on the shell of the reactor. The shell is cylindrical, and its surface is smooth or waved. The maximum diameter of the axisymmetric body is no less than the inner diameter of the annular axisymmetric body. The axisymmetric body is installed on the annular axisymmetric body coaxially. One rotary build-in member and its corresponding shell constitute an unit, and the reactor may have one or more such units. The multiphase reactor can effectively improve the flow pattern of the fluid and the contact of gas-liquid-solid three-phase of the reactants, speed up the mass transfer, and prevent deposition of the solid phase. The reactor is simple in structure and convenient for use. It can be used in the fields such as environmental protection, chemical engineering, metallurgy, and architectural industries.

Owner:SHI HANXIANG

Reaction system capable of hydrolyzing biomass through two steps by aid of carbon-based solid acid catalyst

ActiveCN106191327AFully hydrolyzedIncrease reaction strengthXylose productionGlucose productionXylanHydrolysate

The invention discloses a reaction system capable of hydrolyzing biomass through two steps by the aid of a carbon-based solid acid catalyst. Carbon-based solid acid is taken as a catalyst, biomass materials are completely hydrolyzed through a two-step reaction, and a xylose / xylan and glucose / glucose reaction system is obtained. By the use of the system, two-step hydrolysis of biomass materials can be realized under the condition that the operation strength in the reaction process is reduced, no corrosion is caused to a reaction device, follow-up waste liquids are not required to be neutralized, and the operation cost is reduced; after the reaction, heat of hydrolysate is recovered, and input of total heat of the system is reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

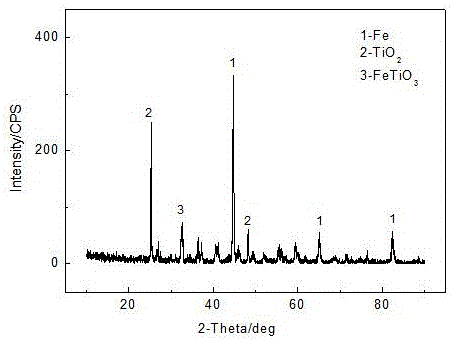

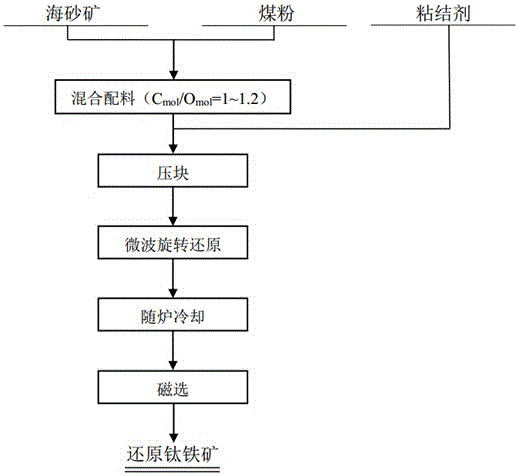

Method for preparing reduced ilmenite for welding electrodes by reducing marine placer through microwaves of rotary hearth furnace

The invention relates to a method for preparing reduced ilmenite for welding electrodes by reducing marine placer through microwaves of a rotary hearth furnace and belongs to the technical field of microwave metallurgy. The method comprises the steps that firstly, the marine placer and coal powder are mixed according to marine placer batch mixing to obtain a mixture, a bonding agent is added into the mixture and mixed evenly and are subjected to wet pressing to be made into green pellets, and the green pellets are dried; secondly, the dried pellets are placed into the microwave rotary hearth furnace for reduction for 10-30 min and then cooled to the room temperature; and thirdly, electromagnetic separation treatment is carried out on the pellets subjected to microwave rotating reduction at magnetic field intensity to obtain the reduced ilmenite, wherein fine coal powder, subjected to an incomplete reaction, in the welding electrodes is removed. According to the method, the rotary hearth furnace is used for block pressing treatment on carbon-containing pellets, so that the material contact area is increased, the reaction intensity is improved, and reduced ilmenite products, meeting the YB / T5141-93 technological requirements, for the welding electrodes are prepared.

Owner:KUNMING UNIV OF SCI & TECH

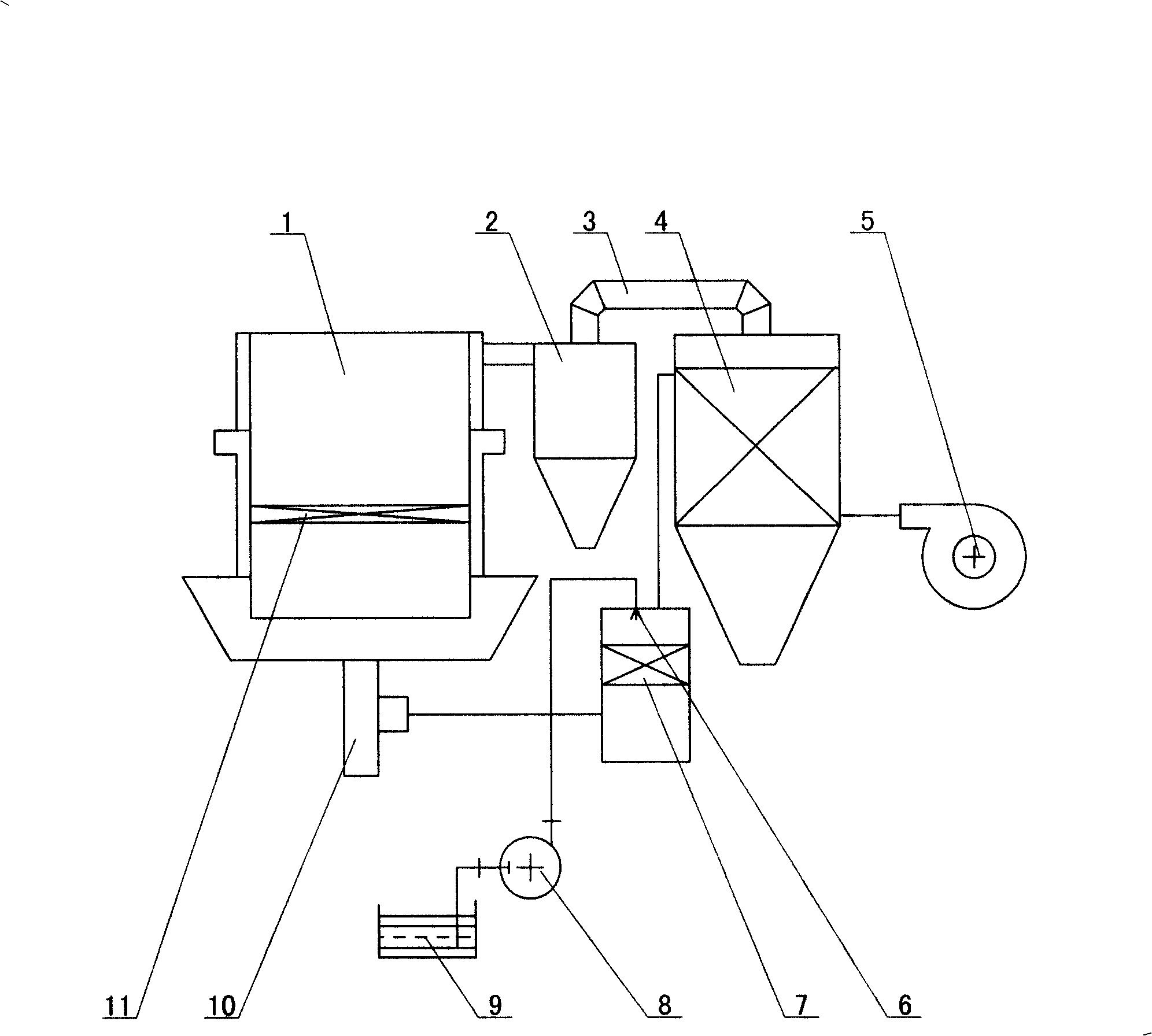

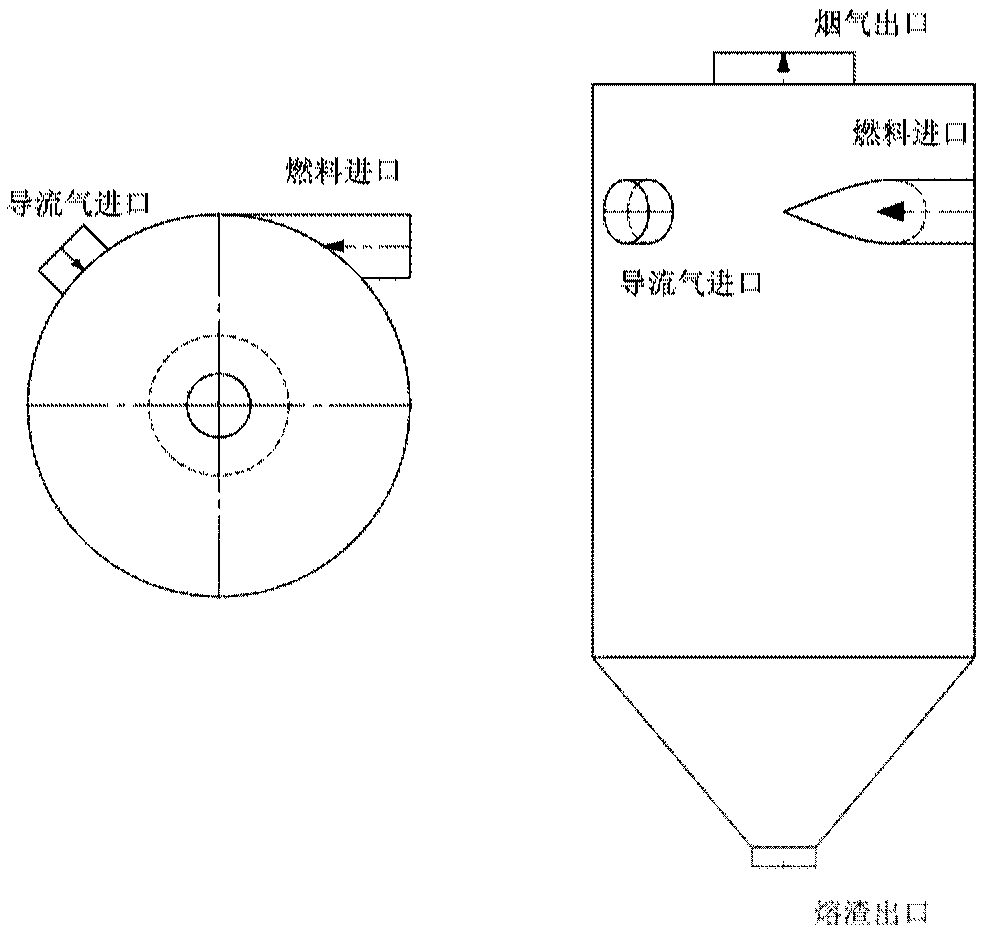

Spray cyclone bed type gas liquid solid tri-phase reactor

InactiveCN1962035AControl the sorting processIncrease profitDispersed particle separationChemical/physical processesCycloneGas liquid reaction

The invention relates to an injection cyclone bed gas-liquid-solid reactor, wherein it uses several circulate pumps, to pump out the slurry of slurry pool, to be accelerated by circulate pumps to form several high-speed flows and injected into the slurry pool at the circumference; then rotates the whole slurry pool. The invention can avoid using mixer, and the whole flow field is stable, to control the selection of solid particles easily. And the oxidization air is poured in the injector; the liquid and gas have large speed difference; the high-speed will break the bubble, to mix the liquid and gas fully, and improve their reaction; the gas forms screw track in slurry pool, to prolong its stay time in pool and improve the oxidization air utilization.

Owner:XI AN JIAOTONG UNIV

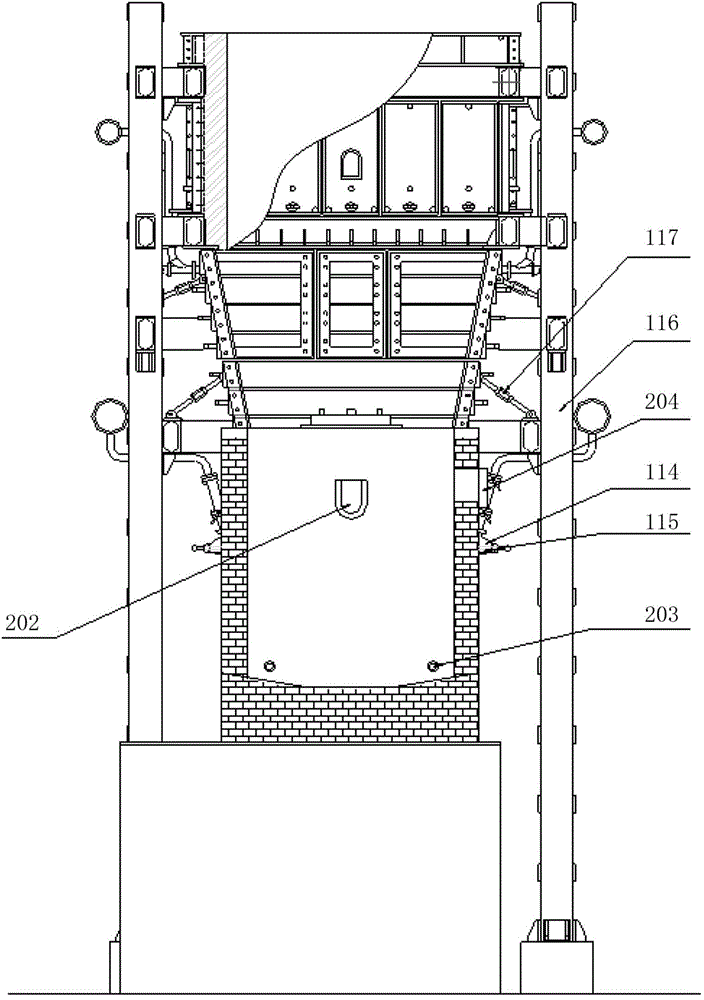

Copper smelting device with high-oxygen-enrichment double-side-blowing melting bat and operation method of copper smelting device

ActiveCN104593617AIncrease useful gas contentReduce take awayRotary drum furnacesCrucible furnacesMelting tankSlag

The invention relates to a copper smelting device with a high-oxygen-enrichment double-side-blowing melting bat and an operation method of the copper smelting device and belongs to the technical field of copper smelting devices and processes. According to the method, a large-volume hearth is used, the continuous production is performed, a single furnace is adopted so as to meet the periodic production of a PS converter, smelting slag continuously overflows from a smelting slag outlet and matte is directly discharged from a matte outlet formed in the bottom end of the hearth. During the smelting slag is discharged, the flowing direction of the smelting slag is controlled by virtue of a switching chute so that the smelting slag can be continuously discharged; the ratio of Fe to SiO2 in the smelting slag is controlled at 1.6-1.8, the ratio of a fuel to input materials is controlled at 2-2.5% and the content of copper in the smelting slag is less than or equal to 0.65%. The method has the characteristics of small construction investment, low production cost, good working environment, high degree of automation, high utilization rate of plant building and the like.

Owner:CHIFENG FUBANG COPPER

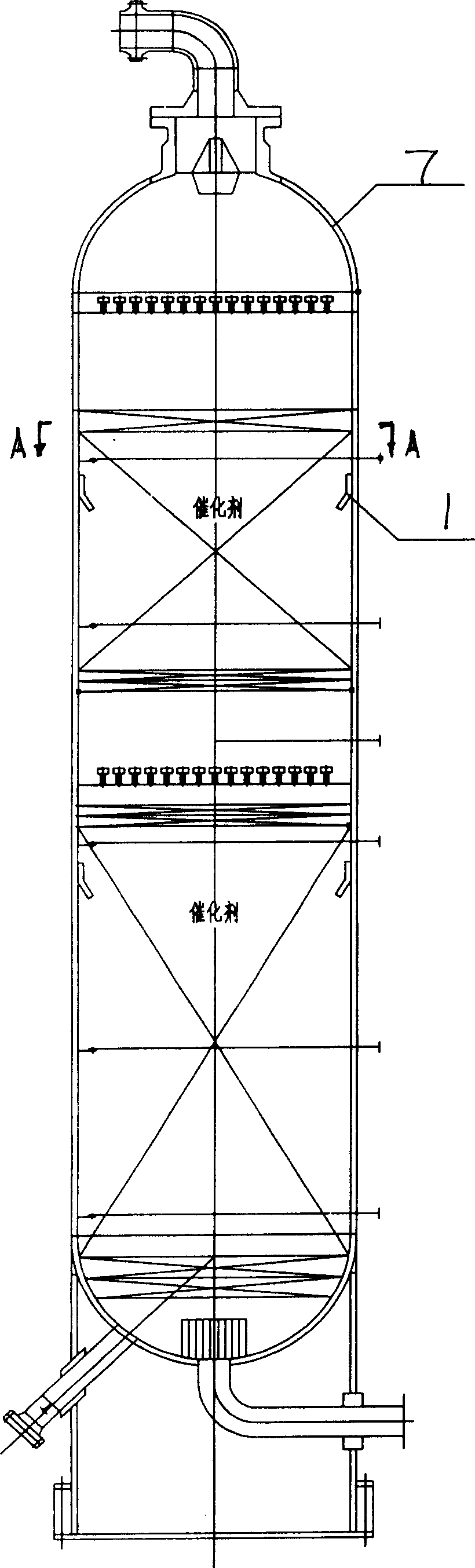

No wall flow technique and equipment for hydrogenation reaction chamber

ActiveCN1915482ASimple structureImprove sealingChemical/physical processesIt equipmentHydrogenation reaction

A technology for eliminating the wall flow of hydrogenating reactor to increase the output rate of reaction and its equipment are disclosed. A conic baffle disc whose diameter is the 3-7% of the internal diameter of reactor is installed above the catalyst bed in reactor in coaxial mode. The conic ring disc is fixed to the baffle cylinder by the connecting plate of fix regulating mechanism. Said baffle cylinder is fixed to inner wall of reactor. A sealing structure is arranged to external surface of said baffle cylinder.

Owner:中国寰球工程有限公司辽宁分公司

Radioactive material with alpha particle cascade decay, propelling plant adopting same and lotus seed propeller

ActiveCN104843198AReduce volumeReduce weightCosmonautic propulsion system apparatusNuclear engineeringHalf-life

The invention discloses a radioactive material with alpha particle cascade decay, a propelling plant adopting the same and a lotus seed propeller. The propelling plant generates propelling force in the mode that the adopted radioactive material radiates high-energy particles through an alpha particle cascade decay reaction. One gram of 242 Cm radioactive element with the half-life period being 163 days can provide propelling force of 3-5 muN, and One gram of 238 Pu radioactive element with the half-life period being 87 years can provide propelling force of 0.02 muN. The propelling plant which adopts the radioactive material and has a specific surface shape can provide propelling force in a specific direction which is perpendicular to the focus plane of the propelling plant. The radioactive material can provide stable propelling force for hundreds years, and is particularly suitable for micro propellers and high-power propellers.

Owner:XIANGTAN UNIV

Modified bamboo fiber enhanced PBT (polybutylene terephthalate) resin based cabinet board and preparation method thereof

InactiveCN106084841AHigh strengthGood compatibilityConjugated synthetic polymer artificial filamentsNon-woven fabricsMethacrylateFiber

The invention discloses a modified bamboo fiber enhanced PBT (polybutylene terephthalate) resin based cabinet board. The bamboo-plastic board is prepared from the following raw materials in parts by weight: 50 to 60 parts of modified bamboo fiber, 20 to 25 parts of PBT resin, 1 to 2 parts of hydroxyl silicone oil, 3 to 5 parts of maleic anhydride grafted polyester, 2 to 3 parts of asphalt-based mesocarbon microbeads, 0.1 to 0.2 part of antioxidants, 5 to 8 parts of ionic liquid and 1 to 2 parts of zinc methacrylate.

Owner:ZBOM HOME COLLECTION CO LTD

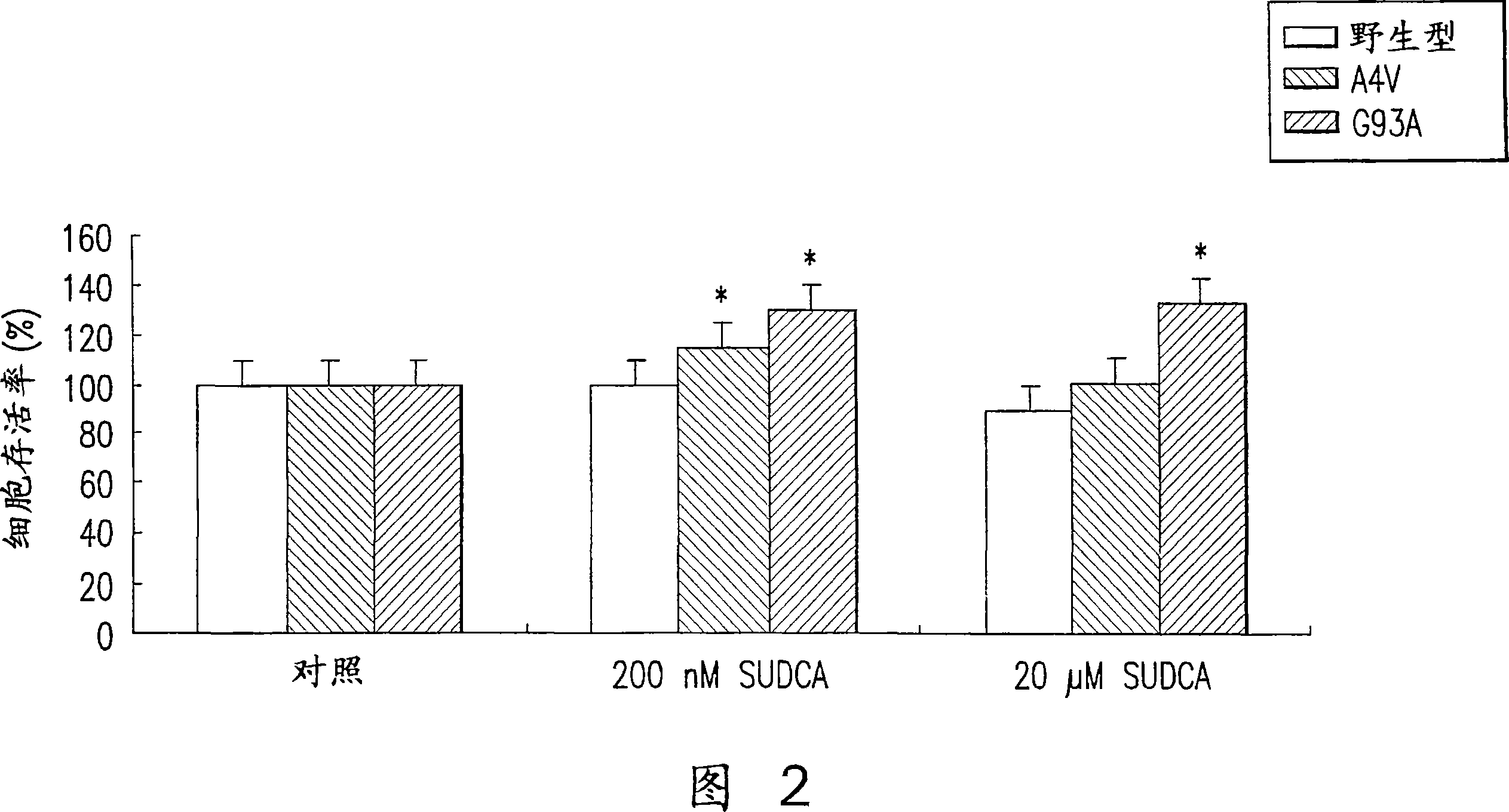

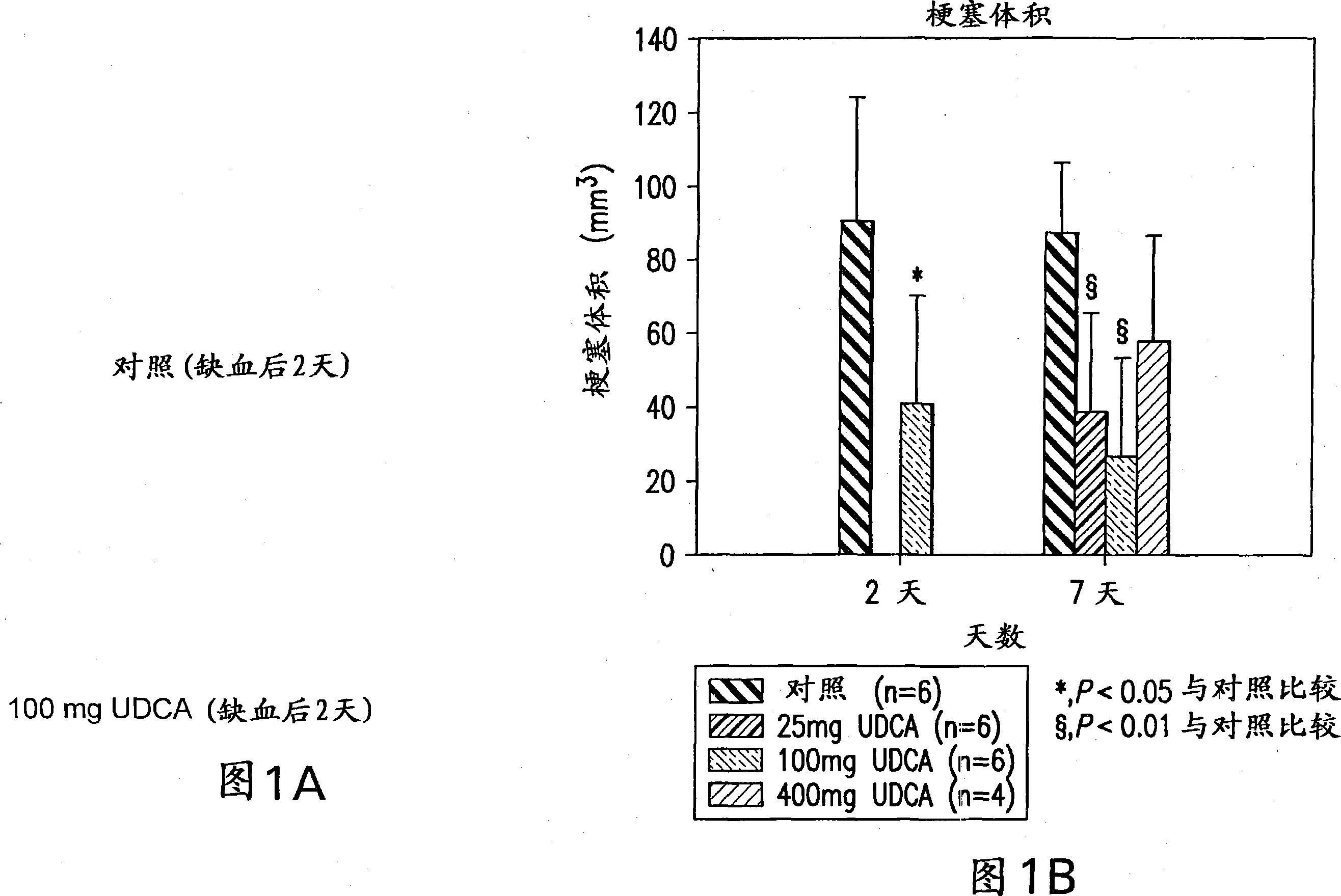

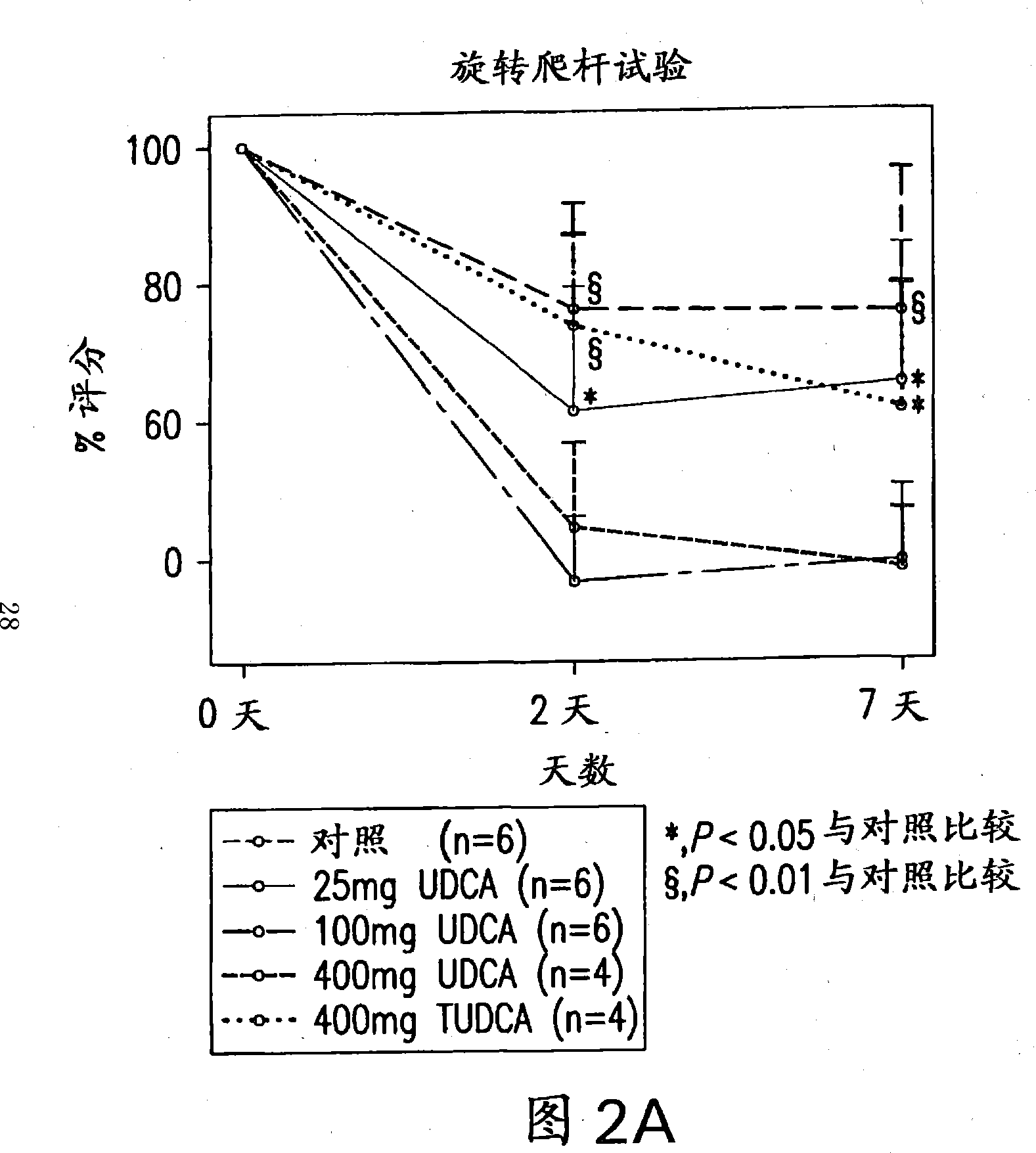

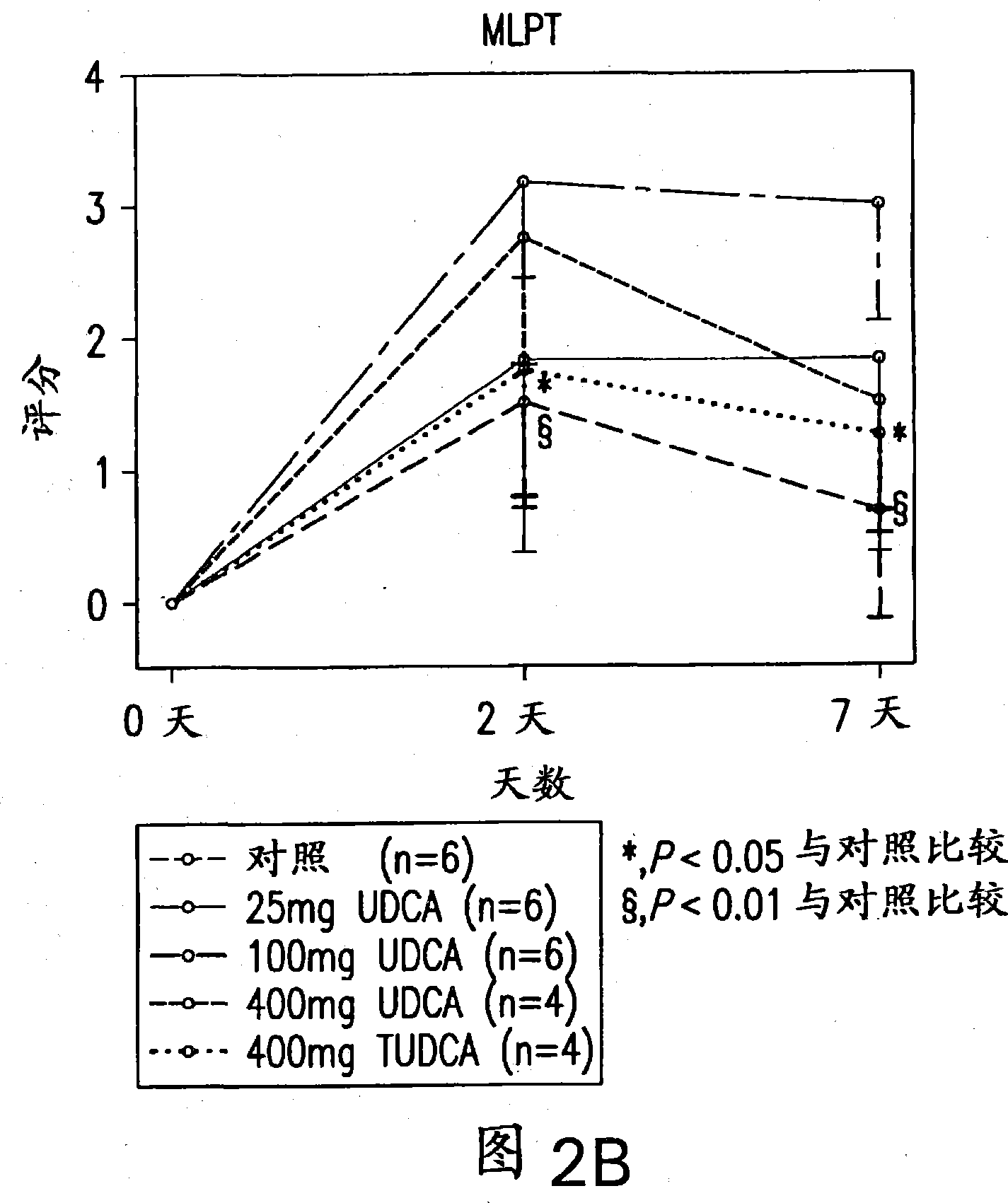

Neuroprotective effect of solubilized UDCA in focal ischemic model

InactiveCN101035541AIncrease reaction strengthLow toxicityOrganic active ingredientsNervous disorderBile acidFunctional recovery

The present disclosure provides compositions and methods for treating, ameliorating, or relieving at least one symptom associated with loss of blood flow to the brain including, without limitation, ischemic stroke. Compositions of the disclosure may comprise a bile acid compound and a carbohydrate, wherein both materials remain in solution for all pH values of the solution within a selected range of pH values. Symptoms may include infarct volume, functional recovery, apoptosis, and / or eNOS expression.

Owner:柳署弘

Antigen used for immunodetection of tuberculosis infected T cell and application thereof

ActiveCN104628834AReduce distractionsIncrease reaction strengthAntibacterial agentsBacterial antigen ingredientsInfected cellEpitope

The invention provides an antigen composition used for immunodetection of a tuberculosis infected cell. The antigen composition comprises a mycobacterium tuberculosis Rv3873 antigen and / or antigen epitope peptides derived from the antigen. In an optimized embodiment, the antigen composition comprises all the antigen epitope peptides contained in the mycobacterium tuberculosis Rv3873 antigen. The invention also provides an application of the antigen composition to preparation of detection reagents used for detecting specific T cell immune response caused by tuberculosis infection in vitro. After lymphocytes of human or animals are stimulated by the antigen composition, cell factors secreted by a tuberculosis specific T cell are detected.

Owner:ICDC CHINA CDC +1

Technology for coupling utilization and co-processing of organic and inorganic hazardous wastes

InactiveCN109402414AEfficient use ofReaching the goal of benefiting waste and not producing waste"Crucible furnacesIndirect carbon-dioxide mitigationSmelting processEngineering

The invention provides a technology for coupling utilization and co-processing of organic and inorganic hazardous wastes. The technology comprises the following steps: 1) pretreating raw materials; 2)blending and loading materials; 3) smelting in a smelting furnace; 4) treating exhaust gas. According to the invention, various organic and inorganic hazardous wastes are pretreated and blended and then are put into the smelting furnace for co-processing; the effective utilization of resources is extremely realized and the purpose of 'controlling pollution, generating no pollution, utilizing wastes and generating no wastes' is achieved in the manner of coupling utilization and co-processing of organic and inorganic hazardous wastes; an oxygen-enriching strengthening smelting process is adopted by the smelting furnace; a single system can be adopted for treating 100000t / a various inorganic hazardous wastes and 100000t / a various organic hazardous wastes; the total processing capacity is 200000t / a; the purpose of 'large-volume and multi-varieties' co-processing of various organic and inorganic hazardous wastes is achieved.

Owner:杨文

System and process for continuous industrial preparation of 3-chloropropylchlorosilanes

InactiveCN101139354AEfficient separationLess prone to cloggingGroup 4/14 element organic compoundsAllyl chlorideChemistry

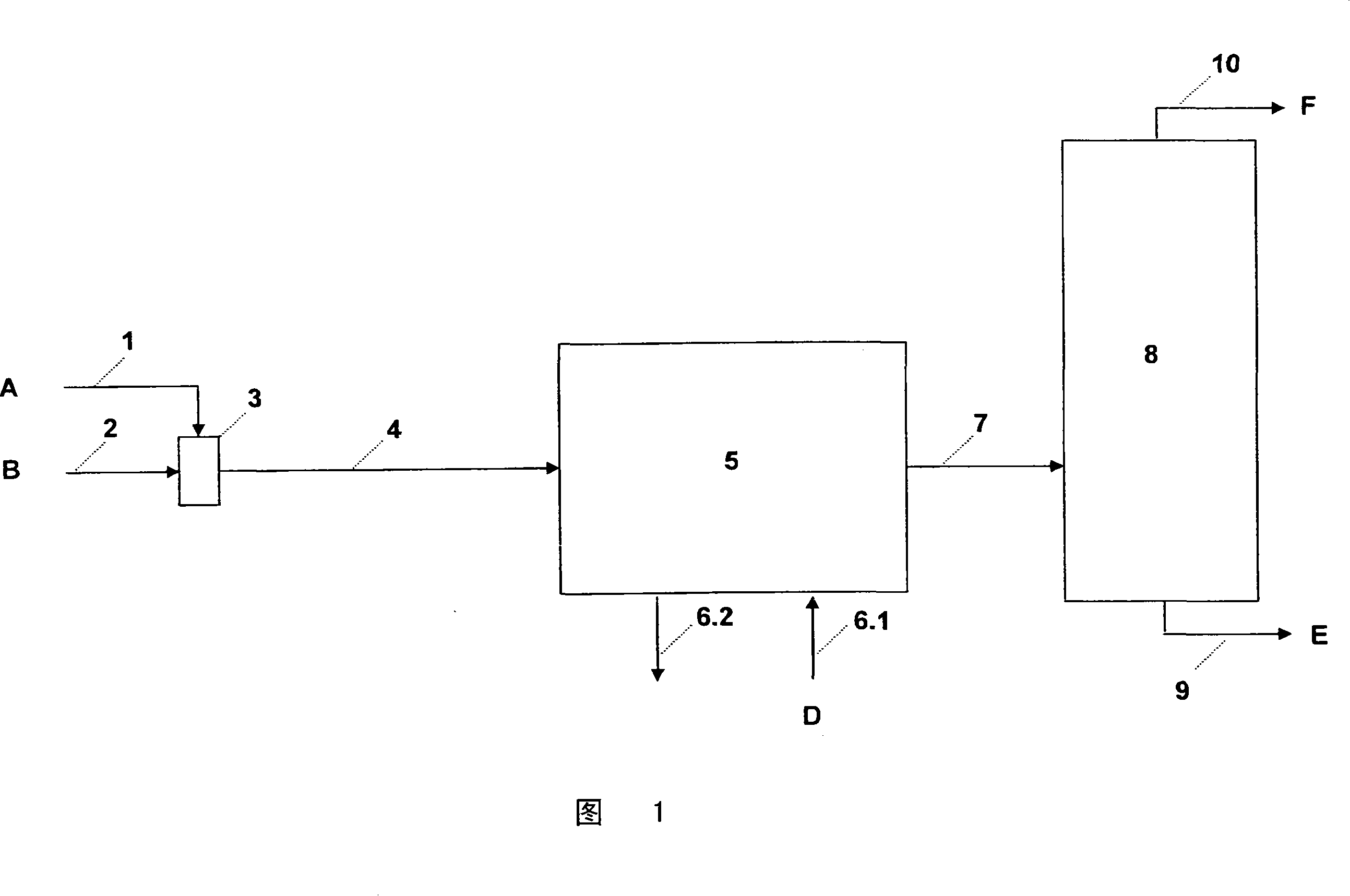

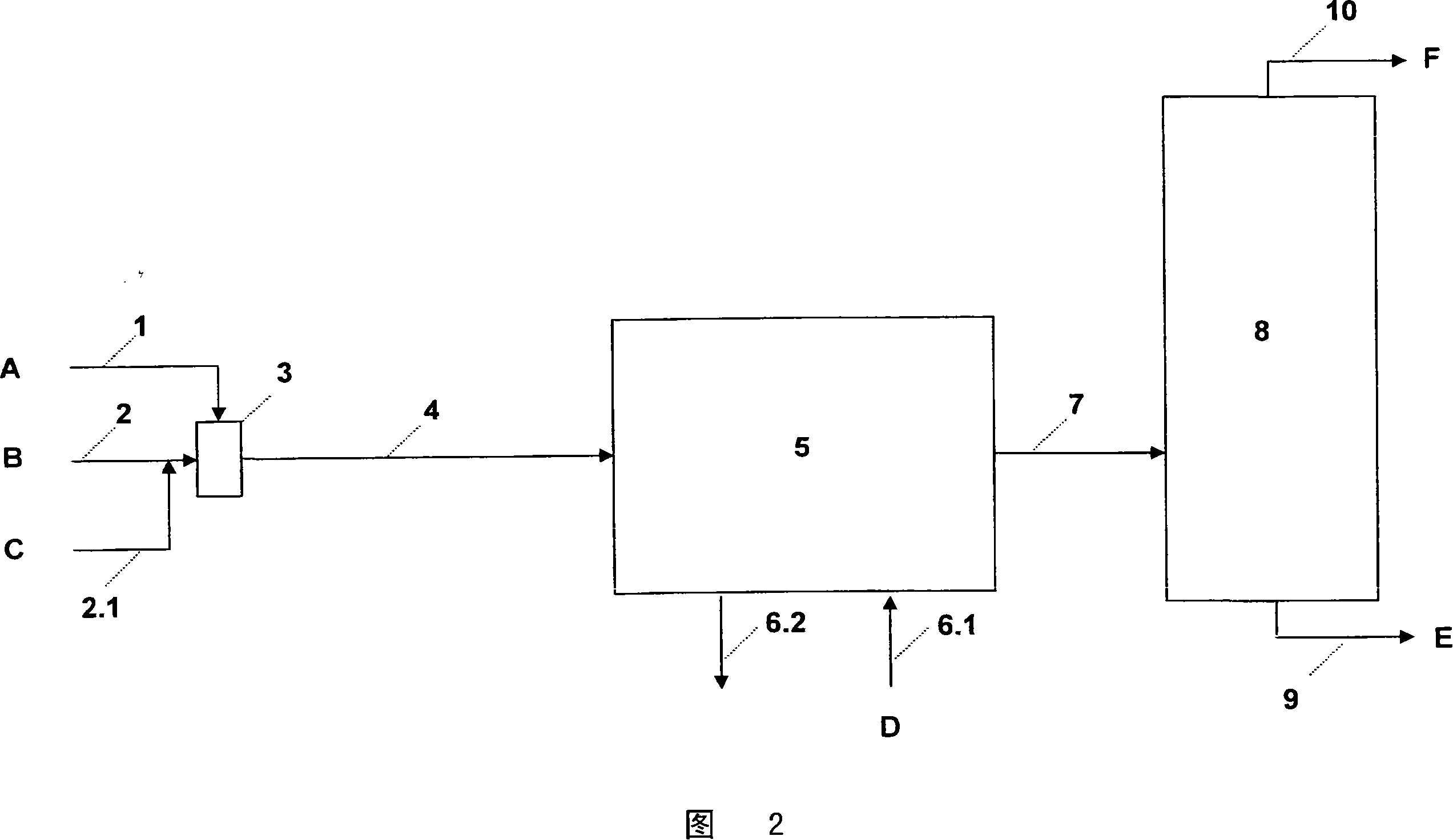

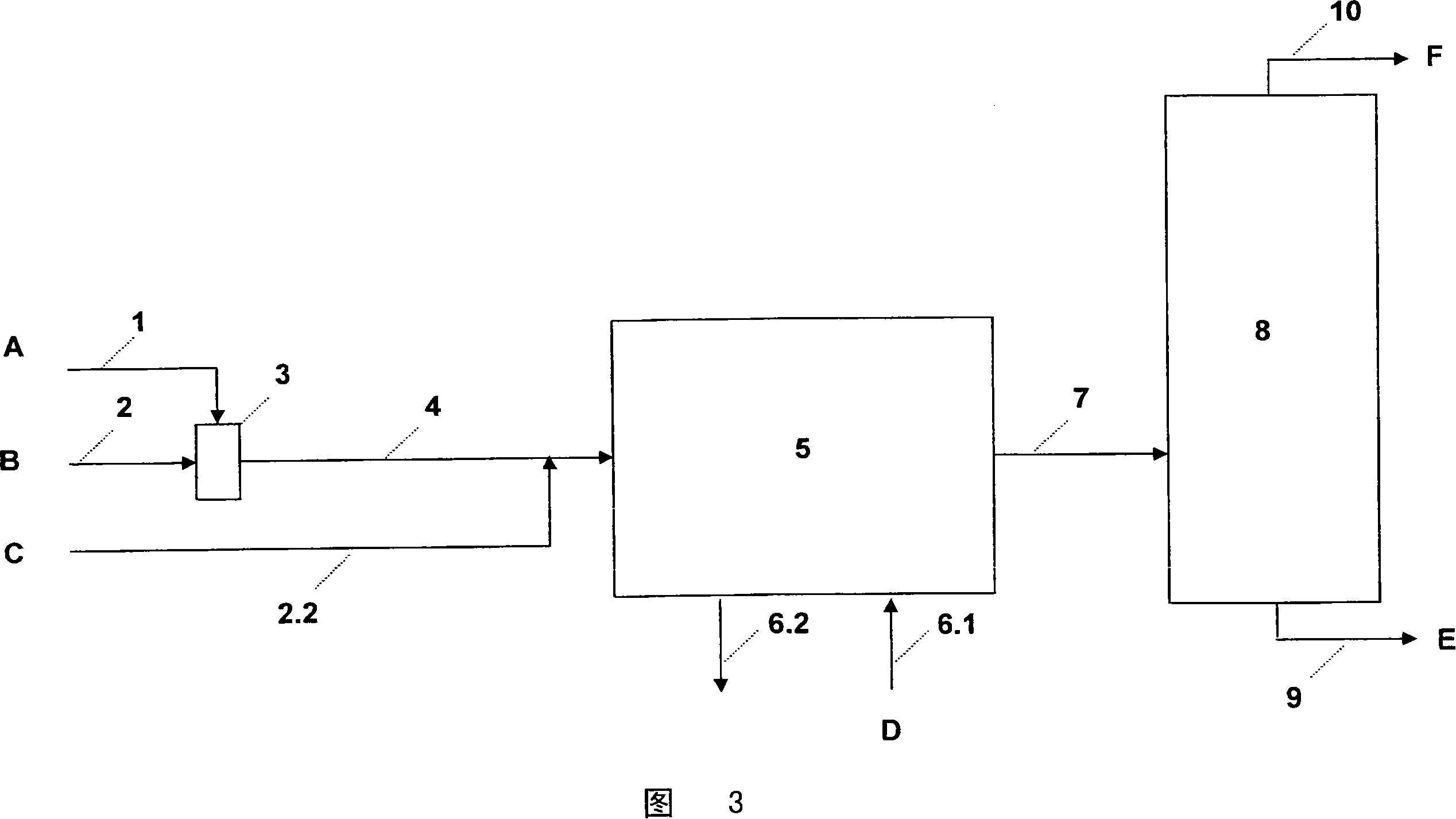

The present invention relates to an equipment, a reactor and a method for the reaction in the continuous industry, wherein the allyl chloride A reacts with the His-compound B at the condition that the catalyst C and the random additional accessory material exist, the equipment at least is based on an educt jointing apparatus (3) of the component A(1) and B(2), at least one multicomponent reactor (5) and a product after-treating device (8), the multicomponent reactor (5) includes at least two reactor component which is the form of replaceable pre-reactor (5.1) and at least one else reactor component (5.3) at the downriver side of the pre-reacting system.

Owner:GOLDSCHMIDT CHEM CORP

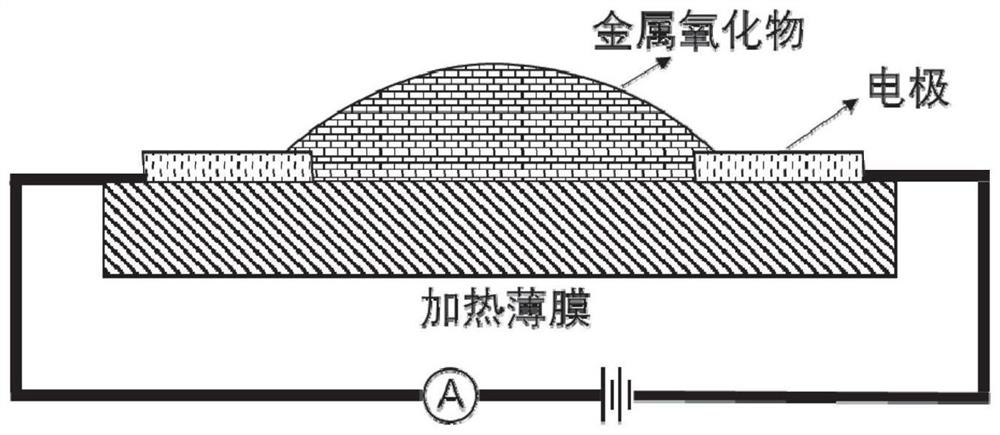

Electrode loaded with multi-layer glucose oxidase magnetic nanospheres and preparation method of electrode

InactiveCN102749376AImprove reaction efficiencyIncrease reaction strengthMaterial analysis by electric/magnetic meansMicrosphereDissolution

The invention discloses a preparation method of an electrode loaded with glucose oxidase magnetic nanospheres. The preparation method comprises the following steps of: preparing the nanospheres and 25 percent ethanol solution into mixed solution with molar ratio of 1:20-1:30 and electromagnetically stirring at room temperature until complete dissolution; transferring a dissolution system into an ice water bath; adding a proper amount of 5-10 percent analytically pure ammonia water, continuously stirring for 0.5-1 hour and aging the colloid at normal temperature for 1-2 hours to prepare nanoparticle sol; taking an electrode substrate, coating the prepared nanoparticle sol on the electrode substrate by using a pulling method at the pulling speed of 6-8 cm / min and standing to prepare a coated substrate; preparing the nanoparticles, toluene solution and water into mixed solution according to a certain molar ratio; vertically soaking the prepared coated substrate in a reactor with mixed solution; applying a horizontal magnetic field to the reactor; and reacting under the magnetic field condition of 5,000-10,000 gausses for 0.5-1 hour to prepare the electrode loaded with the multi-layer nanospheres with enzyme.

Owner:SUZHOU WENXI MEDICAL ELECTRONICS

Coal-gas producer phenolic water high-temperature treating device and treating process

ActiveCN101255363ASolve external pollutionReduce pollutionEnergy inputCombustible gas productionAir preheaterDecomposition

A high temperature phenol water processing device and technique for gas generating furnace are disclosed, which pertains to gas generating device field. The device comprises gas generating furnace, primary dust cleaning device connected to gas generating furnace, which is characterized by disposing phenol water process device connected to primary dust-cleaning device, disposing tee at lower portion of gas generating furnace, by which phenol water processing device communicates with gas generating furnace. The device can thoroughly solve the problem of contamination of waste water, thus protects environment and reduces pollution; it is simple in structure, safe and reliable, easy to operate. The process is heating air inside air pre-heating device by residue heat of gas generating furnace, spraying phenol water into air moisture releaser after hoisting by phenol water pump, evaporating phenol water into gas, entering bottom of gas generating furnace, burning for thoroughly decomposition of phenol at a high temperature of 1200 DEG C. The process is simple.

Owner:山东义丰环保机械股份有限公司

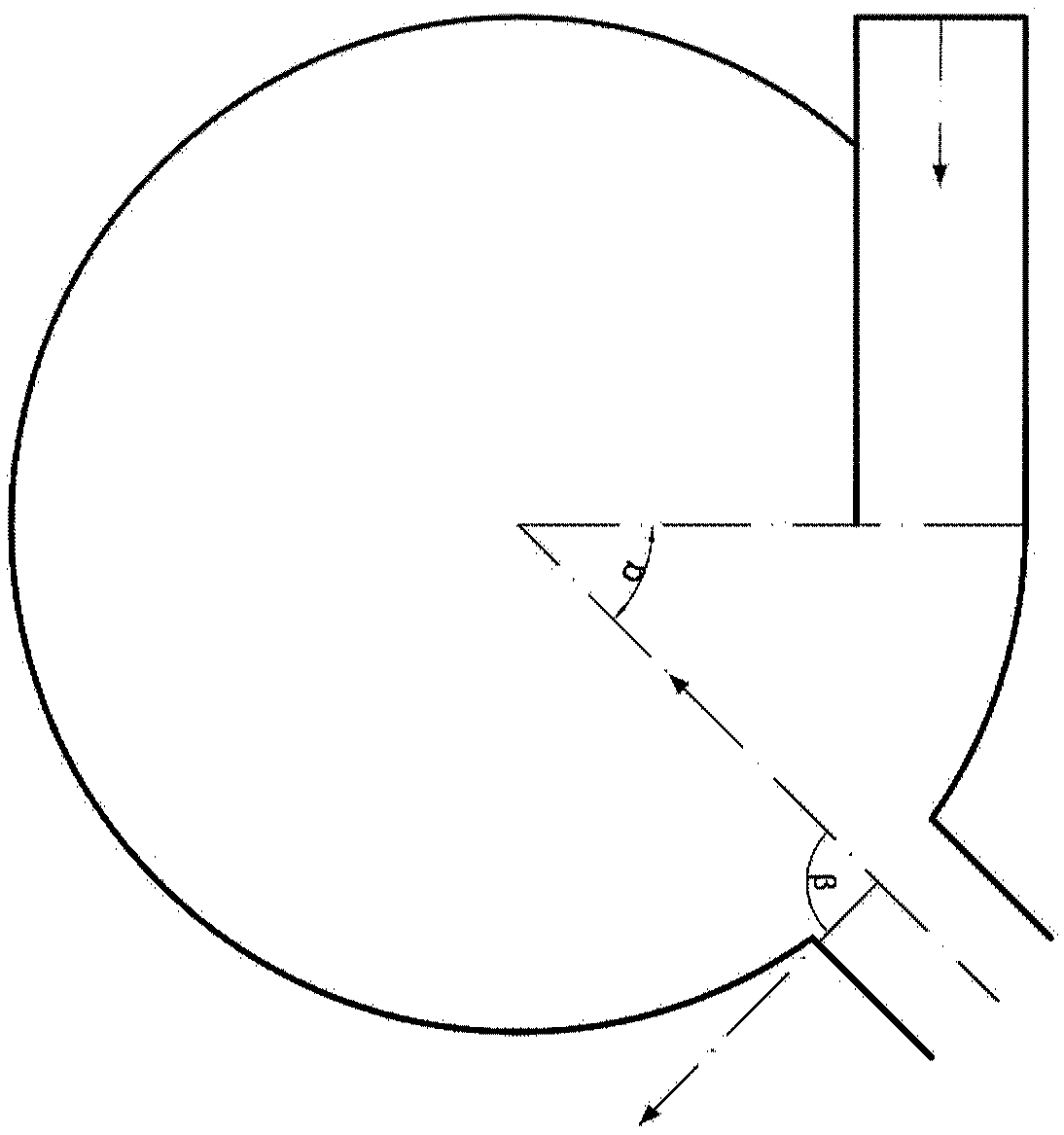

Multiphase reactor

ActiveUS20070183948A1Improve responseSmooth connectionFlow mixersDispersed particle separationFlue gasCompound (substance)

This invention relates to a multiphase reactor which is especially suitable for desulfurization of flue gas. A rotary build-in member comprising a rotator and an annular rotator is fixed on the shell of the reactor. The shell is cylindrical, and its surface is smooth or waved. The maximum diameter of the rotator is no less than the inner diameter of the annular rotator. The rotator is installed on the annular rotator coaxially. One rotary build-in member and its corresponding shell constitute an unit, and the reactor may have one or more such units. The multiphase reactor can effectively improve the flow pattern of the fluid and the contact of gas-liquid-solid three-phase of the reactants, speed up the mass transfer, and prevent deposition of the solid phase. The reactor is simple in structure and convenient for use. It can be used in the fields such as environmental protection, chemical engineering, metallurgy, and architectural industries.

Owner:SHI HANXIANG

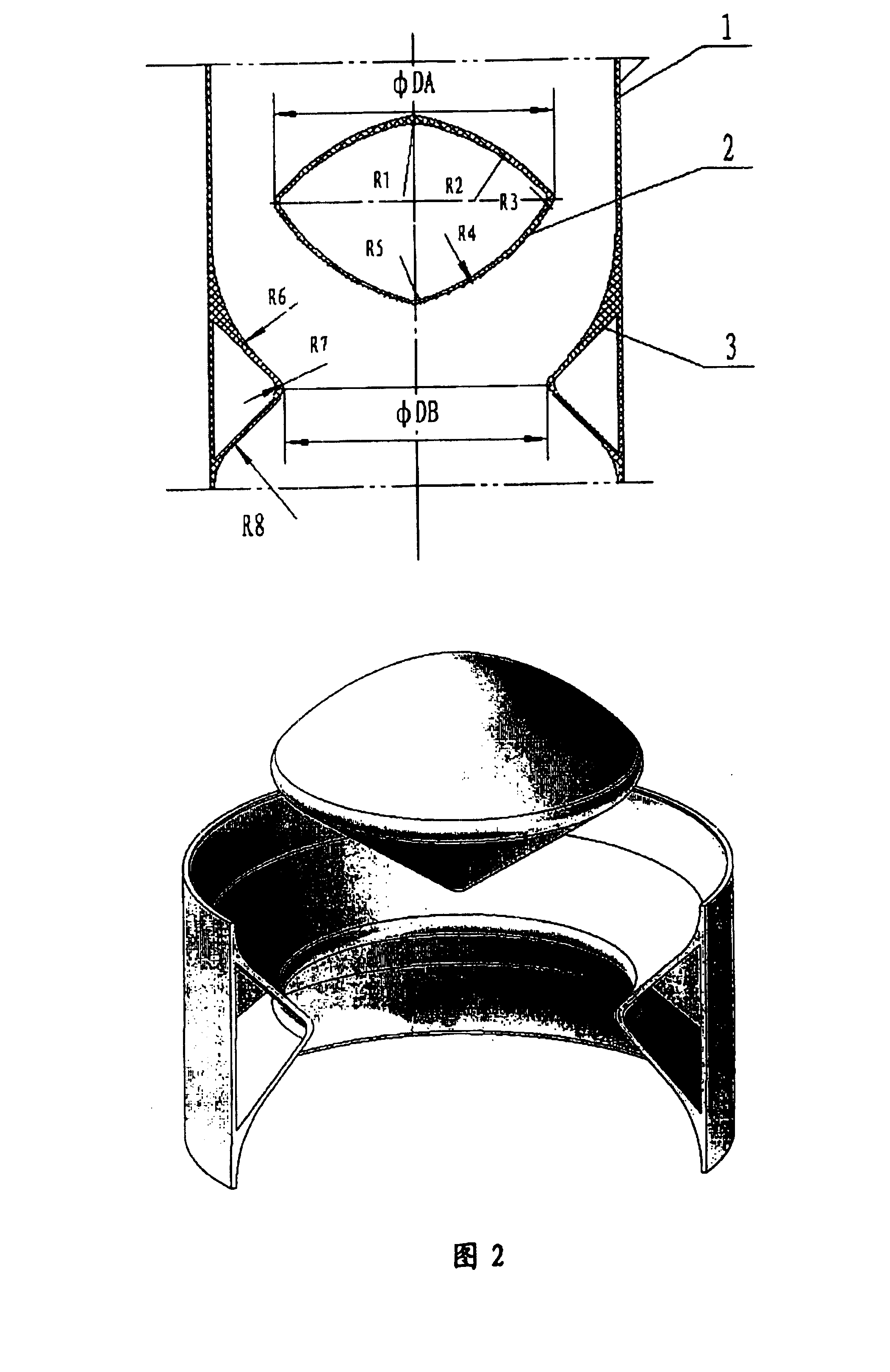

Synthetic method and application of active diluent

ActiveCN103848953AAdjust constructionIncrease reaction strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesive cementPolymer science

The invention relates to the technical field of adhesives, in particular to a synthetic method and application of an active diluent for a hot setting adhesive. The method comprises the following steps: reacting toluene diisocynate (2,4-TDI) with methyl ethyl ketoxime (MEKO) to block a part of -NCO groups, wherein the reaction equivalence ratio of TDI to MEKO is set to 1:(0.6-0.7); removing the remaining -NCO by using polyether glycol (which is 400 in molecular weight, and is called D400 for short) by reacting in an amount which is 10 percent higher than the designed equivalence to obtain a low-viscosity active diluent. By adding the low-viscosity active diluent provided by the invention into an adhesive formula, the construction viscosity of the adhesive can be lowered effectively. Moreover, the diluent participates in chemical reactions, so that the bonding strength of the adhesive can be enhanced remarkably.

Owner:YANTAI DARBOND TECH

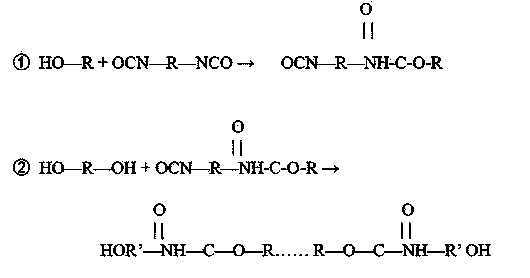

Method for reducing pyrolusite by carrying out microwave heating on biomass

The invention relates to a method for reducing pyrolusite by carrying out microwave heating on biomass and belongs to the technical field of microwave metallurgy. The method comprises the following steps: smashing pyrolusite and biomass, uniformly mixing to obtain a mixed material, then briquetting the mixed material, then putting into a corundum crucible, wrapping the outer wall of the corundum crucible with a thermal insulation material, then putting into a controllable atmosphere box-type microwave reactor, heating to 750-850 DEG C in presence of inert gas, carrying out heat preservation for 15-30 minutes, and carrying out furnace cooling to room temperature, thereby obtaining MnO-containing pellets. The method provided by the invention has the advantages that briquetting is carried out on the pellets, material contact area is increased, and reaction intensity is increased; and the advantages of selectivity and internal heating of the microwave heating are utilized, time required for reaction is shortened, and energy consumption utilization rate is improved.

Owner:YUNNAN MINZU UNIV

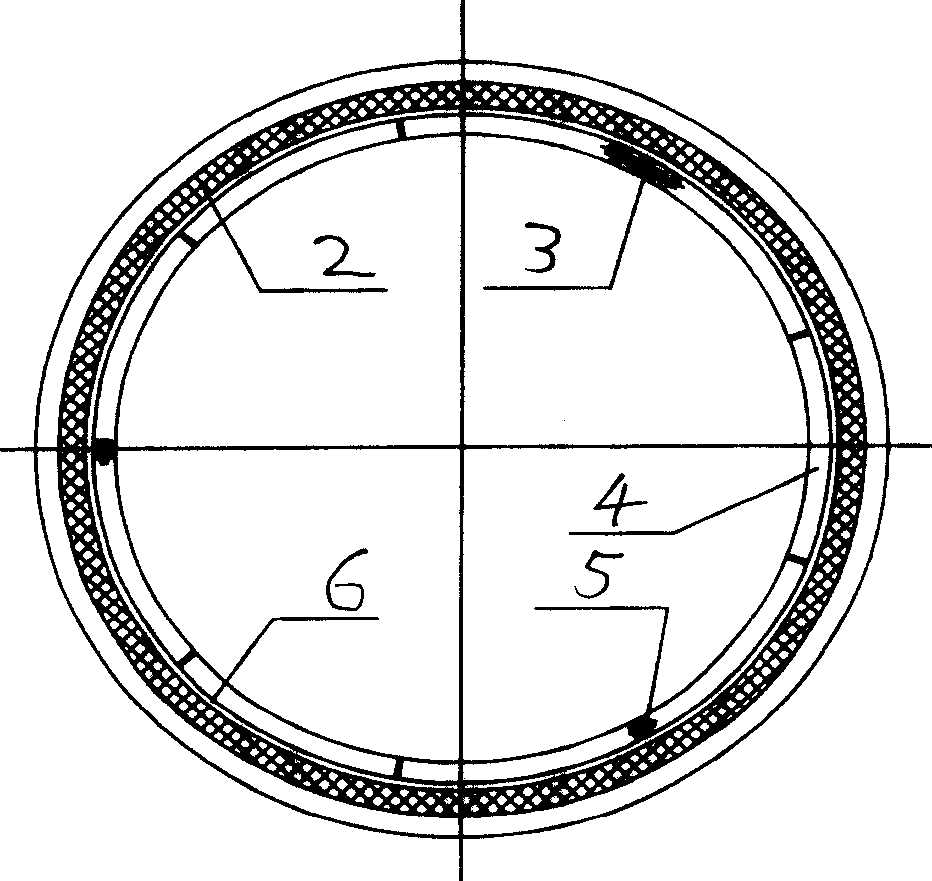

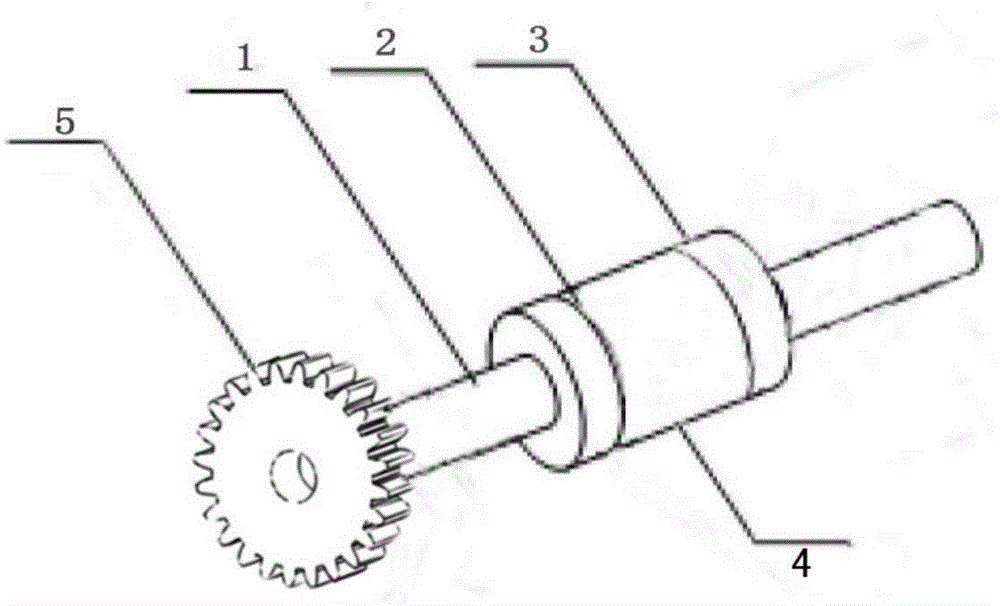

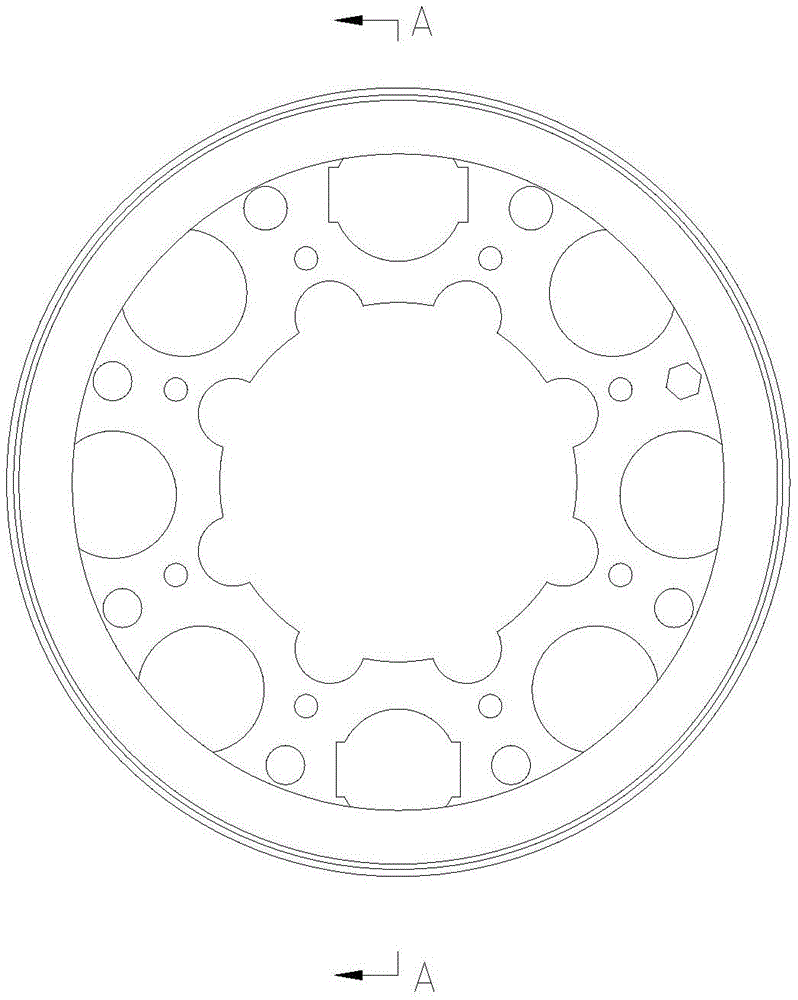

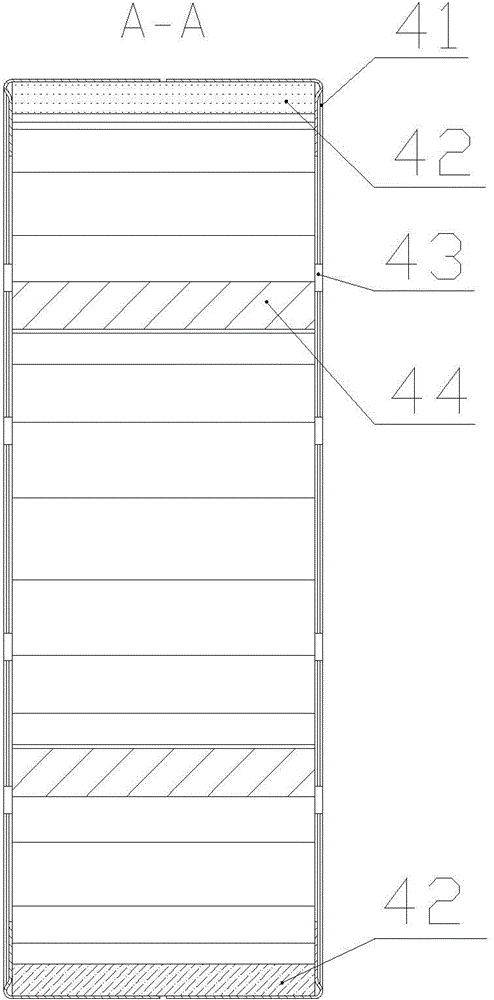

Rotor structure for servo motor

InactiveCN105322679AReduced air gap spaceIncrease reaction strengthMagnetic circuit rotating partsSEMI-CIRCLEMagnet

The invention creatively relates to a rotor structure for a servo motor. A rotor comprises a rotating shaft, an iron core and an annular permanent magnet, wherein the iron core is arranged on the rotating shaft; the annular permanent magnet is fixed on the iron core in a surrounding manner; a gear is arranged on a shaft extension of the rotating shaft; an annular groove is formed in the iron core; circular lug bosses are arranged at two edges of the groove; the annular permanent magnet is embedded and fixed into the annular groove of the iron core; the annular permanent magnet comprises two semi-circle rings; symmetrical inner threaded holes are formed in the left side and the right side of each semi-circle ring; the two semi-circle rings are connected into the annular permanent magnet through bolts; and the rotating shaft, the iron core, the groove of the iron core, the lug bosses on the edges of the groove and the gear are integrally processed and molded. The rotor structure for the servo motor is compact and relatively convenient to install and use; the manufacturing process is simplified; the cost is reduced; the reliability is improved; and the service lifetime is prolonged.

Owner:褚桂娟

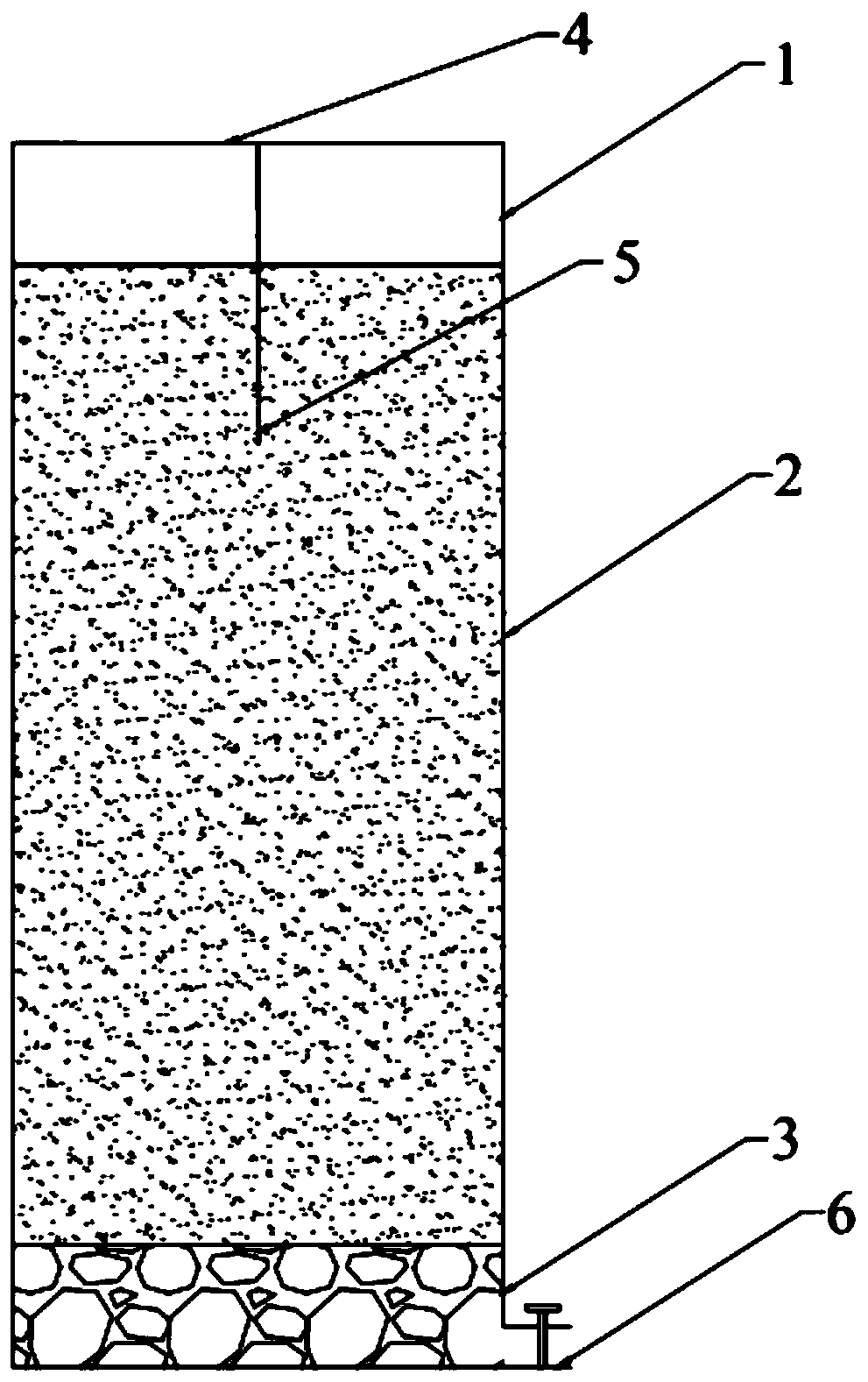

Artificial rapid percolation system for improving treatment capability upon pollutants such as nitrogen and phosphorus in rainwater through medium modification

ActiveCN110746057AEnhance adsorption and interceptionImprove adsorption capacityTreatment using aerobic processesWater contaminantsStormwaterHydraulic load

The invention discloses an artificial rapid percolation system for improving the treatment capability upon pollutants such as nitrogen and phosphorus in rainwater through medium modification. The system aims at the defect that a conventional artificial rapid percolation system is poor in nitrogen and phosphorus removal effect, and the removal capability of the system upon nitrogen and phosphorus is improved by modifying vermiculite with chitosan and optimizing technological parameters of the system. According to the technology, modified vermiculite is mixed with river sand soil proportionally,water is distributed once every other 48 hours with a hydraulic load of 2m / d, the water is fed once for 3 hours, falling drying is performed for 45 hours, the soil thickness is 70-100cm, the water isfed in sections at 30cm under a soil layer according to a ratio of 2:1, and up-to-standard treatment on nitrogen and phosphorus pollutants, of the artificial rapid percolation system, can be achievedunder the process conditions. In general, the system is simple in structure, small in floor space and good in treatment effect.

Owner:BEIJING FORESTRY UNIVERSITY

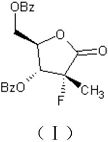

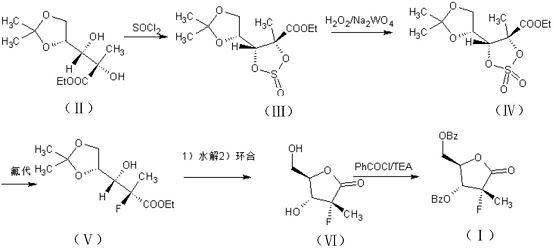

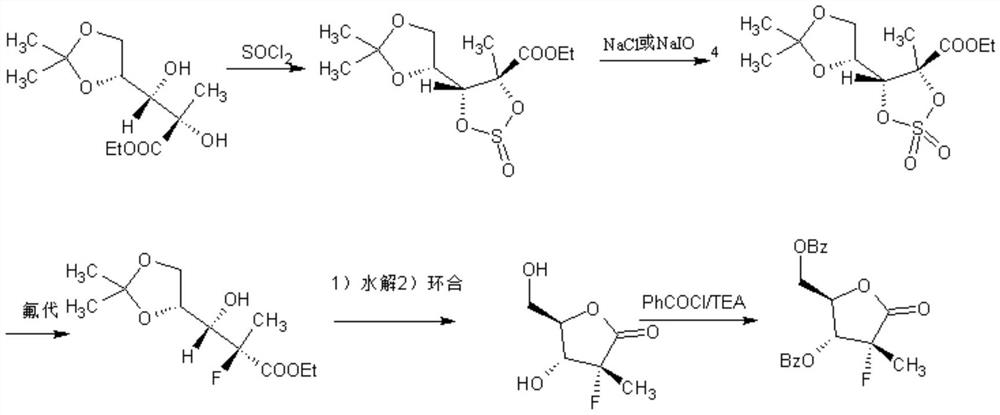

A kind of synthetic method of the intermediate of Sofosbuvir

ActiveCN109438397BLow cost of industrializationIncrease reaction strengthOrganic chemistryPropanoic acidPhenacyl

The present invention relates to a kind of synthetic method of sofosbuvir intermediate shown in formula (I): the present invention uses compound (2S,3R)-ethyl-3-((R)-2,2-dimethyl Base-1,3-dioxolane-4-yl)-2,3-dihydroxy-2-methyl propionate (Ⅱ) as starting material, through thionyl chloride cyclization to form compound (Ⅲ ), then compound (Ⅲ) was oxidized by hydrogen peroxide / sodium tungstate to obtain compound (Ⅳ), and compound (Ⅳ) was fluorinated, hydrolyzed and benzoylated to synthesize sofosbuvir intermediate 3,5-di Benzoyl-2-deoxy-2-fluoro-2methyl-D-ribose-γ-lactone (I), the sofosbuvir intermediate synthesized by the present invention is environmentally friendly and economical, and has huge industrial production prospects.

Owner:JIANGSU COBEN PHARMA CO LTD

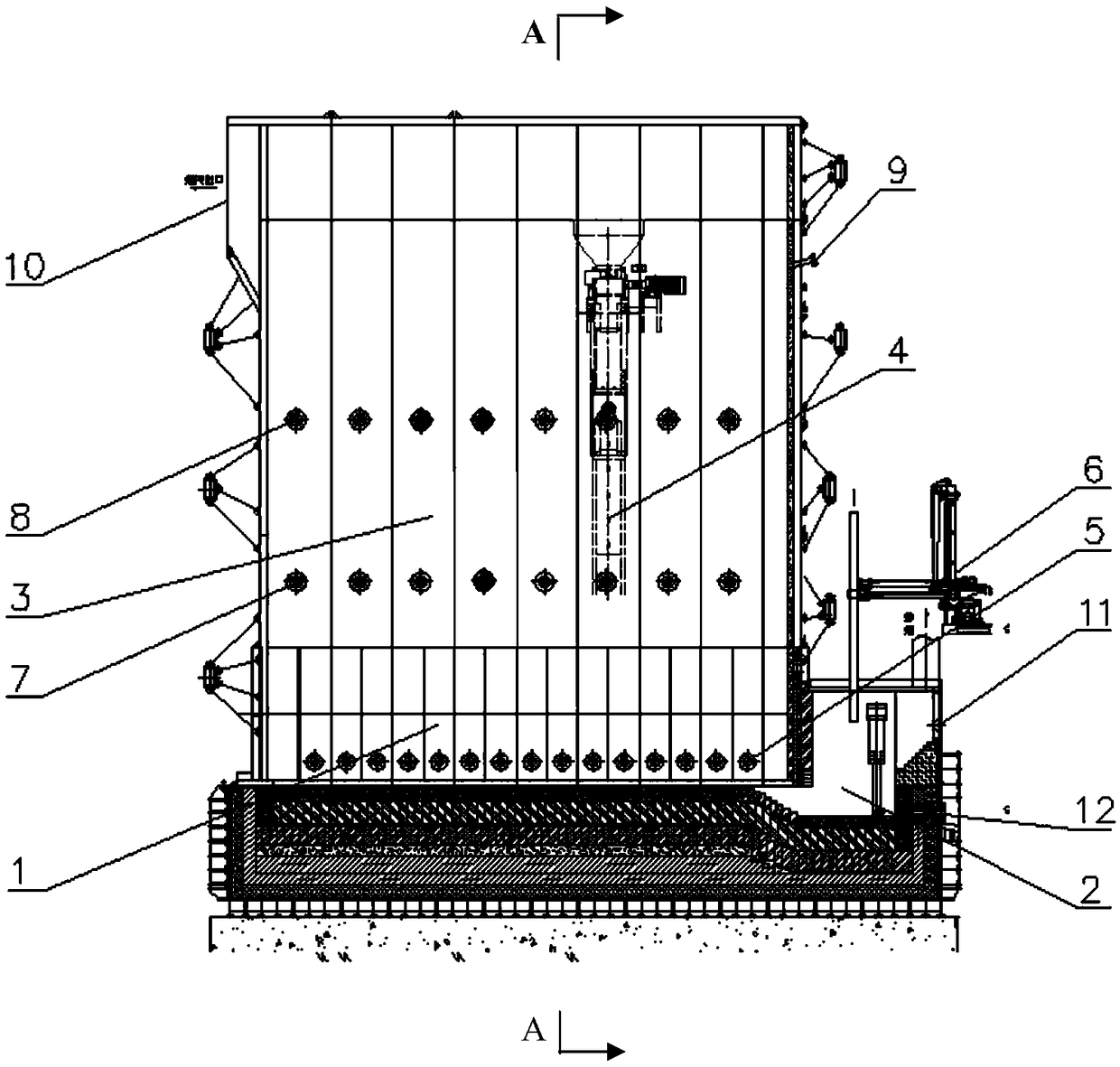

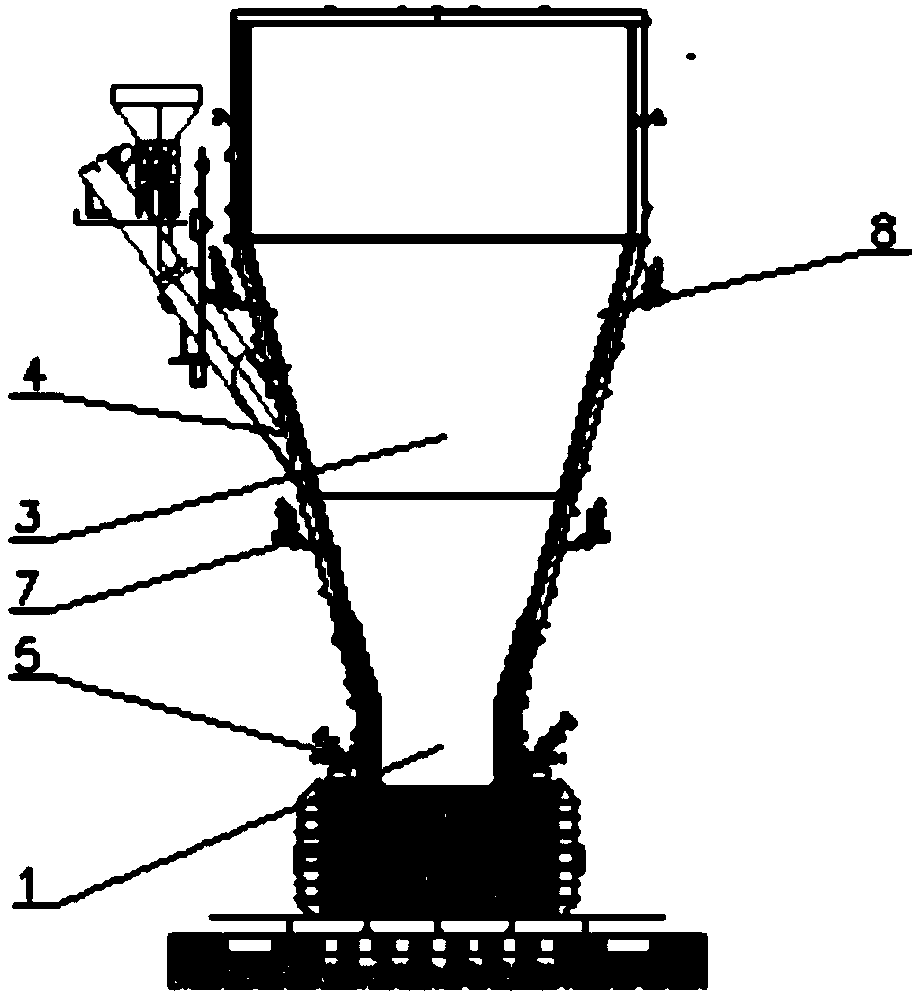

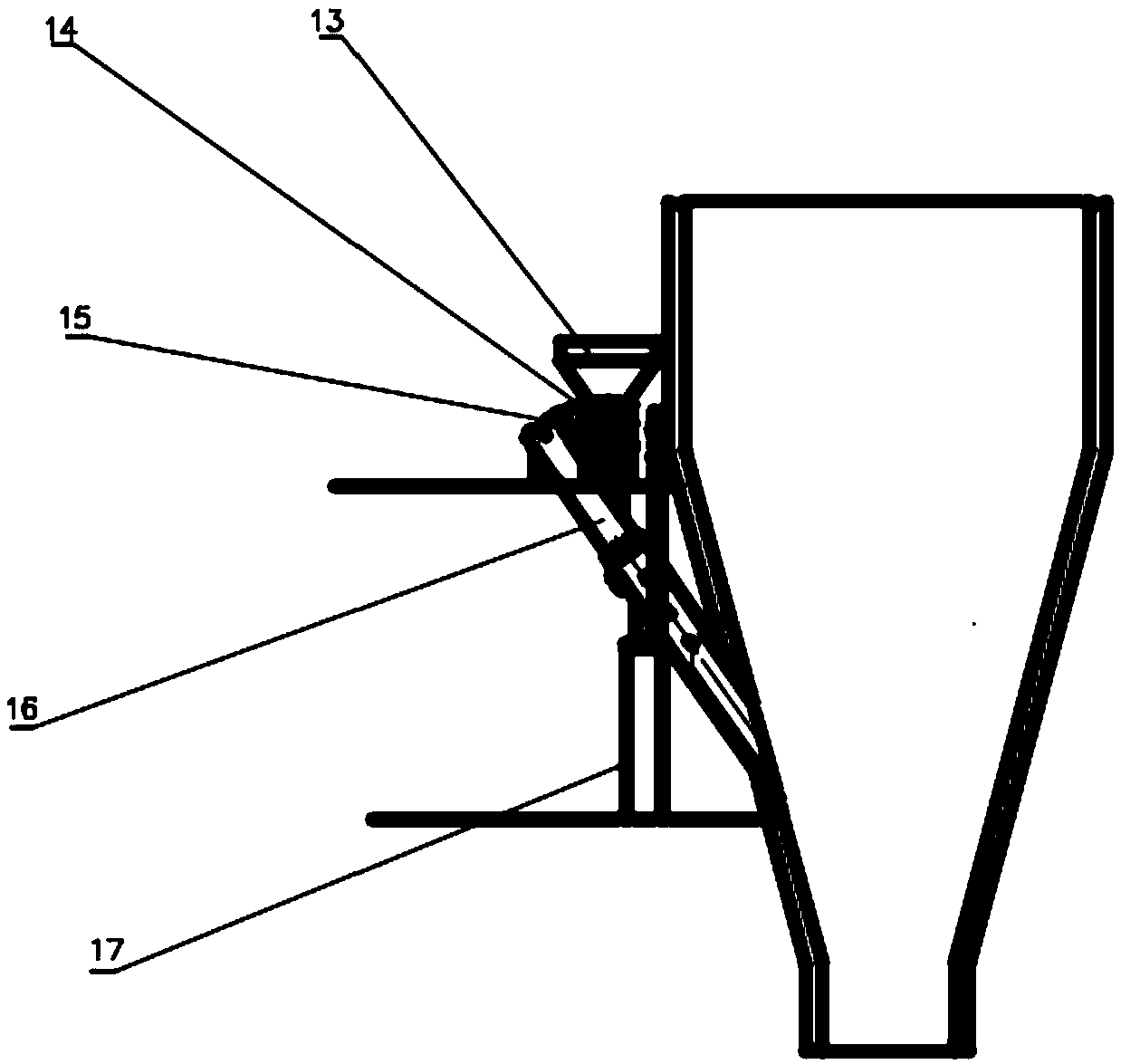

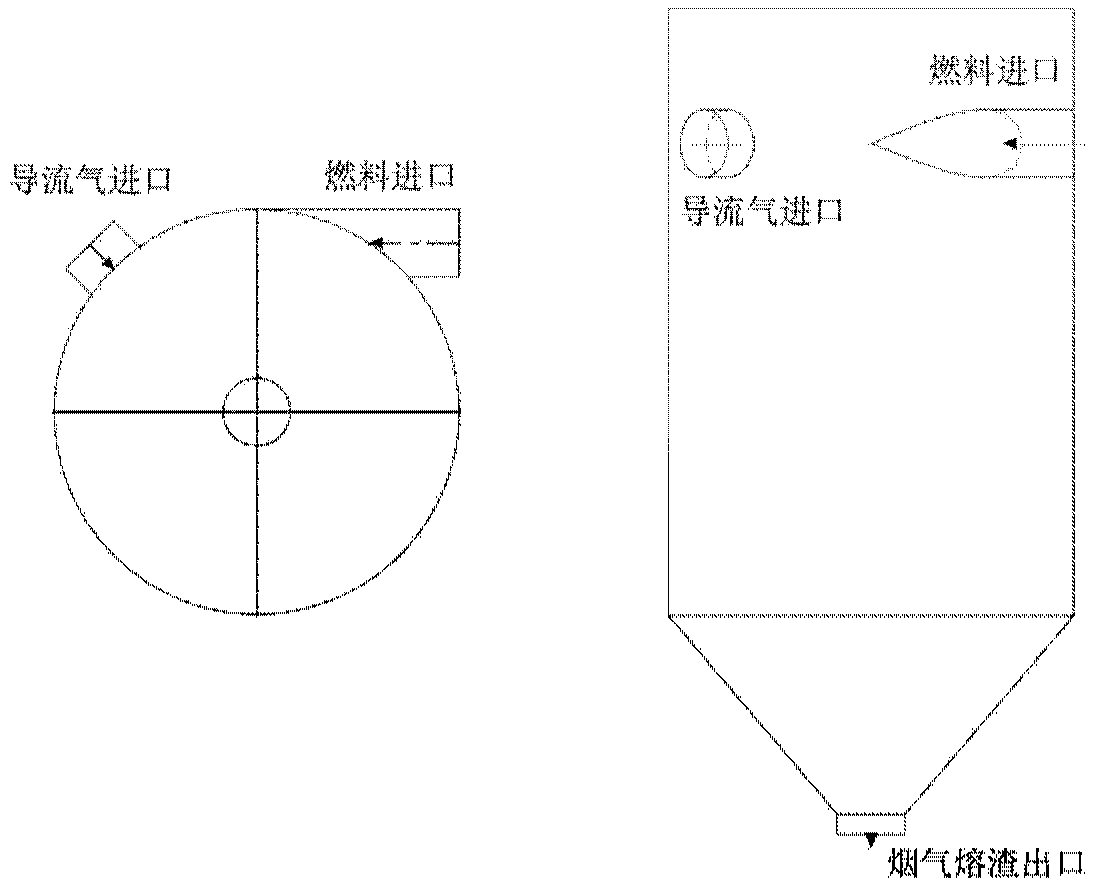

Cyclone melting furnace and using method thereof

InactiveCN110397935AReduce direct washoutIncrease reaction strengthIndirect carbon-dioxide mitigationAir/fuel supply for combustionCycloneMelting furnace

The invention provides a cyclone melting furnace which comprises a furnace body and a fuel inlet, wherein the fuel inlet is tangentially arranged in the furnace body and is configured to introduce reaction fuel; and the furnace body is also provided with a guide gas inlet, and the guide gas inlet is arranged on a target area part, directly impacted by the reaction fuel, in the furnace body. According to the cyclone melting furnace, the reaction strength of the oxygen-enriched air and coke particles in high-temperature solid-containing gas is enhanced through arrangement of the guide gas inlet.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

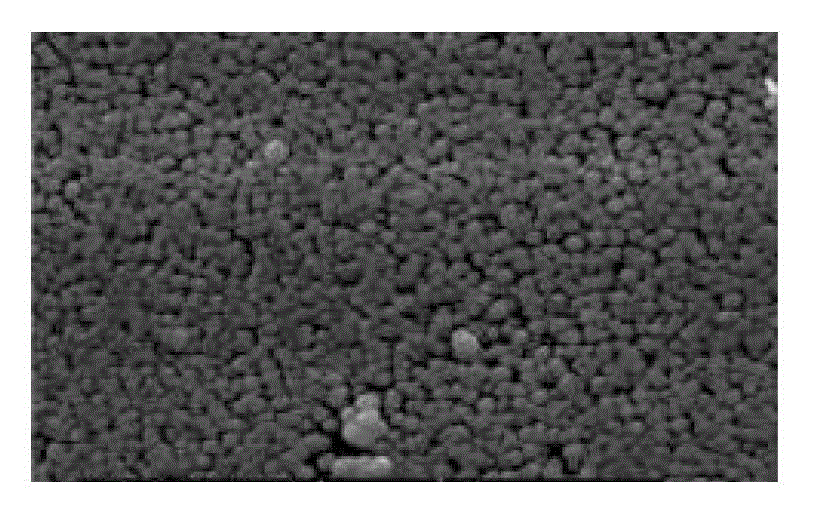

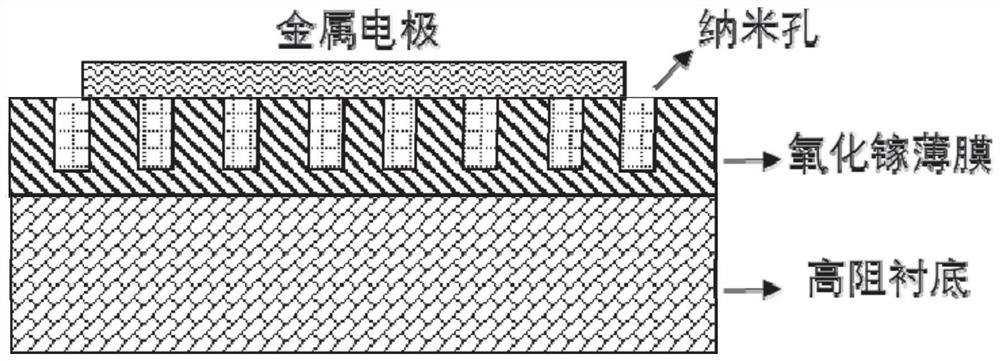

Gallium oxide nanostructure device, and production method and application thereof

The invention discloses a gallium oxide nanostructure device, and a production method and an application thereof. The production method comprises the following steps: depositing metal gallium on a gallium oxide thin film, and corroding a plurality of areas on the surface of the gallium oxide thin film by the metal gallium so as to form a plurality of nanopores in the gallium oxide thin film; and manufacturing an electrode matched with the gallium oxide thin film. According to the production method provided by the invention, the gallium oxide thin film is corroded by the metal gallium to form the nanopores, and the obtained nanopore thin film has a larger specific surface area so that more to-be-detected gas molecules in the environment can be adsorbed, the size of the device is reduced, and a high-integration-level, miniaturized and low-power-consumption detector is realized; and the production process of the nanostructure does not need additional semiconductor processing equipment for etching or corrosion, is beneficial to reducing the cost, is an in-situ corrosion process, does not introduce a new surface state and an interface state, is free of external pollution, and has the characteristics of low damage, no interface pollution and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

A kind of dewatered sludge curing agent, preparation method and use method

ActiveCN105254166BIncrease reaction strengthAvoid the impact of subsequent hydration reactionsSludge treatment by de-watering/drying/thickeningPhosphateSlag

A dewatered sludge solidifying agent, a preparation method and a use method, belonging to the technical field of environmental engineering, the phosphate rock, carbide slag, tailings slag and marble slag in the dewatered sludge solidifying agent are (1-3) by mass percentage: (1 ~3):(1~3):(1~3), the preparation method comprises: washing, drying, crushing and ball milling the phosphate rock, calcium carbide slag, tailings slag and marble slag respectively, and mixing them in proportion uniform. The method of using the dewatered sludge solidifying agent includes: mixing the dewatered sludge and the added dewatered sludge solidifying agent in proportion to achieve solidification. The compressive strength of the cured dewatered sludge can reach 78KPa after 3 days of curing under normal temperature and pressure, and the pH of the leachate is between 5 and 10. The dewatered sludge solidifying agent of the present invention uses solid waste as a raw material, has wide sources of raw materials and low cost, and utilizes the chemical properties of the solid waste itself and the activity excitation between them to realize the solidification and stabilization of the dewatered sludge.

Owner:LIAONING TECHNICAL UNIVERSITY

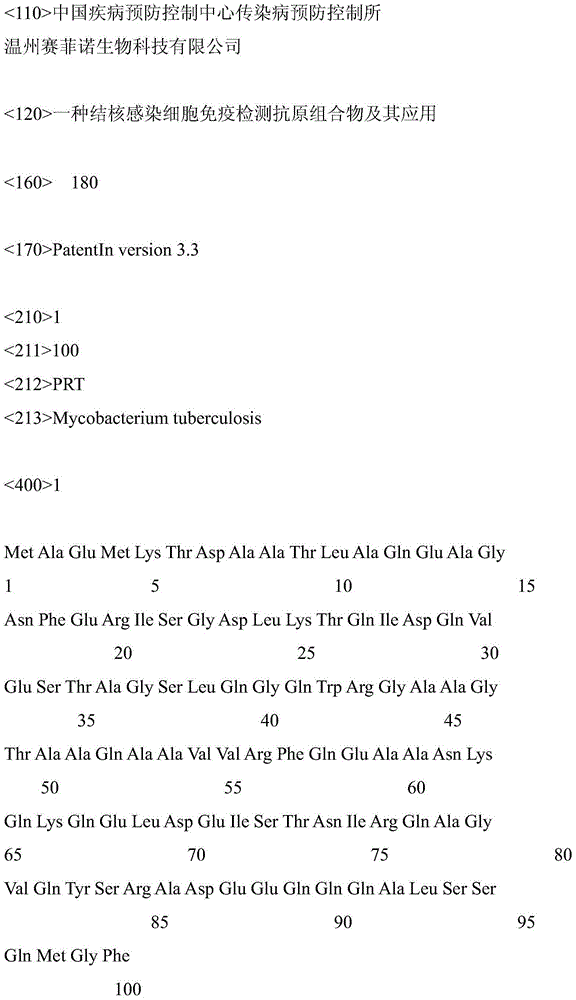

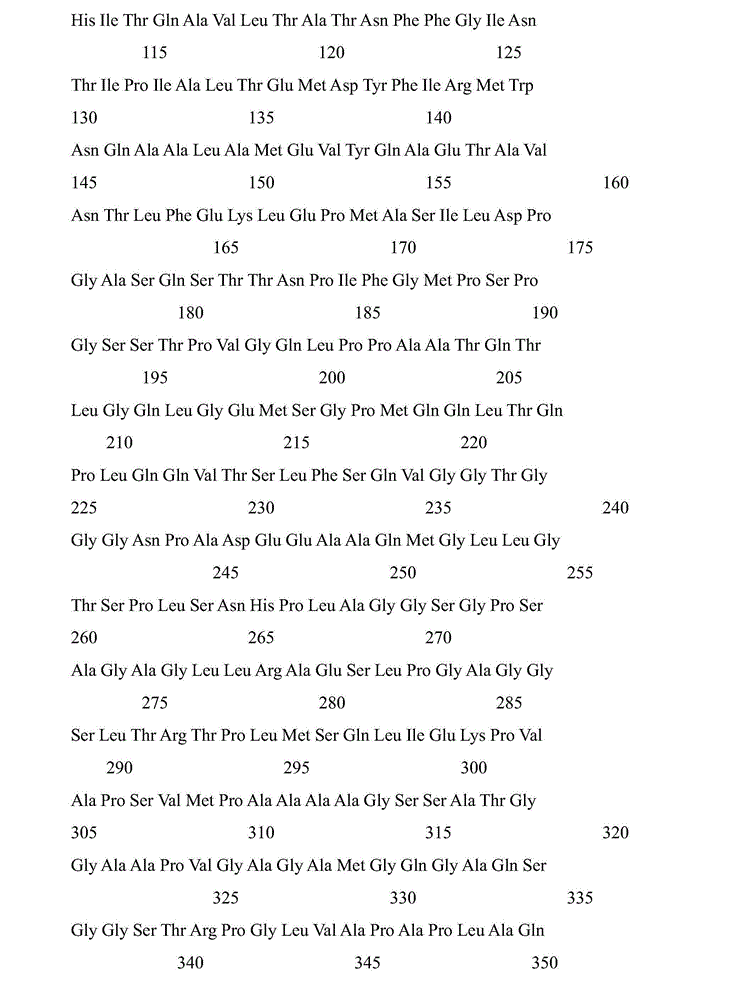

Tuberculosis immunodiagnosis molecular marker and application thereof in preparation of vaccines

ActiveCN106606774AHigh sensitivityImprove featuresAntibacterial agentsBacterial antigen ingredientsAntigenPositive control

Belonging to the field of immunology and molecular biology, the invention relates to a tuberculosis immunodiagnosis molecular marker and application thereof in preparation of vaccines. Specifically, the invention relates to use of protein with an amino acid sequence shown as SEQ ID NO:1 or SEQ ID NO:2 in preparation of anti-tuberculosis drugs or mycobacterium tuberculosis-inhibiting drugs, or use in preparation of drugs detecting tuberculosis or drugs detecting mycobacterium tuberculosis. As an antigen, the protein shown as SEQ ID NO:1 or SEQ ID NO:2 has good sensitivity and specificity, also has reaction intensity significantly higher than that of positive control 38kDa, and has the potential of application to preparation of antituberculosis drugs like anti-tuberculosis vaccines.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com